Installation and operation manual

CO₂ Conveni-Pack outdoor unit and capacity up unit

LRYEN10A7Y1

LRNUN5A7Y1

Installation and operation manual

CO₂ Conveni-Pack outdoor unit and capacity up unit

English

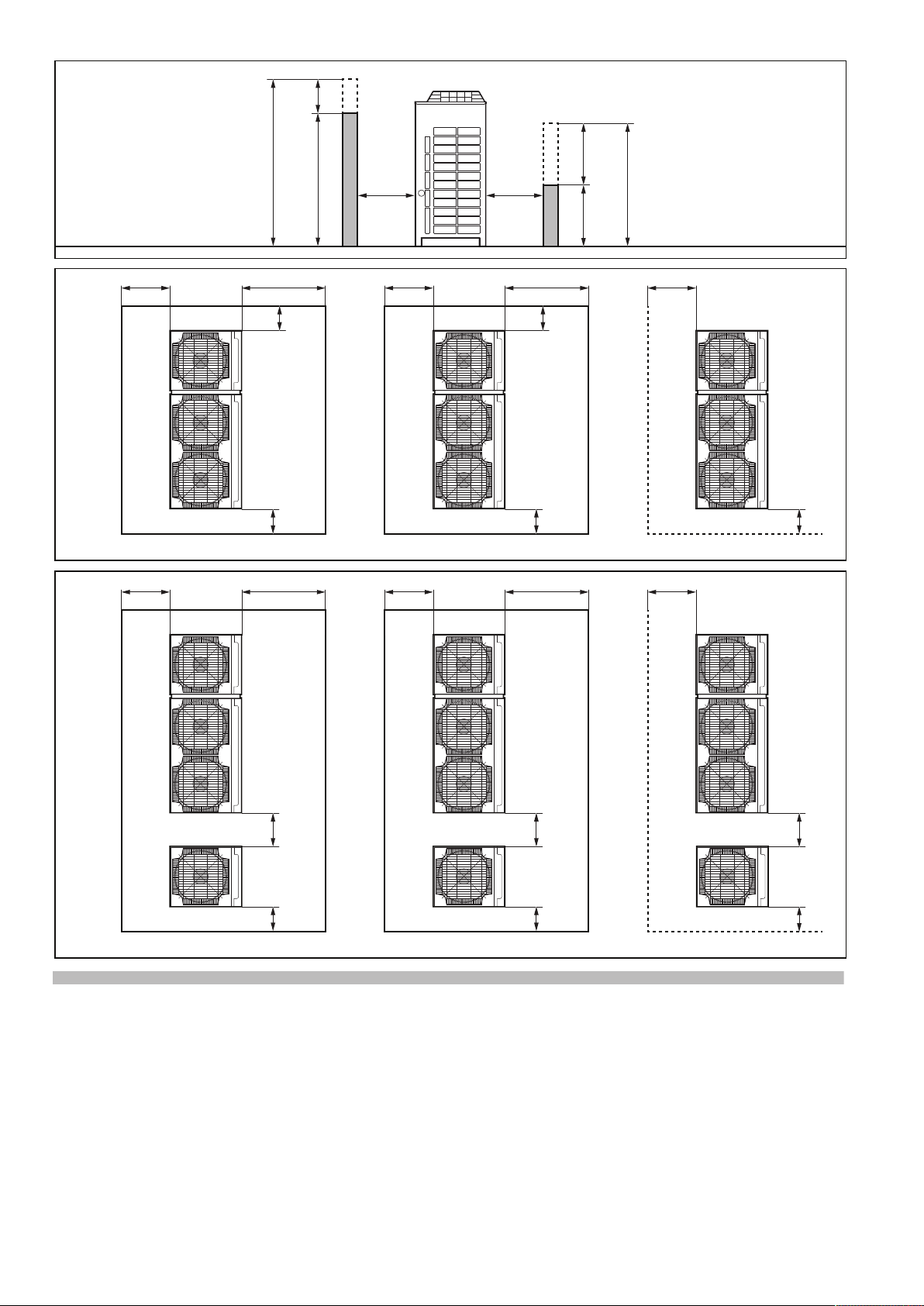

(mm)

≥300 ≥500

≥500

≥10

B

B1 B2 B3

≥100 ≥500

≥500

≥50

≥300

≥200

a

a

C1 C2 C3

C

a

≥300 ≥500

≥20

≥10 ≥50

≥100 ≥500

≥100

≥300

≥400

≥200

a

A

YX

h2

H2

500

h1

H1

1500

1

Table of contents

Table of contents

1 About the documentation 3

1.1 About this document.................................................................. 3

2 Specific installer safety instructions 4

For the user 5

3 User safety instructions 5

3.1 General...................................................................................... 6

3.2 Instructions for safe operation ................................................... 6

4 About the system 8

4.1 System layout............................................................................ 8

5 Operation 8

5.1 Operation range ........................................................................ 8

5.2 Design pressure ........................................................................ 8

6 Maintenance and service 9

6.1 About the refrigerant.................................................................. 9

6.2 Recommended maintenance and inspection ............................ 9

7 Troubleshooting 9

7.1 Error codes: Overview............................................................... 10

8 Relocation 10

9 Disposal 10

For the installer 10

10 About the box 10

10.1 Outdoor unit............................................................................... 10

10.1.1 To unpack the outdoor unit ......................................... 10

10.1.2 To handle the outdoor unit .......................................... 10

10.1.3 To remove the accessories from the outdoor unit....... 11

11 About the units and options 11

11.1 About the outdoor unit ............................................................... 11

11.1.1 Labels on outdoor unit ................................................ 12

11.2 System layout ............................................................................ 12

11.3 Indoor unit constraints ............................................................... 13

12 Unit installation 13

12.1 Preparing the installation site .................................................... 13

12.1.1 Installation site requirements of the outdoor unit ........ 13

12.1.2 Additional installation site requirements of the

outdoor unit in cold climates ....................................... 13

12.1.3 Additional installation site requirements for CO₂

refrigerant.................................................................... 13

12.2 Opening and closing the unit ..................................................... 14

12.2.1 To open the outdoor unit ............................................. 14

12.2.2 To open the electrical component box of the outdoor

unit .............................................................................. 15

12.2.3 To close the outdoor unit ............................................ 15

12.3 Mounting the outdoor unit.......................................................... 16

12.3.1 To provide the installation structure ............................ 16

12.3.2 To install the outdoor unit............................................ 17

12.3.3 To provide drainage .................................................... 17

13.1.5 To select refrigerant branch kits................................... 20

13.1.6 To select expansion valves for refrigeration ................ 20

13.2 Using stop valves and service ports ........................................... 20

13.2.1 To handle the stop valve .............................................. 20

13.2.2 To handle the service port ........................................... 21

13.2.3 Tightening torques ....................................................... 21

13.3 Connecting the refrigerant piping ............................................... 22

13.3.1 To remove the spun pipes ........................................... 22

13.3.2 To connect the refrigerant piping to the outdoor unit ... 22

13.3.3 Guidelines to connect T-joints...................................... 23

13.3.4 Guidelines to install a dryer.......................................... 23

13.3.5 Guidelines to install safety valves ................................ 23

13.4 Checking the refrigerant piping .................................................. 24

13.4.1 Checking refrigerant piping: Setup............................... 24

13.4.2 To perform a leak test .................................................. 24

13.4.3 To perform vacuum drying ........................................... 24

13.5 Insulating the refrigerant piping .................................................. 24

14 Electrical installation 25

14.1 About electrical compliance........................................................ 25

14.2 Field wiring: Overview ................................................................ 26

14.3 Guidelines when knocking out knockout holes........................... 27

14.4 Guidelines when connecting the electrical wiring ....................... 27

14.5 Specifications of standard wiring components ........................... 27

14.6 Connections to the outdoor unit ................................................. 28

14.6.1 Low voltage wiring – Outdoor unit................................ 28

14.6.2 High voltage wiring – Outdoor unit ............................... 29

14.7 Connections to the capacity up unit ........................................... 29

14.7.1 Low voltage wiring – Capacity up unit.......................... 30

14.7.2 High voltage wiring – Capacity up unit ......................... 30

15 Charging refrigerant 31

15.1 Precautions when charging refrigerant....................................... 31

15.2 To determine additional refrigerant amount ............................... 32

15.3 To charge refrigerant .................................................................. 32

16 Configuration 33

16.1 Making field settings ................................................................... 33

16.1.1 About making field settings .......................................... 33

16.1.2 To access the field setting components ....................... 33

16.1.3 Field setting components ............................................. 33

16.1.4 To access mode 1 or 2 ................................................ 33

17 Commissioning 34

17.1 Precautions when commissioning .............................................. 34

17.2 Checklist before commissioning ................................................. 34

17.3 About the test run ....................................................................... 35

17.4 To perform a test run (7-segment display) ................................. 35

17.4.1 Test run checks............................................................ 35

17.4.2 Correcting after abnormal completion of the test run ... 36

17.5 Logbook...................................................................................... 36

18 Troubleshooting 37

18.1 Solving problems based on error codes ..................................... 37

18.1.1 Error codes: Overview ................................................. 37

19 Technical data 40

19.1 Piping diagram: Outdoor unit...................................................... 40

19.2 Piping diagram: Capacity up unit................................................ 41

19.3 Wiring diagram: Outdoor unit ..................................................... 42

1 About the documentation

13 Piping installation 17

13.1 Preparing refrigerant piping ....................................................... 17

13.1.1 Refrigerant piping requirements.................................. 17

13.1.2 Refrigerant piping material .......................................... 17

13.1.3 Refrigerant piping length and height difference .......... 18

13.1.4 To select the piping size ............................................. 18

LRYEN10A7Y1+LRNUN5A7Y1

CO₂ Conveni-Pack outdoor unit and capacity up unit

4P605461-1B – 2020.08

1.1 About this document

Target audience

Authorised installers + end users

Installation and operation manual

3

2 Specific installer safety instructions

INFORMATION

This appliance is intended to be used by expert or trained

users in shops, in light industry and on farms, or for

commercial use by lay persons.

Documentation set

This document is part of a documentation set. The complete set

consists of:

▪ General safety precautions:

▪ Safety instructions that you must read before installing

▪ Format: Paper (in the box of the outdoor unit)

▪ Installation and operation manual of the outdoor unit:

▪ Installation and operation instructions

▪ Format: Paper (in the box of the outdoor unit)

▪ Installer and user reference guide of the outdoor unit:

▪ Preparation of the installation, reference data,…

▪ Detailed step-by-step instructions and background information

for basic and advanced usage

▪ Format: Digital files on http://www.daikineurope.com/support-

and-manuals/product-information/

Latest revisions of the supplied documentation may be available on

the regional Daikin website or via your dealer.

The original documentation is written in English. All other languages

are translations.

Installation site (see "12.1Preparing the installation

site"[413])

CAUTION

Appliance not accessible to the general public, install it in a

secured area, protected from easy access.

This unit, both indoor and outdoor, is suitable for

installation in a commercial and light industrial

environment.

WARNING

All installed safety valves MUST ventilate to the outdoor

space and NOT into a closed area.

CAUTION

If the safety valve operates, CO2 gas may concentrate

inside the casing of the outdoor unit. Therefore, you should

ALWAYS take a distance for your own safety. You can

close the outdoor unit if your portable CO2 detector

confirmed that the concentration of CO2 is at an acceptable

level. For example, if 7 kg CO2 is released inside the

casing, it takes around 5minutes until the concentration of

CO2 is low enough.

WARNING

Do NOT place objects below the indoor and/or outdoor unit

that may get wet. Otherwise condensation on the main unit

or refrigerant pipes, air filter dirt or drain blockage may

cause dripping, and objects under the unit may get dirty or

damaged.

2 Specific installer safety

instructions

Always observe the following safety instructions and regulations.

CAUTION

Do NOT insert fingers, rods or other objects into the air

inlet or outlet. When the fan is rotating at high speed, it will

cause injury.

General installation requirements

WARNING

▪ Make sure to install all necessary countermeasures in

case of refrigerant leakage according to standard

EN378 (see "12.1.3 Additional installation site

requirements for CO₂ refrigerant"[413]).

▪ Make sure to install a CO2 leak detector (field supply)

and enable the function for refrigerant leak detection

(see the installation manual of the indoor unit (air

conditioning)).

WARNING

Make sure installation, servicing, maintenance, repair and

applied materials follow the instructions from Daikin and, in

addition, comply with applicable legislation and are

performed by qualified persons only. In Europe and areas

where IEC standards apply, EN/IEC 60335-2-40 is the

applicable standard.

WARNING

Install the unit only in locations where the doors of the

occupied space are not tight fitting.

NOTICE

Serious injury and/or damage can result from blow off of

the liquid receiver safety valve (see "19.1 Piping diagram:

Outdoor unit"[440]):

▪ NEVER service the unit when the pressure at the liquid

receiver is higher than the set pressure of the liquid

receiver safety valve (86barg±3%). If this safety valve

releases refrigerant, it can cause serious injury and/or

damage.

▪ If the pressure >86 bar, ALWAYS discharge from

pressure relief devices before servicing.

▪ It is recommended to install and secure blow off piping

to the safety valve.

▪ Remove the refrigerant before altering the safety valve

position.

NOTICE

Adverse effects shall be considered. For example, danger

of water collecting and freezing in discharge pipes for

pressure relief devices, accumulation of dirt and debris, or

blockage of the discharge pipes by solid CO2 (R744).

INFORMATION

Instructions on how to fix the unit in a correct way can be

found in "12Unit installation"[413].

Installation and operation manual

4

CO₂ Conveni-Pack outdoor unit and capacity up unit

LRYEN10A7Y1+LRNUN5A7Y1

4P605461-1B – 2020.08

3 User safety instructions

Refrigerant piping installation (see "13Piping

installation"[417])

WARNING

▪ Only use R744 (CO2) as refrigerant. Other substances

may cause explosions and accidents.

▪ When installing, charging refrigerant, maintaining or

performing service, ALWAYS use personal protective

equipment, such as safety shoes, safety gloves and

safety glasses.

▪ If the unit is installed indoors (for example, in a

machine room), ALWAYS use a portable CO2 detector.

▪ If the front panel is open, ALWAYS beware of the

rotating fan. The fan will continue rotating for a while,

even after the power switch has been turned off.

CAUTION

Do NOT reuse piping from previous installations.

CAUTION

Install the refrigerant piping or components in a position

where they are unlikely to be exposed to any substance

which may corrode components containing refrigerant,

unless the components are constructed of materials that

are inherently resistant to corrosion or are suitably

protected against corrosion.

WARNING

▪ Use K65 piping for high-pressure applications with a

working pressure of 120bar or 90bar, depending on its

location in the system.

▪ Use K65 unions and fittings approved for a working

pressure of 120bar or 90bar, depending on its location

in the system.

▪ Only brazing is allowed for connection of pipes. No

other types of connections are allowed.

▪ Expanding of pipes is not allowed.

INFORMATION

To complete the refrigerating system, additional charging

of refrigerant is required. See "15 Charging

refrigerant"[431].

Electrical installation (see "14Electrical installation"[425])

WARNING

▪ If the power supply has a missing or wrong N-phase,

equipment might break down.

▪ Establish proper earthing. Do NOT earth the unit to a

utility pipe, surge absorber, or telephone earth.

Incomplete earthing may cause electrical shock.

▪ Install the required fuses or circuit breakers.

▪ Secure the electrical wiring with cable ties so that the

cables do NOT come in contact with sharp edges or

piping, particularly on the high-pressure side.

▪ Do NOT use taped wires, stranded conductor wires,

extension cords, or connections from a star system.

They can cause overheating, electrical shock or fire.

▪ Do NOT install a phase advancing capacitor, because

this unit is equipped with an inverter. A phase

advancing capacitor will reduce performance and may

cause accidents.

WARNING

▪ All wiring MUST be performed by an authorised

electrician and MUST comply with the applicable

legislation.

▪ Make electrical connections to the fixed wiring.

▪ All components procured on-site and all electrical

construction MUST comply with the applicable

legislation.

WARNING

ALWAYS use multicore cable for power supply cables.

WARNING

Use an all-pole disconnection type breaker with at least

3 mm between the contact point gaps that provide full

disconnection under overvoltage category III.

WARNING

If the supply cord is damaged, it MUST be replaced by the

manufacturer, its service agent or similarly qualified

persons in order to avoid a hazard.

INFORMATION

A wiring diagram can be found on the applicance and its

description of the connections and wiring to external

control devices and supply cord can be found in

"19.3Wiring diagram: Outdoor unit"[442].

For the user

3 User safety instructions

Always observe the following safety instructions and regulations.

LRYEN10A7Y1+LRNUN5A7Y1

CO₂ Conveni-Pack outdoor unit and capacity up unit

4P605461-1B – 2020.08

INFORMATION

The method of connection of the appliance to the electrical

supply and interconnection of separate components is

described in "14.2Field wiring: Overview"[426].

INFORMATION

Details of type and rating of fuses, or rating of circuit

breakers are described in "14Electrical installation"[425].

Installation and operation manual

5

3 User safety instructions

3.1 General

WARNING

If you are NOT sure how to operate the

unit, contact your installer.

WARNING

Children aged from 8 years and above

and persons with reduced physical,

sensory or mental capabilities or lack

of experience and knowledge can only

use this appliance if they have been

given supervision or instruction

concerning the use of the appliance by

a person responsible for their safety.

Children MUST NOT play with the

appliance.

Cleaning and user maintenance MUST

NOT be carried out by children without

supervision.

WARNING

To prevent electrical shocks or fire:

▪ Do NOT rinse the unit.

▪ Do NOT operate the unit with wet

hands.

▪ Do NOT place any objects containing

water on the unit.

CAUTION

▪ Do NOT place any objects or

equipment on top of the unit.

▪ Batteries are marked with the following symbol:

This means that the batteries may NOT be mixed with unsorted

household waste. If a chemical symbol is printed beneath the

symbol, this chemical symbol means that the battery contains a

heavy metal above a certain concentration.

Possible chemical symbols are: Pb: lead (>0.004%).

Waste batteries must be treated at a specialized treatment facility

for reuse. By ensuring waste batteries are disposed of correctly,

you will help to prevent potential negative consequences for the

environment and human health.

3.2 Instructions for safe operation

WARNING

Do NOT modify, disassemble, remove,

reinstall or repair the unit yourself as

incorrect dismantling or installation

may cause an electric shock or fire.

Contact your dealer.

CAUTION

If this unit is equipped with an

electrically powered safety measure,

such as a CO2 refrigerant leak detector

(field supply), in order to be effective,

the unit must be electrically powered at

all times after installation, except for

short service periods.

CAUTION

Do NOT insert fingers, rods or other

objects into the air inlet or outlet. When

the fan is rotating at high speed, it will

cause injury.

▪ Do NOT sit, climb or stand on the

unit.

▪ Units are marked with the following symbol:

This means that electrical and electronic products may NOT be

mixed with unsorted household waste. Do NOT try to dismantle

the system yourself: the dismantling of the system, treatment of

the refrigerant, of oil and of other parts must be done by an

authorized installer and must comply with applicable legislation.

Units must be treated at a specialized treatment facility for reuse,

recycling and recovery. By ensuring this product is disposed of

correctly, you will help to prevent potential negative consequences

for the environment and human health. For more information,

contact your installer or local authority.

Installation and operation manual

6

CAUTION

▪ NEVER touch the internal parts of the

controller.

▪ Do NOT remove the front panel.

Some parts inside are dangerous to

touch and appliance problems may

happen. For checking and adjusting

the internal parts, contact your

dealer.

WARNING

This unit contains electrical and hot

parts.

LRYEN10A7Y1+LRNUN5A7Y1

CO₂ Conveni-Pack outdoor unit and capacity up unit

4P605461-1B – 2020.08

3 User safety instructions

WARNING

Before operating the unit, be sure the

installation has been carried out

correctly by an installer.

CAUTION

It is not good for your health to expose

your body to the air flow for a long

time.

CAUTION

To avoid oxygen deficiency, ventilate

the room sufficiently if equipment with

burner is used together with the

system.

CAUTION

Do NOT operate the system when

using a room fumigation-type

insecticide. Chemicals could collect in

the unit, and endanger the health of

people who are hypersensitive to

chemicals.

CAUTION

NEVER expose little children, plants or

animals directly to the airflow.

WARNING

Do NOT place objects below the indoor

and/or outdoor unit that may get wet.

Otherwise condensation on the main

unit or refrigerant pipes, air filter dirt or

drain blockage may cause dripping,

and objects under the unit may get

dirty or damaged.

WARNING

Do NOT place a flammable spray

bottle near the air conditioner and do

NOT use sprays near the unit. Doing

so may result in a fire.

Maintenance and service (see "6Maintenance and

service"[49])

WARNING: System contains

refrigerant under very high

pressure.

The system MUST be serviced by

qualified persons only.

CAUTION: Pay attention to the fan!

It is dangerous to inspect the unit while

the fan is running.

Be sure to turn off the main switch

before executing any maintenance

task.

WARNING

Never replace a fuse with a fuse of a

wrong ampere ratings or other wires

when a fuse blows out. Use of wire or

copper wire may cause the unit to

break down or cause a fire.

CAUTION

After a long use, check the unit stand

and fitting for damage. If damaged, the

unit may fall and result in injury.

CAUTION

Before accessing terminal devices,

make sure to interrupt all power supply.

DANGER: RISK OF

ELECTROCUTION

To clean the air conditioner or air filter,

be sure to stop operation and turn all

power supplies off. Otherwise, an

electric shock and injury may result.

WARNING

Be careful with ladders when working

in high places.

WARNING

Do NOT let the indoor unit get wet.

Possible consequence: Electric

shock or fire.

About the refrigerant (see "6.1About the refrigerant"[49])

WARNING

▪ Do NOT pierce or burn refrigerant

cycle parts.

▪ Do NOT use cleaning materials other

than those recommended by the

manufacturer.

▪ Be aware that the refrigerant inside

the system is odourless.

LRYEN10A7Y1+LRNUN5A7Y1

CO₂ Conveni-Pack outdoor unit and capacity up unit

4P605461-1B – 2020.08

Installation and operation manual

7

4 About the system

ab

e e

d c

f

h

i

j

k

h

l

i

j

k

l

g

WARNING

The R744 refrigerant (CO2) inside the

unit is odourless, non-flammable and

normally does NOT leak.

If the refrigerant leaks in high

concentrations in the room, it may have

negative effects on its occupants such

as asphyxiation and carbon dioxide

poisoning. Ventilate the room and

contact the dealer where you

purchased the unit.

Do NOT use the unit until a service

person confirms that the part from

which the refrigerant leaked has been

repaired.

Troubleshooting (see "7Troubleshooting"[49])

WARNING

Stop operation and shut off the

power if anything unusual occurs

(burning smells etc.).

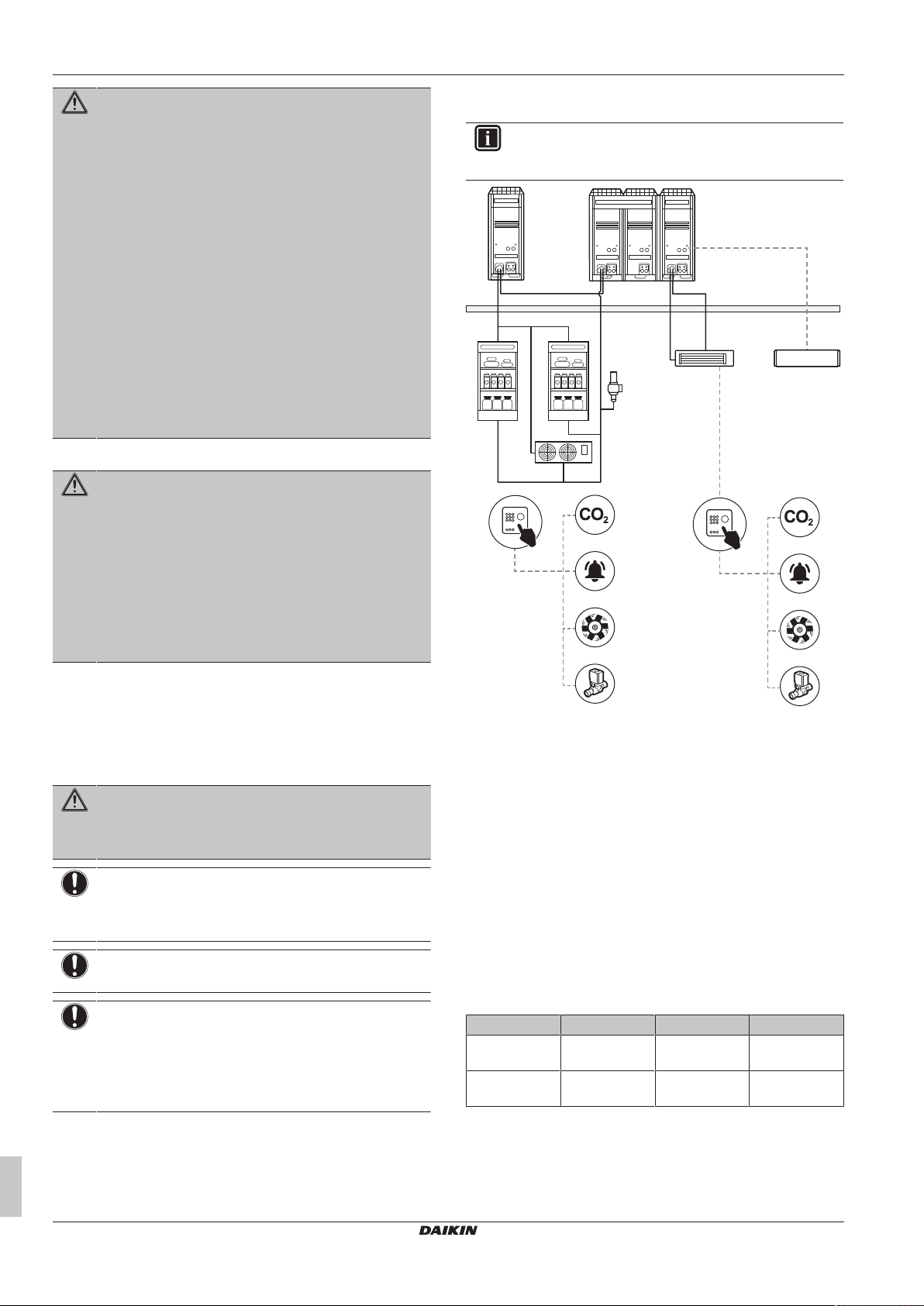

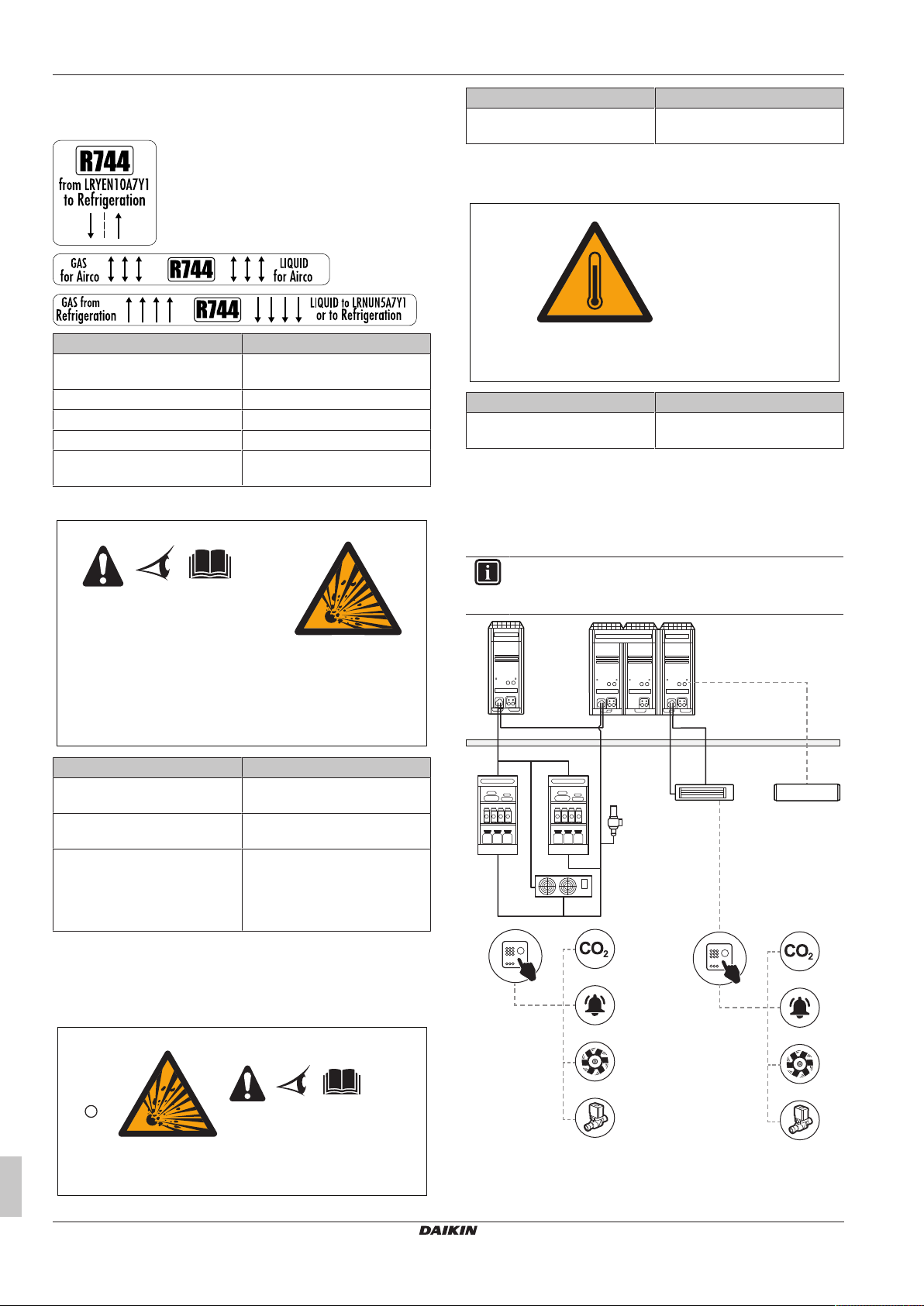

4.1 System layout

INFORMATION

The following illustration is an example and might NOT

match your system layout.

4 About the system

The indoor units can be used for heating/cooling and refrigerating

applications. The type of indoor units which can be used depends on

the outdoor units series.

Leaving the unit running under such

circumstances may cause breakage,

electric shock or fire. Contact your

dealer.

WARNING

Do NOT modify, disassemble, remove, reinstall or repair

the unit yourself as incorrect dismantling or installation may

cause an electric shock or fire. Contact your dealer.

NOTICE

Do NOT use the system for other purposes. In order to

avoid any quality deterioration, do NOT use the unit for

cooling precision instruments or works of art.

NOTICE

Do NOT use the system for cooling water. It may freeze.

NOTICE

For future modifications or expansions of your system:

A full overview of allowable combinations (for future

system extensions) is available in technical engineering

data and should be consulted. Contact your installer to

receive more information and professional advice.

a Main outdoor unit (LRYEN10*)

b Capacity up unit (LRNUN5*)

c Communication box (BRR9B1V1)

d Fan (indoor unit for air conditioning)

e Showcase (indoor unit for refrigeration)

f Blower coil (indoor unit for refrigeration)

g Safety valve

h CO2 control panel

i CO2 detector

j CO2 alarm

k CO2 ventilator

l Shut off valve

5 Operation

5.1 Operation range

Use the system in the following temperature ranges for safe and

effective operation.

Refrigeration A/C cooling A/C heating

Outdoor

temperature

Indoor

temperature

5.2 Design pressure

Always keep the following design pressures in mind:

–20~43°CDB –5~43°CDB –20~16°CWB

— 14~24°CWB 15~27°CDB

Installation and operation manual

8

CO₂ Conveni-Pack outdoor unit and capacity up unit

LRYEN10A7Y1+LRNUN5A7Y1

4P605461-1B – 2020.08

6 Maintenance and service

Side Design pressure

Refrigeration 90bar

Air conditioning 120bar

6 Maintenance and service

NOTICE

Never inspect or service the unit by yourself. Ask a

qualified service person to perform this work.

WARNING

Never replace a fuse with a fuse of a wrong ampere ratings

or other wires when a fuse blows out. Use of wire or

copper wire may cause the unit to break down or cause a

fire.

CAUTION

Do NOT insert fingers, rods or other objects into the air

inlet or outlet. Do NOT remove the fan guard. When the

fan is rotating at high speed, it will cause injury.

CAUTION

After a long use, check the unit stand and fitting for

damage. If damaged, the unit may fall and result in injury.

NOTICE

Do NOT wipe the controller operation panel with benzine,

thinner, chemical dust cloth, etc. The panel may get

discoloured or the coating peeled off. If it is heavily dirty,

soak a cloth in water-diluted neutral detergent, squeeze it

well and wipe the panel clean. Wipe it with another dry

cloth.

6.1 About the refrigerant

This product contains refrigerant gases.

Refrigerant type: R744 (CO2)

WARNING

▪ Do NOT pierce or burn refrigerant cycle parts.

▪ Do NOT use cleaning materials other than those

recommended by the manufacturer.

▪ Be aware that the refrigerant inside the system is

odourless.

WARNING

The R744 refrigerant (CO2) inside the unit is odourless,

non-flammable and normally does NOT leak.

If the refrigerant leaks in high concentrations in the room, it

may have negative effects on its occupants such as

asphyxiation and carbon dioxide poisoning. Ventilate the

room and contact the dealer where you purchased the unit.

Do NOT use the unit until a service person confirms that

the part from which the refrigerant leaked has been

repaired.

6.2 Recommended maintenance and inspection

Since dust collects when using the unit for several years,

performance of the unit will deteriorate to some extent. As taking

apart and cleaning interiors of units requires technical expertise and

in order to ensure the best possible maintenance of your units, we

recommend to enter into a maintenance and inspection contract on

top of normal maintenance activities. Our network of dealers has

access to a permanent stock of essential components in order to

keep your unit in operation as long as possible. Contact your dealer

for more information.

When asking your dealer for an intervention, always state:

▪ The complete model name of the unit.

▪ The manufacturing number (stated on the nameplate of the unit).

▪ The installation date.

▪ The symptoms or malfunction, and details of the defect.

WARNING

▪ Do NOT modify, disassemble, remove, reinstall or

repair the unit yourself as incorrect dismantling or

installation may cause an electric shock or fire. Contact

your dealer.

▪ In case of accidental refrigerant leaks, make sure there

are no naked flames. The refrigerant itself is entirely

safe, non-toxic and non-combustible, but it will

generate toxic gas when it accidentally leaks into a

room where combustible air from fan heaters, gas

cookers, etc. is present. Always have qualified service

personnel confirm that the point of leakage has been

repaired or corrected before resuming operation.

7 Troubleshooting

If system malfunctions are likely to degrade the articles in the room/

showcase, you can ask your installer to install an alarm (example:

lamp). For more information, contact your installer.

If one of the following malfunctions occur, take the measures shown

below and contact your dealer.

WARNING

Stop operation and shut off the power if anything

unusual occurs (burning smells etc.).

Leaving the unit running under such circumstances may

cause breakage, electric shock or fire. Contact your dealer.

The system MUST be repaired by a qualified service person.

Malfunction Measure

If a safety device such as a fuse, a

breaker or an earth leakage breaker

frequently actuates or the ON/OFF

switch does NOT properly work.

If water leaks from the unit. Stop the operation.

The operation switch does NOT work

well.

If the user interface display indicates the

unit number, the operation lamp flashes

and the malfunction code appears.

If the system does NOT operate properly except for the above

mentioned cases and none of the above mentioned malfunctions is

evident, investigate the system in accordance with the following

procedures.

If after checking all above items, it is impossible to fix the problem

yourself, contact your installer and state the symptoms, the complete

model name of the unit (with manufacturing number if possible) and

the installation date (possibly listed on the warranty card).

Turn OFF the main power

switch.

Turn OFF the power

supply.

Notify your installer and

report the malfunction

code.

LRYEN10A7Y1+LRNUN5A7Y1

CO₂ Conveni-Pack outdoor unit and capacity up unit

4P605461-1B – 2020.08

Installation and operation manual

9

8 Relocation

a b

8×8×

a b

7.1 Error codes: Overview

In case a malfunction code appears on the indoor unit user interface

display, contact your installer and inform the malfunction code, the

unit type, and serial number (you can find this information on the

nameplate of the unit).

For your reference, a list with malfunction codes is provided. You

can, depending on the level of the malfunction code, reset the code

by pushing the ON/OFF button. If not, ask your installer for advice.

Code Cause Solution

Electric leakage Restart the unit by

switching operating switch

OFF and ON.

The stop valve of an

outdoor unit is left closed.

The stop valve of an

outdoor unit is left closed.

The air passage is blocked. Remove obstacles that

Lost phase in power

supply.

Insufficient supply voltage Check if the supply voltage

Wrong transmission wiring

between units

Open the stop valve on

both the gas and liquid

side.

Open the stop valve on

both the gas and liquid

side.

block the passage of air to

the outdoor unit.

Check the connection of

the power supply cable.

is supplied properly.

Check the connection of

transmission wiring

between the outdoor unit

and the air conditioner.

Code Cause Solution

Wrong combination of

indoor units

Wrong transmission wiring

between units

Refer to the service manual for other malfunction codes.

If no malfunction code is displayed, check if

▪ power of indoor unit is turned on,

▪ user interface wiring is broken or incorrectly wired,

▪ fuse on PCB has melted.

▪ Check the number of

connected indoor units.

▪ Check if an indoor unit is

installed that is not a

possible combination.

Check the connection of

transmission wiring

between the outdoor unit

and the air conditioner.

8 Relocation

Contact your dealer for removing and reinstalling the total unit.

Moving units requires technical expertise.

9 Disposal

NOTICE

Do NOT try to dismantle the system yourself: dismantling

of the system, treatment of the refrigerant, oil and other

parts MUST comply with applicable legislation. Units

MUST be treated at a specialised treatment facility for

reuse, recycling and recovery.

For the installer

10 About the box

10.1 Outdoor unit

Also see "Label about maximum storage temperature"[412].

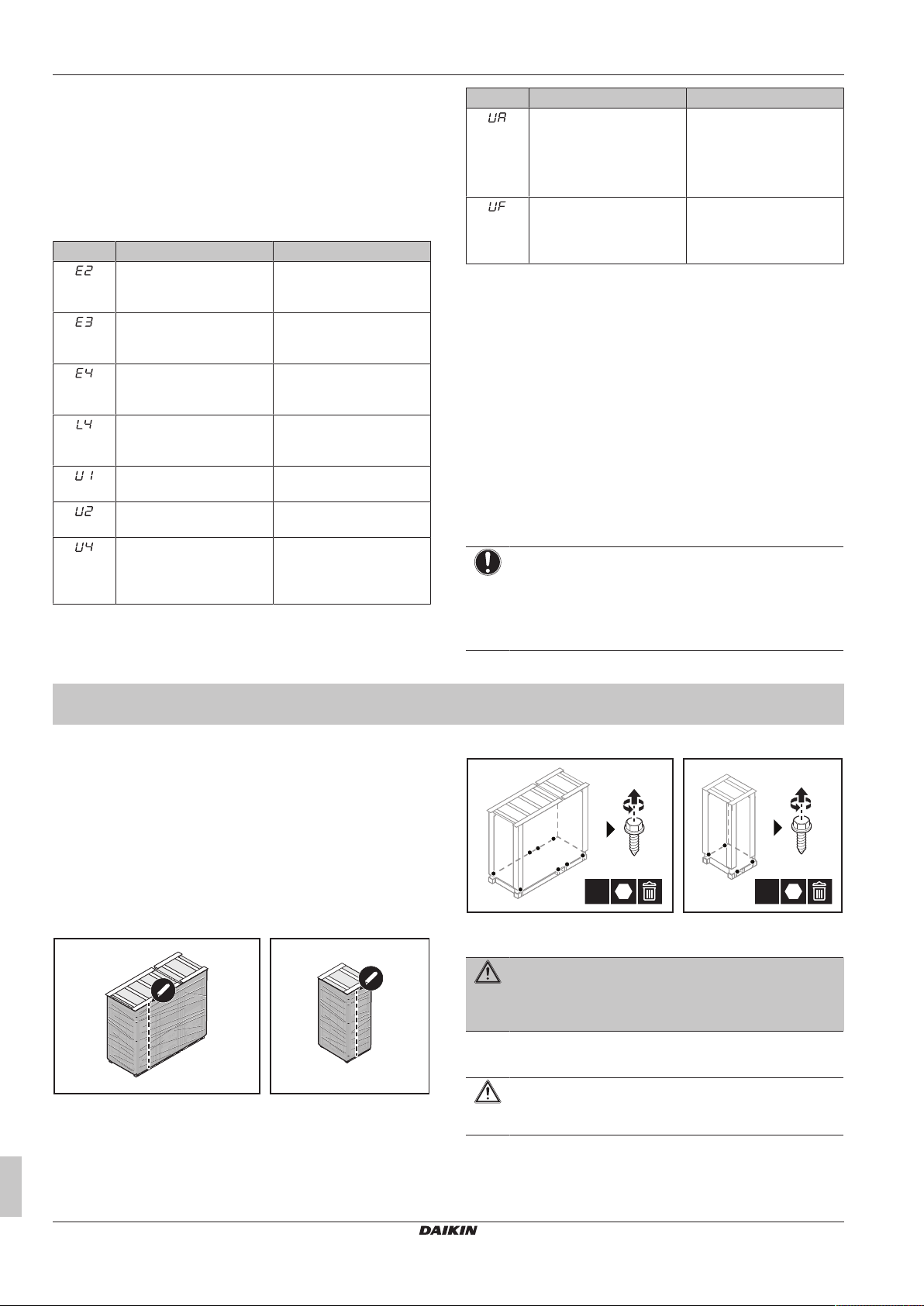

10.1.1 To unpack the outdoor unit

1 Remove the packaging material from the unit. Take care not to

damage the unit when removing the shrink foil with a cutter.

a Outdoor unit

b Capacity up unit

2 The unit is fixed to the pallet with bolts. Remove these bolts.

a Outdoor unit

b Capacity up unit

WARNING

Tear apart and throw away plastic packaging bags so that

nobody, especially children, can play with them. Possible

risk: suffocation.

10.1.2 To handle the outdoor unit

CAUTION

To avoid injury, do NOT touch the air inlet or aluminium

fins of the unit.

Installation and operation manual

10

CO₂ Conveni-Pack outdoor unit and capacity up unit

LRYEN10A7Y1+LRNUN5A7Y1

4P605461-1B – 2020.08

11 About the units and options

a b

d e

a b

c

a

Crane

Lift the outdoor unit preferably with a crane and 2 belts of at least

8 m long as shown in the figure below. Always use protectors to

prevent belt damage and pay attention to the centre of gravity of the

unit.

Outdoor unit

Capacity up unit

10.1.3 To remove the accessories from the outdoor unit

Outdoor unit

a General safety precautions

b Operation and installation manual

c Declaration of conformity

d Copper packings for stop valve caps (15×)

e Copper packings for service port caps (15×)

Capacity up unit

NOTICE

Use a belt sling of ≤20mm wide that adequately bears the

weight of the unit.

Forklift

a Outdoor unit

b Capacity up unit

NOTICE

Use filler cloth on the forklift arms to prevent damage to the

unit. Damage to the painting of the unit decreases the anticorrosion protection.

a Declaration of conformity

11 About the units and options

11.1 About the outdoor unit

This installation manual concerns the outdoor unit and the optional

capacity up unit.

These units are intended for outdoor installation and aimed for air to

air heating, cooling and refrigeration applications.

NOTICE

These units (LRYEN10* and LRNUN5*) are only parts of

an air conditioner system, complying with partial unit

requirements of the International Standard IEC

60335-2-40:2018. As such, they must ONLY be connected

to other units that have been confirmed as complying to

corresponding partial unit requirements of this International

Standard.

General name and product name

In this manual, we use the following names:

General name Product name

Outdoor unit LRYEN10A7Y1

Capacity up unit LRNUN5A7Y1

LRYEN10A7Y1+LRNUN5A7Y1

CO₂ Conveni-Pack outdoor unit and capacity up unit

4P605461-1B – 2020.08

Temperature range

Refrigeration A/C cooling A/C heating

Outdoor

temperature

Indoor

temperature

–20~43°CDB –5~43°CDB –20~16°CWB

— 14~24°CWB 15~27°CDB

Installation and operation manual

11

11 About the units and options

WARNING

Unit is charged and under high pressure.

Set pressure of safety valve is 86 bar g.

If refrigerant temperature is higher than 31°C

there is a possibility that the safety valve will

open during service or power shutdown.

WARNING

Unit is charged and under high pressure.

MAXIMUM STORAGE TEMPERATURE

55°C

ab

e e

d c

f

h

i

j

k

h

l

i

j

k

l

g

11.1.1 Labels on outdoor unit

Label about flow directions

Text on caution label Translation

from LRYEN10A7Y1 to

Refrigeration

Gas for Airco Gas for Airco

Liquid for Airco Liquid for Airco

Gas from Refrigeration Gas from Refrigeration

Liquid to LRNUN5A7Y1 or to

Refrigeration

Label about safety valve

from LRYEN10A7Y1 to

Refrigeration

Liquid to LRNUN5A7Y1 or to

Refrigeration

Text on warning card Translation

Unit is charged and under high

pressure.

Also see "13.2Using stop valves and service ports"[420].

Label about maximum storage temperature

Text on warning label Translation

MAXIMUM STORAGE

TEMPERATURE: 55°C

The unit is factory charged with refrigerant. To avoid the safety relief

valve being opened, the unit must not be exposed to temperatures

above 55°C.

Unit is charged and under high

pressure.

MAXIMUM STORAGE

TEMPERATURE: 55°C

11.2 System layout

Text on warning label Translation

Unit is charged and under high

pressure.

Set pressure of safety valve is 86

bar g.

If refrigerant temperature is

higher than 31°C there is a

possibility that the safety valve

will open during service or power

shutdown.

Check the set pressure of the safety valve at the low pressure side

of the refrigeration cabinet to verify a safe service temperature.

Also see "13.3.5Guidelines to install safety valves"[423].

Card about stop valves and service ports

INFORMATION

The following illustration is an example and might NOT

match your system layout.

Unit is charged and under high

pressure.

Set pressure of safety valve is

86barg.

If refrigerant temperature is

higher than 31°C there is a

possibility that the safety valve

will open during service or power

shutdown.

Installation and operation manual

12

a Main outdoor unit (LRYEN10*)

b Capacity up unit (LRNUN5*)

c Communication box (BRR9B1V1)

d Fan (indoor unit for air conditioning)

e Showcase (indoor unit for refrigeration)

LRYEN10A7Y1+LRNUN5A7Y1

CO₂ Conveni-Pack outdoor unit and capacity up unit

4P605461-1B – 2020.08

12 Unit installation

f Blower coil (indoor unit for refrigeration)

g Safety valve

h CO2 control panel

i CO2 detector

j CO2 alarm

k CO2 ventilator

l Shut off valve

11.3 Indoor unit constraints

NOTICE

The design pressure of high pressure side of the

connected refrigeration parts MUST be 9MPa (90bar).

NOTICE

If the design pressure of the lower pressure side of

refrigeration parts is different from 90 bar (for example:

60 bar), a safety valve MUST be installed on the field

piping according to this design pressure. It is NOT possible

to connect refrigeration parts with design pressure below

60bar.

NOTICE

The design pressure of the connected air conditioning

parts MUST be 12MPa (120bar). If this is not the case,

please contact your dealer for assistance.

WARNING

Only the refrigeration parts that are also designed to work

with CO2 shall be connected to the system.

Individual control with a remote controller

In case of a system with several air conditioners that are controlled

with the same remote controller in the same space:

Capacity class Individual control with a

remote controller

50 NOT allowed

71+112 Allowed

Restrictions

Keep the following restrictions in mind when you connect indoor

units:

Restriction Minimum/maximum

Minimum air conditioning total

capacity class

Maximum air conditioning total

capacity class

Maximum indoor units that can

be connected

For more information about the possible combinations, see the

installer and user reference guide of the outdoor unit.

162

233

≤4

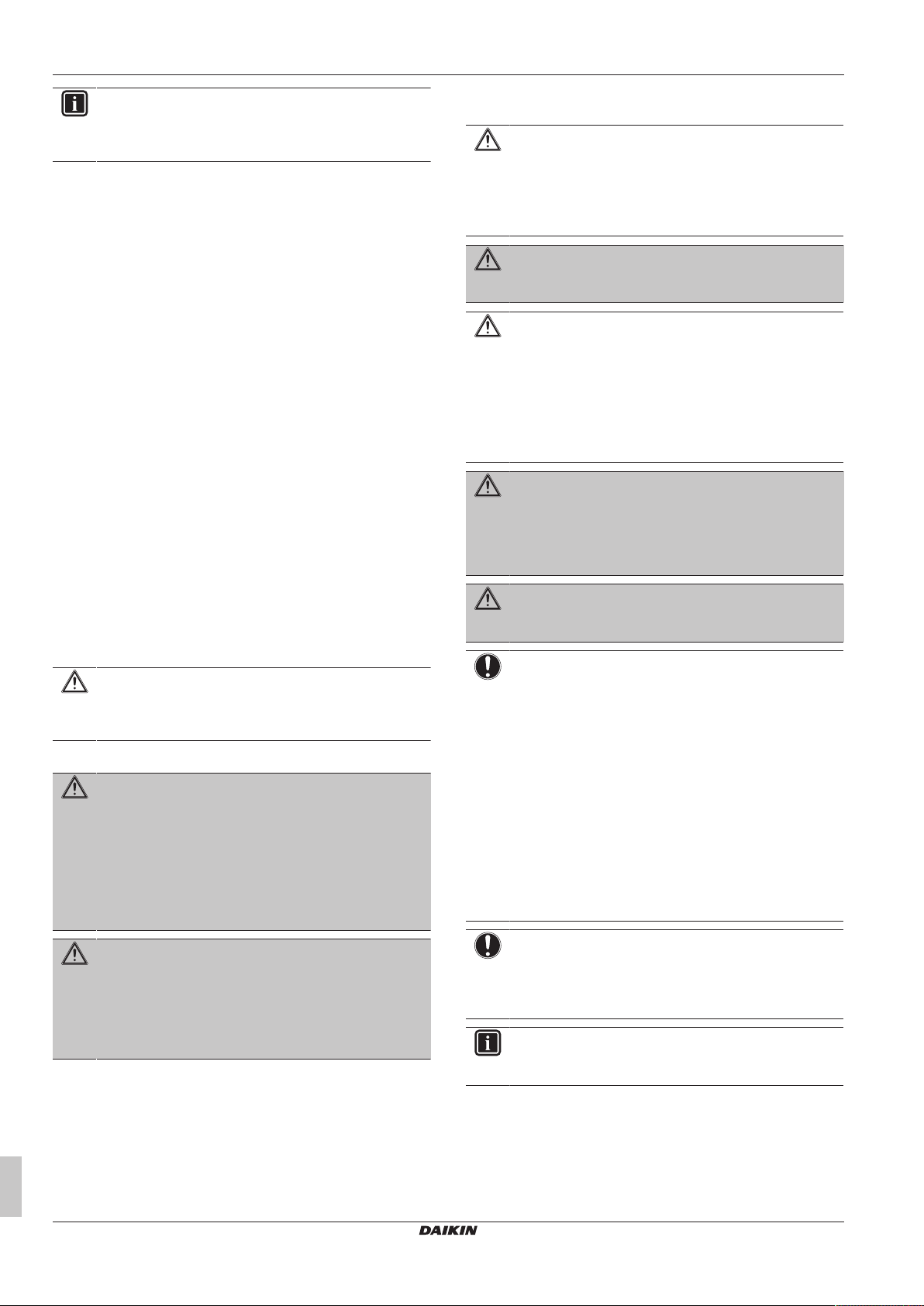

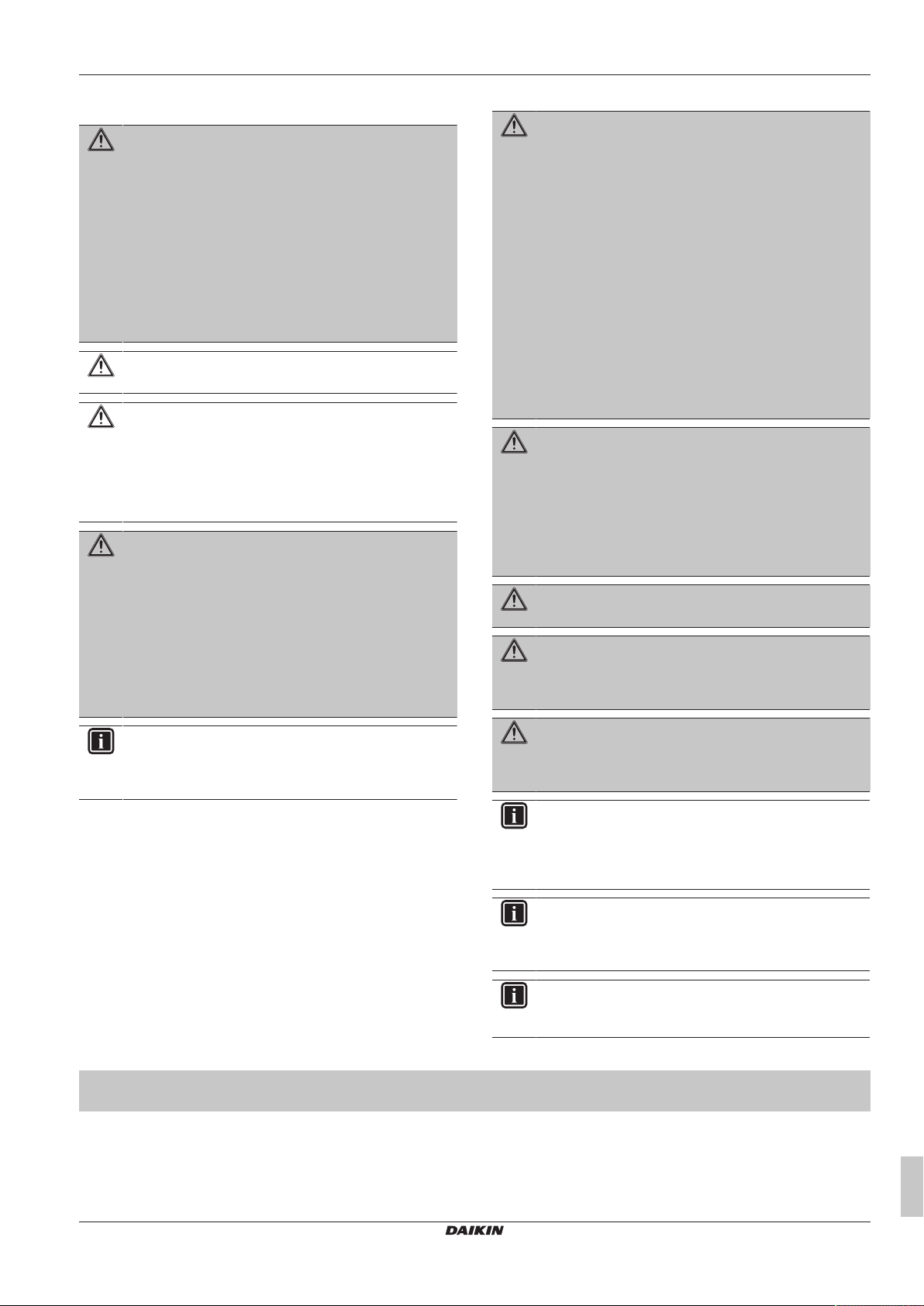

Item Description

B Possible patterns with installation

spaces in case of a single

outdoor unit

(a)(b)(c)(d)

C Possible patterns with installation

spaces in case of an outdoor unit

connected to a capacity up unit

(b)(c)(d)

(a)

h1 H1 (actual height)–1500mm

h2 H2 (actual height)–500mm

X Front side = 500mm+≥h1/2

Y (for patterns B) Air inlet side = 300mm+≥h2/2

Y (for patterns C) Air inlet side = 100mm+≥h2/2

(a)

Wall height front side: ≤1500mm.

(b)

Wall height air inlet side: ≤500mm.

(c)

Wall height other sides: no limit.

(d)

Calculate h1 and h2 as shown in the figure. Add h1/2 for

maintenance space to the front side. Add h2/2 for maintenance

space to the back side (if wall height exceeds above values).

CAUTION

Appliance not accessible to the general public, install it in a

secured area, protected from easy access.

This unit, both indoor and outdoor, is suitable for

installation in a commercial and light industrial

environment.

NOTICE

This is a class A product. In a domestic environment this

product may cause radio interference in which case the

user may be required to take adequate measures.

12.1.2 Additional installation site requirements of the outdoor unit in cold climates

In heavy snowfall areas it is very important to select an installation

site where the snow will NOT affect the unit. If lateral snowfall is

possible, make sure that the heat exchanger coil is NOT affected by

the snow. If necessary, install a snow cover or shed and a pedestal.

INFORMATION

For instructions on how to install the snow cover, contact

your dealer.

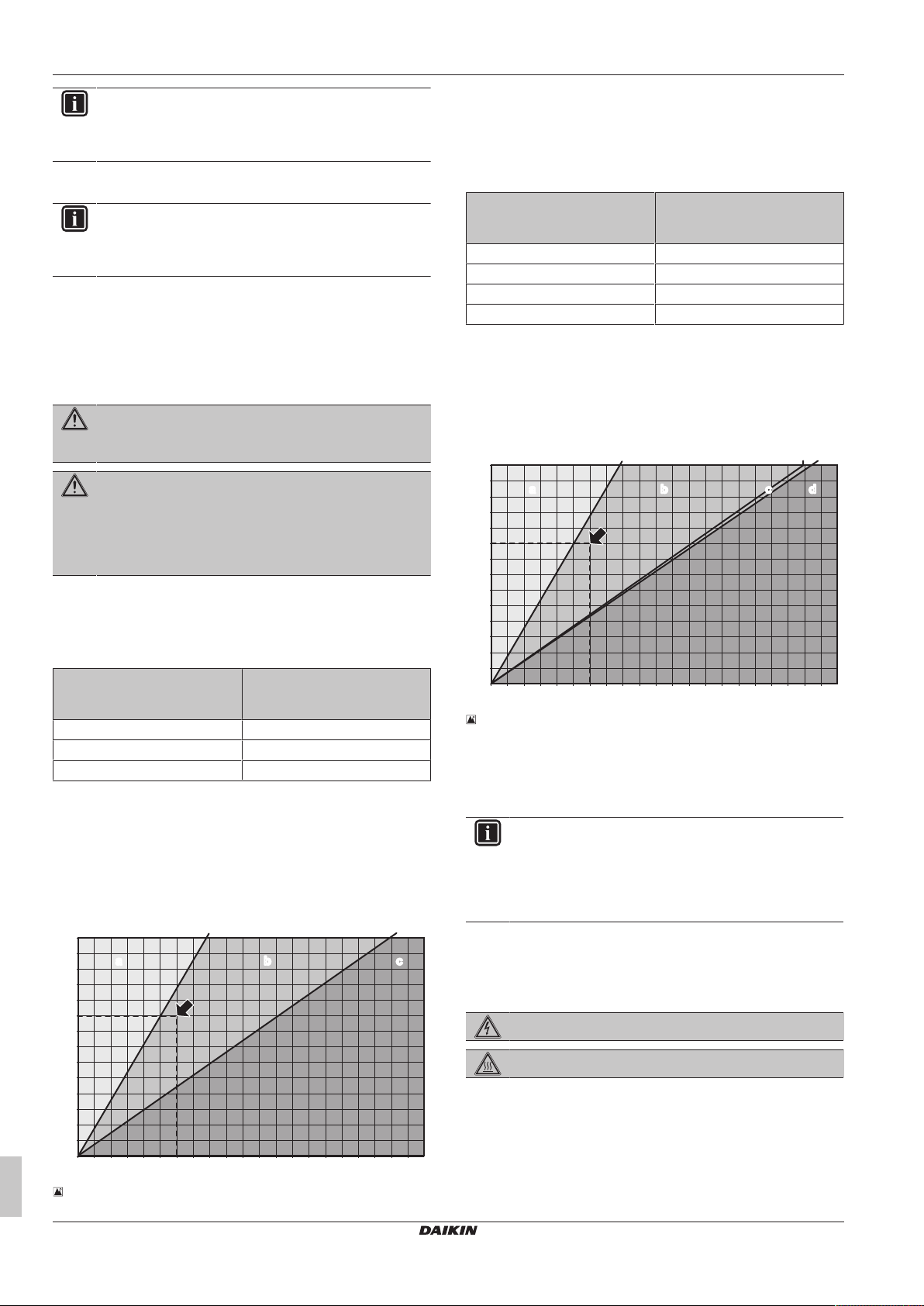

12.1.3 Additional installation site requirements for CO₂ refrigerant

NOTICE

Although it is recommended to install LRYEN10* and

LRNUN5* outdoors, in some cases it might be needed to

install them inside. In such cases, ALWAYS follow the

indoor installation site requirements for CO2 refrigerant.

12 Unit installation

12.1 Preparing the installation site

12.1.1 Installation site requirements of the outdoor unit

Mind the spacing guidelines. See figure 1 on the inside of the front

cover.

Description of text on figure 1:

Item Description

A Maintenance space

LRYEN10A7Y1+LRNUN5A7Y1

CO₂ Conveni-Pack outdoor unit and capacity up unit

4P605461-1B – 2020.08

WARNING

In case of mechanical ventilation, take care the ventilated

air is exhausted to the outdoor space and not into another

closed area.

Refrigerant basic characteristics

Refrigerant R744

RCL (refrigerant concentration limit) 0.072kg/m

QLMV (quantity limit with minimum ventilation) 0.074kg/m

QLAV (quantity limit with additional ventilation) 0.18kg/m

Toxicity limit 0.1kg/m

3

Safety class A1

Installation and operation manual

3

3

3

13

12 Unit installation

A (kg)

B (m³)

0

0

100 15050 200 250 300 350 450 550400 500 600 650 700 750 800 850 900 950 1000

5

10

15

20

25

30

35

40

45

50

55

60

65

70

c

b

a

QLMVQLAV

A (kg)

B (m³)

0

0

100 15050 200 250 300 350 450 550400 500 600 650 700 750 800 850 900 950 1000

5

10

15

20

25

30

35

40

45

50

55

60

65

70

dba

RCLQLAV

QLMV

c

INFORMATION

For more information regarding allowable refrigerant

charge and space volume calculations see the reference

guide of the indoor unit.

Appropriate measures

INFORMATION

Appropriate measures are field supply. Choose and install

all required appropriate measures in accordance with

EN378-3:2016.

▪ (natural or mechanical) ventilation

▪ safety shut-off valves

▪ safety alarm, in combination with a CO2 refrigerant leak detector (a

safety alarm alone is NOT considered an appropriate measure

where occupants are restricted in their movements)

▪ CO2 refrigerant leak detector

WARNING

Install the unit only in locations where the doors of the

occupied space are not tight fitting.

WARNING

When using safety shut-off valves, make sure to install

measures such as a bypassing piping with a pressure relief

valve (from liquid pipe to gas pipe). When the safety shutoff valves close and no measures are installed, increased

pressure may damage the liquid piping.

A Refrigerant charge

B Room volume

a 2 appropriate measures required

b 1 appropriate measure required

c No measure required

For occupancies on the lowest underground floor of the

building

If the total refrigerant charge

(kg) divided by the room

(a)

volume

(m3) is…

…the number of appropriate

measures must be at least…

<RCL 0

>RCL and ≤QLMV 1

>QLMV and <QLAV 2

>QLAV Value CANNOT be exceeded!

(a)

For occupied spaces with a floor area exceeding 250m2, use

250m2 as the floor area for determination of the room volume

(Example: even if the room area is 300m2 and the room height

is 2.5m, calculate the room volume as 250m2×2.5m=625m3)

Example: Total refrigerant change in the system is 45kg and room

volume is 300m3. 45/300=0.15, which is >RCL (0.072) and <QLAV

(0.18), therefore install at least 2 appropriate measures in the room.

To determine the minimum number of appropriate measures

For occupancies other than on the lowest underground floor of

the building

If the total refrigerant charge

(kg) divided by the room

(a)

volume

(m3) is…

<QLMV 0

>QLMV and <QLAV 1

>QLAV 2

(a)

For occupied spaces with a floor area exceeding 250m2, use

250m2 as the floor area for determination of the room volume

(Example: even if the room area is 300m2 and the room height

is 2.5m, calculate the room volume as 250m2×2.5m=625m3)

Example: Total refrigerant charge in the system is 45 kg and room

volume is 300 m3. 45/300=0.15, which is >QLMV (0.074) and

<QLAV (0.18), therefore install at least 1 appropriate measure in the

room.

…the number of appropriate

measures must be at least…

12‒2 Example graph for calculation

A Refrigerant charge limit

B Room volume

a Installation is not allowed

b 2 appropriate measures required

c 1 appropriate measure required

d No measure required

INFORMATION

Even if there is no refrigerating system on the lowest floor,

where the largest system charge (kg) in the building

divided by total volume of the lowest floor (m3) exceed the

value for QLMV, provide a mechanical ventilation in

accordance with EN 378-3:2016.

12.2 Opening and closing the unit

12.2.1 To open the outdoor unit

DANGER: RISK OF ELECTROCUTION

12‒1 Example graph for calculation

Installation and operation manual

14

DANGER: RISK OF BURNING/SCALDING

To gain access to the unit, front plates need to be opened as follows:

1 Remove the screws of the small front plates.

CO₂ Conveni-Pack outdoor unit and capacity up unit

LRYEN10A7Y1+LRNUN5A7Y1

4P605461-1B – 2020.08

a b

7×

2×

a Outdoor unit

a b

4×

12

×

1

2

4

3

2×

1×

1

2

1×

b

a a

12

×

4×

1

2

4

3

2×

1×

a a

2

1

2×

b

b Capacity up unit

2 Remove the front panels.

12 Unit installation

12.2.2 To open the electrical component box of the outdoor unit

NOTICE

Do NOT apply excessive force when opening the

electronic component box cover. Excessive force can

deform the cover, resulting in entering of water to cause

equipment failure.

Electrical component boxes of the outdoor unit

The electrical component boxes behind the left, middle and right

front panel are all opened in the same way. The main switchbox is

installed behind the middle panel.

Electrical component box of the capacity up unit

a Outdoor unit

b Capacity up unit

3 Remove the small front plates.

a Outdoor unit

b Capacity up unit

Once the front plates open, the electrical component box can be

accessed. See "12.2.2To open the electrical component box of the

outdoor unit"[415].

For service purposes, the pushbuttons on the main PCB (located

behind the middle front panel) need to be accessed. To access

these pushbuttons, the electrical component box cover does not

need to be opened. See "16.1.2 To access the field setting

components"[433].

12.2.3 To close the outdoor unit

NOTICE

When closing the outdoor unit cover, make sure that the

tightening torque does NOT exceed 4.1N•m.

1 Reinstall the small front plates.

LRYEN10A7Y1+LRNUN5A7Y1

CO₂ Conveni-Pack outdoor unit and capacity up unit

4P605461-1B – 2020.08

Installation and operation manual

15

12 Unit installation

a b

12×12

×

4×

a b

2×

7×

631

729

765

≥765

BC

A

497

A

B

631

729

765

≥765

(mm)

1 2

a Outdoor unit

b Capacity up unit

2 Reinstall the front panels.

a Outdoor unit

b Capacity up unit

3 Attach the small front plates to the front panels.

Outdoor unit

a Outdoor unit

b Capacity up unit

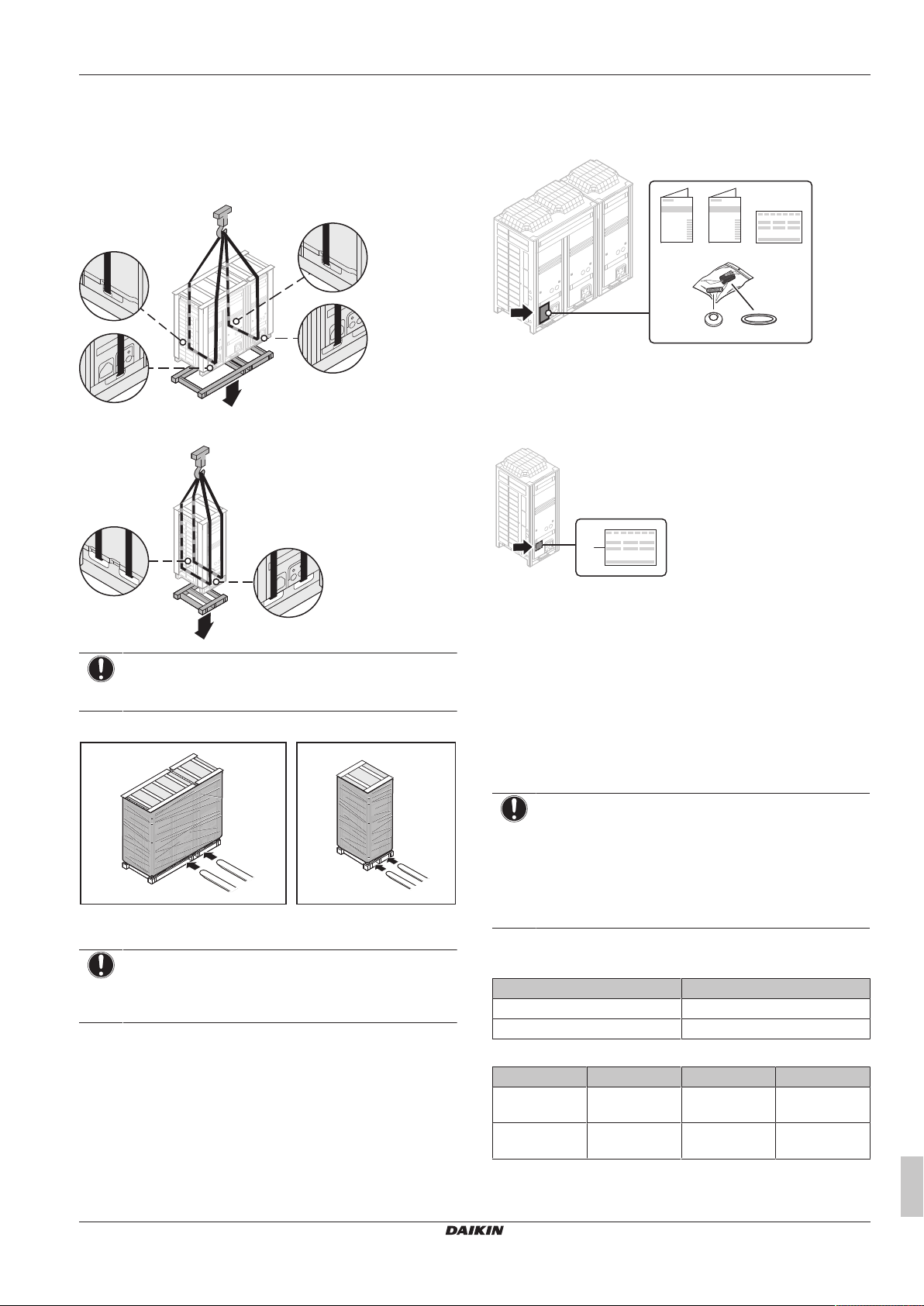

12.3 Mounting the outdoor unit

12.3.1 To provide the installation structure

Make sure the unit is installed level on a sufficiently strong base to

prevent vibration and noise.

NOTICE

▪ When the installation height of the unit needs to be

increased, do NOT use stands to only support the

corners.

▪ Stands under the unit must be at least 100mm wide.

NOTICE

The height of the foundation must at least be 150mm from

the floor. In heavy snowfall areas, this height should be

increased up to the average expected snow level,

depending on the installation place and condition.

Capacity up unit

▪ The preferred installation is on a solid longitudinal foundation

(steel beam frame or concrete). The foundation must be larger

than the grey marked area.

Installation and operation manual

16

Minimum foundation

1 LRYEN10*

2 LRNUN5*

Unit A B C

LRYEN10* 1940 1102 193

LRNUN5* 635 497 —

CO₂ Conveni-Pack outdoor unit and capacity up unit

LRYEN10A7Y1+LRNUN5A7Y1

4P605461-1B – 2020.08

▪ Fasten the unit in place using four foundation bolts M12. It is best

20 mm

a

a

b

8×8×

a b

t

Ø

to screw in the foundation bolts until their length remains 20mm

above the foundation surface.

NOTICE

▪ Prepare a water drainage channel around the

foundation to drain waste water from around the unit.

When the outdoor temperatures are negative, the

drained water from the outdoor unit will freeze up. If the

water drainage is not taken care of, the area around

the unit might be very slippery.

▪ When installed in a corrosive environment, use a nut

with plastic washer (a) to protect the nut tightening part

from rust.

13 Piping installation

a LRYEN10*

b LRNUN5*

3 If transported by crane, remove the slings.

12.3.3 To provide drainage

Make sure that condensation water can be evacuated properly.

13 Piping installation

13.1 Preparing refrigerant piping

12.3.2 To install the outdoor unit

1 Transport the unit by crane or forklift and put it onto the

installation structure.

2 Fix the unit to the installation structure.

a LRYEN10*

b LRNUN5*

13.1.1 Refrigerant piping requirements

WARNING

The unit is partially factory charged with refrigerant R744.

NOTICE

Refrigerant R744 requires strict cautions for keeping the

system clean and dry. Foreign materials (including mineral

oils or moisture) should be prevented from getting mixed

into the system.

NOTICE

The piping and other pressure-containing parts shall be

suitable for refrigerant and oil. Use K65 copper-iron alloy

tube system for high-pressure applications with a working

pressure of 120 bar at the air conditioner side and 90 bar

at the refrigeration side.

NOTICE

Do not use standard hoses and manometers. Use ONLY

equipment that is designed to use with R744.

▪ Foreign materials inside pipes (including oils for fabrication) must

be ≤30mg/10m.

13.1.2 Refrigerant piping material

▪ Piping temper grade and thickness:

Piping refrigeration unit

Piping type Outer

diameter

Liquid piping 12.7mm

Gas piping 15.9mm

(a)

Depending on the applicable legislation and the maximum

working pressure of the unit (see "PS High" on the unit name

plate), larger piping thickness might be required.

Piping air conditioning unit

(Ø)

(1/2")

(5/8")

Temper

grade

R420

(with heat

treatment)

R300

(drawn)

Thickness

(a)

(t)

≥0.85mm

≥1.05mm

LRYEN10A7Y1+LRNUN5A7Y1

CO₂ Conveni-Pack outdoor unit and capacity up unit

4P605461-1B – 2020.08

Installation and operation manual

17

13 Piping installation

t

Ø

a

c

b

a

b

a

b

a

b

Piping type Outer

diameter

Temper

grade

Thickness

(a)

(t)

(Ø)

Liquid piping 15.9mm

(5/8")

Gas piping 19.1mm

(3/4")

(a)

Depending on the applicable legislation and the maximum

working pressure of the unit (see "PS High" on the unit name

plate), larger piping thickness might be required.

R300

(drawn)

R300

(drawn)

≥1.05mm

≥1.30mm

13.1.3 Refrigerant piping length and height difference

Requirements and limits

The piping lengths and height differences must comply with the

following requirements. For an example, see "13.1.4 To select the

piping size"[418].

Requirement Limit

LRYEN10* LRYEN10* +

LRNUN5*

Maximum total piping length

Examples:

(a)

≤Limit

(a)

(a)

(a)

≤Limit

≤Limit

≤Limit

▪ A+B+C+D+(E or F)

▪ a+c+d+(e or f)

▪ A2+B2+(C2 or D2)

▪ a2+b2+(c2 or d2)

Piping length between

LRYEN10* and LRNUN5*

Maximum actual piping length

▪ Example refrigeration side:

▪ C+D+(E or F)

▪ c+d+(e or f)

(a)

(a)

▪ c+g

▪ j

▪ Example air conditioner side:

▪ B2+(C2 or D2)

▪ b2+(c2 or d2)

Maximum

height

difference

between

outdoor unit

and indoor

unit

(a)

(a)

Outdoor higher

than indoor

Example: H2,

H4≤Limit

Outdoor unit

lower than

indoor unit

Example: H2,

H4≤Limit

Maximum height difference

between blower coil and

showcase

▪ Example: H3≤Limit

Refrigeration side: 130m

Air conditioning side: 130m

Not specified, but piping must be

horizontal

Refrigeration side: 50m

Air conditioning side: 30m

35m

"To install an oil trap"[418]

10m

"To install riser piping"[418]

5m

Requirement Limit

LRYEN10* LRYEN10* +

LRNUN5*

Maximum height difference

0.5m

between air conditioners

▪ Example: H1≤Limit

(a)

Whichever is longer

To install an oil trap

If the outdoor unit is installed higher than the indoor unit, install an oil

trap in the gas piping every 5meter. Oil traps will make the oil return

more easily.

a Showcase

b Height difference=5m

c Trap

The refrigerant suction piping must always run down:

a Outdoor unit or indoor unit

b Flow direction in refrigerant suction piping

To install riser piping

If the outdoor unit is installed lower than the indoor unit, install the

riser piping close to the indoor unit. When the compressor of the

outdoor unit starts, a correct installed riser piping will prevent liquid

from flowing back to the outdoor unit.

a Outdoor unit

b Indoor unit

13.1.4 To select the piping size

Determine the proper size using the following tables and reference

figure (only for indication).

Installation and operation manual

18

c Riser piping up to indoor unit.

LRYEN10A7Y1+LRNUN5A7Y1

CO₂ Conveni-Pack outdoor unit and capacity up unit

4P605461-1B – 2020.08

2

A A2

B2 C2

B

CD

G

J

j

f

F

E2

D2

E

H4

H3

H1

H1

H2

e d

g

c a b2

a2

e2

d2

c2

1

3

5

4

4

5

5

3

H4

1 Capacity up unit (LRNUN5*)

e

d

b

c

a

2 Outdoor unit (LRYEN10*)

3 Indoor unit (showcase)

4 Indoor unit (blower coil)

5 Indoor unit (air conditioning)

A~J Liquid piping (side showcases and blower coils)

A2~E2 Liquid piping (side air conditioning)

a~g Gas piping (side showcases and blower coils)

a2~e2 Gas piping (side air conditioning)

H1~H4 Height difference

In case the required pipe sizes (inch sizes) are not available, it is

also allowed to use other diameters (mm sizes), taken the following

into account:

▪ Select the pipe size nearest to the required size.

▪ Use the suitable adapters for the change-over from inch to mm

pipes (field supply).

▪ The additional refrigerant calculation has to be adjusted as

mentioned in the following chapters:

▪ For outdoor unit without capacity up unit: "15.2 To determine

additional refrigerant amount"[432].

▪ For outdoor unit with capacity up unit: see "15.2To determine

additional refrigerant amount" [432] but additional refrigerant is

not needed because the capacity up unit is already precharged.

Piping size between outdoor unit and first branch

When the equivalent pipe length between outdoor unit and the

furthest indoor unit is 90m or more (b+d), the size of the main gas

pipe (b) must be increased (size-up). If the recommended gas pipe

(size-up) is not available, you must use the standard size (which

might result in a small capacity decrease).

13 Piping installation

(a)

For refrigeration piping (A, B, a) and for air conditioner piping (A2,

a2)

Piping size between branching areas or between first and second branch

Indoor unit capacity

index (kW)

Refrigeration side: liquid pipe

x≤10.0 Ø9.5×t0.65 (K65)

10.0<x Ø12.7×t0.85 (K65)

Refrigeration side: gas pipe

x≤6.5 Ø9.5×t0.65 (K65)

6.5<x≤14.0 Ø12.7×t0.85 (K65)

14.0<x Ø15.9×t1.05 (K65)

Air conditioner side: liquid pipe

— Ø12.7×t0.85 (K65)

Air conditioner side: gas pipe

— Ø15.9×t1.05 (K65)

(a)

Piping between branching areas (C, D, c, d)

(b)

Piping from first branch to second branch (B2, b2)

Piping outer diameter size (mm)

(a)

(a)

(b)

(b)

a Outdoor unit

b Main gas pipe

c First refrigerant branch

d Piping between indoor unit and refrigerant branch

e Furthest indoor unit

System side Piping outer diameter size

Refrigeration Ø12.7×t0.85

Air conditioner Ø15.9×t1.05

LRYEN10A7Y1+LRNUN5A7Y1

CO₂ Conveni-Pack outdoor unit and capacity up unit

4P605461-1B – 2020.08

(a)

(mm)

Liquid side Gas side

Ø15.9×t1.05

(K65)

(K65)

(K65)

Ø19.1×t1.3

(K65)

Piping size from branch to indoor unit

Same size as C, D, c, d.

If piping sizes of the indoor units are different, connect a reducer

close to the indoor unit to align piping sizes.

Piping outer diameter size (mm)

Gas pipe Liquid pipe

Refrigeration side

Air conditioner side

(a)

(b)

Ø12.7×t0.85 (K65) Ø9.5×t0.65 (K65)

(a)

Piping from branch to indoor unit (E, F, G, J, e, f, g, j)

(b)

Piping from branch to indoor unit (C2, D2, E2; c2; d2; e2)

Installation and operation manual

19

13 Piping installation

2

A

C

A

A

B

C

C

1

5

3

4

A

B B

A

a a

b b

B

1 2 3

Stop valve size

Refrigeration side

Air conditioner

(a)

side

(a)

Reducers (field supply) may be required to connect the piping.

(a)

Liquid side Gas side

Ø15.9 Ø19.1

Ø15.9 Ø15.9

13.1.5 To select refrigerant branch kits

Always use K65 T-joints with a suitable design pressure for

refrigerant branching.

13.1.6 To select expansion valves for refrigeration

The system controls liquid temperature and liquid pressure. Select

the expansion valves as indicated according to nominal conditions

and design pressure.

Nominal conditions

The following nominal conditions are valid for the liquid piping at the

outlet of the outdoor unit. They are based on an ambient

temperature of 32°C and an evaporate temperature of -10°C.

If showcases or blower coils are connected directly

Liquid temperature 23°C

Liquid pressure 6.8MPaG

Refrigerant condition Subcooled liquid

If capacity up unit is connected between outdoor unit and

showcases or blower coils

Liquid temperature (at outlet of capacity up

unit)

Liquid pressure (at outlet of capacity up unit) 6.8MPaG

Refrigerant condition (at outlet of capacity up

unit)

(optional) If a pressure reduction kit is connected between

outdoor unit and showcases or blower coils

Liquid temperature (at outlet of pressure

reduction kit)

Liquid pressure (at outlet of pressure

reduction kit)

Refrigerant condition Subcooled liquid

Design pressure

Make sure all parts comply to the following design pressure:

3°C

Subcooled liquid

3°C

4.8~5.6MPaG

5 Indoor unit (air conditioning)

A Liquid piping (refrigeration side): 90bar

B Gas piping (refrigeration side): depends on design

pressure of showcase and blower coil. For example,

60bar

C Gas and liquid piping (air conditioning side): 120bar

13.2 Using stop valves and service ports

For more information about the card on the unit, see "Card about

stop valves and service ports"[412].

WARNING

When stop valves are closed during service, the pressure

of the closed circuit will increase due to high ambient

temperature. Make sure the pressure is kept below the

design pressure.

13.2.1 To handle the stop valve

Take the following guidelines into account:

▪ Make sure to keep all stop valves open during operation.

▪ The gas and liquid stop valves are factory closed.

▪ Do NOT apply excessive force to the stop valve. Doing so may

break the valve body.

Open versus closed

All stop valves are of the backseat type and do not have a valve core

for the charge port.

A Fully closed (connected between charge port and indoor

unit side)

B Fully open (connected between outdoor unit and indoor

unit)

a To outdoor unit

b To indoor unit

Installation and operation manual

20

1 Capacity up unit (LRNUN5*)

2 Outdoor unit (LRYEN10*)

3 Indoor unit (showcase)

4 Indoor unit (blower coil)

To open the stop valve

1 Remove the valve cap with 2 spanners.

2 Loosen the packing holder by rotating counterclockwise from

1/8 to 1/2 turn.

3 Turn the valve stem counterclockwise until it stops.

To close the stop valve

1 Turn the valve stem clockwise until it stops. Tighten with the

appropriate tightening torque.

LRYEN10A7Y1+LRNUN5A7Y1

CO₂ Conveni-Pack outdoor unit and capacity up unit

4P605461-1B – 2020.08

13 Piping installation

a

b

a

b

c

A B

a

a

b

2 Tighten the packing holder.

3 Before mounting the valve cap, insert a new copper packing.

4 Apply screw lock agent or silicon sealant to the screw thread

when mounting the valve cap. If not, moisture and condensing

water may penetrate and freeze between the screw thread. As

a result, refrigerant may leak and the valve cap may break.

a Apply screw lock agent

b Do NOT apply screw lock agent

5 Tighten the valve cap.

Also see "13.2.3Tightening torques"[421].

To open the service port

1 Remove the service port cap with 2 spanners and remove the

copper packing.

2 Connect the charge port to the service port.

3 Remove the valve cap with 2 spanners.

4 Insert a hexagonal wrench (4mm) and rotate counterclockwise

until it the end.

To close the service port

1 Insert a hexagonal wrench (4mm) and rotate clockwise until the

end.

2 Tighten the valve cap.

3 Remove the copper packing of the service port cap.

13.2.2 To handle the service port

▪ Always use a charge hose equipped with a valve depressor pin,

since the service port is a Schrader type valve.

▪ After handling the service port, make sure to tighten the service

port cover securely. For the tightening torque, refer to the table

below.

▪ Check for refrigerant leaks after tightening the service port cover.

The figure below shows the name of each part required in handling

the stop valve.

a Service port cap

b Copper packing

c Valve cap

Open versus closed

All service ports are of the backseat type and do not have a valve

core.

a Copper packing

4 Add a new copper packing and mount the service port cap.

Apply screw lock agent or silicon sealant to the screw thread

when mounting the service port cap. If not, moisture and

condensing water may penetrate and freeze between the screw

thread. As a result, refrigerant may leak and the valve cap may

break.

a New copper packing

b Screw lock agent or silicon sealant only on screw thread

5 Tighten the service port cap.

Also see "13.2.3Tightening torques"[421].

13.2.3 Tightening torques

Stop valve

size (mm)

LRYEN10A7Y1+LRNUN5A7Y1

CO₂ Conveni-Pack outdoor unit and capacity up unit

4P605461-1B – 2020.08

A Fully closed

B Fully open

Ø15.9 38.2~46.6 7.4~9.0 13.2~16.0 14.2~17.2

Ø19.1

Tightening torque N•m (turn clockwise to close)

Shaft

Valve cap Packing

pressure

Valve stem Valve core

cap

Installation and operation manual

21

13 Piping installation

1 2 3

a

b

c

d

a

b

A

B

a

b

13.3 Connecting the refrigerant piping

DANGER: RISK OF BURNING/SCALDING

13.3.1 To remove the spun pipes

WARNING

Any gas or oil remaining inside the stop valve may blow off

the spun piping.

If these instructions are NOT followed correctly it may

result in property damage or personal injury, which may be

serious depending on the circumstances.

1 Open the stop valve cap, unlock the valve and check if the

valve is closed.

1 Remove the valve cap with 2 spanners

(counterclockwise).

2 Loosen the packing holder by rotating counterclockwise

from 1/8 to 1/2 turn.

3 Close the valve (clockwise).

2 Open the service port cap slowly and check that there is no

pressure left.

3 Incrementally loosen the valve core to ensure that there is no

pressure left.

4 Cut off the lower part of the gas and liquid stop valve pipes

along the black line. Use only appropriate tools, such as a pipe

cutter or pair of nippers.

13.3.2 To connect the refrigerant piping to the outdoor unit

You can route refrigerant piping to the front or side of the unit.

For the outdoor unit:

a Left side connection

b Front connection (refrigeration)

c Front connection (air conditioner)

d Right side connection

For the capacity up unit:

a Left side connection

b Front connection (refrigeration)

NOTICE

Precautions when making knockout holes:

▪ Avoid damaging the casing.

▪ After making the knockout holes, we recommend you

remove the burrs and paint the edges and areas

around the edges using repair paint to prevent rusting.

▪ When passing electrical wiring through the knockout

holes, wrap the wiring with protective tape to prevent

damage.

Front connection

WARNING

1 Remove the knockout and connect the piping to the outdoor

unit.

Never remove the spun piping by brazing.

Any gas or oil remaining inside the stop valve may blow off

the spun piping.

INFORMATION

If the stop valve was initially open, a small amount of

refrigerant or oil may leak out.

5 Wait until all oil has dripped out before continuing with the

connection of the field piping in case the recovery was not

complete.

You can now connect the ingoing and outgoing refrigerant piping.

Installation and operation manual

22

2 If applicable, remove the knockout and connect the piping to the

A Stop valve (gas – refrigeration)

B Stop valve (liquid – refrigeration)

a Gas piping

b Liquid piping

capacity up unit.

LRYEN10A7Y1+LRNUN5A7Y1

CO₂ Conveni-Pack outdoor unit and capacity up unit

4P605461-1B – 2020.08

13 Piping installation

4×

a

b

c

b

a

A

B

a

b

a

b

c

a

b

c

a

a

b

d

Side connection

1 Remove the knockout on the bottom plate.

a Drill (Ø6mm)

b Knockout plate

c Drill here

2 Connect the piping to the outdoor unit.

A Stop valve (gas – refrigeration)

B Stop valve (liquid – refrigeration)

a Gas piping

b Liquid piping

3 If applicable, connect the piping to the capacity up unit.

13.3.3 Guidelines to connect T-joints

INFORMATION

Piping joints and fittings shall comply with the requirements

of EN14276-2.

CAUTION

ALWAYS use K65 T-joints for refrigerant branching.

K65 T-joints are field supplied.

Liquid piping

Always branch horizontally when connecting the branch piping.

To prevent uneven refrigerant flow, always branch downwards when

using a header.

a Coming from the indoor units

b Going to the outdoor units

c Main refrigerant pipe

d Slanting downwards

NOTICE

Where joints are used on piping, avoid damage caused by

freezing or vibration.

13.3.4 Guidelines to install a dryer

NOTICE

Do NOT operate the unit without a dryer installed on the

liquid pipe of the refrigeration side. Possible

consequence: Without dryer, operating the unit may

cause a choked expansion valve, hydrolysis of the

refrigerant oil and copper plating of the compressor.

Install a dryer on the liquid piping of the refrigeration side:

Dryer type Drops of R744 water capacity at 60°C: 200

Recommended dryer for use with transcritical

CO2:

For LRYEN10*: CO-085-S (by Sporlan)

Where/how Install the dryer as near as possible to the

outdoor unit.

(a)

Install the dryer on the liquid pipe of the

refrigeration side.

Install the dryer horizontally.

When brazing Follow the brazing instructions in the dryer

manual.

Remove the dryer cap immediately before

brazing (to prevent absorption of moisture).

If dryer paint burnt during brazing, repair it. For

repair paint details, contact the manufacturer.

Flow direction If the dryer specifies a flow direction, install

accordingly.

(a)

Follow the instructions in the installation manual of the dryer.

13.3.5 Guidelines to install safety valves

When installing a safety valve, always keep the design pressure of

the circuit in mind. See "5.2Design pressure"[48].

NOTICE

The design pressure of high pressure side of the

connected refrigeration parts MUST be 9MPa (90bar).

NOTICE

If the design pressure of the lower pressure side of

refrigeration parts is different from 90 bar (for example:

60 bar), a safety valve MUST be installed on the field

a Coming from the outdoor units

b Going to the indoor units

Gas piping

Always branch horizontally when connecting the branch piping.

piping according to this design pressure. It is NOT possible

to connect refrigeration parts with design pressure below

60bar.

To prevent refrigerant oil flowing into the indoor units, always set the

branch piping above the main piping.

LRYEN10A7Y1+LRNUN5A7Y1

CO₂ Conveni-Pack outdoor unit and capacity up unit

4P605461-1B – 2020.08

Installation and operation manual

23

13 Piping installation

a

N2

R744

a

b