21o Round Head

Air Frame Nailer

MODEL: CFN21

Part No. 3110396

OPERATING & MAINTENANCE

OPERATING & MAINTENANCE

INSTRUCTIONS

INSTRUCTIONS

0307

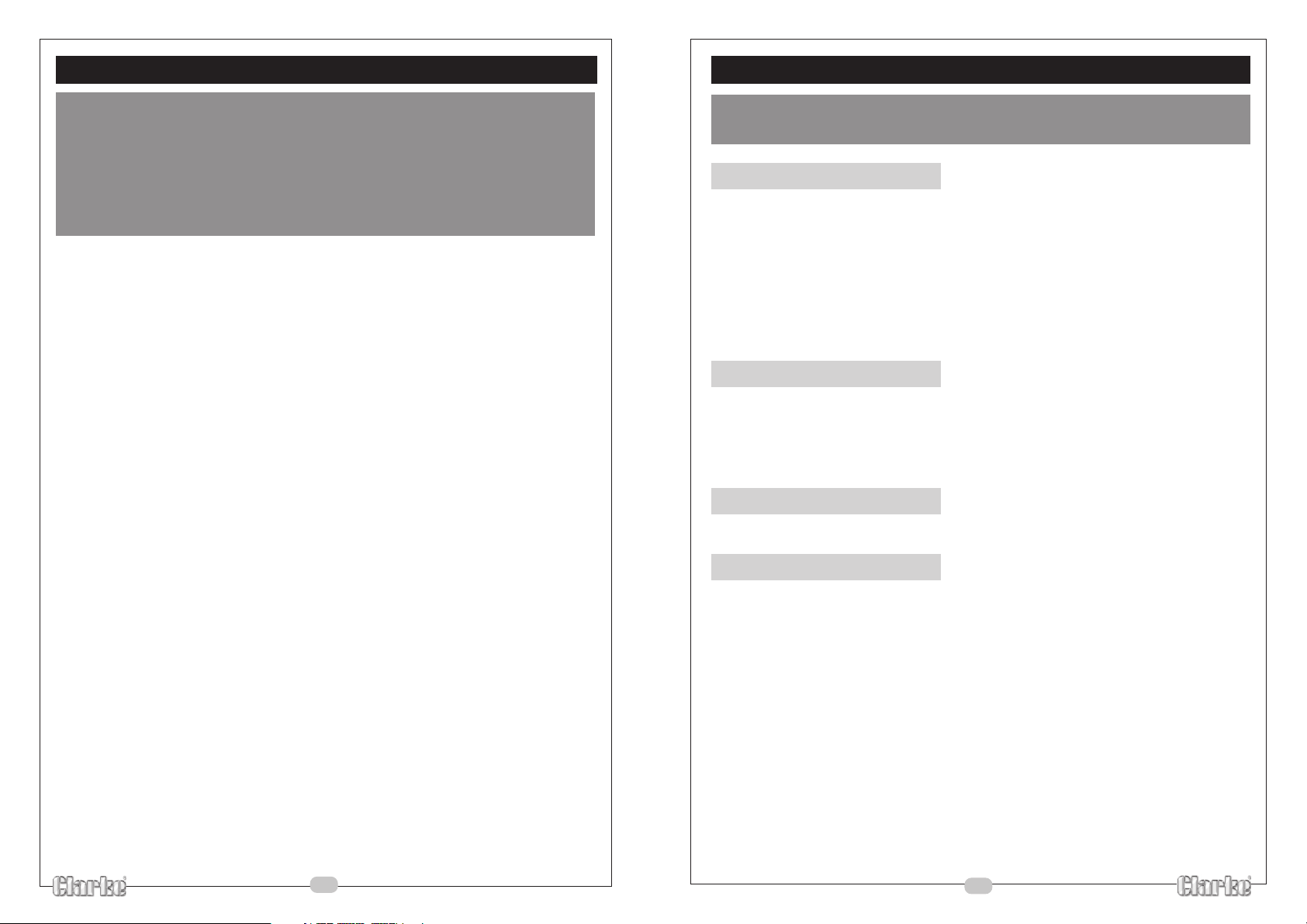

SPECIFICATIONS

Min. Hose Size (ID) ....................................6mm (1/4”)

Ave. Air Consumption.............................. 14.8 cfm

Operating Pressure .................................. 5.51 - 7.58bar (80 - 110psi)

Air Pressure Max ....................................... 8.27bar (120psi)

Nail Size ...................................................... 50-90mm

Magazine Capacity ................................ 60

Drive Speed .............................................. 60 Shots/min

Sound Power Level .................................. 112.5dBL

WA

Weight ....................................................... 3.8kg

Dimensions LxWxH ....................................500 x 120 x 363

Part No .......................................................3110396

Please note that the details and specifications contained herein, are correct at the time of

going to print. However CLARKE International reserve the right to change specifications at

any time without prior notice. Always consult the machine’s data plate

FEATURES

This Nail Gun is suitable for use on materials such as:

• Soft wood, Hardwood • MDF • Plywood • Hardboard • Fibreboard

• Corkboard • Flexible Plastics • Leather, Fabrics • PVC, Polythene sheet

This Nail Gun is NOT suitable for use on materials such as:

• Hard Laminates • Brittle Plastics • Metals (other than light foils)

PACK CONTENTS

• 1 x Nailer

• 1 x Oil Bottle

• 4 x Hexagonal Keys (3, 4, 5 & 6 mm)

• 1 x Instruction Manual

• 1x Moulded Carry Case

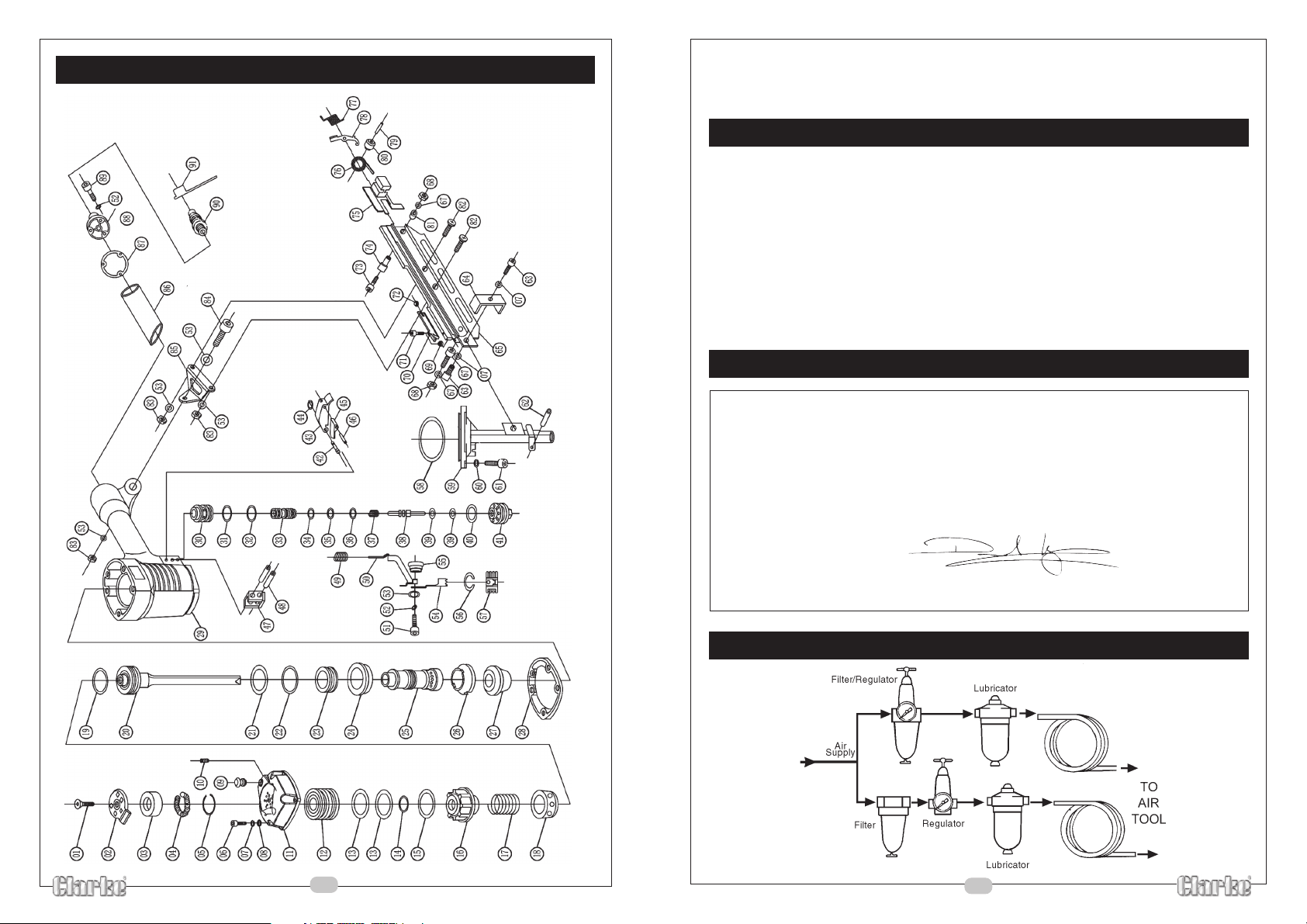

PARTS LIST

No. Description Part No.

1 Bolt M8X16 HTCFN21001

2 Air deflector HTCFN21002

3 Deflector Rubber HTCFN21003

4 Spring HTCFN21004

5 Spring wire HTCFN21005

6 Bolt M6x30 HTCFN21006

7 Spring washer HTCFN21007

8 Flat washer HTCFN21008

9 Cylinder core HTCFN21009

10 Bolt M5x5 HTCFN21010

11 Cylinder cover HTCFN21011

12 Head valve Piston HTCFN21012

13 O-ring 56x3.1 HTCFN21013

14 O-ring 41.7x3 HTCFN21014

15 Washer HTCFN21015

16 Spring seat HTCFN21016

17 Compressed spring HTCFN21017

18 Collar HTCFN21018

19 O-ring HTCFN21019

20 Main piston HTCFN21020

21 O-ring HTCFN21021

22 O-ring HTCFN21022

23 Fixed ring HTCFN21023

24 Sealing ring HTCFN21024

25 Cylinder HTCFN21025

26 Bumper outer lane HTCFN21026

27 Bumper HTCFN21027

28 Cylinder washer HTCFN21028

29 Gun body HTCFN21029

30 Trigger valve seat HTCFN21030

31 O-ring HTCFN21031

32 O-ring HTCFN21032

33 Trigger valve guide HTCFN21033

34 O-ring HTCFN21034

35 O-ring HTCFN21035

36 O-ring HTCFN21036

37 Switch spring HTCFN21037

38 Switch pipe HTCFN21038

39 O-ring HTCFN21039

40 O-ring HTCFN21040

41 Switch seat HTCFN21041

42 Pin HTCFN21042

43 Trigger HTCFN21043

44 O-ring HTCFN21044

45 Safety spacer HTCFN21045

46 Pin HTCFN21046

PARTS & SERVICE TEL: 020 8988 7400

or e-mail as follows:

PARTS: Parts@clarkeinternational.com

SERVICE: Service@clarkeinternational.com

No. Description Part No.

47 Safety guide HTCFN21047

48 Pin HTCFN21048

49 Compressed spring HTCFN21049

50 Safety yolk HTCFN21050

51 Bolt HTCFN21051

52 Spring washer HTCFN21052

53 Flat washer HTCFN21053

54 Safety Nose HTCFN21054

55 Adjust Nut HTCFN21055

56 Copper collar HTCFN21056

57 Safety nose case HTCFN21057

58 O-ring HTCFN21058

59 Drive guide HTCFN21059

60 Spring washer HTCFN21060

61 Bolt HTCFN21061

62 Pin HTCFN21062

63 Bolt HTCFN21063

64 Plate HTCFN21064

65 Magazine HTCFN21065

66 Bolt HTCFN21066

67 Washer HTCFN21067

68 Nut HTCFN21068

69 Washer case HTCFN21069

70 Drive nail bar HTCFN21070

71 Bolt HTCFN21071

72 Spacer HTCFN21072

73 Bolt HTCFN21073

74 Safety pipe HTCFN21074

75 Pusher HTCFN21075

76 Spring HTCFN21076

77 Latch spring HTCFN21077

78 Release latch HTCFN21078

79 Pin HTCFN21079

80 Spring core HTCFN21080

81 Safety pipe case HTCFN21081

82 Bolt HTCFN21082

83 Nut HTCFN21083

84 Bolt HTCFN21084

85 Fixed seat HTCFN21085

86 Rubber handle case HTCFN21086

87 End cap washer HTCFN21087

88 End cap HTCFN21088

89 Bolt HTCFN21089

90 Air plug HTCFN21090

91 Air plug case HTCFN21091

2

11

PARTS DIAGRAM

Thank you for purchasing this Clarke Frame Nailer. Please read these instructions carefully

before attempting to use the tool, to ensure the safety of yourself and others that may be

in the vicinity, and also to ensure the tool provides you with years of satisfactory service.

GUARANTEE

This CLARKE product is guaranteed against faulty manufacture for a period of 12 months

from the date of purchase. Please keep your receipt as proof of purchase.

This guarantee is invalid if the product is found to have been abused or tampered with in

any way, or not used for the purpose for which it was intended.

Faulty goods should be returned to their place of purchase, no product can be returned

to us without prior permission.

This guarantee does not effect your statutory rights.

DECLARATION OF CONFORMITY

We declare that this product complies with the following standard.

• BS EN 792-13: 2000

Model No: CFN21

Serial or Batch number: See product data plate

10

signature:

D. Kemp

ENGINEERING MANAGER

RECOMMENDED AIR SUPPLY CONNECTION

3

SAFETY PRECAUTIONS

MAINTENANCE

WARNING

COMPRESSED AIR CAN BE DANGEROUS. ENSURE THAT YOU ARE THOROUGHLY

FAMILIAR WITH ALL PRECAUTIONS RELATING TO THE USE OF COMPRESSORS AND

COMPRESSED AIR SUPPLY.•

FAILURE TO FOLLOW THESE PRECAUTIONS COULD RESULT IN PERSONAL INJURY,

AND/OR DAMAGE TO PROPERTY.

• Keep the work area clean and tidy.

• Keep children and visitors away - Do not let children handle the nailer. Make sure

that any other persons in the work area are dressed suitably and are wearing eye

and ear protectors.

• Do not operate the nailer where there are flammable liquids or gases.

• Keep the air supply hose away from heat, oil and sharp edges.

• Dress appropriately - Do not wear loose clothing or jewellery. Tie long hair out of

the way.

• Stay alert and use common sense - Do not operate the nailer when you are tired

or under the influence of alcohol, drugs or medication.

• Always wear eye protectors when using the nailer - Eye protectors must provide

protection from flying particles from the front and the side.

• Always wear ear protectors when using the nailer.

• Do not overreach - Keep proper footing and balance at all times.

• Never use any type of bottled gas as a source of power for the nailer.

• Do not connect the air supply hose with your finger on the trigger of the nailer.

• Do not exceed the maximum pressure for the nailer: 116 psi / 8 bar.

• Never point the nailer at yourself or any other person.

• Never actuate the nailer into free space - This will avoid any hazard caused by

free flying nails and excessive strain on the nailer.

• Place the nailer properly on the workpiece - Do not fire nails while holding the

nailer at an acute angle. Do not fire nails on top of other nails.

• Do not use on thin boards, corners or edges - There is a risk of firing through the

workpiece and injuring others.

• Check for the presence of live electric cables, water pipes etc., before use and

avoid.

• Do not use the nailer for any other purpose than that described in this book.

• Do not carry out any alterations or modifications to the nailer.

• Use ONLY replacement parts and accessories provided by CLARKE International.

The use of other parts may invalidate your guarantee.

4

WARNING! MAKE SURE THAT THE AIR NAIL GUN IS DISCONNECTED FROM THE AIR SUPPLY

BEFORE STARTING ANY CLEANING, OR MAINTENANCE PROCEDURES.

LUBRICATION

• Only use the oil provided to lubricate the air nail gun.

• Lubricate the moving parts of the safety yoke and trigger mechanism before

using the nailer.

• Do not use detergent oils or any oil that contains artificial additives as these may

cause the nailer to malfunction.

• Place 2 or 3 drops of lubricating oil into the air intake hose connection point twice

a day when the nailer is being used. A bottle of CLARKE Air Line Oil** is supplied

with the kit.

CLEANING

• Keep the body of the nailer clean and free from debris.

• Make sure that the magazine release lever and the trigger are kept clean and in

good working order.

• Clean the magazine and nail pusher by blowing with compressed air.

SERVICE AND REPAIR

• All servicing and repair must be carried out by qualified service technicians.

NOTES

Be aware that factors other than the tool may effect its operation and efficiency such as

reduced compressor output, excessive drain on the airline, moisture or restrictions in the

line, or the use of connectors of improper size or poor condition which will reduce air

supply.

**Clarke Air Line Oil is available from your CLARKE dealer part no. 3050825.

9

Avoid triggering the nailer when the nail magazine is empty. If the nailer operates

improperly or is defective, disconnect from the air supply and have the tool inspected by

a qualified service technician.

In the event of long breaks in work or at the end of the working session, disconnect the

tool from the air supply and empty the nail magazine.

Disconnecting the air supply

WARNING! NEVER DISCONNECT THE AIR SUPPLY HOSE UNTIL THE COMPRESSOR

HAS BEEN SHUT DOWN AND THE COMPRESSED AIR RELEASED.

1. Refer to the compressor instruction book for the procedures to shut down and

release the compressed air.

2. Once the pressure has been released, disconnect the air supply hose from the nail

gun. Slide the collar on the hose connector away from the nailer. The hose will

release and spring backwards.

3. Remove any nails remaining in the magazine of the nailer .

4. Store the nailer safely in its box in a dry, secure environment

Clearing a jam

To clear a jammed nail, proceed as follows:

1. Follow the compressor procedure to switch off

and release the air pressure.

2. Disconnect the air supply hose.

3. Pull the nail pusher back as far as possible until

the catch clicks into place.

4. Remove the nails from the magazine.

• The jammed nail should then release. If the

jammed nail does not release, proceed as

follows.

5. Remove the bolt indicated using the hexagonal

key supplied.

6. Remove the striker cover.

7. Remove the jammed nail using pliers or similar tool.

8. Replace the striker cover.

SAFETY PRECAUTIONS cont.:

• Always disconnect from the air supply when:

a) Performing any maintenance such as clearing a jammed nail.

b) The nailer is not in use.

c) The nailer will be left unattended.

d) Moving to another work area.

e) Passing the nailer to another person.

• Use only the nails, parts and accessories described in this book.

• Only carry out the maintenance recommended in this booklet. For replacement

of parts or repair, return the nail gun to the place of purchase.

TRANSPORTATION

• Always disconnect from the air supply before moving from one work area to another.

• Always disconnect from the air supply before passing the nailer to another person.

• Never carry the nailer by the air supply hose.

• Never carry the nailer with your finger on the trigger.

STORAGE

• When not in use the nailer must be disconnected from the air supply and stored in

a dry place out of the reach of children (preferably in a locked cabinet).

• Remove any nails from the nailer magazine while in storage.

• Avoid storing the nailer in environments where the temperature can fall to below

0oC.

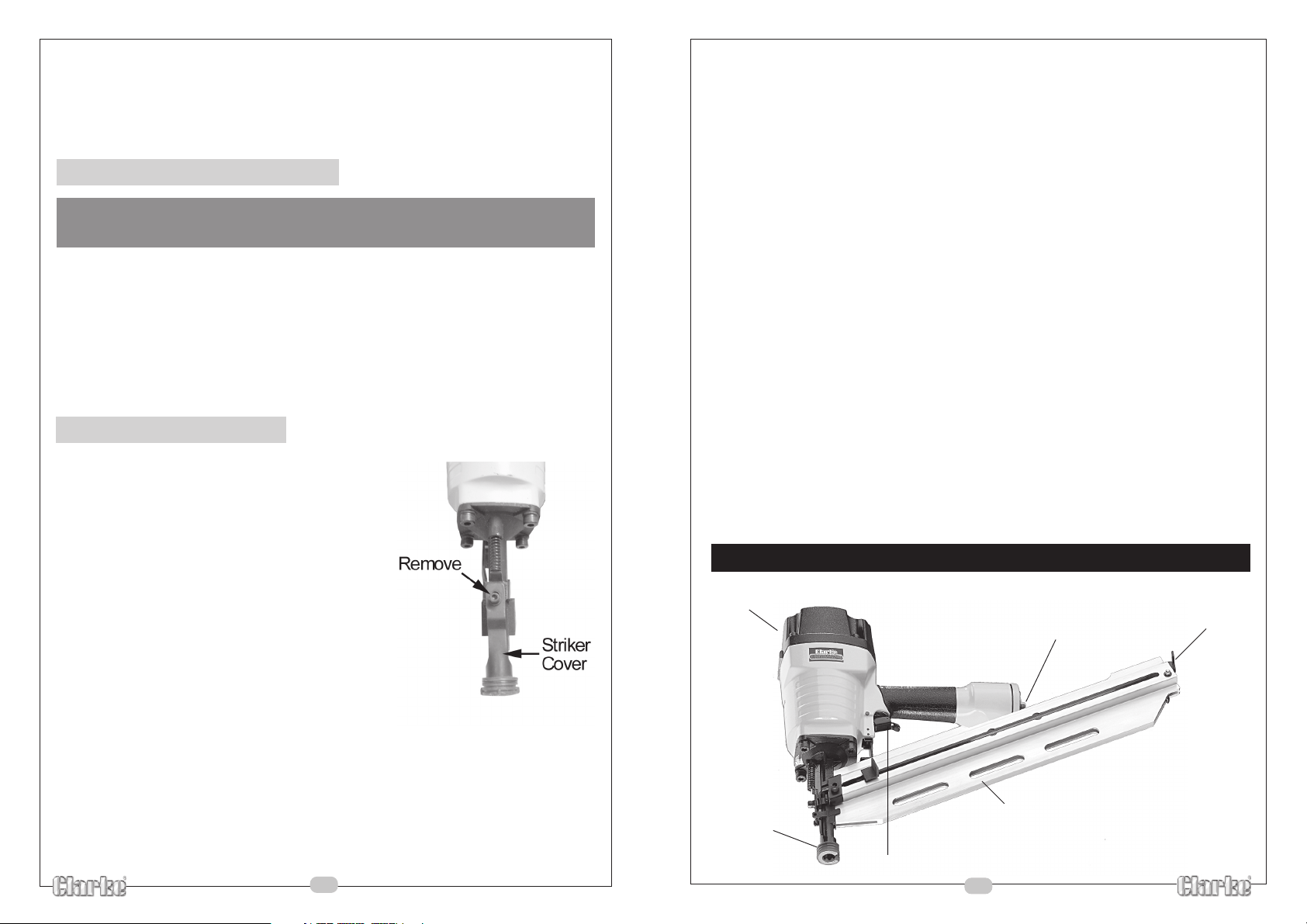

PARTS

Air

Deflector

Quick Fit Coupling

Magazine

Release

Catch

Striker

Magazine

Cover

Trigger

8

5

PREPARATION FOR USE

Screw the quick fit air intake coupling to the

nailer as shown on the right.

Preliminary checks

Make sure that the air supply is not connected to the nailer. Do not put any nails in the air

nail gun until directed to do so in the following procedure.

1. It is essential that the air nail gun is lubricated before each use. Use the machine oil

provided with your nailer to lubricate the safety yoke and trigger mechanism. Do not

use detergent oils or any oil that contains artificial additives these may cause the nail

gun to malfunction.

2. Place 2 or 3 drops of oil in to the air intake twice a day when the nailer is being used.

3. Check all of the nailers screws for tightness.

Connecting the air supply to the nailer

Make sure that you are wearing eye protectors before connecting the air supply.

4. Push the hose from the compressor on to the nailer. The collar on the hose connector

will slide forward and click in place.

5. Refer to the air compressor instruction book for the starting procedures of the compressor.

Set the compressor output to 80 psi/ 5.5 bar.

6. Check that the nailer does not leak air.

Checking the safety mechanism

7. Hold the nailer in mid-air pointing downwards, and pull the trigger.

• The nailer should not operate. If it does the safety mechanism is faulty. Do not use

the nailer. Return it for repair to the place of purchase

8. Release the trigger and with your finger off the trigger, press the safety yoke against a

scrap piece of timber.

• The nailer should not operate. If it does the safety mechanism is faulty. Do not use

the nailer. Return it for repair to the place of purchase.

Checking operation of the nailer

9. Press the safety yoke against a piece of scrap timber and pull the trigger. The nailer

should operate. If it does not return it for repair to the place of purchase.

With the air nail gun off the work piece, pull the trigger and then press the safety yoke

against the workpiece.

• The air nail gun should NOT operate. If it does return for repair to the place of

purchase.

6

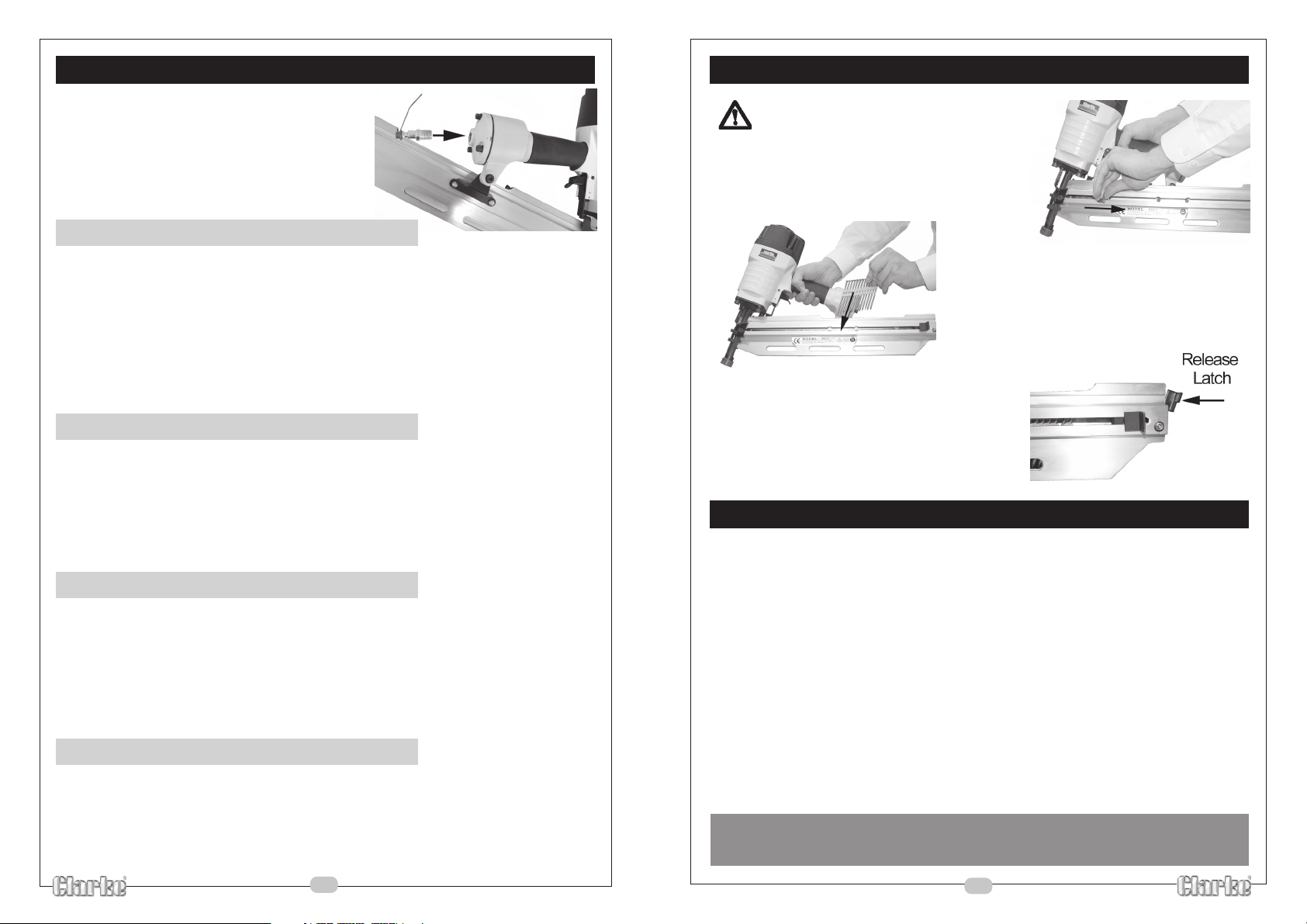

LOADING NAILS

Always disconnect the nailer from the air supply

before loading nails.

1. Pull the nail pusher back as far as possible

until the catch clicks into place.

2. Slide the nails through the loading slot into

the magazine as shown.

3. Press the release latch on the rear of the

magazine and slide the nail pusher forward.

• Your nailer is now ready to use.

OPERATION

1. Turn ON the air supply, and check for air leaks.

• If any are apparent, rectify before proceeding.

2. Ensure the operating pressure is set to between 4-7bar (60-100psi), depending upon

the size of nail used and type of material being worked.

• Harder material, or bigger nails will mean a higher pressure is required.

3. Hold the nailer firmly with the safety yoke flat against the workpiece, and at 90o to it.

4. Squeeze the trigger to drive the nail.

5. Each squeeze of the trigger will drive one nail only.

• If the nail is driven in too deep, reduce the air pressure in increments of 7 psi / 0.5

bar, checking the result after each adjustment. You should aim, to work with the

lowest possible air pressure. This will save energy, produce less noise and reduce

tool wear.

• If the nail is not driven in sufficiently, increase the air pressure in increments of 7 psi

/ 0.5 bar, checking the result after each adjustment.

WARNING! DO NOT EXCEED THE MAXIMUM OPERATING PRESSURE OF THE TOOL;

116 PSI / 8 BAR.

7

Loading...

Loading...