Page 1

PRODUCT DATA SHEET

or

t

ow

n

e

e

ACTUATOR

LA36

Features:

• 12, 24 or 36 V DC Permanent magnetic motor

with resetable thermal overload protection

• Thrust from 500 N - 10.000 N depending on gear

ratio and spindle pitch

• 10.000 N actuator cannot be ordered without

electrical endstop

• 10.000 N actuator can be ordered in push now

and pull from 01-09-207

• Max. speed up to 160 mm/sec. depending on

load and spindle pitch

• Heavy duty aluminium housing for

harsh conditions

• Highly efficient acme thread spindle

• Protection class: IP66 for outdoor use

(dynamic), furthermore the actuator can be

washed down by a high pressure cleaner

(IP69K - static)

• Hand crank for manual operation

• Mechanical overload protection through integrated

slip clutch (adjusted to 1.2 - 1.5 times max. load)

• Integrated brake, high self-lock ability

• End play – 2 mm max.

• Non rotating piston rod eye (turnable 0-90

degrees)

• Back fixture turnable in steps of 30 degrees

tic mot

tection

ing on gear

withou

push n

ding o

can b

Options:

• Built in end stop switches

• Adjustable magnetic sensors for end stop signals

(code no. 1017031)

• Hall effect sensor with A/B –signal

• Potentiometer full scale at 333 mm stroke with

8 mm pitch, 500 mm stroke with 12 mm pitch

and 833 mm with 20 mm pitch

• Different back fixtures and piston rod eyes

• Exchangeable cables in different lengths

Usage:

• Duty cycle at max. load 20% (up to 600 mm

stroke, for strokes between 601-999 mm the max.

duty cycle is 15%) at ambient temperature 25°C

• Ambient operating temperature -30°C to +65°C

full performance from 5 - 40°C

LA36 is ideal for use in harsh conditions. It is our

most solid actuator based on the philosophy

that it must be able to operate under extreme

conditions. The actuator is ideal for mobile “offhighway” equipment such as agricultural, forestry

and construction machines.

Page 2

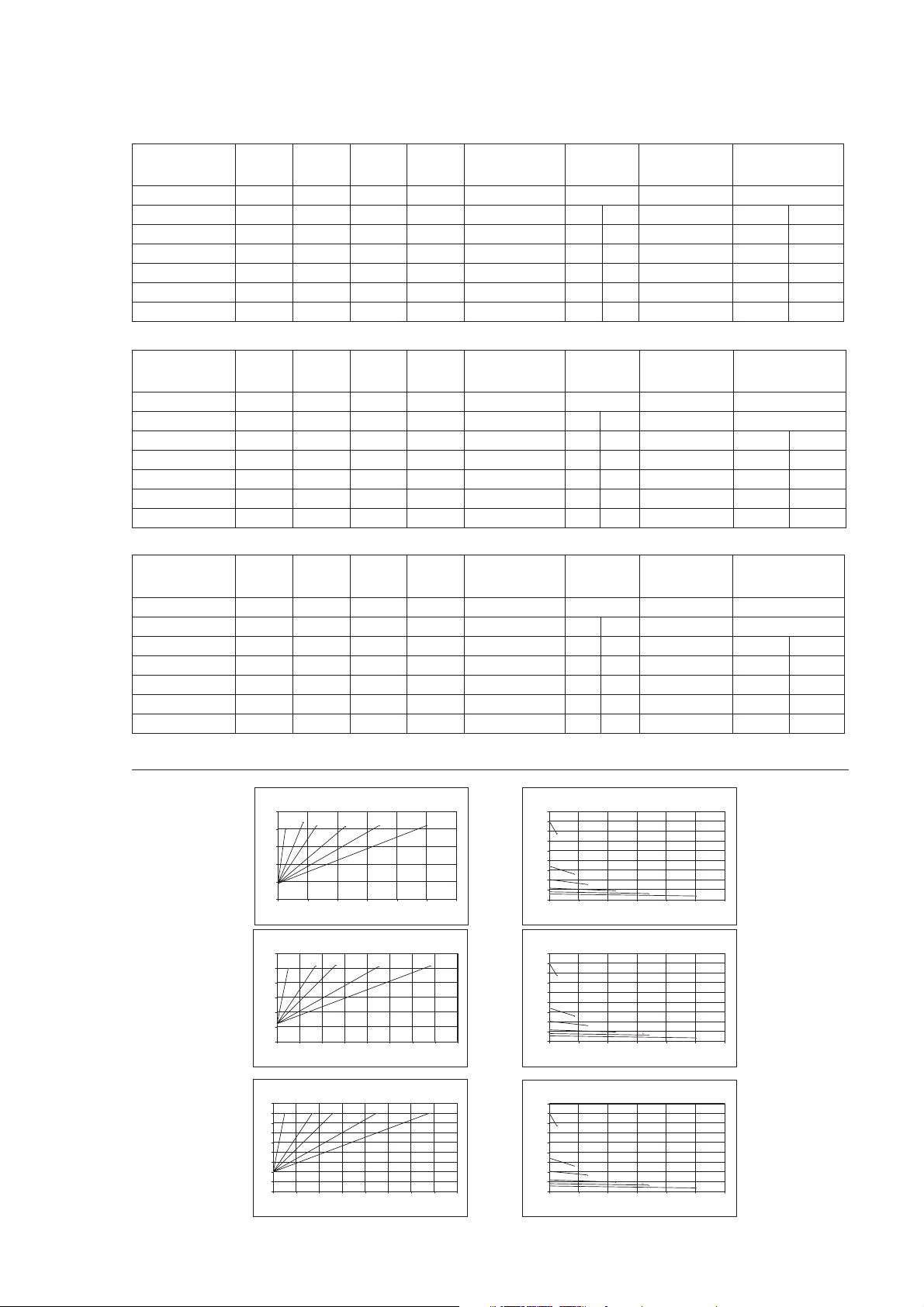

Technical specifi cations

LA36 with 12V motor

Order number Push max.

362CXXXXXXXXXXX 10000 10000 13000 13000 8 11 7 100 - 999* 4.5 22

363AXXXXXXXXXXX 2600 2600 3400 3400 12 40.7 30.6 100 - 999 4.5 21

363BXXXXXXXXXXX 4500 4500 5800 5800 12 23.1 17.8 100 - 999* 4.5 20.7

363CXXXXXXXXXXX 6800 6800 8800 8800 12 15.5 11.9 100 - 999* 4.5 21

365AXXXXXXXXXXX 1700 1700 2200 2200 20 68 52 100 - 999 4.5 22

365FXXXXXXXXXXX 500** 500** 1000 1000 20 160 135 100 - 999 4.5 20

LA36 with 24V motor

Order number Push max.

362CXXXXXXXXXXX 10000 10000 13000 13000 8 11 7 100 - 999* Not tested

363AXXXXXXXXXXX 2600 2600 3400 3400 12 41 32.3 100 - 999 2.4 10.4

363BXXXXXXXXXXX 4500 4500 5800 5800 12 23.3 18.9 100 - 999* 2.4 10.2

363CXXXXXXXXXXX 6800 6800 8800 8800 12 15.7 12.7 100 - 999* 2.4 10.3

365AXXXXXXXXXXX 1700 1700 2200 2200 20 68 52 100 - 999 2.4 10.3

365FXXXXXXXXXXX 500** 500** 1000 1000 20 160 135 100 - 999 2.4 10.0

LA36 with 36V motor

Order number Push max.

362CXXXXXXXXXXX 10000 10000 13000 13000 8 11 7 100 - 999* Not tested

363AXXXXXXXXXXX 2600 2600 3400 3400 12 41 33.5 100 - 999 2.0 8.0

363BXXXXXXXXXXX 4500 4500 5800 5800 12 23.3 19.1 100 - 999* 2.0 8.0

363CXXXXXXXXXXX 6800 6800 8800 8800 12 15.7 12.8 100 - 999* 2.0 8.0

365AXXXXXXXXXXX 1700 1700 2200 2200 20 68 52 100 - 999 2.0 8.0

365FXXXXXXXXXXX 500** 500** 1000 1000 20 160 135 100 - 999 2.0 8.0

* There are limitations on the stroke length if you need full load, please see “ LA36 Load v. Stroke Length” on page 2.

** Note: Fully loaded actuators need a softstart in order to prevent the clutch slipping at start (see curves).

(N)

(N)

(N)

Pull max.

(N)

Pull max.

(N)

Pull max.

(N)

*Self-lock

min. (N)

Push

*Self-lock

min. (N)

Push

*Self-lock

min. (N)

Push

*Self-lock

min. (N)

Pull

*Self-lock

min. (N)

Pull

*Self-lock

min. (N)

Pull

Pitch

(mm/spindle rev.)

Pitch

(mm/spindle rev.)

Pitch

(mm/spindle rev.)

Typical speed

(mm/s)

Load

Standard stroke

lengths (mm)

In steps of 50 mm

Typical amp.

(A)

12 V

no full No load Full load

Typical speed

(mm/s)

Load

Standard stroke

lengths (mm)

In steps of 50 mm

Typical amp.

(A)

24 V

no full No load Full load

Typical speed

(mm/s)

Load

Standard stroke

lengths (mm)

In steps of 50 mm

Typical amp.

(A)

36 V

no full No load Full load

Speed and

current curves:

10.000N not tested

10.000N not tested

LA36 12V motor current v´s load

25

LA365A

LA363A

LA365F*

20

15

10

Ampere

5

0

0 2000 4000 6000 8000 10000 12000

LA36 24V motor current v´s load

12

10

8

6

Ampere

4

2

0

0 1000 2000 3000 4000 5000 6000 7000 8000

LA36 36V motor current v´s load

9

LA365F*

LA365A

8

7

6

5

4

Ampere

3

2

1

0

0 1000 2000 3000 4000 5000 6000 7000 8000

LA363C

LA363B

Load (N)

LA363A

Load (N)

LA363A LA363B LA363C

Load (N)

LA363B

LA362C

LA363CLA365ALA365F*

* Speed and current based on nominal power supply of 12, 24, 36VDC.

LA36 12V motor speed v´s load

180

160

140

LA365F*

120

100

80

LA365A

60

Speed (mm/s)

Speed (mm/s)

Speed (mm/s)

LA363A

40

20

0

0 2000 4000 6000 8000 10000 12000

180

160

140

120

100

80

60

40

20

0

0 2000 4000 6000 8000 10000 12000

180

160

140

120

100

80

60

40

20

0

0 2000 4000 6000 8000 10000 12000

LA363B

Load (N)

LA36 24V motor speed v´s load

LA365F*

LA365A

LA363A

LA363B

Load (N)

LA36 36V motor speed v´s load

LA365F*

LA365A

LA363A

LA363B

Load (N)

LA363C

LA363C

LA363C

LA362C

LA362C

LA362C

Page 3

LA36

Ordering example:

363A11+00xxxA20

Cable:

IP-degree:

0 = No cable

1 = 1.5 m power cable (0367002-1500)

2 = 5 m power cable (0367002-5000)

3 = 0.2 m power cable with AMP connector (0367006)

4 = 1.5 m power and 1.5 signal (0367002-1500+0367003-1500)

5 = 5 m power and 5 m signal (0367002-5000+0367003-5000)

6 = 1.5 m Y-cable, power and signal in one (0367020)

2 = Standard (IP66)

Motor type: A = 12 V DC with clutch

B = 24 V DC with clutch

C = 36 V DC with clutch

Stroke length: XXX = mm Acme spindle:

100, 150....999 mm

Feedback: 0 = Standard (No feedback)

H = Hall signal

P = Potentiometer (not possible with CS36)

End stop: 0 = No limit switches (not for spindle 2 and A)

1 = With limit switches

2 = With limit switches and end-stop signals

3 = CS36

4 = CS36 with end-stop signals

5 = With potential free limit switches

Safety nut: + = Without safety nut - Standard

S = With safety nut - only in push

Piston rod eye: 0 = M20 X 1 female adapter - 0361016

1 = ø 12.9 mm hole, for 1/2" pin - 0361018-B

2 = ø 12.2 mm hole, for 12 mm pin - 0361109-B

3 = M12 X 1.75 male adapter - 0361224

4 = M16 X 1.5 male adapter - 0361135

5 = ø 12.2 hole with slot (like LA34) - 0361138

Back fixture: 0 = M20 X 1 female adapter - 0361128

1 = ø 12.9 mm hole, for 1/2" pin - 0361129

2 = ø 12.9 mm hole turned 90°, for 1/2" pin - 0361129

3 = ø 12.2 mm hole, for 12 mm pin - 0361119

4 = ø 12.2 mm hole turned 90°, for 12 mm pin - 0361119

5 = M12 X 1.75 male adapter - 0361126

6 = M16 X 1.5 male adapter - 0361247

7 = ø 12.2 hole with slot (like LA34) - 0361140

8 = ø 12.2 hole with slot (like LA34) turned 90° - 0361140

Gearbox:

Spindle type:

8 mm pitch 12 mm pitch 20 mm pitch

A = Gear ratio 1 : 18 N.A. 2.600 N 1.700 N

B = Gear ratio 1 : 31 N.A. 4.500 N N.A.

C = Gear ratio 1 : 46 10.000 N 6.800 N N.A.

F = Gear ratio 1 : 7 N.A. N.A. 500 N

2 = 2-threaded acme spindle (8mm pitch)

3 = 3-threaded acme spindle (12 mm pitch)

5 = 5-threaded acme spindle (20 mm pitch)

A = 2 + adjustable reed limit switches (on outer tube)

C = 3 + adjustable reed limit switches (on outer tube)

E = 5 + adjustable reed limit switches (on outer tube)

Actuator type: 36 = LA36

Page 4

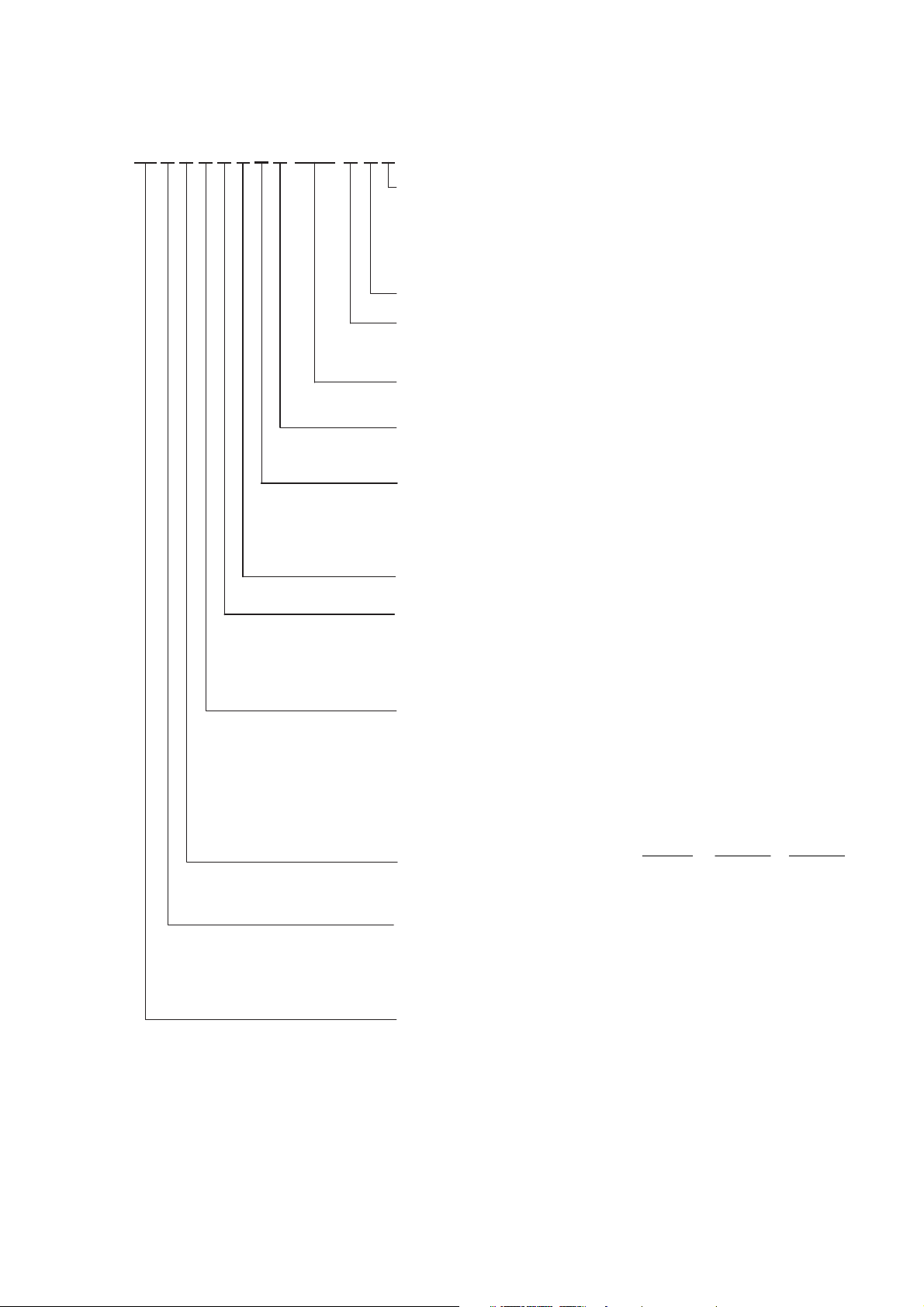

LA36 dimensions:

02= Turned 90˚

LA36 with adapter:

When STROKE >300 = Installation dimension: 250 + STROKE LENGTH

01= Standard

Adapter part number: 0361016 and 0361128

LA36 Load versus Stroke Length

10000

(8 mm)

6800

(12mm)

4500

(12 mm)

2600

(12 mm)

1700

(20 mm)

Load - Push & Pull(N)

500

(20 mm)

0 200 400 600 800 1000

N.B. LA36 500 - 1700 N is with 20 mm spindle pitch

LA36 2600 - 6800 N is with 12 mm spindle pitch

LA36 500 - 10.000 N is with 8 mm spindle pitch

When STROKE <=300 = Installation dimension: 188 + STROKE LENGTH

When STROKE >300 = Installation dimension: 238 + STROKE LENGTH

StrokeLength (mm)

Page 5

Connections diagram:

For 36xxxx+0H/Pxxxxxx and 36xxxx+1H/Pxxxxxx

Hall A

Hall B

Connections diagram:

For 36xxxx+30xxxB20, 36xxxx+3HxxxB20 and 36xxxx+40xxxB20

Connections diagram:

For 36xxxx+2Hxxxxxx

Connections diagram:

For 36xxxxx50xxxxxx

Connections diagram:

For 36xxxx+ 2Pxxxxxx and 36xxxx+20xxxxxx

Hall A

Hall B

End OUT

End IN

Note: If you wish to use the endstop signals, you will have to keep power on the brown and blue wires, otherwise the signal

will be lost.

Page 6

I/O specifications: Power supply - Motor

Item Specification Comment

Power supply

Input voltage 12 VDC, ± 20%

24 VDC, ± 10%

36 VDC, ± 10%

Duty cycle 20% at max. load Ambient temperature 25˚C

Input current

Connection To extend actuator:

2 - 21 Amp. depending on load and voltage (see graphs)

Connect Brown to positive

Connect Blue to negative

To retract actuator:

Connect Brown to negative

Connect Blue to positive

Note: Please note on varients with fast gear (500N-LA365F), it is necessary to use soft start to avoid the actuator clutch slipping when started.

Positioning feedback – Potentiometer.

Item Specification Comment

Absolute positioning

Potentiometer Bourns 0 - 10 K ohm A 5%, 10-Turn Type: 3540 Wirewound

Output range with

8 mm spindle pitch

Output range with 12 mm

spindle pitch

Output range with 20 mm

spindle pitch

Linearity ± 0.25%

Output protection 1 Kohm protection resistor

Connection Common - = Black

Note: Please note that Potentiometer is not possible on varients with fast gear (LA365F) -500N.

0 K ohm = 0 mm stroke

10 K ohm = 333 mm stroke

0 K ohm = 0 mm stroke

10 K ohm = 500 mm stroke

0 K ohm = 0 mm stroke

10 K ohm = 833 mm stroke

+10V exitation = White

0 = 10V out = Violet

Cable dimension: 2 x 2.5mm²

(2 x AWG14) for all different voltages.

Actuator direction can be controlled with a doublethrow switch with the middle position “off”

The same for all LA36 8 mm models.

e.g. 166.6 mm stroke = 5 Kohm

The same for all LA36 12 mm models

e.g. 250 mm stroke = 5 Kohm

The same for all LA36 20 mm models

e.g. 416.5 mm stroke = 5 Kohm

+10V or other value

Positioning feedback – Hall sensors.

Item Specification Comment

Relative positioning

Signal description Can be used for both direction and positioning

Input Voltage 12 - 36 V DC Cable dimension: 6 x 0.5 mm² (6 x AWG20) for all different voltages

Output voltage Always the same as input voltage

Resolution

(Distance the piston

rod moves per count)

Frequency Frequency is 14 - 26 Hz on A signal (and the same on B signal)

Current consumption 15 mA Also when actuator is not running

Switching capacity 40 mA, max. pr. channel Max. 680 nF

Connection Supply = Red

Diagram:

Note: max. output voltage 24 V DC

10000 N: Actuator = 0.124138 mm per count

6800 N: Actuator = 0.165517mm per count

4500 N: Actuator = 0.253846 mm per count

2600 N: Actuator = 0.432558 mm per count

1700 N: Actuator = 0.72093 mm per count

Movement per single Hall pulse:

10000 N Actuator = 0.496551 mm per pulse

6800 N Actuator = 0.662068 mm per pulse

4500 N Actuator = 1.015384 mm per pulse

2600 N Actuator = 1.730232 mm per pulse

1700 N Actuator = 2.88372 mm per pulse

depending on load

Hall A = Yellow

Hall B = Green

Common - = Black

Quadrature

Hall A

Hall B

Count

The Hall sensor signals are generated by the turning of the actuator

gearing

These signals can be fed into a PLC (Programmable Logic Controller).

In the PLC the quadrature signals (fig. 1) can be used to register the

direction and position of the piston rod

Low frequency with a high load

Higher frequency with no load

Input

to

PLC

Represents direction

and position.

Fig. 1

Page 7

LA36 Piston Rod Eye and Back Fixture options

Piston rod eye option

“0” Drawing no.: 0361016

Piston rod eye option

“2” Drawing no.: 0361109-B

Back fixture option

“0” Drawing no.: 0361128

Back fixture option

“3 & 4” Drawing no.: 0361119

Piston rod eye option

“1” Drawing no.: 0361018-B

Piston rod eye option

“3” Drawing no.: 0361224

Back fixture option

“1 & 2” Drawing no.: 0361129

Back fixture option

“5” Drawing no.: 0361126

Piston rod eye option

“4” Drawing no.: 0361135

Back Fixture orientation.

Back fixture option

“6” Drawing no.: 0361247

Piston rod eye option

“5” Drawing no.: 0361138

Back fixture option

“7 & 8” Drawing no.: 0361140

Standard “0” Degrees

“30” Degrees

“60” Degrees

“90” Degrees

“120” Degrees

“150” Degrees

Page 8

Available Circuits (LINAK code 1017031):

415A3

Connection Code V

Cable code 108

Circuit style B

Contact N.O.

Connection PNP

Indication LED

Voltage V DC 5...30

Voltage V AC 5...30

Max voltage drop V 0.1

Max power W 10

Max current mA 50

Varistor V -

Cable size mm

2

3 x 0,14

Sheath PVC

Circuit styles:

Manual hand crank

The manual hand crank can be used in the case of power failure.

The cover over the Allen Key socket must be unscrewed before the Allen Key can

be inserted and the Hand Crank operated.

Hand Crank Torque: Max.16 Nm (at maximum load)

Piston Rod movement per turn

Note:

• The power supply has to be disconnected during manual operation.

• If the actuator is operated as a Hand crank, it must be operated by hand or carefully by machine, otherwise there

is a potential risk of overloading and hereby damage actuator.

Gear A = 10.5 mm

Gear B = 6.0 mm

Gear C = 4.0 mm

Gear F = 27 mm

6 mm Allen key

The LA36 is tested according to the following standards:

Test Specification: Comment

Cold test EN60068-2-1 (Ab)

Dry heat EN60068-2-2 (Bb)

Change of temperature EN60068-2-14 (Na) Rapid change in temperature: +100°C to -30°C

Damp heat EN60068-2-30 (Db)

Salt spray EN60068-2-52 (Kb) Salt spray test: 500 hours incl. spraying periods + humidity storage

Degrees of protection EN60529-IP66 IP6X – Dust: Dust-tight

Chemicals BS7691/96 hours Resistant against: diesel, hydraulic oil, ethylene glycol, urea nitrogen, liquid lime, NPK fertilizers

Free fall Free fall from all sides: 0.4 meters on to steel

Vibration EN60068-2-36 (Fdb)

Bump EN60068-2-29 (Eb) Bump test: Level 40 g for 6 milliseconds. 3,000 bumps

Shock EN60068-2-27 (Ea) Shock test: Level 100 g for 6 milliseconds

Power supply ASAE EP455 (1990) Operating voltages: +10 V - + 16V

HF-immunity EN61000-6-2 Level: 30V/m. at 26 MHz – 1000 MHz; 80% 1 KHz

Emission EN61000-6-4 All levels are well within the norms of the emission standards

Insulation test Level: 500 V AC/25-100 Hz for 1 minute

Automotive transients ISO 7637 Load dump test only accepted on motor power connection

It is the responsibility of the product user to determine the suitability

of LINAK A/S products for a specific application. LINAK will at point of

delivery replace/repair defective products covered by the warranty

if promptly returned to the factory. No liability is assumed beyond

such replacement/repair.

EN60068-2-1 (Ad)

EN60068-2-2 (Bd)

EN60068-2-3 (Ca)

EN60068-2-6 (Fc)

Storage at low temperature: -40°C

Operating at low temperature: -30°C

Storage at high temperature: +90°C

Operating at high temperature: +60°C

Damp heat, Cyclic: Relative humidity 93 - 98 %

High +55°C, low +25°C

Damp heat, Steady: Relative humidity 93 - 95 %

+40°C ± 2°C

IPX6 – Water: No ingress of water causing damage

Random vibration: Short time 6.29 g RMS (Rod Mean Square)

Long time 7.21 g RMS

Sinus vibration: Freq. 5 - 25 Hz, amplitude = 3.3 mm pp

Freq. 25 - 200 Hz, acceleration 4 g

Over voltage +26(V) / 5 min

Specifications subject to change without prior notice.

Copyright © LINAK 2008.07 MA M9-02-148-F . Chapter 5.12

Loading...

Loading...