Page 1

Clarion Co., Ltd.

50 Kamitoda, Toda-shi, Saitama 335-8511 Japan

Service Dept.: 5-66 Azuma , Kitamoto-shi, Saitama 364-0007 Japan

Tel: +81-48-541-2335 / 2432 FAX: +81-48-541-2703

Service Manual

Published by Service Dept.

298-6058-00

Printed in Japan

Feb.2003 P

SPECIFICATIONS

FM tuner section

Frequency range: 87.9MHz to 107.9MHz

Usable sensitivity: 11dBf

50dB quieting sensitivity:

17dBf

Alternate channel selectivity:

75dB

Stereo separation: 35dB(1kHz)

Frequency response: 30Hz to 15kHz(+3/-3dB)

AM tuner section

Frequency range: 530kHz to 1710kHz

Usable sensitivity: 25dBu

Audio amplifier section

Rated power output: 17Wx4(20Hz to 20kHz,1%,4 ohm)

Maximum power output:

46Wx4

Speaker impedance: 4 ohm(4 to 8 ohm)

Input/Output section

Video input: 1.0 +0.2/-0.2Vp-p

(Input impedance 75 ohm)

Audio output: min.200mVrms

LCD monitor section

Screen size: 6.5-inch wide type

(142mm Width x 78mm Height)

Display method: Transmission type TN Liquid

Crystal Display

Drive method: TFT(thin-film transistor) active

matrix driving

Pixels: 280,800(1200 x 234)

6.5" Monitor & FM/AM Radio

with CD/MD/DVD Changer Control

Model

(QC-6710B)

General

Power supply voltage: 14.4V DC

(10.8 to 15.6V allowable)

Ground: Negative

Current consumption: 4.0A(1W)

Auto antenna rated current:

500mA less

Dimensions(mm): Main unit

178(W)x50(H)x157(D)

Remote control unit

44(W)x110(H)x27(D)

Weight: Main unit 1.7kg

Remote control unit 30g

(including battery)

NOTES

* Use a CeNET extension cable that is less than 20m in

length.(including the Y-adapter CCA-519)

* We cannot supply PWB with component parts in prin-

ciple. When a circuit on PWB has failure , please repair

it by component parts base. Parts which are not men-

tioned in service manual are not supplied.

* CD-ROM discs cannot be played in the CD changer.

* This unit can display title data for CD-text CDs and user

titles input with this unit.

* Specifications and design are subject to change without

notice for further improvement.

- 1 -

VRX630

Page 2

COMPONENTS

QC-6710B-A

Main unit ----------- 1

Remote control unit RCB-130-601 1

Battery(SUM-3) ----------- 2

Universal mounting bracket 300-9677-00 1

DCP case 335-6035-41 1

Power supply lead 854-6356-51 1

Outer escutcheon 940-7715-04 1

Parts bag(No.1) -----------

Flat head screw(M5x8) 714-5008-41 4

Sems hexagonal bolt(M5x8) 716-0496-01 5

Parts bag(No.2) -----------

Hook plate 331-0488-20 2

Cord clamp 335-0833-07 1

Spacer 345-3653-20 1

Screw 716-0726-01 1

To engineers in charge of repair or

inspection of our products.

Before repair or inspection, make sure to follow the

instructions so that customers and Engineers in

charge of repair or inspection can avoid suffering

any risk or injury.

1. Use specified parts.

The system uses parts with special safety features against

fire and voltage. Use only parts with equivalent characteristics when replacing them.

The use of unspecified parts shall be regarded as remodeling for which we shall not be liable. The onus of product

liability (PL) shall not be our responsibility in cases where

an accident or failure is as a result of unspecified parts

being used.

2. Place the parts and wiring back in their original positions

after replacement or re-wiring.

For proper circuit construction, use of insulation tubes,

bonding,gaps to PWB, etc, is involved. The wiring connection and routing to the PWB are specially planned using

clamps to keep away from heated and high voltage parts.

Ensure that they are placed back in their original positions

after repair or inspection.

If extended damage is caused due to negligence during

repair, the legal responsibility shall be with the repairing

company.

3. Check for safety after repair.

Check that the screws, parts and wires are put back securely in their original position after repair. Ensure for

safety reasons there is no possibility of secondary ploblems

around the repaired spots.

If extended damage is caused due to negligence of repair,

the legal responsibility shall be with the repairing company.

4. Caution in removal and making wiring connection to the

parts for the automobile.

Disconnect the battery terminal after turning the ignition

key off. If wrong wiring connections are made with the battery connected, a short circuit and/or fire may occur. If extensive damage is caused due to negligence of repair, the

legal responsibility shall be with the repairing company.

5. Cautions regarding chips.

Do not reuse removed chips even when no abnormality is

observed in their appearance. Always replace them with

new ones. (The chip parts include resistors, capacitors,

diodes, transistors, etc). The negative pole of tantalum

capacitors is highly susceptible to heat, so use special care

when replacing them and check the operation afterwards.

6. Cautions in handling flexible PWB

Before working with a soldering iron, make sure that the

iron tip temperature is around 270

ply the iron tip repeatedly(more than three times)to the

same patterns. Also take care not to apply the tip with force.

7. Turn the unit OFF during disassembly and parts replacement. Recheck all work before you apply power to the unit.

. Take care not to ap-

ERROR DISPLAYS

If an error occurs,one of the following displays is displayed.Take the measures described below to eliminate the problem.

Error display

CD

changer

MD

changer

ERROR 2

ERROR 3

ERROR 6

ERROR H

EEROR 2

ERROR 3

ERROR 6

Note:

1. For the DVD changer,refer to the service manual provided with the DVD changer.

2. If an error display other than the ones described above appears, press the reset button.

3. When the reset button is pressed,frequencies of TV/radio stations,titles,etc. stored in the memory are cleared.

Cause

A CD inside the CD changer is not loaded.

A CD inside the CD changer cannot be played due to

scratches,etc.

A CD inside the CD changer cannot be played because it

is loaded upside-down.

Displayed when the temperature in the MD changer is

too high and playback has been stopped automatically.

An MD inside the MD changer is not loaded.

An MD inside the MD changer cannot be played due to

scratches,etc.

A MD inside the MD changer cannot be played because

it is loaded upside-down.

Displayed when a non-recorded MD is loaded in the MD

changer.

- 2 -VRX630

Measure

This is a failure of CD changer's mechanism.

Replace with a non-scratched,non-warped

disc.

Eject the disc then reload it properly.

Lower the surrounding temperature and wait

for a while to cool off MD changer.

This is a failure of MD changer's mechanism.

Replace with a non-scratched,non-warped

disc.

Eject the disc then reload it properly.

Load a pre-recorded MD in the MD changer.

Page 3

TROUBLESHOOTING

Problem

Nothing happens when

buttons are pressd.

Display is not accurate.

Cause

The microprocessor

has malfunction due to

noise,etc.

Measure

Turn off the power,then press the RELEASE lever

and remove the DCP.Press the Reset button for about

2 seconds with a thin rod.

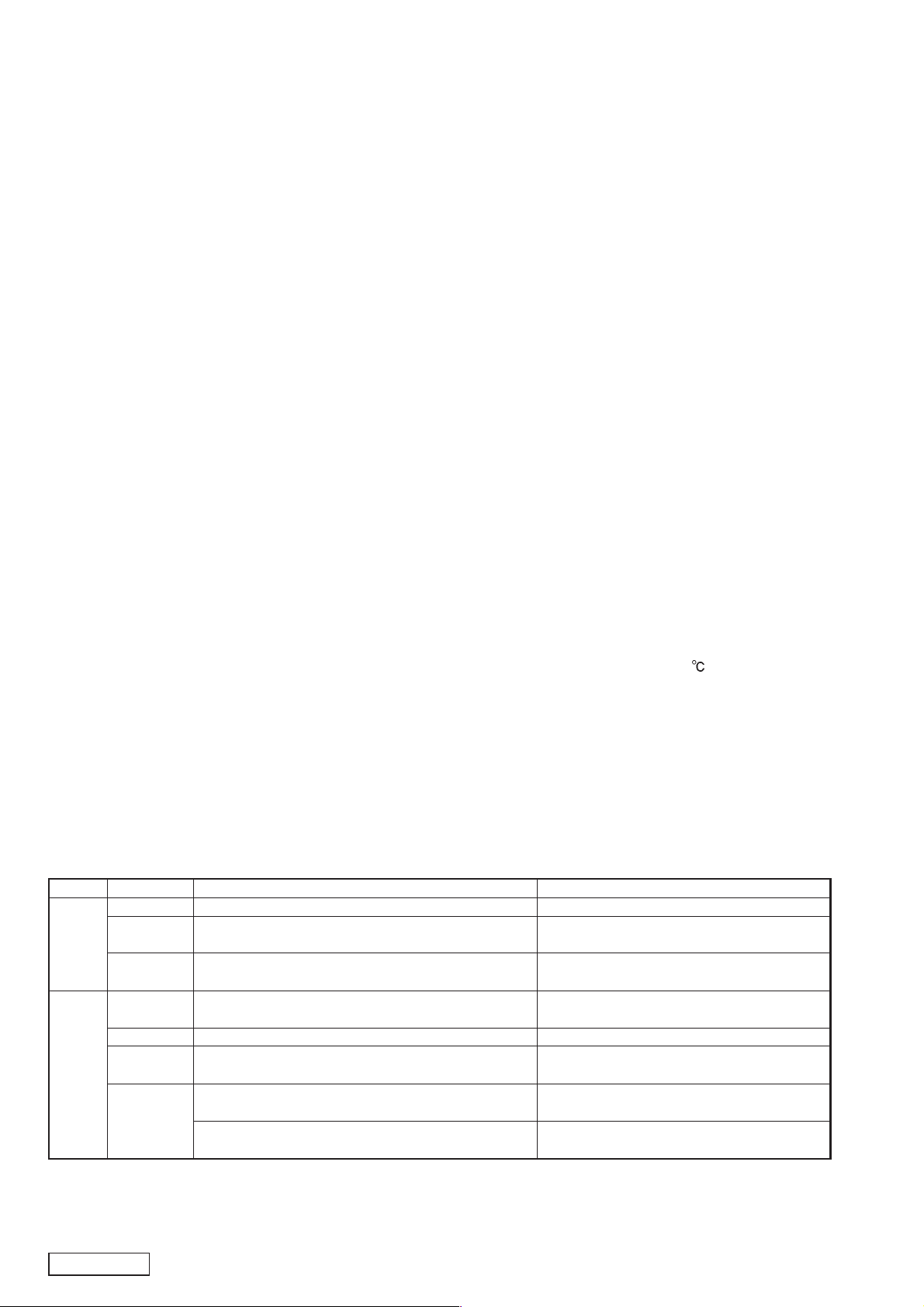

Reset button

CLOCK ADJUSTMENT

1. Press the ADJ button to display the adjustment selection display.

2. Move the JOYSTICK up or down to select CLOCK,then

press ENT at the center of the JOYSTICK to display the

clock adjustment display.

3. Move the JOYSTICK left or right to select HR or MIN,then

move the JOYSTICK up or down to adjust the time.

※The time is displayed in 12-hour format.

4. Pressing ENT at the center of the JOYSTICK when the

cursor is above HR or MIN saves the adjusted value in

memory and simultaneously returns the display to the

previous display(adjustment selection display).

To cancel clock adjustment before completion,use the

JOYSTICK to move the cursor to MENU,then press ENT

at the center of the JOYSTICK.

ADJUSTMENTS

Dot clock adjustment(at Digital PWB)

1. Turn the screen on,and connect TP601(TEST) to GND.

2. Adjust TC601 so that the reading of the frequency counter

at TP602(VSYNC) is 12.00MHz+0.01/-0.02MHz.

DC-DC converter output voltage adjustment

(at LCD PWB)

1. Adjust VR701 so that the voltage of TP703 is 5.05+0.05/

-0.052V.

2. Make sure the voltage has become the following value

at each test point.

TP702 : 7.5+0.5/-0.5V

TP704 : 18.5+1.0/-1.0V

TP701 : -15.5+1.0/-1.0V

Frequency of IC706 adjustment(at LCD PWB)

1. Adjust VR708 so that the frequency of TP712 is 144kHz.

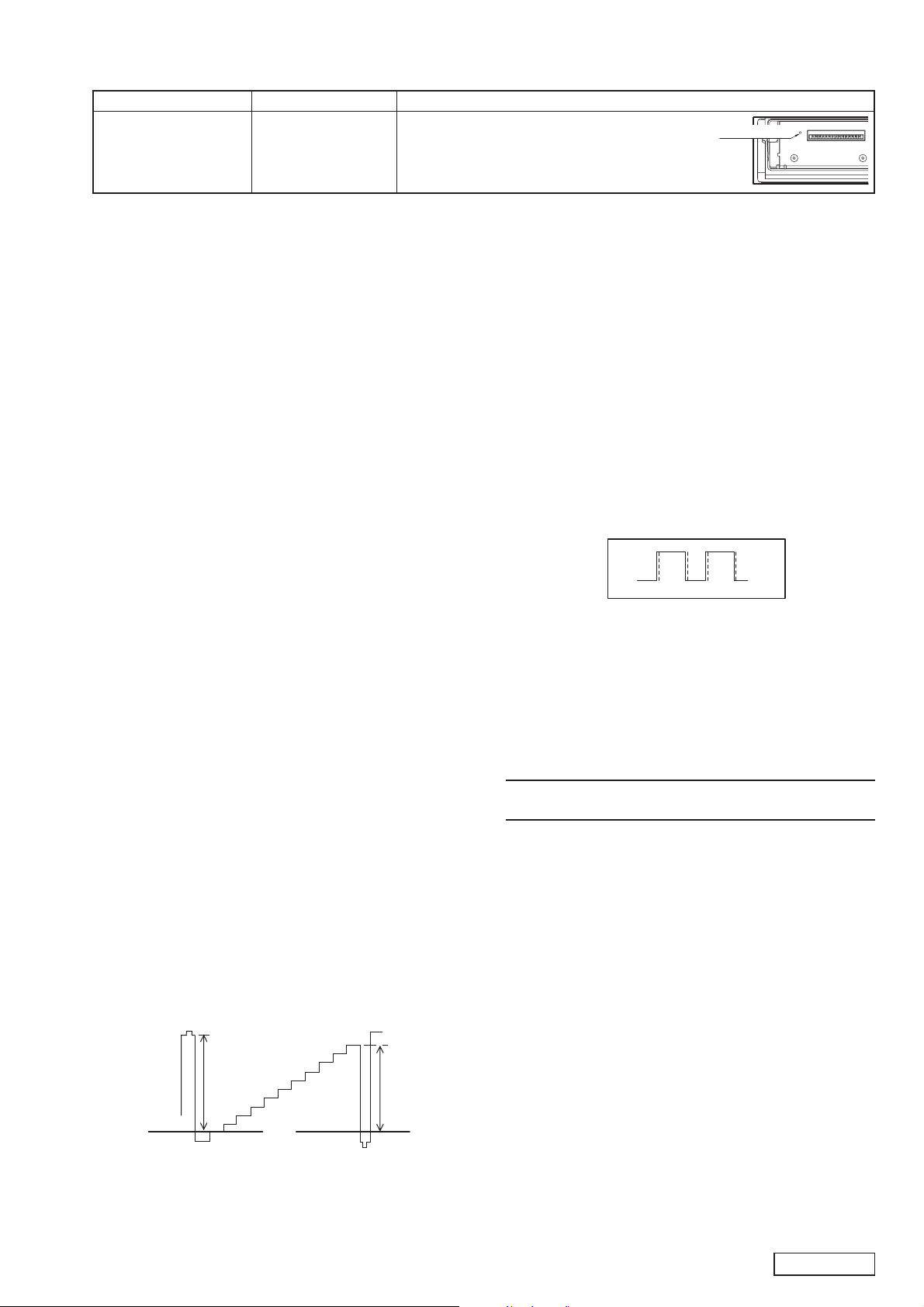

VIDEO signal adjustment(at LCD PWB)

Input the visual signal(10step wave,monochrome,APL=50%,

1.0Vp-p)to the VIDEO input.

10step wave

1. BRIGHT voltage confirmation(NTSC mode)

Make sure the voltage of TP706 is 1.88+0.1/-0.1V.

2. RGB-AMP/CONT-G adjustment(NTSC mode)

Adjust VR707(RBG AMP) so that VBB voltage of TP710

VOLTS/DIV=0.1V(10:1PROVE)

A.B TIME/DIV=10usec.

8

7

3

4

GND

Fig.1

6

5

V

BB

2

1

0

10

9

V

BW

is 4.0+0.5/-0.5V.

Adjust VR703(CONT) so that VBW voltage of TP710 is

3.8+0.05/-0.05V.

3. BRT-R Adjustment(NTSC mode)

Adjust VR705(BRT-R) so that VBB voltage of TP711 is

4.0+0.05/-0.05V.

4. BRT-B Adjustment(NTSC mode)

Adjust VR706(BRT-B) so that VBB voltage of TP709 is

4.0+0.05/-0.05V.

5. COM-AMP adjustment(NTSC mode)

Adjust VR704(COM-AMP) so that the amplitude of TP705

is 6.7+0.1/-0.1Vp-p.

6. Burst cleaning adjustment(PAL mode)

Input a color ber signal.

Adjust L709 so that the wave form of TP709 is in focus.

Burst cleaning

Fig.2

VCOM DC bias adjustment

Adjust VR702(VCOM DC) to obtain the optimum contrast.

EXPLANATION OF IC

M30624MGA-173GP 052-6043-40

AV Center System Controller (Tuner, LCD panel, Ce-NET)

1.Terminal Description

pin 1 : LCD COLOR : O : Color control signal output to LCD panel.

pin 2 : LCD HUE : O : Hue control signal output to LCD panel.

pin 3 : IR IN : IN : Signal input from Remote controller.

pin 4 : AMP REM OUT : O : Amplifier ON signal output terminal.

pin 5 : NU : IN : Not in use.

pin 6 : BYTE : IN : Connect to ground.

pin 7 : CNVSS : IN : Connect to ground.

pin 8 : SUB CLCK I : IN : Crystal connection for sub clock.

pin 9 : SUB CLCK O : O : Crystal connection for sub clock.

pin 10: RESET_ : IN : Reset signal input. Negative logic.

pin 11: X OUT : O : Crystal connection for main clock (10MHz).

pin 12: VSS : - : Ground.

pin 13: X IN : IN : Crystal connection for main clock (10MHz).

pin 14: VCC : - : Positive supply voltage.

pin 15: NMI :IN : Not in use.

pin 16: ACC DET : IN : ACC ON signal input.

pin 17: B/U DET : IN : Backup voltage ON signal input.

pin 18: OPEN/CLOSE : IN : Open/close key input.

pin 19: 27pinCONNECT : IN : IE bus data detect.

pin 20: ACC +B ON : O : LCD back light ON signal output.

pin 21: AV 5V ON : O : 5V power supply ON signal output.

pin 22: NU : O : Not in use.

pin 23: PANEL ON : O : LCD panel power on signal output.

pin 24: BRT : O : LCD panel brightness control signal output.

pin 25: NU : IN : Not in use.

pin 26: IR OUT : O : Signal output to Remote controller.

"L"=Backup OFF.

- 3 -

VRX630

Page 4

pin 27: IE BUS RX : IN : IE Bus communication line.

pin 28: IE BUS TX : O : IE Bus communication line.

pin 29: OSD DO : O : Serial data output to OSD IC.

pin 30: OSD STB : O : Serial strobe output to OSD IC.

pin 31: OSD SCK : O : Clock pulse output to OSD IC.

pin 32: PLL CE : O : PLL chip enable signal output.

pin 33: PLL DO : O : PLL serial data output.

pin 34: PLL DI :IN : PLL serial data input.

pin 35: PLL SCK : O : PLL serial clock output.

pin 36: FM STEREO_ : IN : FM stereo detection signal input.

"L"= Stereo.

pin 37: NU : IN : Not in use.

pin 38: NU : IN : Not in use.

pin 39: A V ON : O : Power supply control signal output.

pin 40: OSD TSC : O : OSD external memory control signal output.

pin 41: NU : IN : Not in use.

pin 42: VOL CLK : O : Clock pulse output to electric volume IC.

pin 43: VOL DO : O : Serial data output to electric volume IC.

pin 44: OPEN : IN : Panel open detection signal input.

pin 45: CLOSE : IN : Panel close detection signal input.

pin 46: NU : O : Not in use.

pin 47: PAL_/NTSC :O : "L"= PAL, "H"= NTSC.

pin 48: EXIO STB : O : Strobe pulse output to the extended ports

pin 49: SEL 2 : IN : AUX IN select signal input.

pin 50: SEL 3 : IN : AUX IN select signal input.

IC.

Ref table 1.

Ref table 1.

pin 51: NU : IN : Not in use.

pin 52: NU : IN : Not in use.

pin 53: NU : IN : Not in use.

pin 54: NU : IN : Not in use.

pin 55: V SEL 1 : O : Image source select signal output.

pin 56: V SEL 2 : O : Image source select signal output.

Ref. Table 2.

Ref. Table 2.

pin 57: BLANK : O : Blanking signal output.

pin 58: NV ON : O : "H"= Navigation RGB, "L"= OSD RGB.

pin 59: VIDEO_/RGB :O : Image select signal input.

"H"= OSD, RGB navigation.

"L"= Black box tuner, Composite naviga-

tion.

pin 60: VCC : - : Positive supply voltage.

pin 61: NU : IN : Not in use..

pin 62: VSS :IN: Ground.

pin 63: IR SEL : O : Remote control signal select.

"L"= Optical input."H"= Micro computer sig-

nal output.

pin 64: PARKING IN : IN : "H"= Parking brake ON.

pin 65: MOTOR F : O : Open/Close control signal output.

pin 66: MOTOR R : O : Open/Close control signal output.

Ref table 3.

Ref table 3.

pin 67: MOTOR ON : O : Motor power supply ON signal output.

pin 68: AMP MUTE : O : "H"= Amplifier Mute.

pin 69: NAVI MUTE : O : "L"= Navigation audio signal ON.

pin 70: KEY REQ : IN : LCD driver key request signal input.

pin 71: ILL DETEC_ : IN : Illumination detect signal input.

Negative logic.

pin 72: TILT_ :IN : "L"= Tilt, "H"= Horizontal.

pin 73: POWER SW : IN : Power key switch input.

pin 74: SYSTM MUTE : O : System mute.

pin 75: LINE MUTE : O : Line mute.

pin 76: BUS A OUT : O : Ce-NET bus input control.

"L"= Audio input.

"H"= Audio output.

pin 77: SYSTM ACC : O : Ce-NET bus system ACC.

pin 78: DISTINATION :IN : Distination select. "L"= USA, "H"= 3rd area.

pin 79: AMP STNBY_ : O : "H"= Amplifier ON.

pin 80: NU : O : Not in use.

pin 81: PHON INT : IN : Telephone interrupt signal input.

pin 82: NU : IN : Not in use.

pin 83: NU : IN : Not in use.

pin 84: FM SD :IN : FM SD input.

pin 85: AM SD : IN : AM SD input.

pin 86: NU : IN : Not in use.

pin 87: NU : O : Not in use.

pin 88: NU : O : Not in use.

pin 89: NU : IN : Not in use.

pin 90: NU : IN : Not in use.

pin 91: NU : IN : Not in use.

pin 92: NU : IN : Not in use.

pin 93: SD SPEED : O : Station detect speed control.

"H"= Normal, "L"= Speed up.

pin 94: A VSS : - : Ground.

pin 95: DCP C E : O : DCP chip enable.

pin 96: Vref : - : Connect to ground.

pin 97: +5V : - : +5V.

pin 98: DCP DI : IN : DCP Serial data input.

pin 99: DCP DO : O : DCP serial data output.

pin100: D CP CK : O : DCP clock pulse output.

Table1. AUX IN select signal input

No connection L L

No connection L H

Image signal interrupt H L

Image sound signal interrupt H H

Table2. Image source select signal output.

Video mute L L

Navigation L H

Black box tuner H L

Black box tuner H H

Table3. Open/Close control signal output.

Free L L

Open L H

Close H L

Brake H H

Sel 3 (pin50) Sel 2 (pin49)

Vsel 2 (pin56) Vsel 1 (pin55)

Motor F (pin65) Motor R (pin66)

052-6044-21 M27C160-100M6 EP-ROM (Character data of On

screen display for USA)

1. Terminal Description

pin 1 : N.C. : No connection.

pin 2 : A 18 : Address input terminal.

pin 3 : A 17 : Address input terminal.

pin 4 : A 7 : Address input terminal.

pin 5 : A 6 : Address input terminal.

pin 6 : A 5 : Address input terminal.

pin 7 : A 4 : Address input terminal.

pin 8 : A 3 : Address input terminal.

pin 9 : A 2 : Address input terminal.

pin 10: A 1 : Address input terminal.

pin 11: A 0 : Address input terminal.

pin 12: CE_ : Chip enable signal input. Negative logic.

pin 13: VSS : Ground.

pin 14: OE_ : Output enable signal input. Negative logic.

pin 15: D 0 : Data output terminal.

pin 16: D 8 : Data output terminal.

pin 17: D 1 : Data output terminal.

pin 18: D 9 : Data output terminal.

pin 19: D 2 : Data output terminal.

pin 20: D 10 : Data output terminal.

pin 21: D 3 : Data output terminal.

pin 22: D 11 : Data output terminal.

pin 23: VCC : Positive supply voltage.

pin 24: D 4 : Data output terminal.

pin 25: D 12 : Data output terminal.

pin 26: D 5 : Data output terminal.

pin 27: D 13 : Data output terminal.

pin 28: D 6 : Data output terminal.

pin 29: D 14 : Data output terminal.

pin 30: D 7 : Data output terminal.

pin 31: D 15 / A-1 : Data output / Address input.

pin 32: VSS : Ground.

pin 33: BYTE_ : L : 1 word = 8 bit

H : 1 word = 16 bit

pin 34: A 16 : Address input terminal.

pin 35: A 15 : Address input terminal.

pin 36: A 14 : Address input terminal.

pin 37: A 13 : Address input terminal.

pin 38: A 12 : Address input terminal.

pin 39: A 11 : Address input terminal.

pin 40: A 10 : Address input terminal.

pin 41: A 9 : Address input terminal.

pin 42: A 8 : Address input terminal.

pin 43: A 19 : Address input terminal.

pin 44: N.C. : No connection.

- 4 -VRX630

Page 5

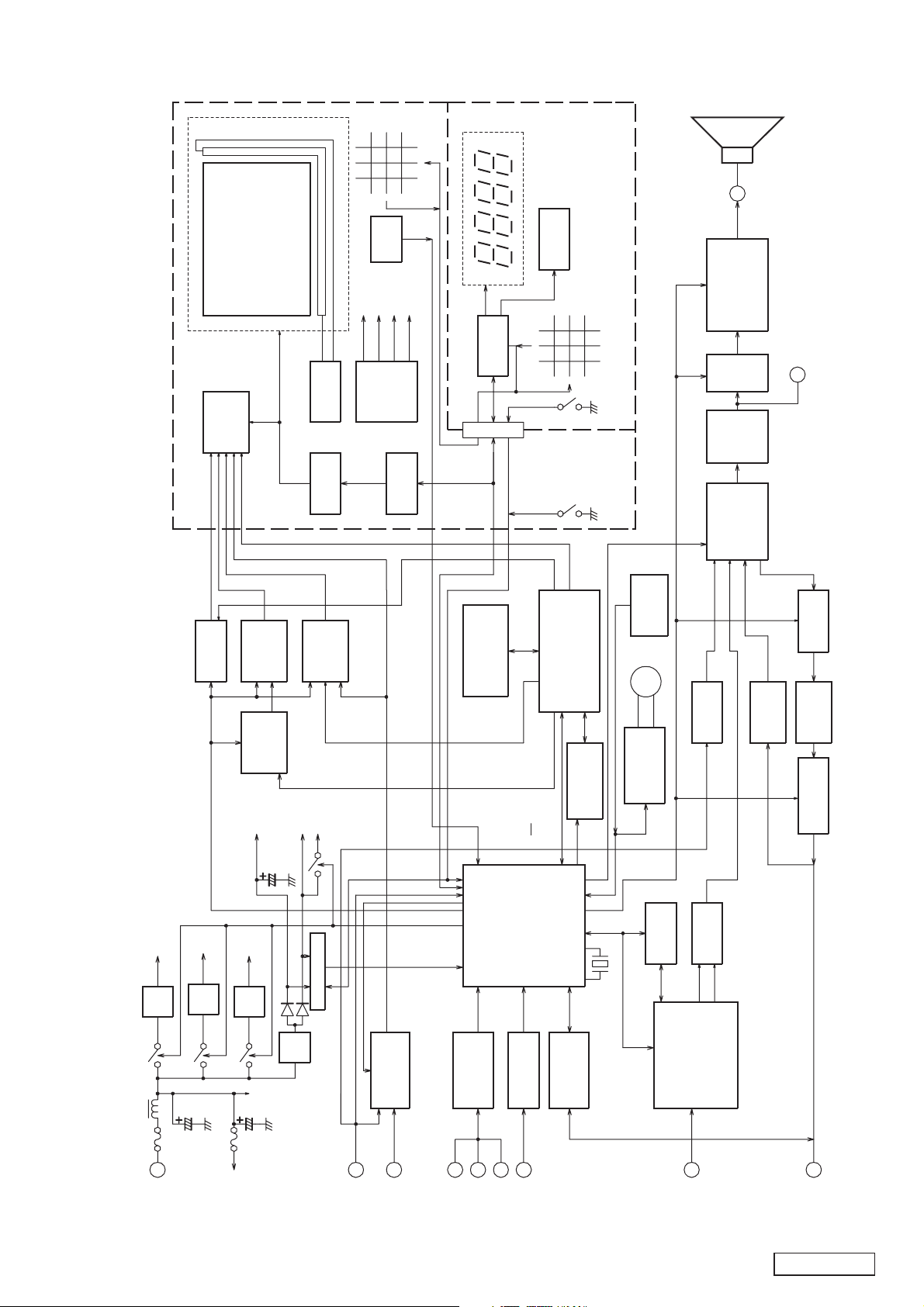

BLOCK DIAGRAM

KEY

INPUT

SPEAKER

IC707

YS

RGB

SYNC

LCD section

IC607

RGB CONT

BLK

VID/RGB

VID/RGB

NTSC/PAL

DECODER

VIDEO

LCDH.V

VOB

BLK

MEMO 5V

6.5 inch LCD

BLK

VID/RGB

IC601

RGB SW

RGB

B/U 5V

IC706

INVERTER

NTSC/PAL

SW

IC608

SYNC SW

VIDEO

ACC 5V

18.5V

IC702

IR901

IR REM

7.5V

5.0V

DC/DC

POWER

-15.5V

SUPPLY

IC701

EX I/O

IR SIG

EXIT STBY

IC901

KEY REQ

DCP CE

DCP CLK

DCP DATA

IC602

DCP CONT

8M ROM

CS

ILL

IC609

SCLK

SIN

KEY INPUT

RESET SW

TILT SW

B-OSDC

IC603

CRYSTAL

NTSC 14.3M

PAL 17.7M

N/_P

DCP section

POWER SW

OPEN/CLOSE SW

OPEN

CLOSE

PHOTO

IC116,117

M

IC504

MOTOR

M-F

M-R

SENSOR

DRIVER

AMP STBY

AMP MUTE

SYS MUTE

CLOCK

DATA

IC115

BUFFER

AUDIO IN

IC101

(40W x 4)

POWER AMP

MUTE

Q107

-110

(AMP)

IC102,106

IC103

E-VOL

M62419

RADIO

BUS AUDIO

LINE MUTE

IC109

BALANCE

IN

BUS AUDIO

4-CH LINE OUT

Q103 - 106

LINE MUTE

IC110,111

BALANCE

OUT

IC113

AUDIO-SW

BUS ON

AV 9 V

Q122

9V

+B

REG

AV O N

Q511

12V

MOT 12V

REG

MOT ON

Ce-NET

9V

B/U

ACC+B

REG

ACC ON

PWR

-AMP

5V

REG

IC112,Q124

ACC ON

RST/BU DET

IC501,503

VSEL

SEL2

AUDIO IN

MINI DIN

8P

VIDEO

VIDEO IF

Q504,504

VIDEO

SEL3

VIDEO

VIDEO IN

B/U DET

RESET

IC610

MOT ON

AV O N

ACC ON

FL PN

ILL

PKB

TEL

Q120,121,518

138,508

ILL

PKB

TEL

ILL

- 5 -

EXT-INPUT

PKB

IC502

TEL

SYSTEM CONTROL

ACC

IC114

IC503

ACC DET

ACC

CA0008AM

BUS DRIVER

BUS+

BUS-

ACC

DIDOCLK

10MHz

ST

CE

IF-REQ

FM+

AM SD

FM SD

IC3

AM+

PLL

MIX

IC104

FM

AM

BL1

FM/AM TUNER

ANT

BUS+

BUS-

Ce-NET

VRX630

BUS AUDIO

13P

Page 6

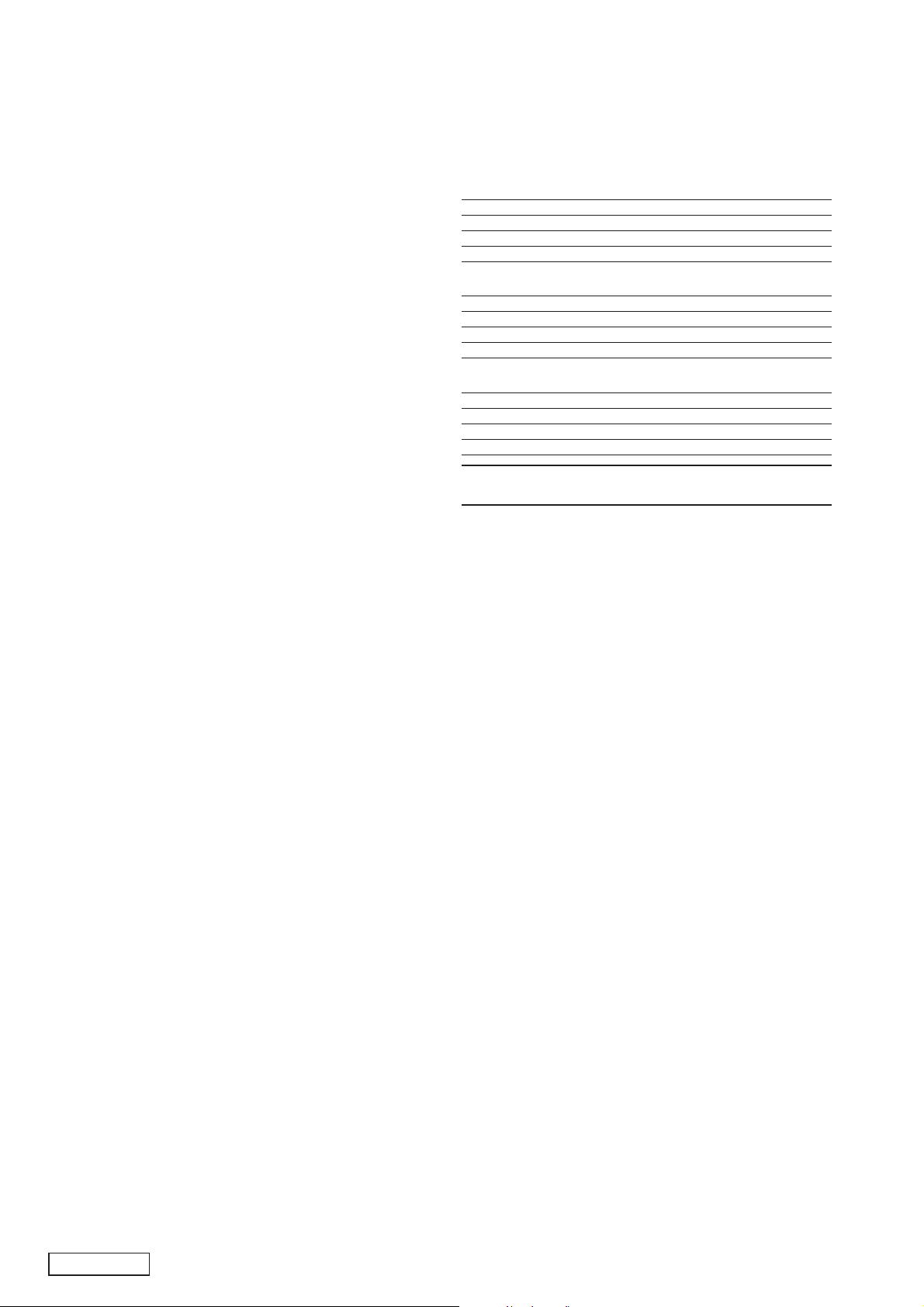

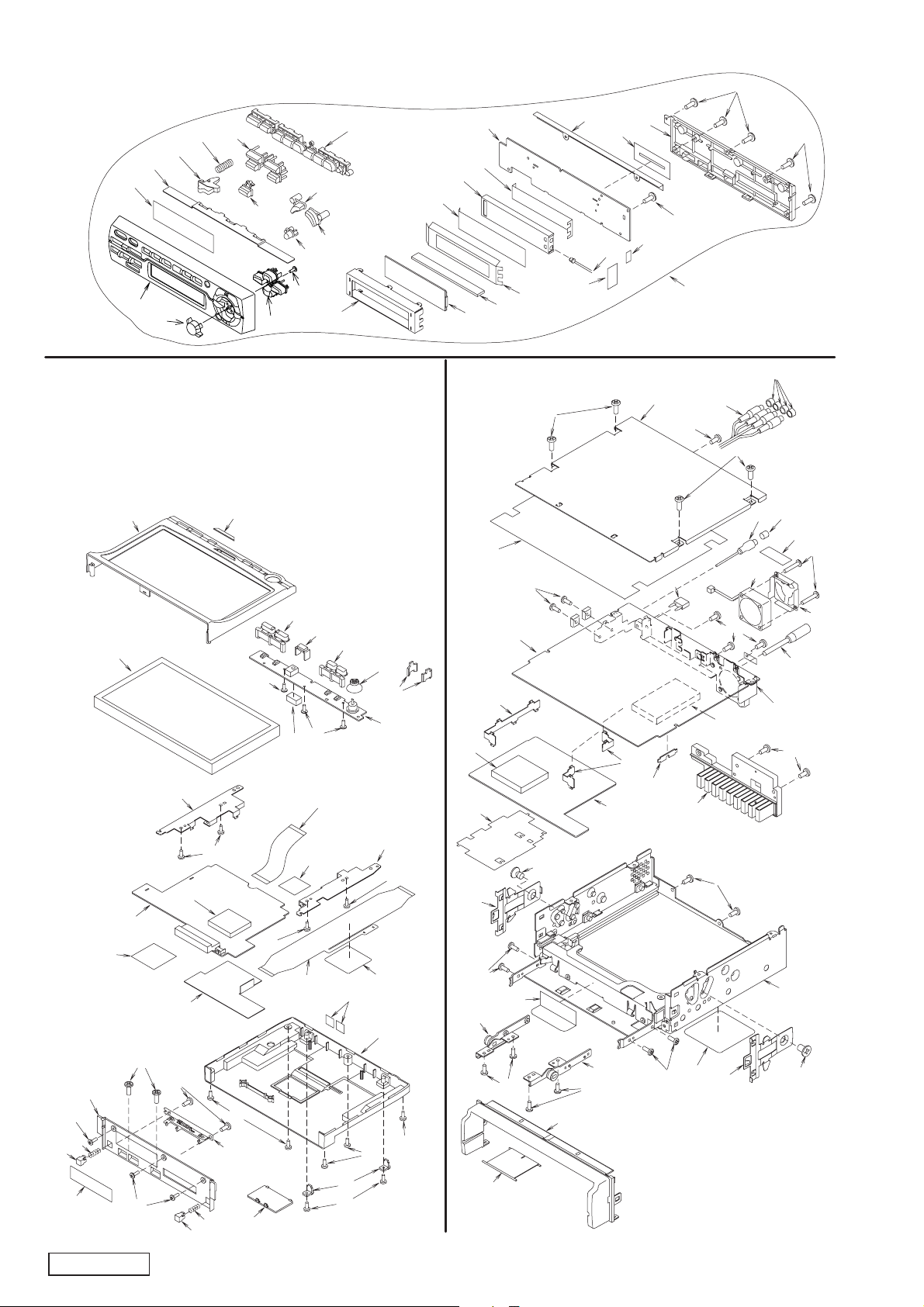

EXPLODED VIEW / PARTS LIST

DCP section

10

5

4

3

7

9

11

12

13

26

24

19

20

23

21

6

25

22

8

26

26

28

14

26

15

2

1

LCD module section

Note:

Please refer to page 8 when you release the LCD

module from the main unit.

6

12

13

19

24

28

7

8

24

20

27

16

17

18

Main section

18

13

34

9

10

29

11

30

28

9

8

7

6

29

29

23

11

22

16

12

37

35

32

18

20

31

23

36

19

21

33

10

17

16

26

34

27

30

15

14

23

27

26

15

3

27

24

14

1

4

14

2

15

25

16

26

5

27

23

22

11

31

32

25

24

25

2

1

4

24

33

1

3

23

27

5

17

21

18

- 6 -VRX630

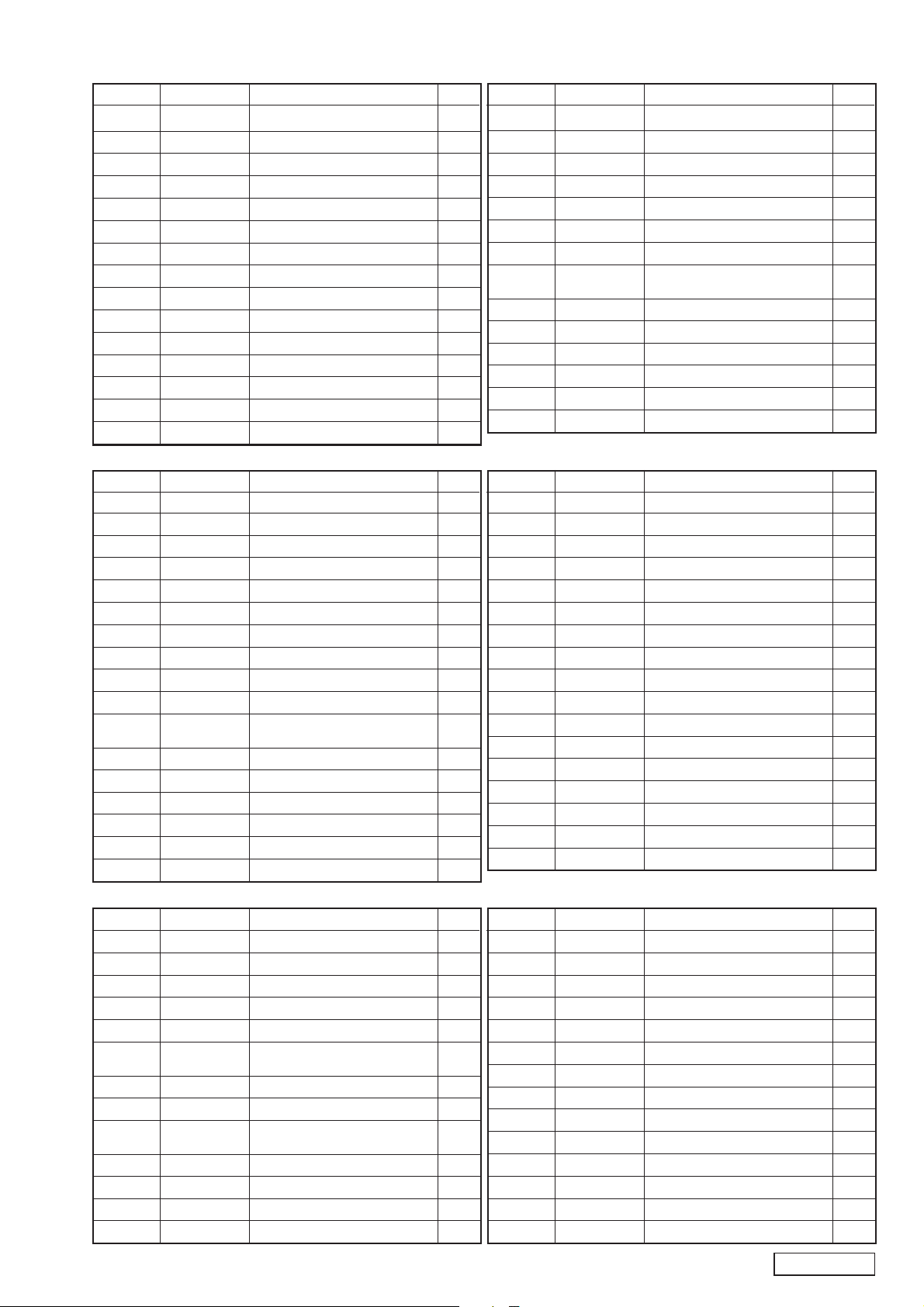

Page 7

DCP section

1 335-6983-00 BUTTON COVER 1

2 370-6921-01 ECSUTCHEON 1

3 331-2770-00 SPACER 1

4 335-6082-00 LEVER(Release) 1

5 750-6696-20 SPRING 1

6 382-6704-01 BUTTON(PRESET) 1

7 371-3912-20 TRIM PLATE 1

8 335-6081-00 BACK PLATE 1

9 382-5455-01 BUTTON(RPT) 1

10 382-5470-02 BUTTON(SCN/RDM/Z-E/ISR) 1

11 382-6702-00 BUTTON(BAND) 1

12 382-6701-00 BUTTON(FUNC) 1

13 382-5466-01 BUTTON(PLAY/PAUSE) 1

14 382-6703-00 BUTTON(VOL) 1

15 331-2771-00 LCD COVER 1

LCD module section

1 335-5147-00 EJECTOR 2

2 750-6697-20 SPRING 1

3 347-5187-21 GUIDE LABEL 1

4 335-6078-00 DCP COVER 1

5 948-0539-00 HOOK-P-ASSY 1

6 373-0909-02 DIAL COVER 1

7 382-5456-02 BUTTON(ADJ/A-M) 1

8 335-6077-00 IR FILTER 1

9 382-5457-02 BUTTON(VISUAL/TITLE) 1

10 380-5452-00 KNOB(JOG) 1

11 039-2328-00 LCD PWB 1

12 379-4024-00 INDICATOR(6.5inch) 1

13 331-2710-00 LCD BRACKET A 1

14 331-2711-00 LCD BRACKET B 1

15 377-2613-02 DIAL SUPPORT 1

16 335-5161-00 LOCK 2

17 335-6089-00 CONNECT COVER 1

(WITHOUT COMPONENT)

Main section

1 335-6075-00 FLEXIBLE PWB COVER 1

2 370-5829-01 ESCUTCHEN 1

3 948-0523-00 TORQUE BUSH L 1

4 948-0523-10 TORQUE BUSH R 1

5 948-0530-20 SLIDE MECH ASSY(cf.p8) 1

6 039-2327-00 DIGITAL PWB 1

7 331-2712-00 PWB HOLDER A 2

8 331-2713-00 PWB HOLDER B 1

9 039-1910-00 MAIN PWB 1

10 331-2714-10 CONNECTOR PLATE 1

11 311-1778-01 LOWER CASE 1

12 313-1761-00 HEAT SINK 1

13 347-6111-20 INSULATOR 1

(WITHOUT COMPONENT)

(WITHOUT COMPONENT)

NO. PART NO. DESCRIPTION Q'TYNO. PART NO. DESCRIPTION Q'TY

16 379-1162-41 INDICATOR(FOR DCP) 1

17 345-8389-20 RUBBER CONNECTOR 1

18 347-5336-00 FILM 1

19 347-6617-00 CCS FILM 1

20 335-5138-00 ILLUMI PLATE 1

21 347-5335-00 REFLECTOR 1

22 001-7046-00 LED

23 039-2329-00 DCP PWB 1

24 347-6155-00 INSULATOR 1

25 347-6115-20 SHADE 1

26 716-0872-11 PAD SCREW 7

27 347-7650-00 SHADE 1

28 347-7649-00 LED COVER 1

29 DCP-457-600 DCP ASSY 1

NO. PART NO. DESCRIPTION Q'TYNO. PART NO. DESCRIPTION Q'TY

18 039-1521-00 FLEXIBLE PWB 1

19 378-0515-00 BADGE(Clarion) 1

20 816-2439-50 FLAT WIRE 1

21 347-6110-00 INSULATOR 1

22 331-2789-00 SHIELD CASE 1

23 702-2605-80 TAP SCREW(2.6x5) 4

24 716-0872-02 PAD SCREW 6

25 702-2606-87 TAP SCREW(2.6x6) 4

26 702-2006-89 TAP SCREW(2.6x6) 2

27 702-2010-87 TAP SCREW(M2x10) 5

28 345-8378-00 SPACER 1

29 335-6076-00 REFLECTOR 2

30 347-6114-00 SHADE 1

31 347-5422-00 SHIELD SHEET 1

32 347-6154-00 SHIELD SHEET 1

33 750-6701-00 SPRING 1

34 347-6371-00 SPACER 2

NO. PART NO. DESCRIPTION Q'TYNO. PART NO. DESCRIPTION Q'TY

14 780-2606-03 IT SCREW(M2.6x6) 4

15 780-2605-02 MACHINE SCREW(M2.6x5) 4

16 778-2605-05 TAP SCREW(M2.6x5) 3

17 714-2610-80 MACHINE SCREW(M2.6x10) 2

18 716-1494-00 IT SCREW 4

19 780-2615-00 MACHINE SCREW(M2.6x15) 2

20 020-3042-00 FAN 1

21 331-2727-02 FAN COVER 1

22 060-8021-07 AUTO FUSE(15A) 1

23 345-3799-20 CAP 5

24 347-6136-00 FLEXIBLE PWB GUIDE 1

25 286-6215-00 SETPLATE 1

26 750-3137-00 SPRING 2

27 714-5008-41 MACHINE SCREW(M5x8) 2

(WITHOUT COMPONENT)

- 7 -

VRX630

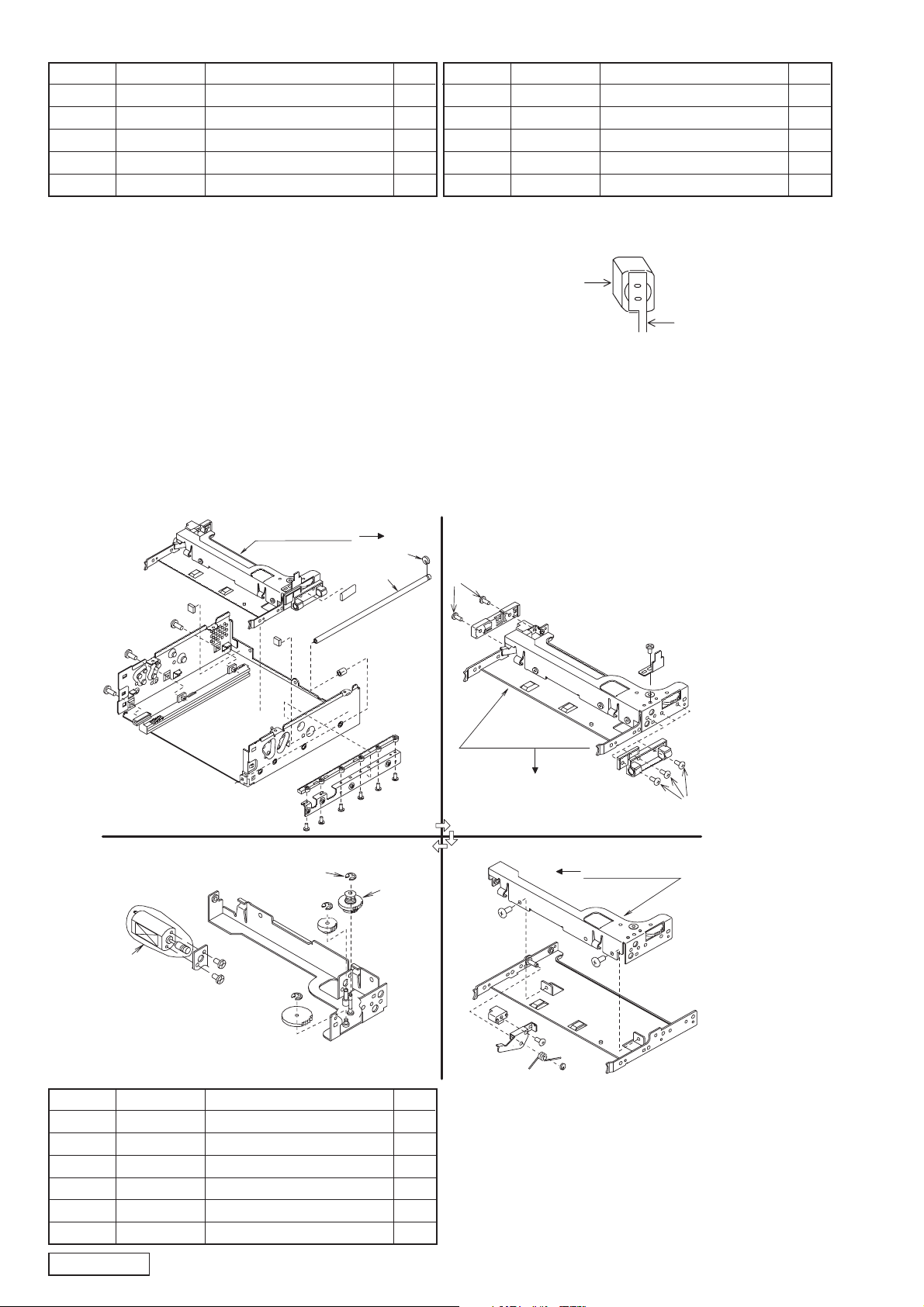

Page 8

28 347-6153-00 SHIELD SHEET 1

29 347-6113-00 SHIELD SHEET 1

30 331-2790-00 SHIELD CASE 1

31 855-5436-50 RCA CORD(VIDEO) 1

32 714-3005-80 MACHINE SCREW(M3x5) 3

How to release LCD module

Refer to the exploded view of the main section on page 6.

1. Remove the machine screws(No.27x2) and the

springs(No.26x2).

2. Remove the IT screws(No.18x4) and the tap screw(No.16x3)

in order to release the lower case(No.11).

3. Remove the escutchen(No.2) and the main PWB

assembly(No.9).

4. Pull out the LCD module,and release the flexible PWB of

the LCD module from the motor of the slide mechanism

assembly(No.5).(Fig.3)

EXPLODED VIEW / PARTS LIST

Slide mechanism section : 948-0530-20

Slide plate assembly

3

NO. PART NO. DESCRIPTION Q'TYNO. PART NO. DESCRIPTION Q'TY

33 092-0701-02 ANTENNA RECEPTACLE 1

34 714-2606-80 MACHINE SCREW(M2.6x6) 2

35 880-2084C FM/AM TUNER PACK 1

36 353-0249-00 SHADE 1

37 855-5427-51 RCA CORD(AUDIO) 1

Slide motor

Flexible PWB

Fig.3

5. Release the hooks of the Flexible PWB cover(No.1) from

the LCD module and the slide mechanism assembly(No.5).

6. Remove the flexible PWB cover(No.1) and the IT

screws(No.14x4).

Slide plate assembly

1

4

Gear plate assembly

6

2

5

NO. PART NO. DESCRIPTION Q'TY

1 744-0041-00 E-RING 1

2 634-0016-00 GEAR ASSY 1

3 612-0402-00 SHAFT 1

4 780-2606-03 IT SCREW 5

5 634-0017-00 MOTOR ASSY 1

6 743-1500-01 E-RING 1

Slide plate sub-assembly

Note:Please replace the IT screws(No.4x5) for keeping

tight when you replace the motor ass'y or gear ass'y.

Slide plate sub-assembly

Gear plate assembly

4

Caution for the replacement of the motor assembly

After you replaced the motor assembly with new one,please

make sure that the current of the motor assembly is 50mA or

less when you input 8V as the power voltage.

If the current is over 50mA,loosen the screws, and adjust the

position of the motor assembly.

Then tighten the screws,and check the current again.

- 8 -VRX630

Page 9

ELECTRICAL PARTS LIST

Main PWB section(B1)

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

BL1 880-2084C AM/FM TUNER

C1 168-1032-55 0.01uF

C2 042-0595-80 50V2.2uF

C3 166-2201-50 22pF CH

C4 166-1801-50 18pF CH

C5 166-2201-50 22pF CH

C6 163-2263-35 16V22uF

C9 168-3335-56 0.033uF

C10 168-3335-56 0.033uF

C11 178-3932-78 0.039uF

C12 168-6822-55 6800pF

C13 168-2222-55 2200pF

C14 168-1022-55 1000pF

C15 168-2232-55 0.022uF

C16 168-1022-55 1000pF

C18 168-2232-55 0.022uF

C19 168-2232-55 0.022uF

C20 168-2212-55 220pF

C25 166-1011-50 100pF CH

C26 166-1011-50 100pF CH

C27 166-1011-50 100pF CH

C29 042-0595-65 16V47uF

C30 168-4735-56 0.047uF

C32 042-0595-65 16V47uF

C33 168-1045-56 0.1uF

C34 042-0595-79 50V1uF

C35 168-1045-56 0.1uF

C36 168-2212-55 220pF

C37 168-8222-55 8200pF

C38 166-1011-50 100pF CH

C40 168-1222-55 1200pF

C41 166-1501-50 15pF CH

C42 166-1801-50 18pF CH

C43 042-0595-79 50V1uF

C44 042-0595-79 50V1uF

C48 168-1022-55 1000pF

C49 166-1011-50 100pF CH

C50 166-1011-50 100pF CH

C57 166-1011-50 100pF CH

C58 166-1011-50 100pF CH

C102 166-4701-50 47pF CH

C103 168-1045-56 0.1uF

C104 042-0592-58 16V10uF

C106 042-0592-58 16V10uF

C107 042-0592-73 50V1uF

C108 042-0592-74 50V 2.2uF

C109 168-6822-55 6800pF

C110 166-2201-50 22pF CH

C112 168-6835-56 0.068uF

C113 168-1022-55 1000pF

C114 168-2212-55 220pF

C115 168-1032-55 0.01uF

C116 178-1055-79 1uF

C118 042-0592-66 35V 4.7uF

C119 042-0592-59 16V22uF

C120 042-0592-58 16V10uF

C121 042-0595-62 16V10uF

C122 042-0592-70 50V0.22uF

C123 042-0592-70 50V0.22uF

C124 042-0592-70 50V0.22uF

C125 042-0592-70 50V0.22uF

C126 168-1045-56 0.1uF

C127 168-3322-55 3300pF

C129 166-4701-50 47pF CH

C130 042-0592-58 16V10uF

C132 042-0595-80 50V2.2uF

C134 184-2283-32 16V2200uF

C135 042-0595-79 50V1uF

C137 168-1032-55 0.01uF

C138 042-0595-62 16V10uF

C139 042-0595-62 16V10uF

C141 166-4701-50 47pF CH

C142 042-0592-58 16V10uF

C143 042-0592-59 16V22uF

C144 042-0592-66 35V 4.7uF

C145 042-0595-66 25V4.7uF

C146 042-0592-58 16V10uF

C147 042-0592-74 50V 2.2uF

C148 168-2212-55 220pF

C149 178-1055-79 1uF

C150 166-2201-50 22pF CH

C152 168-6835-56 0.068uF

C153 168-1022-55 1000pF

C154 042-0595-62 16V10uF

C155 168-6822-55 6800pF

C156 042-0592-59 16V22uF

C157 042-0592-58 16V10uF

C158 168-1045-56 0.1uF

C159 042-0592-73 50V1uF

C160 166-4701-50 47pF CH

C161 042-0592-58 16V10uF

C162 042-0592-58 16V10uF

C165 168-1032-55 0.01uF

C173 168-1032-55 0.01uF

C174 178-1055-79 1uF

C175 042-0595-84 10V100uF

C176 042-0595-84 10V100uF

C177 168-1032-55 0.01uF

C180 042-0595-62 16V10uF

C181 184-2283-32 16V2200uF

C182 166-2201-50 22pF CH

C183 172-1041-11 0.1uF

C184 042-0595-62 16V10uF

C186 042-0592-58 16V10uF

C187 042-0592-58 16V10uF

C188 042-0592-58 16V10uF

C189 166-2201-50 22pF CH

C190 042-0595-62 16V10uF

C191 042-0592-58 16V10uF

C192 168-1032-55 0.01uF

C193 042-0595-62 16V10uF

C194 168-1032-55 0.01uF

C195 042-0592-58 16V10uF

C196 042-0592-58 16V10uF

C197 042-0592-58 16V10uF

C198 042-0592-58 16V10uF

C199 042-0592-58 16V10uF

C200 042-0595-62 16V10uF

C201 166-2201-50 22pF CH

C202 042-0592-66 35V 4.7uF

C203 166-2201-50 22pF CH

C204 042-0595-62 16V10uF

C205 168-1032-55 0.01uF

C207 166-2201-50 22pF CH

C209 166-2201-50 22pF CH

C210 042-0595-62 16V10uF

C211 168-1032-55 0.01uF

C212 042-0592-58 16V10uF

C213 042-0592-66 35V 4.7uF

C214 166-2201-50 22pF CH

C215 042-0592-66 35V 4.7uF

C216 166-2201-50 22pF CH

C217 042-0592-66 35V 4.7uF

C218 168-1032-55 0.01uF

C219 163-1073-35 16V100uF

C220 168-1032-55 0.01uF

C221 163-1073-35 16V100uF

C222 168-1032-55 0.01uF

C223 163-1073-35 16V100uF

C224 042-0635-50 10V47uF

C225 178-2232-78 0.022uF

C226 168-1045-56 0.1uF

Note) Several different parts of the same reference number are alternative parts.

One of those parts is used in the set.

C227 168-1045-56 0.1uF

C228 172-1041-11 0.1uF

C229 168-2212-55 220pF

C230 042-0595-62 16V10uF

C231 042-0592-66 35V 4.7uF

C232 042-0592-66 35V 4.7uF

C235 168-1032-55 0.01uF

C236 042-0595-62 16V10uF

C237 168-2212-55 220pF

C238 168-1045-56 0.1uF

C239 042-0595-62 16V10uF

C240 168-1032-55 0.01uF

C241 042-0595-62 16V10uF

C242 042-0595-64 16V33uF

C244 042-0595-62 16V10uF

C251 168-1022-55 1000pF

C252 168-1022-55 1000pF

C253 168-1022-55 1000pF

C254 168-1022-55 1000pF

D101 001-0516-90 MA111

D102 001-0516-90 MA111

D103 001-2606-90 M1FS4

D104 001-2606-90 M1FS4

D105 001-2606-90 M1FS4

D106 001-2606-90 M1FS4

D111 001-0516-90 MA111

D112 001-0516-90 MA111

D113 001-0516-90 MA111

D114 001-0592-00 RM4Z

D115 001-0516-90 MA111

D116 001-0356-91 1SS184

D117 001-2403-90 M1F60

D118 001-0516-90 MA111

D119 001-0516-90 MA111

D120 001-0516-90 MA111

D121 001-0529-46 MA8091-L

D122 001-0516-90 MA111

D123 001-2403-90 M1F60

D124 001-0529-48 MA8091-H

D125 001-0516-90 MA111

D150 001-0529-25 MA8047-L

F101 060-8023-58 3A

FAN 020-3042-00 FAN MOTOR

IC3 051-6201-90 LC72146M

IC101 051-2023-01 TA8260AH

IC102 051-0350-93 NJM4558M

IC103 051-5008-90 M62419FP

IC104 051-0350-93 NJM4558M

IC105 051-0350-93 NJM4558M

IC106 051-0350-93 NJM4558M

IC108 051-0350-93 NJM4558M

IC109 051-0350-93 NJM4558M

IC110 051-0350-93 NJM4558M

IC111 051-0350-93 NJM4558M

IC112 051-3201-00 AN77L06

IC113 051-7232-08 74VHC4066M

IC114 051-6600-38 CA0008AM

IC115 051-0350-93 NJM4558M

IC116 051-5801-00 GP1S53V

IC117 051-5801-00 GP1S53V

J101 074-1238-00 16P

J102 074-1194-00 13P CE-NET

J103 074-1030-00 MINI-DIN-8P

L1 010-2003-04 COIL

L2 010-2199-54 0.22UH J

L3 010-2174-78 220UH

L5 010-2199-66 2.2UH J

L6 010-2199-66 2.2UH J

P1 074-0977-14 14P

P101 074-0977-19 SOCKET-19P

P102 076-0349-02 2P

- 9 -

VRX630

Page 10

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

P103 074-0977-17 SOCKET-17P

Q5 190-1162-00 2SA1162

Q6 190-1298-00 2SA1298

Q8 108-0669-00 2SK669

Q101 190-1162-00 2SA1162

Q102 190-1162-00 2SA1162

Q103 193-1306-00 2SD1306

Q104 193-1306-00 2SD1306

Q105 193-1306-00 2SD1306

Q106 193-1306-00 2SD1306

Q107 193-1306-00 2SD1306

Q108 193-1306-00 2SD1306

Q109 193-1306-00 2SD1306

Q110 193-1306-00 2SD1306

Q113 191-1237-00 2SB1237

Q114 125-0002-93 RN2403

Q115 190-1162-00 2SA1162

Q116 190-1162-00 2SA1162

Q117 125-2004-93 RN1403

Q118 125-2004-93 RN1403

Q119 125-2004-93 RN1403

Q120 192-2712-00 2SC2712

Q121 190-1313-00 2SA1313O,Y

Q122 103-1683-00 2SD1683

Q123 190-1428-00 2SA1428

Q124 101-1143-00 2SB1143

Q125 190-1428-00 2SA1428

Q126 190-1428-00 2SA1428

Q127 190-1213-00 2SA1213

Q128 125-2004-93 RN1403

Q129 125-0002-93 RN2403

Q130 125-2004-97 RN1407

Q131 125-2004-93 RN1403

Q132 125-2004-93 RN1403

Q133 125-2004-93 RN1403

Q134 125-2004-91 RN1401

Q135 192-2873-00 2SC2873

Q136 190-1162-00 2SA1162

Q137 125-2004-93 RN1403

Q138 192-2712-00 2SC2712

R8 032-0104-73 1/4W 330 ohm

R9 119-3921-15 1/16W 3.9k ohm

R11 119-8221-15 1/16W 8.2k ohm

R14 119-2201-15 1/16W 22 ohm

R15 119-1031-15 1/16W 10k ohm

R16 119-1031-15 1/16W 10k ohm

R17 119-1031-15 1/16W 10k ohm

R18 119-2221-15 1/16W 2.2k ohm

R19 119-1031-15 1/16W 10k ohm

R21 119-1031-15 1/16W 10k ohm

R22 119-1031-15 1/16W 10k ohm

R23 119-2721-15 1/16W 2.7k ohm

R24 119-2721-15 1/16W 2.7k ohm

R25 119-1231-15 1/16W 12k ohm

R26 119-1031-15 1/16W 10k ohm

R27 119-2711-15 1/16W 270 ohm

R28 119-8211-15 1/16W 820 ohm

R29 119-1021-15 1/16W 1k ohm

R30 119-2221-15 1/16W 2.2k ohm

R31 119-1021-15 1/16W 1k ohm

R32 119-1021-15 1/16W 1k ohm

R33 119-1011-15 1/16W 100 ohm

R101 119-1021-15 1/16W 1k ohm

R102 119-2231-15 1/16W 22k ohm

R103 119-1031-15 1/16W 10k ohm

R104 119-3321-15 1/16W 3.3k ohm

R107 119-3331-15 1/16W 33k ohm

R108 119-2231-15 1/16W 22k ohm

R109 119-2221-15 1/16W 2.2k ohm

R110 119-2721-15 1/16W 2.7k ohm

R111 119-4731-15 1/16W 47k ohm

R112 119-4721-15 1/16W 4.7k ohm

R113 119-6831-15 1/16W 68k ohm

R115 119-3331-15 1/16W 33k ohm

R116 119-1021-15 1/16W 1k ohm

R117 119-1031-15 1/16W 10k ohm

R118 119-2731-15 1/16W 27k ohm

R119 119-3331-15 1/16W 33k ohm

R120 119-2231-15 1/16W 22k ohm

R121 119-3331-15 1/16W 33k ohm

R122 119-3321-15 1/16W 3.3k ohm

R123 119-1031-15 1/16W 10k ohm

R124 119-1031-15 1/16W 10k ohm

R125 119-1831-15 1/16W 18k ohm

R126 119-1021-15 1/16W 1k ohm

R127 119-1831-15 1/16W 18k ohm

R128 119-3331-15 1/16W 33k ohm

R130 119-2231-15 1/16W 22k ohm

R131 119-3331-15 1/16W 33k ohm

R132 119-1031-15 1/16W 10k ohm

R134 119-3331-15 1/16W 33k ohm

R135 119-3331-15 1/16W 33k ohm

R137 119-2231-15 1/16W 22k ohm

R138 119-3311-15 1/16W 330 ohm

R139 119-3331-15 1/16W 33k ohm

R140 119-1031-15 1/16W 10k ohm

R141 119-2231-15 1/16W 22k ohm

R142 119-3311-15 1/16W 330 ohm

R143 119-2731-15 1/16W 27k ohm

R144 119-3331-15 1/16W 33k ohm

R145 119-3311-15 1/16W 330 ohm

R146 119-3331-15 1/16W 33k ohm

R147 119-4721-15 1/16W 4.7k ohm

R148 119-2231-15 1/16W 22k ohm

R149 119-3311-15 1/16W 330 ohm

R150 119-1031-15 1/16W 10k ohm

R151 119-2231-15 1/16W 22k ohm

R154 119-6831-15 1/16W 68k ohm

R155 119-1031-15 1/16W 10k ohm

R156 119-2221-15 1/16W 2.2k ohm

R157 119-2721-15 1/16W 2.7k ohm

R158 119-4731-15 1/16W 47k ohm

R159 119-2231-15 1/16W 22k ohm

R160 119-2231-15 1/16W 22k ohm

R161 119-2231-15 1/16W 22k ohm

R162 119-2231-15 1/16W 22k ohm

R163 119-1021-15 1/16W 1k ohm

R164 119-1021-15 1/16W 1k ohm

R165 119-1021-15 1/16W 1k ohm

R166 119-1021-15 1/16W 1k ohm

R167 119-2231-15 1/16W 22k ohm

R168 119-3331-15 1/16W 33k ohm

R170 119-3311-15 1/16W 330 ohm

R172 119-1231-15 1/16W 12k ohm

R174 119-1231-15 1/16W 12k ohm

R183 114-1591-11 1W 1.5 ohm

R186 119-1021-15 1/16W 1k ohm

R187 119-1031-15 1/16W 10k ohm

R188 119-1031-15 1/16W 10k ohm

R189 119-2231-15 1/16W 22k ohm

R191 119-1031-15 1/16W 10k ohm

R192 032-0104-61 1/4W 2.2k ohm

R194 032-0104-67 1/4W 1.2k ohm

R196 119-4721-15 1/16W 4.7k ohm

R197 119-3321-15 1/16W 3.3k ohm

R198 119-1031-15 1/16W 10k ohm

R199 119-2231-15 1/16W 22k ohm

R200 119-4731-15 1/16W 47k ohm

R201 119-4731-15 1/16W 47k ohm

R202 119-2231-15 1/16W 22k ohm

R203 119-2231-15 1/16W 22k ohm

R204 119-4731-15 1/16W 47k ohm

R205 119-4731-15 1/16W 47k ohm

R206 119-2231-15 1/16W 22k ohm

R207 119-2231-15 1/16W 22k ohm

R208 119-1031-15 1/16W 10k ohm

R209 119-4731-15 1/16W 47k ohm

R210 119-1031-15 1/16W 10k ohm

R211 119-1531-15 1/16W 15k ohm

R212 119-4731-15 1/16W 47k ohm

R213 119-1041-15 1/16W 100k ohm

R214 119-2231-15 1/16W 22k ohm

R215 119-2231-15 1/16W 22k ohm

R216 119-2231-15 1/16W 22k ohm

R217 119-1011-15 1/16W 100 ohm

R218 119-1011-15 1/16W 100 ohm

R219 119-1011-15 1/16W 100 ohm

R220 119-1011-15 1/16W 100 ohm

R221 119-1031-15 1/16W 10k ohm

R223 119-1041-15 1/16W 100k ohm

R224 119-1041-15 1/16W 100k ohm

R225 119-1041-15 1/16W 100k ohm

R226 119-1041-15 1/16W 100k ohm

R227 119-2231-15 1/16W 22k ohm

R228 119-1531-15 1/16W 15k ohm

R229 119-2231-15 1/16W 22k ohm

R230 119-1031-15 1/16W 10k ohm

R231 119-5611-15 1/16W 560 ohm

R232 119-1031-15 1/16W 10k ohm

R233 119-2231-15 1/16W 22k ohm

R234 119-2201-15 1/16W 22 ohm

R235 119-1031-15 1/16W 10k ohm

R236 119-1031-15 1/16W 10k ohm

R237 119-1031-15 1/16W 10k ohm

R238 119-1031-15 1/16W 10k ohm

R239 111-6811-81 1/2WS 680 ohm

R240 119-4721-15 1/16W 4.7k ohm

R241 111-6811-81 1/2WS 680 ohm

R242 119-4711-15 1/16W 470 ohm

R243 119-1041-15 1/16W 100k ohm

R244 032-0104-53 1/4W 1k ohm

R245 032-0104-64 1/4W 68 ohm

R246 119-1021-15 1/16W 1k ohm

R247 119-4731-15 1/16W 47k ohm

R248 119-4731-15 1/16W 47k ohm

R249 119-2231-15 1/16W 22k ohm

R250 119-4731-15 1/16W 47k ohm

R251 119-4731-15 1/16W 47k ohm

R252 119-4731-15 1/16W 47k ohm

R253 119-4731-15 1/16W 47k ohm

R254 119-3321-15 1/16W 3.3k ohm

R255 119-2231-15 1/16W 22k ohm

R256 119-2231-15 1/16W 22k ohm

R257 119-4731-15 1/16W 47k ohm

R258 119-2231-15 1/16W 22k ohm

R259 119-1011-15 1/16W 100 ohm

R260 119-4731-15 1/16W 47k ohm

R261 032-0104-50 1/4W 560 ohm

R262 032-0104-50 1/4W 560 ohm

R263 119-5611-15 1/16W 560 ohm

R264 119-1031-15 1/16W 10k ohm

R265 119-2721-15 1/16W 2.7k ohm

R266 119-2231-15 1/16W 22k ohm

R267 119-2231-15 1/16W 22k ohm

R268 119-2231-15 1/16W 22k ohm

SUP1 060-0122-10 DSP-201M-S00B

T101 009-0659-01 0.35mH

X2 061-1066-00 7.2MHz

- 10 -VRX630

Page 11

Digital PWB section(B2)

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

C501 168-1022-55 1000pF

C502 042-0595-62 16V10uF

C503 166-2401-50 24pF CH

C504 166-2701-50 27pF CH

C505 168-1022-55 1000pF

C507 168-1032-55 0.01uF

C508 042-0595-62 16V10uF

C509 168-1022-55 1000pF

C510 043-0296-50 0.1uF

C511 168-1032-55 0.01uF

C512 168-4732-78 16V 0.047uF

C513 168-1022-55 1000pF

C514 178-2242-78 0.22uF

C515 168-1045-56 0.1uF

C516 168-1032-55 0.01uF

C517 042-0595-65 16V47uF

C518 042-0559-00 5.5V0.1uF

C519 168-1032-55 0.01uF

C521 042-0595-65 16V47uF

C522 168-1022-55 1000pF

C523 168-1022-55 1000pF

C524 168-1022-55 1000pF

C525 168-1022-55 1000pF

C526 166-1011-50 100pF CH

C527 166-1011-50 100pF CH

C528 166-1011-50 100pF CH

C529 166-1011-50 100pF CH

C609 178-1055-79 1uF

C610 042-0416-57 10V47uF

C611 168-1045-56 0.1uF

C612 168-1045-56 0.1uF

C613 166-1007-50 10pF CH

C614 042-0416-57 10V47uF

C615 168-1032-55 0.01uF

C616 166-1007-50 10pF CH

C617 168-1045-56 0.1uF

C618 168-1045-56 0.1uF

C619 168-1045-56 0.1uF

C620 168-1045-56 0.1uF

C621 178-1055-79 1uF

C622 168-1045-56 0.1uF

C623 166-4701-50 47pF CH

C624 166-4701-50 47pF CH

C625 042-0595-66 25V4.7uF

C626 168-1045-56 0.1uF

C627 178-1055-79 1uF

C628 168-1032-55 0.01uF

C629 168-1022-55 1000pF

C630 168-1022-55 1000pF

C631 178-1055-79 1uF

C632 178-1055-79 1uF

C637 168-3312-55 330pF

CCT502 050-0122-58 1/16W 470 ohmx4 J

CCT601 050-0122-64 1/16W 330 ohmx4 J

CCT602 050-0122-64 1/16W 330 ohmx4 J

CCT603 050-0122-51 1/16W 47k ohmx4 J

CCT604 050-0122-51 1/16W 47k ohmx4 J

CCT605 050-0122-64 1/16W 330 ohmx4 J

CCT606 050-0122-64 1/16W 330 ohmx4 J

CCT607 050-0122-50 1/16W 10k ohmx4 J

CCT608 050-0122-64 1/16W 330 ohmx4 J

CCT609 050-0122-64 1/16W 330 ohmx4 J

CCT610 050-0122-64 1/16W 330 ohmx4 J

D501 001-0516-90 MA111

D504 001-0516-90 MA111

D505 001-0516-90 MA111

D506 001-2403-90 M1F60

D508 001-2403-90 M1F60

D509 001-0516-90 MA111

D511 001-0584-23 MA8075

D513 001-0529-57 MA8120-H

D605 001-0367-91 1SS226

D606 001-0367-91 1SS226

D607 001-0516-90 MA111

IC501 051-1822-08 S-80732AN-DW-X

IC502 052-6043-40 M30624MGA-173GP

IC503 051-0869-58 NJM2103M

IC504 051-1014-08 TA7291F

IC601 051-1478-08 TC74HC4053AF

IC602 052-6044-21 M27C160-100M6

IC603 051-7100-08 TC4W66F-TE12L

IC607 051-1549-08 TC7W32F

IC608 051-5306-90 MM1117XF

IC609 051-6412-00 MB90092PF-G-BND

IC610 051-5306-90 MM1117XF

IC611 051-7229-08 TC7W74FU

IC612 051-1855-08 TC7W14F

IC613 051-0616-38 MC14538BF

J501 074-1205-88 38P

L501 010-2199-62 1uH

L601 010-2279-50 4.7uH

L602 010-2279-50 4.7uH

L603 010-2329-50 5.6uH

P1 076-0621-14 PLUG(14P)

P101 076-0621-19 PLUG(19P)

P103 076-0621-17 PLUG(17P)

P601 076-0313-02 2P

Q501 192-2712-00 2SC2712

Q502 192-2712-00 2SC2712

Q503 125-2004-92 RN1402

Q504 125-0021-97 DTA113ZU

Q505 125-0021-97 DTA113ZU

Q506 125-2004-93 RN1403

Q507 192-2712-00 2SC2712

Q508 190-1162-00 2SA1162

Q511 192-2873-00 2SC2873

Q517 125-0002-92 RN2402

Q518 125-2004-91 RN1401

Q601 125-2004-93 RN1403

R501 119-1031-15 1/16W 10k ohm

R502 119-1231-15 1/16W 12k ohm

R503 119-4721-15 1/16W 4.7k ohm

R504 119-4721-15 1/16W 4.7k ohm

R505 119-4741-15 1/16W 470k ohm

R506 119-4741-15 1/16W 470k ohm

R507 119-1021-15 1/16W 1k ohm

R508 119-1021-15 1/16W 1k ohm

R509 119-1011-15 1/16W 100 ohm

R510 119-5621-15 1/16W 5.6k ohm

R511 119-1021-15 1/16W 1k ohm

R512 119-4721-15 1/16W 4.7k ohm

R513 119-4731-15 1/16W 47k ohm

R514 119-1021-15 1/16W 1k ohm

R515 119-1021-15 1/16W 1k ohm

R516 119-1031-15 1/16W 10k ohm

R517 119-4721-15 1/16W 4.7k ohm

R518 119-4721-15 1/16W 4.7k ohm

R519 119-1021-15 1/16W 1k ohm

R520 119-4731-15 1/16W 47k ohm

R521 119-1011-15 1/16W 100 ohm

R522 119-4731-15 1/16W 47k ohm

R523 119-4731-15 1/16W 47k ohm

R524 119-1541-15 1/16W 150k ohm

R526 119-1241-15 1/16W 120k ohm

R527 119-1831-15 1/16W 18k ohm

R528 119-8221-15 1/16W 8.2k ohm

R529 119-4321-15 1/16W 4.3k ohm

R530 119-1031-15 1/16W 10k ohm

R531 119-4711-15 1/16W 470 ohm

R532 119-4711-15 1/16W 470 ohm

R533 119-4721-15 1/16W 4.7k ohm

R535 119-2231-15 1/16W 22k ohm

R536 119-1021-15 1/16W 1k ohm

R537 119-2231-15 1/16W 22k ohm

R538 119-0000-05 1/16W 0 ohm JW

R540 119-4731-15 1/16W 47k ohm

R541 119-3311-15 1/16W 330 ohm

R542 119-1001-15 1/16W 10 ohm

R546 119-4711-15 1/16W 470 ohm

R547 119-2231-15 1/16W 22k ohm

R548 119-2231-15 1/16W 22k ohm

R549 119-1041-15 1/16W 100k ohm

R551 119-4731-15 1/16W 47k ohm

R553 119-4731-15 1/16W 47k ohm

R565 119-0000-05 1/16W 0 ohm JW

R568 119-1011-15 1/16W 100 ohm

R605 119-1531-15 1/16W 15k ohm

R606 119-1531-15 1/16W 15k ohm

R607 119-1531-15 1/16W 15k ohm

R608 119-5631-15 1/16W 56k ohm

R609 119-5631-15 1/16W 56k ohm

R610 119-5631-15 1/16W 56k ohm

R611 119-1011-15 1/16W 100 ohm

R612 119-1011-15 1/16W 100 ohm

R613 119-1011-15 1/16W 100 ohm

R614 119-4711-15 1/16W 470 ohm

R615 119-1511-15 1/16W 150 ohm

R616 119-3921-15 1/16W 3.9k ohm

R617 119-2211-15 1/16W 220 ohm

R618 119-0000-05 1/16W 0 ohm JW

R619 119-1031-15 1/16W 10k ohm

R620 119-5611-15 1/16W 560 ohm

R621 119-4731-15 1/16W 47k ohm

R622 119-4731-15 1/16W 47k ohm

R623 119-4731-15 1/16W 47k ohm

R624 111-7501-91 1/4W 75 ohm

R625 119-3311-15 1/16W 330 ohm

R626 119-1041-15 1/16W 100k ohm

R627 119-4731-15 1/16W 47k ohm

R628 119-1011-15 1/16W 100 ohm

R629 119-2211-15 1/16W 220 ohm

R630 119-1021-15 1/16W 1k ohm

R631 119-2221-15 1/16W 2.2k ohm

R632 111-7501-91 1/4W 75 ohm

R633 119-2021-15 1/16W 2k ohm

R634 119-2021-15 1/16W 2k ohm

R635 119-2021-15 1/16W 2k ohm

R636 119-0000-05 1/16W 0 ohm JW

R637 119-4741-15 1/16W 470k ohm

R638 119-4741-15 1/16W 470k ohm

R639 119-4741-15 1/16W 470k ohm

R640 119-6821-15 1/16W 6.8k ohm

TC601 004-1583-52 20pF RED

X501 060-1505-50 10MHz

X502 061-1056-00 32.768kHz

X601 061-1086-50 14.31818MHz

X602 061-3042-00 17.734475MHz

LCD PWB section(B3)

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

C701 163-1063-55 35V10uF

C702 168-1045-56 0.1uF

C703 166-1011-50 100pF CH

C704 176-2221-50 2200pF CH

C705 163-4753-55 35V4.7uF

C706 166-1021-50 1000pF CH

C707 166-1011-50 100pF CH

C708 168-1022-55 1000pF

C709 163-1073-35 16V100uF

C710 042-0528-50 35V15uF

C711 163-3373-15 6.3V330uF

C712 042-0528-50 35V15uF

- 11 -

VRX630

Page 12

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

C713 163-1073-35 16V100uF

C714 042-0528-50 35V15uF

C715 168-1045-56 0.1uF

C716 163-1073-15 6.3V100uF

C717 163-3363-45 25V33uF

C718 168-1045-56 0.1uF

C719 042-0595-62 16V10uF

C720 168-1045-56 0.1uF

C721 168-1045-56 0.1uF

C722 042-0595-62 16V10uF

C723 168-1045-56 0.1uF

C724 178-1055-79 1uF

C725 168-3332-78 16V 0.033uF

C726 168-1022-55 1000pF

C727 168-1045-56 0.1uF

C728 042-0595-62 16V10uF

C729 042-0630-50 16V100uF

C730 168-1032-55 0.01uF

C731 176-1521-50 1500pF CH

C732 178-1055-79 1uF

C733 042-0595-81 50V3.3uF

C734 042-0452-00 6.3V330uF

C735 178-2242-78 0.22uF

C736 168-2232-55 0.022uF

C738 042-0595-62 16V10uF

C740 166-5601-50 56pF CH

C741 168-2222-55 2200pF

C742 168-1045-56 0.1uF

C743 168-1032-55 0.01uF

C744 168-1032-55 0.01uF

C745 178-4742-78 0.47uF

C746 178-4742-78 0.47uF

C747 178-4742-78 0.47uF

C748 168-1032-55 0.01uF

C749 042-0595-79 50V1uF

C750 166-1201-50 12pF CH

C751 168-8212-55 820pF

C752 166-2201-50 22pF CH

C753 043-0499-52 0.082uF

C754 168-6812-55 680pF

C755 042-0397-50 16V1uF TAN

C756 176-5601-52 56pF RH

C757 168-1032-55 0.01uF

C758 168-1032-55 0.01uF

C759 168-4735-56 0.047uF

C760 168-1032-55 0.01uF

C761 168-1032-55 0.01uF

C762 168-1032-55 0.01uF

C763 178-1055-79 1uF

C764 166-8201-50 82pF CH

C765 168-1032-55 0.01uF

C766 178-1055-79 1uF

C767 168-1032-55 0.01uF

C768 168-1032-55 0.01uF

C769 178-1055-79 1uF

C770 178-1055-79 1uF

C771 178-1055-79 1uF

C772 163-1073-35 16V100uF

C774 178-1055-79 1uF

C775 042-0595-77 50V0.47uF

C776 168-1032-55 0.01uF

C777 166-8097-50 8pF CH

C778 166-8097-50 8pF CH

C779 168-1045-56 0.1uF

C780 178-1055-79 1uF

C781 042-0595-81 50V3.3uF

C782 168-1032-55 0.01uF

C783 168-2232-55 0.022uF

C784 043-0499-52 0.082uF

C785 178-1055-79 1uF

C786 168-1045-56 0.1uF

C787 168-1045-56 0.1uF

C788 168-1045-56 0.1uF

C789 168-1045-56 0.1uF

C901 178-1055-79 1uF

D701 001-2606-90 M1FS4

D702 001-0516-90 MA111

D703 001-0516-90 MA111

D704 001-0516-90 MA111

D706 001-2606-90 M1FS4

D707 001-0529-46 MA8091-L

D708 001-0516-90 MA111

D709 001-0506-90 DAN202K

D710 001-0506-90 DAN202K

D711 001-0516-90 MA111

D712 001-0516-90 MA111

D713 001-0516-90 MA111

D714 001-0516-90 MA111

D715 001-0516-90 MA111

D716 001-0516-90 MA111

D717 001-0516-90 MA111

D719 001-0516-90 MA111

D726 001-0516-90 MA111

D901 001-7064-90 CL-170SR

D902 001-7064-90 CL-170SR

F701 060-8023-52 0.75A

IC701 051-7214-38 MC74HC595AF

IC702 051-3903-90 NJM2368M

IC703 051-7202-08 TC7S32F

IC704 051-1292-90 NJM4565M-D

IC705 051-0599-91 NJM2903M

IC706 051-3601-91 TL494CNS

IC707 051-5313-10 IR3Y29BM

IC708 051-1250-08 TC4S66F

IC709 051-1250-08 TC4S66F

IC710 051-7232-08 74VHC4066M

IC711 051-1250-08 TC4S66F

IR901 060-4005-02 GP1U261X

J701 074-1189-85 35P

J703 074-1136-00 15P

J704 074-1199-74 24P

J901 074-1242-80 30P

L701 010-3057-90 100uH

L702 010-2199-86 100uH J

L703 010-3057-90 100uH

L704 010-2199-86 100uH J

L705 010-2199-80 33uH J

L706 010-3014-62 100uH

L707 010-3014-62 100uH

L708 010-2199-83 56uH J

L709 010-4013-00 23.9uH

L710 010-2199-80 33uH J

LCD2 379-1162-41 DISPLAY

P701 076-0529-02 2P

P702 076-0624-80 30P

Q701 190-1213-00 2SA1213

Q702 125-2004-92 RN1402

Q703 125-2036-90 FB1J3P

Q704 192-2873-00 2SC2873

Q705 190-1738-00 2SA1738

Q706 125-0002-93 RN2403

Q707 125-2004-92 RN1402

Q708 125-2004-92 RN1402

Q709 125-2004-92 RN1402

Q710 125-2004-93 RN1403

Q711 125-0002-92 RN2402

Q712 192-3326-00 2SC3326

Q713 197-0528-00 2SJ528(S)-TL

Q714 192-2712-00 2SC2712

Q715 125-2004-92 RN1402

Q716 125-2004-92 RN1402

Q717 192-2873-00 2SC2873

Q718 192-2873-00 2SC2873

Q719 190-1738-00 2SA1738

Q720 125-2004-92 RN1402

Q721 125-2004-93 RN1403

Q722 125-2004-93 RN1403

Q723 125-0002-92 RN2402

Q726 192-2712-00 2SC2712

R700 119-1001-15 1/16W 10 ohm

R701 116-1021-15 1/8W 1k ohm

R702 119-2021-15 1/16W 2k ohm

R703 119-1001-15 1/16W 10 ohm

R704 119-6841-15 1/16W 680k ohm

R705 119-3931-15 1/16W 39k ohm

R706 119-6841-15 1/16W 680k ohm

R707 119-2231-15 1/16W 22k ohm

R708 119-1841-15 1/16W 180k ohm

R709 119-3311-15 1/16W 330 ohm

R710 119-1031-15 1/16W 10k ohm

R711 119-2231-15 1/16W 22k ohm

R712 119-2211-15 1/16W 220 ohm

R713 119-4731-15 1/16W 47k ohm

R714 119-4711-15 1/16W 470 ohm

R715 119-1031-15 1/16W 10k ohm

R716 119-1031-15 1/16W 10k ohm

R717 119-4701-15 1/16W 47 ohm

R718 119-1031-15 1/16W 10k ohm

R719 119-1531-15 1/16W 15k ohm

R720 119-1031-15 1/16W 10k ohm

R721 119-2221-15 1/16W 2.2k ohm

R722 119-4721-15 1/16W 4.7k ohm

R723 119-1531-15 1/16W 15k ohm

R724 119-2231-15 1/16W 22k ohm

R725 119-2231-15 1/16W 22k ohm

R726 119-1041-15 1/16W 100k ohm

R727 119-4731-15 1/16W 47k ohm

R728 119-2231-15 1/16W 22k ohm

R729 119-2231-15 1/16W 22k ohm

R730 119-4731-15 1/16W 47k ohm

R731 119-1021-15 1/16W 1k ohm

R732 119-3301-15 1/16W 33 ohm

R733 119-3321-15 1/16W 3.3k ohm

R734 119-1021-15 1/16W 1k ohm

R735 119-1031-15 1/16W 10k ohm

R736 119-4721-15 1/16W 4.7k ohm

R737 119-2221-15 1/16W 2.2k ohm

R738 119-5621-15 1/16W 5.6k ohm

R739 119-5621-15 1/16W 5.6k ohm

R740 119-1021-15 1/16W 1k ohm

R741 119-1021-15 1/16W 1k ohm

R742 119-3321-15 1/16W 3.3k ohm

R743 119-1831-15 1/16W 18k ohm

R744 119-6821-15 1/16W 6.8k ohm

R745 119-3341-15 1/16W 330k ohm

R746 119-5621-15 1/16W 5.6k ohm

R747 119-5621-15 1/16W 5.6k ohm

R748 119-4721-15 1/16W 4.7k ohm

R749 119-3021-15 1/16W 3k ohm

R750 119-2021-15 1/16W 2k ohm

R751 119-1521-15 1/16W 1.5k ohm

R752 119-2221-15 1/16W 2.2k ohm

R753 119-1041-15 1/16W 100k ohm

R754 119-5641-15 1/16W 560k ohm

R755 119-4791-15 1/16W 4.7 ohm J

R756 119-2431-15 1/16W 24k ohm

R757 119-4711-15 1/16W 470 ohm

R758 119-4711-15 1/16W 470 ohm

R759 119-4711-15 1/16W 470 ohm

R760 119-4711-15 1/16W 470 ohm

R761 119-3341-15 1/16W 330k ohm

R762 119-2231-15 1/16W 22k ohm

R763 119-3331-15 1/16W 33k ohm

R764 119-3931-15 1/16W 39k ohm

R765 119-2731-15 1/16W 27k ohm

R766 032-0140-80 1/16W 18k ohm F

R767 119-5631-15 1/16W 56k ohm

R768 119-3631-15 1/16W 36k ohm

R769 119-5611-15 1/16W 560 ohm

R770 119-1021-15 1/16W 1k ohm

R771 119-3351-15 1/16W 3.3M ohm

R772 119-1011-15 1/16W 100 ohm

- 12 -VRX630

Page 13

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

R773 119-1011-15 1/16W 100 ohm

R774 119-1011-15 1/16W 100 ohm

R775 116-1021-15 1/8W 1k ohm

R776 119-3931-15 1/16W 39k ohm

R777 119-2731-15 1/16W 27k ohm

R778 116-1021-15 1/8W 1k ohm

R779 119-3931-15 1/16W 39k ohm

R780 119-2731-15 1/16W 27k ohm

R781 119-6821-15 1/16W 6.8k ohm

R782 119-4731-15 1/16W 47k ohm

R783 119-1831-15 1/16W 18k ohm

R784 119-1051-15 1/16W 1M ohm

R785 032-0140-89 1/10W 47k ohm F

R786 119-0000-05 1/16W 0 ohm JW

R787 032-0140-99 1/10W 39k ohm F

R788 119-5621-15 1/16W 5.6k ohm

R789 119-1521-15 1/16W 1.5k ohm

R790 032-0140-89 1/10W 47k ohm F

R791 119-3021-15 1/16W 3k ohm

R792 032-0140-99 1/10W 39k ohm F

R793 119-1011-15 1/16W 100 ohm

R794 119-1021-15 1/16W 1k ohm

R795 119-2221-15 1/16W 2.2k ohm

R796 119-3311-15 1/16W 330 ohm

R797 119-1011-15 1/16W 100 ohm

R798 119-6811-15 1/16W 680 ohm

R799 119-1011-15 1/16W 100 ohm

R800 119-5621-15 1/16W 5.6k ohm

R801 119-8221-15 1/16W 8.2k ohm

R802 119-1521-15 1/16W 1.5k ohm

R803 119-4741-15 1/16W 470k ohm

R804 119-4741-15 1/16W 470k ohm

R805 119-4741-15 1/16W 470k ohm

R806 119-4741-15 1/16W 470k ohm

R807 119-4741-15 1/16W 470k ohm

R808 119-6831-15 1/16W 68k ohm

R809 119-2221-15 1/16W 2.2k ohm

R810 119-1031-15 1/16W 10k ohm

R811 119-2211-15 1/16W 220 ohm

R812 119-1021-15 1/16W 1k ohm

R813 032-0092-43 1/10W 3.0k ohm F

R814 032-0092-43 1/10W 3.0k ohm F

R815 119-1011-15 1/16W 100 ohm

R816 119-1011-15 1/16W 100 ohm

R817 119-0000-05 1/16W 0 ohm JW

R818 119-1011-15 1/16W 100 ohm

R901 119-2711-15 1/16W 270 ohm

R902 119-2711-15 1/16W 270 ohm

R903 119-2711-15 1/16W 270 ohm

R904 119-2711-15 1/16W 270 ohm

S1 002-0313-91 THERMISTOR

S701 013-6100-00 SKHLLB

S702 013-7205-50 SPVE1-3

S902 013-6511-50 LS9J2M-1SR

S903 013-6511-50 LS9J2M-1SR

S904 013-6511-50 LS9J2M-1SR

S905 013-6511-50 LS9J2M-1SR

S906 013-9907-00 RKJXM1012

T701 007-1153-90 873AC-1071

T702 007-1152-00 BLC216HP

TH601 002-0216-95 DTN-T203K103KS

VR701 012-6009-52 1k ohm

VR702 012-6009-56 10k ohm

VR703 012-6009-58 33k ohm

VR704 012-6009-58 33k ohm

VR705 012-6009-58 33k ohm

VR706 012-6009-58 33k ohm

VR707 012-6009-58 33k ohm

VR708 012-6009-52 1k ohm

X701 061-1078-00 3.5795MHz

X702 061-3036-00 4.433619MHz

DCP PWB section(B4)

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

C901 178-1055-79 1uF

C902 178-1055-79 1uF

D901 001-7064-90 CL-170SR

D902 001-7064-90 CL-170SR

D903 001-7064-90 CL-170SR

D904 001-0525-90 IMN10

D905 001-0525-90 IMN10

D907 001-7046-00 NSPW310BS

D909 001-2601-90 MA728-TX

D910 001-2601-90 MA728-TX

D911 001-2601-90 MA728-TX

D912 001-0529-36 MA8062-H

D913 001-0529-36 MA8062-H

D914 001-0529-36 MA8062-H

D915 001-0529-36 MA8062-H

D916 001-0529-36 MA8062-H

D917 001-0529-36 MA8062-H

D918 001-0529-36 MA8062-H

D919 001-0529-36 MA8062-H

IC901 051-6001-01 uPD16431AGC-7ET

J901 076-0531-00 15P

L901 010-2323-71 33uH

Q901 125-0002-92 RN2402

Q902 125-2017-97 RN1427

Q903 125-0002-92 RN2402

Q904 125-2017-97 RN1427

R901 116-6811-15 1/8W 680 ohm

R903 116-6811-15 1/8W 680 ohm

R905 116-6811-15 1/8W 680 ohm

R907 116-6811-15 1/8W 680 ohm

R909 116-6811-15 1/8W 680 ohm

R911 116-6811-15 1/8W 680 ohm

R913 116-6811-15 1/8W 680 ohm

R914 119-1021-15 1/16W 1k ohm

R915 119-1021-15 1/16W 1k ohm

R916 119-4711-15 1/16W 470 ohm

R917 119-1021-15 1/16W 1k ohm

R918 119-1041-15 1/16W 100k ohm

R919 119-1021-15 1/16W 1k ohm

R920 119-1021-15 1/16W 1k ohm

R921 119-1021-15 1/16W 1k ohm

R922 119-1021-15 1/16W 1k ohm

R923 119-1031-15 1/16W 10k ohm

R924 119-1041-15 1/16W 100k ohm

R925 119-1511-15 1/16W 150 ohm

R926 119-1511-15 1/16W 150 ohm

R928 119-2221-15 1/16W 2.2k ohm

R929 119-2221-15 1/16W 2.2k ohm

S901 013-6511-50 LS9J2M-1SR

S902 013-6511-50 LS9J2M-1SR

S903 013-6511-50 LS9J2M-1SR

S904 013-6511-50 LS9J2M-1SR

S905 013-6511-50 LS9J2M-1SR

S906 013-6511-50 LS9J2M-1SR

S907 013-6312-50 SKRP-ABE-010

S908 013-6511-50 LS9J2M-1SR

S910 013-6511-50 LS9J2M-1SR

S911 013-6511-50 LS9J2M-1SR

S912 013-6511-50 LS9J2M-1SR

S913 013-6511-50 LS9J2M-1SR

S914 013-6511-50 LS9J2M-1SR

S915 013-6511-50 LS9J2M-1SR

S916 013-6511-50 LS9J2M-1SR

S917 013-6312-50 SKRP-ABE-010

S918 013-6511-50 LS9J2M-1SR

S919 013-6511-50 LS9J2M-1SR

S920 013-6511-50 LS9J2M-1SR

S921 013-6511-50 LS9J2M-1SR

S922 013-6511-50 LS9J2M-1SR

- 13 -

VRX630

Page 14

CIRCUIT DIAGRAM

DCP PWB(B4) section

VRX630

- 14 -

Page 15

LCD PWB(B3) section

- 15 -

VRX630

Page 16

PRINTED WIRING BOARD

LCD PWB(B3) / DCP PWB(B4) section

COMPONENT SIDE

48

37

1

12

13

36

25

24

to PAGE 17

J901 of LCD PWB-B

to PAGE 17

P701 of LCD PWB-A

Caution:

COMPONENT SIDE: Parts on the component side seen

from the component side are indicated.

SOLDER SIDE: Parts on the solder side seen

from the solder side are indicated.

- 16 -

to PAGE 17

J901 of DCP PWB

V R X63 0

Page 17

LCD PWB(B3) / DCP PWB(B4) section

to PAGE 24

J501 of DIGITAL PWB

SOLDER SIDE

to PAGE 16

P702 of LCD PWB-A

to PAGE 16

6.5" INDICATOR

to PAGE 16

J703 of LCD PWB-A

Caution:

COMPONENT SIDE: Parts on the component side seen

from the component side are indicated.

SOLDER SIDE: Parts on the solder side seen

from the solder side are indicated.

- 17 -

VRX630

Page 18

CIRCUIT DIAGRAM

Main PWB(B1) section 1/2

- 18 -

VRX630

Page 19

Main PWB(B1) section 2/2

C127 3300p

A GND

B FRONT LEFT SP(+)

C FRONT LEFT SP(-)

D FRONT RIGHT SP(-)

E FRONT RIGHT SP(+)

F REAR LEFT SP(+)

G REAR LEFT SP(-)

H REAR RIGHT SP(+)

I BACK UP

J ACC

K ILLUMINATION

L PARKING BRAKE

M PHONE INT.

N REMOTE TURN-ON

O NC

P REAR RIGHT SP(-)

1 SEL3

2 SEL2

3 REMOTE CONTROL

4 VIDEO IN

5 AUDIO R-IN

6 AUDIO L-IN

7 GND

8 S-GND

1 GND

2 BACK UP

3 BUS L-ch(+)

4 NC

5 NC

6 BUS(+)

7 BUS R-ch(+)

8 BUS R-ch(-)

9 SYS ACC

10 BUS(-)

11 BUS L-ch(-)

12 ILLUMINATION

13 NC

- 19 -

VRX630

Page 20

PRINTED WIRING BOARD

Main PWB(B1) section

1 GND

2 BACK

3 BUS L-ch(+)

4 NC

5 NC

6 BUS(+)

7 BUS R-ch(+)

8 BUS R-ch(-)

9 SYS ACC

10 BUS(-)

11 BUS L-ch(-)

12 ILLUMINATION

13 NC

Ce-NET

COMPONENT SIDE

A GND

B FRONT LEFT SP(+)

C FRONT LEFT SP(-)

D FRONT RIGHT SP(-)

E FRONT RIGHT SP(+)

F REAR LEFT SP(+)

G REAR LEFT SP(-)

H REAR RIGHT SP(+)

I BACK UP

J ACC

K ILLUMINATION

L PARKING BRAKE

M PHONE INT.

N REMOTE TURN-ON

O NC

P REAR RIGHT SP(-)

VISUAL/CCD

P

O

N

M

L

K

J

I

H

G

F

E

D

C

B

A

1 SEL3

2 SEL2

3 REMOTE CONTROL

4 VIDEO IN

5 AUDIO R-IN

6 AUDIO L-IN

7 GND

8 S-GND

PUR/BLK

GRN/BLK

BLU/WHT

PUR

GRN

BRN

GRY

ORG

GRY/BLK

ORG/WHT

WHT/BLK

RED

WHT

YEL

BLK

P

H

G

N

F

M

E

L

D

K

C

J

B

I

A

to PAGE 24

P103 of DIGITAL PWB

- 20 -

to PAGE 24

P1 of DIGITAL PWB

to PAGE 24

P101 of DIGITAL PWB

VRX630

Caution:

COMPONENT SIDE: Parts on the component side seen

from the component side are indicated.

SOLDER SIDE: Parts on the solder side seen

from the solder side are indicated.

Page 21

Main PWB(B1) section

SOLDER SIDE

Caution:

COMPONENT SIDE: Parts on the component side seen

from the component side are indicated.

SOLDER SIDE: Parts on the solder side seen

from the solder side are indicated.

- 21 -

VRX630

Page 22

CIRCUIT DIAGRAM

Digital PWB(B2) section 1/2

- 22 -

VRX630

Page 23

Digital PWB(B2) section 2/2

- 23 -

VRX630

Page 24

PRINTED WIRING BOARD

Digital PWB(B2) section

COMPONENT SIDE

SOLDER SIDE

to PAGE 20

P1 of MAIN PWB

VIDEO INPUT

to PAGE 20

P101 of MAIN PWB

to PAGE 17

FLEX-PWB / J701 of LCD PWB-A

to PAGE 20

P103 of MAIN PWB

GND

VIDEO

- 24 -

Caution:

COMPONENT SIDE: Parts on the component side seen

from the component side are indicated.

SOLDER SIDE: Parts on the solder side seen

from the solder side are indicated.

VRX630

Loading...

Loading...