Page 1

Installation Guide

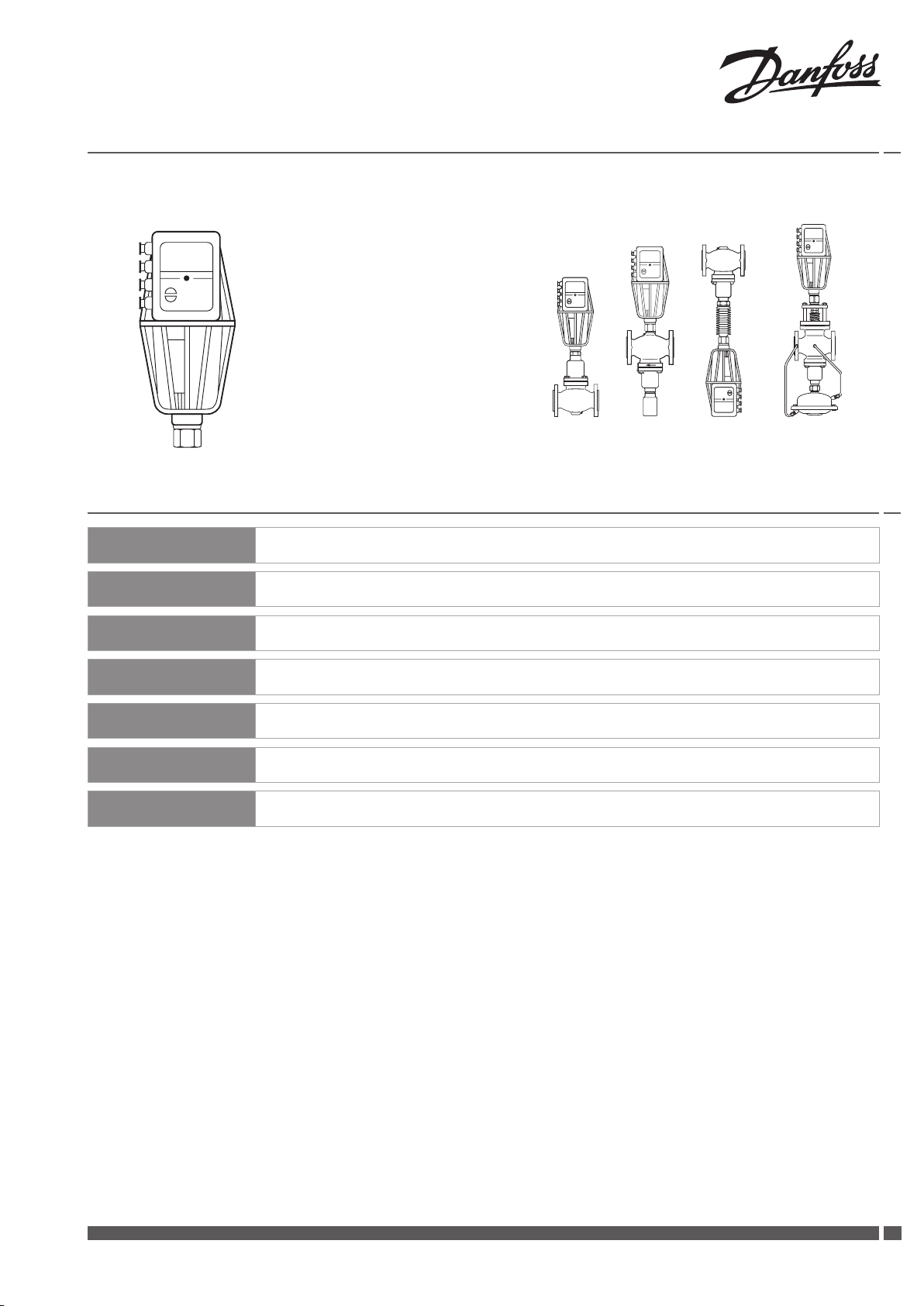

AMV (-H) 610, 613, 633

ENGLISH

DEUTSCH

FRANÇAIS

POLSKI

SRPSKI

中文

РУССКИЙ

VFG 2

VFG 21

VFG 25

Electrical Actuator AMV (-H) 610, 613, 633 www.danfoss.com Page 7

Elektrischer Stellantrieb AMV (-H) 610, 613, 633 www.danfoss.de Seite 10

Servomoteur électrique AMV (-H) 610, 613, 633 www.danfoss.com Page 13

Siłownik elektryczny AMV (-H) 610, 613, 633 www.danfoss.pl Strona 16

Elektro pogon AMV (-H) 610, 613, 633 www.grejanje.danfoss.com Strana 19

电动调节阀驱动器 AMV (-H) 610, 613, 633 www.danfoss.com 共 22 页

Электропривод AMV (-H) 610, 613, 633 www.danfoss.ru Страница 25

VFU 2 VFGS 2 AFQM

Danfoss Heating VI.AA.T2.3K DH-SMT/SI

1

Page 2

2

L

B

L

B

1

Installation Guide AMV (-H) 610, 613, 633

DH-SMT/SI VI.AA.T2.3K Danfoss Heating

❶

B

C

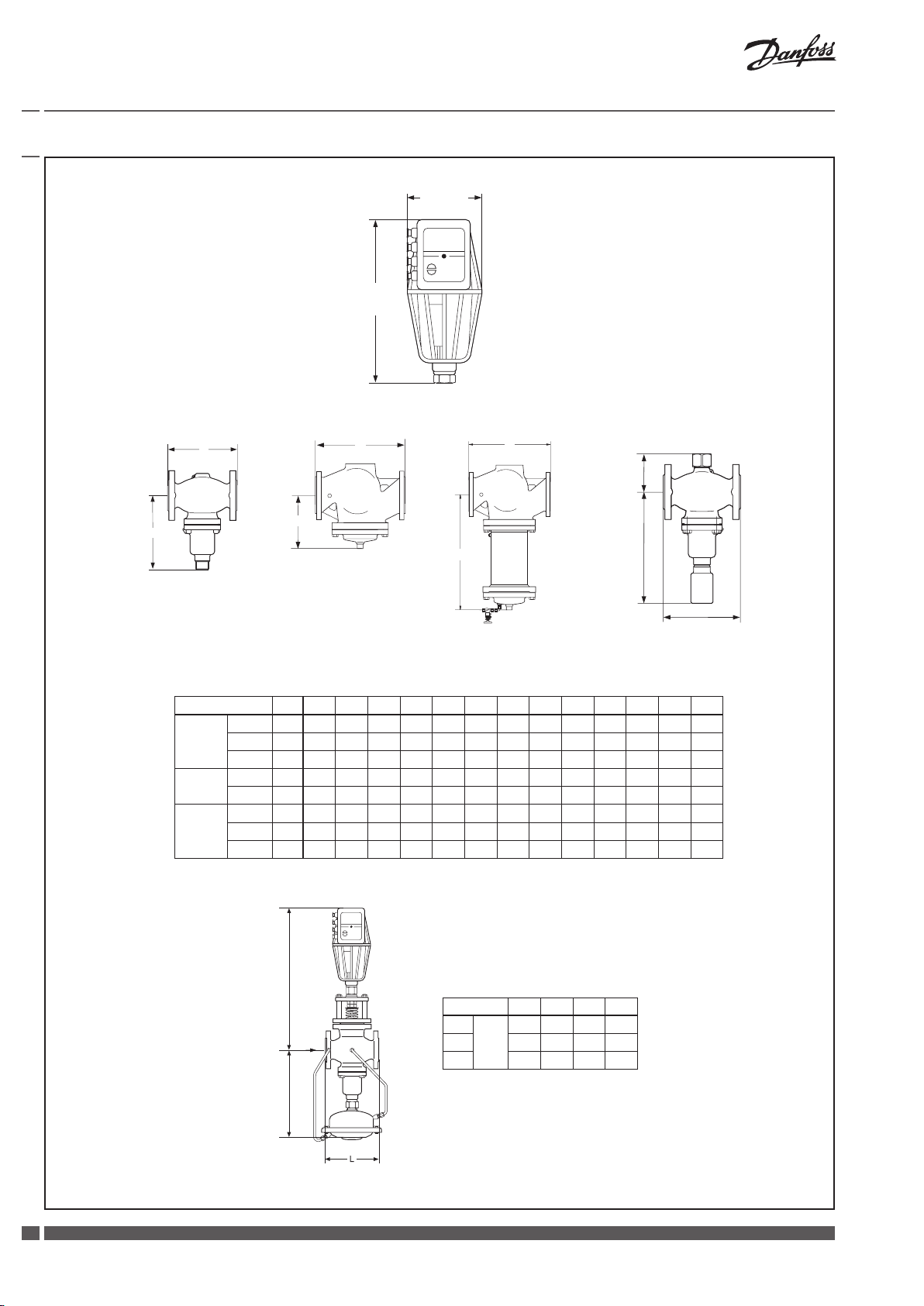

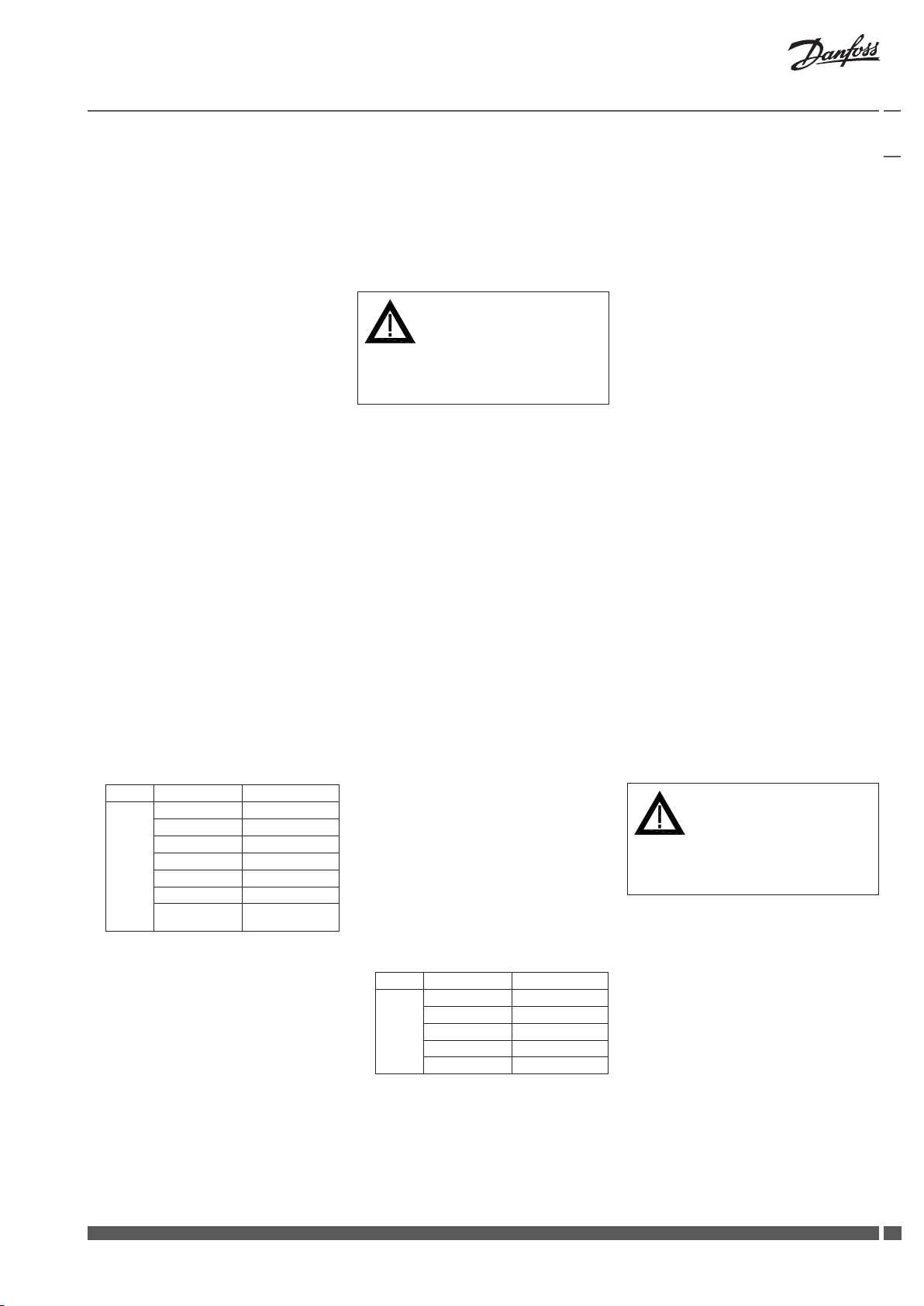

VFG, VFGS DN 15-125 VFG DN 150-250

VFG, VFGS DN 150-250

with body extension

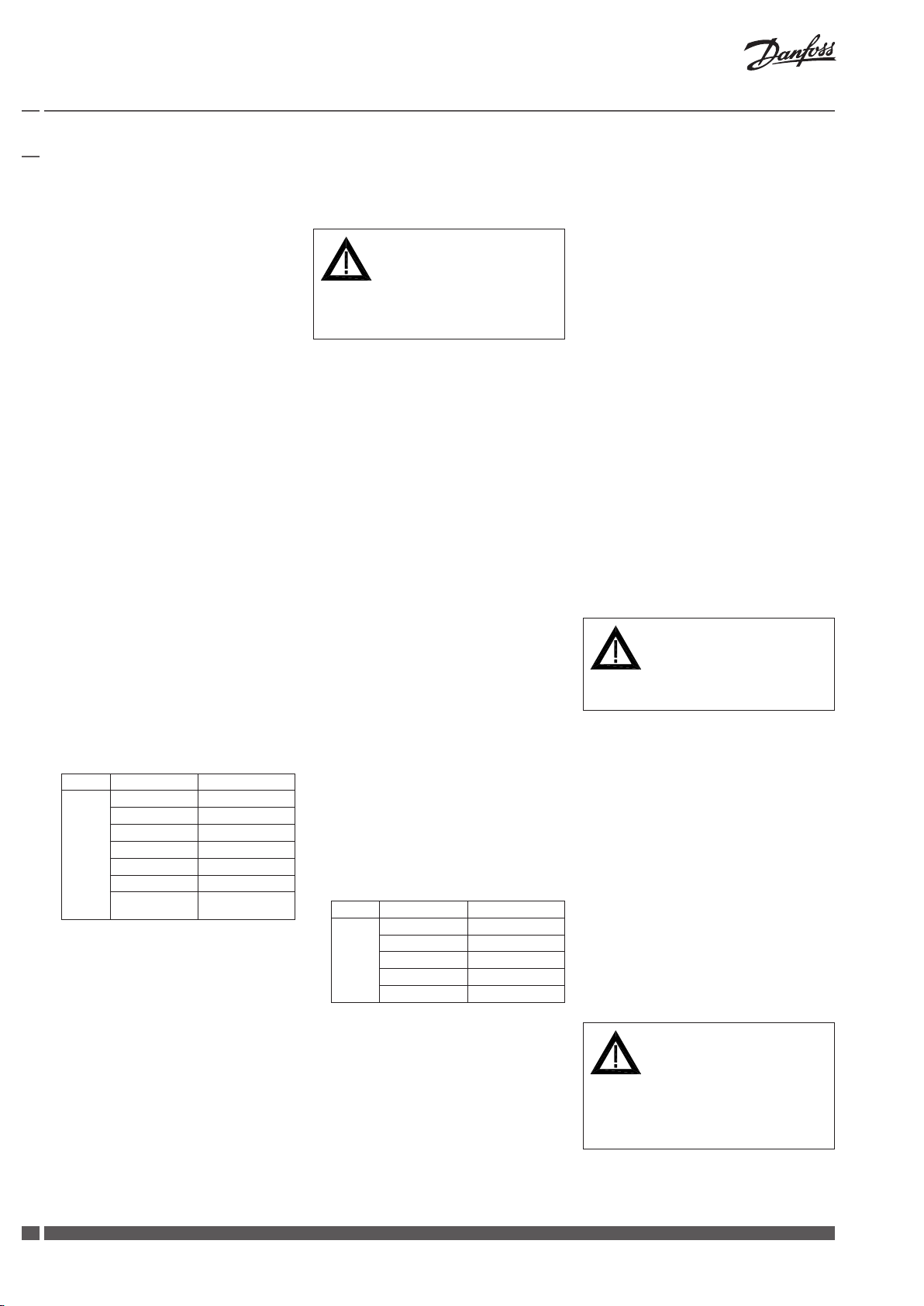

Valves DN 15 20 25 32 40 50 65 80 100 12 5 150 200 250

L mm 130 250 260 280 200 230 290 310 350 400 480 600 730

VFG(S)

VFG(S)

T

300

max

VFU 2

B mm 212 212 238 238 240 24 0 275 275 380 380 326 354 404

Weight kg 7 9 10 13 17 22 33 41 60 79 85 145 228

B1 mm - - - - - - - - - - 630 855 1205

Weight kg - - - - - - - - - - 14 0 210 300

B mm 95 95 106 106 123 12 3 135 135 16 5 16 5 - - -

C mm 3 11 3 11 337 337 339 339 374 374 479 479 - - -

Weight kg 7 9 10 13 17 22 33 41 60 79 - - -

A

DN 65 80 100 125

L

A 600 610 - B 425 425 530 530

290 310 350 400

(mm)

L

VFU DN 15-125

B

AFQM (DN 65-125) + AMV (-H) 6xx

Page 3

Installation Guide AMV (-H) 610, 613, 633

❷

❸

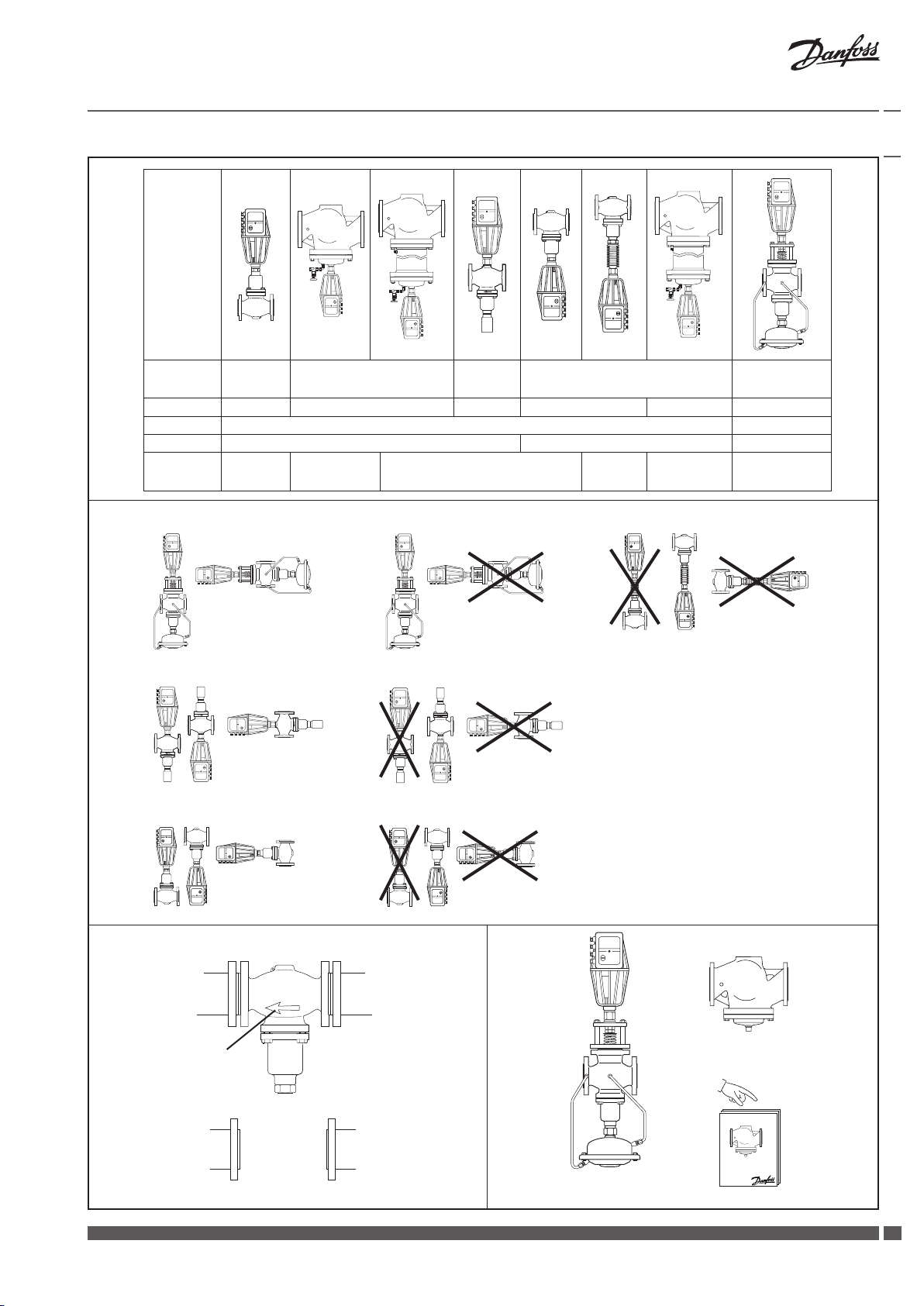

Valve type

DN 15- 125 150-250 15 -125 15- 125 150-250 65 -125

PN 16, 25, 40 25

Medium Hot water Steam Hot water

T

max Medium

①

AFQM

①

VFU 2

①

VFG 2 (21), (25)

VFG 2

VFG 21

VFG 25

VFG 2: 200

VFG 25: 200

VFG 21: 150

VFG 2

VFG 21

140 200 350 300 150

AFQM

②

VFU 2

②

VFG 2 (21), (25)

②

VFU 2 VFGS 2 AFQM

③

VFGS 2

❹ ❺

①

②

AFQM, AFQM 6

Danfoss Heating VI.AA.T2.3K DH-SMT/SI

DN 150-250

DN 150-250

33

Page 4

4

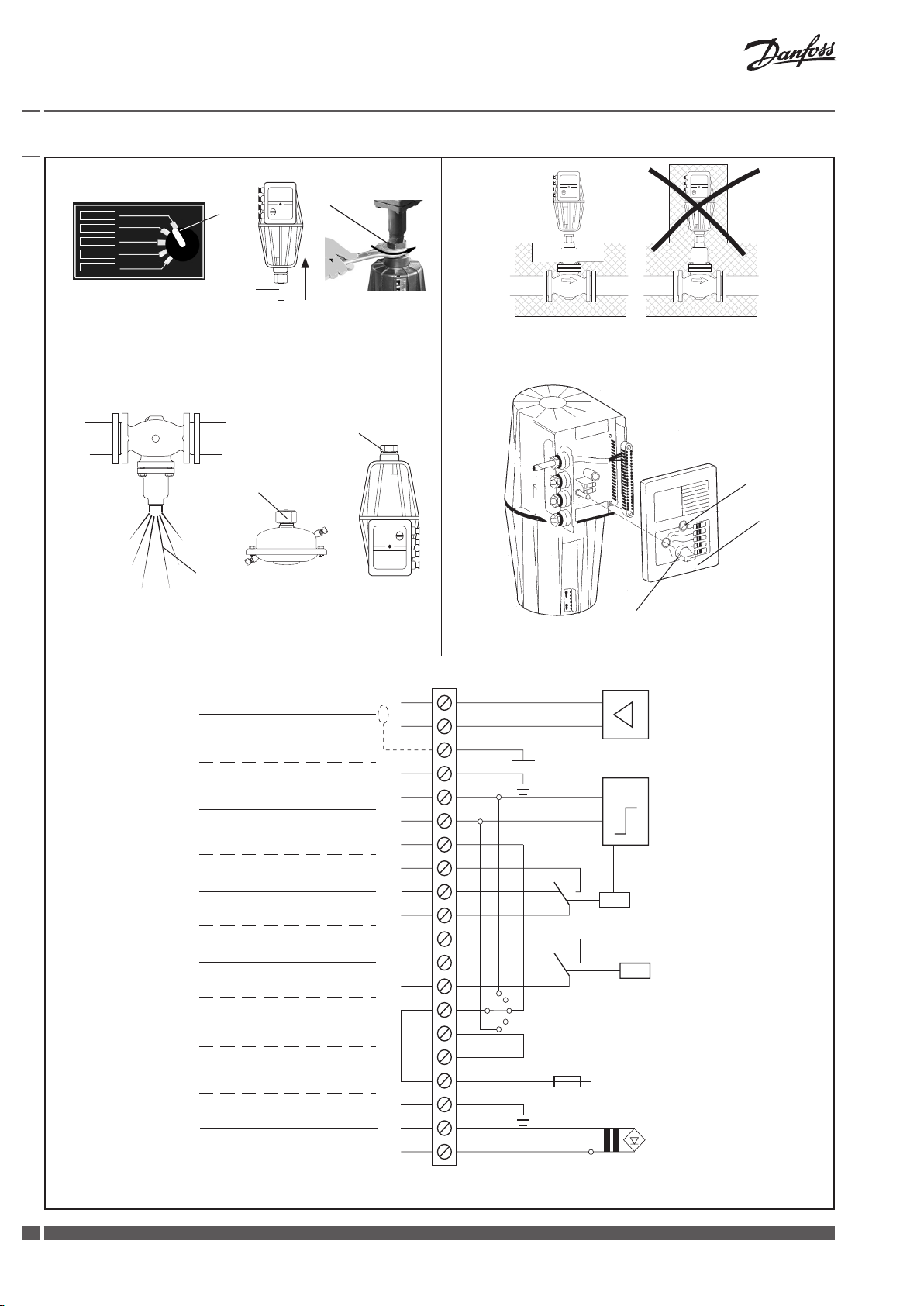

– mA20

1

19

16

18

15

17

14

9

13

11

8

10

7

12

5

4

6

3

2

L

+ mA

Önen

Schließen

PE

L

L

L

PE

N

Handschalter

Önen

Schließen

Ventilhub

0/4 - 20 mA

Externe Regelung

pot. freie Kontakte

Kontakte für Stellung “CLOSE” beschränken

Kontakte für Stellung “OPEN” beschränken

Sicherheitsdruckbegrenzer

Sicherheitstemperaturbegrenzer

Spannungsversorgung

L/N/PE ~ 230 V/50 Hz

Open (Önen)

Stop

Auto

Stop

Close (Schließen)

Zworka

Zworka

Installation Guide AMV (-H) 610, 613, 633

DH-SMT/SI VI.AA.T2.3K Danfoss Heating

❻

❽

OPEN

STOP

AUTO

STOP

CLOSE

①

①

②

②

❼

③

❾

②

②

③

①

❿

①

Page 5

Installation Guide AMV (-H) 610, 613, 633

⓫

①

⑩

VFG.., AFQM

OPEN

STOP

AUTO

STOP

CLOSE

OPEN

STOP

AUTO

STOP

CLOSE

⑫

②

⑪

OPEN

STOP

AUTO

STOP

CLOSE

③

⑤

④

⑬

⑦

0 V

⑮

2 V

⑥

⑧

0 - 2 V

⑨

⑭

⑯

⑰

0 - 2 V

OPEN

STOP

AUTO

STOP

CLOSE

⓬

①

⑩

VFU

OPEN

STOP

AUTO

STOP

CLOSE

OPEN

STOP

AUTO

STOP

CLOSE

②

⑪

OPEN

STOP

AUTO

STOP

CLOSE

③

⑤

④

⑬

⑦

⑱

⑥

⑧

0 - 2 V

⑨

0 V

⑮

OPEN

STOP

AUTO

STOP

CLOSE

⑰

⑫

⑭

⑯

Danfoss Heating VI.AA.T2.3K DH-SMT/SI

55

Page 6

Installation Guide AMV (-H) 610, 613, 633

⓭

⓮

OPEN

STOP

AUTO

STOP

CLOSE

OPEN

STOP

AUTO

STOP

CLOSE

VFG.., AFQM ①

①

④

h

②

VFG.., AFQ VFU 2

⑤

VFG.., AFQ VFU 2

VFU 2 ①

OPEN

STOP

AUTO

STOP

CLOSE

OPEN

STOP

AUTO

STOP

CLOSE

h

②

③

OPEN

STOP

AUTO

STOP

CLOSE

⑥

⑦

⓯

OPEN

STOP

AUTO

STOP

CLOSE

②

③

①

VFG.., AFQ VFU 2

⑥

⑤

VFG.., AFQ VFU 2

6

DH-SMT/SI VI.AA.T2.3K Danfoss Heating

④

⑦

Page 7

Installation Guide AMV (-H) 610, 613, 633

ENGLISH

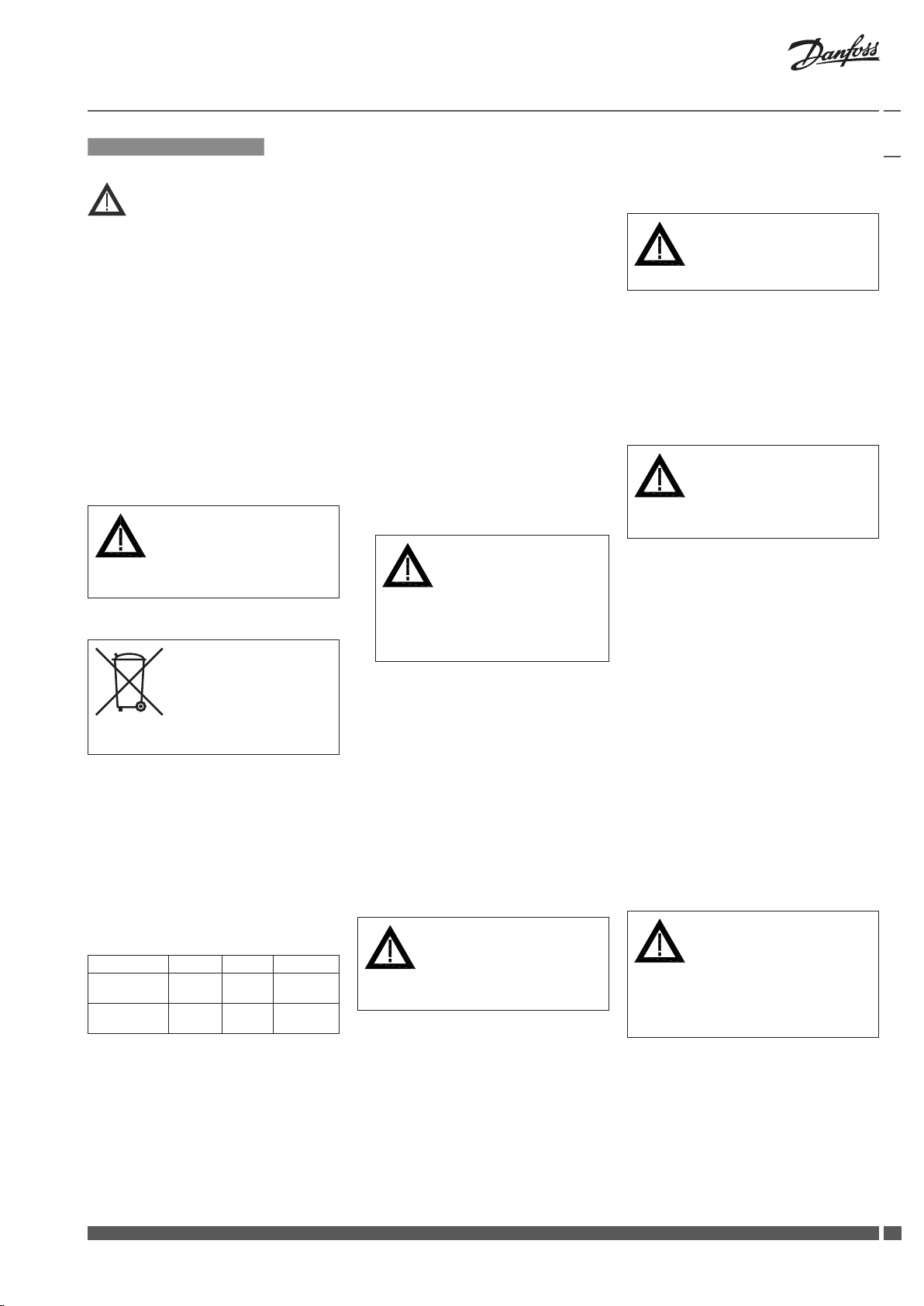

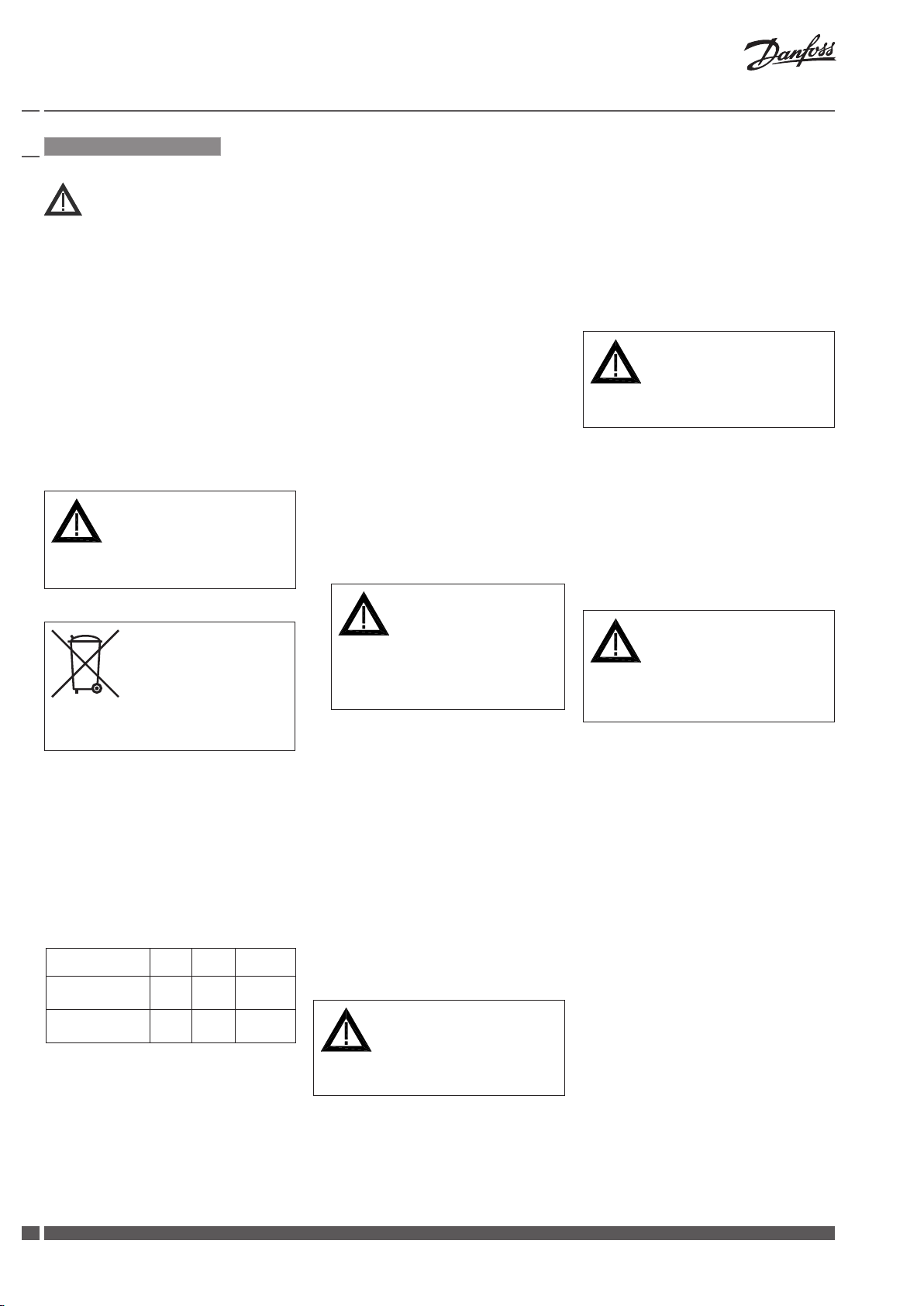

Safety Notes

Mounting

Insulation ❼

Prior to assembly and commissioning

to avoid injury of persons and damages

of the devices, it is absolutely necessary

to carefully read and observe these

instructions.

Necessary assembly, start-up, and

maintenance work must be performed

only by qualified, trained and authorized

personnel.

Prior to assembly and maintenance work

on the controller, the system must be:

- depressurized,

- cooled down,

- emptied and

- cleaned.

Please comply with the instructions of the

system manufacturer or system operator.

Do not remove the cover before the power

supply is fully switched off.

Disposal instruction

This product should be

dismantled and its

components sorted, if

possible, in various groups

before recycling or disposal.

Always follow the local disposal regulations.

Definition of Application

The electrical actuator is used in

connection with the following valves:

VFG 2(21), VFG 25, VFU 2, VFGS 2, AFQM

Fields of application are the temperature

control of water, water-glycol mixtures

and steam for heating, district heating and

cooling systems.

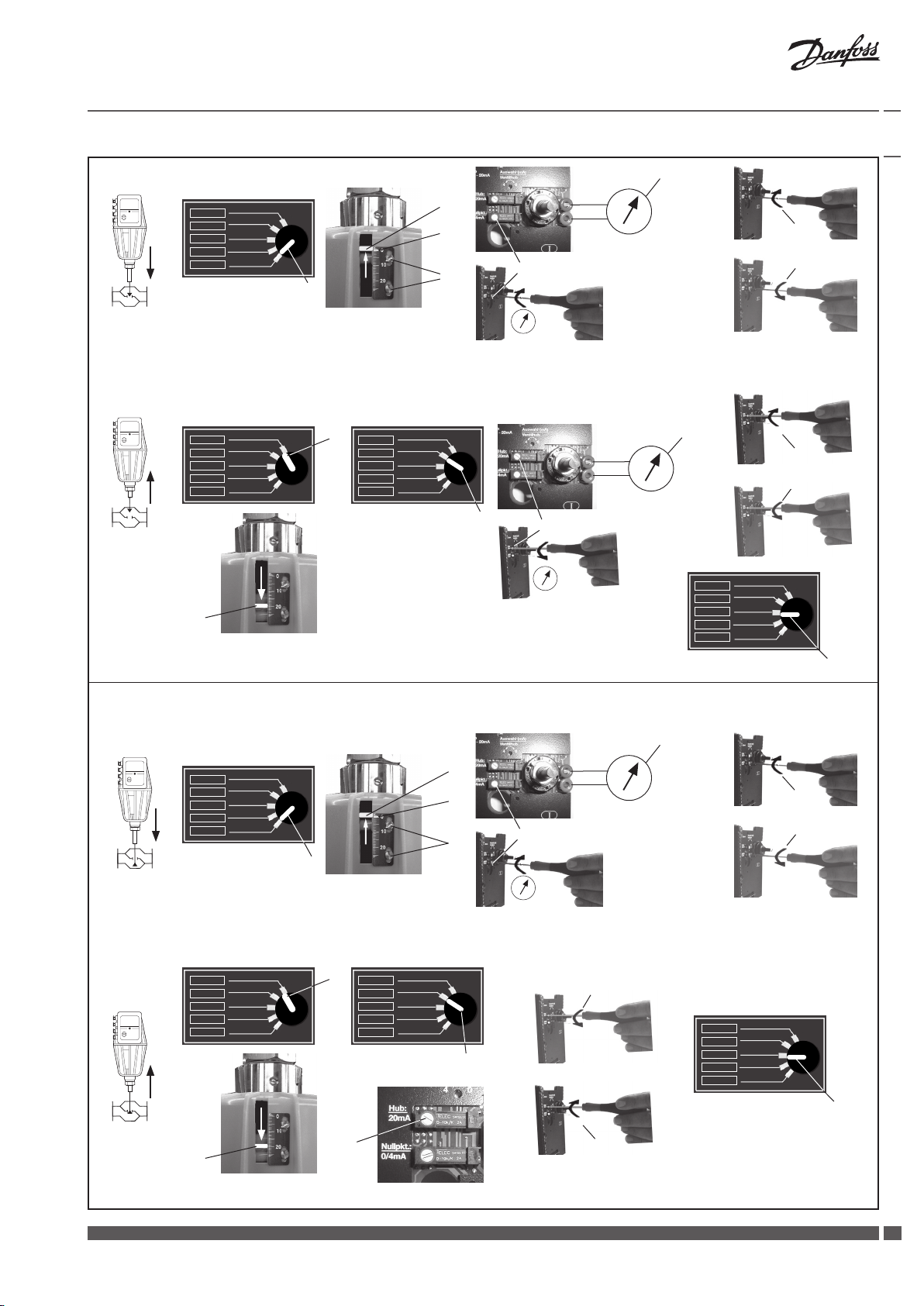

Permissible Installation Positions ❸

① - DN 15-50 (T

valve type AFQM -

- DN 15-80 (T

valve types VFG 2, VFG 21, VFG 25,

VFU 2

② - DN 15-250 (T

all allowed valve types

- DN 65-125 (T

valve type AFQM -

- DN 100-250 (T

valve types VFG 2, VFG 21, VFU 2

③ DN 15-250:

valve type VFGS 2 (steam).

< 120oC):

max

< 120oC):

max

> 120 oC)

max

< 120oC):

max

< 120oC):

max

Valve Installation ❹

1. Install strainer in front of valve.

2. Rinse system before installing valve.

3. Observe flow direction ① on the valve

body

Flanges ② in the pipeline system

must be in parallel direction, the

sealing surfaces must be clean and

undamaged.

4. Install valve.

5. Tighten screws crosswise in 3 steps up

to the maximum torque.

Actuator and Valve Installation

Before mounting ❻:

1. Carry out the electrical connection

procedure acc. to the next paragraph

2. turn the rotary switch to the position

“OPEN” ❻ ① to run the actuator stem

❻ ② completely back

Valves DN 150 - 250 ❺

For these valves the stem of the actuator

must be screwed into the valve stem.

Disassembly of Valve, Actuator ❽

Danger

Danger of injury by steam or hot water! ①

Valve without actuator is open ①,

sealing ② is in the actuator.

It is absolutely necessary to depressurize

system prior to any work.

Carry out disassembly in reverse order as

assembly.

Electrical Connection

HIGH VOLTAGE !

Danger of injury and life in case of

improper handling!

Switch off power supply prior to

connecting lines.

The electrical connection must only be

performed by an expert electrician.

To access electrical panel remove the cover

first.

Removing the cover ❾

1. Loosen slotted screw at the rotary

switch ①, remove rotary switch.

2. Unscrew screw ② and remove cover ③.

Connections

When cover is removed connect lines in

accordance with connection diagram, see ❿:

① Connection for:

STB - Safety Temperature Limiter

STW - Safety Temperature Monitor

SDB - Safety Pressure Limiter

Prior to remounting the cover, carry out

settings at the actuator, see next section.

Overview Actuators AMV(-H) 6..

610/3 0 6 13/33 (-H )613/33

Safety

function

Mechanical

adjustment

- + +

- - +

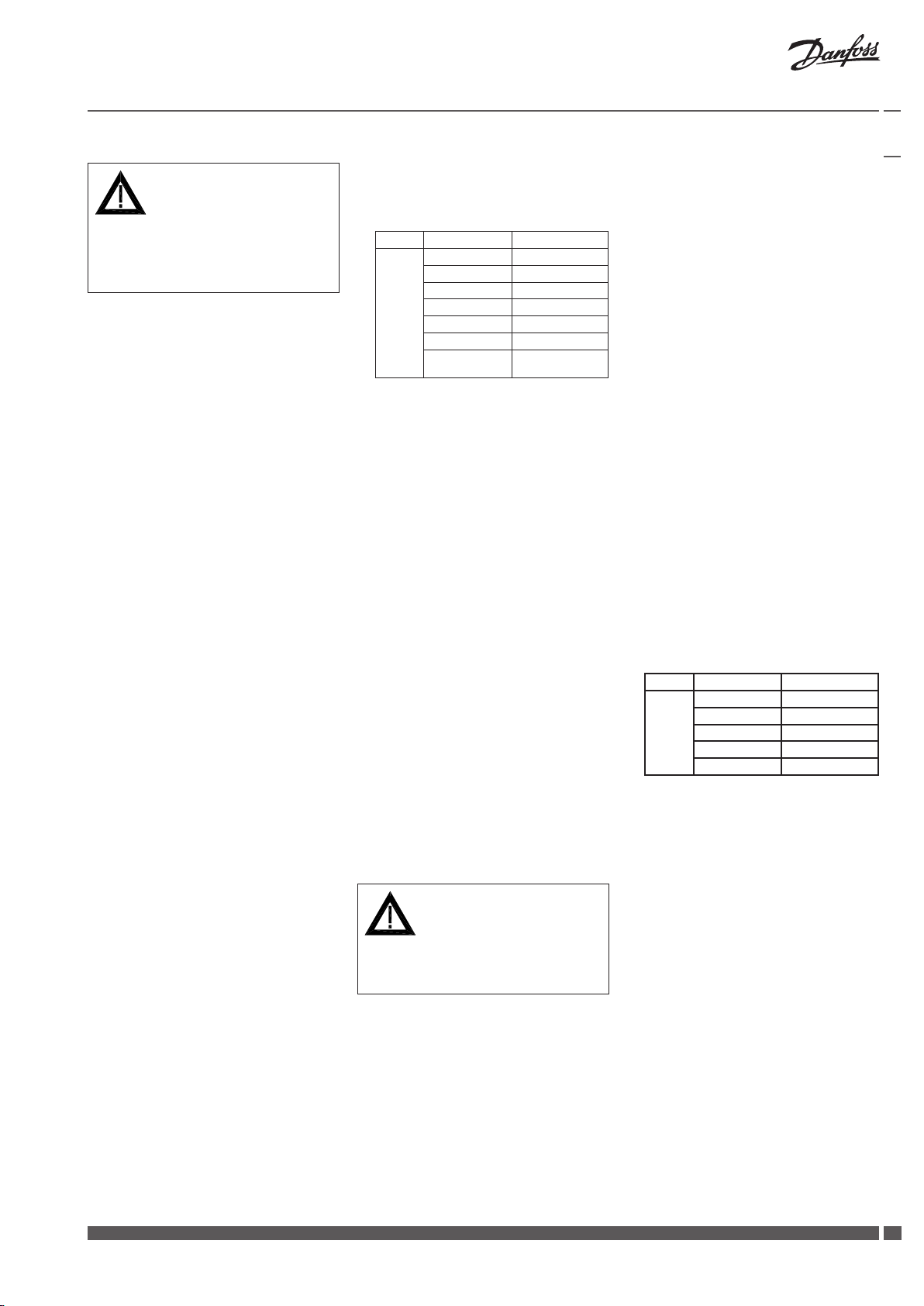

Dimensions, Weights ❶

Flanges:

Connection dimensions acc. to EN 1092-2

Valve Types for AMV(-H) 6..

The electrical actuator AMV(-H) 6.. can be

mounted on the following valves, see ❷.

Danfoss Heating VI.AA.T2.3K DH-SMT/SI

Observe the Operating Instructions

attached to the valves.

Valves DN 15 - 125 ❻

1. Perform electrical connection, see

Electrical Connection Diagrams ❿.

2. Turn rotary switch to position “OPEN”

①, this will retract the actuator stem ②

completely.

3. Turn rotary switch to position “STOP”

4. Place actuator on the valve and align.

5. Tighten union nut ③ torque 100 Nm

Prior to connection it is absolutely

necessry to remove the jumper ❿① -

only types AMV (-H) 613, 633 with safety

return function.

Final Position Settings

After having mounted the valves and the

actuator, the final positions “Valve OPEN”

and “Valve CLOSED” must be set.

Pre-conditions for the settings:

• theactuatorismountedonthevalve

•

the electrical connection is completed.

77

Page 8

8

Installation Guide AMV (-H) 610, 613, 633

DH-SMT/SI VI.AA.T2.3K Danfoss Heating

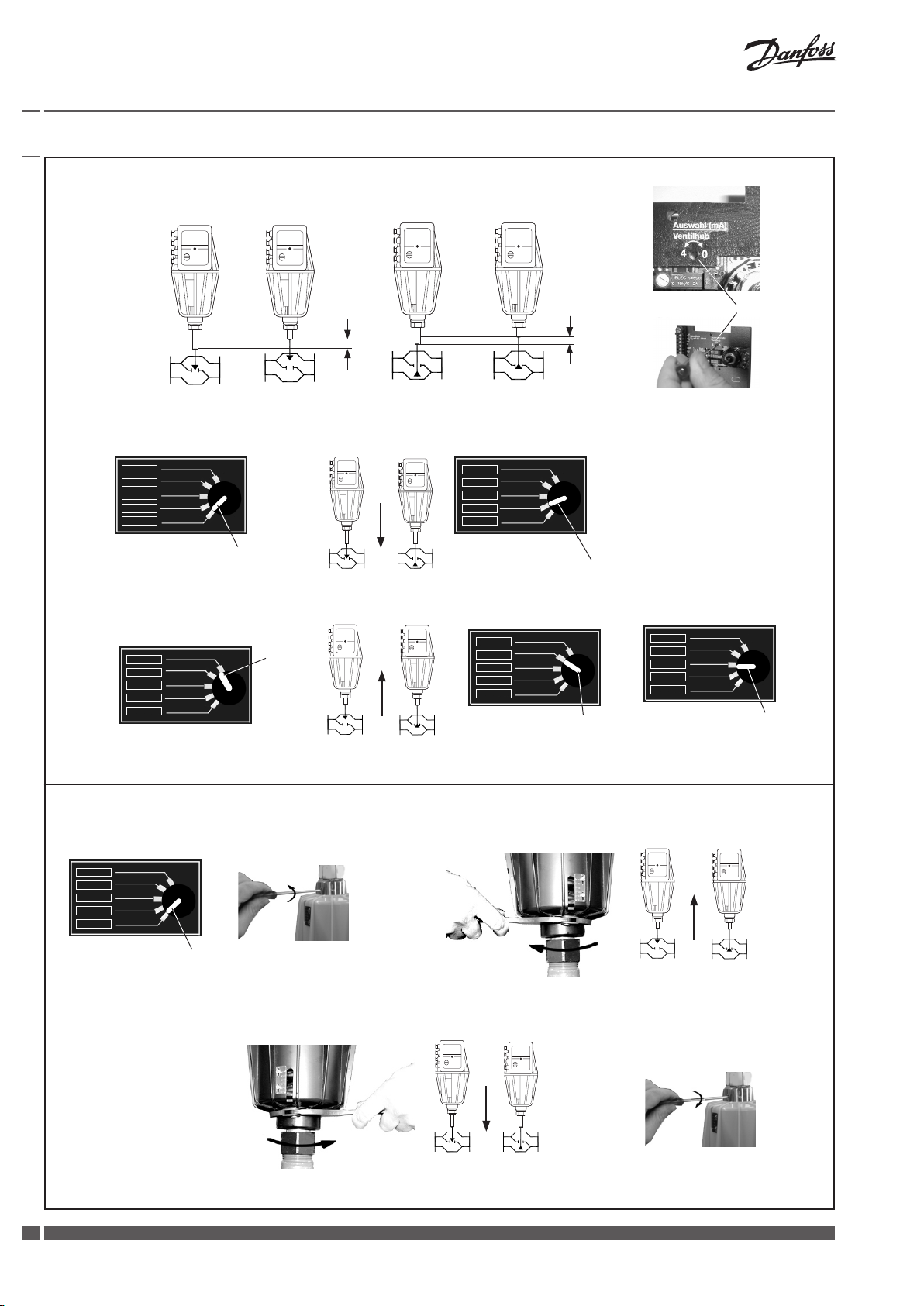

Valves VFG .., AFQM ⓫

Setting the final position

“Valve CLOSED” ①

Procedure:

1. Set rotary switch to position “CLOSE” ②.

The stroke indicator ③ must move in

the direction of the arrow up to its stop.

Valve is completely closed

2. Align stroke indicator:

• Loosenscrews④

• Aligndisplayto0⑤

• Tightenscrews

3. Dismount the cover see ❾

4. If available, connect measuring

device ⑥ to sockets

If no measuring device is available,

continue with step 6.

5. Turn pot ⑦ with a screwdriver until the

measuring device shows 0 V

The final position “Valve CLOSED” is set.

Adjustment without measuring device

6. Turn pot with a screwdriver by about 10

rotations to the right ⑧

7. Afterwards, turn pot to the left ⑨ until

the relay switch is audible, then stop

immediately

If the pot has been turned too far, turn

it again to the right and afterwards

4. Set rotary switch to “AUTO” ⑱

5. Mount Cover and rotary switch.

Valves VFU 2 ⓬

Remarks to VFU 2

In contrary to the valves VFG ..,

AFQM , the valve VFU 2 has a

reversed closing direction.

The valve VFU 2 is opened by the safety

return function.

Setting the final position

“Valve OPEN” ①

Procedure:

1. Set rotary switch to position “CLOSE” ②.

The stroke indicator ③ must move in

the direction of the arrow up to its stop.

Valve is completely opened ①

3. Align stroke indicator:

• Loosenscrews④

• Aligndisplayto0⑤

• Tightenscrews

4. If available, connect measuring

device ⑥ to sockets

If no measuring device is available,

continue with position 6.

5. Turn pot ⑦ with a screwdriver until the

measuring device shows 0 V.

The final position “Valve OPEN” is set.

The final positions are set.

5. Mount cover and rotary switch

6. Set rotary switch to position “AUTO” ⑰

Setting the Output Signal 0(4)-20 mA ⓭

After the adjustment, the output signal is

proportional to the valve stroke “h” ①.

The range of the output signal 0-20 mA or

4-20 mA can be set at the pot ②.

Adjustment is carried out by turning in the

direction of the arrow up to the stop.

Operation

Rotary switch positions electrical

adjustment manual ⓮

• SetrotaryswitchtoCLOSE① and the

actuator runs out ②. After adjustment

set it to “STOP” ③

• SetrotaryswitchtoOPEN④ and the

actuator runs back ⑤. After adjustment

set it to “STOP” ⑥

• SetrotaryswitchtoSTOPandthe

actuator remains in the last positions.

Set rotary switch to AUTO ⑦ and the

actuator is driven by the external

controller

again to the left

The final position “Valve CLOSED” is set.

Setting the final position

“Valve OPEN” ⑩

Procedure:

1. Find the stroke in the table below:

Typ e

VFG 2

VFG 21

VFG 25

AFGM

DN

15, 20, 25 6 mm

32, 40 8 mm

50, 65 12 mm

80 18 mm

100, 125

150, 200, 250 24 mm

150, 200, 250

Valve stroke

20 mm

30 mm

AMV 613-Y60

2. Set rotary to position “OPEN” ⑪

Valve opens, as soon as the stroke ⑫

has been reached, set rotary switch to

position “STOP” ⑬

Example:

DN 100, stroke 20 mm

3. Observe measuring device ⑭, turn

pot ⑮ until 2 V is displayed

The final position “Valve OPEN” is set.

Adjustment without measuring device:

1. Turn pot for about 50 rotations to the

right ⑯

2. Rotary switch to position “OPEN” ⑪

3. Turn pot to the left ⑰

Valve opens, stroke ⑫ moves in the

direction of the arrow. When the stroke

is reached the rotation stops

Adjustment without measuring device

6. Turn pot ⑦ with a screwdriver by about

10 rotations to the right ⑧.

7. Afterwards, turn pot ⑦ to the left ⑨

until the relay switch is audible, then

stop immediately.

If the pot has been turned too far, turn

it again to the right and afterwards

again to the left.

The final position “Valve OPEN” is set.

Setting the final position

“Valve CLOSED” ⑩

1. Find the stroke in the table below:

Typ e

VFU2

DN

15, 20, 25

32, 40

50, 65

80

100, 125

Valve stroke

6 mm

8 mm

12 mm

18 mm

20 mm

Procedure:

2. Set rotary switch to position “OPEN” ⑪

Valve VFU 2 closes, stroke indicator ⑫

moves in the direction of the arrow.

3. As soon as the stroke ⑫ has been

reached, set rotary switch to position

“STOP” ⑬

4. If the stroke is > 20 mm:

Turn pot ⑭ to the left ⑮ until the

relay switch is audible.

If the stroke is < 20 mm:

Turn pot ⑭ to the right ⑯ until the

relay switch is audible.

Standard settings for normal operation

always have to be set.

Mechanical Manual Adjustments ⓯

(only for the actuators AMV 610, AMV-H 613)

In case of a power supply failure or a

operating fault, the valve may be opened

or closed.

Procedure:

1. Turn rotary switch to position

“CLOSE” ①.

2. Loosen security screw ②.

3. With hook wrench (accessory) retract

actuator stem ③.

VFG .., AFQ opens ④

VFU 2 closes ④

4. With hook wrench (accessory) extend

actuator stem ⑤.

VFG .., AFQ closes ⑥

VFU 2 opens ⑥

Prior to switching to automatic operation

(AUTO), it is absolutely necessary to

completely turn the adjustment nut ⑤ to

its stop.

Tighten security screw ⑦.

If this is not observed, the valve cannot be

closed. (VFU ... not be opened).

Page 9

Installation Guide AMV (-H) 610, 613, 633

Translation:

❿

Valve stroke (Ventilhub)

External control (Externe Regelung)

Limit contacts for position «OPEN»

(Kontakte für Stellung “OPEN“ beschränen)

Limit contacts for position «CLOSE»

(Kontakte für Stellung “CLOSE“ beschränen)

Safety pressure limiter

(Sicherheitsdruckbegrenzer)

Safety temperature limiter

(Sicherheitstemperaturbegrenzer)

Power supply (Spannungsversorgung)

Manual switch (Handschalter)

Open (Ö ffnen)

Close (Sc hließe n)

Auto (Auto)

Danfoss Heating VI.AA.T2.3K DH-SMT/SI

99

Page 10

10

Installation Guide AMV (-H) 610, 613, 633

DEUTSCH

Sicherheitshinweise

Um Verletzungen von Personen und

Schäden am Gerät zu vermeiden, ist diese

Anleitung vor der Montage unbedingt zu

beachten.

Montage, Inbetriebnahme und

Wartungsarbeiten dürfen nur von sachkundigen und autorisierten Personen

durchgeführt werden.

Vor Montage und Wartungsarbeiten am

Regler die Anlage

- drucklos machen

- abkühlen lassen

- entleeren und

- reinigen

Die Vorgaben des Anlagenherstellers und

Anlagenbetreibers sind zu beachten.

Montage

Zulässige Einbaulagen ❸

① - DN 15-50 (T

Ventiltyp AFQM -

- DN 15-80 (T

Ventiltypen VFG 2, VFG 21, VFG 25,

VFU 2

② - DN 15-250 (T

alle zulässigen Ventiltypen

- DN 65-125 (T

Ventiltyp AFQM -

- DN 100-250 (T

Ventiltypen VFG 2, VFG 21, VFU 2

③ DN 15-250:

Ventiltyp VFGS 2 (Dampf).

Einbau Ventil ❹

1. Schmutzfänger vor dem Ventil einbauen.

2. Anlage vor dem Einbau des Ventils spülen.

3. Durchflussrichtung ① auf dem

Ventilgehäuse beachten.

< 120oC):

max

< 120oC):

max

> 120 oC)

max

< 120oC):

max

< 120oC):

max

Demontage (Ventil/Stellantrieb) ❽

Gefahr

Verletzungsgefahr durch Dampf oder

Heißwasser! ①

Ventil ist ohne Antrieb offen ①,

Abdichtung ② befindet sich im Antrieb.

Vor Demontage Anlage unbedingt

drucklos machen.

Demontage in umgekehrter Reihenfolge

der Montage durchführen.

Elektrischer Anschluss

GEFAHR DURCH

STROMSCHLAG!

Bei unsachgemäßer Handhabung besteht

Lebens- oder Verletzungsgefahr!

Abdeckung erst entfernen, wenn die

Stromversorgung komplett ausgeschaltet ist.

Entsorgungshinweise

Dieses Produkt sollte vor der

Entsorgung zerlegt und die

Einzelteile für die

Wiederverwertung nach

Materialtyp sortiert werden.

Beachten Sie stets die örtlichen

Entsorgungsbestimmungen.

Bestimmungsgemäße

Verwendung

Der elektrische Stellantrieb wird in

Verbindung mit folgenden Ventilen eingesetzt: VFG 2(21), VFG 25, VFU 2, VFGS 2, AFQM.

Einsatzgebiet ist die Temperaturregelung

von Wasser, Wasser-Glykol-Gemischen und

Dampf (AVDS) in Heizungs-, Fernheizungsund Kühlungsanlagen.

Übersicht Stellantriebe AMV(-H) 6..

610/3 0 613/3 3 (-H )613/33

Sicherheitsfunktion

Mechanische

Verstellung

- + +

- - +

Abmessungen, Gewichte ❶

Flansche:

Anschlussmasse nach EN 1092-2.

Ventiltypen für AMV(-H) 6..

Der elektrische Stellantrieb AMV(-H) 6..

kann auf die folgenden Ventile montiert

werden (siehe ❷).

Flansche ② in der Rohrleitung müssen

parallel, Dichtflächen sauber und

unbeschädigt sein.

4. Ventil einbauen.

5. Schrauben über Kreuz in 3 Stufen bis

zum maximalen Drehmoment anziehen.

Einbau Stellantrieb und Ventil

Vor dem Einbau ❻

1. Elektrischen Anschluss herstellen, siehe

nöchster Abschnitt.

2. Drehschalter auf Stellung “OPEN” ❻ ①

drehen, um die Antriebsstange ❻ ②

ganz einzufahren.

Ventile DN 150 - 250 ❺

Bei diesen Ventilen muss die Antriebsstange

in die Ventilstange eingeschraubt werden.

Den Ventilen beigefügte

Montageanleitungen beachten.

Ventile DN 15 - 125 ❻

1. Elektrischen Anschluss vornehmen,

siehe elektrische Anschlusspläne ❿.

2. Drehschalter auf Stellung “OPEN” ①

drehen, dadurch die Antriebsstange ②

ganz einfahren.

3. Drehschalter auf Stellung “STOP” drehen.

4. Stellantrieb am Ventil ansetzen und

ausrichten.

5. Überwurfmutter ③ anziehen,

Anzugsmoment 100 Nm.

Isolierung ❼

Vor dem Anschluss der Leitungen unbedingt

Spannungsversorgung abschalten.

Durchführung des elektrischen

Anschlusses nur durch Elektrofachkraft.

Deckel abnehmen, um auf elektrisches

Anschlussfeld zugreifen zu können.

Deckel abnehmen ❾

1. Schlitzschraube am Drehschalter

① lösen, Drehschalter abziehen.

2. Schraube ② herausdrehen und

Deckel ③ abnehmen.

Anschluss

Nach Entfernen des Deckels Leitungen

anschließen (siehe Anschlussplan) ❿:

① Anschluss für:

STB - Sicherheitstemperaturbegrenzer

STW - Sicherheitstemperaturwächter

SDB - Sicherheitsdruckbegrenzer

Vor Montage des Deckels Einstellungen

am Stellantrieb vornehmen, siehe nöchster

Abschnitt.

Vor dem Anschluss unbedingt die Brücke

❿① entfernen - nur die Typen AMV (-H)

613, 633 mit Sicherheitsfunktion.

Einstellung der Endlagen

Nach Montage der Ventile und des

Stellantriebs müssen die Endlagen “Ventil

AUF” und “Ventil ZU” eingestellt werden.

Voraussetzungen:

• DerStellantriebistaufdasVentilmontiert.

•

Der elektrischen Anschluss wurde

vorgenommen.

DH-SMT/SI VI.AA.T2.3K Danfoss Heating

Page 11

Installation Guide AMV (-H) 610, 613, 633

Ventile VFG .., AFQM ⓫

Endlage “Ventil ZU” ① einstellen

Vorgehensweise:

1. Drehschalter auf die Stellung “CLOSE” ②

drehen.

Die Hubanzeige ③ muss sich in

Pfeilrichtung bis zum Anschlag

bewegen.

Ventil ist ganz geschlossen

2. Hubanzeige ausrichten:

• Schrauben④ lösen

• Anzeigeauf0⑤ ausrichten

• Schraubenanziehen.

3. Deckel demontieren, siehe ❾.

4. Sofern vorhanden, Messgerät ⑥ an

Buchsen anschließen

Falls kein Messgerät vorhanden, weiter

mit Schritt 6.

5. Poti ⑦ mit Schraubendreher drehen,

bis Messgerät 0 V anzeigt.

Die Endlage “Ventil ZU” ist eingestellt.

Einstellung ohne Messgerät

6. Poti mit Schraubendreher ca. 10

Umdrehungen nach rechts ⑧ drehen.

7. Danach Poti nach links ⑨ drehen, bis

das Relais hörbar schaltet, dann sofort

stoppen.

Falls das Poti zu weit gedreht wurde,

nochmals nach rechts und dann wieder

nach links drehen.

Die Endlage “Ventil ZU” ist eingestellt.

Endlage “Ventil AUF” ⑩ einstellen

Vorgehensweise:

1. Ventilhub aus der folgenden Tabelle

ablesen:

Typ

VFG 2

VFG 21

VFG 25

AFGM

2. Drehschalter auf Stellung “OPEN” ⑪

drehen.

Ventil öffnet, sobald der Hub ⑫ erreicht

ist; Drehschalter auf Stellung “STOP” ⑬

drehen.

Beispiel:

DN 100, Hub 20 mm

3. Messgerät ⑭ beobachten, Poti ⑮ drehen,

bis in der Anzeige 2 V abzulesen sind.

Endlage “Ventil AUF” ist eingestellt.

Einstellung ohne Messgerät:

1. Poti ca. 50 Umdrehungen nach rechts ⑯

drehen.

2. Drehschalter auf Stellung “OPEN” ⑪

drehen.

3. Poti nach links ⑰ drehen

Nennweite (DN)

15, 20, 25 6 mm

32, 40 8 mm

50, 65 12 mm

80 18 mm

100, 125

150, 200, 250 24 mm

150, 200, 250

Ventilhub

20 mm

30 mm

AMV 613-Y60

Ventil öffnet, Hubanzeige ⑫ bewegt

sich in Pfeilrichtung. Sobald der

Ventilhub erreicht ist, Drehung stoppen.

4. Drehschalter auf Stellung “AUTO” ⑱

drehen.

5. Deckel und Drehschalter montieren.

Ventile VFU 2 ⓬

Anmerkungen zum VFU 2

Gegenüber den Ventilen VFG ..,

AFQM verfügt das VFU 2 über

eine umgekehrte Schließrichtung.

Das Ventil VFU 2 wird durch die

Sicherheitsfunktion geöffnet.

Endlage “Ventil AUF” ① einstellen

Vorgehensweise:

1. Drehschalter auf die Stellung “CLOSE” ②

drehen.

Die Hubanzeige ③ muss sich in

Pfeilrichtung bis zum Anschlag

bewegen.

Ventil ist ganz auf ①

3. Hubanzeige ausrichten:

• Schrauben④ lösen

• Anzeigeauf0⑤ ausrichten

• Schraubenanziehen

4. Sofern vorhanden, Messgerät ⑥ an

Buchsen anschließen

Falls kein Messgerät vorhanden, weiter

mit Schritt 6.

5. Poti ⑦ mit Schraubendreher drehen,

bis Messgerät 0 V anzeigt.

Endlage “Ventil AUF” ist eingestellt.

Einstellung ohne Messgerät

6. Poti ⑦ mit Schraubendreher ca. 10

Umdrehungen nach rechts ⑧ drehen.

7. Danach Poti ⑦ nach links ⑨ drehen, bis

das Relais hörbar schaltet, dann sofort

stoppen.

Falls das Poti zu weit gedreht wurde,

nochmals nach rechts und dann wieder

nach links drehen.

Die Endlage “Ventil AUF” ist eingestellt.

Endlage “Ventil ZU” ⑩ einstellen

1. Ventilhub aus der folgenden Tabelle

ablesen:

Typ

VFU2

Vorgehensweise:

2. Drehschalter auf Stellung “OPEN” ⑪

drehen

Ventil VFU 2 schließt, Hubanzeige ⑫

bewegt sich in Pfeilrichtung.

3. Ventil öffnet, sobald der Hub ⑫ erreicht

ist; Drehschalter auf Stellung “STOP” ⑬

drehen.

Nennweite (DN)

15, 20, 25

32, 40

50, 65

80

100, 125

Ventilhub

6 mm

8 mm

12 mm

18 mm

20 mm

4. Ist der Ventilhub größer als 20 mm:

Poti ⑭ nach links ⑮ drehen, bis das

Relais hörbar schaltet.

Ist der Ventilhub kleiner als 20 mm:

Poti ⑭ nach rechts ⑯ drehen, bis das

Relais hörbar schaltet.

Die Endlagen sind eingestellt.

5. Deckel und Drehschalter montieren.

6. Drehschalter auf Stellung “AUTO” ⑰

drehen.

Einstellung Ausgangssignal 0(4) - 20 mA ⓭

Das Ausgangssignal verhält sich nach der

Einstellung der Endlagen proportional zum

Ventilhub “h” ①.

Der Bereich des Ausgangssignals (0-20 mA

bzw. 4-20 mA) kann am Poti ② eingestellt

werden.

Einstellung durch Drehung in Pfeilrichtung

bis zum Anschlag.

Bedienung

Drehschalterstellungen, elektrische

Handverstellungen ⓮

• DrehschalteraufCLOSE①,

Antriebsstange fährt aus ②. Nach dem

Einstellen auf “STOP” ③ drehen

• DrehschalteraufOPEN④,

Antriebsstange fährt ein ⑤. Nach dem

Einstellen auf “STOP” ⑥ drehen

• DrehschalteraufSTOPdrehen,

Antriebsstange bleibt in der letzten

Position stehen.

Drehschalter auf AUTO ⑦ drehen,

Stellantrieb wird über den externen

Regler angesteuert

Standardeinstellungen für den

Normalbetrieb müssen unbedingt

vorgenommen werden.

Mechanische Handverstellungen ⓯

(nur für die Stellantriebe AMV 610, AMV-H 613)

Bei Ausfall der Spannungsversorgung oder

bei einer Störung kann das Ventil von Hand

geöffnet oder geschlossen werden.

Vorgehensweise:

1. Drehschalter auf die Stellung “CLOSE” ①

drehen.

2. Sicherungsschraube ② lösen.

3. Mittels Hakenschlüssel (Zubehör)

Antriebsstange ③ einfahren.

VFG.., AFQM öffnet ④

VFU 2 schließt ④

4. Mittels Hakenschlüssel (Zubehör)

Antriebsstange ⑤ ausfahren.

VFG.., AFQM schließt ⑥

VFU 2 öffne

Danfoss Heating VI.AA.T2.3K DH-SMT/SI

1111

Page 12

12

Installation Guide AMV (-H) 610, 613, 633

Vor dem Umschalten in den

Automatikbetrieb (AUTO) unbedingt

die Einstellmutter ⑤ bis zum Anschlag

eindrehen.

Sicherungsschraube ⑦ anziehen.

Wird das nicht beachtet, dann lässt

sich das Ventil nicht schließen.

(... das VFU nicht öffnen).

Übersetzung:

❶

mit Gehäuseverlängerung

(with body extension)

❷

Ventiltyp (Valve type)

Heißwasser (Hot water)

Dampf (Ste am)

❿

Öffnen (O pen)

Schließen (Close)

Auto (Auto)

DH-SMT/SI VI.AA.T2.3K Danfoss Heating

Page 13

Installation Guide AMV (-H) 610, 613, 633

FRANÇAIS

Consignes de sécurité

Montage

Isolation ❼

Pour éviter les risques de blessure pour les

personnes et les dommages sur l’appareil,

lire attentivement cette notice avant le

montage et la mise en service.

Le montage, la mise en route et les travaux

d’entretien doivent être effectués par du

personnel qualifié, formé et autorisé.

Avant tout travail de montage et d'entretien

du régulateur, l'installation doit être :

- mise hors pression,

- refroidie,

- vidée,

- nettoyée.

Respecter les consignes du fabricant de

l’installation et de l’exploitant de celle-ci.

Ne pas retirer le capot avant d'avoir

totalement coupé l'alimentation.

Instructions de mise au rebut

Ce produit doit être démonté

et tous ses composants

classés, si possible, en

différentes catégories en vue

de leur recyclage ou de leur

mise au rebut.

Toujours respecter les réglementations

locales en matière de mise au rebut des

déchets.

Conditions d’utilisation

Le servomoteur électrique est utilisé en

combinaison avec les vannes suivantes :

VFG 2(21), VFG 25, VFU 2, VFGS 2, AFQM.

Domaines d’application : régulation de la

température de l’eau, de l’eau glycolée et

de la vapeur pour chauffage, chauffage

urbain et installations de réfrigération.

Vue d’ensemble servomoteurs

AMV(-H) 6..

610/3 0 6 13/33 (-H )613/33

Fonction de

secours

Commande

manuelle

mécanique

- + +

- - +

Dimensions, poids ❶

Dimensions raccordement à brides selon

norme EN 1092-2

Types de vannes pour AMV (-H) 6..

Le servomoteur électrique AMV(-H) 6.. peut

être monté sur les vannes suivantes, voir ❷.

Orientations de montage autorisées ❸

① - DN 15-50 (T

type de vanne AFQM -

- DN 15-80 (T

types de vannes VFG 2, VFG 21,

VFG 25, VFU 2

② - DN 15-250 (T

tous types de vannes autorisés

- DN 65-125 (T

type de vanne AFQM -

- DN 100-250 (T

types de vannes VFG 2, VFG 21, VFU 2

③ DN 15-250 :

type de vanne VFGS2 (vapeur).

< 120 oC) :

max

< 120 oC) :

max

> 120 oC)

max

< 120 oC) :

max

< 120 oC) :

max

Montage vanne ❹

1. Monter le filtre devant la vanne.

2. Rincer l’installation avant le montage

de la vanne.

3. Respecter le sens d’écoulement ①

indiqué sur le corps de la vanne.

Les brides ② dans la tuyauterie doivent

être parallèles, les surfaces d’étanchéité

propres et sans dommages.

4. Monter la vanne.

5. Serrer les vis en 3 étapes en croix,

jusqu’au couple de rotation max.

Montage moteur et vanne

Avant le montage ❻ :

1. Respecter la procédure de branchement

électrique, conformément au paragraphe

suivant.

2. Tourner le bouton rotatif sur position

« OPEN » ❻ ① pour rétracter

totalement la tige du moteur ❻ ②.

Vannes DN 150 - 250 ❺

Pour ces vannes, la tige du moteur doit

être vissée dans la tige de la vanne.

Respecter la notice de montage jointe aux

vannes.

Vannes DN 15 - 125 ❻

1. Procéder au branchement électrique, voir

Schéma de branchement électrique ❿.

2. Tourner le bouton rotatif sur position

« OPEN » ①, pour rétracter totalement

la tige du moteur ②.

3. Tourner le bouton sur position «STOP».

4. Positionner le moteur sur la vanne et

procéder à l’alignement.

5. Serrer l’écrou prisonnier ③, facteur de

serrage 100 Nm.

Démontage ❽

Danger

Risques de brûlures par l’eau chaude ①

La vanne n’est pas étanche sans moteur ①,

le cône d’étanchéité ② se trouve dans

l’écrou de fixation du moteur.

Impérativement mettre l’installation hors

pression avant tout démontage.

Pour le démontage, suivre la procédure de

montage dans le sens inverse.

Branchement électrique

Danger d'électrocution !

Lors d’une manipulation non appropriée,

danger de mort ou risques de blessures.

Avant le branchement des câbles,

impérativement couper l’alimentation.

Le branchement doit être effectué

uniquement par du personnel qualifié.

Retirer le capot pour accéder au tableau

électrique.

Dépose du capot ❾

1. Desserrer la vis au niveau du bouton

rotatif ①, retirer le bouton.

2. Dévisser la vis ② et retirer le capot ③.

Branchements

Une fois le capot retiré, raccorder les câbles

selon le schéma de branchement, voir ❿ :

① Branchement pour :

STB – Limiteur de température de sécurité

STW – Contrôleur de température de sécurité

SDB – Limiteur de pression de sécurité

Avant de remettre le capot, effectuer les

réglages sur le moteur, voir paragraphe

suivant.

Lors du branchement, impérativement

retirer le pont ❿① - uniquement types

AMV (-H) 613, 633 avec fonction de secours.

Réglage des positions fins de course

Après le montage, les positions fins de

course « vanne ouverte, fermée » doivent

être réglées.

Conditions pour le réglage :

• lemoteurestmontésurlavanne

•

le branchement électrique est effectué

Danfoss Heating VI.AA.T2.3K DH-SMT/SI

1313

Page 14

14

Installation Guide AMV (-H) 610, 613, 633

Vannes VFG .., AFQM ⓫

Régler la position fin de course

« vanne fermée » ①

Procédure :

1. Tourner le bouton rotatif sur position

« CLOSE » ②.

L’indication de course ③ doit se déplacer

dans le sens de la flèche jusqu’en butée.

La vanne est totalement fermée

2. Aligner l’indication de course :

• Desserrerlesvis④

• Alignerl'achagesur0⑤

• Serrerlesvis

3. Démonter le capot, voir ❾

4. Si disponible, raccorder l’appareil de

mesure ⑥ aux fiches.

Si aucun appareil de mesure n’est

disponible, passer à l'étape 6.

5. Tourner le potentiomètre ⑦ avec un

tournevis, jusqu’à ce que l’appareil de

mesure indique 0 V.

La position fin de course « vanne fermée »

est réglée.

Réglage sans appareil de mesure

6. Tourner le potentiomètre avec un tournevis,

d’environ 10 tours vers la droite ⑧.

7. Ensuite, tourner le potentiomètre vers

la gauche ⑨, jusqu’à l’enclenchement

sonore du relais, puis stopper

immédiatement.

Si le potentiomètre a été trop tourné,

faire quelques tours à droite, puis de

nouveau à gauche.

La position fin de course « vanne fermée »

est réglée.

Régler la position fin de course

« vanne ouverte » ⑩

Procédure :

1. Trouver la course de la vanne dans le

tableau suivant :

Typ e

VFG 2

VFG 21

VFG 25

AFGM

2. Tourner le bouton rotatif sur position

« OPEN » ⑪.

La vanne s'ouvre. Dès que la course de la

vanne ⑫ est atteinte, tourner le bouton

sur « STOP » ⑬.

Exemple :

DN 100, course de la vanne 20 mm

3. Observer l’appareil de mesure, ⑭, tourner

le potentiomètre ⑮ jusqu’à l’indication 2 V.

La position fin de course « vanne ouverte »

est réglée.

DN

15, 20, 25 6 mm

32, 40 8 mm

50, 65 12 mm

80 18 mm

100, 125 20 mm

150, 200, 250 24 mm

150, 200, 250

Course de la vanne

30 mm

AMV 613-Y60

Réglage sans appareil de mesure

1. Tourner le potentiomètre d’environ 50

rotations vers la droite ⑯.

2. Tourner le bouton rotatif sur position

« OPEN » ⑪.

3. Tourner le potentiomètre vers la gauche ⑰.

La vanne s'ouvre. L’indication de course

⑫ se déplace dans le sens de la flèche..

Dès que la course de la vanne est atteinte,

stopper.

4. Tourner le bouton rotatif sur position

« AUTO » ⑱.

5. Monter le capot et le bouton rotatif.

Vannes VFU 2 ⓬

Remarques concernant VFU2

La vanne VFU2 a un sens de

fermeture contraire par

rapport aux vannes VFG..., AFQM.

La vanne VFU2 est ouverte par la fonction

de secours.

Réglage de la position fin de course

« vanne ouverte » ①

Procédure :

1. Tourner le bouton rotatif sur position

« CLOSE » ②.

L’indication de course ③ doit se déplacer

dans le sens de la flèche jusqu’en butée.

La vanne est totalement ouverte ①.

3. Aligner l’indication de course :

• Desserrerlesvis④

• Alignerl'achagesur0⑤

• Serrerlesvis

4. Si disponible, raccorder l’appareil de

mesure ⑥ aux fiches.

Si aucun appareil de mesure n’est

disponible, passer à l'étape 6.

5. Tourner le potentiomètre ⑦ avec un

tournevis, jusqu’à ce que l’appareil de

mesure indique 0 V.

La position fin de course « vanne ouverte »

est réglée.

Réglage sans appareil de mesure

6. Tourner le potentiomètre ⑦ avec un

tournevis, d’environ 10 tours vers la

droite ⑧.

7. Ensuite, tourner le potentiomètre

⑦ vers la gauche ⑨, jusqu’à

l’enclenchement sonore du relais, puis

stopper immédiatement.

Si le potentiomètre a été trop tourné,

faire quelques tours à droite, puis de

nouveau à gauche.

La position fin de course « vanne ouverte »

est réglée.

Régler la position fin de course

« vanne fermée » ⑩

1. Trouver la course de la vanne dans le

tableau suivant :

Typ e

VFU2

DN

15, 20, 25

32, 40

50, 65

80

100, 125

Course de la vanne

6 mm

8 mm

12 mm

18 mm

20 mm

Procédure :

2. Tourner le bouton rotatif sur position

« OPEN » ⑪.

La vanne VFU2 se ferme, l’indication de

course ⑫ se déplace dans le sens de la

flèche.

3. Dès que la course de la vanne ⑫ est

atteinte, tourner le bouton sur « STOP » ⑬.

4. Si la course de la vanne est supérieure à

20 mm :

Tourner le potentiomètre ⑭ vers la

gauche ⑮ jusqu’à l’enclenchement

sonore du relais.

Si la course de la vanne est inférieure à

20 mm :

Tourner le potentiomètre ⑭ vers la

droite ⑯ jusqu’à l’enclenchement

sonore du relais.

Les positions fins de course sont réglées.

5. Monter le capot et le bouton rotatif

6. Tourner le bouton rotatif sur position

« AUTO » ⑰.

Réglage signal de sortie 0(4)-20 mA ⓭

Après le réglage des fins de course, le

signal de sortie est proportionnel à la

course de la vanne « h » ①.

La plage du signal de sortie 0-20 mA

ou 4-20 mA peut être réglée sur le

potentiomètre ②.

Le réglage s’effectue par des rotations

dans le sens de la flèche jusqu’en butée.

Manipulation

Positions du bouton rotatif, commande

manuelle électrique ⓮

• Placerleboutonrotatifsur«CLOSE»

①, la tige du moteur descend ②. Après

l’ajustement, tourner sur « STOP » ③.

• Placerleboutonrotatifsur«OPEN»④,

la tige du moteur se rétracte ⑤. Après

l’ajustement, tourner sur « STOP » ⑥.

• Placerleboutonrotatifsur«STOP»et

la tige du moteur reste dans sa dernière

position.

Placer le bouton rotatif sur « AUTO »

⑦ et le moteur est commandé par un

régulateur extérieur.

DH-SMT/SI VI.AA.T2.3K Danfoss Heating

Page 15

Installation Guide AMV (-H) 610, 613, 633

Traduction:

Réglages standards impératifs pour une

régulation normale.

Commande manuelle mécanique ⓯

(uniquement pour moteurs AMV 610, AMV-H 613)

Lors d’une coupure de l’alimentation ou

lors d’une perturbation, la vanne peut être

ouverte ou fermée manuellement.

Procédure :

1. Tourner le bouton rotatif sur position

« CLOSE » ①.

2. Desserrer la vis de sécurité ②.

3. Rétracter la tige du moteur ③ à l’aide

d’une clé à griffes (accessoire).

VFG..., AFQ s'ouvre ④

VFU2 se ferme ④

4. Descendre la tige du moteur ⑤ à l’aide

d’une clé à griffes (accessoire).

VFG..., AFQ se ferme ⑥

VFU2 s'ouvre ⑥

Avant de commuter dans le mode de

fonctionnement automatique (AUTO),

impérativement serrer l’écrou de réglage

⑤ jusqu’en butée.

Serrer la vis de sécurité ⑦.

En cas de non-respect, la vanne ne peut

pas être fermée (VFU ... ouverte).

❶

avec rallonge de corps (with body extension)

❷

Type de vanne (Valve type)

Fluide (Me dium)

T max fluide (T max Medium)

Eau chaude (Hot water)

Vapeur (Ste am)

❻

Ouvrir (OPEN)

Arrêter (ST OP)

Auto (AUTO)

Arrêter (ST OP)

Fermer (CLO SE)

❿

Course de la vanne (Ventilhub)

Régulateur extérieur (Externe Regelung)

Contacts de limite pour la position « OPEN »

(Kontakte für Stellung “OPEN“ beschränen)

Contacts de limite pour la position « CLOSE »

(Kontakte für Stellung “CLOSE“ beschränen)

Limiteur de pression de sécurité

(Sicherheitsdruckbegrenzer)

Limiteur de température de sécurité

(Sicherheitstemperaturbegrenzer)

Alimentation (Spannungsversorgung)

Bouton manuel (Handschalter)

Ouvrir (Ö ffnen)

Fermer (Sc hließe n)

Auto (Auto)

Danfoss Heating VI.AA.T2.3K DH-SMT/SI

1515

Page 16

16

Installation Guide AMV (-H) 610, 613, 633

POLSKI

Warunki bezpieczeństwa

W celu uniknięcia zranienia osób i uszkodzenia urządzeń należy bezwzględnie przed

montażem i uruchomieniem zaworu zapoznać się dokładnie z niniejszą instrukcją.

Czynności związane z montażem, uruchomieniem i obsługą mogą być dokonywane

wyłącznie przez osoby uprawnione i odpowiednio wykwalifikowane.

Przed montażem i obsługą konserwacyjną

regulatora należy:

- zrzucić ciśnienie,

- ochłodzić urządzenie,

- opróżnić układ,

- wyczyścić układ.

Należy stosować się do instrukcji

producenta i/lub operatora układu.

Nie wolno zdejmować obudowy przed całkowitym odłączeniem napięcia zasilającego.

Instrukcja złomowania

Przed złomowaniem lub

utylizacją niniejszy produkt

należy rozebrać na części i

posortować według grup

materiałowych.

Zawsze stosować się do miejscowych

przepisów w zakresie usuwania odpadów.

Zastosowanie

Siłownik elektryczny jest stosowany

w połączeniu z zaworami: VFG 2(21), VFG 25,

VFU 2, VFGS 2, AFQM

Zastosowanie obejmuje sterowanie

temperaturą wody, roztworu woda glikol oraz pary w układach cieplnych,

instalacjach grzewczych i chłodzenia.

Przegląd siłowników AMV(-H) 6..

(-H)

613/3 3

Funkcja

bezpieczeństwa

Regulacja

mechaniczna

610/3 0

613/3 3

- + +

- - +

Wymiary, masa ❶

Kołnierze:

Wymiary połączeń zgodne z normą EN 1092-2

Typy zaworów do siłowników

AMV(-H) 6..

Siłownik elektryczny AMV(-H) 6.. może

współpracować z zaworami wymienionymi

w tabeli ❷.

Montaż

Dopuszczalne pozycje montażu ❸

① - DN 15-50 (T

typ zaworu AFQM -

- DN 15-80 (T

typy zaworów VFG 2, VFG 21, VFG 25,

VFU2

② - DN 15-250 (T

dozwolone wszystkie typy zaworów

- DN 65-125 (T

typ zaworu AFQM -

- DN 100-250 (T

typy zaworów VFG 2, VFG 21, VFU2

③ DN 15-250:

typ zaworu VFGS 2 (dla pary).

Montaż zaworu ❹

1. Zamontować filtr przed zaworem.

2. Przed zamontowaniem zaworu

przepłukać instalację.

3. Zwrócić uwagę na wskaźnik kierunku

przepływu ① na korpusie zaworu.

Kołnierze ② w rurociągach muszą być

wzajemnie równoległe, a powierzchnie

pod uszczelki powinny być czyste i bez

uszkodzeń.

4. Zamontować zawór.

5. Dokręcać przeciwległe nakrętki w 3

krokach do osiągnięcia maksymalnego

momentu obrotowego.

Montaż siłownika i zaworu

Przed montażem ❻:

1. Wykonać podłączenia elektryczne, patrz

następny rozdział.

2. Ustawić przełącznik obrotowy w pozycji

„OPEN” (Otwarty) ❻ ①, do całkowitego

cofnięcia trzpienia siłownika ❻ ②.

Zawory DN 150 - 250 ❺

W przypadku tych zaworów trzpień siłownika

musi być wkręcony w trzpień zaworu.

Należy zapoznać się z instrukcjami obsługi

dołączonymi do zaworów.

Zawory DN 15 - 125 ❻

1. Wykonać podłączenia elektryczne, patrz:

schematy podłączenia elektrycznego ❿.

2. Ustawić przełącznik obrotowy w pozycji

„OPEN” (Otwarty) ①, do całkowitego

cofnięcia trzpienia siłownika ②.

< 120oC):

maks.

< 120oC):

maks.

> 120oC)

maks.

< 120oC):

maks.

< 120oC):

maks.

3. Ustawić przełącznik obrotowy w pozycji

„STOP” (Zatrzymanie).

4. Umieścić siłownik na zaworze i dopasować

elementy.

5. Dokręcić nakrętkę łączącą ③ momentem

100 Nm.

Izolacja ❼

Demontaż zaworu, siłownika ❽

Uwaga!

Niebezpieczeństwo poparzenia parą lub

gorącą wodą! ①

Zawór bez siłownika jest otwarty ①,

uszczelnienie ② znajduje się w siłowniku.

Przed przystąpieniem do wykonywania

jakichkolwiek prac należy zrzucić ciśnienie

z układu.

Kolejność wykonywanych czynności przy

demontażu jest odwrotna do kolejności

podczas montażu.

Podłączenie elektryczne

WYSOKIE NAPIĘCIE!

Niebezpieczeństwo odniesienia

obrażeń i zagrożenie życia w przypadku

nieprawidłowej obsługi!

Przed podłączeniem przewodów należy

bezwględnie wyłączyć zasilanie.

Podłączenia elektryczne mogą

być wykonywane wyłącznie przez

uprawnionego elektryka.

Aby uzyskać dostęp do panelu

elektrycznego, należy najpierw zdjąć

osłonę.

Zdejmowanie osłony ❾

1. Odkręcić śrubę z rowkiem podłużnym

na przełączniku obrotowym ①,

zdemontować przełącznik obrotowy.

2. Odkręcić śrubę ② i zdjąć osłonę ③.

Połączenia

Po zdjęciu osłony podłączyć przewody

zgodnie ze schematem, patrz ❿:

① Zaciski dla:

STB — bezpiecznika temperatury

STW — strażnika temperatury

SDB — bezpiecznika ciśnienia

Przed założeniem osłony wykonać

wszystkie nastawy siłownika — patrz

następny rozdział.

DH-SMT/SI VI.AA.T2.3K Danfoss Heating

Page 17

Installation Guide AMV (-H) 610, 613, 633

Przed połączeniem należy koniecznie

usunąć zworkę ❿① — dotyczy

wyłącznie typów AMV (-H) 613, 633

z funkcją bezpieczeństwa (powrotu).

Nastawy pozycji krańcowych

Po zamontowaniu zaworów i siłownika

należy ustawić pozycje krańcowe

„Zawór otwarty” i „Zawór zamknięty”.

Warunki wstępne wykonania nastaw:

• siłownikzamontowanynazaworze,

•

wykonano wszystkie podłączenia

elektryczne.

Zawory VFG .., AFQM ⓫

Ustawianie pozycji krańcowej

„Zawór zamknięty” ①

Procedura:

1. Ustawić przełącznik obrotowy w pozycji

„CLOSE” (Zamknięty) ②.

Wskaźnik położenia ③ musi

przemieszczać się zgodnie z kierunkiem

strzałki aż do zatrzymania.

Zawór jest całkowicie zamknięty.

2. Wyregulować wskaźnik położenia:

• poluzowaćśruby④,

• ustawićpozycję0⑤,

• dokręcićśruby.

3. Zdemontować osłonę — patrz ❾.

4. Jeśli na wyposażeniu jest urządzenie

pomiarowe ⑥, należy podłączyć je

do zacisków.

W przypadku braku urządzenia

pomiarowego należy przejść do punktu 6.

5. Śrubokrętem obracać potencjometr ⑦

do momentu aż urządzenie pomiarowe

wskaże wartość 0 V.

Została ustawiona pozycja krańcowa

„Zawór zamknięty”.

Regulacja bez użycia urządzenia

pomiarowego

6. Śrubokrętem obrócić potencjometr o

około 10 obrotów w prawo ⑧.

7. Następnie obracać potencjometr

w lewo ⑨ do momentu usłyszenia

dźwięku przełączenia przekaźnika.

Jeżeli potencjometr został obrócony

za daleko, należy obrócić go ponownie

w prawo, a następnie ponownie w lewo.

Została ustawiona pozycja krańcowa

„Zawór zamknięty”.

Ustawianie pozycji krańcowej

„Zawór otwarty” ⑩

Procedura:

1. Odczytać skok zaworu z poniższej tabeli:

Typ

VFG 2

VFG 21

VFG 25

AFGM

DN

15, 20, 25 6 mm

32, 40 8 mm

50, 65 12 mm

80 18 mm

100, 125 20 mm

150, 200, 250

150, 200, 250

Skok zaworu

AMV 613-Y60

24 mm

30 mm

2. Ustawić przełącznik obrotowy w pozycji

„OPEN” (Otwarty) ⑪.

Zawór otwiera się, kiedy tylko zostanie

osiągnięty skok ⑫, należy ustawić

przełącznik obrotowy w pozycji „STOP”

(Zatrzymanie) ⑬.

Przykład :

DN 100, skok 20 mm

3. Obserwując wartości wskazywane przez

urządzenie pomiarowe ⑭, obracać

potencjometr ⑮ do momentu wskazania

wartości 2 V.

Została ustawiona pozycja krańcowa

„Zawór otwarty”.

Regulacja bez użycia urządzenia

pomiarowego:

1. Obrócić potencjometr o około 50

obrotów w prawo ⑯.

2. Ustawić przełącznik obrotowy w pozycji

„OPEN” (Otwarty) ⑪.

3. Obracać potencjometr w lewo ⑰.

Zawór otwiera się, wskaźnik położenia

⑫ przesuwa się w kierunku strzałki. Po

osiągnięciu skoku zakończyć obracanie.

4. Ustawić przełącznik obrotowy w pozycji

„AUTO” (Automat) ⑱.

5. Zamontować osłonę i przełącznik

obrotowy.

Zawory VFU 2 ⓬

Uwagi dotyczące zaworów

VFU 2

W przeciwieństwie do zaworów

odwrócony kierunek zamykania.

Funkcja bezpieczeństwa (powrotu)

otwiera zawór VFU 2.

Ustawianie pozycji krańcowej

„Zawór otwarty” ①

Procedura:

1. Ustawić przełącznik obrotowy w pozycji

„CLOSE” (Zamknięty) ②.

Wskaźnik położenia ③ musi przemiesz-

czać się zgodnie z kierunkiem strzałki aż

do zatrzymania.

VFG .., AFQM, zawór VFU 2 ma

Zawór jest całkowicie otwarty ①.

3. Wyregulować wskaźnik położenia:

• poluzowaćśruby④,

• ustawićpozycję0⑤,

• dokręcićśruby.

4. Jeśli na wyposażeniu jest urządzenie

pomiarowe ⑥, należy podłączyć je do

zacisków.

W przypadku braku urządzenia

pomiarowego należy przejść do punktu 6.

5. Śrubokrętem obracać potencjometr ⑦

do momentu aż urządzenie pomiarowe

wskaże wartość 0 V.

Została ustawiona pozycja krańcowa

„Zawór otwarty”.

Regulacja bez użycia urządzenia

pomiarowego

6. Śrubokrętem obrócić potencjometr ⑦

o około 10 obrotów w prawo ⑧.

7. Następnie obracać potencjometr ⑦

w lewo ⑨ do momentu usłyszenia

dźwięku przełączenia przekaźnika.

Jeżeli potencjometr został obrócony

za daleko, należy obróć go ponownie

w prawo, a następnie ponownie w lewo.

Została ustawiona pozycja krańcowa

„Zawór otawarty”.

Ustawianie pozycji krańcowej

„Zawór zamknięty” ⑩

1. Odczytać skok zaworu z poniższej tabeli:

Typ

VFU2

DN

15, 20, 25

32, 40

50, 65

80

100, 125

Skok zaworu

6 mm

8 mm

12 mm

18 mm

20 mm

Procedura:

2. Ustawić przełącznik obrotowy w pozycji

„OPEN” (Otwarty) ⑪.

Zawór VFU 2 zamyka się, wskaźnik

położenia ⑫ przesuwa się w kierunku

strzałki.

3. Po osiągnięciu skoku ⑫ ustawić

przełącznik obrotowy w pozycji „STOP”

(Zatrzymanie) ⑬.

4. Jeżeli skok przekracza 20 mm:

Obracać potencjometr ⑭ w lewo ⑮

do momentu usłyszenia dźwięku

przełączenia przekaźnika.

Jeżeli skok jest mniejszy niż 20 mm:

Obracać potencjometr ⑭ w prawo ⑯

do momentu usłyszenia dźwięku

przełączenia przekaźnika.

Pozycje krańcowe zostały nastawione.

5. Zamontować osłonę i przełącznik

obrotowy.

6. Ustawić przełącznik obrotowy w pozycji

„AUTO” (Automat.) ⑰.

Danfoss Heating VI.AA.T2.3K DH-SMT/SI

1717

Page 18

18

Installation Guide AMV (-H) 610, 613, 633

Ustawianie sygnału wyjściowego

w zakresie od 0(4) do 20 mA ⓭

Po regulacji sygnał wyjściowy będzie

proporcjonalny do skoku zaworu „h” ①.

Zakres sygnału wyjściowego od 0 do 20

mA lub od 4 do 20 mA można nastawiać

potencjometrem ②.

Regulację należy wykonać, obracając do

oporu zgodnie z kierunkiem strzałki.

Zasada działania

Pozycje przełącznika obrotowego —

ręczna regulacja elektryczna ⓮

• Ustawićprzełącznikobrotowywpozycji

CLOSE (Zamknięty) ①, siłownik zostanie

wysunięty ②. Po zmianie położenia

ustawić przełącznik w pozycji „STOP”

(Zatrzymanie) ③.

• Ustawićprzełącznikobrotowywpozycji

OPEN (Otwarty) ④, siłownik zostanie

wsunięty ⑤. Po zmianie położenia

ustawić przełącznik w pozycji „STOP”

(Zatrzymanie) ⑥.

• Ustawićprzełącznikobrotowywpozycji

STOP (Zatrzymanie), siłownik pozostaje

w ostatnim położeniu.

Ustawić przełącznik obrotowy w pozycji

AUTO (Automat.) ⑦, siłownik sterowany

jest sygnałem z zewnętrznego regulatora.

Przed przełączeniem w tryb pracy

automatycznej (AUTO (Automat.)) należy

koniecznie pokręcić nakrętką regulacyjną

⑤ do oporu.

Dokręcić śrubę zabezpieczającą ⑦.

W przeciwnym przypadku nie będzie

można zamknąć zaworu. (VFU ... nie

będzie otwierany).

Opis rysunków:

❶

z przedłużonym korpusem

(with body extension)

❷

Typ zaworu (Valve type)

Czynnik (Medium)

T max czynnika (T max Medium)

Woda (Hot water)

Para (Steam)

❻

Otwarty (OPEN)

Zatrzymanie (STOP)

Automat. (AUTO)

Zatrzymanie (STOP)

Zamknięty (CLOSE)

W przypadku normalnego trybu pracy

należy zawsze stosować standardowe

ustawienia.

Regulacja ręczna — mechaniczna ⓯

(dotyczy tylko siłowników AMV 610, AMV-H 613)

W przypadku awarii zasilania lub

nieprawidłowego działania zawór

można otworzyć lub zamknąć.

Procedura:

1. Ustawić przełącznik obrotowy w pozycji

„CLOSE” (Zamknięty) ①.

2. Poluzować śrubę zabezpieczającą ②.

3. Przy pomocy klucza hakowego

(akcesoria) cofnąć trzpień siłownika ③.

VFG .., AFQ otwieranie ④

VFU 2 zamykanie ④

4. Przy pomocy klucza hakowego

(akcesoria) wysunąć trzpień siłownika ⑤.

VFG .., AFQ zamykanie ⑥

VFU 2 otwieranie ⑥

❿

Skok zaworu (Ventilhub)

Sterowanie zewnętrzne (Externe Regelung)

Styki krańcowe dla pozycji „OPEN” (Otwarty)

(Kontakte für Stellung “OPEN” beschränken)

Styki krańcowe dla pozycji „CLOSE”

(Zamkniety)

(Kontakte für Stellung “CLOSE” beschränken)

Ogranicznik cisnienia bezpieczeństwa

(Sicherheitsdruckbegrenzer)

Ogranicznik temperatury bezpieczeństwa

(Sicherheitstemperaturbegrenzer)

Zasilanie (Spannungsversorgung)

Przełącznik do sterowania ręcznego

(Handschalter)

Otwarty (Ö ffnen)

Zamknięty (Sch ließe n)

Automat. (Auto)

Zatrzymanie (Stop)

DH-SMT/SI VI.AA.T2.3K Danfoss Heating

Page 19

Installation Guide AMV (-H) 610, 613, 633

SRPSKI

Mere sigurnosti

Priključenje

Izolacija ❼

Pre montaže i puštanja u rad, da biste

izbegli povređivanje personala i oštećenje

opreme, neophodno je pažljivo pročitati

i pridržavati se ovog uputstva.

Neophodne radove u vezi sa montažom,

puštanjem u rad i održavanjem moraju

obaviti samo kvalifikovana, obučena

i ovlašćena lica.

Pre radova u vezi sa montažom

i održavanjem regulatora, sistem se mora:

- osloboditi pritiska,

- ohladiti,

- isprazniti i

- očistiti.

Molimo Vas da se pridržavate uputstva

proizvođača sistema ili operatora sistema.

Nemojte skidati poklopac pre nego što se

napajanje potpuno isključi.

Odlaganje na otpad

Ovaj proizvod treba

demontirati, a njegove delove

sortirati, ukoliko je to

moguće, u grupe pre reciklaže

ili odlaganja na otpad.

Uvek se pridržavajte važećih propisa

o odlaganju na otpad.

Definicija primene

Elektro pogon se koristi u kombinaciji

sa sledećim ventilima: VFG 2(21), VFG 25,

VFU 2, VFGS 2, AFQM

Polja primene su regulacija temperature

vode, mešavine vode i glikola i regulacija

pare u sistema za grejanje, daljinsko

grejanje i u rashladnim sistemima.

Pregled pogona AMV(-H) 6..

(-H )

613/3 3

Sigurnosna

funkcija

Mehaničko

podešavanje

610/3 0 613/ 33

- + +

- - +

Dimenzije, masa ❶

Prirubnice:

Dimenzije spoja prema EN 1092-2

Tipovi ventila za AMV(-H) 6..

Elektro pogon AMV(-H) 6.. se može

montirati na sledeće ventile, pogledajte ❷.

Dozvoljeni položaji montaže ❸

① - DN 15-50 (T

tip ventila AFQM -

- DN 15-80 (T

tipovi ventila VFG 2, VFG 21, VFG 25,

VFU2

② - DN 15-250 (T

svi dozvoljeni tipovi ventila

- DN 65-125 (T

tip ventila AFQM -

- DN 100-250 (T

tipovi ventila VFG 2, VFG 21, VFU2

③ DN 15-250:

tip ventila VFGS 2 (para).

< 120oC):

max

< 120oC):

max

> 120 oC)

max

< 120oC):

max

< 120oC):

max

Montaža ventila ❹

1. Montirajte hvatač nečistoće ispred ventila.

2. Isperite sistem pre montaže ventila.

3. Pripazite na smer protoka ① na telu

ventila.

Prirubnice ② u cevovodu moraju biti u

paralelno postavljene, površine koje se

zaptivaju moraju biti čiste i neoštećene.

4. Montirajte ventil.

5. Zategnite zavrtnje unakrsno u 3 koraka,

do maksimalnog zateznog momenta.

Montaža pogona i ventila

Pre montaže ❻:

1. Obavite postupak električnog

priključenja prema sledećem odeljku.

2. Okrenite rotacioni prekidač u položaj

“OPEN” (Otvoren) ❻ ① da biste pokrenuli

klip pogona ❻ ② do kraja unazad.

Ventili DN 150 - 250 ❺

Kod tih ventila se klip pogona mora

navrnuti u klip ventila.

Pridržavajte se uputstva za upotrebu

priloženih uz ventile.

Ventili DN 15 - 125 ❻

1. Obavite električno priključenje,

pogledajte Električne spojne šeme ❿.

2. Okrenite rotacioni prekidač u položaj

“OPEN” (Otvoren) ①, čime se klip

pogona ② potpuno uvlači.

3. Okrenite rotacioni prekidač u položaj

“STOP”

4. Stavite pogon na ventil i poravnajte ga.

5. Zategnite spojnu navrtku ③ do

zateznog momenta od 100 Nm.

Demontaža ventila i pogona ❽

Opasnost

Opasnost od povrede usled pare ili vrele

vode! ①

Ventil bez pogona je otvoren ①,

zaptivanje ② je u pogonu.

Neophodno je osloboditi pritisak iz

sistema pre bilo kakvih radova.

Obavite demontažu obrnutim redosledom

od montaže.

Električno priključenje

VISOKI NAPON!

Opasnost od povrede i životna opasnost

u slučaju nepravilnog rukovanja!

Isključite napajanje pre priključivanja vodova.

Električno priključenje mora obaviti

isključivo ovlašćeni električar.

Da biste došli do električne ploče, najpre

skinite poklopac.

Skidanje poklopca ❾

1. Otpustite urezani zavrtanj na rotacionom

prekidaču ① i izvadite rotacioni prekidač.

2. Odvrnite zavrtanj ② i skinite poklopac ③.

Priključci

Kada skinete poklopac, priključite vodove

prema spojnoj šemi, pogledajte ❿:

① Priključak za:

STB - sigurnosni ograničavač temperature

STW - sigurnosni nadzor temperature

SDB - sigurnosni ograničavač pritiska

Pre ponovne montaže poklopca, obavite

podešavanja na pogonu, pogledajte sledeći

odeljak.

Pre priključivanja neophodno je skinuti

džamper ❿① - samo tipovi AMV (-H) 613,

633 sa funkcijom sigurnosnog povrata.

Podešavanje krajnjih položaja

Nakon montaže ventila i pogona, morate

podesiti krajnje položaje “Ventil otvoren”

i “Ventil zatvoren”.

Preduslovi za podešavanje:

• pogonjemontirannaventil

•

završeno je električno priključenje.

Danfoss Heating VI.AA.T2.3K DH-SMT/SI

1919

Page 20

20

Installation Guide AMV (-H) 610, 613, 633

Ventili VFG .., AFQM ⓫

Podešavanje krajnjeg položaja

“Ventil zatvoren” ①

Postupak:

1. Podesite rotacioni prekidač u položaj

“CLOSE” (Zatvoren) ②.

Indikator hoda ③ mora se pomeriti

u smeru strelice do graničnika.

Ventil je potpuno zatvoren

2. Poravnajte indikator hoda:

• Otpustitezavrtnje④.

• Poravnajteočitanjena0⑤.

• Zategnitezavrtnje.

3. Demontaža poklopca, pogledajte ❾.

4. Ukoliko postoji, priključite merni

uređaj ⑥ na kontakte.

Ako merni uređaj ne postoji, pređite

na korak 6.

5. Okrenite potenciometar ⑦ pomoću

odvijača dok merni uređaj ne pokaže 0 V.

Podešen je kraljni položaj

“Ventil ZATVOREN”.

Podešavanje bez mernog uređaja

6. Okrenite potenciometar pomoću

odvijača za oko 10 obrta nadesno ⑧.

7. Nakon toga okrećite potenciometar

nalevo ⑨ dok ne čujete prekidač releja,

a zatim odmah stanite.

Ako ste potenciometar predaleko

okrenuli, ponovo ga okrenite nadesno

i zatim ponovo nalevo.

Podešen je kraljni položaj

“Ventil ZATVOREN”.

Podešavanje krajnjeg položaja

“Ventil OTVOREN” ⑩

Postupak:

1. Nađite hod u donjoj tabeli:

Tip

VFG 2

VFG 21

VFG 25

AFGM

2. Podesite rotacioni prekidač u položaj

“OPEN” (Otvoren) ⑪.

Ventil se otvara. Čim se postigne hod ⑫,

podesite rotacioni prekidač u položaj

“STOP” ⑬.

Primer:

DN 100, hod 20 mm

3. Posmatrajte merni uređaj ⑭ i okrećite

potenciometar ⑮ dok se ne prikaže 2 V.

Podešen je kraljni položaj

“Ventil OTVOREN”.

DN

15, 20, 25 6 mm

32, 40 8 mm

50, 65 12 mm

80 18 mm

100, 125 20 mm

150, 200, 250 24 mm

150, 200, 250

Hod ventila

30 mm

AMV 613-Y60

Podešavanje bez mernog uređaja:

1. Okrenite potenciometar za oko 50 obrtaja

nadesno ⑯.

2. Okrenite rotacioni prekidač u položaj

“OPEN” (Otvoren) ⑪.

3. Okrenite potenciometar nalevo ⑰.

Ventil se otvara, indikator hoda ⑫ se

pomera u smeru strelice. Kada se

postigne hod, rotacija se zaustavlja.

4. Podesite rotacioni prekidač u položaj

“AUTO” (Automatski) ⑱.

5. Montirajte poklopac i rotacioni prekidač.

Ventili VFU 2 ⓬

Napomene za VFU 2

Za razliku od ventila VFG

.., AFQM , ventil VFU 2 ima

obrnuti smer zatvaranja.

Ventil VFU 2 se otvara pomoću funkcije

sigurnosnog povrata.

Podešavanje krajnjeg položaja

“Ventil otvoren” ①

Postupak:

1. Podesite rotacioni prekidač u položaj

“CLOSE” (Zatvoren) ②.

Indikator hoda ③ mora se pomeriti

u smeru strelice do graničnika.

Ventil je potpuno otvoren ①

3. Poravnajte indikator hoda:

• Otpustitezavrtnje④.

• Poravnajteočitanjena0⑤.

• Zategnitezavrtnje.

4. Ukoliko postoji, priključite merni

uređaj ⑥ na kontakte.

Ako merni uređaj ne postoji, pređite na

korak 6.

5. Okrenite potenciometar ⑦ pomoću

odvijača dok merni uređaj ne pokaže 0 V.

Podešen je kraljni položaj

“Ventil OTVOREN”.

Podešavanje bez mernog uređaja

6. Okrenite potenciometar ⑦ pomoću

odvijača za oko 10 obrta nadesno ⑧.

7. Nakon toga okrećite potenciometar ⑦

nalevo ⑨ dok ne čujete prekidač releja,

a zatim odmah stanite.

Ako ste potenciometar predaleko

okrenuli, ponovo ga okrenite nadesno

i zatim ponovo nalevo.

Podešen je kraljni položaj

“Ventil OTVOREN”.

Podešavanje krajnjeg položaja

“Ventil ZATVOREN” ⑩

1. Nađite hod u donjoj tabeli:

Tip

VFU2

DN

15, 20, 25

32, 40

50, 65

80

100, 125

Hod ventila

6 mm

8 mm

12 mm

18 mm

20 mm

Postupak:

2. Podesite rotacioni prekidač u položaj

“OPEN” (Otvoren) ⑪.

Ventil VFU 2 se zatvara, indikator hoda ⑫

se pomera u smeru strelice.

3. Čim se postigne hod ⑫, podesite

rotacioni prekidač u položaj “STOP” ⑬.

4. Ako je hod > 20 mm:

Okrećite potenciometar ⑭ nalevo ⑮

dok ne čujete prekidač releja.

Ako je hod < 20 mm:

Okrećite potenciometar ⑭ nadesno ⑯

dok ne čujete prekidač releja.

Podešeni su krajnji položaji.

5. Montirajte poklopac i rotacioni prekidač.

6. Podesite rotacioni prekidač u položaj

“AUTO” (Automatski) ⑰.

Podešavanje izlaznog signala 0(4)-20 mA ⓭

Nakon podešavanja je izlazni signal

proporcionalan hodu ventila “h” ①.

Opseg izlaznog signala 0-20 mA ili 4-20 mA

može se podesiti na potenciometru ②.

Podešavanje se obavlja okretanjem u smeru

strelice do graničnika.

Rad

Električno ručno podešavanje položaja

rotacionog prekidača ⓮

• Podesiterotacioniprekidačupoložaj

CLOSE (Zatvoren) ① i pogon će se

izvući ②. Nakon podešavanja podesite

ga na “STOP” ③.

• Podesiterotacioniprekidačupoložaj

OPEN (Otvoren) ④ i pogon će se uvući

⑤. Nakon podešavanja podesite ga na

“STOP” ⑥.

• Podesiterotacioniprekidačupoložaj

STOP i pogon ostaje u zadnjem položaju.

Podesite rotacioni prekidač u položaj

AUTO ⑦ i pogon se reguliše pomoću

spoljnog regulatora.

Standardna podešavanja za normalni

rad trebaju se uvek podesiti.

DH-SMT/SI VI.AA.T2.3K Danfoss Heating

Page 21

Installation Guide AMV (-H) 610, 613, 633

Mehanička ručna podešavanja ⓯

(samo za pogone AMV 610, AMV-H 613)

U slučaju nestanka napajanja ili greške

u radu, ventil se može otvoriti ili zatvoriti.

Postupak:

1. Okrenite rotacioni prekidač u položaj

“CLOSE” (Zatvoren) ①.

2. Otpustite sigurnosni zavrtanj ②.

3. Pomoću kukastog ključa (dodatna

oprema) uvucite klip pogona ③.

VFG .., AFQ otvoren ④

VFU 2 zatvoren ④

4. Pomoću kukastog ključa (dodatna

oprema) izvucite klip pogona ⑤.

VFG .., AFQ zatvoren ⑥

VFU 2 otvoren ⑥

Pre prebacivanja na automatski rad

(AUTO), neophodno je potpuno okrenuti

navrtku za podešavanje ⑤ do graničnika.

Zategnite sigurnosni zavrtanj ⑦.

Ukoliko to ne učinite, ventil se ne može

zatvoriti. (VFU ... se ne može otvoriti).

Prevod:

❶

sa produžetkom tela (with body ex tension)

❷

Tip ventila (Valve type)

Medijum (M edium)

T max medijum ( T max Medium)

Vrela voda (Hot water)

Para (Stea m)

❻

Otvoren (O PEN)

Stop (STO P)

Automatski (AU TO)

Stop (STO P)

Zatvoren ( CLOSE)

❿

Hod ventila (Ventilhub)

Spoljna regulacija (Externe Regelung)

Granični kontakti za položaj “OPEN“ (Otvoren)

(Kontakte für Stellung “OPEN” beschränken)

Granični kontakti za položaj “CLOSE“ (Zatvoren)

(Kontakte für Stellung “CLOSE” beschränken)

Sigurnosni ograničavač pritiska

(Sicherheitsdruckbegrenzer)

Sigurnosni ograničavač temperature

(Sicherheitstemperaturbegrenzer)

Napajanje (Spannungsversorgung)

Ručni prekidač (Handschalter)

Otvoren (Öffnen)

Zatvoren (Schließen)

Automatski (Auto)

Danfoss Heating VI.AA.T2.3K DH-SMT/SI

2121

Page 22

22

Installation Guide AMV (-H) 610, 613, 633

中文

安全注意事项

安装

保温 ❼

为避免可能发生的人身和设备事故,安装和

调试前请先仔细阅读本手册。

安装、启动、维护必须由专业人员进行。

在安装和维护驱动器之前,必须将系统:

- 卸压,

- 冷却,

- 排 空 ,以 及

- 清洗。

安装、使用时应与系统设计者或系统操作

者配 合。

切勿在完全切断电源之前,揭开保护盖。

弃置说明

在 回 收 和 处 理 之 前 ,应 拆 卸

本产品,并尽可能将分拆的

组件进行分类。

务必坚持贯 彻当地的回收处

理法规。

本产品的使用场合

本驱动器和下列阀门配合使用: VFG 2(21),

VFG 25, VFU 2, VFGS 2, AFQM

本产品用于供热、区域供热、制冷等系统中

的温度控制,介质可以为水、水-乙二醇混合

物 、蒸 汽 等 。

AMV(-H) 6. 驱动器概述

610/3 0 6 13/33 (-H )613/33

安全功能

机械调整

- + +

- - +

尺寸,重量 ❶

阀兰

尺寸按照 EN 1092-2 标准

允许的安装位置 ❸

① - DN 15-50 (T

阀门类型:AFQM -

- DN 15-80 (T max < 120 o C):

阀门类型:VFG 2, VFG 21, VFG 25,

VFU2

② - DN 15-250 (T

所有允许的阀门类 型

- DN 65-125 (T

阀门类型:AFQM -

- DN 100-250 (T

阀门类型:VFG 2, VFG 21, VFU2

③ DN 15-250:

阀门类型 VFGS 2( 蒸 汽 )。

< 120 o C):

max

> 120 oC)

max

< 120oC):

max

< 120oC):

max

阀体的安装❹

1. 在阀门前安装过滤器。

2. 在安装阀门前应清洗管道。

3. 注意阀体上标记的①介质流动方向

连接阀门的法兰② 其法兰面应互相

平行,且法兰的密封表面应清洁,无

损伤。

4. 安装阀体。

5. 按对角方向拧紧螺栓。

驱动器和阀体的连接

安装前 ❻ :

1. 按下一节中的接线图接好线

2. 将转换开关置于“OPEN”的位置。❻ ①

直到驱动杆完全收缩。❻ ②

对于 DN 150 - 250 ❺

对于这些阀门,驱动器的驱动杆必须拧入阀

体阀 芯的驱动 杆中。

具体情况参见相关阀体的介绍。

阀门,驱动器的拆卸 ❽

注意危险

小心蒸汽或热水! ①

阀门在未安装驱动器时是敞开的①,密 封

② 在驱动器内。

因此在拆卸驱动器前应将系 统内压力卸去。

拆卸阀门的步骤与安装相反。

电气连接

小心高压电!

不适当的操作可能引发危险!

在接线前应断开电源。

接线必须由电气专业人员进行。

取下盖子后才能接触到接线板。

取下盖子 ❾

1. 卸下转换开关的帽。①

2. 松开固定螺丝 ② 并取下接线盒盖子。③

接线

盖子取下后,按接线图接线,见 ❿:

① 用作连接:

STB - 温度限制安全功能

STW - 温度监测安全功能

SDB - 压力限制安全功能

在重新盖上接线盒盖前,先对驱动器进行

设 定 ,具 体 步 骤 见 下 一 章 。

欲使用上述功能, 必须先拆下短接线

❿① - 只有 AMV (-H) 613, 633 才有弹簧

复位功能。

与 AMV(-H) 6. 相配的阀体

见 ❷。

DH-SMT/SI VI.AA.T2.3K Danfoss Heating

对于 DN 15 - 125 ❻

1. 按接线图 ❿ 接好线。

2. 将转换开关置于“OPEN”的位置 ①,

直到驱动杆完全收缩 ②。

3. 将转换开关置于“STOP”位置

4. 将驱动器置于阀体上并对齐。

5. 以 100Nm 的力矩拧紧 ③ 连接螺帽

全开全关位置设定

阀体和驱动器都安装完毕后,需要设定阀门

的“全开”和“全关”位置。

在设定前需具备如下条件:

• 驱动器已正确安装于阀体上

•

接线完毕。

Page 23

Installation Guide AMV (-H) 610, 613, 633

对于阀门 VFG .., AFQM ⓫

设定阀门“全关”位置 ①

步骤:

1. 将转换开关打到“CLOSE” ②

阀位指示器 ③ 必须到达箭头所指处并

不再移动。

此时阀门已完全关闭。

2. 将指示器与刻度:

• 松开螺丝 ④

• 将刻度为 0 处与之对齐 ⑤

• 拧紧螺丝

3. 打开接线盒盖 ❾

4. 如果有电压表,就将电压表 ⑥ 接到测

压点上 若 没 有 万 用 表 ,转 到 第 6 步。

5. 调电位计 ⑦ 使电压表 显示电 压为 0 V

阀门“全关”位置设定完毕。

没有测量设备时的调整方法

6. 将电位计顺时针转大约 10 圈 ⑧

7. 然 后 ,将 电 位 计 ⑨ 向逆时 针 方向旋 转,

直到听到继电器动作的声音并立即停止

若电位计逆时针方向旋转很久也未发现

继电器动作,则应重新顺时针方向转回

去并重新来一次

阀门“全关”位置设定完毕。

设定阀门“全开”位置 ⑩

步骤:

1. 从下表中查出阀体的行程:

类型

VFG 2

VFG 21

VFG 25

AFGM

2. 将转换开关打到 “OPEN” ⑪ 位置

阀门渐渐打开。一旦达到阀体行程值 ⑫

立刻将转换开关打到“STOP” ⑬

比如:

DN 100,行程为 20 mm

3. 观察电压表 ⑭,调 节 电 位 计 ,⑮ 直到显

示为 2 V

阀门“全开”位置设定完毕。

无测量设备时的调整:

1. 将电位计顺时针方向转大约 50 圈 ⑯

2. 将转换开关打到“OPEN” ⑪

3. 将电位计逆时针方向转动 ⑰

阀门渐渐打开,阀位指示器 ⑫ 朝箭头

指示方向移动。 当 达 到 阀 门 行 程 时 ,将

转换开关打到停止位置

4. 将转换开关打到 “AUTO” ⑱

5. 盖上接线盒盖,安好转换柄。

DN

15, 20, 25 6 mm

32, 40 8 mm

50, 65 12 mm

80 18 mm

100, 125 20 mm

150, 200, 250 20 mm

150, 200, 250

阀行程

30 mm

AMV 613-Y60

对于阀 VFU 2 ⓬

注意阀门 VFU 2:

VFU 2阀门与 VFG .., AFQM 阀门

相比,其运动方向与阀门开关

的 对应关系是相反的 。

VFU 2 阀门在安全复位时是打开的。

设定阀门“全开”位置 ①

步骤:

1. 将转换开关打到“CLOSE” ②

阀位指示器 ③ 必须到达箭头所指处并

不再移动。

此时阀门全关 ①

3. 将指示器与刻度:

• 松开螺丝 ④

• 将刻度为 0 处与之对齐 ⑤

• 拧紧螺丝

4. 如果有电压表,就将电压表 ⑥ 接到测

压点上

若 没 有 万 用 表 ,转 到 第 6 步。

5. 调电位计 ⑦ 使电压表 显示电 压为 0 V。

阀门“全开”位置设定完毕。

没有测量设备时的调整方法

6. 将电位计 ⑦ 顺时针方向旋转大约 10

圈 ⑧。

7. 然后将电位计 ⑦ 逆时针方向 ⑨ 旋转,

直到听到继电器动作的声音并立即停止。

若电位计逆时针方向旋转很多圈还未听

见继电器动作,则应将电位计拧回去重

新进行设定。

阀门“全关”位置设定完毕。

设定阀门“全关”位置 ⑩

1. 从下表中查出阀体的行程:

类型

VFU2

步骤:

2. 将旋转开关置于“OPEN” ⑪

阀门 VFU 2 渐渐关闭,阀位指示器 ⑫

向朝箭头指示方向移动。

3. 一旦达到阀门行程位置 ⑫ 立即将转换

开关置于“STOP”位置 ⑬。

4. 如果行程 > 20 mm:

将电位计⑭向逆时针方向⑮旋转,

直到听到继电器动作的声音。

如果行程 < 20 mm:

将继电器 ⑭ 向顺时针方向⑯旋转,

直到听到继电器动作的声音。

全 开 ,全 关 位 置 设 定 完 毕 。

5. 盖上盖子,安上转换开关

6. 将转换开关置于“AU TO”位置 ⑰

DN

15, 20, 25

32, 40

50, 65

80

100, 125

阀行程

6 mm

8 mm

12 mm

18 mm

20 mm

调整阀位反馈信号 0(4)-20 mA ⓭

阀位反馈信号调整完后,其输出值与阀门行

程“h”① 成正比。

电位计 ② 决定了阀 位 反 馈 信号是 0-20

mA 还是 4-20 mA 。

将电位计按箭头所示方向旋转到头即选定

了 0mA 还是 4mA。

操作

用转换开关的手动操作 ⓮

• 将转换开关置于 CLOSE ①,驱 动 器 内 的

驱动杆向外走 ②。 一个行程后将转换

开关置于“STOP”位置 ③

• 将转换开关置于 OPEN ④,驱 动 器 内 的

驱动杆向内收缩 ⑤。 一个行程后将转

换开关置于“STOP”位置 ⑥

• 在任意位置将转换开关置于 STOP,阀 门

的位 置将保持。

将转换开关置于 AUTO ⑦,驱 动 器 的 动

作将由外部控制器控制

必须为设置正常操作时的标准设定。

阀门的机械手动 ⓯

(仅对如下驱动器有效:AMV 610,AMV-H 613)

若发生电源故障或其他操作方面的错误,可

以对阀门机械手动的开或关。

步骤:

1. 将转换开关置于“CLOSE” ①。

2. 松开安全锁定螺丝 ②。

3. 用扳手按如图操作,以使驱动杆向内收

缩 ③。

VFG .., AFQ 阀门打开 ④

VFU 2 阀门关闭 ④

4. 用 扳 手 如 图 操 作 ,以 使 驱 动 杆 向 伸 出 方

向运动 ⑤。

VFG .., AFQ 阀门关闭 ⑥

VFU 2 阀门打开 ⑥

在将转换开关打到自动运行前 (AUTO),

必须将 驱动器按图所示方向操作,⑤ 直

到不能转动。

拧紧锁定螺丝 ⑦。

若 不 这 样 做 ,阀 门 将 不 能 正 常 关 闭 。

(VFU ... 为不能打开)。

Danfoss Heating VI.AA.T2.3K DH-SMT/SI

2323

Page 24

24

Installation Guide AMV (-H) 610, 613, 633

翻译:

❶

带阀体加长件

(with body extension)

❷

阀门类型 (Valve type)

介质 (Mediu m)

介质最大温度 (T max Medium)

热水 (Hot water)

蒸汽 (Steam)

❻

开 (OPEN)

停止 (S TOP)

自动 (AUTO)

停止 (S TOP)

关 (CLOSE )

❿

阀行程 (Ventilhub)

外部控制器 (Externe Regelung)

“OPEN” 位置限制接触

(Kontakte für Stellung “OPEN“ beschränen)

“CLOSE” 位置限制接触

(Kontakte für Stellung “CLOSE“ beschränen)

安全压力限制功能

(Sicherheitsdruckbegrenzer)

安全温度限制功能

(Sicherheitstemperaturbegrenzer)

电源 (Spannungsversorgung)

手动开关 (Handschalter)

开 (Öffn en)

关 (Sch ließen)

自动 (Auto)

停止 (Stop)

DH-SMT/SI VI.AA.T2.3K Danfoss Heating

Page 25

Installation Guide AMV (-H) 610, 613, 633

РУССКИЙ

Правила безопасности

Для предупреждения травматизма

и повреждения оборудования перед

началом работ по его монтажу и вводу

в эксплуатацию следует изучить и соблюдать настоящую инструкцию.

Монтаж, наладку и техническое обслуживание оборудования может выполнять

только квалифицированный персонал,

имеющий допуск к таким работам.

Перед началом работ по монтажу

и обслуживанию контроллера необходимо произвести следующие действия

с трубопроводной системой:

- сбросить давление,

- охладить,

- опорожнить и

- прочистить.

Следуйте указаниям производителя

системы или оператора системы.

Не снимайте крышку до того, как

питание будет полностью выключено.

Инструкция по утилизации

Перед переработкой или

утилизацией следует

разобрать это устройство

и, если возможно, рассортировать его элементы по

группам материалов.

Всегда соблюдайте местные правила

утилизации.

Область применения

Электропривод используется совместно

со следующими клапанами: VFG 2(21),

VFG 25, VFU 2, VFGS 2, AFQM

Области применения: регулирование температуры воды, водного раствора гликоля

и пара в системах централизованного

теплоснабжения или охлаждения.

Обзор электроприводов

AMV(-H) 6..

610/3 0 613 /33 (-H )613/33

Функция

безопасности

Механическая

регулировка

- + +

- - +

Габаритные размеры и массы ❶

Фланцы:

Размеры соединения согласно EN 1092-2

Типы клапанов для AMV(-H) 6..

Электропривод AMV(-H) 6..можно смонтировать на следующих клапанах, см. ❷.

Монтаж

Разрешенные монтажные

положения ❸

① - Ду 15-50 (T

клапан типа AFQM -

- Ду 15-80 (T

ти пы к лапан ов VFG 2, VF G 21, VF G 25,

VFU2

② - Ду 15-250 (T

все допустимые типы клапанов

- Ду 65-125 (T

клапан типа AFQM -