Page 1

Ver. 4

Please refer to the

MODIFICATION NOTICE.

SERVICE MANUAL

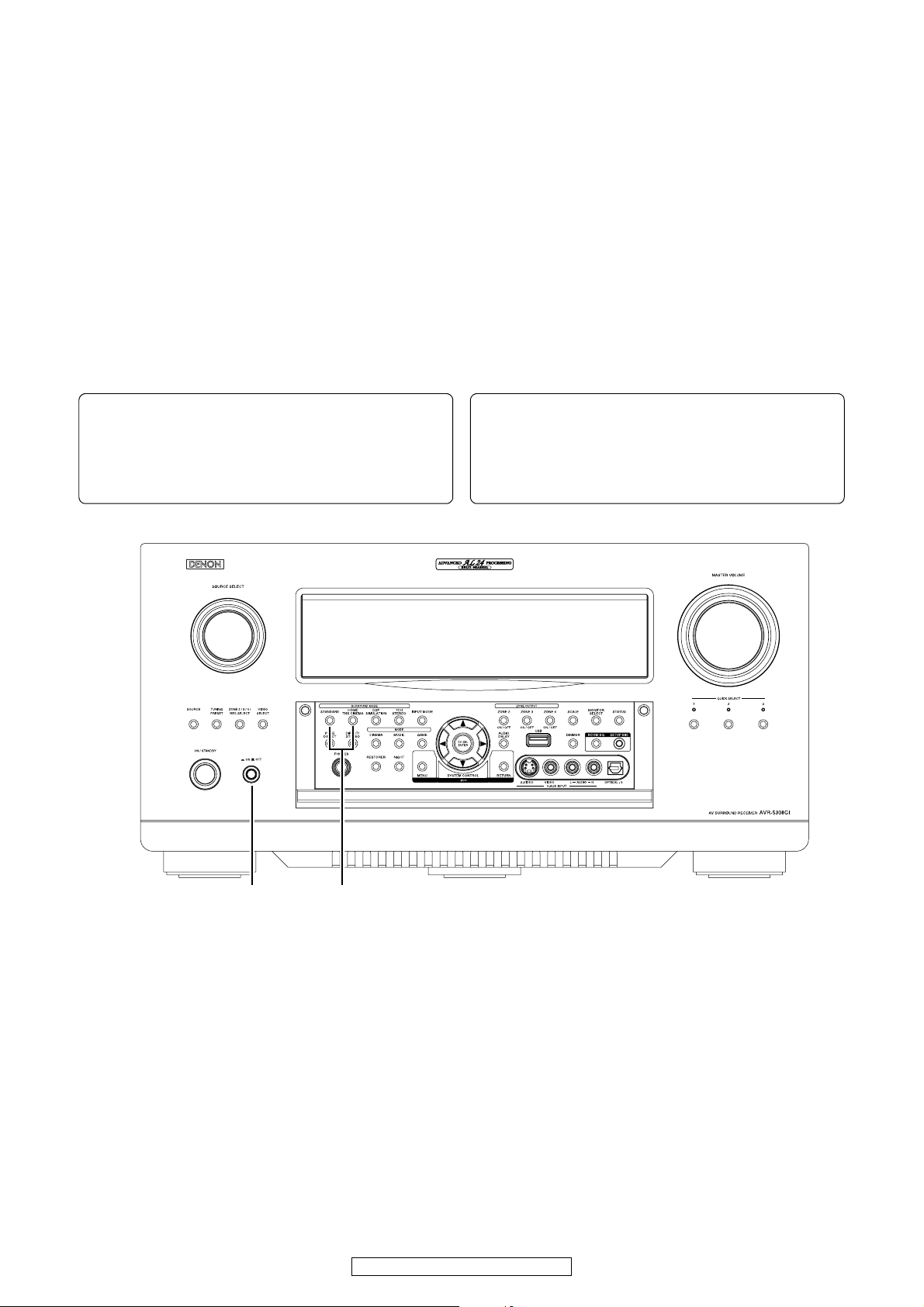

MODEL JP EU EC E2 EK E2A E1C EUT

AVR-5308CI

MODEL JP EU EC E2 EK E2A E1C EUT

AVC-A1HD

3

AV SURROUND RECEIVER

33

AV SURROUND AMPLIFIER

注 意

サービスをおこなう前に、このサービスマニュアルを

必ずお読みください。本機は、火災、感電、けがなど

に対する安全性を確保するために、さまざまな配慮を

おこなっており、また法的には「電気用品安全法」に

もとづき、所定の許可を得て製造されております。

従ってサービスをおこなう際は、これらの安全性が維

持されるよう、このサービスマニュアルに記載されて

いる注意事項を必ずお守りください。

●

For purposes of improvement, specifications and

design are subject to change without notice.

●

Please use this service manual with referring to the

operating instructions without fail.

●

Some illustrations using in this service manual are

slightly different from the actual set.

e

Denon Brand Company, D&M Holdings lnc.

●

本機の仕様は性能改良のため、予告なく変更すること

があります。

●

補修用性能部品の保有期間は、製造打切後 8 年です。

●

修理の際は、必ず取扱説明書を参照の上、作業を行っ

てください。

●

本文中に使用しているイラストは、説明の都合上現物

と多少異なる場合があります。

X0365 V.04 DE/CDM 0805

Page 2

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

CAUTION

Pleaseheedthepointslistedbelowduringservicingandinspection.

◎Heedthecautions!

Spots requiring particular attention when servicing, such

as the cabinet, parts, chassis, etc., have cautions indicated

on labels or seals. Be sure to heed these cautions and the

cautions indicated in the handling instructions.

◎Cautionconcerningelectricshock!

(1) An AC voltage is impressed on this set, so touching in-

ternal metal parts when the set is energized could

cause electric shock. Take care to avoid electric shock,

by for example using an isolating transformer and

gloves when servicing while the set is energized, unplugging the power cord when replacing parts, etc.

(2)There are high voltage parts inside. Handle with extra

care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Though great care is taken when manufacturing parts from

sheet metal, there may in some rare cases be burrs on the

edges of parts which could cause injury if fingers are

moved across them. Use gloves to protect your hands.

◎Inspectforsafetyafterservicing!

Check that all screws, parts and wires removed or disconnected for servicing have been put back in their original positions, inspect that no parts around the area that has been

serviced have been negatively affected, conduct an insulation check on the external metal connectors and between

the blades of the power plug, and otherwise check that

safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and turn the power switch on. Using a 500V insulation resistance tester, check that the insulation resistance between the terminals of the power

plug and the externally exposed metal parts (antenna terminal, headphones terminal, microphone terminal, input

terminal, etc.) is 1MΩ or greater. If it is less, the set must

be inspected and repaired.

CAUTION

Concerningimportantsafety

parts

◎Onlyusedesignatedparts!

The set's parts have specific safety properties (fire resistance, voltage resistance, etc.). For replacement parts, be

sure to use parts which have the same properties. In particular, for the important safety parts that are marked z on

wiring diagrams and parts lists, be sure to use the designated parts.

◎Besuretomountpartsandarrangethe

wiresastheywereoriginally!

For safety reasons, some parts use tape, tubes or other insulating materials, and some parts are mounted away from

the surface of printed circuit boards. Care is also taken with

the positions of the wires inside and clamps are used to

keep wires away from heating and high voltage parts, so

be sure to set everything back as it was originally.

Many of the electric and structural parts used in the set

have special safety properties. In most cases these properties are difficult to distinguish by sight, and using replacement parts with higher ratings (rated power and

withstand voltage) does not necessarily guarantee that

safety performance will be preserved. Parts with safety

properties are indicated as shown below on the wiring diagrams and parts lists is this service manual. Be sure to replace them with parts with the designated part number.

(1) Schematic diagrams ... Indicated by the z mark.

(2) Parts lists ... Indicated by the z mark.

Using parts other than the designated

parts could result in electric shock, fires or

other dangerous situations.

2

AVR-5308CI / AVC-A1HD

Page 3

注 意

サービス、点検時にはつぎのことにご注意願います。

◎注意事項をお守りください!

サービスのとき特に注意を必要とする個所については

キャビネット、部品、シャーシなどにラベルや捺印で注意

事項を表示しています。これらの注意書きおよび取扱説明

書などの注意事項を必ずお守りください。

◎感電に注意!

(1) このセットは、交流電圧が印加されていますので通電

時に内部金属部に触れると感電することがあります。

従って通電サービス時には、絶縁トランスの使用や手

袋の着用、部品交換には、電源プラグを抜くなどして

感電にご注意ください。

(2) 内部には高電圧の部分がありますので、通電時の取扱

には十分ご注意ください。

◎分解、組み立て作業時のご注意!

板金部品の端面の『バリ』は、部品製造時に充分管理をし

ておりますが、板金端面は鋭利となっている箇所が有りま

すので、部品端面に触れたまま指を動かすとまれに怪我を

する場合がありますので十分注意して作業して下さい。手

の保護のために手袋を着用してください。

◎指定部品の使用!

セットの部品は難燃性や耐電圧など安全上の特性を持っ

たものとなっています。従って交換部品は、使用されてい

たものと同じ特性の部品を使用してください。特に配線

図、部品表に z 印で指定されている安全上重要な部品は

必ず指定のものをご使用ください。

◎部品の取付けや配線の引きまわしは、

元どおりに!

安全上、テープやチューブなどの絶縁材料を使用したり、

プリント基板から浮かして取付けた部品があります。また

内部配線は引きまわしやクランパーによって発熱部品や

高圧部品に接近しないように配慮されていますので、これ

らは必ず元どおりにしてください。

◎サービス後は安全点検を!

サービスのために取り外したねじ、部品、配線などが元ど

おりになっているか、またサービスした個所の周辺を劣化

させてしまったところがないかなどを点検し、外部金属端

子部と、電源プラグの刃の間の絶縁チェックをおこなうな

ど、安全性が確保されていることを確認してください。

(絶縁チェックの方法)

電源コンセントから電源プラグを抜き、アンテナやプラグ

などを外し、電源スイッチを入れます。500V 絶縁抵抗計

を用いて、電源プラグのそれぞれの端子と外部露出金属部

[アンテナ端子、ヘッドホン端子、マイク端子、入力端子

など]との間で、絶縁抵抗値が1 MΩ 以上であることを

確認してください。この値以下のときはセットの点検修理

が必要です。

注 意

本機に使用している多くの電気部品、および機構部品は安

全上、特別な特性を持っています。この特性はほとんどの

場合、外観では判別つきにくく、またもとの部品より高い

定格(定格電力、耐圧)を持ったものを使用しても安全性

が維持されるとは、限りません。安全上の特性を持った部

品は、このサービスマニュアルの配線図、部品表につぎの

ように表示していますので必ず指定されている部品番号

のものを使用願います。

(1) 配線図… z マークで表示しています。

(2) 部品表… z マークで表示しています。

安全上重要な部品について

指定された部品と異なるものを使用した場

合には、感電、火災などの危険を生じる恐

れがあります。

3

AVR-5308CI / AVC-A1HD

Page 4

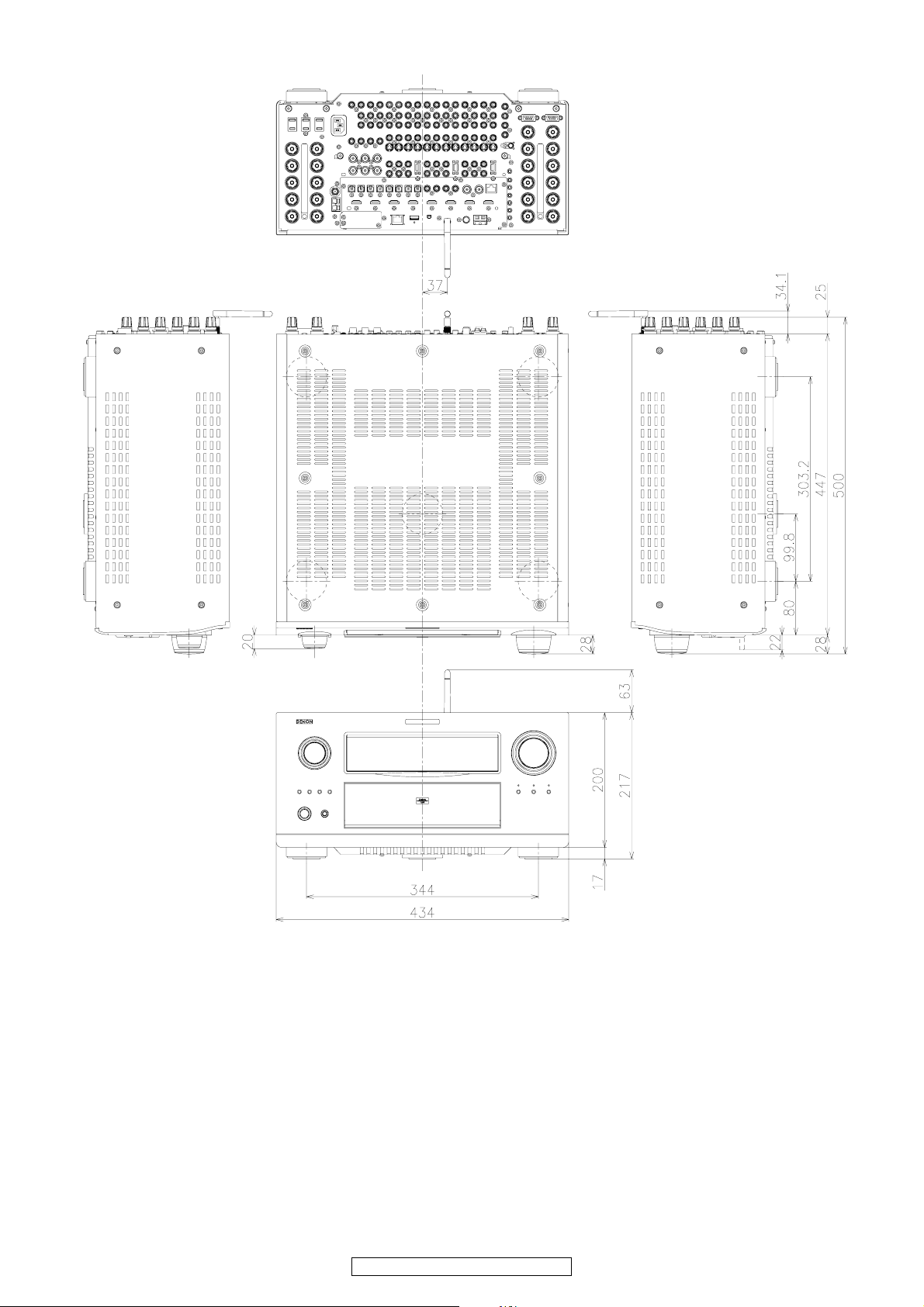

DIMENSION

This illustration is AVR-5308CI.

4

AVR-5308CI / AVC-A1HD

Page 5

WIRE ARRANGEMENT

If wire bundles are untied or moved to perform adjustment

or parts replacement etc.,be sure to rearrange them neatly

as they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise

generation.

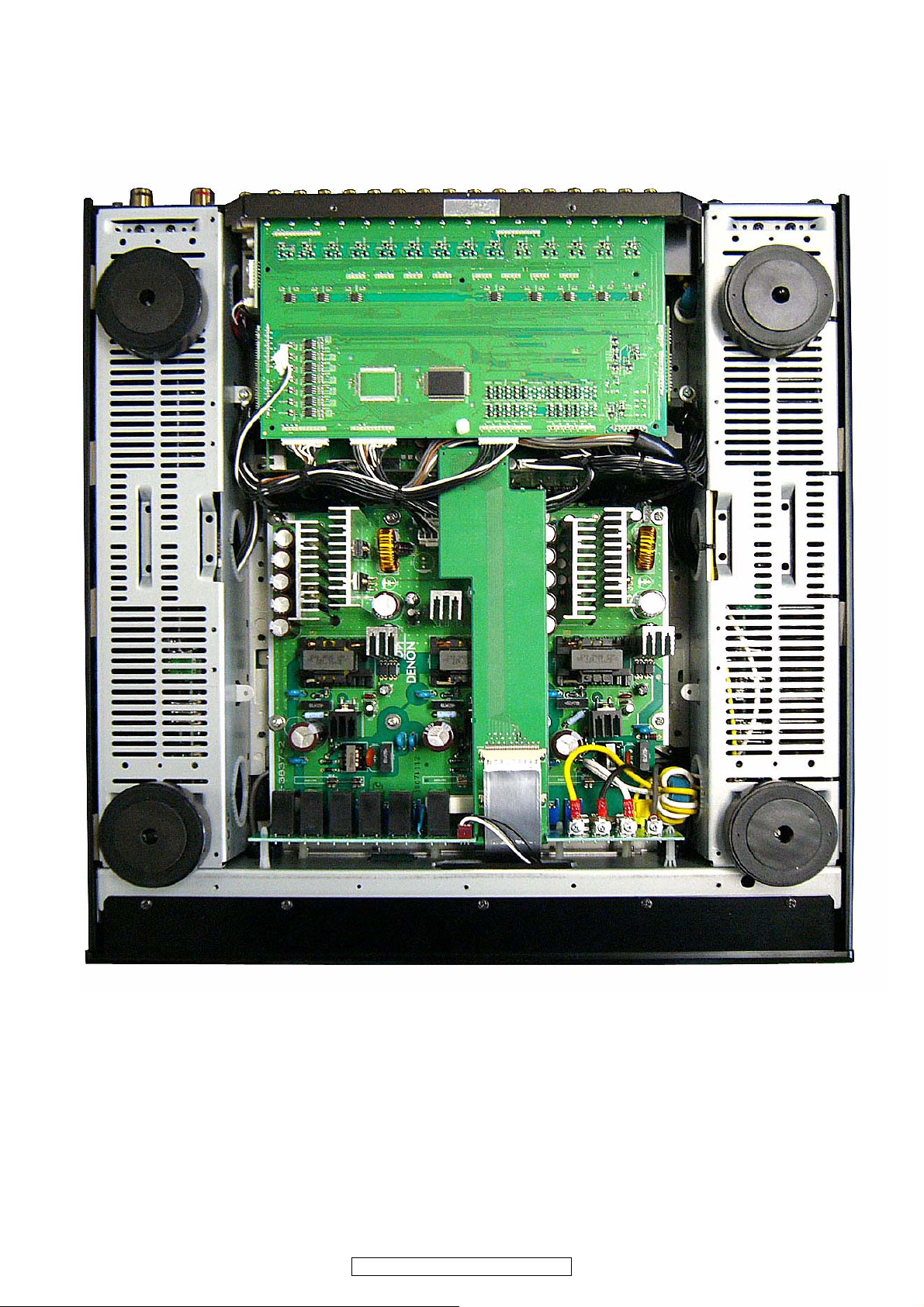

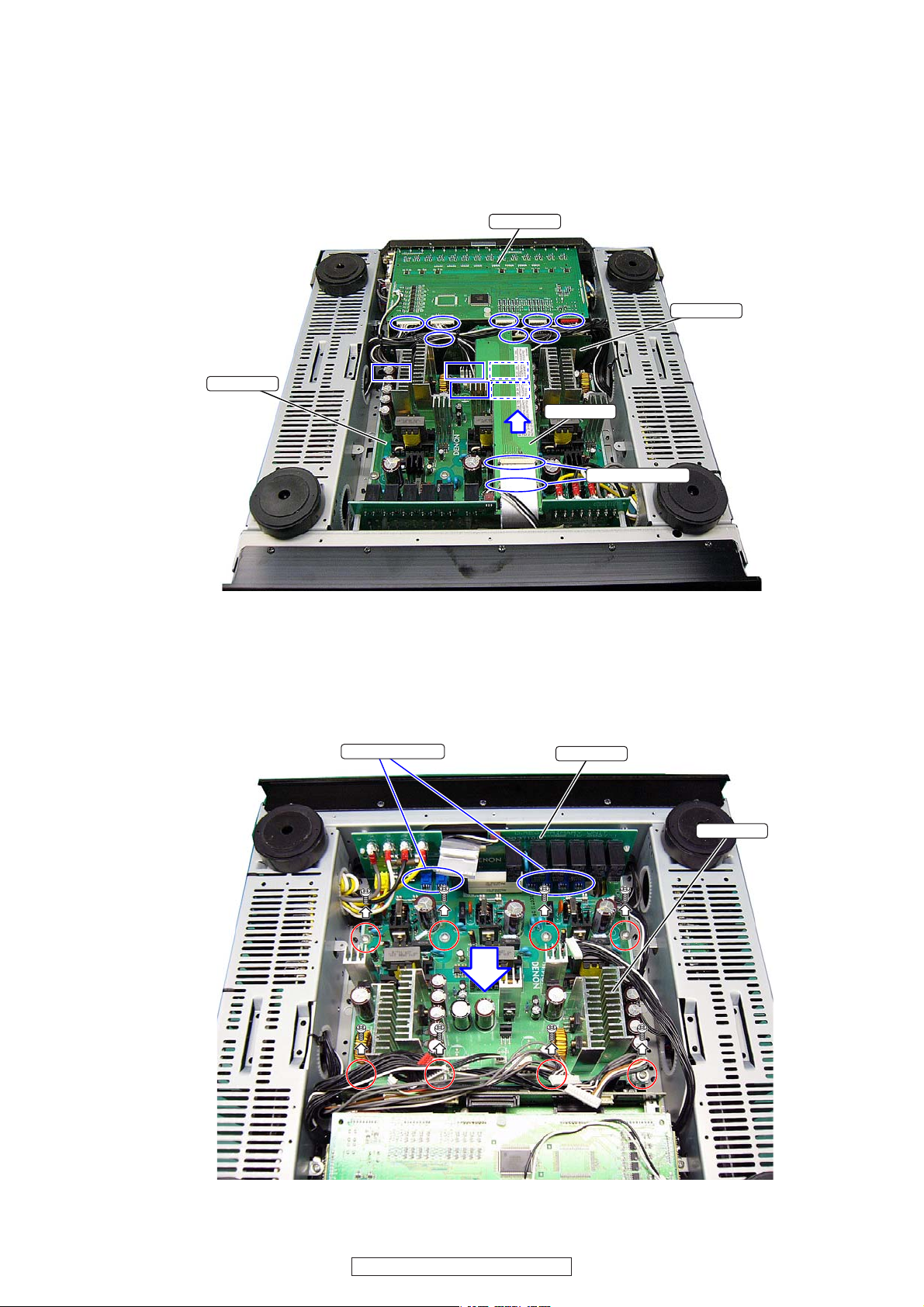

Wire arrangement viewed from the top

Back Panel side

ワイヤー整形図

調整や部品の交換等により、ワイヤー類の結束をはずし

たり移動させた場合には、それらの作業が完了した時点

でワイヤーの整形をおこなってください。正しく整形さ

れていないとノイズ発生の原因となることがあります。

上面からみたワイヤー整形

Front Panel side

5

AVR-5308CI / AVC-A1HD

Page 6

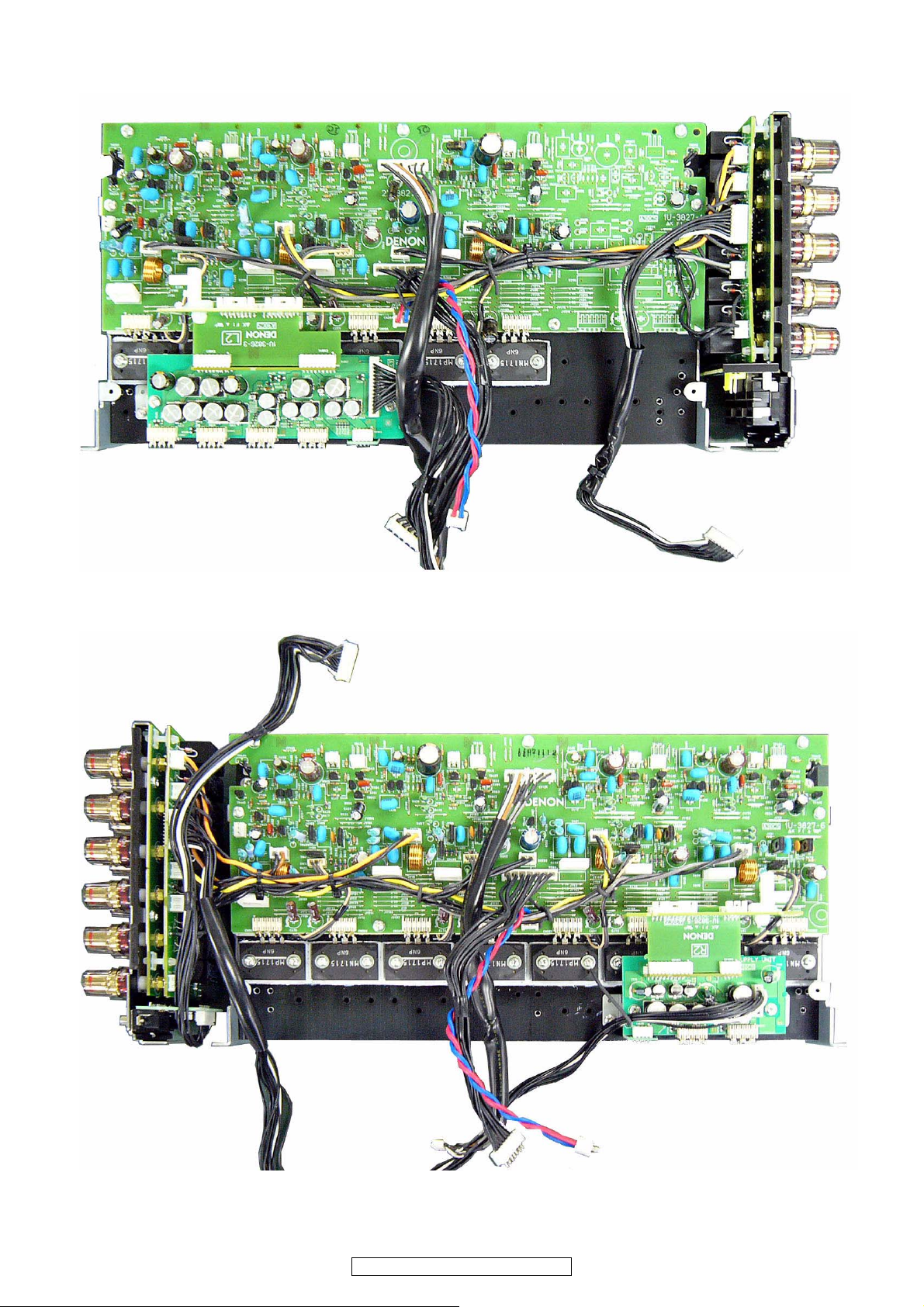

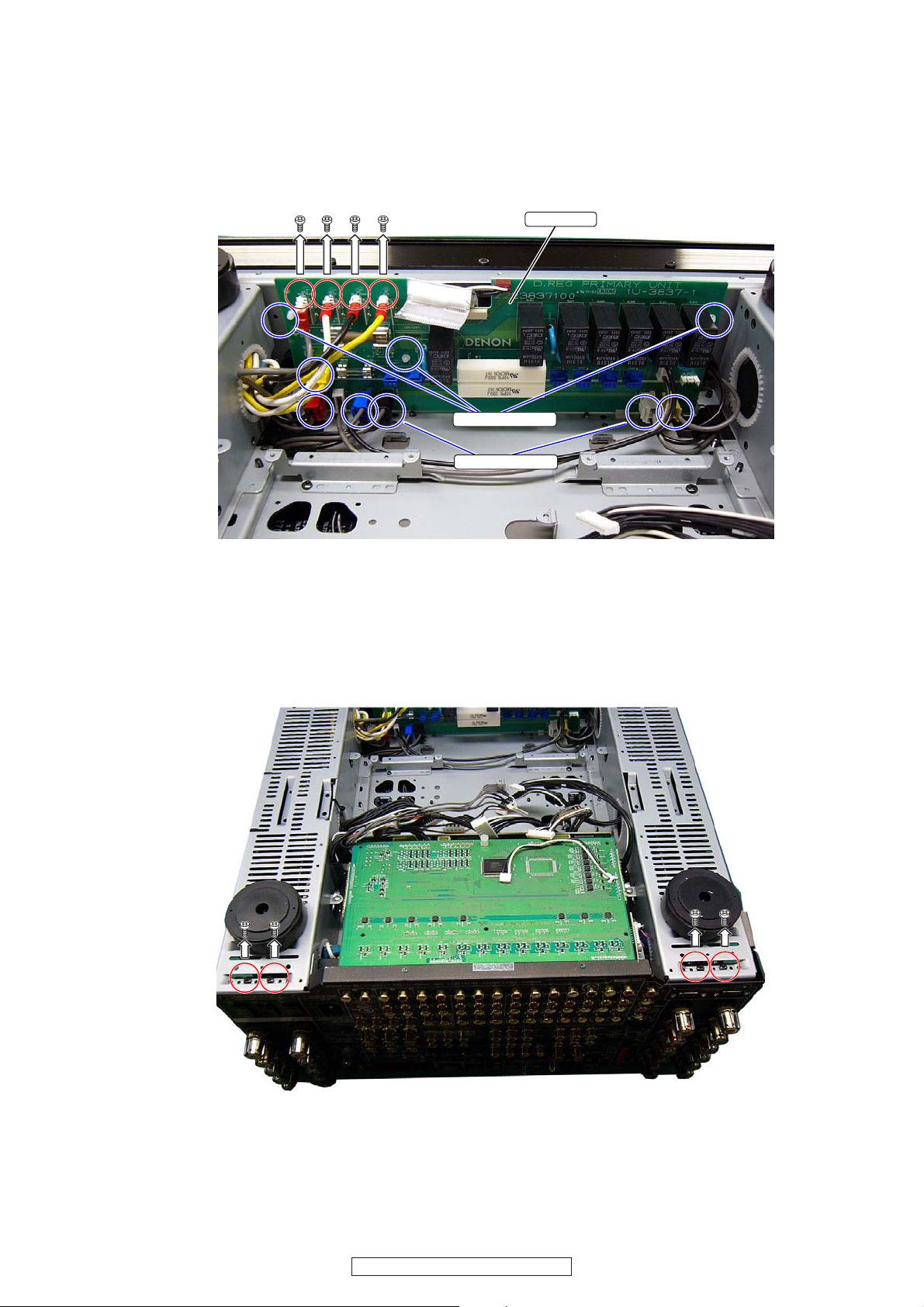

Wire arrangement viewed from the bottom

下面からみたワイヤー整形

Back Panel side

Front Panel side

6

AVR-5308CI / AVC-A1HD

Page 7

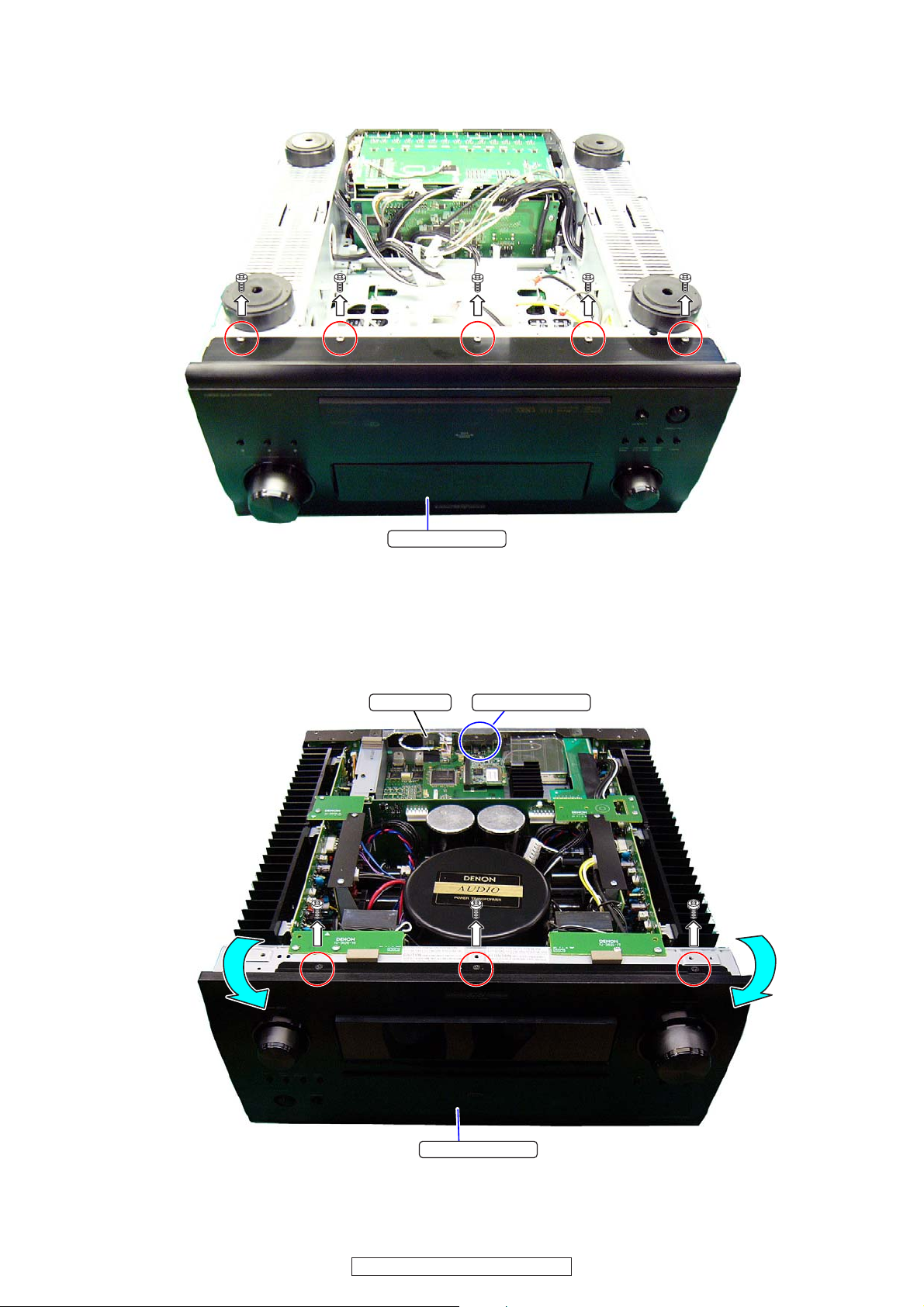

Wire arrangement viewed of Radiator sub

ass’y (left)

Radiator sub ass’y(左側)のワイヤー整形

Wire arrangement viewed of Radiator sub

ass’y (right)

Radiator sub ass’y(右側)のワイヤー整形

7

AVR-5308CI / AVC-A1HD

Page 8

CAUTION IN SERVICING

サービス時の注意事項

Initializing AV SURROUND RECEIVER/AMPLIFIER

AV SURROUND RECEIVER/AMPLIFIER initialization should

be performed when the µcom, peripheral parts of µcom, and

Digital P.W.B. are replaced.

1. Switch off the unit.

2. Hold the following STANDARD button and HOME THX

CINEMA button, and switch on the unit.

3. Check that the entire display is flashing with an interval of

about 1 second, and release your fingers from the 2 buttons and the microprocessor will be initialized.

Note:・If step 3 does not work, start over from step 1.

・ All user settings will be lost and this factory setting

will be recovered when this initialization mode.

So make sure to memorize your setting for restoring after the initialization.

AVサラウンドレシーバー / アンプの初期化

について

マイコンやマイコン周辺部品、Digital 基板等を交換した場

合は、AV サラウンドレシーバー / アンプの初期化を行って

下さい。

1. hONjOFF ボタンを OFF にします。

2. STANDARD ボタンと HOMETHXCINEMA ボタンを同時

に押しながら、hONjOFF ボタンを押して ON にしま

す。

3. ディスプレイ表示が約 1秒間隔で点滅するのを確認後、

2つのボタンから指を離します。

*マイコンが初期化されます。

注意 :・上記 3 の状態にならない場合は、もう一度操作 1

からやり直してください。

・初期化を行うとお客様が設定した内容が工場出

荷状態に戻りますので、あらかじめ設定内容を

控えておき初期化後再設定してください。

1,2

2,3

JIG to use for servicing

When you repair the printing board, you can use the following

JIG (Extension cable kit). Please order to Denon Official Service Distributor in your region if necessary.

00D SPK- 561 EXTENSION UNIT KIT : 1 Set

00D SPK- 562 TUCP CONN. JOINT KIT : 1 Set

AVR-5308CI / AVC-A1HD

サービス時に使用する治具について

基板を修理する際、使用する治具 ( 延長ケーブルキット)

は 下記のとおりです。

必要に応じて販社サービスへ注文下さい。

00DSPK-561EXTENSIONUNITKIT:1 式

00DSPK-562TUCPCONN.JOINTKIT:1 式

8

Page 9

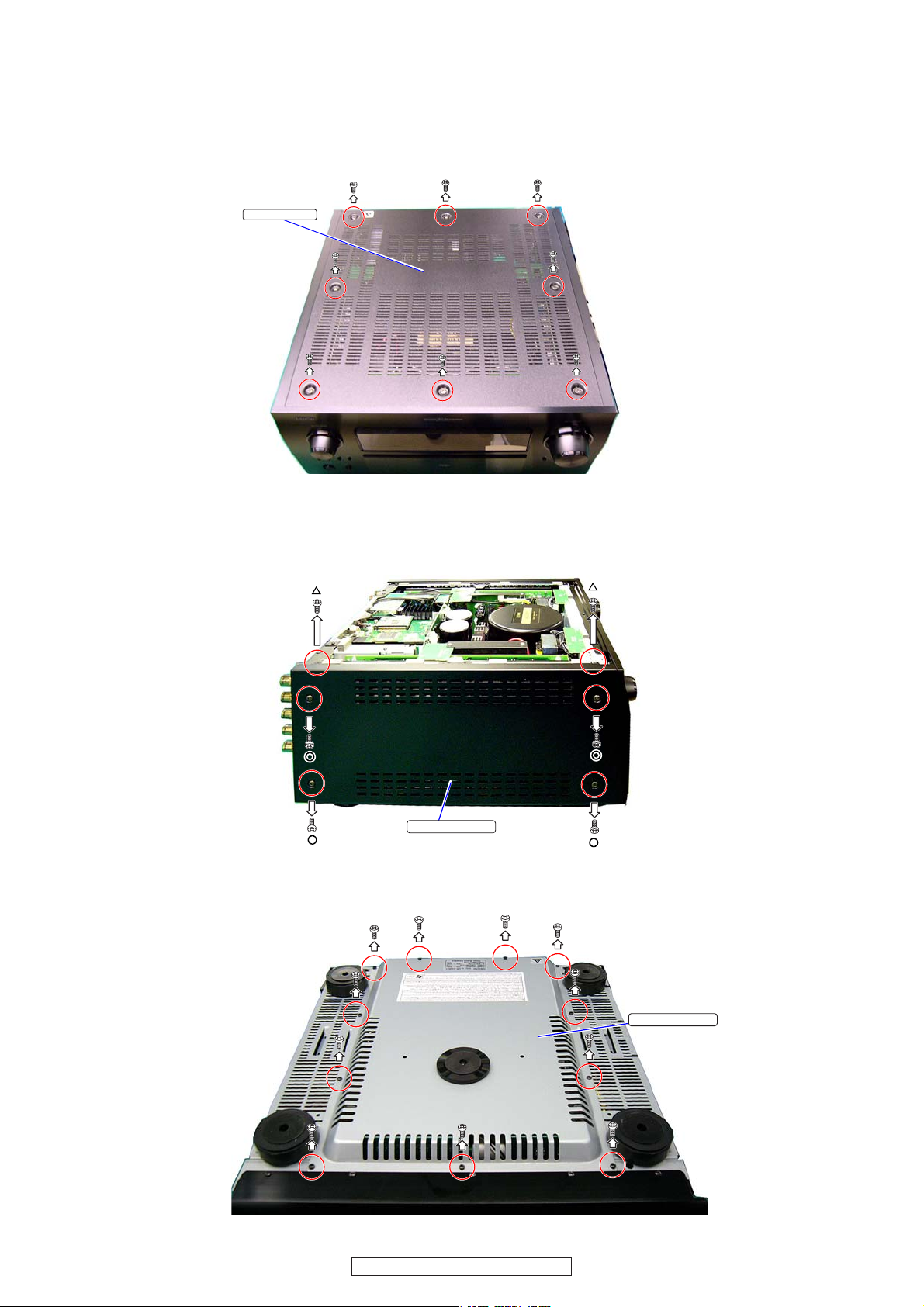

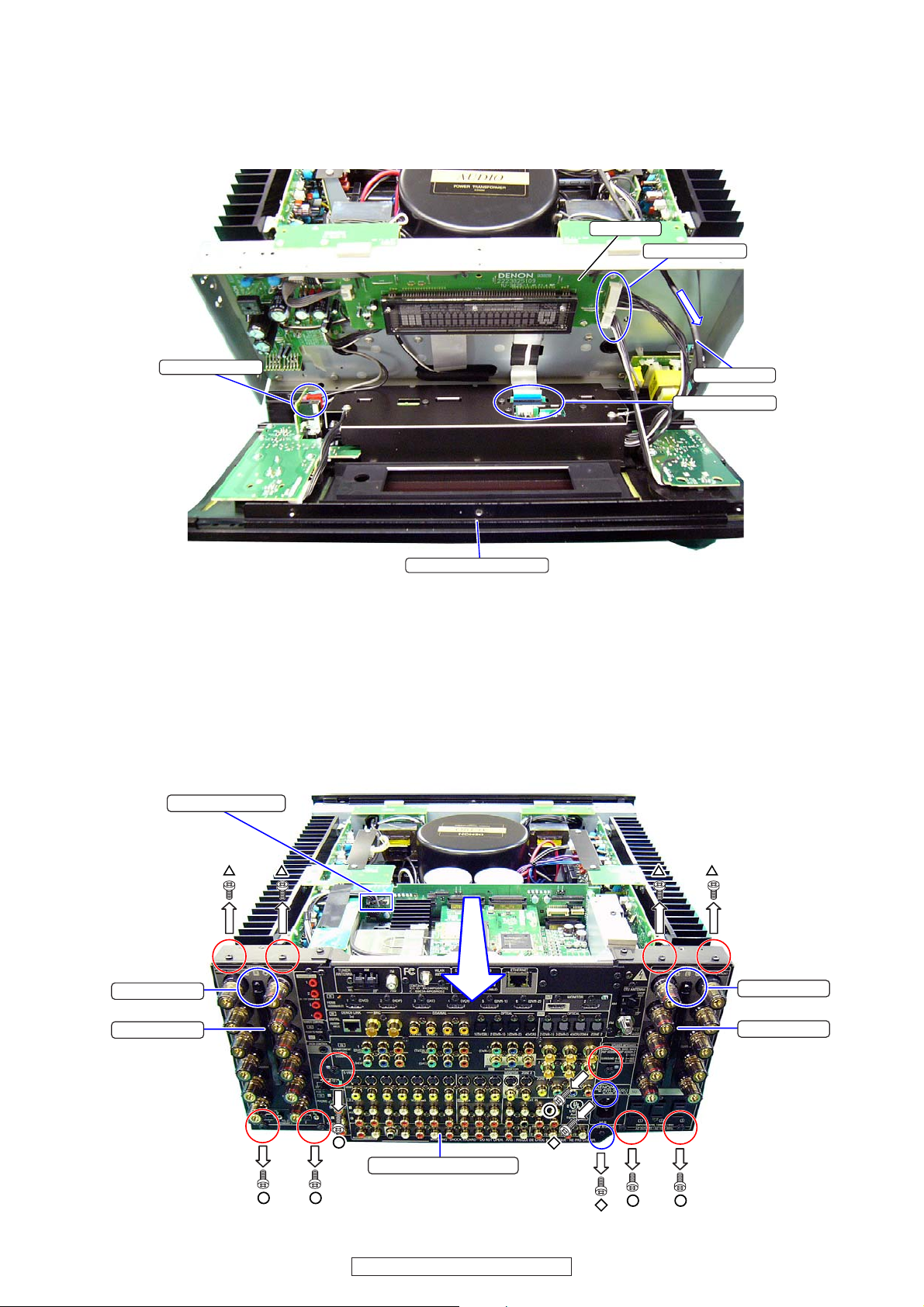

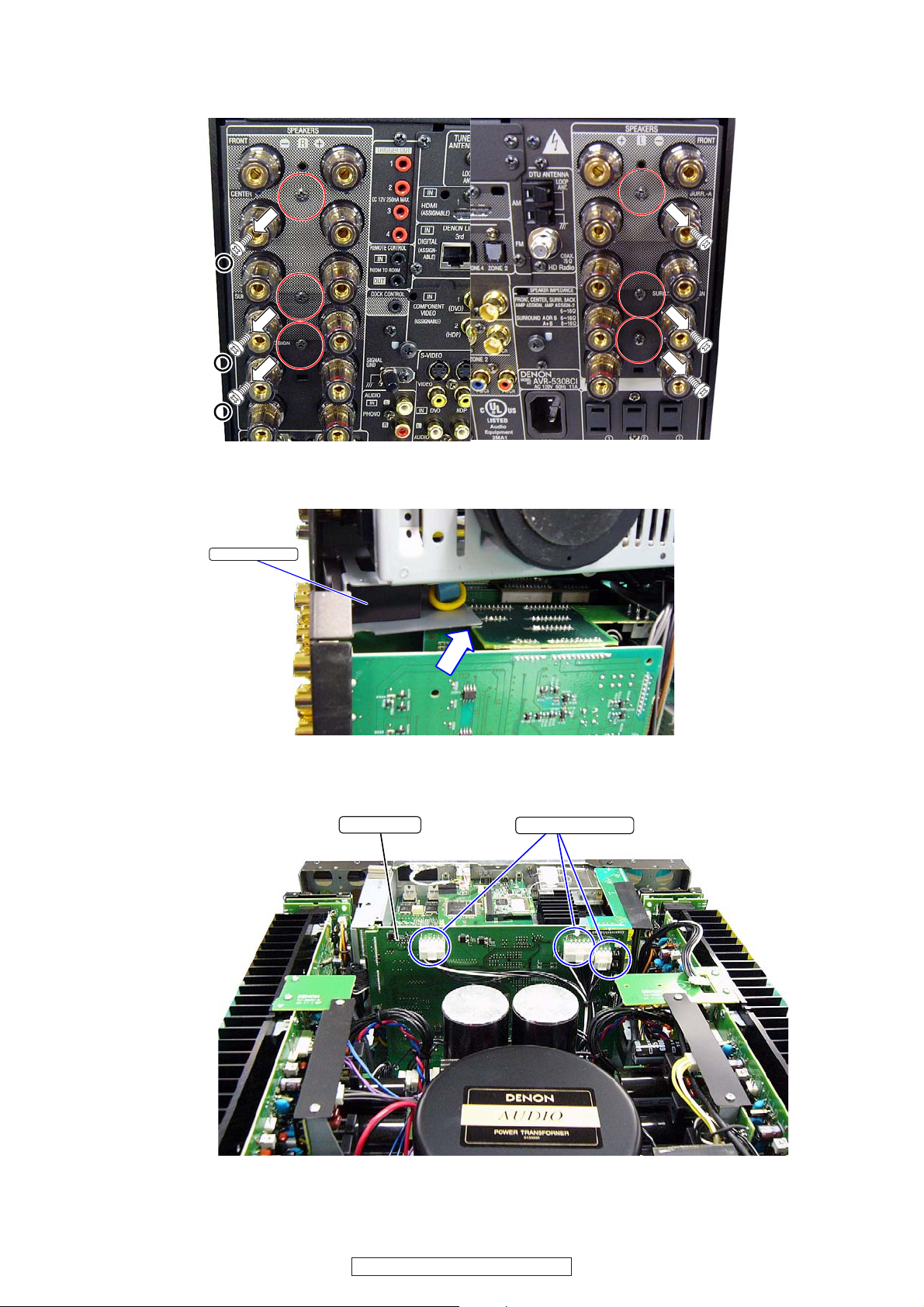

DISASSEMBLY

(Follow the procedure below in reverse order when reassembling.)

1. Top Cover

(1) Remove 8 screws fixing the Top Cover.

TOP COVER

各部のはずしかた

(組み立てるときは、逆の順序で行ってください。)

1. TopCover

(1) ねじを 8 本はずします。

2. Side Cover

(1) Remove 2 screws △ of the top .

(2) Remove 4 screws ○ of the side .

(3) Remove the Side Cover. (Right side is same.)

3. Bottom Cover

(1) Remove 11 screws fixing the Bottom Cover.

2. SideCover

(1) 天面の△ねじを2本はずします。

(2) 側面の○ねじを 4 本はずします。

(3) SIDECOVERをはずします。( 右側も同様。)

SIDE COVER

3. BottomCover

(1) ねじを 11 本はずし Bottomcover を取り外します。

9

AVR-5308CI / AVC-A1HD

BOTTOM COVER

Page 10

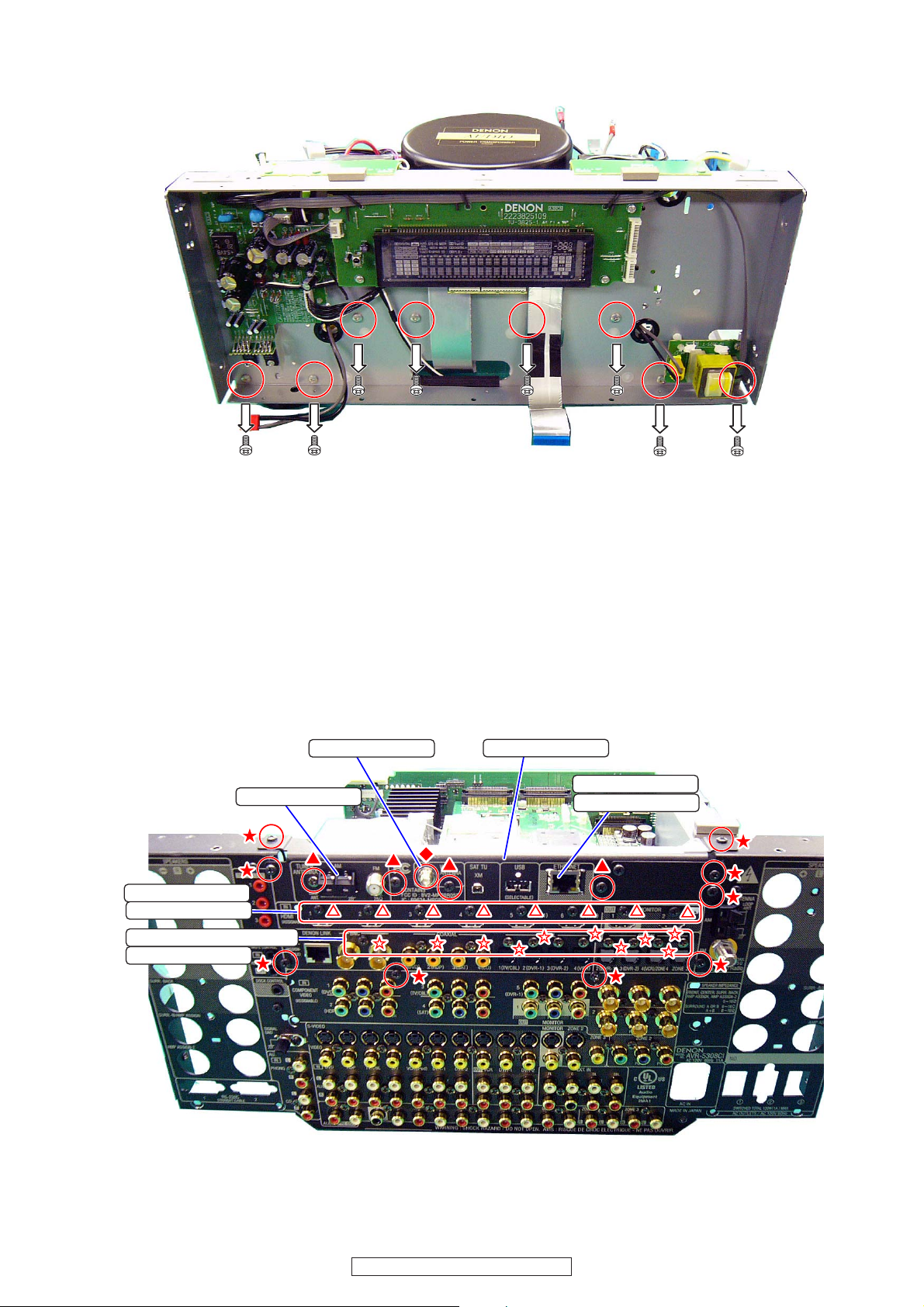

4. 1U-3837 DIGITAL REG. UNIT

(1) Disconnect 5 wires on the 1U-3823-1 : PRE OUT

UNIT and 3 wires on the 1U-3821-1 CPU UNIT.

(2) Disconnect 2 FFC cables. Detach the 1U-3821-2 :

CPU FRONT UNIT.

(3) Disconnect 5 wires on the 1U-3 837-2 : SW REG UNIT.

( □ parts)

1U-3837-2

4. 1U-3837DIGITALREG.UNIT

(1) 1U-3823-1:PREOUTUNITのワイヤー5本 ,1U-3821-

1:CPUUNIT のワイヤー 3 本をはずします。

(2) FFC ケーブル2本をはずし、1U-3821-2:CPUFRONT

UNIT をはずします。

(3) 1U-3837-2:SWREGUNITのワイヤー5本をはずしま

す。(□部分)

1U-3823-1

1U-3821-1

1U-3821-2

FFC Cable

(4) Remove 8 screws fixing the 1U-3837-2 : SW REG

UNIT.

(5) Detach the 1U-3837-2 : SW REG UNIT in the direction

of the arrow. (Board to Board connector for 1U-38371 : PRIMARY UNIT)

Board to Board

(4) 1U-3837-2:SWREGUNIT のねじ 8 本をはずします。

(5) 矢印方向に 1U-3837-2:SWREGUNIT を引き抜きま

す。(1U-3837-1:PRIMARYUNIT との BoardtoBoard

コネクターをはずします。)

1U-3837-1

1U-3837-2

10

AVR-5308CI / AVC-A1HD

Page 11

(6) Disconnect 6 VH wire connectors on the 1U-3837-1 :

PRIMARY UNIT.

(7) Remove 4 screws of Powered wire (3T LUG terminal).

(8) Unlock the CARD SPACER. Detach the 1U-3837-1 :

PRIMARY UNIT.

(6) VH ワイヤーを 6ヶ所はずします。

(7) 電源ワイヤー (3T ラグ端子 ) のねじを 4ヶ所はずしま

す。

(8) CARDSPACER のロックをはずし、1U-3837-1:PRI-

MARYUNIT をはずします。

1U-3837-1

CARD SPACER

VH wire

(9) Remove 4 screws fixing the SPEAKER TERMINAL

ASS’Y of bottom side .

(9) SPEAKERTERMINALASS'Y を固定している底面のね

じを 4 本はずします。

(Left side)

11

AVR-5308CI / AVC-A1HD

Page 12

5. FRONT PANEL ASS’Y

(1) Remove 5 screws of bottom side.

5. FRONTPANELASS'Y

(1) 底面のねじを 5 本をはずします。

Front panel

(2) Disconnect the CX530 5P-SHIELD WIRE on the 1U-

3819 : ETHERNET UNIT.

(3) Remove 3 screws of top side.

(4) Tip the Front panel in the direction of the arrow.

1U-3819

(2) 1U-3819:ETHERNETUNITの CX5305P- シールドワ

イヤーをはずします。

(3) 天面のねじを 3 本をはずします。

(4) 矢印の方向にフロントパネルを傾けます。

CX530 5P-wire

Front panel

12

AVR-5308CI / AVC-A1HD

Page 13

(5) Draw the 5P-shield wire in the arrow direction.

(6) Disconnect the CX134,CX802 connector on the 1U-

3825-1 : FLD UNIT.

(7) Disconnect FFC cable.

(8) Disconnect VH connector for Power switch. Detach

the FRONT PANEL Ass’y.

(5) 5P シールドワイヤーを矢印方向に引き出します。

(6) 1U-3825-1:FLDUNIT のコネクター (CX134,CX802)

をはずします。

(7) FFC ケーブルをはずします。

(8) 電源スイッチの VH コネクターをはずして FRONT

PANELAss'y をはずします。

1U-3825-1

CX134,CX802

VH wire

FRONT PANEL Ass'y

6. BACK PANEL ASS’Y

(1) Remove 4 screws △ of top side.

(2) Disconnect the Wire connector.

(3) Remove 2 Push Rivet. Detach the Screw Cover.

(4) Remove screw of the backside of Screw Cover. (Refer

to the following page.)

(5) Remove 6 screws ○ fixing the Back Panel.

(6) Remove 2 screws ◇ fixing the AC INLET.

(7) Draw BACK PANEL Ass’y slowly.

Wire connector

5P-Shield wire

FFC cable

6. BACKPANELASS'Y

(1) △ねじ 4 本をはずします。

(2) WireConnector をはずします。

(3) PushRivet を 2ヶ所はずし、ScrewCover を取り外し

ます。

(4) 次ページを参考に ScrewCover の裏側のねじをはず

します。

(5) ○ねじ 6 本をはずします。

(6) ACINLET の◇ねじ 2 本をはずします。

(7) BACKPANELAss'y をゆっくり引き出します。

Push Rivet

Screw Cover

Push Rivet

Screw Cover

BACK PANEL Ass'y

13

AVR-5308CI / AVC-A1HD

Page 14

The position of the screw of the backside of Screw Cover.

(Right and left remove three screws together.)

ScrewCover の裏側のねじの位置

(左右ともにねじ 3 本をはずします。)

(8) Put up a set aside. Metal holder maintaining AC INLET

go over P.W.B. board.

AC INLET

(9) Disconnect the Wire connector on the 1U-3821-1 :

CPU UNIT.

1U-3821-1

(8) セットを横に立てて ACINLET を保持している金具

が基板の上を通るようにします。

(9) 1U-3821-1:CPUUNIT のワイヤーコネクターをはず

します。

Wire connector

14

AVR-5308CI / AVC-A1HD

Page 15

(10) Pull out Back Panel to lift it halfway.

INSULATING COVER

INSULATING COVER

1U-3828-8

1U-3828-9

(10) BackPanel は途中から持ち上げるように抜き取りま

す。

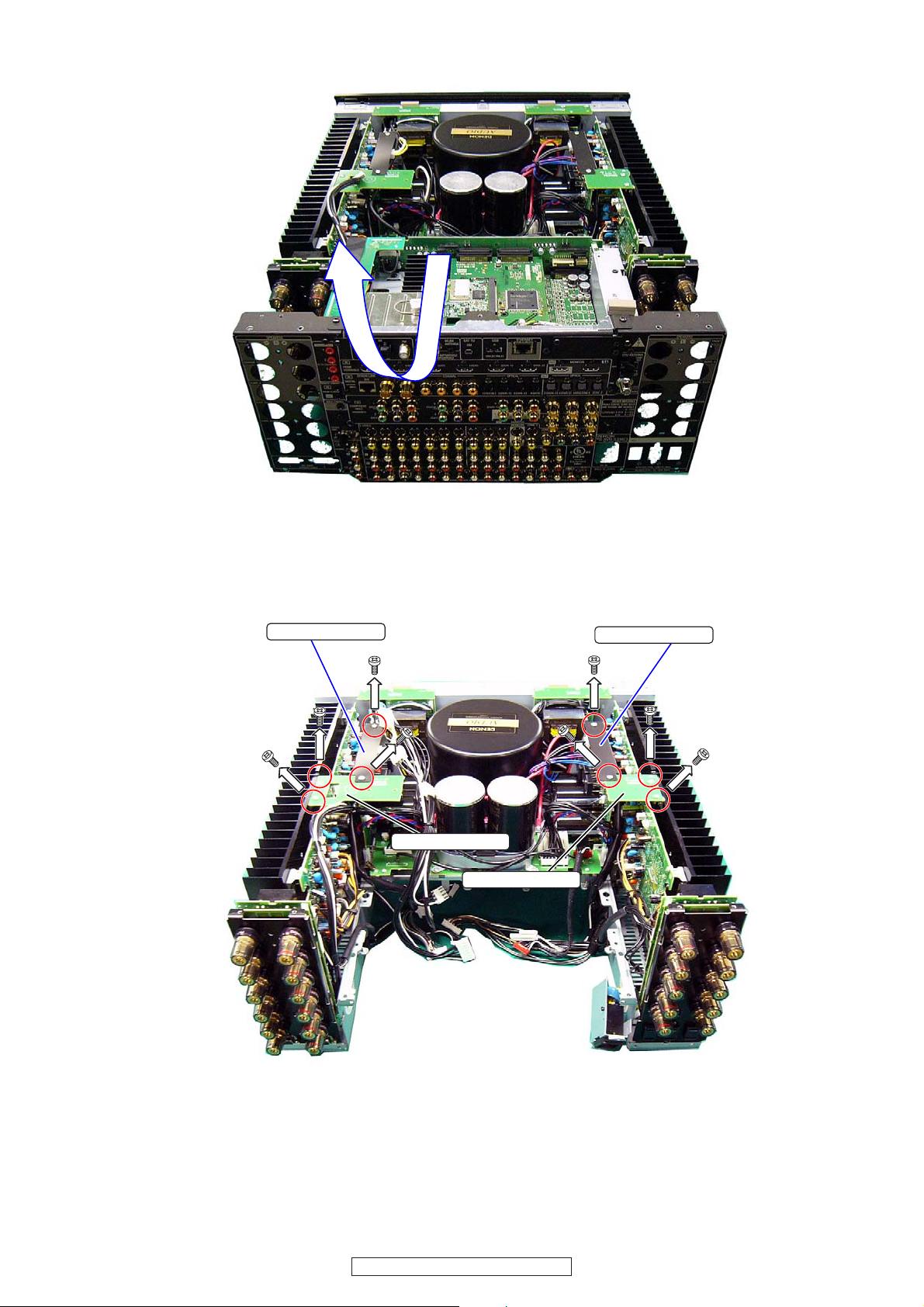

7. AMP (L) UNIT and AMP (R) UNIT

(1) Remove 8 screws. Detach the INSULATING COVER

and 1U-3828-8 :R-SUPPLY JOINT UNIT ,1U-3828-9

:L-SUPPLY JOINT UNIT.

7. AMP(L)UNIT,AMP(R)UNIT

(1) ねじ 8 本をはずして INSULATINGCOVER と接続基板

1U-3828-8:R-SUPPLYJOINTUNIT,1U-3828-9:L-SUP-

PLYJOINTUNIT をはずします。

15

AVR-5308CI / AVC-A1HD

Page 16

(2) Disconnect 4 Wire connectors.

(3) Remove 4 screws. Detach the PWB HOLDER L and

R.

PWB Holder L PWB Holder R

(2) ワイヤーコネクター 4 本をはずします。

(3) ねじ4本をはずして PWBHOLDERL,R を取り外しま

す。

Wire connector

(4) Remove 2 screws.

(5) Detach the 1U-3826-1 : R BLOCKCON UNIT and 1U-

3826-2 : L BLOCKCON UNIT in the direction of the arrow.

Wire connector

(4) ねじ 2 本をはずします。

(5) 1U-3826-1:RBLOCKCONUNIT,1U-3826-2:LBLOCK-

CONUNIT を上に引き抜きます。

1U-3826-1

1U-3826-2

16

AVR-5308CI / AVC-A1HD

Page 17

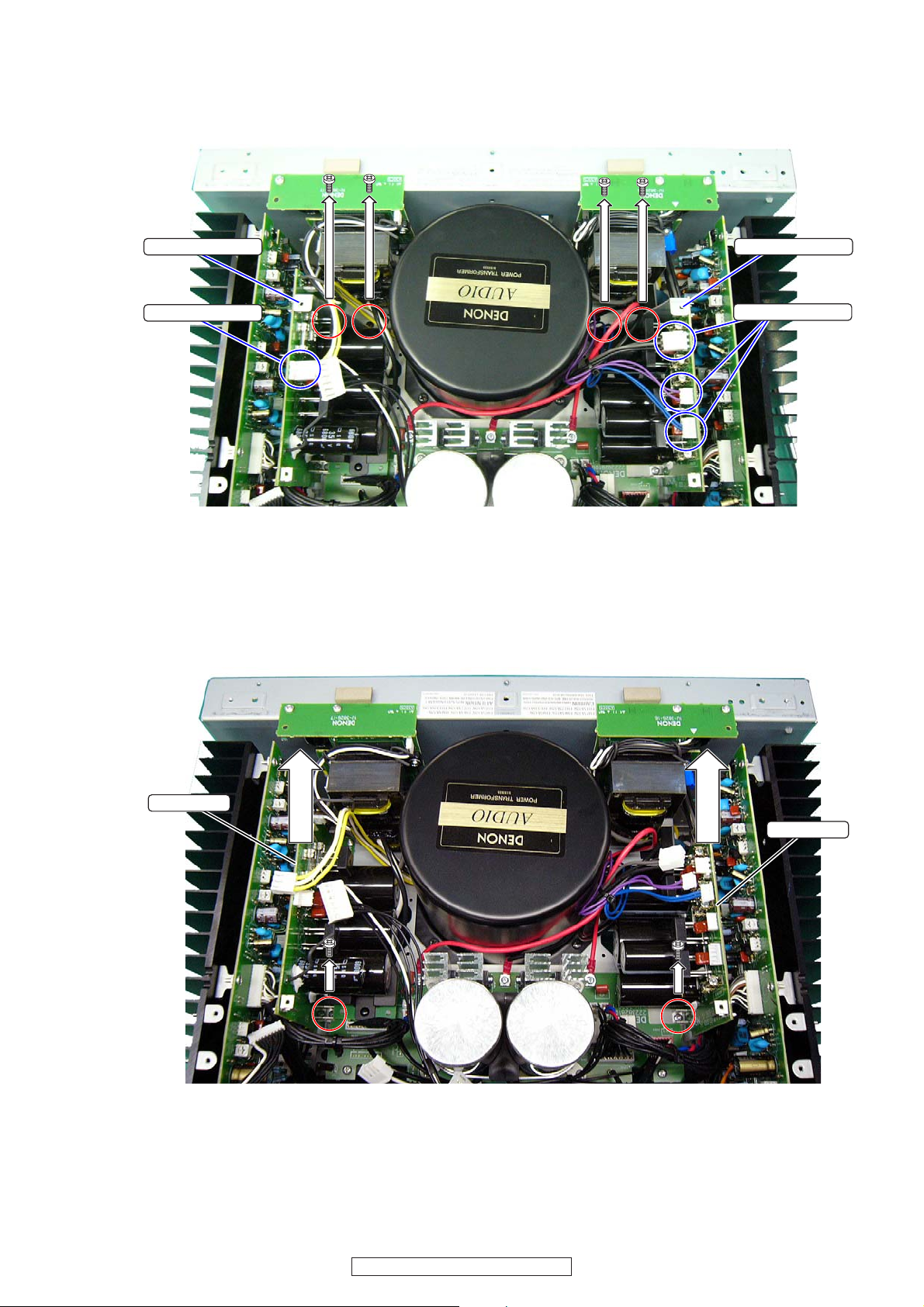

(6) Remove 3 screws fixing the wire .

(7) Remove Push Rivet. Detach the INSULATING COV-

ER.

INSULATING COVER

(6) ワイヤーを固定しているねじを 3 本はずします。

(7) PushRivet をはずして、INSULATINGCOVER を取り

外します。

Push Rivet

(8) Remove 2 screws fixing the wire .

(9) Unlock the 4 CARD SPACER. Detach the 1U-3828-11

: M3 UNIT.

1U-3828-11

(8) ワイヤーを固定しているねじを 2 本はずします。

(9) CARDSPACERのロックを 4ヶ所はずして、1U-3828-

11:M3UNIT をはずします。

CARD SPACERCARD SPACER

CARD SPACER

17

AVR-5308CI / AVC-A1HD

Page 18

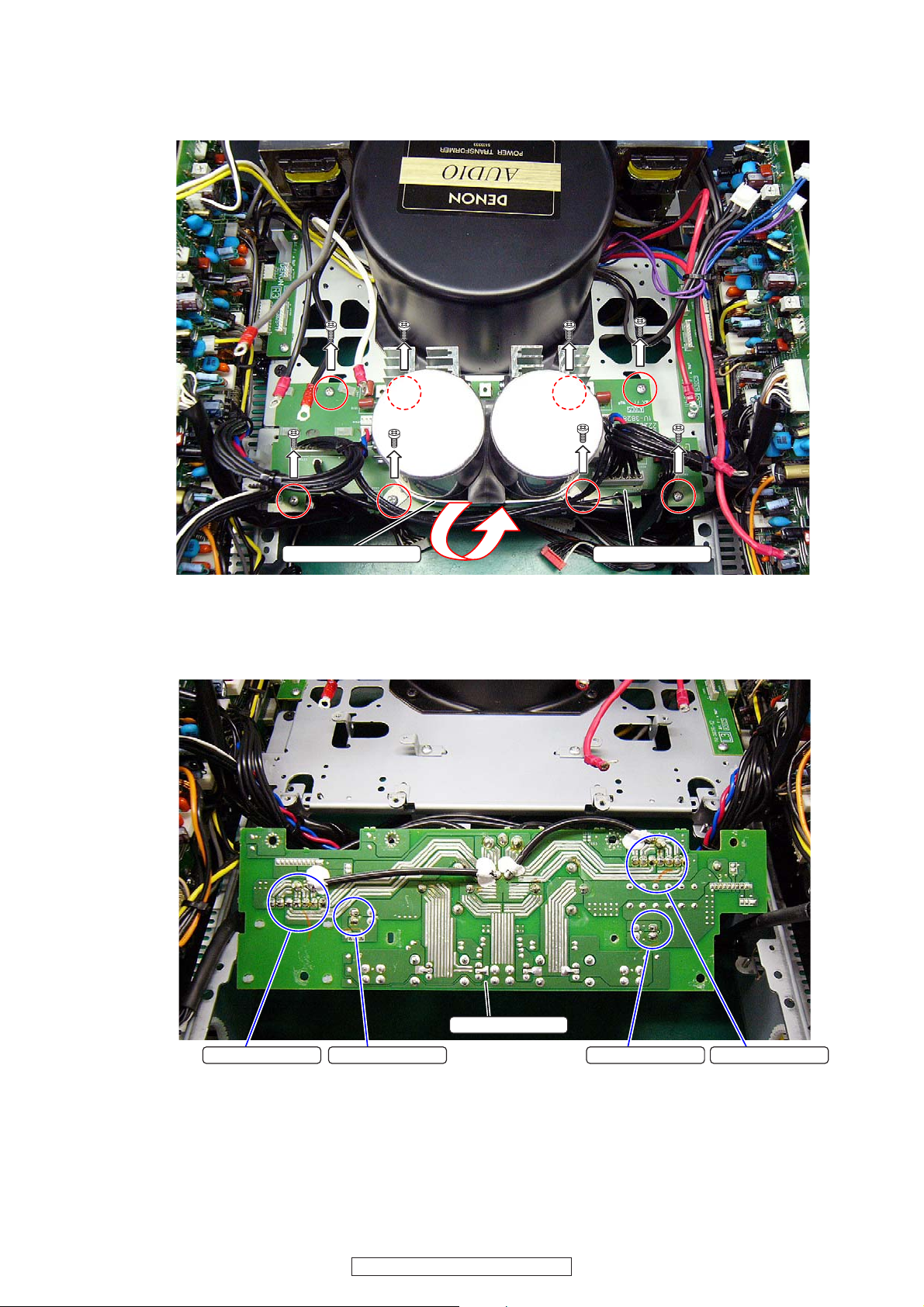

(10) Remove 8 screws fixing the 1U-3828-1 : AMP

1U-3828-1

CZ208 CZ732CZ221CZ738

BLOCKCON UNIT and Condenser holder . Reverse

the 1U-3828-1 .

(10) 1U-3828-1:AMPBLOCKCONUNIT とコンデンサーホ

ルダーを固定しているねじ 8 本をはずして基板を裏

返します。

Condenser Holder

(11) I Remove soldering of connec-

tor(CZ738,CZ221,CZ731 and CZ208). Detach the 1U3828-1 : AMP BLOCKCON UNIT.

1U-3828-1

(11) CZ738,CZ221,CZ731,CZ208 の半田をとってはずして

1U-3828-1:AMPBLOCKCONUNIT 基板をはずしま

す。

18

AVR-5308CI / AVC-A1HD

Page 19

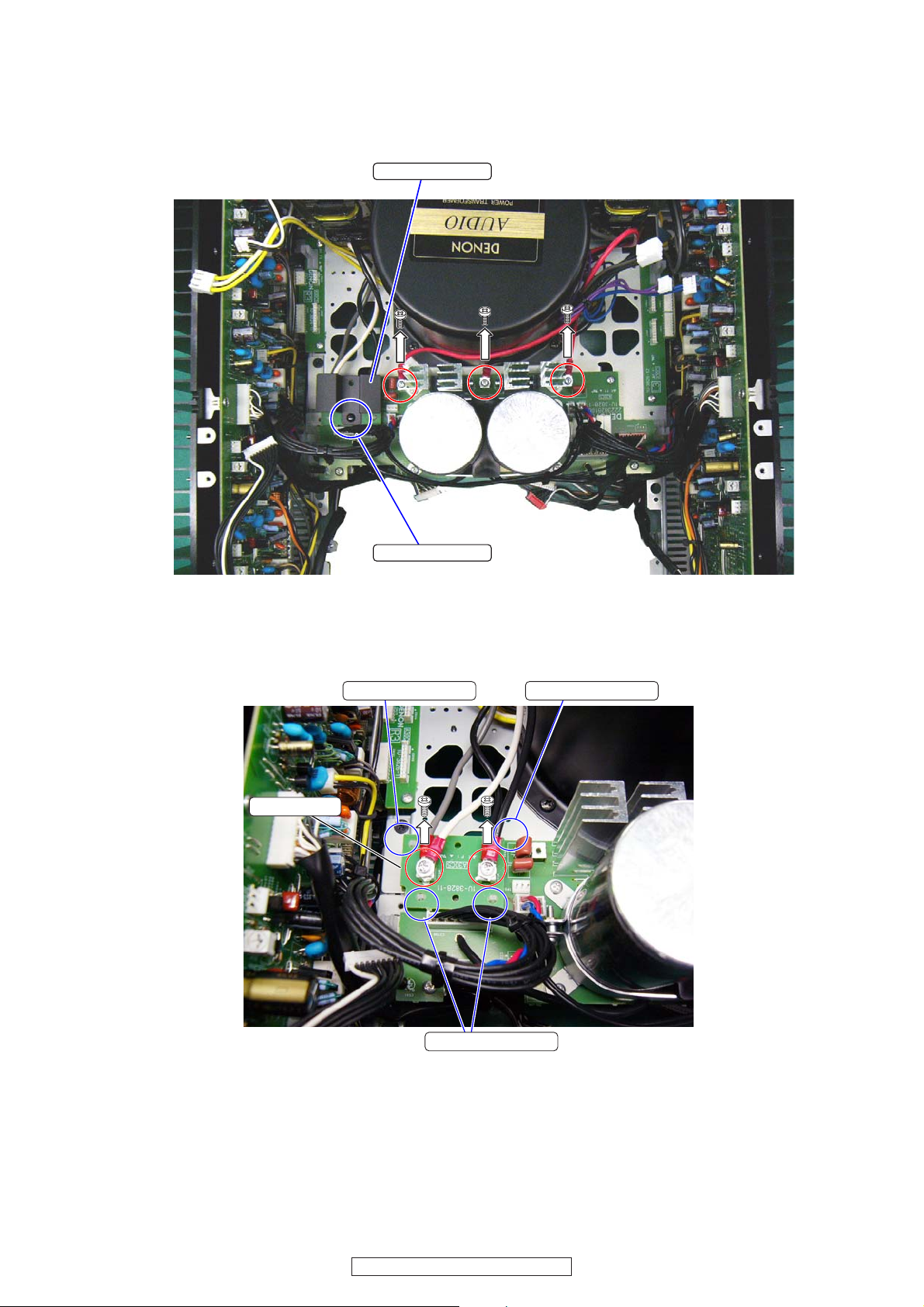

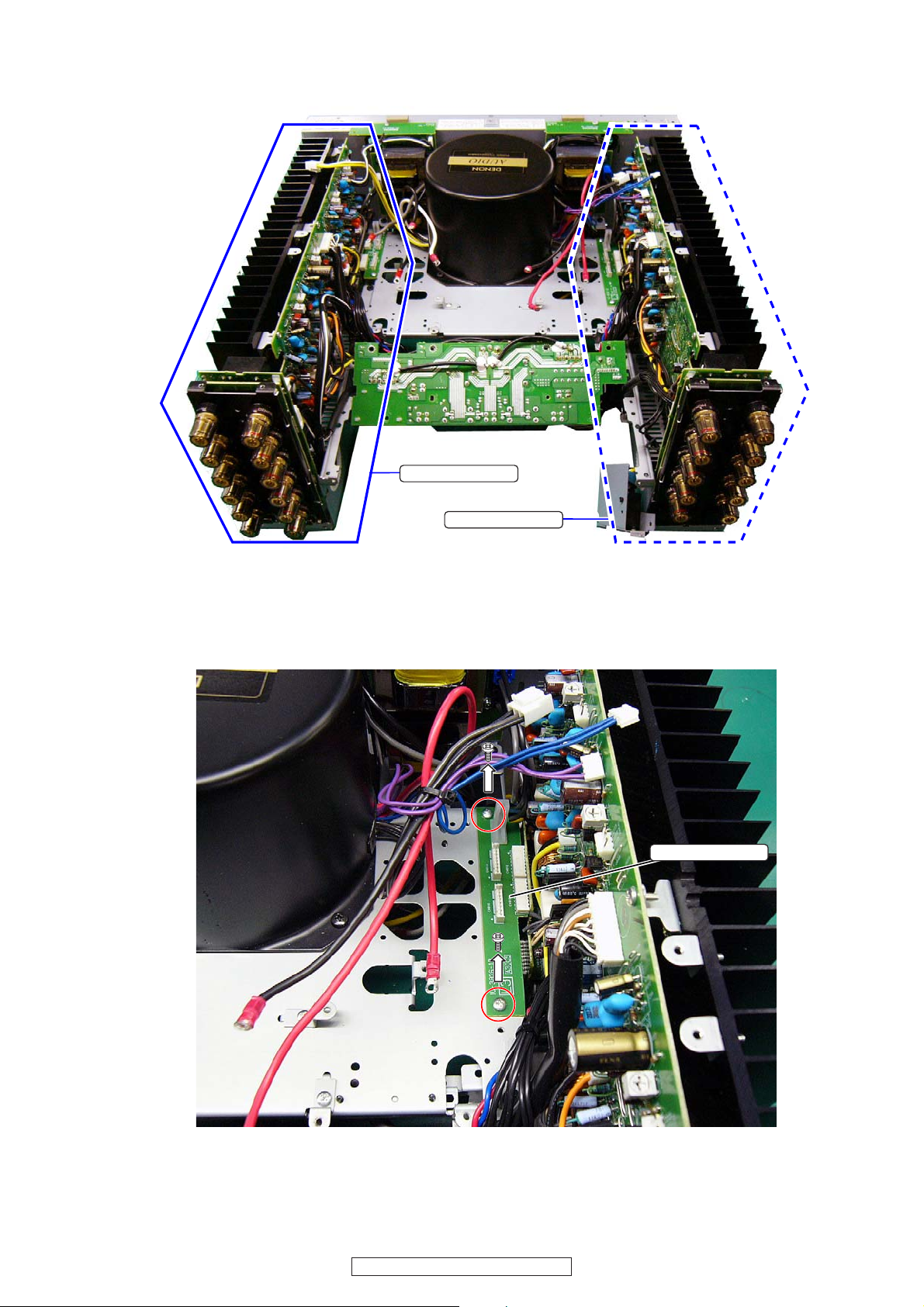

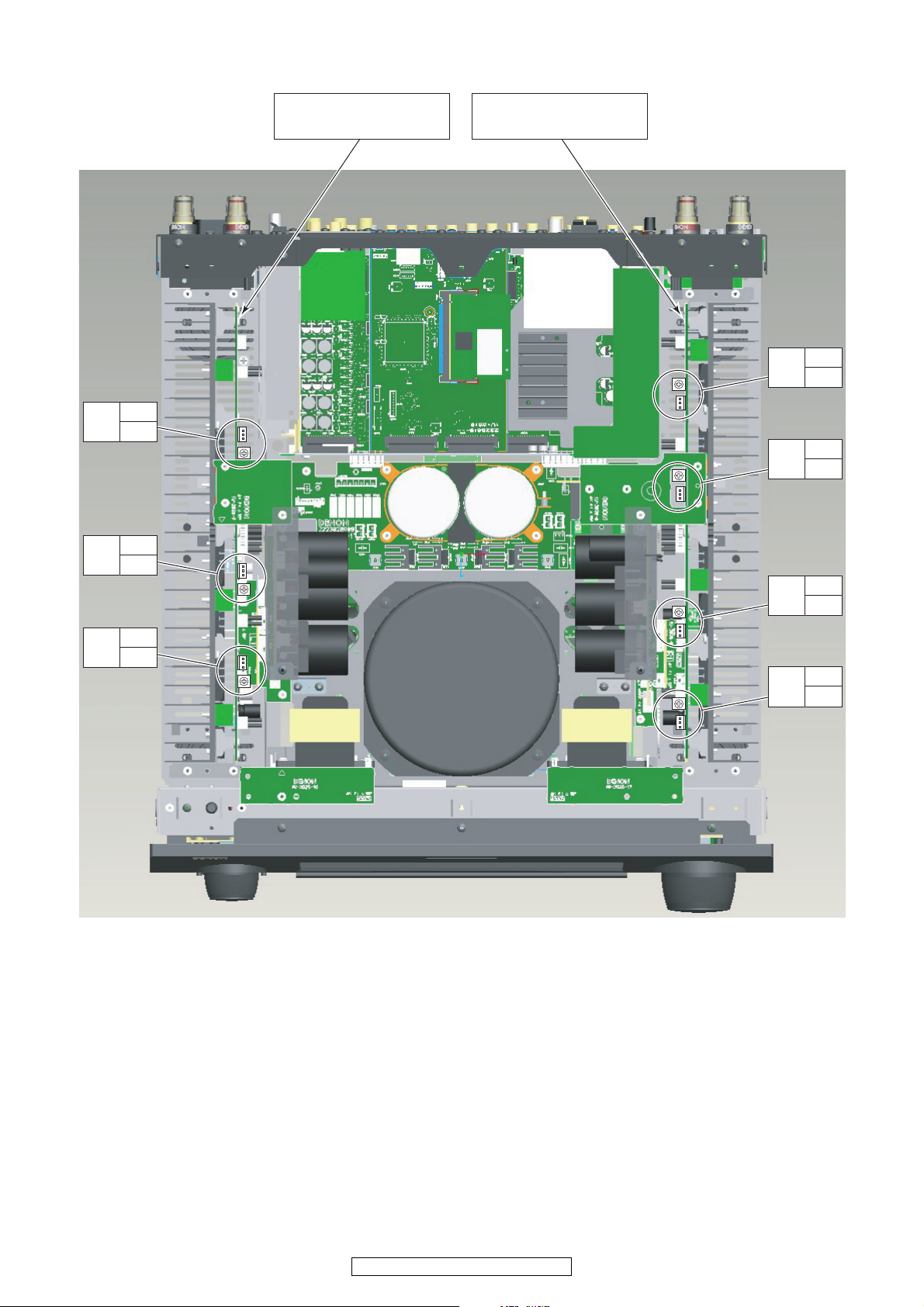

Figure of AMP (L) UNIT/AMP (R) UNIT .

1U-3826-12

AMP(L)UNIT/AMP(R)UNITの形状

AMP(R) UNIT

AMP(L) UNIT

(12) Detach the AMP(L) UNIT.

(12-1) Remove 2 screws fixing the 1U-3826-12 : L

SUPPLY JOINT-3 UNIT. (The board does not yet

come off.)

(12) AMP(L)UNIT をはずします。

(12-1)1U-3826-12:LSUPPLYJOINT-3UNIT を固定して

いるねじ 2 本をはずします。(基板はまだはずれませ

ん。)

19

AVR-5308CI / AVC-A1HD

Page 20

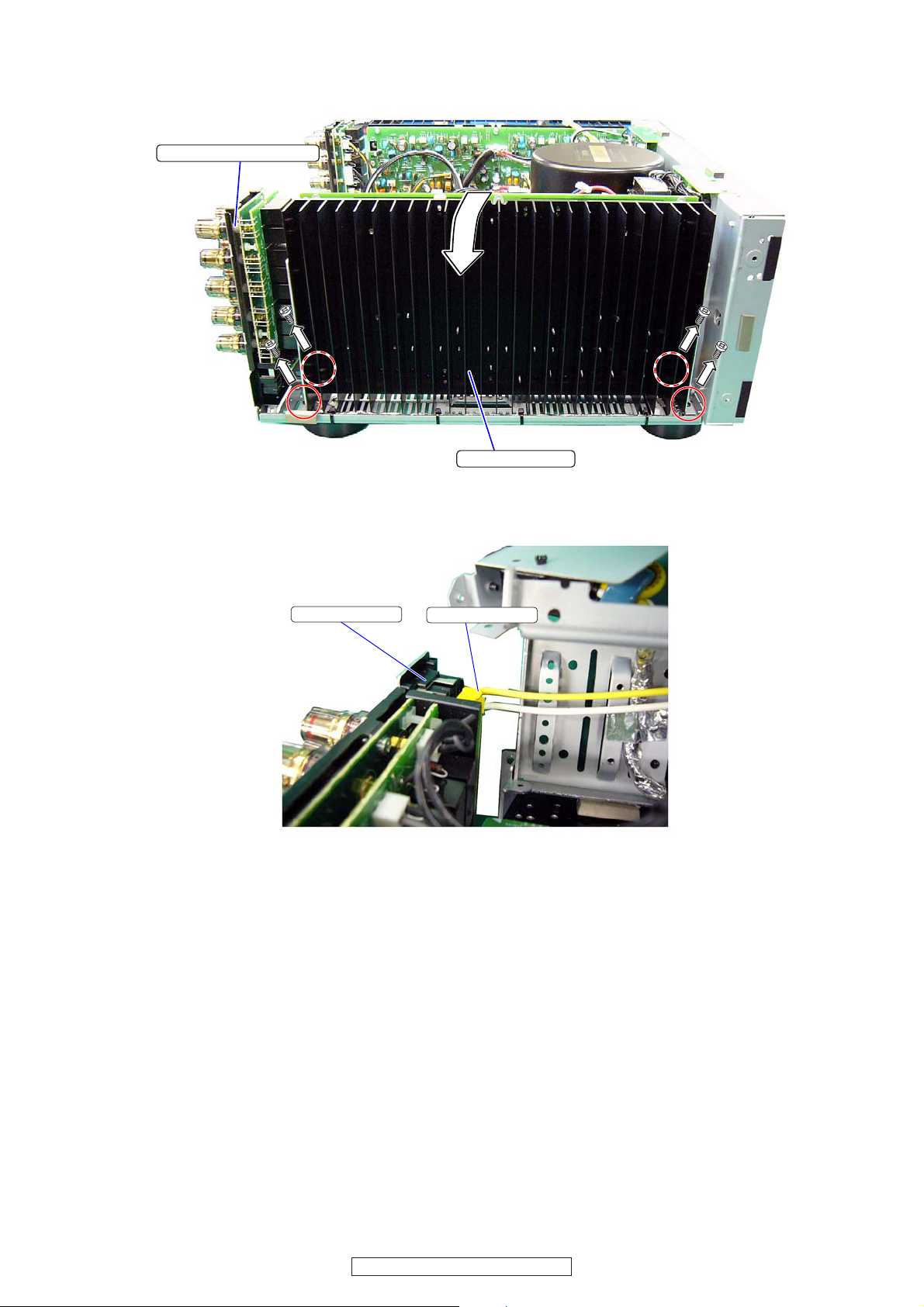

(12-2) Remove 4 screws . Remove RADIATOR UNIT

and SPEAKER TERMINAL UNIT at the same time.

SPEAKER TERMINAL UNIT

(12-2)ねじ 4 本をはずし、RADIATORUNITと

SPEAKERTERMINALUNITを同時に取り外します。

RADIATOR UNIT

(12-3)Detachthe2PWireofACOUTLET.

AC OUTLET

(12-3)ACOUTLETの 2P ワイヤーをはずします。

2P WIRE

20

AVR-5308CI / AVC-A1HD

Page 21

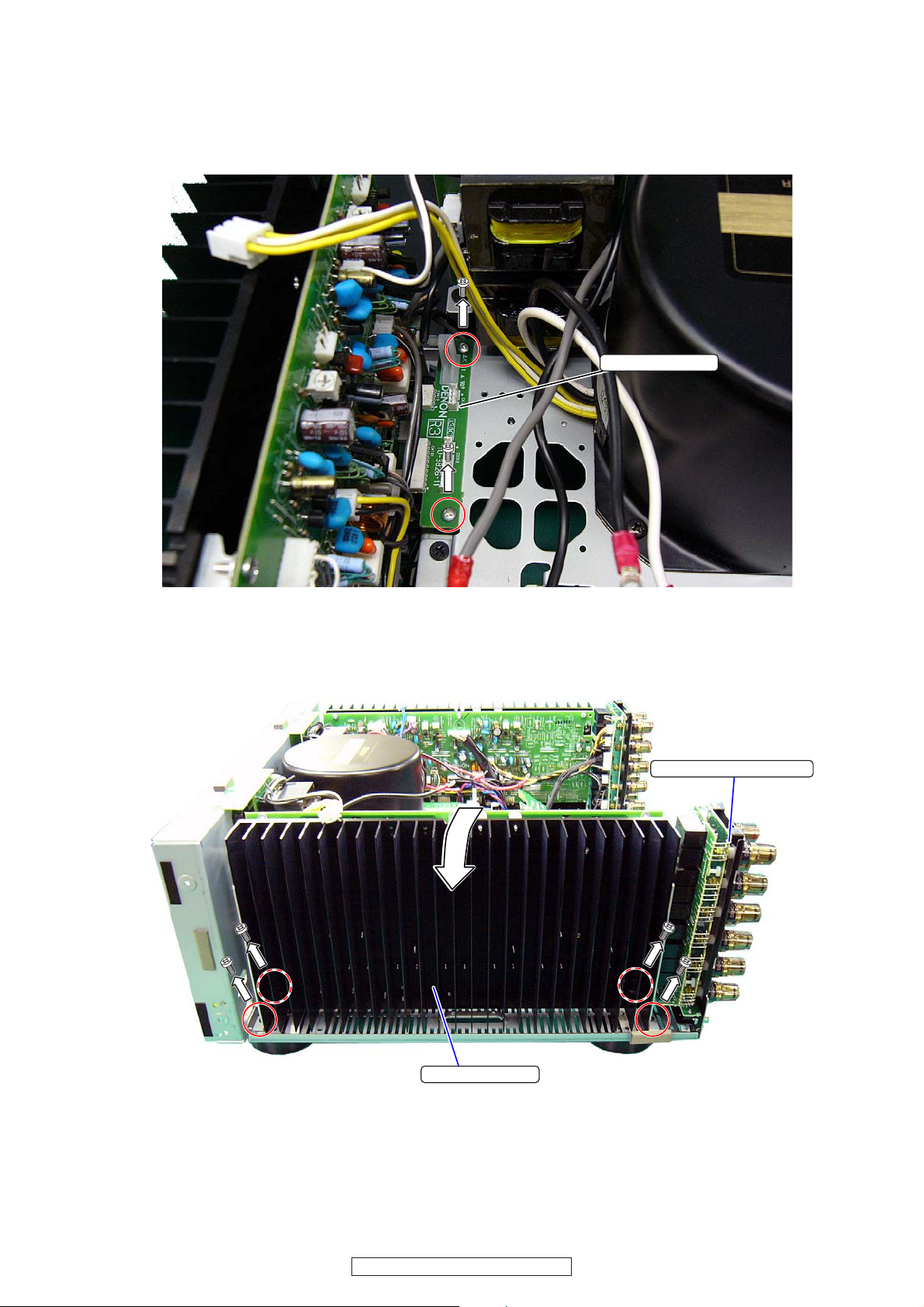

(13) Detach the AMP(R) UNIT.

(13-1) Remove 2 screws fixing the 1U-3826-11 :R

SUPPLY JOINT-1 UNIT.(The board does not yet

come off.)

(13) AMP(R)UNIT をはずします。

(13-1)1U-3826-11:RSUPPLYJOINT-1UNIT を固定し

ているねじ 2 本をはずします。(基板はまだはずれま

せん。)

1U-3826-11

(13-2) Remove 4 screws. Remove RADIATOR UNIT

and SPEAKER TERMINAL UNIT at the same time.

(13-2)ねじ 4 本をはずし、RADIATORUNITと

SPEAKERTERMINALUNITを同時に取り外します。

SPEAKER TERMINAL UNIT

RADIATOR UNIT

21

AVR-5308CI / AVC-A1HD

Page 22

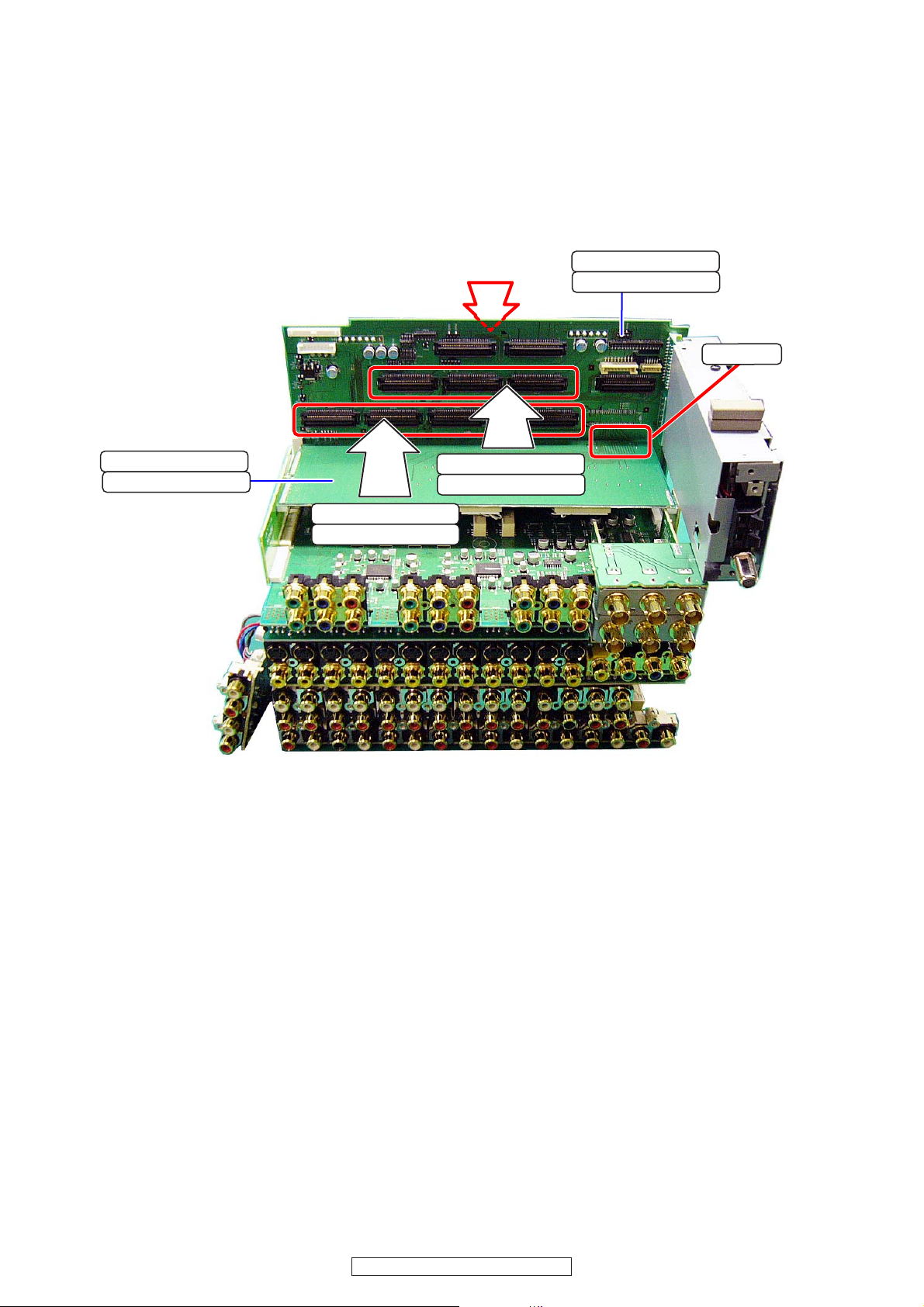

8. FRONT CHASSIS SUB ASS’Y

(1) Remove 8 screws fixing the FRONT CHASSIS.

8. FRONTCHASSISSUBASS'Y

(1) ねじ 8 本をはずし、FRONTCHASSISをはずします。

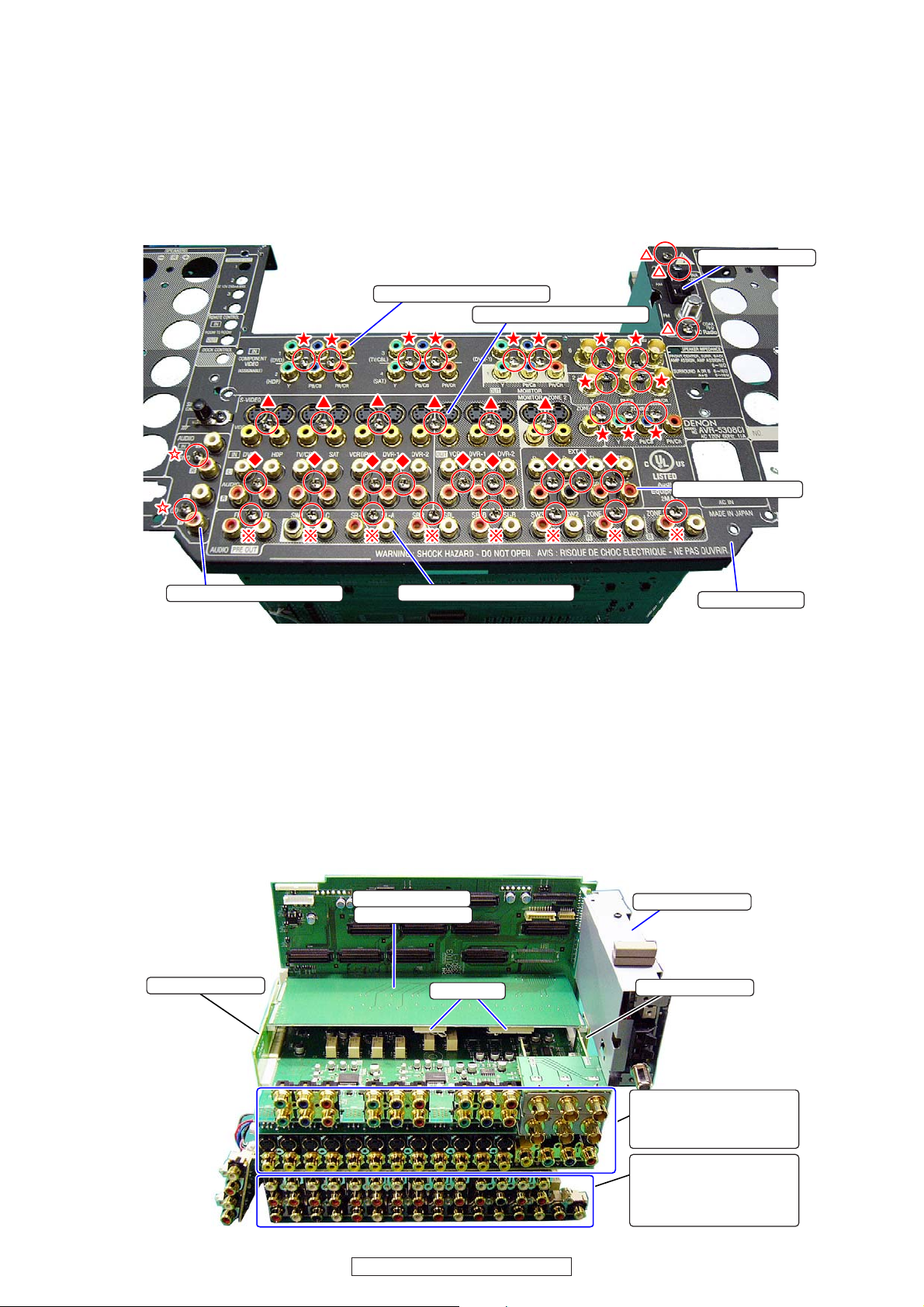

9. BACK PANEL SUB ASS’Y

(1) Remove 9 screws fixing the REAR PLATE.

(2) Remove 2 screws ▲ fixing the TUNER. Remove 2

screws ▲ fixing the 1U-3819 : ETHERNET UNIT. Re-

move Nut ◆ fixing the WLAN Antenna.

(3) Remove 8 screws △ fixing the HDMI Terminals.

(4) Remove 11 screws ★ fixing the Digital Audio Termi-

nals.

(5) Detach the REAR PLATE.

(6) Pull out the 1U-3819 : ETHERNET UNIT,1U-3833 :

DIGITAL VIDEO UNIT and 1U-3818 : DIGITAL AUDIO

UNIT.

WLAN ANT.

TUNER

1U-3833

HDMI TERMINAL

DIGITAL AUDIO TERMINAL

1U-3818

9. BACKPANELSUBASS'Y

(1) REARPLATEを固定しているねじ 9 本をはずします。

(2) TUNER 固定ねじ▲ 2 本、1U-3819:ETHERNETUNIT

固定ねじ▲ 2 本、WLAN アンテナのナット◆をはず

します。

(3) HDMI 端子のねじ△ 8 本をはずします。

(4) DigitalAudio 端子のねじ★ 11 本をはずします。

(5) REARPLATE をはずします。

(6) 1U-3819:ETHERNETUNIT,1U-3833:DIGITALVIDEO

UNIT,1U-3818:DIGITALAUDIOUNIT 基板を抜き取り

ます。

REAR PLATE

1U-3819

ETHERNET UNIT

22

AVR-5308CI / AVC-A1HD

Page 23

(7) Remove 3 screws △ fixing the HD RADIO.

(8) Remove 13 screws★ fixing the COMPONENT VIDEO

Terminals.

▲

(9) Remove 6 screws

nals.

(10) Remove 9 screws

nals.

(11)Remove 8 screws ※ fixing the PRE OUT Terminals.

(12)Remove 2 screws ☆ fixing the PHONO/CD Terminals.

(13)Detach the BACK PANEL.

fixing the ANALOG VIDEO Termi-

◆

fixing the ANALOG AUDIO Termi-

COMPONENT VIDEO TERMINAL

(7) HDRADIO を固定しているねじ△ 3 本をはずします。

(8) COMPONENTVIDEO端子のねじ★ 13 本をはずしま

す。

(9) ANALOGVIDEO 端子のねじ▲ 6 本をはずします。

(10) ANALOGAUDIO 端子のねじ◆ 9 本をはずします。

(11) PREOUT端子のねじ※ 8 本をはずします。

(12) PHONO/CD 端子のねじ☆ 2 本をはずします。

(13) BACKPANELをはずします。

HD RADIO

VIDEO TERMINAL

AUDIO TERMINAL

PHONO/CD TERMINAL

(14) Detach the HD RADIO UNIT.

(15) Detach the 1U-3821-3 : DAC MUTE UNIT.

(15-1) Detach the 1U-3826-14 and 1U-3826-15.

(15-2) Disconnect 2 Wire connector. Detach the 1U-

3821-3 : DAC MUTE UNIT.

(16) Detach the P.W.B. Ass’y of 1U-3822-1 : COMPO-

NENT UNIT,1U-3822-2 : S&CVBS UNIT and 1U3825-10/-11/-12.

(17)Remove 2 screws of the backside of 1U-3821-1 : CPU

UNIT.

(18) Detach the P.W.B. Ass’y of 1U-3823-1 : PRE OUT

UNIT,1U-3823-2 : AUDIO IN UNIT,1U-3824-1 : VOLUME UNIT and 1U-3824-2 : ZONE VOLUME UNIT.

PRE OUT TERMINAL

1U-3821-3

DAC MUTE UNIT

1U-3826-14

BACK PANEL

(14) HDRADIOUNIT をはずします。

(15) 1U-3821-3:DACMUTEUNIT をはずします。

(15-1)1U-3826-14,1U-3826-15 をはずします。

(15-2)ワイヤー2 本をはずして 1U-3821-3:DACMUTE

UNIT をはずします。

(16) 1U-3822-1:COMPONENTUNIT,1U-3822-2:S&CVBS

UNIT,1U-3825-10/-11/-12 の基板 ASS'Y をはずしま

す。

(17) 1U-3821-1:CPUUNITの裏側のねじ 2 本をはずしま

す。

(18) 1U-3823-1:PREOUTUNIT,1U-3823-2:AUDIOIN

UNIT,1U-3824-1:VOLUMEUNIT,1U-3824-2:ZONE

VOLUMEUNITの基板 ASS'Y をはずします。

HD RADIO UNIT

WIRE

1U-3826-15

23

AVR-5308CI / AVC-A1HD

1U-3822-1 COMPONENT

1U-3822-2 S&CVBS

1U-3825-10/11/12

1U-3823-1 PRE OUT

1U-3823-2 AUDIO

1U-3824-1 VOLUME

1U-3824-2 ZONE.VOLUME

Page 24

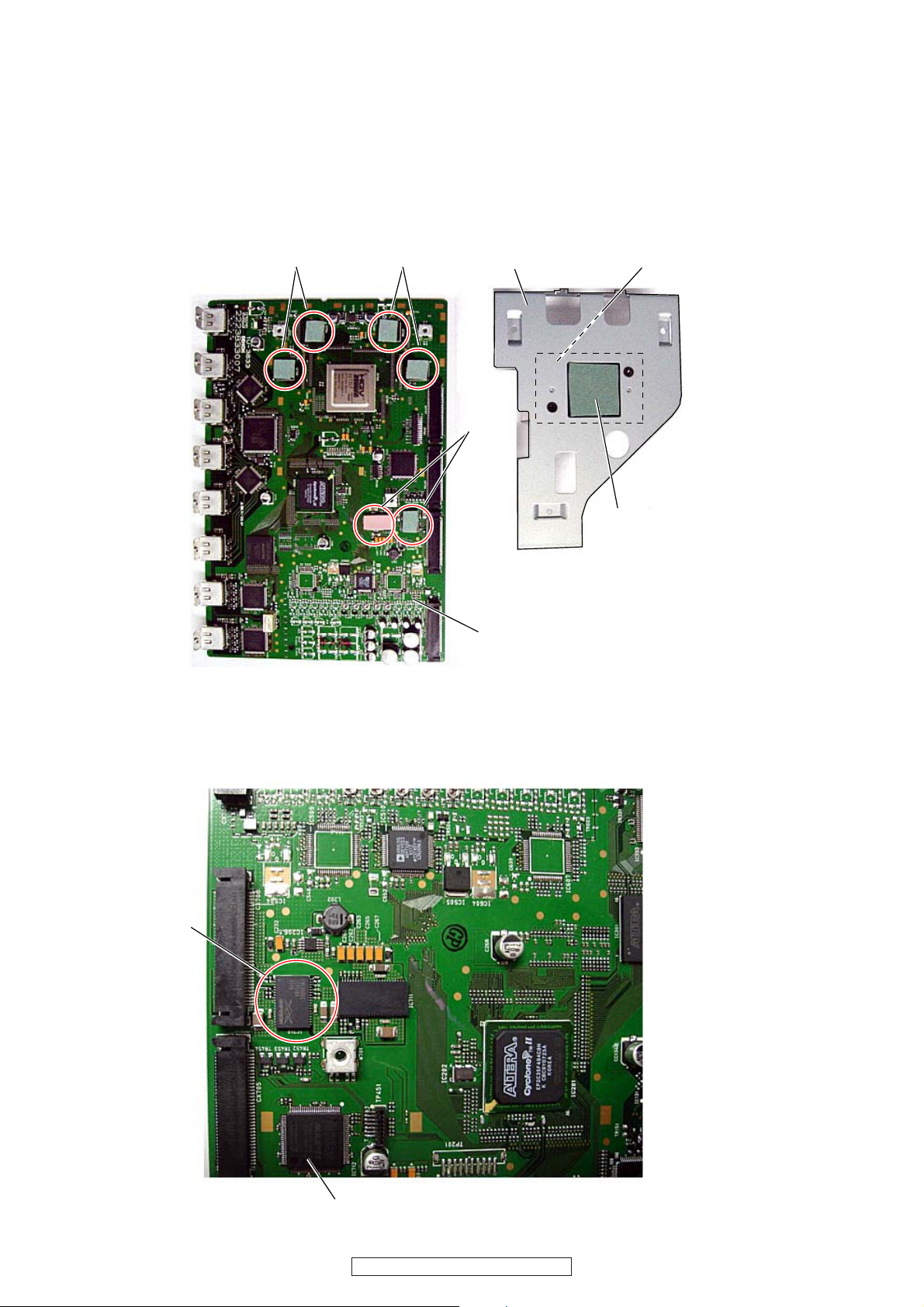

●Mattersthatrequireattentionof

the assembling at the time of the

repair.

1. Attention when assemble RADIATOR

HOLDER on 1U-3833:DIGITAL VIDEO

UNIT.

(1) Paste up the PAD for heat conduction on the IC and

the RADIATOR.

※ Check nothing is dust on the surface of the PAD.

PADPAD

●修理時の組み立て注意点

1. 1U-3833 : DIGITAL VIDEO 基板に RADI-

ATOR HOLDER を取り付ける時の注意

(1) IC と RADIATOR に熱伝導用 PAD が貼ってあること。

※ PAD の表面に異物の付着が無いこと。

RADIATOR HOLDER

PAD

RADIATOR

PAD

(2) Check nothing is chink between the PAD and the

parts, after attach the RADIATOR HOLDER to the 1U3833 :DIGITAL VIDEO UNIT.

(3) It is a regular state that is short-circuited No.30 pin and

GND (No.29 or No.31 pin) of the IC710 on the 1U3833:DIGITAL VIDEO UNIT .

IC710

1U-3833

DIGITAL VIDEO UNIT

(2) 1U-3833:DIGITALVIDEO 基板に RADIATORHOLDER

を取り付けた後に PAD と部品に隙間がないか確認の

こと。

(3) 1U-3833:DIGITALVIDEO 基板:IC710 の No.30 ピン

と GND(No.29 または No.31 ピン ) が短絡されている

のは正規な状態です。

1U-3833

DIGITAL VIDEO UNIT

24

AVR-5308CI / AVC-A1HD

Page 25

2. Attention when assemble 1U3818:DIGITAL AUDIO UNIT and 1U3833:DIGITAL VIDEO UNIT on 1U-38211:CPU UNIT.

(1) Hold the 1U-3821-1:CPU UNIT so that the connector

CX713 on the 1U-3821-3:DAC MUTE UNIT is unstable. Then connect the 1U-3818:DIGITAL AUDIO UNIT

and the 1U-3833:DIGITAL VIDEO UNIT to connector.

2. 1U-3818:DIGITALAUDIO 基板と 1U3833:DIGITALVIDEO基板を 1U-3821-1

:CPU基板に取り付ける時の注意

(1) 1U-3821-3:DACMUTE 基板のコネクター CX713 に

浮きが発生しないように 1U-3821-1:CPU基板を押

えながら 1U-3818:DIGITALAUDIO 基板と 1U-3833:

DIGITALVIDEO 基板をコネクターに差し込んでくだ

さい。

1U-3821-3

DAC MUTE UNIT

HOLD

DIGITAL VIDEO UNIT

1U-3818

DIGITAL AUDIO UNIT

1U-3821-1

CPU UNIT

CX713

1U-3833

25

AVR-5308CI / AVC-A1HD

Page 26

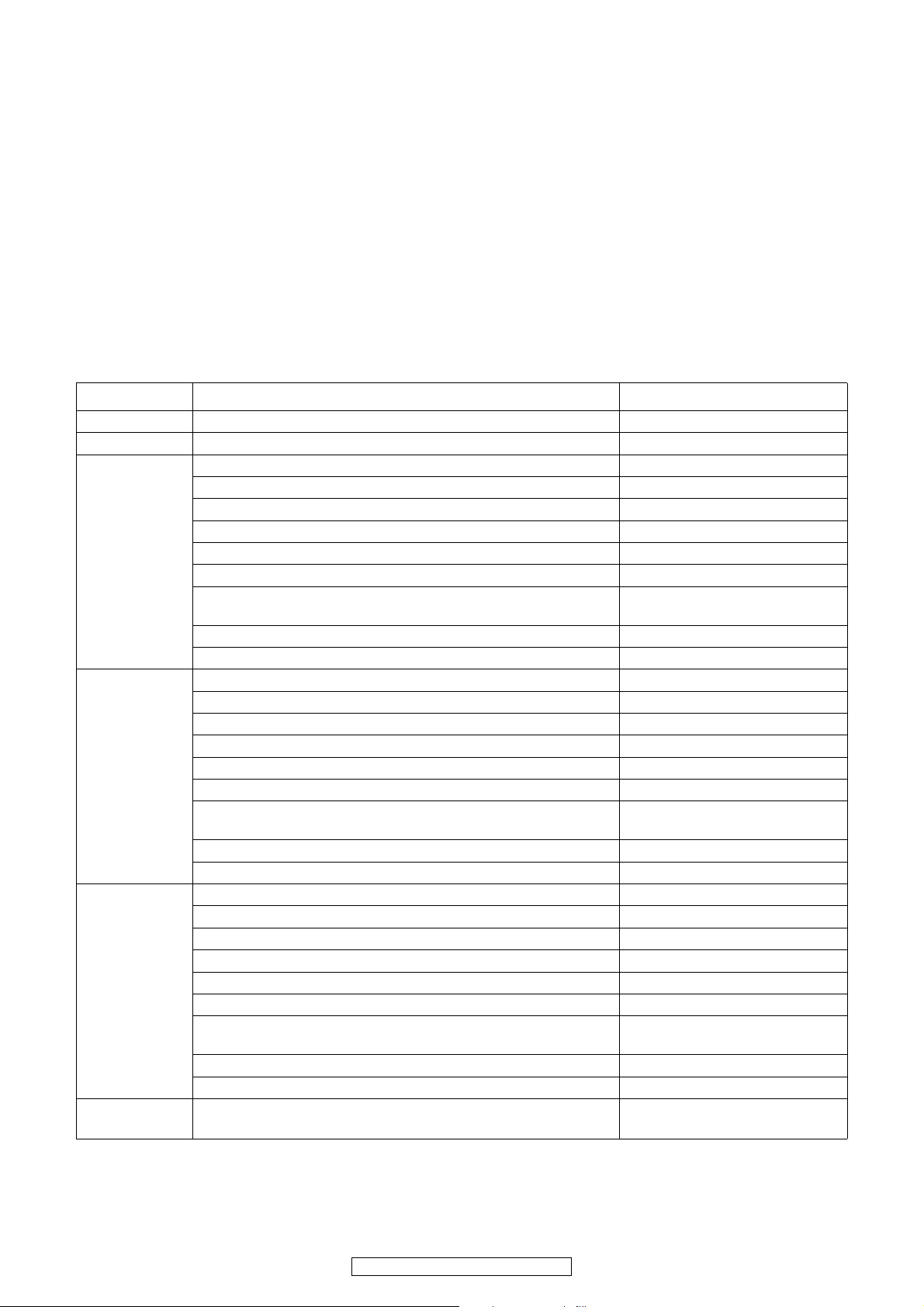

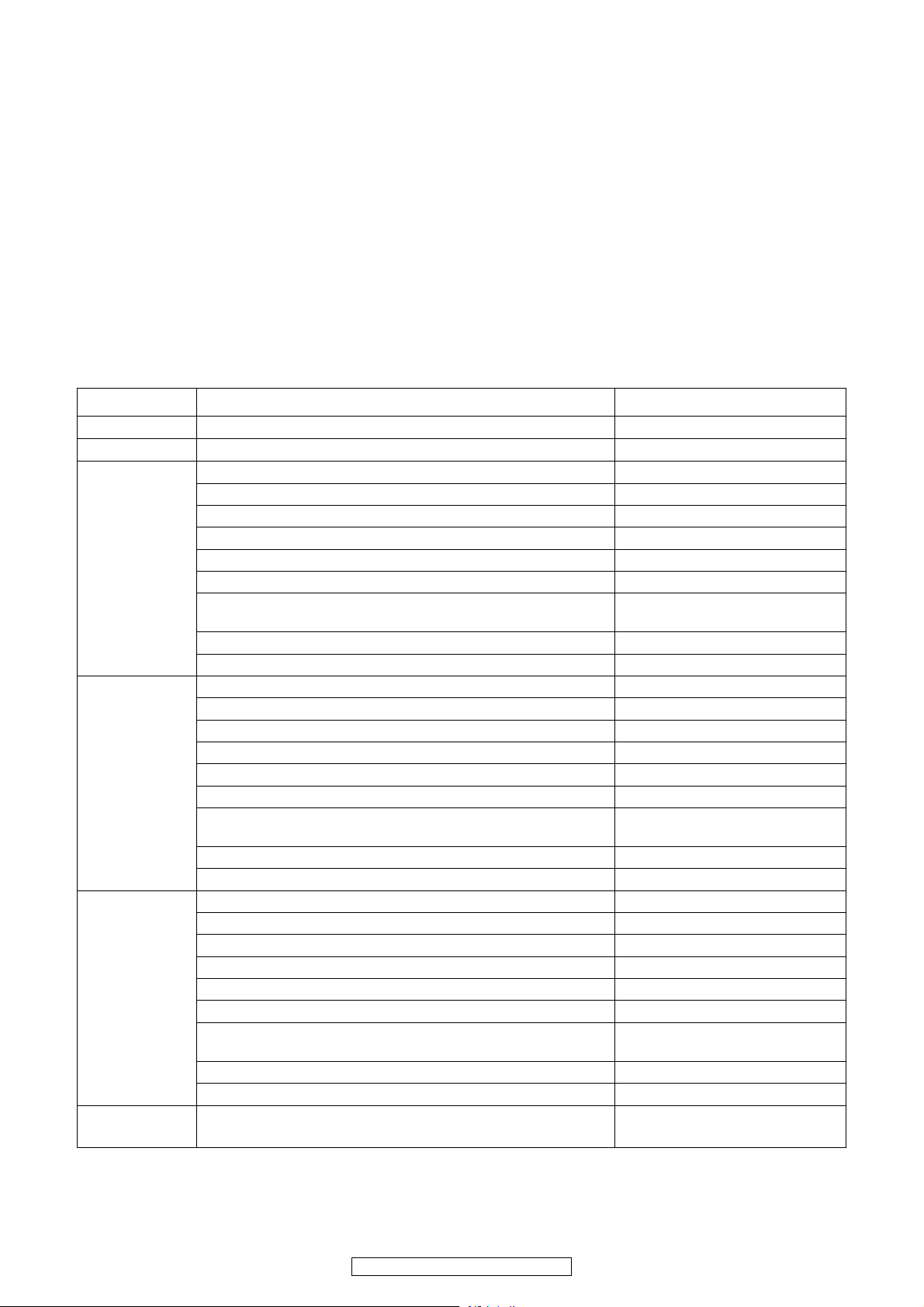

CHECK WITH TEST MODE

µcom/DSP Error Display Mode

1. Operation Spec

µcom version display mode:

When the following conditions are satisfied at its starting state, error information is displayed before version information.

Starting method (same as µcom version display):

While pressing 2 buttons, "STATUS " and "MONITOR SELECT ", turn on Power switch.

Then, press "STATUS" button to display the following information on the FL Display.

2. Display Order

Error information →Destination information →Main-µcom version information → Sub-µcom version information

→ DSP version information

3. Display

Any one of the following list is displayed, in the priority of qwerty..

Condition State Display

Sub-µcom NG

q

w DIR NG

e DSP1 NG

r DSP2 NG

t DSP3 NG

y

Both SUB/DSP

OK

No response from Sub-µcom

No response from DIR

When DSP boot, executing DSP reset makes no change to BUSY port "L".

No change to BUSY port "L" before issuing DSP command.

When DSP data read, executing WRITE="L" makes no change to ACK="H".

When DSP data read, executing REQ="L" makes no change to ACK="L".

When DSP data write, executing WRITE="H" makes no change to ACK="H".

When DSP data write, executing REQ="L" makes no change to ACK="L".

When DSP special code boot, executing DSP reset makes no change to

BUSY port "L".

No change to BUSY port "L" before issuing DSP special read command.

No change to BUSY port "L" before DSP version read.

When DSP boot, executing DSP reset makes no change to BUSY port "L".

No change to BUSY port "L" before issuing DSP command.

When DSP data read, executing WRITE="L" makes no change to ACK="H".

When DSP data read, executing REQ="L" makes no change to ACK="L".

When DSP data write, executing WRITE="H" makes no change to ACK="H".

When DSP data write, executing REQ="L" makes no change to ACK="L".

When DSP special code boot, executing DSP reset makes no change to

BUSY port "L".

No change to BUSY port "L" before issuing DSP special read command.

No change to BUSY port "L" before DSP version read.

When DSP boot, executing DSP reset makes no change to BUSY port "L".

No change to BUSY port "L" before issuing DSP command.

When DSP data read, executing WRITE="L" makes no change to ACK="H".

When DSP data read, executing REQ="L" makes no change to ACK="L".

When DSP data write, executing WRITE="H" makes no change to ACK="H".

When DSP data write, executing REQ="L" makes no change to ACK="L".

When DSP special code boot, executing DSP reset makes no change to

BUSY port "L".

No change to BUSY port "L" before issuing DSP special read command.

No change to BUSY port "L" before DSP version read.

" □ SUB □□ ERROR □01□ "

" □ DIR □□ ERROR □01□ "

"□DSP1 □ ERROR □01□ "

"□DSP1 □ ERROR □02□ "

"□DSP1 □ ERROR □03□ "

"□DSP1 □ ERROR □04□ "

"□DSP1 □ ERROR □05□ "

"□DSP1 □ ERROR □06□ "

"□DSP1 □ ERROR □11□ "

"□DSP1 □ ERROR □12□ "

"□DSP1 □ ERROR □13□ "

"□DSP2 □ ERROR □01□ "

"□DSP2 □ ERROR □02□ "

"□DSP2 □ ERROR □03□ "

"□DSP2 □ ERROR □04□ "

"□DSP2 □ ERROR □05□ "

"□DSP2 □ ERROR □06□ "

"□DSP2 □ ERROR □11□ "

"□DSP2 □ ERROR □12□ "

"□DSP2 □ ERROR □13□ "

"□DSP3 □ ERROR □01□ "

"□DSP3 □ ERROR □02□ "

"□DSP3 □ ERROR □03□ "

"□DSP3 □ ERROR □04□ "

"□DSP3 □ ERROR □05□ "

"□DSP3 □ ERROR □06□ "

"□DSP3 □ ERROR □11□ "

"□DSP3 □ ERROR □12□ "

"□DSP3 □ ERROR □13□ "

(No error display, version display only)

26

AVR-5308CI / AVC-A1HD

Page 27

テストモードによるチェック方法

マイコン・DSP エラー表示モード

1. 動作仕様

マイコンバージョン表示モード :

起動状態にて下記の条件に該当した場合は、バージョン情報表示の前にエラー情報を表示します。

起動方法 ( マイコンバージョン表示と同様 ):

"STATUS","MONITORSELECT" の 2 つのボタンを押した状態で、電源スイッチを押して電源を入れます。

その後、"STATUS" ボタンを押すと下表の内容が FLDisplay に表示されます。

2. 表示順序

エラー情報→仕向地表示→メインマイコンバージョン情報→サブマイコンバージョン情報

→DSP バージョン情報

3. 表示条件

下表のいずれかを表示します。表示の優先順は、qwerty。

条件 状態 表示内容

q

SUB

マイコンが

wDIR が NG

eDSP 1がNG

rDSP 2がNG

tDSP 3がNG

ySUB/DSP 共に

OK

NG

SUB マイコンからの応答がない

DIR からの応答がない

DSP コードブート時、DSP リセットを実行しても BUSY ポートが "L" にならない

DSP コマンド発行前に、BUSY ポートが "L" にならない " □ DSP1 □ ERROR □02□ "

DSP データリード時、WRITE="L" としても ACK="H" とならない " □ DSP1 □ ERROR □03□ "

DSP データリード時、REQ="L" としても ACK="L" とならない " □ DSP1 □ ERROR □04□ "

DSP データライト時、WRITE="H" としても ACK="H" とならない " □ DSP1 □ ERROR □05□ "

DSP データライト時、REQ="L" としても ACK="L" とにならない " □ DSP1 □ ERROR □06□ "

DSP スペシャルコードブート時、DSP リセットを実行しても

BUSY ポートが "L" にならない

DSP スペシャルリードコマンド発行前に、BUSY ポートが "L" にならない " □ DSP1 □ ERROR □12□ "

DSP バージョンリード前に、BUSY ポートが "L" にならない " □ DSP1 □ ERROR □13□ "

DSP コードブート時、DSP リセットを実行しても BUSY ポートが "L" にならない

DSP コマンド発行前に、BUSY ポートが "L" にならない " □ DSP2 □ ERROR □02□ "

DSP データリード時、WRITE="L" としても ACK="H" とならない " □ DSP2 □ ERROR □03□ "

DSP データリード時、REQ="L" としても ACK="L" とならない " □ DSP2 □ ERROR □04□ "

DSP データライト時、WRITE="H" としても ACK="H" とならない " □ DSP2 □ ERROR □05□ "

DSP データライト時、REQ="L" としても ACK="L" とにならない " □ DSP2 □ ERROR □06□ "

DSP スペシャルコードブート時、DSP リセットを実行しても

BUSY ポートが "L" にならない

DSP スペシャルリードコマンド発行前に、BUSY ポートが "L" にならない " □ DSP2 □ ERROR □12□ "

DSP バージョンリード前に、BUSY ポートが "L" にならない " □ DSP2 □ ERROR □13□ "

DSP コードブート時、DSP リセットを実行しても BUSY ポートが "L" にならない

DSP コマンド発行前に、BUSY ポートが "L" にならない " □ DSP3 □ ERROR □02□ "

DSP データリード時、WRITE="L" としても ACK="H" とならない " □ DSP3 □ ERROR □03□ "

DSP データリード時、REQ="L" としても ACK="L" とならない " □ DSP3 □ ERROR □04□ "

DSP データライト時、WRITE="H" としても ACK="H" とならない " □ DSP3 □ ERROR □05□ "

DSP データライト時、REQ="L" としても ACK="L" とにならない " □ DSP3 □ ERROR □06□ "

DSP スペシャルコードブート時、DSP リセットを実行しても

BUSY ポートが "L" にならない

DSP スペシャルリードコマンド発行前に、BUSY ポートが "L" にならない " □ DSP3 □ ERROR □12□ "

DSP バージョンリード前に、BUSY ポートが "L" にならない " □ DSP3 □ ERROR □13□ "

"□SUB□ □ ERROR □01□ "

"□DIR□ □ ERROR □01□ "

" □ DSP1 □ ERROR □01□ "

" □ DSP1 □ ERROR □11□ "

" □ DSP2 □ ERROR □01□ "

" □ DSP2 □ ERROR □11□ "

" □ DSP3 □ ERROR □01□ "

" □ DSP3 □ ERROR □11□ "

( 表示せずにバージョン表示を行う )

27

AVR-5308CI / AVC-A1HD

Page 28

ADJUSTMENT

調整

AUDIO Section

IDLING CURRENT (1U-3827-1,6)

Required measurement equipment: DC Voltmeter

1. PREPARATION

(1) Avoid direct blow from an air conditioner or an electric

fan, and adjust the unit at normal room temperature 15

°C ~ 30 °C (59 °F ~ 86 °F).

(2) Presetting

• POWER (Power source switch) OFF

• SPEAKER (Speaker terminal) No load

(Do not connect speaker, dummy resistor, etc.)

2. ADJUSTMENT

(1 ) Remove Top co ver .

Set VR201,203,204 on 1U-3827-1 : P.AMP(L) Unit

and VR401,402,403,404 on 1U-3827-6 : P.AMP(R)

Unit at fully counterclockwise (

(2) Connect DC Voltmeter to test points (q epin of

TP201,202,203 and TP401,402,403,404).

(3) Connect power cord to AC Line, and turn power switch

"ON".

(4) Turn power switch "ON" with pressing [STANDARD]

and [HOME THX CINEMA] buttons in the door of front

panel.

(5) Presetting.

・MASTER VOLUME :

・SPEAKER (Speaker terminal) : No load

(Do not connect speaker, dummy resistor, etc.)

MODE : 9CH STEREO

FUNCTION : CD

(6) Allow 2 minutes, and turn VR201 clockwise (

adjust the TEST POINT voltage to

3.5 mV ± 0.2 mV DC.

(7) After 10 minutes from preset, turn VR201 to set the

voltage to

4.0 mV ± 0.2 mV DC.

(8) Adjust the Variable Resistors of other channels in the

same way.

c ).

"---" counterclockwise (

cmin.)

x ) to

オーディオセクション

アイドリング電流の調整 (1U-3827-1,6)

調整に必要な測定器 : DCVoltmeter

1. 準備

(1) セットをクーラ、扇風機のそばなど風通しの良い場

所を避け、通常の使用状態に置きます。セットの周

囲温度は 15〜30 ℃、湿度は常湿とします。

(2) プリセット

・電源スイッチ OFF

・スピーカー端子 無負荷

( スピーカー・ダミー抵抗器などを接続しない。)

2. 調整

(1) トップカバーをはずし、1U-3827-1:P.AMP(L) ユニッ

トの VR201,203,204 と 1U-3827-6:P.AMP(R) ユニッ

トの VR401,402,403,404 を反時計方向 (

切った状態にセットします。

(2) テストポイント (TP201,202,203 と

TP401,402,403,404 の q epin)に DCVoltmeterを接

続します。

(3) 電源コードを AC ライン(95〜105Vの範囲であるこ

と)に接続し、電源スイッチを "ON"にします。

(4) フロントパネルのドア内にある「STANDARD」ボタ

ンと「HOMETHXCINEMA」ボタンを押しながら電

源スイッチを "ON"にします。

(5) ON後、次のようにセットします。

・MASTERVOLUME(音量調節つまみ)→反時計方向

(

c)に回す、最小の状態にする。

・SPEAKER(スピーカー端子)→無負荷

(スピーカー、ダミー抵抗器などを接続しない。)

MODE:9CHSTEREO

FUNCTION:CD

(6) 2分以内に VR201を時計方向 (

イントの電圧を次のように調整します。

3.5mV ±0.2mVDC

(7) 予備調整から 10分後 VR201を回し、次のように電

圧を設定します。

4.0mV± 0.2mVDC

(8) 同じ方法で各チャネルの可変抵抗を調整します。

x) に回しテストポ

c)に回し

(9) After 5 minutes from (7), turn VR201 to set the voltage

to

4.0 m ± 0.2 mV DC.

(10)Adjust the Variable Resistors of other channels in the

same way.

AVR-5308CI / AVC-A1HD

(9) (7) 項設定から 5分後 VR201を回し、次のように電

圧を設定します。

4.0mV± 0.2mVDC

(10) 同じ方法で各チャネルの可変抵抗を調整します。

28

Page 29

Position of Test point and Adjustment volume.

テストポイントと調整ボリュームの位置

FL

SL

TP203

VR204

TP202

VR203

P.AMP(L) UNIT

P.AMP(R) UNIT

1U-3827-1 1U-3827-6

C

FR

SR

VR401

TP401

VR403

TP402

VR404

TP403

SBL

TP201

VR201

SBR

VR402

TP404

29

AVR-5308CI / AVC-A1HD

Page 30

VIDEO Section

. MAIN ZONE

I

1. SETTING

(1) Connect the oscilloscope to the Y-signal and C-signal

of S MONITOR OUT terminal and each terminate at

75 Ohms.

(2) Connect the oscilloscope to the Y-signal, P

B-signal, PR-signal and CR-signal of COMPO-

and C

NENT MONITOR OUT2 terminal and each terminate

at 75 Ohms.

※ Use the 75 Ohms resistance must be 1%

(3) DVD test disc : DVDT-S01 or VT-502

(4) COMPONENT VIDEO OUT of DVD player is connect-

ed to COMPONENT IN-5.

2. BEFORE ADJUSTMENT

2.1. Setting the Oscilloscope as below.

(1) PB/CB, PR/CR, C

(a) TIME/DIV : 10μs

(b) VOLT/DIV : 100mV (Use the probe : x10 )

(2) Y

(a) TIME/DIV : 10μs

(b) VOLT/DIV : 200mV (Use the probe : x10 )

Power on. Power Supply : 120V(U.S.A.)

230V(Europe)

100V(Japan)

2.2. Setup the DVD player and confirmation of the stators

(1) Set to "INTERLACED" mode at the COMPONENT

OUT.

(2) Confirm the DVD player’s out put level is equal as the

item 2.4. in following.

2.3. Preparation

(1) Connect power cord to AC Line, and turn power switch

"ON".

(2) Turn the FUNCTION knob to select "VCR/iPOD" input.

(3) Push [OPEN/CLOSE] button of DVD player, then

open the Disc Tray.

Set DVD test disc on the Disc Tray, and then push

[CLOSE] button.

(4) DVD player FL display appear "STOP", push [PLAY]

button to playback DVD.

(5) Push the [DISPLAY] button of remote control of DVD

player unit and then appear the ON-Screen Display

(GUI) on the monitor TV.

(6) [DVD test disc : DVDT-S01]

P u s h t h e [ + 1 0 ] a n d [ 2 ] b u t t o n , s e l e c t T i t l e 1 2 o f D V D .

[DVD test disc : VT-502]

Push the [0] and [3] button, select Title 3 of DVD.

(7) [DVD test disc : DVDT-S01]

Push the [ENTER] button, playback Title 12.

(color bar 75%)

[DVD test disc : VT-502]

Push the [ENTER] button, playback Title 3.

(color bar 100%)

B-signal

ビデオセクション

I.MAINZONE

1. セッティング手順

(1) セットの SMONITOROUT 端子から Y 信号と C 信号

をそれぞれオシロスコープ(終端抵抗:75Ω)に接

続します。

(2) セットの COMPONENTMONITOROUT2 の端子(Y,

B/CB,PR/CR)をそれぞれオシロスコープ(終端抵

P

抗:75Ω)に接続します。

※ 75Ω 抵抗は 1%品を使用する事。

(3) DVD テストディスク:DVDT-S01 または VT-502 を

用意します。

(4) DVD プレーヤーの COMPONENTVIDEOOUT を

COMPONENTIN-5 に接続します。

2. 調整のまえに

2.1. オシロスコープを下記に設定

(1) PB/CB,PR/CR,C

(a) TIME/DIV : 10μs

(b) VOLT/DIV : 100mV(プローブ x10 使用)

(2) Y

(a) TIME/DIV : 10μs

(b) VOLT/DIV : 200mV(プローブ x10 使用)

電源電圧:100V(日本)

2.2. DVD プレーヤの設定と確認

(1) COMPONENTOUT の設定を " インターレース " にしま

す。

(2) DVD プレーヤーの出力が以下 2.4. に合っていること

を確認します。

2.3. 準備手順

(1) 電源コードを AC ラインに接続し、電源スイッチを

"ON"にします。

(2) FUNCTION ノブを回し、入力を "VCR/iPOD" に切り替

えます。

(3) DVD プレーヤーの「OPEN/CLOSE」ボタンを押しト

レイを開き、トレイ上に DVD テストディスクをセッ

ト後、「CLOSE」ボタンを押します。

(4) DVD プレーヤーの表示管上に "STOP" が表示されて

から、「PLAY」ボタンを押し、ディスクを再生しま

す。

(5) DVD プレーヤーのリモコンの「DISPLAY」ボタンを

押しグラフィカル・ユーザー・インターフェイス

(GUI) 画面を出します。

(6) [DVD テストディスク:DVDT-S01 の場合]番号ボタ

ンの「 +10 」 , 「 2 」ボタンを押し、Title12 を選択しま

す。 [DVD テストディスク:VT-502 の場合]番

号ボタンの「0 」, 「 3 」ボタンを押し、Title3 を選択しま

す。

(7) [DVD テストディスク:DVDT-S01 の場合]

「ENTER」ボタンを押し、Title12 を再生します。

(75%カラーバー信号)

[DVD テストディスク:VT-502 の場合]

「ENTER」ボタンを押し、Title3 を再生します。

(100%カラーバー信号)

30

AVR-5308CI / AVC-A1HD

Page 31

2.4. Procedure

(1) Adjust the signal of S MONITOR OUT by the wave of

oscilloscope.

(a) Target, Y-signal

Point : 1U-3833-1 VR504

Adjustment Value : 714 ± 14mV

Waveform

2.4. 手順

(1) セットの SMONITOROUT の信号レベルをオシロス

コープ上の波高値で調整します。

(a) Y 信号レベル

調整個所 : 1U-3833-1VR504

調整値 : 714 ± 14mV

波形

Y

Y-signal of S MONITOR OUT

(b) Target, C-signal

Point : 1U-3833-1 VR505

Adjustment Value : 286 ± 5mV

Waveform

C

C-signal of S-MONITOR

(2) Adjust the signal of COMPONENT OUT by the wave

of oscilloscope.

(a) Target, Y-signal

Point : 1U-3833-1 VR506

Adjustment Value : 714 ± 14mV

Waveform

Y

SMONITOROUT の Y 信号レベル

(b) C 信号レベル

調整個所 : 1U-3833-1VR505

調整値 : 286 ± 5mV

波形

C

SMONITOR の C 信号レベル

(2) COMPONENTOUTの信号レベルをオシロスコープ上

の波高値で調整します。

(a) Y 信号レベル

調整個所 : 1U-3833-1VR506

調整値 : 714 ± 14mV

波形

Y

Y-signal COMPONENT OUT

(b) Target, P

Point : 1U-3833-1 VR507

Adjustment Value :

*700 ± 14mV (VT-502)

Waveform

B/CB-signal

*525 ±10mV (DVDT-S01)

PB/CB

PB/CB-signal COMPONENT OUT

AVR-5308CI / AVC-A1HD

31

Y

COMPONENTOUT の Y 信号レベル

B/CB 信号レベル

(b) P

調整個所 : 1U-3833-1VR507

調整値 : 525 ± 10mV(DVDT-S01)

700 ± 14mV(VT-502)

波形

PB/CB

COMPONENTOUT の PB/CB 信号レベル

Page 32

(c) Target, PR/CR-signal

Point : 1U-3833-1 VR508

Adjustment Value : *525 ±10mV (DVDT-S01)

*700 ± 14mV (VT-502)

Waveform

(c) PR/CR 信号レベル

調整個所 : 1U-3833-1VR508

調整値 : 525 ± 10mV(DVDT-S01)

700 ± 14mV(VT-502)

波形

PR/CR

PR/CR-signal COMPONENT OUT

* : 486 ± 10mV for U.S.A. & Canada model (DVDT-S01)

* : 648 ± 13mV for U.S.A. & Canada model (VT-502)

1U-3833-1 DIGITAL VIDEO UNIT

VR508 PR/CR

VR507 CB/PB

VR506 Y

VR505 C

PR/CR

COMPONENTOUT の PR/CR 信号レベル

VR504 Y

32

AVR-5308CI / AVC-A1HD

Page 33

TROUBLE SHOOTING

トラブルシューティング

1. POWER

1.1. Power not turn on

Power not turn on

YES

Is the ON/STANDBY indicator

on the front panel flashing red?

YES

Is the fuse blown?

YES

Does the power turn on when

the POWER switch is turned off

then back on?

YES YES YES

Check the primary circuitry

parts including the POWER

switch (for poor contacts, etc.),

and replace any defective

parts.

Are there any incomplete connections in the connectors con-

NO

necting between the various

circuit boards?

YES YES

Connect the connectors properly.

NO

Refer to Fuse is blown

Is a DC 6V voltage being supplied from the 1U-3825-6 board

NO

(CY809 pin 3) to the microprocessor?

Check the 1U-3821-1 board's

microprocessor periphery circuitry and replace any defective parts.

Is there a short circuit between

NO

the speaker terminals and the

ground?

Check for damage in the power

amplifier circuitry parts and

replace any defective parts.

Is a DC 6V voltage output when

the cord supplying the power

NO

from the 1U-3825-6 board to

the microprocessor (CY809) is

unplugged?

Check the circuitry and parts

from CY809 on the 1U-3825-6

board to the microprocessor for

damage and short-circuits, and

replace any defective parts.

Correct the short circuit

NO

between the speaker and the

ground.

Check the parts from IC105

and IC106 to the primary cir-

NO

cuitry and replace any defective parts.

1. 電源

1.1. 電源が入らない

電源が入らない

YES

フロントパネルの

ON/STANDBY インジ

ケータが赤色点滅していませ

んか?

YES

ヒューズは断線していません

か?

YES

POWERSW を OFF にして、再

度 POWERSW を ON にすると

電源が入りますか?

YES YES YES

POWERSW等を含む1 次回路部

品 ( 接触不良等 ) を確認し、不

良部品を交換してください。

各基板間を接続しているコネ

NO

クターに不完全な接続部分は

ありますか?

YES YES

コネクターを正しく接続して

ください。

NO

ヒューズが断線しているを参

照してください。

1U-3825-6 基板(CY809 の 3 番

NO

ピン)からマイコンに DC6V が

供給されていますか?

1U-3821-1 のマイコン周辺回路

を確認し、不良部品を交換して

ください。

NO

SP 端子と GND 間が短絡してい

ませんか?

POWERAMP 回路の部品の破損

を確認し、不良部品を交換して

ください。

1U-3825-6 基板からマイコンヘ

NO

電源を供給しているコード

(CY809)を抜いて DC6V が出力

されていますか?

1U-3825-6 基板の CY809 以降

からマイコン電源までの回路

および部品の破損や短絡を確

認し、不良部品を交換してく

ださい

NO

SP 端子と GND 間の短絡を取り

除いてください。

IC105,IC106 〜 1 次回路までの

NO

部品を確認し、不良部品を交換

してください。

1.2. Fuse is blown

YES YES YES

Check for leaks or short circuits

in the primary side parts, and

replace any defective parts.

YES YES YES

Fuse is blown

Check for short circuits in the

rectifier diodes and circuitry of

the secondary side rectifying

circuits, and replace any defective parts.

After repairing, also replace the fuse.

Check for short circuits in the

power stabilizer unit's regulator output terminal and the

ground, and replace any defective parts.

1.2. ヒューズが断線している

YES YES YES

1 次側の部品にリークまたは短

絡を確認し、不良部品を交換し

てください。

YES YES YES

ヒューズが断線している

2 次側のそれぞれの整流回路

で、整流ダイオードおよび回路の

短絡を確認し、不良部品を交換

してください。

修理後、FUSE も交換してください。

電源安定化部のレギュレータ

の出力端子と GND の短絡を確

認し、短絡している場合は、不

良部品を交換してくだい。

33

AVR-5308CI / AVC-A1HD

Page 34

2. Analog video

2.1. MONITOR OUT (CVBS) output NG

2. アナログビデオ

2.1. MONITOROUT(CVBS)出力NG

MONITOR OUT (CVBS/S/COMPONENT)

Checking the video convert ON/OFF settings

Input

CVBS

output NG

Video convert ON

Input

S

A Interlace

Interlace

Input

COMPONENT

Progressive

B

o r

Progressive

no output

※ When checking operation, select

DVD for the function.

(COMPONENT1 input)

MONITOROUT(CVBS/S/COMPONENT)

出力NG

ビデオコンバートON/OFFの設定確認

ビデオコンバートON

入力

CVBS

Aへ インターレース

入力

S

※ 動作を確認する時はファンクショ

ンを DVD に選択してください。

(COMPONENT1入力 )

入力

COMPONENT

or

プログレッシブ

インターレースBへプログレッシブ

出力されません

34

AVR-5308CI / AVC-A1HD

Page 35

A

CVBS/S出力 COMPONENT出力

リレー及びその周辺回路の

ハンダ付け確認

シグナルDETの確認

コネクト基板のコネクト接触不良

及びハンダ付け確認

(CW/CX139,CW/CX138)

もしくは

出力セレクタ及びその周辺回路の

ハンダ付け確認

1U-3833D.VIDEOUNIT

VideoEncoder後

ドライバ(IC511)出力確認

本体-MONITOR間のケーブル

もしくはMONITOR確認

OK

出力Cr: IC205-9pin

IC205-11pin

リレー:

RL205,RL206

NG

出力段AMPの出力確認

出力Y: IC205-13pin

出力Cb:

出力Y:

出力Cb:

出力Cr:

C536+側

C540+側

C535+側

出力Y:

出力Cb:

出力Cr:

NG

DIGITALUNITの不具合

入力セレクタ:

NG

H(+5V)

コネクト基板のコネクト接触不良

及びハンダ付け確認

(CW/CX119,CW/CX115,

CW/CX711)

VR506

1U-3833D.VIDEOUNIT

VideoEncoder後

出力確認

SCPU+5V

A

VR508

VA±5,SCPU+5Vの確認

CX902-1pin

1U-3833D.VIDEOUNIT

VideoDecoder信号入力の確認

H(+5V)V:CW171-3pin:

入力 CVBS/S

1.1電源異常時の

トラブルシューティングへ

NG

CX902-8,9pin

CX902-4,5pin

VA+5:

VA-5:

OK

入力セレクタ及び初段ビデオアンプ、

その周辺回路のハンダ付け確認

もしくは

μCOMUNITの不具合

入力V: IC508-73pin

NG

OK

OK

出力Y:

出力C: CC536

出力Y: C538+側

出力C:

OK

IC511及び周辺回路の

ハンダ付け確認

本体-MONITOR間のケーブル

もしくはMONITOR確認

NG

出力V: IC405-7pin

出力セレクタ:

IC427,IC430

IC406-7pin

NG

OK

OK

VR504

出力Y: IC406-1pin

出力段AMPの出力確認

出力C: VR505

出力V: C539+側

VR507

IC412,IC415,418

ビデオアンプ:

IC432,IC433

Y:CW171-4pin:

入力Y: IC508-71pin

入力C: IC508-75pin

Input

CVBS/S

Check VA±5䋬SCPU+5V

VA+5: CX902-8,9pin

VA-5: CX902-4,5pin

NG

To troubleshooting 1.1

Power not turn on.

SCPU+5V CX902-1pin

OK

1U-3833 D.VIDEO UNIT

Check input of video decoder

signal.

Input V: IC508-73pin

NG

Input Y: IC508-71pin

Input C: IC508-75pin

Check output of driver(IC511)

after 1U-3833 D.VIDEO UNIT

Video Encoder.

Output V: C539 +side Output Y: VR504

Output Y: C538 +side Output C: VR505

OK

Output C: CC536

Output Y:

Output Cb: C540 +side Output Cr:

C536 +side Output Cb:

Output Cr: C535 +side

NG

Check signal DET

V:CW171-3pin: H(+5V)

Y:CW171-4pin: H(+5V)

OK

Check poor contacts of

Conecting board and soldering.

(CW/CX119,CW/CX115,

CW/CX711)

Check output after 1U-3833

D.VIDEO UNIT

Video Encoder.

Output Y: VR506

VR507

VR508

OK

Check input of input selector

NG

and Video AMP, surrounding

circuitry soldering.

IC412,IC415,418

Input:

Video AMP: IC432,IC433

or μCOM UNIT flaw.

NG

DIGITAL UNIT flaw.

CVBS/S output

Check output of AMP

Output V: IC405-7pin

Output Y: IC406-1pin

OK

Output C: IC406-7pin

Check cable between main unit

and monitor or Check monitor.

※ Unless specified, 1U-3822 A.VIDEO UNIT part.

OK

Check soldering of IC511 and

surrounding parts.

NG

Check poor contacts of

Conecting board and soldering.

(CW/CX139,CW/CX138)

or check soldering

outputselector and surrunding

circuitry.

IC427,IC430

Output

Check soldering of relay and

sorrunding circuitry.

RL205,RL206 Output Cb: IC205-11pin

relay:

COMPONENT output

NG

Check output of AMP

Output Y: IC205-13pin

Output Cr: IC205-9pin

OK

Check cable between main unit

and monitor or Check monitor.

※ 特に記載がない場合は 1U-3822A.VIDEOUNITの部品です。

35

AVR-5308CI / AVC-A1HD

Page 36

B

CVBS/S出力 COMPONENT出力

シグナルDETの確認

リレー及びその周辺回路の

ハンダ付け確認

コネクト基板のコネクト接触不良

及びハンダ付け確認

(CW/CX139,CW/CX138)

もしくは

出力セレクタ及びその周辺回路の

ハンダ付け確認

IC427,IC430

出力C:

OK

リレー:

RL205,RL206

出力C: CC536

出力Y: IC406-1pin

出力Cr: C535+側

出力段AMPの出力確認

NG

出力V: IC405-7pin

1.1電源異常時の

トラブルシューティングへ

NG

IC508-72pin

OK

T

R213コレクタ側: H(+5V)

B

入力COMPONENT

1U-3833D.VIDEOUNIT

VideoEncoder後

ドライバ(IC511)出力確認

+9V:

VA+5:

VA-5:

SCPU+5V

1U-3833D.VIDEOUNIT

VideoEncoder後

出力確認

VR505

VR507

出力Cr: VR508

NG

C243+側

VA±5,SCPU+5,+9V

SCPU+5Vの確認

CX902-8,9pin

CX902-4,5pin

CX902-1pin

出力Cb:

出力Cb:

出力C:

NG

ビデオアンプ:

もしくは

μCOMUNITの不具合

入力Y: IC508-76pin

入力Cb: IC508-74pin

OK

入力Cr:

出力セレクタ:

出力Y: C538+側

VR506

C540+側

出力Y:

IC511及び周辺回路の

ハンダ付け確認

OK

出力Y: C536+側

NG

DIGITALUNITの不具合

NG

出力段AMPの出力確認

出力Y: IC205-13pin

OK

1U-3833D.VIDEOUNIT

VideoDecoder信号入力の確認

NG

出力V: C539+側 出力Y: VR504

IC406-7pin

出力Cr:

出力Cb:

本体-MONITOR間のケーブル

もしくはMONITOR確認

OK

IC205-9pin

OK

本体-MONITOR間のケーブル

もしくはMONITOR確認

入力セレクタ及びリレー

初段ビデオアンプ、

その周辺回路のハンダ付け確認

リレー:

IC203

IC205-11pin

入力セレクタ:

IC201

RL201,RL202

コネクト部

及びハンダ付け確認

(CW/CX711)

Input

COMPONENT

Check VA±5䋬SCPU+5䋬+9V

SCPU+5V

VA+5: CX902-8,9pin

VA-5: CX902-4,5pin

SCPU+5V CX902-1pin

+9V: C243+side

OK

NG

To troubleshooting 1.1

Power not turn on.

1U-3833 D.VIDEO UNIT

Check input of video decoder

signal.

Input Y: IC508-76pin

Input Cb: IC508-74pin

Input Cr:

1U-3833 D.VIDEO UNIT

IC508-72pin

OK

Check output of driver(IC511)

after Video Encoder.

Output V: C539 +side Output Y: VR504

Output Y: C538 +side

Output C: CC536 Output Y:

Output Y: C536 +side Output Cb:

Output Cb: C540 +side Output Cr: VR508

Output Cr: C535 +side

NG NG

Check signal DET

TR213 collector side: H(+5V)

OK

Check connect part and

soldering.

Output C:

OK

(CW/CX711)

VR505

VR506

VR507

1U-3833 D.VIDEO UNIT

NG

Check output after Video

Encoder

Check soldering of input selector

and relay, Video AMP and

surrunding circuitry.

Relay:

IC201

RL201,RL202

IC203

Input selector:

Video AMP:

or μCOM UNIT flaw

NG

DIGITAL UNIT flaw.

Check soldering of IC511 and

CVBS/S output

Output V: IC405-7pin

Output Y: IC406-1pin

Output C: IC406-7pin

OK

Check output of AMP

OK

surrounding parts.

NG

Check poor contacts of

Conecting board and soldering.

(CW/CX139,CW/CX138)

or check soldering

outputselector and surrunding

circuitry.

IC427,IC430

Output

COMPONENT output

Check cable between main unit

and monitor or Check monitor.

※ Unless specified, 1U-3822 A.VIDEO UNIT part.

Check soldering of relay and

sorrunding circuitry.

RL205,RL206 Output Cb: IC205-11pin

relay:

NG

Check output of AMP

Output Y: IC205-13pin

Output Cr: IC205-9pin

OK

Check cable between main unit

and monitor or Check monitor.

※ 特に記載がない場合は 1U-3822A.VIDEOUNITの部品です。

36

AVR-5308CI / AVC-A1HD

Page 37

2.2. ZONE2 MONITOR OUT (CVBS) Output NG

2.2. ZONE2MONITOROUT(CVBS)出力 NG

ZONE2 MONITOR OUT (CVBS/S)

Input

CVBS

ZONE2 MONITOR OUT (COMPONENT)

Output NG.

Check ZONE2 is power on. Turn on ZONE2 and check again.

OK

Input

S

C No output

Output NG.

Input

COMPONENT

※ When checking operation, select

DVD for the function.

NG

※ When checking operation, select

DVD for the function.

ZONE2MONITOROUT(CVBS/S)

出力 NG

ZONE2 が POWERON になっていることを確認

OK

入力

CVBS

Cへ 出力されません

ZONE2MONITOROUT(COMPONENT)

入力

S

出力 NG

入力

COMPONENT

※ 動作を確認する時はファンクショ

ンを DVD に選択してください。

NG

ZONE2 を POWERON にして

再確認

※ 動作を確認する時はファンクショ

ンを DVD に選択してください。

Check ZONE2 is power on. Turn on ZONE2 and check again.

OK

Input

CVBS

No output No output D

Input

S

Input

COMPONENT

NG

ZONE2 が POWERON になっていることを確認

OK

入力

CVBS

出力されません 出力されません Dへ

入力

S

入力

COMPONENT

NG

ZONE2 を POWERON にして

再確認

37

AVR-5308CI / AVC-A1HD

Page 38

C

OSD出力バッファ、

出力セレクタ及びそれらの

周辺回路のハンダ付け確認

IC710,IC711

IC701,IC702

IC428,IC431

出力C: IC408-7pin

OK

本体-MONITOR間のケーブル

もしくはMONITOR確認

出力バッファ:

出力セレクタ:

OK

AMPの出力確認

IC712

NG

出力Y: IC407-1pin

もしくは

μCOMUNITの不具合

出力V: IC407-7pin

入力セレクタ及び初段ビデオアンプ、

OSDドライバ、及びそれらの

周辺回路のハンダ付け確認

OSDドライバ:

NG

OSD入力セレクタ及び

その周辺のハンダ付け確認

入力セレクタ: IC413,IC416,IC419

ビデオアンプ: IC434,IC435

シグナルDETの確認

もしくは

μCOMUNITの不具合

Y:CW171-6pin: H(+5V)

OK

NG

V:CW171-5pin: H(+5V)

1.1電源異常時の

トラブルシューティングへ

NG

OSDドライバの入出力確認

入力: IC712-15pin

出力: IC712-13pin

C

入力 CVBS/S

VA±5,SCPU+5Vの確認

OK

VA+5: CX902-8,9pin

VA-5: CX902-4,5pin

SCPU+5V: CX902-1pin

Input

CVBS/S

Check VA±5,SCPU+5V

VA+5 : CX902-8,9pin

VA-5 : CX902-4,5pin

SCPU+5V CX902-1pin

OK

Check the input/output of OSD

Input : IC712-15pin

Output : IC712-13pin

OK

Check the output of AMP

Output V : IC407-7pin

Output Y : IC407-1pin

Output C : IC408-7pin

OK

Check the cable of between

main unit - MONITOR or

MONITOR

NG

To troubuleshooting 1.1

Power not turn on.

NG

NG

Check the signal DET

V : CW171-5pin : H(+5V)

Y : CW171-6pin : H(+5V)

OK

Check soldering of OSD

selector and sorrunding

circuitry

or μCOM UNIT flaw

Check the soldering of OSD

output baffer, output selector and

surrunding circuitry

Output baffer :

Output selector

IC710,IC711

IC701,IC702

IC428,IC431

Check soldering of input selector

NG

and Video AMP, OSD driver and

surrunding circuitry

IC413,IC416,IC419

Input

Video AMP

OSD driver

or μCOM UNIT flaw

IC434,IC435

IC712

※ Unless specified, 1U-3822 A.VIDEO UNIT part.

※ 特に記載がない場合は 1U-3822A.VIDEOUNITの部品です。

38

AVR-5308CI / AVC-A1HD

Page 39

D

T

R214コレクタ側: H(+5V)

もしくは

μCOMUNITの不具合

入力セレクタ: IC202

シグナルDETの確認

入力セレクタ及びリレー

その周辺回路のハンダ付け確認

VA-5: CX902-4,5pin

SCPU+5

V

CX902-1pin

D

入力 COMPONENT

VA+5: CX902-8,9pin

VA±5,SCPU+5,+9V

SCPU+5Vの確認

NG

NG

出力Cb: IC206-11pin

出力Y: IC206-13pin

NG

1.1電源異常時の

トラブルシューティングへ

本体-MONITOR間のケーブル

もしくはMONITOR確認

出力Cr: IC206-9pin

OK

μCOMUNITの不具合

AMPの出力確認

OK

リレー: RL203,RL204

+9V: C243+側

OK

Input

COMPONENT

Check VA±5,SCPU+5,

+9V SCPU+5V

VA+5 : CX902-8,9pin

VA-5 : CX902-4,5pin

SCPU+5V CX902-1pin

+9V : C243+ side

OK

NG

To troubuleshooting 1.1

Power not turn on.

Check output of AMP

Output Y : IC206-13pin Check the signal DET

Output Cb : IC206-11pin TR214 corrector side: H(+5V)

Output Cr : IC206-9pin

OK

Check the cable of between

main unit - MONITOR or

MONITOR

NG NG

OK

μCOM UNIT flaw

※ Unless specified, 1U-3822 A.VIDEO UNIT part.

Check soldering of input

selector, relay and surrunding

circuitry

IC202

Input

RL203,RL204

relay :

or μCOM UNIT flaw

※ 特に記載がない場合は 1U-3822A.VIDEOUNITの部品です。

39

AVR-5308CI / AVC-A1HD

Page 40

2.3. VCR/DVR MONITOR OUT(CVBS) Output NG

2.3. VCR/DVRMONITOROUT(CVBS) 出力 NG

VCR/DVR MONITOR OUT(CVBS) Output NG.

Check ZONE3 is power on. Turn on ZONE3 and check again.

OK

Input

CVBS

E

VCR/DVR1/DVR2 MONITOR OUT(CVBS/S)

Input

S

Output NG.

OK

NG

Input

COMPONENT

No output

※ When checking operation, select

DVD for the function.

※ When checking operation, select

DVD for the function.

Z3MONITOROUT 出力 NG ※ 動作を確認する時はファンクショ

ZONE3 が POWERON になっていることを確認

OK

入力

CVBS

E へ 出力されません

VCR/DVR1/DVR2MONITOROUT(CVBS/S)

入力

S

出力 NG

OK

NG

入力

COMPONENT

ンを DVD に選択してください。

ZONE3 を POWERON にして再確認

※ 動作を確認する時はファンクショ

ンを DVD に選択してください。

Input

CVBS

VCR/DVR1/DVR2:F

Input

S

Input

COMPONENT

No output No output

入力

CVBS

VCR/DVR1/DVR2:F

入力

S

出力されません 出力されません

入力

COMPONENT

40

AVR-5308CI / AVC-A1HD

Page 41

E

DVR2

出力V: IC404-7pin

出力Y: IC404-1pin

出力C: IC405-1pin

出力Y: IC403-1pin

出力C: IC403-7pin

本体-MONITOR間のケーブル

もしくはMONITOR確認

VCR

出力V:

出力Y:

出力C:

IC401-7pin

IC401-1pin

IC402-1pin

DVR1

出力V:

E

入力セレクタ:OKIC414,IC417,IC420

ビデオアンプ: IC436,IC437

出力セレクタ:

IC429

OK

IC402-7pin

出力段AMPの出力確認

NG

出力V:

OK

NG

本体-MONITOR間のケーブル

もしくはMONITOR確認

入力 CVBS/S

VA±5,SCPU+5Vの確認

入力 CVBS/S

VA±5,SCPU+5Vの確認

NG

VA+5: CX902-8,9pin

μCOMUNITの不具合

NG

入力セレクタ:

1.1電源異常時の

トラブルシューティングへ

入力セレクタ及び初段ビデオアンプ、

出力セレクタ及びそれらの

周辺回路のハンダ付け確認

H(+5V)V:CW171-7pin:

IC414,IC417,IC420

OK

ビデオアンプ:

CX902-4,5pin

SCPU+5V CX902-1pin

Y:CW171-8pin:

出力段AMPの出力確認 NG

IC408-1pin

VA-5:

シグナルDETの確認

IC436,IC437

出力セレクタ:

IC429

H(+5V)

入力セレクタ及び初段ビデオアンプ、

出力セレクタ及びそれらの

周辺回路のハンダ付け確認

VA+5:

F

CX902-8,9pin

1.1電源異常時の

トラブルシューティングへ

CX902-1pin

OK

VA-5: CX902-4,5pin

SCPU+5V

Input

CVBS/S

Check VA±5䋬SCPU+5V

CX902-8,9pin

VA+5:

VA-5:

CX902-4,5pin

SCPU+5V

CX902-1pin

NG

To troubleshooting 1.1

Power not turn on.

OK

Check output of AMP

Output V:

IC408-1pin

OK

Check cable between main unit and

monitor or Check monitor.

F

Check signal DET

NG

V:CW171-7pin:

Y:CW171-8pin:

OK

μCOM UNIT flaw

H(+5V)

H(+5V)

Check soldering of input selector and

NG

Video AMP, output selector and

surrunding circuitory.

Input selector: IC414,IC417,IC420

Video AMP: IC436,IC437

Outputselector:

IC429

Input

CVBS/S

Check VA±5䋬SCPU+5V

VA+5: CX902-8,9pin

VA-5: CX902-4,5pin

NG

To troubleshooting 1.1

Power not turn on.

SCPU+5V CX902-1pin

VCR

DVR1

DVR2

Check cable between main unit and

monitor or Check monitor.

※ Unless specified, 1U-3822 A.VIDEO UNIT part.

OK

Check output of AMP

Output V: IC401-7pin

Output Y:

Output C: IC402-1pin

Output V:

IC401-1pin

IC402-7pin

Output Y: IC403-1pin

Output C: IC403-7pin

Output V: IC404-7pin

Output Y: IC404-1pin

Output C: IC405-1pin

OK

Check soldering of Input selector and

NG

Video AMP, output selector and

surrunding circuitory.

Input selector: IC414,IC417,IC420

Video AMP: IC436,IC437

Outputselector:

IC429

※ 特に記載がない場合は 1U-3822A.VIDEOUNITの部品です。

41

AVR-5308CI / AVC-A1HD

Page 42

3. HDMI/DVI

3.1. No picture or sound is output

3. HDMI/DVI

3.1. 映像と音声が出力されない

No picture or sound is output

YES

Check the HDMI/DVI cable connection

YES

Is the HDMI/DVI cable properly

connected?

YES

Are you using an HDMI/DVI selector,

repeater or a device for improving picture

quality?

NO

Are you using a certified HDMI cable (one

with the HDMI stamp)?

YES

Are you using an HDMI/DVI cable less

than 5 meters in length?

YES

Are the picture and sound output when

another HDMI/DVI cable is used?

NO

Checking the DVD player

YES

Is the DVD player's HDMI output setting

correct?

There may be a problem with the HDMI/

NO

DVI cable. Check the connection.

Disconnect everything and connect only

YES

the HDMI/DVI cable to check.

Use a certified HDMI cable (one with the

NO

HDMI stamp).

Replace the HDMI/DVI cable with one

NO

that is less than 5 meters in length (2

meters recommended) to check.

YES

The HDMI/DVI cable is defective.

Check the HDMI output setting, referring

YES

to the DVD player's operating

instructions.

映像と音声が出力されない

YES

HDMI/DVIケーブルの接続を確認する

YES

HDMI/DVI ケーブルは正しく接続され

ていますか?

YES

HDMI/DVI セレクター、リピーターや

画質改善装置を使用していますか?

NO

HDMI 認証品(HDMI 刻印がある)の

HDMI ケーブルを使用していますか?

YES

HDMI/DVI ケーブルは 5m 以下のもの

を使用していますか?

YES

別のHDMI/DVI ケーブルに交換すると

画像と音声が出力されますか?

NO

DVD プレーヤーを確認する

YES

DVD プレーヤーの HDMI 出力設定は

正しいですか?

YES

HDMI/DVI ケーブルは勘合がよくない

NO

ことがあります。接続を確認してくだ

さい。

YES

すべて取り外して HDMI/DVI ケーブル

のみを接続して確認してください。

NO

HDMI ケーブルは HDMI 認証品(HDMI

刻印がある)を使用してください。

HDMI/DVI ケーブルを 5m 以下 ( 推奨

NO

は2 m) に交換して確認してくださ

い。

YES

HDMI/DVI ケーブルが不良です。

DVD プレーヤーの取扱説明書を見て

NO

HDMI 出力を正しく設定してくださ

い。

YES

When using a DENON DVD player, is the fluorescent display tube's

"HDMI" indicator lit?

If using a non-DENON DVD player, proceed to "YES".

YES

NO

Is sound output from the set's speaker terminals when the TV's power is

turned off or the connection cable between the TV and the set is

disconnected?

Are the picture and sound output when

the DVD player's resolution is changed?

NO

NO

Are the picture and sound output when a

different DVD player is used?

NO

Set the DVD player's output resolution

YES

to a resolution with which the TV is

compatible.

The DVD player may not be compatible

YES

with HDCP repeaters. Ask the DVD

player's manufacturer.

YES

The DVD player is defective.

DENON の DVDプレーヤーを使用している場合、FL 管の "HDMI" インジ

ケータが点灯していますか?

他社の DVDプレーヤーを使用している場合は "YES" に進んでください。

NO

TV の電源を切った時や TV と本機間の接続ケーブルをはずした時に、本機

のスピーカー端子から音声を出力しますか?

42

AVR-5308CI / AVC-A1HD

YES

DVDプレーヤーの解像度を変えて画

像と音声が出力されますか?

NO

NO

別の DVDプレーヤーに交換すると画

像と音声が出力されますか?

NO

DVDプレーヤーの出力解像度を、TV

YES

の対応可能な解像度に設定してくだ

さい。

DVDプレーヤーが HDCP リピーター

YES

に対応していない可能性があります。

DVDプレーヤーのメーカーに確認し

てください。

YES

DVDプレーヤーが不良です。

Page 43

Check the TV

TV を確認する

Is the TV HDCP-compatible?

YES

Is the TV compatible with resolutions of 1080P?

YES

Is the TV's input set to HDMI?

YES

Are the picture and sound output when a different TV is used?

YES

Check the set (AVP-A1HDCI/AVP-A1HD)

Is the set's input set to HDMI?

YES

Is the TV information

properly displayed on

the "Monitor info."

display menu?

The set does not recognize the TV.

Is IC333 or IC363 pin 51 on 1U-3833 "H"

NO

(3V-5V)? With the TV connected, check

the voltage of the IC on the side on which

the TV is connected.

Use an HDCP-compatible TV. PC TVs

NO

cannot be used.

If the TV is not compatible with

resolutions of 1080P, no picture will be

NO

output, even if the DVD player's

resolution is set to 1080P.

Check the TV's input setting, referring to

NO

the TV's operating instructions.

NO

The TV is defective.

Check the set's input setting, referring to

NO

the set's operating instructions.

The pattern and circuit from the HDMI

NO

connector (JK331 or JK332) to the IC

(IC333 or IC363) is defective.

TV は HDCP に対応していますか?

YES

TV は 1080P に対応していますか?

YES

TV の入力設定が HDMI 入力になっていますか?

YES

別の TV に交換すると画像と音声が出力されますか?

YES

本機を確認する

本機の入力設定が HDMI 入力になっていますか?

YES

本機が TV を認識していません

Monitorinfo. 表示メニュー

で TV の情報が正しく表示さ

れていますか?

1U-3833のIC333またはIC363の51pin

NO

が "H"(3V-5V) となっていますか?

TV を接続している状態で、TV を接続

している側の IC の電圧を確認してく

ださい。

HDCP に対応している TV を使用して

NO

ください。PC 用の TV は使用できませ

ん。

TV が 1080P に対応していない場合、

NO

DVD プレーヤーを 1080P に設定して

も、画像は出力されません。

NO

TV の取扱説明書を見て入力設定を確

認してください。

NO

TV が不良です。

NO

本機の取扱説明書を見て入力設定を

確認してください。

HDMI コネクター(JK331 または

NO

JK332) から IC(IC333 または IC363) ま

でのパターンおよび回路が不良です。

YES YES

Does the set's wallpaper image appear on the TV when the HDMI/DVI

cable between the DVD player and the set is disconnected?

YES

When using a

DENON DVD player,

is the fluorescent

display tube's "HDMI"

indicator lit?

If using a nonDENON DVD player,

proceed to "NO".

YES YES

The HDMI output circuitry is defective.

(IC101/IC131/IC151/IC201 and surrounding circuitry)

The DVD player does not recognize the

connection with the set.

Is the HDMI connector (JK101/JK102/

NO

JK103/JK104/JK105/JK106) pin 19 on

1U-3833 "H" (5V)? With the DVD player

connected, check the voltage of the HDMI

connector for the input on the side on

which the DVD player is connected.

Are the picture and sound output from

NO

other Monitor Out terminals (VIDEO out,

S-VIDEO out or Component out)?

The pattern and circuit from the HDMI

connector (JK101/JK102/JK103/

NO

JK104/JK105/JK106) to the IC151 is

defective.

NO

The HDMI output

circuitry is

defective.

YES

(IC333/IC363/IC301

and surrounding

circuitry)

YES YES

DVD プレーヤーと本機間の HDMI/DVI ケーブルを取り外した時、TV に本

機の壁紙の画像が表示されますか?

YES

DVD プレーヤーが本機との接続を認

DENON の DVD プレーヤー

を使用している場合、FL 管

の"HDMI"インジケータが点

灯していますか?

他社の DVD プレーヤーを使

用している場合は "NO" に進

んでください。

YES YES

HDMI 入力系の回路が不良です。

(IC101/IC131/IC151/IC201 周辺回路 )

識していません

1U-3833 の HDMI コネクター

(JK101/JK102/JK103/JK104/JK105/

NO

JK106) の 19pin が "H"(5V) となってい

ますか?

DVD プレーヤーを接続している状態

で、DVD プレーヤーを接続している

入力の HDMIコネクターの電圧を確

認してください。

他の MonitorOut(VIDEOout/S-VIDEO

NO

out/Componentout) からは出力され

ますか?

HDMI コネ クター (JK101/JK102/

NO

JK103/JK104/JK105/JK106) か ら

IC151までのパターンおよび回路が不

良です。

NO

HDMI出力系の回路が

YES

不良です。

(IC333/IC363/IC301

周辺回路 )

43

AVR-5308CI / AVC-A1HD

Page 44

4. Network/USB

4.1. Cannot connect to network

4. ネットワーク /USB

4.1. ネットワークに接続できない

For a wired LAN For a wireless LAN

Is the LAN cable properly connected?

YES

Check the LAN cable properly

NO

then turn the power back on.

Checking the environment

Is a LAN cable connected?

Is the wireless LAN antenna

connected?

Is the channel of the wireless

LAN you are attempting to connect to independent from the

channels of other wireless

LANs?

Can other devices (computers,

etc.) be connected to the network in the location where the

AVP-A1HDCI/AVP-A1HD is

installed?

NO

YES

YES

Disconnect the LAN cable then

turn the power back on. Do not

YES

connect a LAN cable when

connecting to a wireless LAN.

Connect the included wireless

NO

LAN antenna to the back panel.

Set the channel of the wireless

LAN to which you are attempt-

NO

ing to connect so that it is not

redundant with the channels of

other wireless LANs.

Check the signal conditions

(strength). If the signal is weak,

try installing the AVP-A1HDCI/

NO

AVP-A1HD in a place where it

is strong, changing the position

of the router, installing an

access point, etc.

有線 LAN の場合 無線 LAN の場合

LANケーブルは正しく接続され

ていますか?

YES

NO

LAN ケーブルを正しく接続し、

電源を入れ直して下さい。

ネットワーク環境の確認

LANケーブルが接続されていま

せんか?

無線LANアンテナは接続されて

いますか?

接続しようとしている無線の

チャンネルが他の無線ネット

ワークから独立しています

か?

本機の設置場所で、他の機器

(PC 等 ) がネットワークに接続

できますか?

NO

YES

YES

LAN ケーブルを抜き、電源を入

れ直して下さい。

YES

無線LANネットワークに接続す

る場合は、LAN ケーブルを接続

しないで下さい。

NO

付属の無線LANアンテナをバッ

クパネルに接続して下さい

接続しようとしている無線LAN

ネットワークのチャンネルを、

NO

他の無線 LAN ネットワークの

チャンネルと重複しないよう

に設定して下さい。

無線の電波状況 ( 強度 ) を確認

して下さい。電波が弱い場合

NO

は、電波の強い位置に本機を設

置するか、ルータの位置を変え

るか、アクセスポイントを設置

するなどして下さい。

Are the AVP-A1HDCI/AVP-A1HD's network settings correct?

YES

Are the router, hub and other peripherals properly connected?

YES

Are the router's settings correct?

YES

Checking the settings

Set the IP address and other parameters properly. For a fixed IP setting,

check whether the IP address is redundant with that of other devices,

NO

and check whether the subnet mask setting is correct. For a wireless

LAN, also check the SSID and security settings.

NO

Connect properly to peripherals.

Check the router's operating instructions and set properly. Check

NO

whether there are connection restrictions due to the MAC address, etc.

YES

本機のネットワークの設定は正しいですか?

YES

ルータ、ハブ等の周辺機器の接続は正しいですか?

YES

ルータの設定は正しいですか?

YES

ネットワーク設定の確認

IP アドレス等を正しく設定して下さい。

NO

固定 IP 設定の場合、IP アドレスが他の機器と重複していないか、サブ

ネットマスクの設定が正しいかを確認してください。

無線 LAN の場合、SSID、セキュリティの設定も確認して下さい。

NO

周辺機器と正しく接続してください。

NO

ルーターの取扱説明書を見て正しく設定して下さい。

MAC アドレス等による接続制限がされていないかを確認ください。

YES

44

AVR-5308CI / AVC-A1HD

Page 45

Checking the set (AVP-A1HDCI/AVP-A1HD)

本機の確認

Can you connect to the network by wireless LAN?

NO

Is a voltage being outputted between CX715 pins 1-30(GND) to 3160(3.3V)?

Is the IC406 output voltage (1.9V) being outputted?

The circuit from IC101 to

YES

JK101 is defective.

YES

NO

Is the wireless LAN module

properly connected?

YES

Is the antenna cable connected

to the wireless LAN module?

YES

Can you connect with a different wireless LAN module?

NO

Can you connect to the network by wired LAN?

The circuit from AC inlet to CX715 or 3.3V device circuitry is defec-

NO

tive.

NO

The IC406 periphery or IC105 periphery circuitry is defective.

Connect the wireless LAN

NO

module properly into CX124.

Connect the antenna cable to

NO

J1 on the wireless LAN module.

The wireless LAN module is

YES

defective.

The circuit of CX124 is defec-

YES

tive.

無線LANでネットワークに接続

できますか?

NO

CX715 の 1 〜 30 ピン (GND)-31 〜 60 ピン (3.3V) 間に電圧は出力され

ていますか?

IC406 の出力電圧 (1.9V) は出力されていますか?

YES

IC101 から JK101 までの回路が

不良です。

YES

NO

無線LANモジュールは正しく接

続されていますか?

YES

無線LANモジュールにアンテナ

ケーブルが接続されています

か?

YES

無線LANモジュールを交換して

接続できますか?

NO

有線LANでネットワークに接続

できますか?

NO

AC インレットから CX715 までの回路、もしくは 3.3V 系デバイスの回

路が不良です。

NO

IC406 周辺もしくは IC105 周辺の回路が不良です。

NO

無線 LAN モジュールを CX124

に正しく接続して下さい。

アンテナケーブルを無線LANモ

NO

ジュールの J1 に接続してくだ

さい。

YES

無線 LAN モジュールが不良で

す。

YES

CX124 周辺の回路が不良です。

YES

Is the wire properly connected between CX974 and CY974?

YES

Is operation normal when the 1U-3819 circuit board is replaced?

YES

The 1U-3821-1 circuit board may be defective.

NO

Connect the wire properly.

NO

The ETHERNET circuitry is defective.

YES

CX974-CY974 間のワイヤは正しく接続されていますか?

YES

1U-3819 基板を交換して正しく動作しますか?

YES

1U-3821-1 基板が不良の可能性があります。

NO

正しく接続して下さい。

NO

ETHERNET 回路が不良です。

45

AVR-5308CI / AVC-A1HD

Page 46

4.2. USB device is not recognized

4.2. USB を接続しても認識されない

Are the USB port settings correct?

YES

Are you using a USB hub?

NO

Is the USB device compatible with the set?

YES

Checking the set (AVP-A1HDCI/AVP-A1HD)

Is the wire properly connected between CX530 and CY530?

Checking the settings

NO

Set the front and rear properly.

Checking the USB device

YES

You do not use the USB hub.

Only mass storage devices in FAT16 or FAT32 formats or MTP-compat-

NO

ible devices are supported.

NO

Connect the wire properly.

USB ポートは正しく設定されていますか?

YES

USB ハブを使用していますか?

NO

USB デバイスは本機に対応可能ですか?

YES

CX530-CY530 間のワイヤーは正しく接続されていますか?

設定の確認

NO

使用している USB 機器の確認

YES

USB ハブは使用しないで下さい。

NO

FAT16 もしくは FAT32 でフォーマットされたマスストレージクラ

ス、もしくは MTP 対応デバイスのみサポートしています。

本機の確認

NO

ワイヤーを正しく接続してください。

Front/Rear を正しく設定して下さい。

YES

Is a voltage (5V) being supplied between pins 1 and 4 of JK102 (back

panel USB connector) and JK903 on the 1U-3822-6 circuit board (front

panel USB connector)?

YES

Is the USB device not recognized for both the front and rear connectors?

NO

YES

Is the IC102 pin 15 output level "L"?

YES

The circuit from IC105 to IC102 is defective.

NO

The IC410 periphery circuitry is defective.

Rear is not recognized

NO

The circuit from IC102 to JK102 is defective.

Front is not recognized

The circuitry from IC102 to JK903 on the 1U-3822-6 circuit board is

defective.

The circuitry from IC905 on the 1U-3821-1 circuit board to IC102 on

NO

the 1U-3819 circuit board is defective.

YES

JK102( バックパネル USB コネクタ ),1U-3822-6 基板の JK903( フロント

パネル USB コネクタ ) の 1 ピン -4 ピン間の電圧 (5V) は供給されていま

すか ?

YES

Front/Rear 共に認識されない状態ですか ?

YES

IC102 の 15 ピンの出力レベルは L になっていますか ?

YES

IC105 から IC102 までの回路が不良です。

NO

NO

IC410 周辺の回路が不良です。

Rear が認識されない

NO

IC102 から JK102 までの回路が不良です。

Front が認識されない

IC102 から 1U-3822-6 基板の JK903 までの回路が不良です。

NO

1U-3821-1 基板の IC905 から 1U-3819 基板の IC102 までの回路が不良

です。

46

AVR-5308CI / AVC-A1HD

Page 47

4.3. No picture or sound is output

4.3. 映像と音声が出力されない

Checking the set (AVP-A1HDCI/AVP-A1HD):(If no picture is output)

Is the wire properly connected CX714 to CW714?

YES

Are video signals output from CX714 pin 16 (Y) and pin 15 (C)?

YES

Check the analog video circuit.

Checking the set (AVP-A1HDCI/AVP-A1HD):(If no sound is output)

Are S/PDIF signals output from IC105 pin 39?

YES

Check the Digital audio circuit.

NO

Connect the wire properly.

NO

The circuit from IC105 to IC404 is defective.

NO

The IC105 is defective.

本機の確認 ( 映像が出力されない場合 )

CX714-CW714 は正しく接続されていますか?

YES

CX714 の 16 ピン (Y)15 ピン (C) からビデオ信号は出ていますか?

YES

アナログビデオ回路を確認して下さい。

本機の確認 ( 音声が出力されない場合 )

IC105 の 39 ピンから S/PDIF 信号が出力されていますか?

YES

デジタルオーディオ回路を確認して下さい。

NO

正しく接続してください。

NO

IC105 から IC404 までの回路が不良です。

NO

IC105 の周辺回路が不良です。

47

AVR-5308CI / AVC-A1HD

Page 48

5. Power AMP (1U-3827)

5. パワーアンプ (1U-3827)

No sound is output

The protector operates.

YES

Is the power transistor open or short

circuit?

MN1715

MP1715

NO

Is the emitter resistance of the power