DAF LF45, LF55 Service manual

4 |

STRUCTURE |

ΛΦ45/55 series

TECHNICAL DATA

DIAGNOSTICS

BE ENGINE FUEL SYSTEM

BE ENGINE INLET/EXHAUST SYSTEM

ENGINE BRAKE, BE ENGINE

CE ENGINE FUEL SYSTEM

CE ENGINE INLET/EXHAUST SYSTEM

ENGINE BRAKE, CE ENGINE

© 200416 |

DW23259402 |

0

1

2

3

4

5

6

7

https://www.truck-manuals.net/

https://www.truck-manuals.net/

4 |

TECHNICAL DATA |

ΛΦ45/55 series |

Contents |

CONTENTS

Page Date 0

1. ENGINE, GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200416 1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200416 1.2 BE engine, general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 . . . . . 200416 1.3 CE engine, general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3 . . . . . 200416

2. BE ENGINE FUEL SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200416 2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200416 2.2 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3 . . . . . 200416

3. CE ENGINE FUEL SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200416 3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200416 3.2 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3 . . . . . 200416

4. BE ENGINE INLET/EXHAUST SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 200416 4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 200416 4.2 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2 . . . . . 200416

5. CE ENGINE INLET/EXHAUST SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 . . . . . 200416 5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 . . . . . 200416 5.2 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2 . . . . . 200416

© 200416 |

1 |

https://www.truck-manuals.net/

TECHNICAL DATA |

4 |

|

Contents |

ΛΦ45/55 series |

|

0

2 |

© 200416 |

https://www.truck-manuals.net/

4 |

TECHNICAL DATA |

||

ΛΦ45/55 series |

Engine, general |

|

|

1. ENGINE, GENERAL |

|

|

|

|

|

0 |

|

1.1 GENERAL |

|

||

BE/CE engine |

|

|

|

Cold engine |

A cold engine is an engine which, having reached |

||

|

operating temperature, has been allowed to cool |

||

|

down for at least six hours. |

||

Warm engine |

A warm engine is an engine which, having reached |

||

|

operating temperature, has not been at a standstill |

||

|

for more than thirty minutes. |

||

Direction of rotation of the engine

First cylinder of the engine

Left-hand and right-hand side of the engine

Engine identification Engine number

The engine number is located in two places on the engine:

The direction of rotation of the engine is clockwise, as seen from the vibration damper end.

The first cylinder of the engine is the cylinder at the vibration damper end of the engine.

The left-hand side of the engine is the side where the air compressor and electronic unit are mounted. The right-hand side of the engine is the side where the turbocharger and oil filter are mounted.

-stamped into the engine block, top of the oil cooler

-on the type plate, fitted on the timing gear case or on the flywheel housing (depending on the production date)

Engine type

The type number CE162C indicates: |

|

|

C engine family |

B = |

3.92 ltr. |

|

C = |

5.88 ltr. |

E engine version |

E = |

electronic timing |

162 engine output in kilowatt (kW) |

|

|

C Euro emissions |

C = |

Euro 3 |

© 200416 |

1-1 |

https://www.truck-manuals.net/

|

|

TECHNICAL DATA |

|

|

4 |

|

|

|

Engine, general |

|

|

ΛΦ45/55 series |

|

|

|

1.2 BE ENGINE, GENERAL |

|

|

|

|

0 |

|

|

|

|

||

|

Engine types |

|

|

|

||

|

|

|

|

|

||

|

|

Coding |

BE 99 C |

|

||

|

|

|

|

BE 110 C |

|

|

|

|

|

|

BE 123 C |

|

|

|

|

General specifications |

|

|

|

|

|

|

Environmental standard |

Euro 3 (C) |

|

||

|

|

Number of cylinders |

4 cylinders in line |

|

||

|

|

Valves |

4 valves per cylinder |

|||

|

|

Bore x stroke |

102 x 120 mm |

|

||

|

|

Cubic capacity |

3.9 litres |

|

||

|

|

Compression ratio |

|

|

|

|

|

|

BE 99 C |

17.0 : 1 |

|

|

|

|

|

BE 110 C |

17.0 : 1 |

|

|

|

|

|

BE 123 C |

17.3 : 1 |

|

|

|

|

|

Fuel injection |

direct injection |

|

||

|

|

Injection sequence |

1-3-4-2 |

|

|

|

|

|

Air inlet system |

Turbocharger intercooling |

|||

|

|

Engine management system |

ECS-DC3 |

|

||

|

|

Cooling |

fluid |

|

||

|

|

Weight |

approx. 400 kg |

|

||

|

|

Engine speeds, BE engine |

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine type |

|

Idling |

|

Maximum no-load rpm |

|

|

|

|

rpm |

|

|

|

|

BE 99 C |

|

600 - 800 |

|

Approx. 2500 |

|

|

|

|

|

|

|

|

|

BE 110 C |

|

600 - 800 |

|

Approx. 2500 |

|

|

|

|

|

|

|

|

|

BE 123 C |

|

600 - 800 |

|

Approx. 2500 |

|

|

|

|

|

|

|

1-2 |

© 200416 |

https://www.truck-manuals.net/

4 |

|

|

|

TECHNICAL DATA |

||

ΛΦ45/55 series |

|

|

Engine, general |

|

|

|

1.3 CE ENGINE, GENERAL |

|

|

|

|

|

|

|

|

|

|

0 |

||

Engine types |

|

|

|

|

||

|

|

|

|

|

||

Coding |

CE 136 C |

|

|

|

||

|

|

CE 162 C |

|

|

|

|

|

|

CE 184 C |

|

|

|

|

General specifications |

|

|

|

|

|

|

Environmental standard |

Euro 3 (C) |

|

|

|

||

Number of cylinders |

6 cylinders in line |

|

|

|

||

Valves |

4 valves per cylinder |

|||||

Bore x stroke |

102 x 120 mm |

|

|

|

||

Cubic capacity |

5.9 litres |

|

|

|

||

Compression ratio |

17,3 : 1 |

|

|

|

|

|

Fuel injection |

direct injection |

|

|

|

||

Injection sequence |

1-5-3-6-2-4 |

|

|

|

|

|

Air inlet system |

Turbocharger intercooling |

|||||

Engine management system |

ECS-DC3 |

|

|

|

||

Cooling |

fluid |

|

|

|

||

Weight |

approx. 500 kg |

|

|

|

||

Engine speeds, CE engine |

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine type |

|

Idling |

|

Maximum no-load rpm |

|

|

|

|

rpm |

|

|

|

|

CE 136 C |

|

600 - 800 |

|

approx. 2500 |

|

|

|

|

|

|

|

|

|

CE 162 C |

|

600 - 800 |

|

approx. 2500 |

|

|

|

|

|

|

|

|

|

CE 184 C |

|

600 - 800 |

|

approx. 2500 |

|

|

|

|

|

|

|

|

|

© 200416 |

1-3 |

https://www.truck-manuals.net/

TECHNICAL DATA |

4 |

|

Engine, general |

ΛΦ45/55 series |

|

0

1-4 |

© 200416 |

https://www.truck-manuals.net/

4 |

|

TECHNICAL DATA |

||||||

ΛΦ45/55 series |

|

BE Engine fuel system |

|

|

||||

2. BE ENGINE FUEL SYSTEM |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

||

2.1 GENERAL |

|

|

|

|

|

|

||

Fuel level element |

|

70 |

||||||

Angular displacement |

|

|||||||

Fuel fine filter |

|

|

|

|

|

|

|

|

Maximum pressure drop across fuel fine filter |

2.0 bar |

|||||||

Lift pump |

|

|

|

|

|

|

|

|

Fuel lift pump pressure in front of fine filter (with |

|

|

|

|

|

|

|

|

engine at idling speed) |

|

5 - 13 bar |

||||||

Fuel lift pump pressure behind fine filter (with en- |

|

|

|

|

|

|

|

|

gine at idling speed) |

|

3 - 11 bar |

||||||

Pressure relief valve opening pressure |

11 bar |

|||||||

Maximum underpressure on suction side of fuel |

|

|

|

|

|

|

|

|

lift pump |

|

0.5 bar |

||||||

High-pressure pump |

|

|

|

|

|

|

|

|

Pump pressure (dependent on the operating |

|

|

|

|

|

|

|

|

mode of the engine and the electronic calibration) |

300 - 1400 bar |

|||||||

Fuel rail |

|

|

|

|

|

|

|

|

Fuel rail pressure (dependent on the operating |

|

|

|

|

|

|

|

|

mode of the engine and the electronic calibration) |

300 - 1400 bar |

|||||||

Fuel rail pressure-limiting valve |

|

|

|

|

|

|

|

|

Opening pressure |

|

1650 bar |

||||||

Injector |

|

|

|

|

|

|

|

|

Number of holes in injector |

8 |

|

|

|

|

|

|

|

Resistance of magnet coil |

0,15 - 0,5 |

|||||||

Injector washer |

|

|

|

|

|

|

|

|

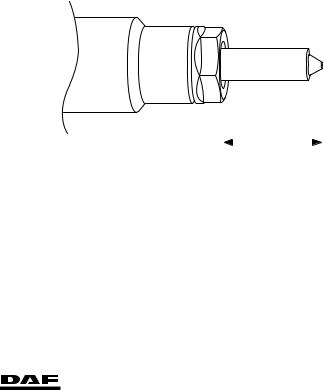

Nozzle length (dis- |

Washer thickness |

|

|

|

|

|

|

|

tance A) |

|

|

|

|

|

|

|

|

21.5 ≥ 0.2 mm |

1.5 mm |

|

|

|

|

|

|

|

23.0 ≥ 0.2 mm |

3.0 mm |

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

i400693 |

||||

© 200416 |

2-1 |

https://www.truck-manuals.net/

|

|

TECHNICAL DATA |

4 |

|

|

|

BE Engine fuel system |

ΛΦ45/55 series |

|

|

|

Fuel return overflow valve |

|

|

0 |

|

|

|

|

|

Fuel return overflow valve opening pressure |

1.2 - 2.0 bar |

||

|

|

|||

|

|

Fuel return pipe |

|

|

|

|

|

|

|

|

|

Maximum return pipe pressure build-up |

0.2 bar |

|

|

|

Return fuel measurement |

|

|

|

|

Maximum quantity of return fuel at idling speed |

120 ml/min. |

|

|

|

Minimum permitted time for filling a measuring |

|

|

|

|

beaker to a volume of 360 ml |

3 min. |

|

2-2 |

© 200416 |

https://www.truck-manuals.net/

4 |

TECHNICAL DATA |

||

ΛΦ45/55 series |

BE Engine fuel system |

|

|

2.2 TIGHTENING TORQUES |

|

|

|

|

|

0 |

|

The tightening torques specified in this section |

|

||

|

|

|

|

are different from the standard tightening torques |

|

|

|

cited in the overview of the standard tightening |

|

|

|

torques. The other threaded connections not |

|

|

|

specified must therefore be tightened to the |

|

|

|

torque cited in the overview of standard |

|

|

|

tightening torques. |

|

|

|

When attachment bolts and nuts are replaced, it |

|

|

|

is important that - unless stated otherwise - these |

|

|

|

bolts and nuts are of exactly the same length and |

|

|

|

property class as those removed. |

|

|

|

Electronic unit cooling plate |

|

|

|

Attachment bolts holding the electronic unit to the |

|

|

|

cooling plate |

10 Nm |

||

Attachment bolts holding the cooling plate to the |

|

|

|

engine block |

24 Nm |

||

VOSS quick-release coupling fittings |

18 Nm |

||

Low-pressure fuel pipes |

|

|

|

Banjo bolts |

24 Nm |

||

VOSS quick-release coupling fittings |

24 Nm |

||

Fuel return overflow valve in cylinder head |

24 Nm |

||

High-pressure pump |

|

|

|

Attachment nuts holding the high-pressure pump |

|

|

|

to the timing gear case |

25 Nm |

||

High-pressure fuel pipe |

|

|

|

High-pressure pipe union nut |

22 Nm |

||

Fuel rail |

|

|

|

Attachment bolts |

24 Nm |

||

Pressure-limiting valve |

100 Nm |

||

Injector pipes |

|

|

|

Injector pipe union nuts |

22 Nm |

||

Fuel supply pipe |

|

|

|

Fuel supply pipe nut |

50 Nm |

||

Injectors |

|

|

|

Injector clamping bracket attachment bolts |

10 Nm |

||

Injector electrical connection |

1.5 Nm |

||

© 200416 |

2-3 |

https://www.truck-manuals.net/

TECHNICAL DATA |

4 |

|

BE Engine fuel system |

ΛΦ45/55 series |

|

0

2-4 |

© 200416 |

https://www.truck-manuals.net/

4 |

|

TECHNICAL DATA |

||||||

ΛΦ45/55 series |

|

CE Engine fuel system |

|

|

||||

3. CE ENGINE FUEL SYSTEM |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

||

3.1 GENERAL |

|

|

|

|

|

|

||

Fuel level element |

|

70 |

||||||

Angular displacement |

|

|||||||

Fuel fine filter |

|

|

|

|

|

|

|

|

Maximum pressure drop across fuel fine filter |

2.0 bar |

|||||||

Lift pump |

|

|

|

|

|

|

|

|

Fuel lift pump pressure in front of fine filter (with |

|

|

|

|

|

|

|

|

engine at idling speed) |

|

5 - 13 bar |

||||||

Fuel lift pump pressure behind fine filter (with en- |

|

|

|

|

|

|

|

|

gine at idling speed) |

|

3 - 11 bar |

||||||

Pressure relief valve opening pressure |

11 bar |

|||||||

Maximum underpressure on suction side of fuel |

|

|

|

|

|

|

|

|

lift pump |

|

0.5 bar |

||||||

High-pressure pump |

|

|

|

|

|

|

|

|

Pump pressure (dependent on the operating |

|

|

|

|

|

|

|

|

mode of the engine and the electronic calibration) |

300 - 1400 bar |

|||||||

Fuel rail |

|

|

|

|

|

|

|

|

Fuel rail pressure (dependent on the operating |

|

|

|

|

|

|

|

|

mode of the engine and the electronic calibration) |

300 - 1400 bar |

|||||||

Fuel rail pressure-limiting valve |

|

|

|

|

|

|

|

|

Opening pressure |

|

1650 bar |

||||||

Injector |

|

|

|

|

|

|

|

|

Number of holes in injector |

8 |

|

|

|

|

|

|

|

Resistance of magnet coil |

0,15 - 0,5 |

|||||||

Injector washer |

|

|

|

|

|

|

|

|

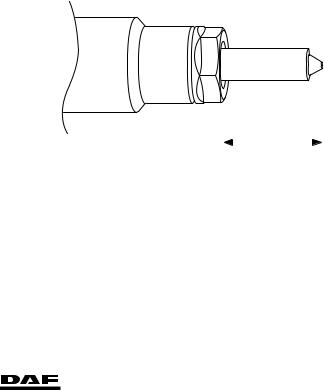

Nozzle length |

Washer thickness |

|

|

|

|

|

|

|

(distance A) |

|

|

|

|

|

|

|

|

21.5 ≥ 0.2 mm |

1.5 mm |

|

|

|

|

|

|

|

23.0 ≥ 0.2 mm |

3.0 mm |

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

i400693 |

||||

© 200416 |

3-1 |

https://www.truck-manuals.net/

|

|

TECHNICAL DATA |

4 |

|

|

|

CE Engine fuel system |

ΛΦ45/55 series |

|

|

|

Fuel return overflow valve |

|

|

0 |

|

|

|

|

|

Fuel return overflow valve opening pressure |

1.2 - 2.0 bar |

||

|

|

|||

|

|

Fuel return pipe |

|

|

|

|

|

|

|

|

|

Maximum return pipe pressure build-up |

0.2 bar |

|

|

|

Return fuel measurement |

|

|

|

|

Maximum quantity of return fuel at idling speed |

180 ml/min. |

|

|

|

Time for filling a measuring beaker to a volume of |

|

|

|

|

360 ml |

> 2 min. |

|

3-2 |

© 200416 |

https://www.truck-manuals.net/

4 |

TECHNICAL DATA |

||

ΛΦ45/55 series |

CE Engine fuel system |

|

|

3.2 TIGHTENING TORQUES |

|

|

|

|

|

0 |

|

The tightening torques specified in this section |

|

||

|

|

|

|

are different from the standard tightening torques |

|

|

|

cited in the overview of the standard tightening |

|

|

|

torques. The other threaded connections not |

|

|

|

specified must therefore be tightened to the |

|

|

|

torque cited in the overview of standard |

|

|

|

tightening torques. |

|

|

|

When attachment bolts and nuts are replaced, it |

|

|

|

is important that - unless stated otherwise - these |

|

|

|

bolts and nuts are of exactly the same length and |

|

|

|

property class as those removed. |

|

|

|

Electronic unit cooling plate |

|

|

|

Attachment bolts holding the electronic unit to the |

|

|

|

cooling plate |

10 Nm |

||

Attachment bolts holding the cooling plate to the |

|

|

|

engine block |

24 Nm |

||

VOSS quick-release coupling fittings |

18 Nm |

||

Low-pressure fuel pipes |

|

|

|

Banjo bolts |

24 Nm |

||

VOSS quick-release coupling fittings |

24 Nm |

||

Fuel return overflow valve in cylinder head |

24 Nm |

||

High-pressure pump |

|

|

|

Attachment nuts holding the high-pressure pump |

|

|

|

to the timing gear case |

25 Nm |

||

High-pressure fuel pipe |

|

|

|

High-pressure pipe union nut |

22 Nm |

||

Fuel rail |

|

|

|

Attachment bolts |

24 Nm |

||

Pressure-limiting valve |

100 Nm |

||

Injector pipes |

|

|

|

Injector pipe union nuts |

22 Nm |

||

Fuel supply pipe |

|

|

|

Fuel supply pipe nut |

50 Nm |

||

Injectors |

|

|

|

Injector clamping bracket attachment bolts |

10 Nm |

||

Injector electrical connection |

1.5 Nm |

||

© 200416 |

3-3 |

https://www.truck-manuals.net/

TECHNICAL DATA |

4 |

|

CE Engine fuel system |

ΛΦ45/55 series |

|

0

3-4 |

© 200416 |

https://www.truck-manuals.net/

4 |

TECHNICAL DATA |

ΛΦ45/55 series |

BE Engine inlet/exhaust system |

4. BE ENGINE INLET/EXHAUST SYSTEM

4.1 GENERAL

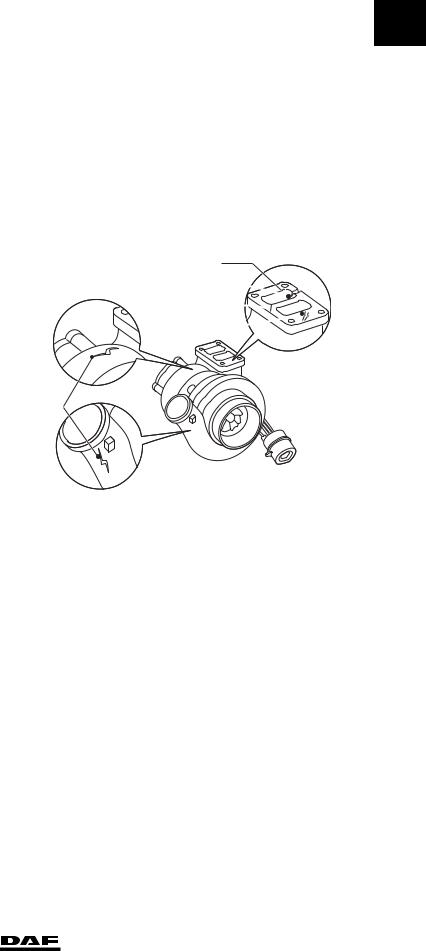

Turbocharger |

|

BE 99 C |

Holset HX 27 W |

BE 110 C |

Holset HX 27 W |

BE 123 C |

Holset HX 27 W |

Minimum actuating pressure of wastegate cap- |

|

sule under which the control rod will move |

2.0 bar |

Axial bearing play of compressor shaft |

0.057 - 0.103 mm |

Radial bearing play of compressor shaft |

0.39 - 0.67 mm |

Rejection standards for cracking

1.Cracks in the connector flange must not reach as far as the attachment holes.

2.Cracks in the connector flange must not

reach from the channels as far as the exterior.

3.Cracks in the connector flange may not be

longer than 15 mm.

4.Cracks in the connector flange must not be less than 6 mm apart.

5. There must be no cracks in the housing. |

5 |

|

Exhaust gas back pressure |

|

At full-load engine speed |

100 mbar |

Maximum back pressure during engine brake ap- |

|

plication |

4.3 bar |

Inlet underpressure |

|

At full-load engine speed (clean air filter) |

25 mbar |

At full-load engine speed (clogged air filter) |

62 mbar |

Glow element |

180 - 220 m |

Resistance value |

0

1

2

3

4

i400784

© 200416 |

4-1 |

https://www.truck-manuals.net/

|

|

TECHNICAL DATA |

4 |

|

|

|

BE Engine inlet/exhaust system |

ΛΦ45/55 series |

|

|

|

4.2 TIGHTENING TORQUES |

|

|

0 |

|

|

|

|

|

The tightening torques specified in this section |

|

|

|

|

|

|

|

|

|

|

are different from the standard tightening torques |

|

|

|

|

cited in the overview of the standard tightening |

|

|

|

|

torques. The other threaded connections not |

|

|

|

|

specified must therefore be tightened to the |

|

|

|

|

torque cited in the overview of standard |

|

|

|

|

tightening torques. |

|

|

|

|

When attachment bolts and nuts are replaced, it |

|

|

|

|

is important that - unless stated otherwise - these |

|

|

|

|

bolts and nuts are of exactly the same length and |

|

|

|

|

property class as those removed. |

|

|

|

|

Turbocharger |

|

|

|

|

Attachment nuts, exhaust manifold flange/turbo- |

43 Nm (1) |

|

|

|

charger |

||

|

|

Oil discharge pipe attachment bolts |

23 Nm |

|

|

|

Oil supply pipe union |

28 Nm |

|

|

|

Turbocharger V-clamp |

10 Nm |

|

|

|

(1) Fasten with Copaslip |

|

|

|

|

Intake manifold |

|

|

|

|

Glow element attachment bolts |

14 Nm |

|

|

|

Air cooler |

|

|

|

|

Hose clamps |

7 Nm |

|

4-2 |

© 200416 |

https://www.truck-manuals.net/

4 |

TECHNICAL DATA |

|

ΛΦ45/55 series |

CE Engine inlet/exhaust system |

|

5. CE ENGINE INLET/EXHAUST SYSTEM

5.1 GENERAL

Turbocharger |

|

CE 136 C |

Holset HY 35 W |

CE 162 C |

Holset HY 35 W |

CE 184 C |

Holset HX 35 W |

Minimum actuating pressure of wastegate cap- |

|

sule under which the control rod will move |

2.0 bar |

Axial bearing play of compressor shaft |

0.038 - 0.093 mm |

Radial bearing play of compressor shaft |

0.329 - 0.501 mm |

Rejection standards for cracking

1.Cracks in the connector flange must not reach as far as the attachment holes.

2.Cracks in the connector flange must not

reach from the channels as far as the exterior.

3.Cracks in the connector flange may not be

longer than 15 mm.

4.Cracks in the connector flange must not be

less than 6 mm apart. |

|

5. There must be no cracks in the housing. |

5 |

|

Exhaust gas back pressure |

|

At full-load engine speed |

100 mbar |

Maximum back pressure during engine brake ap- |

|

plication |

4.3 bar |

Inlet underpressure |

|

At full-load engine speed (clean air filter) |

25 mbar |

At full-load engine speed (clogged air filter) |

62 mbar |

Glow element |

180 - 220 m |

Resistance value |

0

1

2

3

4

i400784

© 200416 |

5-1 |

https://www.truck-manuals.net/

|

|

TECHNICAL DATA |

4 |

|

|

|

CE Engine inlet/exhaust system |

ΛΦ45/55 series |

|

|

|

5.2 TIGHTENING TORQUES |

|

|

0 |

|

|

|

|

|

The tightening torques specified in this section |

|

|

|

|

|

|

|

|

|

|

are different from the standard tightening torques |

|

|

|

|

cited in the overview of the standard tightening |

|

|

|

|

torques. The other threaded connections not |

|

|

|

|

specified must therefore be tightened to the |

|

|

|

|

torque cited in the overview of standard |

|

|

|

|

tightening torques. |

|

|

|

|

When attachment bolts and nuts are replaced, it |

|

|

|

|

is important that - unless stated otherwise - these |

|

|

|

|

bolts and nuts are of exactly the same length and |

|

|

|

|

property class as those removed. |

|

|

|

|

Turbocharger |

|

|

|

|

Attachment nuts, exhaust manifold flange/turbo- |

43 Nm (1) |

|

|

|

charger |

||

|

|

Oil discharge pipe attachment bolts |

23 Nm |

|

|

|

Oil supply pipe union |

28 Nm |

|

|

|

Turbocharger V-clamp |

10 Nm |

|

|

|

(1) Fasten with Copaslip |

|

|

|

|

Glow element |

|

|

|

|

Attachment bolts |

14 Nm |

|

|

|

Air cooler |

|

|

|

|

Hose clamps |

7 Nm |

|

5-2 |

© 200416 |

https://www.truck-manuals.net/

4 |

|

|

DIAGNOSTICS |

|

|||

ΛΦ45/55 series |

|

Contents |

|

|

|||

CONTENTS |

|

|

|

|

|||

|

|

|

Page |

Date |

|

||

1. |

TRACTIVE PROBLEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 1-1 . . . |

. . 200416 |

|

|||

1 |

|||||||

|

1.1 |

Tractive problems |

1-1 |

200416 |

|||

|

|

||||||

2. |

FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 2-1 . . . . |

. 200416 |

|

|||

|

|||||||

|

2.1 |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 2-1 . . . . |

. 200416 |

|

||

|

2.2 |

Fault-finding table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 2-2 . . . . |

. 200416 |

|

||

3. |

INLET/EXHAUST SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 3-1 . . . . |

. 200416 |

|

|||

|

3.1 |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 3-1 . . . . |

. 200416 |

|

||

|

3.2 |

Fault-finding table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 3-2 . . . . |

. 200416 |

|

||

4. |

ENGINE BRAKE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 4-1 . . . . |

. 200416 |

|

|||

|

4.1 |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 4-1 . . . . |

. 200416 |

|

||

|

4.2 |

Fault-finding table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 4-2 . . . . |

. 200416 |

|

||

© 200416 |

1 |

https://www.truck-manuals.net/

DIAGNOSTICS |

4 |

|

Contents |

ΛΦ45/55 series |

|

1

2 |

© 200416 |

https://www.truck-manuals.net/

4 |

DIAGNOSTICS |

||

ΛΦ45/55 series |

Tractive problems |

|

|

1. TRACTIVE PROBLEMS |

|

|

|

1.1 TRACTIVE PROBLEMS |

|

|

|

|

|

|

|

The first test that has to be carried out when |

|

|

1 |

investigating tractive problems is the acceleration |

|

||

test. |

|

|

|

|

|

|

|

© 200416 |

1-1 |

https://www.truck-manuals.net/

DIAGNOSTICS |

4 |

|

Tractive problems |

ΛΦ45/55 series |

|

1

1-2 |

© 200416 |

https://www.truck-manuals.net/

4 |

DIAGNOSTICS |

||

ΛΦ45/55 series |

Fuel system |

|

|

2. FUEL SYSTEM |

|

|

|

2.1 INTRODUCTION |

|

|

|

|

|

|

|

If there is a fault in the system, it is usually |

|

|

1 |

detected by the electronic unit in the form of a |

|

||

fault code. This fault code can be read out using |

|

|

|

|

|

|

|

DAVIE. The fault-finding table contains possible |

|

|

|

causes of symptoms not detected by the |

|

|

|

electronic unit. |

|

|

|

© 200416 |

2-1 |

https://www.truck-manuals.net/

|

|

DIAGNOSTICS |

|

4 |

|

|

Fuel system |

|

ΛΦ45/55 series |

|

|

2.2 FAULT-FINDING TABLE |

|

|

|

|

|

|

|

|

|

SYMPTOM: ENGINE CAN BE STARTED, BUT DOES NOT RUN |

||

1 |

|

|||

|

|

|

|

|

|

Possible cause |

|

Remedy |

|

|

|

|

||

|

|

|

|

|

|

|

Poor fuel quality |

Drain fuel, flush fuel system, replace the fuel filters |

|

|

|

|||

|

|

|

and fill fuel tank with fuel |

|

|

|

|

|

|

|

|

Air in fuel system |

Check for drawing in of air: |

|

|

|

|

- via the suction pipe |

|

|

|

Fuel fine filter/coarse filter clogged |

Replace fuel fine filter and clean the system |

|

|

|

|

|

|

|

|

No fuel supply/high-pressure pump or fuel lift pump |

Check: |

|

|

|

defective; no delivery |

- |

the fuel level |

|

|

|

- |

the rail pressure |

|

|

|

- the pipes for blockage and leaks |

|

|

|

|

- the fuel lift pump |

|

|

|

|

- the high-pressure pump |

|

|

|

|

||

|

|

SYMPTOM: ENGINE STALLS AND RUNS AGAIN AFTER RE-STARTING |

||

|

|

|

|

|

|

|

Possible cause |

|

Remedy |

|

|

Air in fuel system |

Check for drawing in of air: |

|

|

|

|

- via the suction pipe |

|

|

|

|

||

|

|

SYMPTOM: ENGINE STARTS POORLY |

||

|

|

|

|

|

|

|

Possible cause |

|

Remedy |

|

|

|

|

|

|

|

Poor fuel quality |

Drain fuel, flush fuel system, replace the fuel filters |

|

|

|

|

and fill fuel tank with fuel |

|

|

|

Air in fuel system |

Check for drawing in of air: |

|

|

|

|

- via the suction pipe |

|

|

|

Fuel fine filter/coarse filter clogged |

Replace fuel fine filter and clean the system |

|

|

|

|

|

|

|

|

Injector(s) mechanically defective or clogged |

Replace the injectors |

|

|

|

|

|

|

|

|

High-pressure pump or fuel lift pump delivery too |

Check: |

|

|

|

low |

- |

the high-pressure pump |

|

|

|

- the fuel lift pump |

|

|

|

Internal fuel leak between fuel supply pipe(s) and |

Check the quantity of return fuel |

|

|

|

injector(s) |

|

|

|

|

|

||

|

|

SYMPTOM: ENGINE RUNS AT (INCREASED) IDLING SPEED AND DOES NOT RESPOND TO AC- |

||

|

|

CELERATOR PEDAL |

||

|

|

Possible cause |

|

Remedy |

|

|

|

|

|

|

|

Mechanical defect of accelerator pedal sensor |

Check: |

|

|

|

|

- mechanical connection of sensor/accelerator |

|

|

|

|

|

pedal |

|

|

|

- |

accelerator pedal sensor |

2-2 |

© 200416 |

https://www.truck-manuals.net/

4 |

DIAGNOSTICS |

|

||

ΛΦ45/55 series |

Fuel system |

|

|

|

|

|

|

|

|

SYMPTOM: DIESEL KNOCK DURING ACCELERATION |

|

|

||

|

|

|

|

|

Possible cause |

Remedy |

|

|

|

|

|

|

|

|

Poor fuel quality |

Drain fuel, flush fuel system, replace the fuel filters |

|

|

|

1 |

||||

|

and fill fuel tank with fuel |

|

||

|

|

|

||

|

|

|

|

|

Air in fuel system |

Check for drawing in of air: |

|

|

|

|

||||

|

- via the suction pipe |

|

|

|

|

|

|

|

|

Injector defective |

Check the injectors |

|

|

|

|

|

|

|

|

|

|

|||

SYMPTOM: IRREGULAR RUNNING OF ENGINE |

|

|

||

|

|

|

|

|

Possible cause |

Remedy |

|

|

|

Poor fuel quality |

Drain fuel, flush fuel system, replace the fuel filters |

|

|

|

|

and fill fuel tank with fuel |

|

|

|

Air in fuel system |

Check for drawing in of air: |

|

|

|

|

- via the suction pipe |

|

|

|

Fuel fine filter/coarse filter clogged |

Replace fuel fine filter and clean the system |

|

|

|

|

|

|

|

|

Injector(s) mechanically defective or clogged |

Replace the injectors |

|

|

|

|

|

|

|

|

Injector defective |

Check the injectors |

|

|

|

|

|

|

|

|

High-pressure pump or fuel lift pump delivery too |

Check: |

|

|

|

low |

- the high-pressure pump |

|

|

|

|

- the fuel lift pump |

|

|

|

SYMPTOM: REDUCED POWER AT ALL ENGINE SPEEDS

Possible cause |

|

Remedy |

|

|

|

Poor fuel quality |

Drain fuel, flush fuel system, replace the fuel filters |

|

|

and fill fuel tank with fuel |

|

Fuel fine filter/coarse filter clogged |

Replace fuel fine filter and clean the system |

|

|

|

|

Injector(s) mechanically defective or clogged |

Replace the injectors |

|

|

|

|

Mechanical defect of accelerator pedal sensor |

Check: |

|

|

- |

mechanical connection of sensor/accelerator |

|

|

pedal |

|

- |

accelerator pedal sensor |

High-pressure pump or fuel lift pump delivery too |

Check: |

|

low |

- |

the high-pressure pump |

|

- |

the fuel lift pump |

SYMPTOM: REDUCED POWER ABOVE A CERTAIN ENGINE SPEED

Possible cause |

Remedy |

|

|

Fuel fine filter/coarse filter partially clogged |

Replace fuel fine filter and clean the system |

|

|

Injector(s) mechanically defective or clogged |

Replace the injectors |

|

|

Air leak in inlet system |

Pressure-test the inlet system |

|

|

© 200416 |

2-3 |

https://www.truck-manuals.net/

|

|

DIAGNOSTICS |

4 |

|

|

|

Fuel system |

ΛΦ45/55 series |

|

|

|

|

||

|

|

SYMPTOM: REDUCED POWER ABOVE A CERTAIN ENGINE SPEED |

||

|

|

|

|

|

|

|

Possible cause |

Remedy |

|

|

|

|

|

|

|

|

High-pressure pump or fuel lift pump delivery too |

Check: |

|

1 |

|

|||

|

low |

- the high-pressure pump |

||

|

|

- the fuel lift pump |

||

|

|

Fault in electrical components/wiring of: |

Check the electrical system |

|

-connectors

SYMPTOM: ENGINE SLUGGISH WHEN ACCELERATING OR UNDER HIGH LOAD

Possible cause |

|

Remedy |

|

|

|

Internal fuel leak between fuel supply pipe(s) and |

Check the quantity of return fuel |

|

injector(s) |

|

|

High-pressure pump or fuel lift pump delivery too |

Check: |

|

low |

- |

the high-pressure pump |

|

- the fuel lift pump |

|

|

||

SYMPTOM: WHITE/BLUE SMOKE IS EMITTED |

||

|

|

|

Possible cause |

|

Remedy |

|

|

|

Poor fuel quality |

Drain fuel, flush fuel system, replace the fuel filters |

|

|

and fill fuel tank with fuel |

|

Air in fuel system |

Check for drawing in of air: |

|

|

- via the suction pipe |

|

Fuel fine filter/coarse filter clogged |

Replace fuel fine filter and clean the system |

|

|

|

|

Injector(s) mechanically defective or clogged |

Replace the injectors |

|

|

|

|

High-pressure pump or fuel lift pump delivery too |

Check: |

|

low |

- |

the high-pressure pump |

|

- the fuel lift pump |

|

Fault in electrical components/wiring of: |

Check the electrical system |

|

- connectors |

|

|

SYMPTOM: BLACK SMOKE IS EMITTED

Possible cause |

Remedy |

Injector(s) mechanically defective or clogged |

Replace the injectors |

|

|

|

|

SYMPTOM: ENGINE OVERHEATED |

|

|

|

Possible cause |

Remedy |

|

|

Poor fuel quality |

Drain fuel, flush fuel system, replace the fuel filters |

|

and fill fuel tank with fuel |

2-4 |

© 200416 |

https://www.truck-manuals.net/

4 |

DIAGNOSTICS |

|

||

ΛΦ45/55 series |

Fuel system |

|

|

|

|

|

|

|

|

SYMPTOM: FUEL CONSUMPTION TOO HIGH |

|

|

||

|

|

|

|

|

Possible cause |

Remedy |

|

|

|

|

|

|

|

|

Poor fuel quality |

Drain fuel, flush fuel system, replace the fuel filters |

|

|

|

1 |

||||

|

and fill fuel tank with fuel |

|

||

|

|

|

||

|

|

|

|

|

Fuel fine filter/coarse filter clogged |

Replace fuel fine filter and clean the system |

|

|

|

|

||||

|

|

|

|

|

Injector(s) mechanically defective or clogged |

Replace the injectors |

|

|

|

|

|

|

|

|

Leak in fuel system |

Check for leaks |

|

|

|

|

|

|

|

|

|

|

|||

SYMPTOM: REDUCED MAXIMUM ENGINE SPEED |

|

|

||

|

|

|

|

|

Possible cause |

Remedy |

|

|

|

|

|

|

|

|

Air in fuel system |

Check for drawing in of air: |

|

|

|

|

- via the suction pipe |

|

|

|

Fuel fine filter/coarse filter clogged |

Replace the fuel filter and clean the system |

|

|

|

|

|

|

|

|

Injector(s) mechanically defective or clogged |

Replace the injectors |

|

|

|

|

|

|

|

|

High-pressure pump or fuel lift pump delivery too |

Check: |

|

|

|

low |

- the high-pressure pump |

|

|

|

|

- the fuel lift pump |

|

|

|

© 200416 |

2-5 |

https://www.truck-manuals.net/

DIAGNOSTICS |

4 |

|

Fuel system |

ΛΦ45/55 series |

|

1

2-6 |

© 200416 |

https://www.truck-manuals.net/

Loading...

Loading...