Daikin EKHWMX300C, EKHWMXB300C, EKHWMX500C, EKHWMXB500C Operation manuals

Operating instructions

Control unit RoCon mb, EHS157034, EHS157068

Electronic controller for heat pumps

EKHWMX300C

EKHWMXB300C

EKHWMX500C

EKHWMXB500C

07/2019

Operating instructions

Control unit RoCon mb, EHS157034,

EHS157068

English

List of contents

1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Refer to the manual . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Warning signs and explanation of symbols . . . . . 4

1.2.1 Meaning of the warnings. . . . . . . . . . . . . . . . . . . . . .4

1.2.2 Validity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2.3 Handling instructions. . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Avoiding danger . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Use as intended . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Product description. . . . . . . . . . . . . . . . . . . . 6

3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2.1 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2.2 Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Operating concept . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Basic functions and operating modes . . . . . . . . 10

3.4.1 System information (Info) . . . . . . . . . . . . . . . . . . . .10

3.4.2 Setting the operating mode. . . . . . . . . . . . . . . . . . .12

3.4.3 Temperature setting of daytime room temperature.14

3.4.4 Temperature setting of setback mode. . . . . . . . . . .14

3.4.5 Temperature setting of hot water generation . . . . .14

3.4.6 Unscheduled hot water preparation . . . . . . . . . . . . 14

3.4.7 Switching time program. . . . . . . . . . . . . . . . . . . . . .14

3.4.8 System settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.4.9 Terminal function. . . . . . . . . . . . . . . . . . . . . . . . . . .17

3.4.10 Operation with glycol. . . . . . . . . . . . . . . . . . . . . . . .18

3.4.11 Whisper mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4.12 Smart Grid (SG) . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.4.13 EHS emergency operation . . . . . . . . . . . . . . . . . . . 19

3.5 Special functions . . . . . . . . . . . . . . . . . . . . . . . . 20

3.5.1 Manual operation . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.5.2 3-way switching valves reference travel. . . . . . . . .20

3.6 Special system settings . . . . . . . . . . . . . . . . . . . 21

3.6.1 Access rights (technician code) . . . . . . . . . . . . . . . 21

3.6.2 Heat slope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3.6.3 Cooling slope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.6.4 Weather-dependent T-HS control . . . . . . . . . . . . . . 23

3.6.5 Frost protection function . . . . . . . . . . . . . . . . . . . . .23

3.6.6 Interlink function . . . . . . . . . . . . . . . . . . . . . . . . . . .24

3.6.7 Additional alternative heat generator . . . . . . . . . . . 24

3.6.8 Heating support . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.6.9 Special function: switching contacts . . . . . . . . . . . .25

3.6.10 Air purge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3.6.11 Anti-legionella system . . . . . . . . . . . . . . . . . . . . . . . 26

3.6.12 Resetting to factory settings (reset) . . . . . . . . . . . .26

3.6.13 Screed program . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3.6.14 Relay test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.6.15 Settings for optional circulation pump . . . . . . . . . . . 29

3.6.16 Remote control via Internet . . . . . . . . . . . . . . . . . . . 30

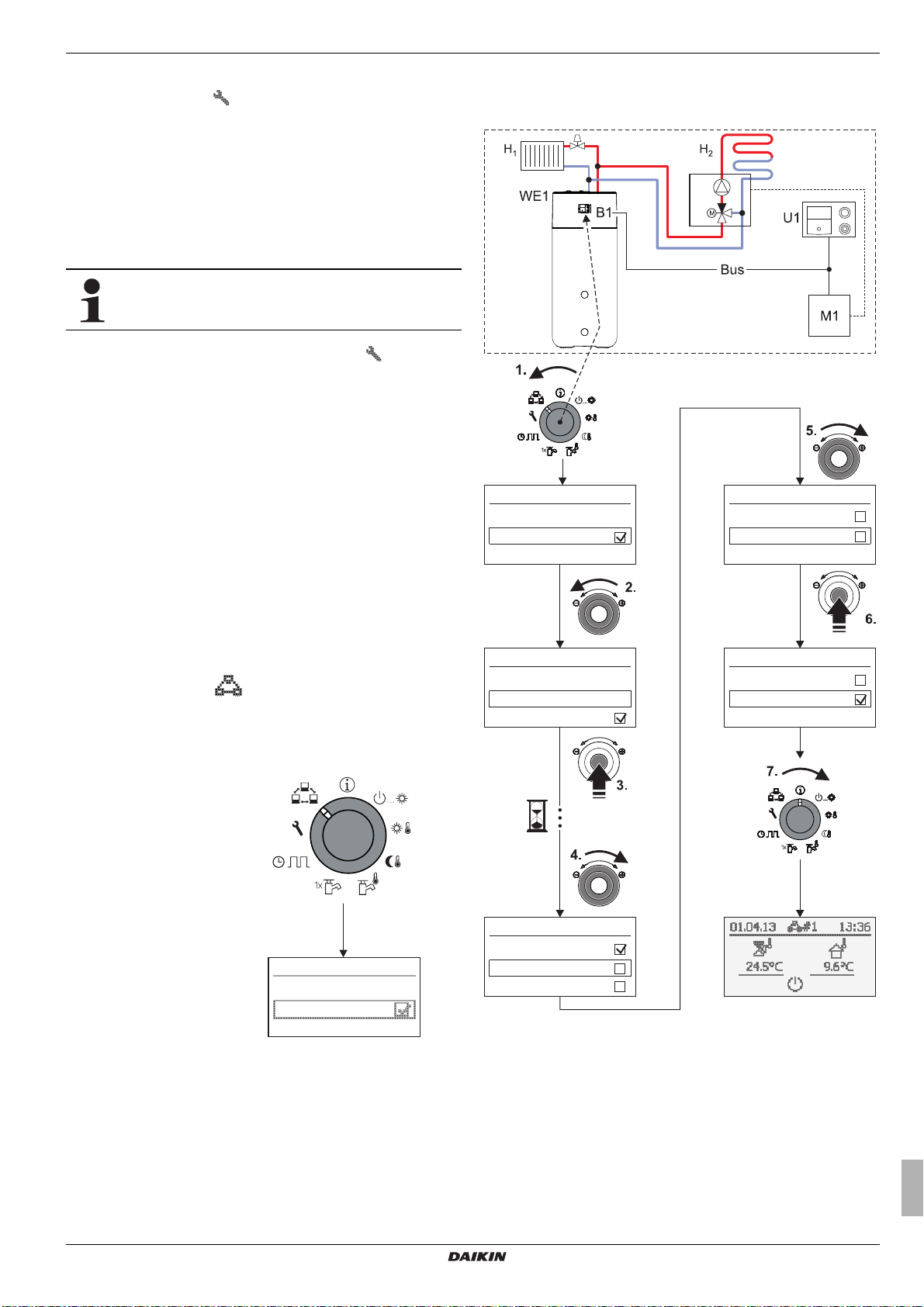

4 Initial start-up . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1 Fundamental aspects of the IDs and

authorisations in the RoCon system . . . . . . . . . 31

4.2 Operating Support during 1st. Commissioning

and during System Extensions. . . . . . . . . . . . . . 32

4.3 Commissioning Daikin Altherma M ECH2O . . . . 33

4.3.1 Assigning the terminal ID on the RoCon B1 control

panel of the Daikin Altherma M ECH2O . . . . . . . . . 33

4.4 Putting optional RoCon system components

into operation . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.4.1 Mixer module EHS157068. . . . . . . . . . . . . . . . . . . 33

4.4.2 EHS157034 room station . . . . . . . . . . . . . . . . . . . 34

4.4.3 Allocating the EHS157068 mixing module to a

heat generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.4.4 Master RoCon function . . . . . . . . . . . . . . . . . . . . . 35

4.4.5 Caretaker function . . . . . . . . . . . . . . . . . . . . . . . . . 35

5 Parameter overview. . . . . . . . . . . . . . . . . . . 36

5.1 For first commissioning or resetting to factory

settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.2 After first commissioning/After successful basic

configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.2.1 Rotary switch setting: Configuration . . . . . . . . . . . 37

5.2.2 Rotary switch setting: DHW Install . . . . . . . . . . . . 38

5.2.3 Rotary switch setting: Operating Mode . . . . . . . . . 38

5.2.4 Rotary switch setting: Set Temp Day . . . . . . . . . . 38

5.2.5 Rotary switch setting: Set Temp Night . . . . . . . . . 38

5.2.6 Rotary switch setting: DHW Set Temp . . . . . . . . . 38

5.2.7 Rotary switch setting: Time Program . . . . . . . . . . 38

5.2.8 Rotary switch setting: Remote Param . . . . . . . . . 38

5.2.9 Rotary switch setting: Info . . . . . . . . . . . . . . . . . . 38

5.2.10 Exit key: Special function. . . . . . . . . . . . . . . . . . . . 38

5.3 Parameter levels for the

EHS157068 mixer module . . . . . . . . . . . . . . . . 38

5.3.1 Rotary switch setting: Info . . . . . . . . . . . . . . . . . . 38

5.3.2 Rotary switch setting: Operating Mode . . . . . . . . . 38

5.3.3 Rotary switch setting: Set Temp Day . . . . . . . . . . 38

5.3.4 Rotary switch setting: Set Temp Night . . . . . . . . . 38

5.3.5 Rotary switch setting: DHW Set Temp . . . . . . . . . 38

5.3.6 Rotary switch setting: DHW Install . . . . . . . . . . . . 38

5.3.7 Rotary switch setting: Time Program . . . . . . . . . . 39

5.3.8 Rotary switch setting: Remote Param . . . . . . . . . 39

5.3.9 Rotary switch setting: Configuration . . . . . . . . . . . 39

6 Parameter settings . . . . . . . . . . . . . . . . . . . 40

6.1 Explanation of the parameter tables . . . . . . . . . 40

6.2 Rotary switch setting: Configuration . . . . . . . . . 40

6.2.1 "Setup" level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.2.2 "System Configuration" level . . . . . . . . . . . . . . . . . 44

6.2.3 "HC Configuration" level . . . . . . . . . . . . . . . . . . . . 45

6.2.4 "DHW Configuration" level. . . . . . . . . . . . . . . . . . . 47

6.3 Rotary switch setting: DHW Install . . . . . . . . . . 47

6.4 Rotary switch setting: Operating Mode . . . . . . 48

6.5 Rotary switch setting: Set Temp Day . . . . . . . . 48

6.6 Rotary switch setting: Set Temp Night . . . . . . . 48

6.7 Rotary switch setting: DHW Set Temp . . . . . . . 48

6.8 Rotary switch setting: Time Program . . . . . . . . 49

6.9 Rotary switch setting: Remote Param . . . . . . . 49

6.10 Rotary switch setting: Info . . . . . . . . . . . . . . . . 49

6.11 Exit key: Special function . . . . . . . . . . . . . . . . . 50

6.12 "Basic Configuration" parameter level. . . . . . . . 51

6.13 Parameter levels of the

EHS157068 mixer module . . . . . . . . . . . . . . . . 51

6.13.1 Rotary switch setting: Configuration ,

"Setup" level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.13.2 Rotary switch setting: Configuration ,

"Mixer Config" level . . . . . . . . . . . . . . . . . . . . . . . . 53

Operating instructions

2

7 Errors, malfunctions and messages . . . . . 55

7.1 Recognising errors, correcting malfunctions . . . 55

7.1.1 Current error display . . . . . . . . . . . . . . . . . . . . . . . 55

7.1.2 Reading out the protocol . . . . . . . . . . . . . . . . . . . . 55

7.1.3 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.2 Emergency operation . . . . . . . . . . . . . . . . . . . . 56

Daikin Control unit

008.1446899_00 – 07/2019 – EN

RoCon mb

7.3 EHS emergency operation . . . . . . . . . . . . . . . . .56

7.4 Malfunctions and fault codes . . . . . . . . . . . . . . .56

8 Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

9 Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

9.1 User-specific settings . . . . . . . . . . . . . . . . . . . . .58

9.1.1 Switching time program. . . . . . . . . . . . . . . . . . . . . 58

9.1.2 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.1.3 IDs in the RoCon CAN bus system . . . . . . . . . . . . 59

9.2 Other items . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

10 List of keywords . . . . . . . . . . . . . . . . . . . . . .63

List of contents

Daikin Control unit

RoCon mb

008.1446899_00 – 07/2019 – EN

Operating instructions

3

1 x Safety

1 Safety

1.1 Refer to the manual

These instructions are the >> translation of the

original version << in your language.

All the activities required for operation and

setting the parameters are described in this instruction manual. All parameters needed for

trouble-free operation have been configured at

the factory.

● Please read through this manual carefully

before operating the heating system or before

adjusting the settings for it.

● Make a note of the preset values before you

make any changes to the unit configuration.

Relevant documents

– Daikin Altherma M ECH

O:

2

– Installation and maintenance instructions

– Operating instructions for the user/owner

– Commissioning checklist

– the operating manual for the user/owner

– Outdoor unit for Daikin Altherma M ECH

2

O:

the respective installation and operating

instructions.

– On connection of a Daikin solar system: the

respective installation and operating instructions.

– On connection of a Daikin FWXV-ATV3: the

respective installation and operating instructions.

– For connecting to another Daikin heat gener-

ator or optional accessories: the associated

installation and operating instructions.

1.2 Warning signs and explanation of

symbols

1.2.1 Meaning of the warnings

Warnings in this manual are classified according

into their severity and probability of occurrence.

DANGER!

Draws attention to imminent danger.

Disregarding this warning can lead to serious

injury or death.

WARNING!

Indicates a potentially dangerous situation.

Disregarding this warning may result in serious

physical injury or death.

CAUTION!

Indicates a situation which may cause possible

damage.

Disregarding this warning may cause damage

to property and the environment.

This symbol identifies user tips and particularly useful information, but not

warnings or hazards.

The guides are included in the scope of supply

for the individual units.

Operating instructions

4

Special warning signs

Some types of danger are represented by

special symbols:

Electric current

Risk of burning or scalding

Daikin Control unit

008.1446899_00 – 07/2019 – EN

RoCon mb

1.2.2 Validity

1 x Safety

Some information in this manual has limited validity. The validity is highlighted by a symbol.

Only valid for Daikin Altherma M ECH2O

with cooling function

Only valid/available with a connected

room station (EHS157034)

Only valid/available with a connected

mixer module (EHS157068)

1.2.3 Handling instructions

● Handling instructions are shown as a list.

Actions for which the sequential order must be

maintained are numbered.

Results of actions are identified with an

arrow.

Display readouts of the RoCon controller

Entry into a setting procedure

Exit from a setting procedure

Certain screen displays or menu items may deviate from those shown in these instructions depending on the national or equipment variant of

the Daikin Altherma M ECH

O or the user status

2

logged onto the controller.

1.3 Avoiding danger

WARNING!

This equipment must only be used by children

aged 8 and above and by persons with restricted physical, sensory or mental capabilities

or with a lack of experience and knowledge, if

they are under supervision or if they have been

instructed in the safe use of the equipment and

understand the dangers arising therefrom.

Children must not play with the equipment.

Cleaning or user maintenance must not be

carried out by children without supervision.

1.4 Use as intended

The RoCon mb controller must only be used in

Daikin Altherma M ECH

O heat pumps that are

2

approved for the Daikin RoCon regulating

system. The Daikin RoCon mb must only be operated as per the data in these instructions.

Any other use outside the intended use is considered as improper. The operator alone shall

bear responsibility for any resulting damage.

For any work on the equipment, which extends

above and beyond the operation of the regulating system, you must observe the details provided in the supplementary documents, particularly with regard to safety instructions.

The Daikin Altherma M ECH

O is built according

2

to the state-of-the-art and the recognised technical rules. However, improper use may result in

serious physical injuries or death, as well as

property damage.

To avoid hazards, only operate the Daikin

Altherma M ECH

O:

2

– as stipulated and in perfect condition,

– with an awareness of safety and the hazards

involved.

This assumes knowledge and use of the contents of this manual, of the relevant accident prevention regulations as well as the recognised

safety-related and occupational health rules.

Daikin Control unit

RoCon mb

008.1446899_00 – 07/2019 – EN

Operating instructions

5

2 x Product description

2 Product description

The RoCon mb controller is part of the Daikin

Altherma M ECH

O.

2

It consists of the RoCon BM1 printed circuit board, to

which the actuators, sensors and further components of the

Daikin RoCon regulating system are connected, and the

RoCon B1 control panel.

In this instruction manual we explain just the functions and

setting possibilities of the control unit. More detailed information

on the Daikin Altherma M ECH

O and other device components

2

can be found in the other applicable documents.

Depending on heater unit, the electronic, digital controller automatically regulates all heating, cooling and hot water functions for

a direct heating circuit, a storage tank charging circuit and, via

mixer modules that can be optionally connected, also further

heating circuits.

It undertakes all safety management for the Daikin Altherma M

ECH

O. This executes a safety switch-off in the event of a water

2

shortage or undefined operating states. A corresponding error

message shows the operator all the information for fault causes.

All function settings for the Daikin Altherma M ECH

O and the

2

optional RoCon devices that are connected via the data bus are

undertaken with the controls of the integrated RoCon B1 control

panel and shown on the plain text display with coloured backlighting.

The following additional, optional devices can be connected to

the Daikin Altherma M ECH

O via the controller data bus:

2

– EHS157034 room station.

– EHS157068 mixer module.

The RoCon mb control unit contains a timer which can be used

to set:

– 2 individual adjustable switching time programs

heating and room cooling

(direct heating circuit),

2)

for room

– 2 individually-adjustable timer programs for hot water gener-

ation,

– 1 individually-adjustable timer program for an optional circu-

lation pump.

2) Use of the switching time programs for room cooling only in combination with a

connected room thermostat

Initial commissioning of the heating system is described in the installation instructions for the Daikin Altherma M ECH

O.

2

Certain menu items of the RoCon mb control unit are only accessible for the heating expert. This security measure ensures that

no undesirable malfunctions arise during operation of the system

through incorrect settings.

The EHS157034 room station has the same user interface as the

Daikin Altherma M ECH

O's integrated RoCon B1 control panel.

2

All settings for the allocated heating circuit can be carried out in

the same way as the operating unit. With activated terminal

function, all operating possibilities that are available on the integrated operating unit are available, with the exception of certain

special functions (e.g. Manual Operation).

After corresponding assignment, a connected EHS157068 mixer

module is also operated using the RoCon B1 control panel and/or

the EHS157034 room station.

In addition, the RoCon mb controller has a frost protection

function for the direct heating circuit and the storage tank

charging circuit as well as an automatic function for heating

support (integration of an additional heat source such as a woodburning boiler or solar system).

The potential-free AUX switching contact can be used to carry out

different control functions in conjunction with external devices

(demand from an external heat generator, switching to bivalent

operating mode, external status display, etc.).

Several inputs for evaluating external control contacts are also

available (external operating mode switching or heat request,

Smart Grid and off-peak EVU functions

1) Utility company (EVU) outputs signals that are used to control power grid capacity utilisation and influence the electricity price and availability.

1)

.

With the optional EKRSC1 outside temperature sensor that is installed on the north side of the building, weather-dependent T-HS

control can be further optimised.

If the optional EHS157056 gateway is installed and connected to

the Internet, the Daikin Altherma M ECH

O can be conveniently

2

monitored and operated by remote control using a mobile phone

(app).

Operating instructions

6

Daikin Control unit

008.1446899_00 – 07/2019 – EN

RoCon mb

3 Operation

3 x Operation

3.1 General

DANGER!

If electrical components come into contact with

water, this can cause an electric shock as well

as cause potentially fatal burns or injuries.

● The displays and the keys of the control unit

must be protected against the effects of

moisture.

● To clean the control unit, use a dry cotton

cloth. Using aggressive cleaning agents

and other fluids can cause damage to

devices or lead to an electric shock.

Maximum energy exploitation

The Daikin Altherma M ECH2O makes the most effective use of energy at the lowest possible return and

target hot water temperature.

If an external heat generator (e.g. the optional backup heater)

is activated at target feed temperatures over 50 °C, the efficiency (COP) of the Daikin Altherma M ECH

(depending on the outside temperature).

O can deteriorate

2

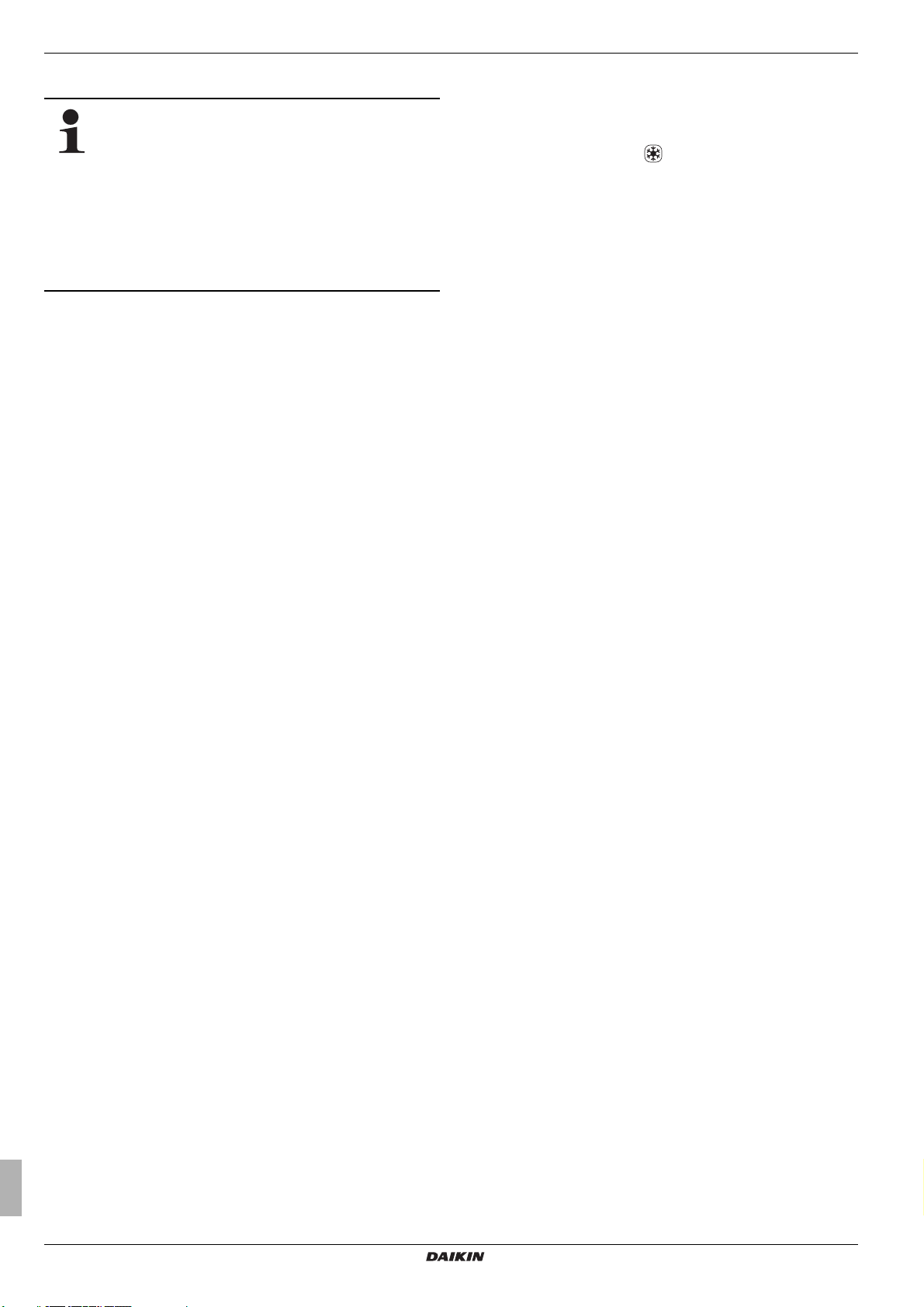

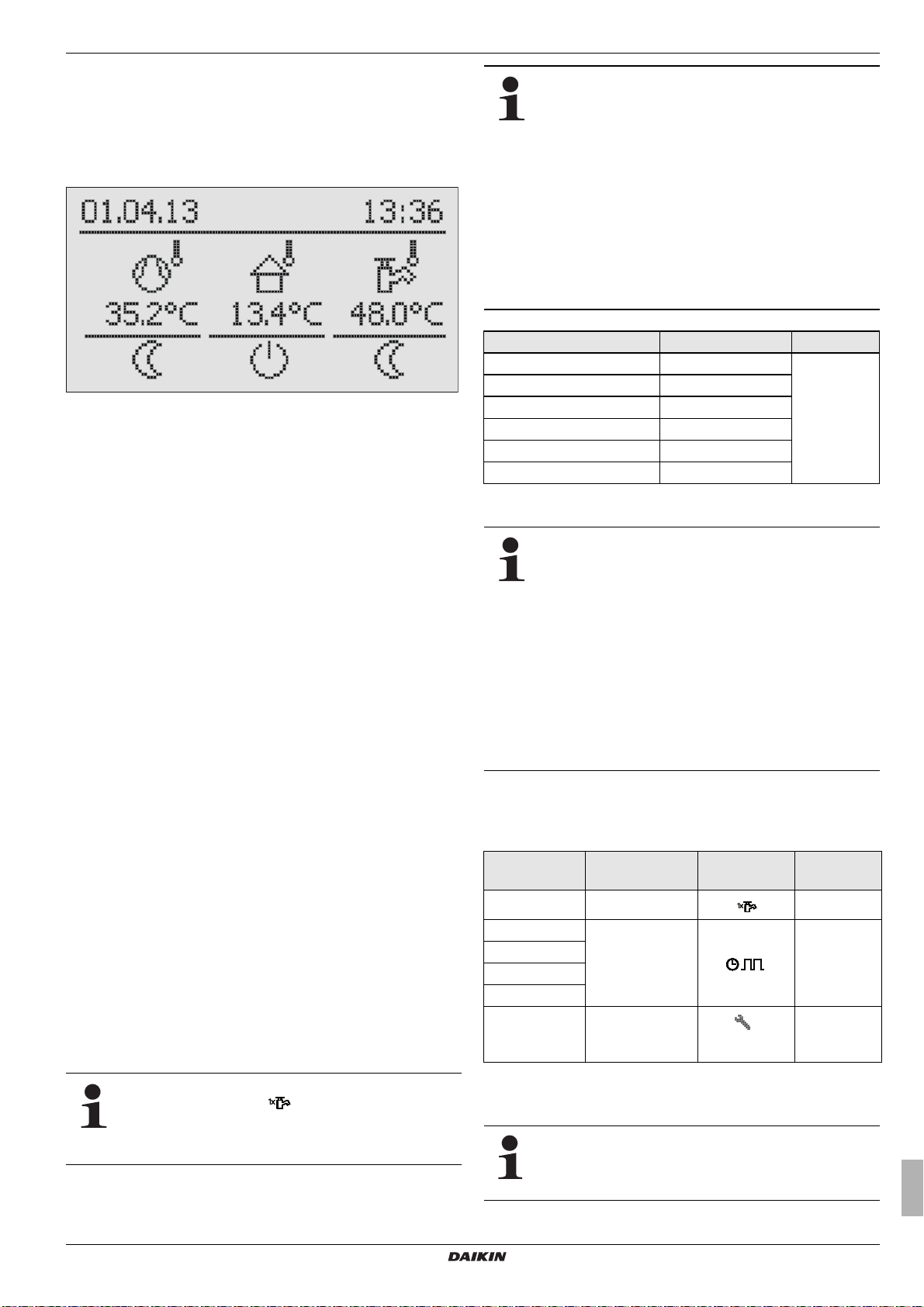

3.2.1 Display

All operating steps are supported by corresponding displays on a

coloured backlit plain text display.

The menu guidance can be displayed 7 languages (see

chap. 3.4.8).

Malfunctions are generally indicated by a fault code and

a clear text fault message on the display.

For troubleshooting instructions, see Chapter 7.

The colour of the backlighting indicates the operational status

and the operating mode:

White: Standard lighting, normal operating display.

Red: Fault status; depending on the type of fault, the

Daikin Altherma M ECH

restrictions.

Green: Operating mode with operator authorisation.

Blue: Operating mode with expert authorisation.

O continues to operate with

2

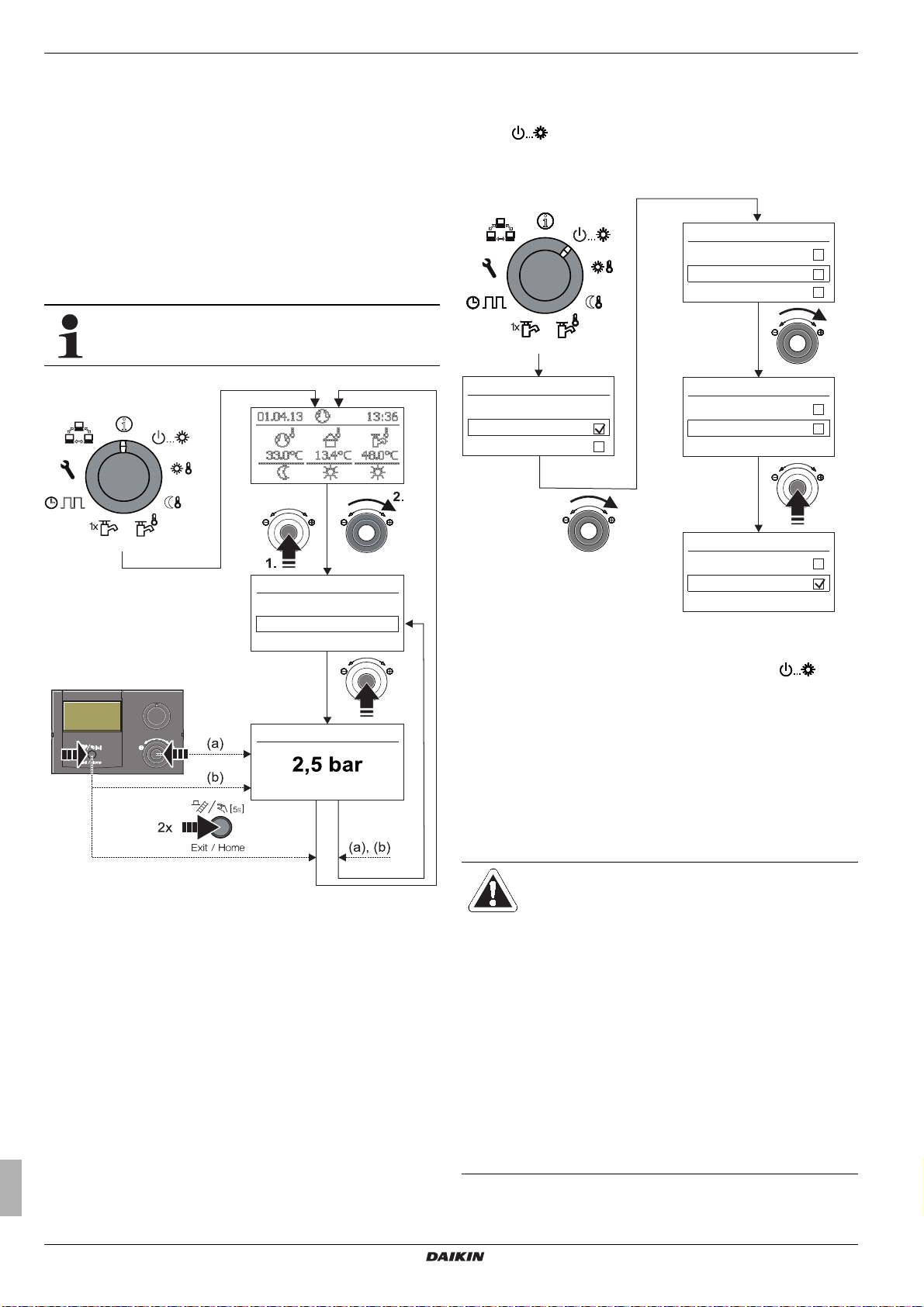

3.2 Display and operating elements

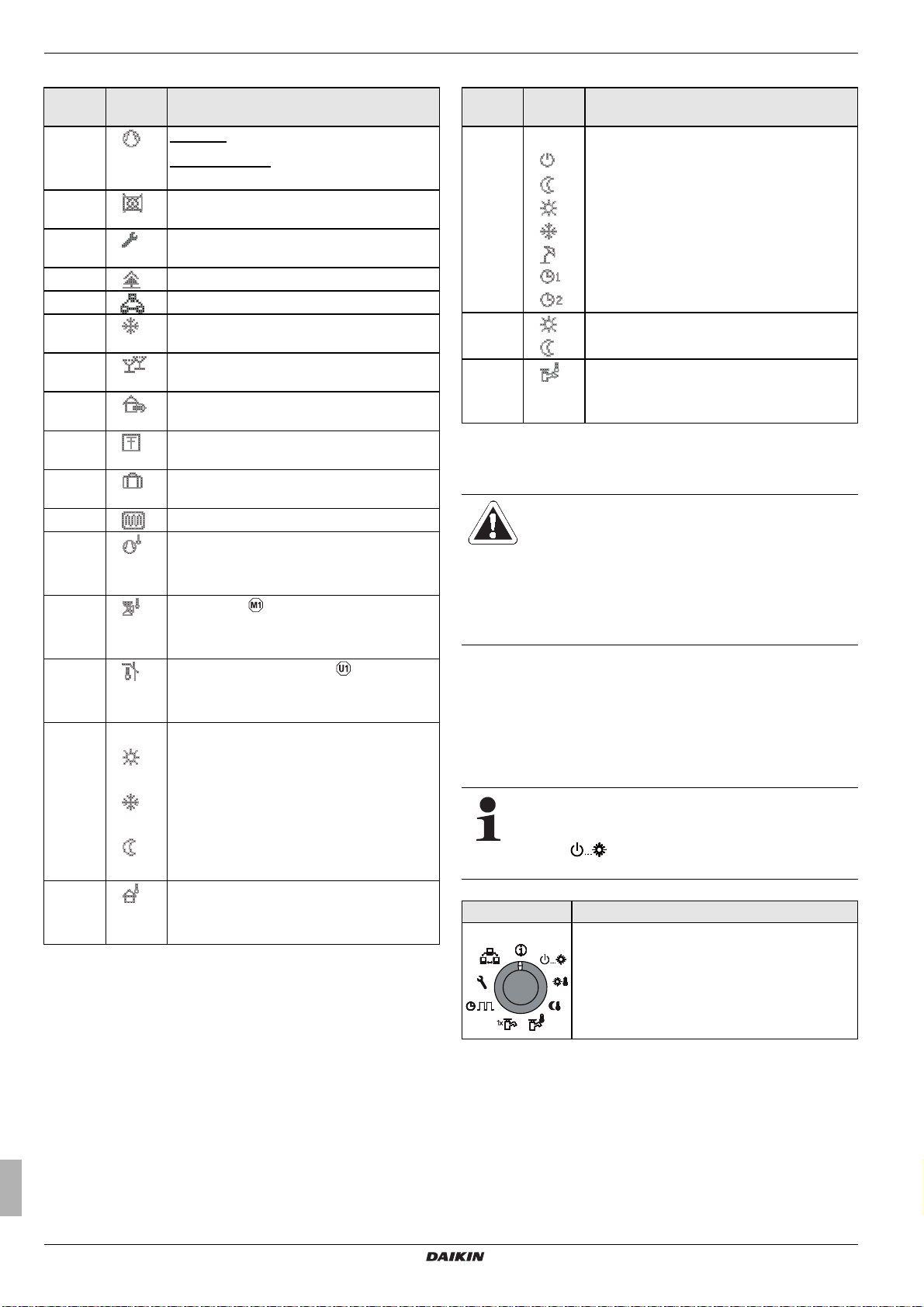

1 Clear text display

2 Setting: Configuration

3 Setting: Remote Param

4 Rotary switch

5 Setting: Info

6 Setting: Operating Mode

Fig. 3-1 Arrangement of display and operating elements

7 Setting: Set Temp Day

8 Setting: Set Temp Night

9 Setting: DHW Set Temp

10 Rotary button

11 Setting: DHW Install

12 Setting: Time Program

13 Exit key

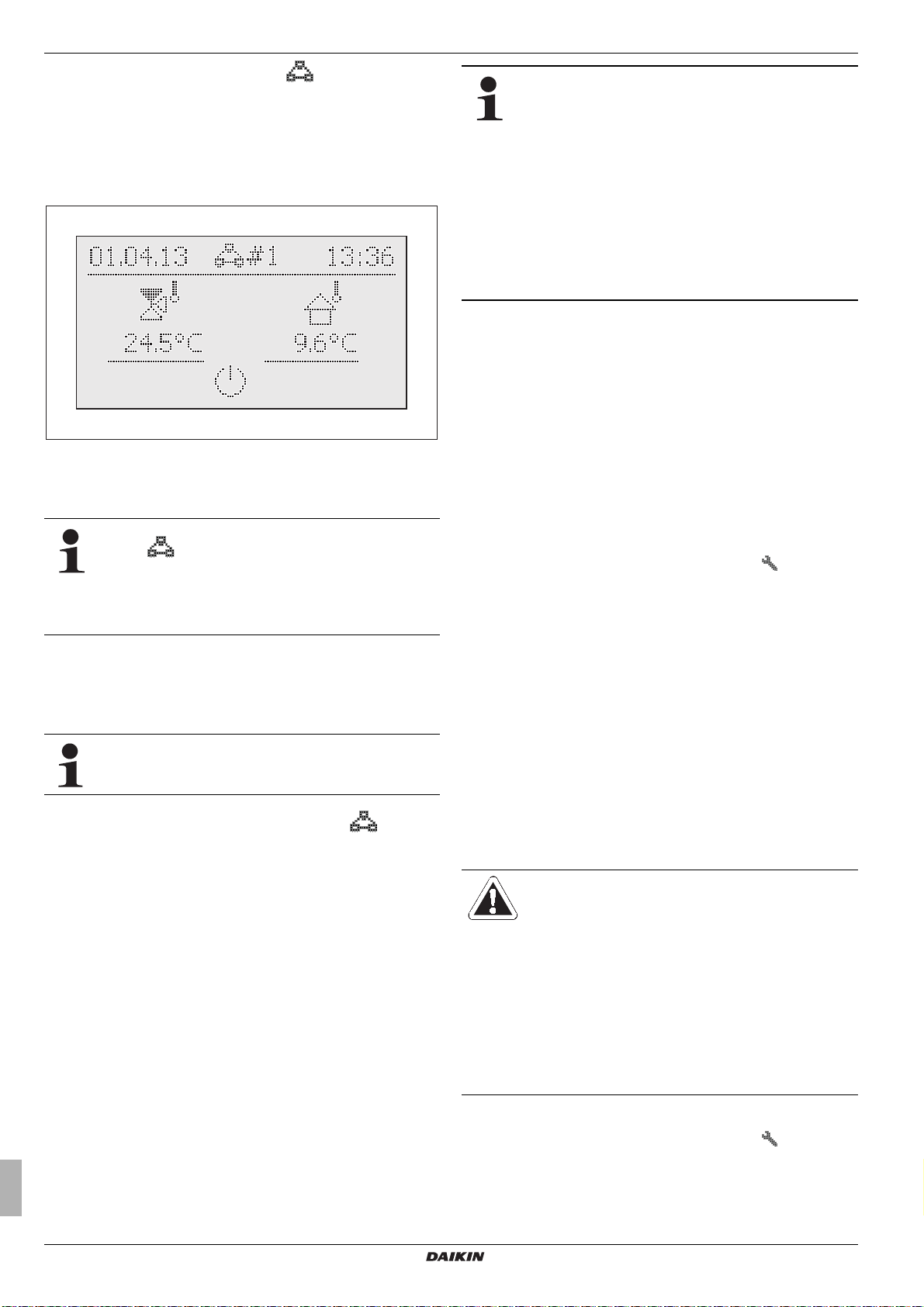

1 Display date

2 Refrigerant compressor

status

3 Status display (e.g. techni-

cian access rights active)

4 Display time

5 Current feed temperature

6 Heating circuit status

Fig. 3-2 Display of the control unit - standard display

7 Current outside temperature

8 Active operating mode

9 Hot water generation status

10 Current storage temperature

Daikin Control unit

RoCon mb

008.1446899_00 – 07/2019 – EN

Operating instructions

7

3 x Operation

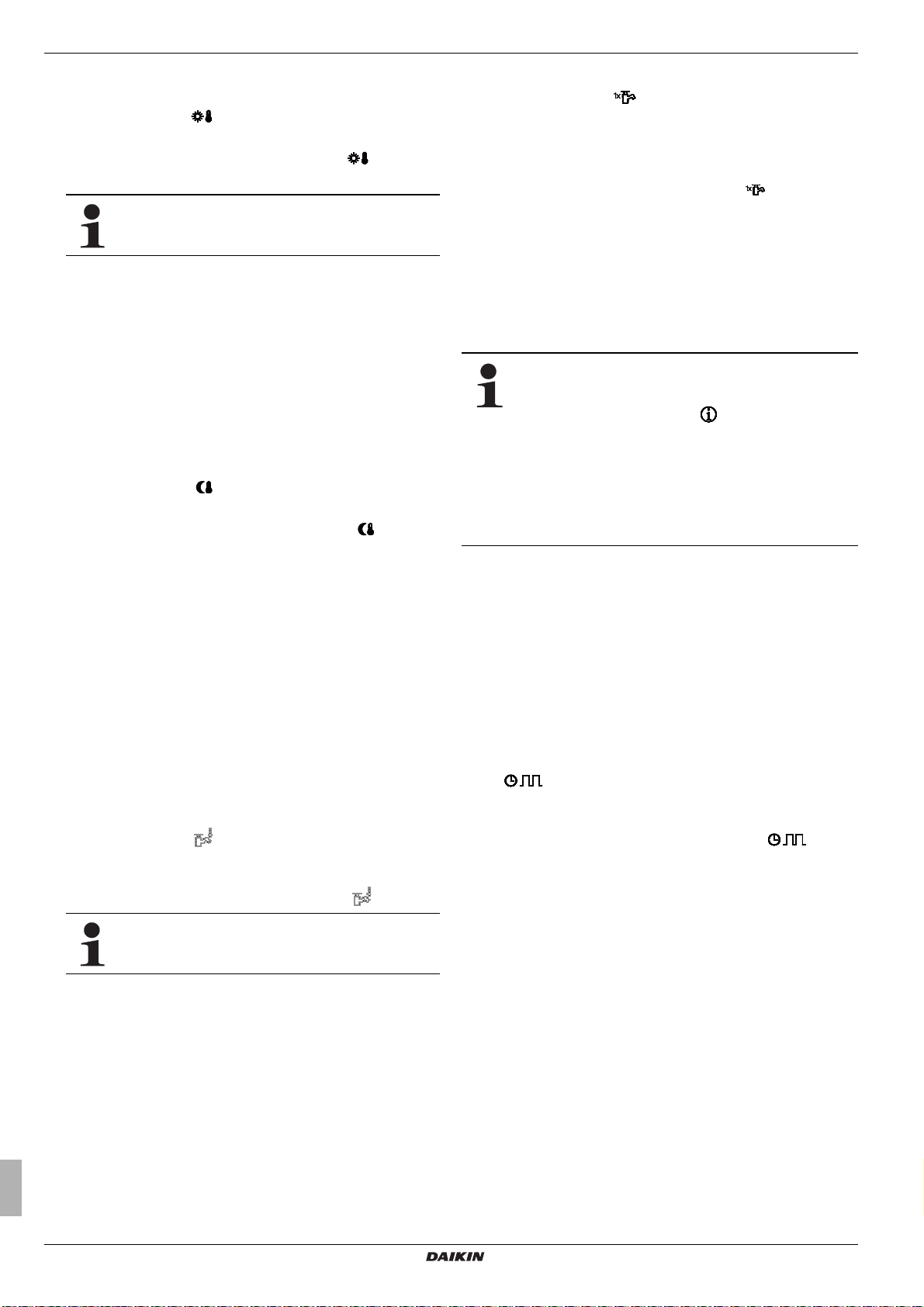

Explanation of symbols

Item

fig. 3-2

2

2

3

2 / 3

2 / 3

2 / 3

2 / 3

2 / 3

2 / 3

2 / 3

2 / 3

5

5

5

6 Heating circuit status

7 External temperature sensor

Icon Explanation

Flashing: heat pump request active

Permanently on: refrigerant compressor operating

No connection to the heat pump outdoor

unit

Expert access rights active (see

chap. 3.6.1)

Air purge active (see chap. 3.6.10)

Terminal function active (see chap. 3.4.9)

Frost protection function active (see

chap. 3.6.5)

Temporary time program "Party" active (see

chap. 3.4.7)

Temporary time program "Away" active

(see chap. 3.4.7)

Temporary time program "Holiday" active

(see chap. 3.4.7)

Temporary time program "Vacation" active

(see chap. 3.4.7)

Screed program active (see chap. 3.6.13)

Direct heating circuit

The current feed temperature t

played beneath this.

Mixer circuit

The current T-HS of the assigned heating

circuit is displayed underneath.

Room temperature sensor

The current room temperature is displayed

underneath.

– Heating circuit active (room heating

function)

– Heating circuit active (room cooling

function)

– Heating circuit not active (currently no

thermal transport in the heating circuit)

The current outside temperature is displayed underneath.

V, BH

is dis-

Item

fig. 3-2

8 Current operating mode (see chap. 3.4.2)

9

10

Tab. 3-1 Explanation of display symbols

Icon Explanation

Standby active

Reducing active

Heating active

Cooling active

Summer active

Automatic 1 active

Automatic 2 active

Hot water generation active

Hot water generation not active

Hot water heating circuit status

The current storage tank temperature t

is displayed beneath this.

DHW

3.2.2 Controls

CAUTION!

Never operate the operating elements of the

control unit with a hard, pointed object. This can

cause damage and can cause the control to

malfunction.

If special key combinations or long key presses are required for

certain functions, these are referred to separately in the respective section of this manual.

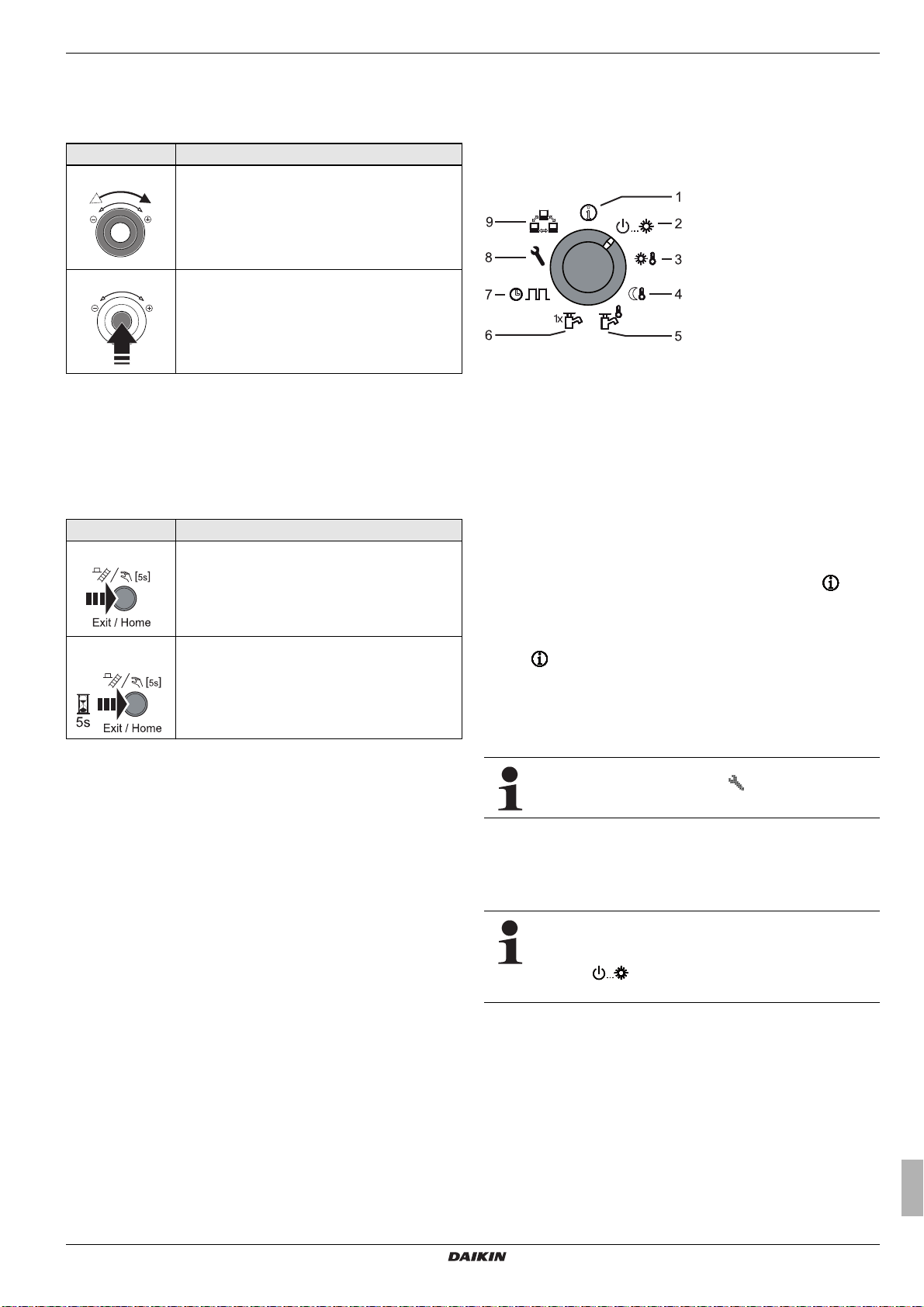

Rotary switch

Frequently required functions and setting options can be quickly

and directly selected using the rotary switch (main function level).

Irrespective of the rotary switch position, the Daikin

Altherma M ECH

ating mode which has been set in the "Operating

Mode"

program.

Action Result

Turning

O operates according to the oper-

2

switch position or activated by a special

Operating instructions

8

Direct selection of the main function level

assigned to this switch position.

Tab. 3-2 Function of the rotary switch

Daikin Control unit

008.1446899_00 – 07/2019 – EN

RoCon mb

3 x Operation

Rotary button

The rotary button can be used to navigate in the respective level,

to select or change the setting value and to accept this change

with a short key press.

Action Result

Turning

To the right (+): increasing adjustment

To the left (–): decreasing adjustment

Touching

Confirm selection, accept setting, execute

function.

Tab. 3-3 Functions of the rotary button

Exit key

This key can be used to jump back to the previous display within

a menu item or to cancel a function/input.

The special level can also be called up using this key (see

chap. 3.5).

Action Result

Touch briefly.

Press for longer

than 5 seconds.

Tab. 3-4 Functions of the Exit key

– Return to the previous display or the pre-

vious level or

– cancel a special function or an active,

temporary time program.

– A special level is called up.

3.3 Operating concept

The operating concept of the RoCon mb control unit is designed

so that frequently required setting options can be accessed

quickly and directly at the main function level (selection by

means of rotary switch) and less frequently required setting options are arranged on a lower lying parameter level.

1 Info (chap. 3.4.1)

2 Operating Mode (chap. 3.4.2)

3 Set Temp Day (chap. 3.4.3)

4 Set Temp Night (chap. 3.4.4)

5 DHW Set Temp (chap. 3.4.5)

6 DHW Install (chap. 3.4.6)

7 Time Program (Chap. 3.4.7)

8 Configuration (Chap. 3.4.8)

9 Remote Param (Chap. 3.4.9)

Fig. 3-3 Illustration of the main function level (rotary switch position)

Certain functions and parameters are restricted by access rights

and can only be configured by a heating expert (see chap. 3.6.1).

In normal operation, the rotary switch should be in the position.

After switching on and successful initialisation, the standard

display automatically shows the display for the rotary switch

setting

During initial start-up, the setting for the language selection is first

displayed.

● Select the language with the rotary button.

● Confirm the selection with a brief push of the rotary button.

.

Adaptations to the special system configuration are

made in the "Configuration"

rotary switch setting

(see chap. 3.4.8).

Daikin Control unit

RoCon mb

008.1446899_00 – 07/2019 – EN

If the system is switched on, the defaults set in the RoCon mb

control unit fully automatically control the operation of the

– room heating, room cooling and

– hot water generation plumbing.

Irrespective of the rotary switch position, the Daikin

Altherma M ECH

O operates according to the oper-

2

ating mode which has been set in the "Operating

Mode"

switch position or activated by a special

program.

If the user sets a value manually, this setting remains active until

the user changes it or until the timer program forces a different

mode of operation.

Operating instructions

9

3 x Operation

The operating modes can be affected by additional functions

such as:

– Weather-dependent T-HS control

– Switching time program

– Setting the temperature target value

– Setting on the room station

– Setting on the room thermostat

– Switch status on the EXT input (external operating mode

changeover)

– Switch status at the EBA input (external requirement request)

– Whisper mode

– Interlink function

– Switch status at the Smart Grid input (EVU function

Smart Grid)

– Switch status at the EVU input (EVU function HT/NT (off-

peak) or Smart Grid)

– Defrost function

– Frost protection function

– Screed function

– Air purge

– Manual operation

– EHS emergency operation

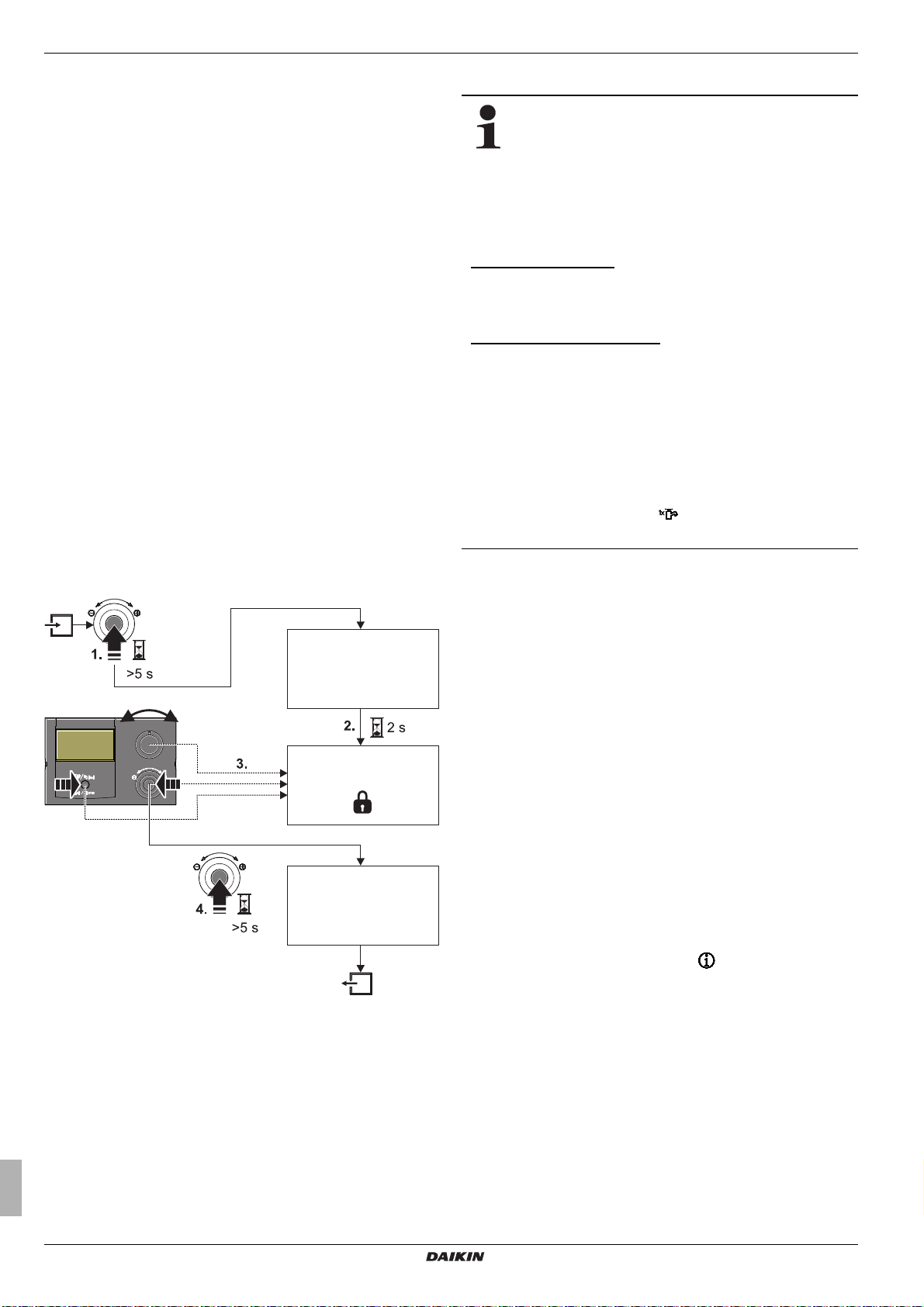

Keylock

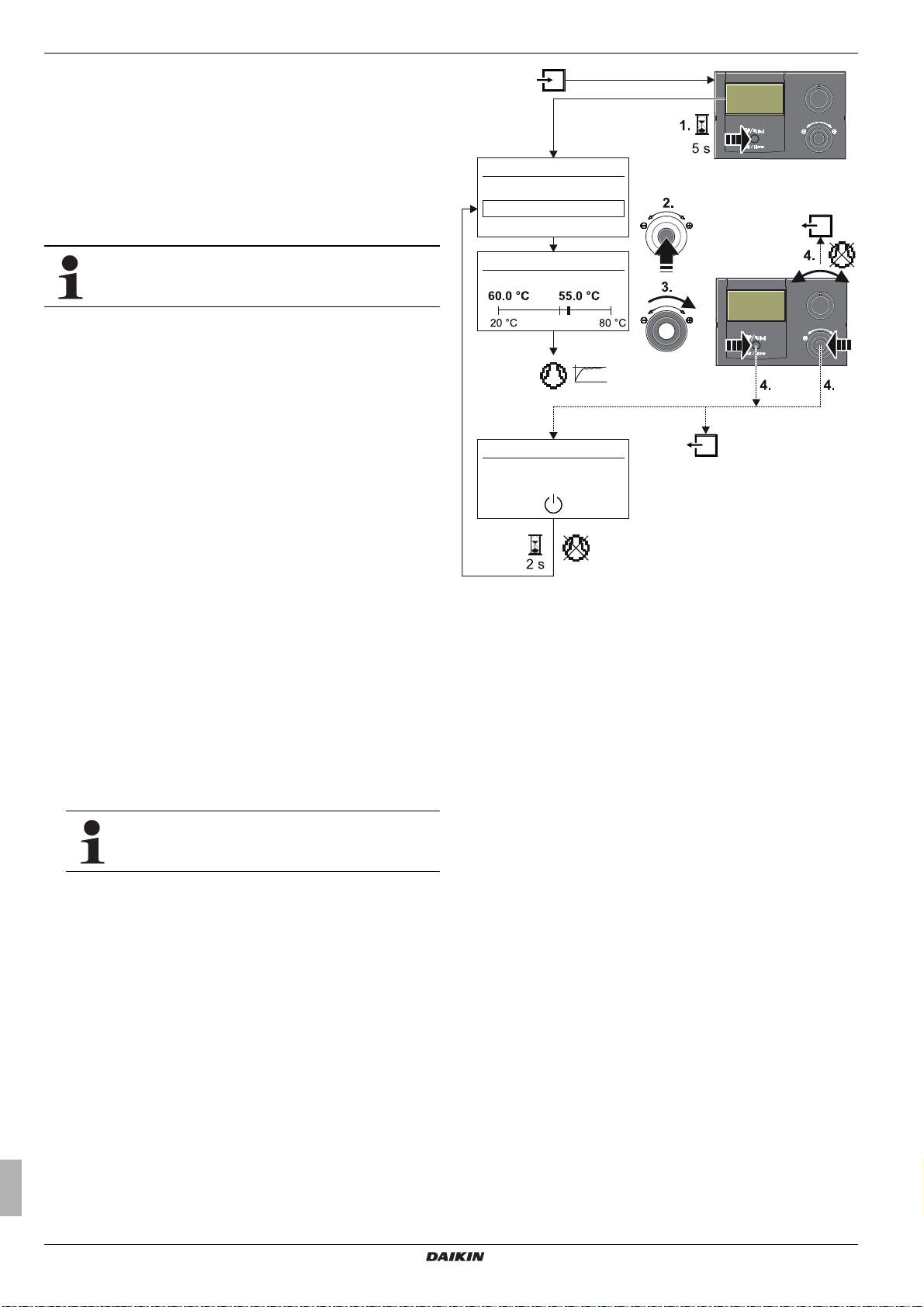

The control panel of the RoCon mb can be locked against inadvertent operation (see fig. 3-4).

It is unlocked in the same way.

Precondition for this function is that the [Keylock Function] parameter at the "Setup" level is set to "On" (see chap. 6.2.1,

tab. 6-1).

Keylock Function

On

Keylock Function

3.4 Basic functions and operating modes

If the storage tank temperature falls below specific

minimum values, the Daikin Altherma M ECH

safety settings prevent the heat pump from being

operated at low outside temperatures:

– Outside temperature < -2 °C, minimum storage tank

temperature = 30 °C

– Outside temperature < 12 °C, minimum storage tank

temperature = 23 °C.

Without backup heater:

The storage tank water must be heated to the required

minimum storage tank temperature with an external heater

booster.

With backup heater (EKBUxx):

At an outside temperature of < 12 °C and a storage tank temperature of < 35 °C, the backup heater (EKBUxx) is automatically switched on to heat the storage tank water to at least

35 °C.

● To speed up the heating process with backup heater,

temporarily set

– parameter [Function Heating Rod] = "1" and

– parameter [Power DHW] to the maximum value of the

backup heater.

– Set the rotary switch to

operating mode, and set the

parameter [1x Hot Water] to "On".

Automatic defrost function

At low outdoor temperatures and corresponding humidity, the

heat pump outdoor unit may ice up. This icing impairs efficient operation. The system detects this status automatically and starts

the defrost function.

While the defrost function is active, heat is drawn from the hot

water storage tank, and the backup heater is activated if necessary. Depending on the heat required for the defrost function,

heating the direct heating circuit may be temporarily interrupted

during the defrosting process.

After a maximum of 8 minutes, the system switches back to

normal operation.

2

O's

Keylock Function

Fig. 3-4 Activating (1.) and deactivating (4.) the key lock

Operating instructions

10

Off

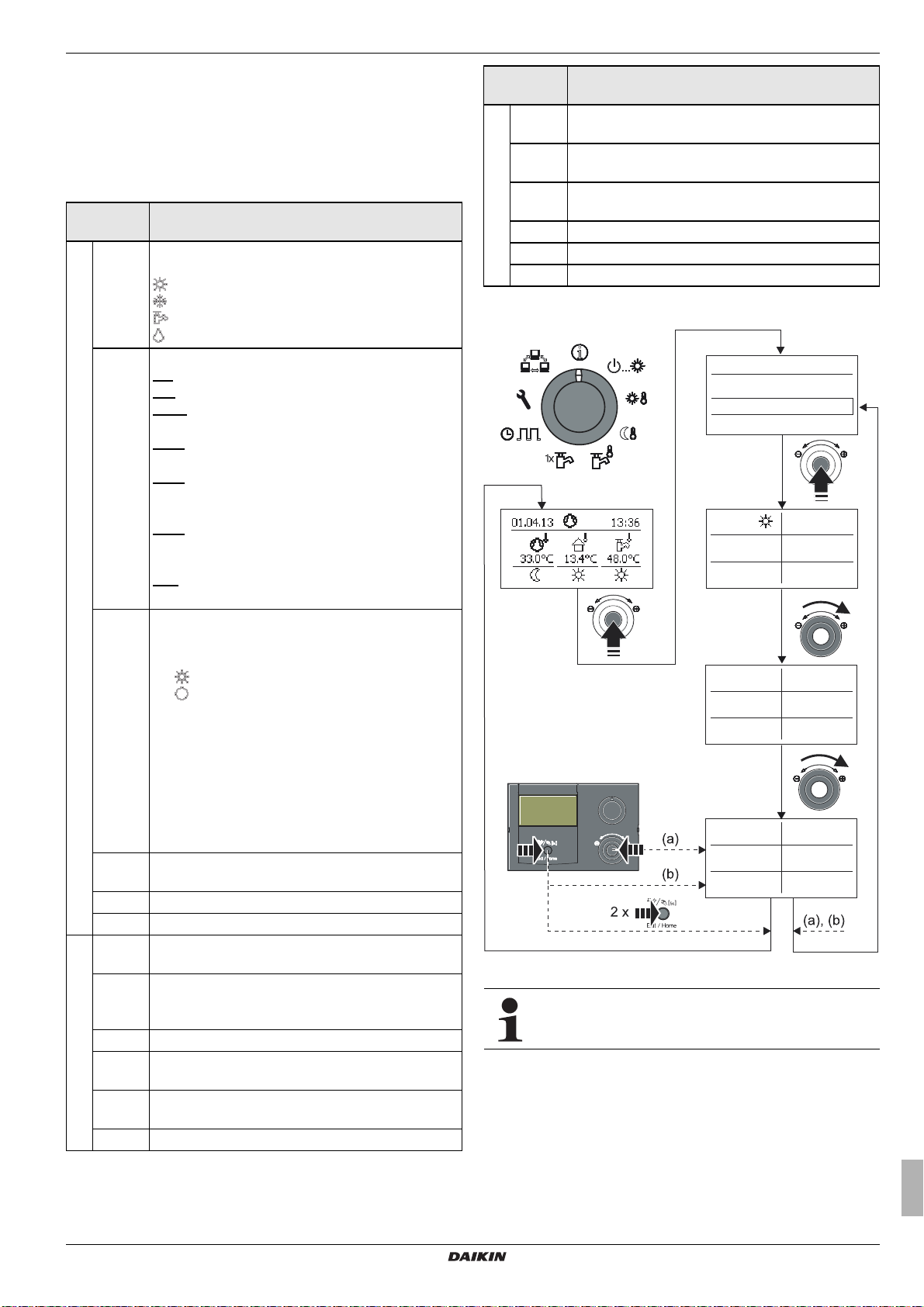

3.4.1 System information (Info)

In this rotary switch position, the rotary button can be used to

query all system temperatures, the Daikin Altherma M ECH

O

2

type, various software information and the operating states of all

system components in succession. The number of displayed parameters depends on which components are connected.

No adjustments can be made to these values.

● Set the rotary switch to the "Info"

position.

Standard display is shown (see fig. 3-2).

● Press the rotary button briefly.

Parameter overview is displayed.

● Use the rotary button to select the desired information level.

● Confirm the selection with a brief push of the rotary button.

Value is displayed (example, see fig. 3-6).

● Use the rotary button to select the individual information.

Further explanations on, and possible display values for, this rotary switch position

can be found in tab. 3-5 and chap. 6.10.

Daikin Control unit

008.1446899_00 – 07/2019 – EN

RoCon mb

3 x Operation

Displaying the operating data overview

On the "Overview" information level, the RoCon mb controller's

display shows the current operating data for the Daikin

Altherma M ECH

The display of the operating data is split over several screen

pages. Adjust the rotary button to navigate between the screen

pages.

Short des-

ignation

Mode Current heat pump mode:

Ext Current heat pump energy mode:

Page 1

RT Parameter [Room thermostat] / [Interlink fct]

Pump Current status of the internal heating circulation

V Actual flow rate in the heating system

EHS Current output of the backup heater in kW

TV Current feed temperature downstream of the plate

TVBH Current heating feed temperature, poss. down-

TR Current temperature of heating return (t

Page 2

Tdhw Current temperature in the hot water storage tank

TA Current outside temperature (measured by the

Psyst Current water-side pressure in the heating system

O.

2

Explanation of the display value

- - -: No heat or cooling request

: Heating

: Cooling

: Hot water generation

: Automatic defrost function active

LT: EVU function HT/NT active and off-peak.

HT: EVU function HT/NT active and peak.

SGN: EVU function Smart Grid active, normal

operation.

SG1: EVU function Smart Grid active, shut-off: no

heat pump operation, no frost protection function.

SG2: EVU function Smart Grid active, switch-on

recommendation, operation at higher target

temperatures, inexpensive electricity.

SG3: EVU function Smart Grid active, switch-on

command and storage tank charging to 70 °C,

inexpensive electricity

- - -: No external mode active, heat pump operates

in standard mode.

= Off: - - -

Parameter [Room thermostat] = On:

– : Heat or cooling request

–

: No heat requirement

Parameter [Interlink fct] = On (priority):

– - - -: Frost protection only

– IL1: Normal target feed temperature

– IL2:

– In heating mode, increased target feed

temperature

– In cooling mode, reduced target feed tem-

perature

pump

heat exchanger (t

V1

)

stream of the heating support heat exchanger

(t

)

V, BH

)

R1

)

(t

DHW

heat pump outdoor unit temperature sensor)

Short des-

Explanation of the display value

ignation

BPV Current position of mixing valve 3UVB1

(100% = A, 0% = B)

3UVD Current position of mixing valve 3UV DHW

(100% = B, 0% = A)

TA2 Current outside temperature (measured by the op-

Page 3

Tliq2 Current refrigerant temperature (t

tional outside temperature sensor EKRSC1)

)

L2

quiet Indicates the whisper mode status

Glycol Glycol present: 0 (No) / 1 (Yes)

Tab. 3-5 Explanation of the operating data displayed as an overview

Info

Overview

Water Pressure

Mode:

Ext:

RT:

TV:

TVBH:

TR:

BPV:

3UVD:

TA2:

Fig. 3-5 Displaying the operating data overview

- - -

- - -

44°C

0%

2°C

Pump:

V:

EHS:

Tdhw:

TA:

Psyst:

Tliq2:

quiet:

Glycol:

On

1205 l/h

3 kW

48°C42°C

1°C

1,9 bar36°C

46°C0%

On

0

At low return flow temperatures and with glycol in the

system, only "ffff" is displayed as the volumetric flow, no

current value.

Daikin Control unit

RoCon mb

008.1446899_00 – 07/2019 – EN

Operating instructions

11

3 x Operation

Displaying the water pressure

On the RoCon mb control unit, the system pressure (water

pressure) of the internal circuit (direct heating circuit) can be displayed when it is switched on. The water pressure is the first info

parameter available after the operating data overview (see

fig. 3-6).

The permissible water pressure range during operation is dependent on the Daikin Altherma M ECH

system. The target values and thresholds may only be set by the

heating expert. If the water pressure drops below the minimum

value (set parameter value), it must be increased by topping up

the system (see Daikin Altherma M ECH

tions, chapter entitled "Inspection and maintenance").

The pressure limits for safety shut-off and the target

pressure can be set in the parameter setting on the

"System Configuration" level.

O and the heating

2

O installation instruc-

2

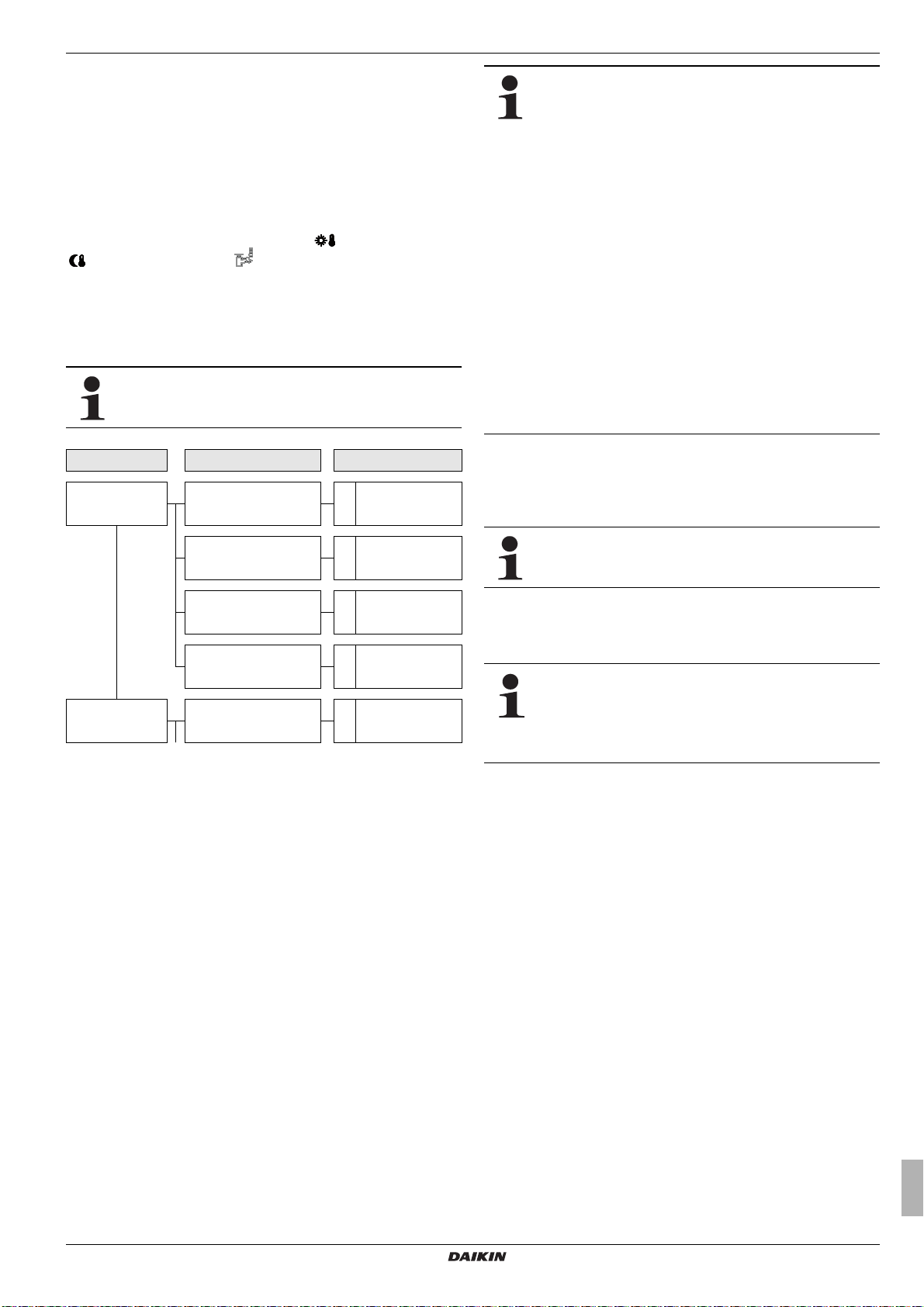

3.4.2 Setting the operating mode

The operating mode in which the Daikin Altherma M ECH2O is to

operate is selected using the rotary switch in the "Operating

Mode"

The selected operating mode is activated by briefly pressing the

rotary button.

Operating Mode

Standby

Reducing

position.

Operating Mode

Heating

Cooling

Summer

Operating Mode

Summer

Automatic 1

Automatic 2

Info

Overview

Water Pressure

T-HS

Water Pressure

Fig. 3-6 Displaying info values (e.g. system pressure)

Operating Mode

Summer

Automatic 1

Automatic 2

Fig. 3-7 Changing the operating mode

(e.g. from "Standby" to "Automatic 1")

● Set the rotary switch to the "Operating Mode"

position.

An overview is displayed.

● Use the rotary button to select the required operating mode.

● Confirm the selection with a brief push of the rotary button.

Daikin Altherma M ECH

O operates according to the set

2

operating mode.

The current operating mode is indicated by an appropriate

symbol on the standard display.

Operating mode Standby (Stand-by)

CAUTION!

A heating system that is not protected against

frost can freeze in the event of frost and thus be

damaged.

Operating instructions

12

● Add glycol to the heating water circuit (see

installation and maintenance instructions)

● Alternatively, drain the heating system on the

water side if there is a danger of frost.

● If the heating system is not drained, the

power supply must be ensured and the

external main switch must remain switched

on if there is a danger of frost.

Daikin Control unit

008.1446899_00 – 07/2019 – EN

RoCon mb

3 x Operation

In this operating mode, the Daikin Altherma M ECH2O is

switched to Stand-by mode. The frost protection function (see

chap. 3.6.5) is maintained. In order to maintain this function, the

system may not be disconnected from the mains.

All controllers integrated in the RoCon system via the CAN bus

are primarily also switched to the "Standby" operating mode.

Fig. 3-8 Standard display in the "Standby" operating mode

(above the frost limit temperature)

Operating mode Reducing

Reduced heating mode (lower target room temperature) according to the target feed temperature set for reducing mode in

the parameter [T-Reduced] (see chap. 3.4.4).

Hot water preparation according to the set target hot water temperatures and switching cycles in the hot water time program

[DHW Program 1] (see chap. 3.4.5).

Heating, Cooling

Heating, cooling mode according to the target room temperature

set in the parameter [T-Room 1 Setpoint] (see chap. 3.4.3).

A connected outside temperature sensor (weather-dependent THS control) or a connected room station also influence the target

feed temperature (prerequisite: parameter [HC Function] = On).

Hot water preparation according to the set target hot water temperatures and switching cycles in the hot water time program

[DHW Program 1] (see chap. 3.4.5).

Operating mode Summer

Hot water preparation according to the set target hot water temperatures and switching cycles in the hot water time program

[DHW Program 1] (see chap. 3.4.5).

All controllers integrated in the RoCon system via the CAN bus

are primarily also switched to the "Summer" operating mode.

Operating mode Automatic 1 (time program)

Automatic heating and setback mode according to the permanent

time programs (see chap. 3.4.7):

– [HC Program 1]

– [DHW Program 1]

Operating mode Automatic 2 (time program)

Automatic heating and setback mode according to the permanent

time programs (see chap. 3.4.7):

– [HC Program 2]

– [DHW Program 2]

If the hot water readiness is in setback mode in the

active operating mode,

heating" can be set with the rotary switch setting

without having to change other standard settings (see

chap. 3.4.6).

a temporary "DHW Re-

Switching contact for external operating mode

switch-over

A potential-free switching contact connected via Daikin

Altherma M ECH2O connection J8 at the "EXT" terminals and

wired with a resistor can also be used to switch the operating

mode from an external device (e.g. modem, …).

In this case, the switching contact functionality is dependent on

the parameter [Function BSC]:

– [Function BSC] = 0 (default setting): evaluation of the resist-

ance values (see tab. 3-6)

– [Function BSC] = 1: evaluation as a burner blocking contact.

If the switching contact is closed, the external heat generator

has priority.

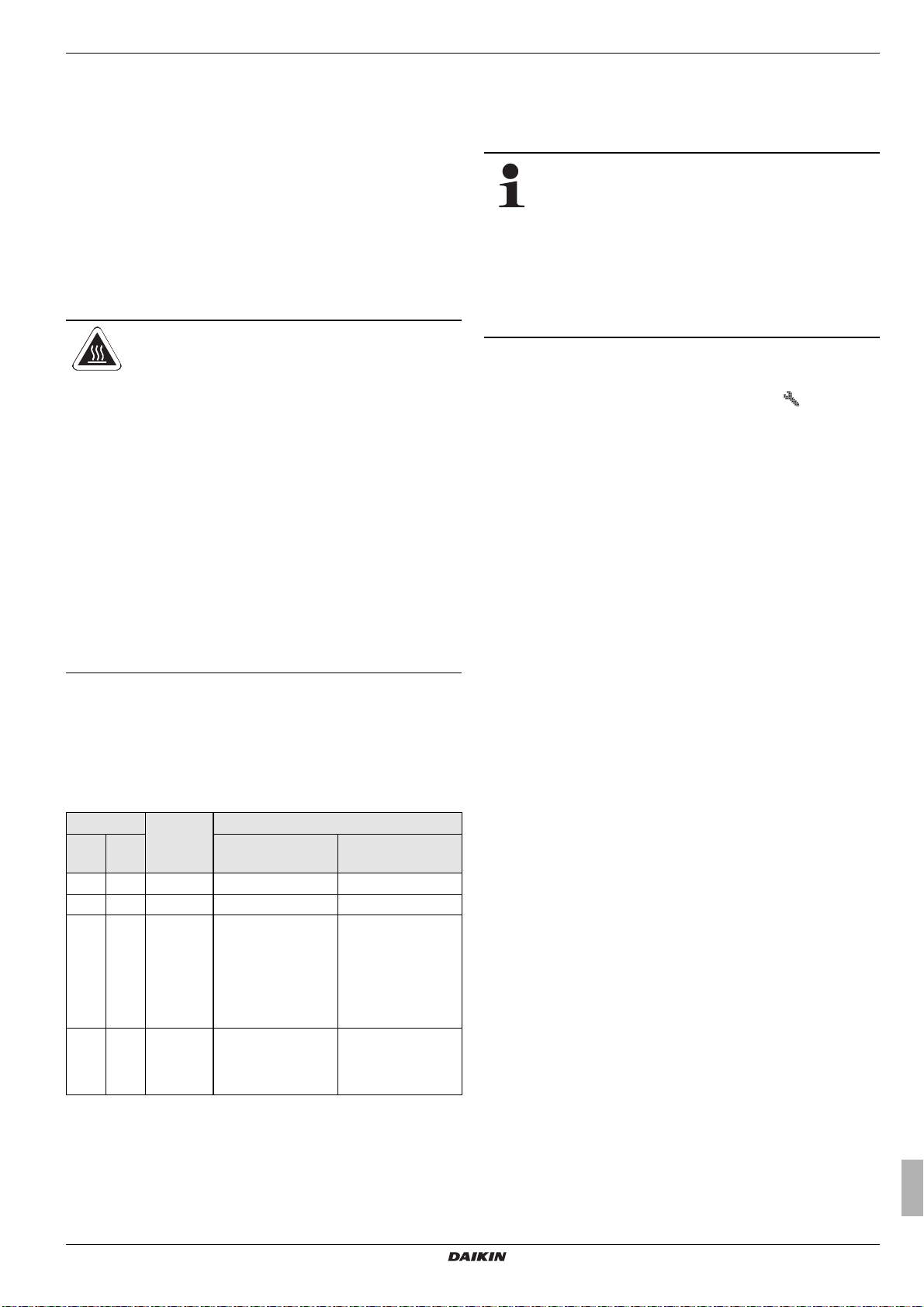

Operating mode Resistance Tolerance

Standby < 680 Ω

Heating 1200 Ω

Reducing 1800 Ω

Summer 2700 Ω

± 5 %

Automatic 1 4700 Ω

Automatic 2 8200 Ω

Tab. 3-6 Resistance values for evaluating the EXT signal

The resistances specified in tab. 3-6 function in a toler-

ance field of 5%. Resistances outside this tolerance

field are interpreted as an open input. The heat gener-

ator switches back to the previously active operating

mode.

The input is not considered for resistance values greater than

the value for "Automatic 2".

If several switching contacts are to be connected to the Daikin

Altherma M ECH

O (e.g. Smart Grid, room thermostat), the re-

2

lated functions may have a higher priority than external operating mode switch-over. The operating mode requested by the

EXT switching contact is then possibly not activated, or is only

activated later.

Besides these operating modes, different temporary heating programs (see tab. 3-7) are available that are carried out with priority

after activation.

Temporary

time program

DHW Install DHW Install

Party

Away

Holiday

Setting/Activa-

tion in the level

Time Program

Rotary switch

setting

Information

Chap. 3.4.6

Chap. 3.4.7

Vacation

Configuration >

Screed*

HC Configura-

Chap. 3.6.13

tion

* only with technician code.

Tab. 3-7 Overview of temporary time programs

If a temporary time program (DHW Install, Party, Away,

Holiday, Vacation, Screed) is started during the se-

lected operating mode, control is carried out primarily

according to the settings for this time program.

Daikin Control unit

RoCon mb

008.1446899_00 – 07/2019 – EN

Operating instructions

13

3 x Operation

3.4.3 Temperature setting of daytime room

temperature

In rotary switch position , the target room temperatures during

the day for room heating are defined.

● Set the rotary switch to the "Set Temp Day" position.

An overview is displayed.

The last digits of the parameter designations (1 - 3)

within this rotary switch setting mark the affiliation to

the respective cycle of the time program.

● Select the temperature block to be set with the rotary button.

● Confirm the selection with a brief push of the rotary button.

Settings are displayed.

● Set the temperature.

● Confirm the selection with a brief push of the rotary button.

Change has been accepted. Jump back to previous dis-

play.

Detailed explanations and possible setting values for this rotary switch setting can

be found in chap. 6.5.

3.4.4 Temperature setting of setback mode

In rotary switch position , the target room temperatures in reducing mode for room heating are defined.

● Set the rotary switch to the "Set Temp Night" position.

An overview is displayed.

● Select the parameter to be set with the rotary button.

● Confirm the selection with a brief push of the rotary button.

– [T-Reduced]: Setting value for "Reducing" operating

mode or reduction through permanent time program.

– [T-Absence]: Setting value for temporary heating/cooling

programs ("Away" and "Vacation").

Settings are displayed.

● Set the temperature.

● Confirm the selection with a brief push of the rotary button.

Change has been accepted. Jump back to previous dis-

play.

Detailed explanations and possible setting values for this rotary switch setting can

be found in chap. 6.6.

3.4.5 Temperature setting of hot water generation

In rotary switch position , the target hot water temperatures

for hot water preparation for the respective time programs are defined.

● Set the rotary switch to the "DHW Set Temp"

position.

The last digits of the parameter designations (1 - 3)

within this rotary switch setting mark the affiliation to

the respective cycle of the time program.

● Select the temperature block to be set with the rotary button.

● Confirm the selection with a brief push of the rotary button.

Settings are displayed.

● Set the temperature.

● Confirm the selection with a brief push of the rotary button.

Change has been accepted. Jump back to previous dis-

play.

Detailed explanations and possible setting values for this rotary switch setting can

be found in chap. 6.7.

3.4.6 Unscheduled hot water preparation

In rotary switch position the hot water can be recharged

manually, outside of a hot water time program, to the target temperature set as default in the parameter [T-DHW Setpoint 1]. The

heating up is carried out with priority and independent of other

heating programs.

● Set the rotary switch to the "DHW Install"

position.

An overview is displayed.

● Select the parameter to be set with the rotary button.

– [1x Hot Water]: Activation of one-time hot water genera-

tion.

● Confirm the selection with a brief push of the rotary button.

● Set the parameter.

● Confirm the selection with a brief push of the rotary button.

The unscheduled hot water generation starts.

After this temporary function has elapsed, the control

unit automatically jumps back to the previously active

operating mode. The rotary switch should therefore be

brought back into the "Info"

position after the

function has been activated.

The function is subject to time limitations.

At the latest, it is cancelled after the maximum loading time set

in the parameter [Max DHW loading time], and can be restarted

at the earliest after the blocking time set in the parameter [DHW

Off Time] has expired (see chap. 6.2.4).

Detailed explanations and possible setting values for this rotary switch setting can

be found in chap. 6.3.

3.4.7 Switching time program

For comfortable and individual room and hot water temperature

control, different (but freely adjustable) time programs preset at

the factory can be selected.

The switching time programs control the assigned heating circuit,

the storage charging circuit as well as an optionally connected

circulation pump according to the specified switching times.

Setting

In the rotary switch setting, the time intervals for the

heating circuit, integrated hot water generation and the optional

circulation pump are set.

● Set the rotary switch to the "Time Program"

position.

An overview is displayed.

● Use the rotary button to select the time program to be set.

● Confirm the selection with a brief push of the rotary button.

Settings are displayed.

● Use the rotary button to select and change the value to be

adjusted.

● Confirm the selection with a brief push of the rotary button.

More detailed explanations and possible setting values for this rotary switch position

can be found in chap. 6.8.

Operating instructions

14

Daikin Control unit

008.1446899_00 – 07/2019 – EN

RoCon mb

3 x Operation

Permanent time programs

Time programs control the heating circuit temperatures or the operating times of the circulation pump according to the specified

switching cycles for the connected heating circuits and the

storage charging circuit. The switching cycles are saved in time

blocks for which different target temperatures can be set.

In the switching cycles, the heating system is controlled differently according to day and reducing mode.

The target temperatures for these time programs are set in the

rotary switch positions "Set Temp Day"

and "DHW Set Temp" .

The following switching time programs are available:

– 2 time programs for the heating circuit, each with 3 possi-

ble switching cycles

– [HC Program 1]

– [HC Program 2]

The times can be entered separately for each individual

weekday or in blocks of "Monday to Friday", "Saturday

to Sunday" and "Monday to Sunday".

Program Time period Switching cycle

HC Program 1

HC Program 2

Tab. 3-8 Menu structure of heating circuit/time program

Individual weekday

(Monday, Tuesday …)

Working week

(Monday to Friday)

Weekend

(Saturday to Sunday)

Whole week

(Monday to Sunday)

See

HC Program 1

, "Set Temp Night"

1.

06:00 -> 22:00

2.

--:-- -> --:--

3.

--:-- -> --:--

1.

06:00 -> 22:00

2.

--:-- -> --:--

3.

--:-- -> --:--

1.

07:00 -> 23:00

2.

--:-- -> --:--

3.

--:-- -> --:--

1.

06:00 -> 22:00

2.

--:-- -> --:--

3.

--:-- -> --:--

1.

2.

3.

See

HC Program 1

Time settings for a switching cycle in a weekday or

block program will also be accepted for other time periods as long as they are for the same weekdays. Examples referring to tab. 3-8:

a) The starting time in the 1st switching cycle is changed from

06:00 am to 05:00 am for the individual weekday "Monday".

The 1st switching cycle is also automatically changed

from 06:00 am to 05:00 am for the "working week" and

"whole week" time periods.

b) The starting time in the 1st switching cycle is changed from

07:00 am to 08:00 am for the "weekend" time period.

The 1st switching cycle is also automatically changed

from 07:00 am to 08:00 am for the individual weekdays

"Saturday" and "Sunday".

c) The end time in the 1st switching cycle is changed from

10:00 pm to 9:30 pm for the "whole week" time period.

The 1st switching cycle is also automatically changed

from 10:00 pm to 9:30 pm in all weekday or block programs.

– 2 time programs for the hot water circuit, each with 3 pos-

sible switching cycles

– [DHW Program 1]

– [DHW Program 2]

The setting and the entry structure of the time programs

are identical with those for the heating circuit time

program (see also tab. 3-8).

– 1 time program for an optionally connected circulation

pump, each with 3 possible switching cycles

– [Circulation Time]

The setting and the entry structure of the time program

are identical with those for the heating circuit time program (see also tab. 3-8).

For further information on settings for an optional circulation

pump, see chap. 3.6.15.

Saved switching time programs can be changed at any time. For

a better overview, it is recommended to write down and safely

store the programmed switching cycles (see chap. 9.1.1).

The permanent time programs are preset according to tab. 3-9.

Daikin Control unit

RoCon mb

008.1446899_00 – 07/2019 – EN

Operating instructions

15

3 x Operation

Switching cycle 1 Switching cycle 2 Switching cycle 3

Time period On Off On Off On Off

Room heating

Temperature setting

Monday - Friday 06:00 22:00 - - : - - - - : - - - - : - - - - : - -

Saturday, Sunday 07:00 23:00 - - : - - - - : - - - - : - - - - : - -

Monday - Friday 06:00 08:00 - - : - - - - : - - - - : - - - - : - -

Saturday, Sunday 07:00 23:00 - - : - - - - : - - - - : - - - - : - -

Temperature setting

Monday - Sunday 00:00 24:00 - - : - - - - : - - - - : - - - - : - -

Monday - Friday 05:00 21:00 - - : - - - - : - - - - : - - - - : - -

Saturday, Sunday 06:00 22:00 - - : - - - - : - - - - : - - - - : - -

Monday - Friday 05:00 21:00 - - : - - - - : - - - - : - - - - : - -

Saturday, Sunday 06:00 22:00 - - : - - - - : - - - - : - - - - : - -

[T-Room 1 Setpoint]: 20 °C [T-Room 2 Setpoint]: 20 °C [T-Room 3 Setpoint]: 20 °C

[T-Reduced]: 10 °C

"HC Program 1"

"HC Program 2"

Domestic hot water generation

[T-DHW Setpoint 1]: 48 °C [T-DHW Setpoint 2]: 48 °C [T-DHW Setpoint 3]: 48 °C

"DHW Program 1"

"DHW Program 2"

"Circulation Time"

Tab. 3-9 Factory setting of the permanent switching time programs

Temporary time programs

4 temporary time programs are available for special situations,

which make the permanent time programs or the currently set

operating mode ineffective for the duration of their validity.

The symbol of the temporary time program is displayed in the

header of the standard display for as long as the time program is

active.

The following temporary time programs can be cancelled at any time due to the manual changing of the

operating mode.

1.

2.

[Party]: Immediate one-off extension of room heating.

a) If an automatic program is activated, the last valid

switching cycle is always extended. In the time prior to

switching cycle 1, control is carried out according to the

target room temperature set in the parameter [T-Room 1

Setpoint].

b) In all other operating modes, control is carried out accord-

ing to the target room temperature set in the parameter [T-

Room 1 Setpoint].

– The hot water generation is not affected.

– The time program runs for the set time period from activa-

tion.

[Away]: Immediate one-time setback up to 6 hours.

– In reducing mode, control is carried out according to the

target room temperature set in the "Set Temp Night"

rotary switch position in the parameter [T-Absence].

– The hot water generation is not affected.

– The time program runs for the set time period from activa-

tion.

3.

[Holiday]: One-time calendar-controlled presence.

– Control is carried out only according to the settings for

"Sunday" in the [HC Program 1].

– The hot water generation is only controlled according to

the settings for "Sunday" in the [DHW Program 1].

4.

[Vacation]: One-time calendar-controlled setback.

– In reducing mode, control is carried out exclusively

according to the target room temperature set in the "Set

Temp Night"

rotary switch position in the parameter

[T-Absence].

– Hot water generation according to the set target tempera-

tures and switching cycles in the [DHW Program 1] hot

water time program (see chap. 3.4.5).

– The calendar-controlled [Vacation] program is not

started if the "Standby" or "Manual Operation" operating

mode is active on the set start date.

Operating instructions

16

Daikin Control unit

008.1446899_00 – 07/2019 – EN

RoCon mb

3 x Operation

3.4.8 System settings

In the "Configuration" rotary switch position, basic setting

of the RoCon mb controller and system configuration for the

installation environment of the Daikin Altherma M ECH

O, the

2

direct heating circuit, hot water preparation and any optionally

connected components are carried out.

Depending on the access authorisation (user or expert), different

parameters are available. Several parameters can only be accessed by the heating expert.

Setting the LCD display, language, date, time

An internally pre-programmed calendar ensures an automatic timeshift for the annually repeating summertime/wintertime changeover dates.

● Set the rotary switch to the "Configuration"

position.

An overview is displayed.

● Use the rotary button to select the "Setup" level.

An overview is displayed.

● With the rotary button, select the parameters [LCD

Brightness] and [LCD Illum Time], and change them if

desired.

● With the rotary button, select and confirm the parameters

[Language], [Date] or [Time].

● Use the rotary button to select and change the value to be

changed within the respective display.

● Confirm the selection with a brief push of the rotary button.

Change has been accepted. Jump back to previous dis-

play.

Detailed explanations and possible setting values of this rotary switch setting can be

found in chap. 3.6 and in chap. 6.2.

The different application and parametrisation options for the use

of the devices and control units in the RoCon system connected

via the CAN bus are described in chap. 4.3.

Remote Param

Bus - Scan

No selection

Remote Param

Contr BM1/BE1 #X

Mix Valve #X

3.4.9 Terminal function

In the "Remote Param" rotary switch setting, other devices

(mixer module control unit or heat generator control components)

integrated in the RoCon system via the CAN bus can also be operated and parametrised as long as the respective control unit

has the required authorisation (see also chap. 4.3).

A list of the recognised devices

is displayed for selection on the

display after activation of the

"Bus - Scan" (external devices

and local device).

After selection and confirmation of an external device,

the terminal function for this

device is activated and the associated standard display for

this device is shown on the

display.

The operating component is

then in terminal operation.

The local control unit functions as a remote control for the external device. In this case, all the control functions are performed

and saved 1:1 as on the external device.

Remote Param

Bus - Scan

No selection

Fig. 3-9 Display of the "Remote

Param" level during

commissioning or after

interim disconnection

from the mains

Remote Param

Bus - Scan

No selection

Remote Param

No selection

Contr BM1/BE1 #X

Mix Valve #X

B1 RoCon B1 control panel of the Altherma M ECH2O

Bus CAN bus (connection line between RoCon devices

and control units)

H

1

H

2

M1 EHS157068 mixer module

U1 EHS157034 room station

WE1 Heat generator Altherma M ECH2O

Fig. 3-10 Example of "Bus - Scan" on a heating system with 1 heat gen-

Direct heating circuit (e.g. radiators)

Mixed heating circuit (e.g. floor heating)

erator, 1 mix valve, 1 room station and activation of the terminal function for remote control of the mixer module

Remote Param

Contr BM1/BE1 #X

Mix Valve #X

Daikin Control unit

RoCon mb

008.1446899_00 – 07/2019 – EN

Operating instructions

17

3 x Operation

If the terminal function is activated, the #X symbol is displayed in the header of the display as additional information on

the remote-controlled device, where "X" is the set device identification of the remote-controlled device.

The displayed values and symbols are always accepted by the

selected device (e.g. mixer circuit T-HS of the EHS157068 mix

valve module with device identification 1).

Fig. 3-11 Example of the display for the remote-controlled mixer module

In order to operate the local device, it must be activated again in

the selection list ([No selection] parameter).

If the "n.A." message is displayed in the rotary switch

setting

the control unit until now.

If the "n.A." message is still displayed, it may be necessary to

update the device software in order to use the terminal function.

Contact the Daikin Service Team for this.

, no valid terminal ID has been assigned to

Activating/deactivating terminal operation

Prerequisite: a valid terminal ID has been assigned to the

RoCon B1 control panel of the Daikin Altherma M ECH

EHS157034 room station.

For setting the terminal ID of optionally connected

devices, see chap. 4.4 or the respective operating

instructions that are supplied.

O or the

2

After an interim disconnection from the power supply,

the display always appears at the "Remote Param"

level, as shown in fig. 3-9.

To be able to use the terminal function for connected devices, a

repeat Bus - Scan must be carried out.

Communication between the RoCon system components also

continues to function without a Bus - Scan, and previously undertaken settings remain active.

The terminal function is activated as shown in fig. 3-10, but after

confirmation of the "Bus - Scan" display, the [New scan?] parameter must be selected with the rotary button and confirmed

with "Yes".

3.4.10 Operation with glycol

Frost can damage the system. To prevent the hydraulic components from freezing, the software is equipped with special frost

protection functions, that include the activation of pump, internal

heaters, and/or backup heater operation in case of low temperatures.

However, in case of a power failure, these functions cannot guarantee protection. It is therefore recommended to add glycol to the

water circuit. To do this, observe the installation and maintenance instructions.

If glycol has been added to the system, the RoCon controller

setting must be adapted accordingly.

● Set the rotary switch to the "Configuration"

position.

An overview is displayed.

● Use the rotary button to select the "Setup" level.

An overview is displayed.

● Use the rotary button to select the [Glycol] parameter.

● Change the parameter if desired.

– Parameter [Glycol] = 0: no glycol added

– Parameter [Glycol] = 1: glycol added

● Confirm the selection with a brief push of the rotary button.

Change has been accepted. Jump back to previous dis-

play.

3.4.11 Whisper mode

● Set the rotary switch to the "Remote Param"

position.

The "Remote Param" level is displayed.

● Use the rotary button to select the [Bus - Scan] parameter.

● Confirm the selection with a brief push of the rotary button.

The context menu is displayed.

● Use the rotary button to select the [Bus - Scan] parameter and

confirm with "Yes".

Bus - Scan is performed.

An overview of all the devices found is displayed (for an

example, see fig. 3-10).

● Use the rotary button to select the device for which the

terminal function should be carried out.

● Confirm the selection with a brief push of the rotary button.

The local control unit functions as a remote control for the

external device.

To end terminal operation and to switch back to the control unit

for the operation of the assigned device, the [No selection] pa-

rameter must be selected and confirmed at the "Remote

Param" level.

Operating instructions

18

Whisper mode means that the heat pump outdoor unit operates

at reduced output. This reduces the operating noise generated by

the heat pump outdoor unit.

CAUTION!

During active whisper mode, the output in room

heating and room cooling mode decreases such

that it may no longer be possible to achieve preset target temperature values.

● With outside temperatures below freezing,

there is a risk of material damage caused by

frost.

Activating / deactivating whisper mode

● Set the rotary switch to the "Configuration" position.

An overview is displayed.

● Use the rotary button to select the "System Configuration"

level.

An overview is displayed.

Daikin Control unit

008.1446899_00 – 07/2019 – EN

RoCon mb

3 x Operation

● Use the rotary button to select the [Quite Mode] parameter.

● Confirm the selection with a brief push of the rotary button.

The setting of the parameter is displayed.

● Set the parameter.

– Parameter [Quite Mode] = 0: deactivated

– Parameter [Quite Mode] = 1: permanently activated

– Parameter [Quite Mode] = 2: only activated at night

● Confirm the selection with a brief push of the rotary button.

Change has been accepted. Jump back to previous dis-

play.

Detailed explanations and possible setting values of this function can be found in

chap. 6.2.2.

3.4.12 Smart Grid (SG)

WARNING!

There is a danger of scalding at target hot water

temperatures over 60 °C. This is possible, as

the utility company (EVU) is entitled to control

current draw optimised according to supply and

demand in the definitions for Smart Grid.

Due to such forced charging, the target hot

water temperature in the hot water storage tank

can exceed 60 °C.

This storage tank charging is carried out even

when "Standby" operating mode is set.

● Install scald protection in the hot water distribution line (e.g. VTA32 + Screw set 1").

A special electricity meter with SG receiver, to which the Daikin

Altherma M ECH

function.

As soon as the function is activated by the parameter [SMART

GRID] = 1, the heat pump is set to an operating mode as per

tab. 3-10 depending on the utility company signal.

2)

Signal

EVU SG Domestic hot

1 0

0 0 Normal Normal operation Normal operation

0 1 Low Switch-on recom-

1 1 Very low Switch-on command,

O must be connected, is required to use this

2

Electric-

ity costs

- - -

water

No operation

mendation, and tar-

get storage tank

temperature value is

increased depending

on the parameter

[Mode SG]

and target storage

tank temperature val-

ue is set to 70 °C

Effect on

Heating installa-

1)

No operation

Switch-on recom-

mendation, and target feed temperature

is increased depending on the parameter

[Mode SG]

Switch-on command

for storage tank

tions

charging

1)

3.4.13 EHS emergency operation

If the heat pump fails, the backup heater can be used as emergency heating, and can undertake all heating requirements either

automatically or non-automatically.

Activation of emergency automatic operation ensures

that heating and hot water requirements are reliably

met even if the heat pump fails. However, the risk is run

that the user only notices the system malfunction after

a certain time, and that electricity consumption is thus increased.

If emergency automatic operation is deactivated (default

setting), it must be activated as described below to meet heating

and hot water requirements in the event that the outdoor unit

fails.

Activating / deactivating emergency automatic

operation

● Set the rotary switch to the "Configuration" position.

An overview is displayed.

● Use the rotary button to select the "Setup" level.

An overview is displayed.

● Use the rotary button to select the [Emergency BUH]

parameter.

● Confirm the selection with a brief push of the rotary button.

The setting of the parameter is displayed.

● Set the parameter.

– Parameter [Emergency BUH] = 0: no automatic emer-

gency operation

– Parameter [Emergency BUH] = 1: automatic emergency

operation

● Confirm the selection with a brief push of the rotary button.

Change has been accepted. Jump back to previous dis-

play.

1) No frost protection function (see chap. 3.6.5).

2) Switching contacts at input J8 of the RoCon BM1 printed circuit board closed

(1) or opened (0).

Tab. 3-10 Use of the SG signal

Detailed explanations and possible setting values of this function can be found in

chap. 6.2.1.

Daikin Control unit

RoCon mb

008.1446899_00 – 07/2019 – EN

Operating instructions

19

3 x Operation

3.5 Special functions

At the "Special Level", different functions (mostly useful functions for the heating expert) can be carried out.

The following special functions are possible:

– Manual operation (see chap. 3.5.1).

– Displaying messages (see chapter 7)

– Reset to factory settings (see chap. 3.6.12)

Detailed explanations of these functions can be found in chap. 6.11.

Special Level

Manual Operation

FA failure

The calling-up of the special functions does not depend

on the rotary switch setting.

● Push the Exit button for at least 5 s.

Menu "Special Level" is displayed.

● Use the rotary button to select the program to be started.

● Confirm the selection with a brief push of the rotary button.

The selected program starts.

● Cancellation and jump back by:

– pressing the Exit key again or

– touching the rotary button or

– selecting another menu using the rotary switch.

3.5.1 Manual operation

Manual operation is used to manually control the Daikin

Altherma M ECH

O to a specific feed temperature. Manual oper-

2

ation should only be used for diagnostic purposes.

With hydraulically controlled priority operation for hot water preparation, it must be ensured that the target feed temperature set in

manual mode is sufficient to achieve the stored target hot water

temperature (parameter [T-DHW Setpoint 1]).

● Push the Exit button for at least 5 s.

Menu "Special Level" is displayed.

● Use the rotary button to select the "Manual Operation"

program.

● Confirm the selection with a brief push of the rotary button.

"Manual Operation" is active.

● Use the rotary button to set the target feed temperature.

Do not confirm this setting with the rotary button,

as the program is otherwise ended.

Manual Operation

Set Point

Special Level

Fig. 3-12 Symbolic brief instructions for manual operation

Current Value

Attention!

Actual mode:

3.5.2 3-way switching valves reference travel

The positions of the two 3-way switch valves 3UVB1 and

3UV DHW in the Daikin Altherma M ECH

tinuously between their two basic settings for optimised energy

utilisation (e.g. heating support function).

To ensure this function, the two 3-way switch valves are always

moved automatically to their basic position (bypass - path AB-A

open) at 11:00 hours.

This function can take up to 5 minutes. It is programmed as

standard and cannot be changed.

O are controlled con-

2

During active manual mode, the storage tank temperature

is permanently regulated to the first target hot water temperature parameter value ([T-DHW Setpoint 1]).

The key lock (if it was activated prior to the start of this

function) is reactivated within 2 s to prevent undesired

cancellation of the function through operation of the

RoCon mb controller.

● Cancellation and jump back by:

– pressing the Exit key again or

– touching the rotary button or

– selecting another menu using the rotary switch.

If manual operation is ended, the RoCon mb control unit

automatically switches to "Standby" operating mode.

Operating instructions

20

Daikin Control unit

008.1446899_00 – 07/2019 – EN

RoCon mb

Loading...

Loading...