Page 1

Clarion Co., Ltd.

50 Kamitoda, Toda-shi, Saitama 335-8511 Japan

Service Dept.: 5-66 Azuma , Kitamoto-shi, Saitama 364-0007 Japan

Tel: +81-48-541-2335 / 2432 FAX: +81-48-541-2703

Service Manual

DVD Multmedia Station with

CeNET & 7-inch Touch Panel Controller

Model

Model

Published by Service Dept.

298-6429-00

Printed in Japan

(QC-6824B-A)

(NTSC/ Region No. "1")

(QC-6824K-A)

Mar.2007

This product is a lead free model.

Lead free solder is used in PWB stamped LF mark.

Please keep the following conditions when you repair.

1. Use lead free solder.

* Koki's lead free solder S3X-55M 0.6mm

(CLARION Parts No.642-0231-01)

* Koki's lead free solder S3X-55M 1.0mm

(CLARION Parts No.642-0231-02)

2. Use a nitrogen solder system.

3. Do not use "General solder" and "Lead free solder"

together.

(PAL/ Region No. "3")

Model

(QC-6824K-B)

(NTSC/ Region No. "3")

Model

(QC-6824K-C)

(PAL/ Region No. "4")

SPECIFICATIONS

FM tuner section

Frequency range: 87.9MHz to 107.9MHz(B-A)

87.0MHz to 108.0MHz(K-A,B,C)

Usable sensitivity: 9dBf

50dB quieting sensitivity:

15dBf

Alternate channel selectivity:

70dB

Stereo separation: 35dB(1kHz)

Frequency response: 30Hz to 15kHz(+3/-3dB)

AM tuner section

Frequency range: 530kHz to 1710kHz(B-A)

531kHz to 1629kHz(K-A,B,C)

Usable sensitivity: 28dBu

- 1 -

VRX775VD

VRX776VD

Page 2

DVD player section

System: Digital versatile disc system with

CDDA capable

Usable discs: DVD video disc,Compact disc

Frequency response: 20Hz to 20kHz(CD)(+1/-1dB)

Dynamic range: 100dB(1kHz)

Distortion: 0.01%

MP3 / WMA section

MP3 Sampling rate: 11.025kHz to 48kHz

MP3 Bit rate: 8kbps to 320kbps/VBR

WMA Bit rate: 48kbps to 192kbps

Logical Format: ISO9660 level1, 2

JOLIET or Romeo

Audio amplifier section

Maximum power output:

50W x 4ch

Rate power output: 14W x 4ch

at 20 Hz to 20kHz,1%,4 ohm

Speaker impedance: 4 ohm(4 to 8 ohm)

Input section

Video input: 1.0V+0.2/-0.2Vp-p

(input impedance 75 ohm)

Audio input: 130mV+60/-60mVrms(High)

600mV+80/-80mVrms(Mid)

840mV+100/-100mVrms(Low)

(input impedance 10k ohm or

greater)

Video output section

Video output: 1.0V+0.2/-0.2Vp-p(output imped-

ance 75 ohm)

LCD monitor section

Screen size: 7-inch wide type

(152mm Width x 85mm Height)

Display method: Transmission type TN liquid

crystal display

Drive method: TFT(thin-film transistor) active

matrix driving

Pixels: 336,960(1440x234)

General

Power source voltage: 14.4V DC

(10.8 to 15.6V allowable)

Ground: Negative

Current consumption: 4.0A(1W)

Auto antenna rated current:

500mA less

Dimensions(mm): Main unit

178(W)x50(H)x165(D)

Remote control unit

54(W)x28.8(H)x155(D)

Weight: Main unit 2.4kg

Remote control unit 100g

(including battery)

* Specifications comply with JEITA Standards.

* Specifications and design are subject to change without

notice for further improvement.

NOTES

* As for this model, the tuner of the DSP type is used.When

you exchange it due to the tuner pack(BL1:880-2091D)

trouble, it is necessary to adjust for S-meter etc.Special

JIG is necessary for an accurate adjustment.The procedure document for the exclusive use jig is appended to

it.

* This DSP IC SAF7730H(051-6706-10) of main PWB is

exposed die soldering pad type.

The middle of this IC package is soldered with the main

PWB, and it cannot remove in an ordinary soldering iron.

Please use special removal JIG at the time of IC exchange.

* We cannot supply PWB with component parts in prin-

ciple. When a circuit on PWB has failure , please repair

it by component parts base. Parts which are not mentioned in service manual are not supplied.

* This DVD player can play the following discs.

DVD video discs,Video CDs,CD text,Audio CDs.

* This DVD video player cannot playback DVD-

Audio,DVD-RAM,Photo CDs,etc.

* This unit can play back CD-R/CD-RW,DVD-R/RW discs

on which MP3/WMA music data have been recorded..

This unit is a ID3 Tag compatible model.

This unit supports the title,artist and album display of

the ID3 Tag versions 1 and 1.1.

After disc loading,the play mode is automatically engaged.

* This product incorporates copyright protection technol-

ogy that is protected by U.S. patents and other intellectual property rights .

Use of this copyright protection tecnology must be authorized by Macrovision, and is intended for home and

other limited viewing uses only unless otherwise authorized by Macrovision.

Reverse engineering or disassembly is prohibited.

* The DVD video system assigns a region number to DVD

video players and DVD discs by sales area.

The DVD video region number is marked on the disc

jacket.

* ,and logo are

trademarks,or registered trademarks of Microsoft Corporation in the United States and/or other countries.

* This product includes technology owned by Microsoft

Corporation and cannot be used or distributed without a

license from MSLGP.

* Manufactured under license from Dolby Laboratories.

"Dolby" and the double-D symbol are trademarks of Dolby

Laboratories.

* "DTS" and "DTS Digital Out" are trademarks of Digital

Theater Systems,Inc.

* "iPod" is for legal or righthoder-authorized copying

only.Do not steal music.

VRX775VD

VRX776VD

- 2 -

Page 3

COMPONENTS

QC-6824B-A,K-A,K-B,K-C

Main unit ----------- 1

Remote control unit RCB-177-200 1

Batteries(AA.SUM-3) ----------- 2

Universal mounting bracket 300-9677-00 1

DCP case 335-6035-60 1

Power supply lead(16P) 854-6420-50 1

RCA pin lead(20P) 855-5543-50 1

Outer escutcheon 940-8145-20 1

Parts bag -----------

Electro tap 060-0018-00 1

Machine screw(M4 x3) 714-4003-8H 4

Flat head screw(M5 x8) 714-5008-4B 4

Sems hex. bolt(M5 x8) 716-0496-51 5

Parts bag -----------

Hook plate 330-8216-01 2

Cord clamp 335-0833-07 1

Rubber cap 345-3653-20 1

Screw(M5 x10) 716-0726-51 1

Parts bag -----------

Pad screw(M1.7 x5 Blk) 716-0872-52 1

Parts bag -----------

RCA CAP 345-3799-20 12

CAUTIONS

Use of controls,adjustment or performance of procedures

other than those specified herein,may result in hazardous

radiation exposure.

The compact disc player should not be adjusted or repaired

by anyone except properly qualified service personnel.

QC-6823B-A

QC-6824B-A

QC-6824B-A

276-0200-00

LF

To engineers in charge of repair or

inspection of our products.

Before repair or inspection, make sure to follow the

instructions so that customers and Engineers in charge

of repair or inspection can avoid suffering any risk or

injury.

1. Use specified parts.

The system uses parts with special safety features against fire

and voltage. Use only parts with equivalent characteristics

when replacing them.

The use of unspecified parts shall be regarded as remodeling

for which we shall not be liable. The onus of product liability

(PL) shall not be our responsibility in cases where an accident

or failure is as a result of unspecified parts being used.

2. Place the parts and wiring back in their original positions after

replacement or re-wiring.

For proper circuit construction, use of insulation tubes, bonding, gaps to PWB, etc, is involved. The wiring connection and

routing to the PWB are specially planned using clamps to keep

away from heated and high voltage parts. Ensure that they are

placed back in their original positions after repair or inspection.

If extended damage is caused due to negligence during repair, the legal responsibility shall be with the repairing company.

3. Check for safety after repair.

Check that the screws, parts and wires are put back securely

in their original position after repair. Ensure for safety reasons

there is no possibility of secondary ploblems around the repaired spots.

If extended damage is caused due to negligence of repair, the

legal responsibility shall be with the repairing company.

4. Caution in removal and making wiring connection to the parts

for the automobile.

Disconnect the battery terminal after turning the ignition key

off. If wrong wiring connections are made with the battery connected, a short circuit and/or fire may occur. If extensive damage is caused due to negligence of repair, the legal responsibility shall be with the repairing company.

5. Cautions in soldering

Please do not spread liquid flux in soldering.

Please do not wash the soldering point after soldering.

6. Cautions in soldering for chip capacitors

Please solder the chip capacitors after pre-heating for replacement because they are very weak to heat.

Please do not heat the chip capacitors with a soldering iron

directly.

7. Cautions in handling for chip parts.

Do not reuse removed chips even when no abnormality is observed in their appearance. Always replace them with new

ones. (The chip parts include resistors, capacitors, diodes, transistors, etc).

Please make an operation test after replacement.

8. Cautions in handling flexible PWB

Before working with a soldering iron, make sure that the iron

tip temperature is around 270 . Take care not to apply the

iron tip repeatedly(more than three times)to the same patterns.

Also take care not to apply the tip with force.

- 3 -

VRX775VD

VRX776VD

Page 4

9. Turn the unit OFF during disassembly and parts replacement.

Recheck all work before you apply power to the unit.

10.Cautions in checking that the optical pickup lights up.

The laser is focused on the disc reflection surface through the

lens of the optical pickup. When checking that the laser optical diode lights up, keep your eyes more than 30cms away

from the lens. Prolonged viewing of the laser within 30cms

may damage your eyesight.

11.Cautions in handling the optical pickup

The laser diode of the optical pickup can be damaged by electrostatic charge caused by your clothes and body. Make sure

to avoid electrostatic charges on your clothes or body, or discharge static electricity before handling the optical pickup.

ERROR DISPLAYS

11-1. Laser diode

The laser diode terminals are shorted for transportation in order to prevent electrostatic damage. After replacement, open

the shorted circuit. When removing the pickup from the mechanism, short the terminals by soldering them to prevent this

damage.

11-2. Actuator

The actuator has a powerful magnetic circuit. If a magnetic

material is put close to it. Its characteristics will change. Ensure that no foreign substances enter through the ventilation

slots in the cover.

11-3. Cleaning the lens

Dust on the optical lens affects performance.

To clean the lens, apply a small amount of isopropyl alcohol to

lens paper and wipe the lens gently.

If an error occurs, one of the following displays is displayed.

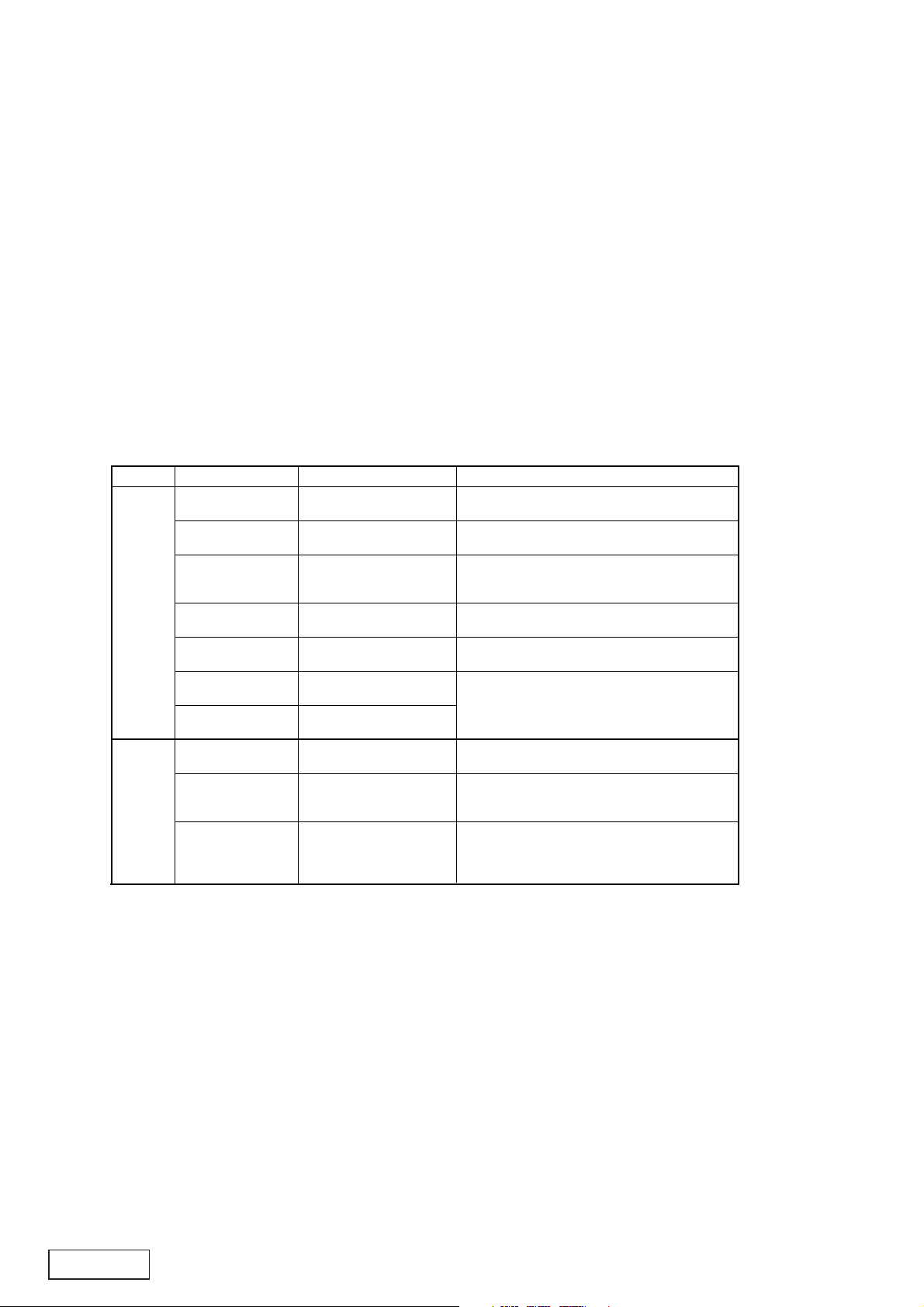

Displa y Cause Measure

ERROR 2 A disc is caught inside the

ERROR 3 A disc cannot be played

ERROR 6 A disc is loaded upside-

DVD

Player

CD

PARENTAL

VIOLATION

WRONG REGION Region code error Eject the disc, and replace correct region code

DRM WMA files protected by

NOT SUPPORT Files not supported by this

ERROR 2 A disc inside the CD

ERROR 3 A disc inside the CD

Changer

ERROR 6 A disc inside the CD

If an error display other than the ones described above appears, press the Reset button. If the problem

persists, turn off the power and consult your store of purchase.

* When the Reset button is pressed, frequencies of radio stations, titles, etc. stored in memory are cleared.

CD deck and is not ejected.

due to scratches, etc.

down inside the DVD deck

and does not play.

Parental level error Set the correct Parental level.

DRM are played.

unit are played.

changer is not loaded.

changer cannot be played

due to scratches, etc.

changer cannot be played

because it is loaded

upside-down.

Take the measures described below to solve the problem.

This is a failure of DVD deck’s mechanism.

Replace with a non-scratched, non-warped disc.

Eject the disc then reload it properly.

disc.

Perform the operation such as skipping a file.

(Scan, repeat and random playback mode may be

canceled.)

This is a failure of CD changer’s mechanism.

Replace with a non-scratched, non-warped disc.

Eject the disc then reload it properly.

VRX775VD

VRX776VD

- 4 -

Page 5

ADJUSTMENT

CH1

CH2

(KI2

* The NTSC (K-A:PAL)composite output signal of the

signal generators of adjustment is performed with the

following output.Video input of visual mode.

A image signal: 714mV

A synchronized signal: 286mV

Sub PWB section

* Refer to the printed circut board(36 page)for an adjustment point and VR.

1. Confirm the power supply voltage

Input signal: 10-steps wave

Measurement is performed by composite screen

display.It measures by digitalbolt meter and DIMMER is

100%.

1-1.Adjust VR551 so that voltage of TP593 is 5.30 +0.02/-

0.02V.

Caution: A LCD controller will be damaged if the voltage

beyond 5.45V is added.

1-2.Confirm that TP556 is 3.3 +0.2/-0.2V

1-3.Confirm that TP558 is 7.5 +0.2/-0.2V

1-4.Confirm that TP559 is 18.5 +0.8/-0.8V

1-5.Confirm that TP555 is -12.0 +0.5/-0.5V

LCD PWB section

* Refer to the printed circut board(39,40 pages)for an

adjustment point and VR.

2. Confirm the PLL lock

Input signal: 10-steps wave

2-1.It checks that see a screen and 10 gradation display do

not have a synchronous flow.

After checking and uniting the freerun frequency of item

9.when the synchronoization cannot be taken.

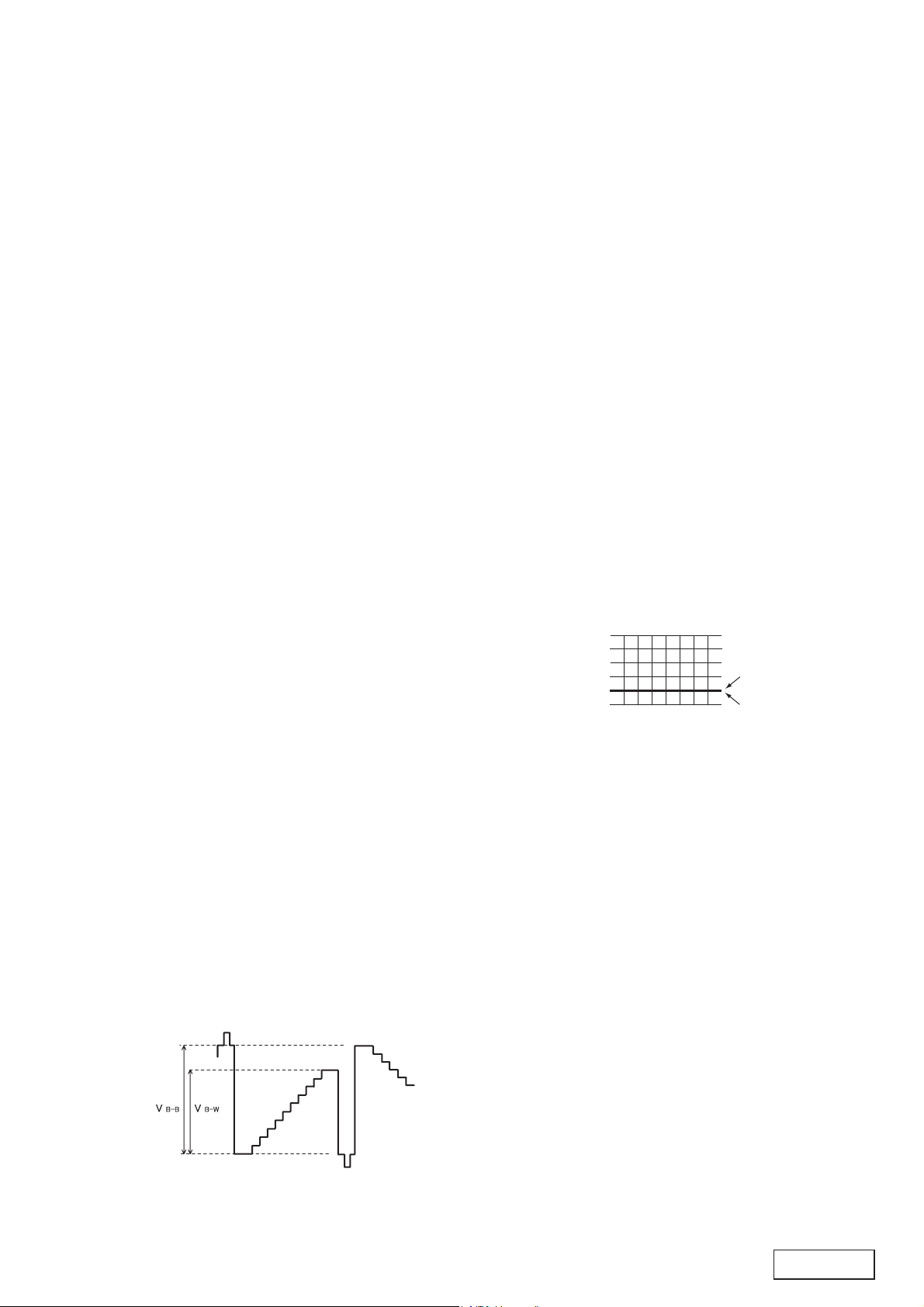

5. Contrast adjustment (black-white)

Input signa: 10-steps wave

Measurement is performed by composite screen display.

It measures with an oscilloscope.

5-1.Adjusts VR801 so that the black-black level (V B-w) of

the waveform of TP861 (G) will become 3.8 +0.1/-0.1V.

(Refer to Fig. 1)

6. Gamma voltage check

Input signal: 10-steps wave

Measurement is performed by composite screen display.

It measures with an oscilloscope.

6-1.Confirm the waveform of TP861(LCD G) that ten grada-

tion has come out.

6-2.It checks that it is the 3rd gradation is 2.3+0.2/-0.2V.

6-3.Confirm that TP806(Gamma 0) is 2.30 +0.20/-0.20V

6-4.Confirm that TP807(Gamma 2) is 2.13 +0.20/-0.20V

7. White balance adjustment

Input signal: 10-steps wave

Measurement is performed by composite screen display.

It measures DC range of an oscilloscope.

* Are careful in order to perform correctly white balance

adjustment.

* The range of CH1,CH2 of an oscilloscope is used as

1V range.

* CH1,CH2 are indicated by GND and GND is united.

(Refer to Fig. 2)

3. BRIGHT voltage adjustment

Input signal: 10-steps wave

Mesurement is performed by composite screen display.

It measures by digital bolt meter.

3-1.Adjust VR804(BRIGHT) so that the voltage of

TP805(BRIGHT) will become 2.00 +0.02/-0.02V.

4. RGB-AMP adjustment (black-black)

Input signal: 10-steps wave

Measurement is performed by composite screen display.

It measures with an oscilloscope.

4-1.Adjusts VR805 so that the black-black level (V B-B) of

the waveform of TP861 (G) will become 4.0 +0.1/-0.1V.

(Refer to Fig. 1)

(KI1

7-1.White balance red adjustment

7-1-1.The waveform of TP861 is displayed on CH1 of an

oscilloscope, and the waveform of TP862(LCD-R) is displayed on CH2.

7-1-2.Adjust VR802(BRT-R) so that the waveform of

TP862(LCD-R) will become the same as the waveform

of TP861.

7-2.White balance blue adjustment

7-2-1.The waveform of TP861 is displayed on CH1 of an

oscilloscope, and the waveform of TP860(LCD-B) is dis-

played on CH2.

7-2-2.Adjust VR803(BRT-B) so that the waveform of

TP860(LCD-B) will become the same as the waveform

of TP861.

8. VCOM AC adjustment

Input signal: 10-steps wave

Measurement is performed by composite screen display.

It measures with an oscilloscope.

8-1.Adjust the VR806(VCOM AC) so that amplitude of a

waveform of TP852(VCOM AC) is 7.0+0.1/-0.1V.

There are no abnormalities, such as distortion, in a wave-

form.

- 5 -

VRX775VD

VRX776VD

Page 6

9. Free run frequency adjustment

Input signal: 10-steps wave

Measurement is performed by composite screen display.

It measures by frequency counter and DIMMER is 100%.

9-1.Adjust VR941 so that the frequency of TP949 will be-

come to 15.734kHz+10/-10Hz.

* TP804 is made to short-circuit to GND. It checks that

the voltage of TP951 is 1.61+0.20/-0.20V at this time.

And checks that the voltage of TP952 is same.

10. PAL burst cleaning coil adjustment

Input signal:The color bar signal of PAL.

It measures with an oscilloscope etc.

10-1.Adjust L803 coil so that change TP860(LCD-B) of a

color waveform may be lost.

11. BRT/COL/HUE check

Input signal: Split color bar signal

11-1.Comfirm that the color bar is normally displayed at state

to begin.

11-2.Comfirm that the BRT/COL/HUE control is moved

screen.

11-3.Comfirm the superimposition display is normally.

12. V-MUTE check

Input signal:Split color bar signal

12-1.Comfirm a composite video screen is mute of V-

MUTE:"H" .

13. Wide mode check

Input signal:Split color bar signal

13-1. Comfirm a wide mode changed screen(Full wide /Wide

/Cinema /Normal).

14.Screen position check

Input signal: Mono-sucpeo signal.

14-1.Comfirm that the screen is displayed in the center by

mono-scope display (Video mode).

14-2.Comfirm that the screen is displayed in the center by

radio screen display (RGB mode).

15.Synchronicity condition check

15-1.Comfirm a normal display by DVD playback (main

menu) of HITOMI.

16.Key sw operation/Illum check

16-1.Comfirm that key operation can be performed.

16-2.Comfirm the key illum lighting .

17. Back light check

Power supply voltage: 13.2V

DIMMER=100%

17-1.Comfirm the TP962 freqency is 63kHz +5/-5kHz.

17-2.Comfirm the TP961 voltage is 5.2V +0.5/-0.5V.

17-3.Comfirm the light on at the power supply voltage to

10V.

17-4.Comfirm check at DIMMER control changes so that

brightness changes.

18. VCOM-DC check

Input signal:10-steps wave

Measurement is performed by composite screen display.

18-1.Adjust VR807(VCOM DC) so that a screen flicker may

become the minimum.

Main PWB section

* Pefer to the printed circuit board (30,31 pages)for an

adjustment point and VR.

19. TV delay time adjustment

Adjustment is performed in TV mode and the stable channel which does not have disorder in a screen is used.

It acts as the monitor of the signal of TP329 (Normal

horizontal synchronous input) and TP421 (Delay output

synchronization).

19-1.To falling of the Horizontal Synchronizing signal of

TP329, VR401 is adjusted so that falling of TP421 may

be overdue 3.50 +0.10/-0.10 uS

19-2.Confirm that Low level time of TP421 is 4.7 +0.7/-0.7uS.

19-3.It checks whether there is any gap in the right-and-left

balance of a superimposition display to TV image, or the

character has not passed by the end after the adjustment.

Recommends connected TV tuner :TTX7501Z(ZT4620B-A) for NTSC,:TTX7504Z(ZT-4610K-A) for PAL(s).

20. S-meter adjustment of BUS-tuner

The adjustment data is written in the memory of

EEPROM(IC502).The special jig and software are necessary for BUS-TUNER adjustment.

* CeNET-analyzer

* Windows installed Personal computer

* SSG

* Adjustment-Software(Ver.Y4-S009-513-20051111)

a. Installation of software in the set-folder of the writing

E2P.

b Connect CeNET-analyzer to the unit with the CeNET-

cable.

c Connect CeNET-analyzer(MASTER/SLAVE side) to the

PC with the serial crossing cable.

d Connect POWER-lead of CeNET-analyzer to the

POWER-lead of the unit.

e Connect the antenna to the unit.(FM-ANT for first ad-

justment)

f Turn on CeNET-analyzer,and press the RESET-button

of it.

20-1.Set up the software

20-1-1.Click [ADJ_DSP].

20-1-2.Click [open Comm PORT].(To open the COM port

of PC)

20-1-3.Click [Initialization of JIG].(The BUS-analyzer

sounds)

20-1-4.Click [Incoming connection].(The unit is recognized

to the BUS-analyzer)

The data is displayed, and the display changes regu-

larly.

20-2.PRN data writing / Set up FM-IF-Offset data

20-2-1.Click [Initial EEPROM with CS 16], and select PRN-

FILE.

The PRN-data is write in EEP-ROM of the unit.

20-2-2.Confirm "OK" display after writing of data.

20-2-3.Click [Setting-prn] under "FM IF-COUNT".(the writ-

ten FM-IF-Offset data becomes effective.)

VRX775VD

VRX776VD

- 6 -

Page 7

20-3.Adjustments FM S-meter

20-3-1.Set SG output to 65dBuV.(FM)

20-3-2.Click [Adj,HI] of "FM S-Meter".(Wait until the value

stops.)

20-3-3.Set SG output to 55dBuV.(FM)

20-3-4.Click [Adj,LO] of "FM S-Meter".(Wait until the value

stops.)

20-3-5.Click [Check].If the display is not within +/-0.5dBuV

of ANT-output level of SG, readjust with "MOD-

ON"(22.5kHz 400Hz).

20-4.Set up FM-IF-Offset data

* Exchange the antenna for "AM-ANT-dummy"

20-4-1.Click [Setting-prn] under "AM IF-COUNT".(The AM-

IF-Offset data of EEPRON is effective.)

20-4-2.Click [Check], and confirm the display is within +/-

500.0.

20-5.Adjustments AM S-meter

20-5-1.Set SG output to 70dBuV.(AM)

20-5-2.Click [Adj,HI] of "AM S-Meter".(Wait until the value

stops.)

20-5-3.Set SG output to 40dBuV.(AM)

20-5-4.Click [Adj,LO].(Wait until the value stops.)

20-5-5.Click [Check]. If the display is not within +/-0.5dBV

of ANT-output level of SG, readjust with "MOD-ON"(30%

400Hz).

Finally, push the reset button of the unit.

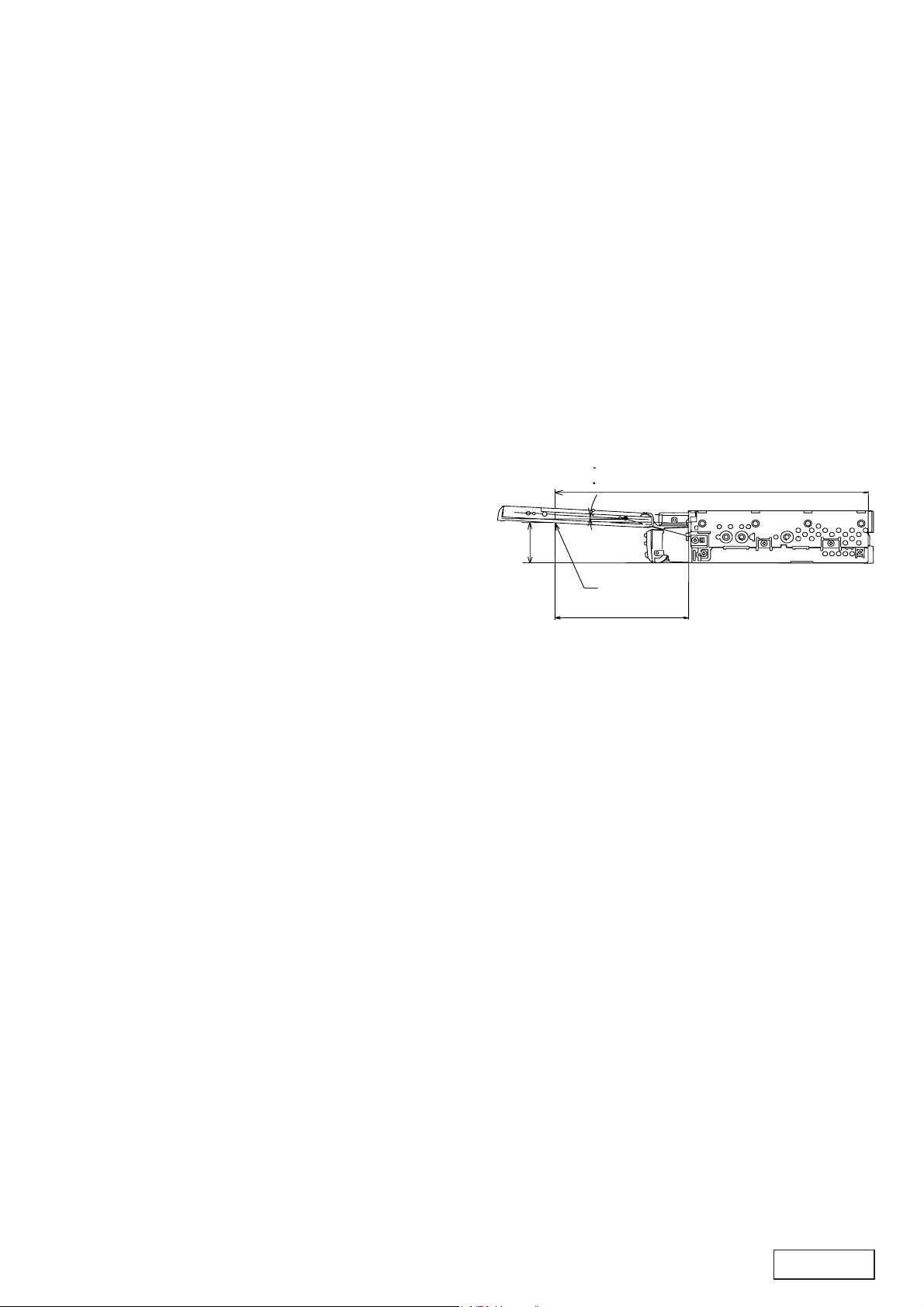

Slide mechanism section

23 Horizontally position

Calibration jig is used in order to memorize a horizontal

level position.

Please refer to an attached figure 3.

It is made to memorize horizontally among a figure in

the position of points.

It is performing giving about 3 degrees of angles intentionally.

If the MUTE button and the ISR button are pushed, a

beep sound will sound.

A calibration begins at the time.

Flow of operation

a. Slide OPEN

b. Tilt up: Memory of 110 degree position

c. Tilt down: Memory of horizontally position (Jig used)

d. Tilt up

e. Tilt down

f. Slide CLOSE

g. Calibration end

#

When computer continues to freeze, click [RESET] of

"MENU", and readjust the lost adjustment point.IF not returning, press the RESET-button of CeNET-analyzer.and

restart adjustment from the first step.

21. OSD dot adjustment

An adjustment screen is performed on the "T-PNL"

screen, or the 9th screen (five-step display) of "COLOR-

BAR" in the test mode.

Please choose the screen which is easy to adjust from

either.

21-1.The hole has opened in the Lower case and it adjusts

by VR451 mounted in the MAIN-PWB solder side.

21-2.In the case of adjustment in a T-PNL screen

It adjusts so that the white line of a 1-dot display long

may be vividly displayed.

21-3.In the case of adjustment by 9th COLOR-BAR

It adjusts so that the white line of top, the bottom and

inside may be displayed as clear white.

Figure 3.

- 7 -

VRX775VD

VRX776VD

Page 8

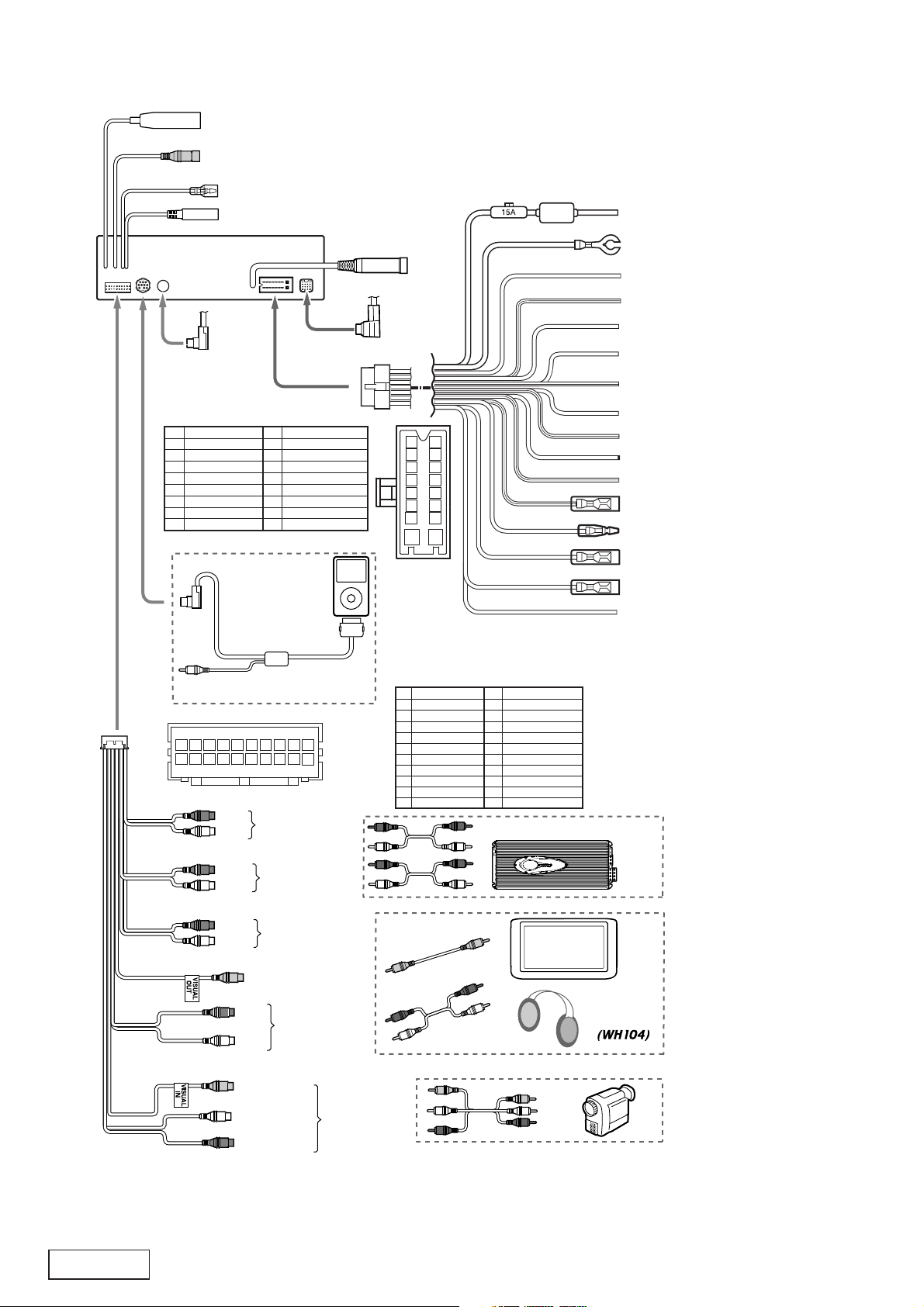

WIRE CONNECTION

Radio antenna jack

Yellow

Video input terminal of TV tuner/

DVD changer/CCD camera

Purple/White

Optical output

connector

No. Description No. Description

1 SP R/L(+)

3 SP F/L(-)

5 SP F/L(+)

7 SP F/R(+)

9 SP F/R(-)

11 SP R/R(+)

13 SP R/R(-)

15 BACK UP

Reverse Gear terminal

Steering wheel remote control

input jack

Connector cable

(CCA-673-600)

2 SP R/L(-)

4 PHONE MUTE

6 ACC

8 AUTO ANT

10 REMOTE

12 ILLUMI

14 PARKING BRAKE

16 GND

iPod

with video

J601

RGB terminal

CeNET

terminal

1

3

5

7

9

11

13

15

Yellow

BACK UP

(+12V main power)

Black

Purple

Purple/Black

Gray/Black

White/Black

2

4

6

8

10

12

14

16

Orange/White

Green/Black

Blue/White

Blue

Brown

Grass-green

Ground

Rear right +

Rear right -

Red

+12V accessory

Gray

Front right +

Front right -

White

Front left +

Front left -

Green

Rear left +

Rear left

Amp. turn-on lead

Illumination

Auto antenna

Phone mute

Parking brake lead

-

P201

Purple

Gray

Green

Black

Red

Gray

Black

Connect to the video of

visual input terminal.

2 4 6 8

1 3 5 7 9

Red

White

Red

White

Red

White

Red

White

10 12 14 16 18

11 13 15 17

Right

Front audio output

left

terminal

Right

Rear audio output

left

terminal

Right

Non fader

output terminal

left

Yellow

Video output terminal

Right

Left

Yellow

Video

White

Audio (left)

Red

Audio (right)

20

19

(2-ZONE

output terminal)

Visual input

terminal

Description

No.

LEFT REAR

1

RIGHT REAR

2

LEFT FRONT

3

RIGHT FRONT

4

S-GND

5

S-GND

6

NF LEFT

7

NF RIGHT

8

S-GND

9

S-GND

10

Description

No.

11

2ZONE LEFT

12

2ZONE RIGHT

13

V OUT GND

14

V IN GND

15

VIDEO OUT

16

VIVEO IN

17

V-AUDIO GND L

18

V-AUDIO GND R

19

V-AUDIO LEFT

20

V-AUDIO RIGHT

4-Channel Amplifier

Rear monitor

Headphone

VTR etc.

Wireless

VRX775VD

VRX776VD

- 8 -

Page 9

BLOCK DIAGRAM

Main unit section

AUDIO OUT

L/R

R

T

E

U

D

A

O

E

-F

N

N

O

N

2ZO

P201 (20P)

1,3

7,8

11,12

SYSTEM

MUTE

SUB-MUTE

LOWPASS

FILTER

IC205

IC206

PROSESSOR

LW/MW/UKW

TUNER PACK

880-2091D

BL101

ANT.

FM/AM

INPUT

J101

H

H

C

C

L

R

R

R

A

A

E

E

/R

T/R

T

N

N

O

O

R

F

FR

2,4

DIGITAL

SIGNAL

SAF7730

IC104

AMP-MUTE

OFFSET-DET

POWER AMP

TB2906H

IC601

SYSTEM

MUTE

LOWPASS

FILTER

IC203

IC204

D/A

CONVERTOR

AK4384

IC201 IC202

I2C

AV8V

SW

Q102

SW

Q104

5V

REGURATER

AN77L05

IC103

(OPTIC

C

C

A

PARKING/

PHONE

DETECTOR

AMP-STB

I2C

RDS

IC301

ITAL

IG

D

J30

/U

B

BUFF

A

H

T 4C

POWER SUPPLY

U

O

CONNECTOR(16P)

P

S

REMOTE+B

A-ANT

PROTECT

R

O

S

S

E

S

O

R

L P

A

IGN

S

L

A

D

TO

REGURATER

M

S

I

N

A

H

C

E

M

z

D

H

V

D

41.6M

TO

REGURATER

Main PWB(B1)

T

S

,R

O

IF

D

I,S

P

S

S

J301

(30P)

DVD

MECHANISM

T

OU

)

K

JAC

L

2

J601

ILLUMI

DETECTOR

REM5V

3.3V

REGURATER

BA033

IC105

1.8V

REGURATER

PHK04P02T

Q106

REM5V

SW

Q303

3.3V

LM1086

IC302

REGURATER

1.8V

LM1086

IC303

CONV

TC7W14

IC604

9V

3V

5V

,3.

M

D

E

V

R

1.8V

D

CONNECTOR

(10PIN)

No. Description

1 AUDIO-L

2 AUDIO-R

3 AUDIO-RETURN

4 ACC IDENTIFY

5 ACC DETECT

6 RX (iPod OUT)

7 TX (iPod IN)

8 GND

9 iPod DET IN

10 CHARGE POWER

B/U

SW&9V

BA09ST

IC304

B/U

SW

T

C

TE

O

R

P

iPod

J603

No. Description

10

11

12

13

14

15

16

R

REGURATER

E

N

TU

D

N

A

K

C

LO

B

IO

REGURATER

D

HA17558AF

U

A

TO

1

SP R/L(+)

2

SP R/L(-)

3

SP F/L(-)

4

PHONE MUTE

5

SP F/L(+)

6

ACC

7

SP F/R(+)

8

AUTO ANT

9

SP F/R(-)

REMOTE

SP R/R(+)

ILLUMI

SP R/R(-)

PARKING BRAKE

BACK UP

GND

B/U

AV8.5V

Q623

4V

IC102

P201 (20P)

19,20

)

L

A

(VISU

IN

IO

D

U

A

REGURATER

SW

3.3V

M

E

R

9.59MHz

ON SCREEN

DISPLAY

YGV629

IC401

TC58FVM5

IC405

32M ROM

IC307

VIDEO-BUF

YK15420MI

IC308

15 16

T

U

O

O

E

ID

V

B/U

3.3V

Q612

IC603

3V

3.

3.3V

M

E

/U

M

B

VIDEO

SELECTOR

BA7652AF

IC306IC305

)

L

IN

A

L

A

U

S

(VISU

I

) V

IN

D

O

V

E

(D

ID

V

TV

No. Description

ONLY VRX775VD

QC-6824B-A

Ce-NET

CONNECTOR

(13P)

J604

DRIVER

HA12187

IC605

B/U ACC B/U

B/U2,ACC

DETECTOR

NJM2078

CONTROL

uPD70F3339GJ-UEN-A

EEPROM

BR93L56

IC502

RGB

SELECTOR

NJM2524V

IC457

O

L

E

IDE

V

V-S

01

3

P

NAVI RGB

(5PIN)

P401

Mini din cord

855-2500-00

NAVI RGB

CONNECTOR

(8PIN)

J201

1 NAVI-B

2 NAVI-SYNC

3 NAVI-R

4N.C

5N.C

6 NAVI-G

7 N.C

8N.C

BUS

MICOM

IC501

B

G

/R

EO

ID

V

ROGIC

VI ON

A

N

MAIN

J303

No. Description

1 GND

2 BACK UP

3 L-CH(+)

4 NAVI(+)

5 NAVI(-)

6 BUS(+)

7 R-CH(+)

8 R-CH(-)

9 SYS-ACC

10 BUS(-)

11 L-CH(-)

12 ILLUMI

13 N.C.

B/U

DETECTOR

S80931

IC503IC504

K

N

A

L

B

SYNC

SELECTOR

MM1227

IC454

EO

GB

ID

R

V

TO LCD PWB CONNECTOR

R

E

Z

H

ORD

C

E

D

4.43M

Z

EO

H

ID

V

3.58M

V

R

04

9

D

0G2AF

0

IC

2

LCD

TC

GEAR

K

C

A

B

MEM3.3V

RESET

DETECTOR

BU4820G

IC505

32.768kHz

3.14MHz

ON

C

I

M

L

E

N

A

P

Y

I

S

H

H

Y

S

TATC

V

C

O

N

T

S

Y

Y

S

OR

T

ER

02

ONV

29BM

8

C

Y

IC

3

C

IR

/D

C

D

MODE1, 2

E LCD

LCD

D

I

W

7'

LCD PWB(B3)

ON

C

D

O

E

M

IR

E

R

W

B/U

FL

SW

Q305

CLAMP

B.C.H

910

OZ9

44

9

IC

T

LIGH

K

C

A

B

EL

PAN

CH

U

O

T

M

O

IC

M

5V DC/DC

CONVERTER

IC576

MD1424R

AV5V

Q575

J551

5V

M

E

R

N

AI

M

B/U

5V

M

E

R

-12V

3.5V

5.3V

7.5V

V

5

18.

5V

M

E

R

3.3V

M

E

R

(35P)

J701

J702

(20P)

Z

4.915MH

102

0

3

M

01

7

IC

ANEL

P

CH

TOU

Sub PWB(B2)

LCD POWER SUPPLY

SW

SUB PWB CONNECTOR

/U

L

B

ON

-SE

V

F

A

1

(20P)

J50

Switch PWB(B4)

(20P)

01

illumi

J11

blinking

TOR

C

E

ONN

matrix

C

B

W

P

W

S

B/U

SW

Q601

F

FAN MOTOR

FL+B

TR

M

CONNECTOR

Sub PWB

(B2)

Slide mechanism

CONVERTERDC/DC

IC552

NJM2368

LCD+B

SW

Q608

RESET

DCP DET

KEY

ILLUMI

BLK LED

KEY

int

SW

IR1101

IR

RECIVER

SW

Q604

10V

REGURATER

TA78DS10

IC602

Q603

P601

B

TR+

MAIN

M

J502

SUB PWB

(14P)

J503

DRIVER

TA7291

IC501

IC502

J502

(12P)

OTO,VR

H

P

MAIN

J602

B/U

SW

M

- 9 -

VRX775VD

VRX776VD

Page 10

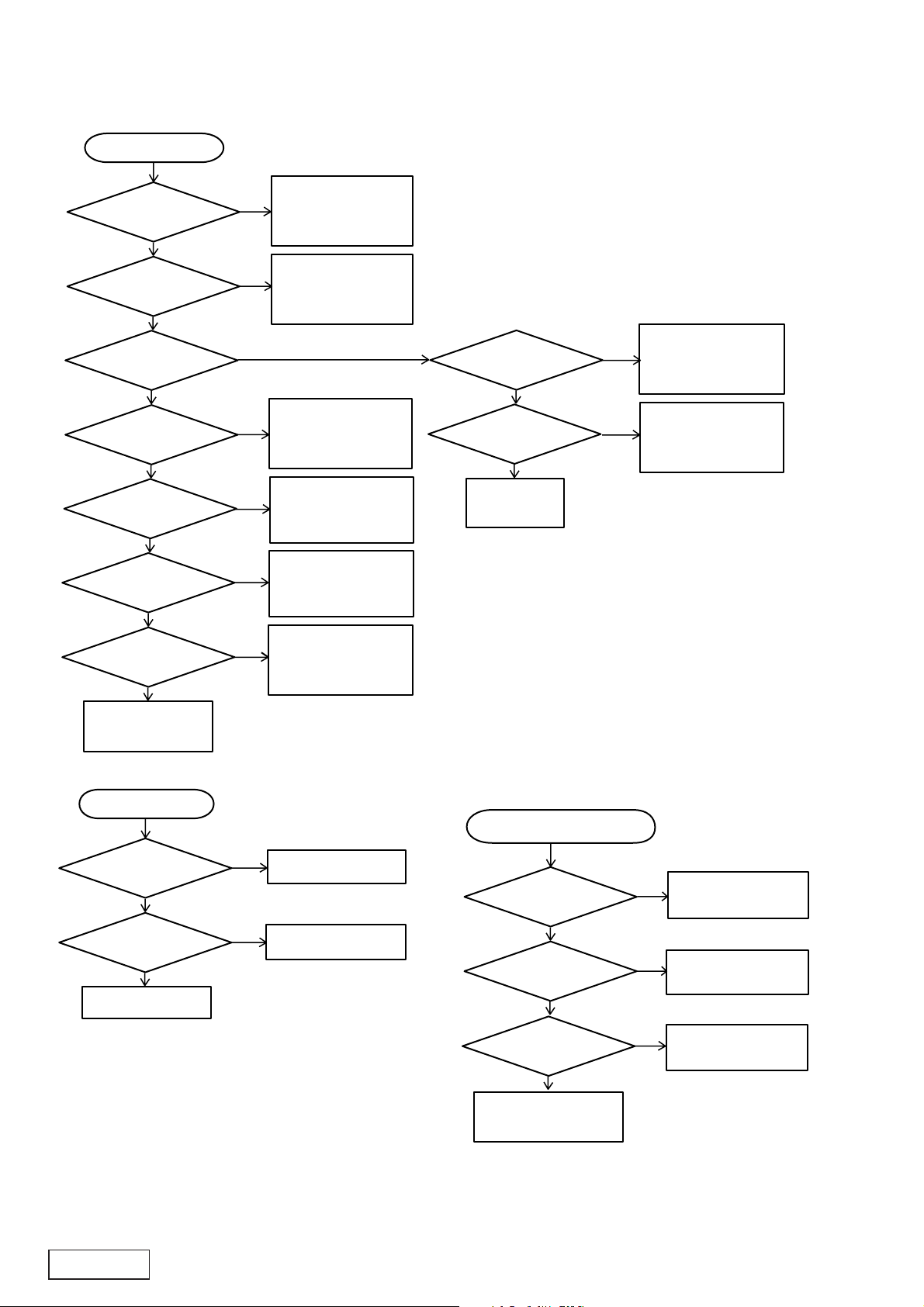

TROUBLESHOOTING

No Power

No Power

Voltage check

emitter of Q612

14V

OK

Voltage check

collector of Q612

4V

OK

Check

the oscillation of

X501

OK

Voltage check

collector of Q504

9V

OK

Check

ACC DET circuit line

OK

Check

signal line

DCP circuit

OK

Check

the oscillation of

X502

OK

Confirm to

IC501,

writing software

Check extension lead

NG

into fuse(15A),

connector

Check

NG

4V stabillation circuit,

(Q612, R622, IC603)

NG

Malfuntion of

NG

B/U9V-DET2 circuit line,

(IC504, Q504, IC501)

Malfuntion of

NG

ACC DET circuit

( IC504, Q505, Q506

ICIC501)

Malfuntion of

NG

DCP circuit,

(S1101, J1101, flat wire,

J501, IC501)

NG

Defective of X502, IC501

Check

RESET normally

OK

Check

B/U DET normally

OK

Confirm to

X501, IC501

Malfuntion of

RESET circuit line,

NG

(S1102, J1101, flat wire,

J501, IC505, IC501)

Malfuntion of

NG

B/U DET circuit line,

(IC503, IC501,R555,

R556)

No operating the key

Check

contact of

the switch

OK

Confirm

KI0-3, KO0-2 line of

J501

OK

Defective IC501

NG

Malfuntion of switch

Malfuntion of flat wire,

NG

J501

Slide Mechanisum section

No operating Slide Mechanisum

Confirm

Irregularity operating

OK

Confirm

the horizontally position

OK

Voltage check

MOTOR10V line

OK

Defective of

IC501, IC502 (Sub PWB)

IC501 (Main PWB)

NG

Confirm

lack and bite of a gear .

NG

calibration of

horizontally position

NG

Defective of Q603,

Q604,IC501, IC602

VRX775VD

VRX776VD

- 10 -

Page 11

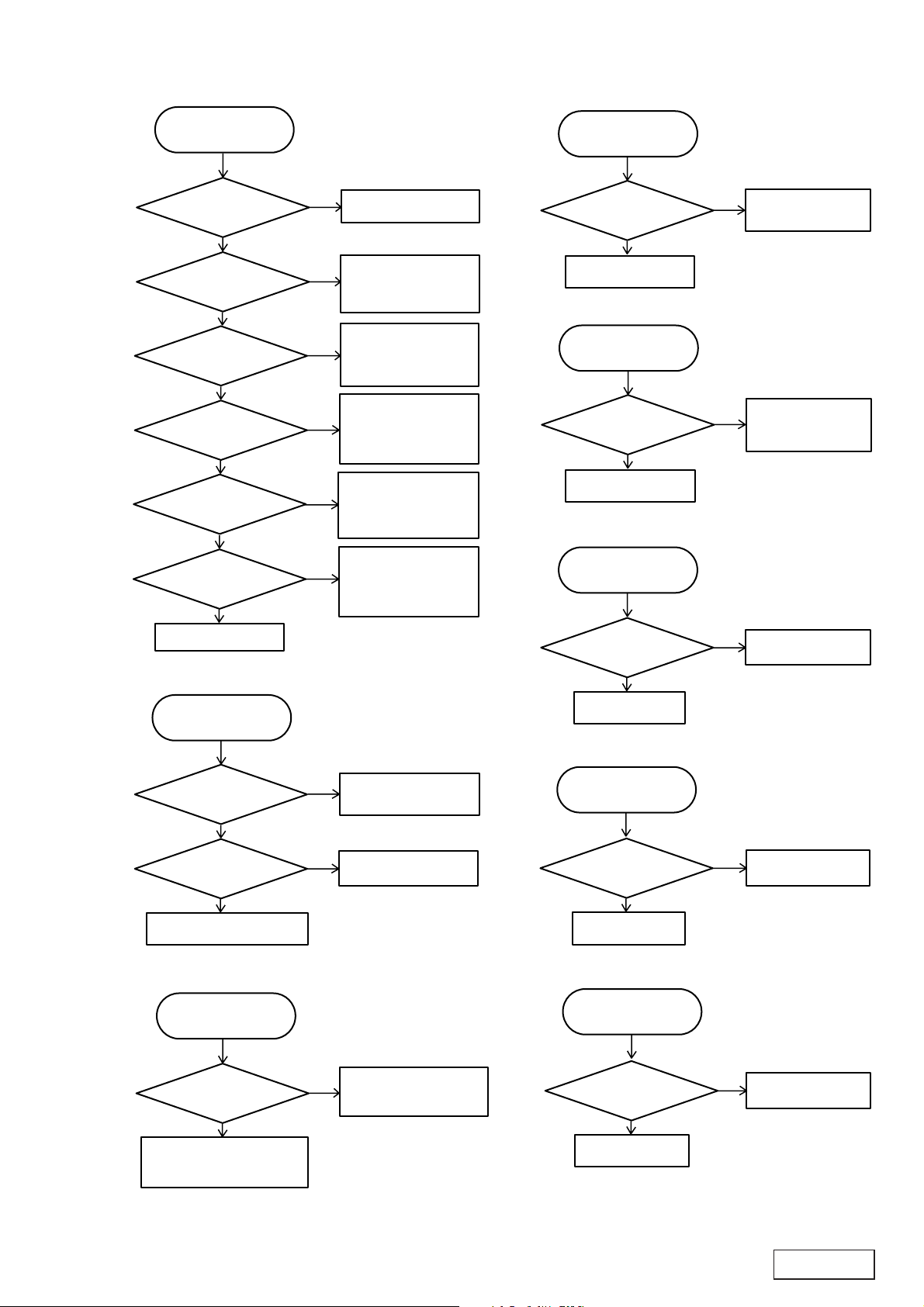

No sound

Power on

No sound all of source

Confirm

"AMP GUARD"

on display

NG

Check

emitter of Q622

OK

Check

15pin of J602

OK

Check

3pin of IC105

(3.5V)

OK

Confirm

SCL, SDA line of

DSPcircuit

OK

Confirm

MUTE circuit

OK

Defective IC501

Power on,

No sound SP-out only

all of source

OK

Malfuntion of IC601

Malfuntion of

NG

8.5V stabillation circuit

(Q622, Q624, Q625)

Malfuntion of

5V DC/DC CON circuit

NG

(IC578),B/U4V circuit

(Q612, R622, IC603)

Malfuntion of

NG

DSP3.3V circuit

(IC105, L112, L113)

NG

Malfuntion of IC104

Malfuntion of

NG

MUTE circuit

(Q201 - Q214,D204,

IC501)

Operating radio,

No sound only

radio

Confirm

IF OUT of BL101

OK

Check DSP circuit

Operating CD/DVD,

No sound only

Confirm

SPDIF line

of DSP IC

OK

Check DSP circuit

Operating Ce-NET in,

No sound

Confirm

the input sound of

DSP IC

OK

Check DSP circuit

NG

Malfuntion of BL101

Malfuntion of

NG

DVD mechanism,

flexible pwb, J301

NG

Defective

C111 - C115

Check

AMP-STB, AMP-MUTE

OK

Check

the input signal of

IC601

OK

Malfuntion of IC601

No sound only pri-out

(P201)all of source

Check

the connection of

AMP REM

OK

Confirm

the connection of AMP REM,

extra AMP

NG

Malfuntion of

IC601, IC501

NG

Defective C281 - C285

Malfuntion of

NG

the AMP REM line

connection

Operating visual,

No sound only

Confirm

the voice input of

DSP IC

OK

Check DSP circuit

Operating iPod voice,

No sound

Confirm

the voice input of

DSP IC

OK

Check DSP circuit

NG

Malfuntion of IC101

NG

Malfuntion

C147 - C149

- 11 -

VRX775VD

VRX776VD

Page 12

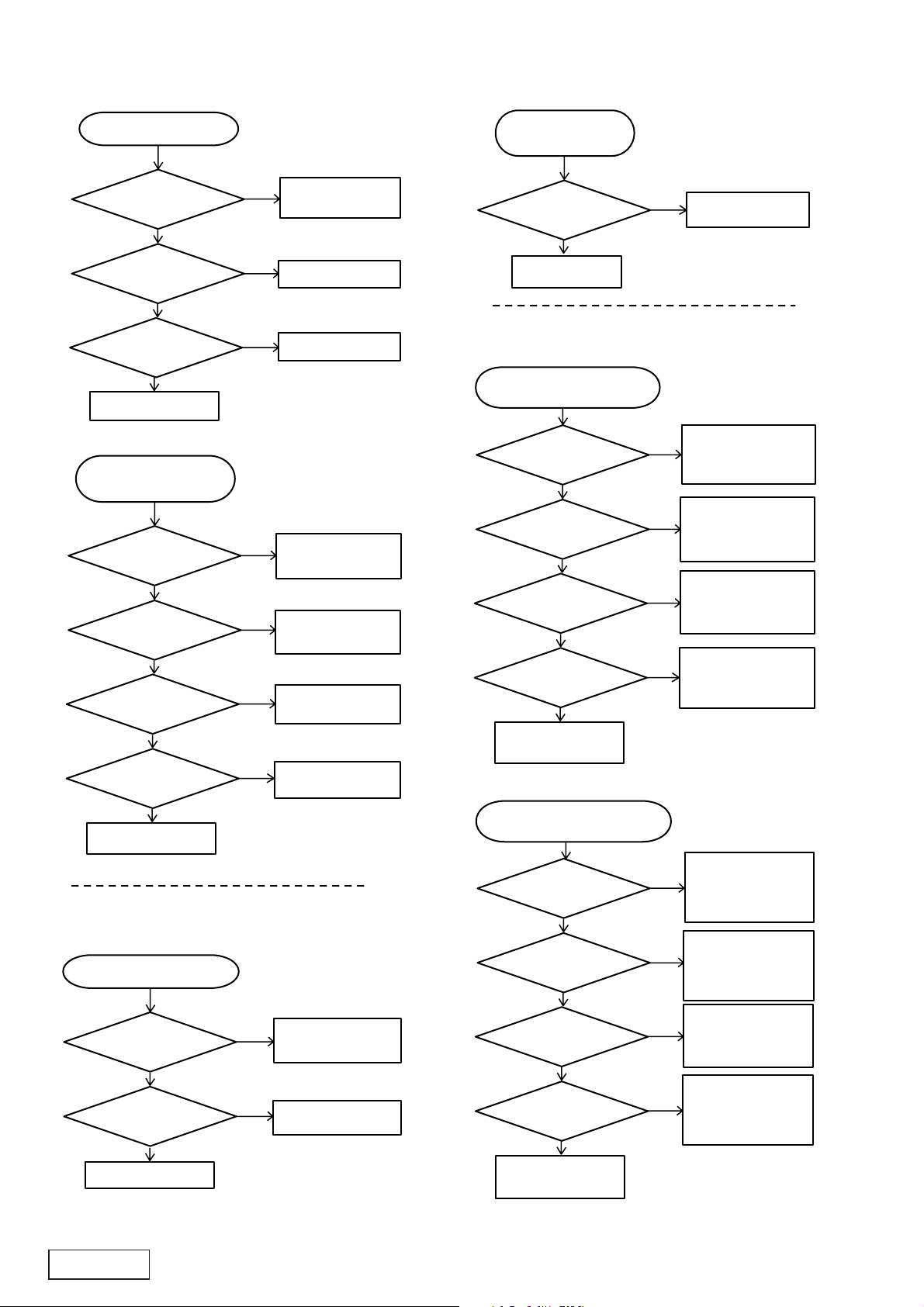

Tuner section

NAVI section

No operating radio

Voltage check

pin5,6 of BL101

8.5v,5v

OK

Check wave

TUN-SDA, SCL signal

OK

Check wave

DSP-SDA, SCL signal

OK

Defective of BL101

Operating radio,

No stop Broadcast

weak reception

Check

the antenna

OK

Voltage check

pin5,6 of BL101

8.5v,5v

OK

Confirm

the reading of

parameter

OK

Confirm

each item point

of parameter

OK

Defective of BL101

Malfuntion of

NG

Q102, Q104, IC103

NG

Defective of BL101

NG

Defective of IC104

Malfuntion of

NG

antenna connection

NG

Defective of

Q102, Q104, IC103

Defective of

NG

IC501, IC502

Rewriting

NG

the parameter

Operating NAVI,

No sound

Confirm

the voice input of

DSP IC

OK

Check DSP circuit

CD/DVD section

No loading CD/DVD,

No eject

Voltage check

4pin of IC304(DVD9V)

OK

Does

the disc detective

work?

OK

Is disc caught?

OK

Does it

stop of movement

in time-out

OK

Defective of

DVD mechanism

CD or DVD is loaded, ejected

No playing normally

NG

Malfuntion of IC102

Defective of

NG

IC304, flexible pwb,

J301

Malfuntion of

NG

DVD mechanism

(detective parts),

Escutcheon section

Malfuntion of

DVD mechanism,

NG

Escutcheon section

used DISC

Malfuntion of

NG

DVD mechanism

(loading parts)

Remoto controll section

No work of remote-controll

Check

REM5V line

of J1101

OK

Check

signal output of

IR1101

OK

Defective of IC501

VRX775VD

VRX776VD

Malfuntion of

NG

REM5V line of Main

NG

Defective IR1101

- 12 -

Check

the disc

OK

Voltage check

DVD5V, 3.3V,

1.8V line

OK

Check

the mechanism

Communication

OK

Check

the farmtware

OK

Malfuntion of

DVD mechanism

Confirm

error display,

NG

region number,

parental level

Defective of IC302,

NG

IC303, Q301, Q303

flexible pwb, J301,

DVD mechanism

Defective of

NG

J301, flexible pwb,

DVD mechanism

Writing the version of

NG

PAL farmware

Page 13

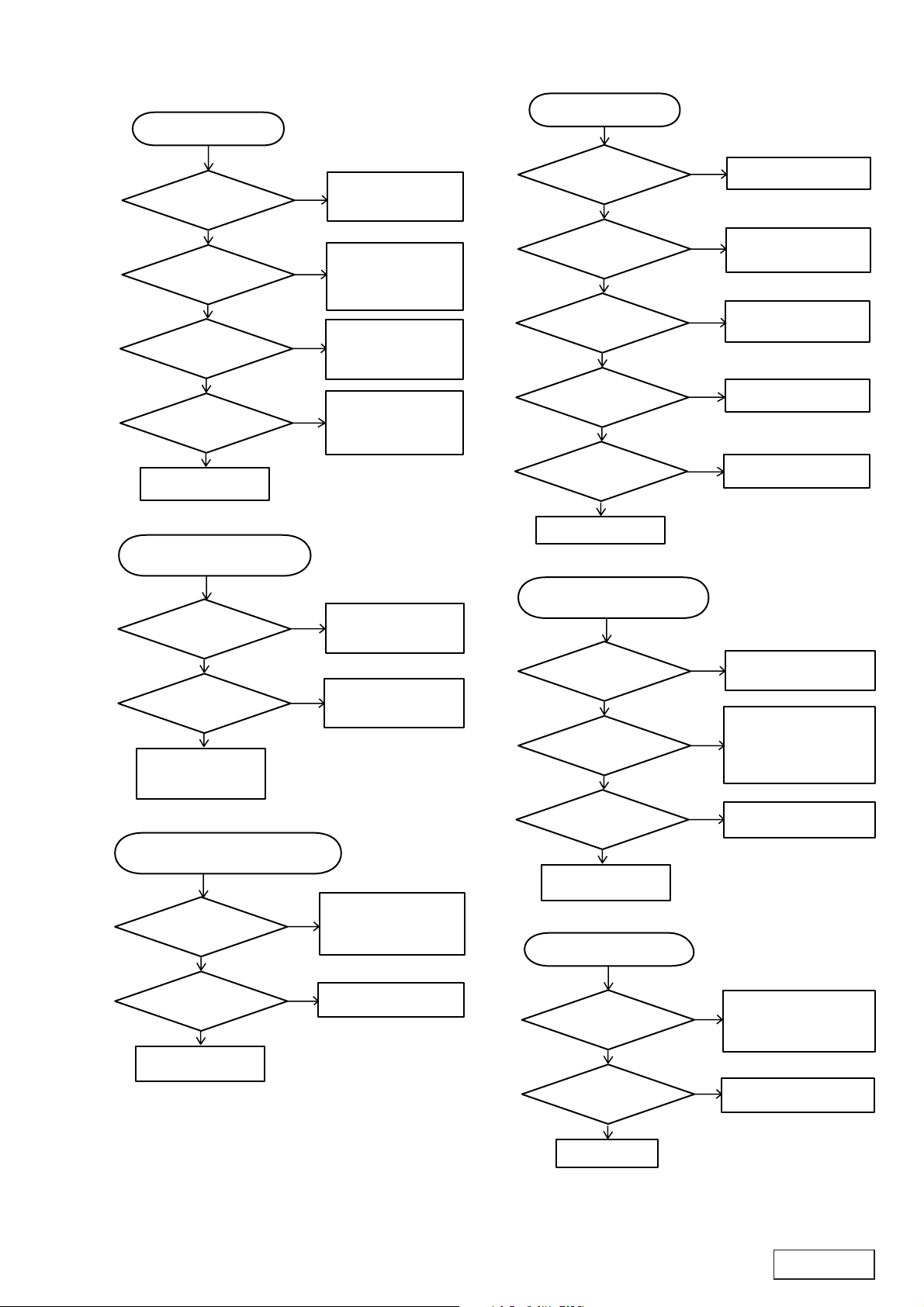

Display section

All display not appear

No display RGB image

Check

the panel section

OK

Check

the slide mechanism

OK

Check

the

power supply line

of LCD

OK

Check

the power supply line

IC701 of LCD-PWB

OK

Dcfective of IC501

No composite video output

Confirm

the panel section

OK

Check

the visual output of

P201

OK

Defective of

IC302, IC303

No NAVI-RGB video output signal

Check

the RGB input of

IC457

OK

Check

the RGB output of

IC457

OK

Defective of IC802

NG

NG

NG

NG

NG

NG

NG

NG

Defective of IC802

and Neighboring parts

( LCD PWB section)

Defective of

slide mechanism,

IC501(position

detection IC)

Malfuntion of

the power of LCD

(Sub PWB section)

Malfuntion of

the power supply 5V

(Sub PWB section)

Defective of IC802

and Neighboring parts

( LCD PWB section)

Confirm a destination

of the image output

Defective of connection

of NAVI-RGB cord,

Confirm the terminator

R478 - 481

Defective of IC457

Confirm

the composite image

OK

Confirm

REM3.3V circuit line

OK

Confirm

REM5V circuit line

OK

Confirm

RGB output of

IC401

OK

Confirm

the output of

IC457

OK

Defective IC802

No turn on LCD back light

Check

the panel section

OK

Confirm

open position

of slide mechanism

OK

Check

the output of

Q305

OK

Defective of IC501

No Lighting LED

Confirm

power supply of

B/U

OK

Operating of

Q1101

OK

Defective LED

NG

Defective IC802

NG

Malfuntion of

REM3.3V circuit line

Malfuntion of

NG

REM5V circuit line

NG

Defective IC401

NG

Defective IC457

Defective of

NG

F701, IC944, LCD

Malfuntion of

slide mechanism,

NG

Calibration of horizontally

position,

Confirm IC501

NG

Defective of Q305

Malfuntion of connection

NG

of power connector(J601),

Fuse of B/U circuit lline

(F601)

NG

Defective Q1101

- 13 -

VRX775VD

VRX776VD

Page 14

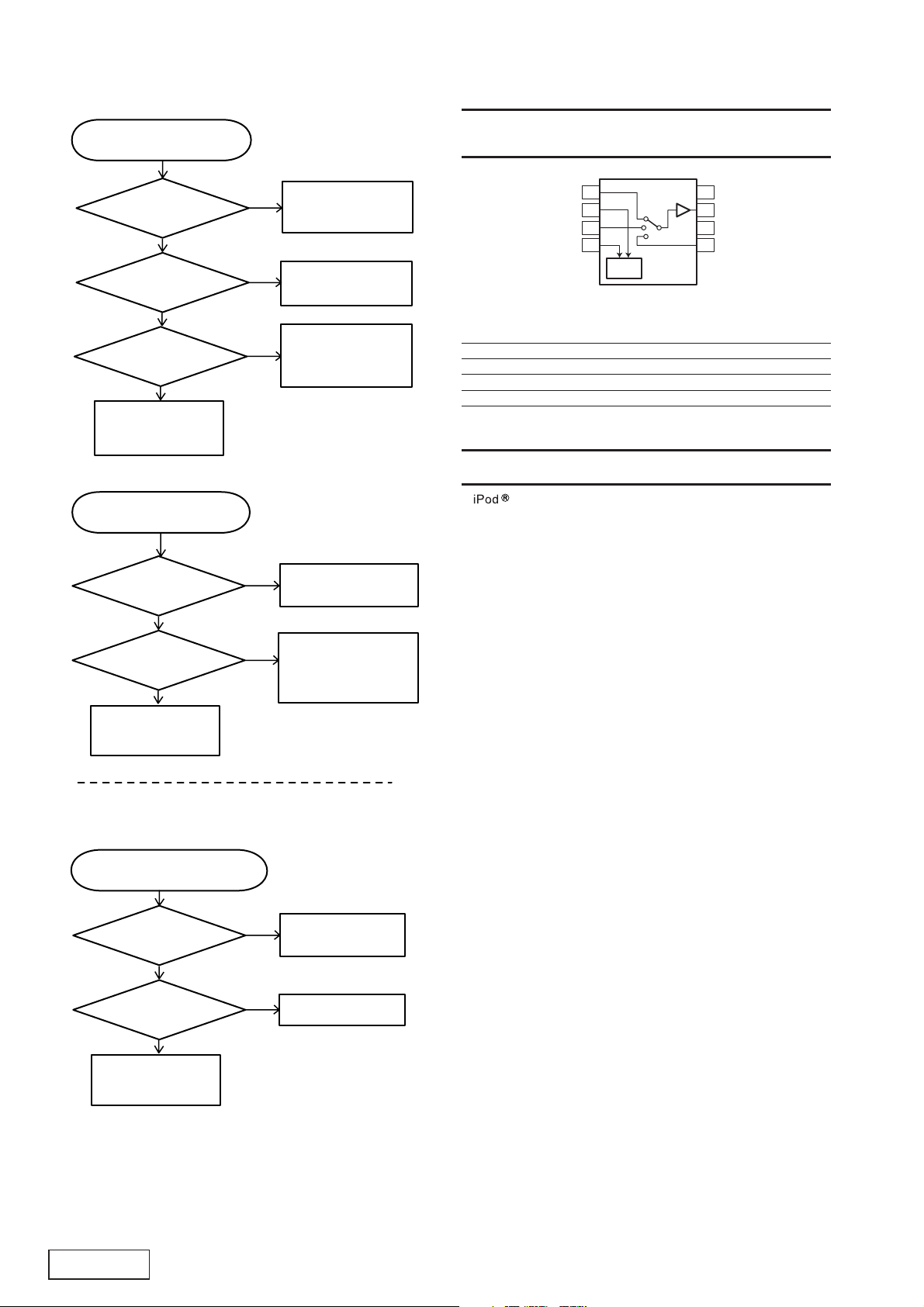

iPod section

Not recognize iPod

EXPLANATION OF IC

051-5348-90 BA7652AF-E2

3-input Video Switch with Buffer Amplifier

work only in ipod?

OK

Check

the cable connection

OK

Check

the iPod DET

OK

Defective of

Q626, Q627, Q628

IC604, IC501

Not charge iPod

Confirm

the cable connection

OK

Does not

a protection circuit

work?

OK

Defective of

Q629, Q630, IC501

Ce-NET section

Not recognize

Ce-NET machinery connection

Confirm of

the cable connection

OK

Check

the power supply

of J604

OK

Defective of

Q631, IC605, IC501

VRX775VD

VRX776VD

Malfuntion of iPod

NG

or confirm

the charge situation

Defective of

NG

the cable, J603

Defective of

NG

ACC IDENT,

the output of iPod

Defective of

NG

the cable, J603

Confirm the connection

NG

of AMP-REM, A-ANT.

Confirmation by

a consumption current

NG

Defective of J604

NG

Defective of F601

GND

1IN 1

2

CNT 1

3

IN 2

4

CNT 2

Logic

Truth Table

OUT ( pin 7 ) CNT 1 ( pin 2 ) CNT 2 ( pin 4 )

= IN 1 ( pin 1 ) L L

= IN 2 ( pin 3 ) H L

= IN 3 ( pin 5 ) L H

MUTE H H

052-7078-10 uPD703276YGJ-512-UEN-A System Controller

is for legal or rightholder-authorized copying only. Don't steal

music.

iPod is a trademark of Apple Computer, Inc., registered in the U.S.

and other countries.

TerminalDescription

pin 1: A Vref 0 : - : Reference voltage for the internal ADC.

pin 2: A V SS : - : Negative voltage supply for analog section.

pin 3: SYS ACC : O : ACC detect signal output.

pin 4: SUB MUTE : O : Sub-zone audio mute signal output.

pin 5: A Vref 1 : - : Reference voltage for the internal DAC.

pin 6: RDS CLK : IN: Not in use.

pin 7: AV ON : O : The ON command output to the power

pin 8: FLASH : IN : The signal input for the flash memory con-

pin 9: VDD : - : Positive voltage supply.

pin 10: REG C : - : The capacitor connection.

pin 11: GND : - : Ground.

pin 12 : X in : IN : Crystal connection. Main 31.4MHz.

pin 13 : X out : O : Crystal connection. Main 31.4MHz.

pin 14: RESET :IN : Reset signal input.

pin 15 : XT I : IN : Crystal connection. Sub 32.758kHz.

pin 16 : XT O : O : Crystal connection. Sub 32.758kHz.

pin 17 : POWER KEY : IN : Power key input.

pin 18 : BU 9V DE T : IN : Backup 9V detection.

pin 19 : BU 6V DE T : IN : Backup 6V detection.

pin 20: NU : IN: Not in use.

pin 21: OSD INT : IN : The interrupt signal input for the on

pin 22: TUN SDA :I/O: I2BUS serial data input/output for the tun-

pin 23: TUN SCL : O : I2BUS serial clock output for the tuner

pin 24: TP REQ : IN: The request signal from the touch panel

pin 25 : iPod/FLASH O : O : Serial data output to iPod or flash memo-

pin 26 : iPod/FLASH IN : IN : Serial data input from iPod or flash mem-

pin 27 : TP RST : O : The reset pulse output to the touch panel

pin 28: DIMMER : O : PWM output.

supply section.

trol.

screen display.

er pack.

pack.

micro computer.

ry.

ory.

micro computer.

8

OUT

7

VCC

6

IN 3

5

- 14 -

Page 15

pin 29 : Motor PLS : IN : Motor Pulse input.

pin 30: NAVI ON : O : The image signal ON command output for

the navigation.

pin 31: IE BUS TX : O : IE Bus serial data output.

pin 32: IE BUS RX : IN: IE Bus serial data input.

pin 33: GND : - : Ground.

pin 34 : E VD D : - : Positive voltage supply.

pin 35 : DSP SDA :I/O: The serial data input/output for the digital

signal processor.

pin 36: DSP SCL : O : SCL output to the digital signal processor.

pin 37: Motor 1 F : O : L = Open.

pin 38: Motor 1 R : O : L = Close.

pin 39: Motor 2 F : O : L = Tilt Up.

pin 40: Motor 2 R : O : L = Tilt Down.

pin 41 : OFFSET DET : IN : Offset-detection input.

pin 42 : Amp Standby : O : The standby signal output to the amplifi-

er.

pin 43: NU : IN: Not in use.

pin 44: NU : IN: Not in use.

pin 45: NU : IN: Not in use.

pin 46: NU : IN: Not in use.

pin 47: NU : IN: Not in use.

pin 48: NU : IN: Not in use.

pin 49: NU : IN: Not in use.

pin 50: NU : IN: Not in use.

pin 51: NU : IN: Not in use.

pin 52: NU : IN: Not in use.

pin 53 : IRI : IN : The remote control signal input.

pin 54: NU : IN: Not in use.

pin 55: NU : IN: Not in use.

pin 56: NU : IN: Not in use.

pin 57: NU : IN: Not in use.

pin 58: OSD RST : O : The reset pulse output for the on screen

display IC.

pin 59: TP RX : IN : The serial data input from the touch pan-

el micro computer.

pin 60: TP TX : O : The serial data output to the touch panel

micro computer.

pin 61: DVD TX : O : The serial data output to the DVD mech-

anism.

pin 62: DVD RX :IN : The serial data input from the DVD mech-

anism.

pin 63 : W REMCOM : IN : Wired remote controller signal input.

pin 64 : BLKO : O : The blanking signal output.

pin 65: VID / RGB : O : L = Video, H = RGB.

pin 66: FL ON : O : The fluorescent light of the LCD ON sig-

nal output.

pin 67 : BEEP : O : Beep out.

pin 68: OSD RX : IN: Serial data input from on-screen-display

IC.

pin 69: OSD TX : O : Serial data output to on-screen-display IC.

pin 70: OSD SCK : O : The clock pulse output to the on screen

display IC.

pin 71: OSD CE : O : Chip enable output to on-screen-display

IC.

pin 72: OSD INH : O : Inhibit pulse output to on-screen-display

IC.

pin 73 : Freq SEL : O : Frequency select.

pin 74: OPN/CL SW :IN : Open/Close switch signal input.

pin 75 : EJECT SW : IN : Eject switch signal input.

pin 76: CATS DET : IN: CATS or DCP detection input.

pin 77: ROM EN : O : ROM enable signal output. L = OSD OFF.

pin 78: NU : O : Not in use.

pin 79: NU : IN: Not in use.

pin 80: iPod PWR ON : O : iPod power ON signal output.

- 15 -

pin 81: Panel ON : O : LCD panel ON signal output.

pin 82: FAN ON : O : The fan on signal output.

pin 83: TV/OTHER : O : Horizontal sync select. H = TV.

pin 84 : FLASH READY :IN : Ready signal input from flash memory.

pin 85: EEP DO : O : The serial data output to the EEP-ROM.

pin 86 : CLK OU T : O : SUB-CLOCK-PLUSE output.

pin 87: EEP CK : O : The clock pulse output to the EEP-ROM.

pin 88: EEP CE : O : The chip enable signal output to the EEP-

ROM.

pin 89: EEP DI : IN: The serial data input from the EEP-ROM.

pin 90: NU : IN : Not in use.

pin 91 : KI 0 : IN : Key scan signal input.

pin 92 : KI 1 : IN : Key scan signal input.

pin 93 : KI 2 : IN : Key scan signal input.

pin 94 : KI 3 : IN : Key scan signal input.

pin 95 : KO 0 : O : Key scan signal output.

pin 96 : KO 1 : O : Key scan signal output.

pin 97 : KO 2 : O : Key scan signal output.

pin 98 : KO 3 : O : Key scan signal output.

pin 99 : USA/3rd : IN : L = Asia, H = North America.

pin100: Mechanism : IN : L = Without the mechanism.

pin101: NTSC/PAL :IN : NTSC/PAL select signal input. L = NTSC.

pin102: FLASH WR : IN: The write flag input for the flash memory.

pin103: B VSS : - : Ground for the bus interface section.

pin104: B VDD : - : Positive voltage supply for the bus inter-

face section.

pin105: ILL DET : IN : Illumination ON signal input.

pin106: BUS ILL : O : Illumination-ON signal output for Ce-NET.

pin107: ILL ON : O : The illumination ON signal output.

pin108: Blink LED : O : LED Blinking signal output.

pin109: DVD ON 2 : O : DVD ON signal output.

pin110: NU : IN : Not in use.

pin111: DVD RST : O : The reset signal output to the DVD mech-

anism.

pin112: DSP RST : O : Reset pulse output to the DSP IC.

pin113: DSP INIT : IN : The initial finished signal input from the

Radio-Audio-DSP.

pin114: SAMPLE :IN: Not in use.

pin115: NU : - : Not in use.

pin116: AM/FM 8V ON : O : AM/FM 8V ON signal output.

pin117: RDS DATA :IN : RDS serial data input.

pin118: AM/FM 5V ON : O : AM/FM 5V ON signal output.

pin119: iPod DET : IN: H = iPod is connected.

pin120: NU : - : Not in use.

pin121: DAC RESET : O : The reset pulse output to DAC.

pin122: SYS MUTE : O : System muting signal output.

pin123: AMP MUTE : O : Muting signal output to the Audio Power

Amplifier.

pin124: NU : - : Not in use.

pin125: Motor PWR : O : L = High Speed.

pin126: Photo Sens :IN : Photo sensor signal input.

pin127: Rear Im Sel 4 : O : Rear image signal selection. Refer Table

2.

pin128: Rear Im Sel 3 : O : Rear image signal selection. Refer Table

2.

pin129: TILT VR : IN: Input-terminal of internal ADC to read the

value of tilt-volume.

pin130: FAN TEMP :IN : The input terminal of the internal ADC to

detect the temperature.

pin131: Rear Im Sel 2 : O : Rear image signal selection. Refer Table

2.

pin132: Rear Im Sel 1 : O : Rear image signal selection. Refer Table

2.

pin133: Frnt Im Sel 3 : O : Front image signal selection. Refer Table

1.

VRX775VD

VRX776VD

Page 16

pin134: Frnt Im Sel 2 : O : Front image signal selection. Refer Table

1.

pin135: Frnt Im Sel 1 : O : Front image signal selection. Refer Table

1.

pin136: SEL 3 : IN : The selection signal input.

pin137: SEL 2 : IN : The selection signal input.

pin138: PKB :IN : The parking brake signal input.

pin139: PHONE INT : IN : The telephone interrupt signal input.

pin140: NU : - : Not in use.

pin141: AMP REM DT : IN : Remote controller wire short detection.

pin142: AMP REM O : O : ON signal output to the amplifier.

pin143: AUTO ANT : O : Auto antenna control signal output.

pin144: ACC IN : IN: ACC ON flag input.

Table 1. Front image signal selection

Visual TV DVD CCD

Frnt Im Sel 1 ( pin 135 ) L H L L

Frnt Im Sel 2 ( pin 134 ) L L H L

Frnt Im Sel 3 ( pin 133 ) H H H L

Table 2. Rear image signal selection

Visual TV DVD DVD A/C

Rear Im Sel 1 ( pin 132 ) L H L L

Rear Im Sel 2 ( pin 131 ) L L H L

Rear Im Sel 3 ( pin 128 ) H H H L

Rear Im Sel 4 ( pin 127 ) L L L H

052-7079-20 TC58FVM5B3AFTG65 CMOS Flash Memory

Terminal Description

pin 1 : A 15 : IN : Address signal input.

pin 2 : A 14 : IN : Address signal input.

pin 3 : A 13 : IN : Address signal input.

pin 4 : A 12 : IN : Address signal input.

pin 5 : A 11 : IN : Address signal input.

pin 6 : A 10 : IN : Address signal input.

pin 7 : A 9 : IN : Address signal input.

pin 8 : A 8 : IN : Address signal input.

pin 9 : A 19 : IN : Address signal input.

pin 10 : A 20 : IN : Address signal input.

pin 11 : WE : IN : Write enable signal input.

pin 12: RESET :IN : Reset signal input.

pin 13: NU : - : Not in use.

pin 14: WP/ACC :IN: The write protection signal input / The

acceleration signal input.

pin 15: RY/BY : O : The ready/busy signal output.

pin 16 : A 18 : IN : Address signal input.

pin 17 : A 17 : IN : Address signal input.

pin 18 : A 7 : IN : Address signal input.

pin 19 : A 6 : IN : Address signal input.

pin 20 : A 5 : IN : Address signal input.

pin 21 : A 4 : IN : Address signal input.

pin 22 : A 3 : IN : Address signal input.

pin 23 : A 2 : IN : Address signal input.

pin 24 : A 1 : IN : Address signal input.

pin 25 : A 0 : IN : Address signal input.

pin 26 : CE : IN : Chip enable signal input.

pin 27 : VSS : - : Negative supply voltage.

pin 28 : OE : IN : Output enable signal input.

pin 29 : D 0 :I/O: Data input/output.

pin 30 : D 8 :I/O: Data input/output.

pin 31 : D 1 :I/O: Data input/output.

pin 32 : D 9 :I/O: Data input/output.

pin 33 : D 2 :I/O: Data input/output.

pin 34 : D 1 0 :I/O: Data input/output.

pin 35 : D 3 :I/O: Data input/output.

pin 36 : D 1 1 :I/O: Data input/output.

pin 37 : VDD : - : Positive supply voltage.

pin 38 : D 4 :I/O: Data input/output.

pin 39 : D 1 2 :I/O: Data input/output.

pin 40 : D 5 :I/O: Data input/output.

pin 41 : D 1 3 :I/O: Data input/output.

pin 42 : D 6 :I/O: Data input/output.

pin 43 : D 1 4 :I/O: Data input/output.

pin 44 : D 7 :I/O: Data input/output.

pin 45 : D 15/A-1 :I/O: Data input/output. A-1 address input.

pin 46 : VSS : - : Negative supply voltage.

pin 47: BYTE/WORD :IN : Byte / Word selection.

pin 48 : A 16 : IN : Address signal input.

EXPLODED VIEW : PARTS LIST

Main section

1 DCP-583-600 DCP ASSY 1

2 ----------- INNER-ES-SECTION 1

3 335-7790-20 TOP-CVR 1

4 370-6925-00 PANEL-ES 1

5 378-0553-00 BADGE(CLARION) 1

6 948-0692-05 SLIDE-MECH-ASSY 1

7 013-9717-00 TOUCH PANEL 1

VRX775VD

VRX776VD

DCP-584-800 DCP-ASSY(K-A,K-B,K-C)

(Refer to page 19)

(Refer to page 19)

Note) Same parts depend on each model.The model name is specified in the description.

(B-A;QC-6824B-A,K-A;QC-6824K-A,K-B;QC-6824K-BA,K-C;QC-6824K-C)

NO. PART NO. DESCRIPTION Q'TYNO. PART NO. DESCRIPTION Q'TY

8 020-3042-01 DC-MOTOR 1

9 039-2793-25 FPC(MAIN-LCD) 1

10 039-2509-25 FPC(45P) 1

11 276-0200-00 SETPLATE(B-A) 1

276-0221-00 SETPLATE(K-A)

276-0222-00 SETPLATE(K-B)

276-0223-00 SETPLATE(K-C)

(WITHOUT COMPONENT)

(WITHOUT COMPONENT)

12 311-1921-00 LOWER CASE 1

13 331-4174-00 MECH-CVR 1

- 16 -

Page 17

14 331-4175-00 MECH-BRKT 1

15 331-4176-00 HEAT SINK CVR 1

16 331-3884-01 LCD BRKT 1

17 335-7163-20 SIDE-CVR(L) 1

18 335-7164-20 SIDE-CVR(R) 1

19 345-3799-20 RCA CAP 1

20 345-5470-20 RUBBER PART 1

21 347-6085-20 DOUBLE FACE 2

22 331-4177-00 FPC-CVR(SIDE) 1

23 347-7038-20 SPACER 2

24 347-8253-00 INSULATOR 1

25 331-4173-00 FPC COVER 1

26 347-7262-20 INSULATOR 1

27 347-7739-20 DOUBLE FACE 1

28 347-8029-20 INSULATOR 1

29 347-8028-20 SHADE 1

30 347-7282-20 FILM 1

31 347-7300-20 INSULATOR 1

32 347-7301-20 FILM 2

33 347-7302-20 DOUBLE FACE 1

34 347-8030-20 PROTECT SHEET 1

35 347-8031-20 PROTECT SHEET 1

36 379-0468-00 INDICATOR(TFT) 1

37 347-8032-20 PROTECT SHEET 1

38 714-2604-8B MACHINE SCREW(M2.6 x 4) 25

39 714-5008-4B MACHINE SCREW(M5 x 8) 2

40 716-0872-61 PAD SCREW(M1.7 x 6 BLK) 7

41 716-0878-50 IT SCREW(M2.6 x 5) 4

42 331-4231-00 EARTH PLATE 2

43 716-1816-50 IT SCREW(M2 x 4) 2

44 731-2608-8B TAPTIGHT 4

45 331-3946-00 COVER PLATE 1

46 039-2792-25 FPC(DVD-MECH) 1

47 816-2650-50 FLAT WIRE(14P L39) 1

48 780-2612-50 SCREW(M2.6 x 12) 2

49 781-1722-50 PLATE SCREW(M1.7 x 2.2) 4

50 781-1750-50 SCREW(1.7 x 2.2) 4

51 781-2002-50 PLATE SCREW(M2 x 2) 4

52 750-3137-03 SPRING(R) 1

53 750-3137-02 SPRING(L) 1

54 929-2506-10 DVD MECHANISM 1

55 347-5867-20 DOUBLE FACE 1

56 076-0349-03 PLUG(3P) 1

57 716-1468-01 SCREW (M2 x 2.5) 2

58 347-8033-20 INSULATOR 1

59 855-5436-50 RCA PIN CORD 1

(WITHOUT COMPONENT)

NO. PART NO. DESCRIPTION Q'TYNO. PART NO. DESCRIPTION Q'TY

60 353-0585-20 SHADE 2

61 ----------- SUB PWB 1

62 074-2001-64 OUTLET SOCKET 3

63 074-2225-62 OUTLET SOCKET 1

64 880-2091D TUNER 1

65 347-7283-20 FILM 1

66 074-2238-80 OUTLET SOCKET(30P DVD) 1

67 074-0881-17 OUTLET SOCKET 1

68 060-8045-00 BUZZER 1

69 074-1194-00 OUTLET SOCKET 1

70 074-1214-00 OUTLET SOCKET 1

71 075-0385-00 JACK 1

72 076-0349-02 PLUG 2

73 076-0353-17 PLUG 1

74 076-0714-20 PLUG 1

75 313-1970-00 HEAT SINK(TR) 1

76 313-1905-00 HEAT SINK(POWER IC) 1

77 074-2209-93 OUTLET SOCKET 1

78 331-4178-00 IC-HOLDER 1

79 331-3850-00 CONECTOR HOLDER 1

80 331-4179-00 IC HOLDER(POWER IC) 1

81 331-4180-00 CONNECTOR HOLD 1

82 331-4182-00 SHIELD CVR 1

83 076-0349-05 PLUG(5P) 1

84 855-2500-00 MINI DIN CORD(RGB) 1

85 347-7285-20 SPACER(FPC) 1

86 ----------- MAIN PWB 1

87 714-2606-8B MACHINE SCREW(M2.6 x 6) 4

88 731-2612-8B TAPTIGHT 2

89 816-3013-50 FLAT WIRE(14P L65) 1

90 074-2011-70 OUTLET SOCKET(20P) 1

91 714-3005-8B MACHINE SCREW(M3 x 5) 1

92 074-1171-10 OUTLET SOCKET 1

93 331-4181-00 SHIELD CVR(R) 1

94 074-4020-00 OUTLET SOCKET(ANT) 1

95 092-2226-00 ANT-RECEPT 1

96 331-4199-00 SHIELD CVR 1

97 074-2225-95 OUTLET SOCKET(45) 2

98 074-2215-54 OUTLET SOCKET(4P) 1

99 074-2001-80 OUTLET SOCKET(30P) 1

100 076-0568-00 PLUG(2P) 1

101 074-2201-85 OUTLET SOCKET(35P) 1

102 321-1036-00 CLAMP(MINI DIN CORD) 1

103 074-2225-70 OUTLET SOCKET(20P) 1

104 ----------- LCD PWB 1

105 855-0609-50 EXTENSION LEAD 1

- 17 -

VRX775VD

VRX776VD

Page 18

43

7

99

21

21

26

39

52

30

36

4

23

18

40

49

97

98

96

45

10

100

104

6

31

97

55

101

103

104

47

62

20

11

43

39

33

9

58

60

14

38

17

11

53

19

59

38

88

50

5

3

32

16

51

24

51

29

38

38

102

40

49

84

105

38

38

8

15

48

78

76

13

89

63

91

81

95

38

35

44

28

34

41

38

44

54

41

46

37

61

82

41

67

90

85

73

77

75

68

64

87

72

65

69

86

93

70

27

94

61

62

80

66

41

71

79

62

92

74

72

56

83

12

25

57

38

VRX775VD

VRX776VD

42

38

22

38

- 18 -

1

2

Page 19

Inner Escutcheon section

1 ----------- SW PWB 1

2 370-6924-00 ESCUTCHEON(INNER) 1

3 382-7862-00 INNER-BUTTON(L) 1

4 382-7863-00 INNER-BUTTON(M) 1

5 382-7864-00 INNER-BUTTON(R) 1

6 335-7788-00 DISC GUIDE 1

7 346-0200-00 LEATHER SHEET 1

8 331-4168-00 DISCGUIDE PLATE 1

9 331-4169-00 ES-PLATE 1

10 382-7865-00 RESET BUTTON 1

11 074-1289-70 OUTLET SOCKET(20P) 1

12 335-7791-20 LED HOLDER(L) 1

13 335-7789-20 LED HOLDER(R) 1

14 347-7854-20 SLIDER 2

15 816-3012-50 FLAT WIRE(20P) 1

16 716-0872-51 PAD SCREW(M1.7 x 6) 13

17 716-0872-21 PAD SCREW(M1.7 x 4) 3

18 624-0016-00 MAGNET 1

19 335-7787-00 IR PLATE 1

20 946-0088-00 MAGNET PLATE ASSY 1

21 331-4170-00 LED COVER(L) 1

22 331-4171-00 LED COVER(R) 1

23 076-0708-02 PLUG(2P) 1

24 076-2010-03 PLUG(3P) 1

25 013-7411-51 SWITCH 1

NO. PART NO. DESCRIPTION Q'TYNO. PART NO. DESCRIPTION Q'TY

26 001-7097-90 DIODE(CL-194S-W) 7

27 013-6312-50 SWITCH 15

28 060-4017-90 IR-RECIEVER 1

29 013-6513-50 LUMI-SWITCH 1

6

16

15

8

16

9

21

1

16

11

26

23

14

27

28

12

17

29

25

27

27

26

3

1

24

1

22

7

16

17

20

18

4

10

14

5

17

19

13

2

DCP section

1 DCP-583-600 DCP ASSY(B-A) 1

1-1 370-6923-20 ESCUTCHEON(F) 1

1-2 373-1102-03 DIAL-CVR(B-A) 1

1-12

DCP-584-800 DCP ASSY(K-A,K-B,K-C)

373-1102-04 DIAL-CVR(B-A)

1-23

1-20

1-15

1-3

1-21

1-22

1-18

1-13

1-16

1-17

1-10

1-1

1-11

1-7

1-12

1-2

1-22

1-24

1-14

1-19

1-4

1-5

1-6

1-9

1-8

1-22

1-22

1

NO. PART NO. DESCRIPTION Q'TYNO. PART NO. DESCRIPTION Q'TY

1-3 335-7781-00 REAR-CVR 1

1-4 382-7852-00 BUTTON(IPOD) 1

1-5 382-7853-01 BUTTON(MAP) 1

1-6 382-7854-00 BUTTON(MENU) 1

1-7 382-7855-00 BUTTON(SRC) 1

1-8 382-7856-00 BUTTON(BND/ADJ/M) 1

1-9 382-7857-00 BUTTON(ISR/OP/EJ) 1

1-10 382-7858-00 BUTTON(MUTE/DOWN) 1

1-11 382-7859-00 BUTTON(T-UP) 1

1-12 382-7860-00 BUTTON(VOL) 2

1-13 347-8023-20 REFLECTOR(L) 1

1-14 347-8024-20 REFLECTOR(R) 1

1-15 335-7782-00 BUTTON HOLDER(VOL) 2

1-16 335-7783-00 RING PLATE 1

1-17 335-7784-00 RING COVER 1

1-18 335-7785-00 ILLUMI PLATE(L) 1

1-19 335-7786-00 ILLUMI PLATE(R) 1

1-20 750-6816-00 SPRING 2

1-21 347-8022-20 DOUBLE FACE(VOL) 2

1-22 716-0872-61 PAD SCREW(M1.7 x 6 BLK) 11

1-23 354-7593-00 MAGNET 1

1-24 335-7787-00 IR PLATE 1

382-7853-00 BUTTON(CONT)

- 19 -

VRX775VD

VRX776VD

Page 20

ELECTRICAL PARTS LIST

Main PWB(B1) section

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

ANT101 092-2226-00 ANT-RECEPT

BL101 880-2091D AM/FM TUNER

C101 166-2201-50 22pF CH

C102 166-1511-50 150pF CH

C104 168-1032-55 0.01uF K

C105 042-0643-51 16V 100uF LOW-SR

C106 168-2232-55 0.022uF K

C107 166-1011-50 100pF CH

C108 168-1022-55 1000pF K

C109 168-1042-78 16V 0.1uF

C110 168-1042-78 16V 0.1uF

C111 042-0560-84 16V 47uF

C112 043-0540-00 6.3V 10uF

C113 043-0540-00 6.3V 10uF

C114 043-0540-00 6.3V 10uF

C115 043-0540-00 6.3V 10uF

C116 168-1042-78 16V 0.1uF

C117 043-0540-00 6.3V 10uF

C118 043-0540-00 6.3V 10uF

C119 043-0540-00 6.3V 10uF

C120 166-2201-50 22pF CH

C121 166-2201-50 22pF CH

C122 178-1052-78 1uF

C123 042-0592-58 16V 10uF

C124 043-0540-00 6.3V 10uF(B-A)

C125 043-0540-00 6.3V 10uF(B-A)

C126 168-1042-78 16V 0.1uF

C127 042-0592-58 16V 10uF

C128 168-1042-78 16V 0.1uF

C129 042-0595-84 10V 100uF

C130 168-1045-56 0.1uF Z

C131 163-4753-55 35V 4.7uF

C132 166-1011-50 100pF CH

C133 166-1011-50 100pF CH

C134 166-1011-50 100pF CH

C135 166-1011-50 100pF CH

C136 168-1042-78 16V 0.1uF

C137 168-1045-56 0.1uF Z

C138 163-1073-15 6.3V 100uF

C139 163-2263-35 16V 22uF

C140 168-4735-56 0.047uF Z

C141 043-0540-00 6.3V 10uF

C142 043-0540-00 6.3V 10uF

C143 166-4701-50 47pF CH

C144 166-4701-50 47pF CH

C145 168-1042-78 16V 0.1uF

C146 166-1011-50 100pF CH

C147 043-0540-00 6.3V 10uF

C148 043-0540-00 6.3V 10uF

C149 043-0540-00 6.3V 10uF

C150 166-1011-50 100pF CH

C151 178-2242-78 0.22uF(B-A)

C152 166-1011-50 100pF CH(B-A)

C153 166-1011-50 100pF CH

C154 178-1052-78 1uF

C155 168-1045-56 0.1uF Z

C156 166-1011-50 100pF CH

C157 168-1042-78 16V 0.1uF

C158 042-0560-84 16V 47uF

C159 168-1045-56 0.1uF Z

C160 042-0643-51 16V 100uF LOW-SR

C161 168-1045-56 0.1uF Z

C162 042-0423-20 10V 10uF

C163 168-3335-56 0.033uF Z

C164 168-3322-55 3300pF K

C165 168-3322-55 3300pF K

C166 168-1045-56 0.1uF Z

C167 163-1073-15 6.3V 100uF

C168 168-3322-55 3300pF K

C169 168-3322-55 3300pF K

C170 168-2232-55 0.022uF K

C171 168-4712-55 470pF K

C173 168-2242-58 0.22uF B

C174 168-2232-55 0.022uF K

C175 168-2232-55 0.022uF K

C178 168-2232-55 0.022uF K

C181 166-1007-50 10pF CH

C182 166-1007-50 10pF CH

C184 168-1022-55 1000pF K

C185 168-1022-55 1000pF K

C186 168-1042-78 16V 0.1uF

C187 166-1011-50 100pF CH

C188 163-4753-55 35V 4.7uF

C189 168-1042-78 16V 0.1uF

C190 168-1022-55 1000pF K

C191 168-1022-55 1000pF K

C192 163-4753-55 35V 4.7uF

C193 168-1042-78 16V 0.1uF

C194 166-1811-50 180pF CH

C195 168-1045-56 0.1uF Z

C196 163-4753-55 35V 4.7uF

C197 042-0416-57 10V 47uF M TAN

C198 168-1042-78 16V 0.1uF

C199 168-1042-78 16V 0.1uF

C201 168-1022-55 1000pF K

C202 043-0540-00 6.3V 10uF

C203 168-1022-55 1000pF K

C204 168-1022-55 1000pF K

C205 043-0540-00 6.3V 10uF

C206 043-0540-00 6.3V 10uF

C207 168-1022-55 1000pF K

C208 168-1022-55 1000pF K

C209 043-0540-00 6.3V 10uF

C210 042-2273-25 10V 220uF M

C211 043-0540-00 6.3V 10uF

C212 168-1022-55 1000pF K

C213 168-4712-55 470pF K

C214 168-4712-55 470pF K

C215 043-0540-00 6.3V 10uF

C217 168-4712-55 470pF K

C218 168-4712-55 470pF K

C219 043-0540-00 6.3V 10uF

C221 168-4712-55 470pF K

C222 168-4712-55 470pF K

C223 043-0540-00 6.3V 10uF

C225 168-4712-55 470pF K

C226 168-4712-55 470pF K

C227 043-0540-00 6.3V 10uF

C229 168-6812-55 680pF K

C230 168-6812-55 680pF K

C231 043-0540-00 6.3V 10uF

C233 168-6812-55 680pF K

C234 168-6812-55 680pF K

C235 043-0540-00 6.3V 10uF

C237 168-6812-55 680pF K

C238 168-6812-55 680pF K

C239 043-0540-00 6.3V 10uF

C241 168-6812-55 680pF K

C242 168-6812-55 680pF K

C243 042-0592-58 16V 10uF

C244 168-1042-78 16V 0.1uF

C245 042-0592-58 16V 10uF

C246 168-1042-78 16V 0.1uF

C247 043-0567-90 25V 22uF

C249 043-0264-56 270pF

C250 166-2701-50 27pF CH

C251 043-0567-90 25V 22uF

C253 043-0264-56 270pF

Note) Same parts depend on each model.The model name is specified in the description.

(B-A;QC-6824B-A,K-A;QC-6824K-A,K-B;QC-6824K-BA,K-C;QC-6824K-C)

Note) Several different parts of the same reference number are alternative parts.

One of those parts is used in the set.

C254 166-2701-50 27pF CH

C256 043-0567-90 25V 22uF

C258 043-0264-56 270pF

C259 166-2701-50 27pF CH

C260 043-0567-90 25V 22uF

C262 043-0264-56 270pF

C263 166-2701-50 27pF CH

C265 043-0567-90 25V 22uF

C266 043-0264-56 270pF

C267 166-2701-50 27pF CH

C268 043-0567-90 25V 22uF

C269 043-0264-56 270pF

C270 166-2701-50 27pF CH

C271 168-1032-55 0.01uF K

C272 043-0567-90 25V 22uF

C273 043-0264-56 270pF

C274 166-2701-50 27pF CH

C275 043-0567-90 25V 22uF

C276 043-0264-56 270pF

C277 166-2701-50 27pF CH

C280 168-1032-55 0.01uF K

C281 042-0592-58 16V 10uF

C282 042-0592-58 16V 10uF

C283 042-0592-58 16V 10uF

C284 042-0592-58 16V 10uF

C285 178-4742-78 0.47uF

C286 178-4742-78 0.47uF

C287 178-4742-78 0.47uF

C288 178-4742-78 0.47uF

C301 168-1042-78 16V 0.1uF

C302 168-1042-78 16V 0.1uF

C304 042-0592-58 16V 10uF

C306 168-1042-78 16V 0.1uF

C307 042-0423-97 16V 10uF

C308 168-1042-78 16V 0.1uF

C310 042-0423-20 10V 10uF

C311 168-1042-78 16V 0.1uF

C312 042-0423-20 10V 10uF

C313 168-1042-78 16V 0.1uF

C314 042-0423-20 10V 10uF

C316 168-1042-78 16V 0.1uF

C317 168-1045-56 0.1uF Z

C318 042-0630-50 16V 100uF

C319 042-0630-50 16V 100uF

C320 168-1042-78 16V 0.1uF

C322 042-0643-51 16V 100uF LOW-SR

C324 042-0643-51 16V 100uF LOW-SR

C325 042-0643-51 16V 100uF LOW-SR

C326 168-1045-56 0.1uF Z

C327 178-1052-78 1uF

C328 178-1052-78 1uF

C329 168-1032-55 0.01uF K

C330 168-1032-55 0.01uF K

C331 168-1032-55 0.01uF K

C332 168-1032-55 0.01uF K

C336 163-4763-15 6.3V 47uF

C337 163-4763-15 6.3V 47uF

C338 166-3096-50 3pF CJ

C339 163-4763-15 6.3V 47uF

C340 163-4763-15 6.3V 47uF

C341 168-1042-78 16V 0.1uF

C342 163-1073-35 16V 100uF

C343 042-1737-90 6.3V 1000uF M

C344 168-4712-55 470pF K

C345 168-4712-55 470pF K

C401 168-1042-78 16V 0.1uF

C402 043-0540-00 6.3V 10uF

C403 043-0540-00 6.3V 10uF

C404 168-1042-78 16V 0.1uF

VRX775VD

VRX776VD

- 20 -

Page 21

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

C405 168-1042-78 16V 0.1uF

C406 168-1042-78 16V 0.1uF

C407 168-4722-55 4700pF K

C408 166-2211-50 220pF CH

C409 168-1042-78 16V 0.1uF

C410 043-0540-00 6.3V 10uF

C411 168-1042-78 16V 0.1uF

C412 166-1007-50 10pF CH

C413 166-1007-50 10pF CH

C414 166-1011-50 100pF CH

C415 168-1042-78 16V 0.1uF

C416 168-1042-78 16V 0.1uF

C417 168-1042-78 16V 0.1uF

C418 168-1042-78 16V 0.1uF

C421 168-1042-78 16V 0.1uF

C422 168-1042-78 16V 0.1uF

C423 043-0540-00 6.3V 10uF

C424 168-1042-78 16V 0.1uF

C425 168-1042-78 16V 0.1uF

C426 168-1042-78 16V 0.1uF

C427 168-1042-78 16V 0.1uF

C428 043-0540-00 6.3V 10uF

C429 168-1042-78 16V 0.1uF

C430 043-0540-00 6.3V 10uF

C431 168-1042-78 16V 0.1uF

C432 168-1042-78 16V 0.1uF

C433 166-1011-50 100pF CH

C434 168-1042-78 16V 0.1uF

C435 166-1011-50 100pF CH

C436 043-0540-00 6.3V 10uF

C437 176-2221-50 2200pF CH

C438 168-2222-55 2200pF K

C439 168-1042-78 16V 0.1uF

C441 168-1042-78 16V 0.1uF

C450 168-1042-78 16V 0.1uF

C451 168-1042-78 16V 0.1uF

C452 166-5601-50 56pF CH

C454 168-1042-78 16V 0.1uF

C455 168-1042-78 16V 0.1uF

C456 168-1042-78 16V 0.1uF

C457 043-0540-00 6.3V 10uF

C458 168-1042-78 16V 0.1uF

C459 168-1042-78 16V 0.1uF

C460 168-1042-78 16V 0.1uF

C461 168-1042-78 16V 0.1uF

C462 168-1042-78 16V 0.1uF

C463 043-0532-50 10V 10uF

C464 043-0532-50 10V 10uF

C465 168-1042-78 16V 0.1uF

C466 166-1201-50 12pF CH

C467 168-1042-78 16V 0.1uF

C468 178-1052-78 1uF

C469 178-1052-78 1uF

C470 178-1052-78 1uF

C471 178-1052-78 1uF

C472 178-1052-78 1uF

C473 178-1052-78 1uF

C474 178-1052-78 1uF

C475 178-1052-78 1uF

C476 178-1052-78 1uF

C477 168-1042-78 16V 0.1uF

C478 168-1042-78 16V 0.1uF

C479 168-1042-78 16V 0.1uF

C480 168-1042-78 16V 0.1uF

C484 168-1042-78 16V 0.1uF

C485 168-1042-78 16V 0.1uF

C486 168-1042-78 16V 0.1uF

C487 166-5601-50 56pF CH

C488 178-1052-78 1uF

C490 168-1022-55 1000pF K

C501 043-0540-00 6.3V 10uF

C502 168-1042-78 16V 0.1uF

C503 043-0540-00 6.3V 10uF

C504 168-1042-78 16V 0.1uF

C505 043-0551-90 6.3V 4.7uF M

C506 166-1801-50 18pF CH

C507 166-2201-50 22pF CH

C508 166-1011-50 100pF CH

C509 168-1042-78 16V 0.1uF

C510 168-1042-78 16V 0.1uF

C511 178-1052-78 1uF

C512 166-1011-50 100pF CH

C513 168-1032-55 0.01uF K