Page 1

VP520S

VP520S

PAL/NTSC to CIF/QCIF Converter

Advance Information

Supersedes version in June 1995 Digital Video & DSP IC Handbook, HB3923-2 DS3504 - 3.2 October 1996

FEATURES

■ Lower Power, pin compatible replacement for VP520

■ Converts CCIR601 luminance and chrominance to CIF

or QCIF resolution, and vice versa, using a 27MHz

system clock.

■ Luminance and chrominance channels have their own

sets of horizontal and vertical filters with on chip line

stores

■ Each filter set may be configured to either decimate or

interpolate.

■ NTSC line insertion or removal mode

■ Produces / expects CIF/QCIF data in macroblock for-

mat.

■ 120 Pin QFP Package

ASSOCIATED PRODUCTS

■ VP510 Colour Space Converter

■ VP2611 H261 Encoder

■ VP2615 H261 Decoder

■ VP2612 Video Multiplexer

■ VP2614 Video Demultiplexer

DESCRIPTION

The VP520S is designed to convert 16 bit multiplexed

luminance and chrominance data between CCIR601 and CIF/

QCIF resolutions. Vertical and horizontal FIR filters are provided, with the vertical filters supported by on chip line stores.

The coefficients used by the filters are user definable, and are

down loaded from an independent host data bus. An internal

address generator supports an external DRAM frame store,

and also provides line to macroblock conversion.

When producing CIF or QCIF video the horizontal filters

precede the vertical filters, and are provided with between 8

and 16 taps. The vertical filters are provided with four CIF line

delays which allow a 5 tap filter to be implemented. When

producing QCIF the available RAM is used to provide six line

delays, which thus allows 7 tap filters to be used.

When the device is producing CCIR601 video, the incoming data must be in macroblock format, and the vertical filters

precede the horizontal filters The inputs are firstly written to a

external CIF sized frame store, and are read out in line format.

The VP520S will support two complete frame stores, and

allows the CIF/QCIF data to be read out twice in order to

produce two interlaced fields of video.

The VP520S supports the conversion between CIF/QCIF

and NTSC video. An extra line is produced for every five lines

when producing CIF data, and one line in six is removed when

producing NTSC video. Poly phase filters are used to provide

the correct decimation and interpolation ratios.

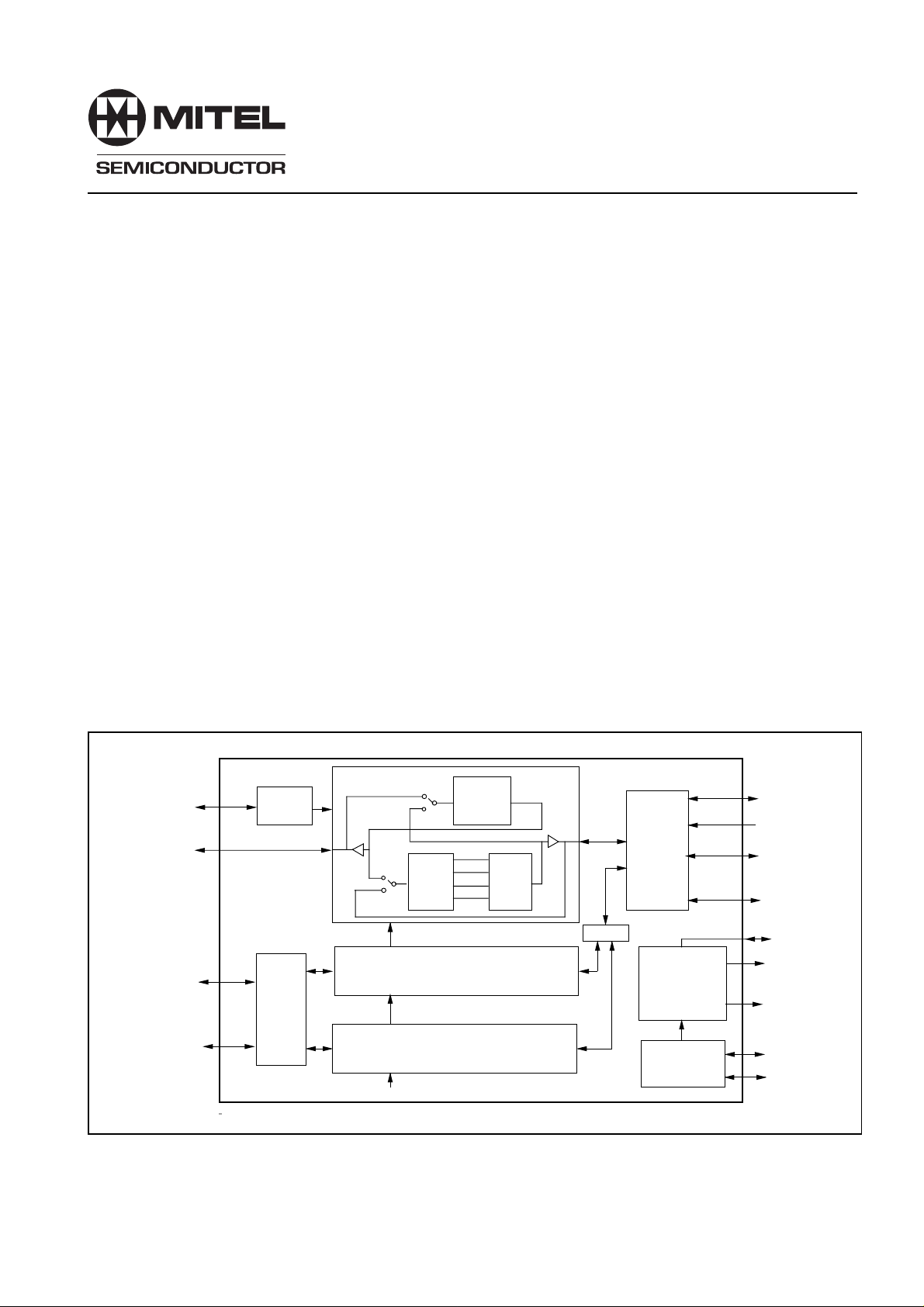

HOST

BUS

8 BIT

LUMINANCE

8 BIT

CHROMINANCE

CREF

COEFF

STORE

MUXING

MUXING

FILTER BLOCK

Horizontal

FOUR

LINE

DELAYS

FILTER BLOCK

FILTER BLOCK

Filters

Fig 1 : Simplified Block Diagram

Vertical

Filters

MUX

VP520S

INPUT/

OUTPUT

FIFO

RAM ADDRESS

GENERATOR

SUPPORTING

LINE TO BLOCK

CONVERSION

SYNC

GENERATOR

MACROBLOCK

STROBE

REQ BLKS

8 BIT

MACROBLOCK

BUS

16 BIT

FRAME STORE

BUS

FRAME START

/ READY

ADDRESS

CONTROL

HREF

VREF

1

Page 2

VP520S

PIN DESCRIPTION

NAME TYPE FUNCTION

Y7:0 I/O Luminance input or output bus

C7:0 I/O Chrominance input or output bus

M7:0 I/O Macroblock input or output bus

D15:0 I/O 16 bit data bus for DRAM frame store

A7:0 O Multiplexed address bus to the DRAM

A8 O Most sig address bit or second CAS

RAS O Row strobe for the DRAM's

CAS O Column strobe for the DRAM's

R/W O Read/ write signal to the DRAM's

HREF I/O Horiz. reference in or horiz. sync out

VREF I/O Vertical reference in or vertical sync out

CREF I/O CREF in or CREF out

FREF I/O Field Indicator in or out

HBLNK O Horizontal Blanking output

CSYNC O Composite sync output in free run mode

CLMP O Defines a black level clamping period

for A/D converters

VRST Frame start identifier. If FRST is low

then a low going edge will reset the

internal sync generator.

FRST Field identifier

REQYUV I Request macroblocks from encoder

MCLK I/O Macroblock I/O strobe

FSIG I/O Frame start/ ready signal

SCLK I System Clock. 27MHz in PAL/NTSC

systems

HD7:0 I/O Host data bus

HA3:0 I Host controller address bits

RD I An active low host read strobe

WR I An active low host write strobe

CEN I An active low enable for the strobes

RST I Power on reset

TDI I JTAG I/P data

TDO O JTAG O/P data

TMS I Test mode select

TCK I JTAG clock

TRST I JTAG reset

TOE I When high all O/P's are high

impedance

NOTE:

"Barred" active low signals do not appear with a bar in the main

body of the text.

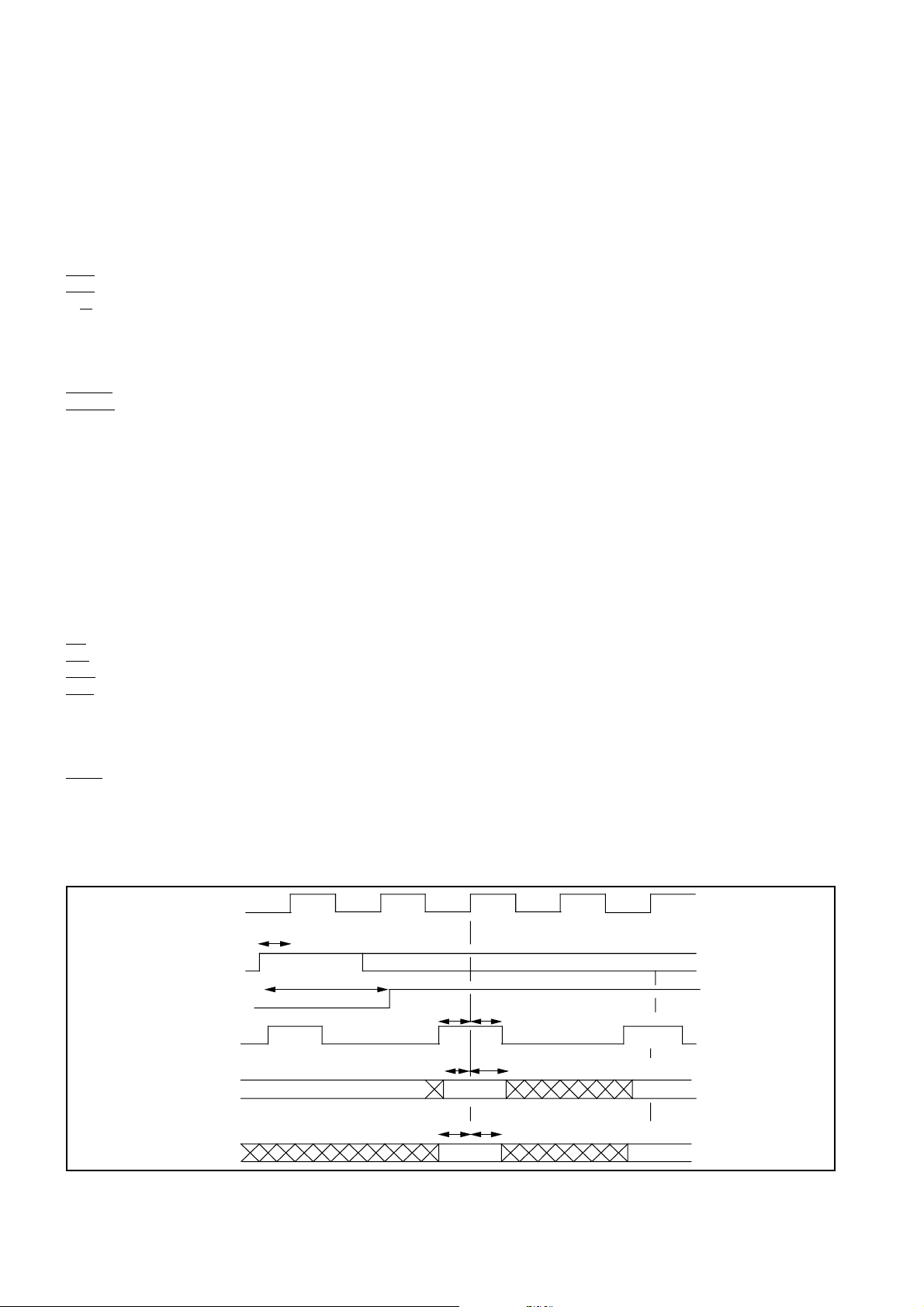

VIDEO COMPRESS MODE ( DECIMATE )

This mode is used when CCIR601 video is to be converted

to CIF or QCIF spatial resolution prior to compression. Incoming luminance and chrominance data does not need any prior

buffering, but must meet the timing requirements given in

Figure 2. A bit in Control register 1 allows the Cb component

to precede the Cr component if necessary. This data is passed

through vertical and horizontal decimating filters before it is

stored in an external frame store. When a complete field has

been decimated it is read out in macroblock format and

transferred to the next system component.

In this mode HREF, VREF, and FREF are normally inputs

which are used to reference active video with respect to video

synchronization pulses. The active going edges are used

internally, and these must meet the set up time with respect to

the system clock as given in Figure 2. Stable inputs are

needed with no jitter due to asynchronous pixel clocks, but

when this is not possible an external FIFO can be used plus

two extra signals as described later. The reference inputs

need only stay active for one system clock period. Note that

the active going edges for HREF and VREF can individually

be defined to be high going or low going, through two bits in

Control Register 0. Also note that CREF is always an input and

is used as a qualifier for SCLK. The actual edges of CREF are

not used.

The internal sync generator can still be used in this mode,

if there is a need to supply sync to the video source. The HREF

and VREF pins are then used to output HSYNC and VSYNC.

Composite sync is supplied on the CSYNC pin.

In addition the CLMP pin provides a pulse [13 SCLK's

wide] which can be used to DC restore the black level in an A/

D converter. It is active high during the back porch.

The horizontal blanking output (HBLANK) defines when

the device expects the first pixel in a line to be supplied, and

is derived from the user supplied HREF input. The delay

between HREF and HBLANK is user definable in multiples of

CREF periods. If the defined value is zero then the HREF input

must be horizontal blanking with the minimum set time specified. The HBLANK output is then not defined.

All data changes are referenced to the system clock. The

edge actually used is indicated by the CREF input signal,

which has a period of double the clock period. The VP520S will

strobe in data on the rising edge of the system clock which

occurs whilst CREF is high.

INPUT

CLOCK

10ns min

HREF

INPUT

HBLNK

O/P

CREF

INPUT

LUM

INPUT

CHROM

INPUT

PROGRAMMED DELAY

2ns

10ns

min

min

10ns

min

2ns

10ns

min

min

First Cr Comp.

2ns

min

Second I/PFirst I/P

First Cb Comp.

Fig 2 : Luminance and chrominance inputs in the decimate mode.

2

Page 3

VP520S

The first video line to be filtered and stored will be derived

from the vertical reference input ( VREF). The user can choose

the number of transitions of the HREF input which must occur,

after VREF has gone active, before starting the filter operation. Data is then not written to the DRAM until after the

pipeline delay through the filters.

The VP520S only expects to use one field of CCIR601

video, which can be selected by the FREF input or internal

logic. A bit in Control Register 1 ( Internal / External Field

Detect ) determines which option is to be used. An additional

Field Select Bit determines whether the field selected should

correspond to FREF being high or low. When the Field Select

Bit and the input are at the same logical level then that field is

used. Note that FREF transitions must be coincident with

active going VREF transitions.

Internal logic is provided which determines the field ( Field

1 ) in which VREF goes active in less than half a line period

after the HREF input last went active.The half line period is

determined by VREF going active between 1 and 432 CREF

qualified SCLK edges after HREF went active (1-429 in NTSC

mode). Note that coincident VREF and HREF edges will

indicate this field on the first CREF qualified SCLK edge.

This logic is used, rather than the FREF input, when the

Internal / External Field Detect Bit is low. Field 1 is selected

when the Field Select in Control register 1 is low, and Field 2

is used when the bit is high.

In the Split Screen mode this logic is overridden, and both

fields are actually used. External logic is assumed to switch

between two sources of video, one for each field. The internal

DRAM address generator is modified such that half area

pictures from the centre of each source are actually stored as

CIF/QCIF data. The first line used in each field will be 72 line

delays in addition to the number which has been defined by the

user. The split screen option is not supported in the QCIF

mode of operation, and a reset is needed after a mode change

in CIF.

The VP520S will insert zero's into the line delays during

vertical blanking. This ensures that all the filter accumulators

are cleared and the edges of the picture are correctly processed. The horizontal filters always give the required results

since four decimated values are ignored at either side of the

picture.

Incoming luminance data could have a black level of 16,

which will be shifted if the filter coefficients are not chosen to

exactly give a gain of unity. A Control Bit is thus provided,

which when set causes 16 to be subtracted from incoming

luminance. A black level of zero will then stay as zero throughout the filter operation. At the output of the filters 16 is always

added to the results, regardless of the state of the Control Bit.

Saturation logic ensures that these addition / subtraction

operations do not produce negative results or values greater

than 254.

A Control Bit is also provided which selects between colour

difference inputs and true Cr Cb chrominance values. Cr Cb

values are 8 bit positive only numbers, with black levels of 128.

These must be converted to two's complement signed numbers by subtracting 128, thus giving a black level of zero

through the filters. The outputs of the filters are always

converted to positive only Cr Cb values by adding 128 to the

results, regardless of the state of the Control Bit.

COPING WITH SYNC JITTER

When input syncs to the VP520S have jitter, due to the use

of a composite video decoder which does not produce a line

locked clock, it is necessary to use an external FIFO line

buffer. For this reason the VP520S supports a system in which

external line buffer writes are controlled by the video source

and line reads are controlled by the VP520S. The VP520S in

the decode loop is assumed to be supplying sync to the

VP520S in the encode loop, but the sync generator must be

reset at the start of a frame to be in step with the video source.

Two pins have been supplied to support this situation, namely:

VRST - pin 34, and FRST - pin 36. The falling edge of VRST

(frame start identifier) when FRST (field identifier) is low

identifies the start of the frame. These two inputs can typically

be supplied by the Brooktree Bt812 Composite Video Decoder. Note that Host Address 3 must be programmed with

the value 02 Hex to enable the reset operation.

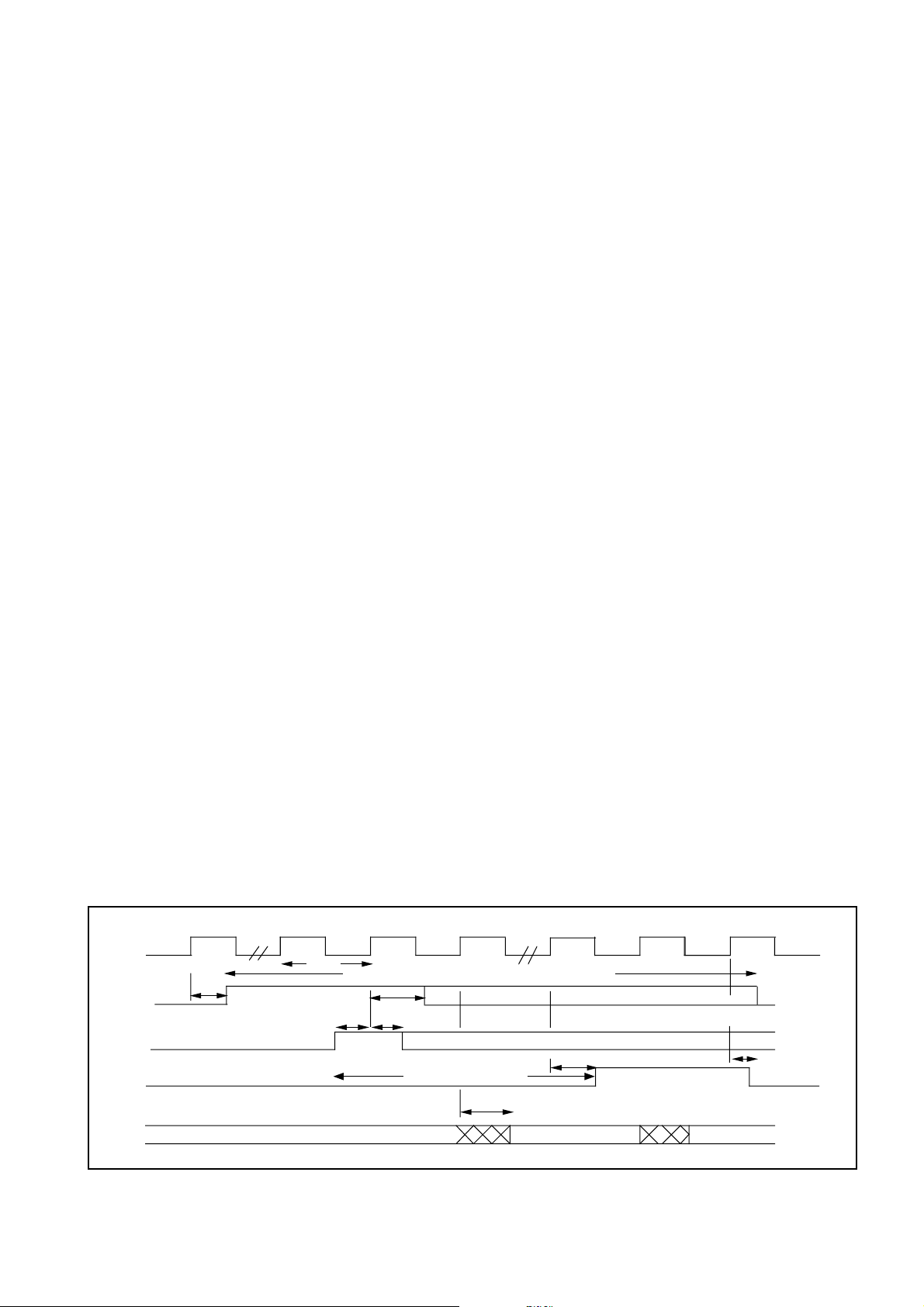

CIF/QCIF MACROBLOCK OUTPUTS

When producing decimated CIF/QCIF data in macroblock

format, the device raises a flag when a frame of data is ready

for reading from the frame store ( FSIG ). The FSIG pin is

automatically configured as an output in the decimate mode,

but will only stay active (high) for the time given in Figure 3. If

a Request Macroblock response (REQYUV) is not obtained

during this period, then FSIG will be taken low and the frame

of data presently available will be ignored. It will go high again

when a new frame of data is available.

SYSCLK

FSIG

O/P

REQYUV

I/P

MCLK

O/P

DATA

O/P

20ns

max

33ns min

Stays high for 11440 (NTSC) or 13284 (PAL) SCLKs if REQYUV not received

20ns max

10ns

2ns

min

min

60 SYSCLK Max , 10SYSCLK Min

20ns max

Fig 3 : Macroblock Output Timing

20ns max

First O/P Valid O/P Valid

20ns max

3

Page 4

VP520S

-

-

-

-

-

-

-

FSIG

I/P

MCLK

DATA

I/P

40ns min

I/P

10ns min 2ns min

4SCLK min

40ns min

Second I/PFirst I/P

Fig 4 : Macroblock Input Timing

When it receives a REQYUV response from the next

system component, it starts to output a macroblock by using

an output strobe derived by dividing down the clock input.

Detailed timing is given in Figure 3. This strobe only occurs

when data is available at the output pins and at a rate of

SYSCLK/4. The 'Request Macroblock' flag must go inactive

and then active again before a further macroblock is made

available.

The Frame Ready flag is only available on the output pin

if the Frame Enable Bit is set in Control Register 1. Through

this control bit a host controller is able to determine whether a

new frame is to be compressed and transmitted. In an alternative arrangement the control bit can be permanently set, and

the Frame Ready Flag is then used as an interrupt to the host

controller. It then generates a signal which is used as the

Frame Ready signal for the next device.

The following sections describe this interface as it applies

to the VP2611 H261 Video Encoder.

TRANSFERING MACROBLOCKS TO THE VP2611

When the VP520S has stored a complete field of decimated video in the DRAM, it raises a Frame Ready Flag ( FSIG

). If the bit in Control Register 1 does not inhibit the output, this

flag becomes the FRMIN input on the VP2611. This responds

to the FRMIN input by generating a Request for Macroblock

Data ( REQYUV ). The VP2611 MUST then receive a complete macroblock ( 384 bytes ) within 1870 cycles of the

system clock. When the VP520S is producing decimated CIF/

QCIF data, writing line data to the DRAM has priority, and only

four macroblock read operations are possible in every 32

clock cycles i.e. one read takes eight cycles. These, however,

are 16 bit word operations and it thus requires 384 x 8/2 = 1536

cycles to output the data. In addition there is a maximum delay

of 60 clock periods from receiving REQYUV to producing the

first output strobe (MCLK). This is still well within the time

available.

The four 16 bit words are stored in the VP520S and

transmitted to the VP2611 as eight bytes using a strobe

( MCLK ) derived from the system clock. This is only present

when valid data is available, and it drives the PCLK input on

the VP2611.

It takes the VP2611 almost exactly all the available time at

30 Hz frame rates to process all the macroblocks. After a field

time ( half an interlaced frame ) the VP520S will start to write

new data to the DRAM, and data could be overwritten during

the last macroblocks. Since there is available space in the

DRAM, a small address offset is used between video fields to

avoid this problem.

INPUT

CLOCK

HBLANK

O/P

CREF

O/P

LUM

OUTPUT

CHROM

O/P

20ns

max

20ns max

20ns max

20ns max 20ns max

33ns min

20ns

max

First O/P Valid

First Cr Component Valid

20ns max

Second O/P Valid

First Cb

Fig 5 : Luminance and Chrominance Output Timing

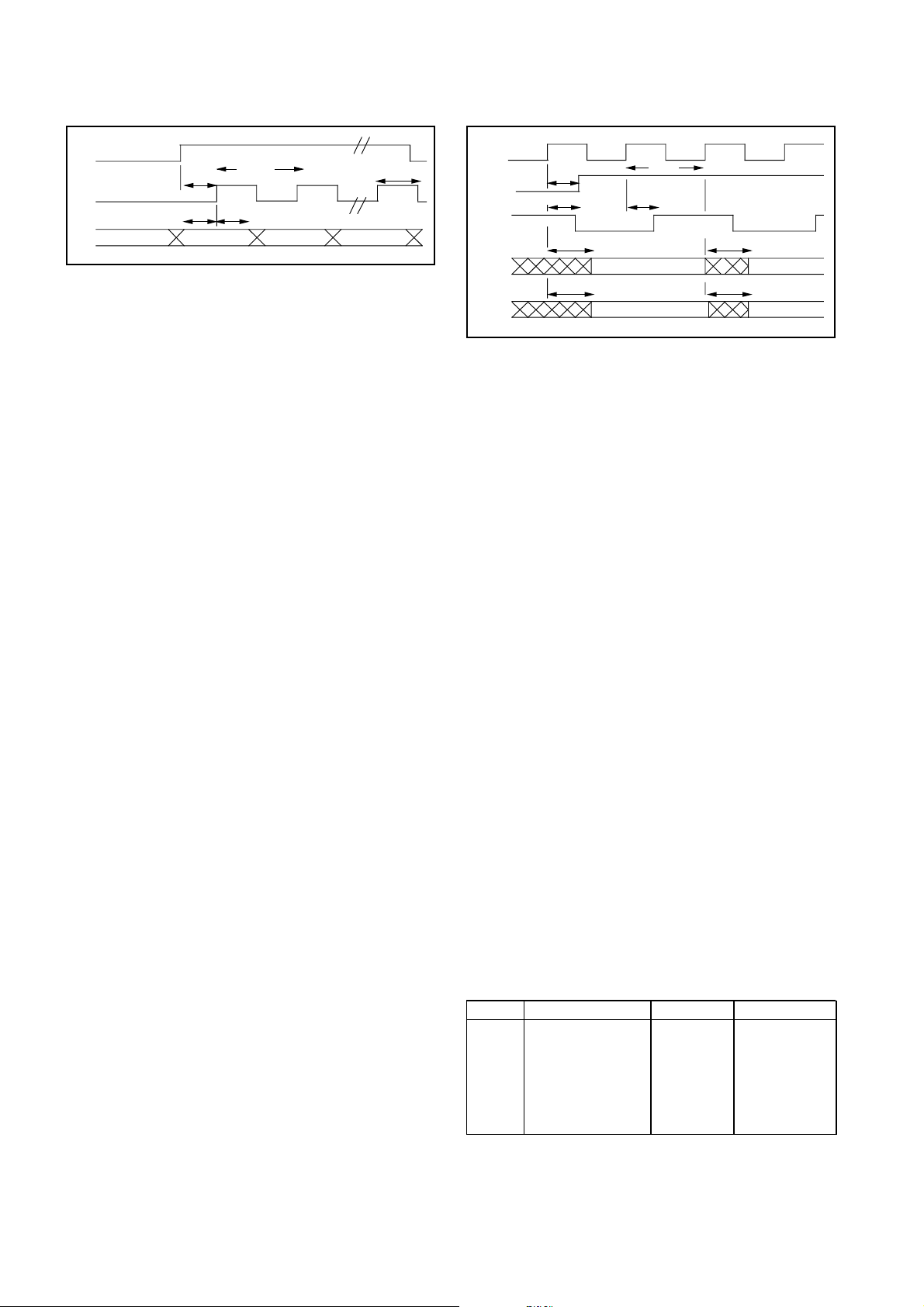

INTERPOLATE MODE

In this mode the VP520S expects to receive CIF/QCIF

data in macroblock format, which it then writes to an external

frame store. This is then read back in line format and passed

through vertical and horizontal interpolating filters to produce

two fields of CCIR601 video. Detailed input timing is given in

Figure 4.

FSIG automatically becomes an input which is used to

identify the start of a frame and to reset the internal address

counter. FSIG must stay high until a complete CIF/QCIF frame

has been received ( internal logic counts macroblocks ). If

FSIG goes low early then the complete frame will be ignored,

and the previously received frame will continue to be displayed.

An input strobe, derived by dividing the system clock by

four, must also be provided in order to input data. This must

only be present when valid data is available on the input pins.

Incoming macroblocks are byte wide, and these are internally

buffered to allow four 16 bit words to be written to the DRAM

every 32 system clock cycles. This is equivalent to a byte input

rate of SCLK/4 which must not be exceeded.

The CIF frame store is double buffered such that a new

frame can be received whilst the previous one is being

displayed. In fact the use of 256K x 16 DRAM's gives sufficient

capacity for more than three complete CIF frames, and the

internal address generator will simply roll around to make full

use of the available space.

Once a complete CIF/QCIF frame has been received, it will

normally be used to generate two interlaced PAL or NTSC

fields. These fields continue to be re-generated until a complete new CIF frame has been received. The rate of receiving

frames depends on the transmission bandwidth, but the

maximum rate is 30 Hz. The changeover to the newly received

frame will occur when the VP520S has finished generating

any one of the pair of interlaced fields for display, it does not

SYMBOL PARAMETER MINIMUM MAXIMUM

t RAC Access time from RAS

t CAC Access time from CAS

t RP RAS precharge time 50ns or under

t CP CAS precharge time 12ns or under

t RAS RAS pulse width 80ns or under

t CAS CAS pulse width 50ns or under

t REF Time between

complete refreshes

105ns or under

25ns or under

4 ms or over

(8 ms with 256k x n)

N.B. All times are quoted assuming 27MHz operation. For lower clock

frequencies increase the above values proportionately.

4

Table 1. External DRAM Timing Requirements

Page 5

VP520S

necessarily have to have generated two interlaced fields from

the received frame. If the VP520S is receiving frames at the

full CIF 30 Hz frame rate but only displaying PAL frames at 25

Hz, then periodically one of the PAL frames ( comprising two

interlaced fields at 50 Hz ) will be generated from two received

CIF/QCIF frames. An incoming CIF/QCIF frame will always be

used since the interlaced field rate is always greater than 30

Hz in either PAL or NTSC.

The data is read from the frame store such that interpolated data becomes available after programmed delays referenced to the VREF and HREF signals. Six bits are available

to define the line delay, and ten are provided to define the

delay from HREF in CREF periods. The actual delays are

greater than the programmed values because of the internal

pipeline delays, which are also mode dependent.

HREF and VREF can either be user supplied inputs, or are

generated internally from a PAL/NTSC timing generator. A bit

in Control Register 0 determines this option, and when the

internal generator is specified the HREF pin becomes an

output which supplies horizontal sync and the VREF pin

supplies vertical sync. A composite sync output is also provided for system level use. In this mode the VREF and HREF

signals used internally are effectively vertical and horizontal

sync, and the programmed delays should be chosen to reflect

this condition.

The signals provided from the internal timing generator

allow the VP520S to drive the VP510 Colour Space Converter

and an RGB monitor. Detailed output timing is given in Figure

5. Note that the chrominance order can be changed. Alternatively they can be used to drive off the shelf composite video

encoders.

External chrominance data can have a zero colour difference value of either 0 or 128. This is defined using the

Chrominance Control Bit. Where 128 is the zero colour

difference value, 128 will be subtracted from incoming

chrominance data and 128 will be added to output chrominace

data. Output values will be limited to lie in the range 16 to 240.

External luminace data can have a black luminace level of

either 0 or 16. This is defined using the Luminace Control Bit.

Where 16 is the black value, 16 will be subtracted from

incoming luminace data and 16 will be added to output

luminace data. Output values will be limited to lie in the range

16 to 235.

The data stored in the CIF frame store will not contain the

black levels normally present during horizontal and vertical

flyback. This is inserted by the VP520S at the appropriate

times in order to ensure that the correct filter operation occurs

at the edges of the picture. In addition to these black levels

during flyback, a bit in Control Register 1 allows all active video

to be replaced by a fixed colour. This colour is user definable

through YUV values in three registers.

FRAME STORE INTERFACE

All read and write operations to the external DRAM frame

stores are based on the use of fast page mode with 13.5 MHz

CAS cycles. Internally a 54 MHz clock is produced from the

27MHz System clock, and this determines the minimum time

interval which can be used in the generation of pulses and

defining precharge times. Any DRAM used must meet the

timing constraints given in Table 1.

Reading and writing rates dictate the need for a 16 bit data

interface, and line data is re-organized to allow a 16 bit word

to consist of either two luminance values or two chrominance

values. This gives compatibility with the macroblock requirements since a sub block is either all chrominance or all

luminance data. Reading or writing macroblock data requires

jumps between pages, but four words can always be read or

written using fast page mode.

Read and write operations must be timeshared to meet the

requirements of the system. This time-sharing is based on the

use of 16 cycles of the 13.5 MHz clock. When reading or

writing line data to the store, 10 cycles are used for eight

words, and six cycles are left free for four exchanges with the

encoder or decoder. The additional cycles are needed when

ADDRESS

CHIP

SELECT

READ

STROBE

DATA

OUT

READ CYCLE

Tas

Tah

Trs

CHARACTERISTIC

Addresss Set Up Time

Address Hold Time

Cip Select Set Up Time

Chip Select Hold Time

Strobe Inactive Time

Data Access Time

Delay to O/P's low Z

Delay to O/P's high Z

Tac

Tlz

SYMBOL

Tas

Tah

Trs

Tsh

Tri

Tac

Tlz

Thz

MIN

10ns

10ns

10ns

2ns

Øns

2Øns

Tsh

Tri

Thz

Data

Valid

MAX

ADVANCED DATA

20 +3Øns

25ns

NOTE

Ø is the period of the

input clock

Fig 6 : Host Interface Timing

ADDRESS

CHIP

SELECT

WRITE

STROBE

DATA

IN

CHARACTERISTIC

Addresss Set Up Time

Address Hold Time

Chip Select Set Up Time

Chip Select Hold Time

Strobe Inactive Time

Strobe Active Time

Data Set Up Time

Data Hold Time

Tas

Tws

WRITE CYCLE

Tah

Twa

SYMBOL

Tas

Tah

Tws

Tsh

Twi

Twa

Tds

Tdh

Tds

MIN

10ns

10ns

10ns

2ns

1Øns

3Øns

10ns

10ns

Data

Valid

Tsh

Twi

Tdh

MAX

5

Page 6

VP520S

using fast page mode in order to guarantee RAS precharge

times and RAS to CAS delays.

The above time partitioning gives a line rate of 6.75 MHz,

which meets real time CIF requirements. The exchange rate

with the encoder or decoder is only half of this, but is adequate

for CIF data at 30 Hz frame rates. In the decode mode the

VP520S produces two fields at 60 Hz rates from every 30 Hz

received frame, thus writing need only be half the rate of

reading. In the decimate mode the VP520S produces a CIF

frame using line rates which could have supported two 60Hz

fields, but only one is used. Thus reading rates need only be

half writing rates since the spare field time is available.

In the interpolate mode two complete CIF frame stores are

required, which dictates the use of 256K word DRAM's. The

A8 pin then provides the ninth address bit needed for such

devices. In the decimate mode only one CIF frame store is

required, and a Control Register Bit allows the user to select

either 256K word DRAM's, or 64K x 16 devices. In the latter

case two such devices are needed, and the A8 pin now

supplies a second CAS strobe to enable the second device.

Refresh cycles generate CAS before RAS sequences.

HOST INTERFACE

The VP520S employs a conventional memory mapped

host interface using a data bus and an address bus. To

minimize on pin count the VP520S only uses four address

lines, and all internal RAM is addressed through counters. All

data is validated with a read or write strobe, and an active low

enabling signal. These strobes can be asynchronous to the 27

MHz clock, but the latter must be present to move the data

through several pipeline delays. Strobes must thus be valid for

several clock periods. Timing is shown in Figure 5.

In the worst case mode ( QCIF to NTSC video ), the device

must store 40 horizontal coefficients and 210 vertical coefficients. Internal storage must thus be provided for a total of 250

eight bit coefficients, and this is split into four blocks. These

consist of storage for 24 horizontal luminance coefficients;

storage for 16 horizontal chrominance coefficients; storage for

70 vertical luminance coefficients; and finally 140 vertical

chrominance coefficients. Each block of RAM has its own

internal address counter, and all counters are simultaneously

reset with a write to address F hex. Each RAM area has an

associated address as listed below, and a read or write using

that address will increment the relevant counter. Attempts to

use more addresses than are applicable to a particular area

will cause undefined behaviour.

Address allocations are given below;

Addr Function

0 Reserved

1 R/W horizontal luminance coefficients. Max 24

2 R/W horizontal chrominance coefficients. Max 16.

3 Normally 00 Hex. When 02 Hex the sync generator can be

reset with the FRST and VRST pins.

4 Reserved for internal use

5 R/W vertical luminance coefficients. Max 70.

6 R/W vertical chrominance coefficients. Max 140.

7 Set to the normal operating value of 01 Hex by RESET. When

loaded with 21 Hex an encoding plus a decoding VP520S can

be connected 'back to back' for test purposes or coefficient

investigations. No other values must be used.

8 Control Register 0. See below.

9 Control Register 1. See below

A Line delay from VREF to first active line. 6MSBs only

A/B Pixel delay from HREF to first active pixel 2 Bits from A

plus 8 from B to give a 10 Bit value. Bit A1 is the MSB

C Blanked screen Y value

D Blanked screen U value

E Blanked screen V value

F Clear all address counters

The bits in control registers 0 and 1 are used individually,

and are defined below. Where necessary the action caused

when changing a control bit is delayed until the start of a new

field.

REGISTER 0 (Address 8)

BIT FUNCTION

0 Interpolate if high, decimate if low

1 PAL if low, NTSC if high

2 QCIF if high, CIF if low

3 If low subtract 16 from Y, add 16 back after filtering

4 If low subtract 128 from chrominance I/Ps, add 128 to O/Ps

5 If low generate sync, if high lock to HREF and VREF

6 If low then active edge of VREF is low going.

7 If low then active edge of HREF is low going.

REGISTER 1 (Address 9)

BIT FUNCTION

0 If low then U inputs precede V inputs and outputs

1 If low use the internal field detect logic

2 Field Select. See text.

3 If low use 64Kx16 DRAM ( encoder only )

4 When high specifies Split Screen mode (encoder only)

5 When low the Frame Ready Flag is enabled

6 When high the screen is blanked (colour defined in addresses

C, D, E)

7 When high DRAM writes are disabled

USE OF ADDRESS 7

By loading Hex 21 into host address 7 it is possible to

connect the encoding and decoding filters into a back to back

configuration. This is useful for test purposes or for evaluating

the filter coefficient values, and it avoids the need for a 'Frame

Start' signal into the filter in the decode path. In normal

operation address 7 should contain 01 which is the default

after a reset operation.

LOADING COEFFICIENTS

The following tables show the coefficient storage locations

for different modes. The filter sections below describe the use

of coefficient sets. Within a set, coefficients are stored in

ascending order, ie. C0, C1, C2 etc. Note that some locations

are shown as not used. However, since each store is loaded

sequentially, the data stream used to load the coefficient

stores must contain padding values corresponding to the

unused addresses. Note also that only the address range

shown in the tables have to be loaded with data.

6

Page 7

VP520S

A: Horizontal Luminance Store

This is a 24 byte RAM and coefficients will be stored as follows.

The full sequence is obtained by writing to Address 1, twenty

four times and supplying the required data.

Mode Addresses Coefficient Set

CCIR -> CIF 0-7 1

CCIR -> QCIF 0-15 1

CIF -> CCIR 0-5 1

6-11 2

QCIF -> CCIR 0-5 1

6-11 2

12-17 3

18-23 4

B: Horizontal Chrominance Store

This is a 16 byte RAM and coefficients will be stored as follows,

by writing to Address 2 the required number of times.

Mode Addresses Coefficient Set

CCIR -> CIF 0-7 1

CCIR -> QCIF 0-15 1

CIF -> CCIR 0-3 1

4-7 2

QCIF -> CCIR 0-3 1

4-7 2

8-11 3

12-15 4

C: Vertical Luminance Store

This is a 70 byte RAM and coefficients will be stored by writing

to Address 5 the required number of times.

Mode Addresses Coefficient Set

625 line -> CIF 0-4 1

525 line -> CIF 0-4 1

5-9 2

10-14 3

15-19 4

20-24 5

25-29 6

625 -> QCIF 0-6 1

525 -> QCIF 0-6 1

7-13 2

14-20 3

21-27 4

28-34 5

35-41 6

CIF -> 625 line 0-4 1, even field

5-9 1, odd field

CIF -> 525 line 0-4 1, even field

5-9 2, even field

10-14 3, even field

15-19 4, even field

20-24 5, even field

25-29 not used

30-34 1, odd field

35-39 not used

40-44 2, odd field

45-49 3, odd field

50-54 4, odd field

55-59 5, odd field

QCIF -> 625 line 0-6 1, even field

7-13 2, even field

14-20 1, odd field

21-27 2, odd field

OCIF -> 525 line 0-6 1, even field

7-13 2, even field

14-20 3, even field

21-27 4, even field

28-34 5, even field

35-41 1, odd field

42-48 2, odd field

49-55 3, odd field

56-62 4, odd field

63-69 5, odd field

D: Vertical Chrominance Store

This is a 140 byte RAM and coefficients will be stored by

writing to Address 6 the required number of times.

Mode Addresses Coefficient Set

625 line -> CIF 0-4 1

525 line -> CIF 0-4 1

5-9 2

10-14 3

625 line -> QCIF 0-6 1

525 line -> QCIF 0-6 1

7-13 2

14-20 3

CIF -> 625 line 0-4 1, even field

5-9 2, even field

10-14 1, odd field

15-19 2, odd field

CIF -> 525 line 0-4 1, even field

5-9 2, even field

10-14 3, even field

15-19 4, even field

20-24 5, even field

25-29 not used

30-34 1, odd used

35-39 not used

40-44 2, odd field

45-49 3, odd field

50-54 4, odd field

55-59 5, odd field

QCIF -> 525 line 0-6 1, even field

7-13 2, even field

14-20 3, even field

21-27 4, even field

28-34 5, even field

35-41 6, even field

42-48 7, even field

49-55 8, even field

56-62 9, even field

63-69 10, even field

70-76 1, odd field

77-83 2, odd field

84-90 3, odd field

91-97 4, odd field

98-104 5, odd field

105-111 6, odd field

7

Page 8

VP520S

112-118 7, odd field

119-125 8, odd field

126-132 9, odd field

133-139 10, odd field

QCIF -> 625 line 0-6 1, even field

7-13 2, even field

14-20 3, even field

21-27 4, even field

28-34 1, odd field

35-41 2, odd field

42-48 3, odd field

49-55 4, odd field

HORIZONTAL FILTERS

Chrominance data is assumed to have already been

decimated down to half the horizontal sampling rate of the

luminance data, before it is applied to the VP520S. When

producing CIF data both luminance and chrominance are then

both decimated by two, when producing QCIF data they are

both decimated by four.

Simulations with actual video have shown that 8 tap CIF

filters and 16 tap QCIF filters give more than adequate

performance in the decimation mode. In the interpolation

mode these same simulations have shown the need for longer

filters in the luminance channel. The hardware thus supports

a 12 tap filter when interpolating luminance from CIF inputs,

but only 8 taps are provided for each chrominance channel.

Even longer filters are needed when QCIF data must be

interpolated, and the luminance channel is provided with 24

taps, and each chrominance channel with 16 taps.

Note that when interpolating by two the output rate is

double the input rate, but every other input will be conceptually

zero. Similarly when interpolating by four there are three

zero's between every data point, even though the output rate

is four times the input rate. Thus during any clock period only

one half or one quarter of the coefficients are actually in use,

and the computational burden is no greater than when doing

the equivalent decimation.

Since all the coefficients are not in use during any clock

cycle, it is convenient to refer to two smaller sets of coefficients. Thus the 12 tap CIF luminance filter, for example, can

be considered to have two sets of 6 coefficients, and the 24 tap

QCIF luminance filter to have four sets of 6 coefficients. The

addressing in the coefficient RAMs uses this concept of sets.

VERTICAL FILTERS

PAL LINES

EVEN

ODD

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

CIF LINES

LUM

CHROM

0

1

2

3

4

5

6

7

8

9

0

0

1

2

2

3

4

4

5

6

6

7

8

8

NTSC LINES

EVEN

ODD

REPEAT

REPEAT

0

1

2

3

4

5

6

7

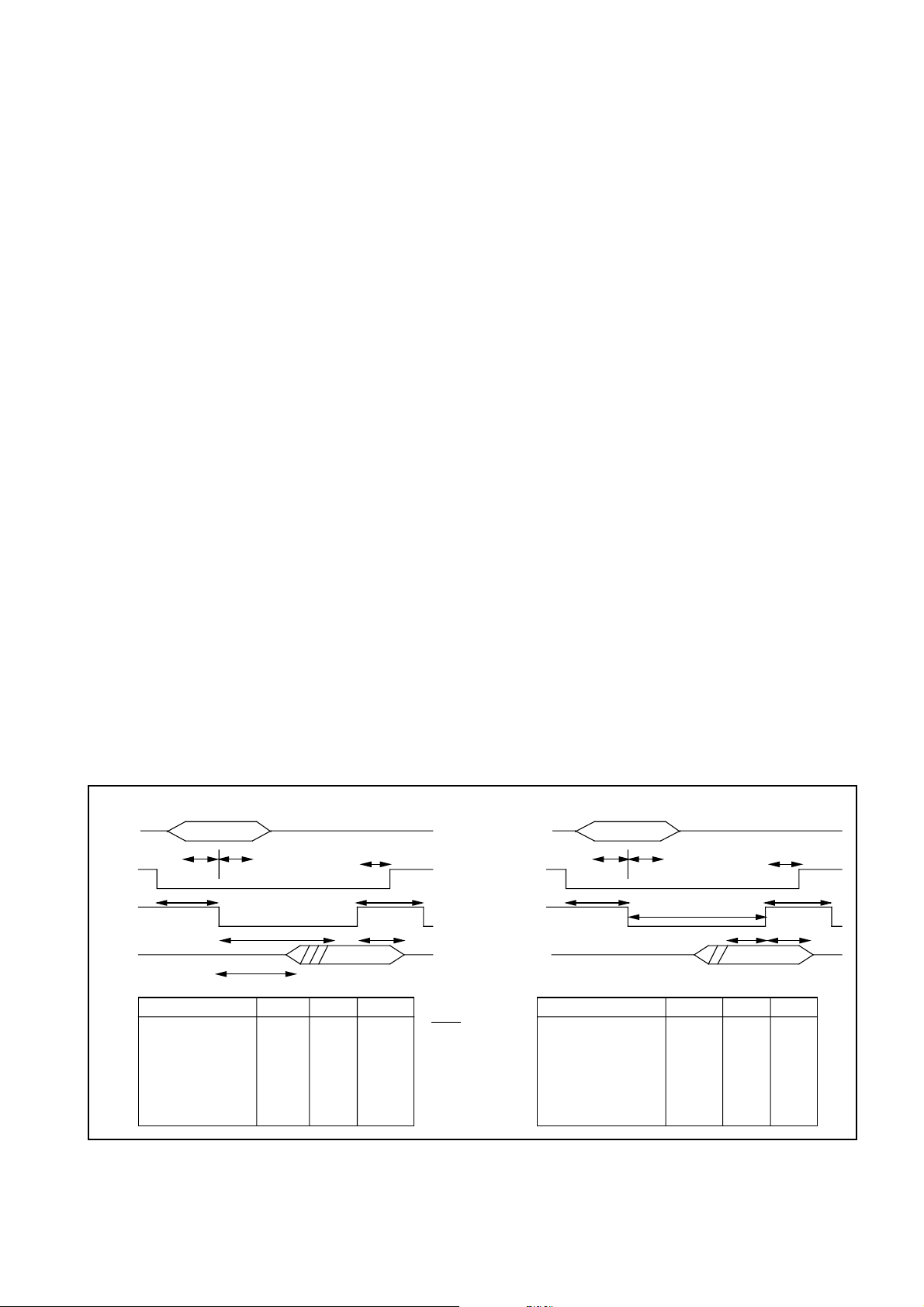

The vertical filters are designed to produce CIF with the

spatial relationship shown in Figure 7, and QCIF with the

spatial relationship shown in Figure 8. Original PAL or NTSC

video contains lines of coincident luminance and chrominance, but the CIF specification requires that the decimated

chrominance information is shifted such that it lies mid way

between two luminance lines. This is achieved by choosing

the centre outputs from the filter which best fit the requirements. The filter outputs actually used by the device are

shown by the arrows in Figures 7 and 8, and are optimal when

the even field provides the original video.

It is assumed that one of the interlaced fields has been

discarded prior to the VP520S, and thus no further decimation

occurs when producing CIF luminance from PAL ( NTSC in

8

10

10

10

11

11

11

12

10

9

10

Fig 7 : CIF Spatial Relationships

8

9

REPEAT

Page 9

VP520S

fact needs some interpolation - see the relevant section ).

Chrominance, however, is decimated by two. When produc-

ing QCIF data the luminance channel is decimated by two, and

the chrominance by four.

When the VP520S is used to derive interlaced CCIR601

video, the internal address generator will read the CIF/QCIF

frame store twice in order to produce the two fields. Each field

has its own set of coefficients.

Internal RAM is provided which will support four CIF line

delays for both chrominance and luminance. Five tap filters

are thus possible for CIF conversions. With a QCIF system the

internal RAM could theoretically be used to provide eight QCIF

line delays. In practice, however, little benefit is obtained by

using vertical filters with more than seven taps, and thus only

six line delays are used.

Polyphase filters are used to support the spatial conversions. PAL conversion is relatively simple and only requires a

set of coefficients for each mode. NTSC conversion requires

several sets of coefficients since the 240 lines in a field must

be converted to 288 lines of CIF. One line is repeated in every

five to produce six lines which are then filtered with their own

coefficients.

The generation of interpolated outputs requires CIF / QCIF

data to be repeatedly read from the frame store at various line

intervals. This is all handled by the internal address generator,

and is transparent to the user. The device then produces

coincident luminance and chrominance data which has been

interpolated from data in the frame store. The first line will be

produced to match the delay from the VREF input which has

been pre-defined. This delay must be greater than the internal

pipeline delay, which itself is mode dependent ( delay yet to be

determined ).

The device introduces black lines at the top and bottom of

the fields. Thus the first and last lines in the interpolated field

will be filtered with varying amounts of black information.

PAL VERTICAL FILTERING

When producing CIF data the five tap filters provide

outputs for every line at the 6.75 MHz decimated line rate.

Every filtered luminance line is used but every other filtered

chrominance line will be discarded. Filter outputs corresponding to odd numbered PAL chrominance lines in any field being

at the centre are used to provide the CIF chrominance lines.

This is shown by the arrows in Figure 7.

When decimating down to QCIF seven tap filters are used,

which provide outputs for every line at the 3.375 MHz line rate.

Only every other filtered luminance line, and every fourth

chrominance line are actually stored in the frame store.

Different PAL lines are used to produce the offset luminance

and chrominance lines as indicated by the arrows in Figure 7.

When interpolating from CIF the luminance channel conceptually uses a 10 tap filter, with every other input line

containing only zero's. Thus only five coefficients are actually

used when producing interpolated lines for the even field, and

five different coefficients are used when producing the odd

field. The device thus stores two sets of five coefficients; one

set for each field produced by reading the CIF frame store

twice.

The chrominance filter is conceptually a 20 tap filter with

three lines of zero's for every actual input. Thus each chrominance channel needs four sets of five coefficients; two sets are

needed to produce one field, and two sets are needed for the

other field. The same chrominance data is read twice for a

given pair of luminance lines, in order to provide inputs for the

filter. Thus the internal line delays contain the same set of

chrominance data on two consecutive lines supplying data to

the filters.

When interpolating from QCIF, seven coefficients can be

PAL LINES

EVEN ODD

0

1

2

3

4

5

6

7

8

9

10

11

12

QCIF LINES

LUM CHROM

0

0

1

2

1

3

4

2

5

6

3

7

8

4

9

10

5

11

NTSC LINES

EVEN ODD

0

1

0

2

3

4

2

5

6

7

8

4

9

0

1

2

3

4

5

6

7

8

9

Fig 8 : QCIF Spatial Relationships

9

Page 10

VP520S

QCIF LINES

LUM CHROM

0

1

2

3

4

5

NTSC LINES

EVEN ODD

0

1

0

2

3

4

2

5

6

7

8

4

9

used in each set since six line delays are provided. The

luminance filter conceptually contains 28 taps ( four sets of

seven coefficients with two sets used to produce each field ).

Similarly the chrominance filter consists of 56 taps arranged

as eight sets of seven coefficients with four sets needed for

each field. In order to provide data for the filters each lumi-

0

nance line is read twice, and each chrominance line is read

four times to produce each field.

NTSC VERTICAL FILTERING

One field of NTSC video consists of 240 chrominance and

1

2

3

4

5

6

7

8

9

luminance lines, which must be converted to 288 lines of CIF

luminance and 144 lines of CIF chrominance. The luminance

increase is mechanized by repeating the first line in every five

to produce six lines, which are then applied to the vertical

filters. A different set of coefficients is used for each line,

requiring a total of 30 to be stored within the device. The line

repeat causes one set of line data to be used twice, but each

time different coefficients are used by the filter. This technique

is equivalent to interpolating the data by six, and then decimating by five. The required coefficients for each of the six sets

can be derived by conceptually using this approach.

The line repeat requires an additional FIFO line delay

before the four delays used by the filters. By reducing the

horizontal blanking time it is possible to read six lines ( one is

repeated ) from the FIFO in the time taken to acquire five lines

of video with blanking.

Chrominance data also passes through the input FIFO

and one line in every five is repeated. This is done in order to

avoid differential delays with the luminance data. Three chrominance lines are only needed, however, for every five original

lines. They are produced by using three sets of five coefficients and discarding two filtered lines in every five. The three

selected filter outputs are chosen such that the centre line of

the filter is closest to the CIF line number needed. The centre

lines which are actually used are shown in Figure 8, and result

in a sequence of two chosen outputs then a gap followed by

one output then a gap. Simply using every other output would

not give the best fit.

A simplified approach is used when decimating down to

QCIF resolution, and the input FIFO is not used. Six luminance

lines are derived from ten NTSC lines by choosing the six

outputs produced when the centre line in the filter is closest to

the QCIF line that is needed. Overall this results in a luminance

sequence consisting of two outputs then a gap, followed by

one output then a gap and is shown in Figure 8.

Three chrominance lines are derived from the same

inputs by using three sets of seven coefficients. The chrominance sequence is also shown in Figure 7, and consists of an

output then three gaps, followed by an output and two gaps.

When interpolating from CIF up to NTSC resolutions, it is

necessary to read lines of data from the CIF frame store with

reduced blanking periods. The timing is calculated such that

six lines are read in the time that five lines would have been

read if they had the correct blanking period. These fast lines

are continuously filtered using all the available information,

and the results are written to an output FIFO. This FIFO is then

read with the correct blanking period inserted in order to

provide NTSC data at the output pins. Thus five lines are read

out in the time taken to load six lines ( one of which need not

actually be written since it is never used )

10

Fig 9 : Interpolating from QCIF to NTSC

Page 11

VP520S

Five sets of coefficients are used to produce the five lines

which are actually stored, but the coefficients are different for

the even and odd field generation. Thus a total of ten sets of

five coefficients are internally stored. In effect we have interpolated by five and then decimated by three in order to

produce the complete NTSC frame.

Each CIF chrominance line is used to produce two filtered

NTSC chrominance lines, and one filtered line in every six is

then ignored. This is mechanized by reading each CIF chrominance line twice for every pair of luminance lines. The same

filtering and discard technique as used in the luminance

channel is then applied, using five sets of coefficients for each

field. Ten sets are thus needed to produce two NTSC fields.

We have effectively interpolated by ten and then decimated by

three to produce 480 chrominance lines for the complete

frame.

When interpolating from QCIF to NTSC the additional

output buffering is not used. Instead a sequence is used which

will generate 10 NTSC lines in any field from six QCIF

luminance lines and three chrominance lines. Figure 9 illustrates how the first and fourth lines are used once and the

second, third, fifth, and sixth used twice to produce QCIF

luminance. Since this 1 - 2 - 2 sequence is used twice in every

ten lines, only five rather than ten sets of coefficients are

actually needed for each field ( ten sets in total ).

The first and third chrominance lines are used three times,

and the second line is used four times. Thus ten sets of

coefficients are needed for each field ( twenty sets in total ).

Each luminance and chrominance set consists of seven

coefficients, since six line delays are provided for the filters.

JTAG Test Interface

The VP520S includes a test interface consisting of a

boundary scan loop of test registers placed between the pads

and the core of the chip. The control of this loop is fully JTAG/

IEEE 1149-1 1990 compatible. Please refer to this document

for a full description of the standard.

The interface has five dedicated pins: TMS, TDI, TDO,

TCK and TRST. The TRST pin is an independent reset for the

interface controller and should be pulsed low, soon after

power up; if the JTAG interface is not to be used it can be tied

low permanently. The TDI pin is the input for shifting in serial

instruction and test data; TDO the output for test data. The

TCK pin is the independent clock for the test interface and

registers, and TMS the mode select signal.

TDI and TMS are clocked in on the rising edge of TCK, and

all output transitions on TDO happen on its falling edge.

Instructions are clocked into the 3 bit instruction register

(no parity bit) and the following instructions are available.

Instruction Register Name

( MSB first )

111 BYPASS

000 EXTEST (Inversion except for

VREF, HREF, CSYNC and

CLMP)

010 SAMPLE/PRELOAD

The TAP controller used in this device does not support a

separate INTEST instruction but allows EXTEST to drive the

internals of the device as well as to drive the output pins.

Output enables are thus present in the chain which are not

connected to pins but which allow EXTEST to be used to

control the impedance of all the outputs. The TOE pin, which

can separately be used to control the impedance of all the

outputs, can be monitored as an input through the scan chain

but cannot be used to control the outputs through the TAP

controller. The signals controlled by the various enables are

listed below:

PAD NAME SIGNALS CONTROLLED

dram_oeb A8:0, RAS, CAS, R/W

refs_oeb FREF, VREF, HREF

csync_oeb CLMP, CSYNC, HBLNK

cgtout_oeb Test function only

d_oeb D15:0

m_oeb M7:0, MCLK, FSIG

c_dec_b CREF

yuv_oeb Y7:0, C7:0

cdata_oeb HD7:0

11

Page 12

VP520S

g

w

ABSOLUTE MAXIMUM RATINGS [See Notes]

Supply voltage VDD -0.5V to 7.0V

Input voltage V

Output voltage V

Clamp diode current per pin IK (see note 2) 18mA

IN

OUT

Static discharge voltage (HMB) 500V

Storage temperature T

Ambient temperature with power applied T

S

Junction temperature 150°C

Package power dissipation 5000mW

-0.5V to VDD + 0.5V

-0.5V to VDD + 0.5V

-65°C to 150°C

AMB

0°C to 70°C

Test

Delay from output

high to output

high impedance

Delay from output

low to output

high impedance

Delay from output

high impedance to

output low

Waveform - measurement level

V

H

V

L

1.5V

0.5V

0.5V

0.5V

NOTES ON MAXIMUM RATINGS

1. Exceeding these ratings may cause permanent damage.

Functional operation under these conditions is not implied.

2. Maximum dissipation or 1 second should not be exceeded,

only one output to be tested at any one time.

3. Exposure to absolute maximum ratings for extended

periods may affect device reliablity.

Delay from output

high impedance to

output high

V - Voltage reached when output driven hi

H

V - Voltage reached when output driven lo

L

1.5V

0.5V

4. Current is defined as negative into the device.

STATIC ELECTRICAL CHARACTERISTICS Operating Conditions (unless otherwise stated)

DD = 5.0v ± 5%

Conditions

Characteristic

Symbol

Min.

Tamb = 0 C to +70°C V

Value

Typ.

Max.

Units

Output high voltage

Output low voltage

Input high voltage

Input low voltage

Input leakage current

Input capacitance

Output leakage current

Output S/C current

ADVANCE

ADVANCE

V

OH

V

OL

V

IH

V

IL

I

IN

C

IN

I

OZ

I

DATA

DATA

SC

2.4

-

2.0

-

-10

-50

10

ORDERING INFORMATION

VP520S/CG/GH1R (Commercial - Plastic QFP package)

10

-

0.4

-

0.8

+10

+50

300

V

V

V

V

µA

pF

µA

mA

IOH = 4mA

IOL = -4mA

V

- 1V for SYSCLK and MCLK

DD

GND < VIN < V

GND < V

OUT

< V

DD

DD

12

Page 13

VP520S

PIN

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

FUNC

GND

A8

A7

A6

A5

VDD

GND

A4

A3

A2

A1

A0

VDD

GND

RW

VDD

GND

RAS

VDD

GND

M7

M6

M5

M4

PIN

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

FUNC

M3

M2

M1

M0

MCLK

VDD

GND

REQYUV

GND

VRST

FSIG

FRST

VDD

RST

TCK

TMS

TRST

TDI

TDO

TOE

VDD

VREF

FREF

HREF

PIN

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

FUNC

CREF

GND

CSYNC

Y0

Y1

Y2

Y3

Y4

Y5

Y6

Y7

VDD

GND

HBLNK

C0

C1

C2

C3

C4

C5

C6

C7

N/C

GND

PIN

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

FUNC

VDD

SCLK

GND

VDD

HA0

HA1

HA2

HA3

WR

RD

CEN

HD0

HD1

HD2

HD3

HD4

HD5

VDD

GND

HD6

HD7

CLMP

VDD

D15

PIN

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

FUNC

D14

D13

D12

GND

VDD

D11

D10

D9

D8

GND

VDD

D0

D1

D2

D3

GND

VDD

D4

D5

D6

D7

CAS

GND

VDD

Table 2: 120 Pin QFP Pin Assignment

13

Page 14

VP520S

Signal

A8

A7

A6

A5

A4

A3

A2

A1

A0

RW

RAS

dram_oeb

M7

M7

M6

M6

M5

M5

M4

M4

M3

M3

M2

M2

M1

M1

M0

M0

MCLK

MCLK

m_oeb

REQYUV

FSIG

FSIG

RST

TOE

VREF

VREF

FREF

FREF

HREF

HREF

CREF

CREF

refs_oeb

c_dec_b

CSYNC

csync_oeb

Y0

Y0

Y1

Y1

Direction

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

IN

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

OUT

OUT

OUT

IN

OUT

IN

JTAG

Bit Number

145

144

143

142

141

140

139

138

137

136

135

134

133

132

131

130

129

128

127

126

125

124

123

122

121

120

119

118

117

116

115

114

113

112

111

110

109

108

107

106

105

104

103

102

101

100

99

98

97

96

95

94

Signal

Y2

Y2

Y3

Y3

Y4

Y4

Y5

Y5

Y6

Y6

Y7

Y7

HBLNK

C0

C0

C1

C1

C2

C2

C3

C3

C4

C4

C5

C5

C6

C6

C7

C7

yuv_oeb

CGTOUT (N/C)

cgtout_oeb

SCLK

HA0

HA1

HA2

HA3

WR

RD

CEN

HD0

HD0

HD1

HD1

HD2

HD2

HD3

HD3

HD4

HD4

Direction

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

OUT

OUT

IN

IN

IN

IN

IN

IN

IN

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

JTAG

Bit Number

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

Signal

HD5

HD5

HD6

HD6

HD7

HD7

cdata_oeb*

CLMP

D15

D15

D14

D14

D13

D13

D12

D12

D11

D11

D10

D10

D9

D9

D8

D8

D0

D0

D1

D1

D2

D2

D3

D3

D4

D4

D5

D5

D6

D6

D7

D7

d-oeb*

CAS

VRST

FRST

Direction

OUT

IN

OUT

IN

OUT

IN

OUT

OUT

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

OUT

IN

IN

JTAG

Bit Number

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

Table 3: JTAG Register Allocation

CGTOUT (N/C) This pin is only used for GPS test purposes and should not be used for system purposes.

14

Page 15

Page 16

http://www.mitelsemi.com

World Headquarters - Canada

Tel: +1 (613) 592 2122

Fax: +1 (613) 592 6909

North America Asia/Pacific Europe, Middle East,

Tel: +1 (770) 486 0194 Tel: +65 333 6193 and Africa (EMEA)

Fax: +1 (770) 631 8213 Fax: +65 333 6192 Tel: +44 (0) 1793 518528

Fax: +44 (0) 1793 518581

Information relating to products and services furnished herein by Mitel Corporation or its subsidiaries (collectively “Mitel”) is believed to be reliable. However, Mitel assumes no

liability for errors that may appear in this publication, or for liability otherwise arising from the application or use of any such information, product or service or for any infringement of

patents or other intellectual property rights owned by third parties which may result from such application or use. Neither the supply of such information or purchase of product or

service conveys any license, either express or implied, under patents or other intellectual property rights owned by Mitel or licensed from third parties by Mitel, whatsoever.

Purchasers of products are also hereby notified that the use of product in certain ways or in combination with Mitel, or non-Mitel furnished goods or services may infringe patents or

other intellectual property rights owned by Mitel.

This publication is issued to provide information only and (unless agreed by Mitel in writing) may not be used, applied or reproduced for any purpose nor form par t of any order or

contract nor to be regarded as a representation relating to the products or services concerned. The products, their specifications, services and other information appearing in this

publication are subject to change by Mitel without notice. No warranty or guarantee express or implied is made regarding the capability, performance or suitability of any product or

service. Information concerning possible methods of use is provided as a guide only and does not constitute any guarantee that such methods of use will be satisfactory in a specific

piece of equipment. It is the user’s responsibility to fully determine the performance and suitability of any equipment using such information and to ensure that any publication or

data used is up to date and has not been superseded. Manufacturing does not necessarily include testing of all functions or parameters. These products are not suitable for use in

any medical products whose failure to perform may result in significant injury or death to the user. All products and materials are sold and services provided subject to Mitel’s

conditions of sale which are available on request.

M Mitel (design) and ST-BUS are registered trademarks of MITEL Corporation

Mitel Semiconductor is an ISO 9001 Registered Company

Copyright 1999 MITEL Corporation

All Rights Reserved

Printed in CANADA

TECHNICAL DOCUMENTATION - NOT FOR RESALE

Loading...

Loading...