135L CEMENT MIXER

MODEL NO: CCM135

PART NO: 3400865

OPERATION & MAINTENANCE

INSTRUCTIONS

ORIGINAL INSTRUCTIONS GC09/22

INTRODUCTION

Thank you for purchasing this CLARKE Cement Mixer.

Before attempting to use this product, please read this manual thoroughly and

follow the instructions carefully. In doing so you will ensure the safety of yourself

and that of others around you, and you can look forward to your purchase

giving you long and satisfactory service.

SPECIFICATION

Model No CCM135

Max drum capacity 135 Litre

Max mixing capacity 100 Litre

Drum speed 25 rpm

Duty cycle classification S6 30%

Drum turning axis 360o

Weight 48 kg

Dimensions: Length x Width x Height 1180 x 713 x 1300 mm

Operating voltage & frequency 230V-50Hz

Rated input wattage 485W

Rated input ampere 2.44A

Power cable length 0.3 m

IP rating IP44D

Sound power guaranteed 91 dB LWA

GUARANTEE

This product is guaranteed against faulty manufacture for a period of 12

months from the date of purchase. Please keep your receipt which will be

required as proof of purchase.

This guarantee is invalid if the product is found to have been abused or

tampered with in any way, or not used for the purpose for which it was

intended. Faulty goods should be returned to their place of purchase, no

product can be returned to us without prior permission.

This guarantee does not effect your statutory rights.

2

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

GENERAL SAFETY PRECAUTIONS

1. ALWAYS keep the work area clean and well lit. Floors should always be kept

clear. Cluttered or dark areas invite accidents.

2. ALWAYS keep children and bystanders away while operating this machine.

Distractions can cause loss of control.

3. ALWAYS stay alert & do not use a machine while you are tired or under the

influence of medication or alcohol.

4. ALWAYS wear suitable protective clothing and eye protection including

industrial gloves, ear defenders & approved impact resistant safety glasses.

(Eye glasses are NOT safety glasses). Wear a dust mask if handling cement.

5. NEVER over-reach. Keep your proper footing and balance at all times to

enable better control of the machine in unexpected situations.

6. NEVER stand on the machine. Injury could occur from a fall.

7. ALWAYS store machines out of reach of children.

8. ALWAYS read and become familiar with the entire operating manual.

9. NEVER allow persons unfamiliar with this manual to operate this machine.

10. ALWAYS maintain the machine with care and keep it clean for best / safest

performance.

11. NEVER use this machine if any part is damaged. Have it inspected and

repaired by a competent technician.

12. NEVER modify this machine in any way. Use it only for the purpose for which

it is designed.

13. ALWAYS ensure the electrical cable is fully protected and there is no

danger of damage from equipment or materials. Always Inspect the cable

before use and replace if any damage is apparent.

14. ALWAYS avoid inhaling cement dust while loading the mixer. Avoid contact

with cement or any mixing additives being used. Wear gloves/face mask if

necessary.

15. ALWAYS disconnect the machine from the power supply when not in use,

and before carrying out any maintenance.

16. NEVER leave the machine running unattended or leave the machine until it

comes to a complete stop.

17. ALWAYS keep your hands well clear of the rotating drum at all times. Never

put your hands inside the drum when the machine is switched on.

3

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

18. NEVER put any tools or other objects in or around the drum while it is

rotating.

19. NEVER wear jewellery or loose clothing that could be snagged by any part

of the rotating drum.

20. NEVER load the drum when the machine is switched off. Always switch on

and ensure the drum is rotating before loading.

21. NEVER operate this machine on a gradient. Always stand the mixer on firm,

level ground where it cannot tip over.

22. ALWAYS switch off and disconnect from the power supply before moving

the machine around the work site.

23. NEVER use the mixer if the power cable or other important parts of the

machine are damaged.

24. If an extension cable is used, the cable and plug must be of watertight

construction. Inadequate extension cables can be dangerous.

ENVIRONMENTAL RECYCLING POLICY

By purchasing this product, the customer is taking on the obligation to deal

with its safe disposal in accordance with the Waste Electrical and Electronic

Equipment (WEEE).

This means that this product must not be disposed of with general household

waste. It must be disposed of according to the laws governing Waste

Electrical and Electronic Equipment (WEEE) at a recognised disposal facility.

If disposing of this product or any damaged components, do not dispose of

with general waste. This product contains valuable raw materials. Metal

products should be taken to your local civic amenity site for recycling of metal

products.

4

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

SAFETY SYMBOLS DISPLAYED ON THE MACHINE

Read instruction

manual before use.

Wear protective

gloves.

Wear ear protection. Protect the environment

Do not use where the

mixer could tip over.

Do not operate on

sloping ground.

Do not insert anything

into the drum while the

mixer is running.

Wear eye protection.

Wear protective

footwear.

when emptying.

Keep bystanders at a

safe distance.

Always disconnect the

power before starting

any maintenance or

cleaning.

Do not remove or

tamper with any

protection or safety

device.

Do not remove drive

guard with power

connected.

Pinch point hazard. Do

not insert fingers or

other objects.

5

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

Do not overload the

mixer.

Keep hands clear of the

machine when running.

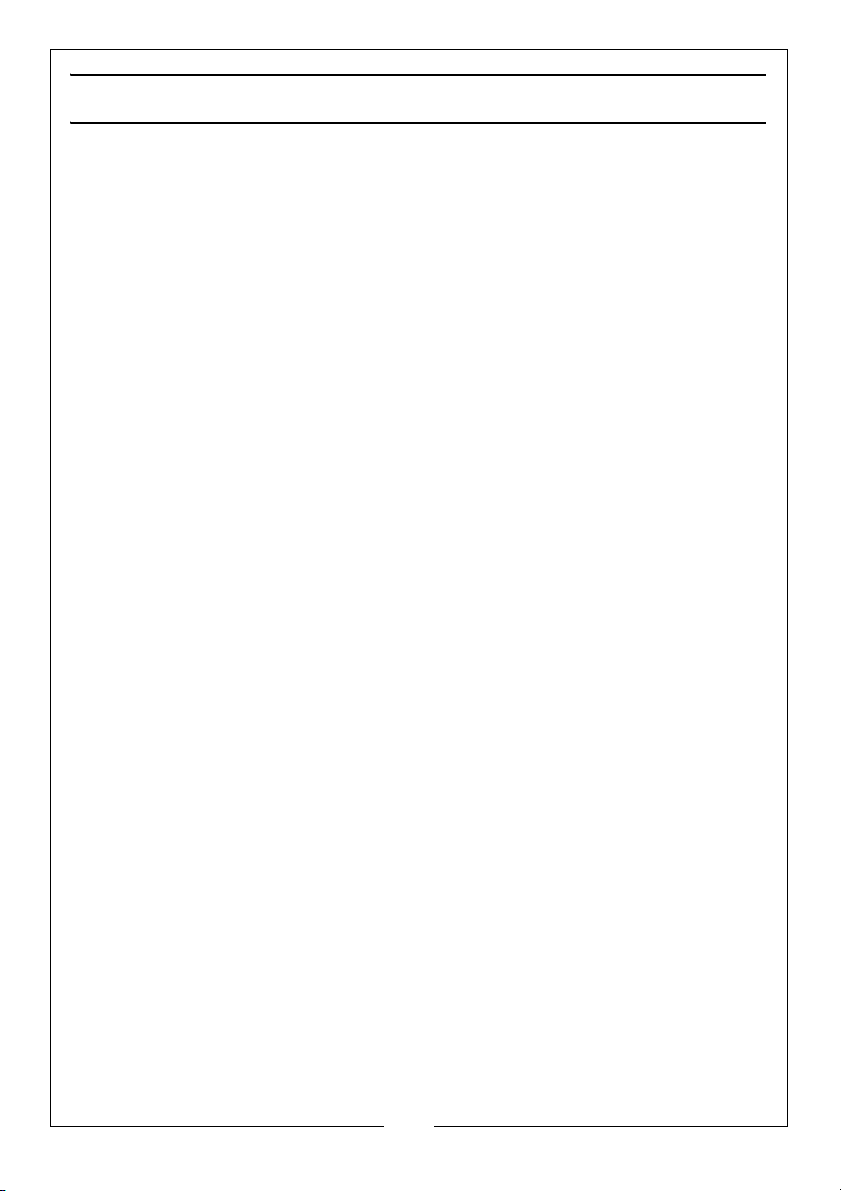

ELECTRICAL CONNECTIONS

WARNING: READ THESE ELECTRICAL SAFETY INSTRUCTIONS

THOROUGHLY BEFORE CONNECTING THE PRODUCT TO THE MAINS

SUPPLY.

Connect the mains lead to a standard, 230 Volt (50Hz) electrical supply

through an approved 13 amp BS1363 plug, or a suitably fused isolator switch.

If the plug has to be changed because it is not suitable for your socket or

because of damage, it must be removed and a replacement fitted, following

the wiring instructions shown below. The old plug must be discarded safely as

insertion into a power socket could cause an electrical hazard.

WARNING: THE WIRES IN THE POWER CABLE OF THIS PRODUCT ARE

COLOURED IN ACCORDANCE WITH THE FOLLOWING CODE:

BLUE = NEUTRAL BROWN = LIVE

The wires in the mains lead should be

wired up in accordance with the

following colour code:

• Connect the BROWN coloured

wire to the plug terminal

marked with a letter “L”.

• Connect the BLUE coloured wire

to the plug terminal marked

with a letter “N”.

We strongly recommend that this machine is connected to the mains supply

via a Residual Current Device (RCD). If you are not sure, consult a qualified

electrician.

DO NOT try to carry out any repairs yourself.

This symbol indicates that this is a Class II product and does not

require an earth connection.

6

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

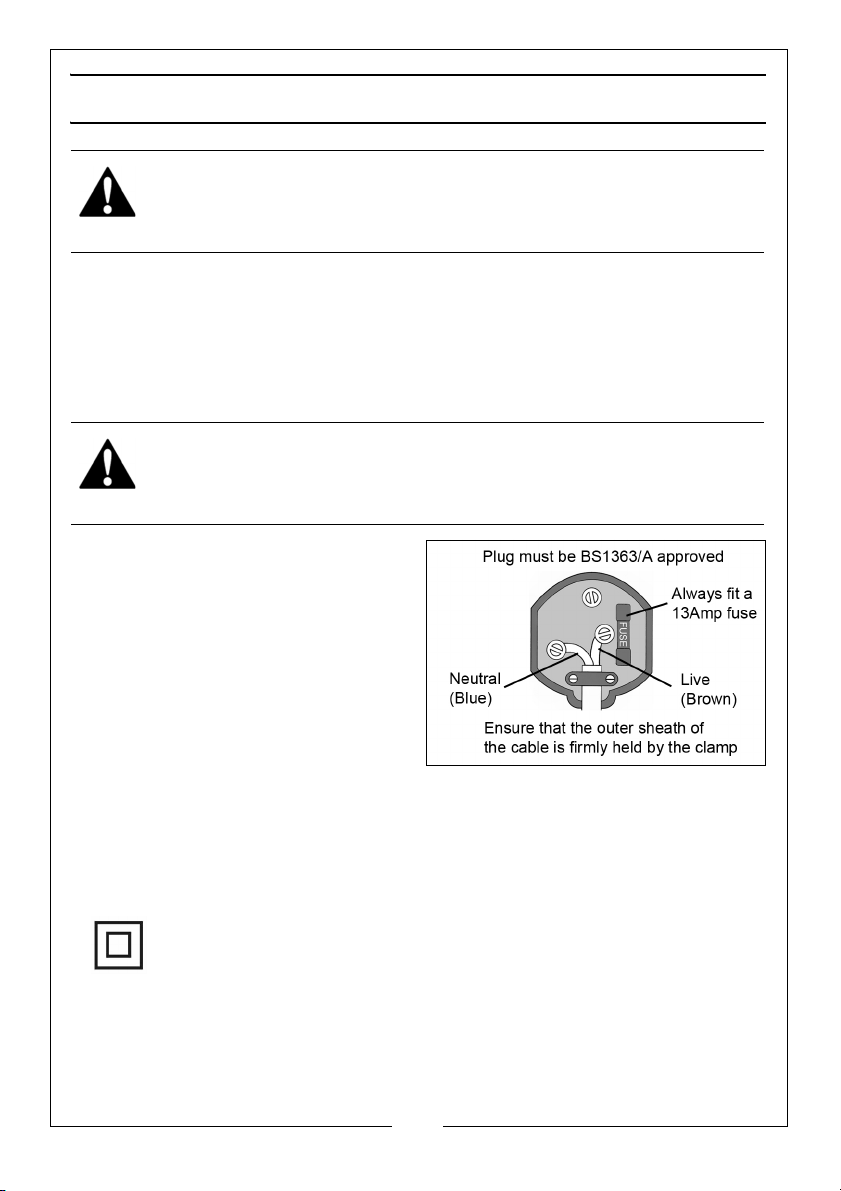

UNPACKING & ASSEMBLY

Remove all components from the packing case and lay them out so that they

can be identified and checked for any possible damage during transit. Should

any component be found to be damaged or missing, please contact your

CLARKE dealer immediately. Check the components against the following list.

1. Mixing blades 5. Stand Legs

2. Drum assembly c/w mixing blades 6. Stand Connector

3. Wheels 7. Fixings Kit (bolts/nuts/washers/pins

4. Handlebars

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

R-clips/cotter pins

7

ASSEMBLY

1. Bolt the handles to the main

frame using the nuts & bolts

supplied.

2. Tip the assembly over and slide

the wheels onto each of the axles

securing them with the large

washers and cotter pins suppled.

3. Bolt the mixing blades to the

mixing drum using the short bolts,

nuts and washers supplied.

4. Assemble the stand by sliding the

four legs into the stand connector.

Fasten in place with the pins and

R-clips provided.

8

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

5. Lift and locate the cement mixer onto

the stand.

• The assistance of another person

will be required to do this.

OPERATION

1. Switch the mixer on by pressing

the green (I) switch on the motor.

Stop by pressing the red (O)

switch.

2. Introduce water first, to prevent

the mixer from clogging.

3. Add cement as required.

4. Add aggregate to suit.

• Do not load the drum when the

machine is switched off. Always set the machine running before

filling.

• Avoid stopping and starting the mixer while there is a heavy weight

of material inside the drum as the extra strain could be harmful to

the motor.

• Keep the drum rotating while emptying the mixture.

9

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

5. When emptying, remove the

locking pin and tilt the mixer

forward while gripping both

handles tightly.

• Only discharge the mixer when

a suitable receptacle for the

cement mix is in position.

• Do not operate this machine

on a steep gradient. Always

stand the mixer on firm, level

ground where it cannot tip over.

WARNING: REMEMBER THAT THE CENTRE OF GRAVITY OF THE LOADED

MIXER MAY PRESENT A HAZARD WHEN OPERATING ON UNEVEN GROUND.

• Always keep water away from the motor and other electrical

components as far as possible.

It is essential that the mixer is kept clean. Dried cement inside the drum will be

very difficult to remove. For the mixer to perform at its best it must be

thoroughly cleaned after every use.

CARE AND MAINTENANCE

BEFORE STARTING WORK

Inspect the power cable and ensure it is free from damage and is not in

danger of being damaged by vehicles, equipment or other operations taking

place on the work site.

AFTER USE

At the end of the working shift it is essential that the machine is hosed down

thoroughly with clean water, being sure to remove all traces of the cement

mix especially from around the mixing blades. The drum may be scoured for a

couple of minutes running using course gravel and water which is then

discharged and the drum finally hosed clean.

Never allow cement residue to harden inside the drum and thereafter be

tempted to beat on the drum with hand tools to dislodge such accumulations

of dried cement.

10

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

The machine is constructed to IP44D ingress protection which enables the

drum and any other areas to be hosed down safety. However, the motor and

plug should not be hosed directly under pressure.

STORAGE

CAUTION: OWING TO THE WEIGHT AND BULK OF THE MIXER, TWO

PEOPLE WILL BE REQUIRED TO LOWER THE MIXER AND RE-FIT THE BOLTS.

The mixer can be better stored with the support

stand folded away.

Remove and lower the mixer to the floor with the

help of an assistant. Loosely re-fit the pins and Rclips into their respective holes for safe keeping.

Leave the mixer with the drum partially inverted to

exclude water or debris and always store the mixer

in a dry place out of reach of children.

OCCASIONALLY

After extensive use, inspect the paint and remove

any rust that may be apparent before touching up

where necessary with a rust resistant paint.

MAINTENANCE FREE ITEMS

The bearings in the machine are sealed for life and require no maintenance.

The drive belt is under constant tension and therefore no adjustment is

required.

11

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

COMPONENT PARTS

12

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

COMPONENT PARTS LIST

ID DESCRIPTION ID DESCRIPTION

1 Drum 34 Bearing 6206-2RS

2 Nut M10 35 Drum rotating shaft

3 Spring washer M10 36 Circlip 62

4 Washer 10 37 Circlip 15

5 Leather washer 10mm 38 O-ring

6 Screw M10 x 25 39 Drive pinion

7 Mixing blade 40 Pin 6 x 25

8 Nut M6 41 Drive

9 Spring washer 6 42 Bearing 6202-2RS

10 Washer 6 43 Cotter pin 5 x 40

11 Leather washer 6 44 Flat washer

12 Gearwheel 45 Wheel

13 Bolt M6 x 25 46 Frame

14 Bolt M6 x 20 47 R-clip

15 Plastic rotator disc 48 Leg connecting bracket

16 Locknut M8 49 Support leg

17 Washer 8 50 Pin

18 Spring washer 8 51 Wire snap ring

19 Bolt M8 x 25 52 Circlip

20 Handle 53 Bearing 61906-2RS

21 Handle grip 32 dia 54 Drive pulley

22 Washer 55 Nut

23 Spring washer 12 56 Bolt

24 Bolt M12 x 30 57 Locknut

25 ST screw 58 Power cable & plug

26 Motor end plate 59 ST screw

27 Motor seat 60 Switch

28 Bolt M8 x 30 61 Switch seal

29 Drive belt 6PJ-L540 62 Motor cover

30 Motor 63 Decorative cover

31 Adjusting washer 64 ST screw

32 Bearing 6305-2RS 65 Tilt locating pin

33 Circlip 30 66 Pin securing chain

13

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

DECLARATIONS OF CONFORMITY-UK

14

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

DECLARATIONS OF CONFORMITY-EU

15

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

Loading...

Loading...