Page 1

GND

FB/SD

V

ref

V

+

CAP

+

OSC

V

OUT

CAP

-

GND

FB/SD

V

ref

V

+

CAP

+

OSC

V

OUT

CAP

-

FEATURES

V

ref

CAP

+

+

-

BANDGAP

REFERENCE

CONTROL

Q

Q

OSC

1.25 V

CAP

-

V

OUT

DRIVE

DRIVE

DRIVE

DRIVE

V +

FB/SD

OSC

GND

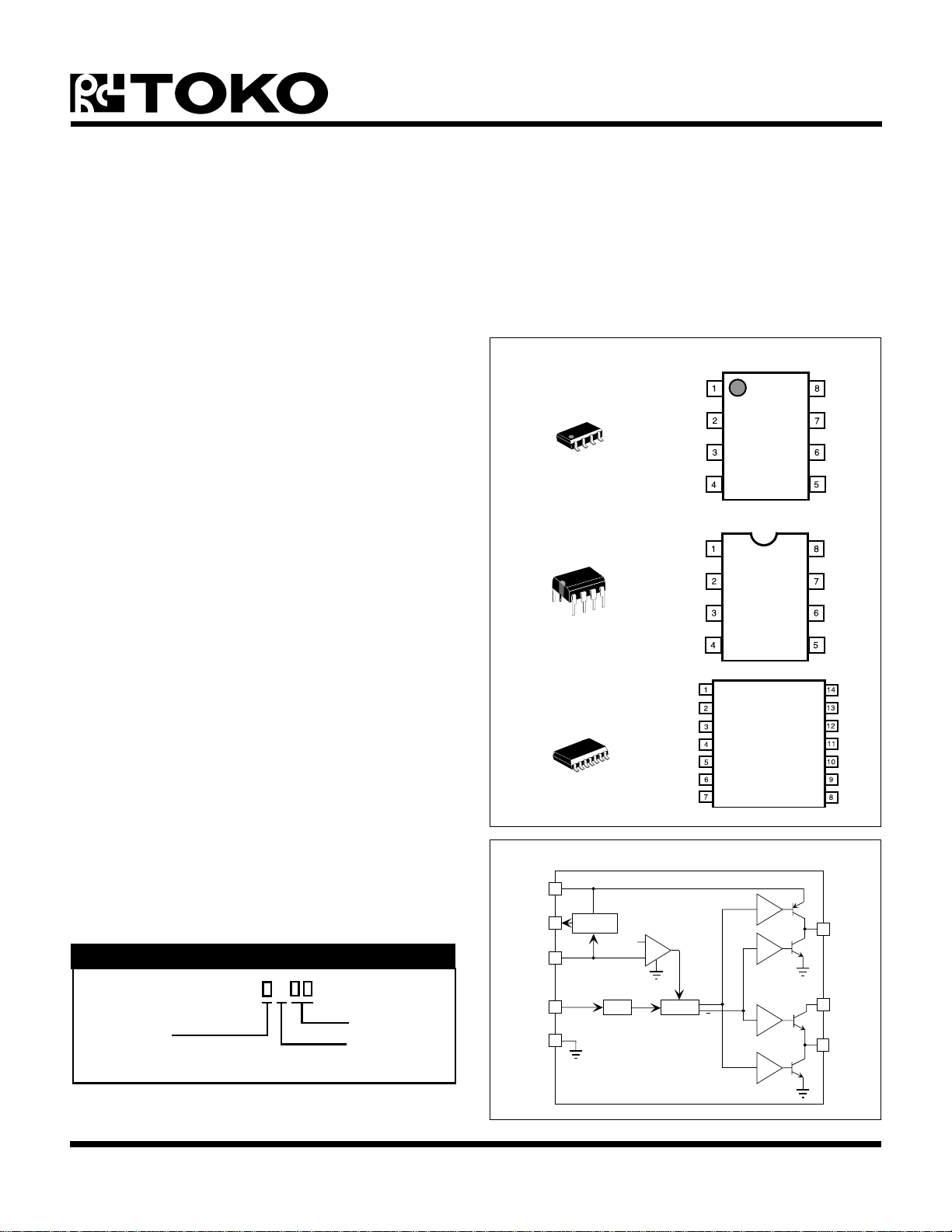

TK75018

SWITCHED CAPACITOR VOLTAGE

CONVERTER WITH REGULATOR

APPLICATIONS

■ 35 mA (typ.) Output Current

■ Operating Range 3.5 to 7 V

■ Reference and Error Amplifier for Regulation

■ External Shutdown

■ External Oscillator Synch

DESCRIPTION

The TK75018 is a monolithic switched capacitor converter

with feedback control. With just two capacitors, the TK75018

can create a negative voltage supply which tracks a

positive supply. As an alternative, the feedback pin can be

used to establish regulation at a desired voltage, and it can

also be used as a shutdown signal input. A single TK75018

can also be configured as a non-inverting step-up converter

or dual output voltage doubler.

With no external timing elements, the converter will selfoscillate at 25 kHz, nominal. This frequency can also be

user adjusted with a small capacitor or synchronized to

another oscillator.

Quiescent current is typically 2.5 mA. Standby current is

guaranteed less than 200 µA over the full operating

temperature and input voltage ranges.

■ Voltage Inverter

■ Negative Voltage Doubler

■ Voltage Regulator

■ Positive Voltage Doubler

TK75018

FB/SD

NC

CAP

GND

NC

CAP

NC

+

V

+

-

NC

OSC

V

ref

NC

NC

V

OUT

BLOCK DIAGRAM

ORDERING INFORMATION

TK75018 C

Package Code

PACKAGE CODE

D: DIP-8

M: SOP-8

V: TSSOP-14

May 1999 TOKO, Inc. Page 1

TEMPERATURE RANGE

C: -20 TO 80 °C

Tape/Reel Code

Temp. Range

TAPE/REEL CODE

TL: Tape Left

Page 2

TK75018

ABSOLUTE MAXIMUM RATINGS

Supply Voltage VIN For Doubler Conf. ....................... 7 V

Supply Voltage VIN For Regulating Conf................... 8 V

Power Dissipation TK75018M (Note 1).............. 600 mW

Power Dissipation TK75018D (Note 2) ............ 1000 mW

Storage Temperature Range ................... -55 to +150 °C

Operating Temperature Range .....................-20 to 80 °C

Junction Temperature .......................................... 150 °C

Lead Soldering Temperature (10 s) ..................... 235 °C

Power Dissipation TK75018V (Note 3) .............. 950 mW

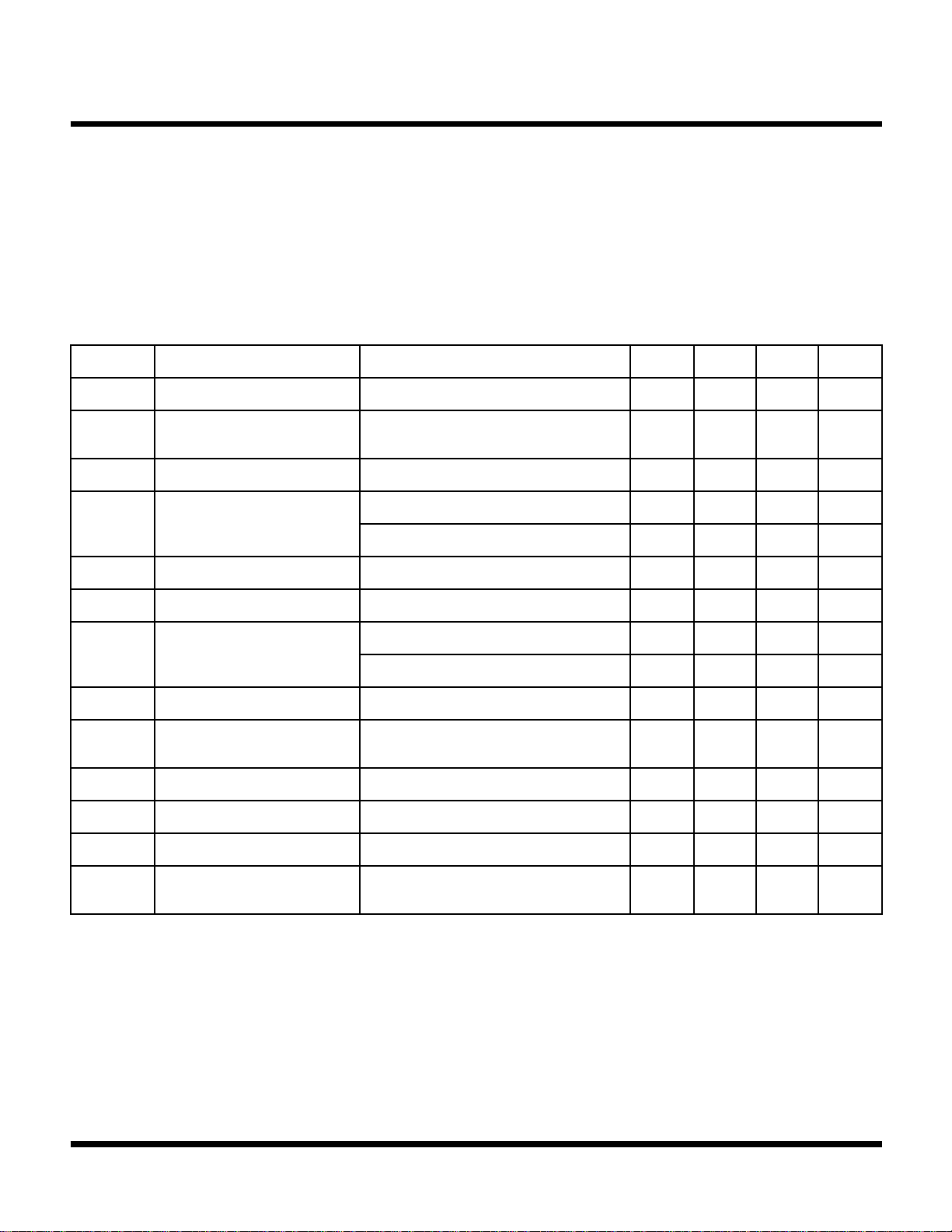

TK75018 ELECTRICAL CHARACTERISTICS

Test conditions: V

SYMBOL PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

I

CC(Reg)

I

CC(Inv)

V

CC

V

LOSS

R

OUT

f

OSC

V

ref

Mode

Reference Voltage

= 5.0 V, TA = Tj = Operating Temperature Range, Note 6 Configuration, unless otherwise specified.

IN

Supply Current Regulating I

Supply Current Inverting

= 0 mA, (Note 6) 2.5 3.5 mA

LOAD

= 0 mA 3.5 4.5 mA

I

LOAD

Supply Voltage Range Under Note 6 Conditions 3.5 7 V

= 1 mA, (Note 4) 0.35 0.55

I

OUT

Voltage Loss (VIN - V

Output Resistance

OUT

)

= 20 mA, (Note 4) 1 1.5

I

OUT

= 1 mA to 20 mA, (Notes 4,5)

∆I

OUT

32 54

Oscillator Frequency 3.5 V ≤ VIN ≤ 7 V, (Note 6) 15 25 35 kHz

= 25 °C 2.35 2.50 2.65 V

T

= T

j

A

= Operating Temp. Range 2.25 2.75 V

T

= T

j

A

V

V

Ω

V

OUT

Line Reg Line Regulation

LoadReg

LoadReg

I

STBY

R

OUT(Ref)

Note 1: Power dissipation is 600 mW when mounted as recommended. Derate at 4.8 mW/°C for operation above 25 °C.

Note 2: Power dissipation is 1000 mW when mounted as recommended. Derate at 8 mW/°C for operation above 25 °C

Note 3: Power dissipation is 950 mW when mounted as recommended. Derate at 7.6 mW/ °C for operation above 25 °C.

Note 4: Device is connected as an inverter, with pins 1, 6, and 7 unconnected; CIN = 2.2 µF tantalum, C

Note 5: Output resistance means the slope of the ∆V

Note 6: Device is connected as a positive to negative converter/regulator with R1 = 44.2 k, R2 = 154 k, C1 = 4.7 nF, C

CIN = 2.2 µF tantalum, C

Regulated Voltage Tj = 25 °C, I

Load Regulation @ 20 mA 1 mA ≤ I

1

Load Regulation @ 35 mA 1 mA ≤ I

2

Standby Current V

Reference Output

Resistance

of the curve.

= 33 µF tantalum.

OUT

3.5 V ≤ V

(Note 6)

= 0 V, (Note 6) 60 200 µA

PIN1

≤ 80 µA 350

V

ref

vs. ∆I

OUT

= 1 mA, (Note 6) -2.8 -3.0 -3.2 V

L

≤ 7 V, I

IN

≤ 20 mA, (Note 6) 20 150 mV

OUT

≤ 35 mA, (Note 6) 60 300 mV

OUT

curve, for output currents of 1 to 20 mA. This represents a linear approximation

OUT

= 1 mA,

L

15 80 mV

= 33 µF tantalum.

OUT

VIN

Ω

= 4.7 µF tantalum,

Page 2 May 1999 TOKO, Inc.

Page 3

C

V

OUT

(V)

-2.8

OUTPUT VOLTAGE

REGULATING @ 35 mA LOAD

VS.

TEMPERATURE

TEMPERATURE (°C)

-50 0 50 100

-3.0

-3.1

-3.2

-3.15

-3.05

-2.85

-2.95

-2.90

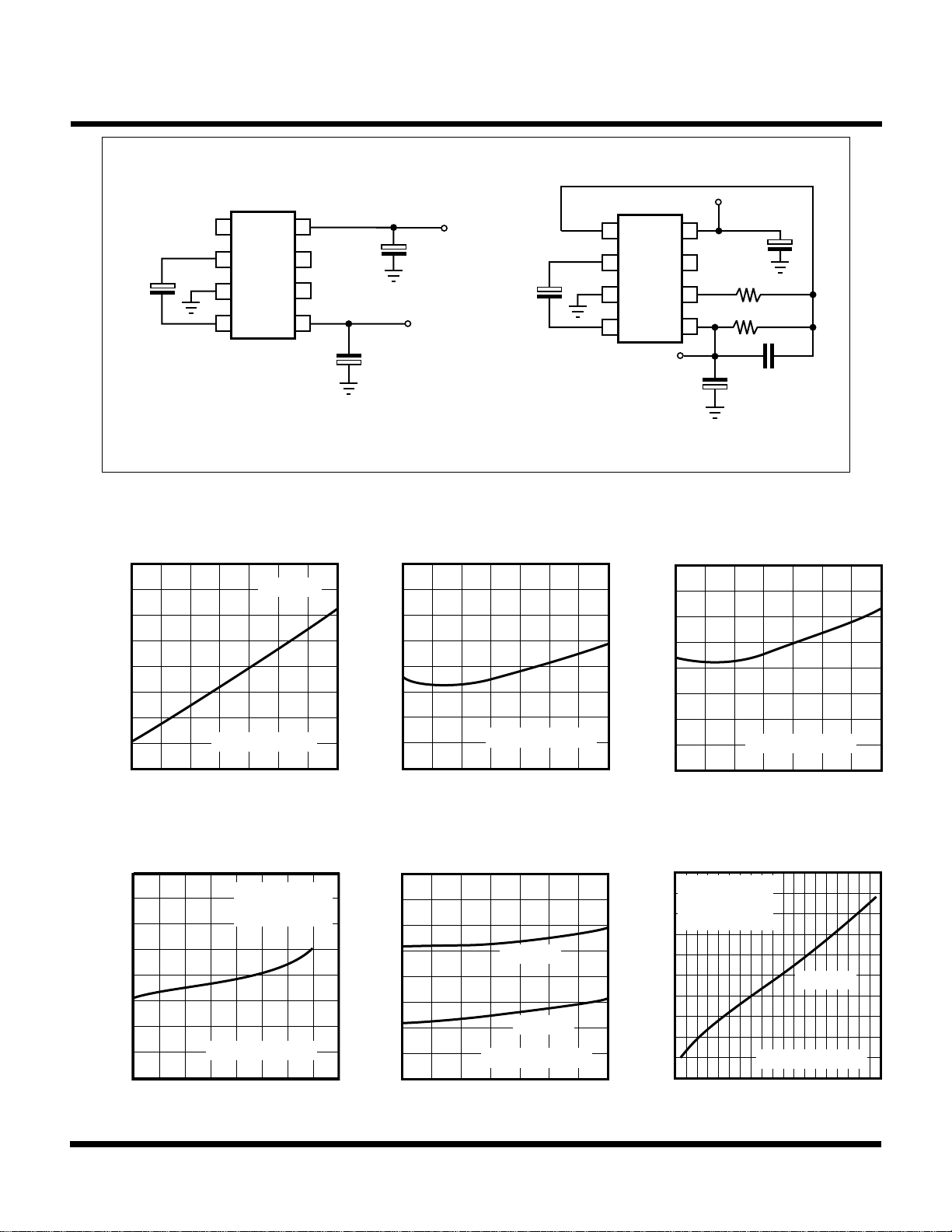

Note 6 Test Circuit

IN

2.2 µF

TK75018

TEST CIRCUITS

V

= 3.5 TO 7 V

IN

R

1

R

2

0.002 µF

+

4.7 µF

+

OUT

VIN = 3.5 to 6 V

+

4.7 µF

V

OUT

FB/SD

V +

C

+

2.2 µF

CAP +

IN

GND

V

ref

CAP -

V

OUT

V

OUT

C

OUT

33 µF

V +

+

CAP +

GND

CAP -

V

OUT

C

33 µF

+

NOTE 4 TEST CIRCUIT (Non Regulating)

REGULATING @ 0 mA LOAD

-2.8

-2.85

-2.9

-2.95

-3.0

-3.05

REGULATING MODE

-3.1

OUT

V

-3.15

-3.2

-50 0 50 100

-2.8

-2.85

(V)

-2.90

-2.95

-3.0

-3.05

-3.1

-3.15

OUT REGULATING MODE

V

-3.2

0 10 20 30 40

May 1999 TOKO, Inc. Page 3

TYPICAL PERFORMANCE CHARACTERISTICS

OUTPUT VOLTAGE

VS.

TEMPERATURE

V

IN

Note 6 Test Circuit

TEMPERATURE (°C)

OUTPUT VOLTAGE

OUTPUT CURRENT

V

= 5 V

IN

CIN = 2.2 µF

C

OUT

Note 6 Test Circuit

I

(mA)

OUT

= 5 V

VS.

= 33 µF

OUTPUT VOLTAGE

REGULATING @ 20 mA LOAD

VS.

TEMPERATURE

-2.8

-2.85

-2.9

-2.95

(V)

-3.0

OUT

V

-3.05

-3.1

-3.15

Note 6 Test Circuit

-3.2

-50 0 50 100

TEMPERATURE (°C)

OUTPUT VOLTAGE

TEMPERATURE

-3.4

-3.6

-3.8

-4.0

-4.2

-4.4

(V) NON REGULATING

-4.6

OUT

-4.8

V

Note 4 Test Circuit

-5.0

-50 0 50 100

TEMPERATURE (°C)

NOTE 6 TEST CIRCUIT (Regulating)

VOLTAGE LOSS

OUTPUT CURRENT

C

= 2.2 µF

IN

C

= 33 µF

OUT

VIN = 5 V

IL = 20 mA

IL = 5 mA

VS.

2

1.8

1.6

1.4

1.2

1

0.8

0.6

(V) NON REGULATING

0.4

LOSS

0.2

V

0

0 4 8 12 16 20 24 28 32 36

VS.

Tj = 25 °C

Note 4 Test Circuit

I

(mA)

OUT

Page 4

TK75018

f

(kH

)

TYPICAL PERFORMANCE CHARACTERISTICS (CONT.)

SUPPLY CURRENT vs.

TEMPERATURE @ 5 V

3

2.8

2.6

(mA)

CC

2.4

I

2.2

Note 6 Test Circuit

2

-50 0 50 100

TEMPERATURE (°C)

STANDBY CURRENT

100

90

80

70

60

(mA)

50

40

STBY

I

30

20

10

0

-50 0 50 100

TEMPERATURE

Note 6 Test Circuit

TEMPERATURE (°C)

VS.

SUPPLY CURRENT

INPUT VOLTAGE

IL = 03

2

(mA)

CC

I

1

Note 6 Test Circuit

0

0 6 12

VIN (V)

STANDBY CURRENT

INPUT VOLTAGE

120

V

100

80

(µA)

STBY

60

I

40

20

0 6 12

PIN1

Note 6 Test Circuit

VIN (V)

VS.

VS.

= 0 V

AVERAGE INPUT CURRENT

OUTPUT CURRENT

30

20

(mA)

IN(AVE)

10

I

Note 6 Test Circuit

0

0 15 30

I

(mA)

OUT

STANDBY THRESHOLD VS.

TEMPERATURE

0.6

V

0.4

(V)

TH(SA)

V

0.2

Note 6 Test Circuit

0

-50 0 50 100

TEMPERATURE (°C)

VS.

PIN1

MAXIMUM SWITCH CURRENT vs.

105

100

95

(mA)

SW

90

I

85

80

-50 0 50 100

TEMPERATURE

CAP+ Current to GND

TEMPERATURE (°C)

(V)

ref

V

2.65

2.60

2.55

2.50

2.45

2.40

2.35

REFERENCE VOLTAGE

TEMPERATURE

Note 6 Test Circuit

-50 0 50 100

TEMPERATURE (°C)

VS.

OSCILLATOR FREQUENCY VS.

TEMPERATURE

35

z

25

V

= 5 V

OSC

15

-75 -25 25 75 125

IN

Note 6 Test Circuit

TEMPERATURE (°C)

Page 4 May 1999 TOKO, Inc.

Page 5

TYPICAL PERFORMANCE CHARACTERISTICS (CONT.)

TK75018

OUTPUT VOLTAGE LOSS

OSCILLATOR FREQUENCY

INVERTER CONFIGURATION

2.0

CIN = 2.2 µF TANTALUM

C

= 33 µF TANTALUM

OUT

(V)

LOSS

1.0

V

0

1 10 100

I

OUT

Note 4 Test Circuit

f

(kHz)

OSC

VS.

=10 mA

(V)

LOSS

V

OUTPUT VOLTAGE LOSS

OSCILLATOR FREQUENCY

INVERTER CONFIGURATION

2.0

CIN = 22 µF TANTALUM

C

= 33 µF TANTALUM

OUT

1.0

0

1 10 100

THEORY OF OPERATION

As in any switched capacitor converter, the means of

conveying energy from input to output is done by charging

a capacitor between two potentials and then switching one

end of the capacitor to a different potential. By some

means of rectification, the other end of the capacitor is then

forced to dump charge into another capacitor at the

converter output, thereby conveying energy.

I

=10 mA

OUT

Note 4 Test Circuit

f

(kHz)

OSC

FIGURE 1: SWITCHED CAPACITOR CIRCUIT

VS.

OUTPUT VOLTAGE LOSS

INPUT CAPACITOR

1.0

INVERTER CONFIGURATION

C

= 33µF TANTALUM

OUT

0.8

f

= 25 kHz

OSC

I

0.6

(V)

LOSS

0.4

V

0.2

0

0 20 40 60 80 100

V

1

f

O

C

C

1

2

OUT

Note 4 Test Circuit

CIN (µF)

V

2

I

L

VS.

= 10 mA

In a simple example shown in Figure 1, a capacitor C1 has

one side tied to ground and another side charged by a

voltage source of potential V1. The non-grounded side of

C1 is then switched over to be connected to one side of a

If the potential V2 is sourcing a current IL, the charge will

have to be delivered at a rate:

capacitor C2, which is at potential V2 and referenced to

ground. V2 represents the output of the converter. The

initial charge on C1 is:

ƒ

= IL /∆q = IL / C1(V1 – V2)

O

Thus, the higher the frequency, the more current that can

q1 = C1 x V

1

be supported by the converter output.

All else being ideal, the effective losses in the converter in

When the switch changes over to the V2 side, C1 is

discharged from potential V1 to potential V2. After discharge

has occurred the charge on C1 is then:

the energy conveyance process is identical to that of a

circuit consisting of a resistor between the potentials V

and V2, with the same load at the output side. This

equivalent resistor is simply:

q2 = C1 x V

This means that the net transfer of charge which has

2

R

= (V1 – V2) / IL = 1 / (

EQUIV

ƒ

x C1)

O

occurred is:

∆q = q1 – q2 = C1 (V1 – V2)

May 1999 TOKO, Inc. Page 5

1

Page 6

TK75018

THEORY OF OPERATION (CONT.)

The illustration in Figure 2 represents an equivalent circuit

to the basic example of a switched capacitor circuit in

Figure 1.

V

1

R

EQUIV

C

2

V

2

I

L

FIGURE 2: SWITCHED CAPACITOR EQUIVALENT

CIRCUIT

The efficiency of the ideal converter is given by the output

power divided by the input power. Since the same current

flows out of each potential, the efficiency, η, is equal to the

ratio of V2 to V1.

PIN DESCRIPTIONS

FEEDBACK AND SHUTDOWN (FB/SD)

By configuring an error voltage divider into the FB/SD pin,

the TK75018 can be used to regulate the output voltage.

It is recommended that the parallel combination of the

divider resistors be greater than approximately 16 kΩ due

to the limited current available from the reference. The

Error Amplifier compares the FB/SD pin against an internal

1.25 V reference and limits the charge rate of CIN, thereby

limiting its peak charged voltage over a given clock period

and, thus, lowering the charge delivery rate to the output.

The characteristic frequency response of the converter

can be tailored by adjusting the ratio of C

OUT:CIN

recommended to keep it around 10:1. A “lead” capacitor

from the negative output to the feedback input is required

to maintain good light-load regulation; 2000 pF is

recommended, regardless of output voltage. For standard

configurations, the magnitude of the regulated voltage

must be less than that which can be achieved without

regulation, |V

OUT

| – V

. Higher regulated output voltages

LOSS

can be achieved by configuring a voltage doubler, at the

expense of maximum available output current.

When the FB/SD pin is pulled below the shutdown threshold

of ~0.45 V (e.g., via an open collector of an NPN transistor),

the reference is shut off and the switching action is

terminated. The drivers are set to allow both CIN and C

to discharge into the output load. The quiescent supply

current will drop to ~ 60 µA. If an error voltage divider is not

, but it is

OUT

Using equalities established above we find:

η = V2 / V1 = {V1 – [IL / (ƒ

x

C1)]} / V1 = 1 – [IL / (ƒ

O

x

C

x

O

V1)]

1

The last term in the equality string shows that efficiency

can be improved by increasing frequency or the value of

C1. Limitations of the circuit and components tend to cause

losses which increase with increasing frequency. Therefore,

at some point in the frequency spectrum losses will be

minimized. Hence, the oscillator of the TK75018 is designed

to run in the frequency band where losses are minimized.

Since the user will primarily be interested in maintaining a

given output voltage, losses are characterized in terms of

the voltage loss.

being used, the TK75018 will automatically restart when

the shutdown signal is removed. If such a divider is being

used, the current through the divider may be sufficient to

keep the device in shutdown until C

is fully discharged,

OUT

since the reference to the amplifier has collapsed during

the shutdown. Although C

is discharged fairly quickly

OUT

(allowing a quick restart), this recycling delay may not be

acceptable in some applications. This recycling delay can

be bypassed by injecting a positive start-up pulse into the

SD/FB pin (see Figure 3). This might be readily configured,

for example, as a TTL level signal which is diode coupled

into the divider. A resistor should be chosen to limit the

voltage pulse injection magnitude to 0.7 to 1.1 V. A pulse

width of ≥ 100 µs is required to guarantee a successfully

coupled start-up signal.

+

V

ref

C

OUT

33 µF

TANTALUM

4.7 µF

R

1

R

2

+

V

OUT

V

RESTART

SHUTDOWN

IN

V +

FB/SD

CAP +

+

CAP -

V

C

IN

2.2 µF

TANTALUM

OUT

GND

FIGURE 3: FEEDBACK AND SHUTDOWN

Page 6 May 1999 TOKO, Inc.

Page 7

PIN DESCRIPTIONS (CONT.)

TK75018

INPUT CAPACITOR CHARGING PINS (CAP+/CAP- )

The positive driving pin of CIN (CAP +) charges the positive

node of the capacitor to VIN during tCH and pulls it down to

ground during t

. The negative driving pin of C

DIS

IN

(CAP -) pulls the negative node of the capacitor to ground

during tCH and is driven into the output during t

DIS

.

CIRCUIT GROUND (GND)

All potentials are referenced to this ground unless otherwise

noted.

OUTPUT VOLTAGE (V

OUT

)

In most applications, a capacitor must be placed from this

pin to ground to integrate the charge pulses delivered by

CIN. A minimum of ten times CIN is recommended. Since

the output voltage serves as the substrate inside the IC,

the design must ensure that this pin is never raised to a

higher potential than ground. This phenomenon will tend to

occur when a positive-supply-to-negative-supply load is

present at the converter output. A circuit, such as the one

shown in Figure 4, is recommended. Under normal

operation, the transistor will appear as a short circuit. But

the sink current will be cut off from the output pin if the

voltage starts to approach ground. The resistor is chosen

to keep the transistor saturated under all steady-state

operating conditions.

+

V

I

L

V +

+

C

IN

CAP +

GND

CAP -

V

OUT

LOAD

C

OUT

+

FIGURE 4: POSITIVE REFERENCED LOAD

The equation below can be used to calculate the values of

the feedback resistors (R1 and R2) needed to achieve a

desired output voltage.

|V

|

R2 = R1 +1 where R1 ≥ 24 kΩ

(

OUT

1.2 V

)

REFERENCE VOLTAGE (V

ref

)

This pin provides a nominal 2.5 V buffered reference for

external use. Normal output current should be kept below

~160 µA.

OSCILLATOR PROGRAMMING (OSC)

This pin can be used to alter the nominal 25 kHz frequency

of the internal oscillator. An internal timing capacitor of

~150 pF is alternately charged during

during

t

with a 7 µA current source to fixed threshold

DIS

t

and discharged

CH

levels. Adding an external capacitor from the OSC pin to

ground will parallel the 150 pF capacitor to slow down the

clock period. Adding a small external capacitor from the

OSC pin to the CAP+ pin will source/sink extra charge into/

out-of the internal timing capacitor to speed up the transition

between thresholds and thereby raise the oscillator

frequency. It is recommended that, in the latter

configuration, the capacitor be kept below ~30 pF.

Synchronization of multiple TK75018s can be accomplished

by adding pull-up resistors from the OSC pin to the

reference voltage and using an open collector from an

NPN transistor to provide the discharge. The NPN is then

driven by a clocking pulse, and the same pulse can be

used to drive multiple devices in the same configuration.

It is not recommended to pull the OSC pin high with a lowimpedance source. To synchronize and regulate with

multiple devices, an external reference can be used as the

reference point for the error voltage divider, thus allowing

the internal reference to be used as the pull-up point for the

OSC pin.

INPUT VOLTAGE (V+)

The input voltage is used to charge CIN during the time t

CH

during each clock period. CIN is then discharged into the

output capacitor during time t

. During tCH, the input

DIS

current will be approximately 2.2 times the output current.

During t

, the input current will be approximately 0.2

DIS

times the output current. A low ESR bypass capacitor will

average out the varying current seen by the input supply yielding an average input current of approximately 1.1

times the output current. The bypass capacitor should be

placed as near to the TK75018 as possible to disallow

inductive spikes on the supply rail of the IC. A minimum of

2 µF is recommended.

May 1999 TOKO, Inc. Page 7

Page 8

TK75018

)

SOP-8

85

PACKAGE OUTLINE

0.76

1.27

5.4

1

e

e

3.9

1.27

Recommended Mount Pad

TSSOP-14

14

0.35

1.0

Marking

8

4.8

DIP-8

1

4

4.89

e

0.42

Dimensions are shown in millimeters

Tolerance: x.x = 0.2 mm (unless otherwise specified

1.27

l

0.12

8

1

Dimensions are shown in millimeters

Tolerance: x.x =

0.1

e

0.3

+

1.45

1.64

0 ~ 0.25

5

4

9.5

2.54

0.46

0.2 mm (unless otherwise specified)

AAAAA

0.5

0 ~ 10

0.2

+

0.3

6.07

Marking

Lot Number

6.4

Country of Origin

0.3

+

3.3

3.8

0.3

+

3.3

0.5 min

+ 0.15

- 0.05

0.25

+ 0.15

- 0.05

0.25

e1

0 ~15

7.62

M

1

Product Code TK75018

YYY

Lot. No.

+0.15

-0.15

0.25

Dimensions are shown in millimeters

Tolerance: x.x = 0.2 mm (unless otherwise specified)

4.4

7

5.0

0.9

1.2 max

e

0.12

0 ~ 0.15

0.65

0.1

M

Marking Information

e

0.65

Recommended Mount Pad

0 ~ 10

0.50

+

0.3

6.4

+0.15

-0.15

0.15

Toko America, Inc. Headquarters

1250 Feehanville Drive, Mount Prospect, Illinois 60056

Tel: (847) 297-0070 Fax: (847) 699-7864

TOKO AMERICA REGIONAL OFFICES

Midwest Regional Office

Toko America, Inc.

1250 Feehanville Drive

Mount Prospect, IL 60056

Tel: (847) 297-0070

Fax: (847) 699-7864

Western Regional Office

Toko America, Inc.

2480 North First Street , Suite 260

San Jose, CA 95131

Tel: (408) 432-8281

Fax: (408) 943-9790

Eastern Regional Office

Toko America, Inc.

107 Mill Plain Road

Danbury, CT 06811

Tel: (203) 748-6871

Fax: (203) 797-1223

Semiconductor Technical Support

Toko Design Center

4755 Forge Road

Colorado Springs, CO 80907

Tel: (719) 528-2200

Fax: (719) 528-2375

Visit our Internet site at http://www.tokoam.com

The information furnished by TOKO, Inc. is believed to be accurate and reliable. However, TOKO reserves the right to make changes or improvements in the design, specification or manufacture of its

products without further notice. TOKO does not assume any liability arising from the application or use of any product or circuit described herein, nor for any infringements of patents or other rights of

third parties which may result from the use of its products. No license is granted by implication or otherwise under any patent or patent rights of TOKO, Inc.

Page 8 May 1999 TOKO, Inc.

© 1999 Toko, Inc.

All Rights Reserved

IC-xxx-TK75018

0798O0.0K

Printed in the USA

Loading...

Loading...