Page 1

Page 2

Page 3

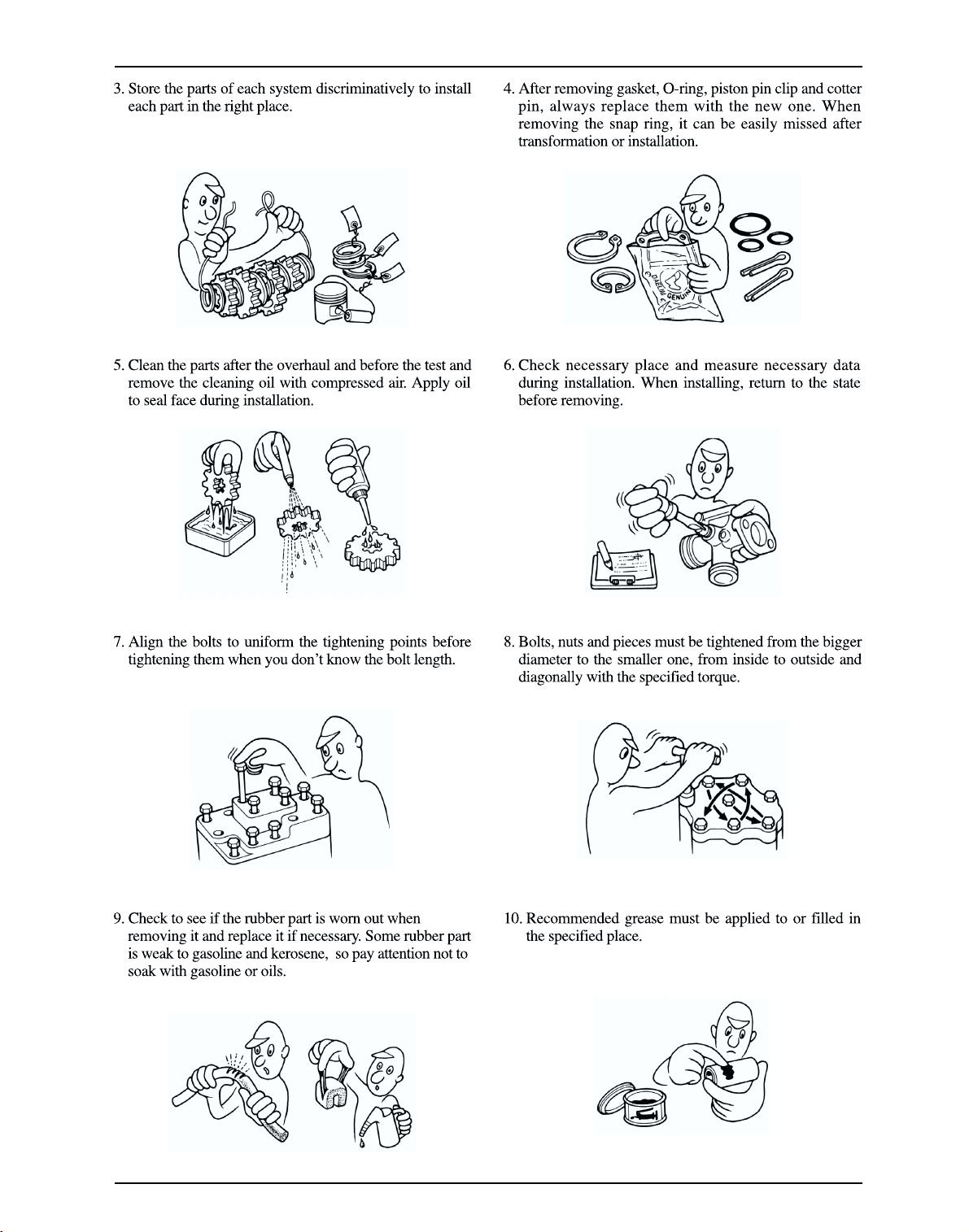

How to use this manual

This manual explains how to maintain procedure for the

S2-125 manufactured by DAELIM MOTOR CO., LTD.

To ensure safety and optimal operating conditions of the

vehicle, carry out regular inspections according to the

maintenance schedule(Section 2).

Sections 1 through 2 provide information on overall

vehicle; section 3, assembly and disassembly procedures

for external components, and section 4 describes

maintenance procedure for the engine, frame and

electrical systems.

To facilitate use of this manual, each page starts with

disassembly and system diagrams, each page starts with

disassembly and system diagrams, service information,

and troubleshooting guide.

Contents of this manual and specifications are subject

to change without prior notice for improvement of

vehicle quality.

No part of this publication may be reproduced without

written permission of DAELIM Motor Co.,Ltd.,

Service Information

1

2

3

4

6

7

8

9

10

11

14

15

16

17

18

Inspections / Adjustments

External Parts

Lubrication System

5

EMS(Engine Management System)

Fuel System

Engine Removal / Installation

LH, Crank Case Cover

Continuously Variable

Transmission

A.C Generator / Starter Clutch

Cylinder Head / Valves

Cylinder Head / Piston

12

Transmission / Crank Shaft

Crank Case

Rear Wheel / Rear Brake /

Suspension / Rear Swing Arm

Charging System

Ignition System

Starter System

Lights / Switches / Horn

19

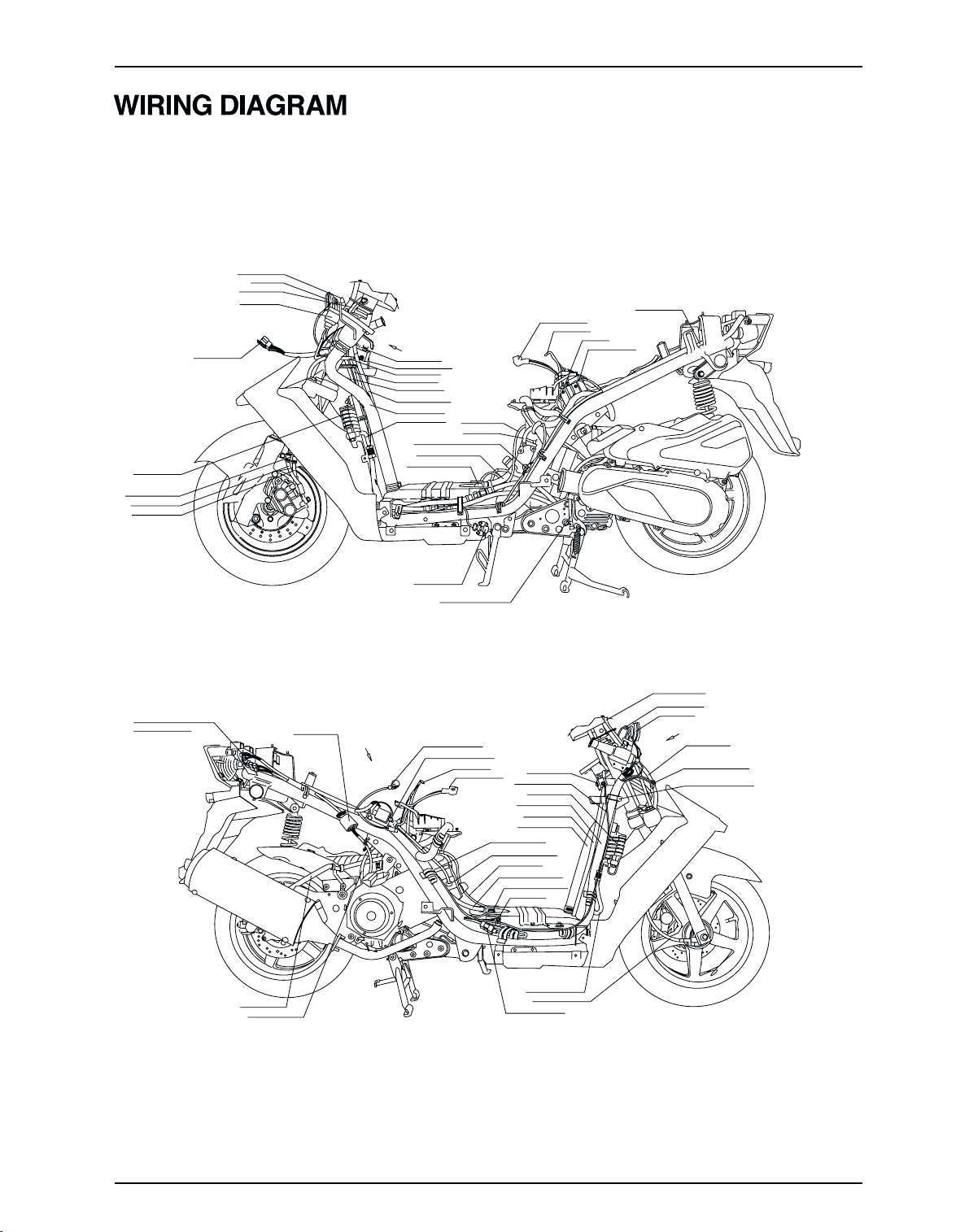

Wiring diagram

Contents

Engine

FrameElectrical

General

13

Front Wheel / Front Fork

/ Steering / Brake

Page 4

Page 5

SERVICE INFORMATION

1

1-1

Page 6

1-2

SERVICE INFORMATION

Page 7

SERVICE INFORMATION

1-3

Page 8

1-4

SERVICE INFORMATION

Page 9

1-5

SERVICE INFORMATION

Page 10

1-6

SERVICE INFORMATION

Page 11

1-7

SERVICE INFORMATION

Page 12

1-8

SERVICE INFORMATION

Page 13

1-9

SERVICE INFORMATION

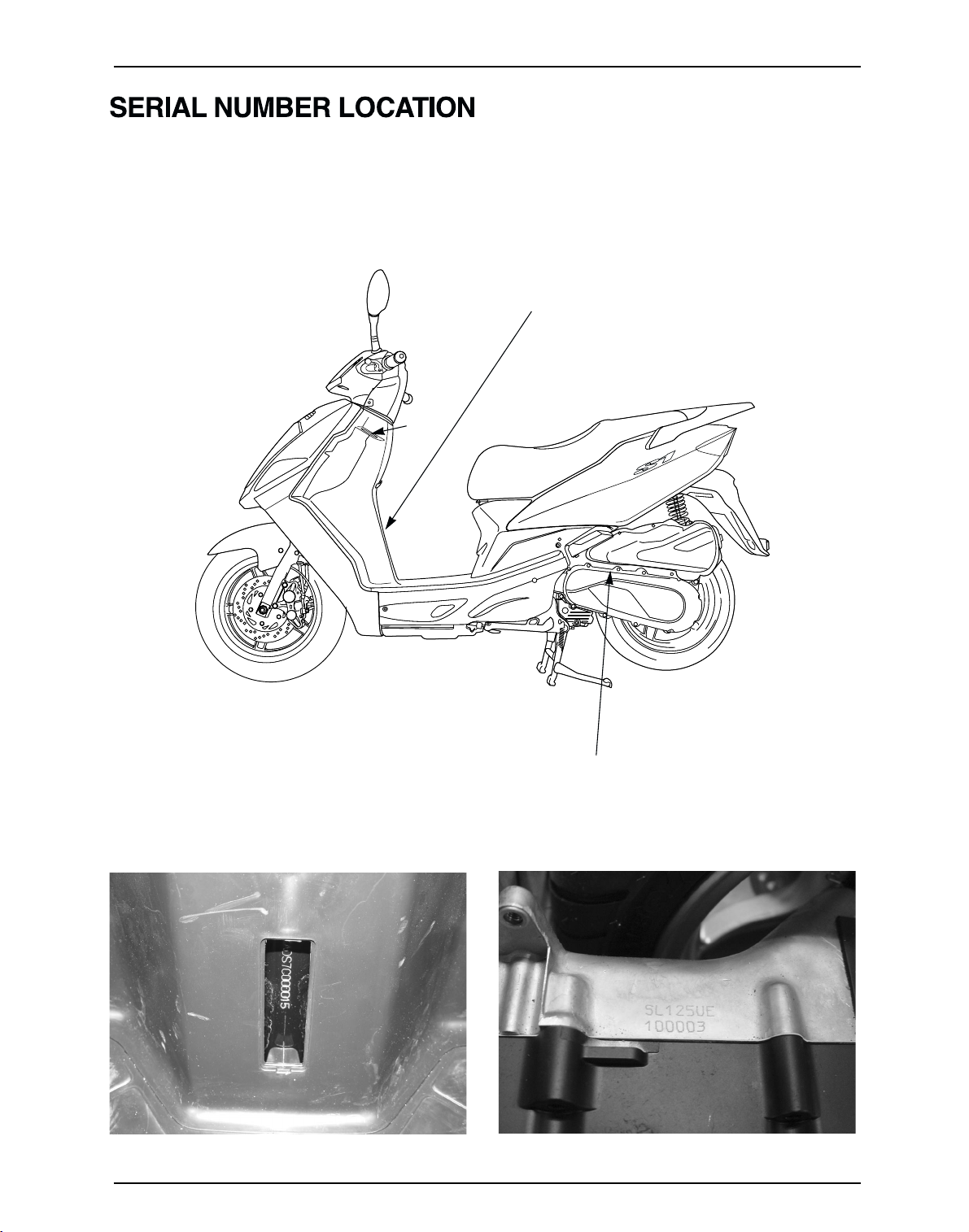

ENGINE SERIAL NUMBER LOCATION

FRAME SERIAL NUMBER LOCATION

ENGINE SERIAL NUMBER LOCATION

FRAME SERIAL NUMBER LOCATION

Page 14

1-10

SERVICE INFORMATION

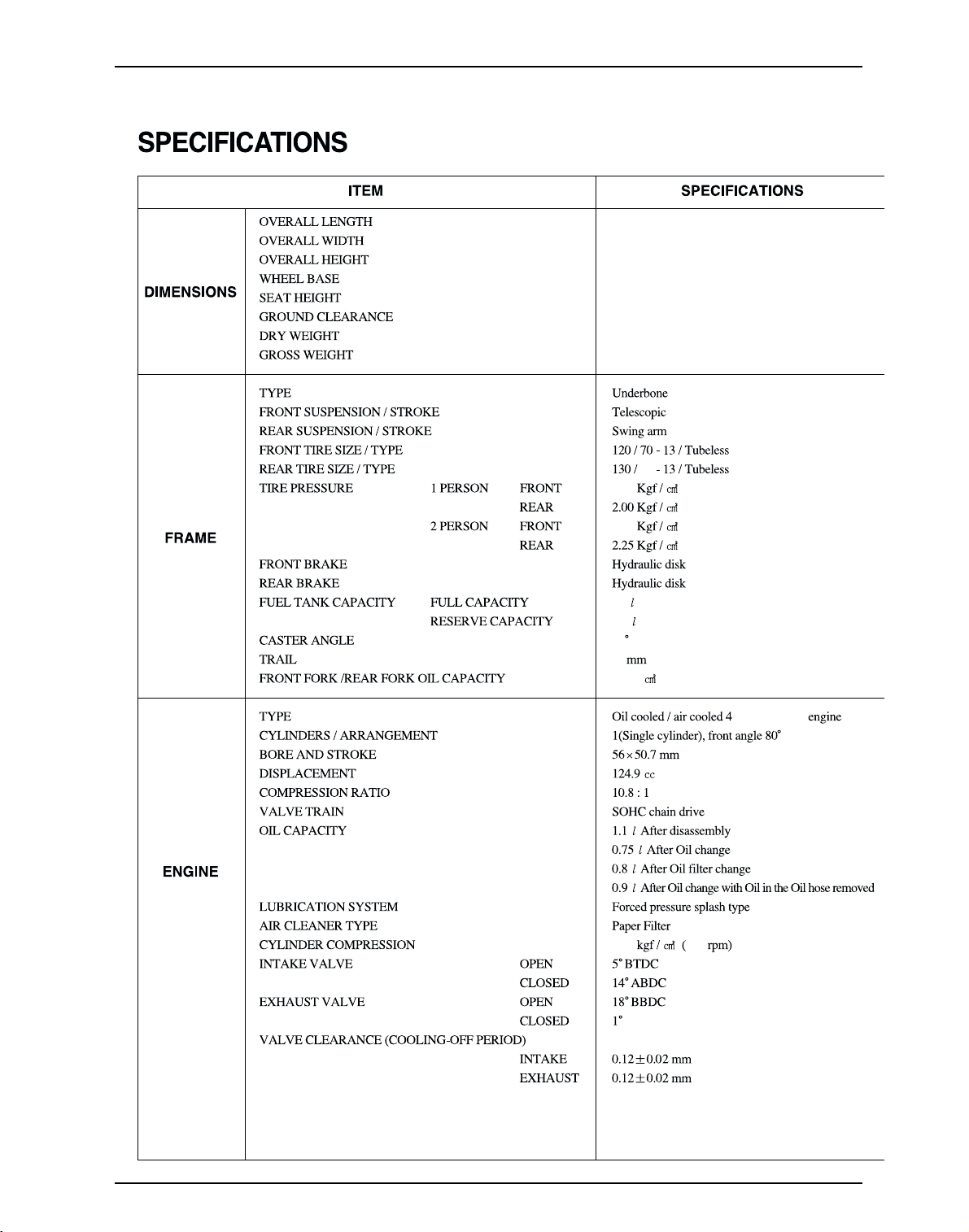

1,965mm

743mm

1,120mm

1,350mm

770mm

126mm

127kg

277kg

60

1.75

2.25

9.6

2.2

25

80

90/70

13.8

stroke SOHC

380

AT D C

Page 15

1-11

SERVICE INFORMATION

, 30A

LED

LED

LED

Page 16

1-12

SERVICE INFORMATION

Page 17

1-13

SERVICE INFORMATION

Page 18

1-14

SERVICE INFORMATION

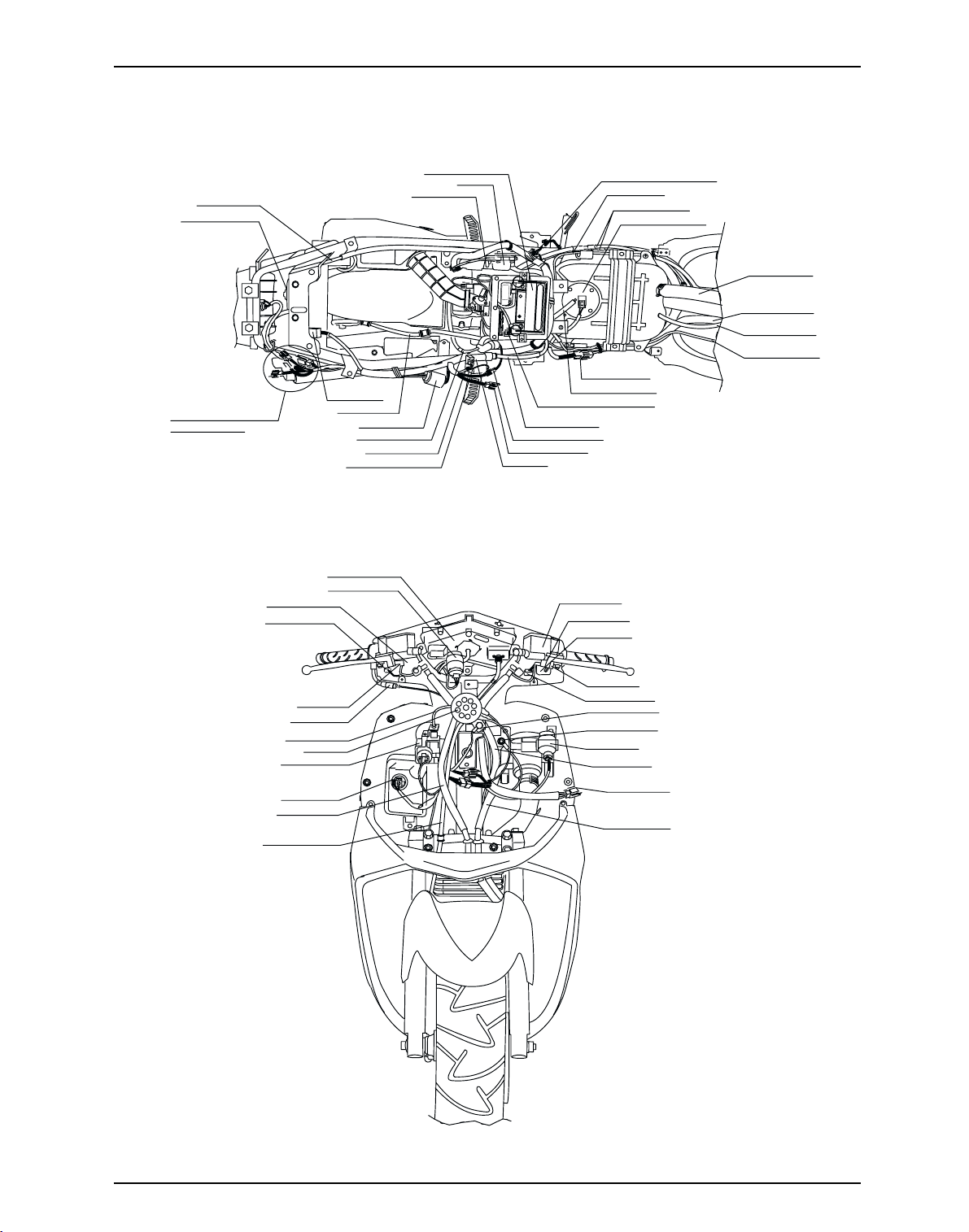

SEAT LOCK CABLE

HORN COMP.

THROTTLE CABLE

HAZARD RELAY

HEAD LIGHT

(COUPLER)

RADIATOR ASS'Y.

BRAKE HOSE CLAMP

FR.BRAKE HOSE C

FR. BRAKE HOSE

Y

RR.BRAKE HOSE A

RR. BRAKE HOSE PIPE

FR.BRAKE HOSE C

THROTTLE CABLE

SEAT LOCK CABLE

FUEL BREATHER TUBE

FUEL SUPPLY TUBE

LH. RADIATOR HOSE

SIDE STAND SW.ø¨∞·∫Œ COUPLER

FUEL HOSE(TO. INJECTOR)

FUEL PUMP(TO. INJECTOR)

THROTTLE CABLE

BREATHER TUBE

BATTERY + CABLE

EARTH CABLE

ECU UNIT

FRM.EARTH CORD

SEAT LOCK CABLE

TAIL & STOP, RR. WINKER R/L

REGULATE RECTIFIER

COUPLER

RR.BRAKE HOSE

START MOTOR CABLE

ACG. & CPS CORD

SIDE STAND SW.

DRAIN TUBE(AIR CLEANER)

SPEEDOMETER CABLE

SEAT LOCK CABLE

HORN COMP.

X

Z

TRUNK LAMP COUPLER

IGNITION COIL EARTH CORD

EARTH CABLE

BATTERY + CABLE

JUNCTION VALVE

RR. BRAKE HOSE PIPE

RADIATOR ASS'Y.

MAIN WIRE HARNESS

FUEL SUPPLY TUBE

FUEL BREATHER TUBE

HIGH TENSION CORD

NOISE SUPPRESSOR CAP

THROTTLE CABLE

FUEL HOSE(TO. INJECTOR)

FUEL PUMP(TO. INJECTOR)

FRAME EARTH

RH. RADIATOR HOSE

SPEEDOMETER CABLE

O2 SENSOR COUPLER

FR. BRAKE HOSE

CHARGE SOCKET COUPLER

HARNESS POSITION CLAMP

Page 19

1-15

SERVICE INFORMATION

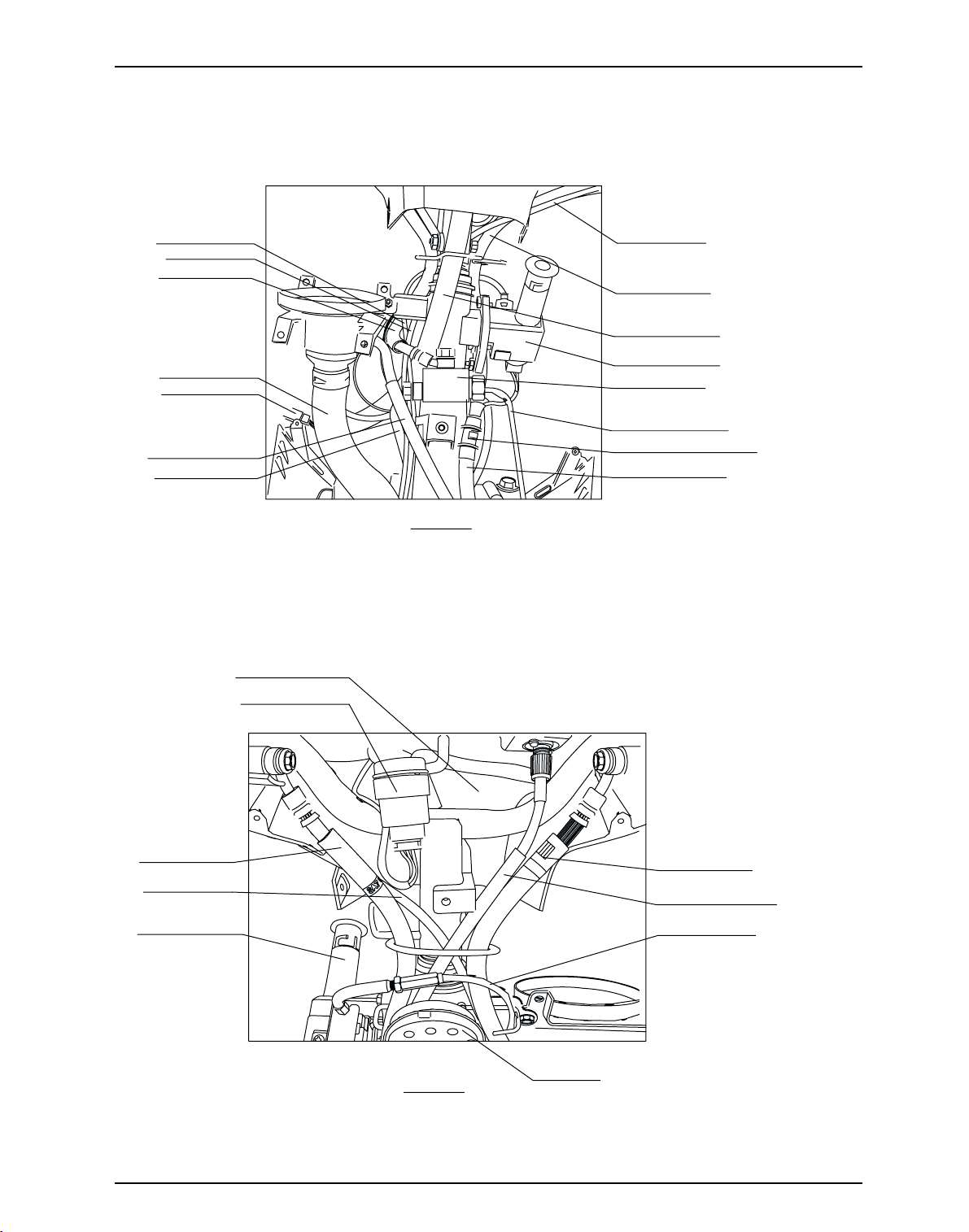

SEAT LOCK CABLE

REGULATE RECTIFIER

TAIL & STOP, RR. WINKER R/L

REGULATE RECTIFIER

COUPLER

LIGHTING S/W UNIT

STARTER S/W UNIT

FUEL PUMP RELAY

RR.BRAKE HOSE

ACG. & CPS CORD

START MOTOR CABLE

IGNITION COIL CORD

IGNITION COIL EARTH CORD

SPEEDO METER ASS'Y

A.P. WINKER RELAY

12V 10AH BATTERY(MF)

ECU UNIT

FRM.EARTH CORD

FUSE

O2 SENSOR COUPLER

FUEL HOSE(TO. INJECTOR)

CAN(≈ÎΩ≈øÎ) CORD

¡∂∏≥πÊ«‚¿∏∑Œ WIRING¿ª Ω«Ω√«“ ∞Õ.

HIGH TENSION CORD

START-MAG. SW. COUPLER

TRUNK LAMP COUPLER

IGNITION COIL

DIMMER S/W UNIT

WINKER S/W UNIT

HORN S/W UNIT

SIDE STAND SWICH COUPLER

THROTTLE CABLE

RH/LH RADIATOR HOSE

FUEL PUMP(TO. INJECTOR)

FUEL SUPPLY TUBE

MAIN WIRE HARNESS

FUEL BREATHER TUBE

RR. BRAKE HOSE PIPE

FR. STOP SW.

THROTTLE CABLE

SEAT LOCK CABLE

HORN COMP.

COMB. & LOCK SW.

CHARGE SOCKET

FR. BRAKE HOSE

SPEEDOMETER CABLE

RR. STOP SW.

HAZARD S/W UNIT

FRAME EARTH

HORN~m_? ^J`)|P~*_5 ~B_&^!`'|( ^3`!|(^!`%|3.

SPEEDO METER EARTH

HAZARD RELAY

RR.BRAKE HOSE A

HEAD LIGHT

(∞·º±øÎ COUPLER)

FR.BRAKE HOSE C

Page 20

1-16

SERVICE INFORMATION

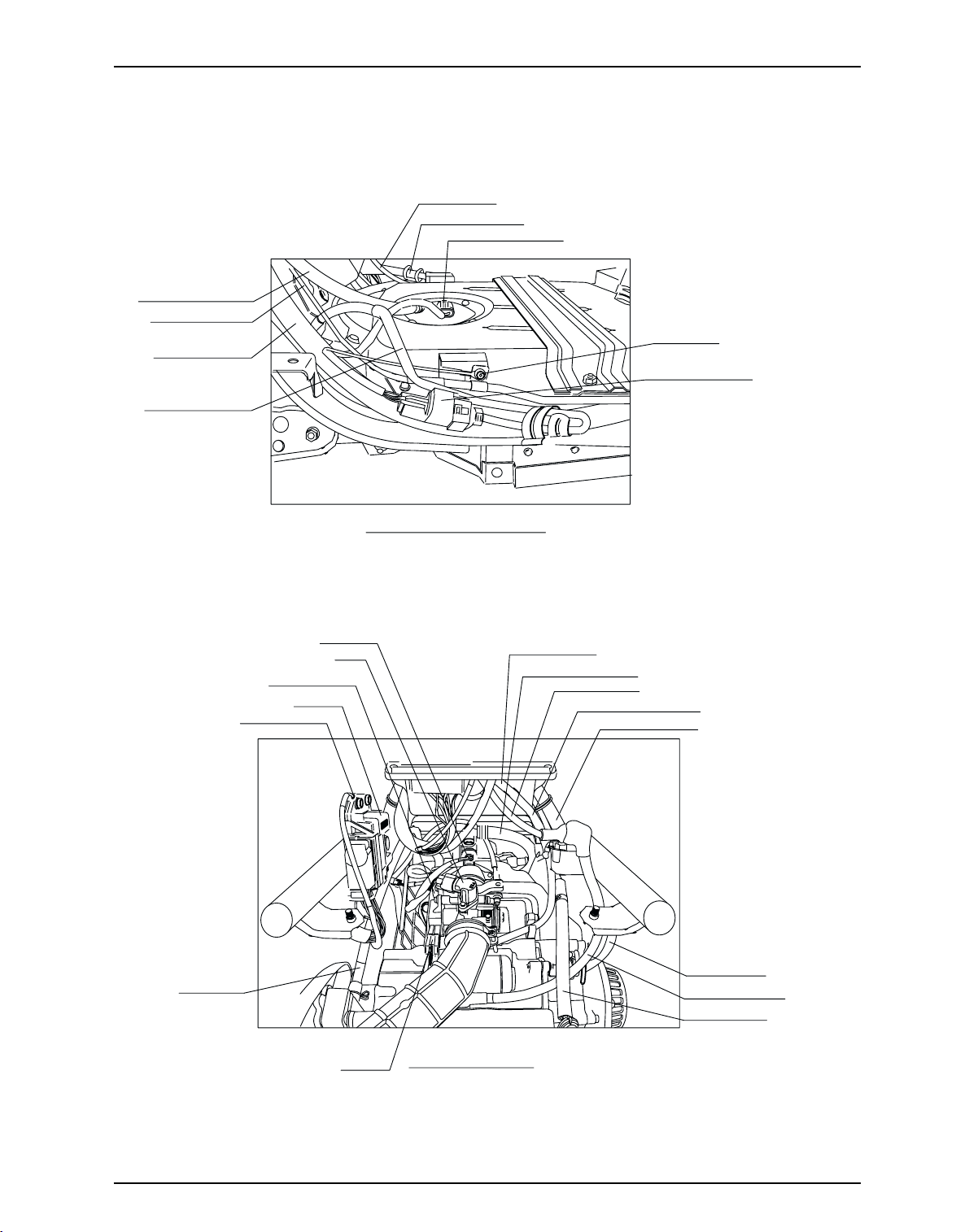

SEAT LOCK CABLE

THROTTLE CABLE

RR.BRAKE HOSE A

FUEL SUPPLY TUBE

HEAD LIGHT

(∞·º±øÎ COUPLER)

FUEL BREATHER TUBE

FR.BRAKE HOSE C

SPEEDO METER ASS'Y

A.P. WINKER RELAY

THROTTLE CABLE

FR. BRAKE HOSE

COMB.METER SOCKET

COMB. & LOCK SW.

JUNCTION VALVE

RR. BRAKE HOSE PIPE

HARNESS ~x_1~/_5 ^!`'|(^-`%|5^R`-|P CLAMP

MAIN WIRE HARNESS

VIEW Y

FR. BRAKE HOSE

THROTTLE CABLE

COMB. & LOCK SW.

VIEW X

RR.BRAKE HOSE A

SPEEDOMETER CABLE

SEAT LOCK CABLE

HORN COMP.

Page 21

1-17

SERVICE INFORMATION

FUEL HOSE(TO. INJECTOR)

RR. BRAKE HOSE PIPE

MAIN WIRE HARNESS

O2 SENSOR CORD

THROTTLE CABLE

RH/LH RADIATOR HOSE

FUEL PUMP(TO. INJECTOR)

FRAME EARTH

HORN~m_? ^J`)|P~*_5 ~B_&^!`'|( ^3`!|(^!`%|3.

O2 SENSOR COUPLER

BREATHER TUBE

MAPAT COUPLER

ECU UNIT

FRM.EARTH CORD

DETAIL OF O2 SENSORS PART

INJECTOR

ISA

THROTTLE CABLE

FUEL HOSE(TO. INJECTOR)

BATTERY + CABLE

START-MAGNET SW. ASS'Y.

MAIN WIRE HARNESS

ACG. & CPS CORD

START MOTOR CABLE

RR.BRAKE HOSE

TPS

VIEW Z

DETAIL OF SENSORS PART

Page 22

MEMO

Page 23

2-1

INSPECTIONS/ADJUSTMENTS

2

Page 24

2-2

INSPECTIONS/ADJUSTMENTS

Page 25

2-3

INSPECTIONS/ADJUSTMENTS

Page 26

2-4

INSPECTIONS/ADJUSTMENTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

NUTS

Page 27

2-5

INSPECTIONS/ADJUSTMENTS

Page 28

2-6

INSPECTIONS/ADJUSTMENTS

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

COMPRESSION GAUGE

COMPRESSION GAUGE

COMPRESSION GAUGE

COMPRESSION GAUGE

COMPRESSION GAUGE

COMPRESSION GAUGE

COMPRESSION GAUGE

COMPRESSION GAUGE

COMPRESSION GAUGE

COMPRESSION GAUGE

COMPRESSION GAUGE

COMPRESSION GAUGE

COMPRESSION GAUGE

COMPRESSION GAUGE

COMPRESSION GAUGE

COMPRESSION GAUGE

COMPRESSION GAUGE

COMPRESSION GAUGE

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

TIMINCT HOlLE CAP

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

COOLING FAN

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

ADJUST WRENCH

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

SPARK PLUG CAP

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

TAPPET ADJUST SCREW

Page 29

2-7

INSPECTIONS/ADJUSTMENTS

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL CHECK HOLE

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

OIL SIGHT GRASS

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

DRIVE FACE

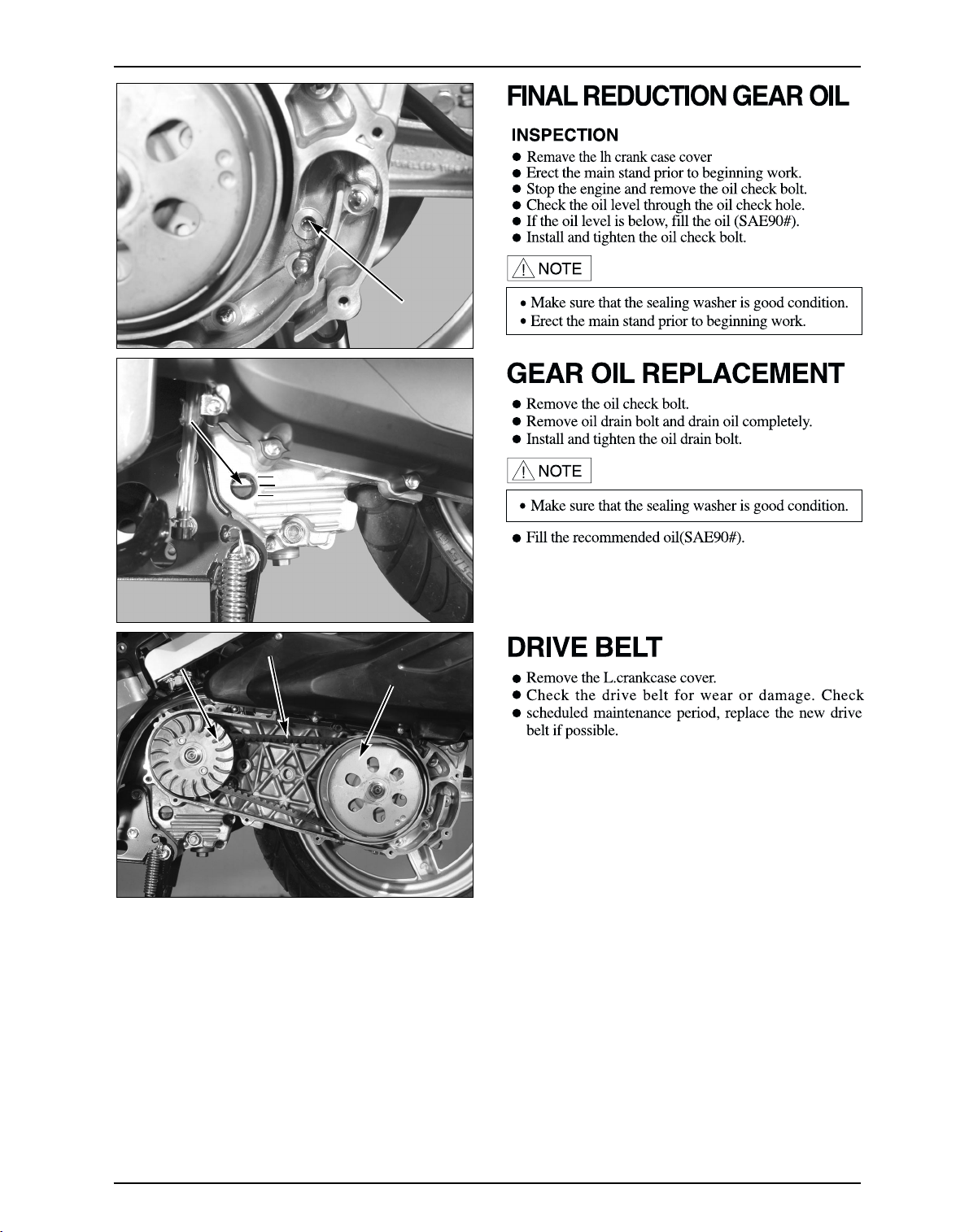

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

DRIVE BELT

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDLE

LOWER

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

DRIVEN PULLEY

Page 30

2-8

INSPECTIONS/ADJUSTMENTS

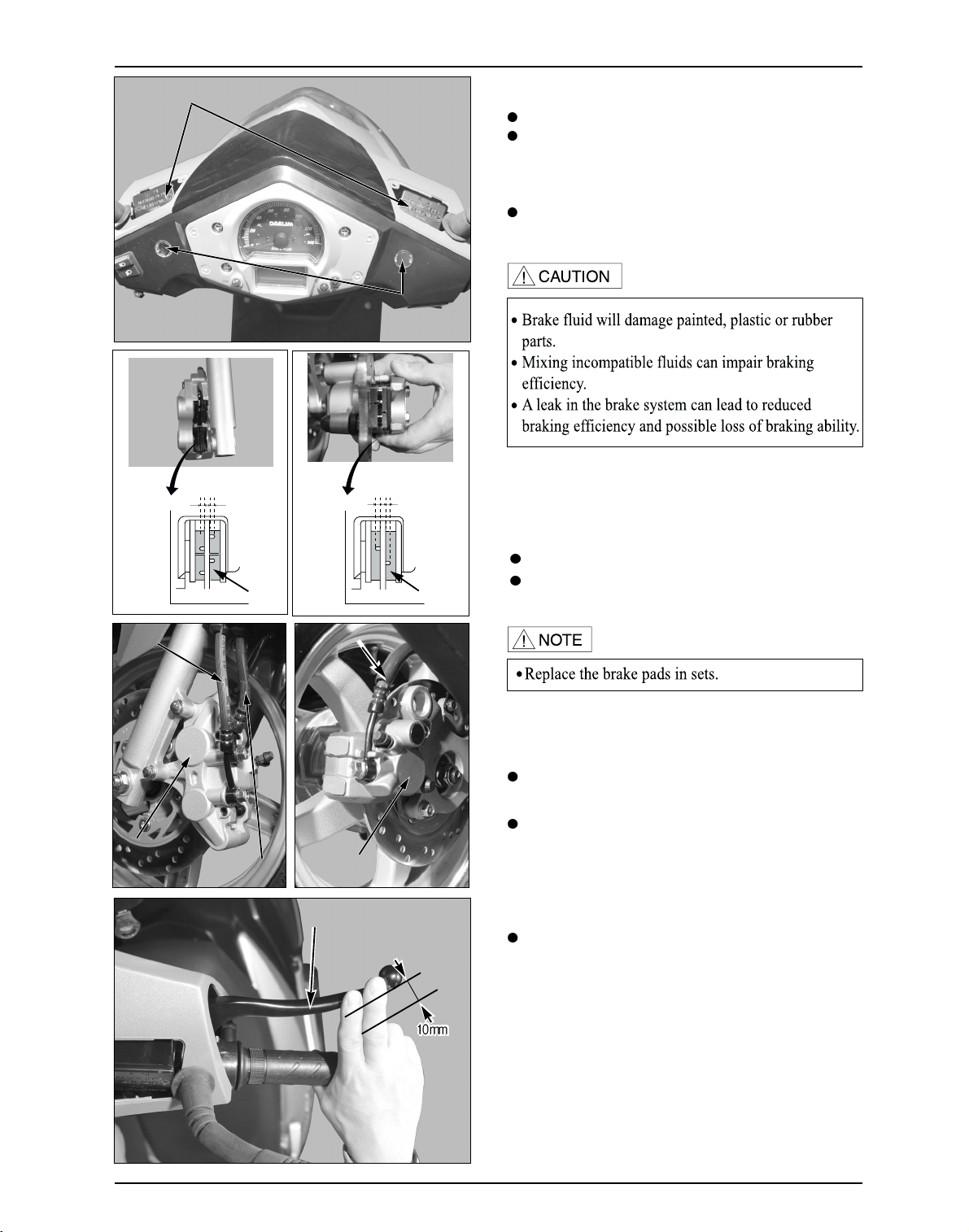

BRAK FLUID

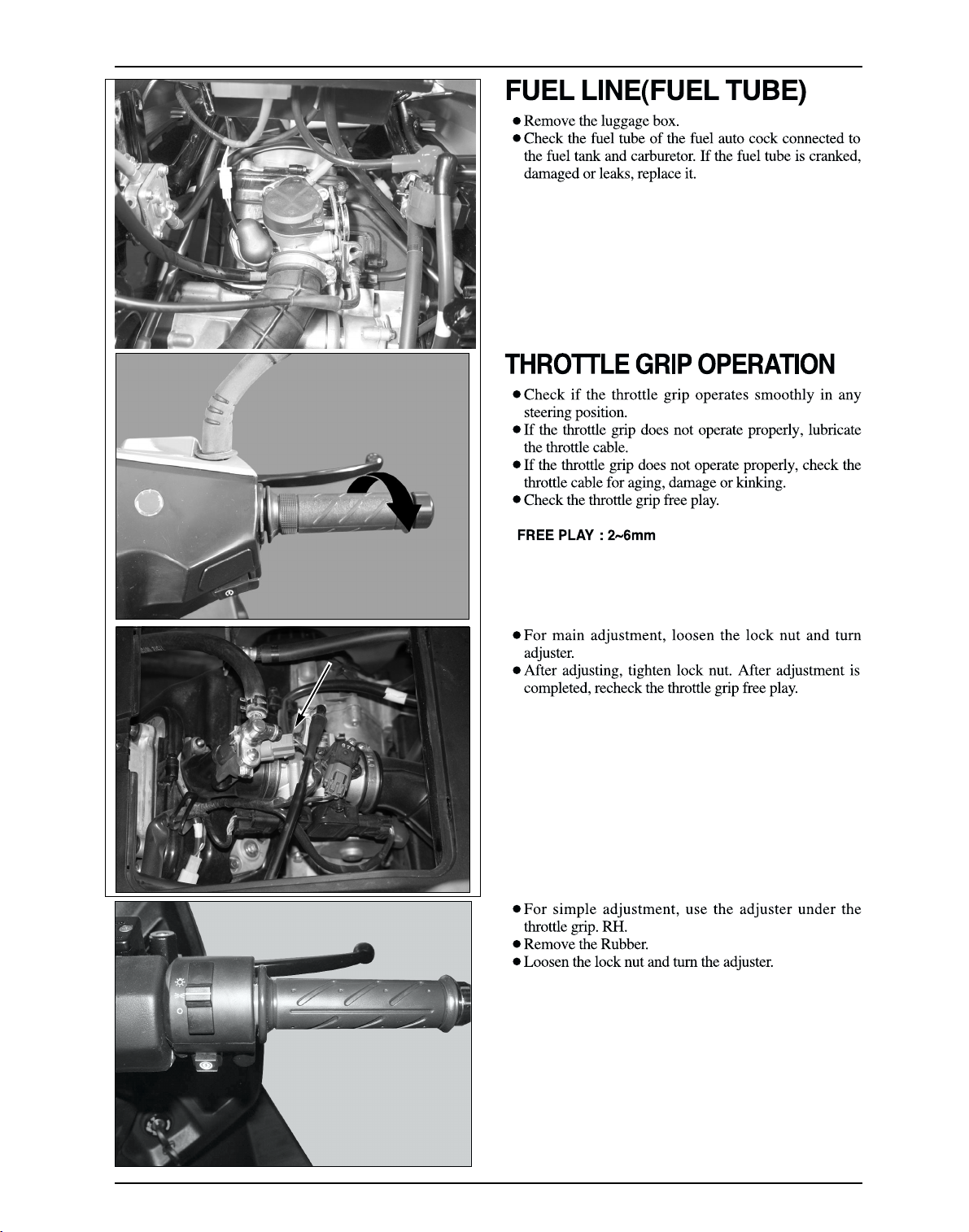

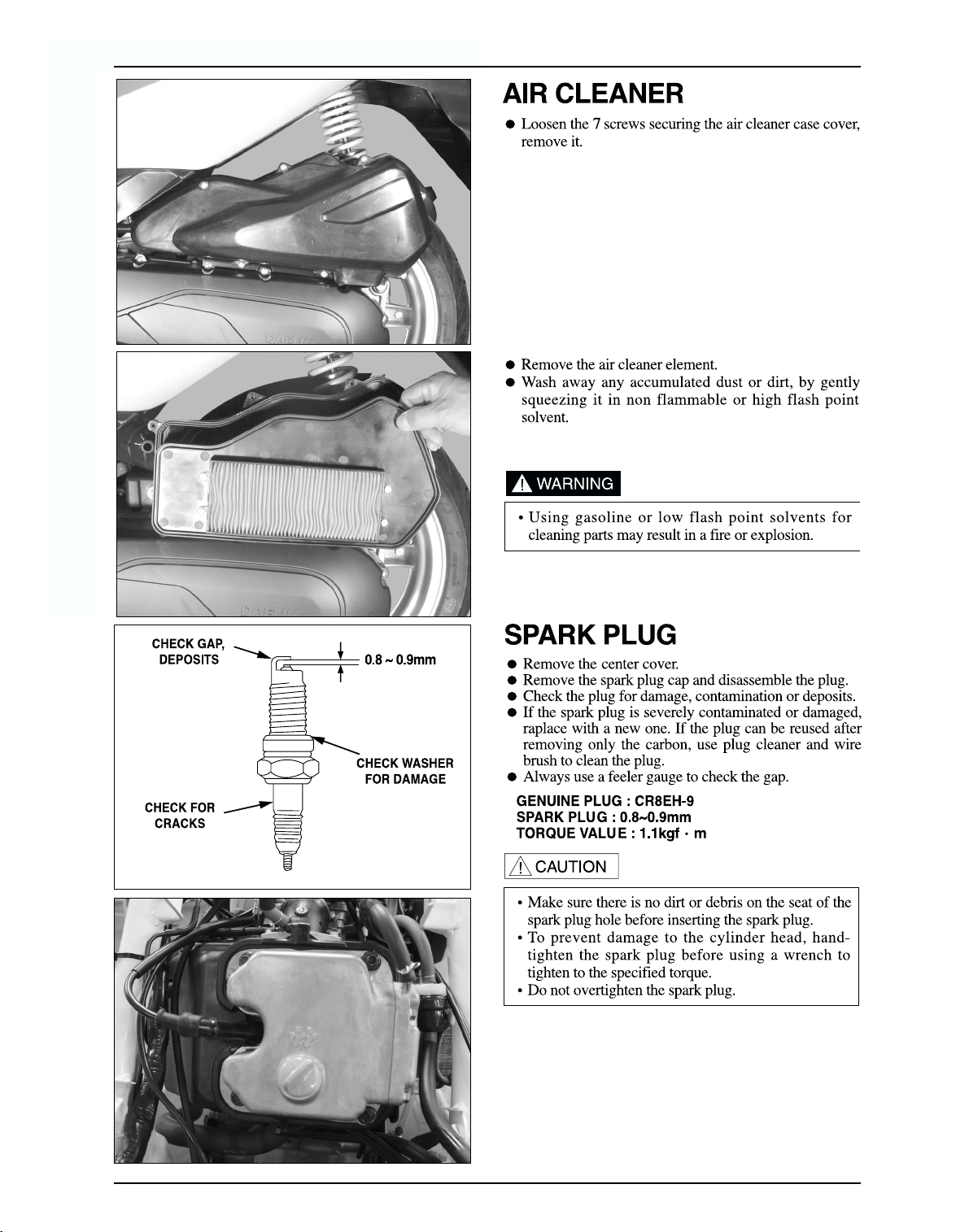

Remove the brake fluid cover.

Check the oil level inside the front brake reservoir.

If the oil level is near the lower limit line, remove

the reservoir diaphrag mand fill DOT3 and DOT 4

brake fluid to the top limit line.

If the brake fluid reaches the lower limit line, check

the entire brake system for leaks.

BRAKE PAD/SHOE

BRAKE PAD REPLACEMENT

Check the brake pads for wear.

If the rod mark on the pad reaches the brake

disc, replace the pads.

BRAKE SYSTEM

Check the front brake hose for cracks or damage.

If any leaks are found,replace immediately

Check the brake rod for looseness or damage,

and replace it if necessary.

BRAKE LEVER FREE PLAY

Check the free play after pulling the lover.

FRONT: 10~20mm

REAR: 10~20mm

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

DUBLE BRAKE HOSE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

FRONT CALLIPE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

REAR BRAKE HOSE

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

DRIVEN LEVER

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

FRONT BRAKE HOSE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

REAR CALLIPE

ROD MARK

BRAKE PAD

ROD MARK

BRAKE PAD

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

0IL CUP CAP

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

BRAKE FLUID

CHECK WINDOW

Page 31

2-9

INSPECTIONS/ADJUSTMENTS

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND

SIDE STAND SWITCH

SIDE STAND SWITCH

SIDE STAND SWITCH

SIDE STAND SWITCH

SIDE STAND SWITCH

SIDE STAND SWITCH

SIDE STAND SWITCH

SIDE STAND SWITCH

SIDE STAND SWITCHSIDE STAND SWITCHSIDE STAND SWITCHSIDE STAND SWITCHSIDE STAND SWITCHSIDE STAND SWITCHSIDE STAND SWITCHSIDE STAND SWITCHSIDE STAND SWITCHSIDE STAND SWITCHSIDE STAND SWITCHSIDE STAND SWITCHSIDE STAND SWITCHSIDE STAND SWITCHSIDE STAND SWITCHSIDE STAND SWITCHSIDE STAND SWITCH

SIDE STAND SWITCH

SIDE STAND SWITCH

SIDE STAND SWITCH

SIDE STAND SWITCH

SIDE STAND SWITCH

SIDE STAND SWITCH

SIDE STAND SWITCH

SIDE STAND SWITCH

SIDE STAND SWITCH

Page 32

2-10

INSPECTIONS/ADJUSTMENTS

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GANGE

TIRE PRESSURE GAUGE

Page 33

3-1

EXTERNAL PARTS

3

Page 34

3-2

EXTERNAL PARTS

FRONT COVER

Loosen the 4tapping screws securing the

front cover

FRONT COVER

Disconnect the wire grommet

Disconnect the front fender

Install in the reverse order of removal

FRONT UNDER COVER A

Remove

- Front fender

- Front wheel

-

The 4 tapping screw securing the underside of inner

box

-

The 2 flange bolts and 2 special screw securing front

under cover

-

The screw (right and left) securing the front side of floor

side cover

- Front under cover

- Install in the reverse order of removal

Loosen the tapping screw securing the front cover

Disconnect the headlight wiring and winker

00wiring0(right and left)

Install in the reverse order of removal

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

ERONT COVER

FRONT COVER

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

WIRE GROMMET

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

ERONT FENER

FRONT FENER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT UNDER COVER

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

FRONT PORK

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

TNNER BOX

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

Page 35

3-3

EXTERNAL PARTS

FRONT HANDLE COVER

Remove the front cover

Loosen the 2 tapping screw securing the front

handle cover B and remove the handle cover B

Loosen the 5 tapping screw and remove the

handle cover

Loosen the 1 tapping screw securing front handle

cover and 2 tapping screw securing rear handle cover

Remove the front handle cover

Install in the reverse order of removal

REAR HANDLE COVER

Loosen the 2 washer bolt securing front under

cover and the 2 tapping screw underside

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

HANDIL COVER B

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

SPEEDO MATER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

REAR HANDIL COVER

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

STEERING HANDIL

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

WASHER

Page 36

3-4

EXTERNAL PARTS

LUGGAGE BOX

Release the seat lock.

Release the seat .

Loosen the special screw and remove the battery cover.

CENTER COVER

Release the seat lock by turning the main key.

Loosen the special screw.

Remove the center cover.

Install in the reverse order of removal.

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

FLANGE NET

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

LUGGAGE BOX

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

BATTERY COVER

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

OPEN SRAY NUTS

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

SPECIAL SCREW 2EA

Page 37

3-5

EXTERNAL PARTS

HANDLE COVER

HANDLE COVER

HANDLE COVER

HANDLE COVER

HANDLE COVER

HANDLE COVER

HANDLE COVER

HANDLE COVER

HANDLE COVER

HANDLE COVER

HANDLE COVER

HANDLE COVER

HANDLE COVER

HANDLE COVER

UNDER

UNDER

UNDER

UNDER

UNDER

UNDER

UNDER

UNDER

UNDER

UNDER

UNDER

UNDER

UNDER

UNDER

HANDLE COVER

HANDLE COVER

HANDLE COVER

HANDLE COVER

HANDLE COVER

HANDLE COVER

HANDLE COVER

HANDLE COVER

HANDLE COVER

HANDLE COVER

HANDLE COVER

HANDLE COVER

HANDLE COVER

HANDLE COVER

UPPER

UPPER

UPPER

UPPER

UPPER

UPPER

UPPER

UPPER

UPPER

UPPER

UPPER

UPPER

UPPER

UPPER

FRONT COVER

FRONT COVER

FRONT COVER

FRONT COVER

FRONT COVER

FRONT COVER

FRONT COVER

FRONT COVER

FRONT COVER

FRONT COVER

FRONT COVER

FRONT COVER

FRONT COVER

FRONT COVER

REAR CARRIER

Loosen the washer bolt(4).

Remove the rear carrier.

Install in the reverse order of removal.

BODY COVER

Loosen the 2 tapping screw securing RH/LH

body side cover and 2 special screw

Loosen the body cover clip(R/L).

Disconnect the rear winker wiring and the

body cover opens with right and left and

pull to backside and remove it.

Install in the reverse order of removal

REAR FENDER

Remove

- Luggage box.

- Body cover.

- Loosen the 4 washer bolts.

- Rear fender.

- Tail right wiring.

Install in the reverse order of removal.

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

REAR FENDER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

BODY COVER

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

4WASHER BOLTS

Page 38

3-6

EXTERNAL PARTS

FLOOR SIDE COVER

Loosen the screw(R/L) in the floor side cover.

Remove the floor side cover(R/L).

Install in the reverse order of removal.

FLOOR PANER

Remove

- Center cover.

- Body cover.

- Floor panel cap.

- Floor side cover.

- 4 washer bilts.

- pull the floor panel backward to remove it.

- Install in the reverse order of removal.

INTER BOX

Remove

- Front fender.

- Front wheel.

- Front under cover.

- Floor side cover.

- Floor panel.

Loosen.

- 4 tapping screw securing fuel cap neck.

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

CENTER COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FLOOR PANEL COVER

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL CAP NECK

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

FUEL SUPPLY TUBE

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

TAPPING SCREN

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

FLOOR SIDE COVER

Page 39

3-7

EXTERNAL PARTS

Loosen the special screw securing back holder.

Remove the charge socket cap by turing the

socket cap to loosen the lock securing mainkey.

Remove the inner box.

Install in the reverse order of removal.

UNDER COVER

Remove the floor side cover.

Loosen the special screw (R/L) and remove

the under cover.

Install in the reverse order of removal.

REAR WHEEL MUD GUARD

Loosen the brake hose clamp and washer bolt

securing.

Remove the air cleaner and washer bolt.

securing mud guard.

Remove the rear wheel mud guard.

Install in the reverse order of removal.

SPEEDO METER

Remove

- The speedometer.

- Coupler and wire.

- Rear handle cover.

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

UNDER COVER

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

CHARGE SOCKER CAP

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

BACK HOLDER

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

SPECIAL SCREW

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

REAR WHEEL GUARD

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

SPEEDO METER

Page 40

EXTERNAL PARTS

3-8

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

MUFFLER

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

FIANGE BOLT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.CAP NUT

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

EX.PIPE CAMP

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

FIANGE NUTS

Page 41

4-1

LUBRICATION SYSTEM

4

4-1

4-2

4-3

4-3

4-4

4-4

4-7

4-8

4-9

Page 42

4-2

LUBRICATION SYSTEM

Page 43

4-3

LUBRICATION SYSTEM

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL SIGHT GLASS

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

OIL DRAIN PLUG BOLT

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

OIL FILTER SCREN

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

TAPPER ADJUST HOLE CAP

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDIE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

UPPER

MIDDLE

LOWER

Page 44

4-4

LUBRICATION SYSTEM

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

FLANGE BOLTS

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL FILTER ELEMENT

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

OIL SEAL

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

START DRIVEN GEAR

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

FLAT SCEWS

Page 45

4-5

SERVICE LUBRICATION SYSTEM

Page 46

4-6

LUBRICATION SYSTEM

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

INNER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

OUTER ROTOR

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

PUMP BODY

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OIL PUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

OILPUMP SHAFT

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

ROLLER

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT

U NUT DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

DRIVEN GEAR

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

OIL PUMP

Page 47

4-7

LUBRICATION SYSTEM

Page 48

4-8

LUBRICATION SYSTEM

RADIATOR

RADIATOR

RADIATOR

RADIATOR

RADIATOR

RADIATOR

RADIATOR

RADIATOR

RADIATOR

RADIATOR

RADIATOR

RADIATOR

RADIATOR

RADIATOR

RADIATOR

RADIATOR

RADIATOR

RADIATOR

RADIATOR

RADIATOR

RADIATOR

RADIATOR

RADIATOR

RADIATOR

RADIATOR

RADIATOR