Page 1

VP2611

VP2611

H.261 Encoder

Supersedes June 1996 edition, DS3487 - 4.0 DS3487 - 4.1 December 1998

FEATURES

■ Fully integrated H261 video encoder

■ Up to full CIF resolution and 30 Hz frame rates

■ Inputs YUV data in 8 x 8 sub block format

■ Outputs run length coded coefficients

■ On chip motion vector estimator with +/-7 pixel search

window

■ Addresses and control generated internally for DRAM

frame store

■ QFP package

ASSOCIATED PRODUCTS

■ VP510 Colour Space Converter

■ VP520S CIF/QCIF Converter

■ VP2612 Video Multiplexer

■ VP2614 Video Demultiplexer

■ VP2615 H.261 Decoder

DESCRIPTION

The VP2611 Video Compression Source Coder forms part

of a chip set used in video conferencing, video telephony and

multimedia applications. It produces data which conforms to

the H261 standard for video compression with rates between

64K and 2M bits per second. With a 27 MHz clock the device

will accept data produced to full CIF resolution at 30 Hz frame

rates. The pipeline latency through the device is only 3 macro

block periods.

The VP2611 contains all the elements necessary for the

compression algorithm. It incorporates a Motion Vector Estimator which performs a +/- 7 pixel search. The decision to use

inter or intra frame compression is made by the device, and the

selected data blocks are read from the frame store. New or

difference data is then passed through a Discrete Cosine

Transformer and quantized. Data from the quantizer is also

inverse quantized and passed through an Inverse Discrete

Cosine Transformer. This re-constructed data is then written

to the frame store for use in the next frame period.This frame

store is managed by an internal DRAM controller, and no

external logic is needed.

The input data must be in YUV space, and must also

conform to the six sub blocks per macro block format defined

by H261. Any conversion from RGB format is performed by

the VP510 Colour Space Converter. Any reduction in spatial

resolution, down to CIF or QCIF requirements, is done by the

VP520 Three Channel Video Filter.

The quantized data is zig-zag scanned and run length

coded before being output, together with block information

and motion vectors.

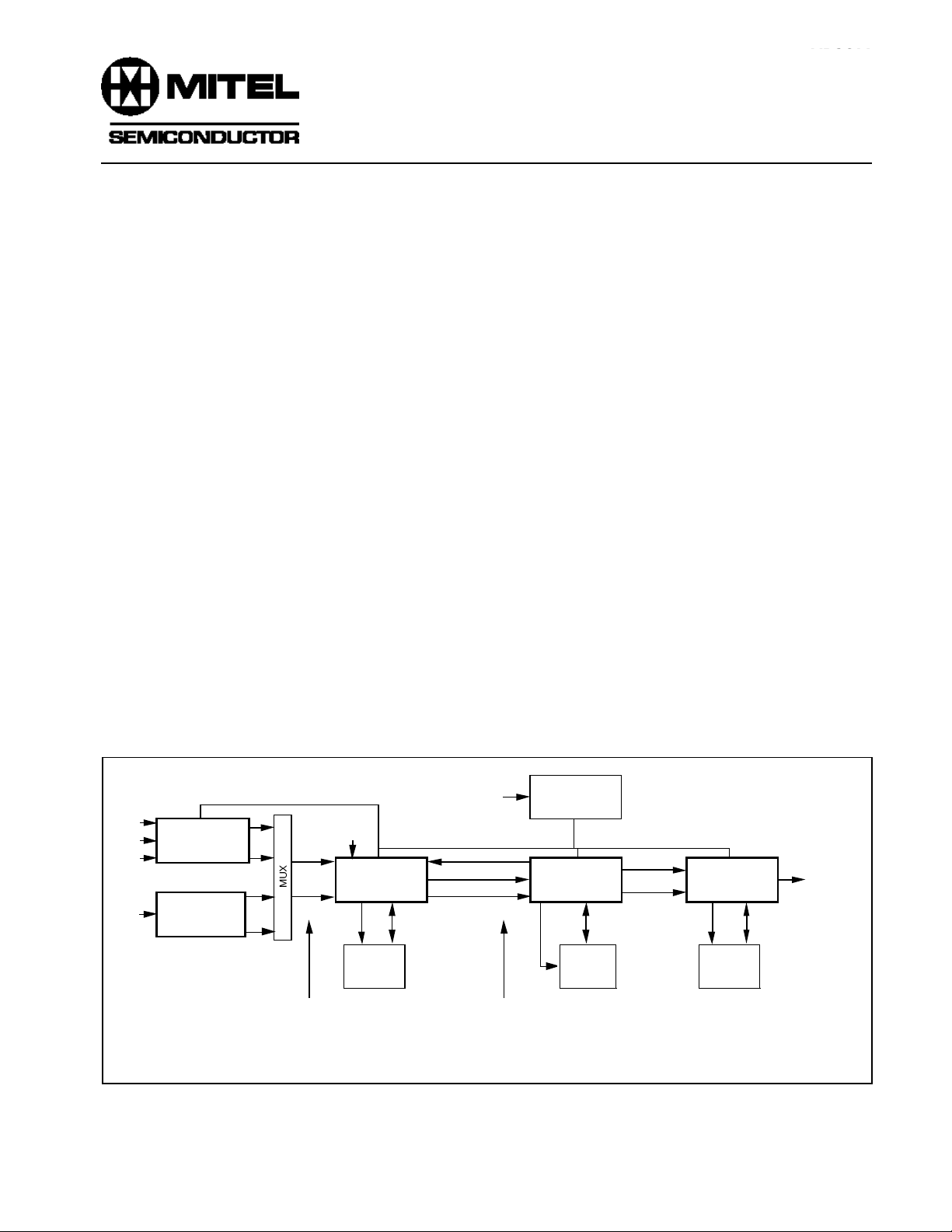

NTSC

PAL

R

COLOUR SPACE

G

B

VP510

CONVERTER

COMP VIDEO

DECODER

VIDEO

SYNC

Y

Cr/Cb

CCIR601 RESOLUTION

Y 720 X 288 Cr/Cb 360 x 288 PAL

Y 720 X 240 Cr/Cb 360 x 240

NTSC

3 CHANNEL

VIDEO FILTER

ADDR

CIF FRAME

16 X128K

VP520

STORE

Fig 1 : Typical Video Conferencing Transmission System

DATA

USER

INTERFACE

REQYUV

FRMIN

MBLK'S

CIF RESOLUTION

Y 352 X 288

Cr/Cb 176 x 144

SYSTEM

CONTROLLER

VP2611

INTEGRATED

VIDEO ENCODER

CIF FRAME

STORE

16X128K

RLC DATA

FLAGS

VP2612

VIDEO

MULTIPLEXER

TX BUFFER

32K X 8

H261

BIT

STREAM

64kb to 2Mb/s

1

Page 2

VP2611

PIN DESCRIPTIONS

YUV7:0 This input bus accepts YUV data one pixel at a

time from the preprocessor, clocked in on the

rising edge of PCLK.

PCLK This signal is used to strobe in data at the YUV

port and must be derived by dividing SYSCLK

with an integer greater than one.

FRMIN This input should be pulled high to prepare the

VP2611 to code a new frame. It must be held

high for at least one SYSCLK cycle and then

must be pulled low again before the next frame

begins. The VP2611 will respond to the rising

edge of FRMIN by asserting REQYUV

appproximately 184 SYSCLK cycles later.

REQYUV This output is pulled high to request that YUV

data be input for a new MacroBlock. It is pulled

low again 1871 SYSCLK cycles later. It remains low during Dummy MacroBlocks and

during the lay period between frames.

DBUS7:0 This output bus serves several functions as

defined by DMODE3:0. In addition to providing

the quantized coefficients and motion vectors,

it is used to output control information.

R/W1 Read/Write control for external DRAM 1.

W2 Read/Write control for external DRAM 2.

R/

N/C if 256k DRAMs.

OE1 Output Enable control for external DRAM 1

or ADR8.

OE2 Output Enable control for external DRAM 2.

N/C if 256k DRAMs.

ADR7:0 Address output for the external DRAMs.

CBUS7:0 Bi-directional data bus for use by a Microproce-

ssor. Data and insructions are clocked on and

off the chip on the rising edge of CSTR.

CSTR Data strobe for the CBUS port.

CEN An enabling signal for the CBUS port.

CADR When high, this signal defines CBUS as a data

bus, and when low as an instruction input.

SYSCLK System clock, run at 27MHz maximum. The

clock must be high for between 35% and 65%

of each clock cycle. This clock is used for all

internal operations.

DMODE3:0 Output flag port for DBUS7:0 bus. The value at

this port identifies the data type appearing on

DBUS7:0 during the same period.

DCLK This output pulses high for a minimum of 37ns

each time new data is output on DBUS or

DMODE. It can be used as an edge sensitive

strobe signal or a level sensitive "valid" signal.

SW15:0 This bidirectional port is connected to the

frame store.

RAS Row Address Strobe output for the external

DRAMs.

CAS Column Address Strobe output for the external

DRAMs.

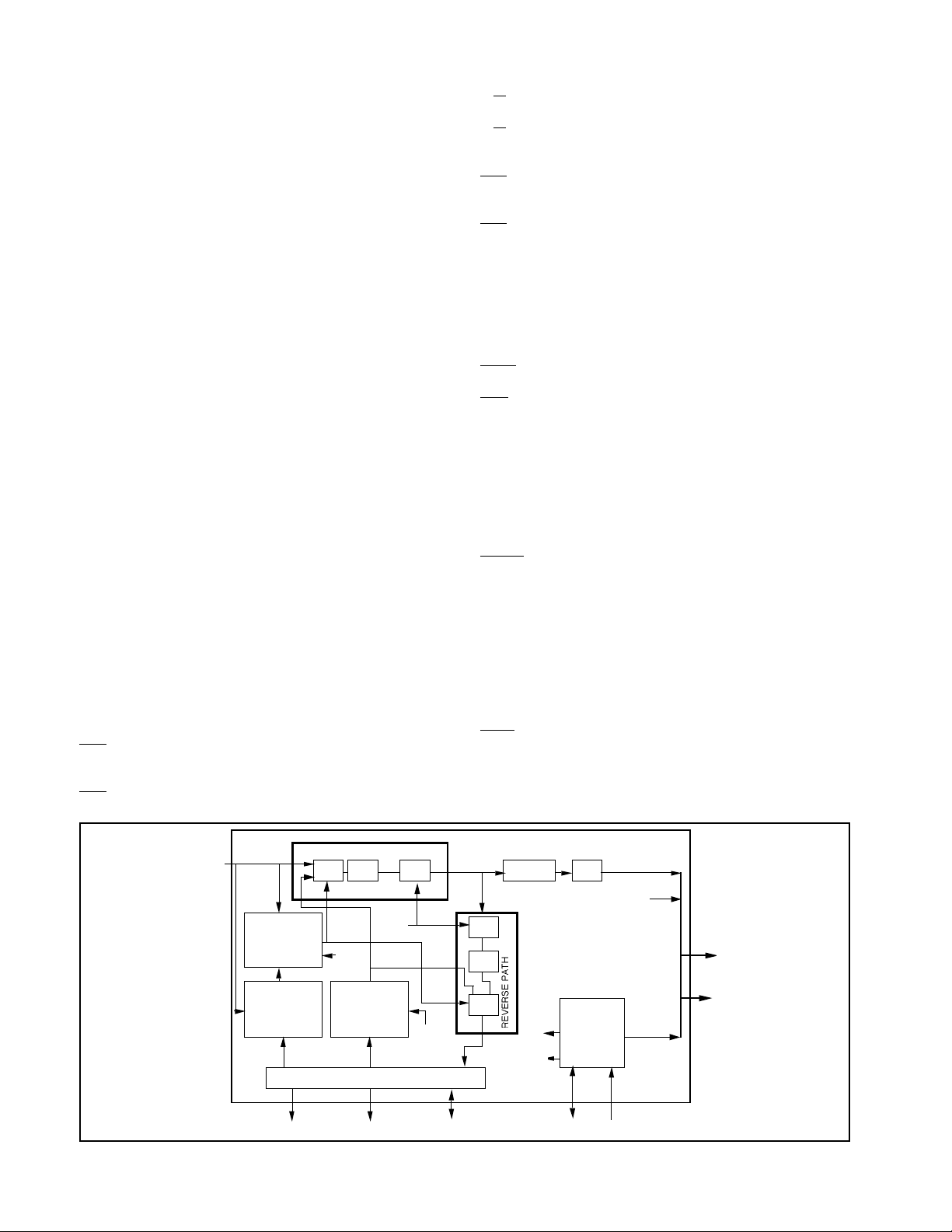

DECISION

MOTION

VECTOR

ESTIMATOR

Search

Window

FORWARD PATH

DCT

SUB

Q Step

Force

Intra

LOW

PASS

FILTER

Predicted

block

FRAME STORE INTERFACE

Q

Force

Filter

YUV

BLOCK

FORMAT

INTER/INTRA

PROCESSOR

RESET Active low power on reset which must be held

low for at least 2064 cycles.

TCK Test clock for JTAG.

TMS Test Mode Select for JTAG.

TDI Input JTAG test data.

TDO Output JTAG test data.

TRST Reset JTAG controller (active low).

NOTE:

"Barred" active low signals do not appear with a bar in the

main body of the text.

RLC

Motion Vectors

CONTROL

LOGIC

Block Info

DATA

BUS

BUS

FLAGS

IDCT

ADD

Zig Zag

IQ

Force

Intra

Force

Filter

ADDRESS

CONTROL

DATA

HOST DATA & CONTROL

Fig 2 : Simplified Block Diagram

2

Page 3

080004080

0

0

0

0

F

-

-

-

-

-

-

-

OPERATION OF MAJOR BLOCKS

Motion Vector Estimator

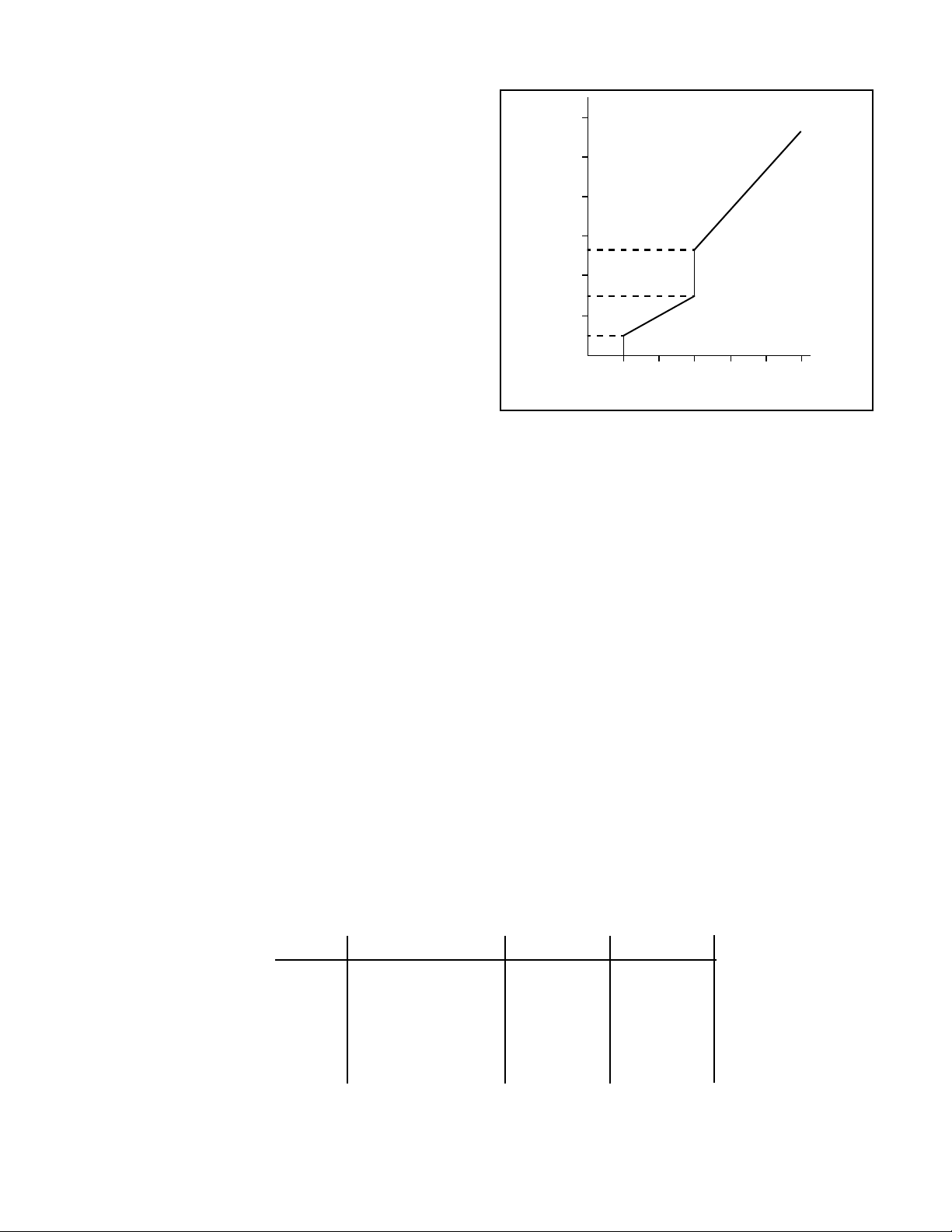

The motion estimator calculates the mean absolute error

( MAE ) for each possible position of the combined luminance

block in a search window from the previous frame. The

combined luminance block consists of 16 x 16 pixels, and in

the search window this is displaced between -7 to +7 vertically,

and -8 to +7 horizontally. The two lsb's of each pixel are

discarded and the MAE value is contained within 14 bits.

The minimum MAE value, representing the best match

between the previous and current block, is passed to the

motion compensation decision block, together with the position of this best fit in the search window. The zero displacement MAE value is also passed to this block, which then

decides whether the best fit is sufficiently better than the zero

displacement fit. It uses the characteristic shown in Figure 3,

where the 14 bit MAE is a Hex value. In the area to the right

of the line all points defined by the two MAE values will cause

motion compensation to be applied. In this case the best fit

MAE value is used by the inter/intra decision processor,

otherwise the zero displacement value is used.

Inter/Intra Decision Processor

The MAE value passed by the motion compensation

decision block is compared to the simplified variance of the

current block. This simplified variance is calculated by summing the moduli of the differences between each luminance

pixel and the mean luminance value over the whole macroblock. Eight bit pixels are used, and the variance value is

expressed in 14 bits by discarding the two lsb's from the actual

16 bit result. It can then be directly compared to the 14 bit MAE

value.

If the MAE value is below a user defined threshold inter

mode coding is always selected. The default threshold is 3, on

a scale from 0 to 255 using the 8 msb's from the 14 bit value.

Above this threshold inter mode is only selected if the variance

of the current block is greater than or equal to the MAE value

in use.

In order to avoid gradual picture degredation, every 61st

Macroblock input to the VP2611 is coded in intra mode

regardless of the above decision. As 61 is a prime number, this

will ensure that each macroblock will be transmitted in intra

mode at least once in every 61 transmissions. If FIX MACROBLOCK or SKIP PICTURE is invoked this `Force Intra'

VP2611

8

180

4

140

MC Off

100

CO

80

8

5

Minimum Mean Absolute Err or in Hex

40

4

20

4

40 80 CO 100 140 180

Zero Movement Absolute Error in Hex

Fig 3 : MC Decision Slope

counter will be disabled.

The user may overide the internal Inter/Intra decision at

any time using the CBUS control port. A user generated

forced inter mode will overide an internally generated `Force

Intra'.

Low Pass Filter

The macroblock selected from the previous frame in

motion compensated inter mode coding, will be filtered before

it is subtracted from the current block. This decision can be

overidden externally by the system controller. The Filter uses

a simple [ 1 2 1 ] characteristic in both vertical and horizontal

dimensions as specified in H.261 on the macroblock boundaries

[010] is used.

x = 1.125y

MC On

SYMBOL PARAMETER MINIMUM MAXIMUM

t RAC Access time from RAS

t CAC Access time from CAS

t RP RAS precharge time 50ns or under

t CP CAS precharge time 15ns or under

t RAS RAS pulse width 90ns or under

t CAS CAS pulse width 50ns or under

t REF Time to refresh 256 rows

N.B. All times are quoted assuming 27MHz operation. For lower clock

frequencies increase the above values proportionately.

Table 1 : External DRAM timing requirements

105ns or under

25ns or under

0.25ms or over

3

Page 4

VP2611

Frame Store Manager

The previous picture is stored in an external CIF DRAM

frame store, which is connected by a glueless interface. The

internal Frame Store Manager controls all read, write, and

refresh operations to these DRAMs. No provision is made to

allow the use of smaller DRAM's, if only QCIF operation is

required.

During the coding of each macroblock columns of the

search window are read from these DRAMs, and finally the

"best fit" macroBlock is obtained. At the completion of coding

the fully processed new macroblock is written to the DRAM's,

after it has been decoded again. In this way the frame store

maintains a bit-accurate duplicate of the image seen by the

Decoder (excepting transmission errors).

Several configurations are possible to make the required

128Kx16 store. Two 64K x 16 DRAMs could be employed; in

this case use the default 1M DRAM mode when setting up the

chip. Otherwise, a single 256K x 16 DRAM or four 256K x 4

DRAMs could be used. In these last two cases use OE1 as

ADR8, RW1 as R/W, and do not connect RW2 and OE2. Also,

use the Setup instruction at the CPORT to put the device into

4M DRAM mode.

Table 1 details the critical timing parameters which the

external DRAM must meet with SYSCLK running at 27MHz.

Note that, if used at slower speeds, the requirements on the

DRAM timing are relaxed with the exception of refresh. The

number of refresh cycles the VP2611 produces is directly

proportional to the SYSCLK frequency.

Discrete Cosine Transform

This circuit performs a Discrete Cosine Transform on each

8x8 sub block, whether in inter or intra mode. In intra mode,

eight bit pixel data is used, with a ninth implied sign bit ( all pixel

data is positive ). In inter mode the difference between the

current and best fit previous block is used. This will be a two's

complement number. Twelve bit coefficients are produced by

the DCT, and passed on to the quantizer.

Quantize

Zig Zag Scan

This is essentially an address generator which reorders

the DCT coefficients according to the standard zig-zag scan

pattern. This has the effect of concentrating the significant

coefficients at the beginning of the sub-block, improving the

efficiency of the Run Length Coder.

Run Length Coder

Each coefficient output from the zig zag scan is examined.

If it is non-zero, then the Run Length Coding circuit will pass

the coefficient magnitude to the output port along with its zero

count i.e. the number of zero magnitude coefficients preceding it within the same 8x8 sub-block.

Inverse Quantize

This circuit replicates the operation of the inverse quantizer in the decoder. It reconstructs the 12 bit DCT coefficients

from the 8 bit quantized inputs, using the 5 bit quantization

value. This is achieved using the following formulae.

If QUANT is odd :

REC = QUANT*(2*LEVEL+1) : LEVEL > 0

REC = QUANT*(2*LEVEL-1) : LEVEL < 0

If QUANT is even :

REC = QUANT*(2*LEVEL+1)-1 : LEVEL > 0

REC = QUANT*(2*LEVEL-1)+1 : LEVEL < 0

For Intra Coded DC Coefficients :

REC = 8*LEVEL

except if LEVEL=255 when REC=1024

If LEVEL=0 then REC=0 in all cases.

The reconstructed values (REC) are passed through a

Clipping Circuit in case of arithmetic overflow.

Thus, the Inverse Quantizer restores the DCT coefficients

to their original value but with quantisation error.

This section quantizes the results of the DCT by dividing

the 12 bit output from the DCT with a host supplied value. The

5 bit quantization value supplied corresponds to division of the

12 bit coefficients ( range ± 2048 ) by values from 2 to 62, but

in steps of 2. This variable quantization strategy allows the

volume of data generated by the encoder to be adjusted

dynamically, depending on the fullness of the transmission

buffer. For H.261 applications it uses the quantisation value

provided at the control port during the previous Macroblock

period (or at some earlier time). An option is provided which

allows two quantisation values to be used, one for use with

inter coded macroblocks, and the other for use with intra

coded macroblocks.

As specified in H.261, the DC coefficient of an Intra coded

Block is treated differently and the 12 bit value is always

divided by 8.

When the quantization value is small, and the DCT coefficient is large, there is a danger of overflow in the eight bit

output. To avoid this a clipping circuit is included at the output

of the quantizer, which saturates at the maximum values.

4

Inverse DCT

This circuit replicates the operation of the Inverse Cosine

Transform in the Decoder, and outputs 9 bit signed pixel data

(intra mode) or pixel difference data (inter mode). The IDCT

fully meets the CCITT specification.

Reconstruction Adder

In Inter Mode, the IDCT data is added to the best fit block

from the previous frame store. In Intra mode, the IDCT data is

simply added to zero. After the adder, the sign bit is removed

from the result to give 8 bit pixels. Clipping circuits ensure that

any pixels with values exceeding 255 are clipped to 255, and

any with negative values are clipped to zero (such values are

possible due to quantization noise).

Page 5

VP2611

Y

K

K

2064 cycles

YUV Input

Frame Store Read

Control Decisions

Frame Store Write

DBUS Output

MB1 MB2 MB3 MB4

DUMMY MB1 MB2 MB3

DUMMY MB1 MB2 MB3

DUMMY DUMMY DUMMY MB1

DUMMY DUMMY DUMMY MB1

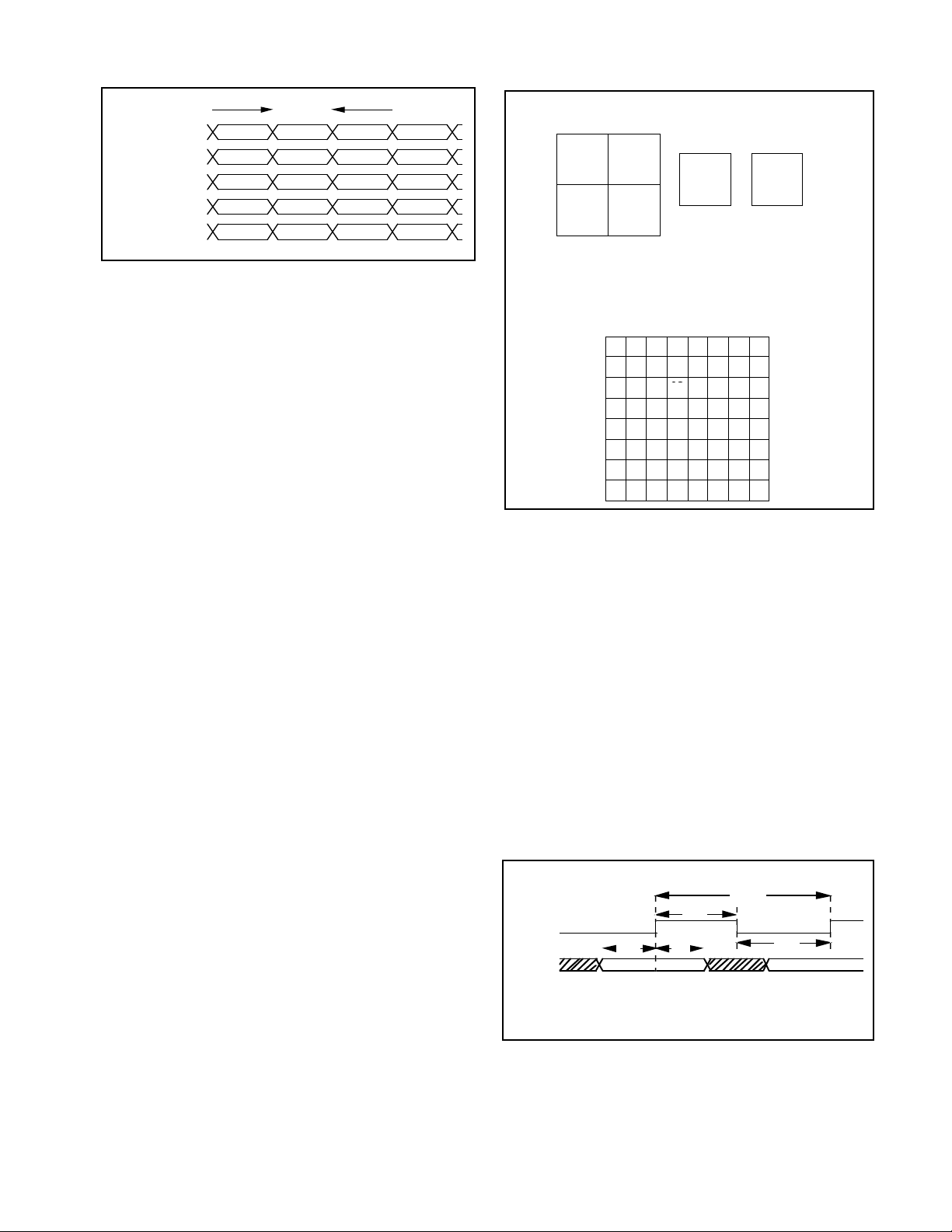

Fig 4: MacroBlock Pipelining

OPERATION OF INTERFACES

Macroblock Delays

The VP2611 has a three macroblock pipeline delay between pixel inputs and run length coded outputs. This is

illustrated in Figure 4. Whilst the second macroblock is being

input, the best fit macroblock from the previous frame is being

identified and then read from the frame store. At this time any

Control Decisions which are to effect the first macroblock must

be supplied by the host controller. The run length coded

outputs for the first macroblock are not available until the

fourth macroblock is supplied at the input pins.

YUV Input Port

The YUV port accepts pixel data from the preprocessor in

block format as illustrated in Figure 5. Within a complete

system the VP2611 is always the master device, and must be

supplied with macroblock data when it makes a demand. The

order in which pixels are supplied is pre-determined, and must

be strictly maintained. There are 64 pixels per sub-block and

4 luminance and 2 chrominance sub-blocks per macroblock.

The macroblocks themselves are divided into groups of blocks

( GOB's ), and the sequence specified in H.261 must also be

maintained. Note that, since the chrominance resolution is half

the luminance resolution both vertically and horizontally, then

the two chrominance blocks cover the same picture area as

the four luminance blocks.

The pre-processor producing macroblock data must produce a frame start signal ( FRMIN ) when it has a complete

frame of data available. This resets the input controller within

the VP2611, which will then generate sequential GOB and

macroblock numbers for the coded outputs referenced to this

input.

FRMIN must go high for at least one system clock period,

and must go low before the next frame is available. The

VP2611 responds to FRMIN with a request for macroblock

data ( REQYUV ), which occurs approximately 184 SYSCLK

periods after FRMIN. It must then receive a complete macroblock within 1871 SYSCLK periods, and at the end of this time

REQYUV will go inactive. The VP2611 must be provided with

a PCLK signal to strobe in the data. This must be derived from

SYSCLK, and must only be present when there is valid data

at the input. Data must meet the set up and hold times with

respect to PCLK as specified in Figure 6.

The maximum peak rate for PCLK is the SYSCLK rate

divided by two, but since there are 384 bytes per macroblock

SUBBLOCK ORDER WITHIN MACROBLOC

1 2

5

3 4

PIXEL ORDER WITHIN SUBBLOC

00 01 02 03 04 05 06 07

08 09 10 11 12 13 14 15

16 17 18 03 20 21 22 23

24 25 26 27 28 29 30 31

32 33 34 35 36 37 38 39

40 41 42 43 44 45 46 47

48 49 50 51 52 53 54 55

56 57 58 59 60 61 62 63

U

19

6

V

Fig 5 : Ordering of Pixels

then theoretically the average rate need only be 384/1871

times the SYSCLK rate. Note that PCLK must always be

obtained by dividing SYSCLK by an integer greater than one.

When the VP520 CIF/QCIF Converter is supplying the VP2611

with data, it provides a peak PCLK rate equivalent to SYSCLK

divided by two, and an average rate of SYSCLK divided by

four.

The mimimum gap between REQYUV going active is

2064 SYSCLK periods. In full CIF mode "dummy" macroblocks are internally inserted between rows, in order to give the

chip sufficient time to load a new search window. No new YUV

data must be loaded during these dummy macroblocks, and

REQYUV will remain inactive. No dummy macroblocks are

required in QCIF mode. With a 27MHz SYSCLK all macroblocks will be coded in less than a 30Hz frame rate period, and

there will be a period of inactivity before FRMIN goes active

again. During this period the output bus will remain static at all

ones, and no output strobe ( DCLK ) will be produced.

SCLK/2

20ns

PCLK

YUV7:0

20ns

10ns

N.B. All timings given are MINIMUM values.

0ns

Fig 6 : Timing at YUV Port

5

Page 6

VP2611

DBUS Output Port

The DBUS port is used to pass data and control information directly to the VP2612 Video Multiplexer. The type of data

on the output pins is identified by the DMODE 3:0 outputs,

using the codes shown in Table 2. An output strobe is also

produced ( DCLK ) which always goes high one system clock

period after the data defined by DMODE 3:0 becomes valid.

This edge is used to strobe the data into the Video Multiplexer,

and thus the data set up time is always one SYSCLK period

minus differential output delays.

The number of SYSCLK periods during which data remains valid is dependent on the type of data, and DCLK

remains high for this same period. It goes low as the result of

the same SYSCLK rising edge which produces a change in

DMODE 3:0. The output delays with respect to SYSCLK are

illustrated in Figure 8, and Figure 9 shows a typical output

sequence during which DCLK remains high for several cycles

as the sub-block number ( code 7 ) is produced. During a Wait

State

( code 15 ) no DCLK transitions are produced. The actual

sequence of output events which occur for each macroblock,

and the duration of each event, are illustrated in Figure 7.

The output events are defined in more detail below;

Control Decisions : This byte shows which control decisions

have been taken for the forthcoming macroblock. DBUS0

will be high if a Fixed Macroblock (FIX MB) was enforced

i.e. no new data will be transmitted this macroblock.

DBUS1 indicates whether Inter (high) or Intra (low) coding

was used for the macroblock. DBUS2 will be high if the

macroblock was filtered, and DBUS3 will be high if motion

compensation was used. DBUS5 will be high if the current

frame is being coded in FAST UPDATE mode. In this

mode the complete frame will be intra coded. DBUS6 will

be high if the current frame is a SKIP FRAME i.e. not being

coded - so no coefficients will be transmitted. DBUS4 and

DBUS7 are not used.

START MB

WAIT

IS IT

A DUMMY

BLOCK?

no

CONTROL (2 cycles)

GOB (2 cycles)

MB

CBP (2 cycles)

QUANT (2 cycles)

HORZ MV (2 cycles)

VERT MV

ARE

ANY BLOCKS

CODED?

yes

WAIT (32 cycles)

SUB BLK NO (15 cycles)

RUN LENGTH

MAGNITUDE

(2 cycles)

yes

(2 cycles)

(2 cycles)

no

(2 cycles)

(2 cycles)

WAIT

(1 cycle)

DMODE3:0 FUNCTION

0000

0001

0010

0011

0100

0101

0110

0111

1000

1001

1010

1011

1100

1101

1110

1111

6

Table 2 : DBUS Functions

GOB Number

MB Number

Control Decisions

Quant Value

Horizontal MV

Vertical MV

Coded Blk Pattern

Sub-Block No

Zero Run Count

RLC Coefficient

Not used

Not used

Not used

Not used

Not used

Wait State

ALL COEFFS

no

yes

no

ALL BLOCKS

yes

END MB

ARE

O/P?

WAIT

ARE

O/P?

WAIT

(wait variable time to make total

time since start of sub-block up

to 335 cycles)

(variable cycles)

Fig 7 : DBUS Port Flow Chart

Page 7

VP2611

N

r

r

SCLK

DCLK

DATA FROM

VP2611

DMODE

3:0

20ns max

25ns max

20ns max

DATA VALID

DATA VALID

Fig 8: Timing diagram

GOB Number : At the start of each new macroblock, the

current GOB Number is output on DBUS3:0. (DBUS3 is

MSB).

MB Number : After the GOB Number, the macroblock

Number is output on DBUS5:0 (DBUS5 is MSB).

Coded Block Pattern : This byte contains a 6 bit linear code

that indicates which of the sub-blocks actually contain

coded data. DBUS6 will be high if sub-block 1 contains

coded data, through to DBUS 1 being high if sub-block 6

contains coded data. DBUS7 and DBUS0 are not used.

Note that if the macro block is not motion compensated

and the coded block pattern is all zero's, the fixed macro

block bit will be set in the control decisions byte.

Quant Value :The quantisation value used in processing the

current macroblock is output on DBUS4:0 (DBUS4 is

MSB). This represents an actual quantisation level between 2 and 62, in steps of 2 and as defined in H.261.

Horizontal MV : If motion compensation is used, the horizontal

component of the motion vector will be output on DBUS4:0

(DBUS4 is MSB). This 5 bit value represents a two's

complement number in the range +/-15

(although only vectors in the range -8 to +7 are currently

possible with the VP2611).

Vertical MV : If motion compensation is used, the vertical

component of the motion vector will be output on DBUS4:0

(DBUS4 is MSB). This 5 bit value represents a two's

complement number in the range ±15 ( although only

vectors in the range ±7 are currently possible with the

VP2611).

CBUS3:0 INSTRUCTIO

0000

0001

0010

0011

0100

0101

0110

0111

1000

1001

1010

1011

1100

1101

1110

1111

Input VAR Threshold

Reserved

Input Inter Quantiser

Input Intra Quantiser

Input Setup Data

Input Control Functions

Reserved

Reserved

Output GOB Numbe

Output MB Numbe

Reserved

Output Control Decisions

Output Setup Data

Reserved

Reserved

Overide internal clock doubler

Table 3 : CBUS Instruction Codes

Sub-block Number : An identifier for the run length coded

coefficients which are about to be made available. DBUS

2:0 contain the coded sub-block number from 1 to 6. All

zero sub-blocks will not be produced at the outputs, and

their corresponding numbers will not appear.

Zero Run Count : The number of zero valued coefficents

preceding the next non zero coefficient is available on

DBUS5:0 (DBUS5 is MSB). Normally, DBUS7:6 are low,

except to signify the end of a Sub-block, when they will

both be high. Zero Run Count is always followed by a

coefficient, even at the end of a sub-block.

RLC Coefficient : This byte contains the 8 bit coefficient value.

It will always be a non-zero value, except when the

previous Zero Run Count signalled the end of sub-Block.

A zero value is then possible since, as stated above, the

run count is always followed by a coefficient byte, which

may be zero if the last coefficient is zero.

Wait State : This indicates that no valid data is being output

from the DBUS port during this cycle. No DCLK is produced for this state.

Pins which are "not used" for certain functions will be

forced low.

This diagram shows a typical Sub-block being output from the VP2611.

DCLK

DMODE

DBUS

15

Both msb's are high showing end of block.

15

1515 7 8 9 8 9 8 9

XX

XX 2 0 4 1 -2 252 0

Fig 9: DBUS Timing

7

Page 8

VP2611

GOOCUS

CBUS Control Port

The CBUS control port is used to input control and setup

information and also to output status information. In order to

save on pin count, a microprocessor driving this port is

required to execute two I/O instructions in order to transfer a

single byte of information to or from the device. The first

transfer is always a write operation, with a low level on the

single address line which is used by the interface. Data on the

bus then defines the instructions listed in Table 3. The second

transfer can be a read or write operation as necessary, but the

address line must then be high with the set up time given in

Figure 10.

In addition to the single addresss line (CADR), data

transfers use a control strobe (CSTR) which is only effective

when a chip enable is present (CEN). Detailed timing informa-

WRITING DATA FROM THE CBUS:

This diagram shows a typical instruction and associated data field being written to the device.

10ns

CEN

CADR

CSTR

CBUS

I/P

20ns

20ns

20ns

20ns

20ns

20ns

20ns

20ns

INSTRUCTION

10ns

10ns

10ns

10ns

10ns

20ns

tion is given in Figure 10, and when writing data or instructions

to the VP2615 the set up and hold times which are referenced

to the rising edge of CSTR must be maintained.

When a write instruction has been defined CADR should

be pulled high, valid data presented to CBUS7:0 and then

strobed in using CSTR. Other system I/O transfers can occur

between defining a write operation and supplying the data to

be written, assuming CEN is not active during those other

transfers. If CSTR does not go active because of I/O transfers

to other devices, then CEN can remain active low between the

instruction and data.

When a read instruction has been specified the requested

data will then be output on CBUS7:0 after the access time

specified from CEN going low, assuming that CADR was

already high. Otherwise the data will become valid after the

access time specified from CADR going high after CEN was

10ns

20ns

20ns

20ns

20ns

DATA IN

10ns

10ns

READING INFORMATION ON CBUS :

This diagram shows a typical instruction and associated data field being read from the device.

CEN

CADR

CSTR

CBUS

If Th is less than 5 ns then CBUS may be driven by the VP2615until CEN going high eventually turns off

the drivers. It will not prevent correct data being read when CEN again goes active

N.B. All timings shown are minimum values except those marked * which are maximums.

20ns

10ns

Th

20ns

20ns

20ns

INSTRUCTION

10ns

10ns

20ns

50ns

Fig 10 : Use of the Control Port

10ns

20ns

20ns

20ns

20ns

*

*

DATA OUT

10ns

10ns

20ns

*

8

Page 9

VP2611

low. Note that in the data read phase CADR must always go

high before CSTR goes high, with the set up time specified.

When CEN goes high, or CADR goes low, the CBUS will go

high impedance after the delay specified.

Note that the access times under the conditions given

above are only true when the gap between CSTR going high

in the instruction phase, and CEN going low in the data phase,

is greater than the minimum specified in figure 10.

Only the four LSBs, CBUS3:0, are used when writing

instructions to the VP2611. The remaining bits, CBUS7:4,

should be pulled low while the instruction is strobed into the

VP2611.

The instructions listed in Table 3 are described below in

greater detail;

Input VAR Threshold: VAR is the difference between the best

fit MAE value and the variance of the current macroblock.

The VAR Threshold is the best fit MAE value below which

Inter Frame Prediction is always used, no matter what the

variance of the current block. Above this threshold inter

mode coding is only used if the best fit value is less than

the current block variance. The default value is 3, within a

range of 0 - 255 using the eight most significant bits of the

14 bit value. In normal operation values below 15 should

be used.

Decision circuitry will be overidden according to CBUS1;

if CBUS1 is HIGH then all subsequent macroblocks will be

intra coded, if it is LOW they will be inter coded. When

CBUS2 is HIGH the on-board Filter Decision circuitry is

overidden according to CBUS3; if CBUS3 is HIGH then the

filter will be forced on, if it is LOW the filter will be forced off.

If CBUS4 is HIGH then FIX MB will be implemented, and

no new data from the current macroblock will be coded. A

two macroblock delay exists between defining the Force

Inter/Intra, Force Filter or FIX MB decisions through the

control bus and data being affected at the outputs. These

decisions will stand for all subsequent macroblocks until

they are again changed. If CBUS5 is HIGH a FAST

UPDATE will be performed on the next frame and all

blocks will be coded in intra mode. If CBUS6 is HIGH then

the next frame will not be transmitted ( SKIP FRAME ).

Note that these two global frame bits do not take effect until

the start of the next frame, and stay in effect for all frames

until they are removed. If CBUS7 is HIGH, then the onboard Force Update Controller will be overidden, and the

user will have to enforce their own Force Update policy

using the Force Intra command. RESET will cause the

options to default to those defined by the LOW state. Note

that SKIP FRAME has priority over any other bits and that

FIXMB has priority over all bits bar SKIP FRAME. See

note below.

Input Inter Quantiser: Coefficents of inter coded macroblocks

will be quantized using the value on CBUS4:0 following

this instruction. Internally this represents a 6 bit number

with the lsb always zero, giving a value between 0 and 62

in steps of two. Where only one quantization value is to be

used for both inter and intra cases, this instruction should

be used. On reset the value will default to the maximum

allowed. See note below.

Input Intra Quantiser: This instruction is similar to the above,

except that it defines the quantization level for intra mode

coding when it is to be different to that of inter mode coding.

See note below.

Input Setup Data: This instruction allows several user defined

options to be specified, using individual bits in the following

data word. If CBUS0 is LOW the device will work in full CIF

mode , if HIGH it uses the QCIF mode. If CBUS3 is HIGH

both inter and intra quantization values will be used,

otherwise a common value will be used. If CBUS5 is high

then the motion compensation circuits will be disabled. If

CBUS6 is high, then the device will be configured to use

256K x 16 or 256K x 4 DRAM's, otherwise it will assume the

use of two 64K x 16 DRAM's. The default conditions after

RESET are those selected by the Low level. CBUS1,

CBUS2, CBUS4 and CBUS7 are not used but must be low

during the definition phase. This instruction may be used

any time after RESET has gone high, but the video input

bus must not be active. If a subsequent mode change

between CIF and QCIF is made then a further RESET is

needed.

Input Control Functions: This instruction specifies several

control options using individual bits in the following data

word. If CBUS0 is HIGH then the on board Inter/Intra

Output GOB Number: This instruction will output the GOB

Number on CBUS3:0, for the data currently being output

on DBUS. CBUS7:4 are not used (always low).

Output MB Number: This instruction will output the macrob-

lock number on CBUS5:0, for the data currently being

output on DBUS. If CBUS6 is low it indicates that the

macroblock number has just changed, or is about to

change. New Quantization Value or Control Function

words should not be written at this time since it is uncertain

which macroblock they will effect. CBUS7 is not used

(always low).

Output Control Decisions: This instruction will output the

details of several control decisions on the CBUS. CBUS0

shows whether the MacroBlock currently being output on

DBUS was inter or intra coded (0=Intra). CBUS1 shows

whether motion compensation was used (1=MC used).

CBUS3 shows whether the macroblock was passed

through the loop filter or not (1=Filtered). CBUS4 will be

high if the FIX MB instruction was enforced. CBUS5 will be

high if FAST UPDATE is currently being undertaken.

CBUS6 will be high if SKIP FRAME is in force. CBUS2 and

CBUS7 are not used.

Output Setup Data: This instruction allows the user to verify

the internal setup previously selected. The bits have the

same significance as in the Input Setup Data Instruction.

Note

For definitive operation the output MB number should be

read first, and these bytes only changed if CBUS b is high.

9

Page 10

VP2611

g

Initialising the VP2611

On power-up, RESET should be low and must remain low

for at least 2064 cycles of SYSCLK. After RESET is pulled

high, FRMIN may be activated to start the first frame. Before

activating FRMIN for the first time, it is advisable to use the

CBUS to implement a FAST UPDATE for the first frame (i.e.

all blocks Intra coded).

JTAG Test Interface

The VP2611 includes a test interface consisting of a

boundary scan loop of test registers placed between the pads

and the core of the chip. The control of this loop is fully JTAG/

IEEE 1149-1 1990 compatible. Please refer to this document

for a full description of the standard.

The interface has five dedicated pins: TMS, TDI, TDO,

TCK and TRST. The TRST pin is an independent reset for the

interface controller and should be pulsed low, soon after

power up; if the JTAG interface is not to be used it can be tied

low permanently. The TDI pin is the input for shifting in serial

instruction and test data; TDO the output for test data. The

TCK pin is the independent clock for the test interface and

registers, and TMS the mode select signal.

TDI and TMS are clocked in on the rising edge of TCK, and

all output transitions on TDO happen on its falling edge.

Instructions are clocked into the 8 bit instruction register

(no parity bit) and the following are available.

Instruction Register Name

( MSB first )

11111111 BYPASS

00000000 EXTEST (No inversion)

01000000 INTEST

XX001011 SAMPLE/PRELOAD

Timing details for the JTAG control signals are shown in fig

11.The maximum TCK frequency is 5 MHz.

The test registers, their positions in the boundary loop and

the corresponding i/o pad are detailed in Table 4. Note that the

three state control signals also have test registers associated

with them which are labelled as TRI in Table 4. DHz is an

output enable for all signals to the DRAM. The order given in

Table 4 determines the serial data stream needed for JTAG

testing.

TCK

Signal

TCK

Signal

TMS toTCK timing

TDI to TCK timing

Chip i/p to TCK timin

TCK to TDO timing

Fig 11 : JTAG Interface timing

Tsu

Thd

Tprop

Tsu Thd Tprop

15

15

15

5

5

5

20

Pad Type Reg No Pad Type Reg No Pad Type Reg No

RESET

CADR

CSTR IN

CEN IN

CBUS0 OP

CBUS1

CBUS2

CBUS3

CBUS4

CBUS5 OP

CBUS6

CBUS7

DCLK OP

DMODE0 OP

DMODE1 OP

DMODE2

DMODE3

DBUS0 OP

DBUS1 OP

DBUS2 OP

DBUS3 OP

DBUS4

IN 93

IN

TRI

IN

OP

IN

OP

IN

OP

IN

OP

IN

IN

OP

IN

OP

IN

OP

OP

OP

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

DBUS5 OP

DBUS6 OP

DBUS7 OP

SW15 OP

SW14 OP

SW13 OP

SW12 OP

SW11 OP

SW10 OP

SW9 OP

SW8 OP

SW7

SW6 OP

SW5 OP

SW4 OP

TRI

IN

IN

IN

IN

IN

IN

IN

IN

OP

IN

IN

IN

IN

SW3 OP

IN

SW2 OP

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

IN

SW1 OP

SW0 OP

REQYUV

IN

IN

DHZ TRI

RAS OP

CAS OP

RW1 OP

RW2 OP

OE1 OP

OE2 OP

ADR0 OP

ADR1 OP

ADR2 OP

ADR3 OP

ADR4 OP

ADR5 OP

ADR6 OP

ADR7 OP

PCLK IN

YUV7

YUV6 IN

YUV5 IN

YUV4 IN

YUV3 IN

YUV2 IN

SYSCLK IN

FRMIN

IN

YUV1 IN

YUV0 IN

IN

OP

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

IN

3

2

1

0

10

Table 4 Pin and JTAG test registers

Page 11

ABSOLUTE MAXIMUM RATINGS [See Notes]

Supply voltage VDD -0.5V to 7.0V

Input voltage V

Output voltage V

Clamp diode current per pin I

Static discharge voltage (HBM) 500V

Storage temperature T

Ambient temperature with power applied T

IN

OUT

(see note 2) 18mA

K

S

Junction temperature 125°C

Package power dissipation 3000mW

NOTES ON MAXIMUM RATINGS

1. Exceeding these ratings may cause permanent damage.

Functional operation under these conditions is not implied.

2. Maximum dissipation for 1 second should not be exceeded,

only one output to be tested at any one time.

3. Exposure to absolute maximum ratings for extended

periods may affect device reliablity.

4. Current is defined as negative into the device.

-0.5V to VDD+ 0.5V

-0.5V to VDD + 0.5V

-55°C to 150°C

AMB

0°C to 70°C

VP2611

STATIC ELECTRICAL CHARACTERISTICS Operating Conditions (unless otherwise stated)

Tamb = 0 C to +70°C VDD = 5.0v ± 5%

Characteristic

Output high voltage

Output low voltage

Input high voltage

Input low voltage

Input leakage current

Input capacitance

Output leakage current

Output S/C current

Symbol

V

OH

V

OL

V

IH

V

IL

I

IN

C

IN

I

OZ

I

SC

Min.

2.4

-

2.0

-

-10

-50

10

Value

Typ.

10

Max.

-

0.4

-

0.8

+10

+50

300

Units

V

V

V

V

µA

pF

µA

mA

Conditions

I

= 4mA

OH

I

= -4mA

OL

V

-1V for SYSCLK and PCLK

DD

GND < V

GND < V

VDD = Max

IN

OUT

< V

< V

DD

DD

ORDERING INFORMATION

VP2611 CG GH1R (Commercial - Plastic QFP power package)

11

Page 12

VP2611

Pin

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

Function

SW3

NC

SW4

SW5

GND

VDD

SW6

SW7

NC

SW8

SW9

SW10

SW11

NC

GND

SW12

NC

VDD

SW13

SW14

NC

SW15

DBUS7

DBUS6

NC

DBUS5

GND

VDD

DBUS4

DBUS3

NC

DBUS2

NC

NC

DBUS1

DBUS0

DMODE3

NC

GND

VDD

DMODE2

DMODE1

DMODE0

Pin

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

Function

DCLK

NC

CBUS7

VDD

CBUS6

GND

VDD

CBUS5

GND

CBUS4

CBUS3

CBUS2

CBUS1

NC

GND

VDD

CBUS0

TRST

CEN

NC

NC

CSTR

NC

CADR

RESET

VDD

GND

TCK

TMS

TDI

NC

TDO

(CLK54)

REQYUV

FRMIN

VDD

NC

SYSCLK

GND

NC

YUV0

YUV1

YUV2

Pin

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

Function

YUV3

NC

YUV4

YUV5

VDD

GND

YUV6

YUV7

NC

PCLK

NC

NC

ADR7

ADR6

ADR5

VDD

GND

NC

ADR4

ADR3

ADR2

ADR1

GND

ADR0

VDD

GND

NC

OE2

OE1

VDD

RW2

RW1

CAS

RAS

VDD

GND

NC

SW0

SW1

SW2

NC

NC

12

Pin out table for GH128 PQFP package

Page 13

Page 14

http://www.mitelsemi.com

World Headquarters - Canada

Tel: +1 (613) 592 2122

Fax: +1 (613) 592 6909

North America Asia/Pacific Europe, Middle East,

Tel: +1 (770) 486 0194 Tel: +65 333 6193 and Africa (EMEA)

Fax: +1 (770) 631 8213 Fax: +65 333 6192 Tel: +44 (0) 1793 518528

Fax: +44 (0) 1793 518581

Information relating to products and services furnished herein by Mitel Corporation or its subsidiaries (collectively “Mitel”) is believed to be reliable. However, Mitel assumes no

liability for errors that may appear in this publication, or for liability otherwise arising from the application or use of any such information, product or service or for any infringement of

patents or other intellectual property rights owned by third parties which may result from such application or use. Neither the supply of such information or purchase of product or

service conveys any license, either express or implied, under patents or other intellectual property rights owned by Mitel or licensed from third parties by Mitel, whatsoever.

Purchasers of products are also hereby notified that the use of product in certain ways or in combination with Mitel, or non-Mitel furnished goods or services may infringe patents or

other intellectual property rights owned by Mitel.

This publication is issued to provide information only and (unless agreed by Mitel in writing) may not be used, applied or reproduced for any purpose nor form part of any order or

contract nor to be regarded as a representation relating to the products or services concerned. The products, their specifications, services and other information appearing in this

publication are subject to change by Mitel without notice. No warranty or guarantee express or implied is made regarding the capability, performance or suitability of any product or

service. Information concerning possible methods of use is provided as a guide only and does not constitute any guarantee that such methods of use will be satisfactory in a specific

piece of equipment. It is the user’s responsibility to fully determine the performance and suitability of any equipment using such information and to ensure that any publication or

data used is up to date and has not been superseded. Manufacturing does not necessarily include testing of all functions or parameters. These products are not suitable for use in

any medical products whose failure to perform may result in significant injury or death to the user. All products and materials are sold and services provided subject to Mitel’s

conditions of sale which are available on request.

M Mitel (design) and ST-BUS are registered trademarks of MITEL Corporation

Mitel Semiconductor is an ISO 9001 Registered Company

Copyright 1999 MITEL Corporation

All Rights Reserved

Printed in CANADA

TECHNICAL DOCUMENTATION - NOT FOR RESALE

Loading...

Loading...