COATS RC-100 User Manual

®

RC100

Rim Clamp® Tire Changer

For servicing motorcycle and ATV tire/wheel assemblies as well as automotive and most light truck tire/wheel assemblies.

See

RIM Safety page iv ÌOperating

Instructions on page iv.

Safety Instructions

Set-up Instructions

Operation Instructions

Maintenance Instructions

READ these instructions before placing unit in service. KEEP these and other materials delivered with the unit in a binder near the machine for ease of reference by supervisors and operators.

1601 J. P. Hennessy Drive, LaVergne, TN USA 37086-3565 615/641-7533 800/688/6359 www.ammcoats.com |

Manual Part No.: |

8182904 06 |

HENNESSY INDUSTRIES INC. Manufacturer of AMMCO®, COATS® and BADA® Automotive Service Equipment and Tools. |

Revision: |

04/13 |

Tire Specifications Diagram

|

|

|

|

|

|

|

|

|

|

|

|

Radial |

|

|

|

Rim diameter |

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

Ratio of height to |

|

|

|

|

|

|

|

|

|

code |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Load index & |

|

||||||||||||||||||||

|

|

width (aspect ratio) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

speed symbol |

|

||||||||

Nominal width of |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

tire in millimeters |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R1 |

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

U.S. DOT tire |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

identification number |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

6 |

|

|

|

|

|

|

|

|

9 |

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

1 |

/ |

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

||||||||||

Passenger |

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

H |

|

|

|

|

|

|

|

|

|||

car tire |

|

|

|

|

P |

|

|

|

|

|

|

B |

|

ESS |

DOT |

|

A |

|

|

|

|

|

|

|

M |

|

|

|

Severe snow |

||||||||||||||

|

|

|

|

|

E |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E |

|

|

|

|

|

|

M |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L |

|

|

|

|

|

|

|

|

L |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

M |

|

|

|

D |

|

|

|

U |

|

|

|

|

|

|

|

|

|

|

|

9 |

A |

|

6 |

|

|

|

|

+ |

|

|

conditions |

||||||||

|

|

|

|

|

|

|

|

|

|

|

L |

T |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

IA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

R |

|

|

S |

|

|

||||||

|

|

N |

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

P |

|

R |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

S |

I |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D |

|

|

|

|

|||||

|

E |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E |

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

M |

|

||||

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P |

|

|

|||||

|

R |

|

|

|

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

||

|

|

|

|

E |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L |

|

|

|

|

|

I |

|

|

|

S |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S |

|

|

|

||

|

|

|

|

|

R |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

I |

|

|

|

|

|

T |

|

|

|

P |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E |

|

|

N |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

X |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

U |

|

|

|

A |

|

|

|

M |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

S |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

F |

|

|

E |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

|

||

|

R |

|

|

L |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

|

|||

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

||||

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

U |

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R |

O |

|

|

C |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

T |

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T |

|

|

|||

|

A |

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D |

|

|

|

|

|

|

|||||||

|

|

E |

|

|

|

|

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S |

|

|

|

|

|

|

|

||

|

|

R |

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

U |

|

|

|

||||

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

I |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E |

|

|

|

|

|

|

|

|

|

|

|

|

|

P |

|

|

|

|

L |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

W |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

X |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

M |

|

|

|

. |

|

M |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

R |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L |

|

|

|

|

|

|

|

|

|

|

||||||

Max. |

|

|

|

E |

|

|

|

|

|

|

|

|

|

D |

|

|

|

|

|

|

|

|

|

|

|

2 |

L |

|

|

|

|

|

|

|

|

|

Tire ply |

||||||

|

|

|

|

|

T |

|

|

|

|

|

|

|

|

R |

|

|

|

|

|

|

|

|

|

P |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

S |

L |

|

|

|

|

|

|

|

|

|

E |

|

|

|

|

|||||

permissible |

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

C |

|

2 |

|

EI |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

XXXXX |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

composition |

|||||||||

|

|

|

|

|

|

|

|

|

N |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R |

|

|

|

||||

inflation |

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T |

|

|

|

|

|

|

|

|

|

and materials |

|

|

|

|

|

|

|

|

|

I |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

T |

C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R |

|

|

|

|

|

|

|

|

|

|

||

pressure |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

A |

R |

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

used |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T |

|

|

|

|

|

|

|

|

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

W |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

22 RA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Treadwear, traction |

|

and temperature grades |

Max. load rating |

ii • |

Important: Always read and follow operating instructions. |

Safety Instructions

Owner’s Responsibility

To maintain machine and user safety, the responsibility of the owner is to read and follow these instructions:

•Follow all installation instructions.

•Make sure installation conforms to all applicable Local, State, and Federal Codes, Rules, and Regulations; such as State, Federal OSHA Regulations and Electrical Codes.

•Carefully check the unit for correct initial function.

•Read and follow the safety instructions. Keep them readily available for machine operators.

•Make certain all operators are properly trained, know how to safely and correctly operate the unit, and are properly supervised.

•Allow unit operation only with all parts in place and operating safely.

•Carefully inspect the unit on a regular basis and perform all maintenance as required.

•Service and maintain the unit only with authorized or approved replacement parts.

•Keep all instructions permanently with the unit and all decals/labels/notices on the unit clean and visible.

•Do not override or bypass safety features.

Operator Protective Equipment

Personal protective equipment helps make tire servicing safer. However, equipment does not take the place of safe operating practices. Always wear durable work clothing during tire service activity. Loose fitting clothing should be avoided. Tight fitting leather gloves are recommended to protect operator’s hands when handling worn tires and wheels. Sturdy leather work shoes with steel toes and oil resistant soles should be used by tire service personnel to help prevent injury in typical shop activities. Eye protection is essential during tire service activity. Safety glasses with side shields, goggles, or face shields are acceptable. Back belts provide support during lifting activities and are also helpful in providing operator protection. Consideration should also be given to the use of hearing protection if tire service activity is performed in an enclosed area, or if noise levels are high.

Definitions of Hazard Levels

Identify the hazard levels used in this manual with the following definitions and signal words:

DANGER

Watch for this symbol:

DANGER

DANGER

It Means: Immediate hazards, which will result in severe personal injury or death.

WARNING

Watch for this symbol:

WARNING

WARNING

It Means: Hazards or unsafe practices, which could result in severe personal injury or death.

CAUTION

Watch for this symbol:

CAUTION

CAUTION

It Means: Hazards or unsafe practices, which may result in minor personal injury or product or property damage.

Watch for this symbol! It means BE ALERT! Your safety, or the safety of others, is involved!

Important: Always read and follow operating instructions. |

• iii |

Safety Notices and Decals

WARNING

WARNING

Failure to follow danger, warning, and caution instructions may lead to serious personal injury or death to operator or bystander or damage to property. Do not operate this machine until you read and understand all the dangers, warnings and cautions in this manual. For additional copies of either, or further information, contact:

Hennessy Industries, Inc.

1601 JP Hennessy Drive

LaVergne, TN 37086-3565

(615) 641-7533 or (800) 688-6359 www.ammcoats.com

For additional information contact:

Rubber Manufacturers Association

1400 K Street N. W., Suite 900 Washington, DC 20005

(202) 682-4800 www.rma.org

Tire Guides, Inc.

The Tire Information Center

1101-6 South Rogers Circle

Boca Raton, FL 33487-2795 (561) 997-9229 www.tireguides.com

Remember R.I.M.

Three Simple Steps To Help Keep Shops Safe

READ INSPECT MOUNT

R.I.M. is a training program developed by Hennessy Industries to help keep tire technicians safe. By following the basic principles of R.I.M., technicians can avoid situations that can cause catastrophic accidents like tire explosions.

R.I.M. stands for read, inspect, and mount:

Read the tire size on a new tire before mounting to make sure it is the proper size for the wheel.

Inspect the wheel for cracks, rust, and or other damage that could cause an unsafe situation.

Mount the tire safely, making sure not to put any part of your body over the tire during inflation.

The most serious of possible accidents is a tire explosion. This is often caused by a tire/rim mismatch.

If a tire explodes on a tire changer, pressure causes it to fly straight up at tremendous speed. If a technician is standing over the tire, he can be seriously injured or killed.

Hennessy’s R.I.M. program allows the technician to avoid situations that can cause tire explosions and other accidents. The full program, including training videos, brochures, posters, and other materials, is available from Coats distributors nationwide.

For more details, contact your Coats distributor or e-mail us.

iv • |

Important: Always read and follow operating instructions. |

Table of Contents

Tire Specifications Diagram..................................... |

ii |

Custom and Special Wheels .................................. |

|

16 |

Safety Instructions .................................................. |

iii |

Tube Type Tires ........................................................ |

|

16 |

Owner’s Responsibility............................................ |

iii |

Maintenance Instructions ............................... |

|

17 - 18 |

Operator Protective Equipment............................... |

iii |

Maintenance (Mount/Demount Tool) Cleaning |

.......17 |

|

Definitions of Hazard Levels.................................... |

iii |

Maintenance (Mount/Demount Tool) |

|

|

Safety Notices and Decals |

iv |

Adjustment............................................................ |

|

18 |

|

|

|

||

Remember R.I.M |

iv |

Oil Injector Maintenance ....................................... |

|

18 |

|

|

|

||

Principle Operating Parts |

2 - 3 |

Setup Instructions .................................................. |

|

19 |

|

|

|

||

Know Your Unit |

2 - 3 |

Location................................................................. |

|

19 |

|

|

|

||

Operating Instructions |

4 -8 |

Air Source.............................................................. |

|

19 |

|

|

|

||

Tire Bead Loosening and Demounting |

4 - 6 |

Electrical Source.................................................... |

|

19 |

|

|

|

||

Tire Mounting |

7 |

Floor Mounting...................................................... |

|

19 |

|

|

|

||

Inflation |

7 - 9 |

Critical Safety Instructions...................... |

Back Cover |

|

|

|

|

||

Stages of Inflation on a Conventional Tire |

|

|

|

|

and Rim .................................................................... |

10 |

|

|

|

Mismatched Tires and Wheels ................................ |

11 |

|

|

|

Automobile Performance, Custom, and Aluminum |

|

|

|

|

Wheels.............................................................. |

12 - 15 |

|

|

|

Aluminum and Custom Wheels............................. |

12 |

|

|

|

Performance Tires and Wheels • Demounting 12 - 14 |

|

|

|

|

Performance Tires and Wheels • Mounting..... |

14 - 15 |

|

|

|

NOTICE

Read entire manual before assembling, installing, operating, or servicing this equipment.

Important: Always read and follow operating instructions. |

• 1 |

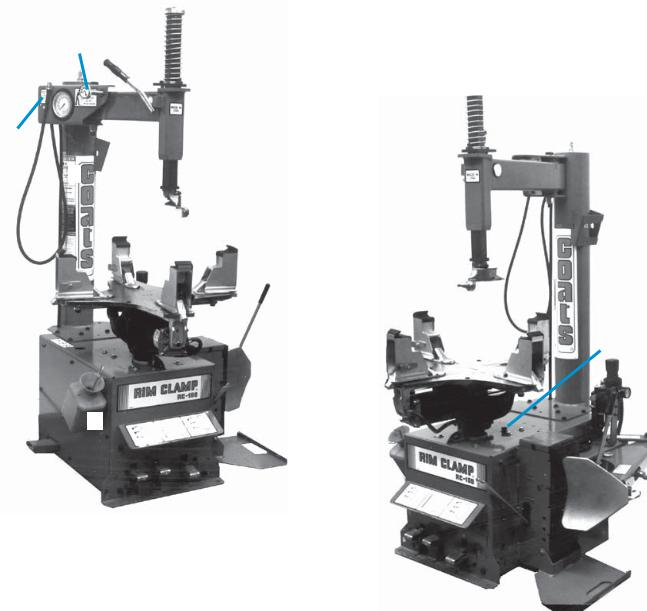

Principal Operating Parts

Do It Now!

Now is a good time to contact product service to start warranty, otherwise warranty starts at time of shipment.

Know Your Unit

Compare this illustration with the unit before placing it into service. Maximum performance and safety will be obtained only when all persons using the unit are fully trained in its parts and operation. Each user should learn the function and location, of all controls.

Prevent accidents and injuries by ensuring the unit is properly installed, operated and maintained.

11 |

12 |

2 |

|

17 18

17 18

1

10

8

7 |

15 |

|

9

3

4 |

6 |

5 |

|

|

|

13 |

|

|

|||

|

14 |

||||

|

|

|

|

|

16

2 • |

Important: Always read and follow operating instructions. |

CAUTION

CAUTION

Replace any damaged or missing safety decals.They are available from COATS, (800) 688-6359.

1 Tower — Support for horizontal and vertical slides, also air storage tank.

2 Air Gauge — Registers tire pressure when air chuck is attached to valve stem and inflation pedal is released.

3 Inflation Pedal — Two-position pedal that allows inflation of tires through air hose and clip-on chuck.

4 Clamp Control Pedal — Three-position pedal that opens, holds or closes rim clamps.

5TableTop Pedal — Three-position pedal that controls rotation of table top (forward, off, reverse).

6 Bead Loosener Control Pedal — Controls operation of bead loosener shoe.

7 Table Top — Rotating chuck for tire changing.

8 Motorcycle or ATV Clamp Adapter — Secures wheel to table top for tire changing.

9 Lube Bottle — Dispenser for rubber lubricant.

10DuckHead® (Combination Mount/DemountTool)

—Mounts and demounts tire from wheel.

11Swing Arm Adjustment Knob — Adjusts swing arm/vertical slide assembly for proper horizontal positioning of mount/demount tool.

12Vertical Slide Locking Handle — Locks and unlocks vertical slide and sets correct vertical position to maintain tool/wheel clearance.

13Bead Lifting Tool — Used to lift and position tire bead correctly on Duckhead mount/demount tool.

14Bead Loosener Shoe — Pivoting shoe for loosening tire beads.

15Oil Check Dipstick — For transmission oil level.

16ATV Riser Plate — Adjusts to raise ATV wheels to centerline of bead loosener.

17Pressure Safety Valve — The high pressure safety valve is set to exhaust at line pressures above 185 PSI.

18Release Valve — Allows the manual release of air pressure from tire when clip-on chuck is attached to tire valve.

Important: Always read and follow operating instructions. |

• 3 |

Operating Instructions

The unit must be properly operated and properly maintained to help avoid accidents that could damage the unit and injure the operator or bystanders. This section of the Operating Instructions manual review basic operations and use of controls. These instructions should be reviewed with all employees before they are allowed to work with the machine. Keep these instructions near the machine for easy reference.

Tire Bead Loosening and Demounting

CAUTION

CAUTION

This machine may operate differently from machines you have previously operated. Practice with a regular steel wheel and tire combination to familiarize yourself with the machine’s operation and function.

Remember to remove all weights from both sides of the wheel. Weights left on back side of wheel may cause the wheel to be clamped unlevel. This may result in the combination mount/demount tool contacting the rim causing scratches. On alloy wheels, always rotate the wheel one turn after setting the tool to insure proper wheel chucking.

NOTE: Always review nicks and scratches with owners of expensive wheel and tire combinations prior to servicing.

IMPORTANT: Review the performance wheel section of this manual prior to servicing performance tire/wheel combinations.

1. Deflate tire completely by removing the valve core from the valve stem (Figure 1).

NOTE: Always loosen the bead on the narrow side of the wheel’s drop center first (motorcycle wheels may not have a narrow or long side, and some ATV wheels may bolt together). See Figure 4 for more information on the drop center.

REMEMBER: The clamps on the table top may extend beyond the table top itself. To avoid damaging the clamps, move them to their full inward position before positioning a tire for bead loosening.

NOTE: Use extra care in positioning the bead loosener shoe on larger wheels/tires, and on alloy wheels. Make sure the shoe rests next to but not on the rim, and not on the tire sidewall. The riser underneath the bead loosener will help properly position ATV wheels.

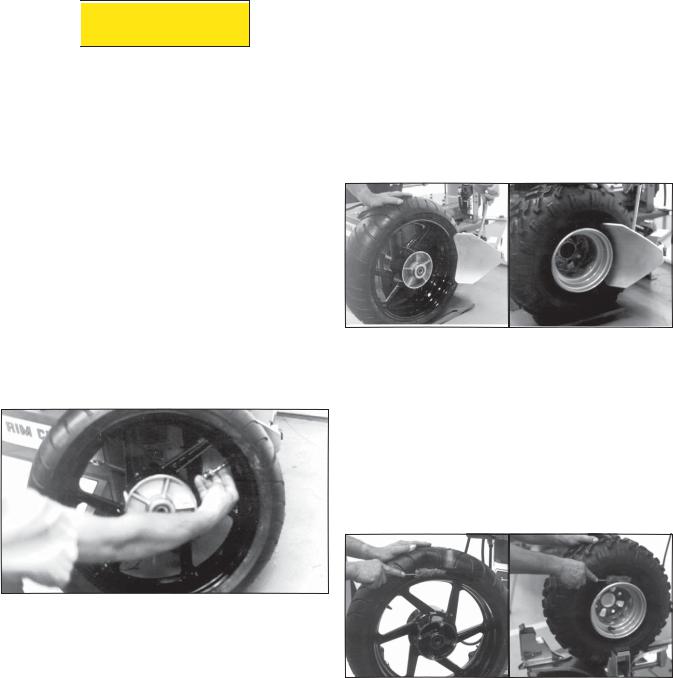

2. Pull the bead loosener shoe away from the machine and roll wheel into position. The valve stem should be in the 3 o’clock position. Position the bead loosener shoe against the tire next to, but not on, the rim. Depress the bead loosener foot pedal to actuate the shoe and loosen the bead. It may be necessary to loosen the bead in multiple locations around the tire (Figure 2).

Motorcycle |

ATV |

|

|

Figure 2 - Position Tire and Bead Loosener Shoe

3.Turn wheel around and repeat loosening procedure on the other side of the wheel. This should be the long side of the drop center.

TIP: It will be easier to clamp the wheel to the table top if the lower bead is loosened last.

4. Apply tire manufacturer’s approved rubber lubricant liberally to entire circumference of both tire beads after loosening.

Figure 1 - Remove Valve Core to Deflate Tire

NOTE: Loosening the beads on a fully inflated tire is unsafe and causes excess movement and friction against the bumper pads and excessive wear on pivots. Deflate the tire completely to prolong the life of your machine.

ATV NOTE: It may be necessary on ATV wheels to leave 5-10 PSI in some of these wheels to facilitate bead loosening.

Motorcycle |

ATV |

|

|

Figure 3 - Apply Rubber Lubricant to Tire Beads

4 • |

Important: Always read and follow operating instructions. |

Loading...

Loading...