Page 1

#’

-SHARP

SPECIFICATIONS

Product Type : l’7%FG lens-integrated CMOS Color Area Sensor for CIF

Yodel No.

%This specifications contains 24 pages including the cover.

If you have any objections,please contact us before issuing purchasing order.

CUSTOMERS AcCEpTANCJ3

DATE :

BY:

LZOP3820

PRESENTED

I Dept. General Manager

REVIEWD BY:

PREPARED BY:

Product Development Dept. II

CCD Development Center

Integrated Circuits Devel

SBABP CORPORATION

Page 2

SHARP

l

Handle this document carefully for it contains material protected by international

copyright law. Any reproduction, full or in part, of this material is prohibited

without the express written permission of the company.

l

Vhen using the products covered herein, please observe the conditions written herein

and the precautions outlined in the following paragraphs. In no event shall the

company be liable for any damages resulting from failure to strictly adhere to these

conditions and precautions,

(1) The products covered herein are designed and manufactured for the following

application areas. Vhen using the products covered herein for the equipment

listed in Paragraph (2>, even for the following application areas, be sure

to observe the precautions given in Paragraph CU. Never use the products

for the equipment listed in Paragraph (3).

*Office electronics

OInstrumentation

#Machine tools

SAudiovisual equipment

*Home appliances

Xommunication equipment other than for trunk lines

and

LZOP3820

measuring equipment

(2) Those contemplating using the products covered herein for the following

equipment which demands high reliability, should first contact a sales

representative of the company and then accept responsibility for incorporating

into the design fail-safe operation, redundancy, and other appropriate

measures for ensuring reliability and safety of the equipment and the overall

system.

*Control and safety devices for airplanes, trains, automobiles, and other

transportation equipment

*Mainframe computers

*Traffic control systems

*Gas leak detectors and automatic cutoff devices

,Bescue and security equipment

*Other safety devices and safety equipment,etc.

(3) Do not use the products covered herein for the following equipment which

demands extremely high performance in terms of functionality, reliability, or

accuracy.

-Aerospace equipment

Xcfnmunications equipment for trunk lines

Control equipment for the nucJear power

BMedical equipment related to life support, etc.

(4) Please direct all queries and comments regarding the interpretation of the

above three Paragraphs

to

a sales representative of the company.

industry

0 Please direct all queries regarding the products covered herein to a sales

representative of the company.

Page 3

SHARP

LZOP3820

CONTENTS

1

1. GENERAL DESCRIPTION

2. ARRANGEMENT OF PIXELS AND COLOR FILTORS

3. BLOCK DIAGRAM

4. PIN CONFIGURATION

5. PIN DESCRIPTION

6. ELECTRIC CHARACTERISTICS~

7. IMAGING CiiABACTERISTICS

8. LENS SPECIFICATIONS

9. TIMING DIAGRAM

. 10. DESCRIPTION OF SERIAL DATA

1 1. EXAMPLE OF STANDARD OPERATING CIRCUIT

12. SPECIFICATION FOR BLEMISH

,..1,1,.111.1...,1...*.1...1.1,.,.,...**.*.

~,I,*o.I.,Ill.l,.II,,.II1II1*1.L,~I~

I.,,,I,..I...I..II.,.1O,IIOI..1,111..

ll,lI1111,1,1111,,,11,,11,1111,1.0,1~111

II.,,,.I,,.11.1..,,I.,,.L,,III,,

II.I......11,1,,I.,,,,.I..I..I,.I

..,.11...1.1,,1.1,,..1....,.1..1..1..

,,1,,,,1111.11111,,1,1~1,11~..~,..~~I1~..1

11111,1,,..1111.1111.011111,1

. . . . ..*..0..111,.1.10,11..1..

1**.111,*111.1,0

,.*..'.ll,,,*,l,ltl.

P. 2

P. 3

P. 4

P. 5

P. 6

P. 7

P. a

p. 9

P. IO

P. 13

P. 16

P. 17

1 3. CAUTIONS FOR USE

14. PACKAGE OUTLINE AND PACKING SPECIFICATI(JN

,1,,1.1,11..10,,,1....‘.,,~......,.~...

Illl,,l#ll.~l*t

P. 18

P. 20

Page 4

SHARF,

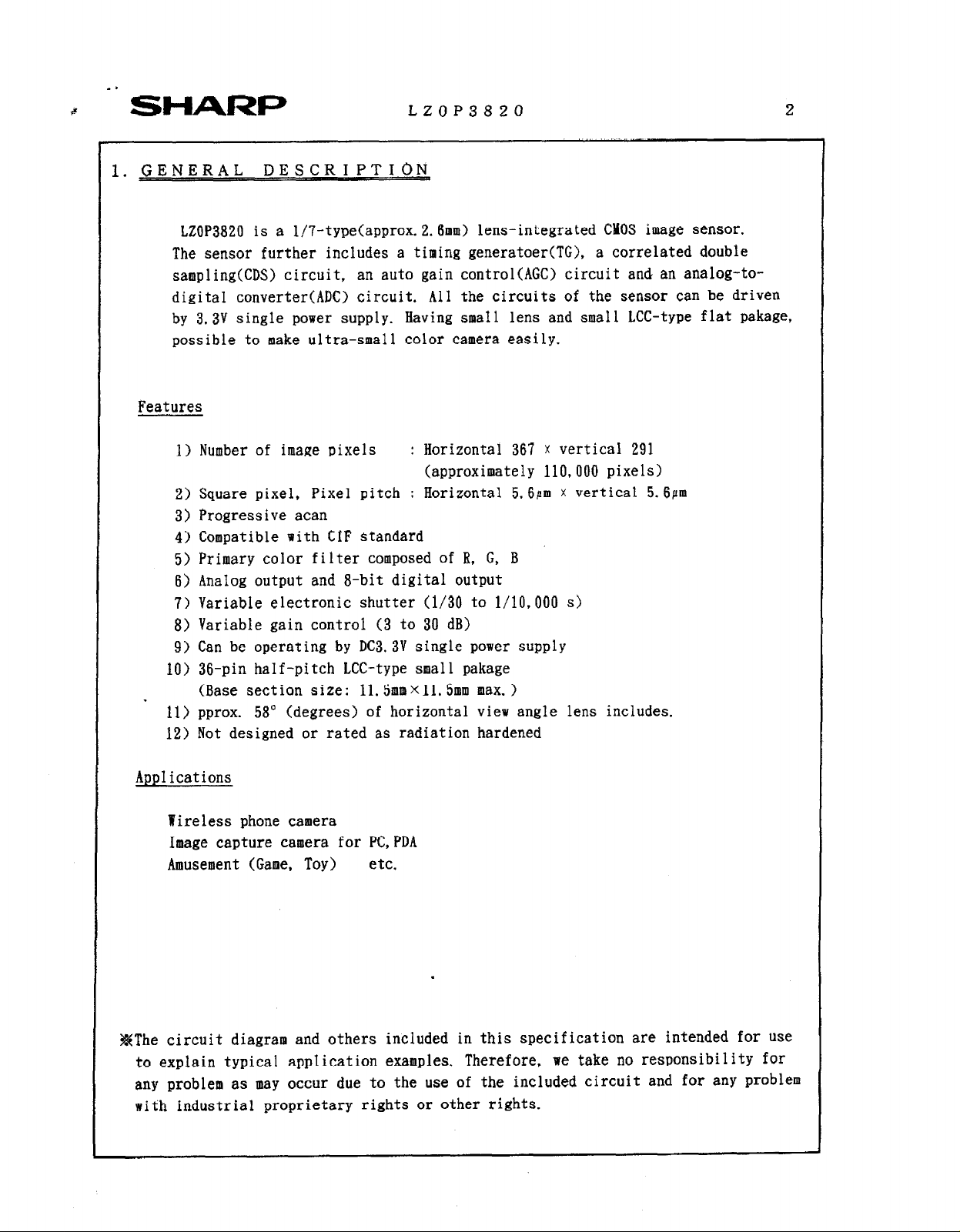

l.GENERAL DESCRIPTION

LZOP3820 is a l/7-type(approx.2.6mm) lens-integrated CMOS image sensor.

The sensor further includes a timing generatoer(TG), a correlated double

sampling(CDS) circuit, an auto gain control(AGC) circuit and an analog-to-

digital converter(ADC) circuit. All the circuits of the sensor can be driven

by 3.3V single power supply. Having smaI1 lens and small LCC-type flat pakage,

possible to make ultra-small color camera easily.

Features

1) Number of image pixels : Horizontal 367 x vertical 291

2) Square pixel, Pixel pitch : Horizontal 5.6Pm x vertical 5.6pm

3) Progressive acan

4) Compatible with CIF standard

5) Primary color filter composed of B. G, B

6) AnaIog output and a-bit digital output

7) Variable electronic shutter (l/30 to l/10,000 s>

8) Variable gain control (3 to 30 dB)

9) Can be operating by DC3.3V single power supply

10) 36-pin half-pitch LCC-type small pakage

(Base section size: ll.5mmXll. 5mm max. )

11) pprox. 58” (degrees) of horizontal view angle lens includes.

12) Not designed or rated as radiation hardened

LZOP3820 2

(approximately 110,000 pixels)

Applications

Yireless phone camera

Image capture camera for PC,PDA

Amusement (Game, Toy) etc.

.

#The circuit diagram and others included in this specification are intended for use

to explain typical application examples. Therefore,

any problem as may occur due to the use of the included circuit and for any problem

with industrial proprietary rights or other rights.

we take no responsibility for

Page 5

SHARP

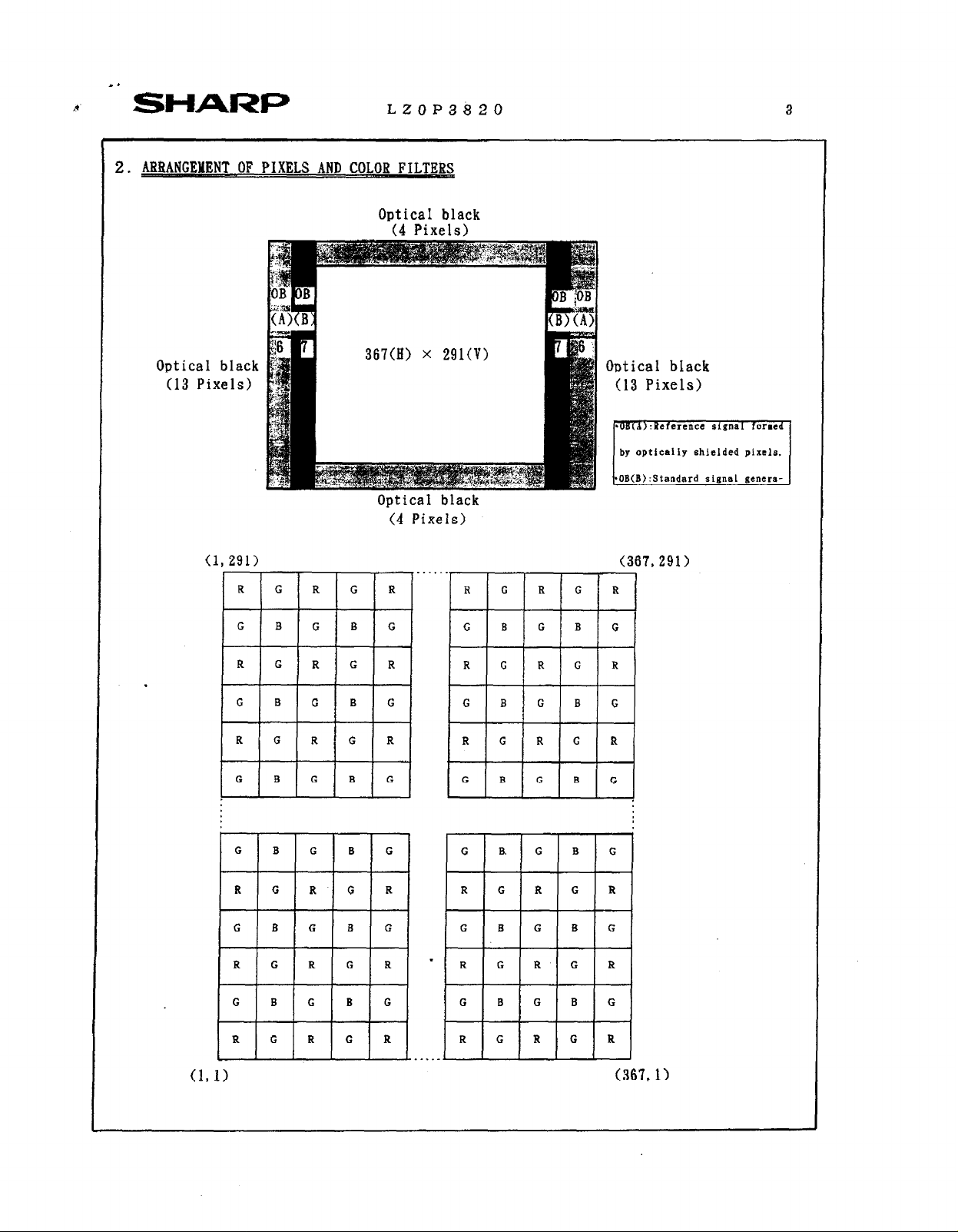

2. -T .OF PIXELS AND COLOR FILTERS

LZOP3820 3

Optical black

(4 Pixels)

Optical black

(13 Pixels)

(1

.

367(H) x 291(V)

Optical black

(4 Pixels)

, 1

R

. . ..-

Optical black

(13 Pixels)

by opticaliy shielded pixels

OB(B):Standard signs1 genera-

(367.291)

lG IRI

(367.1)

Page 6

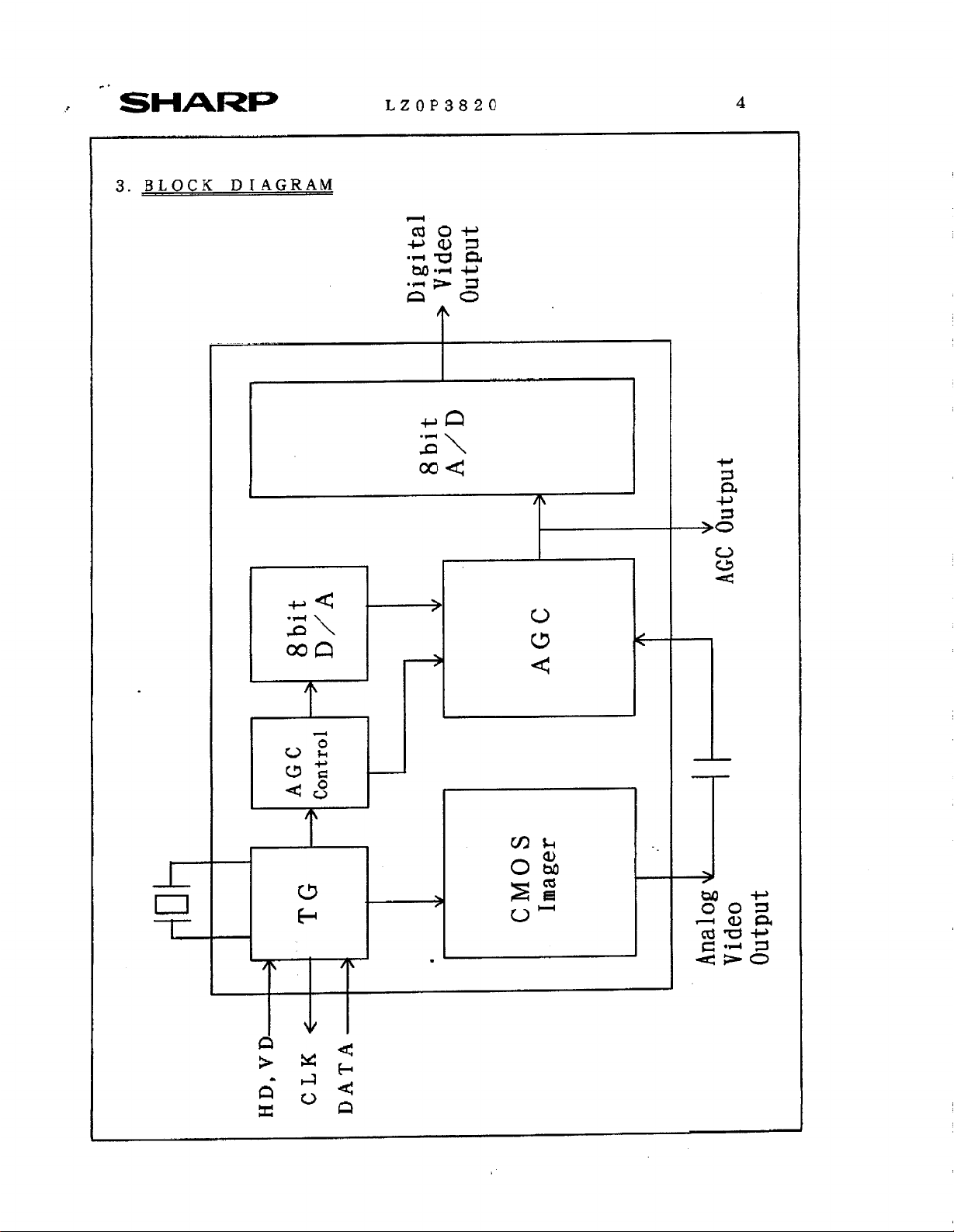

D/A

+ 8bit

Digital

output

-+ Video

8bit

A/D

V

>

AGC

AGC

I

+

HD,VD-

+ Control

TG

3

CLK t-

DATA-

I

V

.

output

Page 7

:*

-’ SHARP

4.PIN CONFIGRATION

LZOP3820

VIEW>

BIAS1

SCLK

CLP

OFS

BIAS2

SICOUT

SIGIN

ACND

AVDD

N. c.

LZOP3820

N. c.

D5

D4

D3

D2

Dl

DO

DGMD

DVDD

Page 8

*a

a

SHARP

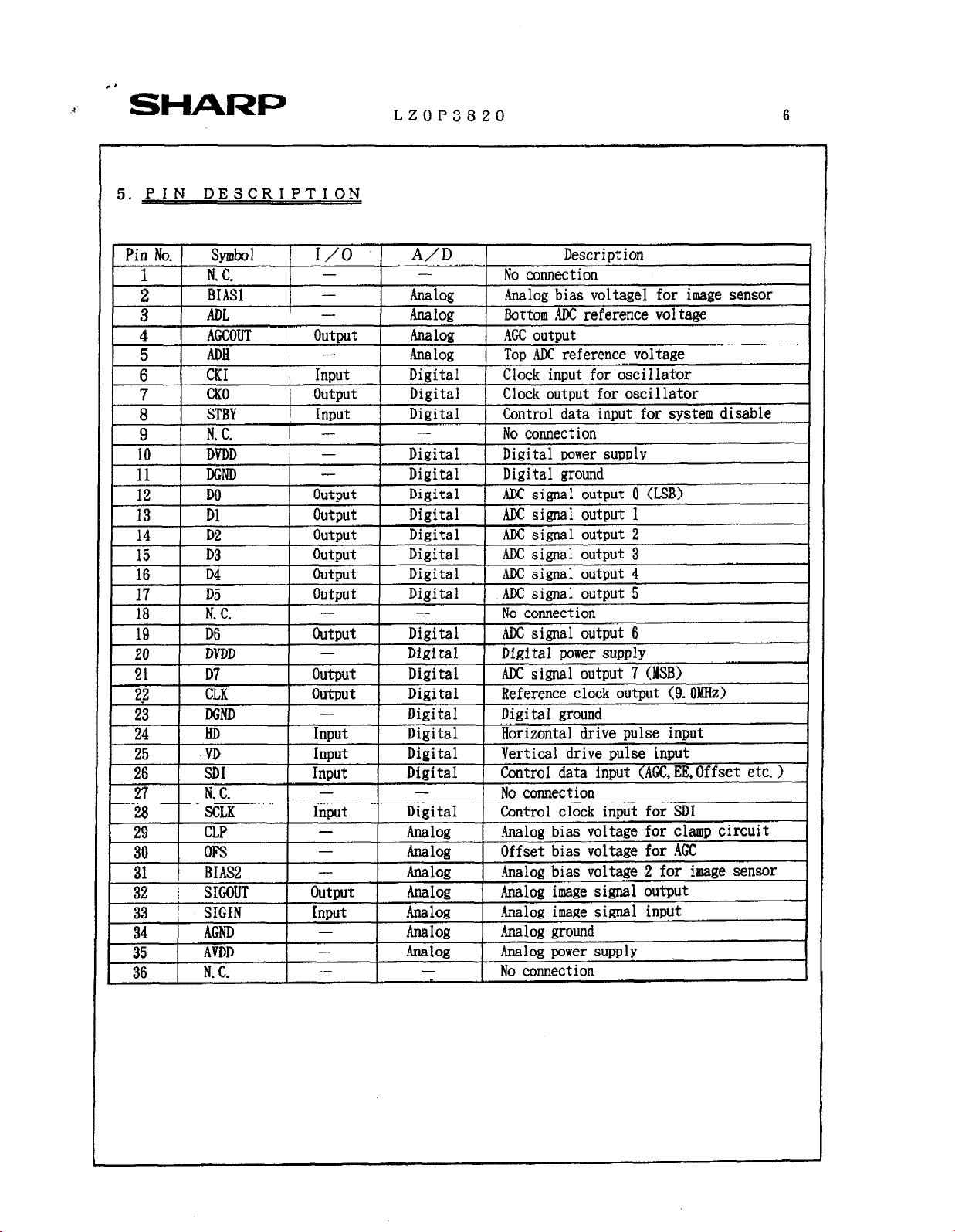

5. PIN DESCRIPTION

LZOP3820 6

STBY

N. C.

DVDD

DGND

ii

13 Dl

14 D2

15 D3

16 D4

17 D5

18 1

19 I D6

I

20

21 D7

sl.7 -7 ” n ‘ .I n1 -~:L-, l--d------- -1--1. -__A.-__A /n rxlR,-\

zg

23 1 DGND I - 1 Digital 1 Digital mound

27 1 N. c. - 28

29 CLP - Analog

DO

N.

C.

DVDD

1 LLh 1 uuqlur 1

HD

VD

I

I iDI

1 SCLK Input Digital 1 Control clock input for SD1

._

rs

BIAS2

I++--

33

34

t=k-

35

1 36 1

SIGOUT

SIGIN

AGND

AVDD

N. C.

Ir;

-

-

1 I

I OutDut I Digital 1 ADC signal output 0 (L SB)

outp,t Digital 1 AJX si&l output 1

output Digital ,

output

output Digital ,

Output Digital 1 AIX s&al output 5 I

- -

I outDut I

-

output Digital ADCsigna _

! I

1 Input

1 hlDUt I

I I I

I Input I

- Analog

Digital 1 Digital power supply

I Di

.gital 1 Digital ground I

1

ADC simal

Digital 1 AM: signal output 3 1

Digital I ADC signal output 6

Digital Digital power SUDDEN 1

mgisal I nererence

-- ~~

Digital Horizontal drive pulse input

Digital Vertical drive Dulse inmt

Diiital I Control data input (AGCiEE,Offset etc. > 1

I ADC siml output 4 I

1 No connection

I No connection

I -~-~~-~ --

Analog bias voltage for clamp circuit

Offset bias voltage for AGC

Analog bias voltage 2 for image sensor

Analog image signal output

-Analog image signal input

Analog ground

Analog power supply

No connection

OutDut 2 I

1 OUtDUt 7

CIWK ouepu~ \Y. urhuu/

(MSB)

I

J

Page 9

SHARP

6.ELECTRIC CHARACTERISTICS

6 - 1. ABSOLUTE MAXIMUM BATINGS

Parameter S)TllbOi Wings Unit

Power supply voltage VDD

Input signal voltage V@

Storage temperature Tstr

6 - 2. BECOBBNDED OPEBATING CONDITIONS

LZOP3820 7

-0.3 - 4.6

-0.3

-20

- VDD+O. 3 V

-70

V

@c

Parameter

Power supply voltage

Oneratine temnerature

or--- ---..a --c-m ~~~ .

Oscillator frequency

Digital input Low level

vo 1 tage High level

Analog input voltage

Analog bias voltage

Note 1

Note 2

Note

: Apply to input pins HD, VD, SD1 and SCLK

: Apply to input pin SIGIN, Please do not connect to DC directly.

3

: Apply to pins BIASI, BIASZ, OFS, ADL, DAL, CLP.

Please do not connect to GND directly.

SYUlbOl

YIN ‘lYP

VDD

Tonr

Fck 9-o MHZ

V9L

VdJH

3. 0 3.3

-10 25

__

0.8VDD VDD V

(Connect to terminal

through capacitor)

(Connect to GND

through capacitor)

MAX Unit Note

3. 6 V

60 "c

0.2VDD V

1

2

3

Page 10

C’

~5

SHARi=

LZOP3820

8

7. 7

Readout mode : l/30 see, Normal mode

Ambient temperature : 25 “C

Driving voltage : 3.3 V

Color temperature of light source : 3200K

*Measurement point : Analog image signal output (pin no.32) before ACC and AD.

I

[Note]'

(a> Vo is the average output voltage of Green channel int the central areaWlO,V/lO) under

uniform illumination. The standard exposure condition is defined when Vo is 150 mV.

(b) The image area is divided into IO x 10 segments under 10 times exposure of the standard

exposure condition, The segment’s voltage is the average output voltages of all pixels

whithin the segments. Vsat is the minimum segment’s voltage of all the segments voltage.

cc> Vdark is the difference between average output voltage of the effective area and that of

the OB area, under non-exposure condition.

Cd).

Image area is divided into 10 X 10 segments under non-exposure condition. DSNU is defined

by

(Vdmax - Vdmin), where Vdmax and Vdmin are the maximum and minimun values of all

the segments voltage, respectively.

-(e> R(G) is the average output voltage of Green channel at central areaWlO.V/lO) when a

1000 Iux light source on a 90% reflector is image.

(f) One mean horizontal line signal <bi> is obtained by adding all the horizontal line

signals <aij> verticalIy and dividing them by the line number, <xi> is the deviation of

the center pixel from the average of successive 5 pixels in <bi>. V-FPN is the maximum

absolute value of (xi>.

(g)The limited resolusion in the central area(H/lO,V/lO) whitch the image of TV resolusion

chart(ex. EIAJ test chart:type-A) can be distinguished on the B/I video monitor when

converted into composite video signal.

(h)The limited resolusion in the perpheral area(image height:Y=O.7) under the conditions

mentioned above.

tilDefined following formura at the brightness of standard output voltage. Cat C-channel]

0ko/Vce)X100C%l

(j)Difference of center between

monitor size.

(k) IVDD is the total current of analog and digital power supply in the dark and on the

standard load condition.

Vco:output voltage of edge of the image. (image height:Y=O. 8)

Vce:output voltage of center of the image.

image

and monitor, Ratio of horizontal underscaning

Page 11

SHARP

8. LENS SPECIFICATIONS

Kondi t ions1

(a> Effective Image Area : (Hj2.06 x (V)l. 63mm

(b) TV distortion is defined the formura, (A y /Y > x 1 0 0 [%I

at capturing rectangular pattern sized Horizontal by Vertcal as 4by 3.

“Y” is defined as the Vertical height of center of Horizontal line.

* y” is defined as the Vertical height of edge of Horizontal line.

LZOP3820

t

(c) The range isthe best points by adjustment by screwing the lens head.

(d) Toruques which are necessary for turning the lens.

(at shipping of products)

.

Page 12

.-

, I

366 364 362. 360 358

64 68 72 7’6 80 84 88 ioie2

CLK(l).

9 - 1. Ho;izontal Pulse Timing

I . .

. .

. .

: * > !

KxXXXxxxrxwxxxxwxxxKxxX

,)B ._......._._._............... 08 2 4 6 8 10

124 128 132 138 140 144 148 152 156 160 164 158 172 176 180 184 188 192 196 200

x x x x x K x x x x x x x x x K x x x x n-T

()B . . . . . . . . . . . . . _ ._... _ . . . . . . .._ 08

1 08 .-.-.-.-.--..................OB

L

di 2 4 8 12 I8 20 24 28 32 36 40 44 48 52 56 60

906 Qld . . .

7 s 3

%Ixxxxxm

104 108 112 116 120

HD

(DO-D7 >

11rror

HD

CLK

nor*a1

(DO-D7)

ADOUT

Mirror

*The rising edge of HD pulse must be between two rising edges of CLKtO> and

*The falling edge of HD pulse must be between two rising edges of CLK(90) and CLK(91).

Page 13

,. ’

SHARP

LZOP3820

11

Page 14

SHARP

LZOP3820

12

,

Page 15

SHARP

LZOP3820

13

10. DESCRIPTION

OF SERIAL DATA

(Fix to

Low level)

D31

D32

D33 SAD1 (MS31

D34

D35

D36

D37

D38

MIRH

MIRV

SAD0 (LSB)

MAX2 (MSB)

MAX 1

MAX0 (LSB)

L PMD

Shutter

(Exposure time is 1 to l/330 frame period)

H:Horizontal mirror inversion image, L:Normal image

H:Vertical mirror inversion image,

Phase select of AD clock

(Fix to Low level)

Fixed gain select

(3

A:Power save mode (AGC and AD off), L:All active

speed control

L:Normal image

to 10 dB)

Page 16

SHARI=

10-l. SETTING OF AUTUN CONTROL

*One LSB of the gain code represents appoximately 0.156dB.

*Nominal gain values at

typical

LZOP3820

codes are shown below.

14

1

10-2.

-One LSB of the offset code represents appoximately 0.002Y.

-Nominal offset values at typical codes are shown below.

20

SETTtNG OF oFFSET LEVEL

H(HI HI RI H]

Page 17

SHARP

-One LSB of shutter speed code represents lfi, where 1H is HD pulse period.

LZOP3820

15

10-4.

*One LSB of gain code represents 1dB.

,SETTING OF FIXED GAIN

Page 18

SHARF,

ll.EXAMPLE OF OPERATING CIRCU

LZOP3820

16

I

1

I

A

3

w

Page 19

,*

.’

SHARP LZOP3820 17

12.SPECIFI&A-JION FOR BLEMISH

1) Definition of blemish

*Size of blemish : d 3 lines square by vertical lines.

[For reference] l Size of stain : 2 4 lines square by vertical lines.

White blemish

{note)

l

B :Blemish level defined in fig. below.

l vout

l

Vstd

: Average

output voltage at

Green channel.

: 150 mV. The standard output voltage defined in the specification of

* 7. Imaging Characteristics ”

<To be J&rmdb

(Green channel : 150mV)

$@efer to note below

2) Measureing conditions

l

Operating temperature : Topr = 25°C

* Operating voltage

l

Measureing point

: VDD = 3.3V

: Analog image signal output(Pin

White blemish

Black blemish

(a) Exposed

(Yout

= 150mV at Green channel)

fig. Definition of blemish level

No.32)

before AGC and AD.

White blemish

(b) Non-exposed

Page 20

SHARP

13. LAUTIONS FOR USE&

1, Package breakage

LZOP3820

In order to prevent the package, the lens holder and lens from being’broken, follow the

instructions below:

1) This CMOS image sensor is a precise optical component and the packaege-base material

is ceramic. Therefore, please be careful about the following instructions.

l

Take care not to drop the device when mounting. handling, or transporting.

l

Avoid giving a shock to the package. Especially when Ieads are fixed to the

shocks or the circuit board, a small shock could break the package more

easily tban when the package isn’t fixed.

2) If any damage or breakage occur on the surface of the lens, its characteristics

could deteriorate.

Therefore.

l Do not hit the Lens.

-Do not give a shock large enough to cause distortion,

*Do not scrub or scratch surface of the lens.

---

Even a soft cloth or applicator, if dry, could cause dust to scratch the Lens.

18

2. Electrostatic Darnage

. As compared with general MOS-LSI, CMOS image sensor has lower ESD.

Therefore, take the following anti-static measures when handling the CHCS image sensor.

1) Always discharge static electricity by grounding the human body and the instrument

to be used. To ground the human body, provide resistance of about 1MQ between the

hman body and the ground to be on the safe side.

2) When directly handling the device with the fingers, hoId the lens holder and do not

touth the lead,

3 > To avoid generating static electricity,

a. do not scrub the body and lens surface with cloth etc.

b. do not attach any tape or labels.

4) Vhen storing or transporting the device, put it in a container of conductive

material.

Page 21

. .

SHARI==

LZOP3820

3. Dust and contamination

Dust or contamination on the surface of lens and the inside of the lens holder could

deteriorate the output characteristic or cause a scar. In order to mini&e dust or

contamination on the device, take the following precautions:

1 > Do not remove the lens from the body.

Especially when adjusting macro, be careful not to remove the lens by turning it

counterclockwise too much

2) Do not touch the surface of the lens with the fingers. If dust or contamination gets

on the surface of the lens, the following cleaning method is recommended:

l IInadle the built-in lens CMOS image sensor in a clean environment such as a

cleaned both.

.(The cleanliness level should be, if possible, if possible class 1000 at least. >

*Dust from static electricity should be blown off with an ionized air blower.

For anti-electrostatic measures, however, ground all the leads on the device

before blowing off the dust.

=The contamination on the surface of the lens should be wiped off with a clean

applicator soaked in isopropyl alcohol. Wipe slowly and gently in one direction

only.

--- Frequently replace the applicator and do not use the same applicator to

clean more than one device.

l

Make sure there is no dust or contamination on the lens and screw it on the

lens holder.

19

4. Other

1) Soldering measure and condition.

*Use ESD-measured soldering iron.

*Do not put too much force onto the lens and the lens holder while soldering.

l

Be careful not to let the soldering iron touch the lens holder.

--- Soldering can be quickly/neatly done by laying the soldering iron so it

lightly touches the border between the package and the circuit board

and sliding it in sideways.

2) There is no guarantee of the performance of the device which haa been removed or

resoldered after being soldered once under the conditions mentioned above.

3 > Avoid using or storing the CMOS image sensor at high temperature or high humidity

as it is a precise optical component. Do not give a mechanical shock to the CMOS

i wage sensor.

4) Do not expose the device to strong light, For the color device, long exposure to

strong light will fade the color of the color filters.

Page 22

SHARP

1 4. PACKAGE OUTLINE AND PACKING SPECIFICATION J

1. Package Outline Specification

Refer to attached drawing

2.

Markings

Marking contents

(1) Product name

(2>Companyname : SHARP

(3)Countryname : JAPAN

(41Datecode : 1

: LZOP3820

I Denotes the production week

LZOP3820

I----- Denotes the production ref.code.(l--2figures)

Denotes the production day of the week

1 2 314

SUN. MON.

(01, ozo3,

Denotes the production year.

(Lower two digits of the year. >

TUE. 1 WED. TIIU. 1 FRI. 1 SAT.

l l l l

,52,53)

51617

Positions of markings are shown in the package outline drawing

But,ntarkings shown in theat drawing are not provided any measurements of their charactuers

and their positions.

!. Packing Specification

3 - 1. Packing materials

Device tray 1 Conductive plastic 1 Device packing(Gays/case)

(SUdevices/tray)

Cover tray

Rubber band

Buffer

Cushion bag

Tape

Label

3 - 2. External appearance of packing

Refer to attached drawing

. Precaution

1) Before unpacking, confirm the imports of the chapter ‘l&CAUTIONS FOE USE” in this

device specifications.

2) Unpacking should be done on the stand treated with anti-ESD. At that time, the same

anti-ED treatment should be done to operater’s body, too.

1 Conductive plastic(2trays/case) Device packing

Device tray fixing

Cardboard

Conductive

Paper

Paper

.

Shock absorber of device tray

Device tray fixing

Sealing cushion bag and device case

Indicates part number,

auantitv and date of manufacture

NIE NUMBER (NOTE)

--_-__________-_-_

C-HS3820A

Page 23

-.

SHARF,

LZOP3820

N

8

: I

: /

:

Page 24

T

,

SHARP

S __

LZOP3820

f

H

;i

w

0

a

d

T

c)

i

-

B

0 ‘g -xoJddy

Page 25

SHARP

LZOP3820

(UNIT :

mm)

!

\\ ---

is?iz

t \i

t4mMAw

yxIL(-T-~-oOUTIIwr a,,E : : : ; : : : 1 : : : : :

WrEGRATKJ CmJfrs (lc) GROW

SHARP CORPORATION

tt +

FTMSH

\

---

8%

NAME

,3--F i:::;;; :::: ;:

. m

DRAWING No.

External

Appearance

of Packing

I *.;:::::

: :

.

II., 9.. ; : :

= L;C:-:H’L’3’8i @A’

* * *

-

\ I

,

* .

;

’

J

Loading...

Loading...