DAIKIN ERLQ018BAVJU, ERLQ024BAVJU, ERLQ030BAVJU INSTALLATION MANUAL

INSTALLATION MANUAL

Outdoor unit for air to water heat pump

ERLQ018BAVJU

ERLQ024BAVJU

ERLQ030BAVJU

Installation manual

Outdoor unit for air to water heat pump

Manuel d’installation

Unité extérieure pour pompe à chaleur air à eau

Manual de instalación

Unidad exterior para bomba de calor de aire-agua

English

Français

Español

ERLQ018BAVJU

ERLQ024BAVJU

ERLQ030BAVJU

Outdoor unit for air to water heat pump

Installation manual

C

ONTENTS

1. Definitions.................................................................................. 1

2. Introduction................................................................................ 2

2.1. General information........................................................................ 2

2.2. Model identification ........................................................................ 2

2.3. Combination and options ............................................................... 2

2.4. Operation range ............................................................................. 2

In cooling mode.............................................................................. 2

In heating mode ............................................................................. 2

In domestic water heating mode .................................................... 2

3. Accessories ............................................................................... 3

4. General safety precautions........................................................ 3

5. Overview of unit......................................................................... 3

5.1. Opening the unit............................................................................. 3

5.2. Main components........................................................................... 3

Unit................................................................................................. 3

Switchbox....................................................................................... 4

5.3. Functional diagram......................................................................... 4

6. Precautions on installation location ........................................... 4

6.1. General precautions....................................................................... 4

6.2. Weather dependent precautions.................................................... 5

6.3. Selecting a location in cold climates .............................................. 5

6.4. Installing near a wall or obstacle.................................................... 5

Wall facing one side....................................................................... 5

Walls facing two sides.................................................................... 5

Walls facing three sides ................................................................. 6

6.5. Additional precautions.................................................................... 6

7. Installation of the unit................................................................. 6

7.1. Unpacking the unit ......................................................................... 6

7.2. Inspection....................................................................................... 6

7.3. Handling the unit ............................................................................ 6

7.4. Installation instructions................................................................... 6

Mounting the outdoor unit .............................................................. 6

Outdoor installation drawing........................................................... 6

Drain work...................................................................................... 7

8. Refrigerant pipe size and allowable pipe length........................ 7

8.1. Refrigerant piping material............................................................. 7

8.2. Piping material selection ................................................................ 7

8.3. Refrigerant piping specifications .................................................... 7

9. Precautions on refrigerant piping............................................... 7

9.1. Guidelines for brazing .................................................................... 7

9.2. Guidelines for flare connection....................................................... 8

9.3. Guidelines for handling the stop valve ........................................... 8

Cautions for handling the stop valve.............................................. 8

How to use the stop valve.............................................................. 8

Cautions for handling the stop valve cover .................................... 9

Cautions for handling the service port ........................................... 9

Tightening torques ......................................................................... 9

10. Piping connection work.............................................................. 9

10.1. Preventing foreign objects from entering........................................ 9

10.2. Leak test and vacuum drying ......................................................... 9

General guidelines ......................................................................... 9

Setup.............................................................................................. 9

Leak test ...................................................................................... 10

Vacuum drying ............................................................................. 10

10.3. Pipe insulation.............................................................................. 10

Selection of heat insulation materials .......................................... 10

11. Charging refrigerant................................................................. 10

11.1. Additional refrigerant charging ..................................................... 11

11.2. Precautions when adding R410A................................................. 11

11.3. Charging amount ......................................................................... 11

12. Pump down operation.............................................................. 11

12.1. Procedure .................................................................................... 11

13. Electric wiring work..................................................................11

13.1. Switch box component list............................................................ 12

13.2. Field wiring................................................................................... 12

Procedure .................................................................................... 12

Notes to observe.......................................................................... 13

14. Start-up and configuration ....................................................... 14

14.1. Pre-operation checks ................................................................... 14

age

P

15. Test operation ..........................................................................14

15.1. Test run recommendations........................................................... 14

15.2. Maintenance and testing logbook ................................................ 14

15.3. Test run ........................................................................................ 15

16. Maintenance and service.........................................................15

16.1. Service mode operation ............................................................... 15

17. Troubleshooting........................................................................ 15

18. Disposal requirements .............................................................15

19. Unit specifications....................................................................15

19.1. Technical specifications ............................................................... 15

19.2. Electrical specifications................................................................ 15

Thank you for purchasing this product.

The original instructions are written in English. All other languages

are translations of the original instructions.

CAREFULLY READ THESE INSTRUCTIONS BEFORE

INSTALLATION. THEY WILL TELL YOU HOW TO INSTALL

AND HOW TO CONFIGURE THE UNIT PROPERLY.

KEEP THIS MANUAL IN A HANDY PLACE FOR FUTURE

REFERENCE.

1. D

EFINITIONS

Installation manual:

Instruction manual specified for a certain product or application,

explaining how to install, configure and maintain it.

Operation manual:

Instruction manual specified for a certain product or application,

explaining how to operate it.

Danger:

Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Warning:

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Caution:

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. It may also be used to alert against

unsafe practices.

Note:

Indicates situations that may result in equipment or property-damage

accidents only.

Dealer:

Sales distributor for products as per the subject of this manual.

Installer:

Technical skilled person who is qualified to install products as per the

subject of this manual.

Service agent:

Qualified person who can perform or coordinate the required service

to the unit.

Legislation:

All international, European, national and local directives, laws,

regulations and/or codes which are relevant and applicable for a

certain product or domain.

Installation manual

1

Outdoor unit for air to water heat pump

ERLQ018~030BAVJU

4PW62590-1 – 07.2010

Accessories:

59

(15)77(25)

122

(50)

5

(–15)

77

(25)

°F DB

(°C DB)

°F

(°C)

A

B

50

(10)

86

(30)

Equipment which is delivered with the unit and which needs to be

installed according to instructions in the documentation.

Optional equipment:

Equipment which can optionally be combined to the products as per

the subject of this manual.

Field supply:

Equipment which needs to be installed according to instructions in

this manual, but which are not supplied by Daikin.

2. I

NTRODUCTION

2.4. Operation range

In cooling mode

°F DB

(°C DB)

A

109

(43)

This manual describes the procedures for handling, installing and

connecting all ERLQ018~030BAVJU units. This manual has been

prepared to ensure adequate maintenance of the unit, and it will

provide help if problems occur.

NOTE

The installation of the indoor unit(s) is described in the

indoor unit installation manual.

2.1. General information

The outdoor units are intended for household heating and cooling.

2.2. Model identification

E R L Q 030 BA VJU

Voltage supply

Series

Capacity Class

Refrigerant R410A

Low ambient type

Outdoor unit

Model produced in Europe

2.3. Combination and options

The outdoor units should be combined with one of the following

indoor units:

■

EKHBH030*VJU: heating only

■

EKHBX030*VJU: heating and cooling

Possible options are:

■

EKHWS050+080*VJU: domestic hot water tank

■

EKSOL**VJU: solar kit

50

(10)

41

(5)

A

Outdoor temperature

B

Leaving evaporator water temperature

Pull down area

72

(22)

In heating mode

A

Outdoor temperature

B

Leaving condensor water temperature

Only backup heater operation (no outdoor unit operation)

In domestic water heating mode

122

(50)

B

°F

(°C)

ERLQ018~030BAVJU

Outdoor unit for air to water heat pump

4PW62590-1 – 07.2010

°F DB

(°C DB)

95

(35)

77

(25)

41

(5)

(–15)

A

B

A

5

113

122

77

(25)

Outdoor temperature

Domestic hot water tank water temperature

Only booster heater operation

(45)

(50)

131

(55)

B

176

°F

(80)

(°C)

Installation manual

2

3. A

CCESSORIES

5. O

VERVIEW OF UNIT

Accessories supplied with this unit:

Installation manual 1x

4. G

ENERAL SAFETY PRECAUTIONS

All activities described in this manual shall be carried out by an

installer.

Be sure to wear adequate personal protection equipment (protection

gloves, safety glasses, …) when performing installation, maintenance

or service to the unit.

If not sure of installation procedures or operation of the unit, always

contact your local dealer for advice and information.

Improper installation or attachment of equipment or accessories

could result in electric shock, short-circuit, leaks, fire or other damage

to the equipment. Be sure only to use accessories and optional

equipment made by Daikin which are specially designed for use with

the products as of subject in this manual and have them installed by

an installer.

DANGER: ELECTRICAL SHOCK

Switch off all power supply before removing the switchbox

service panel or before making any connections or

touching electrical parts.

To avoid electric shock, be sure to disconnect the power

supply 1 minute or more before servicing the electrical

parts. Even after 1 minute, always measure the voltage at

the terminals of main circuit capacitors or electrical parts

and, before touching, be sure that those voltages are

50 V DC or less.

When service panels are removed, live parts can easily be

touched by accident. Never leave the unit unattended

during installation or servicing when the service panel is

removed.

DANGER: DO NOT TOUCH PIPING AND INTERNAL

PA RT S

Do not touch the refrigerant piping, water piping or internal

parts during and immediately after operation. The piping

and internal parts may be hot or cold depending on the

working condition of the unit.

Your hand may suffer burns or frostbite if you touch the

piping or internal parts. To avoid injury, give the piping and

internal parts time to return to normal temperature or, if

you must touch them, be sure to wear protective gloves.

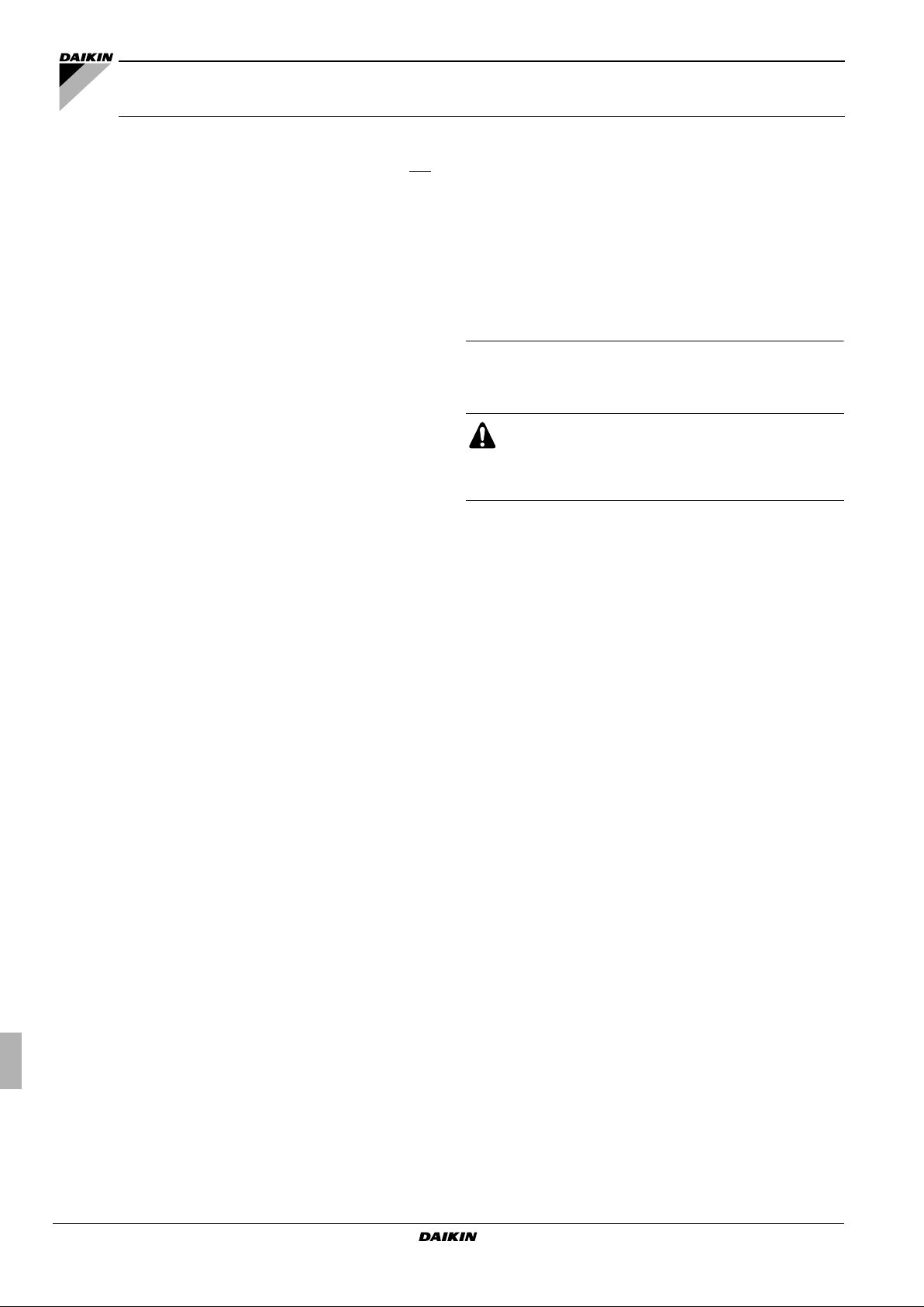

5.1. Opening the unit

1

Cable cover

2

Service panel

3

Stop valve cover

DANGER: ELECTRICAL SHOCK

See "4. General safety precautions" on page 3.

DANGER: DO NOT TOUCH PIPING AND INTERNAL

PA RT S

See "4. General safety precautions" on page 3.

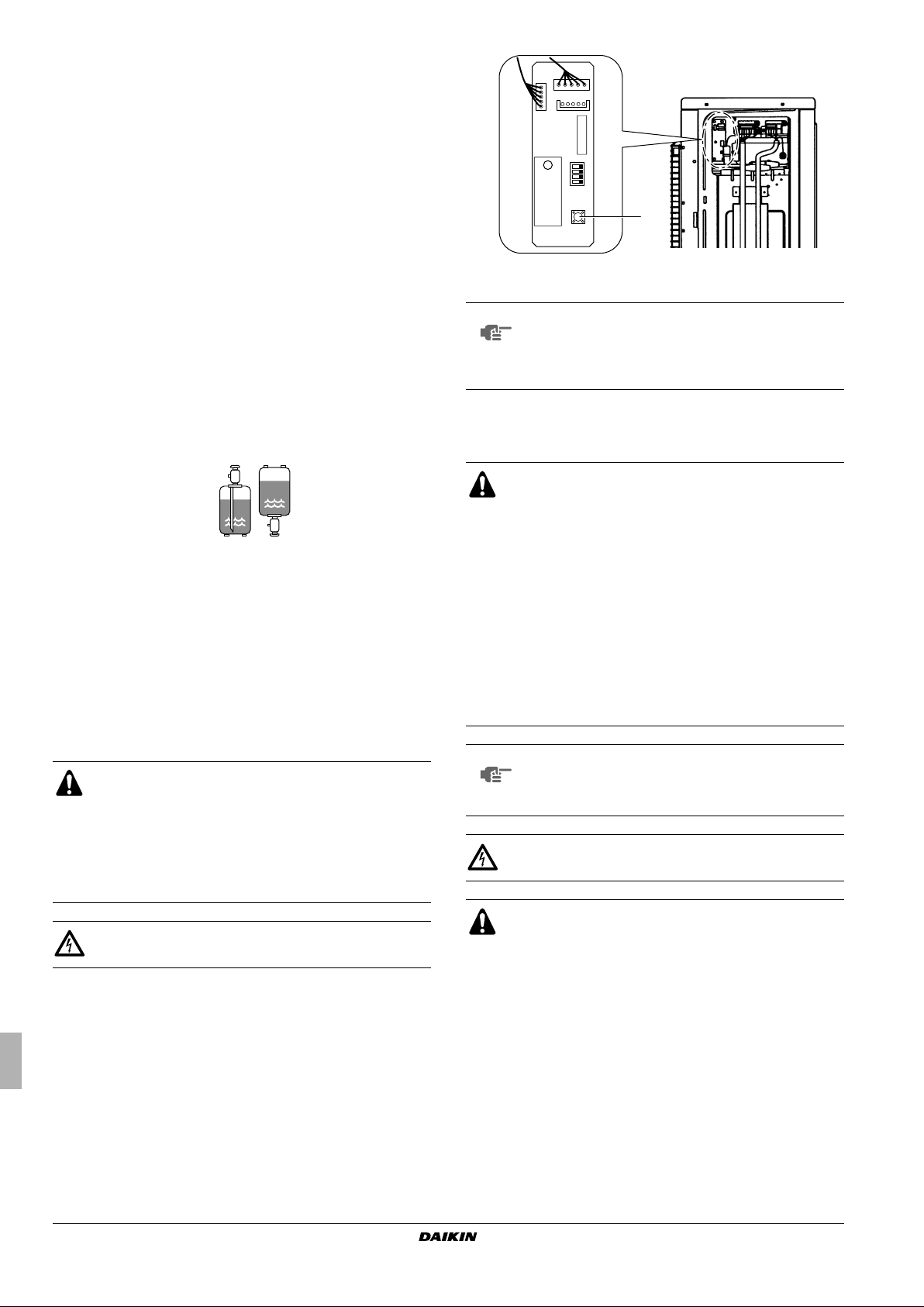

5.2. Main components

Unit

1

23

2 31

6x

Installation manual

3

1

Heat exchanger

2

Fan

3

Electrical component box

4

4-way valve

5

Expansion valve

6

Accumulator

4

5

6

7

8

9

Outdoor unit for air to water heat pump

ERLQ018~030BAVJU

4PW62590-1 – 07.2010

7

4

3

1

2

6

5

7

Compressor

8

Liquid stop valve

9

Gas stop valve

Switchbox

12 3

1

Reactor

2

Inverter PCB

3

Service monitor PCB

4

Power supply terminal

5

Communication terminal

6

Communication bottom plate heater

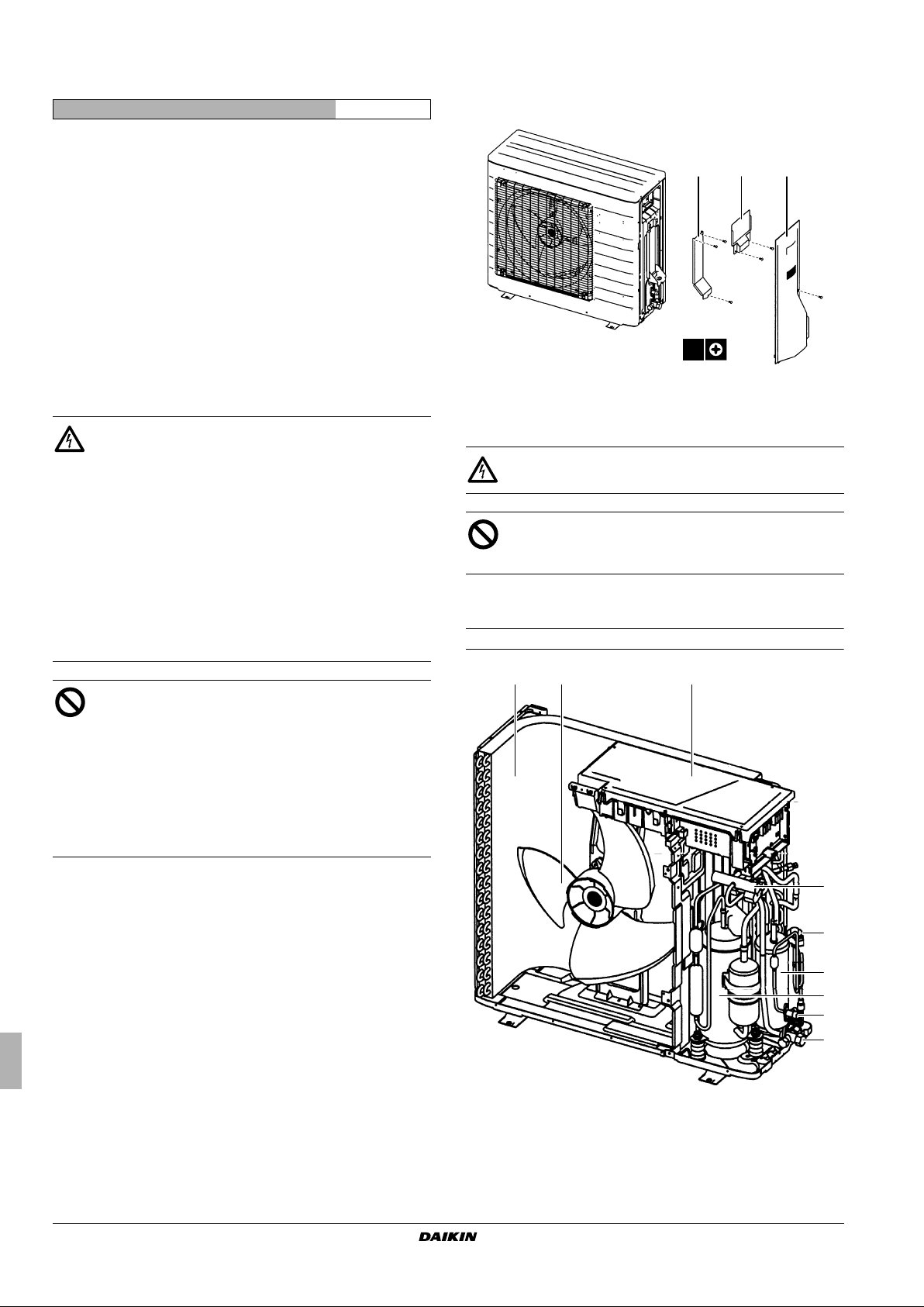

5.3. Functional diagram

6. P

RECAUTIONS ON INSTALLATION LOCATION

WARNING

Be sure to provide for adequate measures in order to

prevent that the unit be used as a shelter by small animals.

Small animals making contact with electrical parts can

cause malfunctions, smoke or fire. Please instruct the

customer to keep the area around the unit clean and clear.

6.1. General precautions

Select an installation site that meets the following requirements:

■

There must be sufficient space for carrying the unit into and out

of the site.

■

4

5

6

6

The foundation must be strong enough to support the weight of

the unit. The floor is flat to prevent vibrations and noise

generation and to have sufficient stability.

■

The space around the unit is adequate for maintenance and

servicing.

■

The space around the unit allows for sufficient air circulation.

■

There is no danger of fire due to leakage of inflammable gas.

■

The equipment is not intended for use in a potentially explosive

atmosphere.

■

Select the location of the unit in such a way that the sound and

discharged cold/hot air generated by the unit does not disturb

anyone, and the location is selected according the applicable

legislation.

■

All piping lengths and distances have been taken into

consideration.

■

Ta ke care that in the event of a water leak, water cannot cause

any damage to the installation space and surroundings.

NOTE

Units cannot be installed hanging from ceiling or

stacked.

■

Do not install the unit in places such as the following:

■

Where there is mist of mineral oil, oil spray or vapour for

example a kitchen.

Plastic parts may deteriorate, and cause them to fall out or

water to leak.

■

Where corrosive gas, such as sulphurous acid gas, is

produced.

Corrosion of copper pipes or soldered parts may cause the

refrigerant to leak.

■

Where there is machinery which emits electromagnetic

waves.

Electromagnetic waves may disturb the control system, and

cause malfunction of the equipment.

■

Where flammable gases may leak, where carbon fiber or

ignitable dust is suspended in the air or where volatile

flammables, such as thinner or gasoline, are handled.

1

2

3

4

5

6

7

Heat exchanger

4-way valve

Compressor

Accumulator

Expansion valve

Liquid stop valve

Gas stop valve

Such gases may cause a fire.

■

Where the air contains high levels of salt such as that near

the ocean.

■

Where voltage fluctuates a lot, such as that in factories.

■

In vehicles or vessels.

■

Where acidic or alkaline vapour is present.

ERLQ018~030BAVJU

Outdoor unit for air to water heat pump

4PW62590-1 – 07.2010

Installation manual

4

6.2. Weather dependent precautions

■

Select a place where the rain can be avoided as much as

possible.

■

Since drain flows out of the outdoor unit, do not place anything

under the unit which must be kept away from moisture.

■

Ensure that water cannot cause any damage to the location by

adding water drains to the foundation and prevent water traps in

the construction.

1

If the water drainage of the unit is not easy, please build up the

unit on a foundation of concrete blocks, etc. (the height of the

foundation should be maximum 5.9 inch (150 mm)).

2

If you install the unit on a frame, please install a waterproof plate

within 5.9 inch (150 mm) of the underside of the unit in order to

prevent the invasion of water from the lower direction.

3

If you install the unit on a building frame,

please install a waterproof plate within

5.9 inch (150 mm) of the underside of the

unit in order to avoid the drainwater

dripping.

■

When installing the unit in a place exposed to strong wind, pay

special attention to the following:

1

Strong winds of 16.40 ft/sec (5 m/sec) or more blowing against

the unit's air outlet causes short circuit (suction of discharge air),

and this may have the following consequences:

- Deterioration of the operational capacity.

-Frequent frost acceleration in heating operation.

- Disruption of operation due to rise of high pressure.

- When a strong wind blows continuously on the face of the

unit, the fan can start rotating very fast until it breaks.

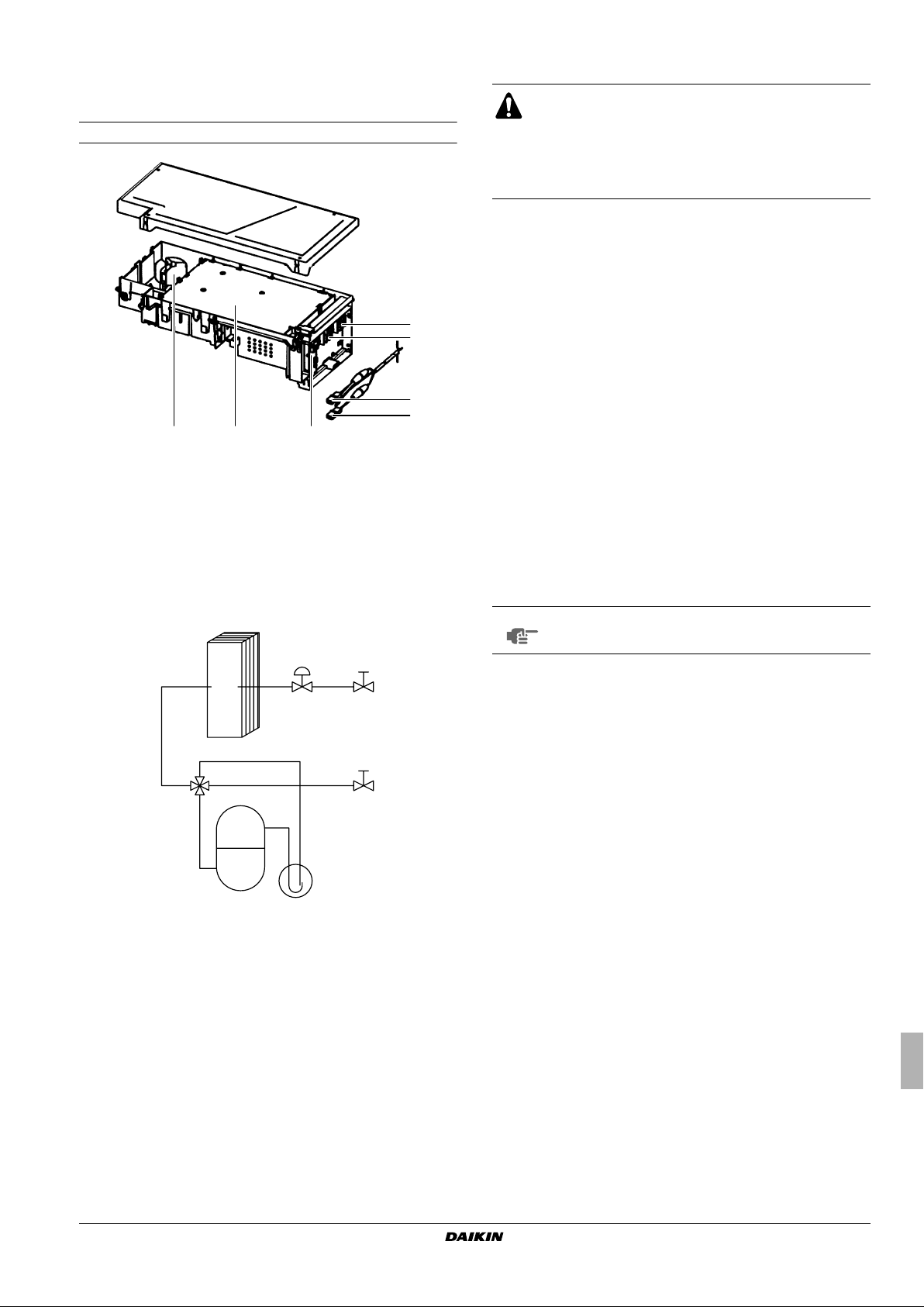

6.3. Selecting a location in cold climates

NOTE

■

■

■

NOTE

■

When operating the unit in a low outdoor ambient

temperature, be sure to follow the instructions

described below.

To prevent exposure to wind, install the unit with its suction side

facing the wall.

Never install the unit at a site where the suction side may be

exposed directly to wind.

To prevent exposure to wind, install a baffle plate on the air

discharge side of the outdoor unit.

Mind the restrictions: refer to "6.4. Installing near a wall

or obstacle" on page 5

In heavy snowfall areas it is very important to select an

installation site where the snow will not affect the unit:

1

2

2

Refer to the figure below for installation of this unit in a place

where the wind direction can be foreseen.

■

Install a baffle plate on the air discharge side of the outdoor unit:

1

1 Baffle plate

NOTE

Mind the restrictions: refer to "6.4. Installing near a wall

or obstacle" on page 5

■

Set the outlet side at a right angle to the direction of the wind.

Strong wind

Blown air Strong wind

1

Construct a large canopy.

2

Construct a pedestal.

Install the unit high enough off the ground to prevent burying

in snow.

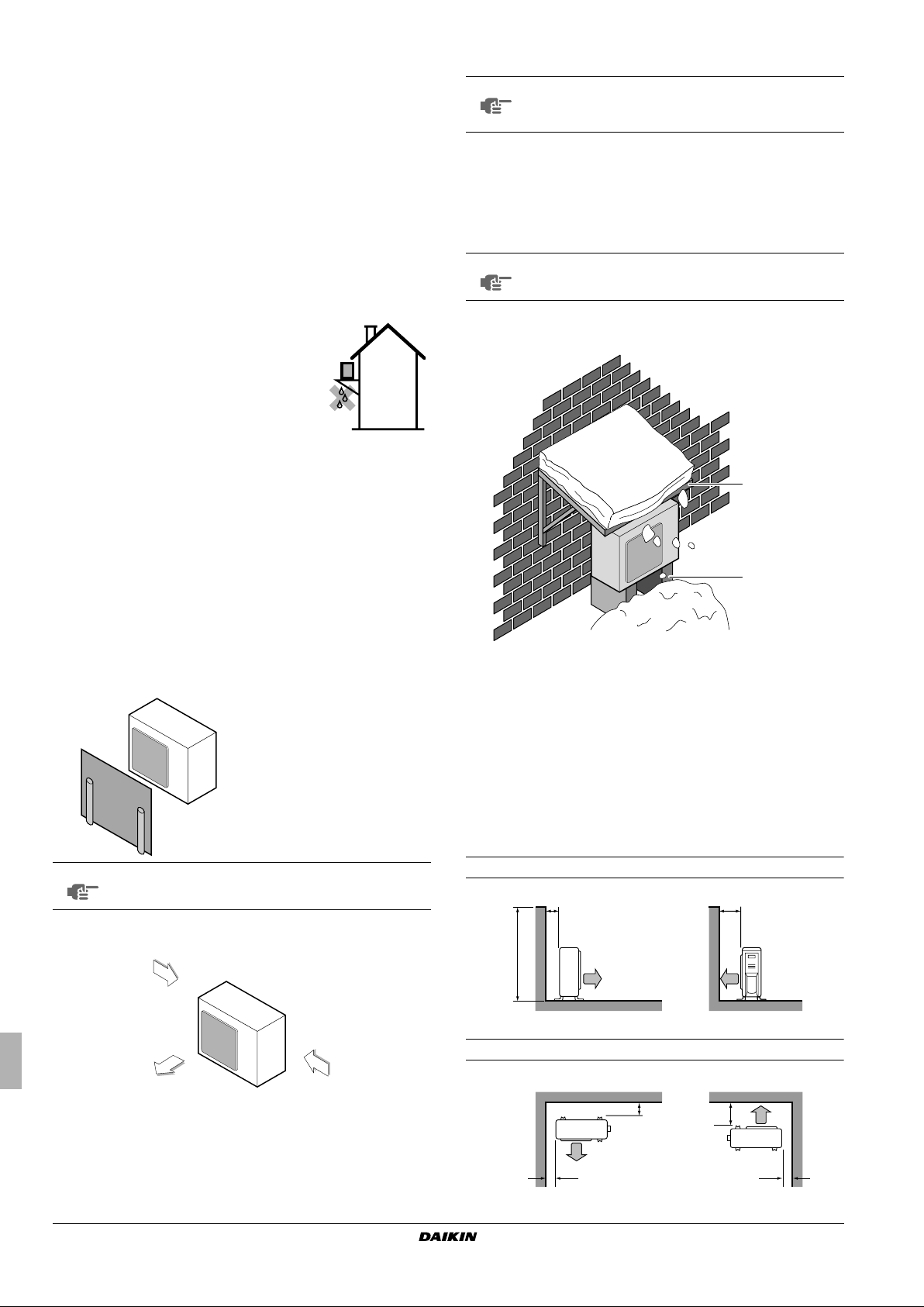

6.4. Installing near a wall or obstacle

■

Where a wall or other obstacle is in the path of the outdoor unit

air intake or exhaust airflow, follow the installation guidelines

below.

■

For any of the installation patterns below, the wall height on the

exhaust side should be 47.24 inch (1200 mm) or less.

Wall facing one side

>3.94 (100) >13.78 (350)

≤47.24 (1200)

inch (mm) inch (mm)

Walls facing two sides

inch (mm) inch (mm)

Installation manual

5

>3.94 (100)

>1.97 (50)

>13.78 (350)

>1.97 (50)

Outdoor unit for air to water heat pump

ERLQ018~030BAVJU

4PW62590-1 – 07.2010

Walls facing three sides

12.99 (330)

22.83 (580)

4.72 (120)

3

1

2

6

4

5

unit: inch (mm)

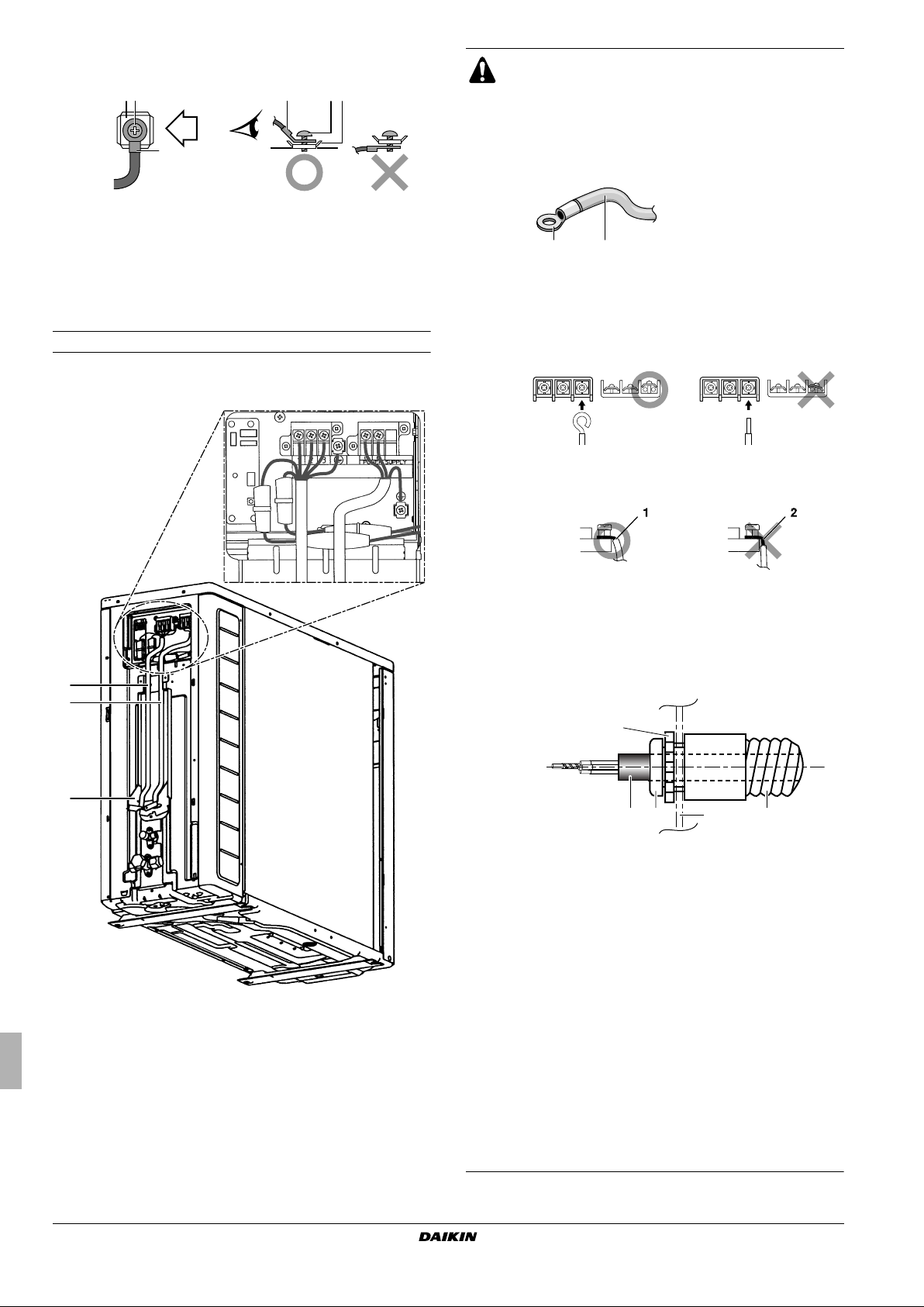

7.4. Installation instructions

inch (mm)

>3.94 (100)

>1.97 (50)

>13.78 (350)

6.5. Additional precautions

It is recommended to install the equipment and electric wires keeping

proper distances away from stereo equipment, personal computers,

etc... In extreme circumstances you shall keep distances of 9.84 ft

(3 m) or more and use conduit tubes for power and transmission

lines.

■

Do not install the unit in places often used as work place.

■

In case of construction works (e.g. grinding works) where a lot of

dust is created, the unit must be covered.

■

Do not place any objects or equipment on top of the unit (top

plate).

■

Do not climb, sit or stand on top of the unit,

■

Be sure that sufficient precautions are taken, in accordance with

the applicable legislation, in case of refrigerant leakage.

7. I

NSTALLATION OF THE UNIT

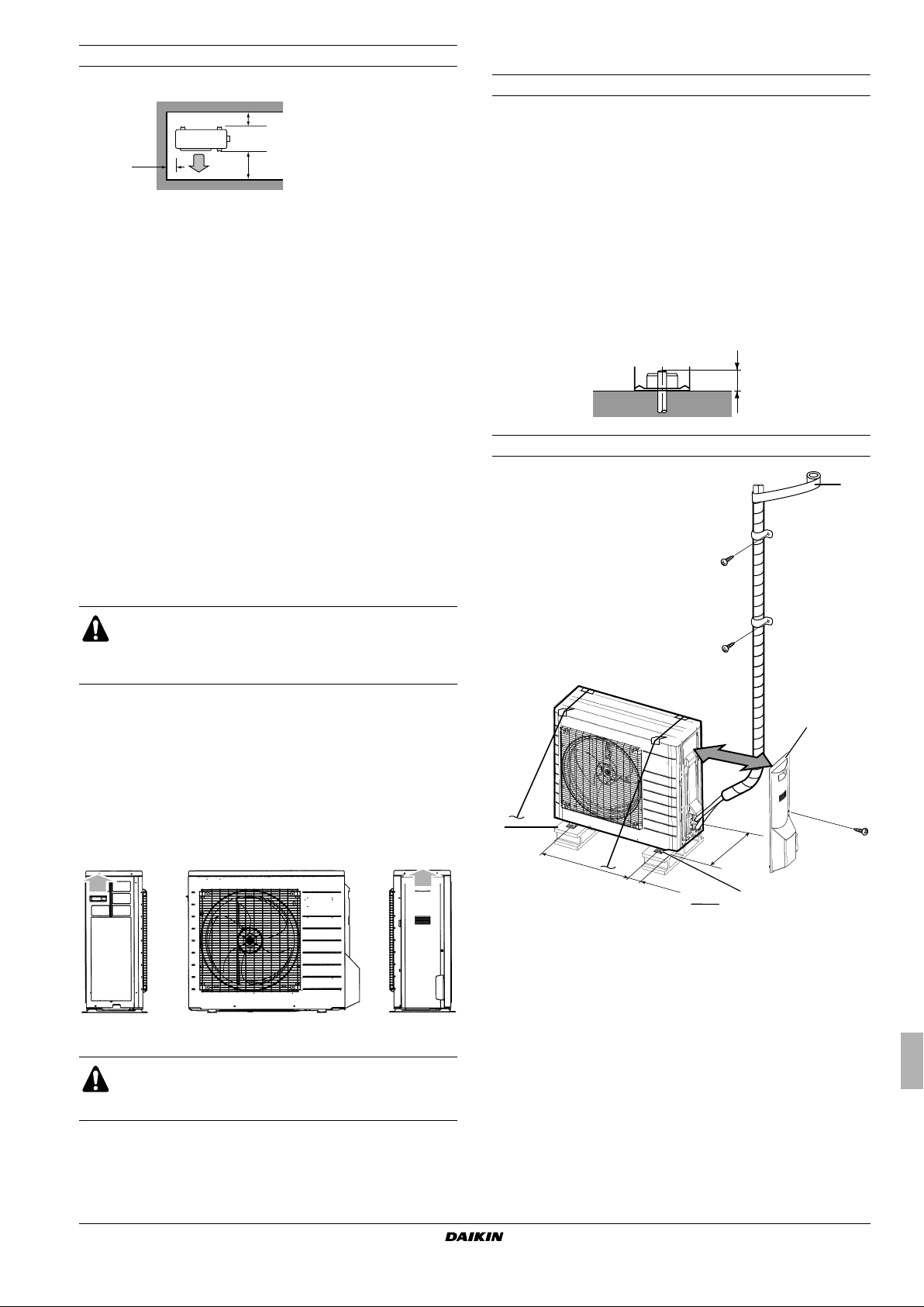

Mounting the outdoor unit

When installing the outdoor unit, please refer to "6. Precautions on

installation location" on page 4 to select an appropriate location.

1 Check the strength and level of the installation ground so that

the unit will not cause any operating vibration or noise after

installation.

2 Prepare 4 sets of 0.31 inch [close to 5/16 inch] (M8) or 0.39 inch

[close to 3/8 inch] (M10) foundation bolts, nuts and washers

each (field supply).

3 Fix the unit securely by means of the foundation bolts in

accordance with the figure below.

It is best to screw in the foundation bolts until their length

remains 0.79 inch (20 mm) above the foundation surface.

(20 mm)

0.79 inch

Outdoor installation drawing

7.1. Unpacking the unit

Check if all unit accessories are enclosed.

WARNING

Tear apart and throw away plastic packaging bags so that

children will not play with them. Children playing with

plastic bags face danger of death by suffocation.

7.2. Inspection

At delivery, the unit must be checked and any damage must be

reported immediately to the carrier's claims agent.

7.3. Handling the unit

As shown in the figure below, bring the unit slowly by grabbing the left

and right grips.

Do not hold the suction inlet in the side of the casing, otherwise the

casing could be deformed.

CAUTION

To avoid injury, do not touch the air inlet or aluminium fins

of the unit.

1 Wrap the insulation pipe with finishing tape from bottom to top.

2 Stop valve cover

3 9.84 inch (250 mm) from wall. Allow space for piping and electrical

servicing.

4 If there is danger of the unit falling or overturning, fix the unit with

foundation bolts, or with wire or other means.

5 Distance from the outer side of the stop valve cover

6 If the location does not have good drainage, place the unit on

block bases. Adjust foot height until the unit is levelled. Failure to

do so may result in water leakage or accumulation.

ERLQ018~030BAVJU

Outdoor unit for air to water heat pump

4PW62590-1 – 07.2010

Installation manual

6

Drain work

9. PRECAUTIONS ON REFRIGERANT PIPING

Refer to "6.2. Weather dependent precautions" on page 5.

■ If drain work from the outdoor unit causes trouble (for example, if

the drain water may splash on people) provide a waterproof

plate (field supply) within 5.9 inch (150 mm) of the underside of

the unit.

■ Make sure the drain works properly.

NOTE

If drain holes of the outdoor

unit are covered by a

mounting base or by floor

surface, raise the unit in

order to provide a free

space of more than

≥3.94 inch

3.94 inch (100 mm) under

(≥100 mm)

the outdoor unit.

8. REFRIGERANT PIPE SIZE AND ALLOWABLE

PIPE LENGTH

8.1. Refrigerant piping material

NOTE

Piping and other pressure containing parts shall

comply with the applicable legislation and shall be

suitable for refrigerant. Use phosphoric acid

deoxidised seamless copper for refrigerant.

CAUTION

R410A, as well as other refrigerants, should always be

recovered and never be released directly into the

environment.

■ Do not allow anything other than the designated refrigerant to

get mixed into the freezing cycle, such as air, etc. If any

refrigerant gas leaks while working on the unit, ventilate the

room thoroughly right away.

■ Use R410A only when adding refrigerant

- Installation tools:

Make sure to use installation tools (gauge manifold charge

hose, etc.) that are exclusively used for R410A installations

to withstand the pressure and to prevent foreign materials

(e.g. mineral oils and moisture) from mixing into the system.

-Vacuum pump:

Use a 2-stage vacuum pump with a non-return valve.

Make sure the pump oil does not flow oppositely into the

system while the pump is not working.

Use a vacuum pump which can evacuate to –14.6 psi

[–100.7 kPa (5 Torr, –755 mm Hg)].

■ In order to prevent dirt, liquid or dust from entering the piping,

cure the piping with a pinch or taping.

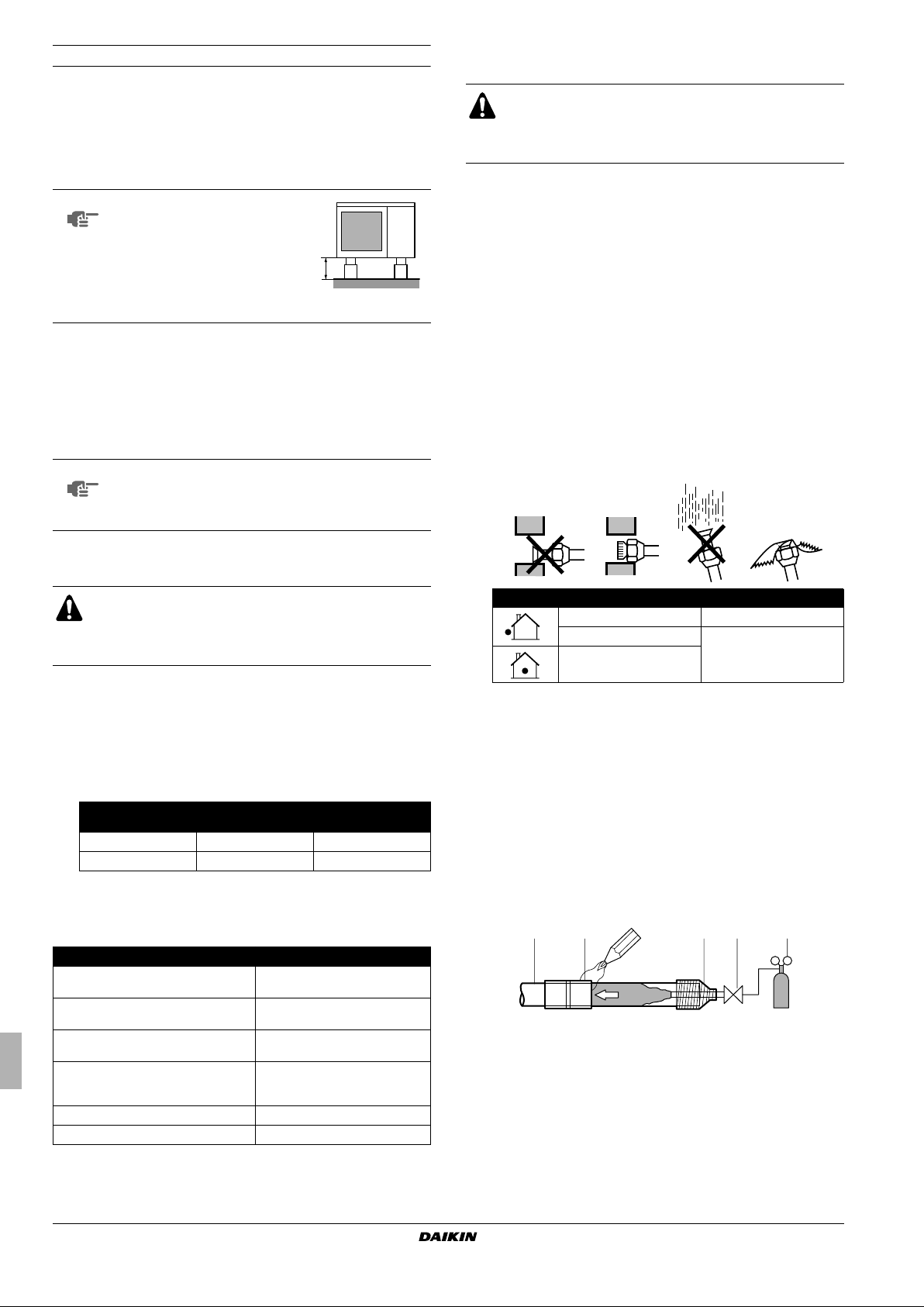

8.2. Piping material selection

CAUTION

Never use piping which has been used for previous

installations. Only use parts which are delivered with the

unit.

■ Foreign materials inside pipes (including oils for fabrication)

must be ≤0.014 grain/ft (30 mg/10 m).

■ Temper grade: use piping with temper grade in function of the

pipe diameter as listed in table below.

■ The pipe thickness of the refrigerant piping shall comply with the

applicable legislation. The minimal pipe thickness for R410A

piping must be in accordance with the table below.

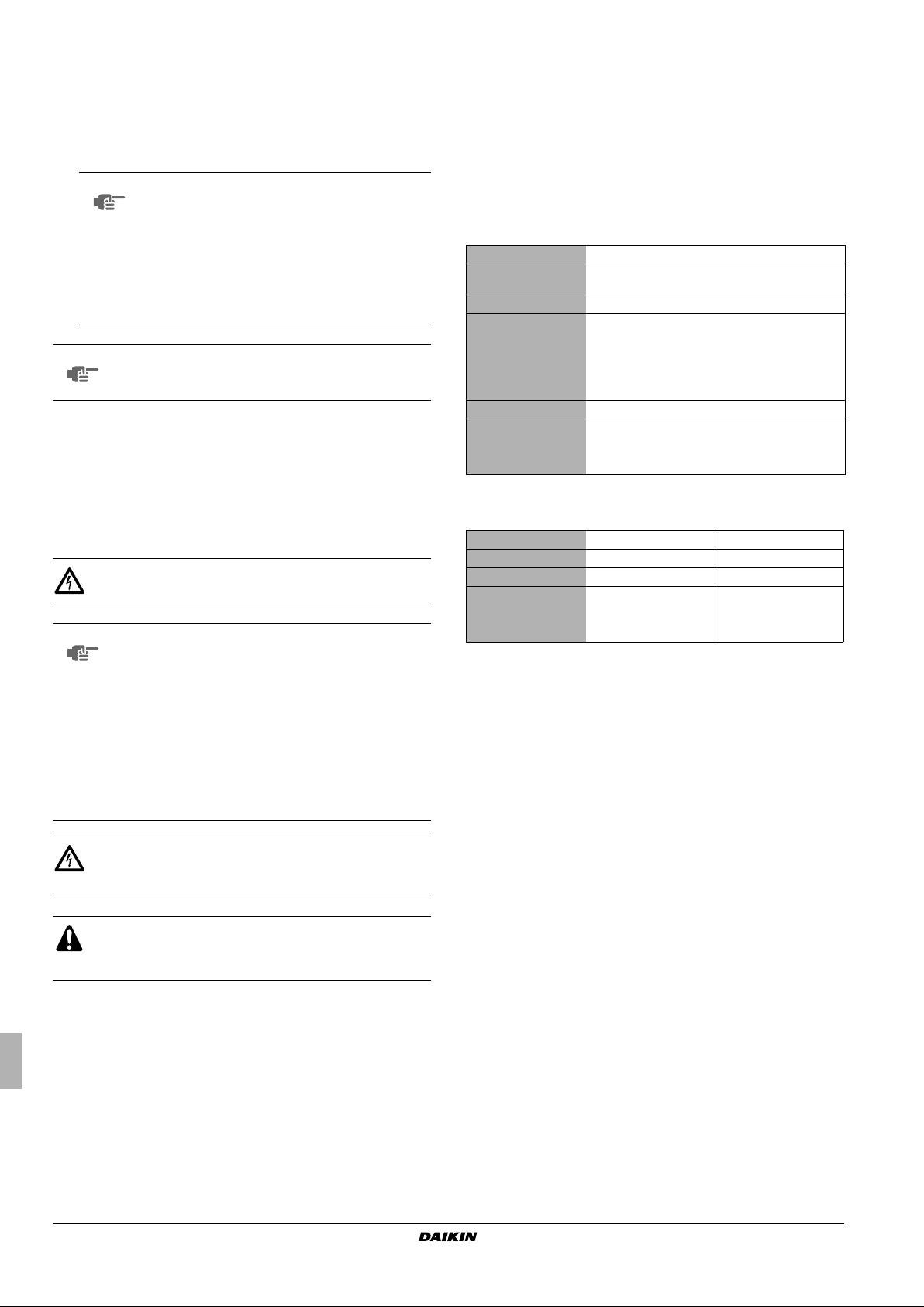

Temper grade of

Pipe size

1/4 inch (Ø6.4 mm) O 0.031 inch (0.8 mm)

5/8 inch (Ø15.9 mm) O 0.039 inch (1.0 mm)

O = Annealed

piping material

Minimal thickness

8.3. Refrigerant piping specifications

Refrigerant piping specifications

Maximum allowable piping length

between outdoor unit and indoor unit

Minimum required piping length

between outdoor unit and indoor unit

Maximum allowable height difference

between outdoor unit and indoor unit

Additional refrigerant required for

refrigerant pipe exceeding 32.8 ft (10 m)

in length

Gas pipe - outer diameter 5/8 inch (15.9 mm)

Liquid pipe - outer diameter 1/4 inch (6.4 mm)

98.4 ft (30 m)

9.8 ft (3 m)

65.6 ft (20 m)

0.013 lbs/ft (20 g/m)

Installation period Protection method

More than a month Pinch the pipe

Less than a month

Regardless of the period

Pinch or tape the pipe

- Great caution is needed when passing copper tubes through

walls.

9.1. Guidelines for brazing

■ Make sure to blow through with nitrogen when brazing.

Blowing through with nitrogen prevents the creation of large

quantities of oxidized film on the inside of the piping. An oxidized

film adversely affects valves and compressors in the

refrigerating system and prevents proper operation.

■ The nitrogen pressure should be set to 2.9 psi (0.02 MPa) (i.e.,

just enough so it can be felt on the skin) with a pressurereducing valve.

12 345

6

1 Refrigerant piping

2 Part to be brazed

3 Taping

4 Hands valve

5 Pressure-reducing valve

6 Nitrogen

■ Do not use anti-oxidants when brazing the pipe joints.

Residue can clog pipes and break equipment.

6

Installation manual

7

Outdoor unit for air to water heat pump

ERLQ018~030BAVJU

4PW62590-1 – 07.2010

■ Do not use flux when brazing copper-to-copper refrigerant

1 Service port and service port cover

2 Stop valve

3 Field piping connection

4 Stop valve cover

piping. Use phosphor copper brazing filler alloy (BCuP) which

does not require flux.

■ Flux has an extremely harmful influence on refrigerant piping

systems. For instance, if chlorine based flux is used, it will cause

pipe corrosion or, in particular, if the flux contains fluorine, it will

deteriorate the refrigerant oil.

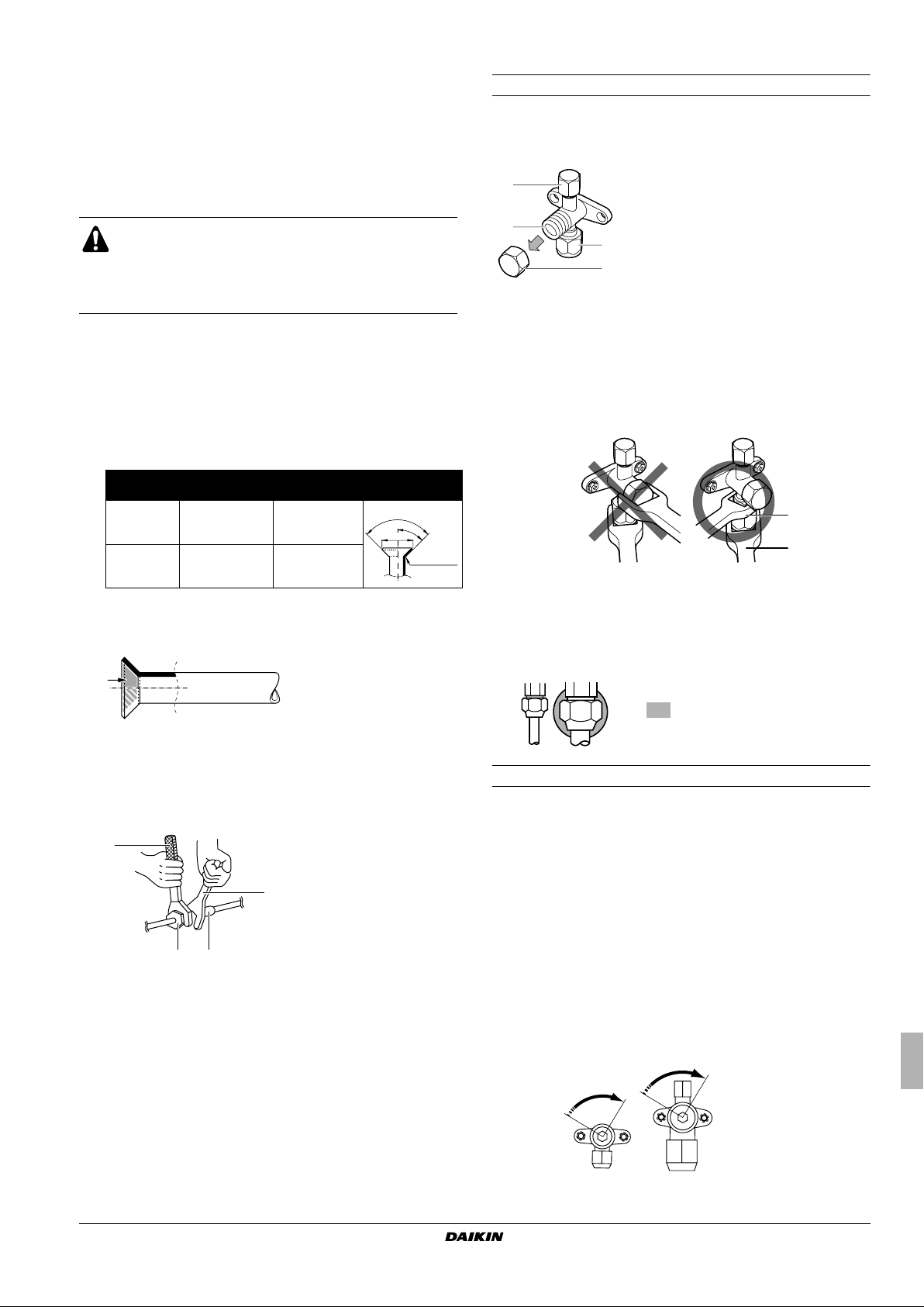

9.3. Guidelines for handling the stop valve

Cautions for handling the stop valve

■ Make sure to keep both stop valves open during operation.

■ The figure below shows the name of each part required in

handling the stop valve.

9.2. Guidelines for flare connection

CAUTION

■ Do not use mineral oil on flared part.

Mineral oil getting into the system would reduce the

lifetime of the units.

■ Incomplete flaring may cause refrigerant gas leakage.

■ Flares should not be re-used. New ones should be made in

order to prevent leaks.

■ Use a pipe cutter and annealed flare tool suitable for the

refrigerant used.

■ Only use the annealed flare nuts included with the unit. Using

different flare nuts may cause the refrigerant to leak.

■ Please refer to the table for flaring dimensions and tightening

torques (too much tightening will result in splitting the flare).

Tightening

Piping size

1/4 inch

(Ø6.4 mm)

5/8 inch

(Ø15.9 mm)

torque

11.06~12.54 lbs•ft

(15~17 N•m)

46.47~55.32 lbs•ft

(63~75 N•m)

■ When connecting the flare nut, coat the flare inner surface with

ether oil or with ester oil and initially tighten 3 or 4 turns by hand

before tightening firmly.

Flare

dimensions A

0.34~0.36 inch

(8.7~9.1 mm)

0.76~0.78 inch

(19.3~19.7 mm)

Flare shape

(mm)

±2

90

45

±2

A

R=0.02~0.04 inch

(=0.4~0.8 mm)

1

2

3

4

■ The stop valve is factory closed.

■ Do not apply excessive force to the stop valve. Doing so may

break the valve body.

Since the stop valve mounting plate may be deformed if only a

torque wrench is used to loosen or tighten the flare nut, always

make sure to secure the stop valve with a spanner, then loosen

or tighten the flare nut with a torque wrench.

Do not place the spanner on the stop valve cover, as this could

cause a refrigerant leak.

1

2

1 Spanner

2 Torque wrench

■ The operating pressure at the refrigerant side can be low,

sufficiently seal the flare nut in the stop valve on the gas line with

silicon sealant to prevent freezing.

■ After all piping has been connected, use nitrogen to perform a

gas leak check.

■ When loosening a flare nut, always use two wrenches together.

When connecting the piping, always use a spanner and torque

wrench together to tighten the flare nut to prevent flare nut

cracking and leaks.

1

4

3

1 Torque wrench

2 Spanner

3 Piping union

2

4 Flare nut

■ After the work is finished, make sure to check that there is no

gas leak.

Silicon sealant

(Make sure there is no gap)

How to use the stop valve

■ Opening the stop valve

1. Remove the stop valve cover.

2. Insert a hexagon wrench (0.15 inch [close to 5/32 inch] (4 mm))

into the stop valve and turn the stop valve counter clockwise.

3. When the stop valve cannot be turned any further, stop turning.

The valve is now open.

■ Closing the stop valve

1. Remove the stop valve cover.

2. Insert a hexagon wrench (0.15 inch [close to 5/32 inch] (4 mm))

into the stop valve and turn the stop valve clockwise.

3. When the stop valve cannot be turned any further, stop turning.

The valve is now closed.

Closing direction

Liquid side Gas side

ERLQ018~030BAVJU

Outdoor unit for air to water heat pump

4PW62590-1 – 07.2010

Installation manual

8

Cautions for handling the stop valve cover

■ The stop valve cover is sealed where indicated by the arrow.

Ta ke care not to damage it.

■ After handling the stop valve, make

sure to tighten the stop valve cover

securely. For the tightening torque,

refer to the table below.

■ Check for refrigerant leaks after

tightening the stop valve cover.

Cautions for handling the service port

■ Always use a charge hose equipped with a valve depressor pin,

since the service port is a Schrader type valve.

■ After handling the service port, make sure to tighten the service

port cover securely. For the tightening torque, refer to the table

below.

■ Check for refrigerant leaks after tightening the service port

cover.

Tightening torques

Item Tightening torque

Stop valve cover, liquid side 15.93~29.21 lbs•ft (21.6~27.4 N•m)

Stop valve cover, gas side 32.53~39.75 lbs•ft (44.1~53.9 N•m)

Service port cover 7.97~10.84 lbs•ft (10.8~14.7 N•m)

10. PIPING CONNECTION WORK

10.1. Preventing foreign objects from entering

■ Plug the pipe through-holes with putty or insulating material

(field supply) to stop up all gaps, as shown in the figure.

1 Putty or insulating material

(field supply)

1

■ Insects or small animals entering the outdoor unit may cause a

short circuit in the electrical box.

10.2. Leak test and vacuum drying

DANGER: ELECTRICAL SHOCK

See "4. General safety precautions" on page 3.

When all piping work is complete, it is necessary to:

■ check for any leakages in the refrigerant piping and

■ to perform vacuum drying to remove all moisture in the

refrigerant piping.

If there is a possibility of moisture being present in the refrigerant

piping (for example, rainwater may have entered the piping), first

carry out the vacuum drying procedure below until all moisture has

been removed.

WARNING

During installation, attach the refrigerant piping securely

before running the compressor.

If the compressor is not attached and the stop valve is

open during pump-down, air will be sucked in when the

compressor is running, causing abnormal pressure in the

freezer cycle which will lead to breakage and even to

injury.

CAUTION

Do never install a drier to this R410A unit in order to

guarantee its lifetime. The drying material may dissolve

and damage the system.

NOTE

1. Installation shall be done by an installer, the

choice of materials and installation shall comply

with the applicable legislation.

2. To persons in charge of piping work:

■ Be sure to open the stop valve after piping

installing and vacuming is complete. Running

the system with the valve closed may break

the compressor.

■ When the refrigerant system is to be opened,

refrigerant must be treated according the

applicable legislation.

■ Ensure that the field piping and connections

are not subjected to stress.

General guidelines

■ All piping inside the unit has been factory tested for leaks.

■ Use a 2-stage vacuum pump with a non-return valve which can

evacuate to a gauge pressure of –14.6 psi [–100.7 kPa

(5 Torr absolute, –755 mm Hg)].

NOTE

■ Do not purge the air with refrigerants. Use a

vacuum pump to evacuate the installation. No

additional refrigerant is provided for air purging.

■ Make sure that the gas stop valve and liquid stop

valve are firmly closed before performing the leak

test or vacuum drying.

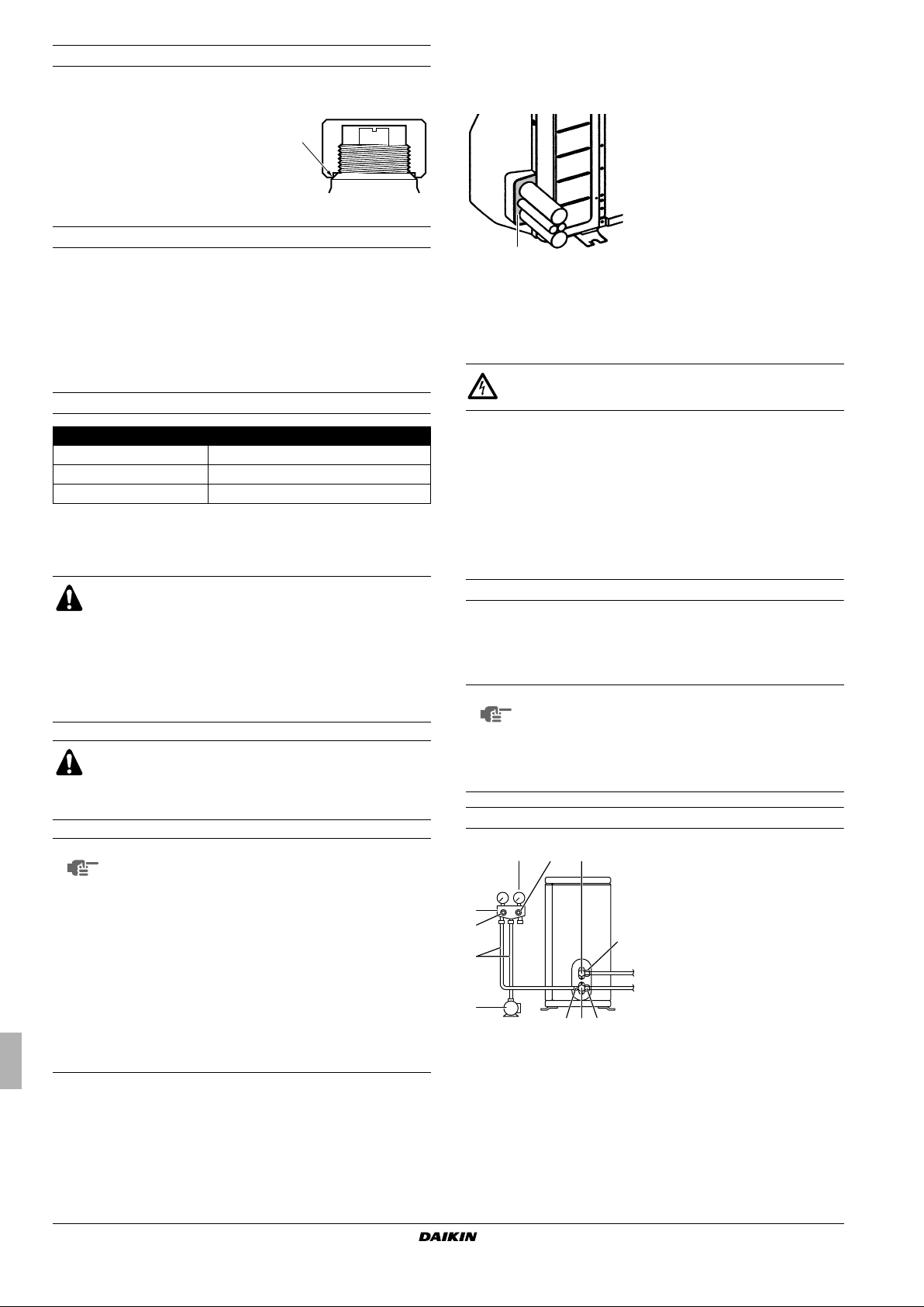

Setup

1

48

2

3

5

6

789

1 Pressure meter

2 Gauge manifold

3 Low-pressure valve (Lo)

4 High-pressure valve (Hi)

5 Charging hoses

10

6 Vacuum pump

7 Service port

8 Stop valve cover

9 Gas stop valve

10 Liquid stop valve

Installation manual

9

Outdoor unit for air to water heat pump

ERLQ018~030BAVJU

4PW62590-1 – 07.2010

Leak test

1

2

3

4

6

5

1 Gas pipe

10.3. Pipe insulation

1 Vacuum leak test

1.1 Fully open the gauge manifold’s low-pressure valve (Lo)

and completely close its high-pressure valve (Hi). The highpressure subsequently requires no operation.

1.2 Evacuate the system from the gas piping to –14.6 psi

[–100.7 kPa (5 Torr, –755 mm Hg)].

1.3 Once reached, close the gauge manifold’s low-pressure

valve (Lo), turn off the vacuum pump and check that the

pressure does not rise for about 4-5 minutes.

1.4 Should the pressure rise, the system may either contain

moisture (see vacuum drying below) or have leaks.

2 Pressure leak test

2.1 Break the vacuum by pressurizing with nitrogen gas to a

minimum gauge pressure of 29 psi [0.2 MPa (2 bar)].

Never set the gauge pressure higher than the maximum

operation pressure of the unit, i.e. 605 psi [4.17 MPa

(41.7 bar)].

2.2 Test for leaks by applying a bubble test solution to all piping

connections.

NOTE

Make sure to use a recommended bubble

test solution from your wholesaler.

Do not use soap water, which may cause

cracking of flare nuts (soap water may

contain salt, which absorbs moisture that will

freeze when the piping gets cold), and/or

lead to corrosion of flared joints (soap water

may contain ammonia which causes a

corrosive effect between the brass flare nut

and the copper flare).

2.3 Discharge all nitrogen gas.

Vacuum drying

To remove all moisture from the system, proceed as follows:

1 Evacuate the system for at least 2 hours to a target vacuum of

–14.6 psi [–100.7 kPa (5 Torr, –755 mm Hg)].

2 Check that, with the vacuum pump turned off, the target vacuum

is maintained for at least 1 hour.

3 Should you fail to reach the target vacuum within 2 hours or

maintain the vacuum for 1 hour, the system may contain too

much moisture.

4 In that case, break the vacuum by pressurizing with nitrogen gas

to a gauge pressure of 7.25 psi [0.05 MPa (0.5 bar)] and repeat

steps 1 to 3 until all moisture has been removed.

5 The stop valves can now be opened, and/or additional

refrigerant can be charged (see "11.1. Additional refrigerant

charging" on page 11).

NOTE

After opening the stop valve, it is possible that the

pressure in the refrigerant piping does not rise. This

might be caused by e.g. the closed state of the

expansion valve in the outdoor unit circuit, but does not

present any problem for correct operation of the unit.

NOTE

Any exposed piping may cause condensation or bruns

if touched.

Selection of heat insulation materials

When using commercial copper pipes and fittings, observe the

following:

■ Insulation material: polyethylene foam

2

Heat transfer rate: 0.285~0.361 BTU.inch/h.ft

.°F (0.041~0.052

W/m•K)

Refrigerant gas pipe's surface temperature reaches 230°F

(110°C) max.

Choose heat insulation materials that will withstand this

temperature.

■ Be sure to insulate both the gas and liquid piping and to provide

insulation dimensions as below.

Pipe insulation

Connection pipe Inner diameter Thickness

1/4 inch

(Ø6.4 mm)

5/8 inch

(Ø15.9 mm)

0.31~0.39 inch

(8~10 mm)

0.63~0.79 inch

(16~20 mm)

≥0.39 inch

(10 mm)

≥0.51 inch

(13 mm)

■ If the temperature is higher than 86°F (30°C) and the humidity is

higher than RH 80%, then the thickness of the sealing materials

should be at least 0.79 inch (20 mm) in order to avoid

condensation on the surface of the sealing.

2 Conduit including

interunit wiring

3 Liquid pipe

4 Liquid pipe insulation

5 Finishing tape

6 Gas pipe insulation

■ Use separate thermal insulation pipes for gas and liquid

refrigerant pipes.

11. CHARGING REFRIGERANT

DANGER: ELECTRICAL SHOCK

See "4. General safety precautions" on page 3.

■ Refrigerant cannot be charged until field wiring has been

completed.

■ Refrigerant may only be charged after performing the leak test

and the vacuum drying.

■ When charging a system, care shall be taken that its maximum

permissible charge is never exceeded, in view of the danger of

liquid hammer.

■ Charging with an unsuitable substance may cause explosions

and accidents, so always ensure that the appropriate refrigerant

R410A is charged.

■ Refrigerant containers shall be opened slowly.

■ Always use protective gloves and protect your eyes when

charging refrigerant.

■ When the refrigerant system is to be opened, refrigerant must

be treated according to the applicable legislation.

ERLQ018~030BAVJU

Outdoor unit for air to water heat pump

4PW62590-1 – 07.2010

Installation manual

10

11.1. Additional refrigerant charging

■ This outdoor unit is factory charged with refrigerant and

depending on pipe sizes and pipe lengths some systems require

additional charging of refrigerant. See "11.3. Charging amount"

on page 11.

■ In case re-charge is required, refer to the nameplate of the unit.

It states the type of refrigerant and necessary amount.

11.2. Precautions when adding R410A

■ The refrigerant requires strict cautions for keeping the system

clean, dry and tight.

- Clean and dry

Foreign materials (including mineral oils or moisture) should

be prevented from getting mixed into the system.

- Tight

Read "9. Precautions on refrigerant piping" on page 7

carefully and follow these procedures correctly.

■ Make sure to charge the refrigerant in liquid state to the liquid

pipe. Since R410A is a mixed refrigerant, its composition

changes if charged in its gaseous state and normal system

operation would then no longer be assured.

■ Before charging, check whether the refrigerant cylinder has a

syphon attached or not and position the cylinder accordingly.

Filling using a cylinder

with a siphon attached

Charge the liquid refrigerant

with the cylinder in upright

position.

Filling using a cylinder

without a siphon attached

Charge the liquid refrigerant

with the cylinder in up-sidedown position.

11.3. Charging amount

If the total length of the piping exceeds 32.8 ft (10 m), additionally

charge with 0.013 lbs/ft (20 g/m) for each additional foot (meter) of

piping.

12. PUMP DOWN OPERATION

In order to protect the environment, be sure to pump down when

relocating or disposing of the unit. The pump down operation will

extract all regrigerant from the piping into the outdoor unit.

WARNING

During pump down operation, stop the compressor before

removing the refrigerant piping.

If the compressor is still running and the stop valve is open

during pump-down, air will be sucked in when the

refrigerant piping is removed, causing abnormal pressure

in the freezer cycle which will lead to breakage and even to

injury.

DANGER: ELECTRICAL SHOCK

See "4. General safety precautions" on page 3.

12.1. Procedure

1 Tu rn on the main power supply.

2 Make sure the liquid stop valve and the gas stop valve are open

(see "How to use the stop valve" on page 8).

3 Press the forced operation switch SW1 to begin forced cooling.

4 After 5-10 minutes (after only 1 or 2 minutes in case of very low

ambient temperatures (<14°F (–10°C)), close the liquid stop

valve.

5 After 2-3 minutes, close the gas stop valve and press the forced

operation switch SW1 again to stop forced cooling.

S102

S2

LED-A

ABCD

SW4

ON

SW1

1 Forced operation switch SW1

NOTE

Ta ke care that while running forced cooling operation

1

the water temperature remains higher than 41°F (5°C)

(see temperature read out of the indoor unit). You can

achieve this, for example, by activating all fans of the

fan coil units.

13. ELECTRIC WIRING WORK

ATTENTION

■ All field wiring and components must be installed by

an installer and must comply with the applicable

legislation.

■ The equipment described in this manual may cause

electronic noise generated from radio-frequency

energy. The equipment complies to specifications that

are designed to provide reasonable protection against

such interference. However, there is no guarantee that

interference will not occur in a particular installation.

It is therefore recommended to install the equipment and

electric wires keeping proper distances away from stereo

equipment, personal computers, etc....

In extreme circumstances you shall keep distances of

9.84 ft (3 m) or more.

NOTE

To persons in charge of electrical wiring work:

Do not operate the unit until the refrigerant piping is

complete. Running the unit before the piping is ready

will break the compressor.

DANGER: ELECTRICAL SHOCK

See "4. General safety precautions" on page 3.

WARNING

■ A main switch or other means for disconnection, having a

contact separation in all poles, must be incorporated in

the fixed wiring in accordance with the applicable

legislation.

■ Use only copper wires.

■ All field wiring must be carried out in accordance with the

wiring diagram supplied with the unit and the instructions

given below.

■ Never squeeze bundled cables and be sure that it does

not come in contact with the non-insulated piping and

sharp edges. Be sure no external pressure is applied to

the terminal connections.

■ Be sure to establish a ground. Do not ground the unit to a

utility pipe, surge absorber, or telephone ground.

Incomplete ground may cause electrical shock.

Installation manual

11

Outdoor unit for air to water heat pump

ERLQ018~030BAVJU

4PW62590-1 – 07.2010

■ Be sure to install a ground fault circuit interrupter in

accordance with the applicable legislation. Failure to do

so may cause electric shock or fire.

■ Be sure to use a dedicated power circuit, never use a

power supply shared by another appliance.

■ When installing the ground fault circuit interrupter be sure

that it is compatible with the inverter (resistant to high

frequency electric noise) to avoid unnecessary opening

of the ground fault circuit interrupter.

■ The ground fault circuit interrupter must be a high speed

type breaker of 30 mA (<0.1 seconds).

■ As this unit is equipped with an inverter, installing a

phase advancing capacitor not only will deteriorate

power factor improvement effect, but also may cause a

capacitor abnormal heating accident due to highfrequency waves. Therefore, never install a phase

advancing capacitor.

■ Be sure to install the required fuses or circuit breakers.

■ Use a cable long enough to cover the entire distance. Do

not use an extension cord.

CAUTION

For use of units in applications with temperature alarm

settings its advised to foresee a delay of 10 minutes for

signalling the alarm in case the alarm temperature is

exceeded. The unit may stop for several minutes during

normal operation for "defrosting he unit", or when in

"thermosta-stop" operation.

13.1. Switch box component list

AC1,AC2.......................Connector

E1,E2............................Connector

E1H...............................Bottomplate heater

FU1...............................Fuse, T 30 A/250 V

FU2,FU3.......................Fuse, T 3.15A/250 V

FU4,FU5.......................Fuse, F 1 A/250 V

HR1,HR2 ......................Connector

L1,L2.............................Live

L1R...............................Reactor

LED A ...........................Light emitting diode

M1C..............................Compressor motor

M1F ..............................Fan motor

MRC/W.........................Magnetic relay

MRM10,MRM20 ...........Magnetic relay

PCB1,2 .........................Printed circuit board

PM1 ..............................Power module

Q1DI .............................Ground fault circuit interruptor

Q1L...............................Overload protector

R1T...............................Thermistor (discharge)

R2T...............................Thermistor (heat exchanger)

R3T...............................Thermistor (air)

S2~S102.......................Connector

SA2...............................Surge arrester

Sheet metal ..................Terminal strip fixed plate

SW1..............................Forced operation ON/OFF switch

SW4..............................Local setting switch

U,V, W ............................Connector

V2,V3,V5,V9,V100........Varistor

X11A,X12A...................Connector

ERLQ018~030BAVJU

Outdoor unit for air to water heat pump

4PW62590-1 – 07.2010

X1M,X2M ..................... Terminal strip

X1Y .............................. Connector

Y1E .............................. Electronic expansion valve coil

Y1R.............................. Solenoid valve (reversing valve)

Z1C~Z7C .....................Ferrite core

13.2. Field wiring

Procedure

1 Strip the insulation from the wire 0.79 inch (20 mm).

2 Connect the connection wires between the indoor and outdoor

units so that the terminal numbers match (see wiring diagram

below). Tighten the terminal screws securely. We recommend a

flathead screwdriver to tighten the screws.

See also caution 2 under "Notes to observe" on page 13 for

wiring guidelines.

1 2 3

X1Y.1 X1Y.2

X2M X1M

1 2 3 15 15a

1

2

3

15

15a

123

X1Y.1 X1Y.2

H05VV

L1L2

2

1~ 60 Hz

L1

L2

208/230 V

1 453

1 Interconnection between indoor unit and outdoor unit: when

wire length exceeds 32.8 ft (10 m), use AWG14 (Ø2.5 mm)

wires instead of AWG16 (Ø1.5 mm wires).

2 Power supply cable (refer to the unit nameplate for maximum

running current)

3 Ground

4 Fuse or circuit breaker

5 Ground fault circuit interrupter

3 Ground terminal installation

WARNING

■ This unit must be grounded.

For grounding, follow the applicable legislation for

electrical installations.

■ Do not use tapped wires, stranded conductor

wires (see caution 1 under "Notes to observe" on

page 13), extension cords, or connections from a

star system, as they may cause overheating,

electrical shock or fire.

■ Do not use locally purchased electrical parts

inside the product and do not branch the power

for the heater tape, etc., from the terminal block.

Doing this may cause electrical shock or fire.

■ Use the following method when installing single core wires.

23

AA'

A'A

3

1

1

1 Single core wire

2 Screw

3 Flat washer

Installation manual

12

■ Use the following method when using round crimp-style

1

2

3

1 Stranded conductor wire

2 Round crimp-style terminal

1 Strip wire end to this point

2

terminals.

3

2

321

B

B

1

1 Round crimp-style terminal

2 Screw

3 Flat washer

4 Pull the connected wire and make sure that it does not

disconnect. Then fix the wires in place in the wire clamp. See

also "Notes to observe" on page 13.

Notes to observe

Observe the notes mentioned below when wiring to the power supply

terminal board.

CAUTION

■ In case the use of stranded conductor wires is

unavoidable for one reason or another, make sure to

install round crimp-style terminals on the tip.

Place the round crimp-style terminal on the wire up to the

covered part and fasten the terminal with the appropriate

tool.

21

■ When connecting the connection wires to the terminal

board using a single core wire, be sure to perform

curling.

Not executing the connections properly may cause heat

and fire.

Strip the wire at terminal block:

Excessive strip length may cause electrical shock

or leakage.

■ When cables are routed from the unit, a protection sleeve

for the conduits (PG-insertions) can be inserted.

3

1 Wire

2 Bush

3 Nut

4 Frame

5 Hose

A Inside

B Outside

AB

1

25

4

When you do not use a wire conduit, be sure to protect

1 Communication wiring

2 Power supply cable

3 Conduit plate

■ Use the specified wire type and connect it securely.

■ Shape wires so that the service panel and cable cover fit

securely (refer to "5.1. Opening the unit" on page 3).

the wires with vinyl tubes to prevent the edge of the hole

from cutting the wires.

■ Follow the electric wiring diagram for electrical wiring

works.

■ Form the wires and fix the cover firmly so that the cover

may be fit in properly.

■ For field wiring use appropriate wire conduits according

to the applicable legislation.

■ Refer to the installation manual attached to the indoor

unit for wiring of indoor unit, etc.

Installation manual

13

Outdoor unit for air to water heat pump

ERLQ018~030BAVJU

4PW62590-1 – 07.2010

14. START-UP AND CONFIGURATION

15. TEST OPERATION

ATTENTION

It is important that all information in this chapter is read

sequentially by the installer and that the system is

configured as applicable.

DANGER: ELECTRICAL SHOCK

See "4. General safety precautions" on page 3.

14.1. Pre-operation checks

After the installation of the unit, first check the following items. Once

all below checks are fulfilled, the unit must be closed, only then can

the unit be powered up.

1 Installation

Check that the unit is properly installed, to avoid abnormal

noises and vibrations when starting up the unit.

2 Electrical wiring

■ Field wiring

Be sure that the field wiring has been carried out according

to the instructions described in the chapter "13. Electric

wiring work" on page 11, according to the wiring diagrams

and according to the applicable legislation.

■ Power supply voltage

Check the power supply voltage on the local supply panel.

The voltage must correspond to the voltage on the

identification label of the unit.

■ Ground wiring

Be sure that the ground wires have been connected properly

and that the ground terminals are tightened.

■ Insulation test of the main power circuit

Using a mega tester for 500 V, check that the insulation

resistance of 2 MΩ or more is attained by applying a voltage

of 500 V DC between power terminals and ground. Never

use the mega tester for the transmission wiring.

■ Fuses, circuit breakers, or protection devices

Check that the fuses, circuit breakers, or the locally installed

protection devices are of the size and type specified in the

chapter "13. Electric wiring work" on page 11. Be sure that

neither a fuse nor a protection device has been bypassed.

■ Internal wiring

Visually check the switch box and the inside of the unit on

loose connections or damaged electrical components.

3 Refrigerant piping

■ Pipe size and pipe insulation

Be sure that correct pipe sizes are installed and that the

insulation work is properly executed.

■ Stop valves

Be sure that the stop valves are open on both liquid and gas

side.

4 Internal unit

■ Damaged equipment

Check the inside of the unit on damaged components or

squeezed pipes.

■ Refrigerant leak

Check the inside of the unit on refrigerant leakage. If there is

a refrigerant leak, call your local dealer. Do not touch any

refrigerant which has leaked out of refrigerant piping

connections. This may result in frostbite.

■ Oil leak

Check the compressor for oil leakage. If there is an oil leak,

call your local dealer.

■ Air inlet/outlet

Check that the air inlet and outlet of the unit is not obstructed

by paper sheets, cardboard, or any other material.

WARNING

■ During tests never pressurize the appliances with a

pressure higher than the maximum allowable

pressure (as indicated on the nameplate of the unit).

■ If refrigerant gas leaks, ventilate the area immediately.

To xic gas may be produced if refrigerant gas comes

into contact with fire.

■ Never directly touch any accidental leaking

refrigerant. This could result in severe wounds caused

by frostbite.

DANGER: DO NOT TOUCH PIPING AND INTERNAL

PA RT S

See "4. General safety precautions" on page 3.

DANGER: ELECTRICAL SHOCK

See "4. General safety precautions" on page 3.

15.1. Test run recommendations

After installation, the installer is obliged to verify correct operation.

Therefore a test run must be performed according to the procedures

described below.

15.2. Maintenance and testing logbook

Provide a logbook and machine card.

In accordance with the applicable legislation, it may be necessary to

provide a logbook with the equipment containing at least: info on

maintenance, repair work, results of tests, stand-by periods, ….

Also, at least, following information shall be provided at an accessible

place of the system:

■ instructions for shutting down the system in case of an

emergency

■ name and address of fire department, police and hospital

■ name, address and day and night telephone numbers for

obtaining service.

NOTE

NOTE

Note that during the first running period of the unit,

required power input may be higher. This phenomenon

originates from the compressor that requires a 50 hour

run elapse before reaching smooth operation and

stable power consumption. Reason is that the moving

parts are made out of iron and that it takes some time

to smooth the surfaces that make contact.

To protect the compressor, be sure to turn on the

power supply 6 hours before starting operation.

ERLQ018~030BAVJU

Outdoor unit for air to water heat pump

4PW62590-1 – 07.2010

Installation manual

14

15.3. Test run

1 Measure the voltage at the primary side of the circuit breaker.

Check that it is 208/230 V.

2 Carry out the test operation in accordance with the indoor

installation manual and operation manual to ensure that all

functions and parts are working properly.

NOTE

■ The unit requires a small amount of power in

its standby mode. If the system is not to be

used for some time after installation, shut off

the circuit breaker to eliminate unnecessary

power consumption.

■ If the circuit breaker trips to shut off the

power to the outdoor unit, the system will

restore the original operation mode when the

power supply is restored.

NOTE

Have the customer actually operate the unit while

looking at the manual included with the indoor unit.

Instruct the customer how to operate the unit correctly.

16. MAINTENANCE AND SERVICE

In order to ensure optimal operation of the unit, a number of checks

and inspections should be carried out on the unit at regular intervals,

preferably yearly.

This maintenance shall be carried out by the installer or service

agent.

DANGER: ELECTRICAL SHOCK

See "4. General safety precautions" on page 3.

NOTE

Touch a metal part by hand (such as the stop valve) in

order to eliminate static electricity and to protect the

PCB before performing service.

■ After measuring the residual voltage, pull out the

outdoor fan connector.

■ The outdoor fan may rotate due to strong

backblow wind, causing the capacitor to charge.

This may result in an electric shock.

After maintenance, make sure the outdoor fan

connector is connected again. Otherwise, the unit may

break down.

18. DISPOSAL REQUIREMENTS

Dismantling of the unit, treatment of the refrigerant, of oil and of other

parts must be done in accordance with relevant local and national

legislation.

19. UNIT SPECIFICATIONS

19.1. Technical specifications

Casing material Painted galvanised steel

Dimensions h x w x d

Weight 126 lbs (57 kg)

Operation range

• cooling (min./max.) 50/109°F (10/43°C)

• heating (min./max.) 5/77°F (–15/25°C)

• domestic hot water

(min./max.)

Refrigerant oil Daphne FVC68D

Piping connection

• liquid 1/4 inch (6.4 mm)

• gas 5/8 inch (15.9 mm)

19.2. Electrical specifications

Phase 1~ 1~

Frequency 60 Hz 60 Hz

Voltage 230 208

Voltage range

• minimum 207 V 187 V

• maximum 253 V 229 V

28.94 x 32.48 x 11.81 inch

(735 x 825 x 300 mm)

5/95°F (–15/35°C)

DANGER: DO NOT TOUCH PIPING AND INTERNAL

PA RT S

See "4. General safety precautions" on page 3.

CAUTION

Do not rinse the outdoor unit. This may cause electric

shocks or fire.

16.1. Service mode operation

Refer to the service manual to carry out any service mode operation.

17. TROUBLESHOOTING

The troubleshooting is described in the installation manual delivered

with the indoor unit.

Installation manual

15

Outdoor unit for air to water heat pump

ERLQ018~030BAVJU

4PW62590-1 – 07.2010

Loading...

Loading...