DAEWOO DDQ-20L6SC Service Manual

Service Manual

TV / DVD Combination

CHASSIS : CN-090

Model : DDQ-20L6SC

S/M No. : TCN090BEF0

July. 2002

DAEWOO ELECTRONICE CO., LTD

http://svc.dwe.co.kr

MODEL DDQ-20L6

TV STANDARD NTSC-M

POWER INPUT AC 120V 60Hz

POWER CONSUMPTION 100W

TUNING RANGES Frequency Synthesizer(FS) Tuning System

TV VHF(L) : CH2-CH6

UHF(H) : CH7-CH13

UHF : CH14-CH69

CATV VHF(L) : 5A, A, B, A-5-A-1

CH2-CH6

VHF(H) : C-W+11

CH7-CH13

UHF : W+12-W+84

SOUND OUTPUT 3W + 3W

SPEAKER 8ohm 3W(NORNAL 3W, MAX 5W) x 2EA

ANTENNA INPUT IMPEDANCE 75ohm Unbalanced

AUXILIARY INPUT TERMINAL REAR PART : S-VHS

VIDEO, AUDIO(L,R)

SIDE PART : VIDEO, AUDIO(L,R)

AUXILIARY OUTPUT TERMINAL REAR PART : VIDEO, AUDIO(L,R)

COAXIAL DIGITAL AUDIO

SIDE PART : EARPHONE

INTERMEDIATE FREQUENCIES PICTURE IF CARRIER FREQUENCY : 45.75MHz

SOUND IF CARRIER FREQUENCY : 41.25MHz

COLOR SUB-CARRIER FREQUENCY : 42.17MHz

REMOTE CONTROL R-52A01

SPECIAL FUNCTION 1) 3-LANGUAGE

2) WITH CAPTION

3) CH LABEL

4) V-CHIP

5) DYNAMIC SOUND

6) SURROUND

7) WAKE-UP/OFF TIMER

8) SLEEP TIMER

9) POWER RESTORE

10) COAXIAL DIGITAL AUDIO OUT

11) EARPHONE

✔

Caution

: In this Manual, some parts can be changed for improving, their

performance without notice in the parts list. So, if you need the

latest parts information,please refer to PPL(Parts Price List) in

Service Information Center (http://svc.dwe.co.kr).

-1-

TABLE OF CONTENTS

1. SAFETY INSTRUCTION ................................................................................................................. 2

2. SPECIFICATIONS ........................................................................................................................... 4

3. CIRCUIT BLOCK DIAGRAM ........................................................................................................... 5

4. ALIGNMENT INSTRUCTIONS ........................................................................................................ 6

4-1 . REMOTE CONTROL(R-52A01) ............................................................................................. 6

4-2 . SERVICE MODE ADJUSTMENTS ......................................................................................... 8

4-3 . ASSEMBLY ADJUSTMENTS ................................................................................................. 9

5. SCHEMATIC DIAGRAM .................................................................................................................. 10

5-1 . MAIN CIRCUIT DIAGRAM ...................................................................................................... 10

5-2 . POWER CIRCUIT DIAGRAM ................................................................................................. 11

6. EXPLODED VIEW ........................................................................................................................... 12

7. ELECTRICAL PARTS LIST ............................................................................................................. 13

8. PRINTED CIRCUIT BOARD ............................................................................................................ 21

8-1 . PCB MAIN ............................................................................................................................... 21

8-2 . PCB POWER .......................................................................................................................... 22

9. IC DESCRIPTION(U-COM : I701) ................................................................................................... 23

9-1 . U-COM(I701) PIN ASSIGN ..................................................................................................... 23

9-2 . PIN DISCRIPTION .................................................................................................................. 24

10. CHIP COMPONENTS POSITION(PCB MAIN) ............................................................................. 25

11. TROUBLE SHOOTING GUIDE .....................................................................................................26

[A] TV PART

(1) NO POWER ............................................................................................................................... 28

(2) NO DEGAUSSING OPERATING ............................................................................................... 29

(3) NO SEARCHING CHANNEL ..................................................................................................... 30

(4) NO INPUTMODE CHANGE ...................................................................................................... 31

(5) NO OSD ..................................................................................................................................... 32

(6) NO REMOCON OPERATING .................................................................................................... 33

(7) NO PICTURE ............................................................................................................................. 34

(8) VERTICAL DEFLECTION PART ............................................................................................... 35

(9) PICTURE PART ......................................................................................................................... 36

(10) COLOR SIGANL PART ............................................................................................................ 37

(11) SOUND PART .......................................................................................................................... 38

[B] DVD PART

(12) NO DVD OPERATING ............................................................................................................. 39

-2-

PRODUCT SAFETY SERVICING GUIDELINES FOR COLOR TELEVISION RECEIVERS

CAUTION

: Do not attempt to modify this product in any way. Unauthorized modifications will not only void the warranty, but may lead to

your being liable for any resulting property damage or user injury.

Service work should be performed only after you are thoroughly

familiar with all of the following safety checks and servicing

guidelines. To do otherwise, increases the risk of potential hazards

and injury to the user.

SAFETY CHECKS

After the original service problem has been corrected, a check should

be made of the following:

SUBJECT : FIRE & SHOCK HAZARD

1. Be sure that all components are positioned in such a way as to

avoid possibility of adjacent component shorts. This is especially

important on those chassis which are transported to and from the

repair shop.

2. Never release a repair unless all protective devices such as insula-

tors, barriers, covers, shields, strain reliefs, and other hardware

have been reinstalled per original design.

3. Soldering must be inspected to discover possible cold solder

joints,frayed leads, damaged insulation (including A.C. cord),

solder splashes or sharp solder points. Be certain to remove all

loose foreign particals.

4. Check for physical evidence of damage or deterioration to parts

and components, and replace if necessary follow original layout,

lead length and dress.

5. No leads or components should touch a receiving tube or a resistor

rated at 1 watt or more. Lead tension around protruding metal surfaces must be avoided.

6. All critical components such as fuses, flameproof resistors, capaci-

tors, etc. must be replaced with exact factory types. Do not use

replacement components other than those specified or make

unrecommended circuit modifications.

7. After re-assembly of the set always perform an A.C. leakage test

on all exposed metallic parts of the cabinet, (the channel selector

knob, antenna terminals, handle and screws) to be sure the set is

safe to operate without danger of electrical shock. Do not use a

line isolation transformer during this test. Use an A.C. Voltmeter,

having 5000 ohms per volt or more sensitivity, in the following

manner : connect a 1500 ohm 10 watt resistor, paralleled by a 15

mfd. 150V A.C. type capacitor between a known good earth

ground (9water pipe, conduit, etc.) and the exposed metallic parts,

one at a time. Measure the A.C. voltage across the combination of

1500 ohm resistor and 0.15 MFD capacitor. Reverse the A.C. plug

and repeat A.C. voltage measurements for each exposed metallic

part. Voltage measured must not exceed 0.75 volts R.M.S. This

corresponds to 0.5 milliamp A.C. Any value exceeding this limit

constitutes a potential shock hazard and must be corrected immediately.

GRAPHIC SYMBOLS :

The lightning flash with arrowhead symbol,within

an equilateral triangle, is intended to alert the

service personnel to the presence of uninsulated “dangerous voltage” that may be of sufficienty magnitude to constitute a risk of electric

shock.

The exclamation point within an equilateral triangle is intended to alert the service personnelto

the presence of important safety informationin

service literature.

Fuse symbol is printed on pcb adjacent to the

fuse, with “RISK OF FIRE REPLACE FUSE AS

MARKED”. The symbol is explained in the service manual with the following wording or equivalent.

“CAUTION :

FOR CONTINUED PROTECTION AGAINST FIRE

HAZARD, REPLACE ONLY WITH SAME TYPE (5A, 125V)” and

“ATTENTION:

AFIN D’ASSU UNE PROTECTION PERMANENTE

CONTRE LES RISQUES D’INCENDIE, REMPLACER UNIQUEMENT PAR UN FUSIBLE DE MEME TYPE ET DE ”5A, 125V”.

SUBJECT : X-RADIATION

1. Be sure procedures and instructions to all service personnel cover

the subject of X-rays in current T.V. receivers is the picture tube.

However, this tube does not emit X-rays when the high voltage is

at the factory specified level. The proper value is given in the applicable schematic. Operation at higher voltages may cause a failure

of the picture tube or high voltage supply and, under certain circumstances, may produce radiation in excess of desirable levels.

2. Only factory specified C.R.T. anode connectors must be used.

Degaussing shields also serve as X-ray shield in color sets.

Always re-install them.

3. It is essential that the serviceman has available an accurate and

reliable high voltage meter. The calibration of the meter should be

checked perio - dically against a reference standard. Such as the

one available at your distributor.

4. When the high voltage circuitry is operating properly there is no

possibility of an X-radiation problem. Every time a color chassis is

serviced, the brightness should be run up and down while monitoring the high voltage with a meter to be certain that the high voltage

does not exceed the specified value and that it is regulating correctly. We suggest that you and your service organization review

test procedures so that voltage regulation is always checked as a

standard servicing procedure. And that the high voltage reading be

recorded on each customer’s invoice.

5. When troubleshooting and making test measurements in a receiver

with a problem of excessive high voltage, avoid being

unnecessarily

close to the picture tub eand the high voltage compartment.

Do not operate the chassis longer than is necessary to locate the

cause of excessive voltage.

6. Refer to HV, B+and Shutdown adjustment procedures described in

the appropriate schematic and diagrams(where used).

10WATT

Good earth ground,

such as the water

pipe, conduit, etc.

1500 OHM

A.C. VOLTMETER

Place this probe

on each exposed

metal part.

0.15 uF

1. SAFETY INSTRUCTION

-3-

SUBJECT : IMPLOSION

1. All direct viewed picture tubes are equipped with an integral implosion protection system, but care should be taken to avoid damage

during installation. Avoid scratching the tube. If scratched, replace

it.

2. Use only recommended factory replacement tubes.

SUBJECT : TIPS ON PROPER INSTALLATION

1. Never install any receiver in closed-in recess, cubbyhole or closely

fitting shelf space over, or close to heat duct, or in the path of

heated air flow.

2. Avoid conditions of high humidity such as : Outdoor patio installations where dew is a factor. Near steam radiators where steam

leakage is a factor, etc.

3. Avoid placement where draperies may obstruct rear venting. The

customer should also avoid the use of decorative scarves or other

coverings which might obstruct ventilation.

4. Wall and shelf mounted installations using a commercial mounting

kit, must follow the factory approved mounting instructions. A

receiver mounted to a shelf or platform must retain its original

feet(or the equivalent thickness in spacers) to provide adequate

are flow across the bottom, bolts or screws used for fasteners

must not touch and parts or wiring. Perform leakage test on customized installations.

5. Caution customers against the mounting of a receiver on sloping

shelf or a tilted position, unless the receiver is properly secured.

6. A receiver on a roll-about cart should be stable on its mounting to

the cart. Caution the customer on the hazards of trying to roll a cart

with small casters across thresholds or deep pile carpets.

7. Caution customers against the use of a cart or stand which has not

been listed by underwriters laboratories, inc. For use with their

specific model of television receiver or generically approved for

use with T.V.’s of the same or larger screen size.

PRODUCT SAFETY SERVICING GUIDELINES FOR COLOR TELEVISION RECEIVERS

-4-

2. SPECIFICATION

MODEL DDQ-20L6SC

TV STANDARD NTSC-M

POWER INPUT AC 120V 60Hz

POWER CONSUMPTION 100W

TUNING RANGES Frequency Synthesizer(FS) Tuning System

TV VHF(L) : CH2-CH6

UHF(H) : CH7-CH13

UHF : CH14-CH69

CATV VHF(L) : 5A, A, B, A-5-A-1

CH2-CH6

VHF(H) : C-W+11

CH7-CH13

UHF : W+12-W+84

SOUND OUTPUT 3W + 3W

SPEAKER 8ohm 3W(NORNAL 3W, MAX 5W) x 2EA

ANTENNA INPUT IMPEDANCE 75ohm Unbalanced

AUXILIARY INPUT TERMINAL REAR PART : S-VHS

VIDEO, AUDIO(L,R)

SIDE PART : VIDEO, AUDIO(L,R)

AUXILIARY OUTPUT TERMINAL REAR PART : VIDEO, AUDIO(L,R)

COAXIAL DIGITAL AUDIO

SIDE PART : EARPHONE

INTERMEDIATE FREQUENCIES PICTURE IF CARRIER FREQUENCY : 45.75MHz

SOUND IF CARRIER FREQUENCY : 41.25MHz

COLOR SUB-CARRIER FREQUENCY : 42.17MHz

REMOTE CONTROL R-52A01

SPECIAL FUNCTION 1) 3-LANGUAGE

2) WITH CAPTION

3) CH LABEL

4) V-CHIP

5) DYNAMIC SOUND

6) SURROUND

7) WAKE-UP/OFF TIMER

8) SLEEP TIMER

9) POWER RESTORE

10) COAXIAL DIGITAL AUDIO OUT

11) EARPHONE

-5-

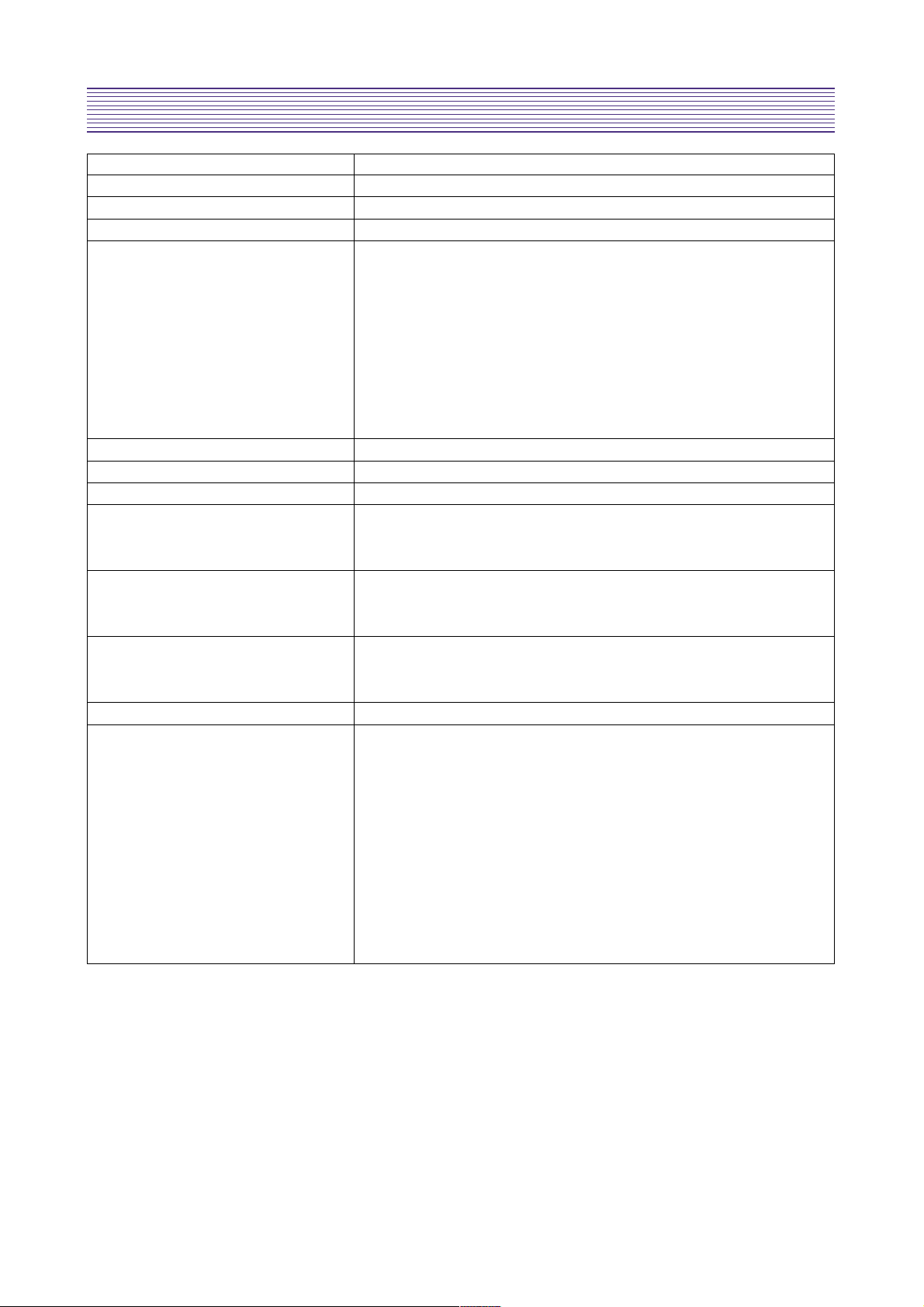

3. CIRCUIT BLOCK DIAGRAM

AA

AA

DT5

NF20FN

VV

VV

SS

SS

ee

ee

ll

ll

ee

ee

cc

cc

tt

tt

ee

ee

dd

dd

OO

OO

UU

UU

TT

TT

LL

LL

OO

OO

uu

uu

tt

tt

RR

RR

OO

OO

uu

uu

tt

tt

VV

VV

RR

RR

kk

kk

SS

SS

II

II

FF

FF

TT

TT

VV

VV

GG

GG

kk

kk

BB

BB

kk

kk

AA

AA

VV

VV

HH

HH

VV

VV

--

--

DD

DD

ii

ii

ff

ff

ff

ff

rr

rr

aa

aa

cc

cc

tt

tt

ii

ii

oo

oo

nn

nn

YY

YY

,,

,,

cc

cc

bb

bb

,,

,,

cc

cc

rr

rr

11

11

99

99

55

55

VV

VV

HH

HH

BB

BB

++

++

LL

LL

,,

,,

RR

RR

DD

DD

AA

AA

V

VV

VV

,,

,,

LL

LL

,,

,,

RR

RR

VV

VV

,,

,,

LL

LL

,,

,,

RR

RR

VV

VV

,,

,,

LL

LL

,,

,,

RR

RR

SW

YY

YY

//

//

CC

CC

ff

ff

oo

oo

rr

rr

CC

CC

NN

NN

--

--

00

00

99

99

00

00

,,

,,

AA

AA

VV

VV

22

22

II

II

nn

nn

pp

pp

uu

uu

tt

tt

,,

,,

SS

SS

--

--

VV

VV

HH

HH

SS

SS

II

II

nn

nn

pp

pp

uu

uu

tt

tt

,,

,,

MM

MM

oo

oo

nn

nn

ii

ii

tt

tt

oo

oo

rr

rr

--

--

OO

OO

uu

uu

tt

tt

,,

,,

CC

CC

oo

oo

mm

mm

pp

pp

oo

oo

nn

nn

ee

ee

nn

nn

tt

tt

DD

DD

VV

VV

DD

DD

::

::

MM

MM

ii

ii

dd

dd

dd

dd

ll

ll

ee

ee

LL

LL

ee

ee

vv

vv

ee

ee

ll

ll

SS

SS

yy

yy

ss

ss

tt

tt

ee

ee

mm

mm

((

((

LL

LL

AA

AA

77

77

66

66

88

88

33

33

77

77

))

))

Out

AUDIO OU

OUT

120V

60Hz

V

RR

RR

2

X

2

2

C

D

S

B

F

F

LL

LL

AA

AA

77

77

66

66

88

88

33

33

77

77

2

E

S

LL

LL

CC

CC

88

88

66

66

33

33

22

22

66

66

00

00

--

--

xx

xx

xx

xx

xx

xx

1

2

2

44

44

LL

LL

CC

CC

11

11

6

6

VD Driver 10V, 5.2

MSP 8V

K

K

SS

SS

CC

CC

55

55

33

33

88

88

66

66

L

L

AA

AA

77

77

88

88

00

00

44

44

1

1

K

K

TT

TT

CC

CC

33

33

22

22

22

22

99

99

XX

XX

33

33

T

T

DD

DD

AA

AA

--

--

88

88

99

99

44

44

44

44

JJ

JJ

RR

RR

PP

PP

Y

Y

D

1

S

8

S

N

T

WW

WW

WW

WW

F

LL

LL

--

-PP

PP

SS

SS

--

-PP

PP

SS

SS

EE

EE

TT

TT

RR

RR

CC

CC

Y

Y

DD

DD

V

rr

rr

22

22

,,

,,

ee

ee

ss

TT

TT

BB

BB

FF

FF

10V to Chroma

D

11

11

YY

YY

EE

EE

KK

KK

ss

ss

ss

DD

DD

nn

nn

EE

EE

ee

ee

LL

LL

SS

SS

rr

rr

PP

PP

MM

MM

AA

AA

--

-

Monitor

-oo

oo

ii

ii

dd

dd

uu

uu

AA

AA

T

T

IIC

EE

EE

NN

NN

UU

UU

TT

TT

IF-OUT

MP

00

00

22

22

44

44

33

33

PP

PP

SS

SS

Monitor Out

MM

MM

IIC

11

11

oo

oo

tt

tt

55

55

AA

AA

AV-1

Reset

ee

ee

vv

vv

ii

ii

rr

rr

DD

DD

--

-TT

TT

RR

RR

CC

CC

TDA-9183P

MM111

In1

K

K

R,G,

Y,

OU

CVBS I

In3

SS

SS

In2

V-D

Y/C IN

MM1111X

AV-2

H-

Out

In1

SS

SS

rr

1

1

rr

ee

ee

vv

vv

ii

ii

rr

rr

DD

DD

--

-VV

VV

L

L

CVB

Y,cb,cr

In2

S-VH

IIC

F

F

II

II

//

//

aa

aa

mm

mm

oo

oo

rr

rr

hh

hh

CC

CC

rr

rr

ee

ee

vv

vv

ii

ii

rr

rr

DD

DD

--

-HH

HH

K

K

rr

rr

cc

cc

,,

,,

bb

bb

cc

cc

,,

,,

YY

YY

T

COAXIAL

Reset

DVD Ou

D-Audio

CC

CC

EE

EE

PP

PP

MM

MM

//

//

rr

rr

ee

ee

vv

vv

ii

ii

rr

rr

DD

DD

DD

DD

VV

VV

DD

DD

6

6

MM

MM

OO

OO

RR

RR

2

2

IIC

Control

V-Sync

H-Sync

CVB

IIC

IIC

Key-in

SW & ID & RES

Tuner

for FBT

33V

125V

))

))

22

22

BB

BB

55

55

44

44

44

44

44

44

--

-MM

MM

SS

SS

TT

TT

((

((

SS

SS

NN

NN

AA

AA

RR

RR

TT

TT

SS

SS

PP

PP

MM

MM

SS

SS

8V 5V 3.3V 2.5V

Indicator

Remocon-in

rr

rr

oo

oo

ss

ss

ss

ss

ee

ee

cc

cc

cc

cc

oo

oo

rr

rr

pp

pp

oo

oo

rr

rr

cc

cc

ii

ii

MM

MM

Control

Power-on

for SW/Chroma/Comb-F

Audio-AMP

6V

13

))

))

ON/OF

00

00

44

44

55

55

22

22

--

-RR

RR

MM

MM

((

((

rr

rr

ee

ee

ww

ww

oo

oo

PP

PP

CC

CC

II

II

AC-IN

VD

5V for Micom

-6-

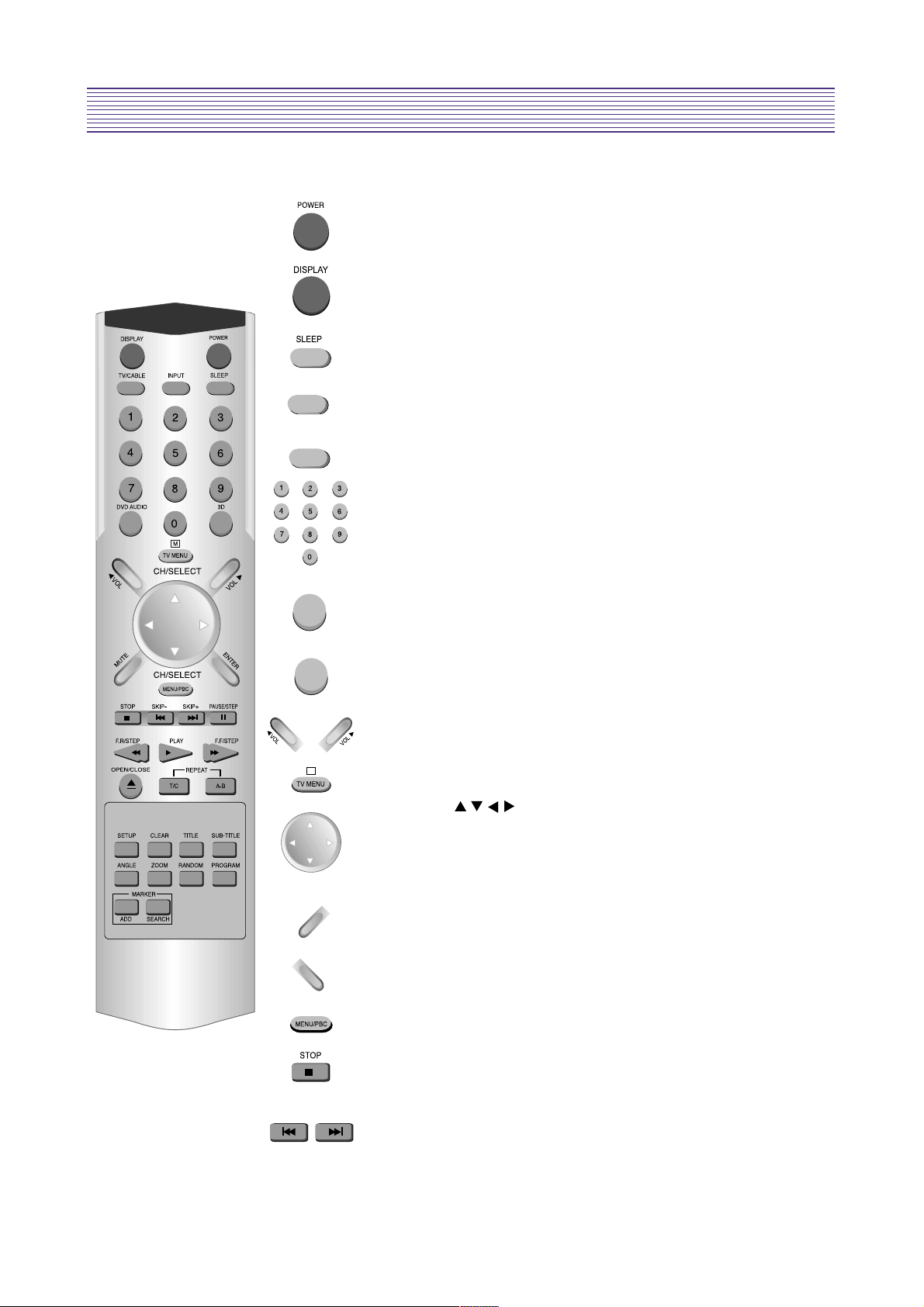

4. ALIGNMENT INSTRUCTIONS

POWER button

If you press the ON/OFF button in the front part of this

product, power is on.

DISPLAY button

Operating status and MENU are displayed in a screen.

SLEEP button

You can set automatic POWER OFF.

INPUT button

You can select input mode(TV

-

> AV1 -> AV2 -> DVD).

TV/CABLE button

You can select air or cable.

NUMBER button

You can enter the relevant number directly or select a

desired channel.

DVD AUDIO button

You can select the desired audio language.

3D button

You can select NORM or 3D surround.

VOLUME button

TV MENU button

CURSOR( ), CHANNEL SELECT button

This button functions as cursor or channel select button

in setting

TV/DVD and operating TV respectively.

MUTE button

Press this button if you only want to turn off the sound.

ENTER button

Press this button if DVD setting is completed.

MENU/PBC button

The DVD menu screen is displayed.

STOP button

SKIP BACK/SKIP FORWARD button

You can skip a screen while playing back or forward.

INPUT

TV/CABLE

DVD AUDIO

3D

M

M

U

T

E

ENTER

SKIP-SKIP+

CH/SELECT

CH/SELECT

4-1. REMOTE CONTROL (R-52A01)

-7-

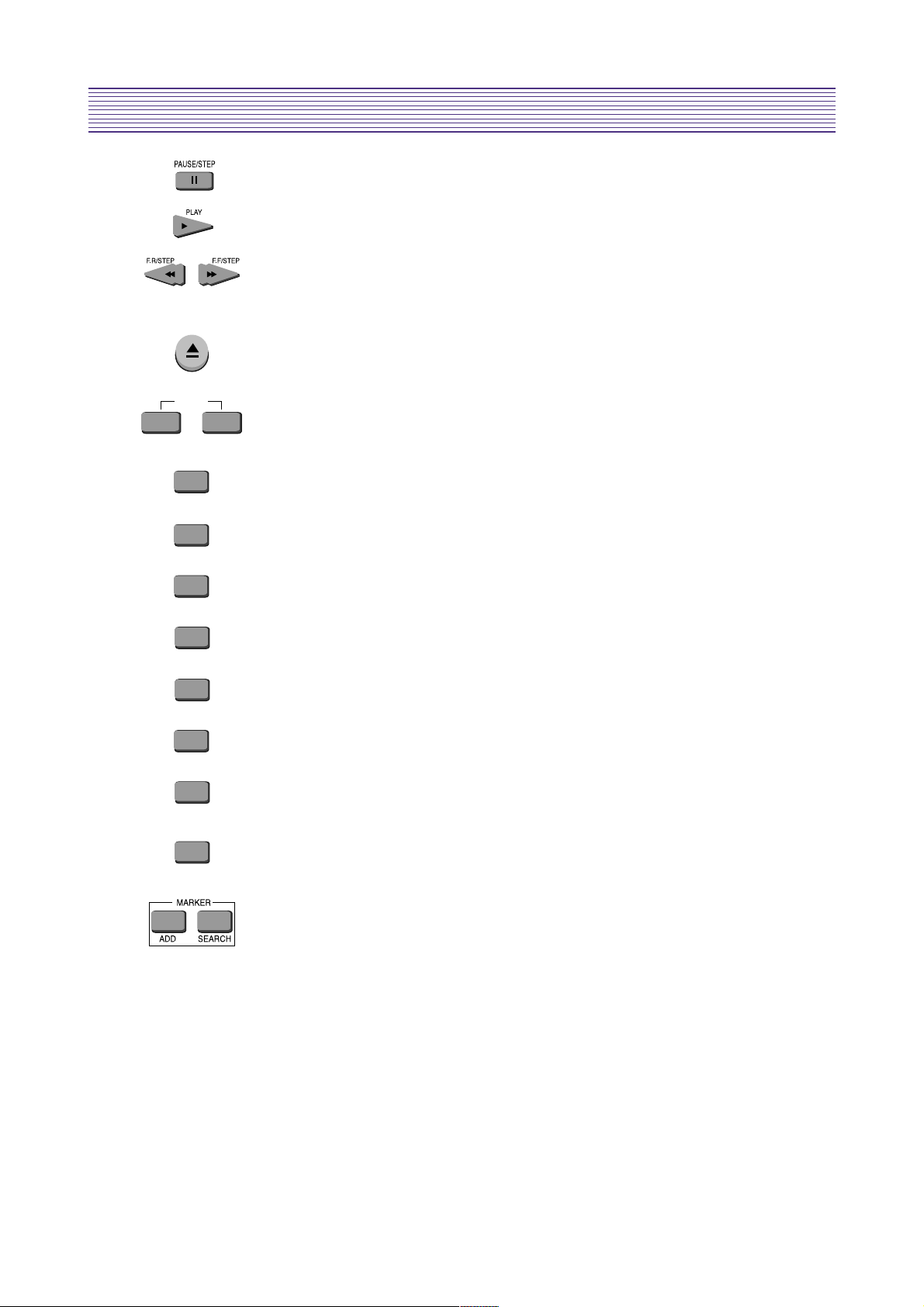

ALIGNMENT INSTRUCTIONS

OPEN/CLOSE

REPEAT

T/C A-B

SETUP

CLEAR

TITLE

SUB-TITLE

ANGLE

ZOOM

RANDOM

PROGRAM

PAUSE/STEP button

Pause screen and step screen are displayed while playing and pausing

respectively.

PLAY button

F.R/STEP or F.F/STEP button

You can search screen while playing back or forward.

DISC TRAY OPEN/CLOSE button

T/C button

You move into REPEAT mode whenever you press this button.

A-B button

You can play the given sections repeatedly.

SETUP button

You can set the DVD player.

CLEAR button

You can clear settings.

TITLE button

You can select the desired title.

SUBTITLE button

You can select the desired subtitle language.

Angle button

You can select the desired screen angle.

ZOOM button

You can zoom in a screen.

RANDOM button

You can play and CD randomly.

PROGRAM button

You can program the desired playing order.

ADD button

You can mark the desired scene.

SEARCH button

You can reach the marked scene.

This button functions as a Marker Search button in DVD.

-8-

ALIGNMENT INSTRUCTIONS

Follow the steps below whenever service adjustment is required.

1) How to enter the service mode using the user remote control

-. Turn the set on.

-. Direct the remote control to the reception window of TV.

-. Push buttons of remote control in sequence as follows.

1 ——> MUTE ——> DISPLAY ——> MUTE

-. Then, the screen will appear as follows.

S2 SCRN

S5 IFC

S6 GEO

S8 W/B

S9 DP

S12 FACT

S7 PTRN

-. Using the channel up or down button, select the item you wish to adjust.

(The color of selected item turns into the red.)

-. Press “ “ button to enter in the service mode you wish to adjust.”

2) How to memorize the adjusted values in the service mode.

-. Must press DISPLAY button the state which the screen is displaying each of

menusafter all adjustments are completed each of all service menu.

4-2. SERVICE MODE ADJUSTMENTS

-9-

ALIGNMENT INSTRUCTIONS

1) SCREEN ADJUSTMENT(S2)

-. Enter the service mode and select service adjustment S2.

-. You can see the one horizontal line on the screen.

-. Adjust the Screen Control Volume(located on FBT)

so that the horizontal line onscreen may be disappeared.

-. Press S2 button again to make the screen normal condition.

< CAUTION >

IN THE SCREEN ADJUSTMENT MODE,

DON’T PRESS OTHER BUTTONS EXCEPT S2 BUTTON.

2) FOCUS ADJUSTMENT

-. Turn in a local station and adjust the Focus Control knob (located on FBT)

for best picture details at high light condition.

3) RF AGC ADJUSTMENT(S5)

-. Enter the service mode and select service adjustment S5.

-. Receive the RF 100% full color bar 60dBuV attenuation signal.

-. Start RF AGC Adj.Start using Service Remocon S5.

-. Check for RF AGC Adj. OK OSD.

-. Press the DISPLAY button to memorize the data.

4) GEOMETRIC ADJUSTMENTS(S6)

-. Enter the service mode and select service adjustment S6.

4-1). Horizontal Position Adjustment

Select H-CENTER item, adjust H-CENTER data value to obtain proper

horizontal centering of the internal cross pattern at the left and right of

the screen.

4-2). Vertical Position Adjustment

Select V-CENTER item, adjust V-CENTER data value to center the raster

properly on the screen.

4-3). Vertical Size Adjustment

“Select “”V.SIZE”” item, adjust “”V.SIZE”” data value to proper vertical size. “

-. Press the DISPLAY button to memorize the data.

5) WHITE BALANCE ADJUSTMENT(S8)

-. Receive a good local channel.

-. Enter the service mode and select service adjustment S8.

-. Using button, adjust service adjustment data of RD/GD/BD and

RB/GB/BB until a good gray scale with normal whites is obtained.

-. Press the DISPLAY button to memorize the data.

6) DIGITAL PRESET(D.P) ADJUSTMENTS(S9)

-. Receive a good local channel.

-. Enter the service mode and select service adjustment S9.

-. Select SUB BRIGHT item,

adjust SUB BRIGHT data value to obtain normal brightness level.

-. Press the DISPLAY button to memorize the data.

7) FACTORY OUTGOING MODE(S12)

-. If you select the S12, then the set becomes factory outgoing status.

“ -. You can see the OSD “”outgoing OK””.”

4-3. ASSEMBLY ADJUSTMENTS

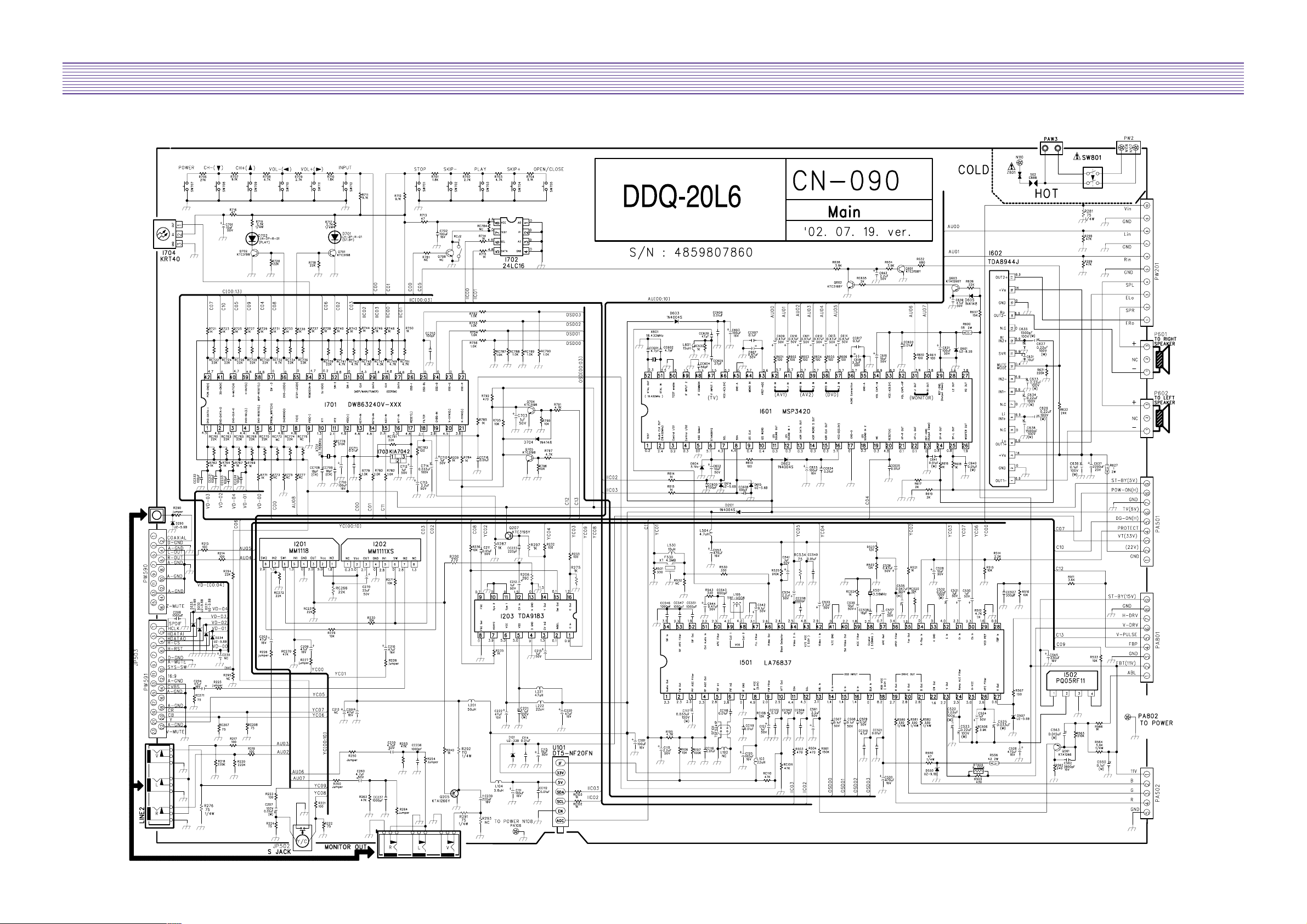

5. SCHEMATIC DIAGRAM

-10-

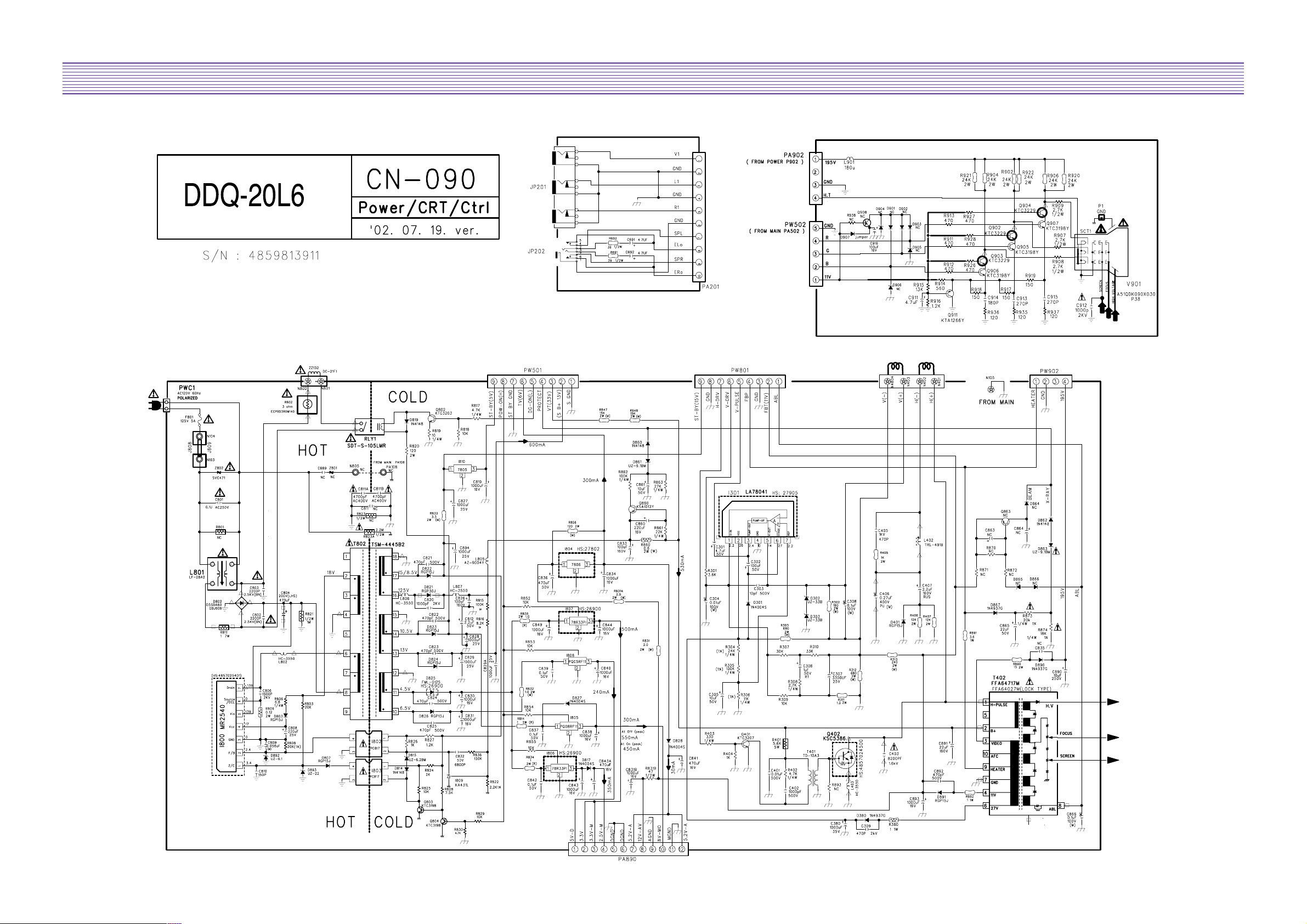

5-1 MAIN CIRCUIT DIAGRAM

SCHEMATIC DIAGRAM

-11-

5-2 POWER CIRCUIT DIAGRAM

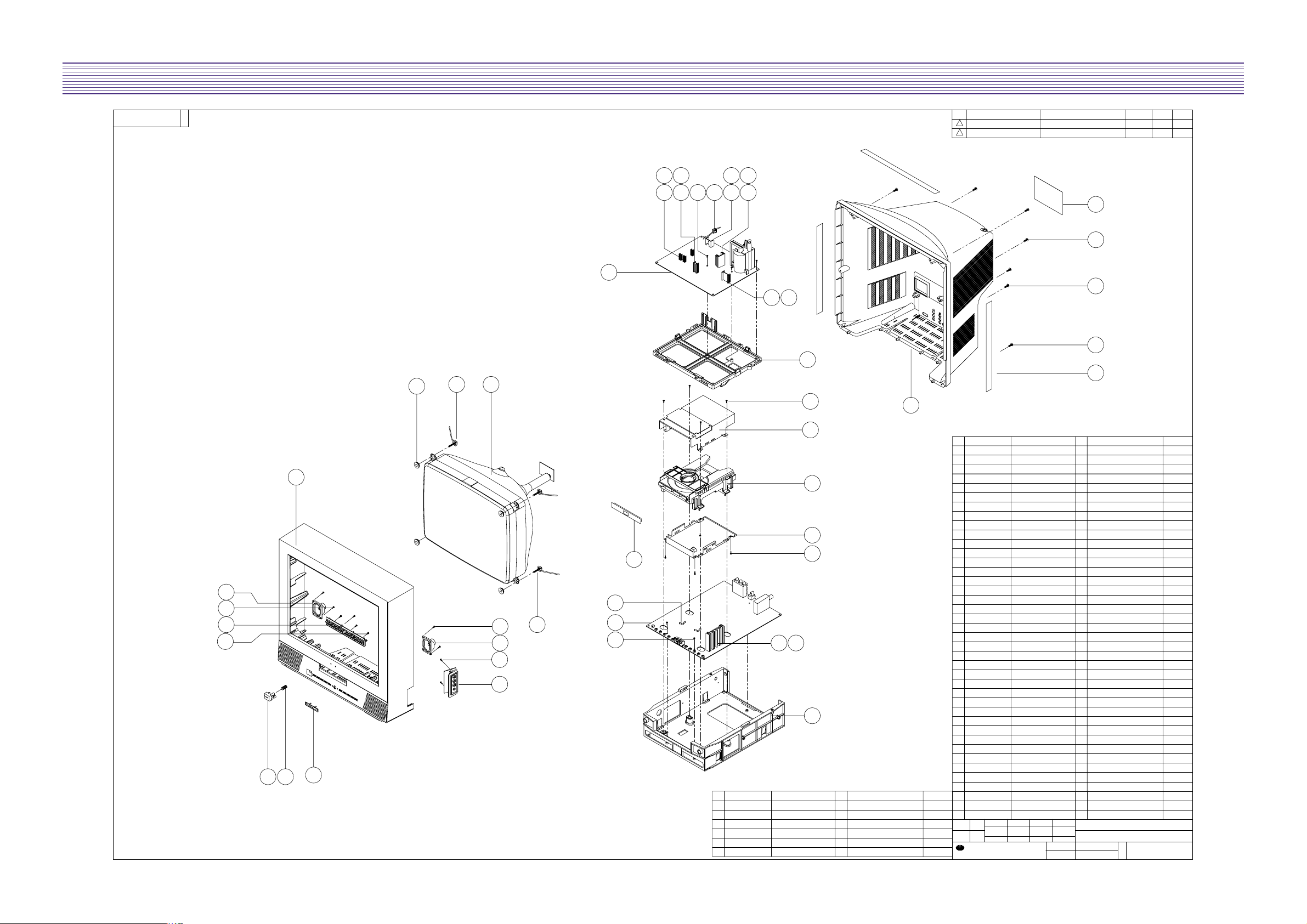

6. EXPLODED VIEW

-12-

32

485009KG

DEVELOPMENT DWG

02/02/26

MASK FRONT

4852080600

6

5

4

3

CN-090

DDQ-21L6

FR HIPS GY

1

19

17

16

10

12

13

14

15

11

9

7

8

18

31

24

20

22

23

21

30

29

25

27

26

28

36

34

35

33

485009KG

1

13

12

14

11

17

16

24

6 7

20

21

9

10

25

37

333834

39

46

40

44

27

28

30 32

29 31 353637

38

39 40

FELT 300X20X0.7

3

CLOTH BLACK

4857817610

7172401612

4852161400

45

44

42

43

41

SCREW TAPPTITE

COVER BACK

TT2 TRS 4X16 MFZN BK

1

1

FR HIPS GY

1

47

46

1918

15

2

2

3

4

5

22

23

26

43

41

3

8

K.G.S

4858304920

SPEAKER

2

SP-50110F03

TT2 WAS 3X10 MFZN

2

SCREW TAPPTITE

7178301011

BUTTON CH AS

4851948000

1

49522+55465

TT2 WAS 3X10 MFZN

4

SCREW TAPPTITE

7178301011

BUTTON POWER

4854862001

ABS GY

1

SPRING

4856716000

SWPA PIE0.5

1

MARK BRAND

48556171SD

1

SILVER DIA-CUTTING

PANEL AV

ABS GY

1

4852328701

TT2 WAS 3X10 MFZN

2

SCREW TAPPTITE

7178301011

5X30XL=190mm YL

2

SCREW CRT FIXING AS

4856013302

WASHER RUBBER

4

CR T2.0

4856219502

5X30XL=80mm YL

2

SCREW CRT FIXING AS

4856013300

CRT(21" FLAT)

1

CABINET BOTTOM

4852221700

1

FR HIPS BK

TT2 WAS 3X8 MFZN

3

SCREW TAPPTITE

7178300811

MAIN PCB

1

330X246Xt1.6

HEAT SINK

SCREW TAPPTITE

7174301011

4857028210

1

1

TT2 RND 3X10 MFZN

AL EX

BRKT EARTH

DOOR CD AS

4851948500

4853953700

C5212P-1/2M T0.2

2823401+5800018

1

2

TT2 WAS 3X8 MFZN

4

SCREW TAPPTITE

7178300811

4857249200

SHIELD BOTTOM

ET T0.4

1

DVD AS

1

4857249100

SHIELD CASE

SECC T0.5

1

TT2 WAS 3X12 MFZN BK

4

SCREW TAPPTITE

7178301212

FRAME POWER

4853818500

1

FR HIPS BK

POWER PCB

246X197Xt1.6

1

HOLDER AC CORD

4853535500

1

NYLON66 UL/CSA

45

TT2 WAS 3X8 MFZN

1

SCREW TAPPTITE

7178300811

PART NAME

REV LIST OF MODIFICATION REASON OF MODIFICATION DATE NAME APPR

Q’ty

Daewoo Electronics CO.,LTD.

Mechanical Design Team, TV Research Center

Checked by

SCALE

UNITS

No

Designed by

N/S

PART CODE

REFERENCE

MODEL

Approved byInspected by

PART NAME

/

D

N

MATERIAL

2

1

/

D

N

2

1

REMARKS

m/m

4857026900

HEAT SINK

3

AL 6063S

TT2 RND 3X8 MFZN

AL EX

TT2 RND 3X8 MFZN

TT2 WAS 3X10 MFZN

AL EX

TT2 RND 3X10 MFZN

AL EX

1

1

1

3

1

1

3

SCREW TAPPTITE

HEAT SINK

SCREW TAPPTITE

SCREW TAPPTITE

HEAT SINK

SCREW TAPPTITE

HEAT SINK

4857024500

7174301011

4857025401

7178301011

7174300811

4857027802

7174300811

42

SCREW TAPPTITE

7174301011

1

TT2 RND 3X10 MFZN

4857027905

HEAT SINK

SCREW TAPPTITE

7174301011

TT2 RND 3X10 MFZN

1

1

AL EX

6

SCREW TAPPTITE

7172401612

TT2 TRS 4X16 MFZN BK

1+41

41+FBT

150ART P/E FILM

SPEC PLATE

4855415800

4859636166

4859007860

485AS00210

4859823911

DVD

Loading...

Loading...