Page 1

1

LF45/55 series

CONTENTS

TECHNICAL DATA

0

DIAGNOSTICS

1

INTERNAL CAB COMPONENTS

2

CAB HEATING

3

EXTERNAL CAB COMPONENTS

4

CAB SUSPENSION

5

CAB TILTING GEAR

SEATS

ACCESSORIES

6

7

8

ǹ 0210

Page 2

blank

Page 3

1

TECHNICAL DATA

LF45/55 series Contents

CONTENTS

Page Date

1. INTERNAL AND EXTERNAL CAB COMPONENTS 1-1 0210........................ ......

1.1 General 1-1 0210......................................................... ......

1.2 Tightening torques 1-8 0210................................................ ......

2. CAB SUSPENSION 2-1 0210.................................................... ......

2.1 General 2-1 0210......................................................... ......

2.2 Tightening torques 2-3 0210................................................ ......

3. CAB TILTING GEAR 3-1 0210................................................... ......

3.1 General 3-1 0210......................................................... ......

3.2 Filling capacities 3-1 0210.................................................. ......

4. SEATS 4-1 0210................................................................ ......

4.1 General 4-1 0210......................................................... ......

4.2 Tightening torques 4-1 0210................................................ ......

5. ACCESSORIES 5-1 0210........................................................ ......

5.1 General 5-1 0210......................................................... ......

5.2 Tightening torques 5-2 0210................................................ ......

0

ǹ 0210

1

Page 4

0

1TECHNICAL DATA

Contents LF45/55 series

2

ǹ 0210

Page 5

1

TECHNICAL DATA

LF45/55 series Internal and external cab components

1. INTERNAL AND EXTERNAL CAB COMPONENTS

1.1 GENERAL

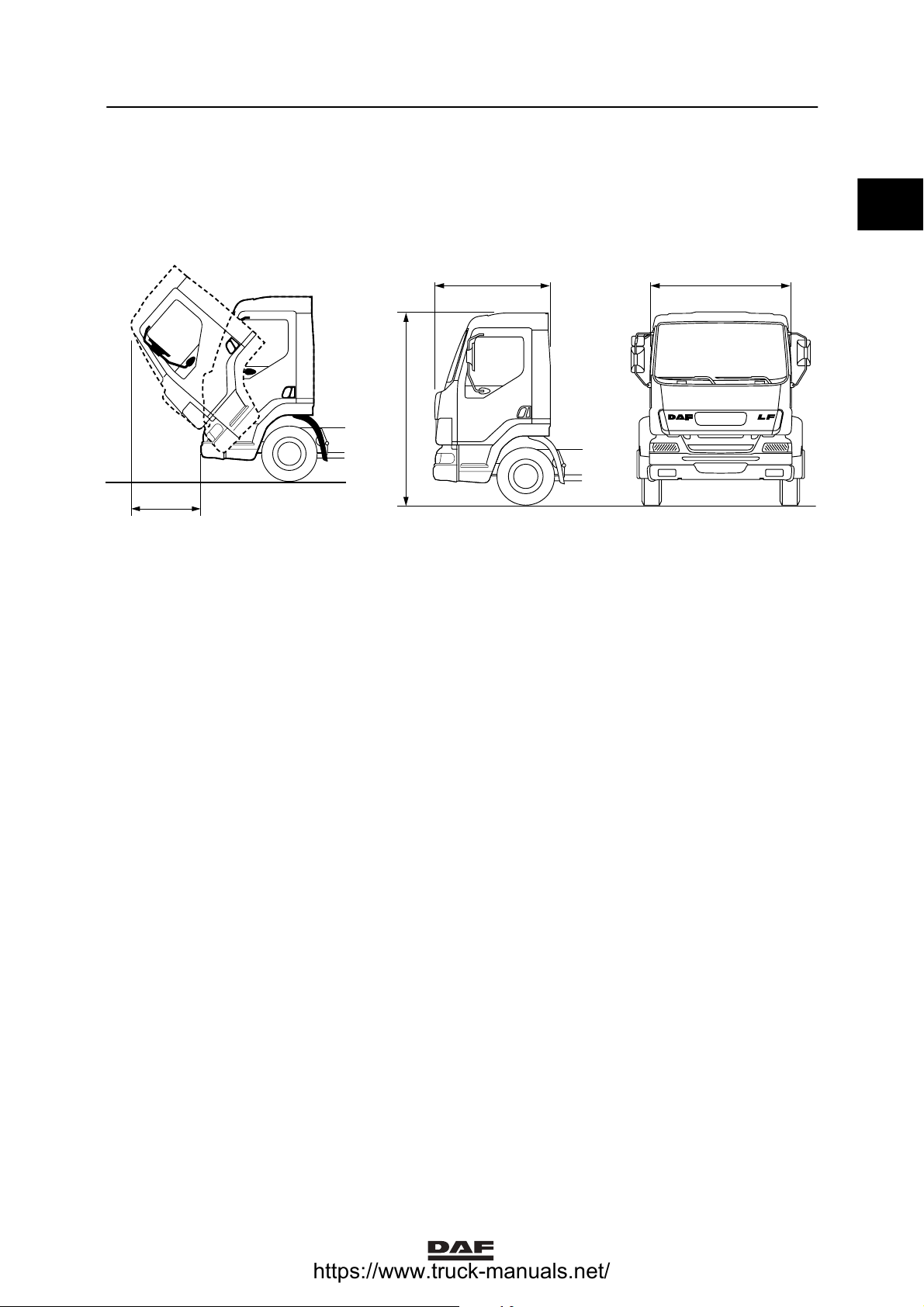

Main dimensions and weights

L

B

H

K

K1 01 170

Cab dimensions in mm: Day cab Sleeper Cab

length (L) 1600 mm 2000 mm

width (B) 2130 mm 2130 mm

max. height (H) 2900 mm

tilting (K) 1105 mm

(1)

(2)

2900 mm

1105 mm

(1)

(2)

0

K1 01 192

Cab weights:

Day cab 595 kg

Sleeper cab 750 kg

Notes:

(1)

Height (H) dependent on version and tyre

size

(2)

Dimension K measured from the front of

the bumper.

ǹ 0210

1-1

Page 6

0

1TECHNICAL DATA

Internal and external cab components LF45/55 series

Permissible cab weights: max.

Roof console evenly distributed 5 kg

Roof evenly distributed 150 kg

Weight on the bunk 125 kg

Cab side members

Welding on cab side members is NOT

permitted.

When repairing the cab side member, you must

use sheet-metal trimming panels.

These must be fitted by spot welding.

1-2

ǹ 0210

Page 7

1

LF45/55 series Internal and external cab components

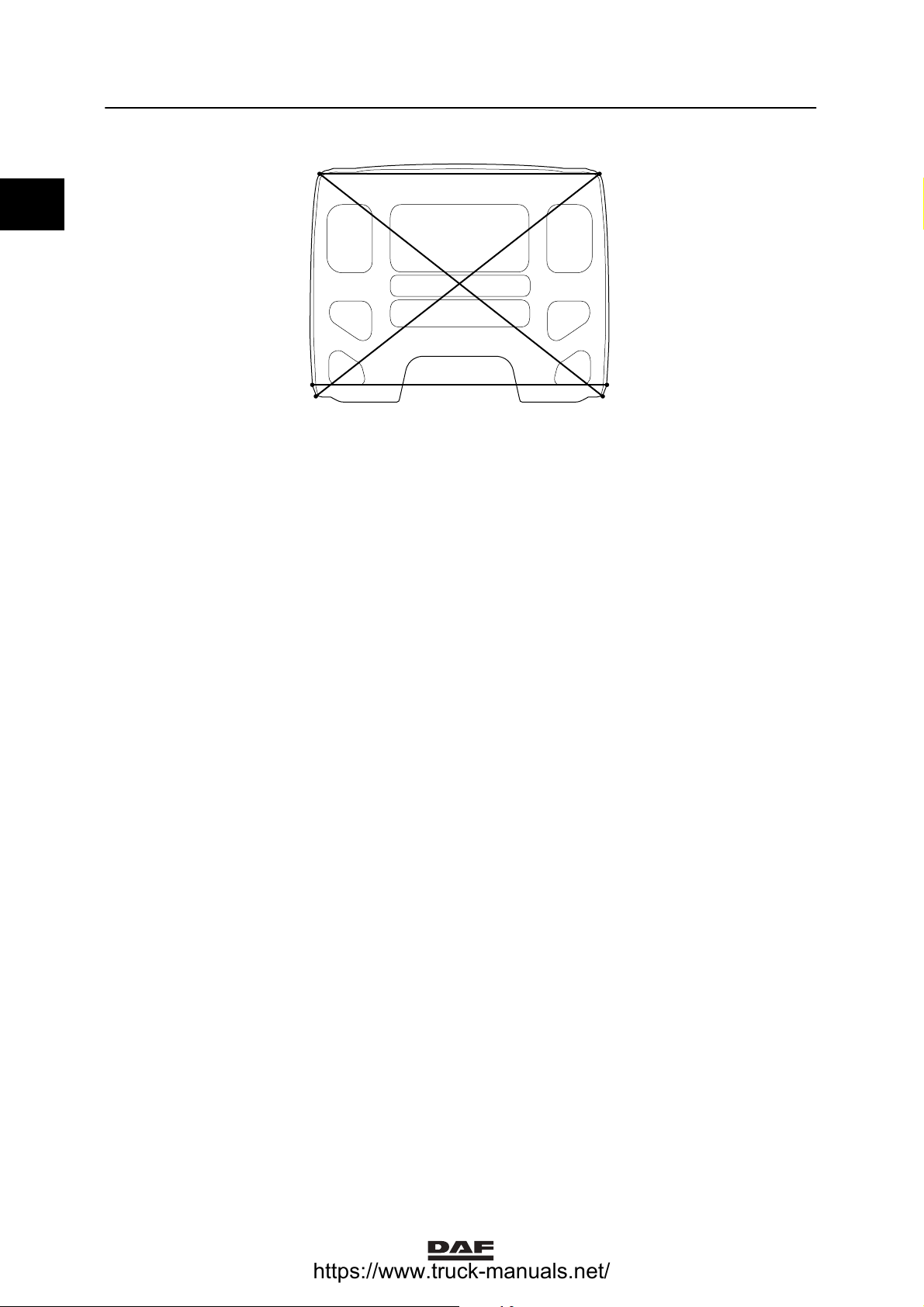

Straightening dimensions

TECHNICAL DATA

Door opening dimensions

A - D 1283 mm

C - F 887 mm

B - E 1591 mm

E

A

F

B

C

D

K1 01 209

0

ǹ 0210

1-3

Page 8

0

1TECHNICAL DATA

Internal and external cab components LF45/55 series

BC

Rear wall dimensions

A - D 2042 mm

B - C 1926 mm

B - E 2435 mm

C - F 2435 mm

A

D

F

E

K1 01 208

1-4

ǹ 0210

Page 9

1

TECHNICAL DATA

LF45/55 series Internal and external cab components

Cab front dimensions

A - B 836 mm

C - D 836 mm

E - F 836 mm

G - I 1973 mm

H - J 1973 mm

Front panel dimensions

N - L 1945 mm

K - M 1945 mm

H

G

BCE

ADF

N K

M

K1 01 210

I

0

J

L

ǹ 0210

1-5

Page 10

0

1TECHNICAL DATA

Internal and external cab components LF45/55 series

Field of vision dimensions

D

1

A

A

2

A

3

A

1

B

1

B

B

B

B

3

5

2

B

4

D

C

C

2

C

3

C

4

C

1

K100237

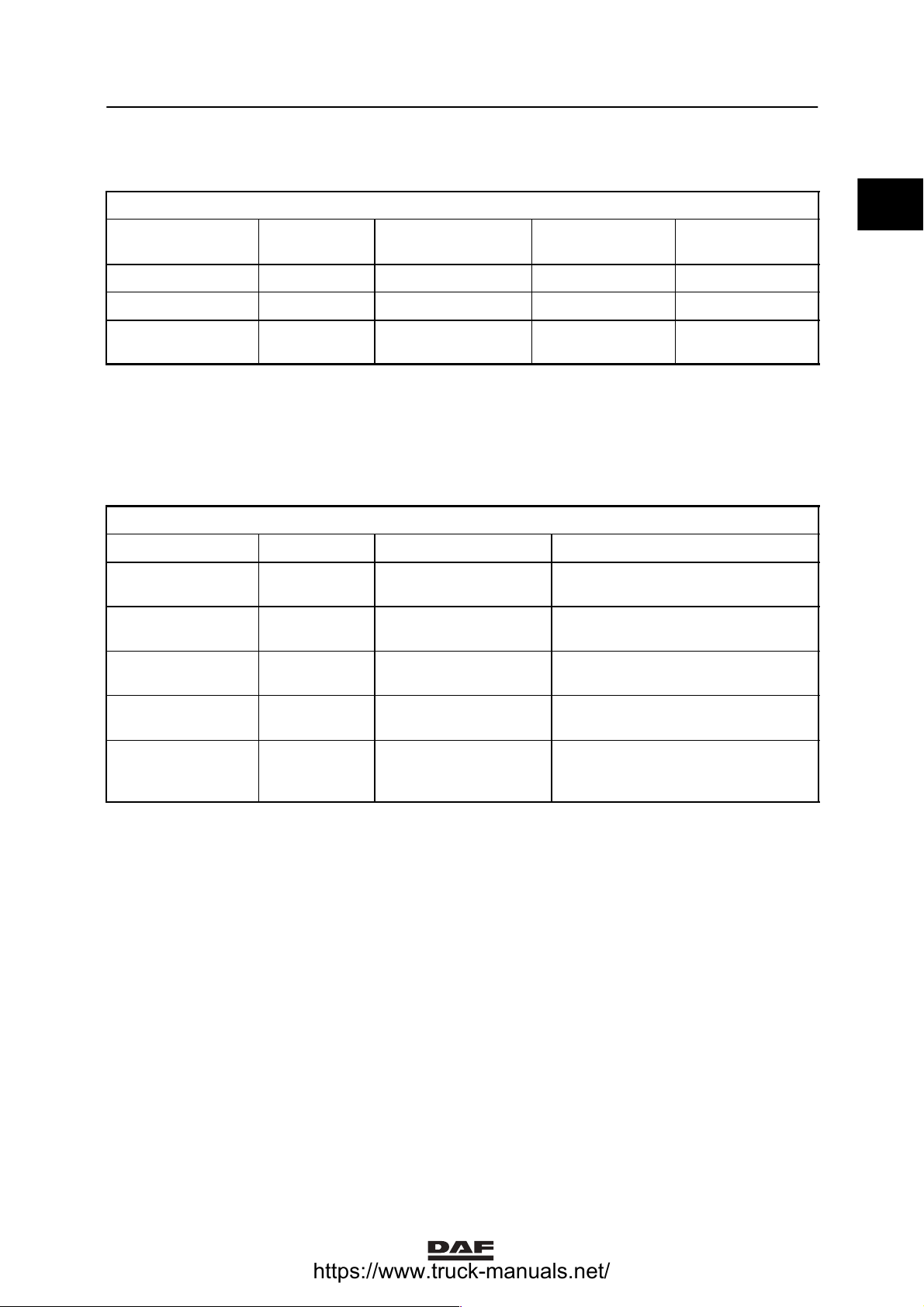

Mirror size 1 size 2 size 3 size 4 size 5

Pavement mirror [A] 1m 1m 1.25 m

Wide-angle mirror [B] 2.5 m 15 m 12.5 m 25 m 3m

Main mirror on co-driver’s

30 m 3.5 m 0.75 m 4m

side [C]

Main mirror on driver’s

10 m 2.5 m

side [D]

1-6

ǹ 0210

Page 11

1

TECHNICAL DATA

LF45/55 series Internal and external cab components

Windscreens

Curing times for windscreen adhesive

Product name DAF number Vehicle mobile in

workshop after:

Sikaflex 255 FC 1271129 6 hours 8hours 12 hours

Sika Tack Ultrafast 1241020 2 hours 4hours 6 hours

Sika Tack plus

booster

Notes:

(1)

If a vehicle is equipped with an airbag, the

curing time is 2 hours

A relative humidity of less than 50% delays

curing, as does a temperature lower than 20_C.

Product name DAF number Properties Applications

Sikaflex 255 FC 1271129 Processing time

Sika Tack UF 1241020 Processing time

1357925 1hour 1 hour

Products applied for bonded windscreens

20 min.

10 min.

Cab can be tilted

after:

(1)

Adhesive (cold process) for

bonding windscreens

Adhesive (warm process) for

bonding windscreens

Vehicle usable

after:

2 hours

0

Sika Tack plus

booster

Sika Aktivator 1312362 Cleaning fluid for cleaning the glass

Sika remover

SR 208

1357925 Processing time

10 min.

1241019 Removal of adhesive which has not

Adhesive (cold process) for

bonding windscreens

and the frame.

yet hardened. Do not use on

surfaces to be bonded.

ǹ 0210

1-7

Page 12

1TECHNICAL DATA

Internal and external cab components LF45/55 series

1.2 TIGHTENING TORQUES

0

The tightening torques stated in this paragraph

are different from the standard tightening

torques stated in the overview of the standard

tightening torques. The other threaded

connections which are not stated must therefore

be tightened to the tightening torque stated in

the overview of standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important - unless stated

otherwise - that these bolts and nuts are of

exactly the same length and property class as

the removed ones.

Steering wheel

Steering wheel attachment bolt 50 ᐔ 5Nm

Universal joint

Universal joint attachment bolt 56 ᐔ 5.6 Nm

Airbag

Airbag module attachment bolt 5 ᐔ 1Nm

Contact unit attachment bolt 1.2 Nm

Electronic unit 10 ᐔ 2Nm

Note:

(1)

Always replace the attachment bolt and

nut.

(1)

1-8

ǹ 0210

Page 13

1

TECHNICAL DATA

LF45/55 series Cab suspension

2. CAB SUSPENSION

2.1 GENERAL

The day cab can be fitted with rubber spring

elements at the front. The version with rubber

spring elements at the front does not have a

stabiliser.

The coil spring elements are fitted with shock

absorbers.

The length of the spring elements and the cab

height cannot be adjusted.

On models equipped with coil spring elements at

the front, a difference in cab height can be

corrected to a certain extent using the stabiliser

bar.

At the rear, coil springs are used. The length of

the spring elements varies depending on

whether a day cab or a sleeper cab is involved.

Cab support, general

The distance between the cab

supports (A) measured from the

left side of the left support to the

left side of the right support is:

1000 mm

0

9

11

15

10

12

16

13

14

K1 00 575

ǹ 0210

2-1

Page 14

1TECHNICAL DATA

Cab suspension LF45/55 series

0

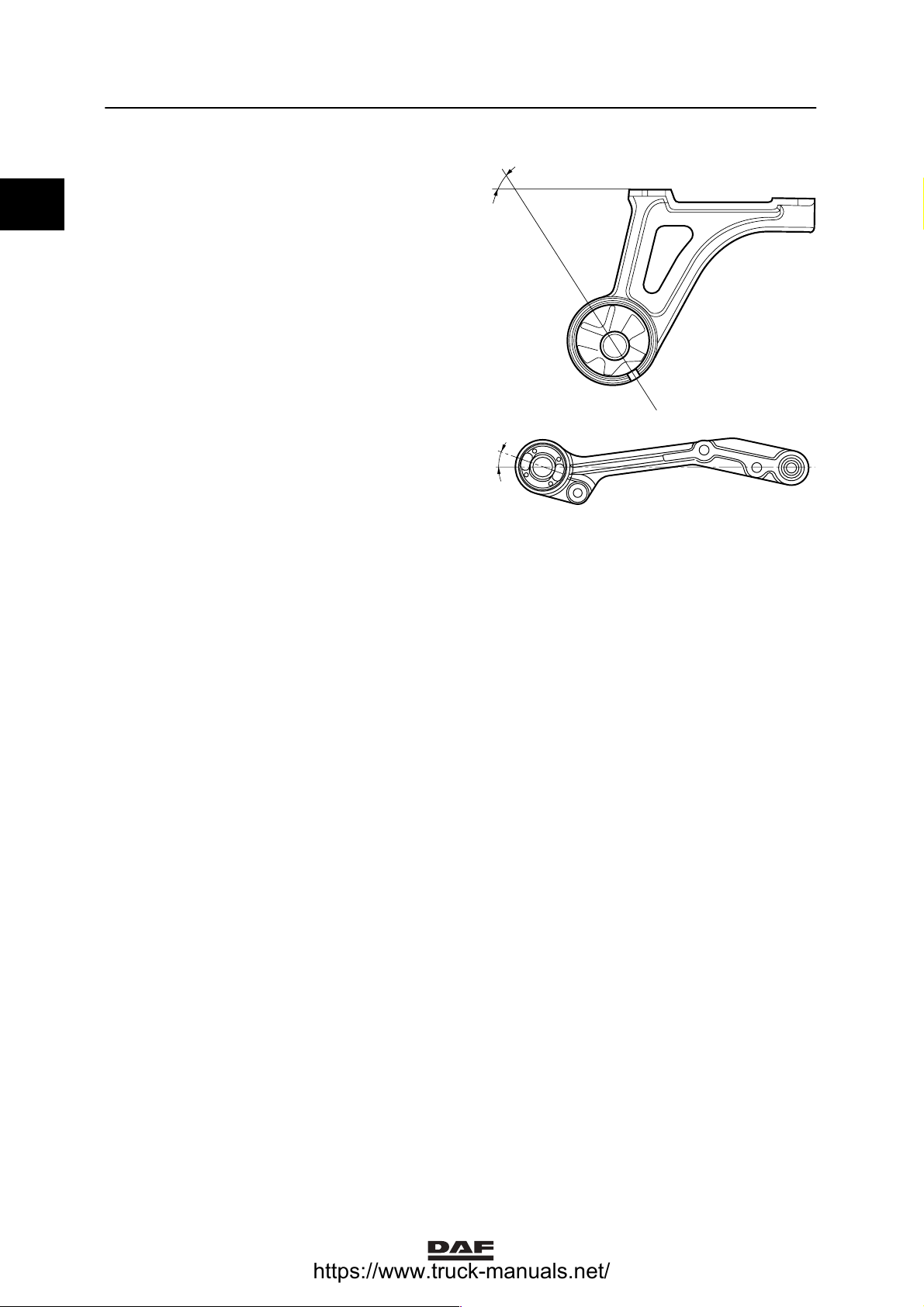

Cab support with silentblock

Silent block mounting angle (A) 67_ -71_

Cab support with coil spring suspension

Silent block mounting angle (A) 18_ -22_

A

K1 01 475

A

K1 01 442

2-2

ǹ 0210

Page 15

1

TECHNICAL DATA

LF45/55 series Cab suspension

2.2 TIGHTENING TORQUES

The tightening torques stated in this paragraph

are different from the standard tightening

torques stated in the overview of the standard

tightening torques. The other threaded

connections which are not stated must therefore

be tightened to the tightening torque stated in

the overview of standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important - unless stated

otherwise - that these bolts and nuts are of

exactly the same length and property class as

the removed ones.

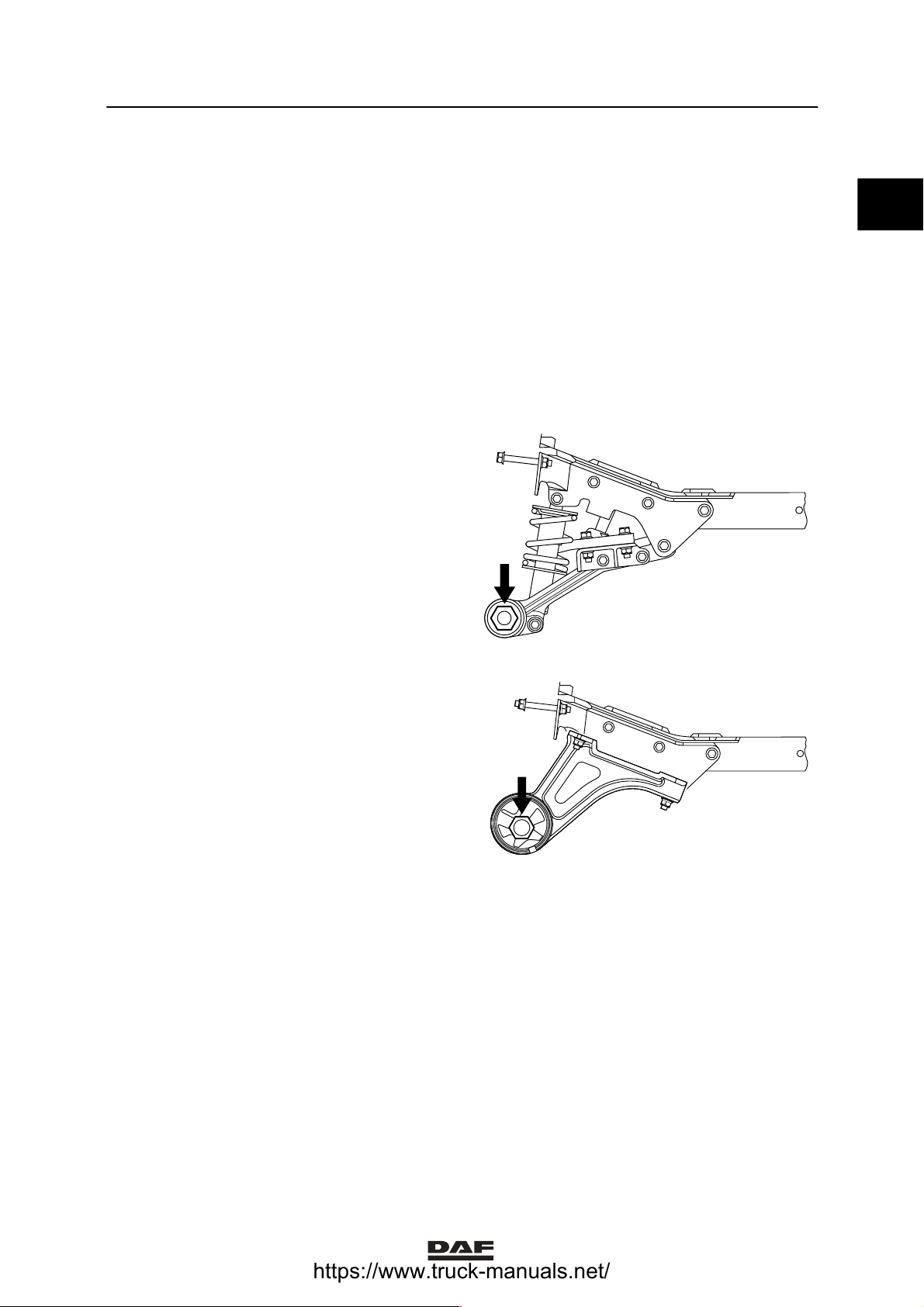

Attachment bolts for cab suspension

using coil springs

Cab suspension

attachment bolt

250 Nm + 150_

angular

displacement

0

K1 01 573

Attachment bolts for cab suspension

using rubber spring elements

Cab suspension

attachment bolt

250 Nm + 150_

angular

displacement

1

K1 01 574

ǹ 0210

2-3

Page 16

0

1TECHNICAL DATA

Cab suspension LF45/55 series

2-4

ǹ 0210

Page 17

1

LF45/55 series Cab tilting gear

TECHNICAL DATA

3. CAB TILTING GEAR

3.1 GENERAL

Lifting cylinder

Nominal pressure 250 bar

Cab tilting pump

Nominal pressure 250 bar

Pressure limiting valve 350 + 30 bar

3.2 FILLING CAPACITIES

Cab tilting pump

Effective oil capacity of the cab-tilting pump. 200 cm

3

0

ǹ 0210

3-1

Page 18

0

1TECHNICAL DATA

Cab tilting gear LF45/55 series

3-2

ǹ 0210

Page 19

1

TECHNICAL DATA

LF45/55 series Seats

4. SEATS

4.1 GENERAL

Height control valve

Adjusting dimension X for height control valve 1 - 2 mm

4.2 TIGHTENING TORQUES

The tightening torques stated in this paragraph

are different from the standard tightening

torques stated in the overview of the standard

tightening torques. The other threaded

connections which are not stated must therefore

be tightened to the tightening torque stated in

the overview of standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important - unless stated

otherwise - that these bolts and nuts are of

exactly the same length and property class as

the removed ones

M8 attachment bolt 22 Nm

M10 attachment bolt 22 Nm

Attachment bolt 7/16″ UNF-2B 37 Nm

.

0

ǹ 0210

4-1

Page 20

0

1TECHNICAL DATA

Seats LF45/55 series

4-2

ǹ 0210

Page 21

1

TECHNICAL DATA

LF45/55 series Accessories

5. ACCESSORIES

5.1 GENERAL

Roof spoiler

Adjusting range of roof spoiler, aerodynamic

and adjustable

Note:

The roof spoiler height can be adjusted using

adjusting mechanism (B).

Thesizeisthedistancemeasuredbetweenthe

highest roof spoiler edge (P) and the cab roof

plate local to the vehicle centreline.

Application compounds for rear air foils and

roof spoilers

Product name

Sikaflex 252

(white)

DAF number Properties Applications

1286578 Working time within

15 min.

Curing time 2 days

0

350 - 850 mm

P

B

K1 01 355

Kit for fender and roof spoiler

attachment

ǹ 0210

5-1

Page 22

1TECHNICAL DATA

Accessories LF45/55 series

5.2 TIGHTENING TORQUES

0

The tightening torques stated in this paragraph

are different from the standard tightening

torques stated in the overview of the standard

tightening torques. The other threaded

connections which are not stated must therefore

be tightened to the tightening torque stated in

the overview of standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important - unless stated

otherwise - that these bolts and nuts are of

exactly the same length and property class as

the removed ones.

Roof spoiler

Attachment nuts 13 Nm

Rear air foil

Attachment nuts 13 Nm

Sun visor

Bracket attachment bolts 13 Nm

Bolt for attaching the sun visor to the bracket 10 Nm

5-2

ǹ 0210

Page 23

1

LF45/55 series Contents

DIAGNOSTICS

CONTENTS

Page Date

1. CAB SUSPENSION 1-1 0210.................................................... ......

1.1 Fault-finding table, cab tilting mechanism 1-1 0210............................ ......

1

ǹ 0210

1

Page 24

1

1DIAGNOSTICS

Contents LF45/55 series

2

ǹ 0210

Page 25

1

DIAGNOSTICS

LF45/55 series Cab suspension

1. CAB SUSPENSION

1.1 FAULT-FINDING TABLE, CAB TILTING MECHANISM

COMPLAINT: TILTING CYLINDER FAILS TO RESPOND

Possible cause Remedy

Damaged or broken pipe. Replace pipe or connection.

Pump reservoir empty. Top up reservoir and check for leakage.

Worn or damaged cylinder seal. Replace the cylinder or seal.

COMPLAINT: PUMP ROD REBOUNDS

Possible cause Remedy

Leaking non-return valve. Disassemble the two-way valve of the pump.

Clean and degrease the valve components.

Replace all seals and assemble the two-way

valve.

COMPLAINT: PUMP ONL Y FUNCTIONS IN THE LAST P ART OF THE STROKE

Possible cause Remedy

Low oil level in oil reservoir. Topupoilreservoir.

Leaking inlet valve (ball). Remove the two-way valve and check the inlet

valve. Clean or replace it.

Polluted inlet strainer. Clean the reservoir and strainer.

1

COMPLAINT: PUMP FAILS TO BUILD UP PRESSURE

Possible cause Remedy

Reservoir level too low. Topupthereservoir.

Leaking inlet valve (ball). Remove the two-way valve and check the inlet

valve. Clean or replace it.

Worn or damaged O-rings on the two-way

valve.

Pressure-relief valve incorrectly set. Check the pressure relief valve and adjust, if

Remove the two-way valve and replace all seals

and O-rings.

necessary.

ǹ 0210

1-1

Page 26

1

1DIAGNOSTICS

Cab suspension LF45/55 series

COMPLAINT: CAB LOCK CANNOT BE OPENED

Possible cause Remedy

Damaged or broken pipe. Replace pipe or connection.

Jammed piston in locking mechanism. Repair or replace the locking mechanism.

COMPLAINT: CAB CANNOT BE TILTED

Possible cause Remedy

Jammed piston in cab locking mechanism. Repair or replace the locking mechanism.

Pump fails to build up pressure. Check the operation of the pump.

1-2

ǹ 0210

Page 27

1

INTERNAL CAB COMPONENTS

LF45/55 series Contents

CONTENTS

Page Date

1. SAFETY INSTRUCTIONS 1-1 0210............................................... ......

2. GENERAL 2-1 0210............................................................ ......

2.1 Overview drawing, interior cab components 2-1 0210.......................... ......

2.2 System description, steering column 2-2 0210................................ ......

3. INSPECTION AND ADJUSTMENT 3-1 0210....................................... ......

3.1 Inspection, steering column setting valve 3-1 0210............................. ......

4. REMOVAL AND INSTALLATION 4-1 0210........................................ ......

4.1 Removal and installation, switches 4-1 0210.................................. ......

4.2 Removal and installation, dashboard panels 4-2 0210.......................... ......

4.3 Removal and installation of complete dashboard 4-9 0210...................... ......

4.4 Removal and installation, pneumatic switch/valve of

steering column adjustment unit 4-15 0210.................................... .....

4.5 Removal and installation, steering column 4-17 0210............................ .....

4.6 Removal and installation, steering wheel 4-22 0210............................. .....

4.7 Removal and installation, door panel 4-26 0210................................ .....

4.8 Removal and installation, manually operated window mechanism 4-28 0210........ .....

4.9 Removal and installation, electrically operated window mechanism 4-29 0210...... .....

4.10 Removal and installation, roof console 4-30 0210............................... .....

4.11 Removal and installation, interior lighting 4-31 0210............................. .....

4.12 Removal and installation, ignition lock 4-31 0210............................... .....

4.13 Removal and installation, complete door lock mechanism 4-32 0210.............. .....

4.14 Removal and installation, door lock cylinder 4-34 0210.......................... .....

4.15 Removal and installation, engine brake switch 4-34 0210........................ .....

4.16 Removal and installation, rear wall lining 4-35 0210............................. .....

4.17 Removal and installation, roof lining 4-36 0210................................. .....

4.18 Removal and installation, side wall lining 4-37 0210............................. .....

4.19 Removal and installation, storage trays (sleeper cab) 4-37 0210.................. .....

2

ǹ 0210

1

Page 28

2

1INTERNAL CAB COMPONENTS

Contents LF45/55 series

2

ǹ 0210

Page 29

1

INTERNAL CAB COMPONENTS

LF45/55 series Safety instructions

1. SAFETY INSTRUCTIONS

General

The cab is equipped with a hydraulic tilting

mechanism. The pump is located on co-driver’s

side at the rear of the cab. The cab locks are

opened hydraulically during pumping.

Before tilting the cab, make sure that the doors

are closed, that there are no loose items in the

cab and that the gear lever is in neutral. Tilt the

cab fully forward if work must be carried out

underneath the cab.

You can stop the cab tilting forward

atanytimebyturningthetaptothe

reverse tilting position.

When working on a tilted cab (for

example when welding,

spray-painting or applying bitumen

coatings), be sure to cover the

piston rod of the lifting cylinder.

Welding spatter and paint on the

piston rod will inevitably cause

damage to the oil seal.

2

Inspection after a collision

Before tilting the cab after a collision, check the

cab rests, the cab hinges and the attachment of

the lifting cylinder to the chassis member and

cab for cracks.

If the vehicle has been involved in a

collision, the cab must under no

circumstances be tilted without due

precautions. The end stop in the

lifting cylinder may be damaged,

which might cause the cab to shoot

past its end stop.

If possible, suspend the cab in slings and put a

stand in front of the cab. Make sure that there is

no one in front of the cab while it is being tilted.

ǹ 0210

1-1

Page 30

2

1INTERNAL CAB COMPONENTS

Safety instructions LF45/55 series

Replacing the lifting cylinder

After a collision, always check the lifting

cylinder for internal damage.

Replace the lifting cylinder if damaged or if you

are in doubt as to the its condition.

Always replace the cylinder if one of the

following points has occurred during a collision:

A. the cab has been pulled out of the cab

locks,

B. the cab locks have been deformed or

damaged,

C. the rear cab springs have been deformed

or damaged.

Airbag and seat belt tensioner safety

instructions

- Never disconnect an electrical connection in

the airbag or seat belt tensioner circuits

with the ignition switched on.

- All work on pyrotechnic systems (systems

with airbag(s) and/or seat belt tensioner(s))

may only be carried out by employees of

approved DAF dealers or workshops who

are sufficiently trained on these systems.

- The use of pyrotechnic systems (systems

with airbag(s) and/or seat belt tensioner(s))

is subject to various national laws. The legal

stipulations must be observed.

1-2

ǹ 0210

Page 31

1

INTERNAL CAB COMPONENTS

LF45/55 series Safety instructions

- Vehicles equipped with a pyrotechnic

system (system with airbag(s) and/or seat

belt tensioner(s)) can be identified by a

sticker with an airbag symbol on the

windscreen and/or with the word AIRBAG

on the airbag unit on the steering wheel.

- If the vehicle is equipped with an airbag and

seat belt tensioner system while there is no

airbag symbol on the windscreen, this

symbol will have to be applied as yet.

K101290

- It is not permitted to install accessories on

airbag and seat belt tensioner parts or in

their operating zones afterwards. The

operating zone covers an area the size of a

ball with a diameter of 80 cm. Only

accessories approved by DAF for vehicles

with an airbag and/or seat belt tensioner

may be installed, in the place indicated by

DAF and in the manner outlined by DAF.

2

- Using equipment or objects that generate

strong electromagnetic fields in the vicinity

of parts of the airbag/seat belt tensioner

system can lead to unwanted activation of

the airbag and/or seat belt tensioner or can

make proper operation of the system

impossible. The use of such equipment or

objects in the vicinity of parts of the

airbag/seat belt tensioner system is

therefore not recommended.

G0 00 235

ǹ 0210

1-3

Page 32

2

1INTERNAL CAB COMPONENTS

Safety instructions LF45/55 series

- It is not allowed to leave pyrotechnic units

(airbags and/or seat belt tensioners)

unattended. If repairs to a vehicle continue

for a long time and pyrotechnic units

(airbags and/or seat belt tensioners) are

involved in the repair, the pyrotechnic units

must be stored safely (under lock and key).

This means that the storage location must

meet local requirements relating to

pyrotechnic materials. The pyrotechnic

units may not be stored together with

different hazardous substances and the

location must have the relevant hazard

warning symbols and fire protection

facilities.

- Before any work is carried out on a

pyrotechnic part (airbag and/or seat belt

tensioner):

a. switch off the ignition.

b. the negative battery terminal clamp

must be separated carefully.

c. wait at least 5 minutes.

- If pyrotechnic units have been activated in a

crash, the electronic unit and the contact

unit must be replaced in addition to the

pyrotechnic units. The cable harness

assembly and connectors must be

inspected visually. If damage or overload is

established, the cable harness assembly

must be replaced.

1-4

ǹ 0210

Page 33

1

INTERNAL CAB COMPONENTS

LF45/55 series General

2. GENERAL

2.1 OVERVIEW DRAWING, INTERIOR CAB COMPONENTS

1 2 3 4 6 7 8 9 10

Legend

1. Left-side ventilation grille

2. Instrument panel

3. Garnish moulding

4. Radio panel

5. Frame rim cover panel

6. Upper dashboard panel on driver’s side

7. Central console control panel

8. Upper side of cover panel

9. Upper side of cover

10. Right-side ventilation grille

1 1. Right-side dashboard panel

12. Lid on central box

13. Lower dashboard panel on co-driver ’s side

14. Ashtray

15. Engine tunnel dashboard panel

16. Lower dashboard panel on driver’s side

17. Steering column dashboard panel

5

11

2

12

13

151617

14

K1 01 438

ǹ 0210

2-1

Page 34

2

1INTERNAL CAB COMPONENTS

General LF45/55 series

2.2 SYSTEM DESCRIPTION, STEERING COLUMN

The tilting angle of the steering column can be

adjusted manually or pneumatically.

A spring-loaded clamping mechanism fixes the

steering column in position.

The pneumatically adjusted steering column is

unlocked using the air cylinder behind the

steering column.

The operating valve (switch) is situated behind

the driver’s seat. This valve can be operated by

the heel.

K1 01 425

K1 01 202

2-2

ǹ 0210

Page 35

1

LF45/55 series Inspection and adjustment

INTERNAL CAB COMPONENTS

3. INSPECTION AND ADJUSTMENT

3.1 INSPECTION, STEERING COLUMN SETTING VALVE

1. Check whether the angle of the steering

column can be adjusted, once the switch is

pressed in with the heel.

2. Check that the adjustment mechanism is

securely locked again when the switch is

released.

3. If this is not the case, check that no air pipe

is trapped. If not, replace the valve (switch).

K1 01 202

2

ǹ 0210

3-1

Page 36

2

1INTERNAL CAB COMPONENTS

Inspection and adjustment LF45/55 series

3-2

ǹ 0210

Page 37

1

LF45/55 series Removal and installation

INTERNAL CAB COMPONENTS

4. REMOVAL AND INSTALLATION

4.1 REMOVAL AND INSTALLATION, SWITCHES

Removing switches

1. Insert a feeler gauge of approx. 1 mm

straight between the switch and the panel at

the side of the finger-sized depression (A),

until it touches the inside of the panel.

B

2. Remove the switch from its locked position

by carefully moving the feeler gauge in the

direction of the arrow (B).

3. Carefully remove the switch from the panel.

In doing so, ensure that the connector lock

does not catch behind the panel, causing

the connector to fall behind the panel.

4. If necessary, remove the switch from the

connector.

Installing switches

1. Fit the connector.

2. Insert the switch into the opening in the

panel and press until you can feel it lock.

A

A

2

K1 01 186

B

K100389

ǹ 0210

4-1

Page 38

2

INTERNAL CAB COMPONENTS

1

Removal and installation LF45/55 series

4.2 REMOVAL AND INSTALLATION, DASHBOARD PANELS

Note:

Dashboard panel removal and installation is

listed in the correct sequence. To allow each

following panel to be removed, the earlier

specified panels must be removed first.

Removing steering column dashboard panel

1. If necessary, remove the floor mat.

2. Using the steering column setting, move the

steering wheel to its highest possible

position.

3. Remove the attachment bolts (1) and panel

plug (2) and subsequently the steering

column dashboard panel.

21

K1 01 427

Removing the lower dashboard panel on

co-driver’s side

1. Remove the attachment bolts from the

lower dashboard panel on co-driver’s side.

Remove the lower dashboard panel on

co-driver’s side

Removing the engine tunnel dashboard

panel

1. Remove the attachment bolts (1) and the

panel plugs (2). Remove the engine tunnel

cover panel.

2. Loosen the 12V power supply connector at

the rear.

K1 01 428

4-2

21

K1 01 429

ǹ 0210

Page 39

1

INTERNAL CAB COMPONENTS

LF45/55 series Removal and installation

Removing the instrument panel

1. Remove the attachment bolts (1) of the

garnish moulding (2) around the instrument

panel (3).

2. Carefully pull the mounting clips (see

arrows) holding down the garnish moulding

(2) from the dashboard panel.

3. Remove the attachment bolts from the

instrument panel (3).

4. Remove the instrument panel (3).

5. Remove the connector from the instrument

panel (3).

Removing the lower dashboard panel on

driver’s side

1. Remove the attachment bolts (1). Remove

the dashboard panel.

2. Loosen the headlamp height adjustment

connector at the rear.

3. Remove the attachment bolts from the

connector block at the rear of the

dashboard panel.

3

1

1

2

2

K1 01 430

1

K1 01 431

4. Remove the connector block.

Removing the window frame cover panel

1. Remove the attachment bolts (1) from the

window frame.

2. Take the cover panel out of the window

frame.

1

K1 01 432

ǹ 0210

4-3

Page 40

2

INTERNAL CAB COMPONENTS

1

Removal and installation LF45/55 series

Removing the upper cover

1. Remove the attachment bolts at the bottom

of the cover.

2. Remove the cover from the upper cover

panel by tilting it upwards.

K1 01 433

Removing the central console control panel

1. Remove the switches (3) from the control

panel in the central console (5).

1

5

2. Remove the ashtray (2) from the control

panel in the central console (5).

3. Remove the attachment bolts (1) from

control panel in the central console (5).

4. Remove the control panel from the central

console (5).

3

5. Disconnect the connector of the cigarette

lighter (4).

Removing the right-side dashboard panel

1. Remove the dashboard panel attachment

bolts.

2. Remove the connector from the stepwell

lighting door switch

2

4

1

K1 01 434

K1 01 435

4-4

ǹ 0210

Page 41

1

INTERNAL CAB COMPONENTS

LF45/55 series Removal and installation

Removing the upper dashboard panel on

driver’s side

1. Remove the attachment bolts (1) from the

radio panel (2).

2. Remove the attachment bolts (3) from the

dashboard panel.

3. Cut the cable binders that are used to

attach the wiring harnesses to the

dashboard panel.

4. Remove the dashboard panel. Unhook the

radio panel (2) from the dashboard panel.

5. Disconnect the connector of the light switch

(4) and the stepwell lighting door switch.

Installing the upper dashboard panel on

driver’s side

1. Fit the connector of the light switch (4) and

the stepwell lighting door switch.

2. Fit the dashboard panel. Hook the radio

panel (2) to the dashboard panel.

3. Fix the removed cable harnesses to the

dashboard panel using cable binders.

3

1

2

42

K1 01 436

3

1

4. Fit the dashboard panel attachment

bolts (3).

5. Fit the attachment bolts (1) of the radio

panel (2) to the dashboard panel.

Installing the right-side dashboard panel

1. Fit the connector of the stepwell lighting

door switch to the right-side dashboard

panel

2. Fit the right-side dashboard panel using the

attachment bolts.

42

K1 01 436

K1 01 435

ǹ 0210

4-5

Page 42

INTERNAL CAB COMPONENTS

1

Removal and installation LF45/55 series

2

Installing the central console control panel

1. Re-fit the connector of the cigarette lighter

(4) to the rear of the control panel of the

central console (5).

2. Fit the control panel of the central console

(5) to the dashboard.

3. Hook up the switches (3) from the control

panel in the central console (5) to the

connectors. Re-fit the switches (3) to the

control panel in the central console (5).

4. Secure the control panel in the central

console (5) using the attachment bolts (1).

5. Fit the ashtray (2) into the control panel in

the central console (5).

Fitting the upper cover

1. Hook the cover into the cover panel. Fit the

cover into the cover panel using the

attachment bolts.

1

5

3

2

4

1

K1 01 434

Fitting the cover panel into the window frame

1. Fit the cover panel into the window frame

using the attachment bolts (1).

K1 01 433

1

K1 01 432

4-6

ǹ 0210

Page 43

1

INTERNAL CAB COMPONENTS

LF45/55 series Removal and installation

Fitting the lower dashboard panel on driver’s

side

1. Fit the connector block to the rear of the

dashboard panel using the attachment

bolts.

2. Fit the connector of the headlamp height

adjustment unit to the dashboard panel.

3. Fit the dashboard panel using the

attachment bolts (1).

Installing the instrument panel

1. Fit the connector of the instrument

panel (3).

2. Fit the instrument panel (3) to the

dashboard panel using the attachment

bolts.

3. Push the garnish moulding (2) back onto

the dashboard panel using the mounting

clips. Fix the garnish moulding (2) onto the

dashboard panel using the attachment

bolts (1)

Fitting the engine tunnel dashboard panel

1. Remove the attachment bolts (1) and the

panel plugs (2). Remove the engine tunnel

cover panel.

2. Fit the connector of the 12V power supply to

the rear of the engine tunnel dashboard

panel.

1

K1 01 431

2

3

1

1

2

K1 01 430

21

K1 01 429

ǹ 0210

4-7

Page 44

2

INTERNAL CAB COMPONENTS

1

Removal and installation LF45/55 series

Fitting the lower dashboard panel on

co-driver’s side

1. Fit the lower dashboard panel on co-driver’s

using the attachment bolts.

K1 01 428

Installing the steering column dashboard

panel

1. Fit the steering column dashboard panel

using the attachment bolts (1) and panel

plug (2).

21

K1 01 427

4-8

ǹ 0210

Page 45

1

INTERNAL CAB COMPONENTS

LF45/55 series Removal and installation

4.3 REMOVAL AND INSTALLATION OF COMPLETE DASHBOARD

7

2

456

Removing the dashboard

1. Disconnect the earth lead from the battery

terminal.

2. Remove the attachment bolts and the panel

plug (6). Remove the steering column cover

panel.

3. Remove the attachment bolts (1), (2) and

(3) and remove the cover panel on

co-driver’s side.

4. Remove the attachment bolts (4) and the

panel plugs (5). Remove the engine tunnel

cover panel. Remove the connector from

the 12V power supply.

5. Remove the attachment bolts (7) and

remove the upper cover panel.

6. Open the grille.

123

K1 01 437

ǹ 0210

4-9

Page 46

INTERNAL CAB COMPONENTS

1

Removal and installation LF45/55 series

2

7. Remove the attachment bolt (1).

8. Remove the protective cover by pressing

the retainer (2) aside.

9. Detach the connectors (1) from the

connecting block.

10. Press the connecting block retainer (2)

inside and push the complete connecting

block inside.

2

1

K1 00 988

2

1

11. Remove the cover plate (2) by releasing the

retainer (1).

1

2

11

K100989

K1 00 994

4-10

ǹ 0210

Page 47

1

INTERNAL CAB COMPONENTS

LF45/55 series Removal and installation

12. Remove the connectors (2).

13. Push the retainers (1) aside and the

connector holder plate inside.

14. Remove the attachment bolts (1) from the

filter casing and remove the filter casing (2).

2

1

2

K1 00 990

1

1

15. Remove the attachment bolts (1).

16. Remove the heater hoses (2) and seal the

heater tubes.

17. Remove the connectors to the left and right

of the steering column.

1

2

K1 01 194

2

1

K1 01 175

ǹ 0210

4-11

Page 48

INTERNAL CAB COMPONENTS

1

Removal and installation LF45/55 series

18. Remove the connectors (2) and the earth

connections (3).

19. Remove the attachment bolts on the

underside of the dashboard, left and right.

2

20. Remove the attachment bolts (4) and (1).

21. Pull the cover plate in the A-pillar out of the

retainer, remove the grip attachment bolt

and remove the grip (5).

22. Remove the floor mats. Remove the

diagnostic and ECAS connectors by taking

the wiring apart and then removing the

attachment bolts. Remove the connectors

from the bracket.

23. Remove the floor plate above the wiring.

24. Remove the seat wiring.

25. Remove the attachment bolts from the

window frame.

26. Remove the attachment bolts on the

underside and remove the complete

dashboard.

Fitting the dashboard

1. Fit the dashboard and secure it in the

window frame using a few attachment bolts.

2. Fit the seat wiring.

1

2

5

3

4

K1 00 986

3. Install the floor plate above the wiring.

4. Fit the ECAS and diagnostic connectors to

the bracket.

5. Fit the grip and the cover panel in the

A-pillar.

6. Fit the connectors in the central box.

7. Remove the seals from the coolant hoses

and attach the hoses.

8. Fit the connectors to the left and right of the

steering column.

4-12

ǹ 0210

Page 49

1

INTERNAL CAB COMPONENTS

LF45/55 series Removal and installation

9. Insert the attachment bolts (1).

10. Fit the heater hoses (2).

11. Fit the filter casing (2). Secure the filter

casing using the attachment bolts (1).

2

1

2

K1 01 175

1

1

1

2

K1 01 194

12. Fit the plate for the connectors via the

inside and press it into the retainers (2).

13. Fit the connectors (1).

14. Fit the cover plate.

2

1

1

K1 00 994

ǹ 0210

4-13

Page 50

INTERNAL CAB COMPONENTS

1

Removal and installation LF45/55 series

2

15. Fit the connecting block via the inside and

press it firmly into the retainers (2).

16. Fit the connectors (1) to the connecting

block. Pay attention to the markings on the

components.

17. Fit the protective cover to the cab lead

through and secure it using the attachment

bolt (1).

2

1

1

2

K1 00 994

1

18. Close the grille.

19. Fit the attachment bolts under the

dashboard to the left and right.

20. Secure the attachment bolts in the window

frame.

21. Fit the dashboard panels on co-driver’s

side.

22. Fit the steering column dashboard panels.

23. Fit the connector of the 12V power supply to

the engine tunnel cover panel.

24. Fit the cover panel to the engine tunnel.

25. Fit the earth lead to the battery terminal.

K1 00 988

4-14

ǹ 0210

Page 51

1

INTERNAL CAB COMPONENTS

LF45/55 series Removal and installation

4.4 REMOVAL AND INSTALLATION, PNEUMATIC SWITCH/VALVE OF

STEERING COLUMN ADJUSTMENT UNIT

Removing the pneumatic switch/valve of the

steering column adjustment unit

1. Lay the floor mat aside.

2. Remove the attachment bolts (1) from the

switch/valve.

3. Remove the bracket holding the

switch/valve. Disconnect the air pipes (2)

and remove the switch/valve.

1

2

K1 01 120

ǹ 0210

2

K1 01 121

4-15

Page 52

2

INTERNAL CAB COMPONENTS

1

Removal and installation LF45/55 series

Fitting the pneumatic switch/valve

1. Fit the air pipes (2) to the switch/valve.

2

K1 01 121

2. Fit the switch/valve and secure them using

the attachment bolts (1).

3. Check the operation of the switch/valve, see

chapter ”Inspection and Adjustment”.

4. Reposition the floor mat.

1

K1 01 120

4-16

ǹ 0210

Page 53

1

INTERNAL CAB COMPONENTS

LF45/55 series Removal and installation

4.5 REMOVAL AND INSTALLATION, STEERING COLUMN

Note:

A steering wheel with an airbag can be

recognised by the inscription ”airbag” on the

cover plate and the ”Airbag” sticker on the

windscreen.

Steering wheel model without airbag

Removing the steering column without

airbag steering wheel

1. Place the steering box in the central

position using the marks.

2. Remove the steering column panel.

3. Depending on the work to be carried out,

remove the floor dust cover or the cover

panels beneath the steering wheel.

4. If applicable, remove the steering column

adjustment air pipe.

2

S7 00 623

5. Remove the connectors from the steering

column.

6. Remove the attachment bolt of one

universal joint of the steering shaft

(depending on the operations to be

performed; either the universal joint beneath

the steering wheel or the universal joint on

the steering box). Before loosening, mark

the position of the universal joint versus the

steering shaft.

7. Remove the attachment bolts. One of the

attachment bolts is a security bolt. Remove

this using a drift.

8. Remove the steering column.

ǹ 0210

4-17

Page 54

2

INTERNAL CAB COMPONENTS

1

Removal and installation LF45/55 series

Installing the steering column without airbag

steering wheel

1. Check whether the steering box is still in the

central position, using the markings.

S7 00 623

2. Fit the steering column to the steering shaft

and make sure that the marks between the

universal joint and steering shaft align.

Fit a new attachment bolt with nut in the

universal joint.

Tighten the attachment bolt to the specified

torque, see main group ”Technical data”.

3. Place the steering column by tightening the

top attachment bolts by hand.

4. Attach the air pipes to the connection block

behind the dashboard. Check to see that

the air pipes are not in contact with any

moving parts.

5. Fit the steering column connectors.

6. Fit the lower attachment bolts and lock the

steering column.

7. Fit the steering column panel and secure it

with the attachment bolts and panel clips.

4-18

ǹ 0210

Page 55

1

INTERNAL CAB COMPONENTS

LF45/55 series Removal and installation

Steering wheel model with airbag

Observe the warnings and safety

instructions applicable to working

on an airbag system.

Removing the steering column with airbag

steering wheel

1. Remove the airbag module.

2. Place the steering box in the central

position using the marks.

3. Remove the panel under the tachograph.

There must at least be 5 minutes

waiting time between disconnecting

the battery leads and loosening the

airbag connector. Non-observance

of the 5 minutes waiting time may

result in the airbag being activated

when the connector is removed.

2

S7 00 623

4. Remove the steering column panel.

5. Depending on the work to be carried out,

remove the floor dust cover or the cover

panels under the steering wheel.

6. If applicable, remove the steering column

adjustment air pipe.

7. Remove the connectors from the steering

column.

ǹ 0210

4-19

Page 56

2

INTERNAL CAB COMPONENTS

1

Removal and installation LF45/55 series

8. Remove the attachment bolt of one

universal joint of the steering shaft

(depending on the operations to be

performed; either the universal joint under

the steering wheel or the universal joint on

the steering box). Before loosening, mark

the position of the universal joint versus the

steering shaft.

9. Lock the steering wheel to prevent it from

turning, using, for example, adhesive tape

If the steering wheel is rotated more

than 3 turns to the left or right from

the centre position, the airbag

contact unit will get damaged.

10. Remove the attachment bolts. One of the

attachment bolts is a security bolt. Remove

this using a drift.

11. Remove the steering column.

4-20

ǹ 0210

Page 57

1

INTERNAL CAB COMPONENTS

LF45/55 series Removal and installation

Installing the steering column with airbag

steering wheel

1. Check that the steering box is still in the

central position, using the marks.

S7 00 623

2. Fit the steering column to the steering shaft

and make sure that the marks between the

universal joint and steering shaft align.

Fit a new attachment bolt with nut in the

universal joint.

Tighten the attachment bolt to the specified

torque, see main group ”Technical data”.

2

3. Place the steering column by tightening the

top attachment bolts by hand.

4. Attach the air pipes to the connection block

behind the dashboard. Check to see that

the air pipes are not in contact with any

moving parts.

5. Fit the steering column connectors.

6. Fit the lower attachment bolts and lock the

steering column.

7. Fit the steering column panel and secure it

with the attachment bolts and panel clips.

8. Fit the panel.

9. Fit the airbag module.

ǹ 0210

4-21

Page 58

INTERNAL CAB COMPONENTS

1

Removal and installation LF45/55 series

4.6 REMOVAL AND INSTALLATION, STEERING WHEEL

Note:

A steering wheel with an airbag can be

recognised by the inscription ”Airbag” on the

cover plate and the ”Airbag” sticker on the

windscreen.

Steering wheel without airbag

2

Removing the steering wheel without airbag

1. Check that the steering wheel is not

equipped with an airbag.

2. Place the steering box in the central

position using the marks.

3. Remove the cover plate from the steering

wheel.

4. Remove the steering wheel bolt (2).

5. Make marks (A and B) on the steering

wheel (1) and the steering shaft (3).

S7 00 623

1

2

A

4-22

B

3

K1 01 321

ǹ 0210

Page 59

1

INTERNAL CAB COMPONENTS

LF45/55 series Removal and installation

6. Fit the steering wheel puller

(DAF no. 1451995) on the steering wheel.

7. Make sure the bottom of the spindle (1) is

level with the bottom of the attachment

bolts (2).

8. Turn the spindle (1) approximately 10 mm

into the steering shaft.

9. Turn both attachment bolts (2)

approximately 10 mm into the steering

wheel.

10. Evenly tighten both attachment bolts (2)

alternately until the steering wheel comes

loose.

Fitting the steering wheel without airbag

1. Fit the steering wheel (1) on the steering

shaft (3) so that the markings on the

steering wheel and steering shaft (A and B)

”align”. Ensure that the ridges on the rear of

the steering wheel fall into the recesses.

Check that the steering box is still in the

central position, if a new steering wheel is

fitted.

212

2

K1 01 324

1

2

A

2. Fit the attachment bolt (2). Tighten the

attachment bolt to the specified torque, see

main group “Technical data”.

3. Fit the cover plate on the steering wheel.

B

3

K1 01 321

ǹ 0210

4-23

Page 60

2

INTERNAL CAB COMPONENTS

1

Removal and installation LF45/55 series

Steering wheel with airbag

Observe the warnings and safety

instructions applicable to working

on an airbag system.

Removing the steering wheel with airbag

1. Disconnect the earth leads from the battery.

2. Place the steering box in the central

position using the marks.

3. Remove the covers from the steering

column.

There must at least be 5 minutes

waiting time between disconnecting

the battery leads and loosening the

airbag connector. Non-observance

of the 5 minutes waiting time may

result in the airbag being activated

when the connector is removed.

4. Remove the steering wheel bolt (2).

5. Make marks (A and B) on the steering

wheel (1) and the steering shaft (3).

S7 00 623

12

A

4-24

B

3

K1 01 505

ǹ 0210

Page 61

1

INTERNAL CAB COMPONENTS

LF45/55 series Removal and installation

6. Fit the steering wheel puller

(DAF no. 1451995) on the steering wheel.

7. Make sure the bottom of the spindle (1) is

level with the bottom of the attachment

bolts (2).

8. Turn the spindle (1) approximately 10 mm

into the steering shaft.

9. Turn both attachment bolts (2)

approximately 10 mm into the steering

wheel.

10. Evenly tighten both attachment bolts (2)

alternately until the steering wheel comes

loose.

Fitting the steering wheel with airbag

1. Fit the steering wheel (1) on the steering

shaft (3) so that the markings on the

steering wheel and steering shaft (A and B)

”align”. Ensure that the ridges on the rear of

the steering wheel fall into the recesses.

Check that the steering box is still in the

central position, if a new steering wheel is

fitted.

212

2

K1 01 324

12

A

2. Fit the attachment bolt (2). Tighten the

attachment bolt to the specified torque, see

main group “Technical data”.

3. Fit the airbag module.

4. Fit the steering column covers.

B

3

K1 01 505

ǹ 0210

4-25

Page 62

INTERNAL CAB COMPONENTS

1

Removal and installation LF45/55 series

4.7 REMOVAL AND INSTALLATION, DOOR PANEL

Removing the door panel

1. Loosen the cap from the grip by pushing a

screwdriver into the recesses (1).

2. Remove the cap from the grip.

2

3. Remove the caps (2) at the bottom of the

door.

4. Remove the attachment bolts from the door.

5. Remove the attachment bolts (1) from the

grip.

6. Disconnect the electric window and mirror

connectors at the inside of the grip.

7. Push the grip down as far as it will go.

8. Push the control cable clip (2) out of the

grip.

9. Remove the control cable from the door

knob. Put the grip aside.

1

2

2

K1 01 407

1

1

2

1

10. Pull the door panel out of the mounting clips

in the door, starting at the bottom.

11. Lift the door panel out of the window frame.

K1 01 409

K1 01 408

4-26

ǹ 0210

Page 63

1

INTERNAL CAB COMPONENTS

LF45/55 series Removal and installation

Installing the door panel

1. Fit the door panel into the upper part of the

window frame.

2. Press the door panel all around into the

door using the mounting clips.

3. Secure the lower part of the door panel

using the attachment bolts and fit the caps.

4. Position the grip on the door panel.

5. Fit the nipple of the control cable in the door

catch of the grip (A). Fit the coupler into the

grip (B).

6. Secure the control cable coupler into the

grip (C) using the mounting clip.

2

7. Fit the automatic mirror and window

connectors into the grip.

8. Fix the grip to the door using the attachment

bolts (1).

9. Fit the grip cap.

A

B

1

C

K1 01 441

1

2

1

ǹ 0210

K1 01 409

4-27

Page 64

2

INTERNAL CAB COMPONENTS

1

Removal and installation LF45/55 series

4.8 REMOVAL AND INSTALLATION, MANUALLY OPERATED WINDOW

MECHANISM

Removing the manually operated window

mechanism

1. Remove the door panel.

2. Remove the door screen.

3. Support the door window using a block (1)

and remove the attachment bolts (4).

Remove the window on the underside so

that it is no longer locked in position.

4. Remove the attachment bolts (3) and the

attachment nut (2) from the window

mechanism.

5. Tilt the window mechanism (5) and remove

it through the bottom of the door.

Installing manually operated window

mechanism

1. Fit the window mechanism (5) through the

bottom of the door.

3

4

2

5

3

2. Remove the block (1) and hook up the door

window in the window mechanism. Secure

the door window with the attachment

bolts (4).

3. Secure the window mechanism with the

attachment bolts (3) and nut.

4. Close the door window until nearly shut.

Check that the top edge of the window is

parallel with the window frame.

Loosen the attachment bolts (4), if

necessary.

Move the window to the correct position and

re-tighten the attachment bolts.

5. Fit the door screen.

6. Install the door panel.

1

K1 00 977

4-28

ǹ 0210

Page 65

1

INTERNAL CAB COMPONENTS

LF45/55 series Removal and installation

4.9 REMOVAL AND INSTALLATION, ELECTRICALLY OPERATED WINDOW

MECHANISM

Removing the electrically operated window

mechanism

1. Remove the door panel.

2. Remove the door screen.

3. Lower the window, remove the attachment

bolts (2) and slide the window up. Support

the window with a block (1).

4. Disconnect the connector (4) from the

electric motor.

5. Remove the attachment bolts (2) and nuts

(3) and remove the window mechanism

from the door through the opening.

Installing the electrically operated window

mechanism

1. Fit the window mechanism in the door and

fit the attachment bolts (2) and attachment

nuts (3).

2. Connect the electric motor connector (4).

3. Lower the window and attach the window

mechanism to the door using the

attachment bolts (2).

4. Operate the window switch.

Close the window until nearly shut.

Check that the top edge of the window is

parallel with the window frame.

Loosen the attachment bolts (2), if

necessary.

Move the window to the correct position and

re-tighten the attachment bolts.

45

2

3

3

2

1

K1 00 974

5. Fit the door screen.

6. Install the door panel.

ǹ 0210

4-29

Page 66

2

INTERNAL CAB COMPONENTS

1

Removal and installation LF45/55 series

4.10 REMOVAL AND INSTALLATION, ROOF CONSOLE

Removing the roof console

1. Remove the top lighting attachment bolts

from the outside of the vehicle and put the

lighting aside.

2. Remove the top lighting connector.

3. Remove the wiring covers in the roof

console.

4. Remove the interior lighting connector.

5. Remove the loudspeaker and its connector.

6. Remove the wiring harness from the roof

console.

7. Remove the attachment bolts (2) from the

roof console in the window frame.

8. Remove the covers (1) at the front and

remove the attachments bolts behind these

covers.

9. Remove the roof console.

Installing the roof console

1. Put the roof console in place and position it

using a few attachment bolts.

2. Place the attachment bolts at the front of

the roof console and tighten them.

3. Fit the connectors for the interior lighting,

loudspeaker and top lighting.

4. Fit the attachment bolts (2) in the window

frame.

5. Secure the top lighting with the attachment

bolts.

6. Fit the covers (1).

1

2

K1 01 123

4-30

ǹ 0210

Page 67

1

INTERNAL CAB COMPONENTS

LF45/55 series Removal and installation

4.11 REMOVAL AND INSTALLATION, INTERIOR LIGHTING

Removing the interior ceiling lighting

1. Put a screwdriver between the glass cover

(1) and the holder (2).

2. Remove the glass cover (1).

3. Bend the lock levers (B) inwards.

4. Unplug the connectors and remove the

lamp holder.

Fitting the interior ceiling lighting

1. Bend the lock levers (B) outwards.

2. Hook up the connectors and fit the lamp

holder (2).

3. Fit the glass cover (1).

2

1

2

K1 01 169

B

K1 00 617

4.12 REMOVAL AND INSTALLATION, IGNITION LOCK

Removing the ignition lock

1. Remove the covers around the steering

column under the steering wheel.

2. Disconnect the connectors (behind the

dashboard).

3. Drill off the head of the security bolt, use a

bit with the same diameter as the hole

where the head falls and remove the

ignition lock.

Installing the ignition lock

1. Install the ignition lock.

2. Tighten the security bolts with such a

tightening torque that the heads break off.

3. Fit the covers around the steering column.

K1 01 134

ǹ 0210

4-31

Page 68

2

INTERNAL CAB COMPONENTS

1

Removal and installation LF45/55 series

4.13 REMOVAL AND INSTALLATION, COMPLETE DOOR LOCK MECHANISM

Removing the complete door lock

mechanism

1. Close the window.

2. Remove the door panel.

K1 01 408

3. Gently remove the plastic screen (1) from

the door.

4. Remove the attachment bolts (6) from the

closing mechanism.

5. Remove the attachment bolts (5) from the

door lock mechanism.

6. Remove the plug (4) from the central door

locking mechanism.

7. Remove the clamping strips (3) holding in

place the main wiring harness (2) and the

wiring harness of the central door locking

mechanism.

8. Lay the main wiring harness (2) aside

9. Remove the control rod by loosening the

control rod locking (1) through tilting and

unhooking the control rod from the locking.

10. Unhook the door lock mechanism from the

door and allow it to be lowered together with

the door locking

11. Remove the attachment bolts (3) from the

door lock mechanism.

6

5

1

2

3

4

K1 01 439

1

4-32

3

2

K1 01 124

ǹ 0210

Page 69

1

INTERNAL CAB COMPONENTS

LF45/55 series Removal and installation

12. Remove the complete door lock mechanism

from the outside.

13. Remove the closing mechanism together

with the motor of the central door locking

from the inside of the door.

K1 01 171

Fitting the complete door lock mechanism

1. Fit the closing mechanism in the door.

2. Hook the control cable (3) in the door lock

mechanism.

2

3. Position the door lock mechanism in the

door.

4. Hook the control rod in the locking (1) of the

operating lever. Lock the control rod by

clicking the locking (1) in place over the

control rod.

5. Fit the attachment bolts (6) of the closing

mechanism.

6. Fit the attachment bolts (5) of the door lock

mechanism.

7. Fit the plug (4).

8. Secure the main wiring harness (2), the

wiring harness of the central door locking

and the plug (4) to the threaded ends at the

inside of the door, using clamping strips.

1

3

2

K1 01 124

6

1

5

2

3

4

9. Fit the door screen (1).

10. Install the door panel.

ǹ 0210

K1 01 439

4-33

Page 70

INTERNAL CAB COMPONENTS

1

Removal and installation LF45/55 series

4.14 REMOVAL AND INSTALLATION, DOOR LOCK CYLINDER

Removing the door lock cylinder

1. Remove the complete door lock

mechanism.

2

2. Remove the circlip (3).

3. Detach the operating lever (4).

4. Loosen the locking spring (1) and remove

the door lock cylinder (2).

Fitting the door lock cylinder

1. Fit the door lock cylinder (2). Fit the locking

spring (1).

2. Fit the operating lever (4).

3. Fit the locking ring (3).

4. Fit the complete door lock mechanism.

123 4

4.15 REMOVAL AND INSTALLATION, ENGINE BRAKE SWITCH

Removing the engine brake switch

1. Remove the covers from the steering

column.

2. Remove the engine brake switch connector

from the connector holder next to the

steering column.

K1 01 440

3. Remove the attachment bolts (1) from the

engine brake switch.

4. Remove the engine brake switch (2).

Installing the engine brake switch

1. Fit the engine brake switch (2).

2. Secure the attachment bolts (1).

3. Fit the connector.

4. Fit the steering column covers.

2

1

K1 01 164

4-34

ǹ 0210

Page 71

1

INTERNAL CAB COMPONENTS

LF45/55 series Removal and installation

4.16 REMOVAL AND INSTALLATION, REAR WALL LINING

Removing the rear wall lining

Note:

When working on the upholstery make sure

hands are clean or wear gloves.

1. Remove the panel clips on the rear wall of

the cab.

2. If applicable, remove the thermostat and

clock from their casing using a small

screwdriver.

3. Remove the rear wall supports.

4. Remove the (entrance) grip.

5. Remove the rear wall lining. Pay attention

to the connectors for the cab heater sensor

and lighting.

Installing the rear wall lining

1. Fit the rear wall using the panel clips. Pay

attention to the connectors for the cab

heater sensor and lighting.

2. Fit the (entrance) grip.

3. Fit the supports to the rear wall.

4. Fit the thermostat and clock if applicable.

2

ǹ 0210

4-35

Page 72

INTERNAL CAB COMPONENTS

1

Removal and installation LF45/55 series

4.17 REMOVAL AND INSTALLATION, ROOF LINING

Removing the roof lining

1. Remove the dashboard.

2. Remove the steering wheel.

Note:

When working on the upholstery make sure

hands are clean or wear gloves.

2

3. Remove the roof console.

4. Remove the rear window cover, if

applicable.

5. Remove the panel clips from the roof lining.

6. Remove the cover panels from the A-pillar.

7. Partially remove the door rubbers.

8. Remove the entrance grips if the vehicle

has a sleeper cab.

9. Remove the connectors from the roof

console lighting.

Installing the roof lining

1. Fit the roof lining from the co-driver’s side.

2. Fit the lighting connectors. Fit the roof

console.

3. Fit the entrance grips.

4. Fit the door rubbers.

5. Fit the panel clips.

6. Fit the rear window cover.

7. Fit the cover panels in the A-pillar.

8. Fit the steering wheel.

9. Fit the dashboard.

4-36

ǹ 0210

Page 73

1

INTERNAL CAB COMPONENTS

LF45/55 series Removal and installation

4.18 REMOVAL AND INSTALLATION, SIDE WALL LINING

Removing the side wall lining

Note:

When working on the upholstery make sure

hands are clean or wear gloves.

1. Remove the caps from the door pillar.

2. Remove the steel plates that are fixed to the

rear wall.

3. If the vehicle has a sleeper cab, the storage

trays under the bed need to be removed.

4. Remove the panel clips and the side wall

lining.

Installing the side wall lining

1. Fit the side wall lining using the panel clips.

2. If applicable, fit the storage trays.

2

3. Fit the steel panels to the side walls.

4. Fit the covers in the door pillar.

4.19 REMOVAL AND INSTALLATION, STORAGE TRAYS (SLEEPER CAB)

Removing the storage trays

1. Remove the wooden bed base.

2. Remove the rear wall panel and the side

panels.

3. Remove the attachment bolts in the bottom

of the storage trays.

4. Remove the storage tray.

Installing the storage trays

1. Put the storage trays in place.

2. Fit the attachment bolts in the bottom of the

storage trays.

3. Fit the rear wall panels and the side panels.

4. Fit the wooden cover.

ǹ 0210

4-37

Page 74

2

INTERNAL CAB COMPONENTS

Removal and installation LF45/55 series

1

4-38

ǹ 0210

Page 75

1

LF45/55 series Contents

CAB HEATING

CONTENTS

Page Date

1. SAFETY INSTRUCTIONS 1-1 0210............................................... ......

2. GENERAL 2-1 0210............................................................ ......

2.1 System description of heater, heater control 2-1 0210.......................... ......

3. REMOVAL AND INSTALLATION 3-1 0210........................................ ......

3.1 Removal and installation, interior filter 3-1 0210............................... ......

3.2 Removal and installation, heater unit 3-2 0210................................ ......

3.3 Removal and installation, heater control panel 3-8 0210........................ ......

3.4 Removal and installation, heater motor 3-10 0210.............................. .....

3.5 Removal and installation, series resistor 3-13 0210............................. .....

3.6 Removal and installation, heater radiator 3-15 0210............................. .....

3

ǹ 0210

1

Page 76

3

1CAB HEATING

Contents LF45/55 series

2

ǹ 0210

Page 77

1

LF45/55 series Safety instructions

CAB HEATING

1. SAFETY INSTRUCTIONS

The air conditioning system may

only be opened and filled by a

specialist. Furthermore, many

countries require official

certification to carry out such

activities.

3

ǹ 0210

1-1

Page 78

3

1CAB HEATING

Safety instructions LF45/55 series

1-2

ǹ 0210

Page 79

1

CAB HEATING

LF45/55 series General

2. GENERAL

2.1 SYSTEM DESCRIPTION OF HEATER, HEATER CONTROL

The heater is installed in the central console as

a complete unit.

The unit contains all control valves, control

handles and switches needed for ventilation and

heating.

There are two models:

- heating/ventilation system

- heating/ventilation system combined with

air conditioning.

The control panel has three rotary knobs.

Knob 1

Five-position switch to control fan speed.

Three-position switch to control fan speed with

recirculation.

Knob 2

Air outlets in the cab.

0 = 0-position

A = windscreen (defroster)

B = windscreen and leg area

C=legarea

D = leg area and dashboard

E = dashboard

3

K1 01 197

AB

C

ǹ 0210

E

D

K1 01 195

2-1

Page 80

3

1CAB HEATING

General LF45/55 series

Knob 3

Temperature control: offers a continuously

variable supply of hot air from 0 to 100%.

K1 01 196

Air distribution

Optimal air distribution in the cab can be

achieved by means of knob 2 in combination

with the rotating and adjustable vents on the

central console and at the sides of the

dashboard.

2-2

ǹ 0210

Page 81

1

CAB HEATING

LF45/55 series Removal and installation

3. REMOVAL AND INSTALLATION

3.1 REMOVAL AND INSTALLATION, INTERIOR FILTER

Removing the interior filter

1. Open the cab grille.

2. Remove the attachment bolts (1) from the

grille on the underside of the filter casing.

3. Open the grille (2) and remove the interior

filter.

Installing the interior filter

1. Fit the interior filter, close the grille (2) and

fit the attachment bolts (1).

2. Close the cab grille.

2

1

K1 01 147

3

ǹ 0210

3-1

Page 82

CAB HEATING

1

Removal and installation LF45/55 series

3.2 REMOVAL AND INSTALLATION, HEATER UNIT

Removing the heater unit

1. Take the cover panel out of the window

frame.

2. Remove all dashboard panels on the

underside.

3. Remove the upper cover panel.

4. Remove the dashboard panels on the

co-driver’s side. Remove the garnish

moulding around the instrument panel.

3

5. Remove the attachment bolts from the

mounting plate at the front of the heater.

Remove the mounting plate and the upper

attachment bolts.

6. Take the heater control out of the radio

panel and place it on the left-hand side of

the heater.

7. Remove the heater unit connectors.

8. Remove the heater unit air ducts.

K1 00 950

9. Remove the upper attachment bolts from

the heater unit.

3-2

K1 00 951

ǹ 0210

Page 83

1

CAB HEATING

LF45/55 series Removal and installation

10. Remove the interior filter casing attachment

bolts (1) and remove the interior filter casing

(2).

1

2

1

1

11. Remove the attachment bolts from heater

unit (1).

12. Partially drain the coolant.

13. Remove the heater hoses (2).

14. Remove the cover (2) at the front by

pressing the retainers (1) aside.

K1 01 194

2

1

K1 01 175

3

2

ǹ 0210

11

K100989

3-3

Page 84

CAB HEATING

1

Removal and installation LF45/55 series

3

15. Remove the connectors (1), press the

retainers (2) inwards and push the holder

complete with connectors inside.

Note:

If the vehicle has air conditioning fitted, any

work on the air conditioning must be done

by a qualified person.

16. If relevant, empty the air conditioning unit.

17. Remove the air conditioning pipes.

18. Remove the coolant hoses and seal the

openings on the heater unit to prevent the

coolant spilling out into the cab.

2

1

K1 00 990

19. Remove the heater unit.

3-4

ǹ 0210

Page 85

1

CAB HEATING

LF45/55 series Removal and installation

Installing the heater unit

1. Fit the heater unit. Push the holder for the

connectors into the scuttle.

2. Fit the attachment bolts (1) and the heater

hoses (2).

3. Fit the interior filter casing (2). Secure it with

the attachment bolts (1).

2

1

3

K1 01 175

1

1

1

2

K1 01 194

4. Connect the air conditioning pipes.

5. Fit the heater unit air ducts.

ǹ 0210

3-5

Page 86

CAB HEATING

1

Removal and installation LF45/55 series

3

6. Fit the connector holder via the inside. Push

it into the retainers (2).

7. Fit the connectors (1).

8. Tighten the upper attachment bolts.

2

1

K1 00 990

9. Tighten the attachment bolts at the front.

K1 00 951

K1 00 950

3-6

ǹ 0210

Page 87

1

LF45/55 series Removal and installation

10. Fit the heater control in the radio panel. Fit

the garnish moulding around the instrument

panel.

11. Re-install all removed dashboard panels.

12. Top up the cooling system.

13. Fill the air conditioning unit, if necessary.

CAB HEATING

3

ǹ 0210

3-7

Page 88

3

CAB HEATING

1

Removal and installation LF45/55 series

3.3 REMOVAL AND INSTALLATION, HEATER CONTROL PANEL

Removing the heater control panel

1. Remove instrument panel cover panel.

2. Remove the control panel from the radio

panel by pushing the right and left clips out.

12 3

3. Put the selection knob (1) in the windscreen

demister position. Mark the position of the

cable. Remove the clip and take the cable

out of the control panel.

4. Set the temperature selection knob (2) to

the hottest position. Mark the position of the

cable. Remove the clip and take the cable

out of the control panel.

5. Set the heater motor selection knob (3) to

the ”stop”-position. Mark the position of the

cable. Remove the clip and take the cable

out of the control panel.

6. If applicable, remove the connector from the

air conditioning button.

7. Remove the control panel.

K1 01 211

3-8

ǹ 0210

Page 89

1

CAB HEATING

LF45/55 series Removal and installation

Installing the heater control panel

1. If applicable, fit the connector of the air

conditioning button.

2. Fit the control cables and secure them with

the clips at the appropriate markings. Make

sure that the selection knobs are in the

correct position.

3. Fit the control panel and push it into the

retainer.

4. Fit the instrument panel cover panel and

secure it with the attachment bolts.

3

ǹ 0210

3-9

Page 90

CAB HEATING

1

Removal and installation LF45/55 series

3.4 REMOVAL AND INSTALLATION, HEATER MOTOR

Removing the heater motor

1. Remove the fire extinguisher, if applicable.

2. Remove the dashboard panel on the engine

tunnel.

3. Remove the ashtray and the ashtray holder.

Take out the cigarette lighter connector and

remove the ashtray lighting.

4. Remove the connectors from the heater

cover.

3

5. Remove the cover attachment bolts and put

the cover aside.

K1 00 953

6. Remove the connectors from the series

resistor.

If applicable, remove the connectors from

the air conditioning thermostat.

7. Remove the cover.

3-10

K1 00 954

ǹ 0210

Page 91

1

CAB HEATING

LF45/55 series Removal and installation

8. Remove the heater motor attachment bolts.

K1 00 955

9. Remove the heater motor.

3

Installing the heater motor

1. Install the heater motor and secure it with

the attachment bolts.

2. Fit the connectors to the series resistor.

ǹ 0210

K1 00 956

3-11

Page 92

3

CAB HEATING

Removal and installation LF45/55 series

3. If applicable, fit the connectors to the air

conditioning thermostat.

4. Fit the cover and secure it with the

attachment screws.

5. Fit the connectors to the cover.

6. Fit the dashboard panel to the engine

tunnel.

1

3-12

ǹ 0210

Page 93

1

CAB HEATING

LF45/55 series Removal and installation

3.5 REMOVAL AND INSTALLATION, SERIES RESISTOR

Removing the series resistor.

1. Remove the fire extinguisher, if applicable.

2. Remove the dashboard panels on the

underside.

K1 01 133

3. Remove the attachment screws from the

series resistor and remove the series

resistor from the cover.

3

4. Detach the connectors from the series

resistor and remove the series resistor.

ǹ 0210

K1 00 957

K1 00 958

3-13

Page 94

3

CAB HEATING

1