Data sheet

Actuator 2 point, ON/OFF control

AMI 120 NL-1

Description

The AMI 120 NL-1 is a 2 point (ON/ OFF), 3

wire actuator used with the AB-QM pressure

independent control valves installed on hot or

chilled water system applications. This actuator is

installed on AB-QM valve sizes ranging from 1/2”

to 1- 1/4”. The AB-QM assembly is suitable for

installation within fan coil units, VAV, induction

units or additional units that require combined

balancing and valve control, which could be

located within enclosures or plenum rated

spaces.

As a 3 wire actuator, it receives constant power to

travel to its default position and upon receipt of

input signal will travel in the opposite direction.

Designed within the actuator is an overload and

gap function to prevent unnecessary travel from

the actuator.

Main data:

• 2-point, ON/ OFF, 3 wires required

• Force switch-off at stem down position

prevents overload of actuator and valve

• Gap function detection on stem up travel

• No tools required for mounting

• Maintenance free during lifetime

• Low noise operation

• 1/2” Conduit hole, removable plate

• Wiring terminal block

• In accordance with UL 2043 for plenum

installation

• UL listed

Ordering

Technical data

Typ e Supply voltage Speed Code No.

AMI 120 NL-1 24VAC 10 s/mm @ 60Hz (12 s/mm @ 50Hz) 082H5003

Power supply V 24 AC; +10%... -15%

Electrical Connection ” 1/2 electrical conduit, wiring terminal block

Power consumption VA 1 VA

Frequency Hz 50 / 60

Control Input ON/OFF, 3-wire

Output Signal End travel position feedback

Actuator Force lbf (N) 45.0 (200)

Max. Stem Travel mm 5

Travel Speed 12s/mm @ 50Hz, 10s/mm @ 60Hz

Max. Medium Temperature

Ambient temperature 32 to 131 (0 to 55)

Humidity 5 to 95% RH, noncondensing

Weight lb (kg) 0.66 (0.3)

USA

C US

Canada

Europe

°F (°C)

UL Listed , CCN XABE, File E480529 ; to ANSI/UL 60730-1 and ANS I/ UL 60730-2-14

Investig ated and approved f or plenum use in accor dance with UL 2043

UL listed , CCN XABE7, File E480529; to CAN/CS A-E60730-1:13 and CAN/CSA-E60730 -2-14:13

CE Mark - Danf oss declares that t his product comp lies with all relev ant CE-marking

directives

24 8 (120)

© Danfoss | 2019.12 AI313849082591en-000201 | 1

Data sheet Actuator 2 point, ON/OFF control AMI 120 NL-1

1 3

42

1 3

42

Installation Mechanical

The actuator should be mounted with the valve

stem in either horizontal position or pointing

upwards.

The actuator is fixed to the valve body by means

of a mounting ring which requires no tools for

mounting. The ring should be tightened by hand.

Electrical

Important: Prior to energizing the actuator

should be assembled to the AB-QM.

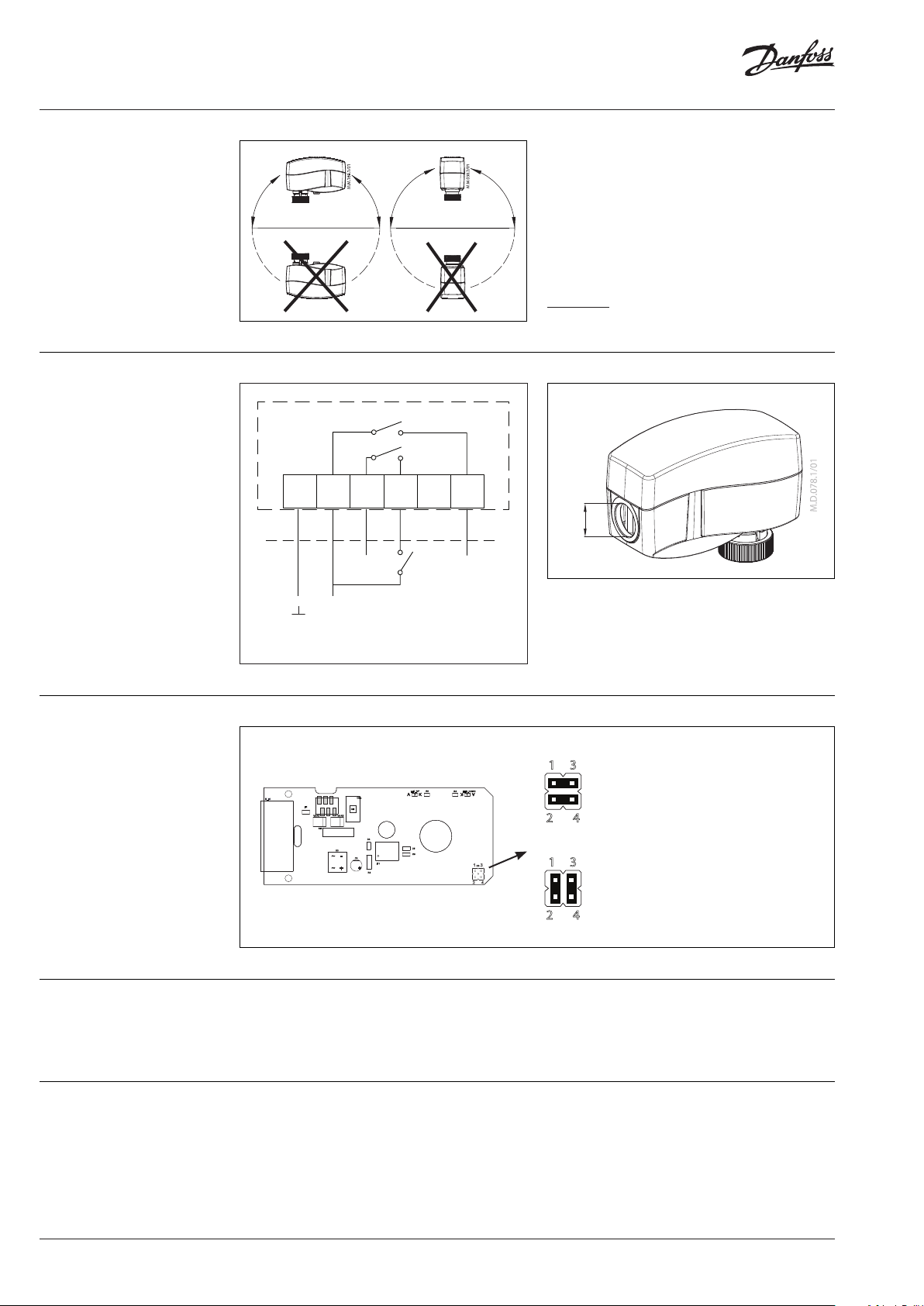

Wiring

AMI 120 NL-1

SP

SN 4 1 5

½”

Travel Direction

~ AC 24V

50/60Hz

(Oponal)

(Oponal)

Note: Directi on of actuator stem moveme nt is defined with

jumper posi tion. Look bottom chap ter "Travel Direction".

R5LED_UP

R4 LED_DOWN

C6

C5

XS1 3

2

4

F1

VAR1 VAR2

MOTOR

CMa

CM

RM

D4

D3

C3

IC1

R3

A field supplied 1/2” trade size electrician’s fitting

and lock nut can be mounted to the actuator

enclosure. Insert wiring material through the

removable plug or conduit fitting, and wire

connection to the terminal block.

Jumper Pos ition “A” (Factory Set ting)

“On” at term inal block posit ion “1”: Actuator drives u p

and valve o pens, optional te rminal 4 closes.

“Off ” at terminal blo ck position “1”: Actuato r drives down

and valve cl oses, optional t erminal 5 closes .

Jumper Pos ition “B”

“On” at term inal block posit ion “1”: Actuator drives

down and va lve closes, opti onal terminal 4 clo ses.

“Off ” at terminal blo ck position “1”: Actuato r drives up

and valve o pens, optional te rminal 5 closes.

Disposal The actuator must be dismantled and the

elements sorted into various material groups

before disposal.

Commissioning The factory position of the actuator spindle is in a

full stem up position allowing easier mechanical

connection of the actuator on the valve.

2 | AI313849082591en-000201 © Danfoss | 2019.12

Data sheet Actuator 2 point, ON/OFF control AMI 120 NL-1

Installation and

commissioning procedure

(if required)

Do not touch anything on

the PCB! Before removing the

cover in need of hand operation

with Allen key power supply

must be disconnected.

Lethal voltage!

1. Check the valve neck. The actuator should be

in the full up position (factory setting). If it is

not, manually reposition the actuator to its

full up position.

2. The actuator is fixed to the valve body by

means of a ribbed nut which requires no tools

for mounting. The ribbed nut should be hand

tightened only.

‘External position indication

located at the neck of the

motor actuator’

3. For applications requiring conduit, a field

supplied 1/2” trade size electrician’s fitting

and lock nut can mounted in the actuator

enclosure. Make all wiring connections in

accordance with local, national, or regional

regulations.

4. Insert wiring material through the removable

plug or conduit fitting, and connect to

the terminal block according to the wiring

diagram - see page 2.

Manual override

(for service purposes only)

Caution:

Do not manually operate the

drive under power!

②

①

①

• Remove cover ①

• Press and hold the button ② (on the

bottom side of the actuator) during manual

override ③

• Replace cover ④

• Install actuator on valve ⑤

Remark:

A ”click” sound after energizing the actuator

means that the gear wheel has jumped into

normal position.

②

AI313849082591en-000201 | 3© Danfoss | 2019.12

Data sheet Actuator 2 point, ON/OFF control AMI 120 NL-1

Dimensions (mm)

4.66in (118.5mm) 2.09in (53mm)

3. 58in (91mm)

6.16in (156.5mm)

© Danfoss | DHS-SRMT/SI | 2019.124 | AI313849082591en-000201

Loading...

Loading...