Page 1

Page 2

HOW TO USE THIS MANUAL

This manual describes effective maintenance procedure

for the SL125 manufactured by DAELIM Motor Co., Ltd.

To ensure safety and optimal operating conditions of the

vehicle, carry out regular inspections according to the

maintenance schedule (Section 3).

Sections 1 through 3 provide information on overall

vehicle; section 4, assembly and disassembly procedures

for external components, and section 5 describes

maintenance procedure for the engine, frame and electrical

systems.

To facilitate use of this manual, each page starts with

disassembly and system diagrams, service information,

and troubleshooting guide. If you cannot find the cause of

trouble, refer to Section 20: Troubleshooting.

Contents of this manual and specifications are

subject to change without prior notice for

improvement of vehicle quality .

No part of this publication may be reproduced

without written permission of DAELIM Motor Co.,

Ltd.,

CONTENTS

SERVICE INFORMATION

LUBRICA TION

INSPECTIONS / ADJUSTMENTS

EXTERNAL P ARTS

FUEL SYSTEM

ENGINE REMOV AL

LH.CRANK CASE COVER / KICK ST ARTER /

CONTINUOUSL Y V ARIABLE TRANSMISSION

A.C.GENERA TOR / ST ARTER CLUTCH

CYLINDER HEAD / V ALVE

CYLINDER / PISTON

TRANSMISSION/CRANKSHAFT/CRANK CASE

FRONT WHEEL / FRONT FORK / STEERING

REAR WHEEL / BRAKE / SUSPENSION /

REAR SWING ARM

BRAKE SYSTEM

GENERAL

ENGINE

FRAME

ELECTRICAL SYSTEM

CHARGING SYSTEM / BATTERY

STARTER SYSTEM

LIGHTS/METER/SWITCHES

IGNITION SYSTEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

WIRING DIAGRAM

17

TROUBLESHOOTING

18

19

20

Page 3

1-1

1. SERVICE INFORMATION

GENERAL SAFETY

················

1-1

SERVICE RULES

····················

1-1

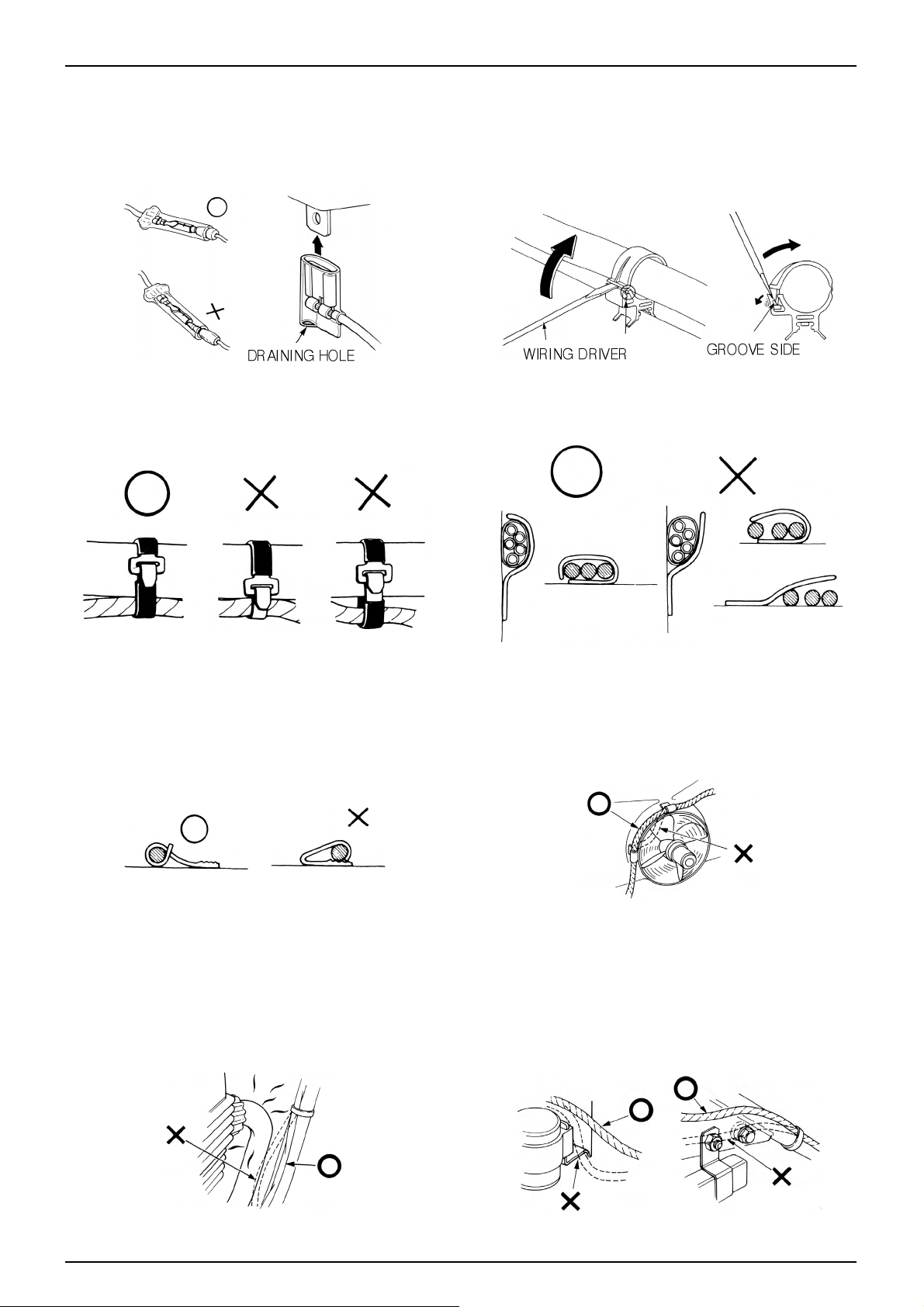

CAUTION WHEN WIRING

··········

1-5

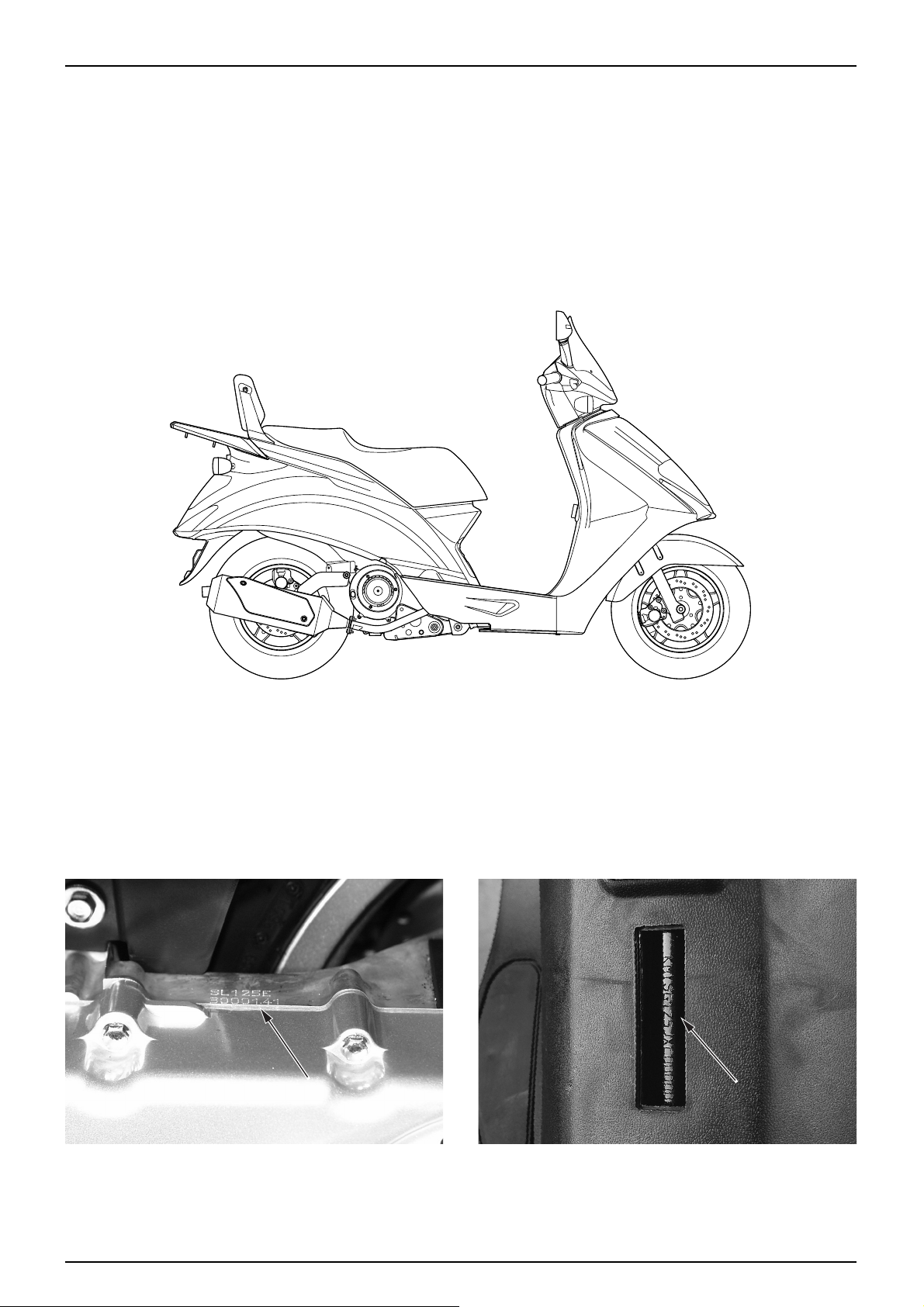

SERIAL NUMBER LOCATION

······

1-9

SPECIFICATIONS

··················

1-10

TORQUE VALUES

··················

1-12

SYMBOLS / ABBREVIATIONS

······

1-14

WIRING DIAGRAM

················

1-15

GENERAL SAFETY

WARNING

1. Do not run the engine for a long time in closed or not well-ventilated area because the exhaust gas contains toxic

substances such as carbon monoxide, hydrocarbon, nitric oxide.

2. The battery fluid(lean sulfuric acid) is extremely toxic. It is dangerous if skin is exposed to it or if it enters into the eye.

Be careful in handling. When exposed to the battery fluid, wash it with water and get a medical check up.(store the

battery fluid in a safe place to avoid touching by the children)

3. Pay attention not to be burned and always put on the protection gears because the engine or the muffler is hot right after

engine stops.

4. Gasoline is extremely flammable. Maintenance must performed in the place free of the open fire or electric spark.

5. When more than two person are working, always pay attention to other worker’s action and alway have safety in mind.

6. The skin exposed to used engine oil can be a major reason of the skin cancer. Pay attention not to exposed and wash

carefully with soap and water after handling.

7. If compressed air is used to clean the brake, dust scattered in the air can be breathed in by workers. Please take action not

to scatter dust in the brake cleaner, etc.

8. Flammable nitrogen gas is generated during charging the battery so charging must be performed in well-ventilated area

and free of the open fire and spark.

SERVICE RULES

1. Parts and lubrication oil must be DAELIM genuine or

recommended parts.

2. Before maintenance, remove deposit or dust from the

chasis.

1

Page 4

1-2

SERVICE INFORMATION

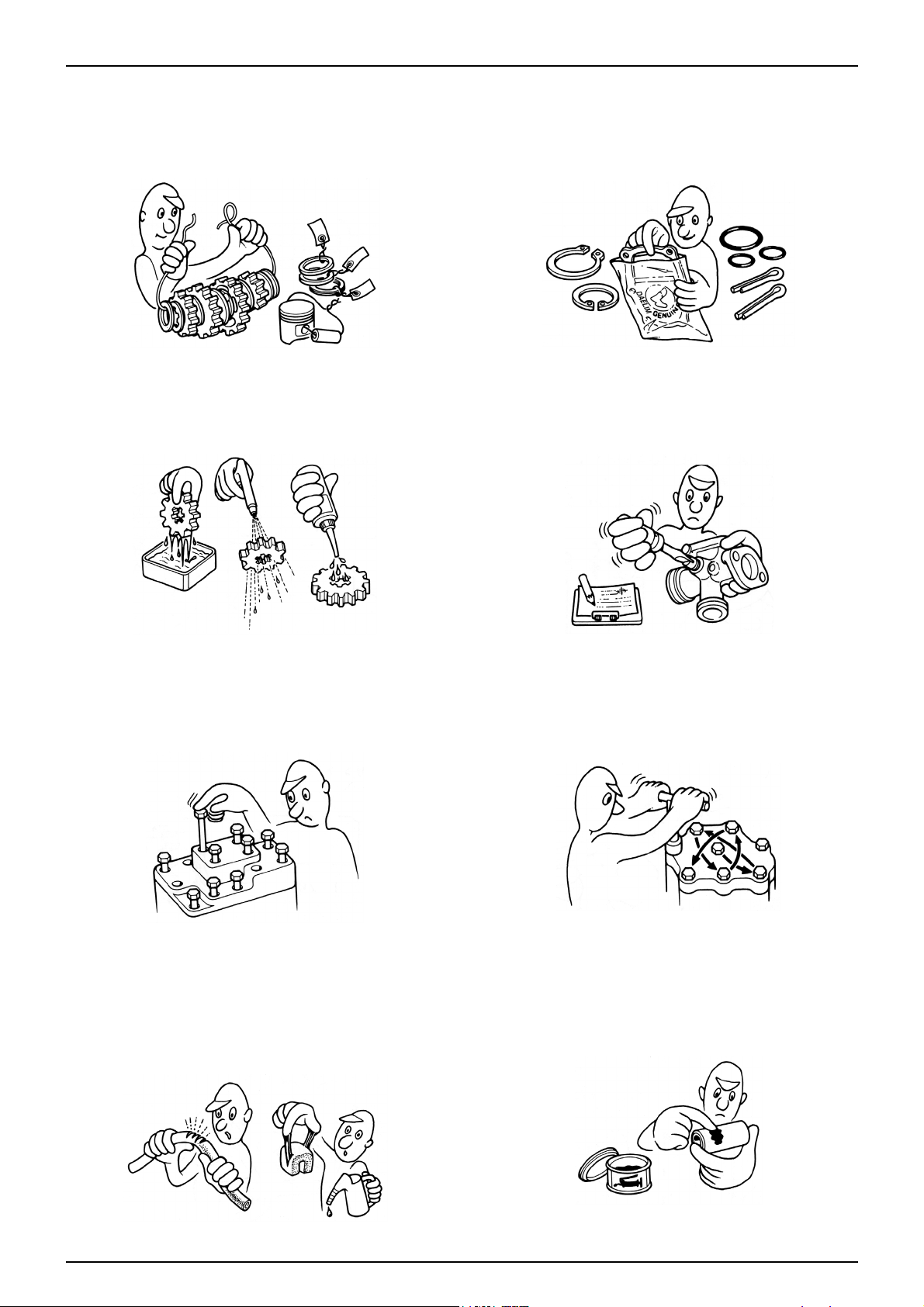

9. Check to see if the rubber part is worn out when

removing it and replace it if necessary . Some rubber part

is weak to gasoline and kerosene, so pay attention not to

soak with gasoline or oils.

10. Recommended grease must be applied to or filled in

the specified place.

7. Align the bolts to uniform the tightening points before

tightening them when you don’t know the bolt length.

8. Bolts, nuts and pieces must be tightened from the bigger

diameter to the smaller one, from inside to outside and

diagonally with the specified torque.

5. Clean the parts after the overhaul and before the test and

remove the cleaning oil with compressed air. Apply oil

to seal face during installation.

6. Check necessary place and measure necessary data

during installation. When installing, return to the state

before removing.

3. Store the parts of each system discriminatively to install

each part in the right place.

4. After removing gasket, O-ring, piston pin clip and cotter

pin, always replace them with the new one. When

removing the snap ring, it can be easily missed after

transformation or installation.

Page 5

1-3

SERVICE INFORMATION

11. Maintenance needed to use the specialized tools must

performed with the right tool.

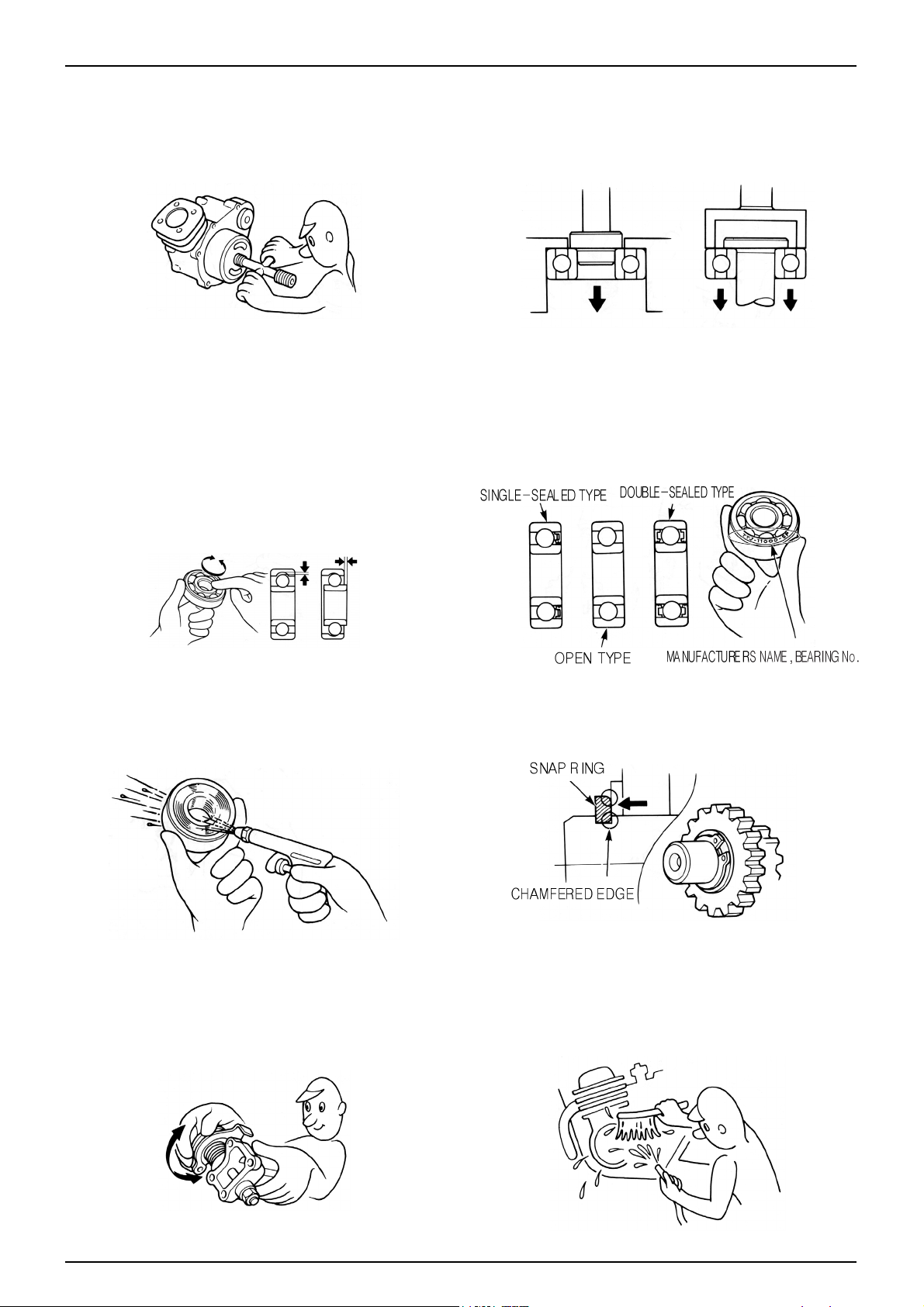

12. Never reuse the ball bearing removed with the ball

applied pressure when removing press-fitted the

bearing.

13. Check the smooth rotation of inner or outer race of the

ball bearing by rotating it manually .

• Replace the ball bearing having excessive axial/

longitudinal hanging.

•Wipe the ball bearing likely to have hanging with

cleaning oil.(except double-sided sealed type ball

bearing)

• Replace the ball bearing of which press-fitted part is

slacked at the case or shaft.

14. Pay attention to installation direction in case of the

single-sided sealed ball bearing. Install the opendirection or double-sided sealed bearing in the way

that the face marked with manufacturer and size

should direct to the outer axle.

15. When blowing the ball bearing with compressed air

after cleaning, keep the race from rotating. High speed

rotation of the race may damage the bearing. Prior to

installation, apply oil or grease to the bearing.

16. Install the snap ring so that chamfered side directs to

the load-applied side. After installation, check the

proper installation by rotating the snap ring.

17. Check each part for proper tightening and operation

after installation.

18. The brake fluid and coolant can damage the painted

plastic or rubber parts. Keep these parts from

contacting with them and wash these parts with water

in case of contact.

’

Page 6

1-4

SERVICE INFORMATION

21. Keep the pneumatic system interior or the engine

interior from the infiltration of dust.

22. Install the gasket mounted in the contact surface of

each case of the engine while removing gasket

material completely. Remove damaged contact surface

by wiping with the oil stone equally .

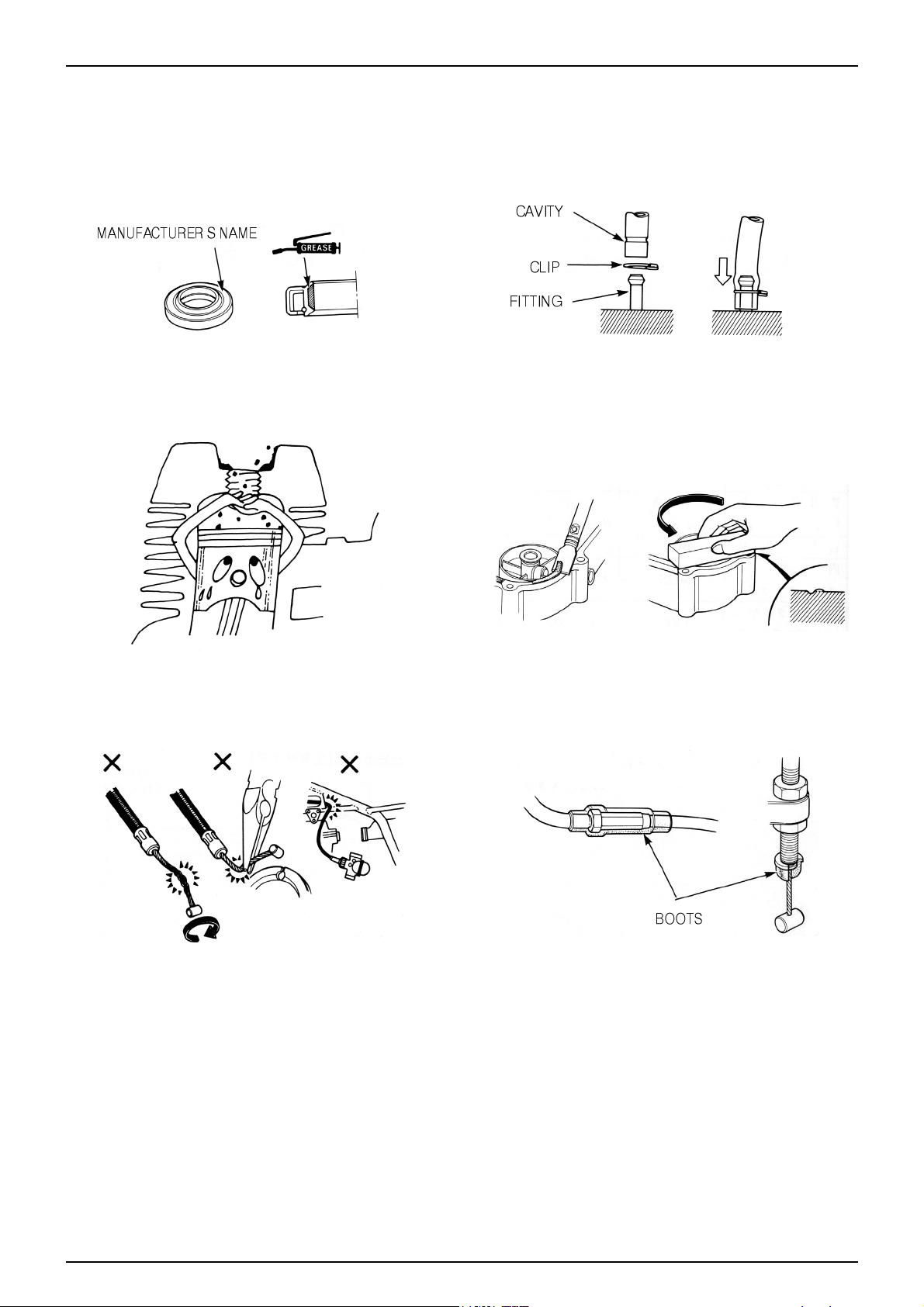

19. Install the oil seal so that the manufacturer marked

surface directs outer surface.(direction not covered

with oil)

• Pay attention not to bend or damage the lip

• Apply the grease to the lip

20. Connect the tube until the tube fully inserted in the

joint. Install the clip if it is supplied. Replace the tube

having slacked end.

23. Pay attention not to bend the cable excessively.

Transformed or damaged cable may cause malfunction

or damage.

24. Install the boots with the installing groove by inserting

the boots into the groove.

’

Page 7

1-5

SERVICE INFORMATION

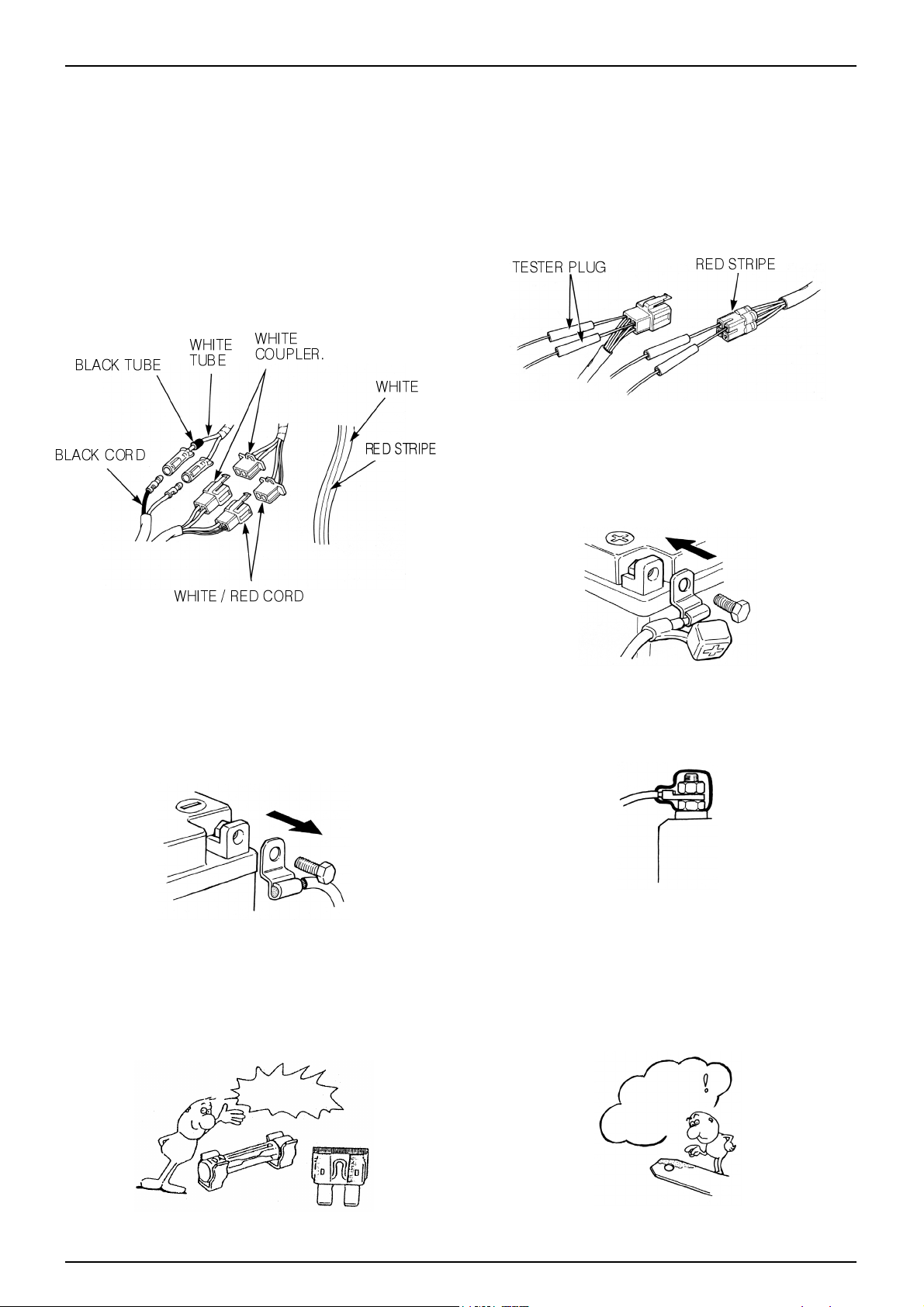

•Each cord must be connected depending on its color.

When connecting different cord, attach color tube

around the connector. Connect the coupler to the

connector with same color and same pin number .

•Identify the two-colored cord by main color first and

then spriped color .

•When measuring voltage or resistance of the cord

terminal using tester, contact the tester plug behind of

the coupler. Pay attention not to open the cord terminal

and contact the tester plug from the front of the coupler

in case of water-proof coupler.

•Recheck the condition of contact, securing and

continuity of each part after maintenance.

•When connecting the battery, the plus terminal must be

connected first.

•After connecting the terminal, apply the grease to the

terminal.

•When disconnecting the battery, the minus terminal

must be disconnected first.

•Make sure that the tool such as spanner do not contact

with the frame.

•Connect covers to the terminal after maintenance.

•If the fuse is short-circuited, find out the cause and

repair. Replace with the fuse having the specified

capacity .

•If there is rust in the terminal, remove the rust with sand

paper prior to connecting.

CAUTION WHEN WIRING

VALIDATION

OF CAPACITY!

REMOVE

THE

RUST!

Page 8

1-6

SERVICE INFORMATION

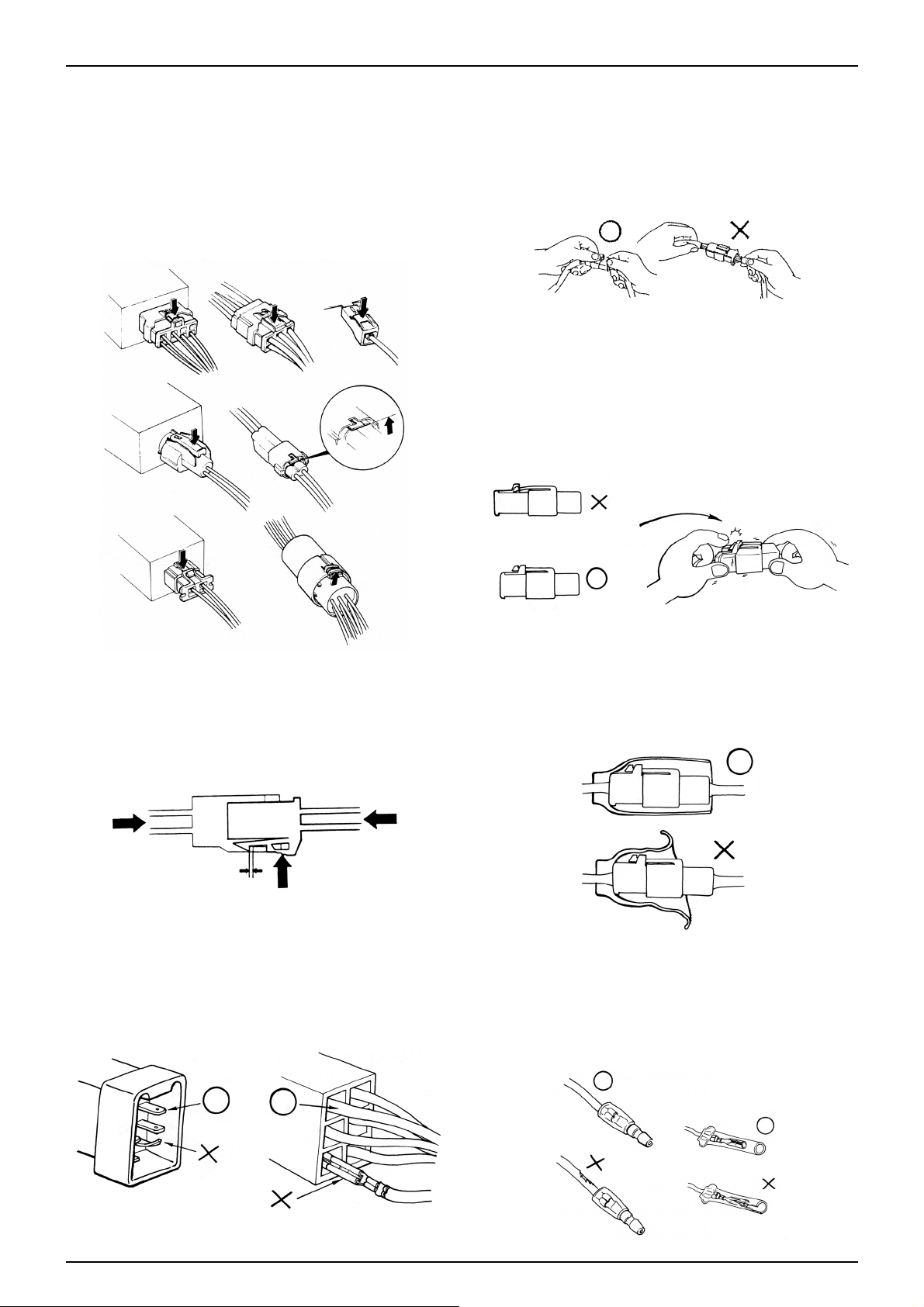

•Insert the lock of the coupler until the lock is fully

secured.

•Turn off the main switch before connecting/disconnecting.

•Release the lock to disconnect the lock of the coupler.

•The lock of the coupler has two types according to

releasing method(press type and pull type) so release it

properly according to the shape.

- Typical releasing method of the coupler is illustrated in

the following.

•When disconnecting the coupler, disconnect it while

holding the coupler body. Pull while holding the wire

harness cord and do not remove the coupler connection.

•Release the lock by inserting the coupler slightly and

then narrowing connection to remove the coupler .

•Pay attention not to damage the vinyl cover of the

coupler.

•Check to see if there is bended terminal and secure it to

avoid disconnecting.

•If the wire harness coating is damaged, repair by

winding vinyl tape or replace it.

•Prior to connecting the connector, make sure that the

cover is not damaged and the mess terminal is not

opened.

Page 9

1-7

SERVICE INFORMATION

•Wire band must be secured firmly in the specified

location of the frame. In case of aluminium band,

secure the wire harness to the coated part.

•Secure the wire harness firmly using the clamp.

•Insert the connector until the vinyl cover is fully

inserted into the terminal.

•The opening of the vinyl cover must face at the ground

direction but in case of the plain connector, the draining

opening must face at the sky direction.

•When removing T-start, broaden the groove of T-start

using the wiring driver and release the torque.

•Connect the harness and the hose to T-start and then

insert until the groove is locked.

•When removing T-start from the frame, replace it with

the new one.

•In case of the weld clamp, do not clamp in the welded

part.

•When clamping the wire harness, make sure that the

harness is not contacted with the shaft or rotating part.

•When clamping the wire, pay attention not to contact

with hot part.

•The wire harness must be routed without contacting

with the end of the lamp or any sharp edge.

•The wire harness must be routed without contacting

with the end of the bolt or the piece.

Page 10

1-8

SERVICE INFORMATION

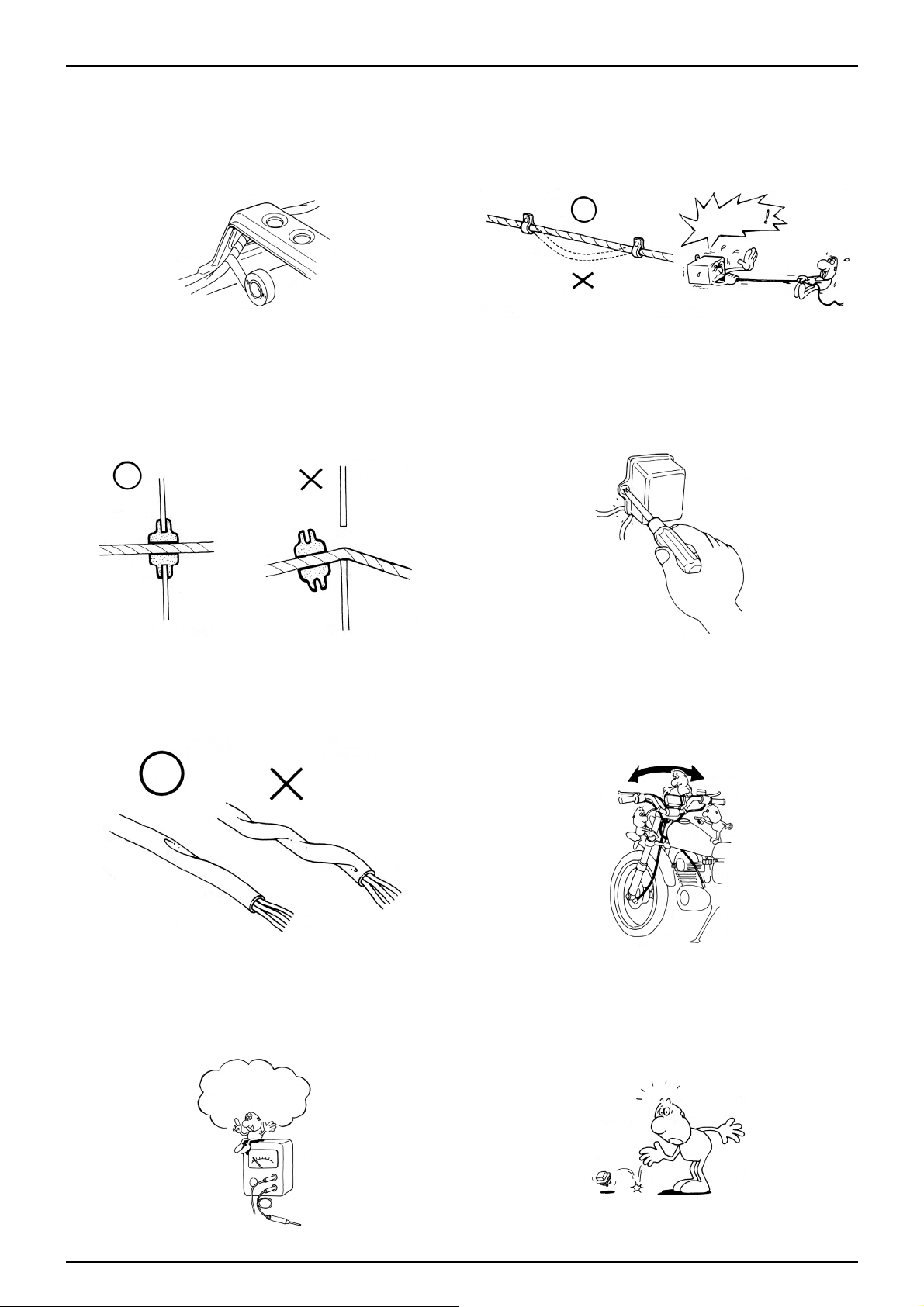

•If necessary, lock the wire harness properly . •When mounting parts, make sure that the wire harness

is not pressed by the parts.

•In case that the wire harness is contacted with the end or

the sharp edge, protect both parts with tube or tape.

•The wire must not hang down or be pulled excessively.

•Do not twist the wire harness. •Wire the wire harness not to be pulled or expanded

when the handle is turned to the right or the left

completely. Avoid excessive bending or chewing and

interference with the engine.

•Prior to using the tester, please read the manual care-

fully and understand the contents.

•When testing the resistance of the tester, the zero

adjustment must be performed before testing.

•Do not drop or throw the parts especially

semiconductor contained parts because these parts may

be damaged by the impact of the drop.

NOT TO

PULL!

Is this

measurement range or

configuration in accord

with the manual?

Page 11

1-9

SERVICE INFORMATION

SERIAL NUMBER LOCATION

ENGINE SERIAL NUMBER LOCA TION FRAME SERIAL NUMBER LOCA TION

Page 12

1-10

SERVICE INFORMATION

ITEM SPECIFICATIONS

1,965 mm

690 mm

1,230 mm

1,350 mm

780 mm

120 mm

125 kg

255 kg

Underbone

Telescopic / 77mm

Swing arm / 66mm

120 / 70 - 12 53k / Tubeless

130 / 70 - 12 62k / Tubeless

2.00 Kgf / ㎠ (200 kPa)

2.00 Kgf / ㎠ (200 kPa)

2.00 Kgf / ㎠ (200 kPa)

2.25 Kgf / ㎠ (225 kPa)

Hydraulic disk

Drum brake

8.0ℓ

1.7ℓ

25。

86 mm

90 ㎠

Oil cooled / air cooled 4 cycle SOHC engine

1(Single cylinder), front angle 80。

56

×50.7 mm

124.9 ㏄

10.8 : 1

SOHC chain drive

1.1ℓAfter disassembly

0.75ℓAfter Oil change

0.8ℓAfter Oil filter change

0.9ℓAfter Oil change with Oil in the Oil hose removed

Forced pressure splash type

Wet sump

14.0 kgf / ㎠ (550 rpm)

5。BTDC

14。ABDC

18。BBDC

1。BTDC

0.12±0.12 mm

0.12±0.12 mm

OVERALL LENGTH

OVERALL WIDTH

OVERALL HEIGHT

WHEEL BASE

SEAT HEIGHT

GROUND CLEARANCE

DRY WEIGHT

GROSS WEIGHT

TYPE

FRONT SUSPENSION / STROKE

REAR SUSPENSION / STROKE

FRONT TIRE SIZE / TYPE

REAR TIRE SIZE / TYPE

TIRE PRESSURE 1 PERSON FRONT

REAR

2 PERSON FRONT

REAR

FRONT / REAR BRAKE

PARKING BRAKE

FUEL TANK CAPACITY FULL CAPACITY

RESERVE CAPACITY

CASTER ANGLE

TRAIL

FRONT FORK OIL CAPACITY

TYPE

CYLINDERS / ARRANGEMENT

BORE AND STROKE

DISPLACEMENT

COMPRESSION RATIO

VALVE TRAIN

OIL CAPACITY

LUBRICATION SYSTEM

AIR CLEANER TYPE

CYLINDER COMPRESSION

INTAKE VALVE OPEN

CLOSED

EXHAUST VALVE CLOSED

CLOSED

VALVE CLEARANCE (COOLING-OFF PERIOD)

INTAKE

EXHAUST

DIMENSIONS

FRAME

ENGINE

SPECIFICA TIONS

Page 13

1-11

SERVICE INFORMATION

ITEM SPECIFICATIONS

CV type ( vacuum ) 24.2 mm

BDS 26 - 112

Auto-bystarter

# 95

1 and ½ trust out

13 mm

1.800±100 ( rpm )

Automatic Transmission

3.231 (42/13)

2.786 (39/14)

C.D.I Ignition

15。BTDC / 1.800 ( rpm )

12V 10A / 5,000 ( rpm )

Closed type (MF) 12V 8AH

CR8EH - 9 (NGK)

0.8 - 0.9 mm

15A

Kick / starter motor

12V 60 / 55W

12V 5W

12V 10W

×4

12V 21 / 5W

14V 3W

14V 3W

×2

12V 1.7W

×2

14V 1.4W

12V 5W

14V 3W

TYPE / VENTURI BORE

MODEL MARK

CHOKE TYPE

MAIN JET

PILOT SCREW INITIAL SETTING

FLOAT LEVEL

IDLE SPEED

CLUTCH TYPE

PRIMARY REDUCTION

SECONDARY REDUCTION

IGNITION SYSTEM

IGNITION TIMING F MARK

AC GENERATOR CAPACITY

BATTERY TYPE / CAPACITY

SPARK PLUG

SPARK PLUG GAP

FUSE CAPACITY

STARTING SYSTEM

HEADLIGHT ( HIGH / LOW )

POSITION LIGHT

WINKER LIGHTS ( FR / RR )

TAIL / STOP LIGHT

HIGH-BEAM PILOT

WINKER PILOT

METER LIGHTS

TRUNK LAMP

LICENSE LAMP

PARKING BRAKE PILOT

CARBURETOR

DRIVE TRAIN

ELECTRICAL

SYSTEM

Page 14

1-12

SERVICE INFORMATION

ITEM REFERENCETORQUE VALUE

THREAD DIA

(mm)

Q’TY

1.1 kgf·m

2.5 kgf·m

0.8 kgf·m

1.0 kgf·m

5.5 kgf·m

7.5 kgf·m

5.5 kgf·m

1.0 kgf·m

1.2 kgf·m

5.5 kgf·m

2.0 kgf·m

1.0 kgf·m

0.4 kgf·m

0.9 kgf·m

1.2 kgf·m

1.0 kgf·m

0.9 kgf·m

1.0 kgf·m

9.5 kgf·m

0.9 kgf·m

3.2 kgf·m

1.0 kgf·m

1.0 kgf·m

Apply engine oil

20

12

5

6

12

12

12

8

12

30

8

6

6

6

6

8

8

6

22

6

12

6

6

1

1

4

2

1

1

1

1

1

1

4

2

1

4

8

1

1

3

1

2

4

3

1

OIL FILTER CAP

OIL DRAIN PLUG BOLT

VALVE ADJUST SCREW LOCK NUT

CYLINDER HEAD BOLT

FLYWHEEL BOLT

DRIVE FACE NUT

CLUTCH OUTER BOLT

CAM CHAIN TENSIONER PIVOT BOLT

SPARK PLUG

DRIVE PLATE

CAM SHAFT HOLDER NUT

CAM CHAIN TENSIONER FLANGE BOLT

CAM CHAIN TENSIONER PAN SCREW

CYLINDER HEAD COVER BOLT

MISSION COVER BOLT

MISSION COVER DRAIN BOLT

MISSION COVER CHECK BOLT

COOLING FAN BOLT

STARTING CLUTCH NUT

STARTER MOTOR FLANGE BOLT

RADIATOR OIL BOLT

OIL PUMP FLAT SCREW

OIL PUMP DRIVEN GEAR NUT

TORQUE V ALUES

ENGINE

ITEM REFERENCETORQUE VALUE

THREAD DIA

(mm)

Q’TY

7.0 kgf·m

0.20 kgf·m

6.0 kgf·m

7.5 kgf·m

2.0 kgf·m

5.0~7.0 kgf·m

4.0~4.5 kgf·m

4.0~4.5 kgf·m

6.0~8.0 kgf·m

4.5 kgf·m

4.0 kgf·m

1.5 kgf·m

Initial torque

Apply locking agent

26

26

10

10

8

12

8

8

14

10

10

10

1

1

1

4

2

1

3

3

1

2

2

1

STEERING STEM NUT

STEERING TOP THREAD NUT

HANDLE POST NUT

FRONT FORK BOTTOM BRIDGE BOLT

FRONT FORK SOCKET BOLT

FRONT AXLE NUT

FRONT BRAKE DISK BOLT

REAR BRAKE DISK BOLT

REAR AXLE NUT

ENGINE HANGER NUT

MAIN STAND BOLT

SIDE STAND PIVOT BOLT

FRAME

Page 15

1-13

SERVICE INFORMATION

ITEM REFERENCETORQUE VALUE

THREAD DIA

(mm)

Q’TY

4.5 kgf·m

2.7 kgf·m

0.6 kgf·m

2.3 kgf·m

1.8 kgf·m

1.8 kgf·m

0.15 kgf·m

3.0 kgf·m

1.0 kgf·m

1.0 kgf·m

10 kgf·m

0.4 kgf·m

4.0 kgf·m

4.0 kgf·m

4.0 kgf·m

Apply locking agent

Apply locking agent

10

8

8

8

8

8

4

10

6

6

6

5

10

10

10

1

2/2

1/1

1/1

1/1

2/2

2/2

2/2

1/1

1/1

1

1

1

1

1

SIDE STAND PIVOT NUT

FRONT / REAR BRAKE CALIPER BRACKET BOLT

FRONT / REAR BRAKE CALIPER BLEEDER VALVE

FRONT / REAR BRAKE CALIPER SLIDE PIN

FRONT / REAR BRAKE CALIPER BRACKET PIN BOLT

FRONT / REAR BRAKE HANGER PIN

FRONT / REAR MASTER CYLINDER RESERVOIR CAP SCREW

FRONT / REAR BRAKE HOSE OIL BOLT

FRONT / REAR MASTER CYLINDER LEVER PIVOT BOLT

FRONT / REAR MASTER CYLINDER LEVER PIVOT LOCK NUT

REAR BRAKE ARM FLANGE BOLT

SPEEDOMETER GEAR BOX OVAL SCREW

REAR CUSHION UPPER BOLT

REAR CUSHION LOWER BOLT

REAR CUSHION DAMPER ROD LOCK NUT

ITEM ITEMTORQUE VALUE

TORQUE VALUE

0.5 kgf·m

1.0 kgf·m

2.2 kgf·m

3.5 kgf·m

5.5 kgf·m

0.4 kgf·m

0.9 kgf·m

1.2 kgf·m

2.7 kgf·m

4.0 kgf·m

5mm BOLT, NUT

6mm BOLT, NUT

8mm BOLT, NUT

10mm BOLT, NUT

12mm BOLT, NUT

5mm SCREW

6mm SCREW

6mm FLANGE BOLT, NUT

8mm FLANGE BOLT, NUT

10mm FLANGE BOLT, NUT

Torque values listed above are for specific tightening points. T orque values for other items are listed in the following table.

SH (Small Head) : Indicates 6mm bolt of 8mm flange head.

Page 16

SYMBOL

CAUTION

NOTE

SYMBOL

1-14

SERVICE INFORMATION

SYMBOLS / ABBREVIATIONS

The following symbols are used in this manual to represent job-related warnings or cautions.

MEANING

Indicates dangerous area. Serious

accident may result if instructions are not

followed.

The following symbols indicate oil adding, oil change, or parts.

MEANING

Add oil. If there is no specific oil indicated, use the designated or recommended engine oil.

Apply grease

Indicates reference page. (example : Refer to page 3-1)

MEANING

Indicates important work. Minor injury or

vehicle part damage may result if instruction

are not followed.

Indicates general safety matters. Provides

safety and appropriate handling procedures.

(⇨3-1)

ASS’Y

The following abbreviations are used in this manual.

ASSEMBLY

Left

Right

LH.

RH.

SYMBOL

WARNING

OIL

GREASE

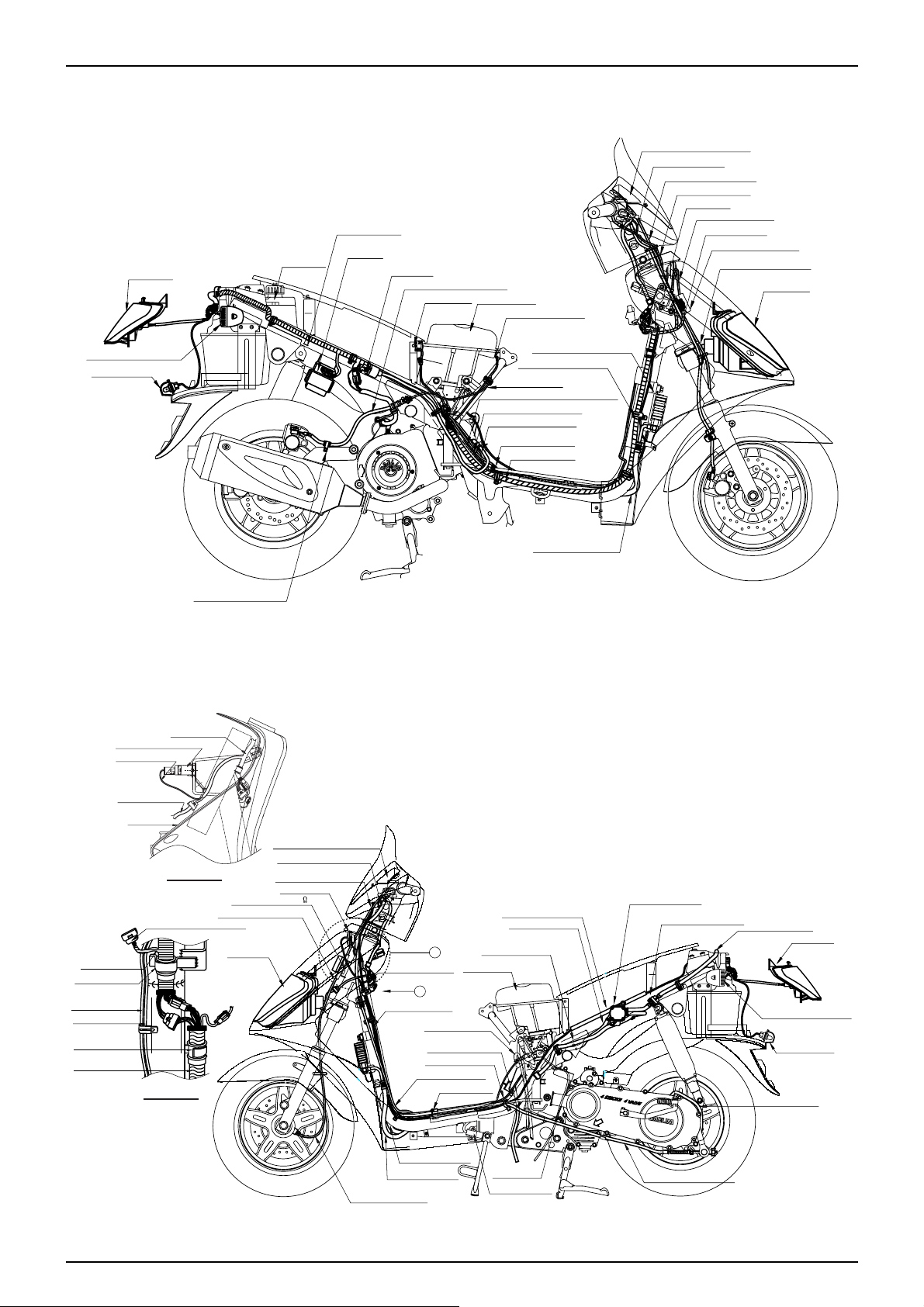

Page 17

1-15

SERVICE INFORMATION

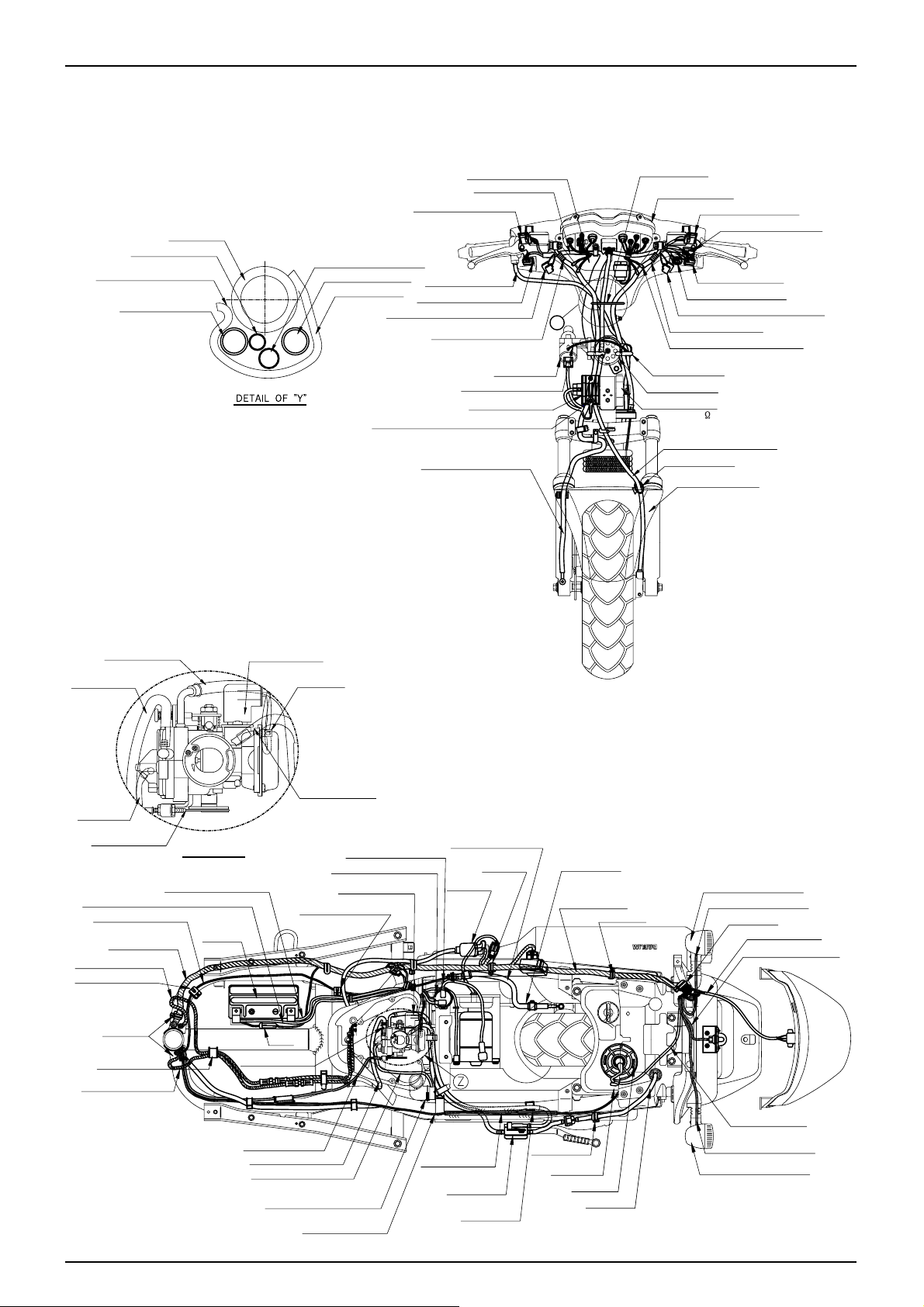

WIRING DIAGRAM

FR.BRAKEHOSE

FRAMEEARTHCONNECTOR

(TIGHTATTHESAMETIMEWITHTHEREG.REC.)

THROTTLECABLE

STARTERS/WUNIT

FR.STOPS/WCONNECTOR

FR.BRAKEHOSE

SEATOPENCABLE

REG.RECTIFIER

MAINS/W

SPEEDOMETERCABLE

CABLEGUIDE

RR.BRAKEHOSE

RR.STOPS/WCONNECTOR

HAZARDS/WUNIT

HORNS/WUNIT

RR.BRAKEHOSE

LH.FR.WINKERLIGHT

CONNECTINGCONNECTOR

CABLEGUIDE

RESISTOR

30W5.9

LIGHTINGS/WUNIT

HEADPIPE

SPEEDOMETER

CABLEGUIDE

SOCKETCOMP.

A.P.WINKERRELAY

DIMMERS/WUNIT

WINKERS/WUNIT

FRONTFENDER

CABLEGUIDE

THROTTLECABLE

PRESSTOATTACHTHE

SEL.SECTIONTOTHEPIPE

FR.BRAKEHOSE

HORNCOMP.

SPEEDOMETERCABLE

Y

SEATLOCKCABLE

THROTTLECABLE

BREATHERTUBE

DRAINTUBE(CARB.)

AIRCLEANERINLETDUCT

FUELUNIT

FUELTUBE

FUELTANK

FUELPUMP

TUBECLAMP

CABLECLIP

CABLESETT.PIPE

LH.RR.WINKERCORD

LH.RR.WINKERLIGHT

FUELUNITCORD

LH.RADIATORHOSE

BATTERY

DETAILOF"Z"

THROTTLECABLE

FULETUBE(INSU)

FULETUBE(CARB)

CORDCLIP

PLUNGERASS'Y.

DRAINTUBE

BREATHERTUBE

FUSE

BREATHERTUBE

STARTERMAGNETICBATTERY+CABLE

BATTERYEARTHCABLE

RR.BRAKEHOSEB

RH.RADIATORHOSE

RR.BRAKEHOSEB

WIREHARNESS

WIRECLIP

HOSECLAMP

WIREHARNESS

HOSECLAMP

RH.RR.WINKERCORD

RH.RR.WINKERLIGHT

WIRECLIP

WIRECLIP

WIRECLIP

TAILLIGHTCORD

LICENSELIGHTCORD

I/G.COIL

RR.BRAKEHOSEB

STARTERMOTORCABLE

HIGHTENTIONCORD

STARTERMAGNETICS/W

PLUNGERASS'Y

Page 18

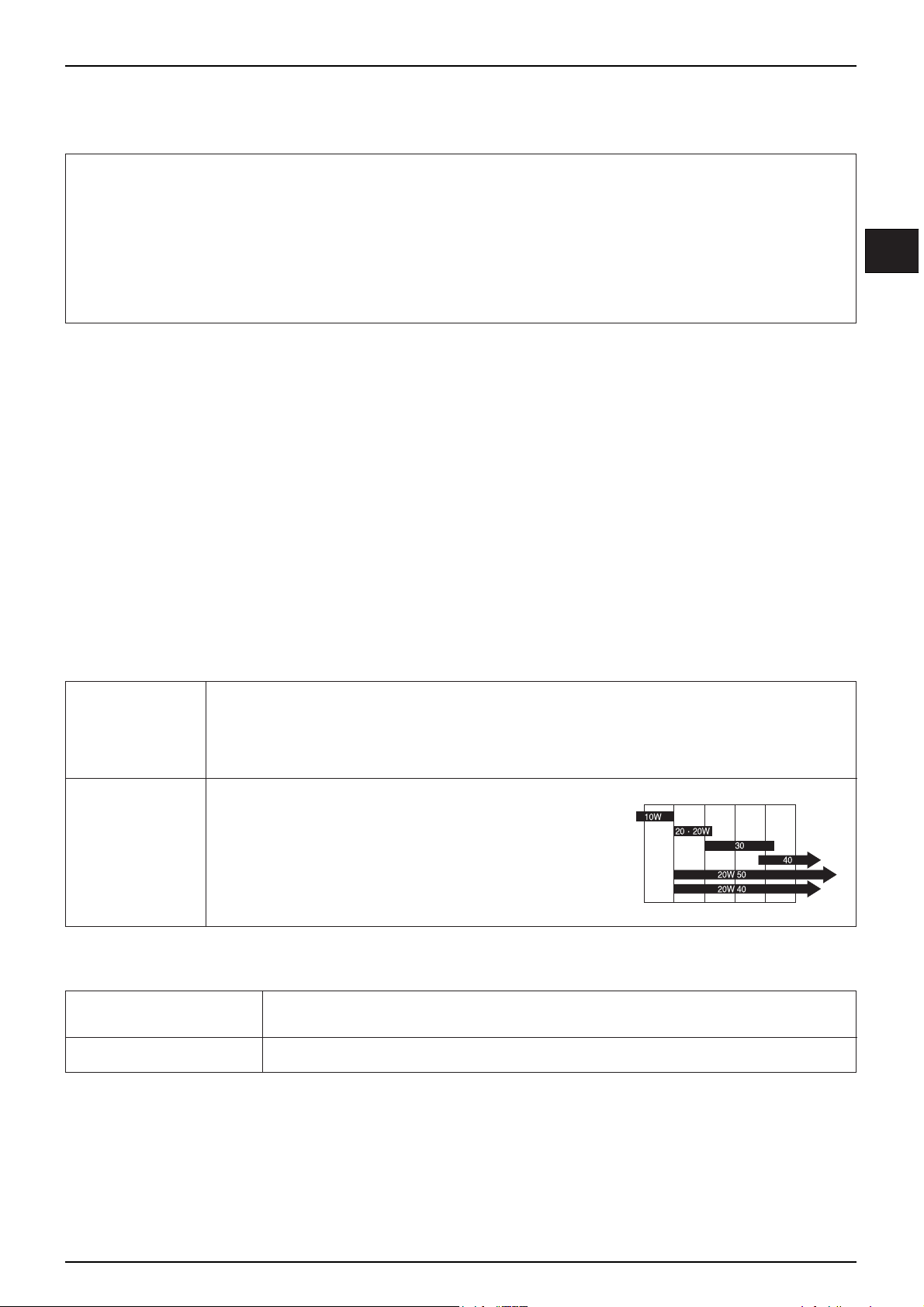

1-16

SERVICE INFORMATION

MASTERCYLINDERASS'Y

FR.BRAKEHOSE

SPEEDOMETERCABLE

THROTTLECABLE

MAINS/W

SEATLOCKCABLE

WIREHARNESS

AIRCLEANER

TRUNKLAMP

TRUNKLAMPS/W

PARKINGBRAKECABLE

RR.BRAKEHOSEB

BLEEDERTUBE

BATTERYEARTHCABLE

HIGHTENSIONCORD

THROTTLECABLE

WIREHARNESS

RH.RADIATORHOSE

STARTERMAGNETICBATTERY+CABLE

STARTERMOTORCABLE

I/G.COIL

CDIUNIT

FUELTANK

TAILLIGHT

RH.RR.WINKERLIGHT

LICENSELIGHT

RR.BRAKEHOSEB

WIREHARNESS

REGULATERECTIFIER

SPEEDOMETERCABLE

HEADLIGHT

MASTERCYLINDERASS'Y

RR.BRAKEHOSEA

SOCKETCOMP.

CHARGESOCKETASS'Y

WIREHARNESS

HEADLIGHTCORD

INNERBOX

DETAILOF"A"

HEADLIGHT

HEADLIGHTCONNECTING

COUPLER(4P.FEMAIL)

THROTTLECABLE

AIRCLEANER

FUELTUBE(CARB')

FUELTUBE(INSU.)

FUELPUMPASS'Y

FUELSTRAINERCOMP.

FUELTUBE(TANK)

TAILLIGHT

LH.RR.WINKERLIGHT

LICENSELIGHT

BREATHERTUBE

PARKINGBRAKECABLE

CABLESETTINGPIPE

RR.BRAKEHOSEB

X

A

DRAINTUBE

SIDESTANDS/W

SEATLOCKCABLE

THROTTLECABLE

CABLECLAMP

BREATHERCABLE

RR.BRAKEHOSEB

RH.RADIATORHOSE

LH.RADIATORHOSE

SPEEDOMETERCABLE

SPEEDOMETERCABLE

SPEEDOMETERCABLE

SOCKETCOMP.

WIRECLAMP

(SOCKETCOMP.)

SEATLOCKCABLE

THROTTLECABLE

WIREHARNESS

WIRECLAMP

HORNCOMP.

RESISTOR30W5.9

VIEW"X"

Page 19

2-1

2. LUBRICATION

SERVICE INFORMATION

GENERAL SAFETY

WARNING

1.The exhaust gas contains poisonous substance. Do not keep engine idling in a closed or poorly ventilated place for a

long period of time.

2.Used engine oil may cause skin cancer if repeatedly left in contect with the skin for prolonged periods. It is desirable

not to handle used oil frequently; however, wash your hands thoroughly with soap and water immediately after

handling the used oil.

3.The oil pump can be serviced without removing the engine from the frame.

ENGINE OIL

TRANSMISSION OIL

TORQUE VALUES

OIL FILTER SCREEN CAP

1.5㎏f·m

OIL FILTER COVER BOL T

1.1㎏f·m

OIL PUMP MOUNTING BOLT

1.1㎏f·m

OIL DRAIN PLUG BOLT

2.5㎏f·m

2

SERVICE INFORMATION

······

2-1

TROUBLESHOOTING

··········

2-2

ENGINE OIL LEVEL INSPECTION··2-3

ENGINE OIL CHANGE

········

2-3

OIL FILTER ELEMENT CHANGE··2-4

OIL PUMP

··················

2-4

RADIATOR

··················

2-7

TRANSMISSION OIL INSPECTION··2-8

LUBRICATION POINTS

······

2-9

OIL CAP ACITY

RECOMMENDED

OIL

1.1ℓ (After disassembly)

0.9ℓ (After Oil change with Oil in the Oil hose removed)

0.8ℓ (After Oil filter change)

0.75ℓ (After Oil change)

API service classification : SE, SF, SH grade

Viscosity : SAE10W-30

(Use appropriate type of oil with viscosity satisfying

the atmospheric temperature

In your riding area based on the table shown on the

right side.)

OIL CAP ACITY

RECOMMENDED OIL

0.15ℓ (Full capacity)

0.14ℓ (After oil change)

DMC Pure mission oil or SAE 80W/90

-10 0 10 20 30 40℃

Page 20

2-2

LUBRICA TION

TROUBLESHOOTING

Oil level low

•Oil consumption.

•External oil leaks.

•Worn piston ring or incorrect piston ring installation.

•Worn valve guide or seal.

Oil contamination

•Oil or filter not changed often enough.

•Faulty head gasket.

•Worn piston rings.

Low or no oil pressure

•Clogged oil orifice.

•Incorrect oil being used.

Page 21

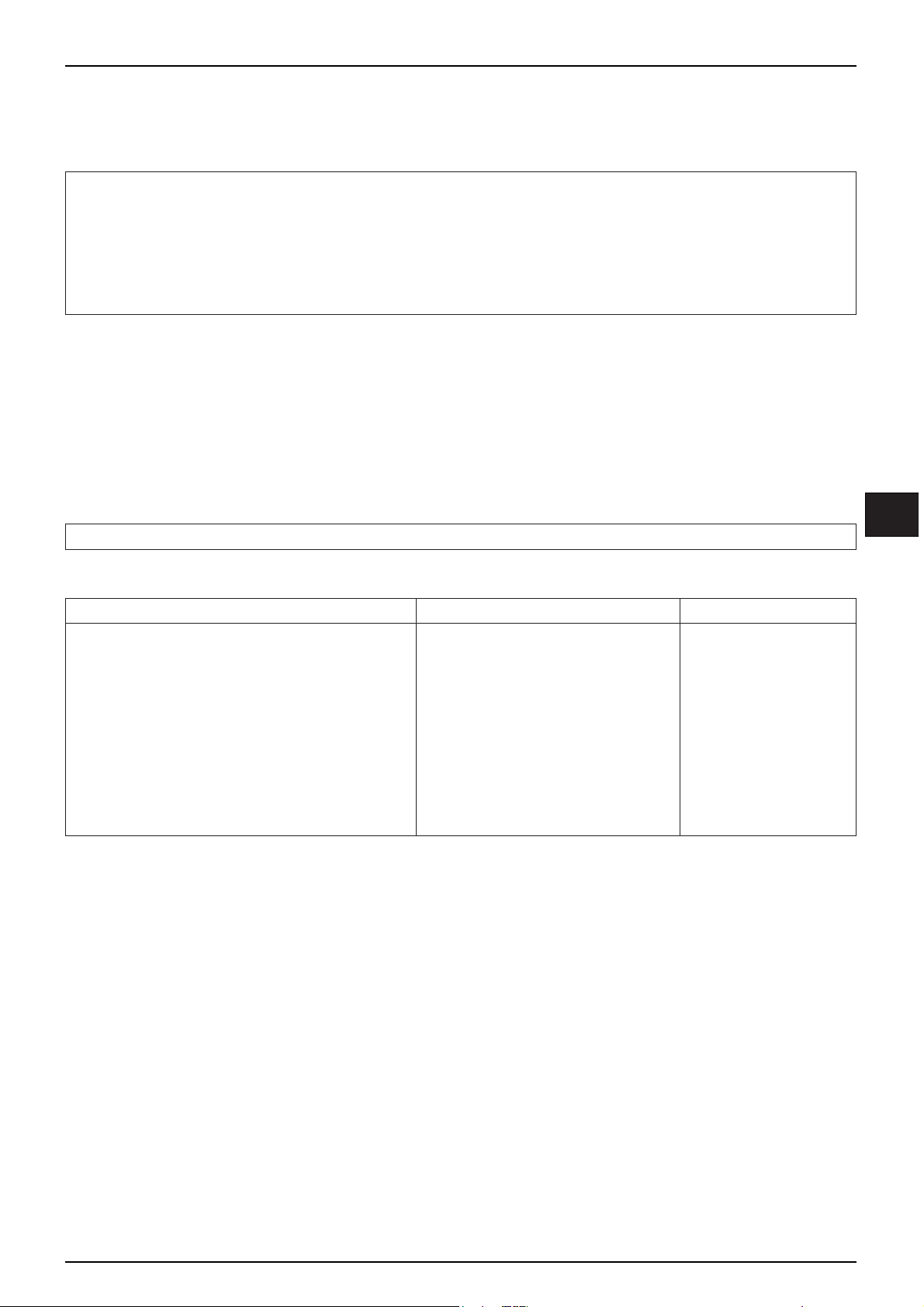

ENGINE OIL LEVEL INSPECTION

● Erect the motorcycle on the main stand.

● Warm up the engine to heat the engine oil to an

appropriate level.

● Stop the engine, and check the oil level line on the

sight-glass installed on the LH. crank case cover .

● If the oil level is between the lower and higher sightglass oil level line, oil level is satisfactory. If the oil

level is below or near the lower level mark, add the

recommended engine oil.

ENGINE OIL CHANGE

NOTE

•To completely and rapidly drain engine oil, warm up

engine and erect the motorcycle on its side stand.

● Loosen the oil drain plug bolt and drain engine oil.

● Operate the kick starter arm several times to remove

the remaining oil from the engine.

● Tighten the oil drain plug bolt.

TORQUE VALUE : 2.0-3.0 kgf·m

CAUTION

•It is extremely important to replace oil filter or clean

the oil filter screen at the first maintenance interval

(after 1,000Km).

•Clean the oil filter screen every 4,000Km.

•Clean the filter screen with fresh cleaning oil.

•Check the hole cap O-ring for satisfactory condition.

•Tighten the hole cap with specified tightening torque.

TORQUE VALUE : 1.5 kgf·m

● Loosen the special screw, remove the plug maintenance

cover.

● Fill the recommended oil after opening oil filter cap of

cylinder head cover .

OIL CAPACITY : 1.1ℓ(After disassembly)

0.9ℓ(After Oil change with Oil in

the Oil hose removed)

0.8ℓ(After Oil filter change)

0.75ℓ(After Oil change)

● API service classification : SE, SF , SH grade.

● Start the engine and keep it idle for a few minutes.

● Stop the engine and check the oil level. If the oil level

is low , add the recommended engine oil.

● Check on oil leaks.

2-3

LUBRICA TION

UPPER LINE

PROPER LINE

LOWER LINE

SIGHT GLASS

OIL DRAIN PLUG

TAPPET ADJUSTING

HOLE CAP

OIL PICK

UP COLLAR

OIL FILTER

SCREEN

OIL FILTER CAP

Page 22

OIL FILTER ELEMENT CHANGE

●Drain engine oil. (⇨2-3)

●Loosen the 3 flange bolts securing the oil filter cover,

remove the oil filter cover.

●Remove the oil filter element and oil filter spring.

●Change the oil filter element with a new one.

●Check if the oil filter seal is in good condition.

●Assemble the filter element spring and filter cover, and

tighten bolts.

TORQUE VALUE : OIL FILTER COVER 1.1kgf·m

NOTE

•Always use a genuine oil filter element.

•Be sure to replace the oil filter seal when removing oil

filter element.

•Be careful not to lose the oil filter spring when

assembling the oil filter element.

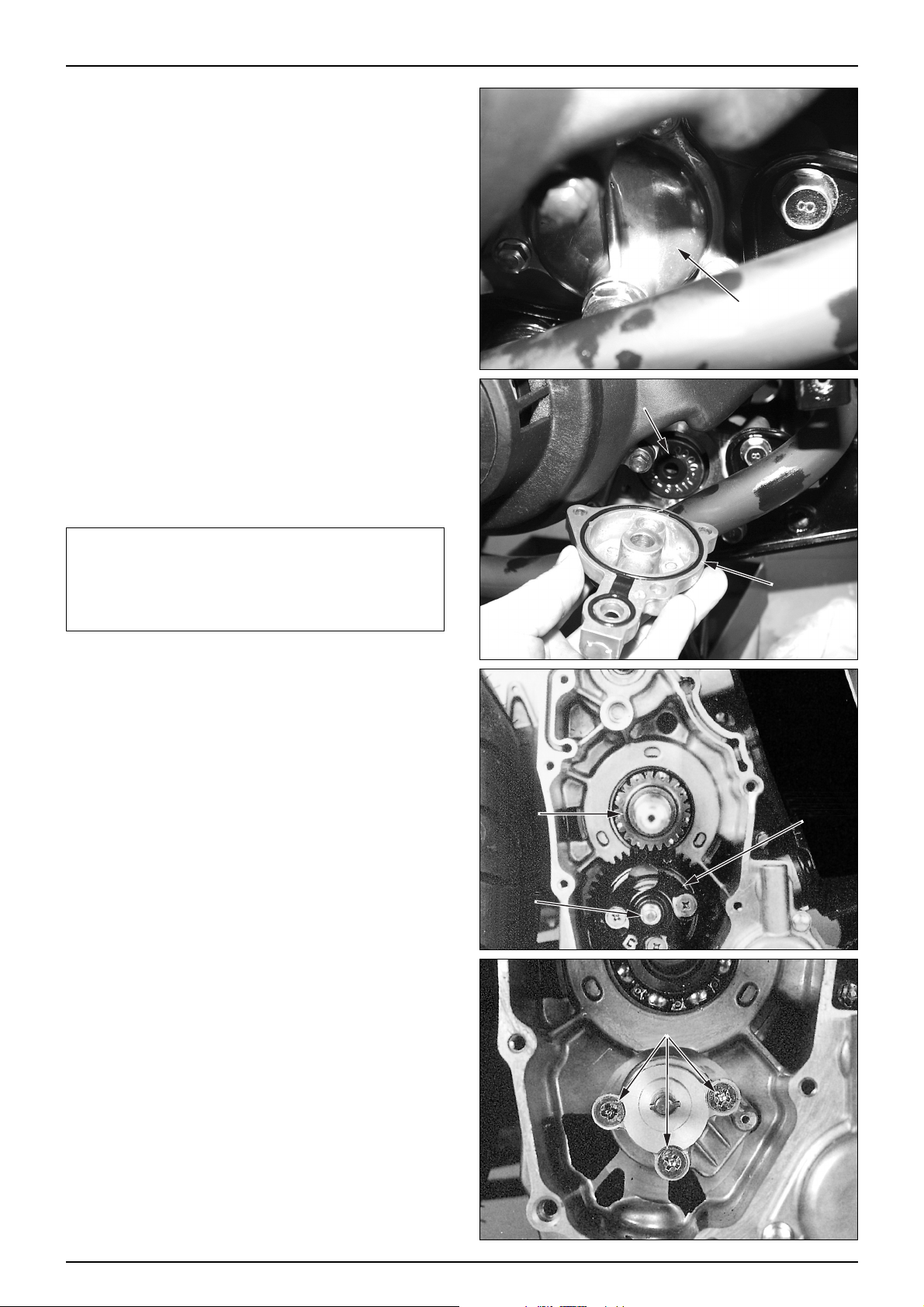

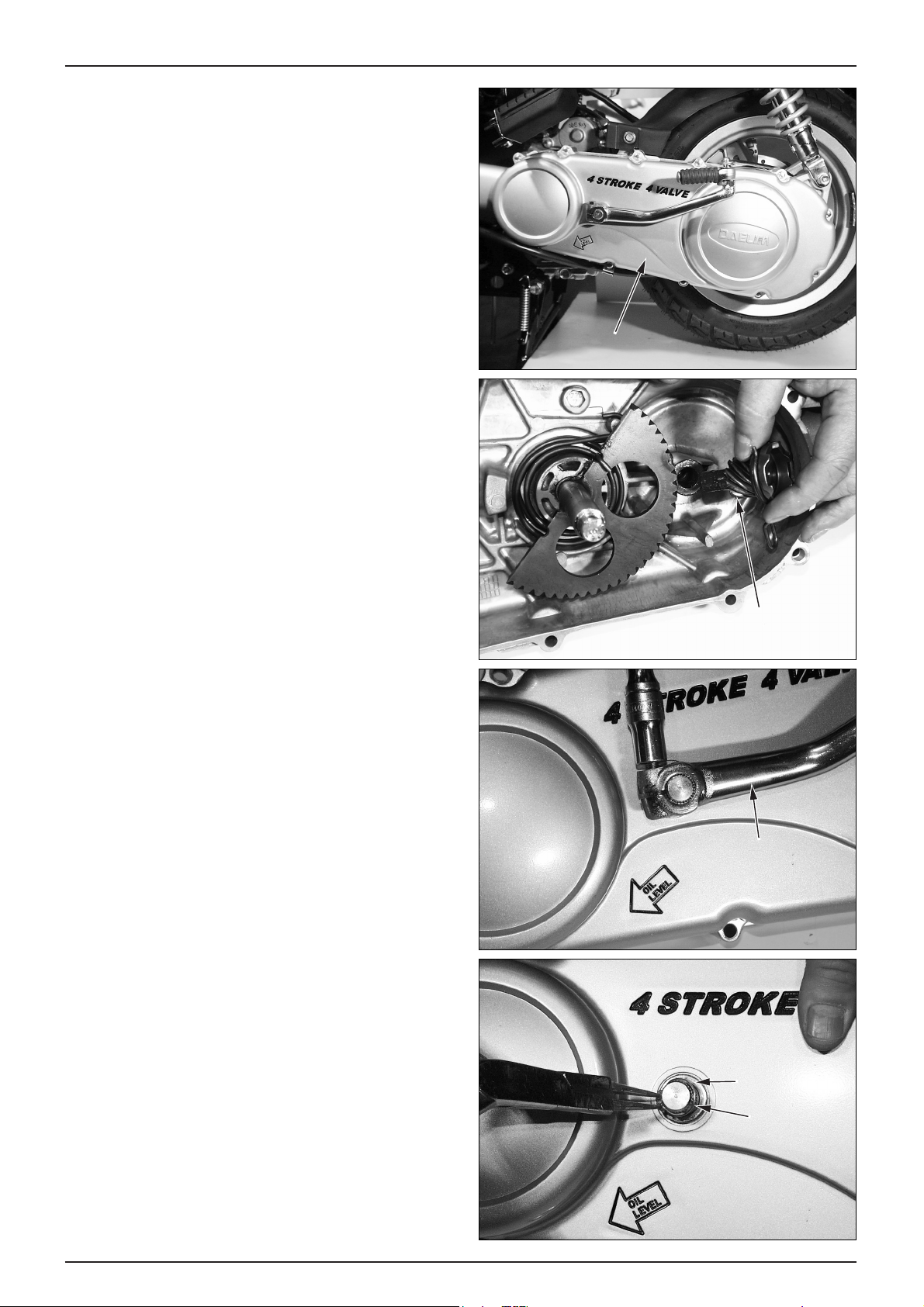

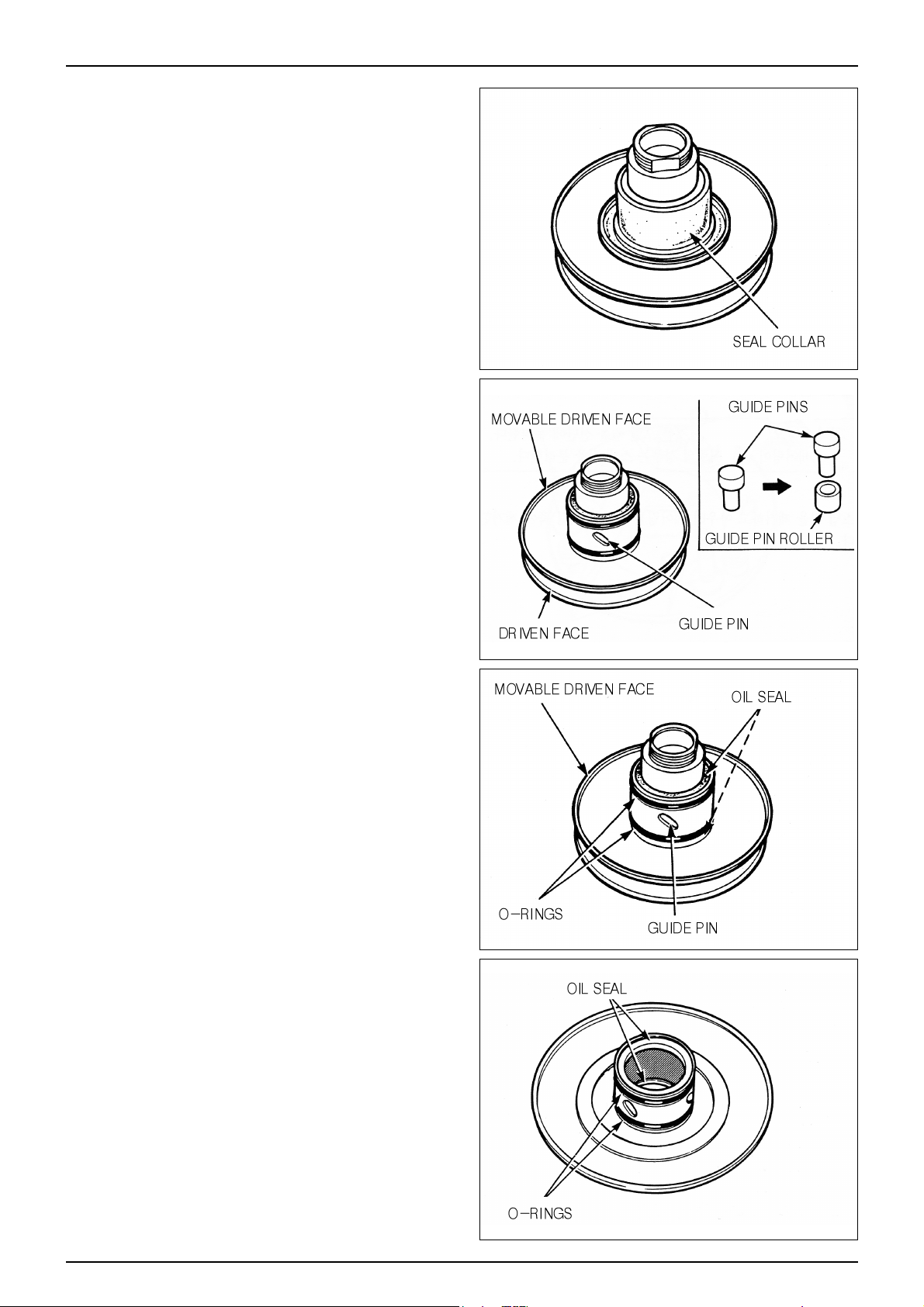

OIL PUMP

REMOV AL

●Remove the following parts :

-Rear cushion lower bolt (⇨13-7)

-Muffler (⇨4-12)

-Rear swing arm (⇨13-8)

-Rear caliper (⇨14-6)

-Shroud (⇨8-2)

-Cooling fan (⇨8-2)

-A.C. generator (⇨8-2)

-RH. crankcase cover (⇨8-4)

-Starter driven gear (⇨8-6)

-Reduction gear (⇨8-5)

-Starting clutch assembly (⇨8-6)

●Loosen the oil pump driven gear setting nut.

●Remove the oil pump driven gear.

●Remove the oil pump drive gear.

●Loosen the 3 flat screws securing the oil pump.

●Remove the oil pump.

2-4

LUBRICA TION

OIL FILTER COVER

DRIVE

GEAR

NUT

ELEMENT

OIL FILTER SEAL

DRIVEN GEAR

FLAT SCREW

Page 23

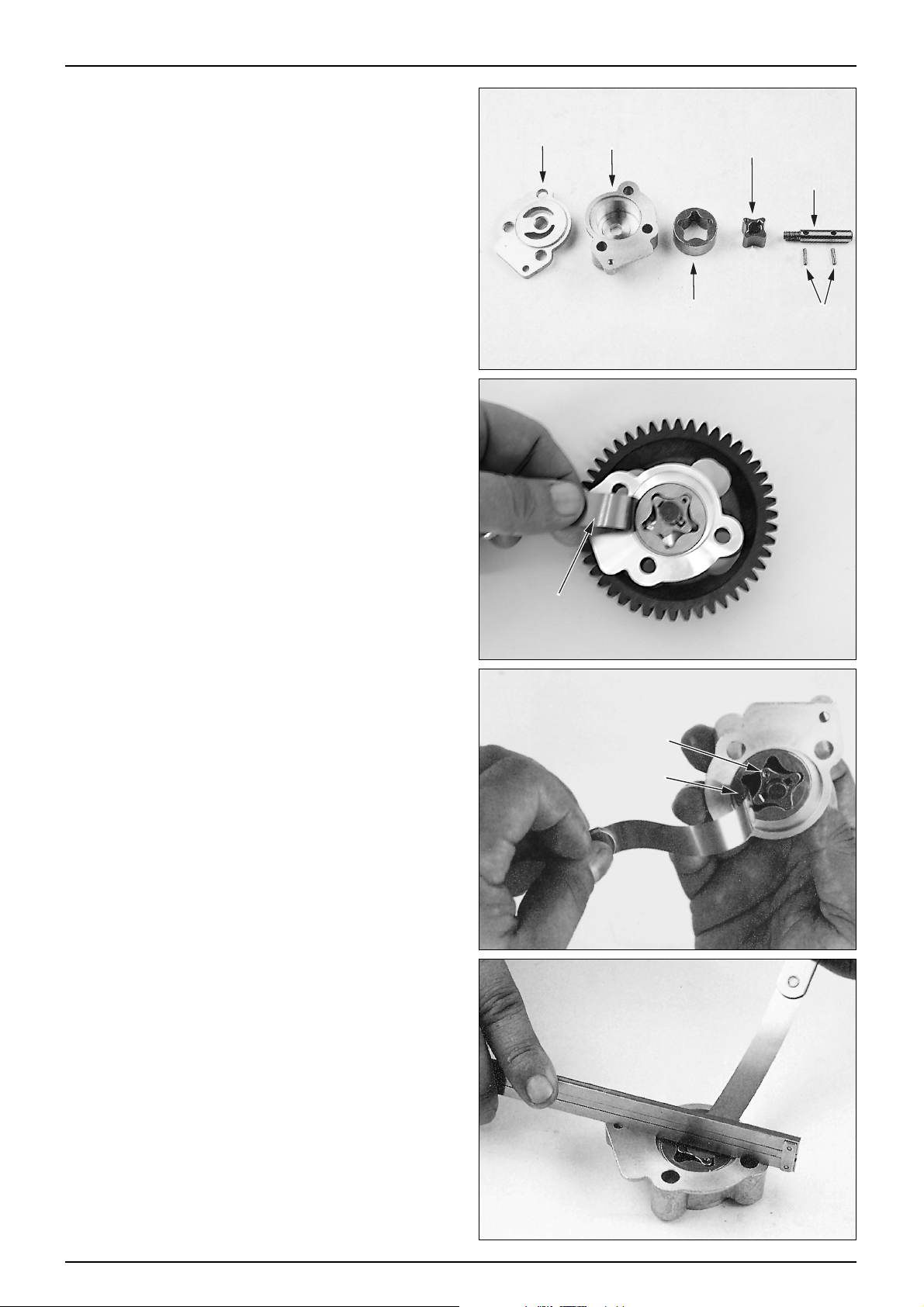

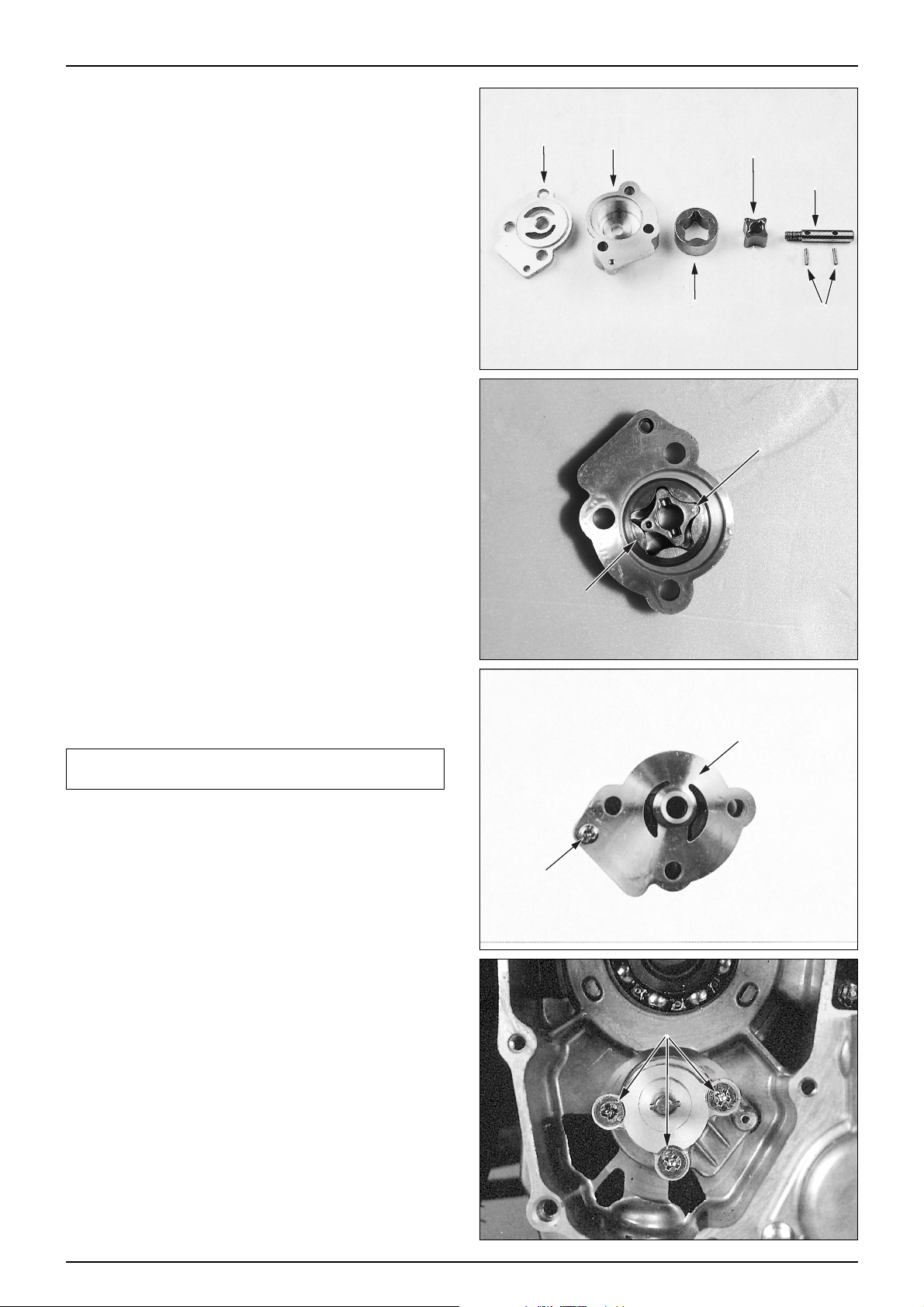

OIL PUMP DISASSEMBLY

●Loosen the screw securing the oil pump plate.

●Remove the oil pump body and the oil pump plate.

●Clean the oil pump body, inner and outer rotors with

fresh cleaning oil.

OIL PUMP INSPECTION

●Assemble the inner and outer rotors to the oil pump

body .

●Measure the pump body clearance.

SERVICE LIMIT : 0.23mm

TOOL : FEELER GAUGE

●Measure the rotor tip clearance.

SERVICE LIMIT : 0.18mm

●Measure the pump side clearance

SERVICE LIMIT : 0.12mm

2-5

LUBRICA TION

PUMP PLATE

PUMP BODY

OUTER ROTOR

INNER ROTOR

PUMP SHAFT

ROLLER2.5x11.8

FEELER GAUGE

INNER ROTOR

OUTER ROTOR

Page 24

2-6

LUBRICA TION

OIL PUMP ASSEMBLY

●Clean all parts with fresh cleaning oil.

●Install the inner and outer rotors to the pump body.

●Assemble the pump shaft with setting pin.

●Install the oil pump plate to the pump body.

●Tighten the pan screw.

NOTE

•After installing, check the oil pump to operate

smoothly .

OIL PUMP INST ALLATION

●Install the oil pump to the RH. crankcase.

●Install the following parts.

-Oil pump drive gear and driven gear .

-Starting clutch assembly . (⇨8-8)

-Starter driven gear and reduction gear (⇨8-6)

-A.C. generator (⇨8-2)

-RH. crank case cover (⇨8-6)

-Shroud and cooling fan (⇨8-2)

-Rear swing arm (⇨13-8)

-Rear caliper (⇨14-6)

-Muffler (⇨4-12)

PUMP PLATE

PUMP BODY

OUTER ROTOR

INNER ROTOR

PUMP SHAFT

ROLLER2.5x11.8

INNER ROTOR

OUTER ROTOR

PUMP PLATE

PAN SCREW

FLAT SCREW

Page 25

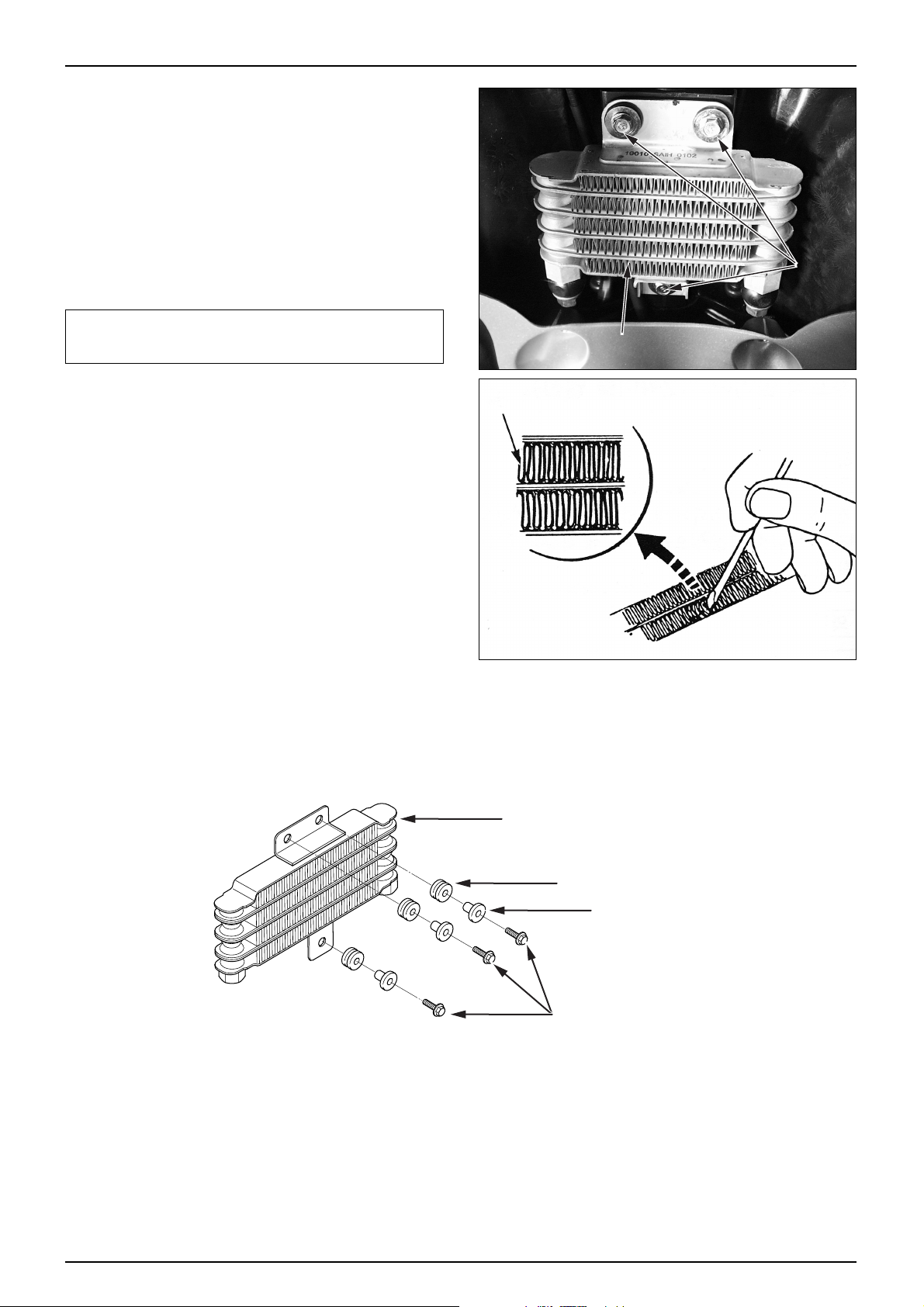

RADIATOR

REMOV AL

●Remove the front cover. (⇨4-3)

●Remove the front wheel. (⇨12-5)

●Loosen the 2 oil bolts and the 4 drain cock packings

from the main pipe bracket.

●Loosen the 3 flange bolts securing the radiator.

●Remove the radiator.

CAUTION

•Be careful not to damage the radiator when removing it.

•Pay attention not to turn over the vehicle.

INSPECTION

●Check the oil line connections for leaks.

●Check the oil cooler for bent or collapsed fins.

Straighten the bent or collapsed fins with a suitable,

small, blade-type screw driver if necessary .

●Check the air passages for clogging or restriction. Blow

dirt out from between core fins with compressed air or

wash off dirt with water .

●After installing, start the engine and check for leak. Stop

the engine and check the oil level.

2-7

LUBRICA TION

FLANGE

BOLT

RADIATOR

FIN

OILRADIATOR

RADIATORRUBBER

RADIATORCOLLAR

FLANGEBOLT

Page 26

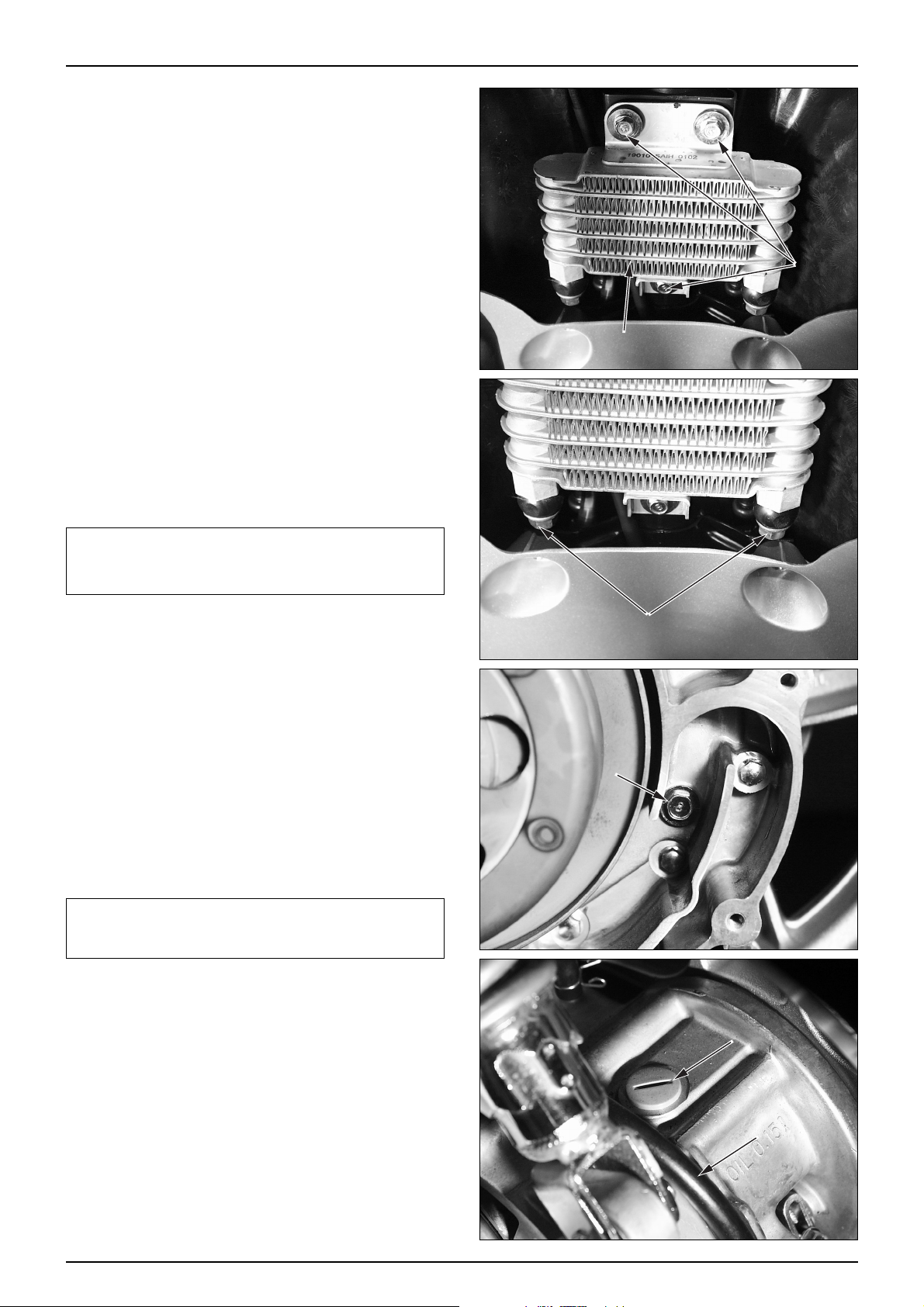

RADIA T OR INSTALLATION

●Tighten the 3 radiator setting flange bolts to the main

pipe bracket.

●Tighten the drain cock packings and oil bolts.

TORQUE VALUE : 3.2kgf·m

●Install the front wheel. (⇨12-9)

●Install the front cover. (⇨4-3)

CAUTION

•Pay attention not to turn over the vehicle.

•When installing the radiator, tighten the oil bolts with

specified tightening torque.

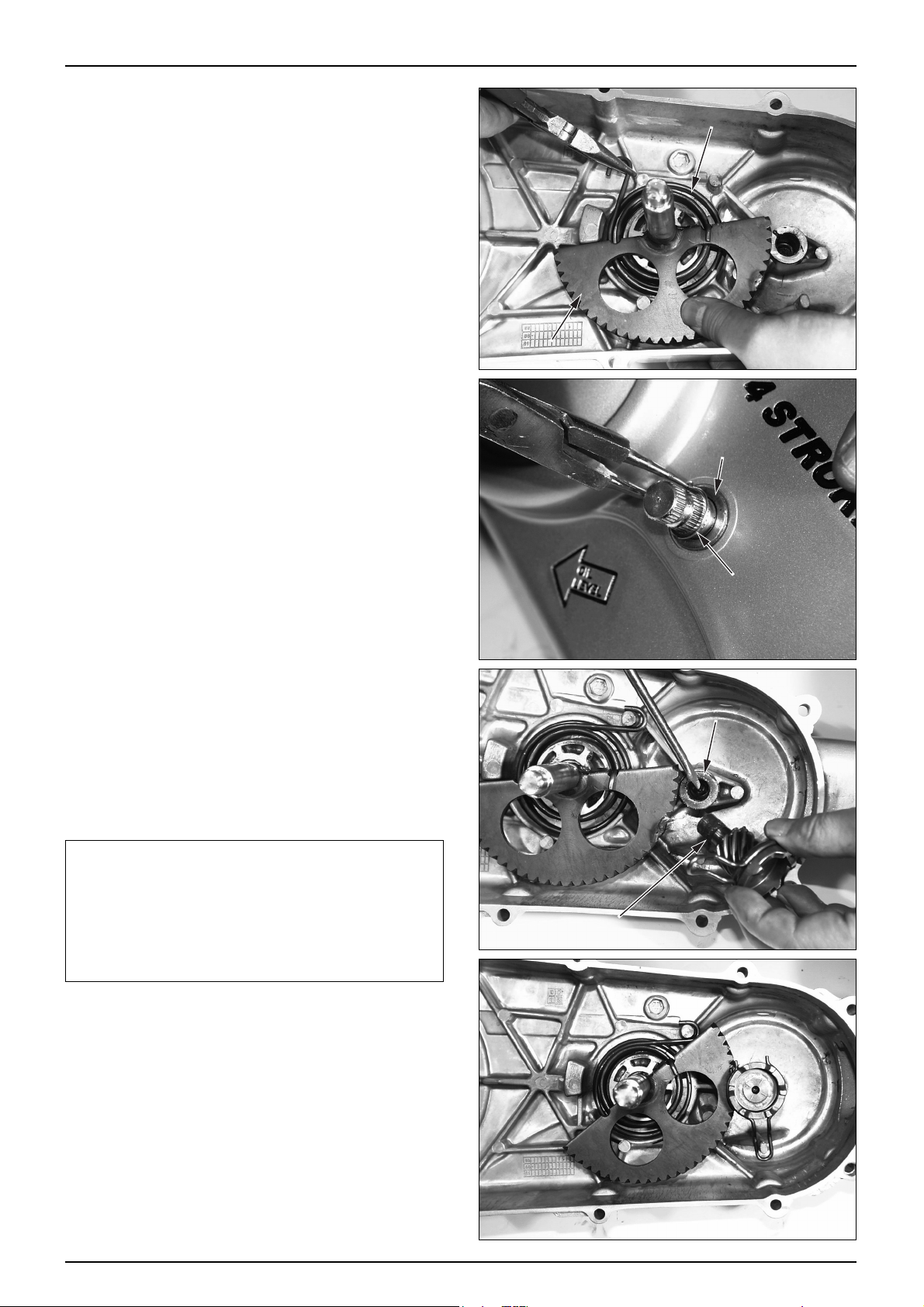

TRANSMISSION OIL INSPECTION

●Remove the LH. crankcase cover. (⇨7-2)

●Check the body and the connection of each engine

component for any leak.

●Remove the oil check bolt and check to see if the oil

overflows from the oil check hole.

●If only the small amount of oil overflows. fill the

recommended transmission oil through the oil filler

hole gradually .

NOTE

•Oil level inspection must be performed in the flat

ground with the vehicle being straight by raising the

main stand.

RECOMMENDED OIL : SAE 80W/90

●Tighten the oil check bolt.

TORQUE VALUE : 0.9 kgf·m

●Start the engine and check for leak.

●Install the LH. crankcase cover. (⇨7-2)

2-8

LUBRICA TION

FLANGE

BOLT

RADIATOR

OIL BOLT

OIL CHECK BOLT

A.C.GENERATOR CAP

BREATHER TUBE

Page 27

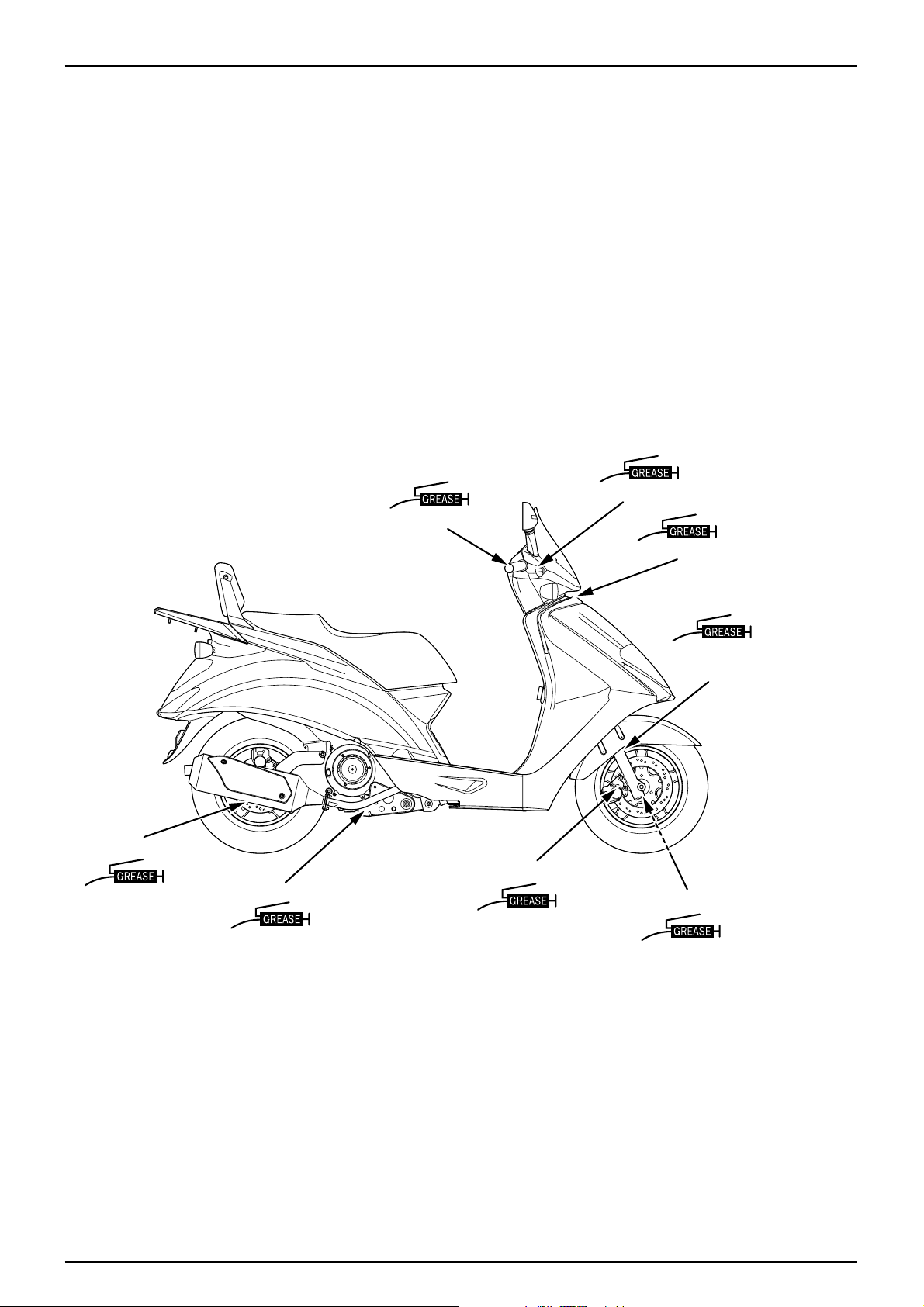

LUBRICATION POINTS

Unless specifically designated, use general grease to

lubricate the lubrication points. For sliding parts not

shown here, add oil or grease.

CONTROL CABLE LUBRICA TION

Remove and clean the upper assembly of the throttle

cable, and apply oil. If the cable has expanded, replace it.

2-9

LUBRICA TION

FRONTBRAKELEVERPIVOT

THROTTLEGRIP

STEERINGHEADBEARING

FRONTFORK

DUSTSEAL

WHEELBEARING/SPEEDOMETERGEAR

BRAKECALIPERBRACKET

SIDE/MAINSTANDPIVOT

WHEELBEARING

Page 28

MEMO

Page 29

3-1

3. INSPECTIONS/ADJUSTMENTS

SERVICE INFORMATION

WARNING

●The exhaust gas contains poisonous substance. Do not keep engine idling in a closed or poorly ventilated place for a

long period of time.

SPECIFICA TIONS

TIRES

3

SERVICE INFORMATION

······

3-1

MAINTENANCE SCHEDULE

··

3-3

FUEL LINE (FUEL TUBE)

······

3-4

THROTTLE GRIP OPERATION

····

3-4

AIR CLEANER

··············

3-4

SPARK PLUG

··············

3-5

VALVE CLEARANCE

········

3-5

CYLINDER COMPRESSION PRESSURE

··

3-6

CARBURETOR IDLE SPEED

····

3-6

BRAKE FLUID

················

3-7

BRAKE PAD/SHOE

··········

3-7

BRAKE SYSTEM

············

3-7

BRAKE LEVER FREE PLAY

··

3-8

HEADLIGHT AIM

············

3-8

SIDE STAND

················

3-8

SUSPENSION

··············

3-9

BOLTS, NUTS, FASTENERS

····

3-9

WHEELS/TIRES

··············

3-10

STEERING HEAD BEARING

··

3-10

THROTTLE GRIP PLA Y 2- 6mm

SP ARK PLUG CR8EH-9

SP ARK PLUG GAP 0.8-0.9mm

IN 0.12±0.02mm

EX 0.12±0.02mm

CARBURETOR IDLE SPEED 1,800±100rpm

CYLINDER COMPRESSION PRESSURE 14±2kgf/㎠㎠( 550rpm )

NOTE

•For information on engine oil and oil filter, refer to sections 2-3 and 2-4

•Stand the main stand prior to beginning work.

VALVE CLEARANCE

COLD TIRE

PRESSURE

TIRE SIZE

MIN, TREAD

DEPTH “”

DRIVER ONL Y

DRIVER AND A

PASSENGER

FRONT TIRE

REAR TIRE

FRONT TIRE

REAR TIRE

FRONT TIRE

REAR TIRE

FRONT TIRE

REAR TIRE

200kPa (2.00kgf/㎠㎠)

200kPa (2.00kgf/㎠㎠)

200kPa (2.00kgf/㎠㎠)

225kPa (2.25kgf/㎠㎠)

120/70 - 12 53k(Tubeless)

130/70 - 12 62k(Tubeless)

0.5mm

0.5mm

Page 30

TORQUE VALUES

SPARK PLUG 1.1kgf·m

CYLINDER HEAD COVER BOLTS 1.0kgf·m

VALVE ADJUSTING NUTS 1.1kgf·m

TIMING HOLE CAP 0.6kgf·m

TOOLS

WRENCH 8X9mm

ADJUST WRENCH

COMPRESSION GAUGE

3-2

INSPECTIONS / ADJUSTMENTS

Page 31

3-3

INSPECTIONS / ADJUSTMENTS

MAINTENANCE SCHEDULE

● Carry out pre-operation check at each scheduled maintenance period based on the information described in the owner’s

manual.

I : INSPECT AND CLEAN, ADJUST, LUBRICATE OR REPLACE IF NECESSARY.

R : REPLACE L : LUBRICATE C : CLEAN

● These instructions are based on the assumption that the motorcycle will be used exclusively for its designed purpose.

Sustained high speed operation, or operation in unusually wet or dusty conditions, will require more frequent service

than specified in the following chart.

* If there are no appropriate type of tools and maintenance data available, or if you do not have mechanical technology

contact authorized maintenance shops, dealers or other designated repair shops for maintenance and inspections.

To ensure safety, inspections and maintenance of these parts must be carried out by authorized maintenance shops,

dealers or other designated repair shops.

NOTE

1. After the odometer reading exceeds 12,000km, repeat maintenance service at intervals indicated in the table.

2. After riding in areas with high humidity or pollution, carry out maintenance service more frequently.

3. Replace every 2 years. Proper technology is required for this job.

*

*

*

*

*

*

*

*

*

*

*

*

*

FUEL LINE(FUEL TUBE)

FUEL FILTER

THROTTLE GRIP OPERATION

AIR CLEANER

SPARK PLUG

VALVE CLEARANCE

TRANSMISSION OIL

ENGINE OIL

ENGINE OIL FILTER

CARBURETOR IDLE SPEED

BRAKE FLUID

BRAKE SHOE/PAD WEAR

BRAKE SYSTEM

BRAKE STOP SWITCH

HEADLIGHT ADJUSTMENT

SIDE ST AND

SUSPENSION

BOLTS, NUTS, FASTENERS

WHEELS/TIRES

STEERING HEAD BEARING

DRIVE BELT

WEIGHT ROLLER

SLIDE PIECE

OIL FILTER SCREEN

MOVABLE DRIVE FACE INNER PART

NOTE 2

NOTE 3

NOTE 3

I

R

I

I

I

R

R

I

I

I

I

I

I

I

R

I

I

I

R

R

I

I

I

I

I

I

I

I

I

I

I

I

I

C

L

I

R

I

I

I

R

R

I

I

I

I

I

I

I

I

I

I

I

I

I

I

C

L

I

R

I

I

I

R

R

R

I

I

I

I

I

I

I

I

I

I

I

I

I

C

L

Every 1,000㎞ : C

FREQUENCY

ODOMETER READING(NOTE 1)

61218

14812REMARK

ITEM

x 1000Km

MONTH

Page 32

FUEL LINE(FUEL TUBE)

● Remove the luggage box.(⇨4-4)

● Check the fuel tube of the fuel pump connected to the

fuel tank and carburetor. If the fuel tube is cracked,

damaged or leaks, replace it.

THROTTLE GRIP OPERA TION

● Check if the throttle grip operates smoothly in any

steering position.

● If the throttle grip does not operate properly, lubricate

the throttle cable.

● If the throttle grip does not operate properly, check the

throttle cable for aging, damage or kinking.

● Check the throttle grip free play.

FREE PLAY : 2~6mm

● For adjustment, loosen the lock nut and turn adjuster.

● After adjusting, tighten lock nut. After adjustment is

completed, recheck the throttle grip free play .

AIR CLEANER

● Release the seat lock by turning the main switch key to

open the seat.

● Loosen the 6 screws securing the air cleaner case cover,

remove it.

● Loosen the 2 screws securing the air cleaner element

holder, remove it.

● Remove the air cleaner element.

● Remove the air cleaner trap comp.

● Wash away any accumulated dust or dirt, by gently

squeezing it in non flammable or high flash point

solvent.

WARNING

•Using gasoline or low flash point solvents for

cleaning parts may result in a fire or explosion.

CAUTION

•Cleaning the element with gasoline or any acid,

alkaline, or organic, volatile type oil may cause

improper ignition, deterioration of the element, or a

loosening of the element adhesive.

3-4

INSPECTIONS / ADJUSTMENTS

FUEL PUMP

FUEL TUBE

SCREW

AIR CLEANER

ELEMENT

AIR CLEANER

TRAP

SCREW

Page 33

● Be sure to allow the element to dry thoroughly before

applying oil. Otherwise, the oil will be diluted by the

and the filtering ability of the filter will be much less

effective.

● Spread clean #80~90 gear oil on the element, rubbing

inthoroughly over the surface with both hands, and then

squeeze out any excess oil.

CAUTION

•Using air filter oil when riding in extremely dusty

conditions prevents premature engine wear due to

dust/dirt drawn into the engine. Apply air filter oil to

the entire surface of the element and rub it with both

hands to saturate the element with oil. Squeeze out

excess oil.

SPARK PLUG

● Remove the plug maintenance cover.

● Remove the spark plug cap and disassemble the plug.

● Check the plug for damage, contamination or deposits.

● If the spark plug is severely contaminated or damaged,

raplace with a new one. If the plug can be reused after

removing only the carbon, use plug cleaner and wire

brush to clean the plug.

● Always use a feeler gauge to check the gap.

GENUINE PLUG : CR8EH-9

SPARK PLUG GAP : 0.8~0.9mm

TORQUE VALUE : 1.1 kgf·m

CAUTION

•Make sure there is no dirt or debris on the seat of the

spark plug hole before inserting the spark plug.

•To prevent damage to the cylinder head, hand-tighten

the spark plug before using a wrench to tighten to the

specified torque.(torque : 14kgf·m)

•Do not overtighten the spark plug.

VALVE CLEARANCE

● Remove the following parts.

-Luggage box. (⇨4-4)

-Center cover. (⇨4-5)

● Loosen the 4 cylinder head bolts.

NOTE

•Inspect and adjust the valve clearance when the

engine is cool. (under 35°C / 95°F)

•Remove the cylinder head cover.

•Turn the flywheel counterclockwise, and align the

“T” mark on the flywheel with the index mark on

the RH. crank case cover .

•The piston at this time must be at the top dead center

of the compression stroke.

● Measure valve clearance with a feeler gauge.

VALVE CLEARANCE : Intake : 0.12±0.02mm

Exhaust : 0.12±0.02mm

3-5

INSPECTIONS / ADJUSTMENTS

TIMING CHECKING

RH. SHROUD

→

→→

CHECK GAP,

DEPOSITS

CHECK FOR

CRACKS

0.8mm~0.9mm

CHECK WASHER

FOR DAMAGE

CYLINDER HEAD

COVER

Page 34

● Loosen the lock nut with a valve wrench, and set valve

clearance to a prescribed level by turning the adjusting

screw with a valve adjusting wrench.

● After setting clearance to the prescribed level, hold the

adjuster screw with a valve adjusting wrench, and

tighten the lock nut.

TORQUE VALUES : 1.1kgf·m

TOOLS : WRENCH 8X9mm

ADJUSTING WRENCH B

FEELER GAUGE

● Measure the valve clearance again.

● Install the cylinder head cover and tighten the bolts.

TORQUE VALUES : 1.0 kgf·m

CYLINDER COMPRESSION PRESSURE

● Start and warm up the engine.

● Remove the plug maintenance cover.

● Stop engine, and remove the spark plug cap and spark

plug.

● Install a compression gauge.

● Open the throttle completely, and crank the engine with

the starter motor until the gauge reading rising.

TOOL : COMPRESSION GAUGE

NOTE

•The maximum reading is usually reached within 4~7

seconds.

COMPRESSION PRESSURE : 13.8 kg/cm

2

● If the pressure is low, check the following:

-Inadequate valve clearance adjustment

-Valve leakage

-Leakage from the cylinder head gasket

-Piston/cylinder worn

● If pressure is high, check the following:

-Carbon deposits on the piston head, and cylinder head.

CARBURETOR IDLE SPEED

● Remove the plug maintenance cover . (⇨4-5)

● Check the idle speed and adjust if necessary by turning

the throttle stop screw .

NOTE

•Verify all engine adjustments satisfy specifications.

Make adjustments, if necessary .

•Heat the engine to make accurate idling inspection

and adjustment. Stand the vehicle on the main stand.

•Turn the throttle stop screw and make adjustments to

prescribed idling speed.

3-6

INSPECTIONS / ADJUSTMENTS

ADJUSTER

WRENCH

FEELER

GAUGE

SPARK PLUG

COMPRESSION

GAUGE

THROTTLE STOP SCREW

Page 35

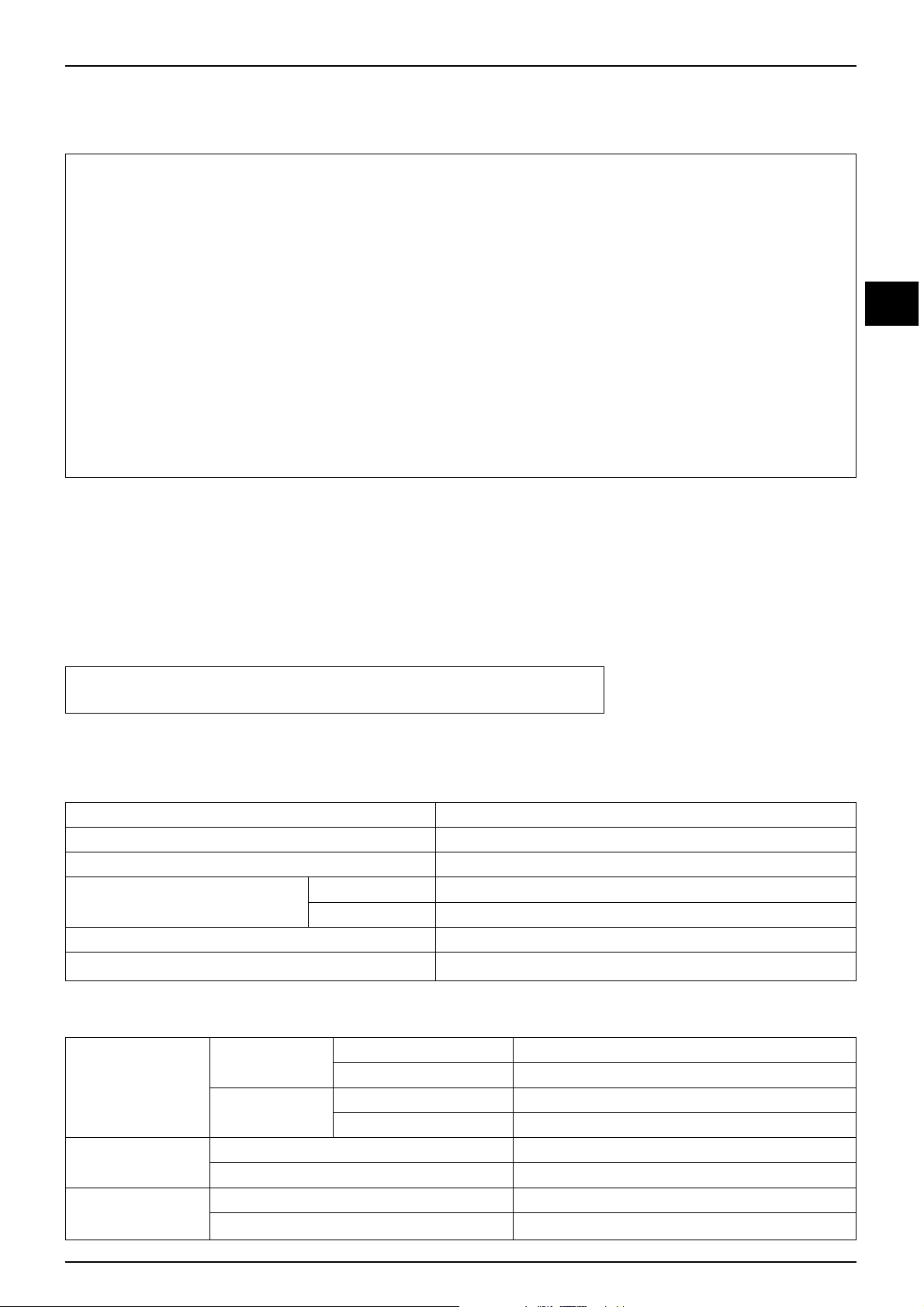

BRAKE FLUID

● Loosen the 3 screen setting screws securing the wind

screen.

● Remove the oil cup cap covers.

● Check the oil level inside the front/rear brake

reservoirs. If the oil level is near the lower limit line,

remove the reservoir diaphragms and fill DOT 3 and

DOT 4 brake fluid to the top limit line.

● If the brake fluid reaches the lower limit line, check the

entire brake system for leaks.

CAUTION

•Brake fluid will damage painted, plastic or rubber

parts.

•Mixing incompatible fluids can impair braking

efficiency.

•Foreign materials can clog the system, causing a

reduction or complete loss of braking ability.

•A leak in the brake system can lead to reduced

braking effiency and possible loss of braking ability.

BRAKE PAD/SHOE

BRAKE P AD REPLACEMENT

● Check the brake pads for wear.

● If the red mark on the pad reaches the brake disk,

replace the pads.

NOTE

•Replace the brake pads in sets.

PARKING BRAKE SHOE REPLACEMENT

● If the arrow mark of the wear limit aligns with the ‘△’

mark when the parking brake lever is tightly depressed,

it indicates the brake lining has reached the service

limit. Replace the brake shoes.

BRAKE SYSTEM

● Check the front brake hose for cracks or damage. If any

leaks are found, replace immediately .

● Check the brake rod for looseness or damage, and

replace it if necessary .

3-7

INSPECTIONS / ADJUSTMENTS

FRONT

MASTER CYLINDER

<FRONT>

WEARLIMITLINE

REAR

MASTER CYLINDER

<REAR>

WEARLIMITLINE

"△" MARK

FRONT CALIPER

REAR CALIPER

Page 36

BRAKE LEVER FREE PLAY

● Check the free play after pulling the lever.

FRONT : 10~20mm

REAR : 10~20mm

PARKING BRAKE FREE PLAY ADJUSTMENT

● Turn the adjuster nut to adjust the free play.

● After initial adjustment, check the operation of the

parking brake light switch. Make additional

adjustments, if necessary .

HEADLIGHT AIM

● Adjust the headlight beam level by operating the

adjusting screw located on the upper side of the front

fender.

NOTE

•Adjust the beam level according to local laws and

regulations.

•Improper beam level adjustment may blind

oncoming drivers, or may incorrectly light the road

ahead.

SIDE STAND

● Erect the main stand.

● Pull the lower end of the side stand, and see if it moves

freely .

● If the side stand does not move smoothly, apply grease

to the pivot area.

● If the side stand moves too freely, check the side stand

spring.

● Check the axial movement of the side stand.

3-8

INSPECTIONS / ADJUSTMENTS

ADJUSTER NUT

VERTICAL

ADJUSTING SCREW

HORIZONTAL

ADJUSTING SCREW

Page 37

● Check the side stand ignition cut-off switch :

-Put the side stand up.

-Start the engine.

-Lower the side stand. The engine should stop as you

put the side stand down.

● If there is a problem with the system, check the side

stand switch.

SUSPENSION

NOTE

•Do not ride motorcycle with an unsatisfactory

suspension. Loose or worn suspension parts will lead

to deterioration in the vehicle’s safety and operation

efficiency.

FRONT WHEEL

● Hold the brake lever, and compress the front cushion

up and down several times to check the operating

conditions.

● Check the front fork for oil leakage, parts damage or

looseness.

REAR WHEEL

● Compress the near cushion up and down several times

to check the operating conditions.

● Check the rear fork for oil leakage, parts damage or

looseness.

BOL TS, NUTS, FASTENERS

● Check all nuts and bolts of the frame during the regular

maintenance to check if they meet the prescribed

torque value.

● Check all pins, clips, hose clamps and cable stays.

3-9

INSPECTIONS / ADJUSTMENTS

SIDE STAND

SWITCH

Page 38

WHEELS/TIRES

NOTE

•Check the tire pressure when the tires have been

cooled off. Check the tread (the part making contact

with the road surface) and side for wear, cracks or

damage. Replace damaged tires.

ST ANDARD PRESSURE

● Check the tread depth at the tire center.

● If the tread depth has reached the service limit, replace

the tire.

SERVICE LIMIT :0.5mm

STEERING HEAD BEARING

NOTE

•Check the cable if it interferes with the handle

operation.

● Lift the front wheel and check if the handle moves right

and left smoothly. If the handles move heavily, check if

the cable or electric cord interferes with the handle. If

the handle moves satisfactorily, adjust the steering head

bearing.

3-10

INSPECTIONS / ADJUSTMENTS

FRONT WHEEL

2.00(200)

2.00(200)

REAR WHEEL

2.00(200)

2.25(225)

ITEM

DRIVER ONLY

DRIVER AND A PASSENGER

㎏f/㎠ (kpa)

TIRE PRESSURE GAUGE

WEAR INDICATOR LOCATION MARKING

Page 39

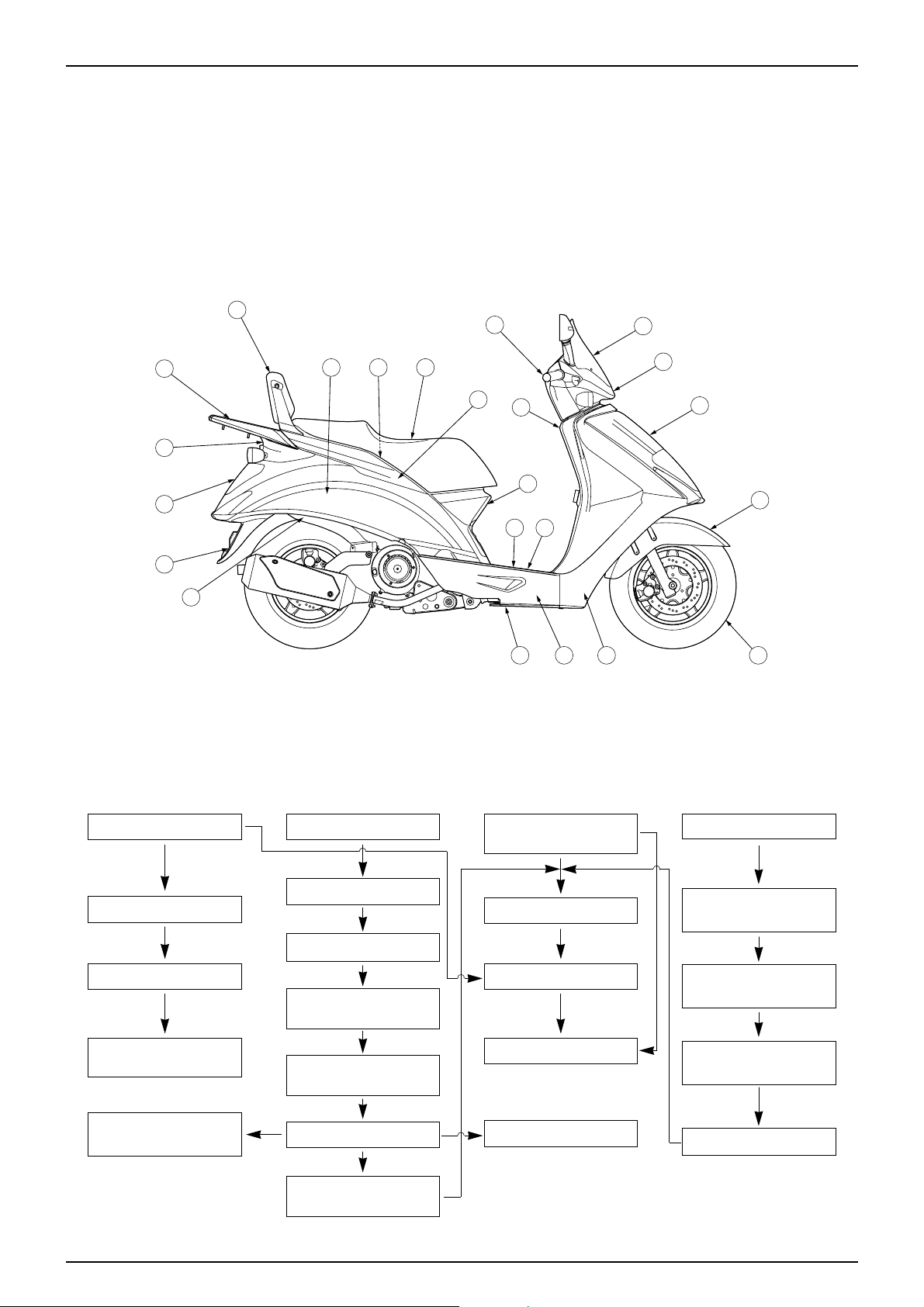

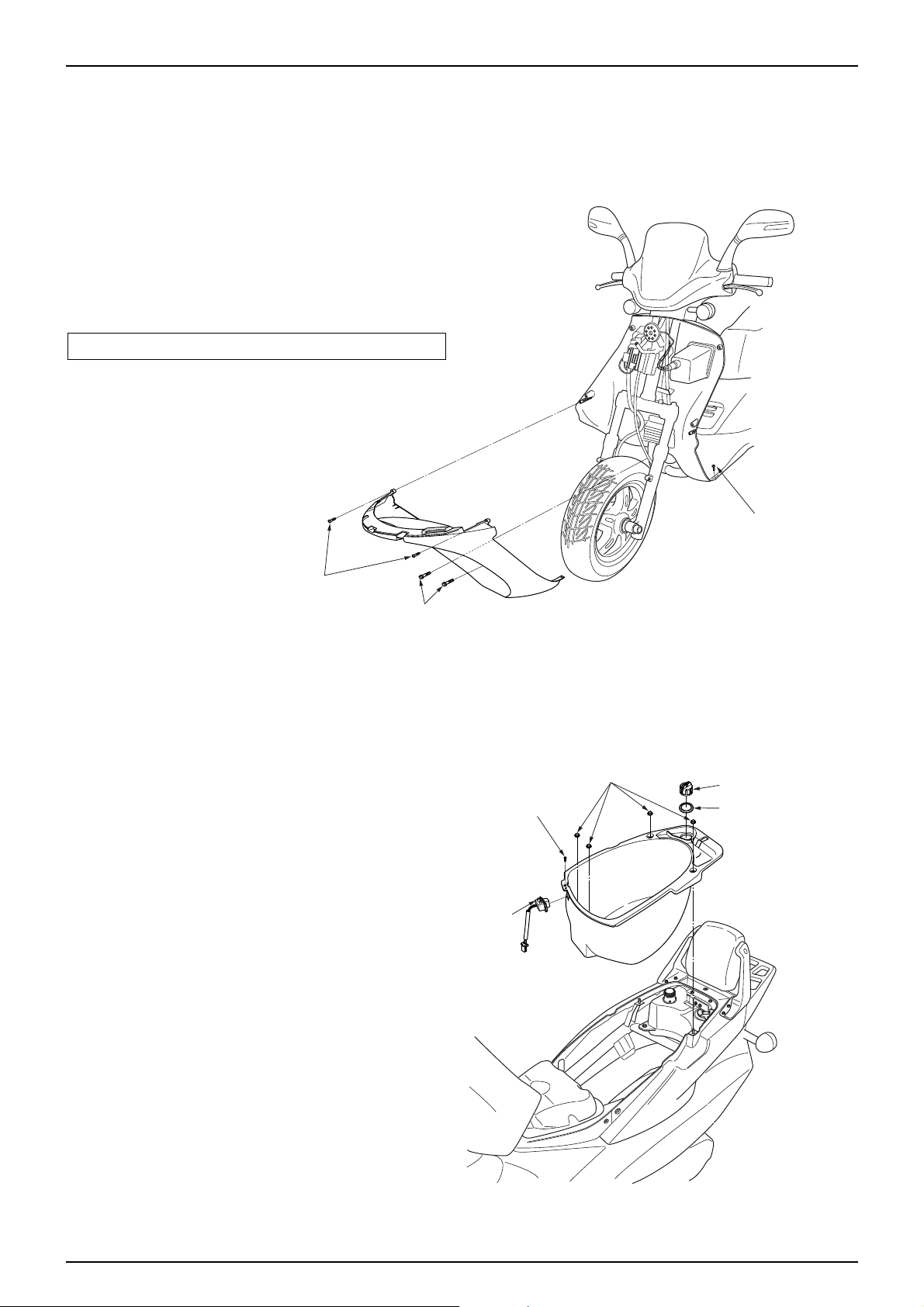

4-1

4. EXTERNAL PARTS

SERVICE INFORMATION

NOTE

● This section describes external parts removal/installation.

● Do not apply unreasonable force when disassembling covers, to prevent possible damage.

● A muffler is hot. Do not service it immediately after the engine is stopped.

4

SERVICE INFORMATION

····

4-1

MAINTENANCE PRECEDURE

····

4-2

EXTERNAL PARTS

REMOVAL / INSTALLATION··4-3

MUFFLER

················

4-12

Page 40

4-2

EXTERNAL P ARTS

2

4 31316

21

17

11

8

9

9

10 6 5

12

15

20

7

22 14

1

19

18

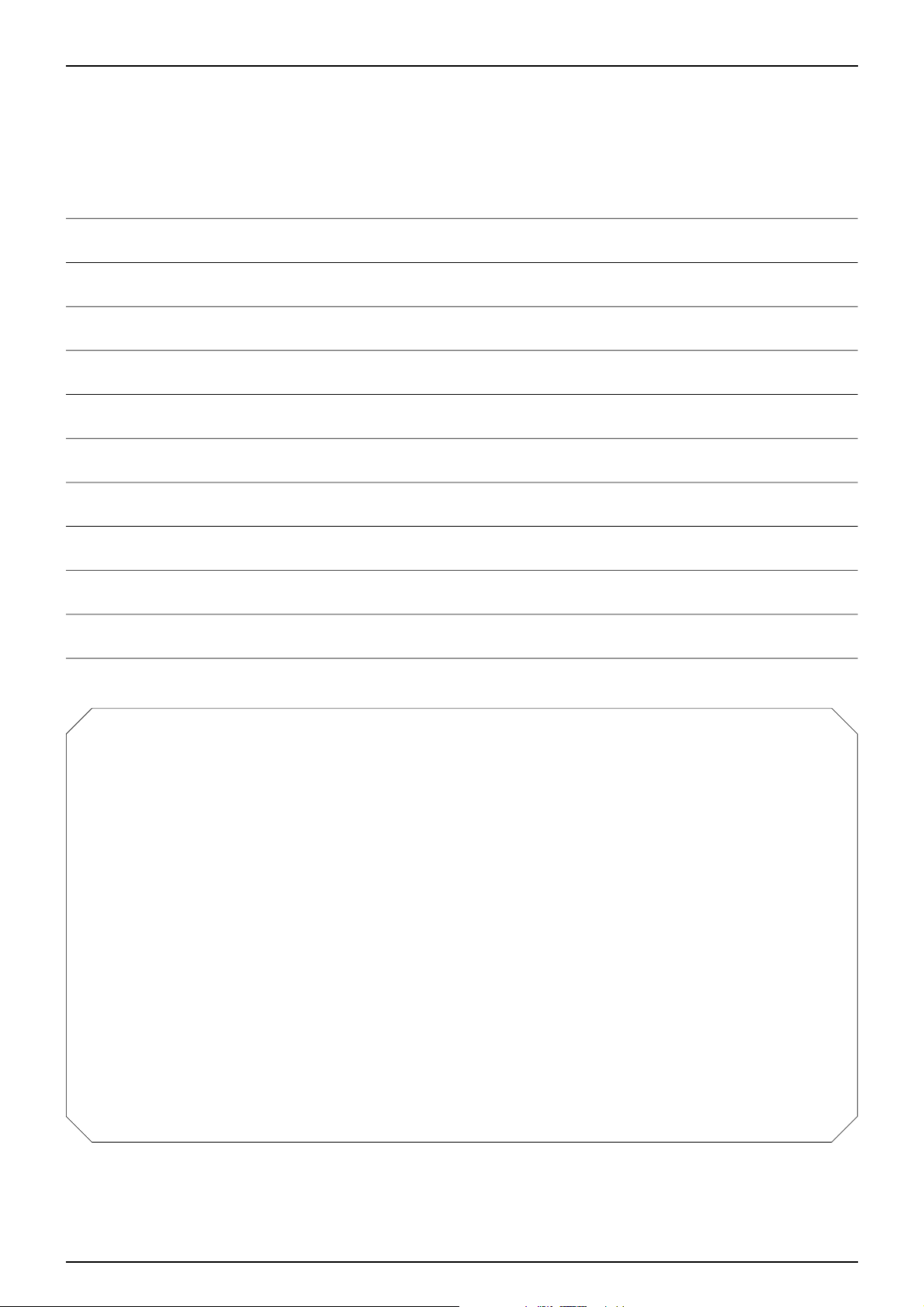

MAINTENANCE PROCEDURE

NAMES OF FRAME COVERS

● This chart shows arrows connected in the order of disassembling covers.

①

FRONT COVER

② FRONT FENDER

③

FRONT WHEEL

④

FRONT UNDER

COVER

⑪

REAR COMBINA TION

LIGHT

⑤ SEAT

⑥ LUGGAGE BOX

⑧ REAR CENTER

COVER

⑨ REAR CARRIER

/ BACK REST

⑫ UPPER BODY

COVR

⑩ BODY COVER

⑦

CENTER COVER

⑬ FLOOR SIDE

COVER

⑭ FLOOR PANEL

⑮ INNER BOX

⑯ UNDER COVER

⑰ REAR FENDER

⑱ WIND SCREEN

⑲ FRONT HANDLE

COVER

⑳ REAR HANDLE

COVER

REAR WHEEL

MUDGUARD

BA TTERY COVER

Page 41

4-3

EXTERNAL P ARTS

SPECIALSCREW

SPECIALSCREW

SPECIALSCREW

SPECIALSCREW

FRONTCOVER

SPECIALSCREW

SPECIALSCREW

FRONTFENDER

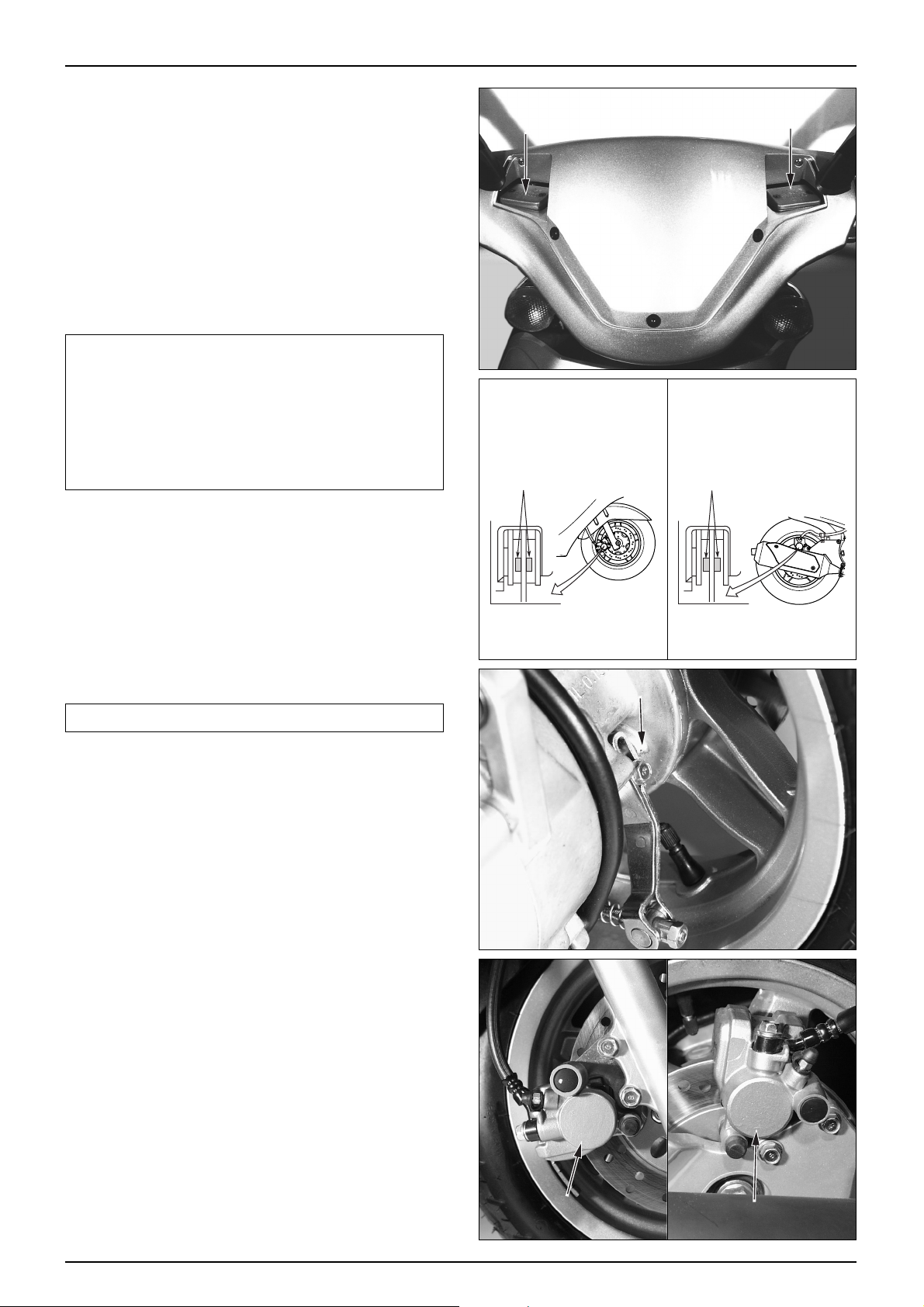

FRONT COVER

● Loosen the 4 special screws securing the inner box.

● Loosen the special screw securing the front of the front

cover.

● Loosen the 2 special screws securing the front under

cover.

● Draw the upper part of the front cover to remove it.

● Disconnect the headlight wiring and remove the

front cover.

● Loosen the 4 flange bolts securing the headlight,

remove the headlight.

● Loosen the 4 tapping screws securing the top cover,

remove the front protector .

● Install in the reverse order of removal.

FRONT FENDER

● Loosen the oval screw securing the speedometer gear

box, remove the speedometer cable.

● Remove the wire grommet from the front fender.

● Loosen the 2 special screws securing the LH. front

cushion.

● Loosen the 2 special screws securing the RH. front

cushion.

● Install in the reverse order of removal.

Page 42

4-4

EXTERNAL P ARTS

TAPPINGSCREW

FLANGEBOLT

SPECIALSCREW

OPENSTAYNUT

FUELTANKCAP

FUELGUIDERUBBER

SCREW

TRUNKLAMP

FRONT UNDER COVER

● Remove the front fender. (⇨4-3)

● Remove the front wheel. ( ⇨12-5)

● Loosen the 4 tapping screws securing the inner box.

● Remove the floor mat, and loosen the 2 special screws

securing the front of the floor panel.

● Loosen the 2 flange bolts securing the frame under

cover bracket.

● Remove the front under cover.

● Install in the reverse order of removal.

NOTE

•Pay attention not to turn over the vehicle.

LUGGAGE BOX

● Release the seat lock by turning the main switch key to

open the seat.

● Loosen the 4 open stay nuts.

● Loosen the fuel tank cap, remove the fuel guide rubber.

● Disconnect the trunk lamp wiring.

● Remove the luggage box.

● Loosen the tapping screw securing the luggage box,

remove the trunk lamp.

● Install in the reverse order of removal.

Page 43

4-5

EXTERNAL P ARTS

SEAT

WASHERSCREW

SPECIALSCREW

PLUGMAINTENANCECOVER

CENTERCOVER

FLANGEBOLT

HINGEPIN

SPECIALSCREW

REARCENTERCOVER

SPECIALSCREW

WASHERSCREW

RH.REARWINKERASSEMBLY

REFLEXREFLECTOR

SPECIALSCREW

SPECIALSCREW

LH.REARWINKER

ASSEMBLY

WASHERSCREW

CENTER COVER

● Release the seat lock by turning the main switch key to

open the seat.

● Loosen the flange bolt securing the frame, and remove

the hinge pin, and then remove the seat.

● Loosen the plug maintenance cover setting special

screw securing the center cover, remove the plug

maintenance cover .

● Loosen the 2 washer screws securing the body cover.

● Loosen the special screw securing the front of the floor

panel.

● Draw the upper part of the center cover to remove it.

● Install in the reverse order of removal.

REAR CENTER COVER

● Loosen the 4 special screws securing the body cover.

● Remove the rear center cover, disconnect the RH./LH.

winker wiring.

● Loosen the RH./LH. winker setting washer screws

securing the rear center cover, remove the RH./LH.

winker.

● Remove the rear reflex reflector securing the rear

center cover .

● Install in the reverse order of removal.

Page 44

4-6

EXTERNAL P ARTS

SPECIALBOLT

BACKREST

FLANGEBOLT

REARCARRIER

FLANGEBOLT

SPECIALSCREW

SPECIALSCREW

BODYCOVERCLIP

UPPERBODYCOVER

REARREFLECTOR

TAPPINGSCREW

TAPPINGSCREW

SPECIALSCREW

BODYCOVERCLIP

BODYCOVER

REAR CARRIER/BACK REST

● Remove the rear center cover. (⇨4-5)

● Loosen the 2 flange bolts(R/L) securing the frame.

● Loosen the 2 flange bolts(R/L) securing the rear carrier.

● Remove the rear carrier.

● Loosen the 4 back rest setting special bolts(R/L),

Remove the back rest.

● Install in the reverse order of removal.

BODY COVER/UPPER BODY COVER

● Release the seat lock by turning the main switch

key to open the seat.

● Remove the following parts.

-Luggage box (⇨4-4)

-Center cover (⇨4-5)

-Rear center cover (⇨4-5)

-Rear carrier (⇨4-6)

-Back rest (⇨4-6)

● Loosen the 4 special screw (R/L) securing the floor

panel.

● Loosen the 2 special screw (R/L) securing the

frame, disconnect the rear combination light wiring.

● Loosen the 2 body cover clips (R/L) securing the

rear fender.

● Draw the upper part of the body cover to remove it.

● Loosen the 2 washer screws securing the body

cover, remove the rear combination light.

● Loosen the 4 tapping screws securing the body

cover, remove the rear reflector.

● Loosen the 2 tapping screws (R/L) and 2 body

cover clips securing the body cover, remove the

upper body cover.

● Loosen the 2 body cover clips (R/L) securing the

body cover, remove the RH./LH. body cover.

● Install in the reverse order of removal.

Page 45

4-7

EXTERNAL P ARTS

TAPPINGSCREW

REARCOMBINATIONLIGHT

WASHERSCREW

BODYCOVER

SPECIALSCREW

BODYCOVERCLIP

LH.FLOORSIDECOVER

SPECIALSCREW

REAR COMBINATION LIGHT

● Release the seat lock by turning the main switch key to

open the seat.

● Remove the seat.

● Remove the following parts.

-Luggage box (⇨4-4)

-Center cover (⇨4-5)

-Rear center cover (⇨4-5)

-Rear carrier (⇨4-6)

-Back rest (⇨4-6)

-Body cover (⇨4-6)

● Loosen the 2 washer screws securing the body

cover, remove the rear combination light.

● Install in the reverse order of removal.

FLOOR SIDE COVER

● Remove the floor mat.

● Loosen the 2 special screws (R/L) securing the front

part of the front under cover .

● Remove the 4 body cover clips (R/L) securing the floor

panel

● Loosen the 2 special screws (R/L) securing the rear

part of the floor panel.

● Loosen the 2 special screws (R/L) securing the side of

the floor panel.

● Remove the RH./LH. floor side cover.

● Install in the reverse order of removal.

Page 46

4-8

EXTERNAL P ARTS

FLOORMAT

TAPPINGSCREW

BATTERYCOVER

FLOORPANEL

UNDERCOVER

SETTINGSCREW

BATTERY

WASHERBOLT

WASHERBOLT

FLOOR PANEL

● Release the seat lock by turning the main switch key to

open the seat.

● Remove the following parts.

-Seat and center cover (⇨4-5)

-Rear carrier and back rest (⇨4-6)

-Floor mat

-Body cover (⇨4-6)

-RH./LH. floor side cover (⇨4-7)

● Loosen the 2 tapping screws securing the floor

panel, remove the battery cover.

● Disconnect the battery wiring to remove the battery.

CAUTION

•Be sure to remove the negative pole ⊖ side cord

first and the position pole ⊕ side cord next.

•Make sure that terminals do not contact with

other adjacent parts when handling ⊕ / ⊖

terminal.

Contact with other parts may cause spark

resulting in electrical equipment malfunction, fire

and electric shock.

● Loosen the 4 washer bolts (R/L) securing the floor

panel.

● Remove the floor panel from the connecting groove

of the inner box by lifting the rear part of the panel

slightly.

● Install in the reverse order of removal.

UNDER COVER

● Remove the floor side cover. (⇨4-7)

● Loosen the 2 upper cover setting screws (R/L) securing

the frame.

● Remove the under cover.

● Install in the reverse order of removal.

4-8

Page 47

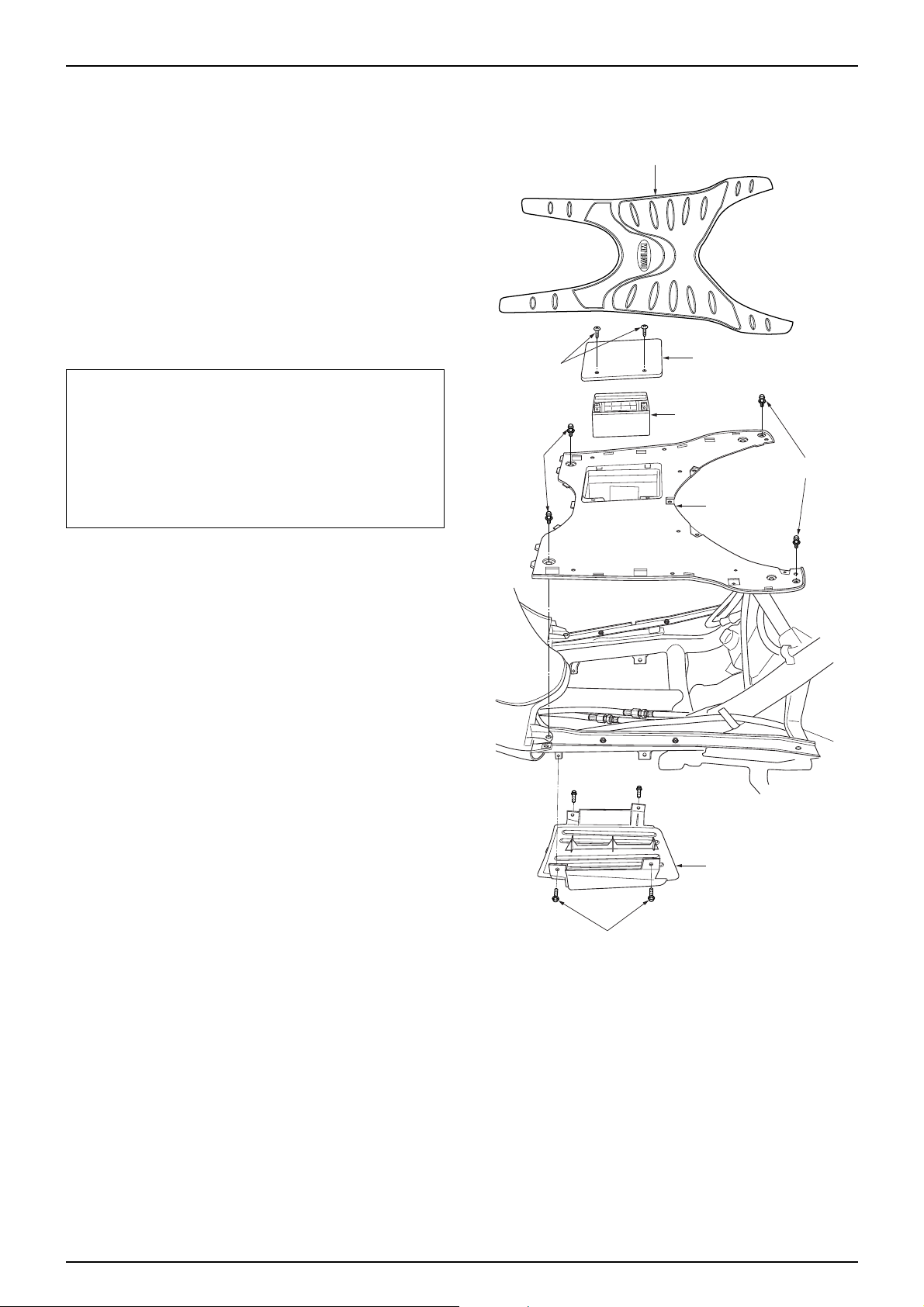

INNER BOX / INNER BOX LID

● Remove the following parts.

-Front cover (⇨4-3)

-Luggage box (⇨4-4)

-Center cover (⇨4-5)

-Rear center cover (⇨4-5)

-Rear carrier and back rest (⇨4-6)

-Body cover (⇨4-6)

-Floor side cover (⇨4-7)

-Floor panel (⇨4-8)

● Loosen the 2 tapping screws securing the front

under cover.

● Loosen the 2 special screws (R/L) securing the rear

part of the front under cover.

● Loosen the 2 pan screws securing the bag holder,

remove the bag holder.

● Turn the main key cover slightly to release the

locking and remove the main key cover.

● Loosen the pan screw securing the parking brake

lever, remove the parking brake grip.

● Disconnect the coupler of the charge socket,

remove the charge socket from the inner box.

● Remove the inner box.

● Loosen the 2 tapping screws, remove the parking

brake lever seal.

● Remove the inner box lid from the inner box.

● Remove the lock key setting spring, and remove the

inner box lid key.

● Install in the reverse order of removal.

REAR FENDER

● Release the seat lock by turning the main switch

key to open the seat.

● Remove the seat.

● Remove the following parts.

-Luggage box (⇨4-4)

-Center cover (⇨4-5)

-Rear center cover (⇨4-5)

-Rear carrier (⇨4-6)

-Back rest (⇨4-6)

-Body cover (⇨4-6)

● Disconnect the license lamp wiring, loosen the

washer screw securing the rear fender, and remove

the license lamp assembly.

● Loosen the 2 washer bolts securing the fuel tank

support stay.

● Remove the rear fender.

● Install in the reverse order of removal.

4-9

INNERBOX

BACKHOLDER

SPECIALSCREW

TAPPINGSCREW

PARKINGBRAKE

PANSCREW

CHARGE

SOCKET

WASHERSCREW

WASHERBOLT

REARFENDER

LICENSELAMPASSEMBLY

EXTERNAL P ARTS

Page 48

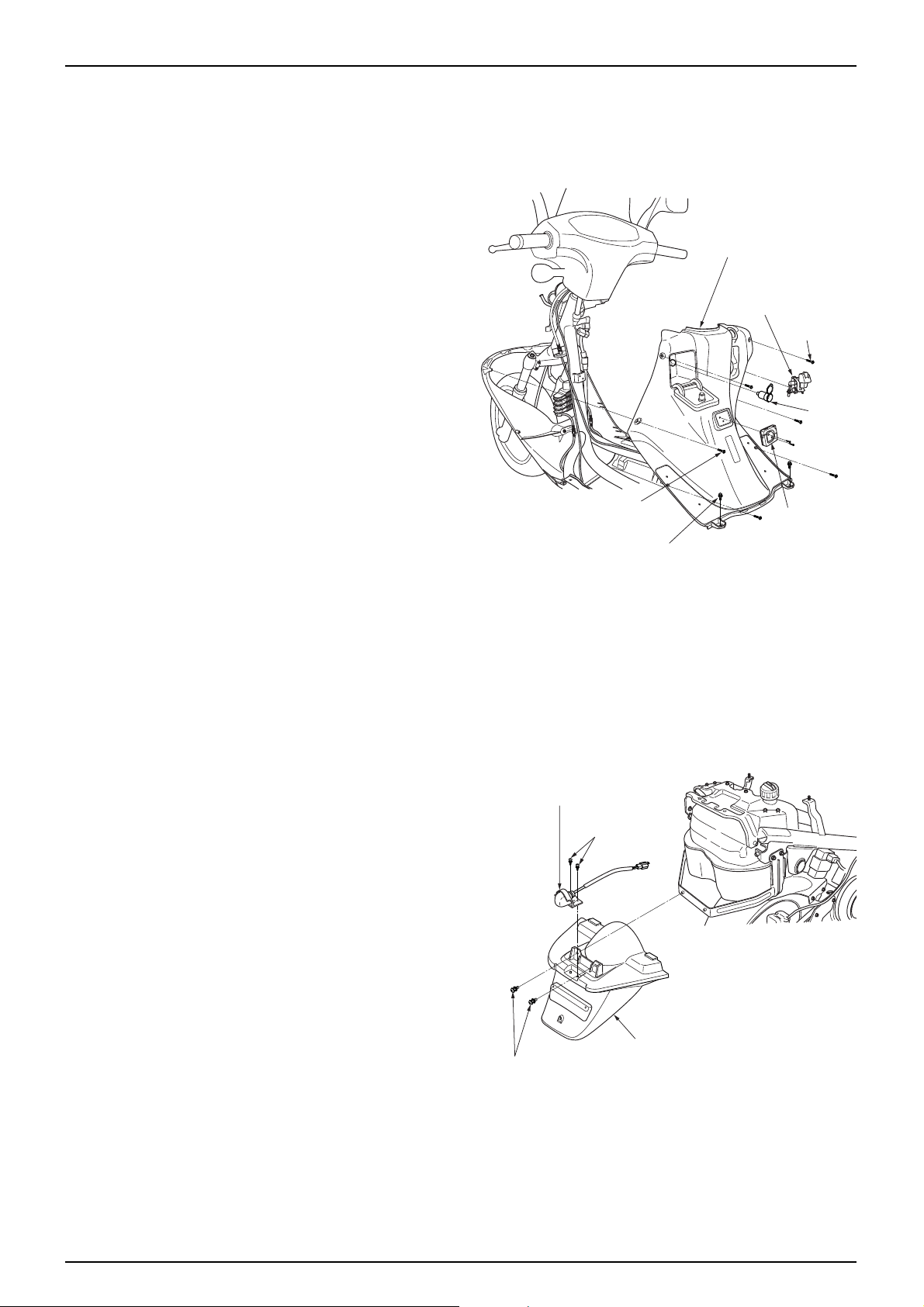

WIND SCREEN /

FRONT HANDLE COVER

● Loosen the 3 screen setting screws securing the

front handle cover.

● Pulling the cover to the under slightly and remove

the wind screen from the front handle cover groove.

● Loosen the 4 tapping screws (FR./RR.) securing the

rear handle cover.

● Loosen the front handle cover LH./RH. setting pan

screws (2EA) securing the steering handle.

● Remove the handle cover, disconnect the RH./LH.

winker wiring.

● Remove the 3 wind screen setting nuts securing the

front handle cover.

● Loosen the RH./LH. winker setting hex nuts

securing the front handle cover, remove the

RH./LH. winker.

● Install in the reverse order of removal.

REAR HANDLE COVER

● Remove the front handle cover. (⇨4-10)

● Loosen the 2 tapping screws securing the steering

handle.

● Remove the speedometer cable from the meter.

● Disconnect the stop switch wiring of the RH./LH.

master cylinder assembly .

● Disconnect the winker relay wiring securing the winker

relay .

● Remove the rear handle cover from the steering handle.

● Disconnect the right and left switch wiring, remove the

switches.

● Loosen the 4 speedometer setting tapping screws

securing the rear handle cover .

● Remove the rear handle cover.

● Install in the reverse order of removal.

NOTE

•Check each switch for proper operation after

installation.

•Wires and cables must be connected properly.

4-10

TAPPINGSCREW

TAPPINGSCREW

LH.WINKERASSEMBLY

RH.WINKERASS'Y

FRONT

HANDLECOVER

HEXNUT

SETTINGSCREW

SPEEDOMETERASSEMBLY

TAPPINGSCREW

REARHANDLECOVER

TAPPINGSCREW

TAPPINGSCREW

EXTERNAL P ARTS

Page 49

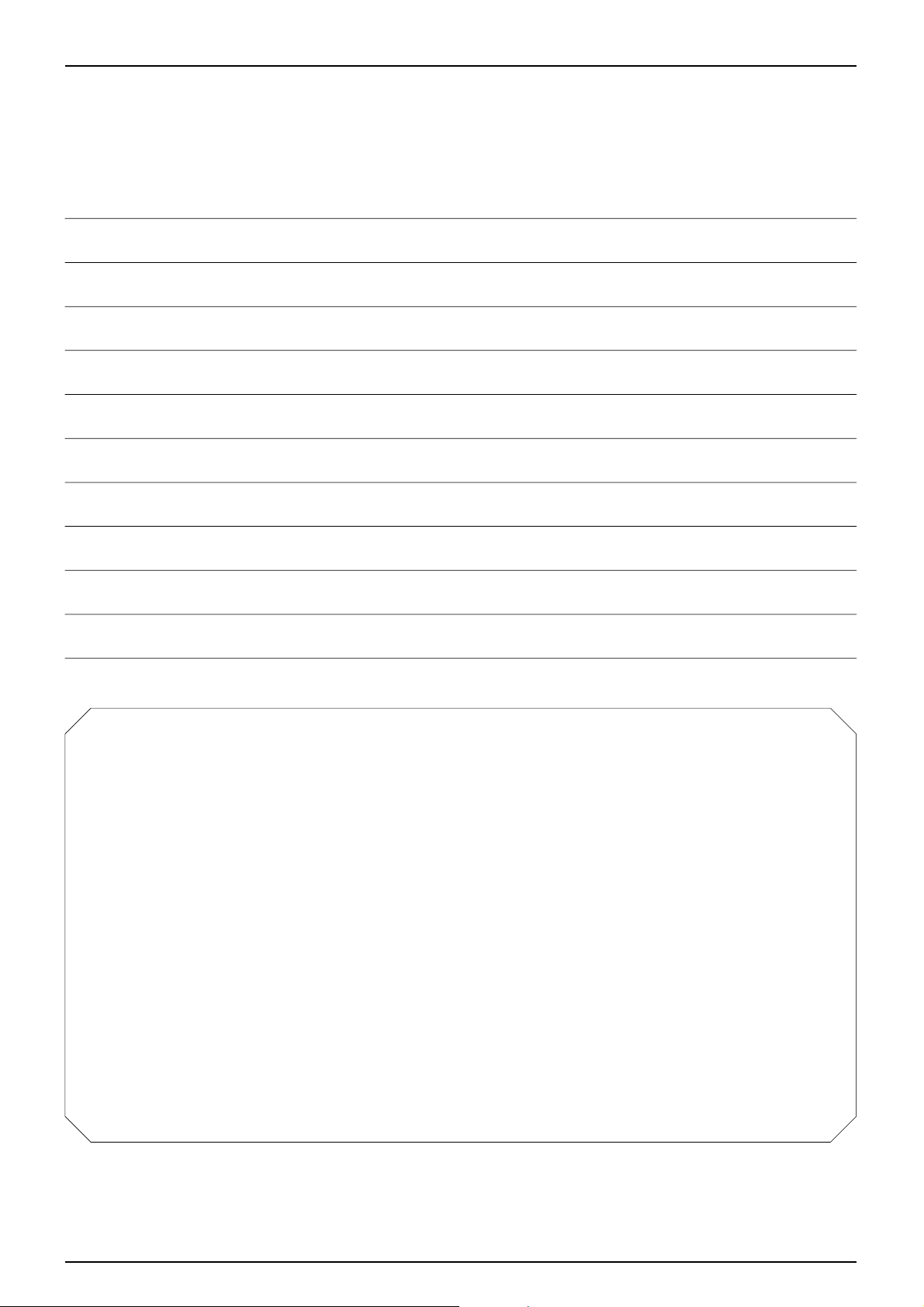

REAR WHEEL MUD GUARD

● Loosen the washer bolt securing the LH. crankcase.

● Loosen the washer bolt securing the RH. crankcase.

● Loosen the washer bolt securing EX. muffler bracket.

● Remove the rear wheel mud guard.

● Install in the reverse order of removal.

NOTE

•Never perform the maintenance of the muffler right

after stopping the vehicle because the muffler is

extremely hot.

4-11

WASHERBOLT

WASHERBOLT

REARWHEELMUDGUARD

EXTERNAL P ARTS

Page 50

MUFFLER

REMOV AL

● Loosen the 3 cap nuts securing the EX. pipe comp.

● Loosen the flange bolt securing the upper part of

the RH. crankcase cover.

● Loosen the rear brake hose setting bolt.

● Loosen the flange bolt securing the rear wheel mud

guard.

● Loosen the 2 flange bolts securing the lower part of

the rear swing arm.

● Remove the EX. muffler comp.

WARNING

•Never perform the maintenance of the muffler right

after stopping the vehicle because the muffler is

extremely hot.

EX. PIPE REMOV AL

● Remove the plug maintenance cover.

● Loosen the 2 flange bolts securing the cylinder

comp.

● Remove the EX. pipe by drawing it to the ground

direction.

INST ALLATION

● Insert the EX. pipe gasket to the EX. pipe.

● Insert the EX. pipe to the cylinder comp, and

tighten the 2 flange nuts with specified torque.

● Install the plug maintenance cover.

NOTE

•Tighten the flange nuts diagonally and alternately

and tighten with specified torque in the end.

● Insert the flange gasket to the EX. muffler comp.

● Tighten the flange bolt securing the RH. crankcase

cover.

● Tighten the 2 flange bolts securing the swing arm.

TORQUE VALUE :5.5 kgf·m

● Tighten the 3 cap nuts securing the EX. pipe comp.

● Tighten the rear brake hose setting nut.

● Tighten the flange bolt securing the rear wheel mud

guard.

NOTE

•When installing the gasket, replace it with the new

one.

•Check to see if there is any evacuation after

installing the muffler.

4-12

EXTERNAL P ARTS

EX. MUFFLER

FLANGE BOLT

FLANGE BOLT

CAP NUT

EX. PIPE

FLANGE NUT

FLANGE BOLT

EX.MUFFLER

FLANGE NUT

FLANGE BOLT

FLANGE BOLT

CAP NUT

Page 51

MEMO

Page 52

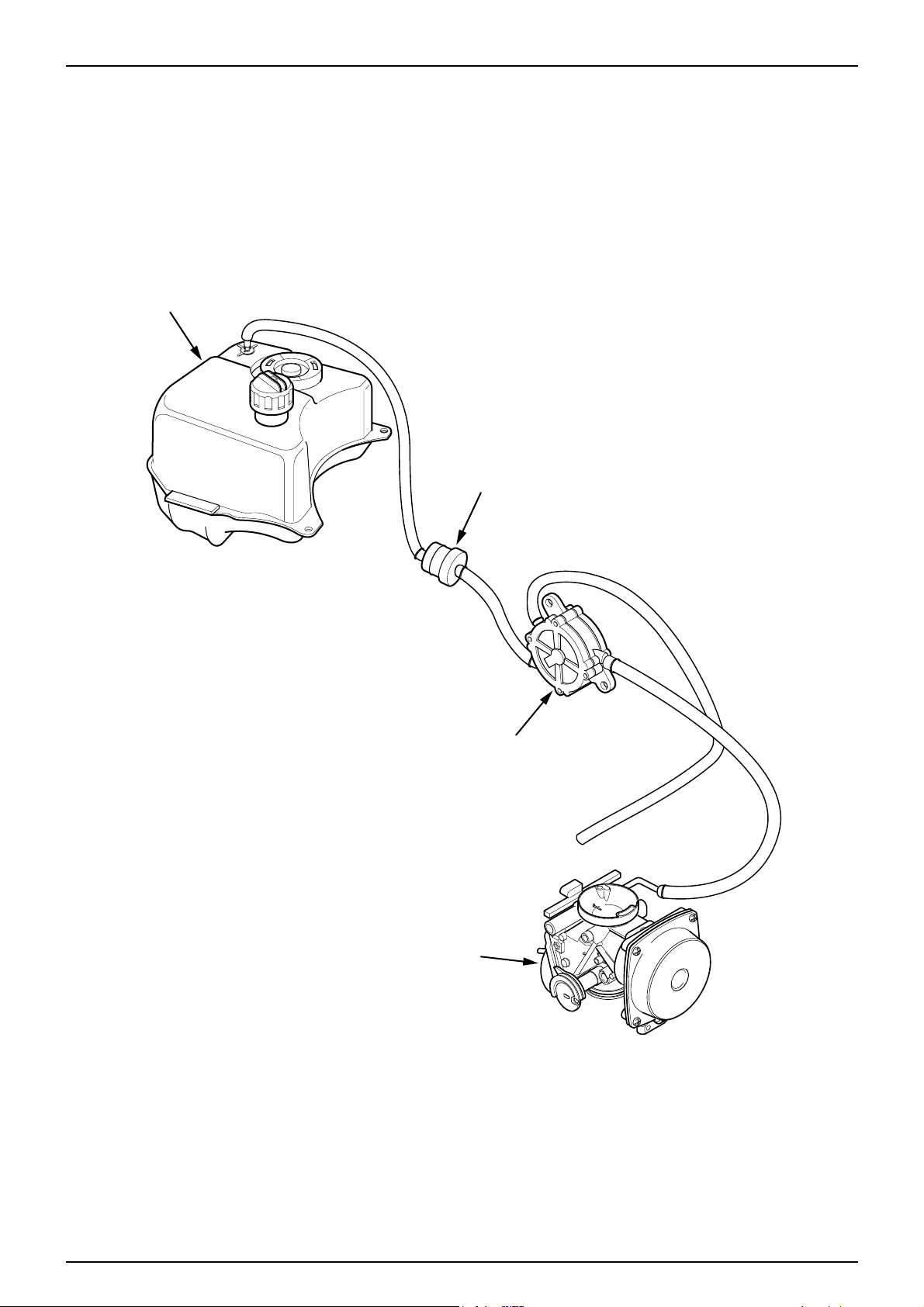

FUEL SYSTEM

5-0

FUELTANK

FUELSTRAINER

FUELPUMP

CARBURETOR

Page 53

SERVICE INFORMATION

GENERAL SAFETY

WARNING

● Gasoline is extremely flammable. Avoid fire in the work place, also paying particular attention to sparks. Furthermore,

the evaporated (gasified) gasoline is highly explosive. Work in a well-ventilated areas.

● Exhaust gas contains poisonous substance. Do not keep engine running for a long period of time in a closed, or poorly

ventilated area.

CAUTION

● Do not excessively bend or twist cable. Distorted or damaged cable may lead to mechanical malfunctions.

● Pay particular attention to the position of O-ring. Replace with new ones when disassembled.

● If it is desired to store a vehicle for a period longer than 1 month, drain gasoline out of the carburetor float chamber.

Gasoline left in the float chamber will be deteriorated causing the slow jet to be clogged with deposits, and idling may

become unstable.

SPECIFICA TIONS

FUEL T ANK CAPACITY : 8ℓ

RESER VE FUEL CAPACITY: 2ℓ

CARBURETOR

TOOL

FLOAT LEVEL GAUGE

5-1

5. FUEL SYSTEM

5

SERVICE INFORMATION

····

5-1

TROUBLESHOOTING

········

5-2

FUEL TANK

················

5-3

ITEM

TYPE/THROTTLE BORE

MODEL MARK

MAIN JET No.

PILOT SCREW OPENING

FLOAT LEVEL

IDLING SPEED

THROTTLE GRIP FREE PLAY

STANDARD

CV TYPE (VACUUM)/24.2mm

BDS26 - 112

#95

1½ RETURNS

13.0mm

1,800±100rpm

2-6mm

AIR CLEANER

··············

5-4

CARBURETOR

··············

5-4

PILOT SCREW ADJUSTMENT··5-10

Page 54

5-2

FUEL SYSTEM

TROUBLESHOOTING

The vehicle does not start.

● No gasoline in fuel tank.

● Fuel is not coming out of carburetor.

● Too much fuel is flowing into cylinder.

● No spark emitted from spark plug.

● Air cleaner is blocked.

● Suction system is experiencing secondary intake of air.

● Using low quality gasoline.

● Starter is damaged.

● Throttle cable is working improperly.

● Fuel tank is functioning improperly.

Idle is unstable and engine turns off after starting.

● Starter is damaged.

● Ignition system is damaged.

● Using low quality gasoline.

● Suction system is experiencing secondary intake of air.

● Idle is adjusted improperly.

● Air screw is adjusted improperly.

● Compression pressure is low.

● Air/Fuel mixture is either too lean or rich.

● Carburetor is blocked.

Mis-firing occurs when driving at high speeds.

● Ignition system is damaged.

● Mixture is too lean.

Back firing

● Ignition system is damaged.

● Mixture is too lean.

Insufficient power and high fuel consumption.

● Air cleaner is blocked.

● Ignition system is damaged.

● Mixture is too rich.

Air/Fuel mixture is extremely lean

● Fuel jet is blocked.

● Float valve is damaged.

● Oil level is low.

● Bad ventilation of air in tank cap.

● Fuel strainer screen is blocked.

● Fuel tube is bent, creased or blocked.

● Suction system is receiving secondary suction of air.

Air/Fuel mixture is extremely rich.

● Air jet is blocked.

● Float valve is damaged.

● Oil level is too high.

● Starter is damaged.

● Air cleaner is blocked.

Page 55

5-3

FUEL SYSTEM

FUEL TANK

FUEL TUBE

FUEL PUMP

FUEL TANK

REMOV AL

WARNING

•Gasoline is extremely flammable. Avoid fire during

work, and pay particular attention to electric sparks.

Furthermore, the evaporated (gasified) gasoline is

highly explosive. Work in a well-ventilated areas.

● Release the seat lock by turning the main switch key to

open the seat.

● Remove the following parts.

- Luggage box. (⇨4-4)

- Plug maintenance cover.(⇨4-5 )

- Center cover. (⇨4-5)

- Rear center cover. (⇨4-5)

- Rear carrier/Back rest. (⇨4-6)

- Body cover. (⇨4-6)

● Remove the fuel tube from the fuel tank.

NOTE

•Use the tube clip or the cap to prevent the gasoline

from leaking.

● Remove the fuel unit wire coupler.

● Remove the license lamp wire coupler.

● Loosen the 4 flange bolts securing the fuel tank support

stay, remove the fuel tank with the fuel tank support

stay and rear fender from the frame.

● Loosen the 2 flange bolts securing the fuel tank,

remove the fuel tank by drawing down it slightly.

NOTE

•After removing the fuel tank, be sure to close the fuel

tank cap.

INST ALLATION

● Install in the reverse order of removal.

NOTE

• Check for gasoline leakage.

•“Gasoline”mark is on the fuel tank cap.

• Check this mark when filling gasoline.

FUEL UNIT

COUPLER

FLANGE BOLT

FLANGE

BOLT

FUEL TANK CAP

Page 56

5-4

FUEL SYSTEM

FLANGE BOLT

COUPLING

BAND A

INTAKE

COUPLING

COUPLING

BAND B

AIR CLEANER

DUCT CLIP

INLET DUCT

AIR CLEANER

REMOV AL

● Remove the luggage box. (⇨4-4)

● Remove the center cover. (⇨4-5)

● Loosen the intake coupling band B securing the

carburetor, remove the air cleaner from the carburetor.

● Remove the air band hose securing the air cleaner.

● After pressing the duct clip securing the air cleaner,

remove the air cleaner inlet duct.

● Loosen the 3 flange bolts (left 1, right 2) securing the

frame body .

● Remove the air cleaner.

● Install in the reverse order of removal.

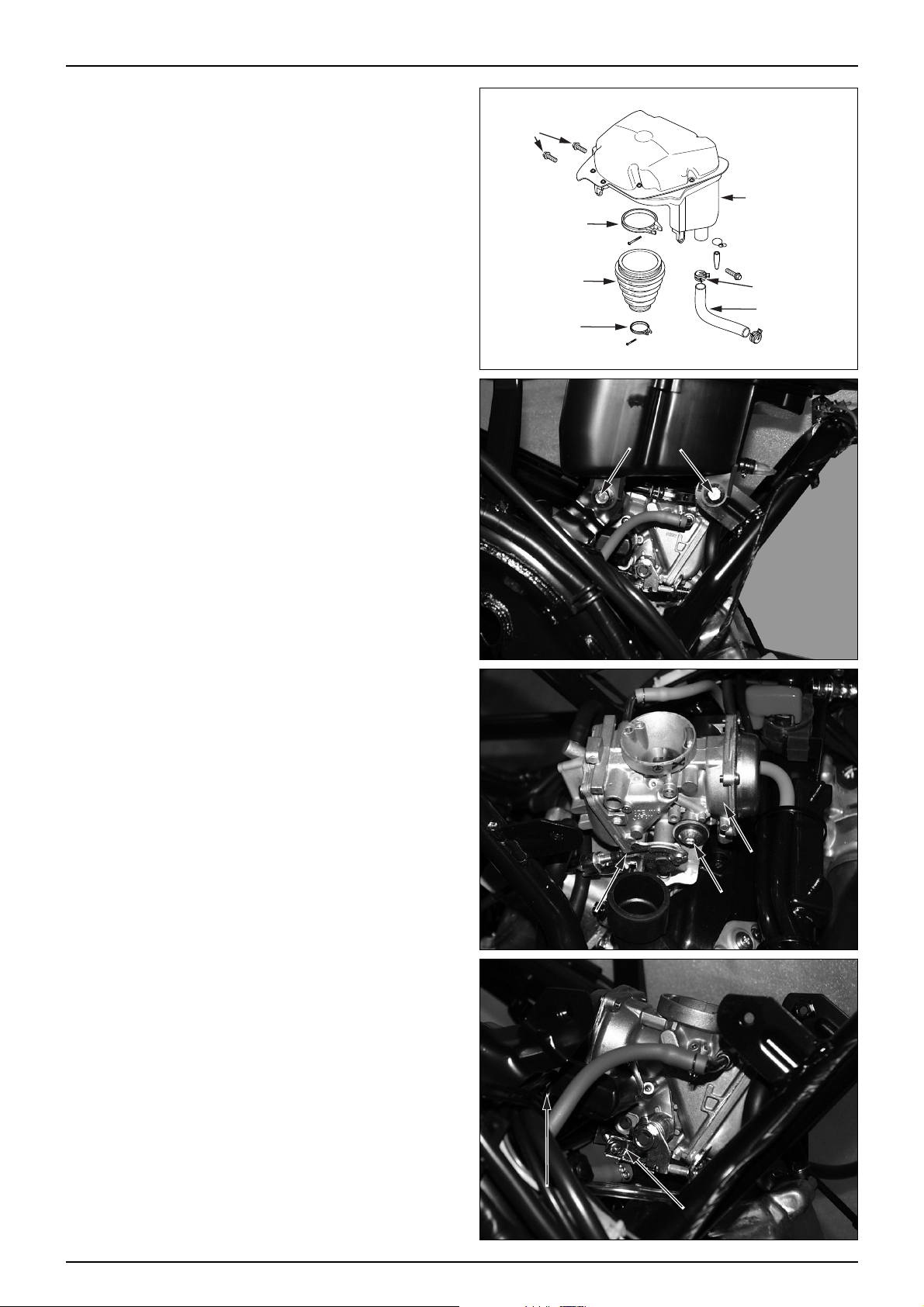

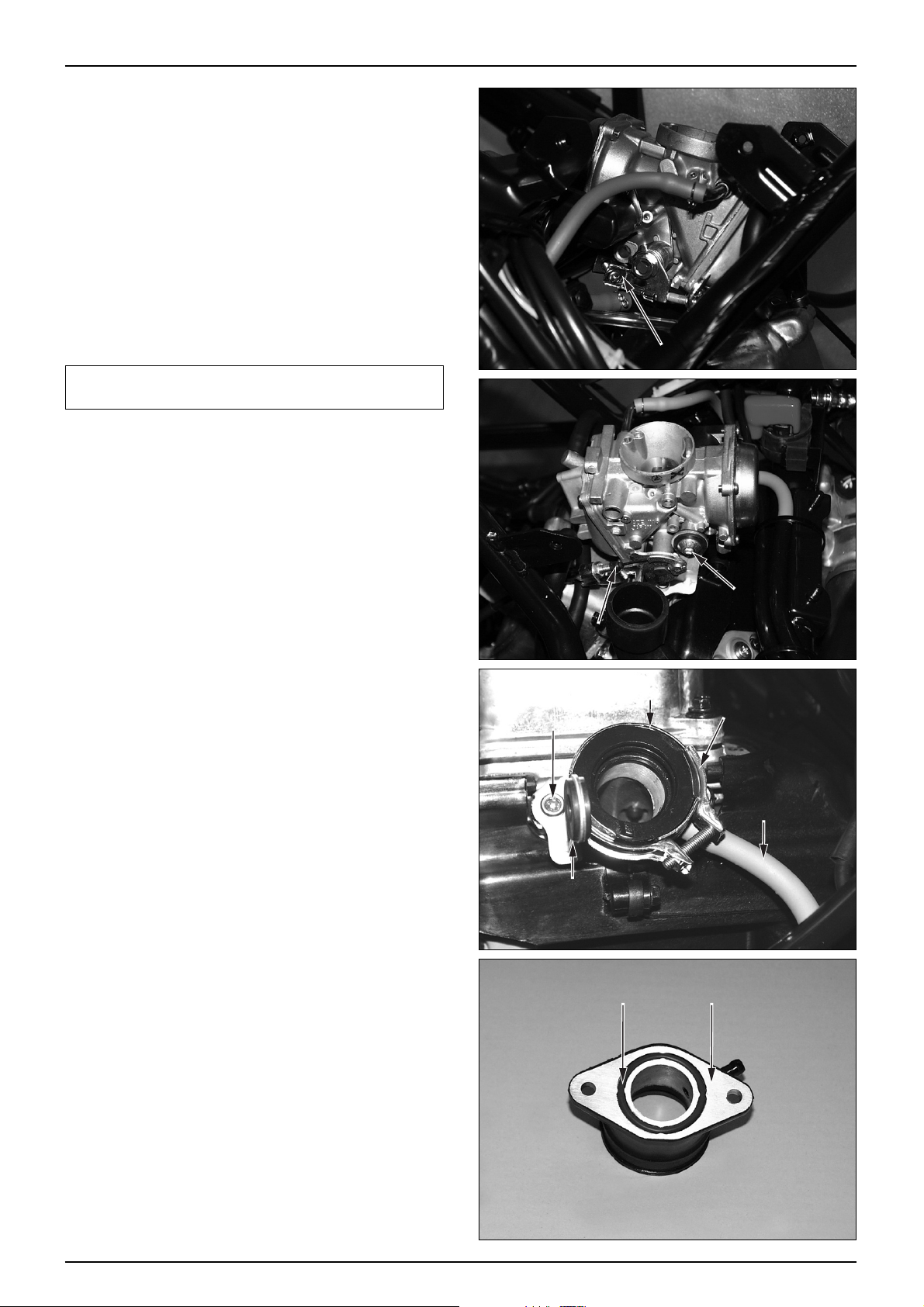

CARBURETOR

REMOVAL

● Remove the luggage box. (⇨4-4)

● Remove the center cover. (⇨4-5)

● Remove the air cleaner. (⇨5-4)

● Loosen the throttle cable lock nut, and remove the

throttle cable from the carburetor .

● Remove the fuel tube from the carburetor.

● Remove the wiring coupler of the auto bystarter.

● Loosen the set plate setting screw.

● Loosen the screw of the carburetor insulator band 46.

● Remove the carburetor.

AIR CLEANER

FLANGE BOLT

CARBURETOR

THROTTLE CABLE

AUTO BYSTARTER

WIRING

SETTING SCREW

INSULATOR BAND 46

Page 57

5-5

FUEL SYSTEM

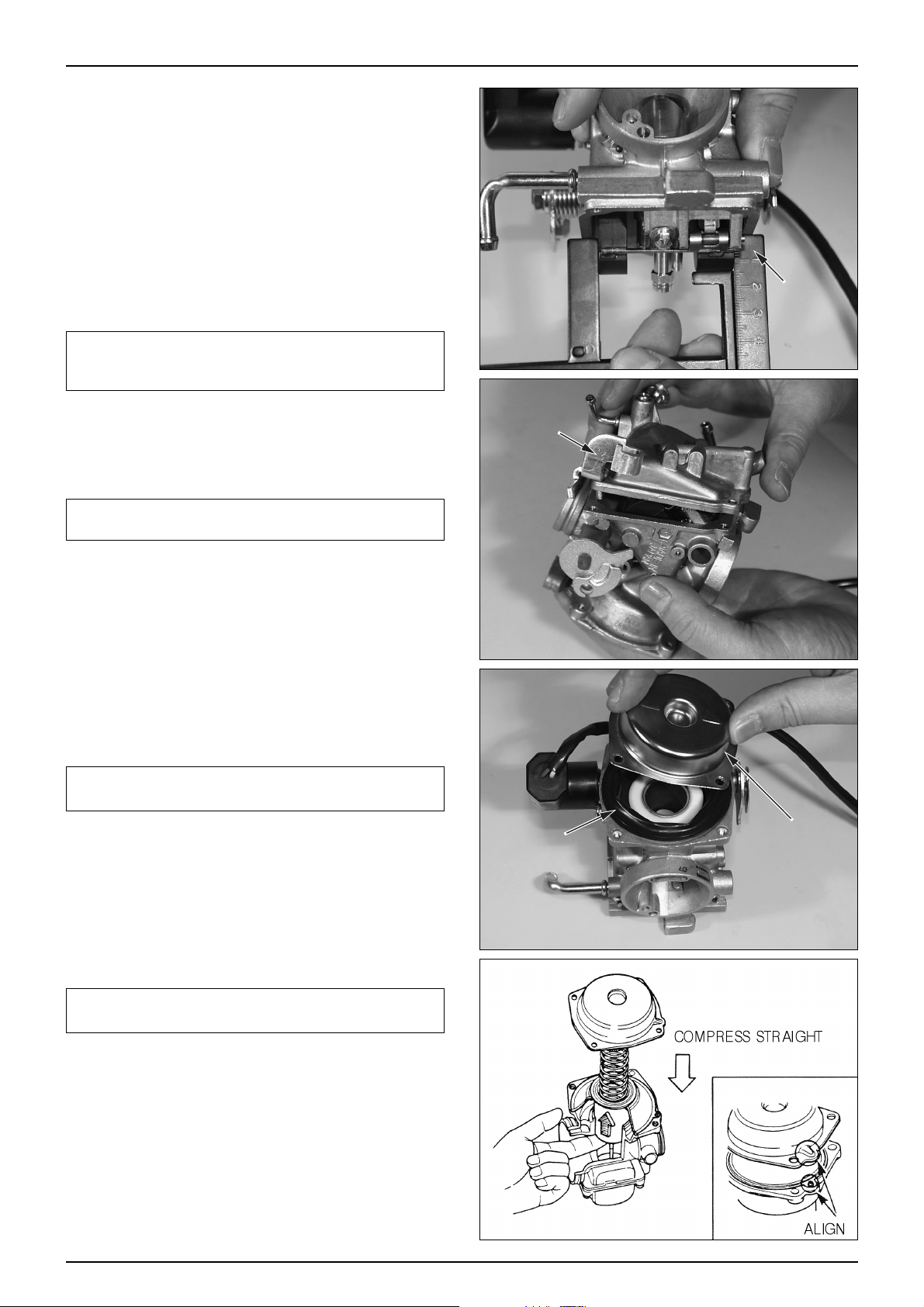

CARBURETOR DISASSEMBLY

● Remove the drain tube and air band hose.

● Loosen the 4 diaphragm cover setting screws.

● Remove the diaphragm cover.

● Remove the diaphragm spring, diaphragm assembly.

● Turn the jet needle with a ⊖ screwdriver, and remove

the needle spring, spring holder, and jet needle from the

vacuum piston.

CARBURETOR INSPECTION

● Check the jet needle for stepped wear and replace if

necessary .

● Check the vacuum piston for damage and replace if

necessary .

● Check the diaphragm for damage, pin holes, wrinkles

and bends and replace if necessary .

NOTE

•Air leaks out of the vacuum chamber if the

diaphragm is damaged in any way-even a pin hole.

DRAIN TUBE

DIAPHRAGM COVER

SCREW

AIR BAND HOSE

DIAPHRAGM

DIAPHRAGM SPRING

NEEDLE SCREW

SPRING HOLDER

JET NEEDLE

HOLDER

DIAPHRAGM

JET NEEDLE

SPRING

Page 58

5-6

FUEL SYSTEM

FLOAT CHAMBER/FLOAT/JET

DISASSEMBLY

● Loosen the 4 screws securing the float body.

● Remove the float pin, float, and float value.

● Check the float valve and valve seat for scores, scratches,

clogging and damage. Replace if necessary .

● Check the float valve operation.

● Remove the main jet, main jet holder, holder washer,

jet screw, jet washer, needle jet, slow jet, pilot jet,

washer and O-ring.

NOTE

•Turn in the pilot jet and record the number of turns it

takes before it seats lightly .

•Do not force the pilot screw against its seat ;

the seat will be damaged.

FLOAT BODY ASS'Y

SCREW

SCREW

FLOAT VALVE

PIN

FLOAT

FLOAT VALVE

SLOW JET

SEAT

MAIN JET

HOLDER

MAIN JET

Page 59

5-7

FUEL SYSTEM

CARBURETOR BODY

CARBURETOR CLEANING

● After removing all parts, blow open air and fuel

passages in the carburetor body with compressed air .

CAUTION

•Cleaning the air and fuel passages with a piece of

wire will damage the carburetor body or fuel pump.

FLOAT CHAMBER/FLOAT/JET

ASSEMBLY

● Install the needle jet, needle jet holder, main jet and

slow jet.

● Tighten the pilot jet until it seats lightly, then turn it

out as much as the number recorded during removal.

● Install the pilot jet rubber.