Page 1

Denon Brand Company, D&M Holdings lnc.

e

Ver. 3

●

For purposes of improvement, specifications and

design are subject to change without notice.

●

Please use this service manual with referring to the

operating instructions without fail.

●

Some illustrations using in this service manual are

slightly different from the actual set.

注 意

サービスをおこなう前に、このサービスマニュアル

を必ずお読みください。本機は、火災、感電、けが

などに対する安全性を確保するために、さまざまな

配慮をおこなっており、また法的には「電気用品安

全法」にもとづき、所定の許可を得て製造されてお

ります。従ってサービスをおこなう際は、これらの

安全性が維持されるよう、このサービスマニュアル

に記載されている注意事項を必ずお守りください。

●

本機の仕様は性能改良のため、予告なく変更すること

があります。

●

補修用性能部品の保有期間は、製造打切後 8 年です。

●

修理の際は、必ず取扱説明書を参照の上、作業を行っ

てください。

●

本文中に使用しているイラストは、説明の都合上現物

と多少異なる場合があります。

Please refer to the

MODIFICATION NOTICE.

SERVICE MANUAL

MODEL JP E3 E2 EK E2A E1C E1K EUT

DVD-3800BDCI

BLU-RAY DISC/DVD VIDEO PLAYER

3

X0380 V.03 DE/CDM 0902

Page 2

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

LASER RADIATION

Caution - Class 1M visible and invisible laser radiation when open.

Do not view directly with optical instruments.

CAUTION

Please heed the points listed below during servicing and inspection.

◎ Heed the cautions!

Spots requiring particular attention when servicing, such

as the cabinet, parts, chassis, etc., have cautions indicated

on labels or seals. Be sure to heed these cautions and the

cautions indicated in the handling instructions.

◎ Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching in-

ternal metal parts when the set is energized could

cause electric shock. Take care to avoid electric shock,

by for example using an isolating transformer and

gloves when servicing while the set is energized, unplugging the power cord when replacing parts, etc.

(2)There are high voltage parts inside. Handle with extra

care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Though great care is taken when manufacturing parts from

sheet metal, there may in some rare cases be burrs on the

edges of parts which could cause injury if fingers are

moved across them. Use gloves to protect your hands.

◎ Inspect for safety after servicing!

Check that all screws, parts and wires removed or disconnected for servicing have been put back in their original positions, inspect that no parts around the area that has been

serviced have been negatively affected, conduct an insulation check on the external metal connectors and between

the blades of the power plug, and otherwise check that

safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and turn the power switch on. Using a 500V insulation resistance tester, check that the insulation resistance between the terminals of the power

plug and the externally exposed metal parts (antenna terminal, headphones terminal, microphone terminal, input

terminal, etc.) is 1MΩ or greater. If it is less, the set must

be inspected and repaired.

CAUTION

Concerning important safety

parts

◎ Only use designated parts!

The set's parts have specific safety properties (fire resistance, voltage resistance, etc.). For replacement parts, be

sure to use parts which have the same properties. In particular, for the important safety parts that are marked z on

wiring diagrams and parts lists, be sure to use the designated parts.

◎ Be sure to mount parts and arrange

the wires as they were originally!

For safety reasons, some parts use tape, tubes or other insulating materials, and some parts are mounted away from

the surface of printed circuit boards. Care is also taken with

the positions of the wires inside and clamps are used to

keep wires away from heating and high voltage parts, so

be sure to set everything back as it was originally.

DVD-3800BDCI

Many of the electric and structural parts used in the set

have special safety properties. In most cases these properties are difficult to distinguish by sight, and using replacement parts with higher ratings (rated power and

withstand voltage) does not necessarily guarantee that

safety performance will be preserved. Parts with safety

properties are indicated as shown below on the wiring diagrams and parts lists is this service manual. Be sure to replace them with parts with the designated part number.

(1) Schematic diagrams ... Indicated by the z mark.

(2) Parts lists ... Indicated by the z mark.

Using parts other than the designated

parts could result in electric shock, fires or

other dangerous situations.

2

Page 3

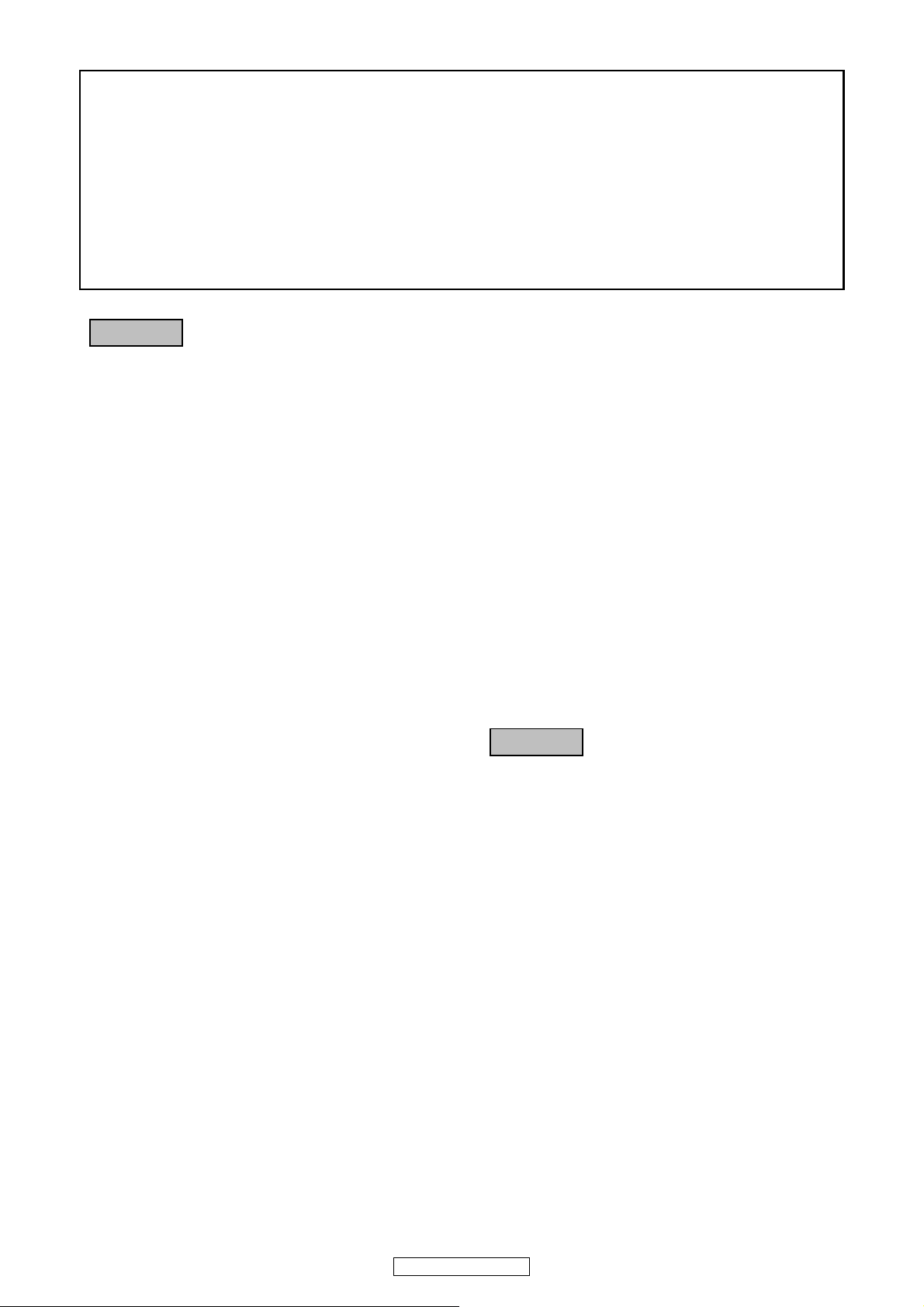

DIMENSION

3

DVD-3800BDCI

Page 4

WIRE ARRANGEMENT

If wire bundles are untied or moved to perform adjustment or parts replacement etc., be sure to rearrange

them neatly as they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise generation.

Wire arrangement viewed from the top

4

DVD-3800BDCI

Page 5

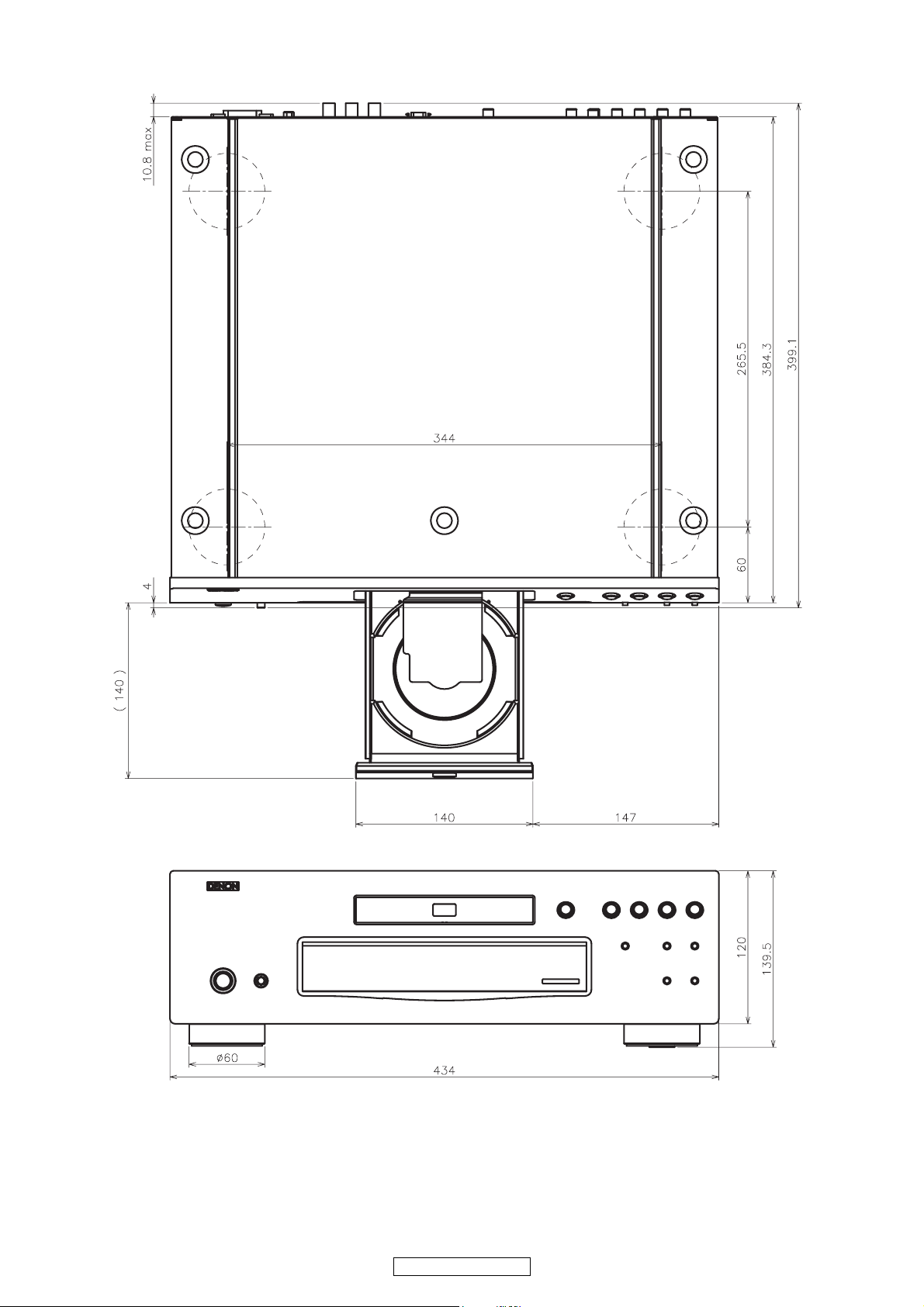

SPECIFICATIONS

5

DVD-3800BDCI

Page 6

6

DVD-3800BDCI

Page 7

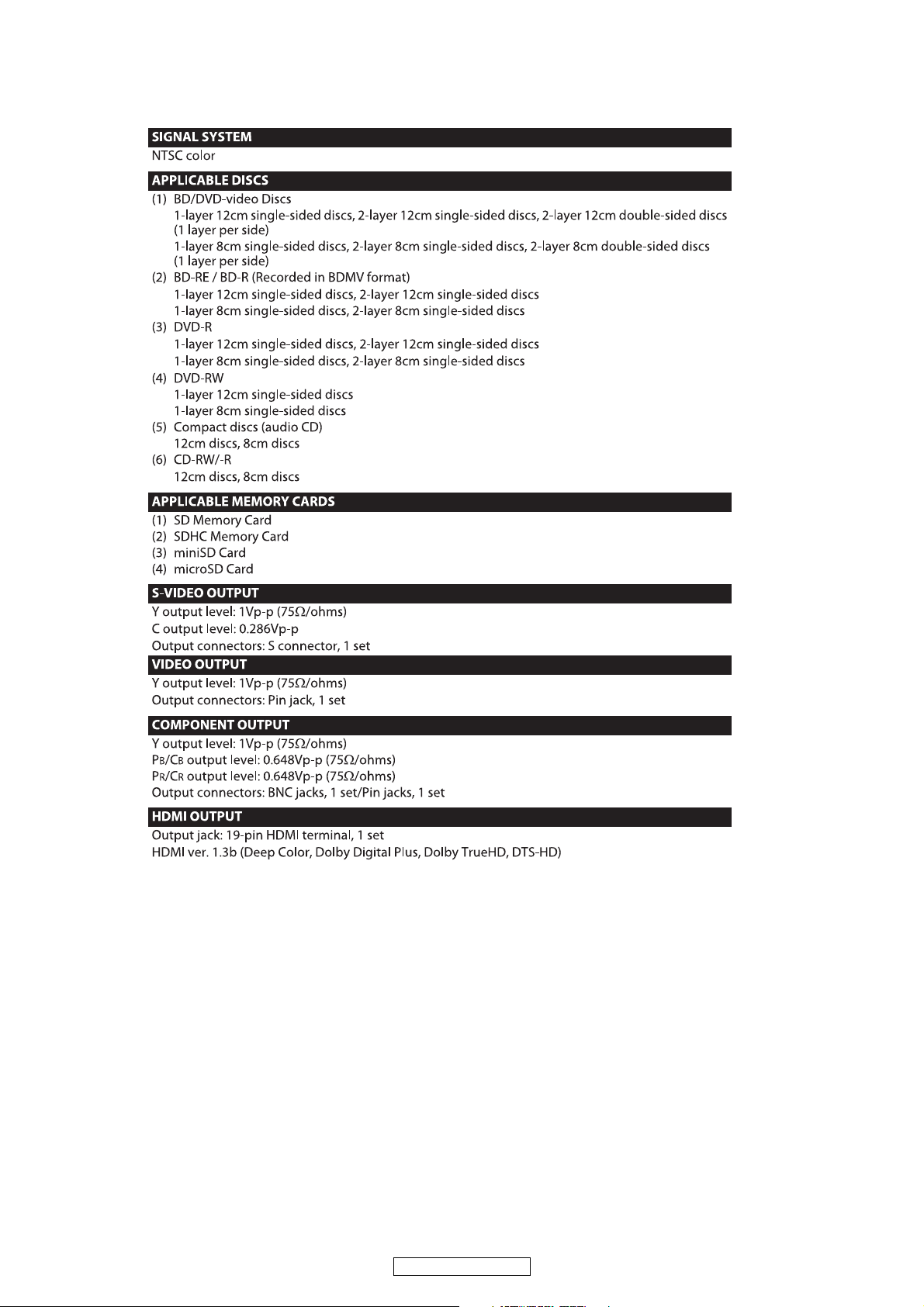

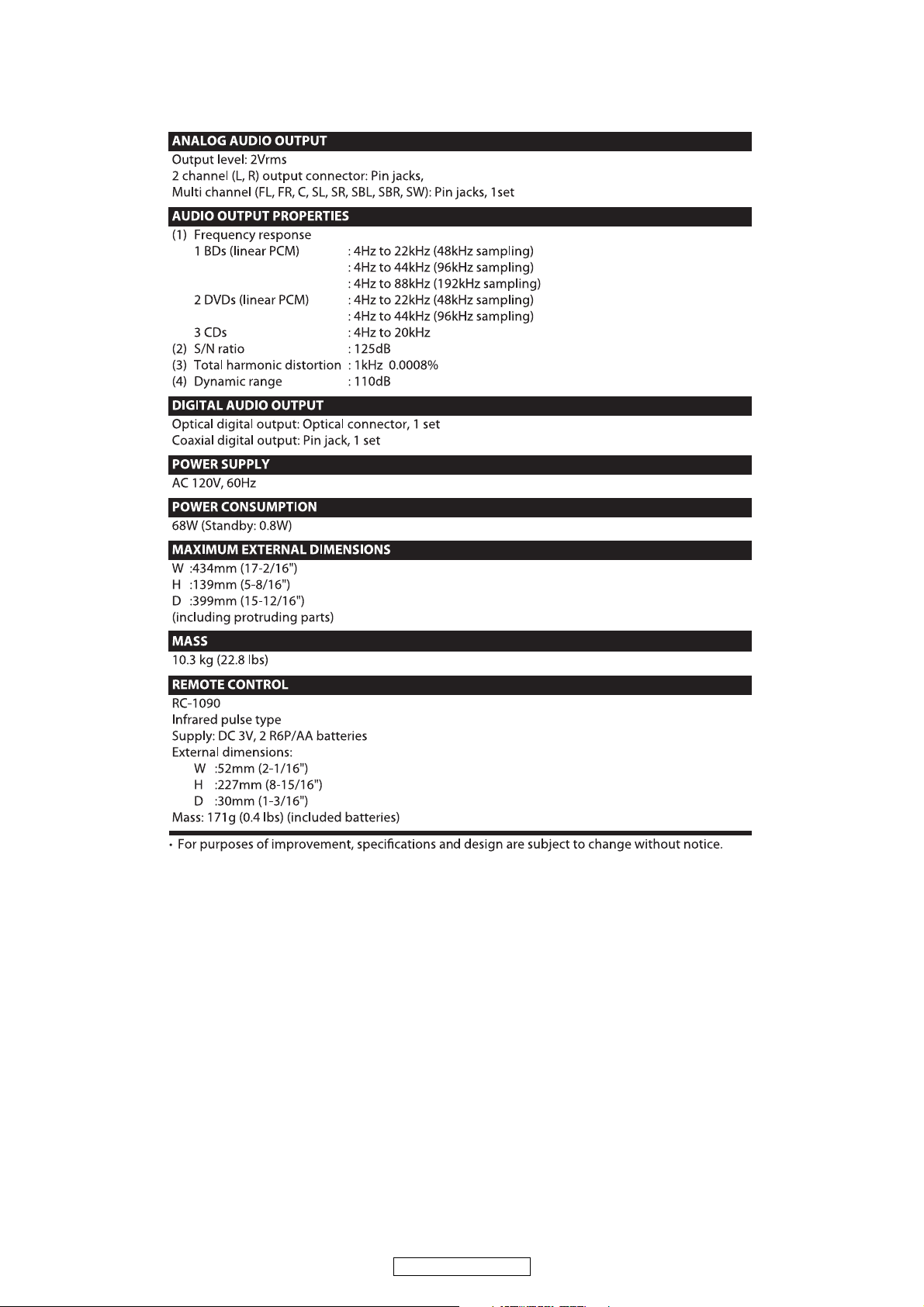

LASER BEAM SAFETY PRECAUTIONS

This BD player uses a pickup that emits a laser beam.

The laser beam is emitted from the location shown in the figure. When checking the laser diode, be sure to keep

your eyes at least 30 cm away from the pickup lens when the diode is turned on. Do not look directly at the laser

beam.

CAUTION: Use of controls and adjustments, or doing procedures other than those specified herein, may result in

hazardous radiation exposure.

Location: Top of BD mechanism.

Do not look directly at the laser beam coming

from the pickup or allow it to strike against your

skin.

Drive Mechanism Assembly

Laser Beam Radiation

Laser Pickup

Turntable

LASER RADIATION

WHEN OPEN. DO NOT

STARE INTO BEAM.

CAUTION

B1.0 Mechanism Assembly

d

7

DVD-3800BDCI

Page 8

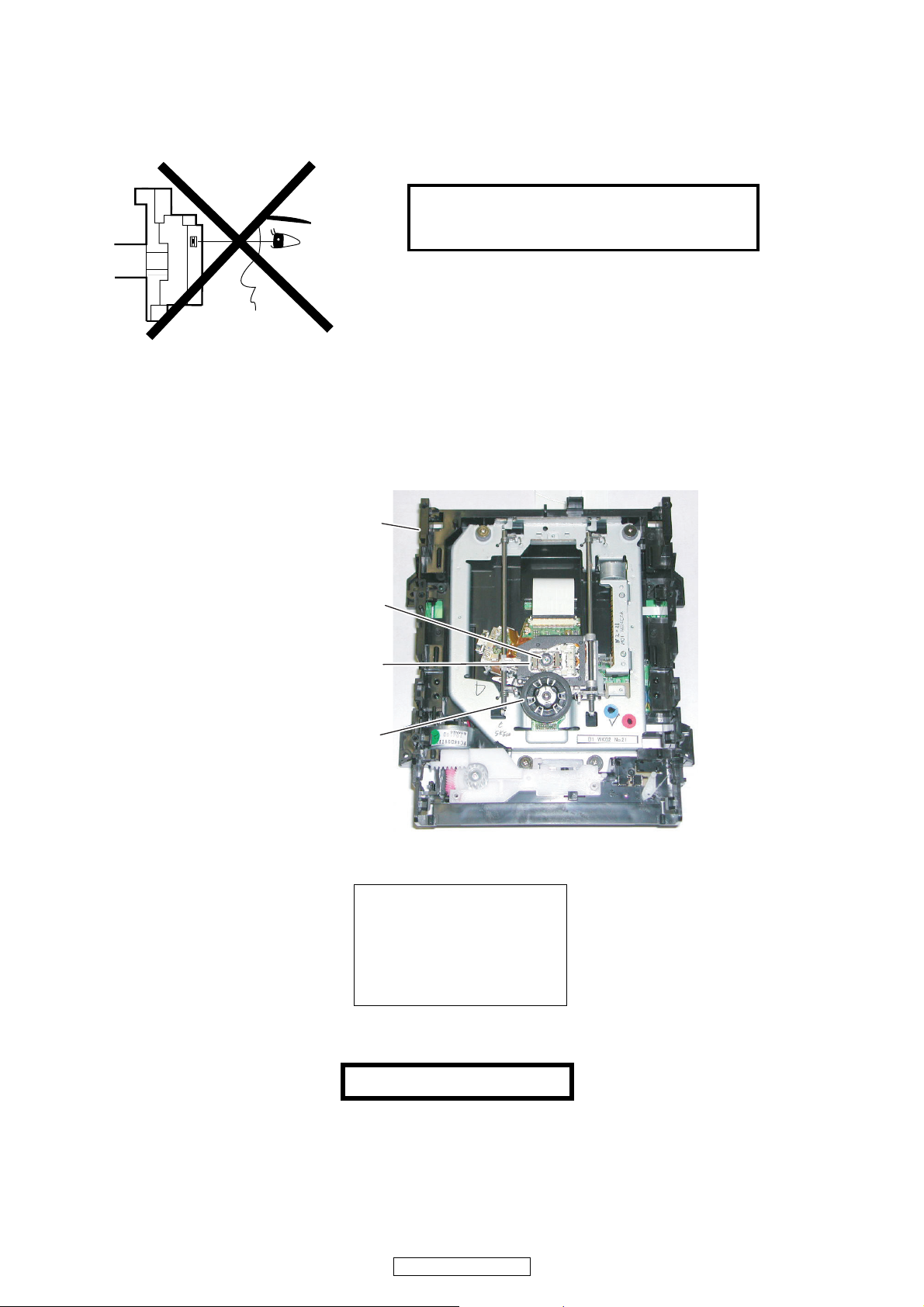

LASER BEAM SAFETY PRECAUTIONS

This BD player uses a pickup that emits a laser beam.

The laser beam is emitted from the location shown in the figure. When checking the laser diode, be sure to keep

your eyes at least 30 cm away from the pickup lens when the diode is turned on. Do not look directly at the laser

beam.

CAUTION: Use of controls and adjustments, or doing procedures other than those specified herein, may result in

hazardous radiation exposure.

Location: Inside Top of BD mechanism.

Do not look directly at the laser beam coming

from the pickup or allow it to strike against your

skin.

Drive Mechanism Assembly

Laser Beam Radiation

Laser Pickup

Turntable

d

B1.5 Mechanism Assembly

8

DVD-3800BDCI

Page 9

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts, and

wires have been returned to their original positions. Afterwards, do the following tests and confirm the specified

values to verify compliance with safety standards.

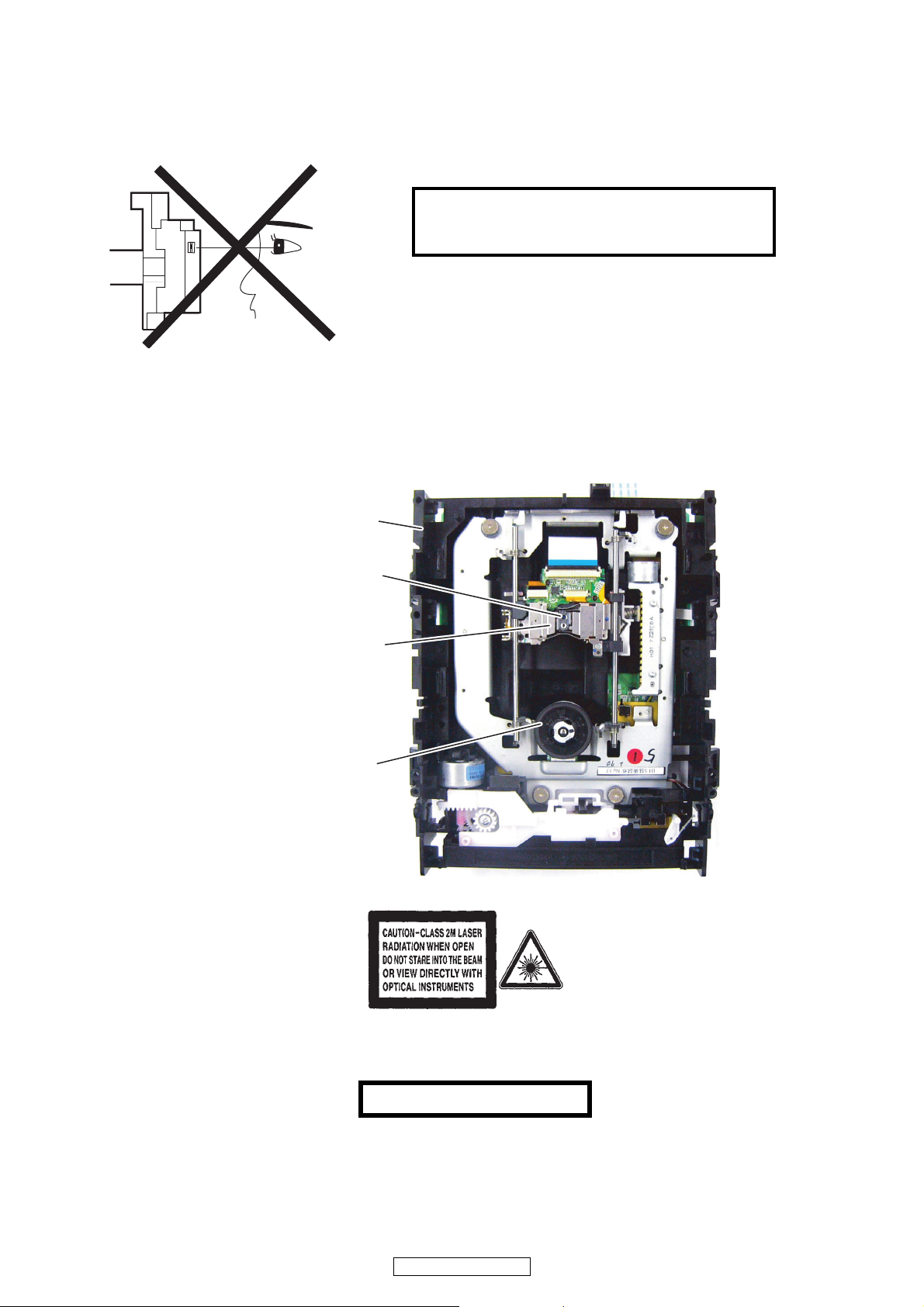

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d’) between

soldered terminals, and between terminals and

surrounding metallic parts. (See Fig. 1)

Table 1: Ratings for selected area

Note: This table is unofficial and for reference only. Be

sure to confirm the precise values.

2. Leakage Current Test

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs) and

externally exposed accessible parts (RF terminals,

antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.) is

lower than or equal to the specified value in the table

below.

Measuring Method (Power ON):

Insert load Z between B (earth ground, power cord plug

prongs) and exposed accessible parts. Use an AC

voltmeter to measure across the terminals of load Z.

See Fig. 2 and the following table.

Table 2: Leakage current ratings for selected areas

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

AC Line Voltage Clearance Distance (d), (d’)

120 V ≥ 3.2 mm (0.126 inches)

AC Line Voltage Load Z Leakage Current (i) Earth Ground (B) to:

120 V

0.15 μF CAP. & 1.5 kΩ RES.

Connected in parallel

i ≤ 0.5 mA Peak Exposed accessible parts

Chassis or Secondary Conductor

Primary Circuit

Fig. 1

d' d

AC Voltmeter

(High Impedance)

Exposed Accessible Part

B

Earth Ground

Power Cord Plug Prongs

Z

Fig. 2

9

DVD-3800BDCI

Page 10

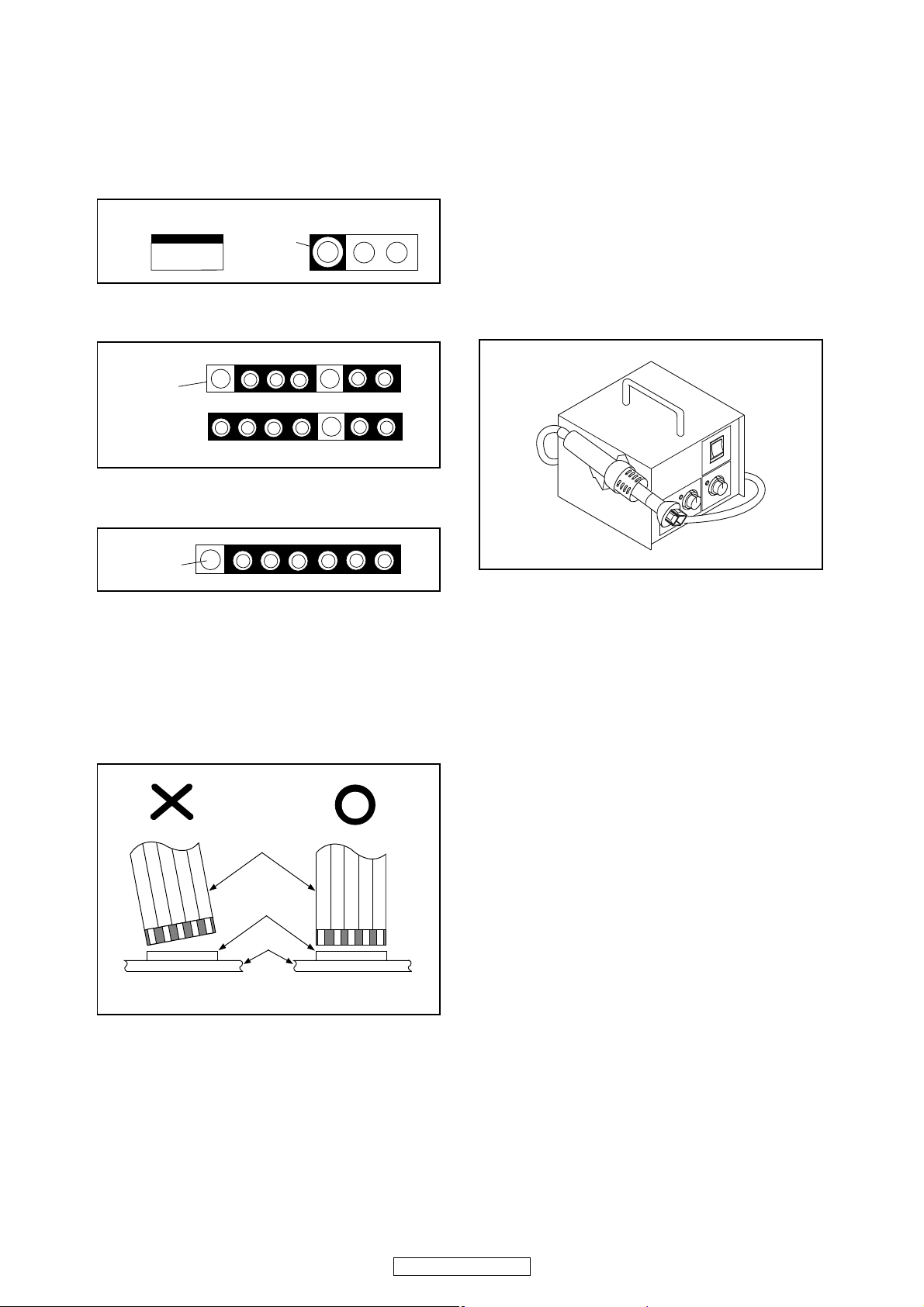

STANDARD NOTES FOR SERVICING

Circuit Board Indications

1. The output pin of the 3 pin Regulator ICs is

indicated as shown.

2. For other ICs, pin 1 and every fifth pin are

indicated as shown.

3. The 1st pin of every male connector is indicated as

shown.

Instructions for Connectors

1. When you connect or disconnect the FFC (Flexible

Foil Connector) cable, be sure to first disconnect

the AC cord.

2. FFC (Flexible Foil Connector) cable should be

inserted parallel into the connector, not at an

angle.

Pb (Lead) Free Solder

When soldering, be sure to use the Pb free solder.

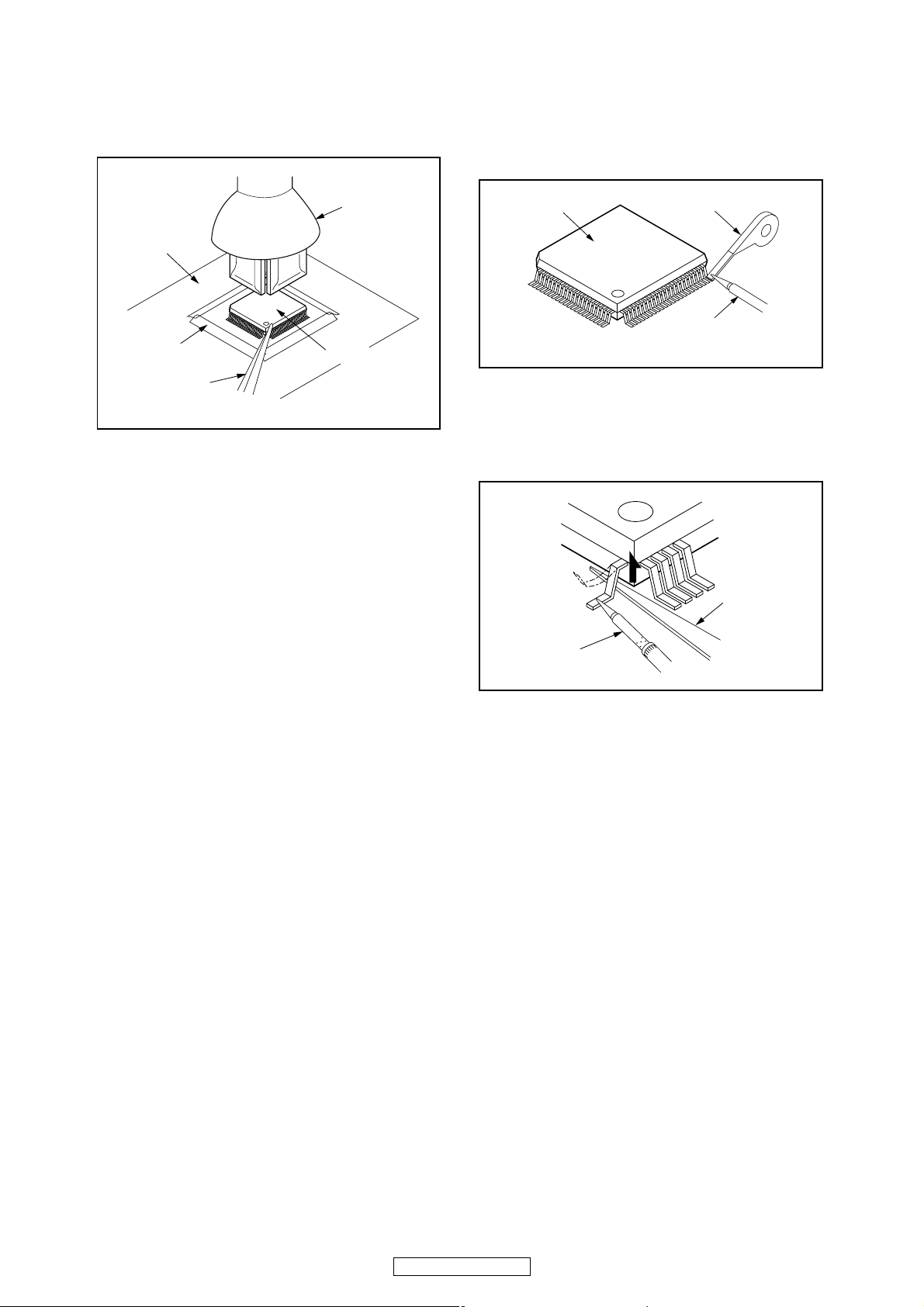

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:

1. Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

2. Remove the flat pack-IC with tweezers while

applying the hot air.

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

CAUTION:

1. The Flat Pack-IC shape may differ by models. Use

an appropriate hot-air flat pack-IC desoldering

machine, whose shape matches that of the Flat

Pack-IC.

2. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage

to the chip parts may occur. Put masking tape

around the flat pack-IC to protect other parts from

damage. (Fig. S-1-2)

Top View

Out

In

Bottom View

Input

5

10

Pin 1

Pin 1

FFC Cable

Connector

CBA

* Be careful to avoid a short circuit.

Fig. S-1-1

10

DVD-3800BDCI

Page 11

3. The flat pack-IC on the CBA is affixed with glue, so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when

removing it.

With Soldering Iron:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

2. Lift each lead of the flat pack-IC upward one by

one, using a sharp pin or wire to which solder will

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air desoldering

machine. (Fig. S-1-4)

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Hot-air

Flat Pack-IC

Desoldering

Machine

CBA

Flat Pack-IC

Tweezers

Masking

Tape

Fig. S-1-2

Flat Pack-IC

Desoldering Braid

Soldering Iron

Fig. S-1-3

Fine Tip

Soldering Iron

Sharp

Pin

Fig. S-1-4

11

DVD-3800BDCI

Page 12

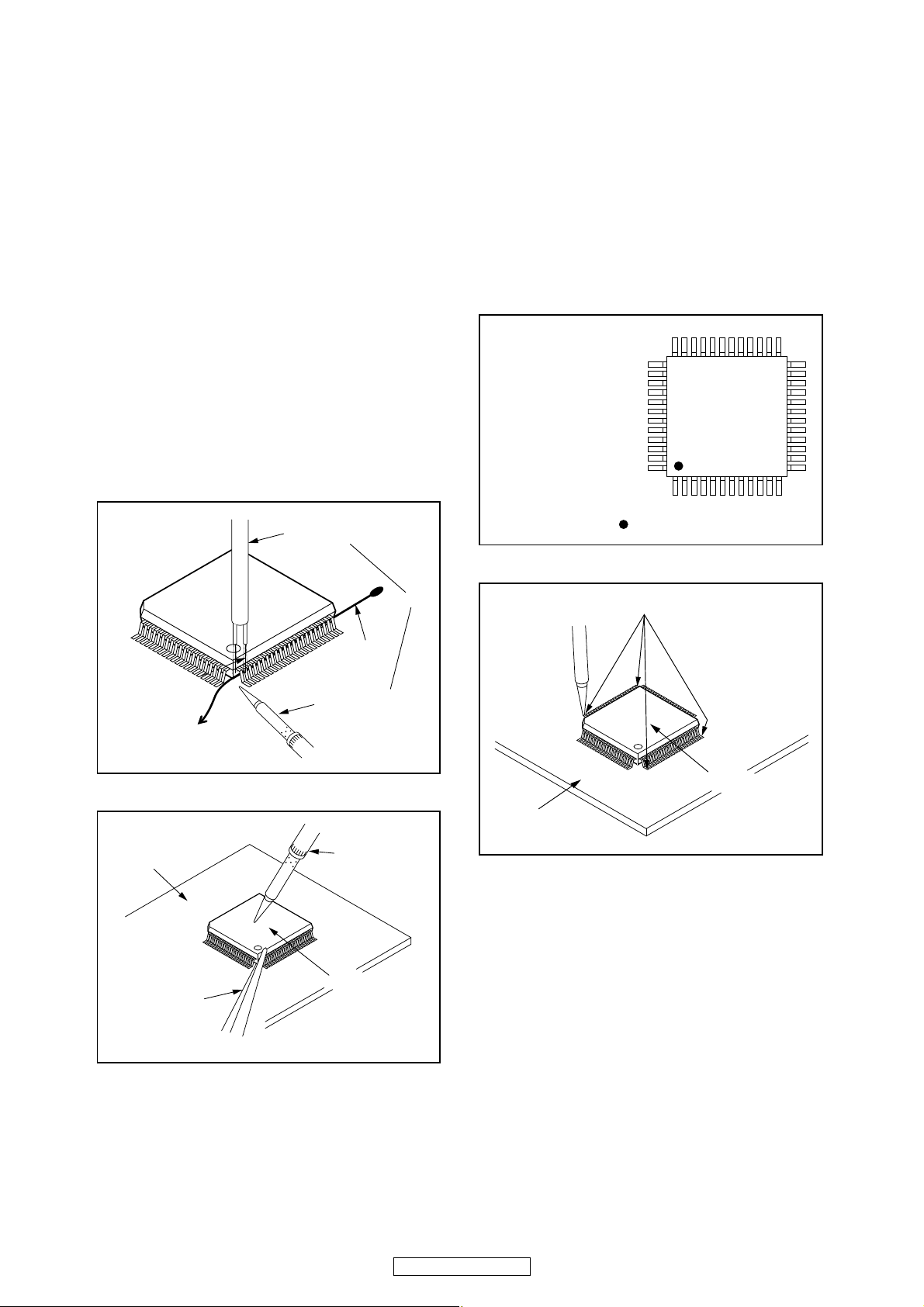

With Iron Wire:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

2. Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

3. While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solder

melts so as to lift the IC leads from the CBA

contact pads as shown in Fig. S-1-5.

4. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

5. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Note: When using a soldering iron, care must be

taken to ensure that the flat pack-IC is not

being held by glue. When the flat pack-IC is

removed from the CBA, handle it gently

because it may be damaged if force is applied.

2. Installation

1. Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA

so you can install a replacement flat pack-IC more

easily.

2. The “●” mark on the flat pack-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mark matches the 1

on the PCB when positioning for installation. Then

presolder the four corners of the flat pack-IC. (See

Fig. S-1-8.)

3. Solder all pins of the flat pack-IC. Be sure that

none of the pins have solder bridges.

To Solid

Mounting Point

Soldering Iron

Iron Wire

or

Hot Air Blower

Fig. S-1-5

Fine Tip

Soldering Iron

CBA

Flat Pack-IC

Tweezers

Fig. S-1-6

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

Presolder

CBA

Flat Pack-IC

Fig. S-1-8

12

DVD-3800BDCI

Page 13

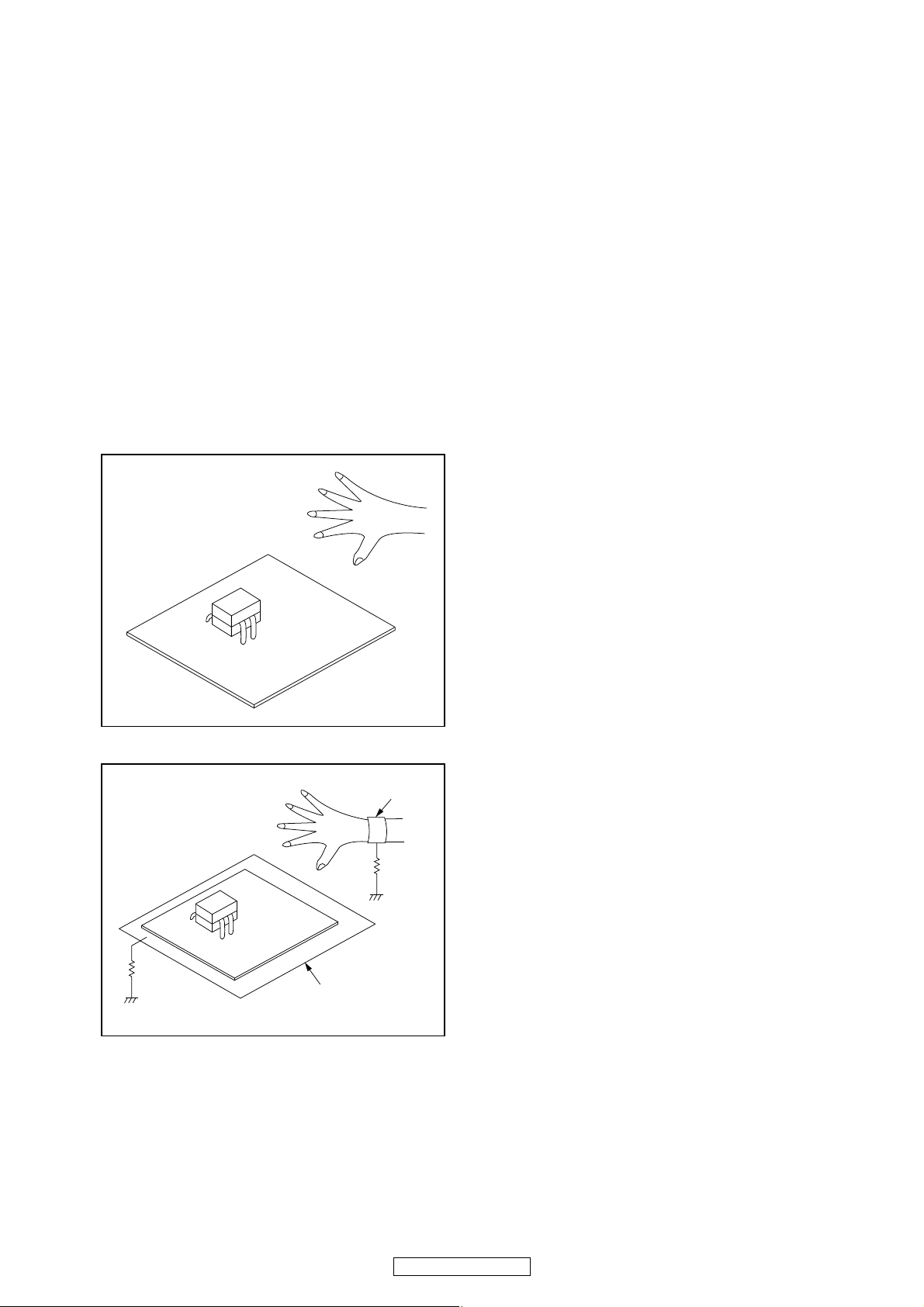

Instructions for Handling Semiconductors

Electrostatic breakdown of the semi-conductors may

occur due to a potential difference caused by

electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1 MΩ) that is

properly grounded to remove any static electricity that

may be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate

with proper grounding (1 MΩ) on the workbench or

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on

clothing will not escape through the body grounding

band, be careful to avoid contacting semi-conductors

with your clothing.

<Incorrect>

CBA

Grounding Band

Conductive Sheet or

Copper Plate

1MΩ

1MΩ

<Correct>

CBA

13

DVD-3800BDCI

Page 14

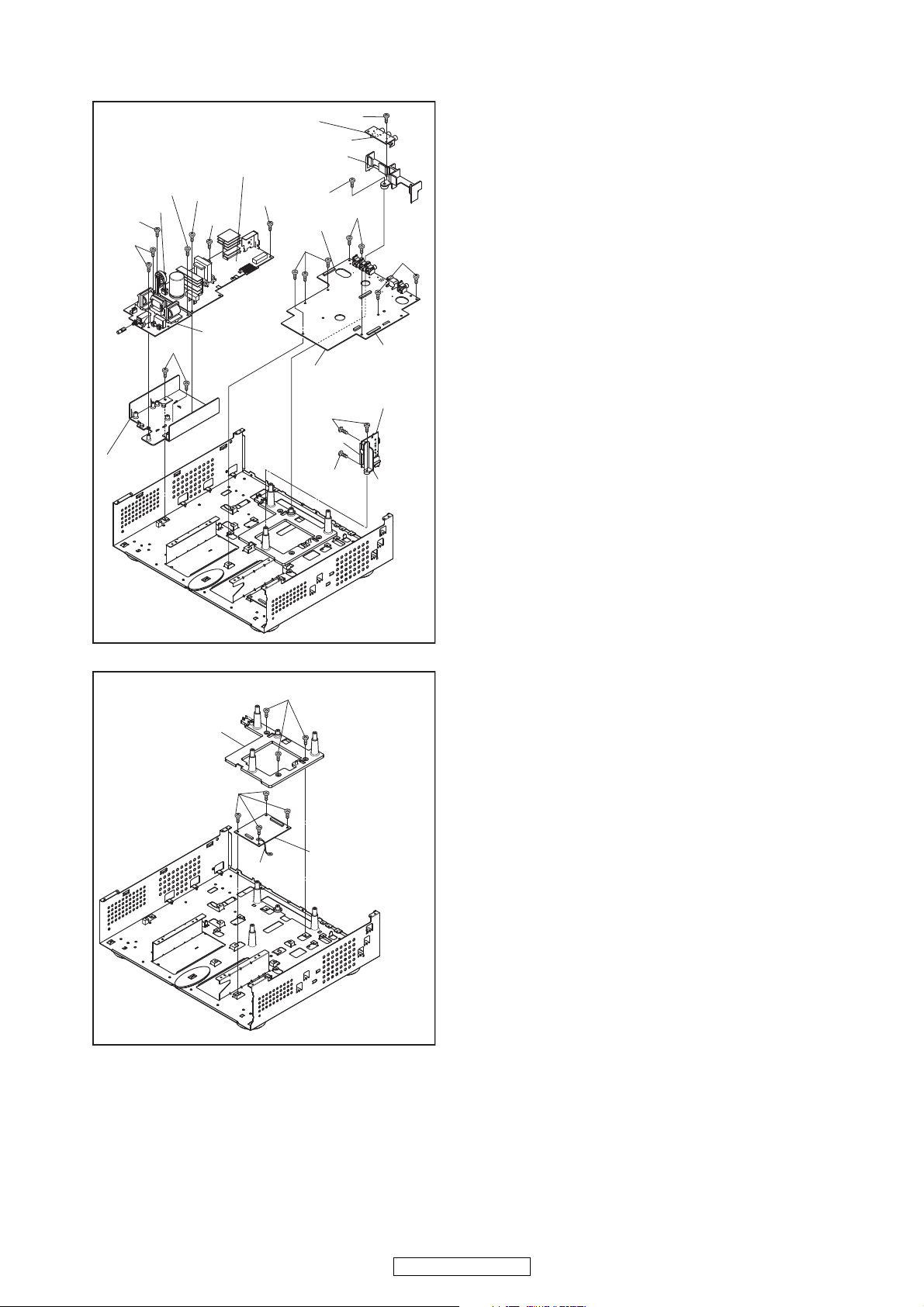

CABINET DISASSEMBLY INSTRUCTIONS

1. Disassembly Flowchart

This flowchart indicates the disassembly steps to gain

access to item(s) to be serviced. When reassembling,

follow the steps in reverse order. Bend, route, and

dress the cables as they were originally.

2. Disassembly of Main parts

When replacing the main parts, see the following procedures. For more details, refer to Fig. D1~D10.

*About *[9](S-14), remove only (S-14) of Rear Panel.

3. Disassembly Method

Part Steps

[10] BE Main CBA Unit [1] → [2] → *[9](S-14) → [10]

[11] Scaler CBA Unit

[1]→[2]→ [3]→ *[9](S-14)→ [10]

→ [11]

[12] D-Audio CBA Unit [1] → [2] → [9] → [12]

[13] F-Audio CBA Unit [1] → [2] → [9] → [12] → [13]

[14] S-Audio CBA Unit [1]→[2]→[9]→ [12]→[13]→[14]

[15] ADSP CBA Unit

[1]→[2]→[9]→[10]→[11]→ [12]

→ [13] → [14] → [15]

[16]

FE Main CBA & BD

Mechanism

Assembly

[1]→[2]→ [3]→ *[9](S-14)→ [10]

→ [16]

[17] Fan Holder

[1] → [2] → *[9](S-14) → [10] →

[11] → [17]

[1] Top Cover

[6] Power Switch CBA

[7] SD CBA

[3] Tray Panel

[4] Front Assembly

[8] Front Bracket

[2] Top Panel

[19] RS232C CBA

[20] Jack CBA

[23] AV CBA

[25] Pedestal

[21] Power

Supply CBA

[22] Sub Power

CBA

[24] Sub

Microcontroller

CBA

[9] Rear Panel

[10] BE Main CBA Unit

[11] Scaler CBA Unit

[12] D-Audio CBA

[13] F-Audio CBA

Analog Audio CBA Unit

[14] S-Audio CBA

[15] ADSP CBA Unit

[16] FE Main CBA & BD Mechanism Assembly

[18] Fan Motor

[5] Front CBA

[17] Fan Holder

[18] Fan Motor

[1] → [2] → *[9](S-14) → [10] →

[11] → [17] → [18]

[19] RS232C CBA [1]→[2]→ [9]→[10]→[11]→[19]

[20] Jack CBA

[1]→[2]→ [9]→[10]→[11]→[19]

→ [20]

[21] Power Supply CBA

[1] → [2] → *[9](S-14) → [10] →

[11] → [17] → [21]

[22] Sub Power CBA [1] → [2] → [3] → [4] → [8] → [22]

[23] AV CBA

[1]→ [2]→ [3]→ [9]→ [10]→ [11]

→ [12] → [13] → [14] → [23]

[24]

Sub Microcontroller

CBA

[1] → [2] → [12] → [13] → [14] →

[24]

ID/

Loc.

No.

Part

Removal

Fig.

No.

Remove/*Unhook/

Unlock/Release/

Unplug/Desolder

Note

[1] Top Cover D1 9(S-1), 2(S-2) --[2] Top Panel D2 10(S-3) --[3] Tray Panel D3 *2(L-1) 1

[4]

Front

Assembly

D3

2(S-4), 2(S-5), (S-5a),

*3(L-2), *CN2001,

*CN4002

1

[5] Front CBA D4 7(S-6) ---

[6]

Power

Switch CBA

D4 2(S-7), Desolder ---

[7] SD CBA D4

2(S-8), SD PCB

Holder

---

[8]

Front

Bracket

D5 2(S-9) ---

[9] Rear Panel D5

2(S-10), 2(S-11),

2(S-12), 18(S-13),

4(S-14), 3(S-15),

2(S-16) *CN1001

2

[10]

BE Main

CBA Unit

D6

4(S-17), *CN6401,

*CN7001, *CN7401,

*CX813

2

[11]

Scaler CBA

Unit

D6

4(S-18), 3(S-19),

3(S-20), *CX874,

*CX875, *CY080,

BE Scaler Holder, BE

Scaler Sub Holder

---

[12]

D-Audio

CBA

D7 2(S-21), *CX877 ---

14

DVD-3800BDCI

Page 15

Note:

(1) Identification (location) No. of parts in the figures

(2) Name of the part

(3) Figure Number for reference

(4) Identification of parts to be removed, unhooked,

unlocked, released, unplugged, unclamped, or

desoldered.

P = Spring, L = Locking Tab, S = Screw,

CN = Connector

* = Unhook, Unlock, Release, Unplug, or Desolder

e.g. 2(S-2) = two Screws (S-2),

2(L-2) = two Locking Tabs (L-2)

(5) Refer to “Reference Notes.”

About tightening screws

When tightening screws, tighten them with the

following torque.

Reference Notes

1. CAUTION 1: Locking Tabs (L-1) and (L-2) are

fragile. Be careful not to break them.

1) Release three Locking Tabs (L-2).

2) Disconnect connectors CN2001, CN4002, then

remove the Front Assembly.

2. CAUTION 2: When installing the BE Main CBA

Unit with a screw, hold and press the BE Main

CBA Unit to align the HDMI connector with the

connector’s hole for HDMI on the Rear Panel.

[13]

F-Audio

CBA

D7

3(S-22), *CN061,

*CN10, *CX201,

*CY281

---

[14]

S-Audio

CBA

D7 3(S-23) ---

[15]

ADSP CBA

Unit

D7

2(S-24), (S-25),

4(S-26), 2(S-27),

*CX876, DSP PCB

Holder, Audio PCB

Holder

---

[16]

FE Main

CBA & BD

Mechanism

Assembly

D8 4(S-28), *CN2601 ---

[17] Fan Holder D8 2(S-29), *CN2500 --[18] Fan Motor D8 2(S-30) ---

[19]

RS232C

CBA

D9

3(S-31), *CN2551,

RS232C Holder

---

[20] Jack CBA D9

(S-32), (S-33),

*CN2730, BNC PCB

Holder

---

[21]

Power

Supply

CBA

D9

2(S-34), 2(S-35),

*CN101, *CN2501

---

[22]

Sub Power

CBA

D9

3(S-36), 2(S-37),

Power PCB Holder

---

[23] AV CBA D9 7(S-38), *CN2503 ---

[24]

Sub

Microcontro

ller CBA

D10 4(S-39) ---

[25] Pedestal D10 3(S-40) ---

↓

(1)

↓

(2)

↓

(3)

↓

(4)

↓

(5)

ID/

Loc.

No.

Part

Removal

Fig.

No.

Remove/*Unhook/

Unlock/Release/

Unplug/Desolder

Note

Torque

0.45 ± 0.05 N·m

(S-2)

(S-2)

(S-1)

(S-1)

(S-1)

(S-1)

(S-1)

Fig. D1

[1] Top Cover

15

DVD-3800BDCI

Page 16

(S-3)

(S-3)

(S-3)

(S-3)

[2] Top Panel

Fig. D2

[3] Tray Panel

[4] Front Assembly

(S-5)

(S-4)

(S-5a)

(S-5)

(S-4)

CN4002

(L-2)

(L-1)

(L-1)

CN2001

Fig. D3

(S-6)

(S-6)

(S-7)

(S-8)

Fig. D4

[6] Power Switch CBA

[7] SD CBA

[5] Front CBA

SD PCB

Holder

Desolder

Lead with

blue stripe

CN1001

(S-15)

(S-10)

(S-10)

(S-15)

(S-15)

(S-12)

(S-14)

(S-14)

*(S-14)

(S-11)

(S-13)

(S-13)

(S-13)

(S-13)

(S-13)

(S-16)

Fig. D5

[9] Rear Panel

(S-9)

(S-9)

[8] Front Bracket

16

DVD-3800BDCI

Page 17

(S-17)

(S-17)

(S-18)

(S-18)

(S-19)

(S-20)

(S-19)

CN6401

BE Scaler

Holder

BE Scaler

Sub Holder

CN7001

CX813

CY080

CN817

CN7401

[11] Scaler

CBA Unit

[10] BE Main

CBA Unit

CX874

CX875

Fig. D6

(S-21)

(S-22)

(S-22)

(S-22)

(S-23)

(S-27)

(S-27)

(S-26)

(S-24)

(S-25)

(S-26)

CX876

Audio PCB Holder

DSP PCB Holder

[12] D-Audio CBA

[13] F-Audio CBA

[14] S-Audio CBA

[15] ADSP CBA

Unit

CY281

CX201

CX877

CN061

CN10

Fig. D7

(S-28)

(S-28)

(S-28)

(S-29)

(S-29)

(S-30)

CN2500

CN2601

[16] FE Main CBA &

BD Mechanism Assembly

[17] Fan Holder

[18] Fan Motor

Fig. D8

17

DVD-3800BDCI

Page 18

(S-31)

(S-31)

(S-34)

(S-34)

(S-35)

(S-35)

(S-36)

(S-36)

Power PCB

Holder

RS232C

Holder

BNC PCB Holder

(S-38)

(S-38)

(S-32)

CN2730

(S-33)

(S-38)

(S-37)

CN101

CN2551

CN2501

CN2503

Fig. D9

[19] RS232C CBA

[21] Power Supply CBA

[20] Jack CBA

[22] Sub

Power CBA

[23] AV CBA

(S-39)

Wire

(S-40)

Fig. D10

[24] Sub

Microcontroller

CBA

[25] Pedestal

18

DVD-3800BDCI

Page 19

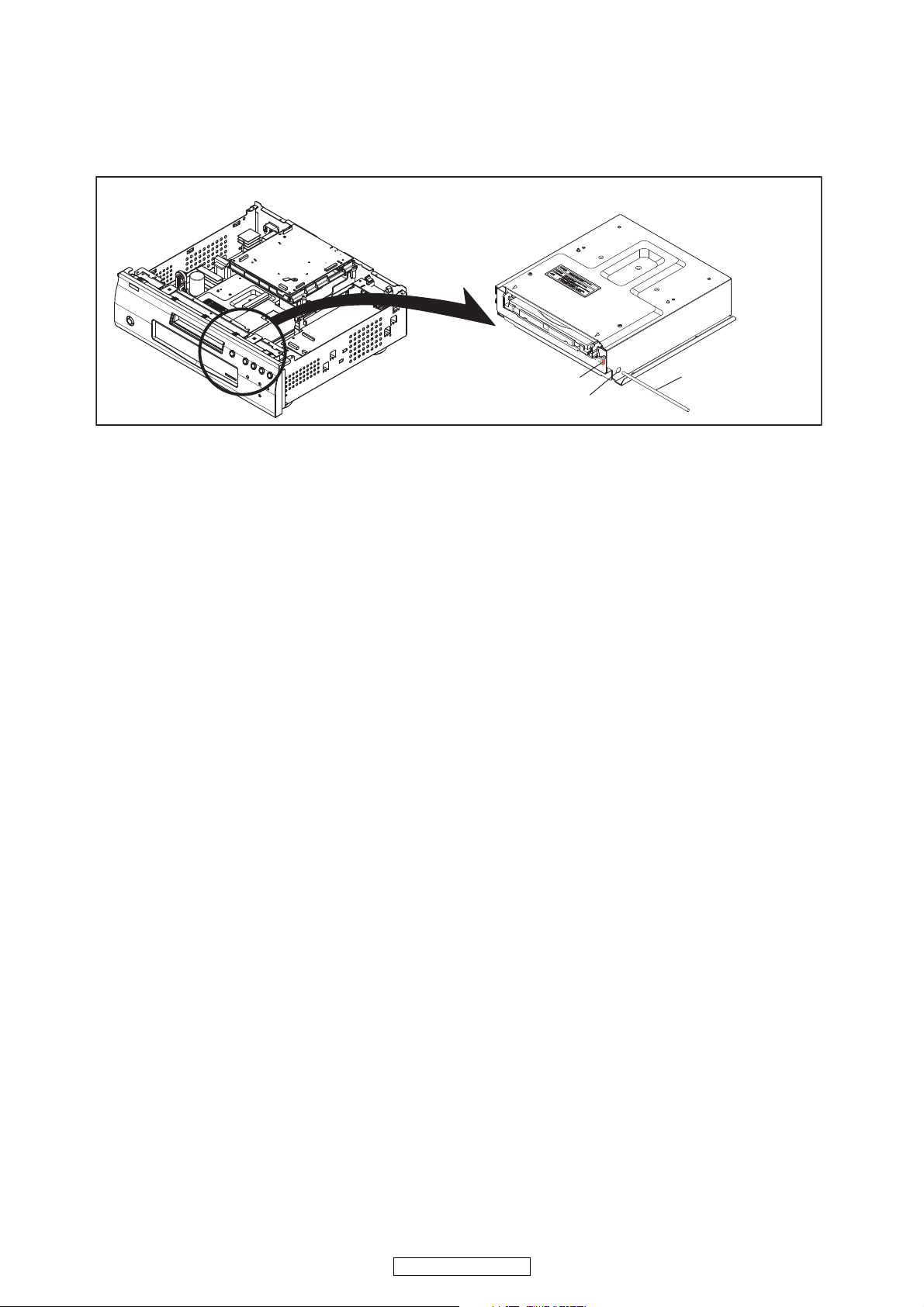

4. How to Eject Manually

1. Remove the Top Cover and the Top Panel.

2. Insert a screwdriver, etc. into the Hole A straightly so that the Portion A is pushed.

3. Pull the tray out manually and remove a disc.

Portion A

Hole A

Screwdriver,

hexagon wrench

19

DVD-3800BDCI

Page 20

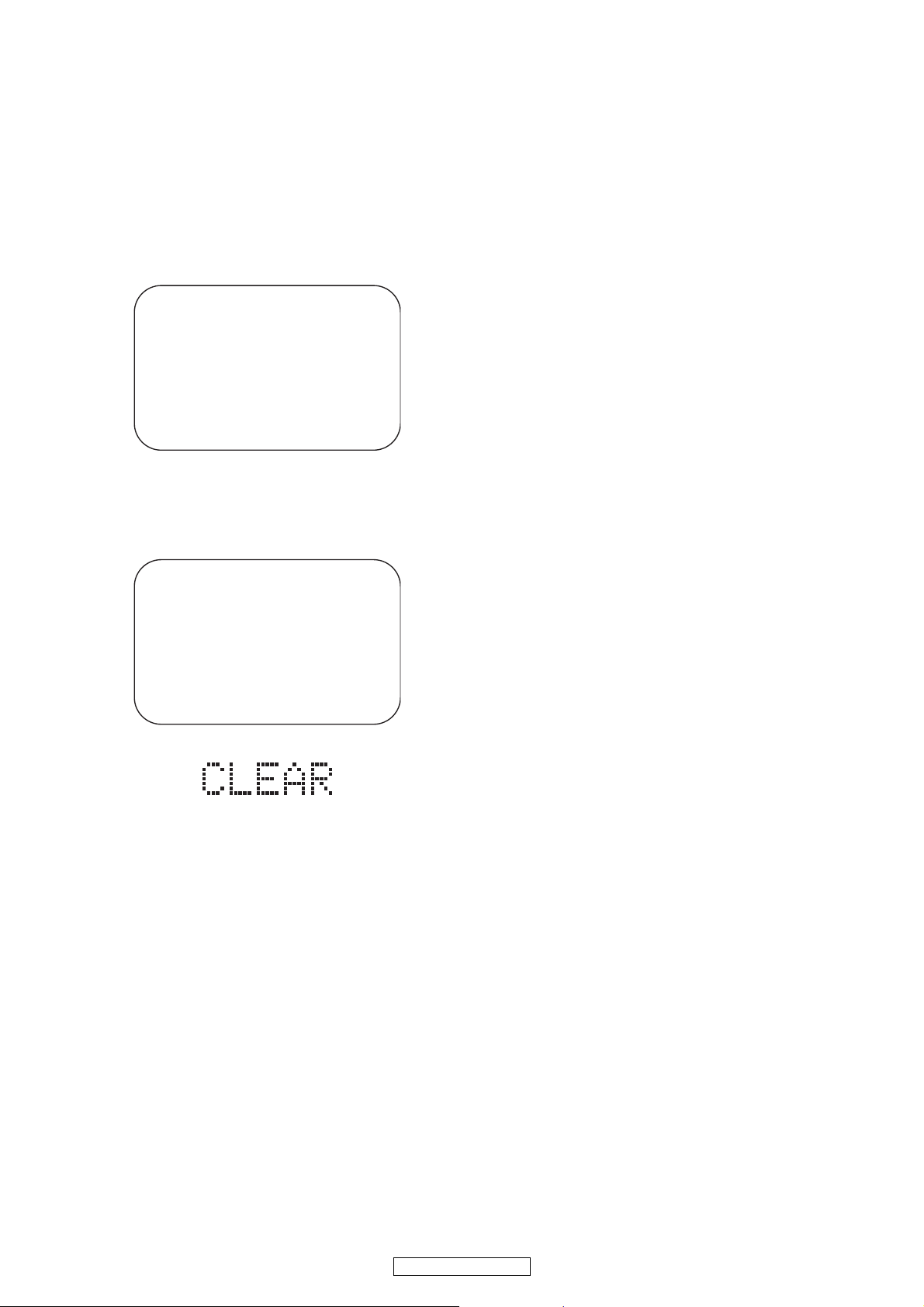

HOW TO INITIALIZE THE BLU-RAY DISC PLAYER

To put the program back at the factory-default,

initialize the BD player as the following procedure.

1. Turn the power on.

2. Remove the disc on the tray and close the tray.

3. Press [1], [2], [3], [4], and [DISPLAY] buttons on

the remote control unit in that order.

Fig. a appears on the screen.

4. Press [STOP] button on the remote control unit.

Fig. b appears on the screen and Fig. c appears

on the VFD.

5. To exit this mode, press [POWER OFF] button.

Fig. a

"

*******

" differ depending on the models.

Model Name : *******

Version

: *.***

Region

: *-*

ADSP1/2 Ver. : ****/****

PLD Ver. : *

FPGA Ver. : **

I/P Scaler Ver. : ******

EXIT: POWEREEPROM CLEAR : STOP

Fig. b

"

*******

" differ depending on the models.

Model Name : *******

Version

: *.***

Region

: *-*

ADSP1/2 Ver. : ****/****

PLD Ver. : *

FPGA Ver. : **

I/P Scaler Ver. : ******

EXIT: POWEREEPROM CLEAR : STOP

EEPROM CLEAR : OK

Fig. c

d

20

DVD-3800BDCI

Page 21

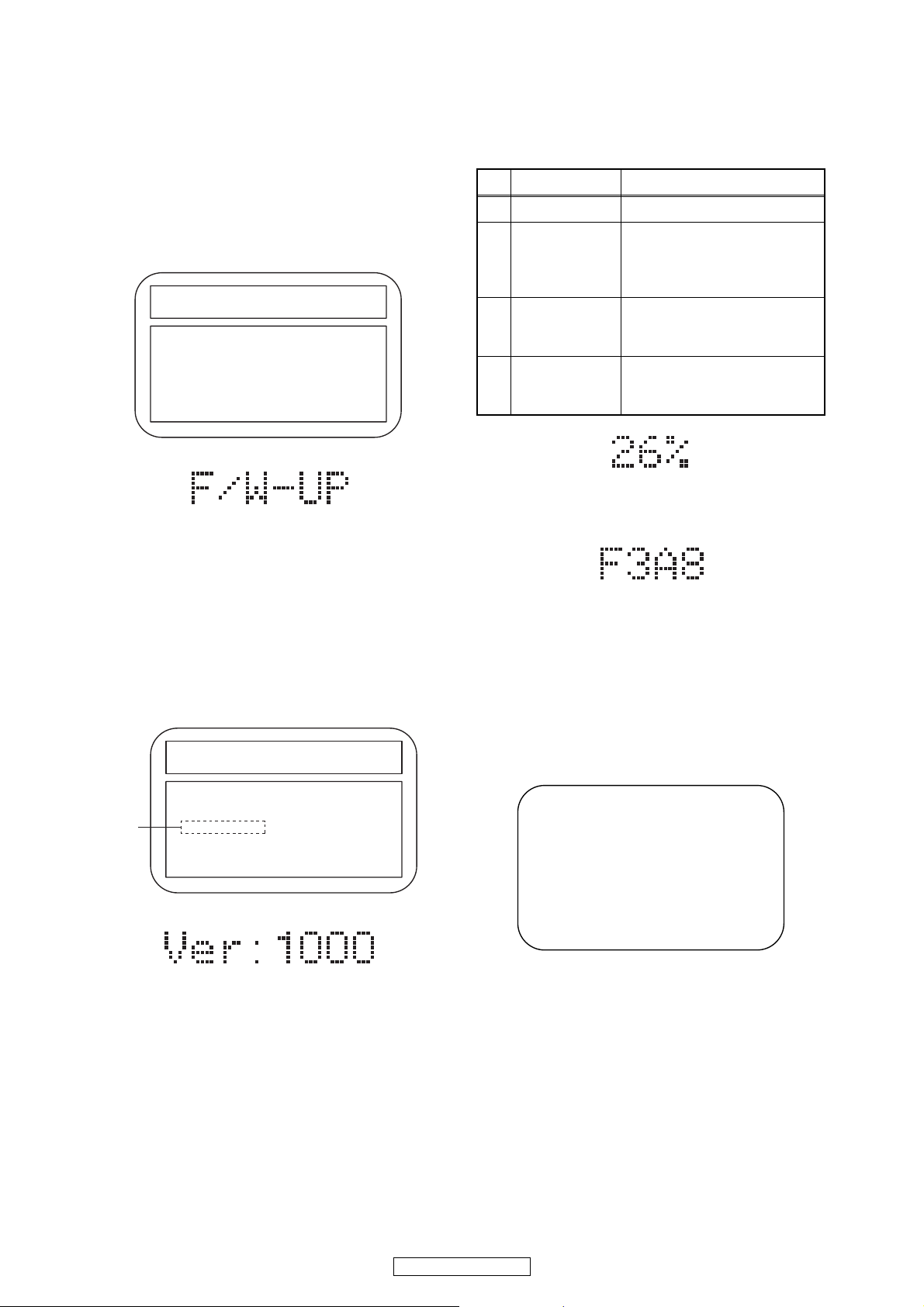

FIRMWARE RENEWAL MODE

1. Turn the power on and remove the disc on the tray.

2. To put the BD player into version up mode, press

[9], [8], [7], [6], and [POP UP MENU/MENU]

buttons on the remote control unit in that order.

The tray will open automatically.

Fig. a appears on the screen and Fig. b appears

on the VFD.

The BD player can also enter the version up mode

with the tray open. In this case, Fig. a will be

shown on the screen while the tray is open.

3. Load the disc for version up.

4. The BD player enters the F/W version up mode

automatically. Fig. c appears on the screen and

Fig. d appears on the VFD. If you enter the F/W for

different models, “Disc Error” will appear on the

screen, then the tray will open automatically.

The appearance shown in (*1) of Fig. c is

described as follows:

5. After programming is finished, the checksum on

the VFD (Fig. f).

At this time, no button is available.

6. Unplug the AC cord from the AC outlet. Then plug

it again.

7. Turn the power on.

8. Press [1], [2], [3], [4], and [DISPLAY] buttons on

the remote control unit in that order.

Fig. g appears on the screen.

F/W VERSION UP MODE Model No : ******* Ver. : *.***

ADSP 1/2 Ver. : ***/***

Please insert a DISC

for F/W Version Up.

"

*******

" differs depending on the models.

Fig. a Version Up Mode Screen

Fig. b VFD in Version Up Mode

1. ALL

Now Loading...

Ver. : *.** ************A*.bin

(*1)

F/W VERSION UP MODE Model No : ******* Ver. : *.***

ADSP 1/2 Ver. : ***/***

"

*******

" differs depending on the models.

Fig. c Programming Mode Screen (Example

)

Fig. d VFD in Programming Mode (Example)

No. Appearance State

1 Now Loading... Loading the disc

2 Reading...

Sending files into the

memory.

After reading, automatically

the tray opens.

3

Remove the

disc

Reading has finished.

Remove the disc and close

the tray.

4 See FL display

Writing new version data,

the progress will be displayed

as shown in Fig. e.

Fig. e VFD in Version Up Mode

Fig. f VFD upon Finishing the Programming Mode (Example)

Fig. g

"

*******

" differ depending on the models.

Model Name : *******

Version

: *.***

Region

: *-*

ADSP1/2 Ver. : ****/****

PLD Ver. : *

FPGA Ver. : **

I/P Scaler Ver. : ******

EXIT: POWEREEPROM CLEAR : STOP

d

21

DVD-3800BDCI

Page 22

9. Press [STOP] button on the remote control unit.

Fig. h appears on the screen and Fig. i appears on

the VFD.

10. To exit this mode, press [POWER OFF] button.

How to Verify the Firmware Version

1. Turn the power on.

2. Remove the disc on the tray and close the tray.

3. Press [1], [2], [3], [4], and [DISPLAY] buttons on

the remote control unit in that order.

Fig. j appears on the screen.

4. To exit this mode, press [POWER OFF] button.

Fig. h

"

*******

" differ depending on the models.

Model Name : *******

Version

: *.***

Region

: *-*

ADSP1/2 Ver. : ****/****

PLD Ver. : *

FPGA Ver. : **

I/P Scaler Ver. : ******

EXIT: POWEREEPROM CLEAR : STOP

EEPROM CLEAR : OK

Fig. i

Fig.

j

"

*******

" differ depending on the models.

Model Name : *******

Version

: *.***

Region

: *-*

ADSP1/2 Ver. : ****/****

PLD Ver. : *

FPGA Ver. : **

I/P Scaler Ver. : ******

EXIT: POWEREEPROM CLEAR : STOP

d

b The region setting can be changed up to five

times (including factory preset).

If you exceed the region change limit, DVD

playback images will be affected by noise.

Version Up Mode

s

Realta update (GU-3867: DIGITAL VIDEO UNIT)

1. The RS-232C terminal of DVD3800BD and PC are

connected with RS-232C cable.

2. The 6-2 (Version Up mode with RS-232C) is

selected from the service mode (Refer to page

22).

3. The Realta version up software is started with PC,

and the firmware is rewritten. (Refer to the Realta

version up manual )

22

DVD-3800BDCI

Page 23

SERVICE MODE

Service Mode

Note: If some test are performed continuously, any error will occur.

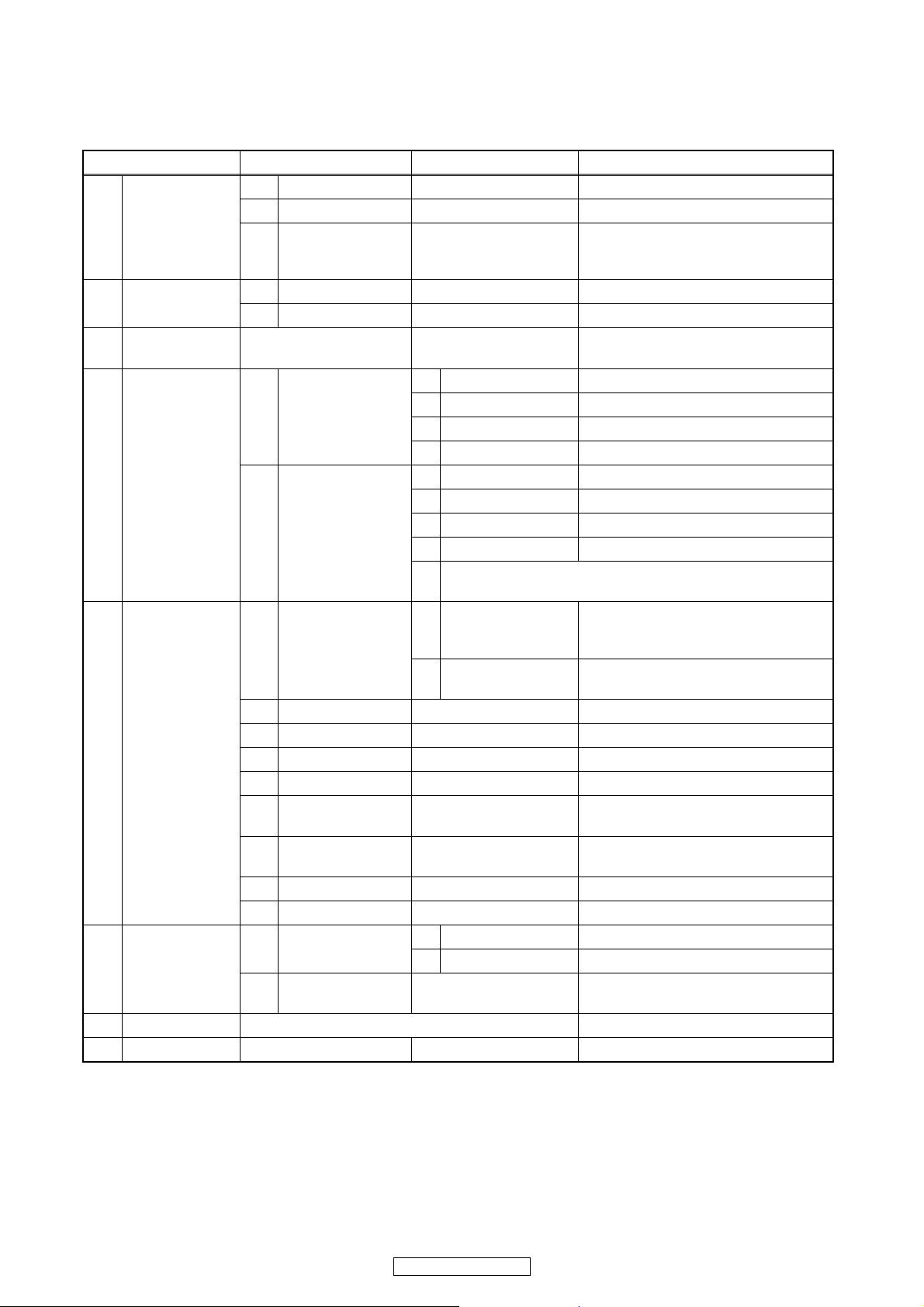

1st level 2nd level 3rd level Description

1 Mecha test

1 Tray Aging Aging of tray open/close

2 TOC Read TOC reading

3 Heat Run

Tray close -> TT1 playback -> TT10

playback -> Tray open -> Tray

close

2 VFD/LED Test

1 All On Turning on all VFD

2 All Off Turning off all VFD

3 Error Rate

Displaying Error rate, Jitter

during playback

4 LD Test

1LD Power

1 Off Turning off LD

2 BD Turning on BD LD

3 DVD Turning on DVD LD

4 CD Turning on CD LD

2 Operating Time

1 BD Displaying BD LD Operation Time

2 DVD Displaying DVD LD Operation Time

3 CD Displaying CD LD Operation Time

4STOP

Clear LD Operation Total Time

※

When the mechanism is replaced, LD Operation Total

Time is cleared.

5 Channel Level

1 TEST TONE

1

Center/

Subwoofer/Front

LR

2

Surround LR/

Surround Back LR

2 Front Lch

3 Center

4 Front Rch

5 Surround Rch

6

Surround Back

Rch

7

Surround Back

Lch

8 Surround Lch

9 Sub woofer

6 RS-232C

1 Parity Setting

1 Even Setting even parity

2 Non Setting non parity

2 Version Up Mode

Realta Version up with connecting

RS-232C

7 SD Card Test

8 Default Setting Default setting

s

23

DVD-3800BDCI

Page 24

Entering Service Mode

In power on condition, no discs and tray close, it will be entered into service mode by the following operation using

the remote controller. However, it will not be entered when Media Select Item is SD Memory.

Service Mode by using remote controller

Press the following buttons on the remote controller in power on condition, no discs and tray close;

[2]->[5]->[8]->[0]->[CLEAR]

Release from Service Mode

Press the [POWER OFF] button to turn off power.

Screen saver/Auto Power Off in Service Mode

These functions are not performed in Service Mode.

After entering, Fig. j appears on the screen and Fig. k appears on the VFD.

Available button in service mode

Note:Press the number key to select items. Or, press the cursor button (up/down) to select items and press

[ENTER] button.

Button condition

ENTER Enter the next level

POWER Turn the power off (when the service mode is completed)

1~8 Enter the selected item (next level)

OTHER Not available

INDICATION DESCRIPTION REMARK

Model Name Model Name E5E***D, etc.

Region BD region - DVD region A-1, etc.

Rel. Ver. Release version

Service Mode

1. Mecha Test

2. VFD/LED Test

3: Error Rate

4: LD Test

5: RS-232C

6: Channel Level

7: SD Card Test

8: Default Setting

Model: :E5E**UD Region :A-1

Release Ver. :*.***

ADSP1/2 Ver.: ****/**** PLD Ver. :*

FPGA Ver.:** I/P Scaler Ver.:*****

Fig. j Service Mode (Main menu)

* Firmware Version differs depending on the

models, and this indication is one example.

Fig. k Service Mode

24

DVD-3800BDCI

Page 25

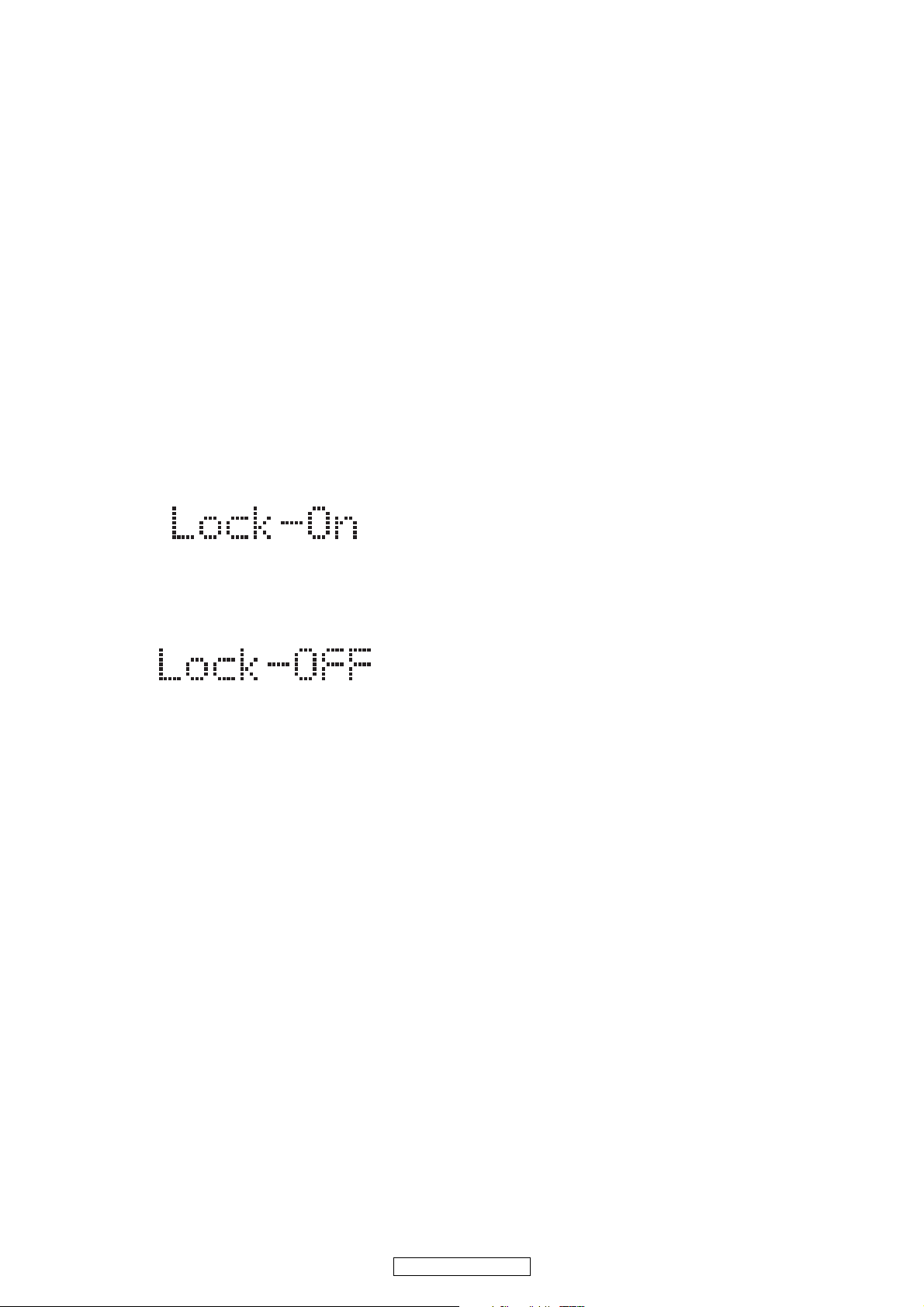

TRAY LOCK MODE

Tray Lock Mode prevents the tray opening or closing to

prevent disc theft in demo mode.

Enter this mode using the following procedure.

1. Confirm that the TV Monitor is connected.

2. With playback stopped, press [SETUP], [TOP

MENU], [3], [AUDIO], [0] and [SETUP] buttons on

the remote control unit in that order. "Trade On" will

appear in the upper right corner on the screen, and

on VFD for 2 seconds.

3. To exit this mode, press [SETUP], [TOP MENU],

[3], [AUDIO], [0] and [SETUP] buttons on the

remote control unit in that order. "Trade Off" will

appear in the upper right corner on the screen, and

on VFD for 2 seconds.

Fig.a VFD

Fig.b VFD

25

DVD-3800BDCI

Page 26

REMOTE LOCK MODE

SETTING MENU:

Remote Lock Off Mode:

This mode receives an input signal from the remote

control unit or from the Remote In-Jack on the rear

panel.

Remote Lock On Mode:

This mode dose not receive an input signal from

the remote control unit or from the Remote In-Jack

on the rear panel.

Perform the setting using the following procedure.

1. Press [ON/STANDBY] and [STOP] buttons on the

front panel simultaneously for over 3 seconds to set

"Remote Lock Mode" and display mode.

2. Press [STILL/PAUSE] button on the remote control

unit to set to "On" or "Off". When "Remote Lock

On", "Remote Lock On" will appear in the upper

right corner on the screen and appears on the VFD.

When "Remote Lock Off", "Remote Lock Off" will

appear in the upper right corner on the screen and

appears on the VFD.

a. If [STILL/PAUSE] button is not pressed for 5

seconds or any other button is pressed within 5

seconds, the unit will be released from

"Remote Lock Mode".

b. When initializing, set the Remote Lock Mode

"off".

Fig.a VFD

Fig.b VFD

26

DVD-3800BDCI

Page 27

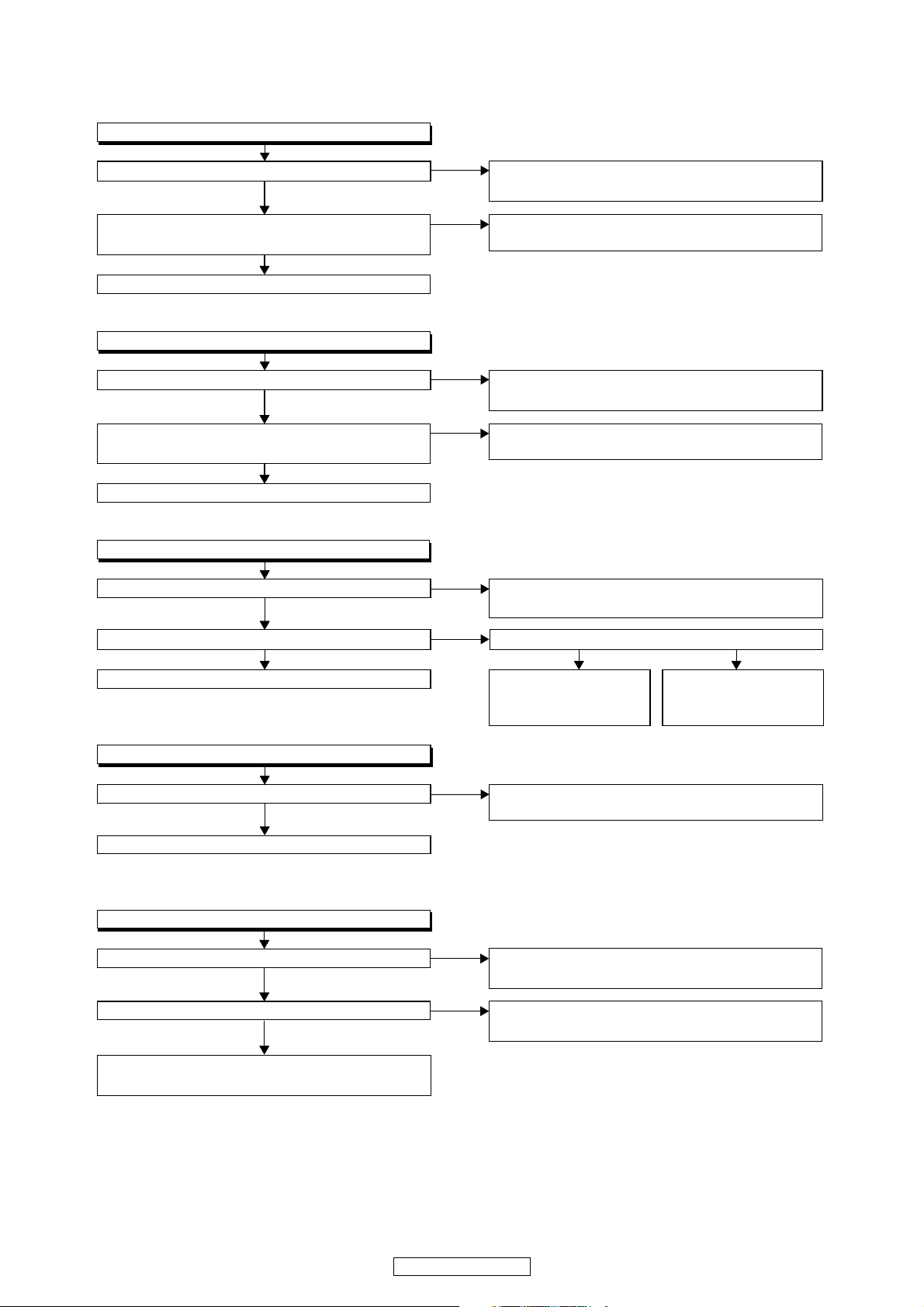

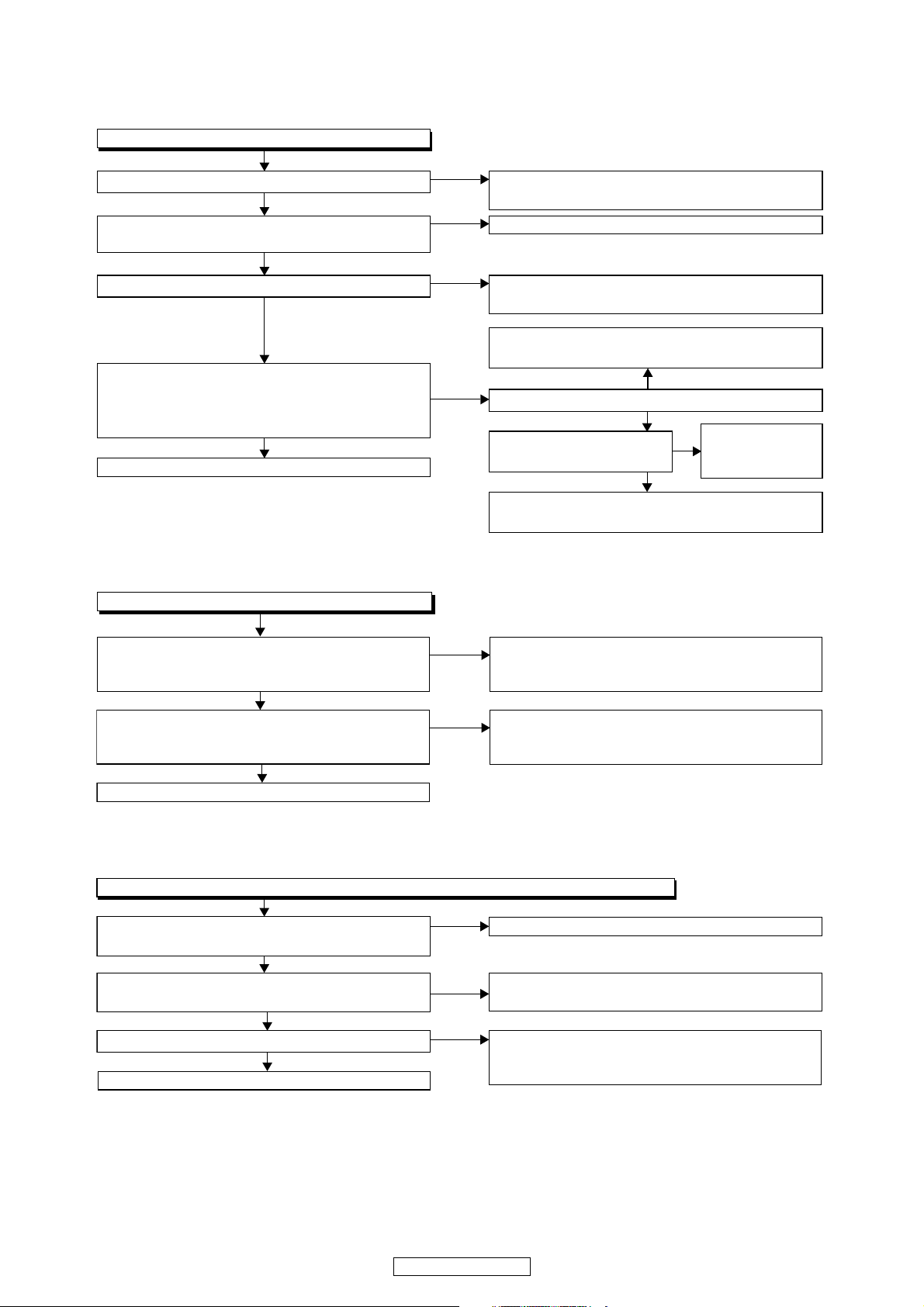

TROUBLESHOOTING

FLOW CHART NO.2

The fuse blows out.

After servicing, replace the fuse.

Check the presence that the primary component

is leaking or shorted and service it if defective.

Check the presence that the rectifying diode or

circuit is shorted in each rectifying circuit of

secondary side, and service it if defective.

FLOW CHART NO.3

When the output voltage fluctuates.

Ye s

No

FLOW CHART NO.4

When buzz sound can be heard in the vicinity of power circuit.

Check if there is any short-circuit on the rectifying diode and the circuit in each rectifying circuit of the secondary

side

, and service it if defective.

(D1112, D1113, D1114, D1115, D1116, D1118, D1120, D1121,D1122, D1124, D1146,

IC1105, IC1106, IC2600, IC2601, Q2600, Q2606, Q2608, Q2610, Q2611)

Does the photo coupler circuit on the secondary

side operate normally?

Check D1107, IC1101, IC1103 and their periphery,

and service it if defective.

Check D1117, D1129, IC1103 and their periphery,

and service it if defective.

FLOW CHART NO.5

-FL is not outputted.

Is -30V voltage supplied to the emitter of Q2503?

Check D1118, D1130, C1126 and periphery circuit,

and service it if defective.

Check Q2503 and their periphery, and service it if

defective.

Check FL-SW line and service

it if defective.

Is the "L" signal outputted to the collector of

Q2507?

Ye s

Ye s

Ye s

Ye s

No

No

No

No

No

FLOW CHART NO.1

The power cannot be turned on.

Is the fuse normal?

Is normal state restored when once unplugged

power cord is plugged again after several seconds?

Is the AL+5V line voltage normal?

See FLOW CHART No.2 <The fuse blows out.>

Check if there is any leak or short-circuiting on the

primary circuit component, and service it if defective.

(D1101, D1102, D1103, D1104, D1109, D1110,

IC1101, Q1103, T1101, C1110, R1117)

Check each rectifying circuit of the secondary circuit

and service it if defective.

Ye s

Ye s

Ye s

No

No

No

Is 3.3V voltage supplied to the emitter of Q2504?

Ye s

Is 3.3V voltage outputted to collector of Q2504?

Is the "H" signal inputted to the base of Q2507?

Replace Q2507.

Replace Q2504.

Check EV+3.3V line and service it if defective.

27

DVD-3800BDCI

Page 28

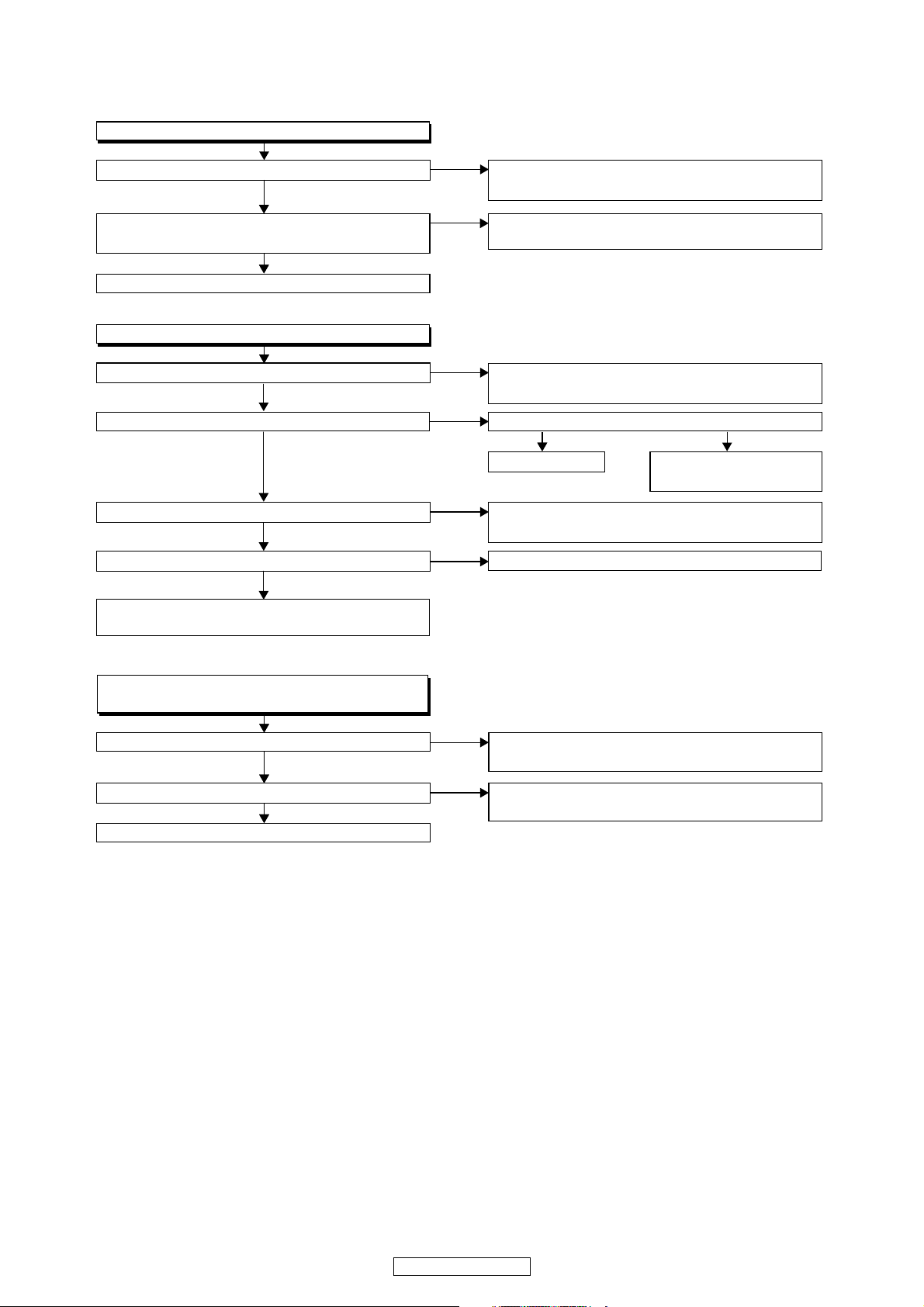

FLOW CHART NO.6

Is 5V voltage inputted to the emitter of Q2610?

Replace Q2611.

Ye s

No

Is 11V voltage inputted to the base of Q2611? Is 13.5V voltage inputted to the base of Q2605?

Check D1122, D1128, C1124, L1105

and

their periphery, and service it if defective.

No

FLOW CHART NO.7

FLOW CHART NO.8

P-ON+10.5V is not outputted.

Is 13.5V voltage inputted to the collector of Q2611?

Ye s Ye s No

Ye s

Check D1115, C1119

and their periphery circuit,

and service it if defective.

Check Q2605, D2601,

and their periphery, and

service it if defective.

Check Q2604,

and

PWSW3 line, and

service it if defective.

Is 2.5V voltage supplied to Pin(1) of IC2601?

Ye s

No

FLOW CHART NO.9

P-ON+1.2V is not outputted.

Replace IC2601.

Is the voltage of base on Q2610 lower than the

voltage of emitter on Q2610 when turning the power on?

Replace Q2610.

Check Q2607 and PWSW3 line and service it if

defective.

Ye s

No

Check D1112, D1113, D1114, D1129, C1125, C1132

and their periphery, and service it if defective.

Is 5V voltage inputted to the emitter of Q2606?

Ye s

No

Is the voltage of base on Q2606 lower than the

voltage of emitter on Q2606 when turning the power on?

Replace Q2606.

Check Q2607 and PWSW3 line and service it if

defective.

Ye s

No

No

Check D1112, D1113, D1114, D1129, C1125, C1132

and their periphery, and service it if defective.

P-ON+5V (2) is not outputted.

FLOW CHART NO.10

P-ON+3.3V is not outputted.

Is 5V voltage supplied to Pin(1) of IC2600?

ls "L" signal outputted to the collector of Q2603?

Check D1112, D1113, D1114, D1129, C1125, C1132 and

their periphery circuit, and service it if defective.

Check IC2600, D2600 and their periphery circuit,

and service it if defective.

Ye s

Ye s

No

Check Q2603 and PWSW3 line and service it if

defective.

No

P-ON+5V (1) is not outputted.

DVD-3800BDCI

28

Page 29

EV+3.3V(2) is not outputted.

(AL+5V is output normally.)

FLOW CHART NO.11

Is 14V voltage inputted to the emitter of Q2609?

Replace Q2613.

Ye s

No

Is 2.6V voltage inputted to the base of Q2613?

Check D1145, R1128, R1129, R1130

and

their periphery, and service it if defective.

No

FLOW CHART NO.12

Check Q2612

and A33-PW-CONT line,

and service it if defective.

FLOW CHART NO.13

Is 3.3V voltage inputted to the emitter of Q2613?

Ye s

Ye s

Is the voltage of base on Q2609 lower than the

voltage of emitter on Q2609 when turning the power on?

Replace Q2609.

Check Q2604 and PWSW3 line and service it if

defective.

Ye s

No

Check D1121, D1127, C1123, L1104 and their

periphery, and service it if defective.

Is -12V voltage inputted to the emitter of Q2600?

Ye s

No

No

Is 5V voltage inputted to the emitter of Q2602?

Replace Q2601.

Check PWSW3 line and

service it if defective.

Ye s

Is 5V voltage outputted to the collector of Q2602?

Replace Q2602.

Ye s

Ye s

No

Ye s

Check Q2600

and their periphery, and service

it if defective.

No

Check D1124, D1125, C1121, L1102

and their periphery, and service it if defective.

No

No

Check D1112, D1113, D1114, D1129, C1132, C1125

and their periphery, and service it if defective.

P-ON-12V is not outputted.

ls "L" signal outputted to the collector of Q2601? ls "H" signal inputted to the base of Q2601?

P-ON+15V is not outputted.

DVD-3800BDCI

29

Page 30

Ye s

No

FLOW CHART NO.15

The key operation is not functioning.

Are the contact point and the installation state of

the key switches (SW3000-3004,

SW3006-SW3010, SW3100) normal?

When pressing each switches (SW3000-3004,

SW3006-SW3010, SW3100), do the voltage of

Pin(3,4) of IC2000 increase?

Check the switches (SW3000-3004,

SW3006-SW3010,SW3100) and their periphery,

and service it if detective.

Check the line between the

RS3000 (remote control

receiver)

and the

Pin(27) of IC2000,

and service it if

detective.

No

Re-install the switches (SW3000-3004,

SW3006-SW3010, SW3100) correctly or replace

the poor switch.

Replace IC2000.

Ye s

FLOW CHART NO.16

No operation is possible from the remote control unit.(Operation is possible from the unit.)

Replace the RS3000 (remote control receiver) or

remote control unit.

Is the "L" pulse sent out Pin(1) of RS3000 (remote

control receiver) when the remote control unit is activated?

Is the "H" pulse inputted to the Pin(27) of IC2000?

Replace IC2000.

Is 5V voltage supplied to Pin(1) of RS3000

(remote control receiver) ?

Ye s

No

Check EV+5V line and service it if defective.

No

No

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

No

No

No

No

FLOW CHART NO.14

The fluorescent display tube does not light up.

Is 3.3V voltage supplied to Pin(64) of IC3001?

Is the voltage of approximately -30V supplied to

Pin(56) of IC3001?

Is there 1.8MHz oscillation at Pin(58) of IC3001?

Are the filament voltage supplied between Pin(1)

and Pin(62) of the fluorescent display tube?

And the negative voltage applied between these

pins and GND?

Replace the fluorescent display tube.

Check the P-ON+3.3V line and service it if

defective.

Check the -FL line and service it if defective.

Check R3006, C3003, IC3001 and their periphery,

and service it if defective.

Check FL-SW

line, and service

it if defective.

Is the "H" signal inputted

to the base of Q2507?

Check D1116, D1123, C1117 and their periphery,

and service it if defective.

Is -20V voltage supplied to collector of Q2502?

No

Ye s

Ye s

No

Check Q2502, Q2508 and their periphery,

and service it if defective.

30

DVD-3800BDCI

Page 31

Ye s

FLOW CHART NO.18

The disc tray cannot be opened and closed.

[No Disc] indicated.

Picture does not appear normally.

Audio is not outputted normally.

Replace the BE Main CBA Unit.

Original BE Main CBA Unit is poor.

Replace the FE Main CBA & BD Mechanism

Assembly.

No improvement can be found.

No

Ye s

FLOW CHART NO.17

The disc tray cannot be opened and closed. (It can be done using the remote control unit.)

Is the normal control voltage inputted to Pin(3) of

IC2000?

Refer to "FLOW CHART NO.15" <The key

operation is not functioning.>

Refer to "FLOW CHART NO.18" <The disc tray

cannot be opened and closed.>

Replace the "OPEN/CLOSE" switch (SW3006).

No

31

DVD-3800BDCI

Page 32

Is 5V voltage supplied to the Pin(4,18) of IC2302

and Pin(4) of IC2303?

Replace IC2302

or IC2303.

Check P-ON+5V(2) line and

service it if detective.

Are the video signals outputted to each pin

of IC2302 or IC2303?

Ye s

No

Ye s

Ye s

No

IC2302 20PIN VIDEO-Y(I/P)

IC2302 17PIN VIDEO-Pb/Cb

IC2302 15PIN VIDEO-Pr/Cr

IC2303 5PIN VIDEO-Y(I)

IC2303 6PIN VIDEO-CVBS

IC2303 7PIN VIDEO-C

Check the periphery of VIDEO OUT terminal

(JK2300, JK2304, JK2305) from Pin(15,17,20)

of IC2302 and service it if detective.

Check

the periphery of VIDEO OUT terminal

(JK2302)

from Pin(6) of IC2303

and service

it if detective.

Check

the periphery of

S-

VIDEO OUT terminal

(JK2303)

from Pin(5) of IC2303

and service

it if detective.

Check

the periphery of

S-

VIDEO OUT terminal

(JK2303)

from Pin(7) of IC2303

and service

it if detective.

Are the video signals outputted to the specific

output terminal?

Are the component video signals outputted to the

VIDEO OUT terminal (JK2300, JK2304, JK2305)?

Are the luminance video signals outputted to the

S-VIDEO OUT terminal (JK2303)?

Are the chrominance video signals outputted to the

S-VIDEO OUT terminal (JK2303)?

No

No

No

No

Are the composite video signals outputted to

the VIDEO OUT terminal (JK2302)?

FLOW CHART NO.19

Picture does not appear normally.

Set the disc on the disc tray, and playback.

Are the video signals outputted to each pin of

CN2301 or CN2304?

Replace the BE Main CBA Unit or

FE Main CBA &

BD Mechanism Assembly.

Check the line between each pin of CN2301or

CN2304 and each pin of IC2302 or IC2303 on

the ,and service it if detective.

CN2304 9PIN → IC2303 3PIN VIDEO-Y(I)

CN2304 7PIN → IC2303 1PIN VIDEO-C

CN2301 1PIN → IC2302 1PIN VIDEO-Y(I/P)

CN2301 3PIN → IC2302 3PIN VIDEO-Pb/Cb

CN2301 5PIN → IC2302 5PIN VIDEO-Pr/Cr

Are the video signals shown above inputted into

each pin of IC2302 or IC2303?

Ye s

No

No

CN2304 9PIN VIDEO-Y(I)

CN2304 7PIN VIDEO-C

CN2301 1PIN VIDEO-Y(I/P)

CN2301 3PIN VIDEO-Pb/Cb

CN2301 5PIN VIDEO-Pr/Cr

IC2303 3PIN VIDEO-Y(I)

IC2303 1PIN VIDEO-C

IC2302 1PIN VIDEO-Y(I/P)

IC2302 3PIN VIDEO-Pb/Cb

IC2302 5PIN VIDEO-Pr/Cr

DVD-3800BDCI

32

Page 33

FLOW CHART NO.20

Audio is not outputted normally.

No Improvement can be found after replacing

the ANALOG AUDIO CBA UNIT.

Original ANALOG AUDIO CBA UNIT is poor.

No

No Improvement can be found after replacing

the ADSP CBA UNIT.

Original

ADSP

CBA UNIT is poor.

No

Ye s

No Improvement can be found after replacing

the SCALER CBA UNIT.

Original

SCALER

CBA UNIT is poor.

No

Ye s

No Improvement can be found after replacing

the BE MAIN CBA UNIT.

Original

BE MAIN

CBA UNIT is poor.

No

Ye s

Replace FE MAIN CBA & BD MECHANISM

ASSEMBLY.

Ye s

33

DVD-3800BDCI

Page 34

GU-3866 (ADSP UNIT)

Contents: BD (LPCM 8ch)

Setup: Multi Channel

Check connection to Digital Video UNIT

GU-3866 (ADSP UNIT)

· {CX874} {CX875} output signal.

O.K.

N.G

Check soldering, FFCcable

· {CX874} {CX875}

· {CX815} {CX816}: GU-3867

· FFC cable, Insert condition

Check input signal: IC151

GU-3866 (ADSP UNIT)

· RE916 (LRCK.)

· RE917 (BCK.)

· RE918 (MCK.)

· RE911 (DATA_IN0.)

· RE912 (DATA_IN1.)

· RE913 (DATA_IN2.)

· RE914 (DATA_IN3.)

· RE915 (DATA_IN4.)

· RR174 (LRCK1.)

· RR173 (BCK1.)

· RR172 (MCK1.)

· RR178 (DATA_IN10.)

· RR177 (DATA_IN11.)

· RR176 (DATA_IN12.)

· RR175 (DATA_IN13.)

· RE919 (SPDIF.)

Check Soldering

RE916

RE917

RE918

RE911

RE912

RE913

RE914

RE915

RR174

RR173

RR172

RR178

RR177

RR176

RR175

RE919

N.G

O.K.

Check input signal: IC201

GU-3866 (ADSP UNIT)

· R-228 (DSP1IN64fs)

· R-218 (DSP1INfs)

· RE997 (DSP1INF)

· RE999 (DSP1INC)

· RE901 (DSP1INS)

· RE902 (DSP1INSB)

Check Soldering

R-228, RE995

R-218, RE996

RE997

RE999

RE901

RE902

Check Power Supply Voltage(3.3V )

{CX876} 2-3pin

Check Power Supply Voltage(1.2V )

R-262, R-263

Check nDFRST signal for IC151

RR115

O.K.

Check output signal: IC201

GU-3866 (ADSP UNIT)

· RE904 (DSP1OUT64fs.)

· RE905 (DSP1OUTfs.)

· R-245 (DSP1OUTF)

· R-233 (DSP1OUTC)

· R-225 (DSP1OUTS)

· R-217 (DSP1OUTSB)

Check Soldering

R-211, RE904

R-229, RE905

R-245

R-233

R-225

R-217

Check /RESET signal for IC201(24pin)

TR202 (collector)

Check CLKIN for IC201(18pin)

R-232

O.K.

34

DVD-3800BDCI

Page 35

Check input signal: IC251

GU-3866 (ADSP UNIT)

· RE268 (DSP2IN64fs)

· RE278 (DSP2INfs)

· RE103 (DSP2INF)

· RE107 (DSP2INC)

· RE108 (DSP2INS)

· RE105

(

DSP2INSB

)

Check Soldering

RE268, RE101

RE278, RE102

RE103

RE107

RE108

RE105

O.K.

Check output signal: IC251

GU-3866 (ADSP UNIT)

· RE106 (DSP2OUT64fs)

· RE104 (DSP2OUTfs)

· RE288 (DSP2OUTF)

· RE295 (DSP2OUTSW)

· RE251 (DSP2OUTS)

· RE228 (DSP2OUTSB)

Check Soldering

RE294, RE106

RE298, RE104

RE288

RE295

RE251

RE228

Check Power Supply Voltage(3.3V )

RR248, RR249, RR250

Check Power Supply Voltage(1.3V)

RR286, RR287

Check /RESET signal for IC251(36pin)

TR251 (collector)

Check CLKIN for IC251(244pin)

RR253

O.K.

Check Output signal: IC151for DAC

GU-3866 (ADSP UNIT)

· {CX873}

5(WDCK(MIX)_0), 7(BCK(MIX)_0),

9(MCK(MIX)_0), 3(DATA_OUT0),

4(DATA_OUT1), 15(LRCK_0),

17(BCK_0),19(MCK_0),

11(DATA_OUT2), 12(DATA_OUT3),

13(DATA_OUT4), 14(DATA_OUT5),

28(XRST), 25(AMUTE),

2(DACMUTEL),16(DACMUTER)

Check Soldering

CX873,

RE928, RE927

RE149, RE929,

RE155, RE153,

RE152, RE151,

RE154, RE156,

RE158, RE160

Check Soldering

RE190, RE157,

RE940, RE941

Check Output signal: IC151for HDMI

GU-3866 (ADSP UNIT)

· {CX875}

7(LRCK_0H), 5(BCK_0H), 3(MCK_0H),

11(DATA_OUT0H), 10(DATA_OUT1H),

9(DATA_OUT2H), 8(DATA_OUT3H)

O.K.

N.G

Check Soldering

CX875,

RE171, RE172,

RE174, RE179,

RE184, RE188

Check Output signal: IC151 for Opt./Coax

GU-3866 (ADSP UNIT)

· {CX877}

3(SPDIF_0.)

Check Soldering

CX877

RR101

O.K.

A

nalog Audio UNIT

O.K.

Digital Video

O.K.

O.K.

A

V-D-Audio

35

DVD-3800BDCI

Page 36

GU-3867(D.VIDEO UNIT

)

(1) Component480i output [Y, Cb, Cr] does not be outputted.

Check Power Supply Voltages Check Soldering

• Digital Power Supply Voltages 䍃[CY080] 5pin(+5.0V_V3), 6-8pin(+3.3V_D2)

+3.3V_D2, +1.8V_V1, +5.0V_V3 䍃Circumference of [IC603] (LM1117MPX-1.8/NOPB)

Check Digital signal for Video Check Soldering

• Video Encoder [IC602](ADV7340) input: 䍃[CX813]: 7,9,11,13,15,17,19,21,26pin

[YUV0-7] 䍃R315-R322,R894,R744-746

[PCLK] 䍃Circumference of [IC602]

Check control signal for Video Encoder Check Soldering

䊶[IC602](ADV7340) : [SDA], [SCK] 䍃[CX813]: 30,32pin

䍃Circumference of [IC602]

Check Video Encoder circuit Check Soldering.

䊶[IC602](ADV7340) 䊶[IC602]

and circumference soldering of [IC602]

Check Video Buffer circuit Check Soldering.

䊶[Yp/Yi] : [TR606] 䊶[TR606-608]

䊶[Pb/Cb] : [TR607] and circumference soldering of [TR606-608]

䊶[Pr/Cr] : [TR608] 䊶CX817 : 1,3,5pin

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

Continue to the check

process of AV PWB

㪥㪅㪞㪅

㪦㪅㪢㪅

36

DVD-3800BDCI

Page 37

GU-3867(D.VIDEO UNIT

)

(2)HDMI/Component output (without component480i) does not be outputted.

Check Power Supply Voltages. Check Soldering.

• +3.3V_D2, +5.0V_V3, +1.5V_D1, • [CY080]

+2.5V_D3,+1.2V_D2

• Circumference of [IC409](LP2995M),

• VTT(+1.25V)

[IC801](BA00HC5FP)

• VREF (+1.25V)• Circumference of [IC302](EN5330DC)

• MAVREF1, MAVREF2, MBVREF1, • Circumference of [IC303](EN5360DI)

MBVREF2(1.25V) • R455,R456,R459,461,R463,

• VPLL-AVDD (+3.3V) R464,R470,R475

• SPLL-AVDD (+3.3V) • R471,R472,R484,R485,

• MPLL-AVDD (+3.3V) R479,R480,R489,R490

• SIMD-AVDD (+3.3V) • RR257,RR258,RR254,RR255

• C124,C125,C121,C122

• FB

101-FB104

Check Digital signal for Video[1]. Check Soldering.

• I/P Convertor [IC101](SXT2LF-400)input: • [CX813] : 3-22, 25-27pin

[Y0-9],[CbCr0-9],[PCLK],[HSYNC],[VSYNC] • [RR119-138],[RR139],

[RR117-118],[R323-330]

Check oscillation waveform. Check Soldering.

• [IC101](SXT2LF-400): [REFCLKA] • Circumference of [X101](66.666MXTAL)

Check point: [RR251]: 66.666MHz •

Circumference of [IC101]

• [IC101](SXT2LF-400): [PCICLK] • Circumference of [IC401-408]

Check point: [RR300]: 33MHz

• [IC401,403,405,407](K4D261638K-LC40): [ACK]

Check point: [RR372,373]: 250MHz

• [IC402,404,406,408](K4D261638K-LC40): [BCK]

Check point: [RR582,583]: 250MHz

Check control signal for I/P Convertor [IC101]. Check Soldering.

• [V_RST], [V_SCL], [V_SDA] • [CX813]:29,30,32pin

• [RESETN], [IIC0_CLK], [IIC0_DAT] • RR113,RR114,RR153,RR158,

RR164,RR157

• Circumference of

[IC103](SN74LVC1G3208DBV)

• Circumference of [IC102](TC7W241FU)

Check Digital signal for Video[2]. Check Soldering.

• [IC101](SXT2LF-400)output: • Circumference of [IC101](SXT2LF-400)

䇭[YO0-9], [CO0-9],[SO0-9] • RR167-196

[P_VSYNC-1], [P_HSYNC-1], • RR204,RR205,RR207,RR220,

[C_REF-1], [PS_CLK-1] RR160,R897

Check control signal for PLD[IC802]. Check Soldering.

䇭[IC802](EPM240T100) : [PLD_RST] • R981,R995, R954

N.G.

O.K.

O.K.

O.K.

O.K.

O.K.

N.G.

N.G.

N.G.

N.G.

N.G.

s

s

s

s

s

37

DVD-3800BDCI

Page 38

Check Digital output for Video[3]. Check Soldering.

• [IC802](EPM240T100C5N)output: • Circumference of

䇭[YO0.-9.], [CbCr0.-9.], [S0.-9.]

[IC802](EPM240T100C5N)

[P_VSYNC-1.], [P_HSYNC-1.], [P_HSYNC-2], • R812-818,R820,R822,R824

[C_REF-1.], [PS_CLK-1.], [PS_CLK-2.] • R834-853

• R830-833,R717,R745

Check control signal for HDMI Tx/Video Encoder. Check Soldering.

• HDMI Tx control signal • HDMI Tx control signal

䇭[IC804](MN864704) : [SDA], [SCK], [HDMI_RST] 䇭R313, R908-910

• Video Encoder control signal • Video Encoder control signal

䇭[

IC602](ADV7340) : [SDA], [SCK] 䇭R628,R630

Check HDMI Tx/Video Encoder output. Check Soldering.

• HDMI Tx output • HDMI Tx output

䇭[IC804](MN864704) : [TX0+.,TX0-.], 䇭L801-L803, L806

[TX1+.,TX1-.], [TX2+.,TX2-.], [TXC+.,TXC-.] 䇭CX812

• Video Encoder output • Video Encoder output

䇭Video buffer circuit : [Yp/Yi], [Pb/Cb], [Pr/Cr] 䇭Circumference of [IC602](ADV7340)

䇭TR606-TR6

08

CX817 : 1,3,5pin

O.K.

END

O.K.

O.K.

N.G.

N.G.

N.G.

s

s

s

s

s

s

s

s

38

DVD-3800BDCI

Page 39

GU-3879(AUDIO UNIT)

○

CD,DVD-VIDEO,BD,SD CARD

Check connection DSP PWB UNIT Check Soldering,FFC cable

GU-3866(DSP UNIT) N.G. 䊶[CY281]:GU-3879-1

䊶[CY281]input signal 䊶[CX873]:GU-3866

䊶FFC cable, insert condition

O.K.

Check DATA Signal Check Soldering,FFC cable

GU-3879-1(MIX UNIT) 䊶[CX201]:GU-3879-1

䊶[ IC101](DAC for 2ch(Mix) L/R) 䊶[

CY201]:GU-3879-2

1,2,4,6,7pin(WCK=16/8/4fs, 䊶FFC cable, insert condition

BCK=1024/512/256fs,

DATA,MCK=1024/512/256fs)

*fs=48/96/192

䊶[IC301](DAC for FL/FR) N.G.

4䌾7pin(LRCK=1fs,BCK=64fs,

DATA,MCK=256fs)

GU-3879-2(SURROUND UNIT)

䊶[IC601](DAC for SW/C)

䊶[IC801](DAC for SR/SL)

䊶[IC401](DAC for SBR/SBL)

4䌾7pin(LRCK=1fs,BC

K=64fs,

DATA,MCK=256fs)

O.K.

Check DAC output Check Soldering

GU-3879-1(MIX UNIT) 䊶[IC101][IC301]

䊶[IC101][IC301]:output 䇭10䌾12,14pin(control line)

GU-3879-2(SURROUND UNIT) 䊶[IC601][IC801][IC401]

䊶[IC601][IC801][IC401]:output 䇭10䌾12,14pin(control line)

Check Power Supply Voltage

䊶[CN010]:GU-3879-1

N.G. 1pin:about+12V

,2pin:about-12V,

4pin:about+3.3V

䊶[CX061]:GU-3879-1

3pin:about+3.3V,4pin:about+5V,

5pin:about-9V,6pin:about+9V

䊶[CY061]:GU-3879-2

1pin:about+9V,2pin:about-9V,

3pin:about+5V,4pin:about+3.3V

䊶Check Cable, insert condition, Soldering

O.K.

s

s

39

DVD-3800BDCI

Page 40

Check OP AMP output Check Soldering

GU-3879-1(MIX UNIT) 䊶[IC102][IC103][IC105][IC106]

䊶[IC102][IC103][IC105][IC106] 䊶[IC302][IC303][IC305][IC306]

䊶[IC302][IC303][IC305][IC306] N.G. POWER C,R

GU-3879-2(SURROUND UNIT) 䊶[IC602][IC603][IC605][IC606]

䊶[IC602][IC603][IC605][IC606] 䊶[IC802][IC803][IC805][IC806]

䊶[IC802][IC803][IC805][IC806] 䊶[IC402][IC403][IC405][IC406]

䊶[IC402][IC403][IC405][IC406] POWER C,R

O.K.

Check AUDIO OUT Check Soldering

GU-3879-1(MIX UNIT) MUTE circuit:MUTE TR

䊶Check OUTPUT terminal GU-3879-1(MIX UNIT)

(Each channels) 䊶TR112,TR113,TR115,TR116,

GU-3879-2(SURROUND UNIT) TR171䌾TR173,TR177,TR180,TR181

䊶Check OUTPUT terminal 䊶TR312,TR313,TR315,TR316,

(Each channels) TR371䌾TR373,TR377,TR380,TR381

N.G. GU-3879-2(SURROUND UNIT)

䊶TR612,TR613,TR615,TR616,

TR671䌾TR673,TR677,TR680,TR681

䊶TR812,TR813,TR815,TR816,

TR871䌾TR873,TR877,TR880,TR881

䊶TR412,TR413,TR415,TR416,

TR471䌾TR473,TR477,TR480,TR481

TR-BASE terminal:about-9V(at MUTE off)

䊶Check Soldering, Output Jack

O.K.

END

40

DVD-3800BDCI

Page 41

BD Mechanism Replacement Guidelines

The guidelines describe how to determine whether a BD Mechanism Assembly is defective or not.

Confirm that the malfunction is eliminated after replacing the defective BD Mechanism Assembly with a new one.

*The BD Mechanism Assembly shall be acceptable when the following test disc can be played successfully;

*Select [4: LD Test] and select [2: Operating Time] in Service Mode.

If the Operating Time shows 3,000 hours or more, the BD Mechanism Assembly shall be determined that it has

reached the end of its life.

*The BD Mechanism Assembly has 2 types (BD 1.0 and BD 1.5) with different pickup versions, each of which is

compatible.

You can check the version by the second letter printed on the serial number label on the bottom cover of the BD

Mechanism Assembly.

Be sure to perform an upgrade after replacing the BD Mechanism Assembly.

The upgrading method differs depending on the version of the BD Mechanism Assembly that has been judged

defective, and the pickup version of the non-defective BD Mechanism Assembly.

Perform according to the following approach.

BD-ROM BLX-201S3(SONY) chp12

BD-R SBD-8284(ALMEDIO)

(ex)

Identification code

N2008418A3

77D2A00064

7 : B1.0 (Set Serial No. with B1.0 : 00001~19999)

J : B1.5 (Set Serial No. with B1.5 : 20001~)

Refer to FIRMWARE RENEWAL MODE (page 21).

Refer to FIRMWARE RENEWAL MODE (page 21).

Refer to FIRMWARE RENEWAL MODE (page 21).

Refer to Replacement procedure of B1.5 Loader Unit

from B1 Loader Unit (page 42, 43).

What is the

version of the

defective

mechanism?

What is the version

of the non-defective

mechanism?

What is the version

of the non-defective

mechanism?

B1.0

B1.5

B1.0

B1.5

B1.0

B1.5

FE Main CBA

& BD Mechanism Assembly

Replacement of FE Main CBA & BD Mechanism Assembly

1. Remove the Top Cover, Top Panel, Tray Panel and BE Main CBA Unit.

2. Disconnect Connectors and replace the FE Main CBA & BD Mechanism Assembly.

Refer to CABINET DISASSEMBLY INSTRUCTIONS.

d

DVD-3800BDCI

41

Page 42

Replacement procedure of B1.5 Loader Unit

from B1 Loader Unit

1. Replacement Note

1. When replacing the Loader Unit, be sure to

confirm the loader model label

( B1:

N77F*AUN

,

B1.5:

N7JF*AUN )stuck on the bottom of Loader

Unit.

2. If the loader model label is

“N77F*AUN”

, replace

the B1 Loader Unit with B1.5 Loader Unit and

update the firmware by using the Firmware Update

Disc.

2. How to make Firmware

Update Disc

1. Write the data of “E5E**UD_dummy_.bin”,

“E5E**UD*****A1.bin” or “E5H**UD*****A1.bin” in

blank CD-R disc.

3. Firmware Update Procedure

3.1. Update for FE recognition of B1.5

Loader Unit

1. Turn the power on and remove the disc on the tray.

2. To put the BD player into version up mode, press

[9], [8], [7], [6], and [POP MENU/MENU] buttons on

the remote control unit in that order. The tray will

open automatically.

Fig. a appears on the screen and Fig. b appears on

the VFD.

The BD player can also enter the version up mode

with the tray open. In this case, Fig. a will be shown

on the screen while the tray is open.

3. Load the firmware update disc.

4. The BD player enters the F/W version up mode

automatically. Fig. c appears on the screen. Select

the “E5E**UD_dummy_.bin”, then press

[ENTER(OK)] button.

5. When the data of “E5E**UD_dummy_.bin” is read,

“Now Loading... ” is displayed on the screen. When

it finishes reading data, Fig. d appears on the

screen. Select the “4. BE NAND” pressing arrow

buttons, then press [ENTER(OK)] button.

6. Fig. e appears on the screen.

The appearance shown in (*1) of Fig. e is described

as follows:

]

7. After programming is finished, the checksum is

displayed on the VFD (Fig. g).

At this time, no button is available.

8. Unplug the AC cord from the AC outlet. Then plug it

again.

F/W VERSION UP MODE Model No. ******* Ver. *.***

Please insert a Disc

for F/W Version Up

"

*******

" differs depending on the models.

Fig. a Version Up Mode Screen

Fig. b VFD in Version Up Mode

E5H**UD*****A1.bin

E5E**UD_dummy_.bin

"

*******

" differs depending on the models.

Fig. c Firmware Select Screen

F/W VERSION UP MODE Model No. ******* Ver. *.***

EXIT : POWER

No. Appearance State

1

Now

Loading...

It means that BD-player begin

to read the data of the disc.

2Reading...

Sending files into the memory.

When BD-player finishes

reading data, it will open a tray

automatically.

3

Remove the

Disc

It has finished reading data.

Please remove the updata disc,

and close the tray.

4

See FL

Display

It renews data. progress

degree is displayed on VFD like

Fig. f.

1. ALL

2. FE

3. BE NOR

4. BE NAND

Please select F/W Update Mode

"

*******

" differs depending on the models.

Fig. d Update item Select Screen

F/W VERSION UP MODE Model No. ******* Ver. *.***

EXIT : POWER

4. BE NAND

Now Loading...

Ver. *.*** E5E**UD_dummy_.bin

(*1)

"

*******

" differs depending on the models.

Fig. e Programming Mode Screen (Example

)

F/W VERSION UP MODE Model No. ******* Ver. *.***

EXIT : POWER

Fig. f VFD in Version Up Mod

e

Fig. g VFD upon Finishing the Programming Mode (Example)

d

42

DVD-3800BDCI

Page 43

3.2. Update for the latest firmware

1. Carrying out Steps 1~3 in the “

3.1. Update for FE

recognition of B1.5 Loader Unit”

.

Note:

If the screen background in fig. h has not

changed into blue, repeat the procedure from step 4

in the “

3.1. Update for FE recognition of B1.5

Loader Unit”

.

2. The BD player enters the F/W version up mode

automatically. Fig. h appears on the screen. Select

the “E5E**UD*****1A.bin” or “E5H**UD*****1A.bin”,

then press [ENTER(OK)] button.

3. When the data of E5E**UD*****1A.bin” or

“E5H**UD*****1A.bin” is read, “Now Loading... ” is

displayed on the screen. When it finishes reading

data, Fig. i appears on the screen. Select the “1.

ALL” pressing arrow buttons, then press

[ENTER(OK)] button.

4. Fig. j appears on the screen.

The appearance shown in (*1) of Fig. j is described

as follows:

5. After programmi

ng is finished, the checksum is

displayed on the VFD (Fig. l).

At this time, no button is available.

6. Unplug the AC cord from the AC outlet. Then plug it

again.

No. Appearance State

1

Now

Loading...

It means that BD-player begin

to read the data of the disc.

2Reading...

Sending files into the memory.

When BD-player finishes

reading data, it will open a tray

automatically.

3

Remove the

Disc

It has finished reading data.

Please remove the updata disc,

and close the tray.

E5H**UD*****A1.bin

E5E**UD_dummy_.bin

"

*******

" differs depending on the models.

Fig. h Firmware Select Screen

F/W VERSION UP MODE Model No. ******* Ver. *.***

EXIT : POWER

1. ALL

2. FE

3. BE NOR

4. BE NAND

Please select F/W Update Mode

"

*******

" differs depending on the models.

Fig. i Update item Select Screen

F/W VERSION UP MODE Model No. ******* Ver. *.***

EXIT : POWER

1. ALL

Now Loading...

Ver. *.*** E5H**UD*****A1.bin

(*1)

"

*******

" differs depending on the models.

Fig.j Programming Mode Screen (Example

)

F/W VERSION UP MODE Model No. ******* Ver. *.***

EXIT : POWER

4

See FL

Display

It renews data. progress

degree is displayed on VFD like

Fig. k.

No. Appearance State

Fig. k VFD in Version Up Mod

e

Fig. l VFD upon Finishing the Programming Mode (Example)

b The region setting can be changed up to five

times (including factory preset).

If you exceed the region change limit, DVD

playback images will be affected by noise.

43

DVD-3800BDCI

Page 44

BLOCK DIAGRAMS

System Control Block Diagram

A33-PW-CONT

SCALER-PWSW

A33-PW-CONT

SCALER-PWSW

IC2000

IC6905 (EEPROM)

IC6001

SUB

MICRO CONTROLLER

(MAIN MICRO CONTROLLER)

4

63 62 61 60

SW3100

D3101

POWER

CN3101

CN2001 CN3000

IC3001

FL3000

VFD

(VFD DRIVER)

SDA

SCL

CS

RESET

CN3001

33

POWER-KEY

515KEY-1

416KEY-2

614REMOTE

713FL-RESET

812FL-CS

911FL-SCL

10 10FL-SDA

XRST

XTRST

CN2503CN2304CN7001 CN2000

15 9SUB-TXD

14 11SYS-RESET

13 12RDY

16 6SUB-RXD

218LED-R

119LED-G

55LED-R

66LED-G

CN2551CN2504

11

REMOTE

55R1-OUT

44T1-IN

POWER SW CBA

FRONT CBABE MAIN CBA UNIT SUB MICROCONTROLLER CBA

RS232C CBAAV CBA

AV CBA

RS3000

REMOTE

SENSOR

KEY SWITCHKEY SWITCH

27

20

34

33

44

55

43

M3

Q2004

BUFFER

LED DRIVE

14

8

9

RESET

48

SUB-TXD

49

L3

A16

SUB-RXD

LED-R

SYS-RESET

RDYRDY

B18

TXD1

G18

A18

A17

RXD1

SCL

SDA

SCL

SDA

FL-SDA

FL-SCL

FL-CS

REMOTE

KEY-1

3KEY-2

OSC2

OSC1

8MHz

X'TAL

X2000

EV+3.3V

IC2001

RESET

D+3.3V

D+3.3V

Q2000

54

LED DRIVE

LED-G

Q2001

Q6702

Q6703

Q6701

10 25

RS232C-RXD

926

RS232C-TXD

20 15

RS232C-SW

14 21

REMOTE

19

RS232C-RXD

18

RS232C-TXD

15 20

PWSW2

17 18

PWSW3

13 22

FL-SW

30 5

FAN-LOCK

12 23

A33-PW-CONT

16 19

SCALER-PWSW

29

PWSW237PWSW3

PWSW2

CN2000

CN2000

CN2503

CN2503

PWSW3

26

FL-SW

FL-SW

RS232C-TXD

RS232C-RXD

62

FAN-LOCK

FAN-LOCK

TO POWER

SUPPLY

BLOCK

DIAGRAM

TO VIDEO

BLOCK

DIAGRAM

Q6704

5

6

STANDBY

POWER

131516

14

232629

24

RESET

IC6702

1

D+3.3V

Either IC6701 or IC6702 is used for BE MAIN CBA UNIT.

D+3.3V

RESET

IC6701

2 1

3

IC2500

REMOTE

-IN

REMOTE

-OUT

RS232C

I/F

13

14

CN2550

RS232C-

CONNECTOR

3RXD

2TXD

11

12

391

2

14413

12

41

RS232C-SW

IC2501

(AMP)

IC2502

(SELECTOR)

JK2550

AMP

1

SW

CTL

7

RS232C

INTERFACE

30

25

10

11

3.3V

DVD-3800BDCI

44

Page 45

Digital Signal Process 1 Block Diagram

BD MECHANISM FE MAIN CBA

W1

V2

U3

HU(+) 5

HU(-) 6

HV(+) 7

HV(-) 8

HW(+) 9

HW(-) 10

CN903

IC001 (MAIN MICRO CONTROLLER/FE DIGITAL SIGNAL PROCESS)

IC902 (ACTUATOR DRIVE) IC301 (OP AMP)

FOCUS

ACTUATOR

DRIVE

OEIC

(CD/DVD)

IC903 (MOTOR DRIVE)

IC904

IC301 (OP AMP)

(MOTOR DRIVE)

16MBIT

NOR

FLASH

ROMDQ(0-15)

ROMA(1-20)

DQ(0-15)

A(0-11)

IC402 (NOR FLASH)

IC002 (RF AMP)

TO DIGITAL

SIGNAL PROCESS 2

BLOCK DIAGRAM

(CN6401)

SCK

SI

SCK_0

SO_0

CN501

3-18

AG22-AG24,

AH20-AH24,

AJ20-AJ22,

AK20-AK24

21,22,24,

25,27,29

AH12-AH18,

AG15-AG19

2-13,

42-53

1-9,

16-25,48

29-36,

38-45

22-26,

29-35

AJ11-AJ15,

AJ18,AJ19,

AK10-AK13,

AK15-AK19

N27,N28,N30,

P27-P30,R27-R30,

T27-T30,U27,U29,

U30,V27,W27

H28-H30,J28-J30,

K27-K30,L27,L28,

L30,M27,M28,M30

IDE1D(0-15)

37,38,40,

42,45,47

A5-A7,

B5-B7

C5-C7,

D5-D7

64MBIT

SDRAM

IC401 (SDRAM)

IC403 (EEPROM)

ATAP I

I/F

MEMORY

I/F

FE

DIGITAL

SIGNAL

PROCESS

MATRIX

RF EQ

6

5

AG28

AH4

AG5

U4

U3

R3T1R4

T2

AA1

Y3

K4100

125-128

AH29

/CEE2CS

1

AH28

SOSI_0

2

AH30

247

9

1011121314

SLD2(+) 4

SLD2(-) 3

SLD1(+) 2

SLD1(-) 1

CN902

LOAD(+) 5

LOAD(-) 6

LDSNS1 2

LDSNS2 1

CN901

FCS(+) 2

FCS(-) 3

TRK(+) 1

TRK(-) 4

EXPA(+) 6

EXPA(-) 7

EXPB(+) 8

EXPB(-) 9

A-D 20-23

E-H 25-28

XOUT 29

RF(+) 16

RF(-) 17

BDRF(+) 13

BDRF(-) 14

SD ATA 4 0

SCLK

SD ATA

SCLK

SD ATA

SCLK

38

CN101

CN101

151617

18

141312

11

141315

16

LOADING

MOTOR DRIVE

10

9

COLLIMATE

LENS

MOTOR DRIVE

SLED

MOTOR DRIVE

SPINDLE

MOTOR

DRIVE

TRACKING

ACTUATOR

DRIVE

FOCUS2-CONTROL

ADR(0-5)

ADW(0-5)

SWRF

FOCUS1-CONTROL

TRACKING2-CONTROL

TRACKING1-CONTROL

SLED1-CONTROL

SLED2-CONTROL

LOAD1-CONTROL

LDSNS1

LDSNS2

SPINDLE-CONTROL

SPINDLE-FG

LOAD2-CONTROL

LOAD-CONTROL

EXPA-CONTROL

EXPB-CONTROL

1

26

5

6

U2

U1

23

26

1

2

V4

AG10

AK5

3

V1

22 14 13

W1

19

115-118

114

141

140

143

142

75

74

J2

K2

102

103

SE

PI

K1

J3

104

105

TE

CE

H3106

FE

C2

C1

8

9

RF ADC

WOB ADCWOB FE

7

1

536

2

OEIC

(BD)

LDD

SLED

MOTOR

SPINDLE

MOTOR

LOADING

MOTOR

VIDEO SIGNAL AUDIO SIGNAL

45

DVD-3800BDCI

Page 46

Digital Signal Process 2 Block Diagram

*

2: 3,5,7,9,11,13,15,17,19,21

AV CBA

SD CBA BE MAIN CBA UNIT

STREAM

CONTROL

ATAPI I/F

ED (0-7)

ED (0-15) ED (0-15)

EA (1-22)

C0DQ (0-31)

PC0A (0-12)

C1DQ (0-31)

PC1A (0-12)

MEDIA

PROCESSOR

Java (BD-J)

MPEG-2

DECODER

HD (TS)

SD (PS)

COPY

PROTECT

AACS

/BD+

SD

CARD

SLOT

TO DIGITAL

SIGNAL PROCESS 1

BLOCK DIAGRAM

(CN501)

CN4001 CN7602

CN6401

CN4002 CN2304CN7001

CN7801

CN7801

MOMORY

I/F

SD I/F

IC6001 (BE DIGITAL SIGNAL PROCESS)

F25

G25

B26

A3

F8

C14

F27

C13

B14

IC6901

(NAND FLASH MEMORY)

NAND FLASH

MEMORY (512Mbit)

IC6902 (NOR FLASH MEMORY)

(DDR SDRAM)

NOR FLASH

MEMORY (64Mbit)

IC6501,6502,6503,6504

DDR SDRAM

(64Mbit)

3-18 IDE1D(0-15)

13 13SDDAT0

15 15SDDAT1

11SDDAT2

33SDDAT3

11 11SDCLK

99 VIDEO-Y

77 VIDEO-C

77SDCD

(DDR SDRAM)

IC6507,6508,6509,6510

DDR SDRAM

(64Mbit)

D33,D34,E32-E34,

F32-F34,G30,G32,

H29,H30,H32,

J28-J30

A8,A9,A11,B10,B11,

C11,E13,F14,G13,G14

15,16,18,