Page 1

GAS-FIRED INFRARED CONSTRUCTION HEATER

OWNER’S MANUAL

MODELS 125-R AND 125-RN

IMPORTANT: Read and understand this manual before

assembling, starting or servicing heater. Improper use

of heater can cause serious injury. Keep this manual for

future reference.

GENERAL HAZARD WARNING:

Failure to comply with the precautions and instructions

provided with this heater, can result in death, serious

bodily injury and property loss or damage from hazards

of fire, explosion, burn, asphyxiation, carbon monoxide

poisoning and/or electrical shock.

Only persons who can understand and follow the instructions should use or service this heater.

If you need assistance or heater information such as an instructions manual, labels, etc. contact the manufacturer.

Save this manual for future reference.

For more information, visit www.desatech.com

Page 2

Safety Information ............................................... 2

TABLE OF CONTENTS

Product Identification ...........................................

Unpacking ........................................................... 3

Theory of Operation ............................................ 3

Gas Supply .......................................................... 4

Ventilation ............................................................

Installation Instructions ........................................ 4

Locating Heater ................................................... 5

Piping .................................................................. 5

Operating Instructions ......................................... 6

3

Maintenance ........................................................ 7

Specifications ...................................................... 7

Operating Instructions ......................................... 7

Troubleshooting ................................................... 8

4

Replacement Parts .............................................. 9

Accessories ......................................................... 9

Illustrated Parts Breakdown and Parts List ....... 10

Warranty and Repair Service ..............Back Cover

SAFETY INFORMATION

WARNING: This product

contains and/or generates

chemicals known to the State

of California to cause cancer or

birth defects or other reproduc

tive harm.

WARNING: Fire, burn, inhalation and explosion hazard.

Keep solid combustibles, such

as building materials, paper or

cardboard, a safe distance away

from the heater as recommended

by the instructions. Never use

the heater in spaces which do or

may contain volatile or airborne

combustibles or products such

as gasoline, solvents, paint thinner, dust particles or unknown

chemicals.

WARNING: Not for home or

recreational vehicle use.

WARNING: Do not exceed

1/2 psi (14" w.c.) gas pressure

to the gas control valve.

The heater is designed for use as a construction heater in accordance with ANSI Z83.7/CGA 2.14. Other

standards govern the use of fuel gases and heating

products for specific uses. Your local authority

can advise you about these. The primary purpose

of construction heaters is to provide temporary

heating of buildings under construction, alteration

or repair. Properly used, the heater provides safe

economical heating. Products of combustion are

vented into the area being heated.

-

We cannot foresee every use which may be made of

our heaters. Check with your local fire safety au

thority if you have questions about heater use.

Other standards govern the use of fuel gases and

heat producing products for specific uses. Your

local authorities can advise you about these.

Carbon Monoxide Poisoning: Some people are

more affected by carbon monoxide than others.

Early signs of carbon monoxide poisoning re

semble the flu, with headaches, dizziness and/or

nausea. If you have these signs, the heater may not

be working properly. Get fresh air at once! Check

for proper ventilation and have heater serviced.

Propane Gas: Propane gas is odorless. An odor-

making agent is added to propane gas. The odor

helps you detect a propane gas leak. However, the

odor added to propane gas may fade. Propane gas

may be present even though no odor exists.

Make certain you read and understand all warn

ings. Keep this manual for reference. It is your

guide to safe and proper operation of this heater.

1. Install and use heater with care. Follow all

local ordinances and codes. In the absence

of local ordinances and codes, refer to the

Standard for Storage and Handling of Liq

uefied Petroleum Gas, ANSI/NFPA 58 and

the Propane Installation Code, CAN/CGA

B149.2. This instructs on the safe storage and

handling of propane gases.

2. Use only the hose and factory preset regulator

provided with the heater.

3. Use only propane gas set up for vapor with

drawal (125-R only).

4. Provide adequate ventilation. Before using

heater, provide at least a .35 m

opening of fresh, outside air.

5. Do not use heater in occupied dwellings or in

living or sleeping quarters.

6. Do not use heater in basement or below ground

level.

2

(3.75 ft2)

-

-

-

-

-

2

www.desatech.com

114248-01B

Page 3

SAFETY INFORMATION

Continued

7. Keep appliance area clear and free from combustible materials, gasoline, paint thinner and

other flammable vapors and liquids. Dust is

combustible. Do not use heater in areas with

high dust content.

8.

Minimum heater clearances from combustibles:

Sides Top

1.54 m (5 ft) 1.22 m (4 ft)

9. Keep heater at least 6.0 m (20 ft) from propane

tank(s).

10. Keep propane tank(s) below 38° C (100° F).

11. Check heater for damage before each use. Do

not use a damaged heater.

12. Check hose before each use of heater. If highly

worn or cut, replace with hose specified by the

manufacturer before using heater.

13. Locate heater on stable and level surface if

heater is hot or operating.

14. Not intended for use on finished floors.

15. Never block air inlet (bottom of combustion

chamber) or air outlet (glowing combustion

chamber) of heater.

16. Keep heater away from strong drafts, wind,

water spray, rain or dripping water.

17. Do not leave heater unattended.

18. Keep children and animals away from

heater.

19. Never move, handle or service a hot or operat

ing heater. Severe burns may result. Wait 15

minutes after turning heater off.

20. To prevent injury, wear gloves when handling

heater.

21. Never attach duct work to heater.

22. Do not alter heater. Keep heater in its original

state.

23. Do not use heater if altered.

24.

Turn off gas supply to heater when not in use

25. Use only original replacement parts. This

heater must use design-specific parts. Do

not substitute or use generic parts. Improper

replacement parts could cause serious or fatal

injuries.

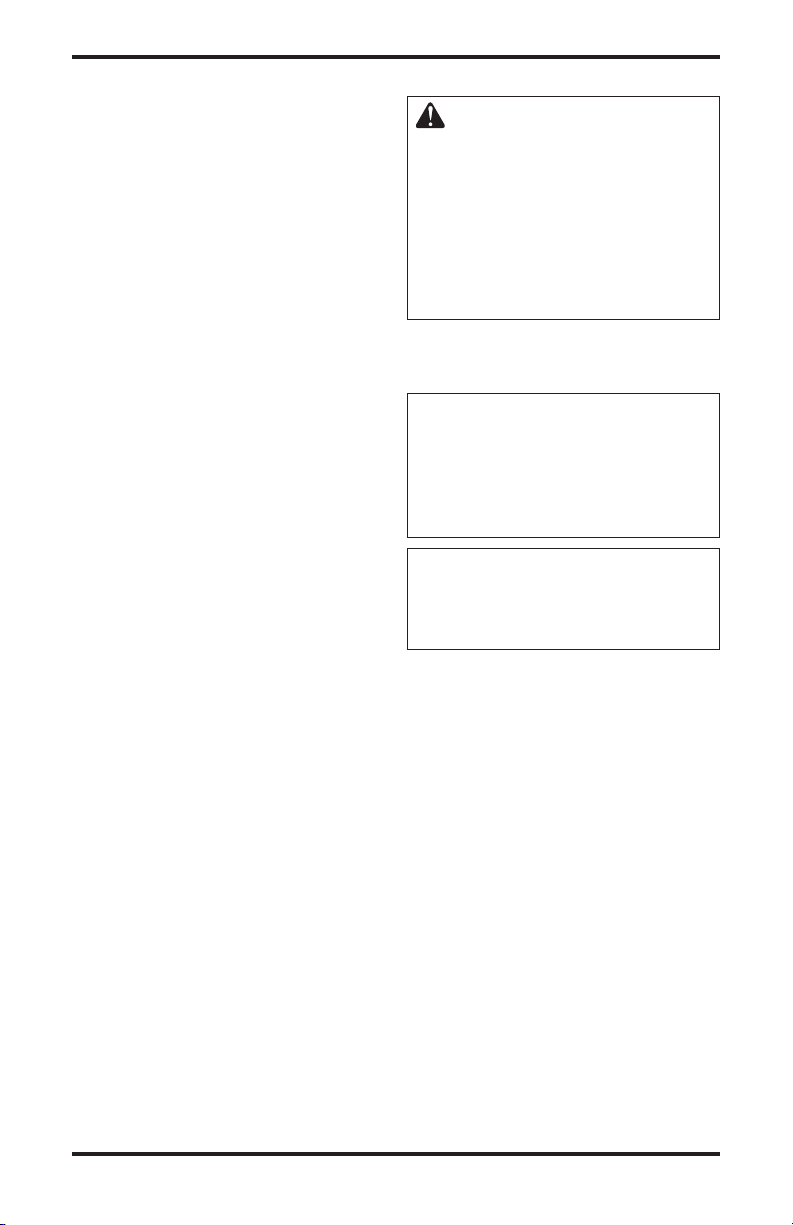

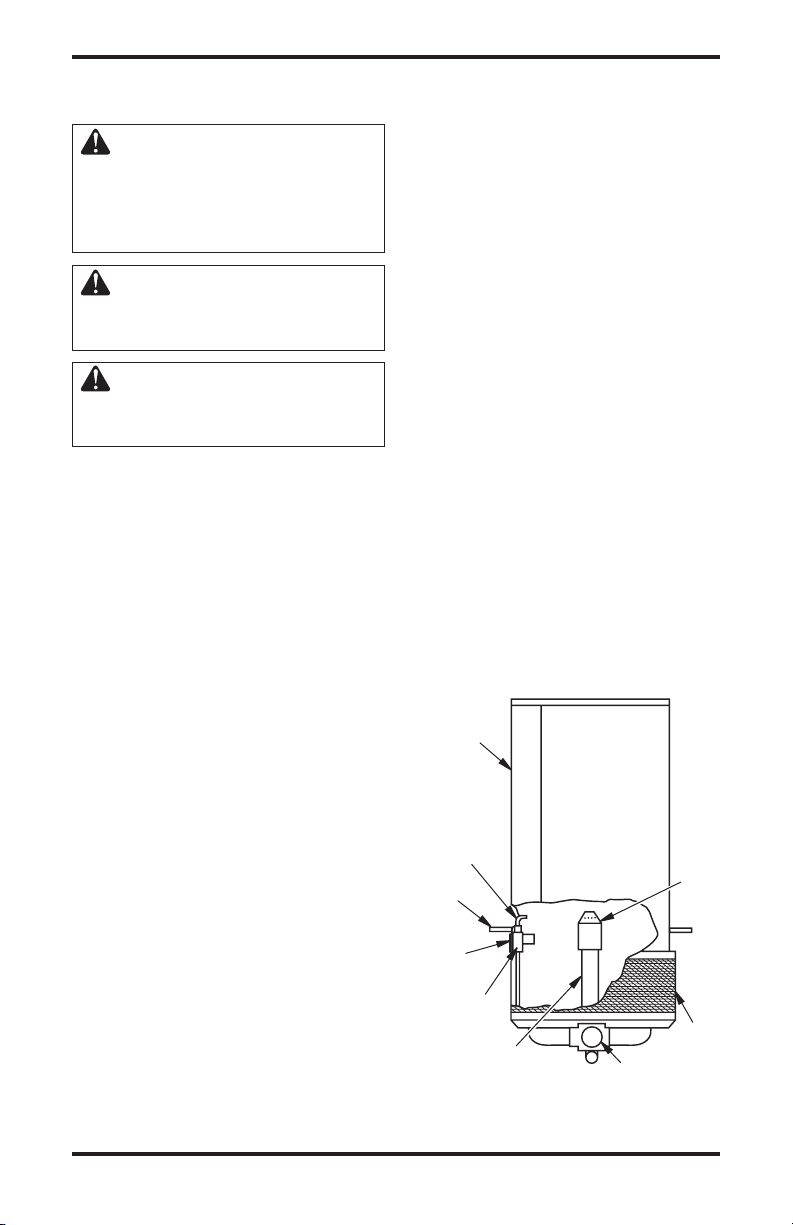

PRODUCT

IDENTIFICATION

Top

Protective

Screen

Combustion

Chamber

Cover

Lighting

Port

Control knob

Figure 1 - Product Identification

UNPACKING

1. Remove all packing items applied to heater for

shipment. Keep plastic cover caps (attached to

valve inlet and hose/regulator assembly) for

storage.

2. Remove all items from carton.

-

3. Check all items for shipping damage. If heater

is damaged, promptly inform dealer where you

bought heater.

THEORY OF OPERATION

The Fuel System: For propane units, the hose/

regulator assembly attaches to the propane gas

supply. For natural gas units, the gas supply at

taches to the heater through user supplied hose or

.

pipe. This provides fuel to the heater.

The Ignition System: The piezo ignitor lights the

burner fuel supply.

The Automatic Control System: This system causes

the heater to shut down if the flame goes out.

-

114248-01B

www.desatech.com

3

Page 4

GAS SUPPLY

PROPANE/LP GAS MODEL 125-R ONLY

Propane gas and propane tank(s) are to be furnished by the user.

Use this heater only with a propane vapor

withdrawal supply system. See Chapter 5 of the

Standard for Storage and Handling of Liquefied

Petroleum Gas, ANSI/NFPA 58 and/or CAN/CGA

B149.2. Your local library or fire department will

have this booklet.

The amount of propane gas ready for use from

propane tanks varies. Two factors decide this

amount.

1. The amount of liquid propane gas in tank(s)

2. The temperature of tank(s)

The chart below shows the minimum number of 45

kg (100 lb) tanks needed to run the heater. Connect

tanks together with a manifold.

Average Temperature Number Of Tanks

°C (°F) At Tank Location 45 kg (100 lb)

4° (40°) to 0° (32°) 2

Below 0° (32°) 3

Less gas is vaporized at lower temperatures. Your

local propane gas dealer will help you select the

proper supply system.

NATURAL GAS MODEL 125-RN ONLY

The user must furnish the natural gas supply and

the connections to the heater.

Regulate the natural gas supply down from a mini

mum 7" w.c. to a maximum of 1/2 psi. The natural

gas supply capacity should be able to supply a

minimum of 125 cubic feet of gas at pressure for

each heater connected to the system.

Consult your natural gas supplier for proper sizing

of the natural gas supply lines.

Follow all local ordinances and codes. In the ab

sence of local ordinances and codes, refer to the

National Fuel Gas Code Handbook, NFPA54/ANSI

Z223.1 and the Natural Gas Installation Code, CAN/

CGA B149.1

.

VENTILATION

WARNING: Provide at least

a .35 m2 (3.75 ft2) opening of

fresh, outside air while running

heater. If proper fresh, outside

air ventilation is not provided,

carbon monoxide poisoning

can occur. Provide proper fresh,

outside air ventilation before

running heater.

INSTALLATION

INSTRUCTIONS

Read these instructions carefully. Read and adhere to these

instructions. Do not allow anyone who has not read these

instructions to assemble, light,

adjust or operate this heater.

Do not attempt to operate the

heater with any gas other than

that indicated on the heater

nameplate.

For the U.S. and/or Canada, the installation of this

appliance must comply with local and/or Provin

cial codes or, in the absence of these codes, with

the (U.S.) National Fuel Gas Code, ANSI Z223.1

– Latest Edition (for natural and propane/LP gas

operation) and with the (U.S) Standard for the

Storage and Handling of Liquefied Petroleum

Gases, ANSI/NFPA 58 (for propane/LP gas opera

tion) or with the current (Canadian) CAN/CGA

B149.1 and B149.2 installation codes.

This heater (including hose and regulator assembly

if applicable) must be inspected before each use

and at least annually by a qualified service person.

If the hose for model 125-R shows evidence of

excessive abrasion or wear or if the hose is cut, it

must be replaced prior to the heater being put into

operation. The replacement hose assembly shall be

that specified by the manufacturer.

-

-

4

www.desatech.com

114248-01B

Page 5

LOCATING HEATER

The heater (and propane/LP gas supply cylinder

if applicable) must be located on a hard, flat, level

surface to minimize the risk of accidental tipping. If

an propane/LP gas supply cylinder is used (propane/

LP model only), the cylinder should be adequately

restrained to prevent accidental tipping. DO NOT

operate this heater with the supply cylinder in

any other than the upright position.

This appliance must be installed only in locations

where the potential for physical damage to the

appliance (i.e., due to physical contact) is reduced

to a minimum.

The installer must inform the owner/operator of

this appliance that precautions must be taken to

protect the appliance from physical damage.

This appliance produces radiant heat. Therefore,

it must be located at least 6 feet away from

any propane/LP gas container and must not be

directed toward any propane/LP gas container

within 20 feet.

The heater must be installed in a location such that

it will not be exposed directly to water spray, rain

and/or dripping water.

Use of this heater in a draft/windy area decreases

its efficiency. If possible, operate the unit in a

draft free area.

PIPING

FOR MODEL 125-R (FOR USE WITH

PROPANE/LP GAS ONLY)

This model may be connected to a self-contained

propane/LP gas supply system using the hose and

regulator assembly supplied with the appliance

OR, it may be connected to a permanently installed

propane/LP gas supply system.

If connected to a self-contained propane/LP

gas supply system, the hose assembly must be

inspected prior to each use of the heater. If it is

evident that there is excessive abrasion or wear or

if the hose is cut, it must be replaced prior to the

heater being put into operation.

WARNING: Never use a fork

lift truck type cylinder.

The connection of model 125-R to a propane/LP

cylinder must be made in a well ventilated area

using the regulator and hose assembly supplied

with the appliance. DO NOT attempt to adjust

this regulator. It has been preset at the factory

to provide safe and proper operation of the appliance. Use a 7/8" open end wrench to connect

the POL fitting (supplied with the propane/LP

regulator) to the propane/LP cylinder. Turn the

POL nut in a counterclockwise direction (left hand

thread) until tight. DO NOT use pipe compound

on POL threads.

The heater must be located at least six feet away

from any propane/LP cylinder and must not be

directed toward any propane/LP cylinder within

20 feet. If more than one heater is used, they

and the supply cylinders must be separated by at

least 20 feet.

The gas supply must be turned off at the propane/LP

supply cylinder when the heater is not in use.

When the heater is to be stored indoors, the connec

tion between the propane/LP supply cylinder and

the heater must be disconnected and the cylinder

removed from the heater and stored in accordance

with Chapter 5 of the Standard for the Storage and

Handling of Liquefied Petroleum Gases. ANSI/

NFPA 58 (U.S.) OR CAN/CGA B149.2 (Canada)

If connected to a permanently installed propane/LP

supply system, the system requires the use of a

two-stage gas regulator assembly which is nor

mally provided by your propane/LP dealer as part

of the propane/LP supply system. Consult with

your local propane/LP dealer for details concerning proper equipment and installation.

FOR MODEL 125-RN (FOR USE

WITH NATURAL GAS ONLY)

Piping must be clean and free from scale or burrs.

Install regulator supplied with heater. Connect with

1/2" NPT nipple to control valve.

Connect the appliance to an appropriately designed

and installed fuel supply system. This system must

include an approved manual shutoff valve which

is readily accessible and is located within 6 feet

of the appliance. Additionally, a sediment trap or

drip leg must be located upstream of this manual

shutoff valve. Refer to the appropriate (natural gas)

installation code noted above. If a flexible connec

tor is used, it must be of an approved type.

WARNING: Never use a flame

for gas leak testing.

-

.

-

-

114248-01B

www.desatech.com

5

Page 6

OPERATING

INSTRUCTIONS

WARNING: If you do not follow these instructions exactly,

a fire or explosion may result

causing property damage, personal injury or loss of life.

CAUTION: This appliance

is hot during normal operation,

avoid physical contact.

CAUTION: Do not place

clothing or other combustible

materials on this appliance.

DO NOT operate this heater if any part has been

under water. Call a qualified service technician to

inspect the appliance and to replace any part of

the control system or gas control valve which has

been under water.

LIGHTING HEATER

1. Before attempting to light the heater, smell

all around the heater area for gas. Turn on

the gas supply to the appliance and check all

fittings and connections for gas leaks using a

mild soap and water solution. NEVER use a

match to check for gas leaks. Should a gas leak

occur, shut off the gas supply to the appliance

immediately. Wait a minimum of five minutes

before repairing the leak.

2. Use only the fuel intended for this appliance.

Check the appliance rating plate for the correct

fuel information.

3. Turn the control knob clockwise to the OFF

position. See Figure 1, page 3 and Figure 2

for location of appliance parts.

4. Wait a sufficient length of time (at least five

minutes) to allow gas which may have ac

cumulated in burner compartment to escape.

5. Turn on the main gas supply.

6. Turn control knob counterclockwise to the

PILOT position.

7a.

Press and turn control knob counterclockwise to

PILOT position and hold for 1 to 2 minutes. This

may take longer to purge air from supply hose

depending on length of the hose being used.

Press red spark ignition button to light pilot

flame (repeat until pilot lights) and continue to

hold control knob at PILOT position for 30-60

seconds to enable pilot light safety system. Fully

turn control knob to HI position to light burner.

7b. To match light the pilot, move the lighting

hole cover aside (see Figure 2) and place a

lighted match into hole. Press control knob

and hold while lighting and observing pilot

burner. Ensure that pilot burner ignites from

match. Allow pilot to burn approximately 30

seconds before releasing control knob. If pilot

does not remain lit, repeat lighting operation

allowing a longer period of time before releasing control knob.

Note: In cases where long runs of gas supply lines

have been installed ahead of the appliance, it may

be necessary to bleed trapped air out of supply lines

before lighting pilot. New installations generally

require bleed of supply lines. Wait a minimum of

five minutes after bleeding supply lines before

attempting to light heater.

Adjust pilot if necessary as noted under Pilot

Burner Adjustment

8. Turn control knob counterclockwise to the ON

position. The burner will light. DO NOT oper

ate heater in any position other than full ON.

IMPORTANT: DO NOT attempt to adjust the

main burner input using the main gas supply valve.

This may cause the pilot and thermocouple to shut

down the burner.

Combustion

Chamber

Thermocouple

Mounting

Brace

-

Match

Lighting

Hole Cover

Pilot Assembly

Gas Manifold

Figure 2 - Appliance Parts Identification

, page 7.

Control knob

-

Burner

Filter

6

www.desatech.com

114248-01B

Page 7

OPERATING

INSTRUCTIONS

Continued

SHUTTING OFF HEATER

• For short periods of time, turn the main burner

off by turning control knob clockwise to the

PILOT position.

• For extended periods of non use, turn appli

ance completely off by turning control knob

clockwise to the PILOT position, press knob

slightly, then turn knob fully clockwise to

the OFF position.

models, also turn off gas supply cylinder.)

Note: For propane/LP gas

PILOT BURNER ADJUSTMENT

1. Remove pilot adjustment cap. The pilot adjust-

ment cap is a slotted screw located in front

of the PILOT designation stamped on top of

valve body just below control knob.

2. Adjust pilot key to provide properly sized

flame. Rotate the key clockwise to decrease

flame or counterclockwise to increase flame.

3. Replace pilot adjustment cap.

MAINTENANCE

WARNING:

• Never attempt to service

heater while it is connected to

propane supply, operating or

hot. Severe burns can occur.

• Keep heater clear and free

from combustible materials,

gasoline and other flammable

vapors and liquids.

• Do not block the flow of combustion or ventilation air.

1. Keep heater clean. Clean heater annually or as

needed to remove dust and debris. If heater is

dirty or dusty, clean heater with a damp cloth.

Use household cleaners on difficult spots.

2. Inspect heater before each use. Check connec

tions for leaks. Apply mixture of liquid soap

and water to connections. Bubbles forming

show a leak. Correct all leaks at once.

3. Inspect hose/regulator assembly before each

use. If hose is highly worn or cut, replace.

4. Have heater inspected yearly by a qualified

service agency.

SPECIFICATIONS

Propane/LP Model 125-R

Rating

Fuel Propane Vapor Only

Fuel Consumption per Hour

5.17 liters (1.3 gallon)

2.6 kg (5.8 pounds)

Supply Pressure To Regulator (for input adjustment)

Maximum 1380 kPa (200 psi)

Minimum 138 kPa (20 psi)

Manifold Pressure 2.3 kPa (9.5 inches W.C.)

Weight

Heater 17.69 kg (39 lbs)

Shipping 20.86 kg (46 lbs)

Size - L x W x H 40.6 x 45.7 x 109.2 cm

(16 x 18 x 43 inches)

Min Temperature -29 °C (-20° F) Surrounding

Air Temperature

Natural Gas Model 125-RN

Rating

Fuel Natural Gas Only

Fuel Consumption

per Hour 3.5 m

Manifold Pressure 1.5 kPa (6 inches W.C.)

Weight

Heater 17.69 kg (39 lbs)

Shipping 20.86 kg (46 lbs)

Size - L x W x H 40.6 x 45.7 x 109.2 cm

(16 x 18 x 43 inches)

Min Temperature -29 °C (-20° F) Surrounding

Air Temperature

-

125,000 Btu/Hr (131,882 kj)

125,000 Btu/Hr (131,882 kj)

3

(125 ft3)

114248-01B

www.desatech.com

7

Page 8

TROUBLESHOOTING

WARNING: Never attempt to service heater while it is connected

to propane supply, operating or hot. Severe burns can occur.

SYMPTOM

Burner fails to light

Pilot lights but goes out when

automatic control valve button

is released

Burn rate is low

POSSIBLE CAUSE

1. Gas supply valve closed

2. Exce ss-flo w ch eck valve

closed (p ropane/LP units

only)

3. Blockage in burner orifice

4. Piezo ignition system not

sparking

1. Not enough warm-up time

2. Low gas pressure

3. Thermocouple loose or needs

to be replaced

4. Automatic control valve needs

to be replaced

1. Main burner valve not fully

open

2. Plugged gas orifices

3. Low gas pressure

4. Low fuel supply

REMEDY

1. Open gas supply valve slowly

2. Close propane supply valve

on propane tank and reopen

slowly

3. Replace burner orifice

4. Assure ignitor electrode gap is

5.0 mm (.195 in). Check wire

lead for damage Replace piezo

ignitor and/or ignitor electrode

as necessary. Do not bend elec

trode, this may cause breakage

1. Relight, hold automatic control

valve button in 45 seconds

2. Check for proper gas supply

3. Tighten connection or replace

thermocouple

4. Replace automatic control

valve

1. Fully open main burner valve

by pushing in control knob

and turning counterclockwise

towards HIGH position until

it stops

2. Replace gas orifice

3. Check gas supply; check

regulator output

4. Consult gas supplier to determine adequate supply. If using

propane/LP gas, the tank could

be empty

-

8

www.desatech.com

114248-01B

Page 9

REPLACEMENT PARTS

WARNING: Use only original

replacement parts. This heater

must use design-specific parts.

Do not substitute or use generic

parts. Improper replacement

parts could cause serious or fatal injuries. This will also protect

your warranty coverage for parts

replaced under warranty.

PARTS UNDER WARRANTY

Contact authorized dealers of this product. If they

canʼt supply original replacement part(s), either call

DESA Heating Productsʼ at 1-866-672-6040 or

DESA Industries at 1-905-826-8010.

When calling DESA, have ready:

• your name and address

• model and serial numbers of your heater

• how heater was malfunctioning

• purchase date

In most cases, we will ask you to return the part

to the factory.

PARTS NOT UNDER WARRANTY

Contact authorized dealers of this product. If they

canʼt supply original replacement part(s), call DESA

Heating Productsʼ at 1-866-672-6040 or DESA

Industries at 1-905-826-8010..

When calling DESA, have ready:

• model and serial numbers of your heater

• the replacement part number

ACCESSORIES

Purchase accessories and parts from your nearest

dealer or service center. If your dealer or service

center can not supply an accessory or part, call

DESA Heating Products at 1-866-672-6040 or

DESA Industriesʼ at 1-905-826-8010. You can

also write to the addresses listed on the back page

of this manual.

FUEL GAS CONNECTOR - LPA4020

Connects regulator to all standard propane tanks.

U.L. and AGA listed.

114248-01B

www.desatech.com

9

Page 10

ILLUSTRATED PARTS BREAKDOWN

20

14

22

9

23

8

19

16

18

1

17

6

7

24

4

11

5

3

21

15

12

13

10

2

MODELS 125-R AND 125-RN

10

www.desatech.com

114248-01B

Page 11

PARTS LIST

This list contains replaceable parts used in your heater. When ordering parts, follow the instructions

listed under Replacement Parts on page 9 of this manual.

KEY PART NUMBER

NO. 125-R 125-RN DESCRIPTION QTY.

1 104119-01 104119-01 Manual Control Valve 1

2 114049-01 114049-01 Filter/Diffuser 1

3 114120-01 114148-01 Pilot Orifice 1

4 114121-01 114121-01 Thermocouple 1

5 114128-01 114128-01 Pilot Burner 1

6 114134-01

_____

7

8 114244-01 114244-01 Pilot Supply Tube 1

9 114153-01 114153-01 Ignitor 1

10 102445-01 102445-01 Piezo 1

11 114243-01 114243-01 Spacer 1

12 114154-01 114154-01 Axle 1

13 114156-01 114156-01 Axle Brackets 1

14 114157-01 114157-01 Handle 1

15 114208-01 114208-01 Wheel 2

16 114209-01 114209-01 Valve Supply Tube Clamp 1

17 114212-01 114212-01 Valve Supply Tube 1

18 114213-01 114213-01 Burner Manifold 1

19 114216-01 114216-01 Burner 1

20 ** ** Frame Assembly 1

21 ** ** Combustion Chamber 1

22 ** ** Top Plate 1

23 114241-01 114241-01 Burner Mounting Plate 1

24 114242-01 114242-01 Pilot Mounting Bracket 1

114245-01 114245-02 General Info Decal 1

114246-01 114246-01 Caution Decal 1

113985-02 113985-03 Tradename Decal 1

115297-01 115297-01 Hang Tag 1

** Not a field replaceable part

_____

Hose/Regulator Assembly 1

103406-03 Regulator 1

PARTS AVAILABLE - NOT SHOWN

114248-01B 11

www.desatech.com

Page 12

WARRANTY AND REPAIR SERVICE

KEEP THIS WARRANTY

Model

Serial No.

Date of Purchase

LIMITED WARRANTY

DESA warrants this product and any parts thereof, to be free from defects in materials and workmanship for

one (1) year from the date of first purchase when operated and maintained in accordance with instructions. This

warranty is extended only to the original retail purchaser, when proof of purchase is provided.

This warranty covers only the cost of parts and labor required to restore the product to proper operating condition.

Transportation and incidental costs associated with warranty repairs are not reimbursable under this warranty.

Warranty service is available only through authorized dealers and service centers.

This warranty does not cover defects resulting from misuse, abuse, negligence, accidents, lack of proper main

tenance, normal wear, alteration, modification, tampering, contaminated fuels, repair using improper parts or

repair by anyone other than an authorized dealer or service center. Routine maintenance is the responsibility

of the owner.

THIS EXPRESS WARRANTY IS GIVEN IN LIEU OF ANY OTHER WARRANTY EITHER EXPRESSED

OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICU

LAR PURPOSE.

DESA assumes no responsibility for indirect, incidental or consequential damages. Some states do not allow

the exclusion or limitation of incidental or consequential damages or limitations or exclusions may not apply

to you. This Limited Warranty gives you specific legal rights and you may also have other rights which vary

from state to state.

We reserve the right to amend these specifications at any time without notice. The only warranty applicable is our

standard written warranty. We make no other warranty, expressed or implied.

WARRANTY SERVICE

Should your heater require service, return it to your nearest authorized service center. Proof of purchase must be

presented with the heater. The heater will be inspected. A defect may be caused by faulty materials or workmanship.

If so, DESA will repair or replace the heater without charge.

REPAIR SERVICE

Return your heater to your nearest authorized service center. Repairs not covered by the warranty will be billed at

standard prices. Each Service Center is independently owned and operated. We reserve the right to amend these

specifications at any time without notice.

When writing for information regarding your heater, be sure to include the model number and serial number as shown

on the model plate.

For more information about this warranty, write:

-

-

2701 Industrial Drive

P.O. Box 90004

Bowling Green, KY 42102-9004

ATTN: Customer Service Department

2220 Argentia Road, Unit #4

Mississauga, Ontario

L5N2K7

Page 13

APPAREIL DE CHAUFFAGE DE CHANTIER AU GAZ À

INFRAROUGE

MANUEL D’UTILISATION

MODÈLES 125-R ET 125-RN

IMPORTANT : Lisez et comprenez ce manuel avant d’assembler,

d’allumer ou de réparer l’appareil de chauffage. Une mauvaise

utilisation de l’appareil de chauffage peut causer des blessures

graves. Conservez ce manuel pour référence future.

AVERTISSEMENT DE RISQUE GÉNÉRAL :

Tout manquement aux précautions et aux instructions four

nies avec cet appareil de chauffage peut causer la mort, des

blessures corporelles graves ainsi que des pertes matérielles

et des dommages causés par les risques associés au feu, à

une explosion, aux brûlures, à l’asphyxie, à l’empoisonne

ment au monoxyde de carbone et par les chocs électriques.

Seuls les individus qui comprennent et suivent les instruc

tions peuvent utiliser ou réparer cet appareil de chauffage.

Si vous avez besoin d’assistance ou de renseignements con

cernant l’appareil de chauffage tels que le mode d’emploi, les

étiquettes, etc., communiquez avec le fabricant.

Conservez ce mode d’emploi pour consultation future.

Pour plus de détails, visitez le site www.desatech.com

-

-

-

-

Page 14

TABLE DES MATIÈRES

Information relative à la sécurité ......................... 2

Identification du produit ....................................... 3

Déballage ............................................................ 3

Théorie de fonctionnement .................................. 3

Alimentation en gaz ............................................. 4

Ventilation ............................................................ 4

Instructions pour l’installation .............................. 4

Placement de l’appareil de chauffage ................. 5

Tuyauterie ............................................................

Notice d’utilisation ............................................... 6

Entretien .............................................................. 7

Spécifications ...................................................... 7

Notice d’utilisation ............................................... 7

Dépannage .......................................................... 8

Pièces de rechange ............................................. 9

Accessoires ......................................................... 9

Vue détaillée et liste des pièces ........................ 10

5

Service de garantie et de réparation ..Couverture arrière

INFORMATION RELATIVE

À LA SÉCURITÉ

AVERTISSEMENT : cet appareil

contient ou produit des produits

chimiques déterminés par l’État de

Californie comme cancérigènes et

pouvant causer des malformations

congénitales et d’autres problèmes

liés à la reproduction.

AVERTISSEMENT : danger d’incendie, de brûlure, d’inhalation et

d’explosion. Garder les produits com

bustibles solides comme les matériaux

de construction, le papier et les cartons,

à une distance sûre de l’appareil de

chauffage tel que recommandé dans

les instructions. Ne jamais utiliser l’ap

pareil de chauffage dans des espaces

susceptibles de contenir des com

bustibles volatils ou atmosphériques

ou des produits tels que de l’essence,

des diluants, du solvant à peinture,

des particules de poussières ou des

produits chimiques inconnus.

AVERTISSEMENT : cet appareil

n’est pas conçu pour usage domestique

ou dans les véhicules de camping.

AVERTISSEMENT : la pression

ne doit pas dépasser 34 hPa (0,5

lb/po3 ou 14 po CE) à la vanne de

contrôle de gaz.

Cet appareil de chauffage est conçu comme appareil de

chauffage de chantier en conformité avec les normes

ANSI Z83.7/CGA2.2.14. Dʼautres normes régissent

lʼutilisation des gaz combustibles et des produits

de chauffage pour des utilisations particulières. Les

2

-

-

-

www.desatech.com

autorités locales peuvent vous conseiller à propos de

ces normes. La fonction principale des appareils de

chauffage de chantier est la production temporaire de

chaleur pour des édifices en construction ou en cours

de modification ou de réparation. Utilisés correctement,

ces appareils de chauffage représentent une source de

chaleur économique et sûre. Les produits de combustion sont évacués dans lʼespace qui est chauffé.

Nous ne pouvons pas prévoir toutes les utilisations

possibles de nos appareils de chauffage. Vérifiez

auprès de votre responsable local de la sécurité-incendie si vous avez des questions relatives à

lʼutilisation de lʼappareil de chauffage.

Dʼautres normes régissent lʼutilisation des gaz combustibles et des produits de chauffage pour des utilisations particulières. Les autorités locales peuvent

vous conseiller à propos de ces normes.

Empoisonnement au monoxyde de carbone : certaines

personnes sont plus sensibles au monoxyde de carbone

que dʼautres. Les premiers symptômes dʼun empoisonnement au monoxyde de carbone ressemblent à la grippe

avec des maux de tête, du vertige ou de la nausée. Si

vous avez ces symptômes, il se pourrait que lʼappareil de

chauffage ne fonctionne pas bien. Respirez tout de suite

de lʼair frais ! Vérifiez si la ventilation est suffisante et

faites réparer lʼappareil de chauffage.

Gaz propane : le gaz propane nʼa pas dʼodeur. Un pro-

duit odorant est ajouté au gaz propane. Cette odeur vous

permet de détecter une fuite de propane. Cependant,

cette odeur ajoutée au propane peut se dissiper. Du gaz

propane peut être présent même sʼil nʼy a pas dʼodeur.

Lisez et comprenez tous les avertissements. Conservez ce manuel pour consultation future. Il vous permettra de faire fonctionner cet appareil de chauffage

correctement et en toute sécurité.

1.

Installez et utilisez lʼappareil de chauffage avec précaution. Suivez toutes les lois et les codes locaux. En

lʼabsence de codes ou de règlements locaux, consultez

la Norme pour lʼemmagasinage et la manipulation

du gaz de pétrole liquéfié (ANSI/NFPA 58) et le Code

dʼinstallation du gaz propane (CAN/CGA B149.2). Ces

documents décrivent les précautions à prendre pour

lʼentreposage et la manutention du gaz propane.

2. Nʼutilisez que le tuyau et le détendeur réglé en usine

qui ont été fournis avec lʼappareil de chauffage.

3. Nʼutilisez que du gaz propane composé pour

le retrait de vapeur (modèle 125-R).

114248-01B

Page 15

INFORMATION RELATIVE À

LA SÉCURITÉ

4. Assurez une ventilation suffisante. Avant dʼutiliser

le radiateur, aménagez une prise dʼair frais de

lʼextérieur dʼau moins 0,35 m2 (3,75 pi2).

5. Nʼutilisez pas lʼappareil de chauffage dans un édifice

habité ou dans des endroits où lʼon vit et dort.

6. Nʼutilisez pas lʼappareil de chauffage dans les

sous-sols ou sous le niveau du sol.

7. Dégagez lʼemplacement du radiateur et gardez-le

libre de matériaux combustibles, dʼessence, de

solvant à peinture ou dʼautres vapeurs et liquides

inflammables. La poussière est combustible.

Nʼutilisez pas lʼappareil de chauffage là où il y a

beaucoup de poussière.

8. Distances minimales entre lʼappareil de chauffage

et les produits combustibles :

Côtés Dessus

1,52 m (5 pi) 1,22 m (4 pi)

9. Placez lʼappareil de chauffage à au moins 6,1 m

(20 pi) des réservoirs de propane.

10.

Conservez les réservoirs de propane à moins de

38 °C (100 °F).

11. Vérifiez lʼappareil de chauffage avant chaque

utilisation. Nʼutilisez pas dʼappareil de chauffage

endommagé.

12. Avant chaque utilisation de lʼappareil de chauffage,

vérifiez si le tuyau nʼest pas endommagé. Sʼil est très

usé ou fendu, remplacez-le par un tuyau spécifié par

le fabricant avant dʼutiliser lʼappareil de chauffage.

13. Placez lʼappareil de chauffage sur une surface

stable et de niveau si lʼappareil est chaud ou en

fonctionnement.

14. Cet appareil nʼest pas conçu pour utilisation sur des

planchers finis.

15. Ne jamais obstruer lʼentrée dʼair (au bas de la

chambre de combustion) ou la sortie dʼair (chambre

de combustion radiante) du radiateur.

16. Éloignez lʼappareil de chauffage des courants dʼair,

du vent, des éclaboussures, de la pluie ou de lʼeau

ruisselante.

17. Ne laissez pas lʼappareil de chauffage sans sur

veillance.

18. Ne laissez pas les enfants et les animaux sʼappro

cher de lʼappareil de chauffage.

19. Ne déplacez, ne manipulez et ne révisez jamais un

appareil de chauffage brûlant ou en opération. Vous

risqueriez de vous brûler gravement. Attendez 15

minutes après avoir éteint lʼappareil de chauffage.

20. Pour ne pas vous blesser, portez des gants lorsque

vous manipulez lʼappareil de chauffage.

21. Ne raccordez jamais de tuyauterie de ventilation à

lʼappareil de chauffage.

22. Ne modifiez pas lʼappareil de chauffage. Maintenez

lʼappareil de chauffage dans son état initial.

114248-01B

Suite

www.desatech.com

23.

Nʼutilisez pas lʼappareil de chauffage sʼil a été

modifié.

24. Fermez lʼalimentation en propane de lʼappareil de

chauffage sʼil nʼest pas utilisé.

25. Utilisez seulement des pièces de rechange dʼori

gine. Cet appareil de chauffage utilise des pièces

conçues spécifiquement pour lui. Nʼutilisez pas de

substituts ou de pièces génériques. Lʼutilisation de

pièces de rechange inappropriées peut causer des

blessures graves ou fatales.

IDENTIFICATION DU

PRODUIT

Dessus

Écran de

protection

Chambre de

combustion

Orifice

d’allumage du

couvercle

Bouton de réglage

Figure 1 - Identification du produit

DÉBALLAGE

1. Enlevez le matériau dʼemballage appliqué sur

lʼappareil de chauffage pour son expédition.

Conservez les bouchons en plastique (fixés à

lʼentrée de la vanne et à lʼassemblage du tuyau

et du détendeur) pour lʼentreposage.

2. Retirez toutes les pièces de lʼemballage.

3. Inspectez toutes les pièces pour voir si elles ont

été endommagées pendant le transport. Si lʼappa-

reil de chauffage est endommagé, informez-en au

plus vite le revendeur où vous lʼavez acheté.

-

THÉORIE DE FONCTIONNEMENT

Système d’alimentation en carburant : lʼassemblage

du tuyau et du détendeur est relié à lʼalimentation en

gaz propane. Dans le cas des appareils au gaz naturel,

lʼalimentation en carburant est connectée au radiateur

avec un tuyau ou un tube fournis par lʼutilisateur. Il

achemine le combustible à lʼappareil de chauffage.

Circuit d’allumage : lʼallumeur piézo-électrique allume

lʼalimentation du brûleur.

Système de contrôle automatique : ce système provo-

que lʼarrêt de lʼappareil de chauffage en cas dʼextinction

de la flamme.

-

3

Page 16

ALIMENTATION EN GAZ

MODÈLE 125-R AU GAZ PROPANE

ET GPL SEULEMENT

Le gaz propane et les réservoirs de propane doivent

être fournis par lʼutilisateur.

Nʼutilisez cet appareil de chauffage quʼavec un

système dʼapprovisionnement à retrait de vapeur

de propane. Consultez le chapitre 5 de la

pour lʼemmagasinage et la manipulation du gaz

de pétrole liquéfié, ANSI/NFPA 58 et/ou CAN/CGA

B149.2. Votre bibliothèque ou votre service dʼin-

cendie ont cette publication.

La quantité de gaz propane utilisable dans les réservoirs

varie. Deux facteurs influencent cette quantité :

1. La quantité de gaz propane contenue dans les

réservoirs

2. La température des réservoirs

Le tableau ci-dessous indique le nombre minimum

de réservoirs de 45 kg (100 lb) à utiliser pour faire

fonctionner lʼappareil de chauffage. Raccordez les

réservoirs entre eux avec un collecteur.

Température moyenne

°C (°F) à l’emplacement Nombre de réservoirs

des réservoirs 45 kg (100 lb)

4° (40°) à 0° (32°) 2

Sous 0° (32°) 3

Moins de gaz se vaporise à basse température.

Votre fournisseur de gaz propane local vous aidera

à choisir le système dʼalimentation qui convient.

MODÈLE 125-RN AU GAZ NATUREL

SEULEMENT

Lʼutilisateur doit fournir lʼalimentation en gaz et

les raccordements au radiateur.

Régulez lʼalimentation en gaz entre un minimum

de 17 hPa (7 po CE) et un maximum de 34 hPa (0,5

lb/po). La capacité de lʼalimentation en gaz naturel

devrait pouvoir fournir au moins 3,54 m

de gaz à la pression recommandée à chacun des

radiateurs connectés au système.

Consultez votre fournisseur local de gaz naturel au

sujet des dimensions appropriées des canalisations

de gaz naturel.

Suivez toutes les lois et les codes locaux. En

lʼabsence de codes ou de règlements locaux,

reportez-vous au Guide national du gaz naturel

(NFPA54/ANSI Z223.1) et au Code dʼinstallation

du gaz naturel (CAN/CGA B149.1)

.

Norme

3

(125 pi3)

VENTILATION

AVERTISSEMENT : il doit y

avoir une ouverture sur l’air extérieur d’au moins 0,35 m

2

(3,75 pi2)

pendant le fonctionnement du radiateur. Si aucune ventilation d’air

frais de l’extérieur n’est fournie, un

empoisonnement au monoxyde

de carbone peut se produire.

Prévoyez une entrée d’air frais de

l’extérieur suffisante avant d’utili

-

ser l’appareil de chauffage.

INSTRUCTIONS POUR

L’INSTALLATION

Lisez attentivement ces instructions. Conformez-vous à

ces instructions. Ne laissez

personne assembler, allumer,

régler ou faire fonctionner ce

radiateur si cette personne n’a

pas lu ces instructions.

N’essayez pas de faire fonctionner cet appareil de chauffage

avec tout autre gaz que celui

spécifié sur la plaque signalétique de l’appareil.

Aux États-Unis et au Canada, lʼinstallation de cet

appareil doit se conformer aux codes locaux et

provinciaux ou, en leur absence, au Code national

du gaz naturel (États-Unis) ANSI Z223.1 - dernière

édition (pour le fonctionnement au gaz propane,

au GPL et au gaz naturel), à la Norme pour lʼem-

magasinage et la manipulation du gaz de pétrole

liquéfié ANSI/NFPA 58 (pour le fonctionnement au

gaz propane ou au GPL) ou avec les codes dʼinstallation canadiens mis à jour (Canada) CAN/CGA

B149.1 et B149.2.

Cet appareil de chauffage (incluant lʼensemble

tuyau et détendeur, sʼil y a lieu) doit être examiné

avant chaque utilisation et au moins une fois lʼan

par un technicien qualifié. Si le tuyau du modèle

125-R montre des signes dʼabrasion excessive ou

dʼusure, ou sʼil est fendu, il doit être remplacé

avant de mettre le radiateur en marche. Le rem

placement doit être conforme aux spécifications

du fabricant.

-

4

www.desatech.com

114248-01B

Page 17

PLACEMENT DE

L’APPAREIL DE CHAUFFAGE

Lʼappareil de chauffage (et le réservoir de gaz

propane ou de GPL sʼil y a lieu) doit être placé sur

une surface solide, plane et de niveau pour mini

miser les risques de renversement. Si un réservoir

dʼalimentation en gaz propane ou en GPL est utilisé,

le réservoir doit être solidement arrimé pour préve

nir un renversement accidentel. NʼUTILISEZ PAS

cet appareil de chauffage avec un réservoir qui

nʼest pas en position verticale.

Cet appareil ne doit être placé quʼà un endroit où le

potentiel de dommage matériel au radiateur (dû à

un contact physique, par exemple) est minimal.

Lʼinstallateur doit informer le propriétaire ou lʼutilisateur que des précautions doivent être prises pour

protéger lʼappareil contre les dommages matériels.

Cet appareil produit une chaleur radiante. Par

conséquent, il doit être placé à au moins 1,83 m

(6 pi) de tout réservoir de gaz propane ou de GPL

et ne doit pas être dirigé vers un tel réservoir situé

à moins de 6,1 m (20 pi).

Lʼappareil de chauffage doit être placé dans un

endroit à lʼabri des éclaboussures, de la pluie et

de lʼeau ruisselante.

Lʼutilisation de ce radiateur dans un endroit

venteux ou avec des courants dʼair réduit son

rendement. Si possible, utilisez cet appareil dans

un endroit sans courants dʼair.

TUYAUTERIE

POUR LE MODÈLE 125-R

(UTILISATION AVEC GAZ PROPANE

OU GPL SEULEMENT)

Ce modèle peut être connecté à un système autonome dʼalimentation en gaz propane ou en GPL

en utilisant lʼassemblage de tuyau et de détendeur

fourni avec lʼappareil OU à une installation perma

nente dʼalimentation en gaz propane ou en GPL.

Lorsque connecté à un système autonome dʼalimentation en gaz propane ou en GPL, lʼassemblage

du tuyau doit être vérifié avant chaque utilisation.

Si le tuyau montre des signes dʼusure ou dʼabrasion

excessive ou sʼil est fendu, remplacez-le avant

dʼutiliser lʼappareil de chauffage.

AVERTISSEMENT : n’utilisez pas un

réservoir de type chariot élévateur.

Le branchement du modèle 125-R à un réservoir de

gaz propane ou de GPL doit se faire dans un endroit

bien aéré en utilisant lʼassemblage de tuyau et de

détendeur fourni avec lʼappareil. NʼESSAYEZ

PAS de régler ce détendeur. Il a été réglé en usine

pour assurer un fonctionnement sûr et satisfaisant

de lʼappareil. Utilisez une clé ouverte de 7/8 po

pour connecter le raccord POL (fourni avec le

détendeur de propane ou de GPL) au réservoir de

gaz propane ou GPL. Tournez le raccord POL dans

-

le sens inverse des aiguilles dʼune montre (filets

inversés) et serrez. NʼUTILISEZ PAS de mastic

pour joints de tubes sur des filets POL.

-

Le radiateur doit être placé à au moins 1,83 m (6

pi) de tout réservoir de gaz propane ou de GPL et

ne doit pas être dirigé vers un tel réservoir situé à

moins de 6,1 m (20 pi). Si plus dʼun radiateur est

utilisé, la distance qui les sépare des réservoirs doit

être dʼau moins 6,1 m (20 pi).

Lʼalimentation en gaz doit être coupée à la bouteille de propane ou de GPL lorsque lʼappareil ne

fonctionne pas.

Lorsque le radiateur doit être entreposé à lʼintérieur, le raccordement entre le réservoir de gaz

propane ou de GPL et lʼappareil de chauffage

doit être déconnecté et le réservoir doit être gardé

à lʼextérieur conformément au chapitre 5 de la

Norme sur lʼemmagasinage et la manutention de

gaz de pétrole liquéfié ANSI/NFPA 58 (États-Unis)

ou CAN/CGA B149.2 (Canada)

Lorsque connecté à un système permanent dʼalimentation en gaz propane ou en GPL, le système

exige lʼutilisation dʼun assemblage de détendeur

à double détente, lequel est habituellement fourni

par le revendeur local de gaz propane ou de GPL

et fait partie du système dʼalimentation. Consul

tez votre revendeur local de gaz propane ou de

GPL pour plus de renseignements sur le matériel

approprié et son installation.

.

POUR LE MODÈLE 125-RN (UTILISATION

AVEC GAZ NATUREL SEULEMENT)

La tuyauterie doit être propre, libre de calamine

et de bavures.

Installez le détendeur fourni avec le radiateur. Con-

nectez-le à la vanne de contrôle avec un mamelon

PTN de 1,3 cm (0,5 po).

Branchez lʼappareil à un système dʼalimentation en

gaz bien conçu et installé correctement. Ce système

doit comprendre une vanne dʼarrêt manuelle approu

vée, facilement accessible et placée à moins de 1,83 m

(6 pi) du radiateur. En outre, un piège à sédiments ou

un collecteur de condensats doit être placé en amont

de cette vanne dʼarrêt manuelle. Reportez-vous aux

codes dʼinstallation appropriés (pour le gaz naturel)

mentionnés plus haut. Si vous utilisez un raccord

flexible, celui-ci doit être dʼun type approuvé.

AVERTISSEMENT : n’utilisez

jamais de flamme pour recher

cher les fuites.

-

-

-

114248-01B

www.desatech.com

5

Page 18

NOTICE D’UTILISATION

AVERTISSEMENT : si vous

ne suivez pas ces instructions à

la lettre, il pourrait se produire un

incendie ou une explosion, causant

des dégâts matériels, des blessures ou même la mort.

ATTENTION : cet appareil devient chaud en fonctionnement normal; évitez tout contact physique.

ATTENTION : ne placez pas

de vêtements ou d’autre matériau

combustible sur cet appareil.

NʼUTILISEZ PAS cet appareil de chauffage sʼil a été

plongé dans lʼeau même en partie. Appelez un technicien compétent pour inspecter lʼappareil et remplacer

la vanne de contrôle de gaz ou toute autre pièce du

système de contrôle qui aurait été submergée.

ALLUMAGE DE L'APPAREIL DE

CHAUFFAGE

1. Recherchez les odeurs de gaz autour de lʼappareil avant de tenter dʼallumer le radiateur.

Ouvrez lʼalimentation en gaz et vérifiez

tous les raccords et branchements avec une

solution dʼeau savonneuse pour détecter les

fuites. NʼUTILISEZ JAMAIS dʼallumette

pour détecter les fuites de gaz. Sʼil y a une

fuite, fermez lʼalimentation en gaz de lʼappareil immédiatement. Attendez au moins cinq

minutes avant de réparer la fuite.

2. Nʼutilisez que le combustible prévu pour cet

appareil. Consultez la plaque signalétique de

lʼappareil pour plus de renseignements sur le

combustible approprié.

3. Tournez le bouton de réglage dans le sens des

aiguilles dʼune montre à la position OFF (Ar

rêt). Consultez la figure 1, page 3, et la figure

2 pour localiser les pièces de lʼappareil.

4. Attendez suffisamment de temps (au moins

cinq minutes) pour permettre la diffusion du

gaz accumulé dans le radiateur.

5. Ouvrez lʼalimentation principale en gaz.

6. Tournez le bouton de réglage dans le sens

inverse des aiguilles dʼune montre à la position

PILOT (Veilleuse).

7a. Appuzez sur le bouton de réglage et tournez-le

dans le sens inverse des aiguilles dʼune montre

à la position PILOT (Veilleuse) et gardez-le en

foncé pendant 1 à 2 minutes. Il peut falloir plus

de temps pour purger lʼair du tuyau dʼalimentation selon la longueur de ce dernier. Appuyez

sur le bouton rouge dʼallumage pour allumer

la veilleuse (répétez jusquʼà ce que la veilleuse

sʼallume) et continuez de maintenir le bouton

de réglage à la position PILOT (Veilleuse)

pendant 30 à 60 secondes pour enclencher le

système de sécurité de la veilleuse. Tournez

complètement le bouton de réglage en position

HI (Haut) pour allumer le brûleur.

7b. Pour allumer la veilleuse avec une allumette,

poussez le couvercle de lʼorifice dʼallumage

vers le côté (voir figure 2) et insérez une allumette allumée dans lʼorifice. Appuyez sur le

bouton de réglage et gardez-le enfoncé tout en

observant le brûleur de la veilleuse. Assurezvous que le brûleur de la veilleuse sʼallume

avec lʼallumette. Laissez la veilleuse allumée

pendant 30 secondes environ avant de relâcher

le bouton de réglage. Si la veilleuse ne reste

pas allumée, reprenez le processus dʼallumage

en gardant enfoncé le bouton de réglage plus

longtemps.

Remarque : si des canalisations dʼalimentation

en gaz longues ont été installées avant lʼappareil,

il sera peut-être nécessaire de purger lʼair avant

dʼallumer la veilleuse. Les nouvelles installations

exigent habituellement une purge. Après avoir

purgé le système, attendez au moins cinq minutes

avant dʼallumer l'appareil.

Réglez la veilleuse sʼil y a lieu tel quʼindiqué sous

la rubrique Ajustement de la veilleuse, page 7.

Chambre de

combustion

Thermocouple

Entretoise

de montage

-

Couvercle

de l’orifice

d’allumage

Assemblage

de la veilleuse

Collecteur

de gaz

Figure 2 - Identification des pièces de

-

Brûleur

Bouton de

réglage

l’appareil

Filtre

6

www.desatech.com

114248-01B

Page 19

NOTICE D’UTILISATION

Suite

8. Tournez le bouton de réglage dans le sens

inverse des aiguilles dʼune montre à la position ON (Marche). Le brûleur sʼallumera. NE

FAITES PAS fonctionner le radiateur dans une

autre position que ON (Marche).

IMPORTANT : NʼESSAYEZ PAS de régler lʼen

trée du brûleur principal par la vanne principale

dʼalimentation en gaz. Cela pourrait provoquer lʼarrêt du brûleur par la veilleuse et le thermocouple.

ARRÊT DE L’APPAREIL DE

CHAUFFAGE

•

Pour de courtes périodes, fermez le brûleur en tournant le bouton de réglage dans le sens des aiguilles

dʼune montre à la position PILOT (Veilleuse).

• Pour de longues périodes de non-utilisation,

fermez complètement lʼappareil en tournant le

bouton de réglage dans le sens des aiguilles dʼune

montre à la position PILOT (Veilleuse) et, en appuyant légèrement sur le bouton, tournez-le dans

le sens des aiguilles dʼune montre complètement à

la position OFF (Arrêt). Remarque : Dans le cas

des modèles au gaz propane ou au GPL, fermez

aussi la vanne du réservoir.

AJUSTEMENT DU BRÛLEUR DE LA

VEILLEUSE

1. Retirez le capuchon dʼajustement de la veilleuse.

Le capuchon dʼajustement de la veilleuse est une

vis à filets interrompus située devant lʼestampillage

PILOT (Veilleuse) sur le dessus du boîtier de la

vanne juste en dessous du bouton de réglage.

2.

Réglez la clavette de la veilleuse afin dʼobtenir

une flamme appropriée. Tournez la clavette dans

le sens des aiguilles dʼune montre pour diminuer la

flamme et dans le sens inverse pour lʼaugmenter.

3.

Replacez le capuchon dʼajustement de la veilleuse.

ENTRETIEN

AVERTISSEMENT :

• Ne tentez jamais de réparer

l’appareil de chauffage pendant

qu’il est branché au réservoir

de propane, qu’il fonctionne ou

qu’il est chaud. Des brûlures

graves peuvent en résulter.

• Dégagez le radiateur et ne

placez pas de matériaux

combustibles, d’essence et

d’autres vapeurs ou liquides

inflammables à proximité.

• Ne bloquez pas la circulation du

combustible ou la ventilation.

1.

Gardez lʼappareil de chauffage propre. Nettoyezle une fois lʼan et retirez la poussière et les débris

quand cʼest nécessaire. Si lʼappareil de chauffage

est sale ou poussiéreux, nettoyez-le avec un chif

fon humide. Employez des produits de nettoyage

domestique sur les taches tenaces.

2. Inspectez lʼappareil de chauffage avant chaque

utilisation. Vérifiez si les branchements ne fuient

pas. Appliquez un mélange de savon liquide

et dʼeau aux raccords. La présence de bulles

indique une fuite. Réparez toutes les fuites

immédiatement.

3. Inspectez lʼassemblage du tuyau et du détendeur

avant chaque utilisation. Si le tuyau est très usé

ou fendu, remplacez-le.

4. Faites inspecter lʼappareil de chauffage une fois

lʼan par une entreprise de service qualifiée.

SPÉCIFICATIONS

Modèle 125-R Propane ou GPL

Rendement 131 882 kJ (125 000 Btu/hr)

Combustible Propane gazeux seulement

Consommation de carburant à lʼheure

5,17 litres (1,3 gallons)

2,6 kg (5,8 livres)

Pression de lʼalimentation au détendeur (pour réglage

de lʼentrée)

Maximum 1380 kPa (200 lb/po

Minimum 138 kPa (20 lb/po

Pression au collecteur (CE) 24,13 cm (9,5 po)

Poids

Radiateur 17,69 kg (39 lbs)

Expédition 20,86 kg (46 lbs)

Dimensions - L x P x H 40,6 x 45,7 x 109,2 cm

(16 x 18 x 43 pouces)

Température minimale -29 °C (-20 °F)

Température de lʼair ambiant

Modèle 125-RN au gaz naturel

Rendement 131 882 kJ (125 000 Btu/hr)

Combustible Gaz naturel seulement

Consommation de carburant

à lʼheure 0,35 m

Pression au collecteur (CE) 1,5 kPa (6 po)

Poids

Radiateur 17,69 kg (39 lbs)

Expédition 20,86 kg (46 lbs)

Dimensions - L x H x L 40,6 x 45,7 x 109,2 cm

(16 x 18 x 43 pouces)

Température minimale -29 °C (-20 °F)

Température de lʼair ambiant

3

(125 pi3)

3

)

-

3

)

114248-01B

www.desatech.com

7

Page 20

DÉPANNAGE

AVERTISSEMENT : ne tentez jamais de réparer l’appareil de chauffage pendant qu’il est branché au réservoir de propane, qu’il fonctionne

ou qu’il est chaud. Des brûlures graves peuvent en résulter.

SYMPTÔME

Le brûleur ne sʼallume pas

La veilleuse sʼallume, mais elle

sʼéteint dès que le bouton de la

vanne de contrôle automatique

est relâché

Le taux de combustion est bas

CAUSE POSSIBLE

1. Vanne dʼalimentation en gaz

fermée

2. Vanne de limitation de débit

fermée (modèles au propane

et au GPL seulement)

3. Lʼorifice du brûleur est bouché

4. Le système dʼallumage pié

zo-électrique ne produit pas

dʼétincelles

1. Le préchauffage ne dure pas

assez longtemps

2. La pression du gaz est trop

faible

3. Le thermocouple est desserré

ou doit être remplacé

4. La vanne de contrôle automa

tique doit être remplacée

1. Vanne principale du brûleur

partiellement ouverte

2. Orifices des gaz bouchés

3. La pression du gaz est trop

faible

4. Il nʼy a pas assez de carburant

SOLUTION

1. Ouvrez lentement la vanne

dʼalimentation en propane

2.

Fermez le robinet dʼalimentation en propane du réservoir de

propane et rouvrez-le lentement

3. Remplacez lʼorifice du brûleur

-

4. Assurez-vous que lʼespacement

de lʼélectrode dʼallumage est de

5,0 mm (0,195 po). Vérifiez les

extrémités des fils, remplacez

lʼallumeur piézo-électrique et

lʼélectrode dʼallumage si néces

saire. Ne pliez pas lʼélectrode,

elle pourrait se briser

1. Rallumez et appuyez sur le

bouton de la vanne de con

trôle automatique pendant 45

secondes

2. Vérifiez si lʼalimentation en

gaz est adéquate

3. Resserrez le branchement ou

remplacez le thermocouple

4. Remplacez la vanne de con

trôle automatique

1. Ouvrez complètement la van

ne principale du brûleur en

appuyant sur le bouton de ré

glage tout en le tournant dans

le sens inverse des aiguilles

dʼune montre à la position HI

(Haut) jusquʼà la butée

2. Remplacez lʼorifice de gaz

3. Vérifiez lʼalimentation en gaz

et la sortie du détendeur

4.

Consultez votre fournisseur de

gaz pour déterminer une alimen

tation appropriée. Si vous utilisez

du gaz propane ou du GPL, le

réservoir pourrait être vide

-

-

-

-

-

-

8

www.desatech.com

114248-01B

Page 21

PIÈCES DE RECHANGE

AVERTISSEMENT : n’utilisez

que des pièces de rechange

DESA. Cet appareil de chauffage

utilise des pièces conçues spécifiquement pour lui. N’utilisez

pas de substituts ou de pièces

génériques. L’utilisation de pièces

de rechange inappropriées peut

causer des blessures graves ou

fatales. Ceci protégera également

la garantie des pièces remplacées

sous garantie.

PIÈCES SOUS GARANTIE

Communiquez avec les revendeurs autorisés de ce

produit. Sʼils ne peuvent pas vous fournir de pièces

de rechange DESA dʼorigine, communiquez avec

DESA Heating Products au 1-866-672-6040 ou

DESA Industries au 1-905-826-8010.

Lorsque vous appelez DESA, ayez sous la main :

• votre nom et votre adresse

• le modèle et le numéro de série de lʼappareil de

chauffage

• comment lʼappareil de chauffage est tombé en

panne

• la date de lʼachat

En général, nous vous demanderons de retourner

la pièce à lʼusine.

PIÈCES QUI NE SONT PAS SOUS

GARANTIE

Communiquez avec les revendeurs autorisés de ce

produit. Sʼils ne peuvent pas vous fournir de pièces

de rechange dʼorigine, appelez DESA Heating

Products au 1-866-672-6040 ou DESA Industries

au 1-905-826-8010.

Lorsque vous appelez DESA, ayez sous la main :

• le modèle et le numéro de série de lʼappareil de

chauffage

• le numéro de la pièce de rechange

ACCESSOIRES

Achetez les accessoires et les pièces chez le

revendeur ou au centre de service le plus proche

de chez vous. Si votre revendeur ou si le centre

de service ne peuvent vous procurer une pièce ou

un accessoire, appelez DESA Heating Products

au 1-866-672-6040 ou DESA Industries au

1-905-826-8010. Vous pouvez aussi nous écrire

aux adresses inscrites à lʼarrière de ce manuel.

RACCORD D’ALIMENTATION EN

GAZ - LPA4020

Permet de connecter le détendeur à tout réservoir de

propane standard. Inscrit auprès de UL et AGA.

114248-01B

www.desatech.com

9

Page 22

VUE DÉTAILLÉE DES PIÈCES

20

14

22

9

23

8

19

16

18

1

17

6

7

24

4

11

5

3

21

15

12

13

10

2

MODÈLES 125-R ET 125-RN

10

www.desatech.com

114248-01B

Page 23

LISTE DES PIÈCES

Cette liste contient les pièces de rechange utilisées dans votre appareil de chauffage. Quand vous commandez

des pièces, reportez-vous aux instructions de la section Pièces de rechange, à la page 9 de ce manuel.

N° NUMÉRO DE PIÈCE

125-R 125-RN DESCRIPTION QTÉ.

1 104119-01 104119-01 Robinet de contrôle manuel 1

2 114049-01 114049-01 Filtre-diffuseur 1

3 114120-01 114148-01 Orifice de la veilleuse 1

4 114121-01 114121-01 Thermocouple 1

5 114128-01 114128-01 Brûleur de la veilleuse 1

6 114134-01

_____

7

8 114244-01 114244-01 Tube d’alimentation de la veilleuse 1

9 114153-01 114153-01 Allumeur 1

10 102445-01 102445-01 Piézo-électrique 1

11 114243-01 114243-01 Entretoise 1

12 114154-01 114154-01 Essieu 1

13 114156-01 114156-01 Supports d’essieu 1

14 114157-01 114157-01 Poignée 1

15 114208-01 114208-01 Roue 2

16 114209-01 114209-01 Pince à tuyau d’alimentation de la vanne 1

17 114212-01 114212-01 Tuyau d’alimentation de la vanne 1

18 114213-01 114213-01 Tubulure du brûleur 1

19 114216-01 114216-01 Brûleur 1

20 ** ** Assemblage du châssis 1

21 ** ** Chambre de combustion 1

22 ** ** Plaque supérieure 1

23 114241-01 114241-01 Plaque de montage du brûleur 1

24 114242-01 114242-01 Support de montage de la veilleuse 1

114245-01 114245-02 Décalque d’information générale 1

114246-01 114246-01 Décalque d’avertissement 1

113985-02 113985-03 Décalque de marque de commerce 1

115297-01 115297-01 Étiquette à fil 1

** Remplacement à l’usine seulement.

_____

Assemblage de tuyau et de détendeur 1

103406-03 Détendeur 1

PIÈCES DISPONIBLES — PAS ILLUSTRÉES

114248-01B 11

www.desatech.com

Page 24

SERVICE DE GARANTIE ET DE RÉPARATION

114248 01

CONSERVEZ CETTE GARANTIE

Modèle

Numéro de série

Date de l’achat

DESA Heating Products garantit ce produit et toutes les pièces quʼil contient contre tout défaut de matériau et de

GARANTIE LIMITÉE

fabrication pour un (1) an à partir de la date dʼachat originale lorsque utilisé et entretenu selon les instructions. Cette

garantie ne protège que lʼacheteur au détail dʼorigine lorsquʼune preuve dʼachat est fournie.

Cette garantie ne couvre que le coût des pièces et de la main-dʼœuvre requis pour restaurer le produit à son

état de fonctionnement normal. Le transport et les frais incidents associés aux réparations sous garantie ne

sont pas remboursables sous cette garantie.

Les réparations sous garantie sont disponibles seulement par lʼintermédiaire des revendeurs et des centres

de service autorisés.

Cette garantie ne couvre pas les défauts causés par la mauvaise utilisation, lʼabus, la négligence, les accidents, le

manque dʼentretien adéquat, lʼusure normale, les modifications, les altérations, le trafiquage, les combustibles contaminés, les réparations avec des pièces inadéquates ou les réparations par quelquʼun dʼautre quʼun revendeur ou un

centre de service autorisé. Lʼentretien de routine est la responsabilité du propriétaire.

CETTE GARANTIE EXPRESSE REMPLACE TOUTE AUTRE GARANTIE EXPRESSE OU IMPLICITE, Y

COMPRIS LES GARANTIES DE COMMERCIALITÉ ET DʼADÉQUATION À UN BESOIN PARTICULIER.

DESA International nʼassume aucune responsabilité pour les dommages indirects, accessoires ou immatériels. Certains

états ou provinces ne permettent pas lʼexclusion ou la restriction des dommages imprévus ou incidents et certaines

restrictions ou exclusions pourraient ne pas sʼappliquer à votre cas. Cette garantie limitée vous donne des droits

spécifiques selon la loi; vous pourriez aussi avoir dʼautres droits selon lʼétat ou la province où vous habitez.

Nous nous réservons le droit de modifier ces spécifications à tout moment sans préavis. La seule garantie

valable est notre garantie écrite standard. Nous nʼoffrons aucune autre garantie, expresse ou implicite.

RÉPARATION SOUS GARANTIE

Si votre appareil de chauffage a besoin de réparation, retournez-le au centre de service autorisé le plus

près de chez vous. Une preuve dʼachat doit être présentée avec lʼappareil de chauffage. Lʼappareil de

chauffage sera inspecté. Un défaut peut être causé par des matériaux défectueux ou un défaut de fabri

cation. Si tel est le cas, DESA réparera ou remplacera lʼappareil de chauffage sans frais.

SERVICE DE RÉPARATION

Retournez votre appareil de chauffage au centre de service autorisé le plus proche de chez vous. Les

réparations non couvertes par la garantie seront facturées aux prix normaux. Chaque centre de service est

autonome. Nous nous réservons le droit de modifier ces spécifications à tout moment sans préavis.

Lorsque vous nous écrivez pour obtenir des renseignements concernant votre appareil de chauffage, veillez

à inclure les numéros de modèle et de série qui sont inscrits sur la plaque signalétique de lʼappareil.

Pour tout renseignement concernant cette garantie, écrivez-nous à :

-

2701 Industrial Drive

P.O. Box 90004

Bowling Green, KY 42102-9004, USA

ATTN: Customer Service Department

2220 Argentia Road, Unit #4

Mississauga, Ontario

L5N2K7

114248-01

Rev. B

01/05

NOT A UPC

Loading...

Loading...