Data sheet

Actuators for modulating control

AME 85, AME 86

Description

Ordering

Actuator

Typ e Power supply Speed Code No.

AME 85 24 V~ 8 s/mm 082G1452

AME 86 24 V~ 3 s/mm 082G1462

The actuators AME 85 and AME 86 are used with

VFM 2 (DN 150-250), VFS 2 (DN 65-100),

VF2/3 (DN 125, 150) and AFQM (DN150-250) valves.

Features:

• “Self stroking” function

• Load related “Switch o“ function that

prevents overloading

• Manual operation

• Diagnostic LED

Main data:

• Nominal voltage:

- 24 VAC , 50 Hz/60 Hz

• Control input signal:

- 0(4)-20 mA

- 0(2)-10 V

• Force: 5000 N

• Stroke: 40 mm

• Speed: 8 s/mm (AME 85), 3 s/mm (AME 86)

• Max. medium temperature: 200 °C

• Manual operation

Accessories

Typ e Code No.

Stem heater 065Z7021

Technical data

DEN-SMT/SI

Typ e AME 85 AME 86

Power supply V 24 AC +10 to –15%

Power consumption VA 12. 5 25

Frequency Hz 50 / 60

Control input Y

Output signal X V 0 to 10 (2 to 10)

EMC IEC 801/2 - 5

Closing force N 5000

Max. stroke mm 40

Speed s/mm 8 3

Max. medium temperature

Ambient temperature 0 to 55

Storage and transport temperature –40 to +70

Protection Class

Grade of enclosure IP 54

Weight kg 9.8 10.0

- marking in accordance with the standards

VD.AB.R6.02 © Danfoss 09/2015

V 0 to 10 (2 to 10) Ri = 200 Ω,

mA 0 to 20 (4 to 20) Ri = 500 Ω

200

°C

III (24 V)

Low Voltage Directive 73/23/EEC and 93/68/EEC , EN 60730/2/14

EMC Directive 89/336/EEC, 92/31/EEC, 93/68/EEC, EN 50081-1 and

EN 50 082-1

1

Data sheet Actuators for modulating control AME 85, AME 86

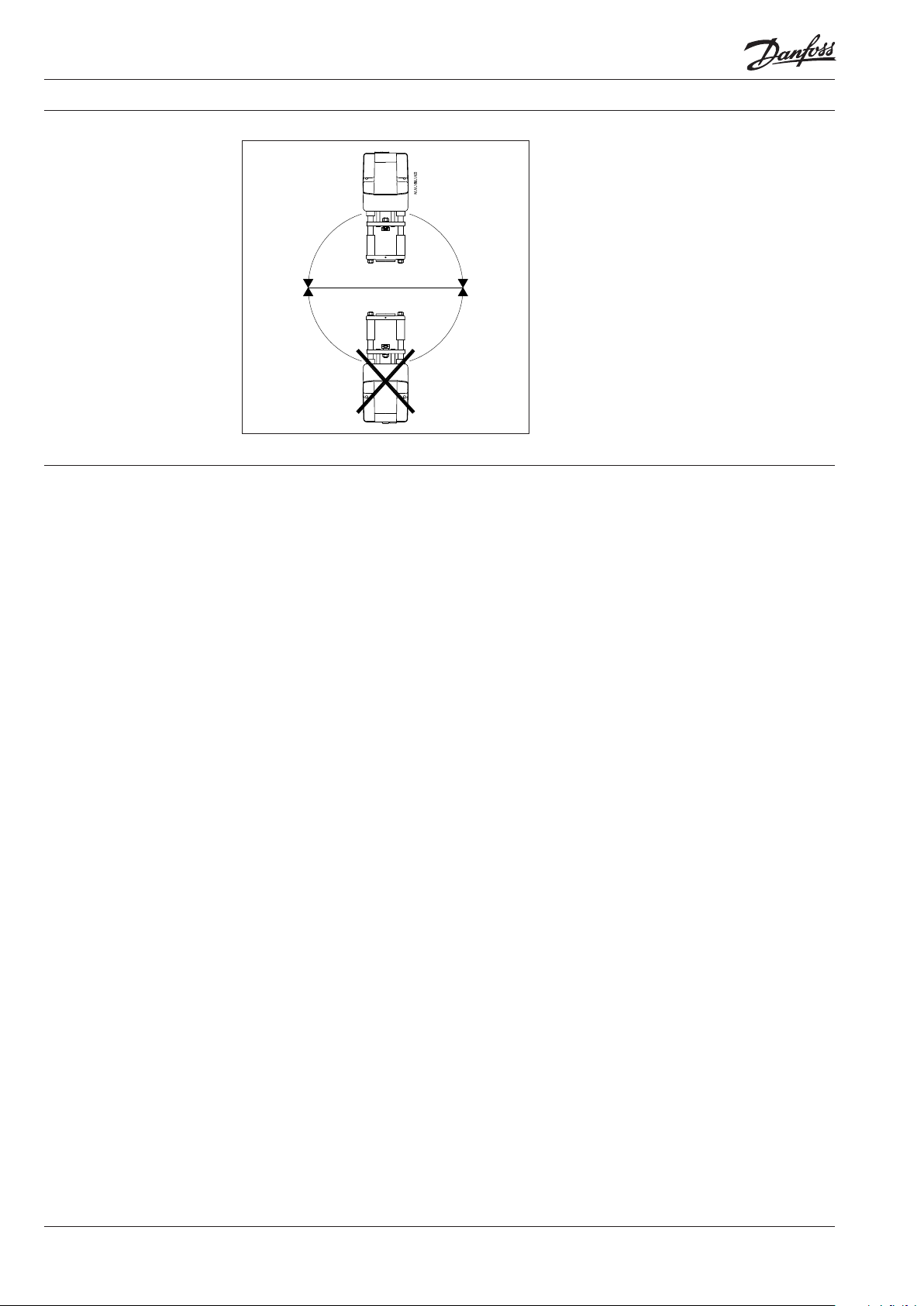

Installation

Disposal

Mechanical

The actuator should be mounted with the valve

stem in either horizontal position or pointing

upwards. Use the 57 mm castellated nut

(supplied) to t the actuator to the valve body.

While the actuator is being tted, a 8 mm Allen

key can be used to tighten the pinch screw in the

valve body ring to stop the valve turning.

Allow for necessary clearance for maintenance

purposes.

Electrical

Electrical connections can be accessed by

removing the cover. Two M16 x 1.5 cable entries

are provided. Both entries are provided with a

rubber grommet for use with exible cable. Note

that in order to maintain the enclosure IP rating,

appropriate cable glands must be used.

The actuator must be dismantled and the

elements sorted into various material groups

before disposal.

2

VD.AB.R6.02 © Danfoss 09/2015

DEN-SMT/SI

Data sheet Actuators for modulating control AME 85, AME 86

DIP switch setting

The actuator has a function selection DIP switch

under the removable cover. In particular, if SW6 is

set to ON, the actuator will perform as

3-point actuator.

The switch provides the following functions:

• SW1: U/I - Input signal type selector:

If set to OFF position, voltage input is selected. If

set to ON position, current input is selected.

• SW2: 0/2 - Input signal range selector:

If set to OFF position, the input signal is in the

range from 2 V to 10 V (voltage input)

or from 4 mA to 20 mA (current input). If set to

ON position, the input signal is in the range from

0 V to 10 V (voltage input) or from 0 mA to 20 mA

(current input).

• SW3: D/I - Direct or inverse acting selector:

If set to OFF position, the actuator is direct acting

(stem lowers as voltage increases). If actuator is

set to ON position the actuator is inverse acting

(stem raises as voltage increases).

• SW4: —/Seq - Normal or sequential mode

selector:

If set to OFF position, the actuator is working

in range 0(2)..10V or 0(4)..20mA. If set to ON

position, the actuator is working in sequential

range; 0(2)..5 (6)V or (0(4)..10 (12)mA) or (5(6)..10V)

or (10(12)..20mA).

• SW6: Prop./3-pnt - Modulating or 3-point

mode selector:

If set to OFF position, the actuator is working

normally according to control signal. If set to

ON position, the actuator is working as 3-point

actuator.

• SW7: LOG/LIN - Equal percentage or linear

ow through valve selector1:

If set to OFF position, the ow through valve is

equal percentage. If set to ON position, the he

ow through valve is linear according to control

signal.

• SW8: 100% KVS/Reduced KVS - Flow reduction

through valve selector1:

If set to OFF position, the ow through valve is

not reduced. If set to ON position, the he ow

through valve reduced by half of increment

standard KVS values (exsample: valve with KVS 16

and SW8 set to ON – maximum ow through the

velve is KVS13 (meiidle between standard KVS 16

and KVS 10).

1

NOTE: To be used only in comb ination with valves with equa l

percentage characteristic.

• SW9: Reset:

Changing this switch position will cause the

actuator to go through a self stroking cycle.

DEN-SMT/SI

• SW5: 0..5V/5...10V - Input signal range in

sequential mode:

If set to OFF position, the actuator is working in

sequential range 0(2)..5 (6)V or 0(4)..10 (12)mA.

If set to ON position, the actuator is working in

sequential range; 5(6)..10V or 10(12)..20mA.

VD.AB.R6.02 © Danfoss 09/2015

3

Data sheet Actuators for modulating control AME 85, AME 86

Wiring

24 Vac only.

Wiring length

0 - 50 m 0.75 mm

> 50 m 1.5 mm

Recommended

square of the wiring

2

2

Automatic self stroking feature

When power is rst applied, the actuator will

automatically adjust to the length of the valve

stroke. Subsequently, the self stroking feature

can be re-initialised by changing position of SW9.

DIP 6 = OFF

Diagnostic LED

The red diagnostic LED is located on the pcb

under the cover. It provides indication of three

operational states:

• Actuator Healthy (Permanently ON),

• Self Stroking (Flashes once per second),

• Error (Flashes 3 times per second - seek

technical assistance).

SN 0 V Neutral

SP 24 VAC Power supply

Y

1

24 VAC Input

3

X 0(2) -10 V Output

0(2)-10 VAC

0(4) -20 mA

Input

Controller with relay output

Controller with triacs output

DIP 6 = ON

DIP 6 = ON

SN

SP

1

24 VAC Input

3

X 0(2 )-10 V DC Output

SN 24 V Power supply

SP 0 V Neutral

1

24 VAC Input

0 V

24 VAC

Neutral

Power supply

3

4

VD.AB.R6.02 © Danfoss 09/2015

DEN-SMT/SI

Data sheet Actuators for modulating control AME 85, AME 86

Commissioning Commissioning / testing feature

Complete the mechanical and electrical

installation and perform the necessary checks

and tests:

The actuator can be driven to the fully open or

closed positions (depending on valve type) by

connecting SN to terminals 1 or 3.

• Isolate control medium. (e.g. self stroking

in a steam application without suitable

mechanical isolation could cause a hazard).

• Apply the power. Note that the actuator will

now perform the self stroking function.

• Apply the appropriate control signal and

check the valve stem direction is correct for

the application.

• Ensure that the actuator drives the valve over

its full stroke, by applying the appropriate

control signal. This action will set the valve

stroke length.

The unit is now fully commissioned.

Manual override

(1)Remove grommets (2)Push (3)Turn

The manual override is applied by rotating the

8 mm Allen key (not supplied) to the required

position. Observe the direction of rotation

symbol.

• Disconnect power

• Remove grommets and push the button

• Adjust valve position using an 8 mm Allen key

• Set valve to closed position

• Restore power

Note:

Actuator will restore position required by

Y signal.

DEN-SMT/SI

VD.AB.R6.02 © Danfoss 09/2015

5

Data sheet Actuators for modulating control AME 85, AME 86

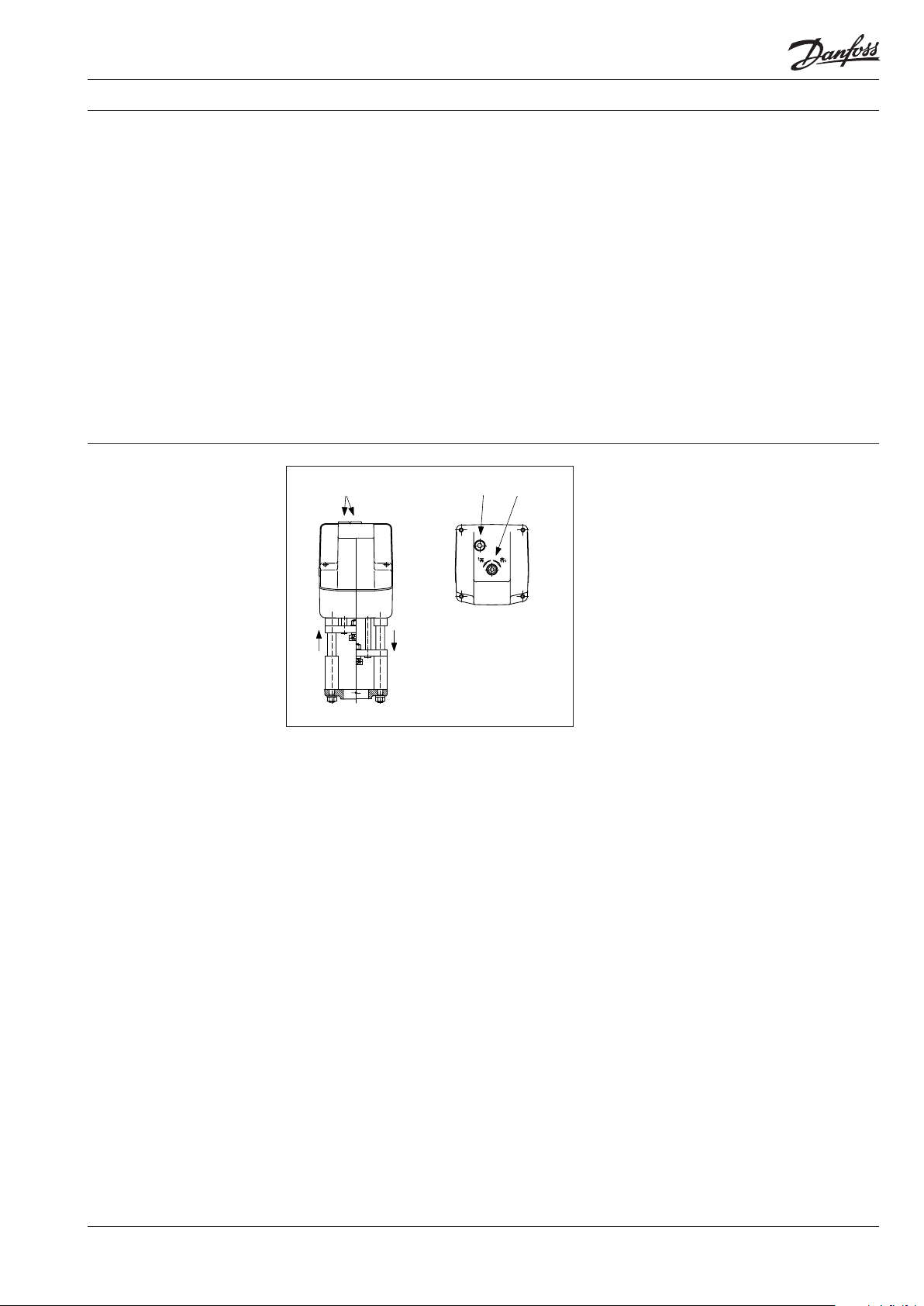

Dimensions

6

VD.AB.R6.02 © Danfoss 09/2015

DEN-SMT/SI

Data sheet Actuators for modulating control AME 85, AME 86

Actuator - valve

combinations

AME 85/86 + VFS 2 (DN 65 - 100)

AME 85/86 + VF 3 (DN 125 - 150)

AME 85/86 + VFM 2 (DN 150-250)AME 85/86 + VF 2 (DN 125 - 150)

DEN-SMT/SI

VD.AB.R6.02 © Danfoss 09/2015

AME 85/86 + AFQM (DN 150 - 250)

7

Data sheet Actuators for modulating control AME 85, AME 86

8

VD.AB.R6.02 Produce d by Danfoss A/S © 09/2015

Loading...

Loading...