Page 1

parteinvert

ACL – DC8

REV

00

Date

June 2020

Supersedes

/

Installation and Operation Manual

D-EIOCP00206-20_00EN

Page 2

Installation and Operation Manual D-EIOCP00206-20_00EN

2/76

ALC-DC8

TABLE OF CONTENTS

1 SAFETY CONSIDERATIONS ........................................................................................................... 4

General ....................................................................................................................................... 4

Avoid electrocution ..................................................................................................................... 4

Additional Safety Devices Info ................................................................................................... 4

Available sensors ....................................................................................................................... 5

2 GENERAL DESCRIPTION ................................................................................................................ 6

Basic Information ........................................................................................................................ 6

Abbreviations used ..................................................................................................................... 6

Controller Operating Limits......................................................................................................... 7

ALC DC8 to chiller units compatibility table ............................................................................... 8

Standard and optional devices. .................................................................................................. 9

Device Overview ........................................................................................................................ 9

ALC connection diagram .......................................................................................................... 11

3 USING THE CONTROLLER ........................................................................................................... 12

General Recommendation ....................................................................................................... 12

Navigating ................................................................................................................................ 13

Passwords ................................................................................................................................ 13

Editing....................................................................................................................................... 14

Basic Control System Diagnostic ............................................................................................. 15

Controller maintenance ............................................................................................................ 16

Optional Remote User Interface ............................................................................................... 16

Embedded Web Interface......................................................................................................... 17

4 MENU STRUCTURE ....................................................................................................................... 19

Main Menu ................................................................................................................................ 19

4.1.1 View/Set Unit .................................................................................................................................. 19

4.1.2 View/Set Circuit .............................................................................................................................. 21

4.1.3 Active Setpoint ................................................................................................................................ 25

4.1.4 Commission Unit ............................................................................................................................ 25

4.1.5 Alarms ............................................................................................................................................ 28

4.1.6 Diagnostic ....................................................................................................................................... 28

4.1.7 About .............................................................................................................................................. 28

5 DEVICE INSTALLATION AND CONNECTION .............................................................................. 29

Installing and connecting ALC DC8 Hardware ......................................................................... 29

5.1.1 STEP 1, Cable routing ................................................................ .................................................... 29

5.1.2 STEP 2, Power cable...................................................................................................................... 30

5.1.3 STEP 3, Main Modbus cable connection ........................................................................................ 30

5.1.4 (Optional) STEP 4, Ethernet cable connection ............................................................................... 31

5.1.5 (Optional) STEP 5, BMS cable connection ..................................................................................... 31

5.1.6 (Optional) STEP 6, Antenna coaxial cable connection ................................................................... 32

5.1.7 (Example) STEP 7, MTII Modbus cable connection ....................................................................... 32

5.1.8 (Example) STEP 8, Enter into setting menu ................................................................ ................... 33

5.1.9 (Example) STEP 9, MTII access password ................................................................................... 34

5.1.10 (Example) STEP 10, MTII access password .................................................................................. 34

5.1.11 STEP 10 – Power ON ALC DC8 ..................................................................................................... 35

6 ALC-DC8 PANEL COMMISSIONING ............................................................................................. 36

Commissioning of standard version without BMS .................................................................... 36

Page 3

ALC-DC8

Installation and Operation Manual D-EIOCP00206-20_00EN

3/76

Commissioning of Modbus RS485 BMS version. .................................................................... 38

Commissioning of BACnet IP BMS version. ............................................................................ 40

7 PLANT ACTIVATION AND FIRST CONNECTION TO DAIKIN ON SITE. .................................... 43

Daikin on Site activation on ALC-DC8 Controller ..................................................................... 43

7.1.1 Configure custom IP on ALC panel ................................................................................................ 44

Verifying the connection and Daikin On Site Activation Key retrieving .................................... 46

Plant Registration and Configuration ....................................................................................... 47

8 APPENDIX A: MAPPING TABLE ................................................................................................... 51

Note on BMS datapoint mapping and circuit elements selection. ............................................ 51

MCQ Screw Chiller datapoints and setpoints mapping. ........................................................... 53

USA Centrifugal Chiller datapoints and setpoints mapping. .................................................... 64

Common (DoS) datapoints and setpoints mapping . ............................................................... 73

Unit and Circuit Status .............................................................................................................. 74

Page 4

Installation and Operation Manual D-EIOCP00206-20_00EN

4/76

ALC-DC8

1 SAFETY CONSIDERATIONS

General

Installation, start-up and servicing of equipment can be hazardous if certain factors particular to the

installation are not considered: operating pressures, presence of electrical components and voltages

and the installation site (elevated plinths and built-up up structures). Only properly qualified

installation engineers and highly qualified installers and technicians, fully trained for the product, are

authorized to install and start-up the equipment safely.

During all servicing operations, all instructions and recommendations, which appear in the installation

and service instructions for the product, as well as on tags and labels fixed to the equipment and

components and accompanying parts supplied separately, must be read, understood and followed.

Apply all standard safety codes and practices.

Wear safety glasses and gloves.

Use the proper tools to move heavy objects. Move units carefully and set them down gently.

Avoid electrocution

Only personnel qualified in accordance with IEC (International Electrotechnical Commission)

recommendations may be permitted access to electrical components. It is particularly recommended

that all sources of electricity to the unit be shut off before any work is begun. Shut off main power

supply at the main circuit breaker or isolator.

IMPORTANT: This equipment uses and emits electromagnetic signals. Tests have shown that the

equipment conforms to all applicable codes with respect to electromagnetic compatibility.

RISK OF ELECTROCUTION: Even when the main circuit breaker or isolator is switched off,

certain circuits may still be energized, since they may be connected to a separate power

source.

RISK OF BURNS: Electrical currents cause components to get hot either temporarily or

permanently. Handle power cable, electrical cables and conduits, terminal box covers and

motor frames with great care.

ATTENTION: In accordance with the operating conditions the fans can be cleaned

periodically. A fan can start at any time, even if the unit has been shut down.

Additional Safety Devices Info

This device needs to be connected to an external Air Conditioning unit. So, no further info can be

directly integrated in the present manual.

Page 5

ALC-DC8

Installation and Operation Manual D-EIOCP00206-20_00EN

5/76

For further info and recommendations related to safety consideration about the external units,

any related equipment installed within, and the integration with a third part devices, please refer

to the specific installation and operation manual of that unit itself.

Available sensors

In this first HW/SW release of this devices, no optional sensors are still integrated with it. If sensors

will be integrated in future, every info and recommendations related to safety consideration will be

reported in this paragraph.

Page 6

Installation and Operation Manual D-EIOCP00206-20_00EN

6/76

ALC-DC8

2 GENERAL DESCRIPTION

Basic Information

The ALC DC8 panel is used to connect old McQuay Screw and Centrifugal chillers based on Microtech

II (MTII) controller to Daikin On Site. The core of the ALC panel is a Microtech®III controller. It manages

any operation and communication between the chiller and DoS. If a BMS system is connected to the

chiller via Modbus RS485 or a Bacnet IP cable/protocols, the ALC can also manage suck kind of

communication by an optional Microtech module.

More in details, ALC DC8 is currently compatible with the following units:

• MCQ “screw” units – PFS, ALS, WHS, McAir, MTM (MNG, HPI)

• USA/MCQ “centrifugal” units – WDC, WSC, WPV, WCC, HSC, TSC, HDC, WMC

• a BMS already connected and compatible with mapping of abovementioned chiller units.

The ALC MTII controller can be connected to the MTIII-bases units by means of Modbus protocol, 3wires cable and a dedicated serial card (i.e. EKAC200J model) that needs be installed on the related

serial card slot of the MTII Chiller Control Unit.

Please refer to ALC DC8 to chiller units compatibility table for more details about chiller units

connectable to Daikin On Site by means of ALC DC8.

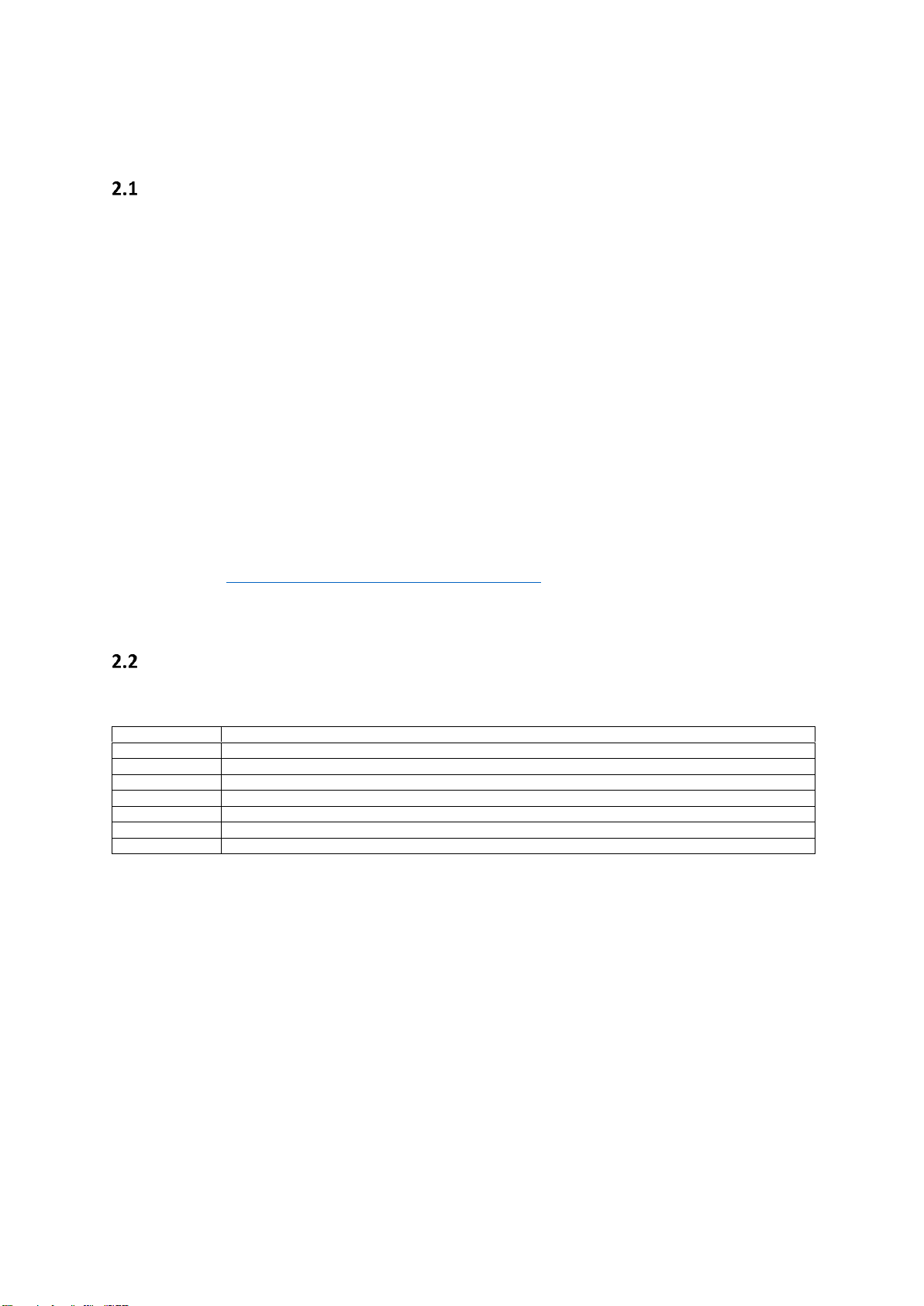

Abbreviations used

In this manual, the following abbreviations are used:

A/C

Air Cooled

(ALC) DC8

(ALC) Daikin-on-site Connectable v.8

BMS

Building Management Systems

E/M

Energy Meter Module

HMI

Human Machine Interface

M2M

Machine-to-machine

UC

Unit controller (Microtech III)

W/C

Water Cooled

Page 7

ALC-DC8

Installation and Operation Manual D-EIOCP00206-20_00EN

7/76

Controller Operating Limits

Operation (IEC 721-3-3):

• Temperature -40...+70 °C

• Restriction LCD -20… +60 °C

• Restriction Process-Bus -25….+70 °C

• Humidity < 90 % r.h (no condensation)

• Air pressure min. 700 hPa, corresponding to max. 3,000 m above sea level

Transport (IEC 721-3-2):

• Temperature -40...+70 °C

• Humidity < 95 % r.h (no condensation)

• Air pressure min. 260 hPa, corresponding to max. 10,000 m above sea level.

Page 8

Installation and Operation Manual D-EIOCP00206-20_00EN

8/76

ALC-DC8

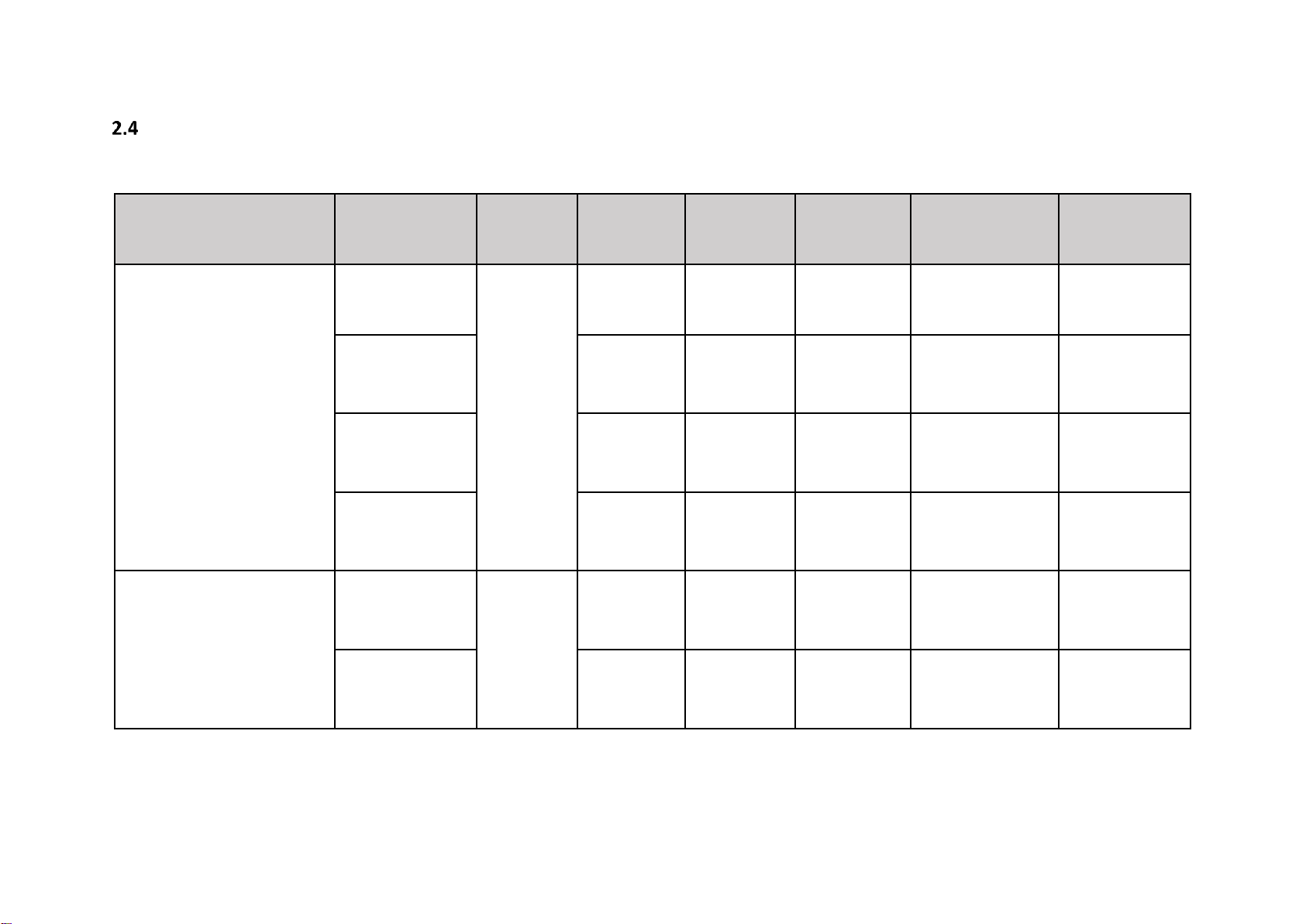

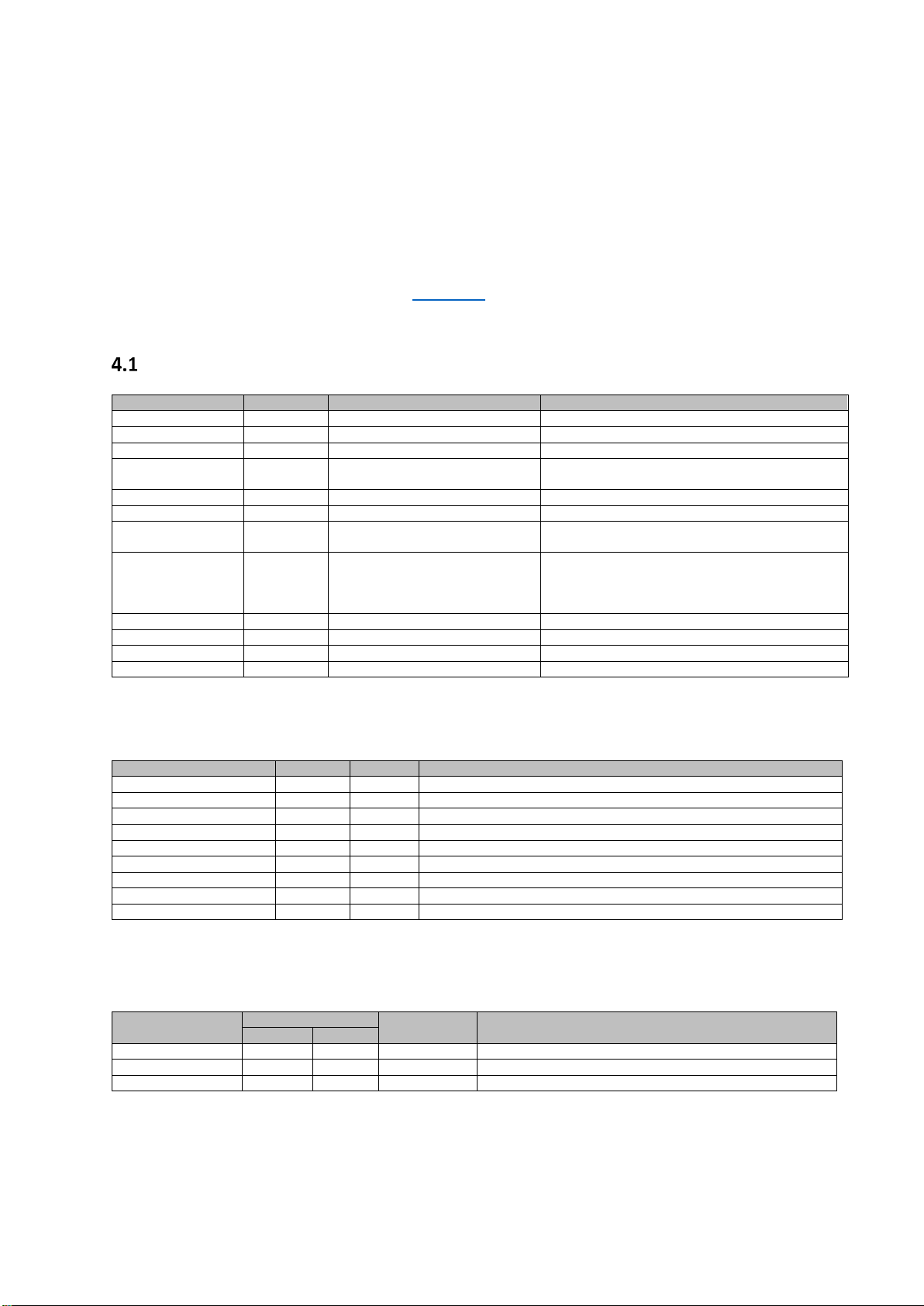

ALC DC8 to chiller units compatibility table

CHILLER FAMILY

UNIT NAME

MAX NUM.

MAPPED

DATAPOINTS

MAX NUMBER

OF

COMPRESSOR

MAX NUMBER

OF CIRCUIT

N° OF

COMPRESSOR

PER CIRCUIT

BMS

MODBUS/BACNETIP

COMPATIBILITY*

M2M

COMPATIBILITY*

Screw Chiller

PFS

~ 200

2 2 1 Y Y

ALS/WHS

4 4 1 Y Y

MCAIR

4 4 1 Y Y

MTM (MNG, HPI)

2 2 1 Y Y

Centrifugal Chiller

WSC, WDC, WPV,

WCC, HSC, TSC HDC

~ 130

2 1 2 Y Y

WMC

2 1 2 Y Y

Table 1: ALC DC8 compatibility table

*Hardware options

Page 9

ALC-DC8

Installation and Operation Manual D-EIOCP00206-20_00EN

9/76

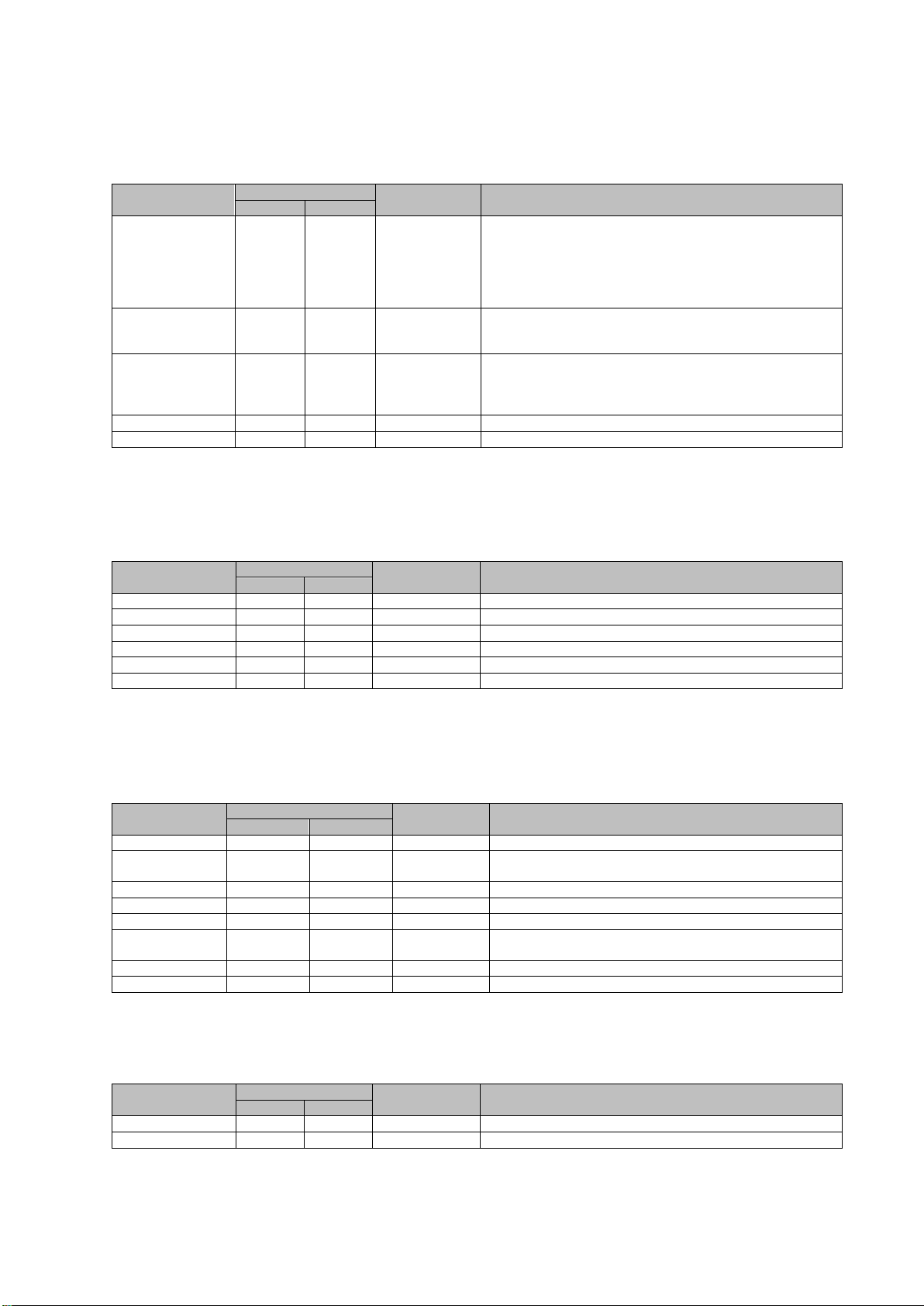

Standard and optional devices.

The ALC DC8 can handle different kinds of communication, the one with the chiller unit MTII controller

apart. The following table shows the standard and optional modules or electronic equipment

necessary to manage any main or further data communication implemented so far.

ITEM

DETAILS

NOTES

STANDARD

PANEL

ALC PANEL COST WITH POL687

Controller

Standard configuration includes MTIII

controller.

(Optional)

DoS M2M Kit

4G Router WiFi kit.

Required if you can not connect the

ALC DC8 to DoS to a LAN connection

and by means of ethernet cable.

(Optional)

Coms Modules

and probes

Bacnet IP Communication Module

POL908

In case the connection with BMS in

BacNet is required

Modbus Communication Module

POL902

In case the connection with BMS in

Modbus is required

Serial card module EKAC200J

For communication with chiller MTII

controller

Device Overview

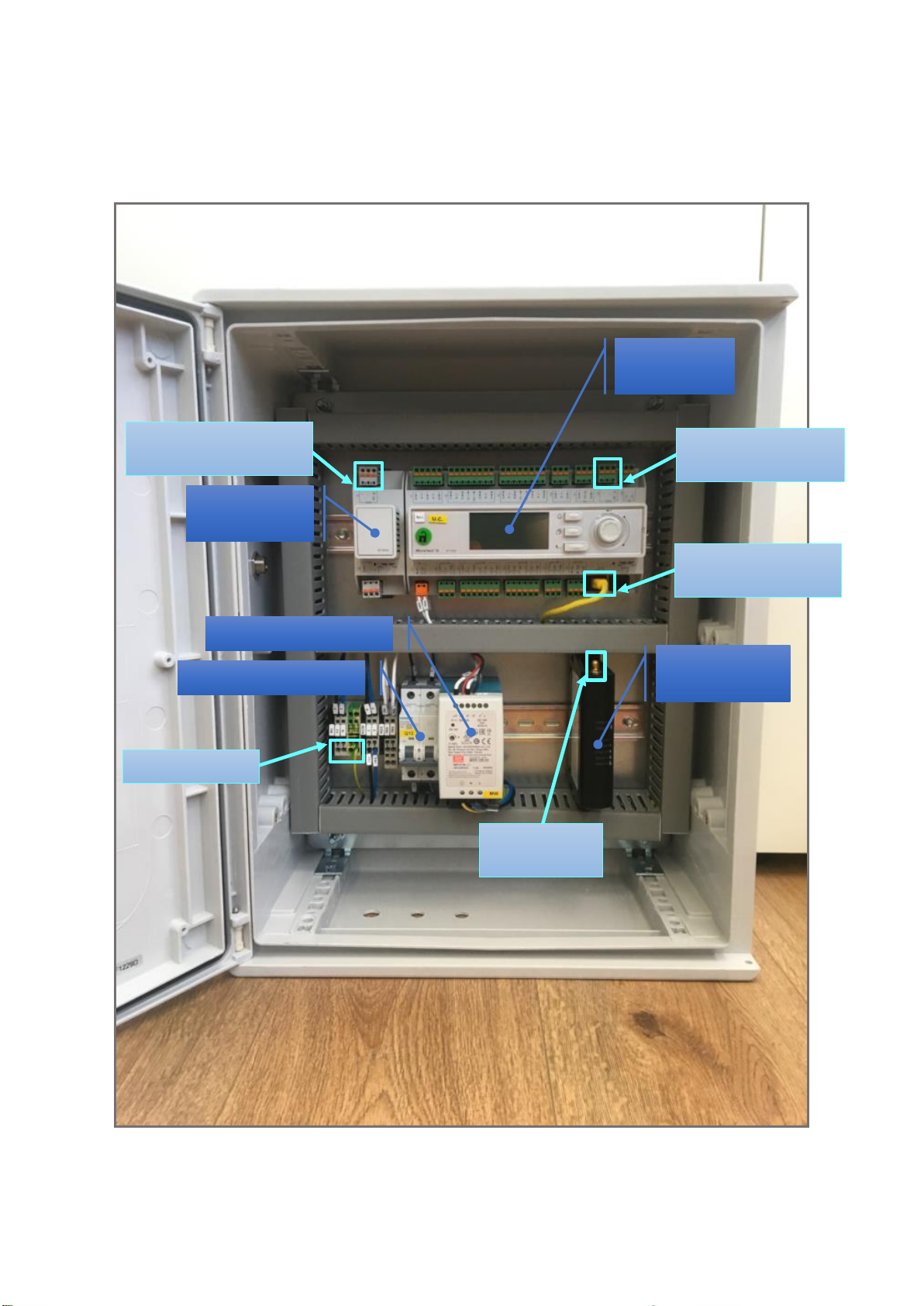

Below is reported a picture that shows how is made the new ALC DC8. In particular, the components

and devices used so far (blue) are reported in this paragraph and the new connections requested (light

blue) are described in paragraph ALC connection diagram.

The ALC DC8 is mainly composed of the following devices:

➢ Power supply - a MDR-100-24 Meanwell power supply units that can be input powered at 85

VAC to 264 VAC or 120 VDC to 370 VDC and provide output up to 96W 24V 4A. A bit

“oversized” to powering all the currently foreseen devices and in future any additional

modules.

➢ Main On/Off Switch - to power on/off all the devices within the ALC DC8 cabinet.

➢ Main MTIII controller - a POL687.70 which also guarantees good HW and SW potential

growth.

➢ (Optional) M2M Kit – a Teltonika RUT240 in case of 4G connection.

➢ (Optional) BMS Communication Module - POL902 in case of BMS Modbus connection,

POL908 in case of BMS BacNet connection.

Page 10

Installation and Operation Manual D-EIOCP00206-20_00EN

10/76

ALC-DC8

➢ MTII Modbus communication serial card – even if not shown in the overview image, it is

necessary to install on the MTII a serial card for Modbus communication (if not already

installed) between ALC DC8 and MTII. The referenced model is the Carel EKAC200J.

Figure 1: ALC DC8 main components

Power Supply

(Optional)

BMS Module

Main On/Off Switch

(Optional) 4G

Modem

MTIII

Controller

1) Power Cable

2) Modbus cable

(MTII Communication)

3) Ethernet cable

(DoS Connection)

4) ModBus/Bacnet cable

(BMS Communication)

5) 4G Antenna

SMA connector

Page 11

ALC-DC8

Installation and Operation Manual D-EIOCP00206-20_00EN

11/76

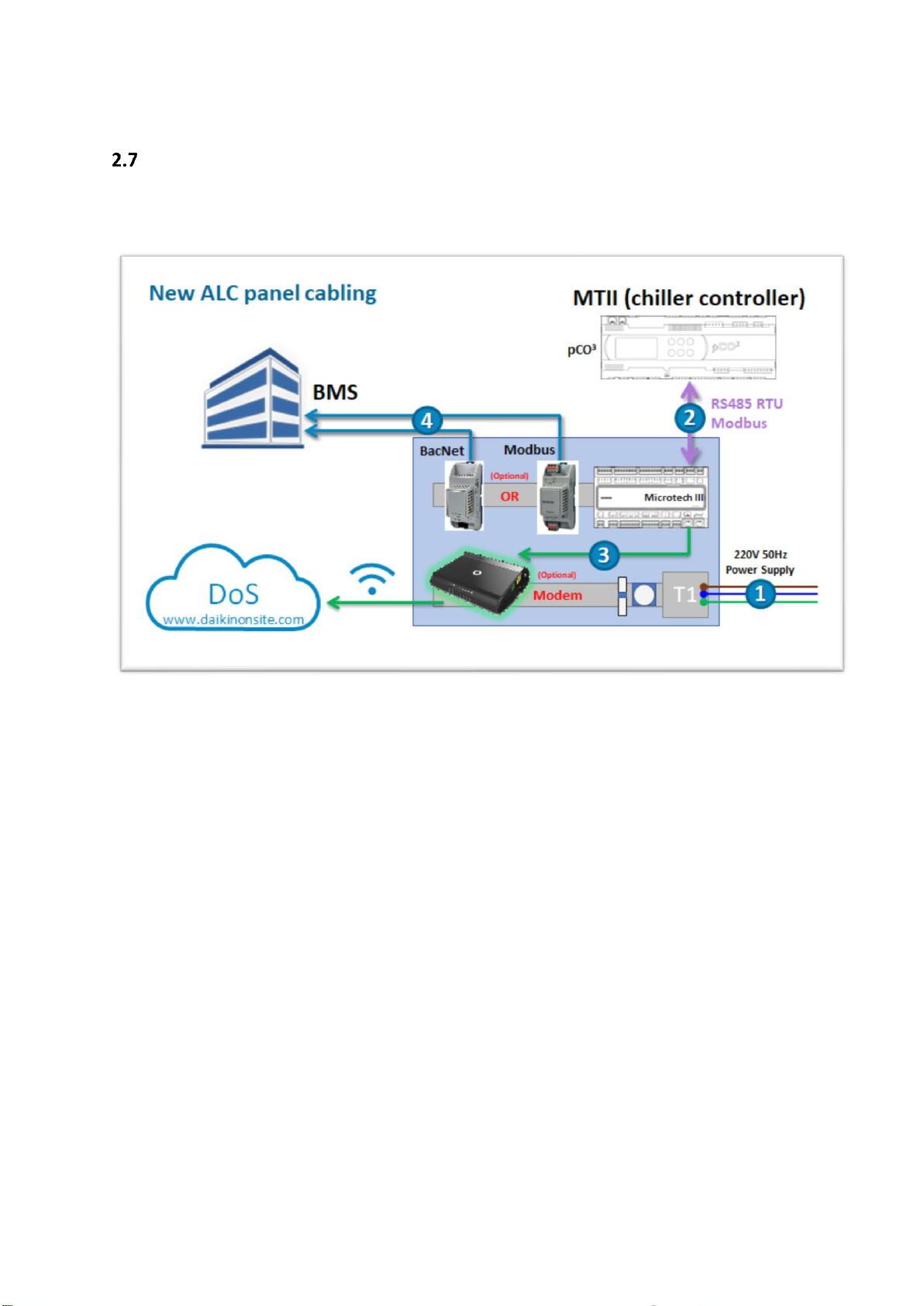

ALC connection diagram

The ALC DC8 provides new diagram connections as shown in the following figure. With respect to the

previous versions of ALC, the internal MTIII controller now manages every communication.

Figure 2: ALC DC8 connection diagram

As reported in the diagram, excluding the power supply cable, the type connections are mainly 5. With

reference to the numbering also used in the ALC overview image, these are:

1. The new ALC operates with a single-phase power supply (100→240VAC, 50/60Hz)

2. The main communication connection, always provided, is a 3-wire cable (+ / - / Gnd ref) that

allows the ALC to communicate with the MTII of the chiller unit via RS485 RTU Modbus

protocol.

3. An ethernet cable that allows the ALC to reach the networks and so Daikin On Site. Optionally

a 4G modem can be requested for a wireless connection.

4. (Optional) In case of link to BMS through optional POL modules, a cable that allow the ALC to

communicate with the BMS itself by means of Bacnet IP or Modbus RS485 connection.

5. (Optional) In case of 4G modem, an external antenna can improve the reception of the signal.

It is strongly antenna suggested to use a high gain external 4G if you are in an ambient that is

not easily reachable by the 4G signal to avoid sporadic and inefficient communications.

Page 12

Installation and Operation Manual D-EIOCP00206-20_00EN

12/76

ALC-DC8

3 Using the Controller

Knowing how to use the control system is necessary for a correct use of the same, as well as to

complete the installation as indicated in the subsequent chapters or to carry out maintenance

operations.

The control system consists of a unit controller (UC) to which can be connected POL extension modules

or other devices that implement additional features. All POL modules communicate via an internal

peripheral bus with the UC. The Microtech III continuously manages the information received from

these devices. The UC incorporates a program that controls the unit.

The standard HMI consists of an inbuilt display (A) with 3 buttons (B) and a push’n’roll control (C).

The keypad/display (A) consists of a 5-line by 22 character display. The function of the three buttons

(B) is described below:

Alarm status (from any page it links with the page with alarm list, alarm log and alarm snapshot if available)

Back to Main Page

Back to the previous level (it can be the Main Page)

The push’n’roll command (C) is used to scroll between the different menu pages, settings and data

available on the HMI for the active password level. Rotating the wheel allows to navigate between

lines on a screen (page) and to increase and decrease changeable values when editing. Pushing the

wheel acts as an Enter Button and will jump from a link to the next set of parameters.

General Recommendation

Before switching on the unit read the following recommendations:

• When all the operations and all the settings have been carried out, close all the switchbox

panels

• The switchbox panels can only be opened by trained personnel

• When the UC requires to be accessed frequently the installation of a remote interface is

strongly recommended

• The LCD display of the unit controller and other devices within the panel may be damaged by

extremely low temperatures. For this reason, it is strongly recommended to never power off

the unit during winter, especially in cold climates.

A

B

C

UC

Page 13

ALC-DC8

Installation and Operation Manual D-EIOCP00206-20_00EN

13/76

Navigating

When power is applied to the control circuit, the controller screen will be active and display the Home

screen, which can also be accessed by pressing the Menu Button The navigating wheel is the only

navigating device necessary, although the MENU, ALARM, and BACK buttons can provide shortcuts as

explained previously.

An example of the HMI screens is shown in the following picture.

M a i n M e n u 1 /

11

E n t e r P a s s w o r d

U n i t S t a t u s = O f f : U n i t S W

A c t i v e S e t p t = 7 . 0 °

C

A bell ringing in the top right corner will indicate an active alarm. If the bell doesn’t move it means

that the alarm has been acknowledged but not cleared because the alarm condition hasn’t been

removed. A LED will also indicate where the alarm is located between the unit or circuits.

M a i n M e n u 1 /

E n t e r P a s s w o r d

U n i t S t a t u s =

O f f : U n i t S W

A c t i v e S e t p t = 7 . 0 °

C

The active item is highlighted in contrast, in this example the item highlighted in Main Menu is a link

to another page. By pressing the push’n’roll, the HMI will jump to a different page. In this case the

HMI will jump to the Enter Password page.

E n t e r P a s s w o r d 2 / 2

E n t e r P W * * *

*

Passwords

The HMI structure is based on access levels that means that each password will disclose all the settings

and parameters allowed to that password level. Basic information about the status including the active

alarm list, active setpoint and controlled water temperature can be accessed without the need to

enter the password. At user level, UC handles one level of passwords:

MAINTENANCE

2526

The following information will cover all data and settings accessible with the maintenance password.

INFO: to access with higher level rights (i.e. Daikin Service role), please contact Daikin On Site

Smart Center to assess if possible (it is up to the membership of Daikin company).

In the Enter Password screen, the line with the password field will be highlighted to indicate that the

field on the right can be changed. This represents a setpoint for the controller. Pressing the push’n’roll

the individual field will be highlighted to allow an easy introduction of the numeric password. By

changing all fields, the 4 digits password will be entered and, if correct, the additional settings available

with that password level will be disclosed.

Page 14

Installation and Operation Manual D-EIOCP00206-20_00EN

14/76

ALC-DC8

E n t e r P a s s w o r d 2 /

2

E n t e r P W 5 * *

*

The password will time out after 10 minutes and is cancelled if a new password is entered or the

control powers down. Entering an invalid password has the same effect as continuing without a

password.

Once a valid password has been entered, the controller allows further changes and access without

requiring the user to enter a password until either the password timer expires or a different password

is entered. The default value for this password timer is 10 minutes. It is changeable from 3 to 30

minutes via the Timer Settings menu in the Extended Menus.

Editing

The Editing Mode is entered by pressing the navigation wheel while the cursor is pointing to a line

containing an editable field. Then:

• Once in the edit mode pressing the wheel again causes the editable field to be highlighted.

• Turning the wheel clockwise while the editable field is highlighted causes the value to be

increased.

• Turning the wheel counter-clockwise while the editable field is highlighted causes the value

to be decreased.

• The faster the wheel is turned the faster the value is increased or decreased.

• Pressing the wheel again cause the new value to be saved and the keypad/display to leave the

edit mode and return to the navigation mode.

• A parameter with an “R” is read only; it is giving a value or description of a condition.

• An “R/W indicates a read and/or write opportunity; a value can be read or changed (providing

the proper password has been entered).

Example 1: Check the Model name. Start at Main Menu and scroll down by means of wheel until the

submenu About Chiller is highlighted. There will be an arrow at the right side of the box, indicating

that a jump to the next level is possible. Press the wheel to execute the jump. You will arrive at About

Chiller link concerning info about the chiller itself and including the name of the model.

Example 2: Change a Set point, the Daikin On Site Communication Start for example. From the Main

Menu select View/Set Unit. The arrow indicated that this is link to a further menu. Press the wheel

and jump to the next menu View/Set Unit and use the wheel to scroll down to Daikin On Site. Select

the item “Comm Start” and press the wheel to jump to the item change page. Rotate the wheel to

adjust the set point to the desired value (Start). When this is done press the wheel again to confirm

the new value. With the Back button it will be possible to jump back to the Daikin On Site menu where

the new value will be displayed.

Page 15

ALC-DC8

Installation and Operation Manual D-EIOCP00206-20_00EN

15/76

Example 3: Clear Alarms. The presence of a new alarm is indicated with a Bell ringing on the top right

of the display. If the Bell is frozen one or more alarm had been acknowledged but are still active. To

view the Alarm menu from the Main Menu, scroll down to the Alarms line or simply press the Alarm

button on the display. Note the arrow indicating this line is a link. Press the wheel to jump to the next

menu Alarms There are some lines her: Alarms are cleared from the Active Alarm link. Press the wheel

to jump to the next screen. Then press again the wheel on Acknowledge. Change this value to Execute

to acknowledge the alarms. If the alarms can be cleared, then the alarm counter will display 0

otherwise it will display the number of alarms still active. When the alarms are acknowledged the Bell

on the top right of the display will stop to ring if some of the alarms are still active or will disappear if

all the alarms are cleared.

Basic Control System Diagnostic

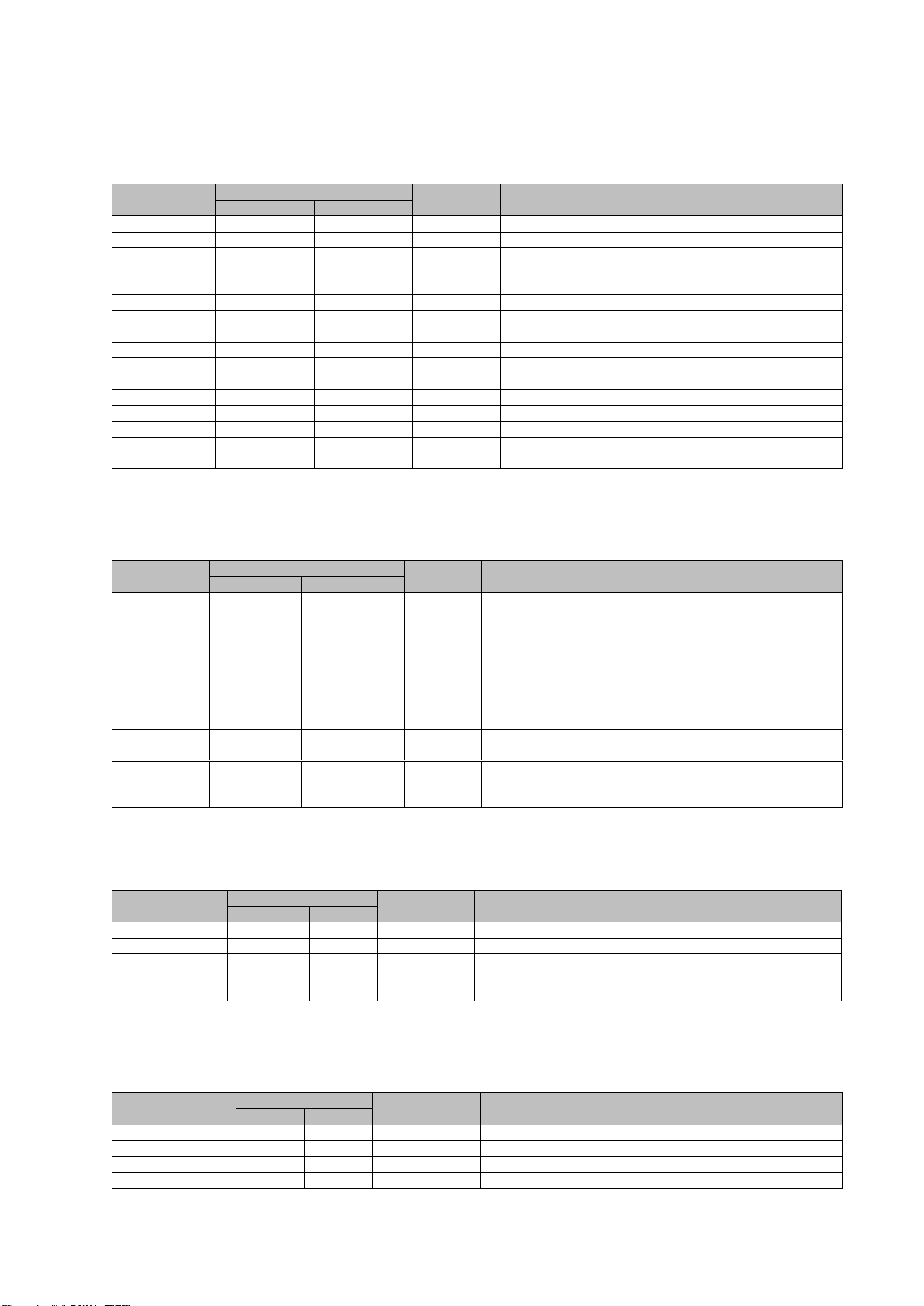

MicroTech III controller, extension modules and communication modules are equipped with two

status LED (BSP and BUS) to indicate the operational status of the devices. The BUS LED indicates the

status of the communication with the controller. The meaning of the two status LED is indicated

below.

Main Controller (UC)

BSP LED

Mode

Solid Green

Application running

Solid Yellow

Application loaded but not running (*) or BSP Upgrade mode active

Solid Red

Hardware Error (*)

Flashing Green

BSP startup phase. The controller needs time for starting.

Flashing Yellow

Application not loaded (*)

Flashing Yellow/Red

Fail safe mode (in case that the BSP upgrade was interrupted)

Flashing Red

BSP Error (software error*)

Flashing Red/Green

Application/BSP update or inizialization

(*) Contact Service.

Extension modules (currently not used for ALC)

BSP LED

Mode

BUS LED

Mode

Solid Green

BSP running

Solid Green

Communication running, I/O working

Solid Red

Hardware Error (*)

Solid Red

Communication down (*)

Flashing Red

BSP Error (*)

Solid Yellow

Communication running but parameter from the

application wrong or missing, or uncorrect factory

calibration

Flashing Red/Green

BSP upgrade mode

Communication modules

BSP LED (same for all modules)

BSP LED

Mode

Solid Green

BPS running, communication with controller

Solid Yellow

BSP running, no communication with controller (*)

Solid Red

Hardware Error (*)

Flashing Red

BSP Error (*)

Flashing Red/Green

Application/BSP update

(*) Contact Service.

Page 16

Installation and Operation Manual D-EIOCP00206-20_00EN

16/76

ALC-DC8

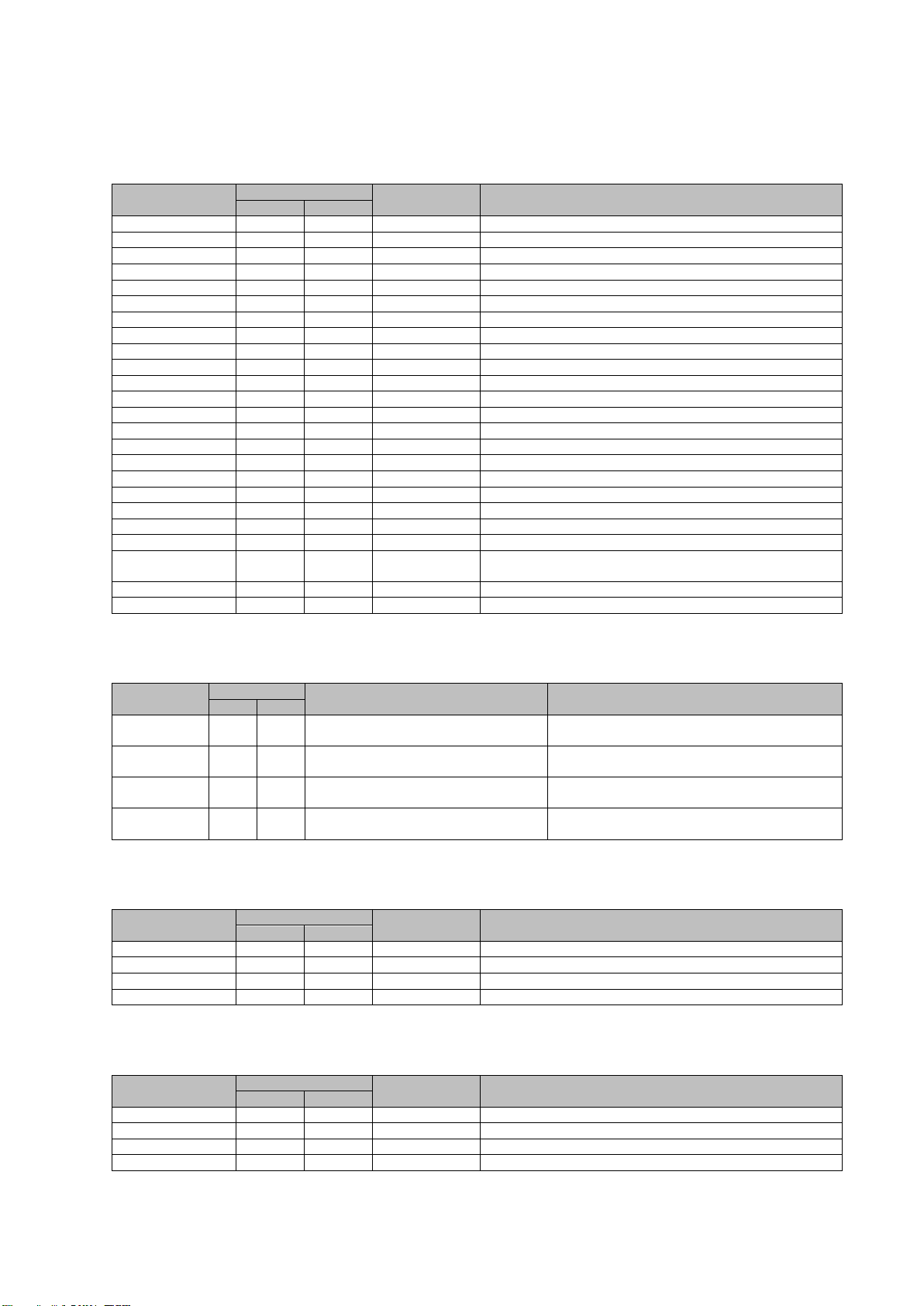

BUS LED

BUS LED

Bacnet IP

Modbus

Solid Green

Ready for Communication. The BACnet Server is

started. It doesn't indicate an active communication

All Communication running

Solid Yellow

Startup. The LED stays yellow until the module

receives a IP Address, therefore a link must be

established.

Startup, or one configured channel not communicating to

the Master

Solid Red

BACnet Server down. Automatic restart after 3

seconds is initiated.

All configured Communications down. Means no

communication to the Master. The timeout can be

configured. In case that the timeout is zero the timeout is

disabled.

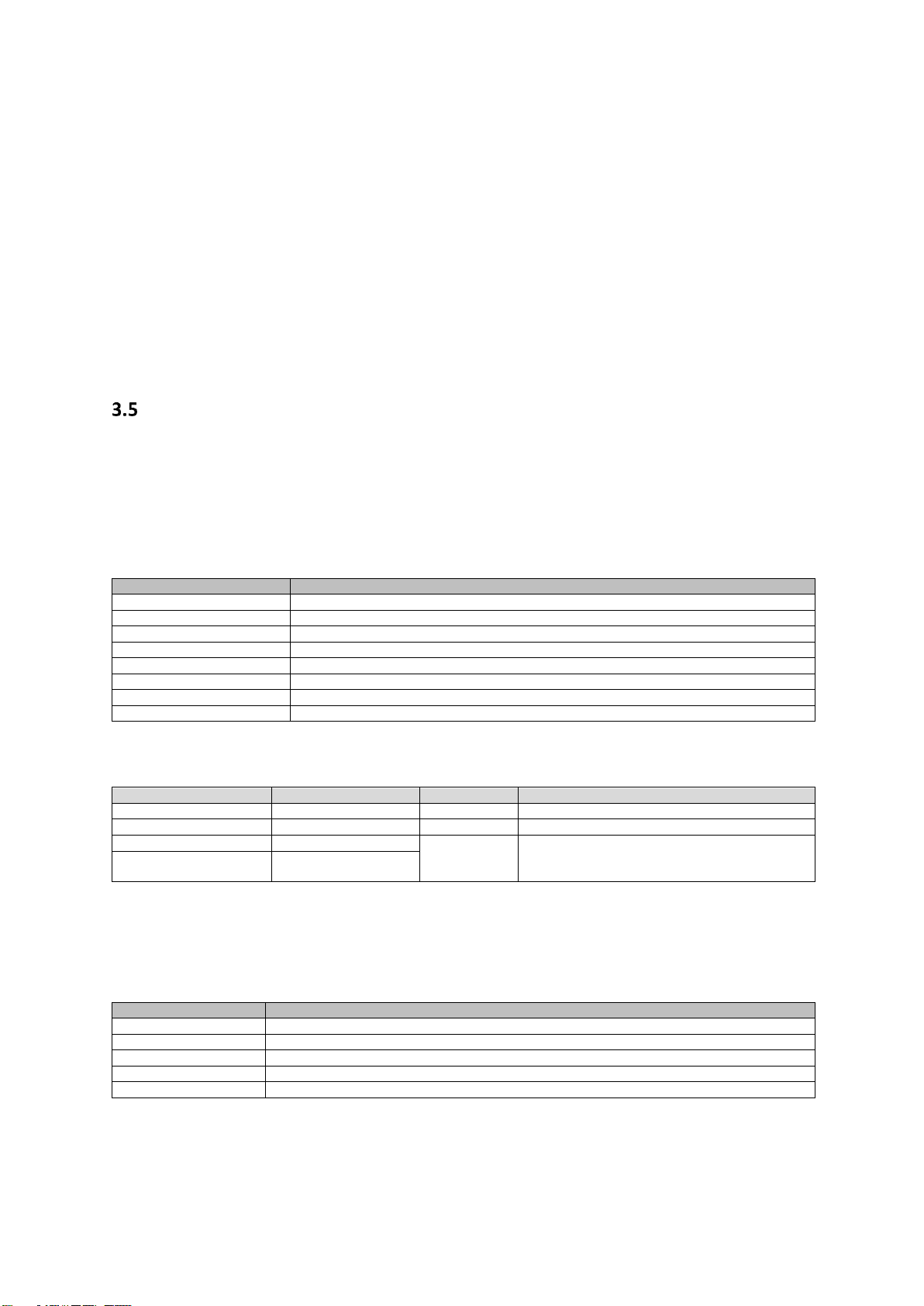

Controller maintenance

The controller requires to maintain the installed battery. Every two years it’s required to replace the

battery. Battery model is: BR2032 and it is produced by many different vendors.

To replace the battery, remove the plastic cover of the controller display using a screw driver as shown

in the following pictures:

Be careful to avoid damages to the plastic cover. The new battery shall be placed in the proper battery

holder, which is highlighted in the following picture, respecting the polarities indicated into the holder

itself.

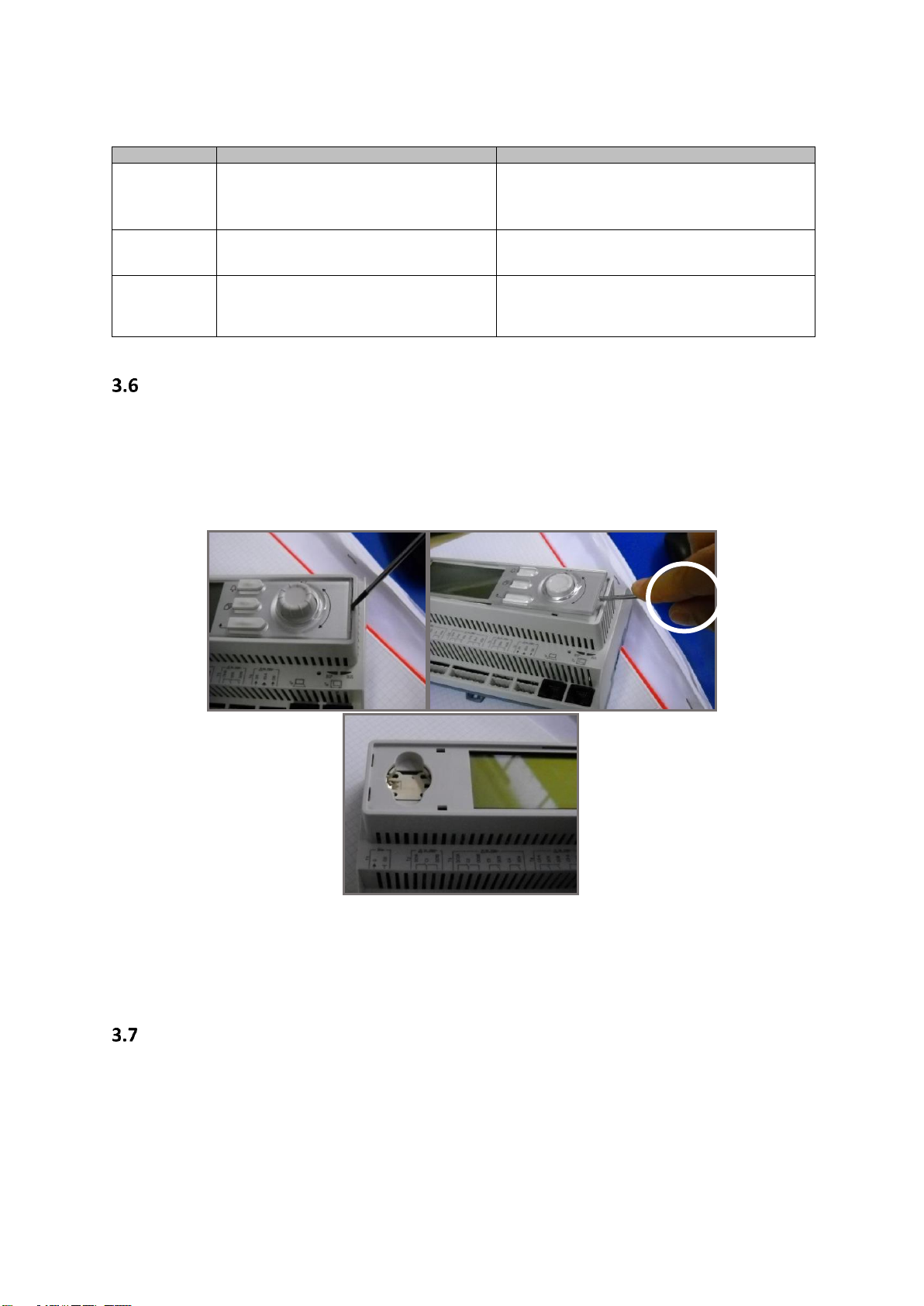

Optional Remote User Interface

As an option an external Remote HMI can be connected on the UC. The Remote HMI offers the same

features as the inbuilt display plus the alarm indication done with a light emitting diode located below

the bell button.

Page 17

ALC-DC8

Installation and Operation Manual D-EIOCP00206-20_00EN

17/76

The Remote can be ordered with the unit and shipped loose as a field installed option. It can also be

ordered any time after chiller shipment and mounted and wired on the job as explained on the

following page. The remote panel is powered from the unit and no additional power supply is

required.

All viewing and setpoint adjustments available on the unit controller are available on the remote

panel. Navigation is identical to the unit controller as described in this manual.

The initial screen when the remote is turned on shows the units connected to it. Highlight the desired

unit and press the wheel to access it. The remote will automatically show the units attached to it, no

initial entry is required.

The Remote HMI can be extended up to 700m using the process bus connection available on the UC.

With a daisy-chain connection as below, a single HMI can be connected to up to 8 units. Refer to the

specific HMI manual for details.

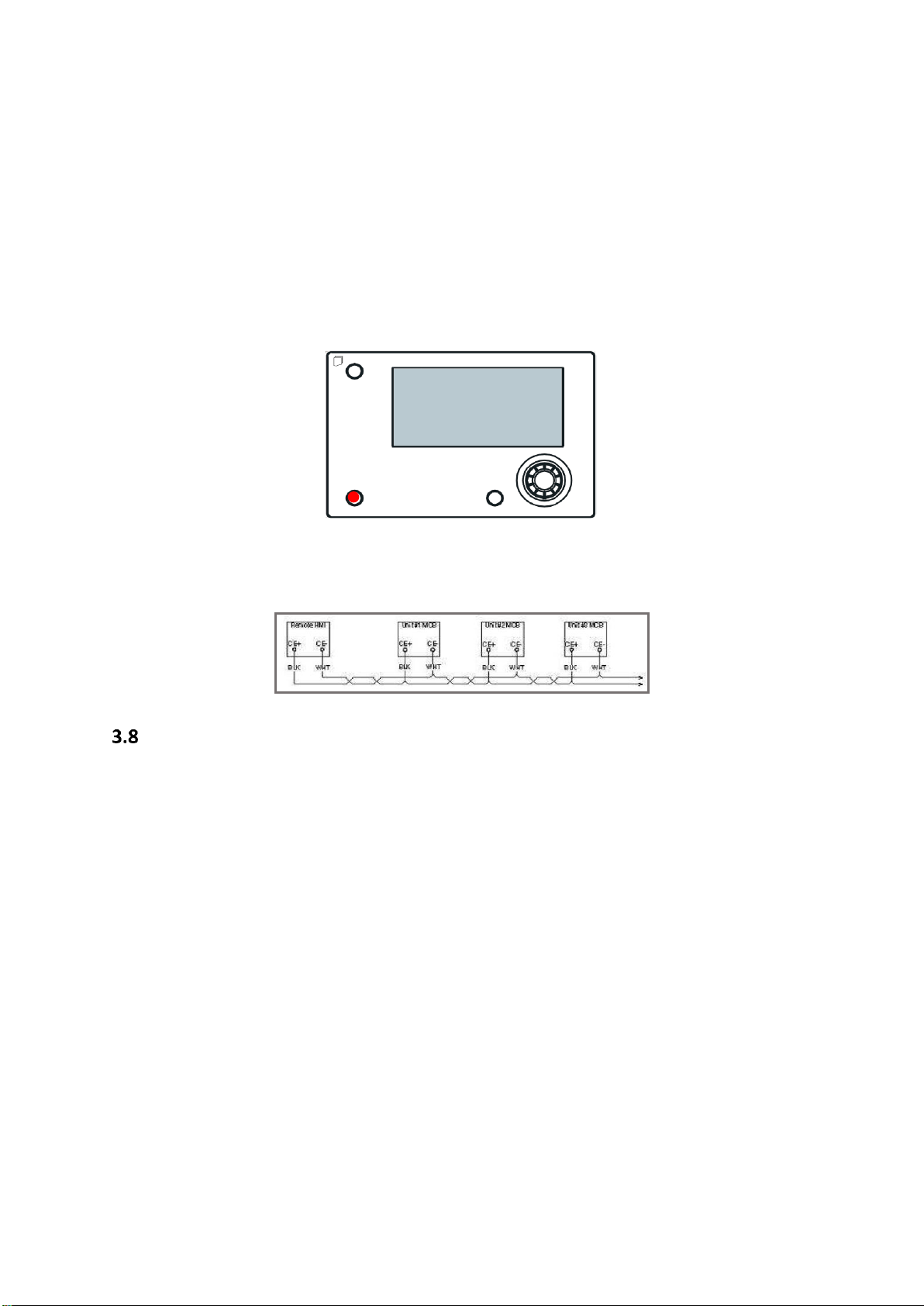

Embedded Web Interface

The MicroTech III controller has an embedded web interface that can be used to monitor the unit

when connected to a local network. It is possible to configure the IP addressing of the MicroTech III as

a fixed IP of DHCP depending on the network configuration.

With a common web browser, a PC can connect with the unit controller entering the IP address of the

controller or the host name, both visible in the “About Chiller” page accessible without entering a

password. When connected, it will be required to enter a username and a password. Enter the

following credential to get access to the web interface:

User Name: ADMIN

Password: SBTAdmin!

MicroTech® III

Page 18

Installation and Operation Manual D-EIOCP00206-20_00EN

18/76

ALC-DC8

The Main Menu page will be displayed. The page is a copy of the onboard HMI and follows the same

rules in terms of access levels and structure.

In addition, it allows to trend log a maximum of 5 different quantities. It’s required to click on the

value of the quantity to monitor and the following additional screen will become visible:

Depending on the web browser and its version the trend log feature may not be visible. It’s required

a web browser supporting HTML 5 like for example:

• Google Chrome v.37,

• Mozilla Firefox v.32.

These browsers are only an example of the supported ones and the versions indicated have to be

intended as minimum versions.

Page 19

ALC-DC8

Installation and Operation Manual D-EIOCP00206-20_00EN

19/76

4 Menu Structure

All settings are divided in different menus. Each menu collects in a single page other sub-menus,

settings or data related to a specific function (for example Power Conservation or Setup) or entity (for

example Unit or Circuit). In any of the following pages a grey box will indicate changeable values and

the defaults.

The submenu items to which a user can have access, depend upon his role and the password entered

as described in the paragraph dedicated to Passwords.

Main Menu

Setpoint/Sub-Menu

Default

Range

Description

Enter Password

-

Submenu to activate access levels

View/Set Unit

-

Submenu for unit data and settings

View/Set Circuit

-

Submenu for circuit data and settings

Unit Status=

NULL

NULL, 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12,

13, 14, 15, 16

Status of the Unit

Active Setpoint=

0°C,

-

Water temperature active setpoint + link to Setpoint page

Actual Capacity=

0.0%,

-

Unit capacity + link to “Capacity” page

Evaporator LWT=

-273.1°C,

-

Evaporator leaving water temperature + link to

“Temperatures” page

Unit Mode=

NULL

NULL,

Ice,

Cool,

Heat

Unit Mode

Alarms

-

Submenu for alarms; same function as Bell Button

Commission Unit

-

Submenu for commission unit

Diagnostic

-

Submenu for diagnostic

About Chiller

-

Application Info submenu

4.1.1 View/Set Unit

Setpoint/Sub-Menu

Default

Range

Description

Thermostat Ctrl

-

Submenu for Thermostatic control

Network Ctrl

-

Submenu for Network control

Pumps

-

Submenu for pump settings

Date/Time Schedules

-

Submenu Date, Time and Quiet Night mode schedule

Power Conservation

-

Submenu Unit Limiting functions

Ctrlr IP Setup

-

Submenu for controller IP-address setup

Daikin on Site

-

Submenu for connection to Daikin cloud DoS

Modbus

-

Submenu for Modbus configuration (only with inserted CommCard)

BACnetIP

-

Submenu for BACnetIP configuration (only with inserted CommCard)

4.1.1.1 Thermostat Ctrl

This page resumes all the parameters related to the unit thermostatic control.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

Start DT=

2.5°C - -64…64°C

Offset to start thermostat control

Stop DT=

2.0°C - -64…64°C

Offset to stop thermostat control

Stop to start=

180s - 0…3600s

Compressor stop delay before start

Page 20

Installation and Operation Manual D-EIOCP00206-20_00EN

20/76

ALC-DC8

4.1.1.2 Network Ctrl

This page resumes all settings related to Network control.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

Control Source=

Supervisor

On/Off

Supervisor

On/Off

Supervisor

On/Off possible,

Supervisor

On/Off NOT

possible,

NULL

Local Network control selection

Netwrk En SP=

Require

Unit OFF

Require

Unit OFF

Require Unit OFF,

Require Unit ON,

NULL

Enable unit command from BMS

Netwrk Mode SP=

Cool

Cool

Null,

Ice,

Cool,

Heat

HVAC mode

Netwrk Cap Lim=

100%

100%

0…100%

Capacity limitation from BMS

Netwrk Ice SP=

-

-3.8°C

-10…10°C

Ice setpoint from BMS

4.1.1.3 Pumps

This page resumes all settings related to the unit pumps.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

E. Pump 1 RH=

0 h - -64…64h

Run hours of evaporator pump #1

C. Pump 1 RH=

0 h - -64…64h

Run hours of condenser pump #1

Evap Pump 1 RH=

-

0 h

-64…64h

Run hours of evaporator pump #1

Cond Pump 1 RH=

-

0 h

-64…64h

Run hours of condenser pump #1

Evap Pump 2 RH=

-

0 h

-64…64h

Run hours of evaporator pump #2

Cond Pump 2 RH=

-

0 h

-64…64h

Run hours of condenser pump #2

4.1.1.4 Date/Time Schedules

This page resumes all settings related to daylight saving (DLS) mode.

Setpoint/SubMenu

Default

Range

Description

MCQ

USA

Actual Time=

hh:mm:ss

hh:mm:ss

-

Current time

Actual Date=

Mm/dd/yyyy

Mm/dd/yyyy

-

Current date

UTC Diff=

-60 min

-60 min

-

Difference from UTC

DLS Enable=

Yes

Yes

Yes, No

Daylight saving enable setpoint

DLS Strt Month=

3 3 1…12

Daylight saving start month

DLS Strt Week=

6 6 0…6

Daylight saving start weekday. Numbers between 0 and 6, where 0

is Monday and 6 is Sunday

DLS End Month=

10

10

1…12

Daylight saving end month

DLS End Week=

6 6 0…6

Daylight saving end weekday

4.1.1.5 Power Conservation

This page resumes all settings related to unit limiting functions.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

Unit Capacity=

0%

0%

-64…64%

Unit capacity actual value

Demand Limit=

0%

0%

-64…64%

Demand limit value

Page 21

ALC-DC8

Installation and Operation Manual D-EIOCP00206-20_00EN

21/76

4.1.1.6 Ctrlr IP Setup

This page resumes all settings and data related to controller IP-address setup

Setpoint/SubMenu

Default

Range

Description

MCQ

USA

Apply Changes=

Off

Off

On, Off

Command to restart the controller

DHCP=

On

On

On Off

Enable DHCP to assign controller IP address

M2M Modem=

None

None

None

MachineLink

Teltonika

Type of M2M device

Act IP=

192.168.1.42

192.168.1.42

0…255

Actual IP address assigned to controller

Act Msk=

255.255.255.0

255.255.255.0

0…255

Actual IP address assigned to network subnet mask

Act Gwy=

192.168.1.1

192.168.1.1

0…255

Actual IP address assigned to gateway

Gvn IP=

192.168.1.42

192.168.1.42

0…255

Given IP address setpoint to be assigned to controller

Gvn Msk=

255.255.255.0

255.255.255.0

0…255

Given IP address setpoint to be assigned to subnet mask

Gvn Gwy=

192.168.1.1

192.168.1.1

0…255

Given IP address setpoint to be assigned to gateway

Prim DNS=

192.168.1.1

192.168.1.1

0…255

Primary DNS IP address

Sec DNS=

0.0.0.0

0.0.0.0

0…255

Secondary DNS IP address

Host Name=

POL**********

POL**********

-

Hostname for the controller inside the network

MAC

xx-xx-xx-xx-xxxx

xx-xx-xx-xx-xxxx

x=0…9, A...Z

Controller MAC address

4.1.1.7 Daikin On Site

This page resumes all settings related to connect the controller to Daikin cloud DoS

Setpoint/SubMenu

Default

Range

Description

MCQ

USA

Comm Start=

Start

Start

Off, Start

Command to enable communication with Daikin cloud

Comm State=

- - - ,

IPErr,

Init,

InitErr,

Reg,

RegErr,

Description,

Connected

State of the communication with cloud

Serial Number=

xxxxx

xxxxx

x=0…9

Unique serial number of the controller. The serial number can be

composed by four or five numbers.

Activation Key=

xxxxxx- xxxxxxxxxx- xxxxxxxxxx

xxxxxx- xxxxxxxxxx- xxxxxxxxxx

x=1…9, A…Z

Unique alphanumeric key of 26 characters to register the controller

in the cloud platform

4.1.2 View/Set Circuit

Setpoint/SubMenu

Default

Range

Description

MCQ

USA

C1

-

Link for Circuit #1 page

C2 - - Link for Circuit #2 page

C3 - - Link for Circuit #3 page

C4 -

-

Link for Circuit #4 page

4.1.2.1 View/Set Cir-X

This page resumes all settings and data related to the Circuit number “-X”, where X = 1,2,3,4.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

Data=

-

Link for “Data” page

Compressor=

-

Link for “Compressor” page

Condenser=

-

Link for “Condenser” page

EXV=

-

Link for “EXV” page

Page 22

Installation and Operation Manual D-EIOCP00206-20_00EN

22/76

ALC-DC8

4.1.2.2 Data

This page resumes all main settings and data for the selected circuit.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

Circuit Status=

-

Link for “Circuit Status”

Capacity=

0%,

0%

-64…64%

Actual capacity of the unit

Evap Press=

0 bar,

-

-64…64 bar

Current evaporator pressure

Evap Press 1=

-

0 bar

-64…64 bar

Current evaporator pressure from probe#1

Evap Press 2=

-

0 bar

-64…64 bar

Current evaporator pressure from probe#2

Cond Press=

0 bar,

-

-64…64 bar

Current condenser pressure

Cond Press 1=

-

0 bar

-64…64 bar

Current condenser pressure from probe#1

Cond Press 2=

-

0 bar

-64…64 bar

Current condenser pressure from probe#2

Evap Sat Temp=

0°C,

-

-64…64°C

Current evaporator saturated temperature

Evap Sat Temp 1=

-

0°C

-64…64°C

Current evaporator saturated temperature from probe#1

Evap Sat Temp 2=

-

0°C

-64…64°C

Current evaporator saturated temperature from probe#2

C. Sat Tmp=

0°C,

-

-64…64°C

Current condenser saturated temperature

C. Sat Tmp 1=

-

0°C

-64…64°C

Current condenser saturated temperature from probe#1

C. Sat Tmp 2=

-

0°C

-64…64°C

Current condenser saturated temperature from probe#2

Suct Temp=

0°C,

-

-64…64°C

Current value of suction temperature

Suct Temp 1=

- -64…64°C

Current value of suction temperature from probe#1

Suct Temp 2=

-

0°C

-64…64°C

Current value of suction temperature from probe#2

Disch Temp=

0°C,

-

-64…64°C

Current value of discharge temperature

Disch Temp 1=

-

0°C

-64…64°C

Current value of discharge temperature from probe#1

Disch Temp 2=

-

0°C

-64…64°C

Current value of discharge temperature from probe#2

Oil Press=

0 bar,

-

-64…64 bar

Current value of oil pressure

EXV Position

0 steps,

-

-64…64 steps

Current value of expansion valve position

Evap LWT=

0°C

0°C

-64…64°C

Current value of water temperature entering the evaporator

Evap EWT=

0°C

0°C

-64…64°C

Current value of water temperature leaving the evaporator

Circuit Status

This page resumes the current state of the circuit, for each circuit.

Setpoint/SubMenu

Default

Range

Description

MCQ

USA

C1=

NULL

NULL

NULL*1*2*3*4*5*6*7*8*9*10*

*11*12*13*14*15*16*17*18*19*20*21*22

Circuit status value for Circuit#1

C2=

NULL - NULL*1*2*3*4*5*6*7*8*9*10*

*11*12*13*14*15*16*17*18*19*20*21*22

Circuit status value for Circuit#2

C3=

NULL - NULL*1*2*3*4*5*6*7*8*9*10*

*11*12*13*14*15*16*17*18*19*20*21*22

Circuit status value for Circuit#3

C4=

NULL - NULL*1*2*3*4*5*6*7*8*9*10*

*11*12*13*14*15*16*17*18*19*20*21*22

Circuit status value for Circuit#4

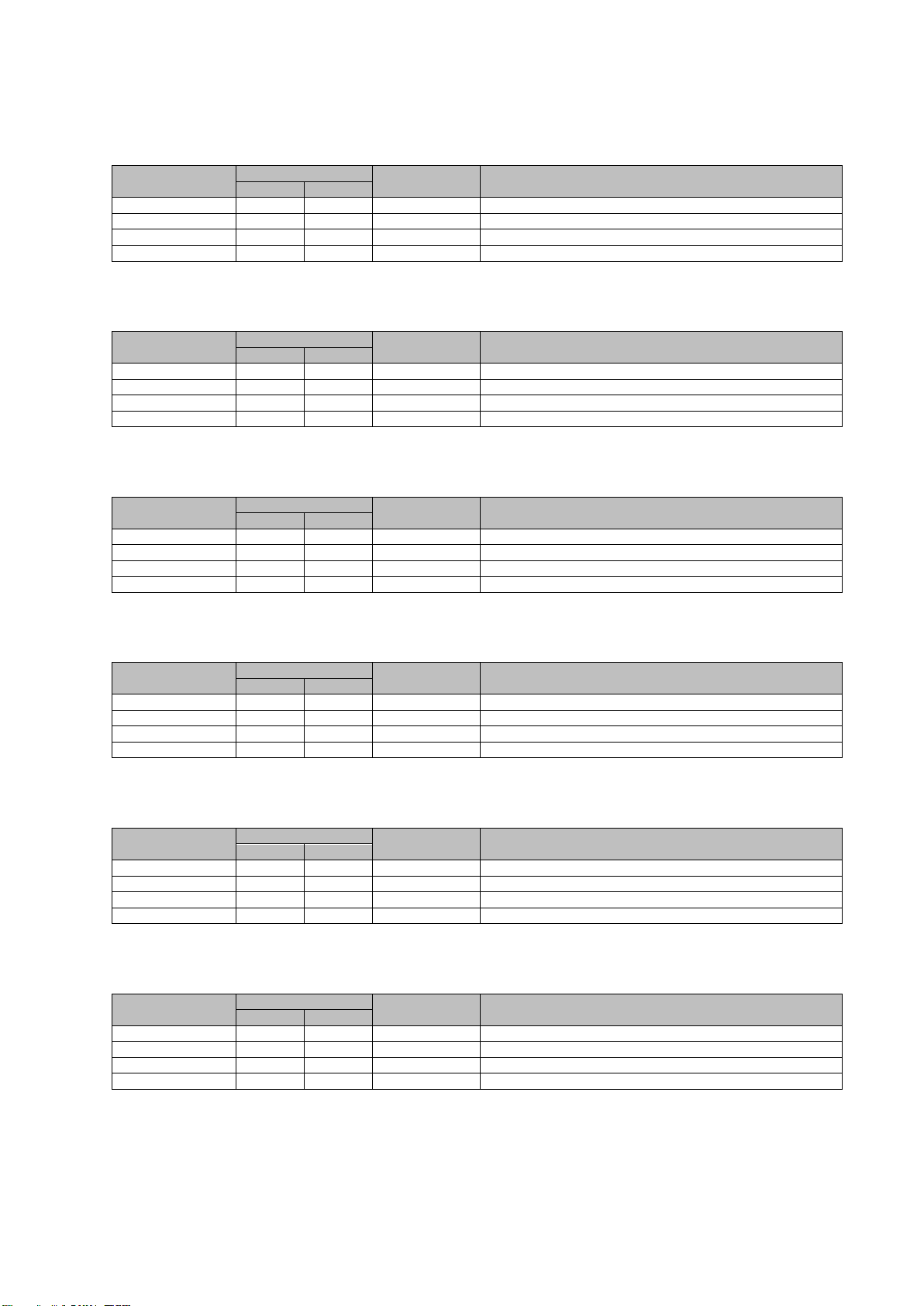

Capacity

This page resumes all the capacity value of the circuit, for each circuit.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

C1=

0% - -64…64%

Capacity value for Circuit#1

C2=

0% - -64…64%

Capacity value for Circuit#2

C3=

0% - -64…64%

Capacity value for Circuit#3

C4=

0% - -64…64%

Capacity value for Circuit#4

Evap Pressure

This page resumes all the evaporator pressures of each circuit.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

C1=

0 bar - -64…64 bar

Evaporator pressure for Circuit#1

C2=

0 bar - -64…64 bar

Evaporator pressure for Circuit#2

C3=

0 bar - -64…64 bar

Evaporator pressure for Circuit#3

C4=

0 bar - -64…64 bar

Evaporator pressure for Circuit#4

Page 23

ALC-DC8

Installation and Operation Manual D-EIOCP00206-20_00EN

23/76

Cond Pressure

This page resumes all the condenser pressures of each circuit.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

C1=

0 bar - -64…64 bar

Condenser pressure for Circuit#1

C2=

0 bar - -64…64 bar

Condenser pressure for Circuit#2

C3=

0 bar - -64…64 bar

Condenser pressure for Circuit#3

C4=

0 bar - -64…64 bar

Condenser pressure for Circuit#4

Evap Sat Temp

This page resumes all the evaporator saturated temperatures of each circuit.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

C1=

0°C - -64…64°C

Evap. saturated temperature for Circuit#1

C2=

0°C - -64…64°C

Evap. saturated temperature for Circuit#2

C3=

0°C - -64…64°C

Evap. saturated temperature for Circuit#3

C4=

0°C - -64…64°C

Evap. saturated temperature for Circuit#4

C Sat Temp

This page resumes all the condenser saturated temperature, for each circuit.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

C1=

0°C - -64…64°C

Cond. saturated temperature for Circuit#1

C2=

0°C - -64…64°C

Cond. saturated temperature for Circuit#2

C3=

0°C - -64…64°C

Cond. saturated temperature for Circuit#3

C4=

0°C - -64…64°C

Cond. saturated temperature for Circuit#4

Suct Temp

This page restores all the suction temperatures of each circuit.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

C1=

0°C - -64…64°C

Suction temperature for Circuit#1

C2=

0°C - -64…64°C

Suction temperature for Circuit#2

C3=

0°C - -64…64°C

Suction temperature for Circuit#3

C4=

0°C - -64…64°C

Suction temperature for Circuit#4

Disch Temp

This page resumes all the discharge temperatures of each circuit.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

C1=

0°C - -64…64°C

Discharge temperature for Circuit#1

C2=

0°C - -64…64°C

Discharge temperature for Circuit#2

C3=

0°C - -64…64°C

Discharge temperature for Circuit#3

C4=

0°C - -64…64°C

Discharge temperature for Circuit#4

Oil Pressure

This page resumes all the oil pressures of each circuit.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

C1=

0 bar - -64…64 bar

Oil pressure for Circuit#1

C2=

0 bar - -64…64 bar

Oil pressure for Circuit#2

C3=

0 bar - -64…64 bar

Oil pressure for Circuit#3

C4=

0 bar - -64…64 bar

Oil pressure for Circuit#4

Page 24

Installation and Operation Manual D-EIOCP00206-20_00EN

24/76

ALC-DC8

EXV Position

This page resumes all data relating to the expansion valve position, for each circuit.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

C1=

0steps,

-

-64…64 steps

EXV position for Circuit#1

C2=

0steps,

-

-64…64 steps

EXV position for Circuit#2

C3=

0steps,

-

-64…64 steps

EXV position for Circuit#3

C4=

0steps,

-

-64…64 steps

EXV position for Circuit#4

4.1.2.3 Compressor

This page resumes all main settings and data related to the compressor of selected circuit.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

No. Starts=

0,

0,

-64…64

Number of starts of compressor for selected circuit + Link to “No.

Starts” page

Run Hours=

0h,

0h,

-64…64 h

Run hours of compressor for selected circuit + Link to “Run Hours”

page

Capacity=

0%,

-

-64…64%

Capacity of selected circuit + Link to “Capacity” page

Load St=

Unit not

required

to load

-

Unit not required

to load,

Unit required to

load,

NULL

Load state of compressor for selected circuit

Unload St=

Unit not

required

to unload

-

Unit not required

to unload,

Unit required to

unload,

NULL

Unload state of compressor for selected circuit

No. Starts

This page resumes all the number of starts of compressor.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

C1= 0 0

-64…64

Number of starts of compressor for Circuit#1 (MCQ); Number of

starts of compressor#1 for Circuit#1 (USA);

C2= 0 0

-64…64

Number of starts of compressor for Circuit#2 (MCQ); Number of

starts of compressor#2 for Circuit#1 (USA);

C3= 0 -

-64…64

Number of starts of compressor for Circuit#3 (MCQ)

C4= 0 -

-64…64

Number of starts of compressor for Circuit#4 (MCQ)

Run Hours

This page resumes all the run hours of compressor.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

C1=

0h

0h

-64…64 h

Run hours of compressor for Circuit#1 (MCQ); Run hours of

compressor#1 for Circuit#1 (USA);

C2=

0h

0h

-64…64 h

Run hours of compressor for Circuit#2 (MCQ); Run hours of

compressor#2 for Circuit#1 (USA);

C3=

0h - -64…64 h

Run hours of compressor for Circuit#3 (MCQ)

C4=

0h - -64…64 h

Run hours of compressor for Circuit#4 (MCQ)

Page 25

ALC-DC8

Installation and Operation Manual D-EIOCP00206-20_00EN

25/76

4.1.2.4 Condenser

This page resumes all main settings and data related to the condenser of the selected circuit.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

C. Sat Tmp=

0°C,

-

-64…64°C

Saturated temperature of condenser for the selected circuit + Link to

“C Sat Temp” page

Cond Press=

0 bar,

-

-64…64 bar

Condenser pressure for the selected circuit + Link to “Cond Press”

page

C. Sat Tmp 1=

-

0°C

-64…64°C

Saturated temperature of condenser related to compressor#1 (single

circuit)

Cond Press 1=

-

0 bar

-64…64 bar

Condenser pressure related to compressor#1 (single circuit)

C. Sat Tmp 2=

-

0°C

-64…64°C

Saturated temperature of condenser related to compressor#2 (single

circuit)

Cond Press 2=

-

0 bar

-64…64 bar

Condenser pressure related to compressor#2 (single circuit)

4.1.2.5 EXV

This page resumes all main settings and data relating to the expansion valve.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

EXV Position=

0 steps,

-

-64…64 steps

Position of EXV and link to “EXV Position” page

Evap Press=

0 bar,

-

-64…64 bar

Evaporator pressure and link to “Evap Pressure” page

4.1.3 Active Setpoint

4.1.3.1 Tmp Setpoint

This page resumes all settings to configure the leaving water temperatures setpoints.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

Cool LWT

7.0°C

6.7°C

-64…64°C

Leaving water temperature setpoint for cooling mode

Heat LWT

45.0°C

50.0°C

-64…70°C

Leaving water temperature setpoint for heating mode

Ice LWT

-

-3.8°C

-10…10°C

Leaving water temperature setpoint for ice mode

4.1.4 Commission Unit

4.1.4.1 Configuration

Unit

This page resumes all settings to configure the unit.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

Unit Type=

Select

Unit

Name

Select

Unit

Name

PFS

ALS

WHS

MCAIR

MTM

WSC

WDC

WPV

WCC

HSC

TSC

HDC

WMC

Select Unit Name

Setpoint for specifying the unit model to which ALC device is

connected.

Page 26

Installation and Operation Manual D-EIOCP00206-20_00EN

26/76

ALC-DC8

No. Of Compr.=

0 0 0, 1, 2, 3, 4

Setpoint to configure the number of:

• compressors (USA)

• circuits (MCQ)

Write Enable=

Write Sp

Disabled

Write Sp

Disabled

Write Sp Disabled,

Write Sp from DoS,

Write Sp from BMS

Setpoint to enable editing/writing of all setpoint (sp) values.

Setp Values=

Copy

Values

MT2

Copy

Values

MT2

Copy Values MT2,

ALC default or MT3

Setpoint to choose the current values of all setpoints.

MB Comm Time Int=

5.0s

5.0s

-64…64s

Setpoint to setup the time interval of MODBUS communication

protocol.

MB Comm State=

-

-

Ok, Communication

ERROR!

Information on the state of MODBUS communication protocol.

Modem

This page resumes all settings and data related to the Circuit number “-X”, where X = 1,2,3,4.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

Modem=

None

None

None,

MachineLink,

Teltonika

Setpoint to configure the modem model, when the unit is

connected to Internet with a M2M device.

4.1.4.2 Calibrate Sensors

This page resumes all data relating to the sensors installed on the chiller unit.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

Unit=

-

Submenu with information on the unit sensors.

C1=

-

Submenu with information on the Circuit#1.

C2= - - Submenu with information on the Circuit#2

C3= - - Submenu with information on the Circuit#3

C4= - - Submenu with information on the Circuit#4

Unit

This page resumes all information about unit sensors.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

Evap EWT=

0°C

0°C

-64…64°C

Current value of evaporator entering water temperature

Evap LWT=

0°C

0°C

-64…64°C

Current value of evaporator leaving water temperature

Cond EWT=

0°C

0°C

-64…64°C

Current value of condenser entering water temperature

Cond EWT=

0°C

0°C

-64…64°C

Current value of condenser leaving water temperature

Heat Rec EWT=

0°C - -64…64°C

Current value of heat recovery entering water temperature

Heat Rec LWT

0°C - -64…64°C

Current value of heat recovery leaving water temperature

C-X

This page resumes all information about circuit sensors for the circuit number X, where X=1,2,3,4.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

Evap Press=

0 bar - -64…64 bar

Current value of evaporator refrigerant pressure for the selected

circuit

Cond Press=

0 bar - -64…64 bar

Current value of condenser refrigerant pressure for the selected

circuit

Oil Press=

0 bar - -64…64 bar

Current value of oil pressure for the selected circuit

Suct Temp=

0°C - -64…64°C

Current value of suction temperature for the selected circuit

Disch Temp=

0°C - -64…64°C

Current value of discharge temperature for the selected circuit

Evap Press 1=

-

0 bar

-64…64 bar

Current value of evaporator refrigerant pressure, related to the

compressor#1 (single circuit)

Evap Press 2=

-

0 bar

-64…64 bar

Current value of evaporator refrigerant pressure, related to the

compressor#2 (single circuit)

Cond Press 1=

-

0 bar

-64…64 bar

Current value of condenser refrigerant pressure, related to the

compressor#1 (single circuit)

Page 27

ALC-DC8

Installation and Operation Manual D-EIOCP00206-20_00EN

27/76

Cond Press 2=

-

0 bar

-64…64 bar

Current value of condenser refrigerant pressure, related to the

compressor#2 (single circuit)

Suct Temp 1=

-

0°C

-64…64°C

Current value of suction temperature, related to the compressor#1

(single circuit)

Suct Temp 2=

-

0°C

-64…64°C

Current value of suction temperature, related to the compressor#2

(single circuit)

Disch Temp 1=

-

0°C

-64…64°C

Current value of discharge temperature, related to the

compressor#1 (single circuit)

Disch Temp 2=

-

0°C

-64…64°C

Current value of discharge temperature, related to the

compressor#2 (single circuit)

4.1.4.3 Manual Control

This page resumes all setting for operating the unit manually.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

Unit=

-

Submenu with settings for the unit.

C1=

-

Submenu with settings for Circuit#1.

C2= - - Submenu with settings for Circuit#2.

C3= - - Submenu with settings for Circuit#3.

C4= - - Submenu with settings for Circuit#4.

Unit

This page resumes all information about the input/output state of unit probes and pumps.

Setpoint/Sub-Menu

Default

Range

Description

c

USA

Evap Flow Inp St=

Evaporator

flow present

Evaporator

flow present

Evaporator flow

present,

Evaporator flow

LOSS,

NULL

Status of the flow entering the evaporator.

Cond Flow Inp St=

Condenser

flow present

Condenser

flow present

Condenser flow

present,

Evaporator flow

LOSS,

NULL

Status of the flow entering the condenser.

E.Pmp1 Out St=

Main Pump

is OFF

Main Pump is

OFF

Main Pump is OFF,

Main Pump is ON,

NULL

Output status of the evaporator pump.

C.Pmp1 Out St=

Main Pump

is OFF

Main Pump is

OFF

Main Pump is OFF,

Main Pump is ON,

NULL

Output status of the condenser pump.

C-X

This page resumes all information about the fans state for the selected circuit.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

Fan 1 out st=

Fan #1 OFF

-

Fan #1 OFF

Fan #1 ON

NULL

Output state of fan#1 for the selected circuit. (MCQ only)

Fan 2 out st=

Fan #2 OFF

-

Fan #2 OFF

Fan #2 ON

NULL

Output state of fan#2 for the selected circuit. (MCQ only)

Fan 3 out st=

Fan #3 OFF

-

Fan #3 OFF

Fan #3 ON

NULL

Output state of fan#3 for the selected circuit. (MCQ only)

Fan 4 out st=

Fan #4 OFF

-

Fan #4 OFF

Fan #4 ON

NULL

Output state of fan#4 for the selected circuit. (MCQ only)

Fan 5 out st=

Fan #5 OFF

-

Fan #5 OFF

Fan #5 ON

NULL

Output state of fan#5 for the selected circuit. (MCQ only)

Fan 6 out st=

Fan #6 OFF

-

Fan #6 OFF

Fan #6 ON

Output state of fan#6 for the selected circuit. (MCQ only)

Page 28

Installation and Operation Manual D-EIOCP00206-20_00EN

28/76

ALC-DC8

NULL

4.1.5 Alarms

This page resumes all information about alarms.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

Alarm Active

-

Submenu with a list of currently active alarms.

Alarm History

-

Submenu with a list of all alarms.

Alarm Snapshot

-

Submenu with a list of alarm snapshot.

Advanced

-

Submenu with advanced options and information about alarms.

EventHistory

-

Submenu with a list of all events.

4.1.6 Diagnostic

This page resumes all information for the diagnostic of the controller.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

MT3 Run Hours=

x x x=0,1,2…

Operational time for MT3 controller.

Reset Cause=

Command

Command

Power,

Command,

Watchdog,

Unexpected

Event that restart the controller.

Nr. Of Reset=

x x x=0,1,2…

Counter for the number of controller reset

Internal Temp=

x x x=-64…64°C

Controller internal temperature

Mem. Used=

x x x=0…100%

Percentage of used memory

Cycle Time=

110

110

94…253ms

Cycle time for the controller

4.1.7 About

This page resumes all information about MTIII unit controller and unit.

Setpoint/Sub-Menu

Default

Range

Description

MCQ

USA

Model name=

Select

Unit

Name

Select

Unit

Name

PFS

ALS

WHS

MCAIR

MTM

WSC

WDC

WPV

WCC

HSC

TSC

HDC

WMC

Select Unit Name

Unit model to which ALC device is connected.

Unit S/N=

Enter

Data

Enter

Data

-

Serial number of the unit.

SW name=

ALC

ALC - Name of the software installed on the controller.

BSP Ver=

10.36

10.36

-

Firmware version installed on the controller.

App Ver=

8.00.A

8.00.A

-

Software version installed on the controller.

Page 29

ALC-DC8

Installation and Operation Manual D-EIOCP00206-20_00EN

29/76

5 Device Installation and Connection

Installing and connecting ALC DC8 Hardware

Hereafter a step-by-step guide with detailed images to see how each device have to be connected to

the chiller unit and to the other facilities.

5.1.1 STEP 1, Cable routing

Depending on chosen ALC DC8 hardware configuration, firstly it necessary to pass through the

bottom of the cabinet some cables and secure them by means of cable clamps. In the example below

have been provided:

• An external VAC power supply cable (in black)

• An external MTII communication Modbus 3 wire cable (in grey)

Optionally it may be necessary to provide the passage of other cables, such as:

• External Ethernet Cable, in case of connection to Daikin On Site by means of LAN connection

• External 3G/4G antenna coaxial cable

• External (Modbus/Bacnet) BMS cable

WARNING: To allow cables to pass through the cable clamps of the cabinet, any connector must be

before disconnected.

Also remember to reserve the correct length of each cable passed to correctly allow the connections

indicated below. In this regard, it may be useful to loosen and tighten the cable clamps after making

all the connections and passing the cables through the internal raceways of the cabinet

For configuration steps and details, please refer to the operator's manual of specific chiller unit.

Page 30

Installation and Operation Manual D-EIOCP00206-20_00EN

30/76

ALC-DC8

5.1.2 STEP 2, Power cable

Using a screwdriver of the right size, connect and

ensure the VAC Power cable, respecting the

indications on the headers with the respect to the

3-wire of the power cable itself:

• Protective earth – green/yellow wire

• Neutral (N) – blue wire

• Line, single phase(L) – brown wire

5.1.3 STEP 3, Main Modbus cable

connection

Using a screwdriver of the right size, connect and

ensure the 3-wires coming from the Modbus

Cable on the header corresponding to the T12-

RS485 of the MTIII controller. In particular, it is

suggested to note down the colors of the wires

corresponding to the signals:

• +

• -

• REF

to subsequently facilitate the connection

operations to the Modbus serial board of the

chiller unit's MTII controller.

1

2

Page 31

ALC-DC8

Installation and Operation Manual D-EIOCP00206-20_00EN

31/76

5.1.4 (Optional) STEP 4, Ethernet cable

connection

If it has been chosen to connect the ALC to Daikin

On Site via a local area network, instead of using

a 3G / 4G modem, it is necessary to connect this

cable to the Tip - RJ45 socket of the MTIII

controller.

In the "Configuring ALC DC8 for Daikin On Site

connection" paragraph are reported the details

of the configuration of the ALC for

communication with Daikin On Site.

5.1.5 (Optional) STEP 5, BMS cable

connection

If it has been requested to connect the ALC to a

BMS it is necessary to connect this cable

depending on the type of communication

foreseen. In particular:

• Bacnet Communication Module POL908 –

Connect the RJ45 cable to the (only) RJ45

connector on the module

• Modbus Communication Module POL902 –

Connect the 3-wire RTU Modbus to the header

T1-RS485 respecting polarity (+ / - / Ref) with

respect to BMS cable already connected.

3

4

Page 32

Installation and Operation Manual D-EIOCP00206-20_00EN

32/76

ALC-DC8

5.1.6 (Optional) STEP 6, Antenna

coaxial cable connection

In order to improve the reception of the signal it is

suggested to optionally connect an external

antenna. Connect the SMA male connector of the

antenna coaxial cable to the SMA female

connector of the 3G/4G router and screw it to

ensure connection.

WARNING: the following steps are just referred to an example of modbus communication

configuration on an MTII device. The example reported is valid for an ALS unit, but the

steps may differ for other compatible types chiller units shown in table ALC Compatibility

Table.

For configuration steps and details, please refer to the operator's manual of specific

chiller unit.

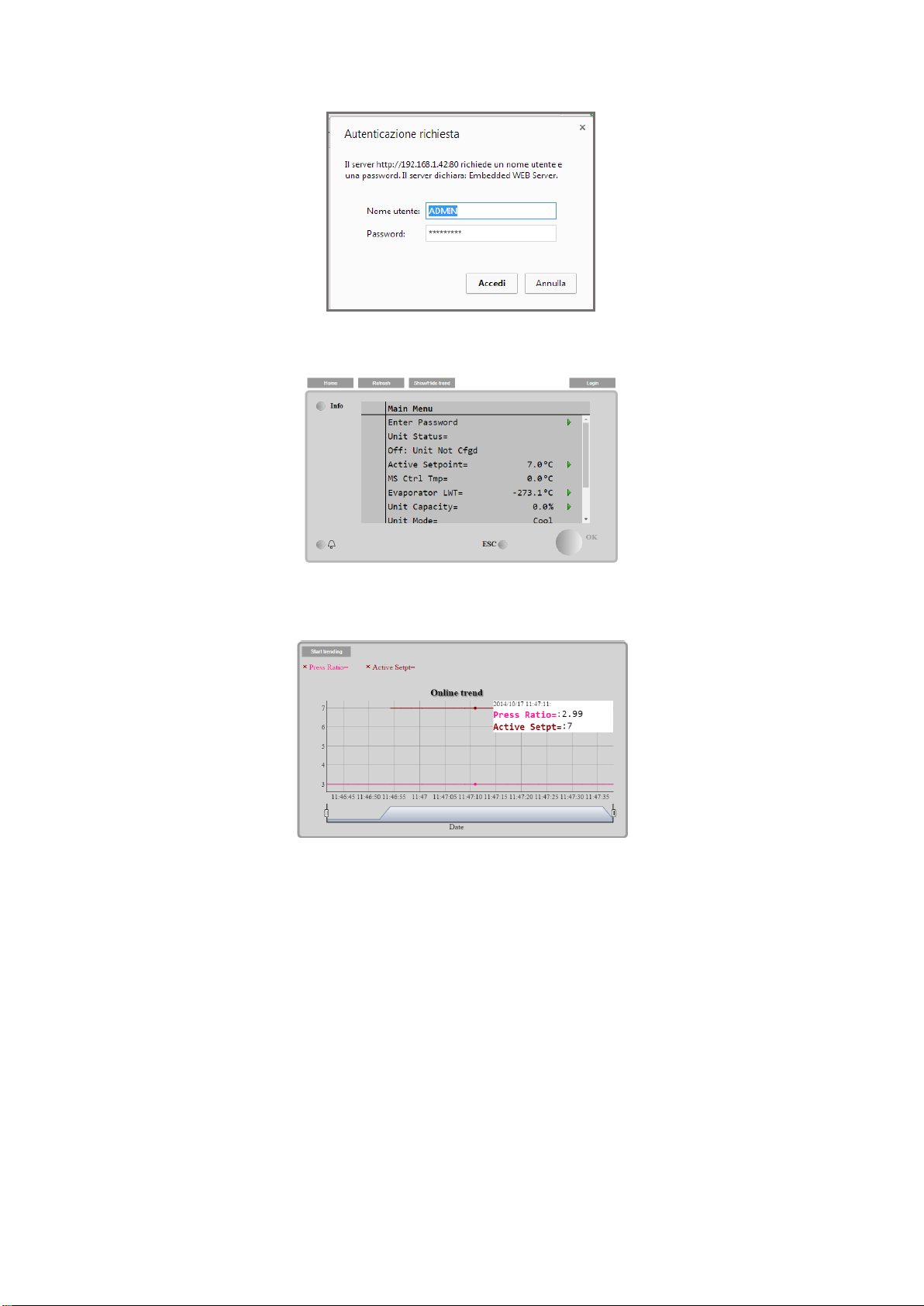

5.1.7 (Example) STEP 7, MTII

Modbus cable connection

Connect the Modbus cable to the

EKAC200J card previously inserted in

the "serial card" slot of the MT2.

Remember to respect the wire

polarity noted down at the step STEP

3, Main Modbus cable connection

also considering the datasheet of the

EKAC200J of which it is reported, for

convenience an extract.

5

6

Page 33

ALC-DC8

Installation and Operation Manual D-EIOCP00206-20_00EN

33/76

5.1.8 (Example) STEP 8, Enter

into setting menu

In order to verify or change the setting

related to the Modbus connection,

press “Prog” button on the MTII panel.

7

Page 34

Installation and Operation Manual D-EIOCP00206-20_00EN

34/76

ALC-DC8

5.1.9 (Example) STEP 9, MTII

access password

Insert the correct Password by using

the arrows ↑ and ↓ then press ←

(Enter) to proceed.

5.1.10 (Example) STEP 10, MTII

access password

Enter in the Modbus configuration

submenu by using the arrows ↑ and

↓ then insert the following setting

values:

• Protocol : MODBUS

• Supervisor Com. Speed: 19200

• Identificat. No: 1

Then press ← (Enter) and Esc to

proceed

INFO: some other setting values could be requested in the case of other units, such as

• Number of bits : 8

• Parity: None

8

9

Page 35

ALC-DC8

Installation and Operation Manual D-EIOCP00206-20_00EN

35/76

5.1.11 STEP 10 – Power ON ALC DC8

After completing the wiring and configuration of the

MTII controller, set the ALC power switch to ON

(press it up).

Then proceed with the commission of the ALC

(MTIII) controller and with the first connection to

Daikin On Site as reported in the next two chapters.

9

10

Page 36

Installation and Operation Manual D-EIOCP00206-20_00EN

36/76

ALC-DC8

6 ALC-DC8 panel commissioning

Commissioning of standard version without BMS

ALC DC8 panel configuration, with respect to the specific chiller unit, can be done by means of the

controller HMI. Starting from the main page first of all go to the submenu path:

“Commission Unit” > “Configuration” > “Unit”

The below options can be set in the configuration menu.

• “Unit Type” refers to the unit model

and includes the MCQ screw units and

the USA centrifugal unit.

1) PFS

2) ALS

3) WHS

4) MCAIR

5) MTM

6) WSC

7) WDC

8) WPV

9) WCC

10) HSC

11) TSC

12) HDC

13) WMC

• “No. of Compr.” is the total number

of compressors in the unit, counting

them on all circuits (so it has different

meaning for between the two unit

families USA and MCQ).

Possible values 1→4

To select the correct number, please

also look up the ALC Compatibility

Table .

Page 37

ALC-DC8

Installation and Operation Manual D-EIOCP00206-20_00EN

37/76

• “Write Enable” allows the

modification/writing of the setpoint (sp)

values. Possible values are:

0) Write Sp Disabled

1) Write Sp from DoS

2) Write Sp from BMS

• “Setp Values” regards the current

setpoint values in case of:

o initialization

o reconnection of cable,

o restore after an error

of the Modbus connection between ALC

and chiller unit’s MTII.

There are 2 possible setting:

1) Copy values MT2 [extended name: Copy chiller values (MT2)] which is the default and

suggested condition

The MTII setpoints are “cloned” by ALC and maintained in case of first connection or reconnection of

the MODBUS communication. This ensures that no value of what is already present on the chiller unit

controlled by the MTII is changed or overwritten. Only a write request from DoS or BMS can change

the values on the chiller unit's MTII.

2) ALC default or MT3 [extended name: ALC default or last values (MT3)]

The setpoint values currently set on the ALC are written to the MTII chiller unit on first connection (or

in case of reconnection). If they have not been changed (via BMS or via Daikin On Site), the ALC default

setpoint values are written.

This option is more useful if you are installing a an old MTII-based chiller unit with setpoint not yet set

or if you want to force setpoint values directly from the ALC to the MTII chiller unit first connection

(or in case of reconnection).

INFO: the setting is “exclusive”. Therefore it will be possible to write these values only from

DoS or only from the BMS!

Page 38

Installation and Operation Manual D-EIOCP00206-20_00EN

38/76

ALC-DC8

WARNING: These settings are effective only if the previous setpoint, "Write Enable", has

been set on

• “0) Write Sp Disabled”

• “1) Write Sp from DoS”.

In the case "Write Enable", is on:

• “2) Write Sp from BMS”

BMS will overwrite instantly all dell'MT2 setpoint with its setpoint values just on the

first connection between the BMS and ALC. Therefore, pay attention to the setpoint

values preset on the BMS before connecting it to ALC.

• “MB Comm Time Int” indicates the

time interval between one Modbus

read/write cycle and the next.

The value of 5 seconds was considered

optimal following tests on some chiller

units (both MCQ Screw units and USA

Centrifugal units) and should not be

changed.

WARNING: Changing one or more of these options requires a controller restart: this reset

can be performed stetting the "Apply Changes" option to “ON” on the configuration

submenu. The controller will restart automatically.

Commissioning of Modbus RS485 BMS version.

In the case of is required a communication between MT2 and an external BMS by means of RS485

Modbus protocol, it is necessary to connect the related external BMS cable to "Modbus

Communication Module POL902" as indicated in paragraph STEP4 - BMS cable connection

To complete the commissioning, in addition to the parameters listed in previous section ALC

commissioning - basic version without BMS it is necessary to configure some additional parameters.

Starting from the main menu page (and entering the password) go to the submenu path:

“View/Set Unit” > “Modbus”

Page 39

ALC-DC8

Installation and Operation Manual D-EIOCP00206-20_00EN

39/76

INFO: the “Modbus” submenu only appears if a POL902 module has been previously

connected to the ALC controller.

With reference to the previous HMI screen, these are the main parameters that must be set to

establish a connection with the BMS via RS485 Modbus:

• Slave Address – The slave address expected by the BMS (Master) for ALC (Slave).

Normally, this value is 1 or in any case can be reused the value previously used by the MT2

chiller unit controller (previously connected directly to the BMS).

• Baud Rate - The Baud Rate (speed) expected by BMS for the communication. Normally,

this value is 9600 or in any case can be set the value previously used by the MT2 chiller

unit controller (previously connected directly to the BMS).

• Stop bits - The Stop bit expected by BMS for the communication. Normally, this value is

two (2) or in any case can be set the value previously used by the MT2 chiller unit

controller (previously connected directly to the BMS).

• Parity - The parity check expected by BMS for the communication. Normally, this value is