Page 1

Delta Dual V4/V6 (DMS-217/079)

Installation Instructions

For Ground Water Applications

01992 523523

T.

info@deltamembranes.com

E.

www.deltamembranes.com

W.

Page 2

Delta Dual V4/V6

Legal information/Copyright

All rights reserved. Contents provided herein must neither be distributed, copied, reproduced, edited or

processed for any other purpose, nor otherwise transmitted, published or made available to a third party

without express written consent from Delta Membranes.

Subject to technical modication without prior notice.

© Delta Membranes 2015

DDV4V6-M-V1-12.15

Page 3

Delta Dual V4/V6

Contents

1.0 Dual V4/V6 Overview 4

2.0 Parts Included 4

2.1 Optional Extras 4

3.0 Discharge Pipework & Fittings 5

4.0 Chamber Overview 6

5.0 Spare Parts 6

6.0 Technical Information 7

7.0 Pump Chamber Depth Limits 8

8.0 Installation Guidelines 9

9.0 Pump Station Location 9

10.0 RC Box Dimensions 9

11.0 Installation of Chamber 10

Section A - Construction of reinforced concrete box 10

Section B1 - Connecting 110mm pipework 11

Section B2 - Connecting perimeter channel to chamber 12

Section B3 - Connecting perimeter channel via a 1.5"/40mm inlet pipe 13

Section C - Connecting discharge and cable duct 14

Section D1 - Backll around chamber with concrete (RC Box) 16

Section D2 - Backll around chamber with concrete (Ground) 17

Section D3 - Backll around chamber with concrete (Reinforced cage) 18

Section E - Installing pumps and high level alarm in chamber 19

12.0 Wiring Diagram 22

13.0 Maintenance 23

14.0 Health and Safety 23

15.0 Guarantee 23

16.0 Troubleshooting 24

17.0 Self Commissioning 25

18.0 Notes 27

For technical support, please call 01279 757400 3

Page 4

Delta Dual V4/V6

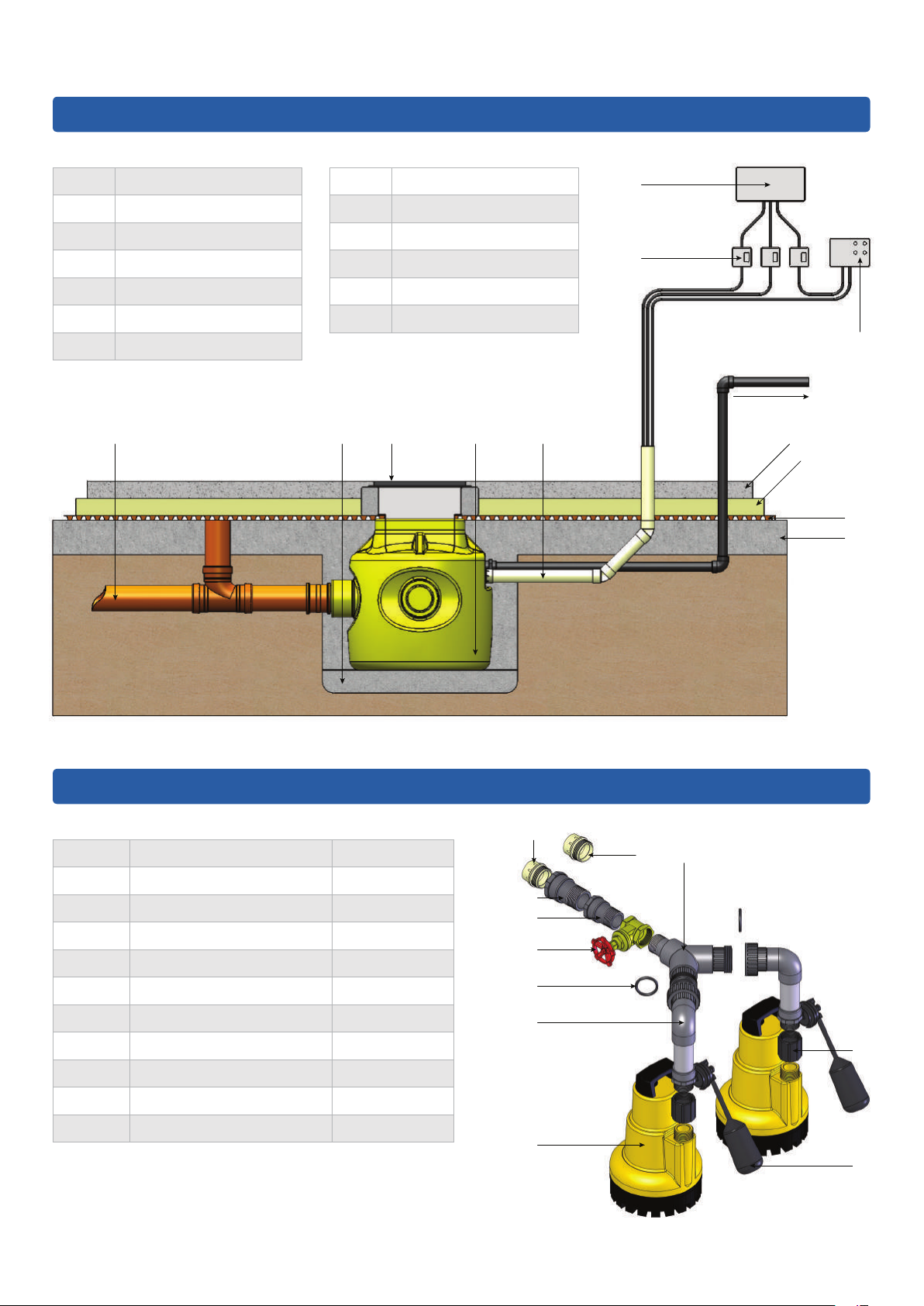

1.0 Dual V4/V6 Overview

The Delta Dual V4/V6 is a packaged pump station designed to collect ground water via perimeter channel or Delta

129 detail and/or clear opening to the top of the chamber - please visit our website for water collection details.

Typically, the Dual V4/V6 would be used to collect ground water from a basement up to 150m² and/or surface water

from a light well up to 12m² to a maximum head of 7m and 9m respectively.

The pump station has been specically designed for below ground applications. The chamber is manufactured from

HDPE and when installed correctly, it is able to withstand hydrostatic forces encountered in high water tables.

The pump station is delivered as a complete package including, the chamber, internal pipework and two powerful

V4/V6 pumps. It is designed to be installed by contractors with competent building, plumbing and electrical skills.

The pumps operate by xed arm oats, the duty pump is set at a standard height (210mm to base of oat) and the

backup pump is set at a high level (380mm to base of oat). The high level alarm (where tted) will operate if the duty

pump fails leaving the backup pump to discharge water.

A high level alarm (DMS-270) is oered as a recommended extra to alert the property occupant when the water level

in the chamber becomes too high. A battery backup (DMS-320) is recommended to power the pumps during power

outage. Please see section 2.1 for more details about optional extras designed for the Dual V4/V6 pump station.

2.0 Parts Included

Chamber - 660 diameter

(902 across spigots) x

800mm deep

2.1 Optional Extras

1.25” Internal Pipework

2 x V4/V6 Pumps 2” Discharge Male Iron

for temp. site installation.

2" Cable Duct Male Iron

AlertMaxx High Level

Alarm (DMS-270)

4 For technical support, please call 01279 757400

Power Plus Battery

Backup (DMS-320)

2" Discharge Pipework

and various ttings

Page 5

Delta Dual V4/V6

3.0 Discharge Pipework & Fittings

A selection of discharge pipework and ttings are available for the Dual V4/V6 pump station.

Should you require to place an order for any of these items, please complete the form below, scan and email to

purchasing@deltamembranes.com to allow us to process your order.

Part Description Part No. Qty Req.

2" Pipe - 3m Length (Class E) DMS-0154

2" 90° Elbow - Plain/Plain DMS-0155

2" 45° Elbow - Plain/Plain DMS-0156

2" Socket - Plain/Plain DMS-0157

2" Socket - BSP Mail Thread/BSP Male Thread DMS-0339

2" Male Iron - Plain/BSP Male Thread DMS-0153

2" Male Iron - Plain/BSP Male Thread (Non-pressure) DMS-335

110mm to 2" Adaptor DMS-341

Saddle Clamp - 110mm to 2" (BSP Female Thread) including 1.25" Male Iron DMS-0151

Saddle Clamp - 160mm to 2" (BSP Female Thread) including 1.25" Male Iron DMS-0152

2" Pipe Clip DMS-059

500ml PVC Solvent Cement DMS-0158

Name:

Company Name:

Property Address:

Email:

Phone No.: Mobile No.:

Sign: Date:

5

Please scan this order form and email to the purchasing@deltamembranes.com

Page 6

Delta Dual V4/V6

4.0 Chamber Overview

Part Description

A

B

C

D

E

F

A C E

Inlet Pipe

Concrete Base

Inspection Cover

Pump Chamber

Cable Duct

Fused Spur

G

H

I

J

K

L

B D

Distribution Board

High Level Alarm Box

Screed

Insulation

MS20

Basement Slab

G

F

H

TO SEWER

I

J

K

L

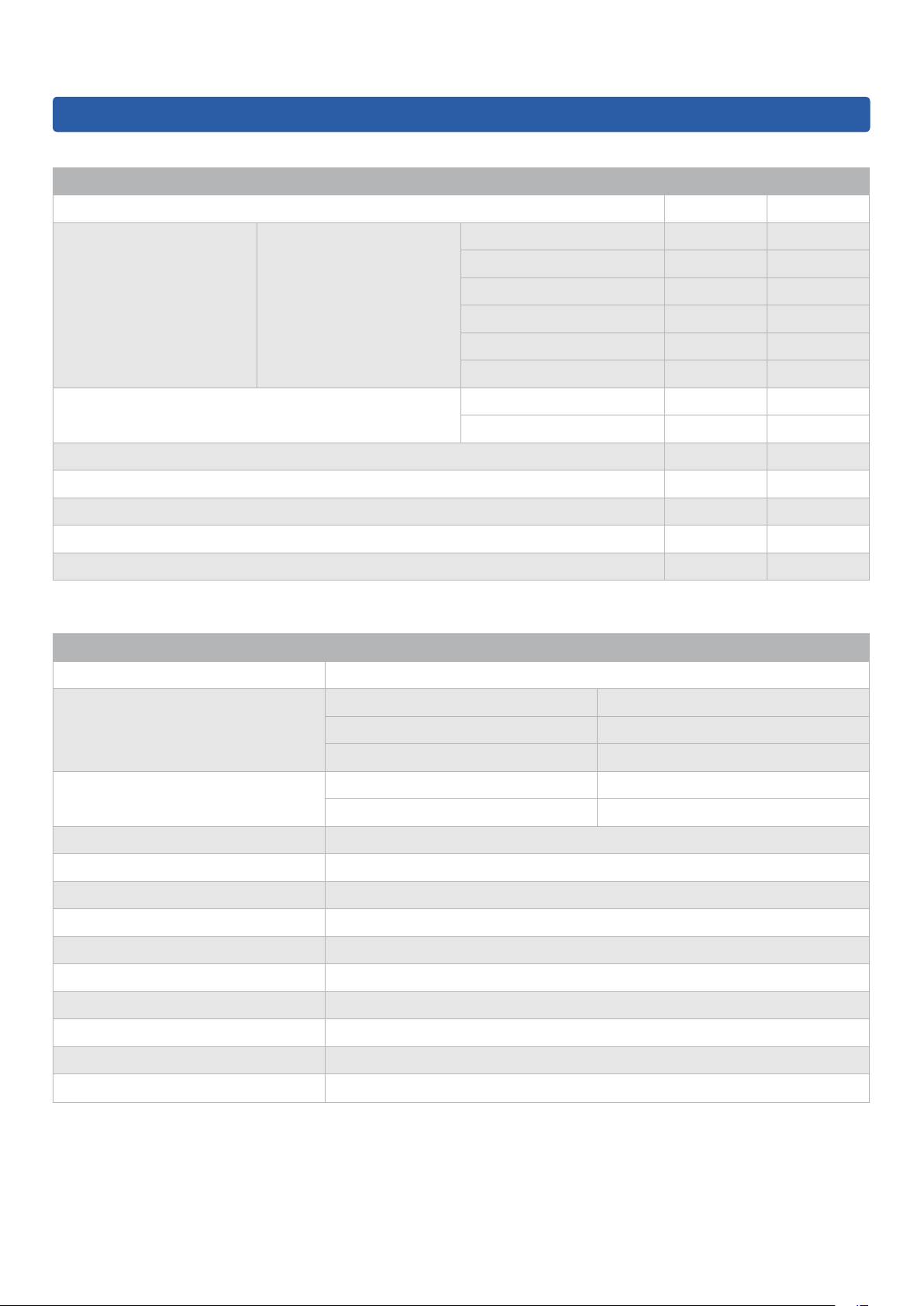

5.0 Spare Parts

Part Description Part No.

1

1.1

1.2

2

3

4

5

6

7

8

V4/V6 Pump c/w 1.1 & 1.2 DMS-216/084

Float & Switch Assembly DMS-344

Non-return Valve DMS-328

Discharge Arm DMS-326

‘O’ Ring DMS-132

1.25” Brass Gate Valve DMS-329

Connector Piece DMS-338

Connector Adaptor DMS-337

2” Non-pressure Male Iron DMS-335

Y-piece c/w 2 ’O’ rings DMS-321

7

6

5

4

3

2

1

7

8

1.2

1.1

6 For technical support, please call 01279 757400

Page 7

Delta Dual V4/V6

6.0 Technical Information

Pump Specication

Pump Type V4 V6

Typical Duty (I/s) Head (m)

Power P

Current (a)

Power Phase

Fuse Spur Rating (a)

Max. Temperature (°C)

Weight (kg)

Chamber Specication

Chamber Material

High Density Polyethnylene - ICO1314 grade

3

3.5

4

4.5

5

6

(kW)

1

P2 (kW)

3.25 3.75

3.10 3.60

3.00 3.50

2.90 3.40

2.75 3.30

2.40 3.00

0.75 1.05

0.35 0.50

4.00 4.90

Single Single

13 13

50 50

7.17 7.40

Size (mm) Chamber Diameter

Overall Diameter

Depth

Volume (L) Below Inlet

Total

Inspection Cover

Clear opening to chamber (mm)

Fixed Inlets

Cable Duct (mm)

Vent

Discharge Connection

Internal Pipework Manifold

RCBO Rating (a)

Cable Length (m)

Non-switched Fuse Spur Rating (a)

2" / 50mm BSP Female - External to chamber

660

902 (across spigots)

800

137

273

Not supplied

310 x 310

3 x 110 / 160mm

50

N/A

1.25" / 32mm BSP Class C

16

10

13

For technical support, please call 01279 757400 7

Page 8

Delta Dual V4/V6

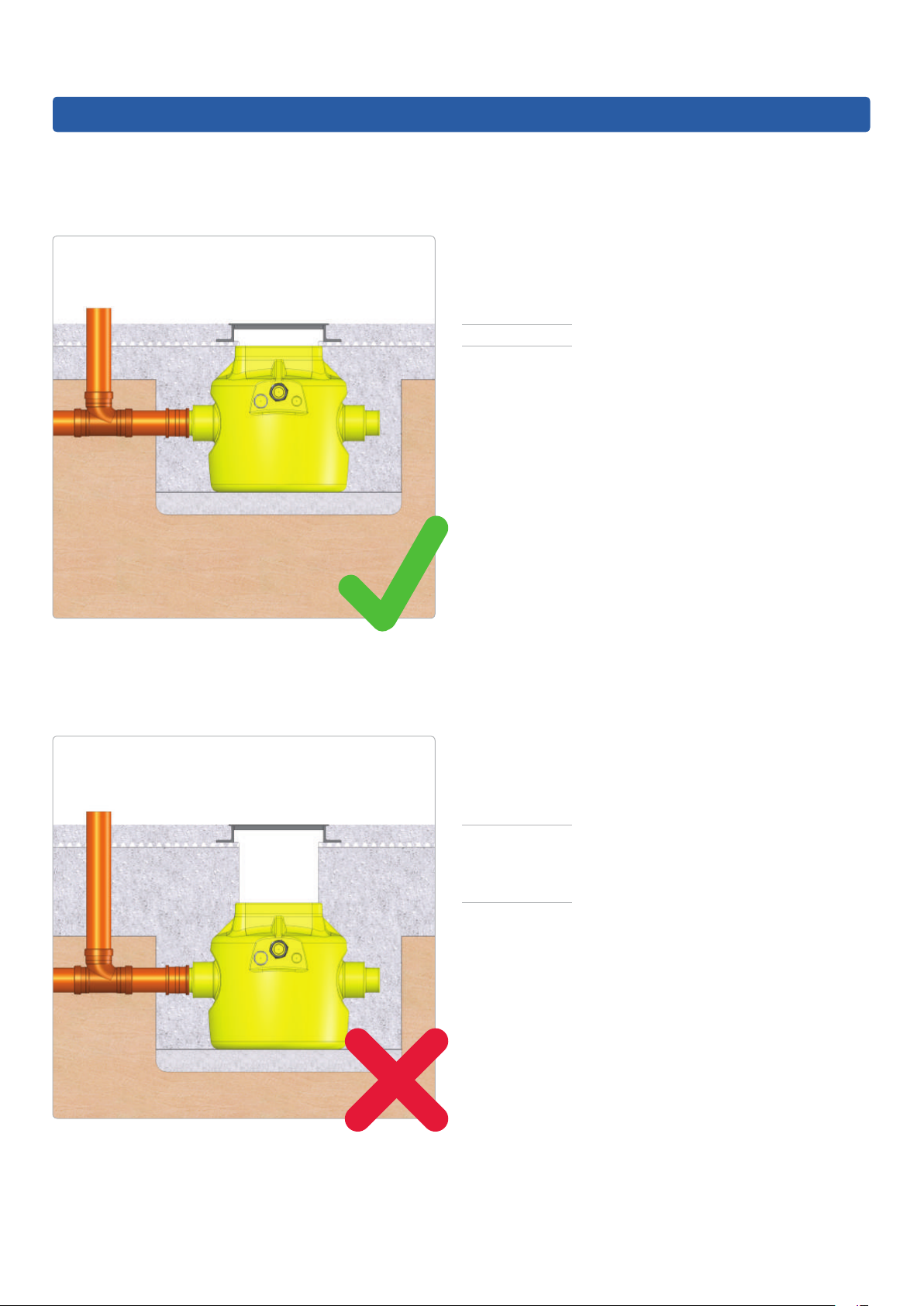

7.0 Pump Chamber Depth Limits

If the inlet does not allow the pump chamber to be within depth limits, please contact PPS on 01279 757400 to

discuss chamber options.

< 500mm

The pump chamber must be installed no more than

500mm below oor nishes.

> 500mm

A pump chamber installed more than 500mm below

oor nishes cannot be serviced safely in accordance

with CDM regulations.

8 For technical support, please call 01279 757400

Page 9

Delta Dual V4/V6

8.0 Installation Guidelines

The following instructions are for guidance only and it is the contractor's responsibility to ensure that the

installation is in accordance with the prevailing ground conditions and good building practice, to eliminate any

potential damage to the pump station either during or after installation.

Please read these instructions carefully prior to installing the chamber. If there is anything that is unclear, our technical

help desk is available on 01279 757400.

9.0 Pump Station Location

This station requires routine maintenance, therefore it is important that careful consideration is taken to position the

chamber in a location that allows permanent access to the chamber.

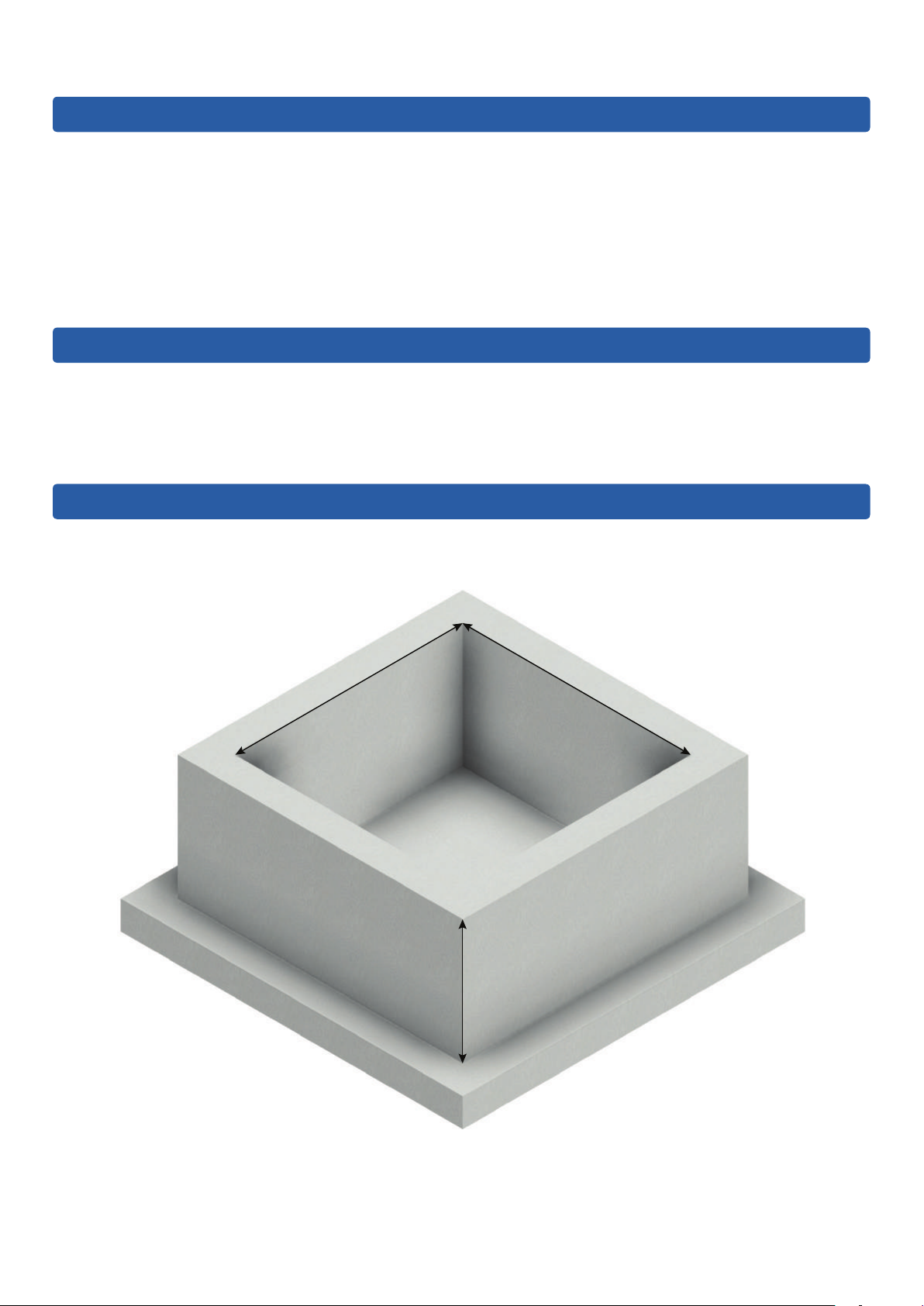

10.0 RC Box Dimensions

1200mm

1200mm

800mm

For technical support, please call 01279 757400 9

Page 10

Delta Dual V4/V6

11.0 Installation of Chamber - Section A

Construction of reinforced concrete box

1

Excavate hole for chamber. Refer to section 10.0 for

RC box internal dimensions.

2

Install re-bar as per structural engineer's drawings.

3

Lay inlet and discharge pipework. Allow pipework to

protrude into RC box by a minimum of 100mm.

4

Pour concrete to form RC box as per structural

engineer's drawings.

10 For technical support, please call 01279 757400

Page 11

11.0 Installation of Chamber - Section B1

Connecting 110mm pipework

Delta Dual V4/V6

5

Saw o socket end/s, where inlet pipe/s are to

be connected.

6

Position chamber in RC box.

7

Fit push t coupler.

8

Connect inlet pipework to the required chamber spigot.

For technical support, please call 01279 757400 11

Page 12

Delta Dual V4/V6

11.0 Installation of Chamber - Section B2

Connecting perimeter channel to chamber

To be followed when installing perimeter channel directly into upper side of chamber.

9

Mark perimeter channel position on side of chamber.

10

Drill holes in the corners inside the area marked in red.

11

Cut around the marked line outlining the perimeter

channel using a jigsaw.

12

Insert the perimeter channel into the chamber allowing

35mm of overhang inside the chamber.

12 For technical support, please call 01279 757400

Page 13

11.0 Installation of Chamber - Section B3

Connecting perimeter channel via a 1.5"/40mm inlet pipe

Delta Dual V4/V6

13

Mark position of the 40mm pipe on the side of

the chamber and cut out the marked line using a

1.5"/40mm holesaw.

14

Cut 40mm pipe to length allowing an overhang of

35mm inside the chamber.

15

Saw o 110mm socket end/s to be used.

16

Attach a DMS-341 adaptor to the 40mm pipe and

connect the adaptor to the chamber via a 110mm

push t coupler.

For technical support, please call 01279 757400 13

Page 14

Delta Dual V4/V6

11.0 Installation of Chamber - Section C

Connecting discharge and cable duct

17

Wrap the thread on a DMS-0153 high pressure

male iron with PTFE tape.

18

Screw the high pressure male iron into the female iron.

19

Apply DMS-0158 high pressure glue around the rst

20mm of the external face of the discharge and cable

duct pipe and internal side of their respective male iron.

20

Push discharge and cable duct pipe into their

respective male iron, twisting the pipe as it is pushed

into the male iron to remove any trapped air.

14 For technical support, please call 01279 757400

Page 15

11.0 Installation of Chamber - Section C cont.

Connecting discharge and cable duct

21

Delta Dual V4/V6

Ensure a draw cord is pulled through the cable duct as

the cable duct is built.

For technical support, please call 01279 757400 15

Page 16

Delta Dual V4/V6

11.0 Installation of Chamber - Section D1

Backll around chamber with concrete

To be followed when installing chamber in an RC box.

22

Check all pipes are connected to the chamber

correctly.

23

Completely ll chamber with water.

24

Fill void between RC box and chamber with concrete

(min. C35 grade) or as per engineer's drawings.

16 For technical support, please call 01279 757400

Page 17

11.0 Installation of Chamber - Section D2

Backll around chamber with concrete

To be followed when installing chamber in the ground.

Delta Dual V4/V6

25

Completely ll chamber with water.

26

Fill void between soil and chamber with concrete

(min. C35 grade) or as per engineer's drawings.

27

Allow concrete to cure.

For technical support, please call 01279 757400 17

Page 18

Delta Dual V4/V6

11.0 Installation of Chamber - Section D3

Backll around chamber with concrete

To be followed when installing chamber in the ground with a reinforced cage.

28

Completely ll chamber with water.

29

Fill void between soil and chamber with concrete

(min. C35 grade) or as per engineer's drawings.

30

Allow concrete to cure.

18 For technical support, please call 01279 757400

Page 19

11.0 Installation of Chamber - Section E

Installing pumps and high level alarm in chamber

Delta Dual V4/V6

31

Pump out water from chamber.

32

Manually remove any debris from chamber and

residual water using a wet vac.

33

Remove discharge arms from 'Y' piece manifold and

screw 'Y' piece on to gatevalve. Ensure gatevalve is

fully open.

34

Wrap PTFE tape around thread located on male irons

at the bottom of the discharge arms and screw

discharge arms on to pumps.

For technical support, please call 01279 757400 19

Page 20

Delta Dual V4/V6

11.0 Installation of Chamber - Section E cont.

Installing pumps and high level alarm in chamber

35

Fill chamber half full with water.

36

Lower pumps in to chamber. Ensure 'O' rings are

correctly seated in unions and screw discharge arms to

'Y' piece manifold.

37

When installing a high level alarm, refer to the high

level alarm installation instructions.

38

Pull pump and high level alarm cables through cable

duct.

20 For technical support, please call 01279 757400

Page 21

11.0 Installation of Chamber - Section E cont.

Installing pumps and high level alarm in chamber

Delta Dual V4/V6

39

Isolate main supply and connect each pump and

high level alarm cable to a separate non-switched

fused spur.

40

Turn mains supply on and lift each pumps oat arm to

test water is discharging correctly.

41

To test oat switch, refer to the high level alarm

installation instructions.

42

Re-t temporary site cover to protect the pump station.

For technical support, please call 01279 757400 21

Page 22

Delta Dual V4/V6

Issue: 14/10/14.1.PPS/DPWD

12.0 Wiring Diagram

Available as part of a

and separatly.

level alarm, please see the

packaged pump chamber

High Level Alarm (DMS-270)

high level alarm instruction

manual.

For internal wiring of the high

13 Amp Non-switched fused spur

Separate 16 Amp RCBO's

fused spur

13 Amp Non-switched

L NE L NE L NE

with a 10m cable length.

- The pump and float switch is supplied

- When only using the standard 10m

Cable Length

than 6m, please follow the cable

- If the cable duct needs to be longer

appropriate cable core diameter.

cable attached to pump, the cable duct

extension guide to select an

length should be no longer than 6m.

(where fitted)

Battery Backup

22 For technical support, please call 01279 757400

Page 23

Delta Dual V4/V6

13.0 Maintenance

British Standards requires pump chambers to be serviced on a regular basis to ensure reliable operation of

equipment. PPS recommends that the pump station is serviced biannually.

PPS strongly recommends that a service agreement is taken out, please see the back page for further information.

14.0 Health and Safety

In order to minimise the risk of accidents when installing and servicing pump chambers, the following health and

safety guidelines should be followed:

• Obey all health and safety hazards.

• Observe strict cleanliness.

• Ensure power to the pump chamber is isolated before carrying out any maintenance to the pump chamber.

• Always ensure correct PPE is worn.

• All personnel working with sewage chambers must be vaccinated against diseases to which they may

be exposed to.

• A rst aid kit must be close to hand.

15.0 Guarantee

The Dual V4/V6 pump chamber comes with a 12 month component guarantee, which covers any manufacturing faults

and defects as a result of poor workmanship.

Pump chambers that have not been commissioned have a 12 month component guarantee from date of delivery.

Pump chambers that have been commissioned have a 12 month component guarantee from date of commissioning.

Any defects or malfunctions should be reported to Delta Membranes immediately to avoid any damage to other

components. All broken components must be sent to Delta Membranes at the customers cost. Any pumps to be

retuned must be returned complete with their cable attached.

We exclude all liability for any consequential or other damage or losses which may occur. We will not be liable if

the pumping system fails due to it having been incorrectly specied (e.g. where a pump is subjected to ow rates

higher than recommended or where a pump is used to discharge inappropriate uids/solids, such as building

debris or materials).

For technical support, please call 01279 757400 23

Page 24

Delta Dual V4/V6

16.0 Troubleshooting

Please ensure the installation process has been completed thoroughly and all steps have been followed correctly.

Use the table below to assist with troubleshooting and if problems still occur, please contact PPS for further technical

support on 01279 757400.

Fault Cause

Water leaking from discharge arms. 'O' rings missing or not installed correctly in unions.

PTFE tape not applied to male irons on discharge arms

when attached to pumps.

Pump isn't running. Pump hasn't got power - check wiring with reference to

section 12.0 wiring diagram.

Float arm isn't lifting - check oat arm is free moving

and not catching on chamber or other pump - make sure

pumps are positioned as diagram 36.

Float arm not turning on pump - can you hear a click

when lifted slowly? If not, call PPS for further assistance.

Pump running but not pumping water or discharging

very slow (more than 40 seconds to empty chamber.

Pump is tripping. Pump is wired incorrectly or not on a separate supply -

Gate valve isn't open or partially closed - turn valve

anticlockwise to open.

Pump is air locked - make sure there is a level of water

to the top of the pumps, remove pump from union and

lower back into water, lift oat arm to activate pump

before reconnecting to discharge arm.

Discharge pipe is blocked - a drainage company is

required.

Pump impellor is jammed - turn o power and isolate

pump, remove pump from chamber, unscrew pump base

using Torx screwdriver and free impellor.

WARNING! - Insure mains power and pump is

isolated before taking pump apart and seek advice

from a qualied electrician.

refer to section 12.0 wiring diagram.

Pump impellor is jammed - turn o power and isolate

pump, remove pump from chamber, unscrew pump base

using Torx screwdriver and free impellor.

WARNING! - Insure mains power and pump is

isolated before taking pump apart and seek advice

from a qualied electrician.

High Level Alarm not functioning. Refer to the high level alarm installation & operating

instructions.

24 For technical support, please call 01279 757400

Page 25

Delta Dual V4/V6

17.0 Self Commissioning

Name: Inspectors Name:

Property Address: Company Name & Address:

Property Contact: Company Contact:

Date complete:

Description of equipment (delete as appropriate): Delta Dual V4 / Delta Dual V6

Location of Chamber: Location of Alarm: Location of Electrics:

Pump 1 Serial Number: Pump 2 Serial Number:

Commissioning requirements Complete

Chamber is clear of silt and debris.

Check activation of oat switches by hand making sure they can operate without obstruction.

Cable joining kits (if tted) to be moved away from pumps/oats and secured.

Turn gate valve anticlockwise to ensure it is fully open.

Electrically isolate pump set to standard height (duty pump), ll chamber with water and check pump

discharges in less than 40 seconds.

While standard height pump is isolated, ll chamber with water and check the high level alarm sounds

(alarm should operate between pump 1 and pump 2).

Electrically isolate pump set to high level (backup pump), ll chamber with water and check pump

discharges in less than 40 seconds.

Check pipework is connected correctly (look for leaks).

Check all cables are securely cable tied to manifold and clear of oat switches.

Check each pump is wired to an individual 13A non-switched spur.

Check each spur is wired to an individual 16A RCBO (not RCD).

Label spurs using stickers provided.

Check power is on.

Check battery backup is switched on correctly if available (refer to manual).

Any additional comments: (further space overleaf)

Property Signature: Inspectors Signature:

Print Name: Print Name:

Date: Date:

Please scan this commissioning form and email to service@ppsgroupuk.com

Page 26

Delta Dual V4/V6

17.0 Self Commissioning

Further comments:

Please scan this commissioning form and email to service@ppsgroupuk.com

Page 27

18.0 Notes

Delta Dual V4/V6

For technical support, please call 01279 757400 27

Page 28

After Sales Service

All Delta Membrane pump systems are tted & can be maintained by our partners, Packaged Pump Systems.

With our long-term relationship we ensure that the system selected is t for your requirements, is delivered on time,

professionally installed & oers hassle free on-going operation & maintenance.

• Fully stocked vans

• Emergency breakdown service

• Out of hours service

• Planned maintenance

• Factory trained engineers

Precise

Passionate

Service

Precise

Fully trained in-house service engineers to maintain, enhance & replace equipment.

Passionate

Bespoke design, manufacturing & installation ensuring our equipment is t for every requirement.

Service

From tting to scheduled maintenance we ensure your needs come rst.

01279 757400

T.

info@ppsgroupuk.com

E.

www.ppsgroupuk.com

W.

Unit 12, Haslemere Ind. Est., Pig Lane, Bishop’s Stortford. CM23 3HG

Loading...

Loading...