Page 1

August 1994 2

Philips Semiconductors Product specification

Class AB stereo headphone driver TDA1308

FEATURES

• Wide temperature range

• No switch ON/OFF clicks

• Excellent power supply ripple rejection

• Low power consumption

• Short-circuit resistant

• High performance

– high signal-to-noise ratio

– high slew rate

– low distortion

• Large output voltage swing.

GENERAL DESCRIPTION

The TDA1308 is an integrated class AB stereo headphone

driver contained in an SO8 or a DIP8 plastic package. The

device is fabricated in a 1 mm CMOS process and has

been primarily developed for portable digital audio

applications.

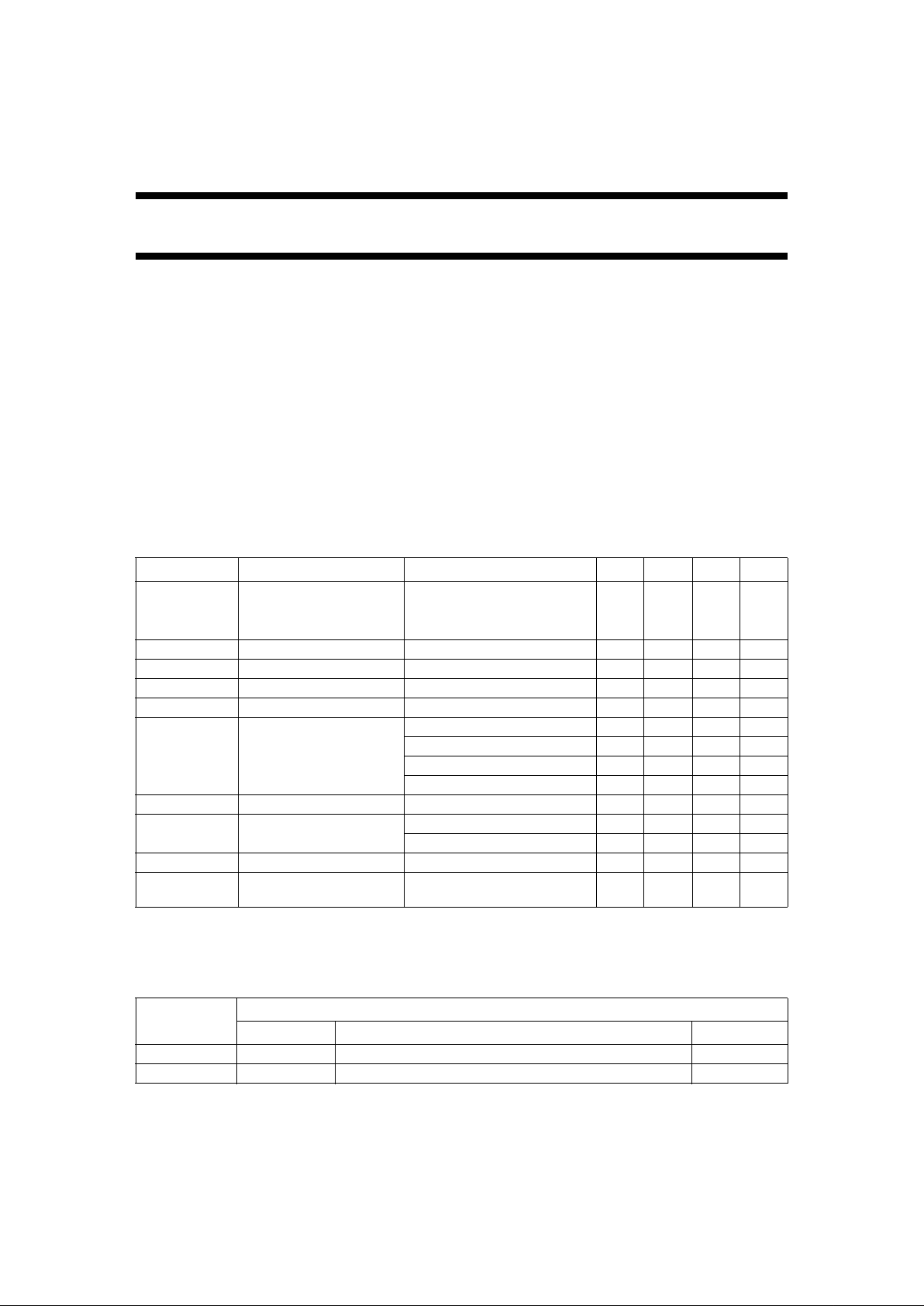

QUICK REFERENCE DATA

VDD= 5 V; VSS= 0 V; T

amb

= 25 °C; fi= 1 kHz; RL= 32 Ω; unless otherwise specified.

Note

1. V

DD

= 5 V; V

O(p-p)

= 3.5 V (at 0 dB).

ORDERING INFORMATION

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

DD

supply voltage

single 3.0 5.0 7.0 V

dual 1.5 2.5 3.5 V

V

SS

negative supply voltage −1.5 −2.5 −3.5 V

I

DD

supply current no load − 3 5 mA

P

tot

total power dissipation no load − 15 25 mW

P

o

maximum output power THD < 0.1%; note 1 − 60 − mW

(THD + N)/S total harmonic distortion plus

noise-to-signal ratio

note 1

− 0.03 0.06 %

− −70 −65 dB

RL= 5 kΩ − −101 − dB

S/N signal-to-noise ratio 100 110 − dB

α

cs

channel separation − 70 − dB

RL = 5 kΩ − 105 − dB

PSRR power supply ripple rejection fi= 100 Hz; V

ripple(p-p)

= 100 mV − 90 − dB

T

amb

operating ambient

temperature

−40 − +85 °C

TYPE NUMBER

PACKAGE

NAME DESCRIPTION VERSION

TDA1308 DIP8 plastic dual in-line package; 8 leads (300 mil) SOT97-1

TDA1308T SO8 plastic small outline package; 8 leads; body width 3.9 mm SOT96-1

Page 2

August 1994 3

Philips Semiconductors Product specification

Class AB stereo headphone driver TDA1308

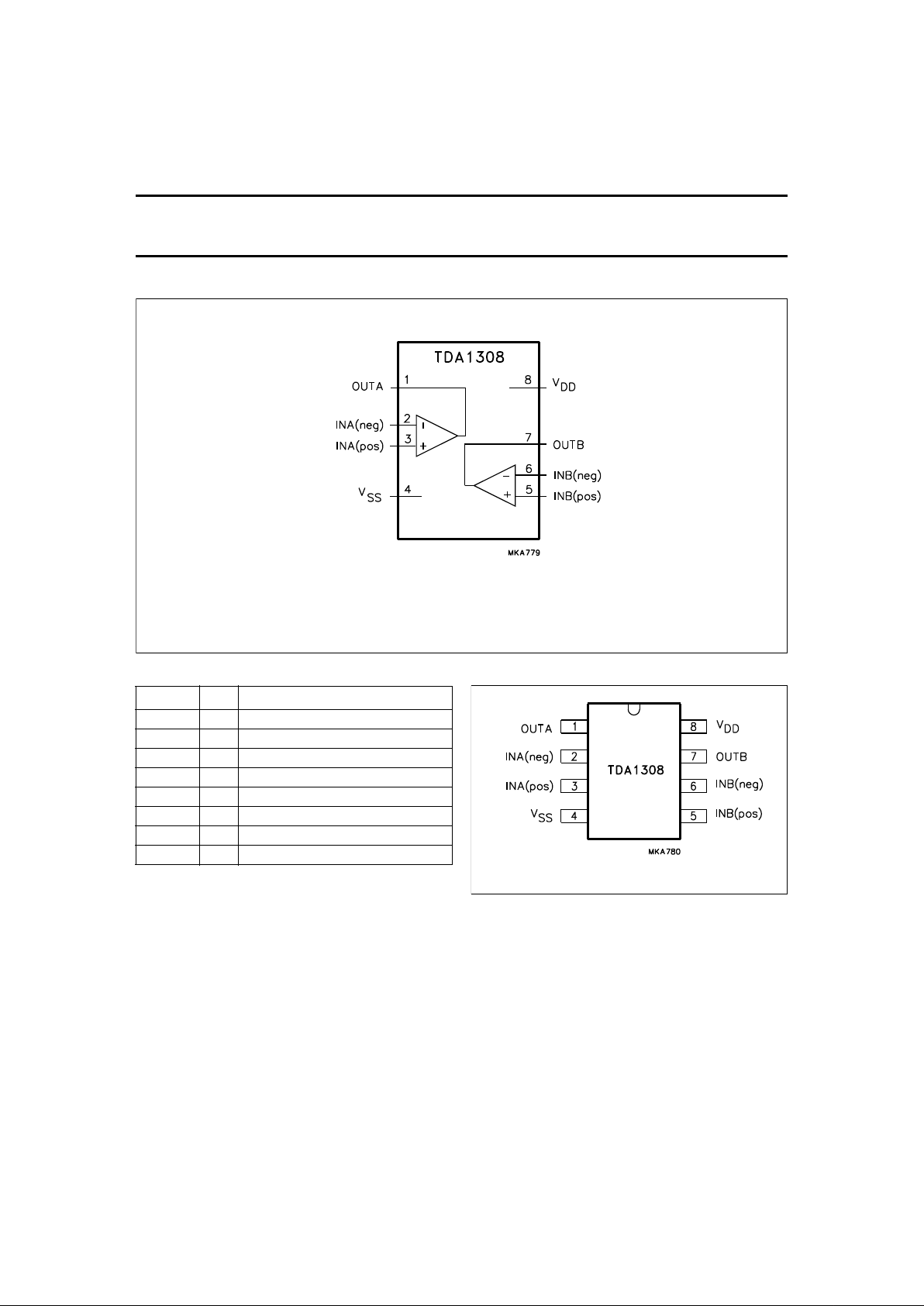

BLOCK DIAGRAM

Fig.1 Block diagram.

PINNING

SYMBOL PIN DESCRIPTION

OUTA 1 output A

INA(neg) 2 inverting input A

INA(pos) 3 non-inverting input A

V

SS

4 negative supply

INB(pos) 5 non-inverting input B

INB(neg) 6 inverting input B

OUTB 7 output B

V

DD

8 positive supply

Fig.2 Pin configuration.

Page 3

August 1994 4

Philips Semiconductors Product specification

Class AB stereo headphone driver TDA1308

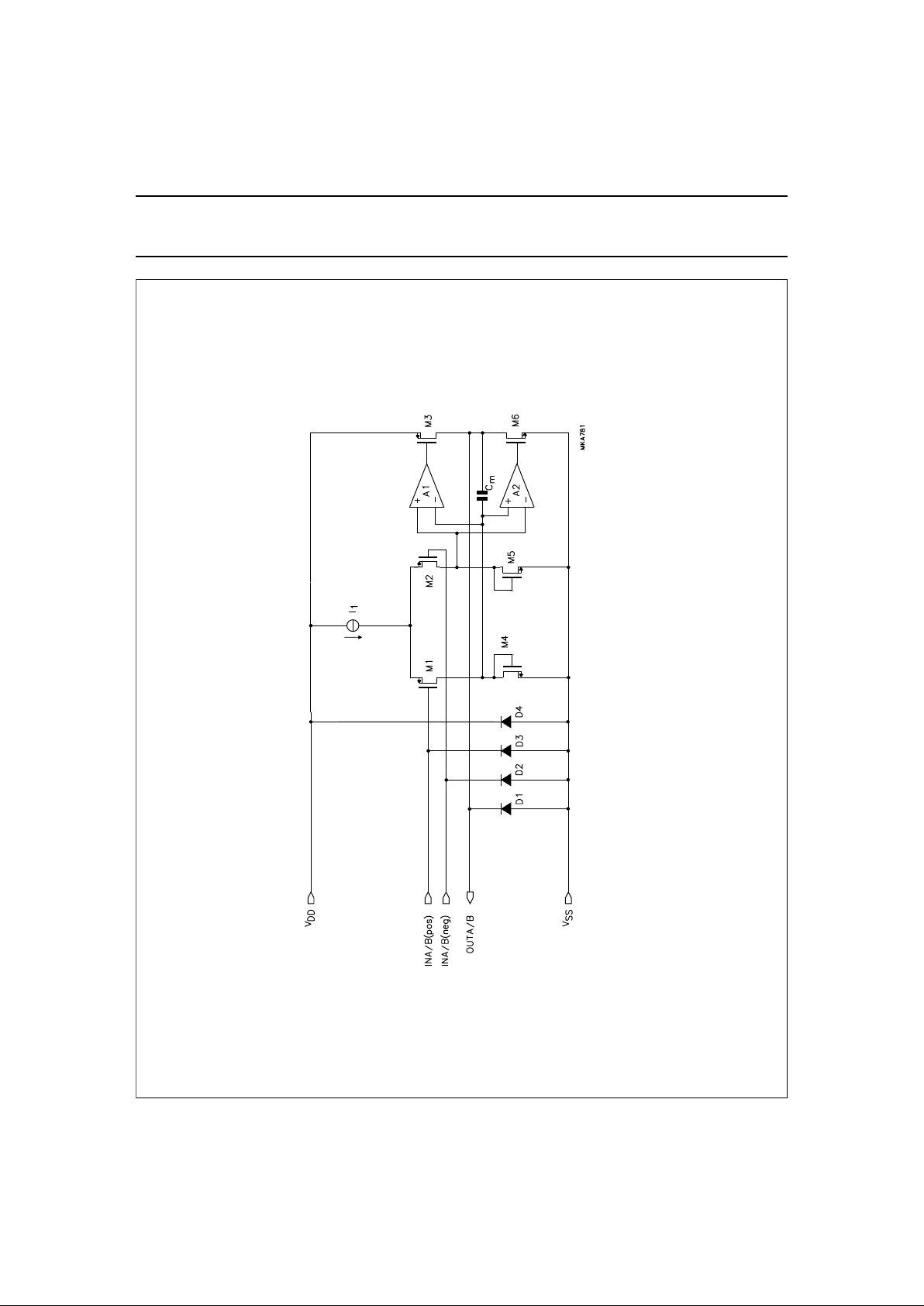

Fig.3 Equivalent schematic diagram.

Page 4

August 1994 5

Philips Semiconductors Product specification

Class AB stereo headphone driver TDA1308

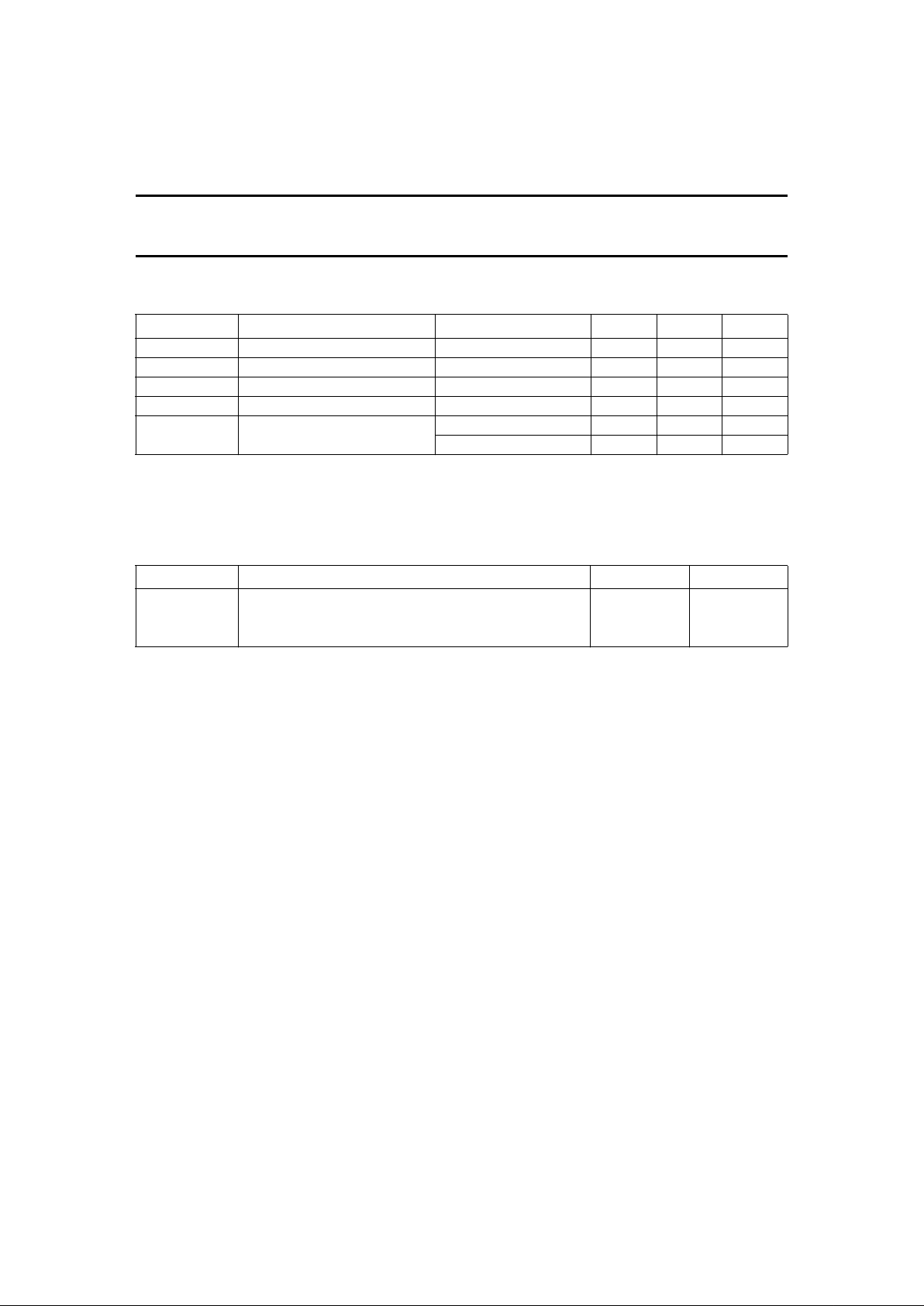

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC134).

Notes

1. Human body model: C = 100 pF; R = 1500 Ω; 3 pulses positive plus 3 pulses negative.

2. Machine model: C = 200 pF: L = 0.5 mH: R = 0 Ω; 3 pulses positive plus 3 pulses negative.

THERMAL CHARACTERISTICS

QUALITY SPECIFICATION

In accordance with

“UZW-BO/FQ-0601”

. The numbers of the quality specification can be found in the

“Quality Reference

Handbook”

. The handbook can be ordered using the code 9398 510 63011.

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

DD

supply voltage 0 8.0 V

t

SC(O)

output short-circuit duration T

amb

= 25 °C; P

tot

= 1 W 20 − s

T

stg

storage temperature −65 +150 °C

T

amb

operating ambient temperature −40 +85 °C

V

esd

electrostatic discharge note 1 −2000 +2000 V

note 2 −200 +200 V

SYMBOL PARAMETER VALUE UNIT

R

th j-a

thermal resistance from junction to ambient in free air

DIP8 109 K/W

SO8 210 K/W

Page 5

August 1994 6

Philips Semiconductors Product specification

Class AB stereo headphone driver TDA1308

CHARACTERISTICS

VDD= 5 V; VSS= 0 V; T

amb

= 25 °C; fi= 1 kHz; RL= 32 Ω; unless otherwise specified.

Notes

1. Values are proportional to VDD; (THD + N)/S < 0.1%.

2. VDD= 5.0 V; V

O(p-p)

= 3.5 V (at 0 dB).

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supplies

V

DD

supply voltage

single 3.0 5.0 7.0 V

dual 1.5 2.5 3.5 V

V

SS

negative supply voltage −1.5 −2.5 −3.5 V

I

DD

supply current no load − 3 5 mA

P

tot

total power dissipation no load − 15 25 mW

DC characteristics

V

I(os)

input offset voltage − 10 − mV

I

bias

input bias current − 10 − pA

V

CM

common mode voltage 0 − 3.5 V

G

v

open-loop voltage gain RL= 5 kΩ − 70 − dB

I

O

maximum output current (THD + N)/S < 0.1% − 60 − mA

R

O

output resistance − 0.25 − Ω

V

O

output voltage swing note 1 0.75 − 4.25 V

RL= 16 Ω; note 1 1.5 − 3.5 V

RL= 5 kΩ; note 1 0.1 − 4.9 V

PSRR power supply rejection ratio fi= 100 Hz;

V

ripple(p-p)

= 100 mV

− 90 − dB

α

cs

channel separation − 70 − dB

RL= 5 kΩ − 105 − dB

C

L

load capacitance − − 200 pF

AC characteristics

(THD + N)/S total harmonic distortion plus

noise-to-signal ratio

note 2 − −70 −65 dB

− 0.03 0.06 %

note 2; R

L

= 5 kΩ − −101 − dB

− 0.0009 − %

S/N signal-to-noise ratio 100 110 − dB

f

G

unity gain frequency open-loop; RL= 5 kΩ − 5.5 − MHz

P

o

maximum output power (THD + N)/S < 0.1% − 60 − mW

C

i

input capacitance − 3 − pF

SR slew rate unity gain inverting − 5 − V/µs

B power bandwidth unity gain inverting − 20 − kHz

Page 6

August 1994 7

Philips Semiconductors Product specification

Class AB stereo headphone driver TDA1308

TEST AND APPLICATION INFORMATION

Fig.4 Measurement circuit for inverting application.

Fig.5 Example of application with TDA1545A (stereo continuous calibration DAC).

Page 7

August 1994 8

Philips Semiconductors Product specification

Class AB stereo headphone driver TDA1308

Fig.6 Open-loop gain as a function of input

frequency.

Fig.7 Crosstalk as a function of input

frequency.

Fig.8 Output power as a function of supply

voltage.

Page 8

August 1994 9

Philips Semiconductors Product specification

Class AB stereo headphone driver TDA1308

Fig.9 Total harmonic distortion plus noise-to-signal ratio as a function of input frequency.

Fig.10 Total harmonic distortion plus noise-to-signal ratio as a function of output voltage level.

Page 9

August 1994 10

Philips Semiconductors Product specification

Class AB stereo headphone driver TDA1308

PACKAGE OUTLINES

Fig.11 Plastic dual in-line package; 8 leads (300 mil); DIP8; SOT97-1.

Dimensions in mm.

handbook, full pagewidth

8.25

7.80

0.38 max

10.0

8.3

7.62

MSA252 - 1

6.48

6.20

1.73 max

5

8

41

1.15

max

0.53

max

0.254 M

3.2

max

4.2

max

3.60

3.05

9.8

9.2

2.54

(3x)

0.51

min

seating plane

Page 10

August 1994 11

Philips Semiconductors Product specification

Class AB stereo headphone driver TDA1308

handbook, full pagewidth

pin 1

index

0.7

0.3

0.49

0.36

1.27

0.25 M

(8x)

1

4

5

0.1 SS

5.0

4.8

4.0

3.8

6.2

5.8

A

8

MBC180 - 1

0.25

0.19

0.7

0.6

1.75

1.35

1.45

1.25

detail A

1.0

0.5

0.25

0.10

0 to 8

o

Fig.12 Plastic small outline package; 8 leads; body width 3.9 mm. (SO8; SOT96-1).

Dimensions in mm.

Page 11

August 1994 12

Philips Semiconductors Product specification

Class AB stereo headphone driver TDA1308

SOLDERING

Plastic dual in-line packages

B

Y DIP OR WAVE

The maximum permissible temperature of the solder is

260 °C; this temperature must not be in contact with the

joint for more than 5 s. The total contact time of successive

solder waves must not exceed 5 s.

The device may be mounted up to the seating plane, but

the temperature of the plastic body must not exceed the

specified storage maximum. If the printed-circuit board has

been pre-heated, forced cooling may be necessary

immediately after soldering to keep the temperature within

the permissible limit.

REPAIRING SOLDERED JOINTS

Apply the soldering iron below the seating plane (or not

more than 2 mm above it). If its temperature is below

300 °C, it must not be in contact for more than 10 s; if

between 300 and 400 °C, for not more than 5 s.

Plastic small outline packages

BY WAVE

During placement and before soldering, the component

must be fixed with a droplet of adhesive. After curing the

adhesive, the component can be soldered. The adhesive

can be applied by screen printing, pin transfer or syringe

dispensing.

Maximum permissible solder temperature is 260 °C, and

maximum duration of package immersion in solder bath is

10 s, if allowed to cool to less than 150 °C within 6 s.

Typical dwell time is 4 s at 250 °C.

A modified wave soldering technique is recommended

using two solder waves (dual-wave), in which a turbulent

wave with high upward pressure is followed by a smooth

laminar wave. Using a mildly-activated flux eliminates the

need for removal of corrosive residues in most

applications.

B

Y SOLDER PASTE REFLOW

Reflow soldering requires the solder paste (a suspension

of fine solder particles, flux and binding agent) to be

applied to the substrate by screen printing, stencilling or

pressure-syringe dispensing before device placement.

Several techniques exist for reflowing; for example,

thermal conduction by heated belt, infrared, and

vapour-phase reflow. Dwell times vary between 50 and

300 s according to method. Typical reflow temperatures

range from 215 to 250 °C.

Preheating is necessary to dry the paste and evaporate

the binding agent. Preheating duration: 45 min at 45 °C.

R

EPAIRING SOLDERED JOINTS (BY HAND-HELD SOLDERING

IRON OR PULSE

-HEATED SOLDER TOOL)

Fix the component by first soldering two, diagonally

opposite, end pins. Apply the heating tool to the flat part of

the pin only. Contact time must be limited to 10 s at up to

300 °C. When using proper tools, all other pins can be

soldered in one operation within 2 to 5 s at between 270

and 320 °C. (Pulse-heated soldering is not recommended

for SO packages.)

For pulse-heated solder tool (resistance) soldering of VSO

packages, solder is applied to the substrate by dipping or

by an extra thick tin/lead plating before package

placement.

Page 12

August 1994 13

Philips Semiconductors Product specification

Class AB stereo headphone driver TDA1308

DEFINITIONS

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

Loading...

Loading...