Clock Audio SM 80S-RF User Manual

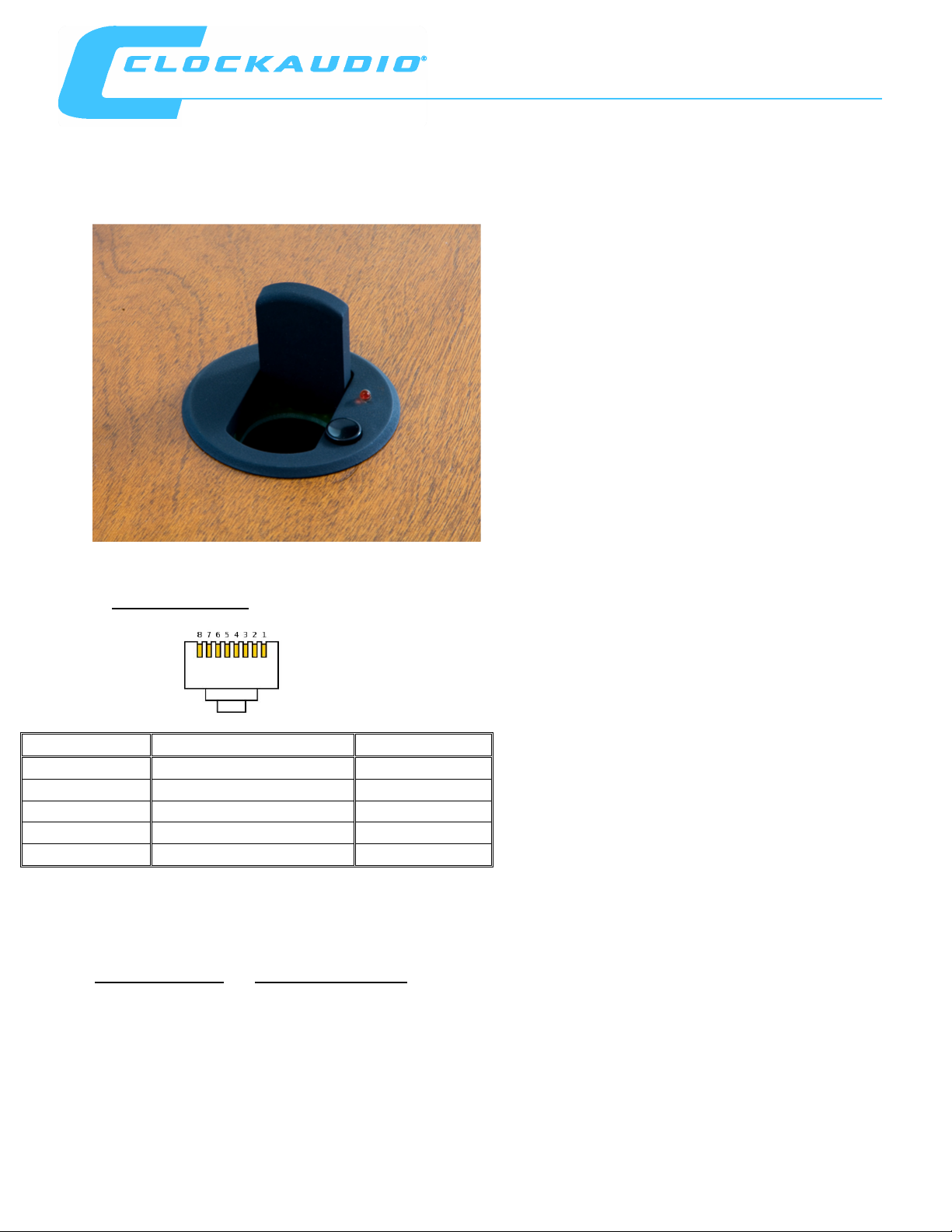

SM 80S-RF

Cable colour

Function

RJ 45 Pin number

Red

Red LED

2

Blue

-ve switch

3

Brown

+ve 12/24V dc switch

4

Yellow

Switch Logic control

5

Green

Green LED

6

PROFESSIONAL MICROPHONE SYSTEMS

A low profile through table shock mount microphone base fitted with a flip cover to conceal the

www.clockaudio.com

• Designed for remote switching.

Applicable for Clockaudio microphones only

Architects and Engineers Specifications for

shall be a Clockaudio SM 80S-RF.

connector when closed.

Switch connections

• Low profile table mounted microphone base.

• Requires a minimum table thickness of 25mm (1”)

• Includes a concealed flap to allow the table to be

used for other purposes.

• Built in shock mount to eliminate surface bound

noise.

• Fitted with momentry (PTT) or latching switch.

• Bi-colour common anode LED to confirm status

• Housing PPA-RF for use with Clockaudio mics C

3100, C 310R, C 313/SR, C 314/SR.

• Terminated with RJ 45 connector and supplied

with RJ 45 coupler which allows connection via RJ

12 or RJ 45 plug back to dsp.

3 Pin Tini Q Wiring 3 Pin Male XLR Wiring

PIN 1 Phase – PIN 1 Ground

PIN 2 Phase + PIN 2 Phase +

PIN 3 Ground PIN 3 Phase -

Microphone Shock Mount SM 80S-RF

It shall come complete with a dedicated phantom

power adaptor designed to power the C 3100

miniature gooseneck microphones terminated with

Tini Q 3 pin connectors. The Phantom power adaptor

shall accept 9 to 48 volts DC and have impedance of

200 ohms. The phantom power adaptor shall also

include filters, which shall eliminate all GSM

frequencies from 800-1200 MHz and be terminated

with a male 3 pin XLR. The microphone shock mount

shall be available in satin Nickel or Black Nextel

finishes. The through table microphone shock mount

SM 80S-RF

www.clockaudio.com

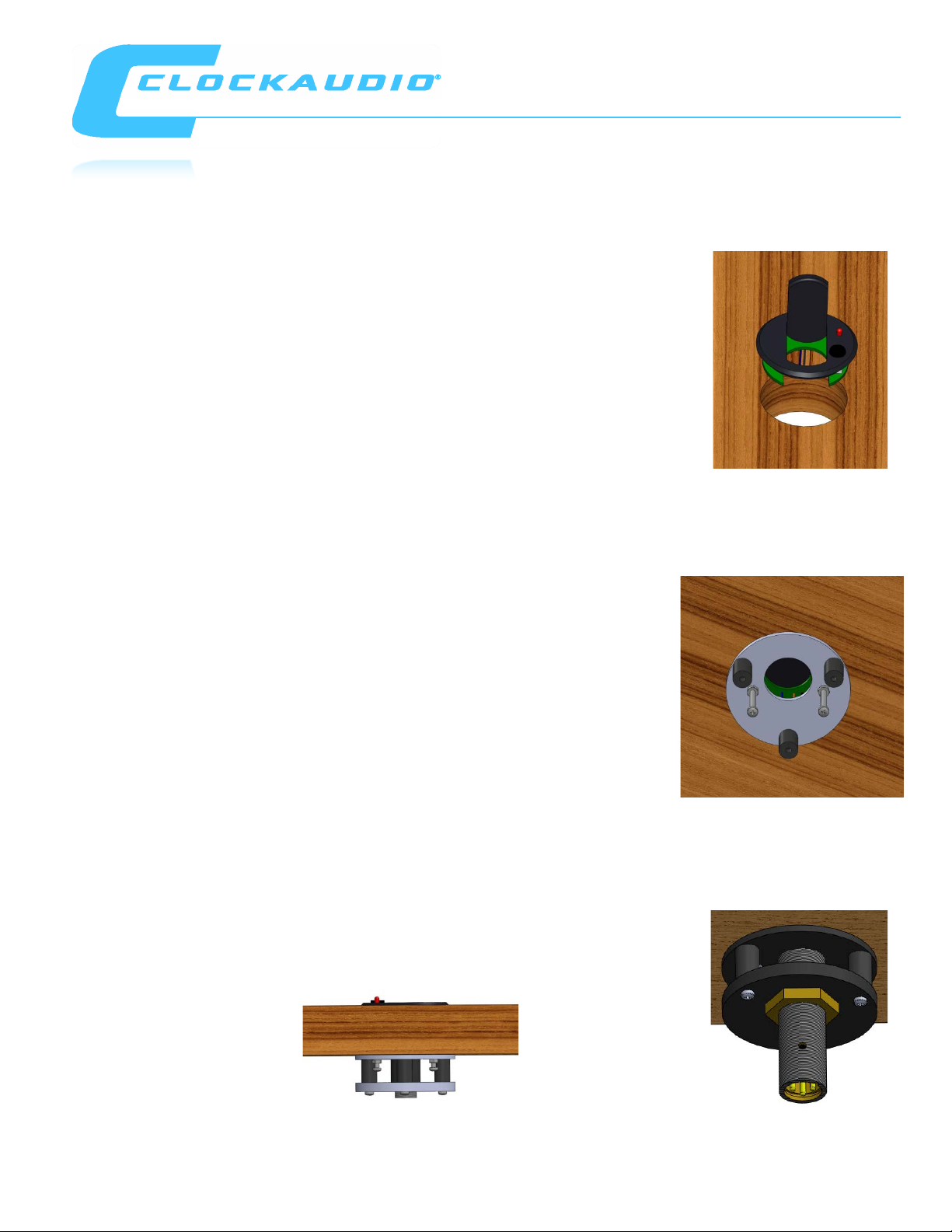

Installation guide

1) Ensure minimum table thickness of 25mm

Fig H

Fig G

Fig F

Fig E

(1”).

2) Drill a 50mm (2”) hole through the table

see fig A.

3) Remove the 3 M3 pan headed screws from

the bottom plate see fig B.

4) Remove the 2 M3 x 30mm pan headed

screws securing the base plate to the top

assembly see fig C

5) Select the LED voltage by moving the

jumper to the required position see fig D.

6) Fit the top assembly through the 50mm

(2”) hole see fig E.

7) Re-fit the base plate to the assembly using

the 2 M3 x 30mm screws adjusting the

nuts to clamp the top assembly and the

bottom plate to the table ensuring that the

top assembly is correctly aligned before

finally tightening the nuts see fig F.

8) Re-fit the bottom plate to the shock

mounts using the 3 M3 pan headed screws.

Adjust the height of the PPA-RF and secure

with nut supplied see fig G.

9) Installation complete see fig H.

Loading...

Loading...