Page 1

Data sheet

Electrical actuator AME 855

Description

Actuator AME 855 can be controlled by electronic

controllers with modulating or 3-point control

output.

Actuator can be used with VF3 valves (DN 200-300).

Features:

• 3-point or modulating control

Easy to use manual operation ( monitoring on

•

terminal R)

• Position indication

• LED signaling

• Direct or inverse function

• Automatic adaptation of stroke to valve’s end

positions which reduces commissioning time

• Voltage or current input Y

• Voltage or current output X

(for current output, accessory is needed)

• Frost protection function (for detailed

information read the Functions section in the

data sheet)

• Blockage detection

• Internal temperature control – integrated

heater + overheat protection

• Wire break detection (only modulating

actuator)

• Selectable hysteresis

• Auto test function

• Auto pause function

• Potential-free position switches (accessory)

• Remote reset possibility

Main data:

Nominal voltage:

•

- 24 V AC

- 115 V or 230 V AC

• Control input signal: 3-point or modulating

Actuator is primarily designed to regulate valve

in the respond to the demand of a controller in

District Heating/cooling, Heating, Ventilation and

Air conditioning systems.

Ordering Accessories

DEN-SMT/SI

Actuator

Picture Typ e

AME 855

VD.IR .M2.02 © Danfoss 05/2015

Power supply

23 0/ 115 082G3511

(V)

24 082G3510

Code No.

• Force: 15.000 N

• Stroke: 80 mm

• Speed: 2 s/mm

• Max. medium temperature: 130 °C

Typ e Code No.

Current output PCB 082G3512

Position switches (2x) PCB 082G3513

1

Page 2

Data sheet Electrical actuator AME 855

Technical data

Power supply V 24 (AC) or 115 / 230 (AC); ±10%

Power consumption VA

Frequency Hz 50 / 60

Control input Y

Control output X

Closing force N 15000

Max. stroke mm 80

Speed s/mm 2

Max. medium temperature

Ambient temperature –10 … +50

Storage and transport temperature –20 … +65

Protection Class II

Grade of enclosure IP 54

Weight kg

Manual operation Mechanical

1)

when Y is selec ted as 2-10 V DC or 4-20 mA, X sig nal is starting from 0-10V DC or 0-20 mA

1)

°C

- marking in accordance with the standards

0 – 10 V DC; ≥1200 Ohm; I = 8 mA (max.)

Council Directive 2004/108/EC

Council Directive 2006/95/EC

50 (24V)

63 (230V)

0 – 10 V DC; 77 kOhm

2 – 10 V DC; 77 kOhm

0 – 20 mA; 510 Ohm

4 – 20 mA; 510 Ohm

0 – 20 mA; ≤500 Ohm

4 – 20 mA; ≤500 Ohm

130

11 ( 24V)

11, 4 (2 30 V)

Directive 2006/42/EC

Disposal

Commissioning

Installation

The actuator must be dismantled and the

elements sorted into various material groups

before disposal. Before disassembly please contact

Danfoss support for disassembly instructions.

Complete the mechanical and electrical

installation (see instructions) and perform the

necessary checks and tests:

• Turn on the power

• Press initialization button (INIT)

• Set the appropriate control signal and check

the valve stem direction is correct for the

application

7 mm

7 mm

7 mm

7 mm

Mechanical

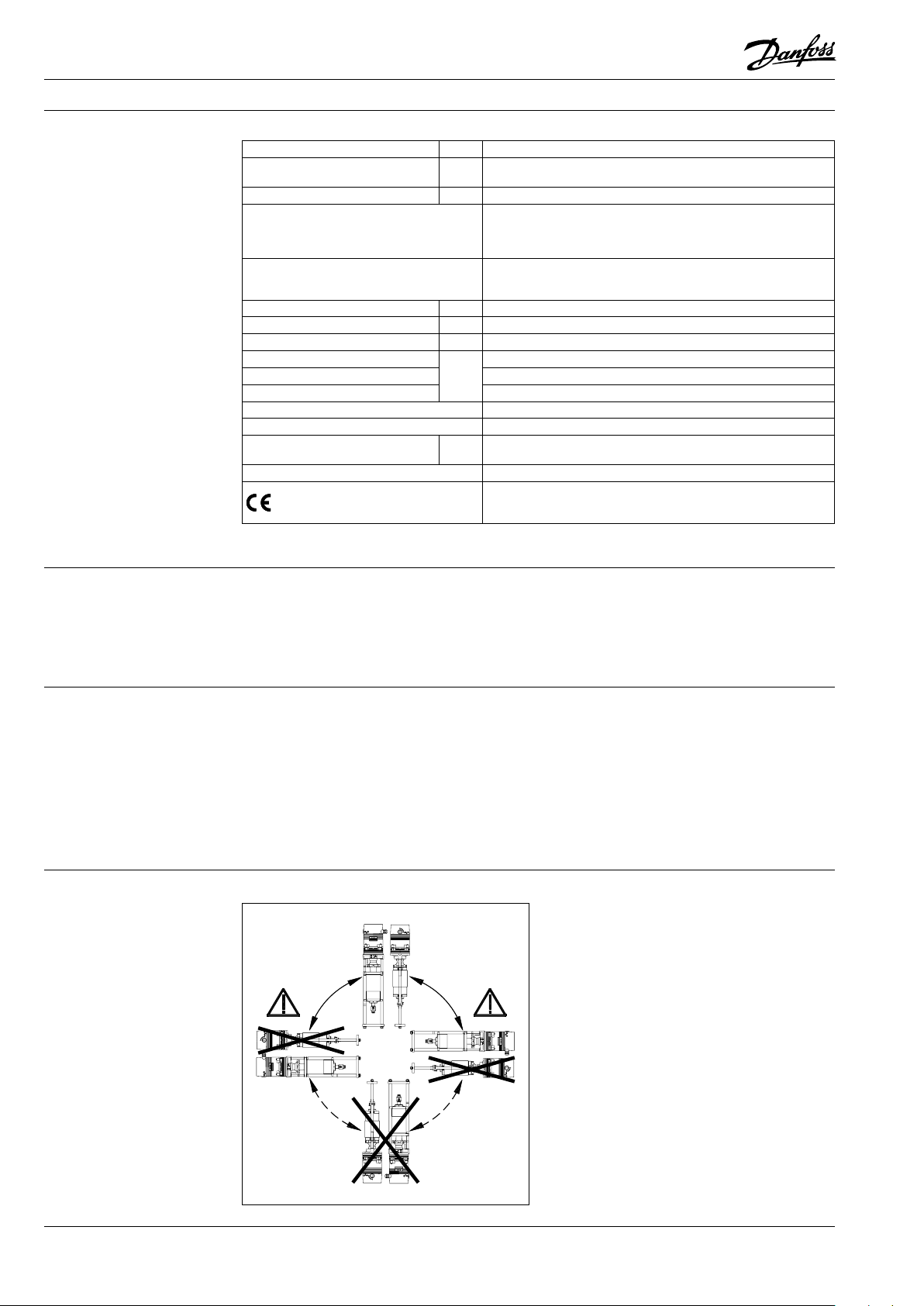

Please check what are allowed installation

positions for the valve in combination. Use

appropriate key (not supplied) to fit the actuator

to the valve body. Allow for necessary clearance

for maintenance purposes. To link valve and

actuator stems use appropriate key (not

supplied). The actuator has position indication

rings which should be pushed together before

el. connection; after self-stroking they indicate

end positions of the stroke.

Electrical

Electrical connections can be accessed by

removing the cover. Four cable entries on

removable gland support are provided for

M 16×1,5 cable glands. Note that in order to

maintain the enclosure IP rating, appropriate

cable glands must be used.

2

VD.IR .M2.02 © Danfoss 05/2015

DEN-SMT/SI

Page 3

Data sheet Electrical actuator AME 855

Design

1. Actuator housing

2. Cross head

3. Coupling piece

4. Union nut

5. Spindle nut

6. Position indicator

7. Protecting tube

8. Distance sleeve

9. Bridge

10. Gear housing

11. Sheeting

12. Knob

13. Hand wheel

14. Viewing panel

15. Guiding sleeve

16. Engine / motor

17. Push-fit PCB for 24 V or 230 V

18. Main board

19. Cover for 24 V or 230 V

20. Cable lead-in M20 × 1.5

21. Cable lead-in M16 × 1,5

22. Safety disk

23. Blank

24. Bolt

25. Hexagon nut M12

26. Type p late

27. Wiring diagram on cover

Wiring

230 VAC version:

Do not touch anything on the

PCB!

Do not remove the cover

before the power supply is fully

switched off.

230V AC

24V AC

Terminal Description

L, N1 Supply voltage

2 Control voltage for downward movement during three-point mode

3 Control voltage for upward movement during three -point mode

R

B1, B2 Binary input / frost protection function

N2

Y Input signal continuous mode

X Output signal continuous mode

20, 21, 22 Terminals path switch unit WE1

23, 24, 25 Terminals path switch unit WE2

Return signal during “manual” mode

• R= 24 V DC max. 35 mA

Zero potential of signals X, Y and R

• When the zero potentials of signals X, Y and R are identical to

the zero potential of the supply voltage it is possible to bridge

terminals N1 and N2 (230V only).

• If you run the actuator in continuous mode at 230 V you will have to

connect N2.

• If you run the actuator in three-point mode at 230 V you will have to

connect N2 if you wish to use X or R at the same time.

DEN-SMT/SI

VD.IR .M2.02 © Danfoss 05/2015

3

Page 4

Data sheet Electrical actuator AME 855

Led signalling/

Actuator operating modes

LED operating mode indicator:

The two-colour (green / red) LED function

indicators are located in the actuator cover. They

indicate different operating modes:

• Normal operation (green LED is permanently

lit, actuator waiting for Y signal command)

• Standard operation (blinking green LED

with short-short rhythm - 0.5s LED is ON and

0.5s LED is off - actuator is following Y signal

command)

• Wire break detection (blinking greed LED

with short-long rhythm - 0.2s LED is ON and

1.5s LED is OFF – input signal Y has dropped

below 1V or 2 mA in operating mode 2-10V or

4-20mA)

• Blockage detection only in modulating

• Remote reset function - continuous signal on

terminals 2,3 (blinking green LED with longshort rhythm – 2.5s LED is ON and 0.5s LED is

OFF – a simultaneous signal at terminals 1 and

3 will result in reset or initialization process

where actuator will adapt its stroke to valve

end positions. Actuator will switch off after 4

unsuccessful attempts)

• Temperature is in normal range (red LED is

off)

• Heating mode (red LED is ON)

• Actuator is overheating (blinking red LED

with short-short rhythm – 0.25s LED is ON

and 0.25s LED is OFF – overheating protection

mode)

control (blinking green LED with long-long

rhythm – 2.5s LED is ON and 2.5s LED is OFF –

actuator is mechanically blocked)

LED Indication type Operating status / error

Constantly lit

Normal operation, ready for operation

The LED is pe rmanently lit, a ctuator waitin g for command signal .

Green LED:

Red LED :

Flashing

0,5s / 0,5s / 0, 5s / 0,5s …

Flashing

0,2s / 1,5s / 0,2 s / 1,5s …

Flashing

2,5s / 2,5s / 2, 5s / 2,5s …

Flashing

1,5s / 0,2s / 1,5s / 0,2 s …

No indication

Constantly lit Heating mode

Flashing

0,25s / 0,2 5s / 0,25s / 0,25s…

Standard Operation

Actuator carries out traverse command.

Wire break detection

Input sig nal has dropped be low 1 V or below 2 mA in op erating

modes

2 … 10 V DC or 4 … 20 .

Blockage detection (continuous mode only)

The linea r actuator is mec hanically bloc ked.

Continuous signal on terminal 2 and 3

A simulta neous control sign al at terminal 2 and 3 wi ll result in an

initiali sing cycle (max. 4 at tempts).

The linea r actuator will au tomatically swi tch off after 4 un successful

attempts.

Temperature in normal range

Actuator overheating

4

VD.IR .M2.02 © Danfoss 05/2015

DEN-SMT/SI

Page 5

Data sheet Electrical actuator AME 855

DIP switch setting

Actuator has a selection of DIP switches under the cover:

• DIP SW 1: Must always be in ON position for stable operation

• DIP SW 2: DIR / INV Y signal(direct or inverse acting mode)

1. DIR position (ON position) – actuator is direct acting to input signal

2. INV position (OFF position) – actuator is inverse acting to input signal

• DIP SW 3: DIR / INV X signal(direct or inverse acting mode)

1. DIR position (ON position) – actuator is giving direct acting output signal

2. INV position (OFF position) – actuator is giving inverse acting output signal

• DIP SW 4: 0-10 V / 2-10V or 0-20mA / 4-20 mA input signal Y

1. 0-10V / 0-20 mA (ON position)

2. 2-10V / 4-20 mA (OFF position)

• DIP SW 5: Without function, do not change switch setting

• DIP SW 6: Auto test function

1. Auto test enabled (ON position)

2. Auto test disabled (OFF position)

• DIP SW 7: Limit position setting

1. Actuator spindle extended (ON position)

2. :Actuator spindle retracted (OFF position)

• DIP SW 8 and 9: Hysteresis settings

1. 0.15 V (SW 8 and 9 in position ON)

2. 0.05 V (SW 8 in ON and SW 9 in OFF position)

3. 0.3 V (SW 8 in OFF and SW 9 in ON position)

4. 0.5 V (SW 8 and 9 in OFF position)

• DIP SW 10: Input signal Y as voltage (V) or current (mA)

1. Drive actuator via current signal from controller (ON position)

2. Drive actuator via voltage signal from controller (OFF position)

DEN-SMT/SI

VD.IR .M2.02 © Danfoss 05/2015

5

Page 6

Data sheet Electrical actuator AME 855

Functions • Internal temperature control:

• Modulating control mode:

System controller pre-sets the position of the

linear actuator whilst inside the linear actuator

the input signal (Y) of the system control

is continuously compared with the output

signal (X) of the linear actuator. In doing so the

output signal depends on the position of the

linear actuator approximated to the valve end

positions.

• 3-point control mode:

The direction of the rotation is set via control

voltage on terminal 2 and 3 on the main PCB.

When the control voltage is applied to terminal

1 the spindle of the actuator will be extending,

when control voltage is applied to terminal 3

the spindle of the actuator will be retracting.

• Frost protection function:

The terminals B1 and B2 on the main PCB

are bridged during the normal operation.

If the electric circuit between B1 and B2 is

interrupted, the linear actuator will store the

current position (3-point mode) and then

automatically move the set end position on DIP

SW 7. The actuator will stay in the selected end

position as long as the circuit between B1 and

B2 is interrupted. After the circuit between B1

and B2 will be restored again, the actuator will

automatically go to the stored position (3-point

mode) or to the desired position by the Y signal

in modulating control mode. Safety thermostat

could be used to control the circuit between B1

and B2 terminals.

• Blockage detection:

If the linear actuator is blocked during

movement, the linear actuator will briefly

move back and then retry to reach the desired

position (will try to remove the blockage). If

this procedure will be unsuccessful after 7

attempts, the linear actuator will turn off in

order to prevent damage of actuator and valve.

A blockage detection is indicated via green

LED indication.

When the temperature inside the actuator

housing exceeds a certain limit (65 °C) the

motor will be turned off. After the temperature

will fall down below limit, actuator will restart

automatically.

When the temperature inside the actuator

housing drops below 15°C the motor will

be switched in the heating mode during

stoppages. Actuator heating will be switched

off automatically when the temperature in

the housing will exceed 22°C. The actuator

heating does not effect on functions of the

actuator. Heating of actuator also prevents the

formation of condensation inside the actuator

and ensures easier movement of the gears

even at temperatures down to -10°C.

Heating mode and motor stoppage are

displayed as a red LED signalization.

• Wire break detection:

Only available in modulating control mode

with 2-10 V or 4-20 mA Y signal. Wire break

detection is displayed as green LED indication.

• Hysteresis setting:

It serves to prevent permanent oscillations

around set hysteresis thresh-hold on DIP SW 8

and 9 when there are minor Y signal changes.

• Auto test function:

If a valve does not operate for a while the cone

of the valve might get stuck. Auto test function

acts a prevent measure for that to happen.

Linear actuator will after 10 days of no activity

move to the end position of the valve set on

DIP SW 7 and then move to the previous initial

position.

• Auto pause function:

This function is used to prevent over-oscillating

behaviour of the actuator in response to the

Y control signal. If there are more than 20

direction varying Y signal commands per

minute, actuator will go in a pause for 3s and

then continue to follow Y signal.

6

VD.IR .M2.02 © Danfoss 05/2015

DEN-SMT/SI

Page 7

Data sheet Electrical actuator AME 855

Manual operation Actuator AME 855 can be manually operated

when the manual operation clutch is in upper

position. Actuator has default factory setting

in automatic mode (manual operation clutch in

down position). If the actuator is under supply

①

Auto

④

voltage when in manual operation mode, R

terminal will give position output signal. After

the manual operation, the manual operation

clutch must be put in down position for the

automatic mode to be applied again.

③

②

Click

Manual

④

Dimensions

Ø120

~770

200

Stroke113

DEN-SMT/SI

VD.IR .M2.02 © Danfoss 05/2015

Ø5 7,1

120

170

M14

+0,1

15

7

Page 8

Data sheet Electrical actuator AME 855

Actuator - valve

combination

min. 200

1

H

Typ e DN

200 600 276 10 68

VF3

250 730 316 1080

300 850 378 1113

L H H

mm

1

H

L

8

VD.IR .M2 .02

Produce d by Danfoss A/S © 05/2015

Loading...

Loading...