Page 1

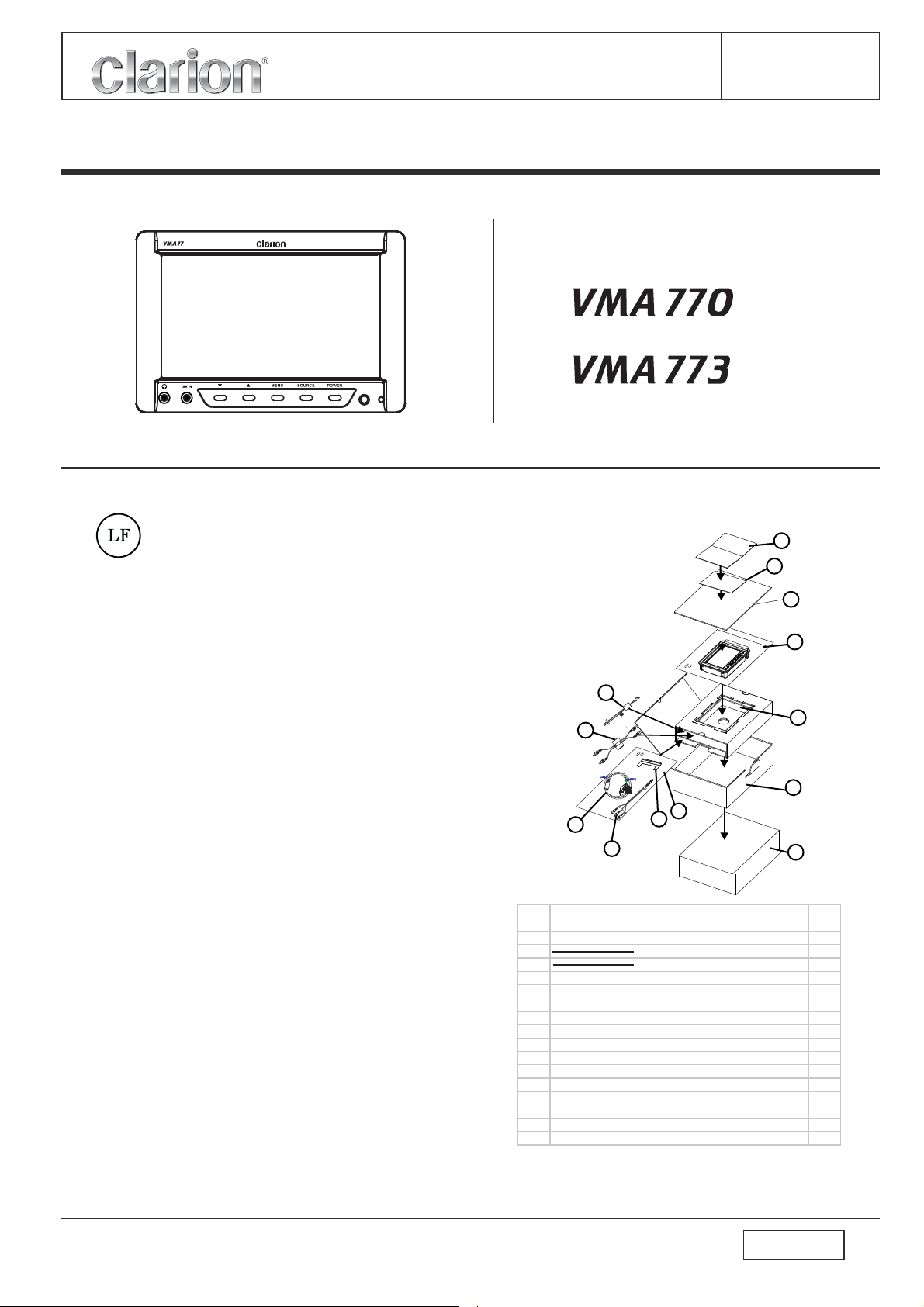

REF PART No. DESCRIPTION Q'TY

1 MA2A-704002-1R User’s Manual (VMA770) 1

1 MA2A-704003-1R User’s Manual (VMA773) 1

2 Warranty card USA (VMA770) 1

2 Warranty card EUROPE(VMA773) 1

3 PA2B612002-1R E PEspacer 1

4 PA2P701002-1R P Ebag 180*270*0.5 mm 1

5 BX20612002-1R Inner corrugated box 1

6 CL-4216-02-1R P OWERFILTER 1

7 CL-2292-01-1R AUDIO FILTER 1

8 CL-8872-01-1R RCA AV CABLE 1

9 CL-1312-01-1R RCA cable 1

10 PA2B612005-1R METAL IN SERT CARD(VM A773) 1

10 PA2B707005-1R PLATICINSERTCARD(VMA770) 1

11 PA2B707005-1R PEbag 163*342*0.2 mm 1

12 BX20612001-1R Inner white box 1

13 BX20705005-1R Gift box (VMA770) 1

13 BX20705004-1R Gift box (VMA773) 1

Reedition: 2008.01.29

Clarion Co., Ltd.

7-2,Shintoshin, Chuo-ku, Saitama-shi,Saitama 330-0081 Japan

ServiceDept.: 7-2,Shintoshin, Chuo-ku,Saitama-shi,Saitama 330-0081Japan

Tel:+81-48-601-3705 FAX:+81-48-601-3804

Published by Service Dept.

298-6491-00

Printed in Taiwan R.O.C

Jan.2008

Service Manual

0

7” Wide Screen Color LCD Monitor

Model

(ZM-5003B-A)

Model

(ZM-5002E-A)

This product is a lead free model.

Lead free solder is used in PWB stamped LF mark.

Please keep the following conditions when you repair.

1. Use lead free solder.

2. Use a nitrogen solder system.

3. Do not use "General solder" and "lead free

solder" together.

SPECIFICATIONS

Display Unit

Display type: Color TFT Active Matrix

LCD Screen size: 7”

Pixels: 480 RGB (H) x 234 (V)

Screen resolution: 336,960 dots

Video input lever(RCA):

1.0 volts peak to peak

Video format: NTSC, PAL

Power requirement: 12V DC (10.8V-15.6V)

Power consumption: 7 watts,power on - typical0.6amps

(600mA) - typical

Dimensions(mm): 192.7(W)x133.5(H)x32.5(D)(with

Bezel)

Weight: 400g

COMPONENTS

6

TER

DCFIL

GND

+12V

7

04

-

8

10

9

11

1

2

3

4

04

-

5

12

13

NOTES

* The technical dataand the design ofthe equipment may

change for the sake of technical improvement without

prior notice.

-1-

VMA770

VMA773

Page 2

Toengineersinchargeof

Repair or Inspection of our

products:

Before repair orinspection, make sureto

follow the instructionsso that customersand

Engineers in chargeof repair orinspection

can avoid sufferingAny riskorinjury.

1. Use specified parts.

The system uses partswithspecialsafetyfeatures

against Fire and voltage.Useonlypartswithequivalent

characteristics when replacing hem. The use of

unspecified parts shall beregardedasremodelingfor

which we shall notbeliable. The onus of product

liability (PL) shall notbeourresponsibilityincases

where an accident orfailureisasaresultofunspecified

parts being used.

2. Place the partsandwiringbackintheiroriginal

positions after replacement orre-wiring.

For proper circuit construction,useofinsulationtubes,

bonding, gaps to PWB,etc,isinvolved.Thewiring

connection and routing tothePWBarespecially

planned using clamps tokeepawayfromheatedand

high voltage parts. Ensurethattheyareplacedbackin

their original positions afterrepairorinspection.

If extended damage iscausedduetonegligenceduring

repair, the legal responsibilityshallbewiththerepairing

company.

3. Check for safetyafterrepair.

Check that the screws,partsandwiresareputback

securely in their originalpositionafterrepair.Ensurefor

safety reasons there isnopossibilityofsecondary

p oblems around therepairedspots. If extended

r

damage is caused duetonegligenceofrepair,thelegal

responsibility shall be withtherepairingcompany.

4. Caution in removalandmakingwiringconnectiontothe

parts for the automobile.

Disconnect the battery terminalafterturningtheignition

key off. If wrongwiringconnectionsaremadewiththe

battery connected, a shortcircuitand/orfiremayoccur.

If extensive damage iscausedduetonegligenceof

repair, the legal responsibilityshallbewiththerepairing

company.

5. Cautions in soldering

Please do not spreadliquidfluxinsoldering.

Please do not washthesolderingpointaftersoldering.

6. Cautions in solderingforchipcapacitors

Please solder the chipcapacitorsafterpre-heatingfor

replacement because they areveryweaktoheat.

Please do not heatthechipcapacitorswithasoldering

iron

directly.

7. Cautions in handlingforchipparts.

Do not reuse removedchipsevenwhennoabnormality

is observed in theirappearance.Alwaysreplacethem

with new ones. (Thechippartsincluderesistors,

capacitors, diodes, transistors,etc).

Please make an operationtestafterreplacement.

8. Cautions in handlingflexiblePWB

Before working with asolderingiron,makesurethatthe

iron tip temperature isaround270.Takecarenotto

apply the iron tiprepeatedly(morethanthreetimes)to

the same patterns. Also

take care not toapplythetipwithforce.

9. Turn the unitOFFduringdisassemblyandparts

replacement.

Recheck all work beforeyouapplypowertotheunit.

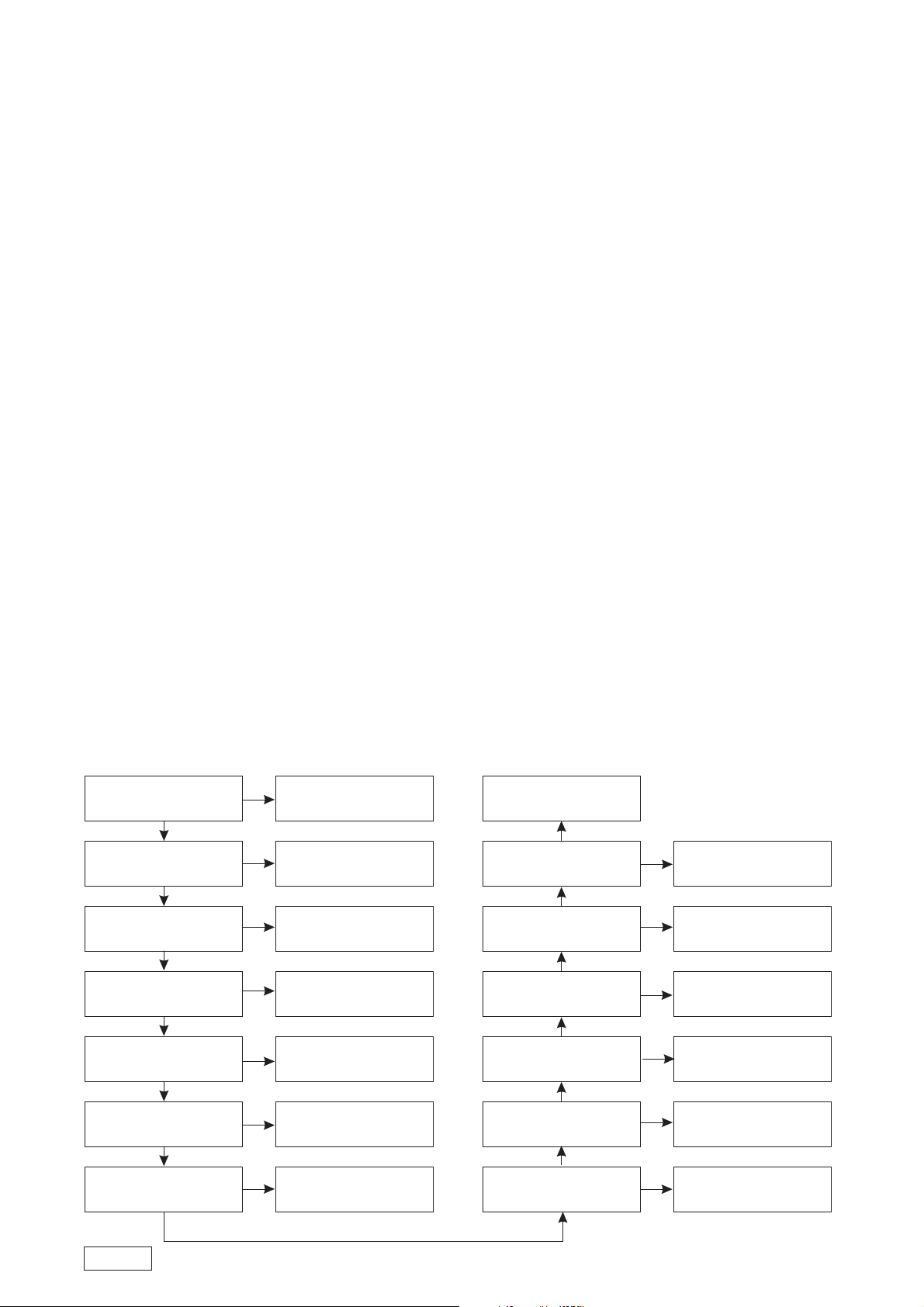

TROUBLESHOOTING

1. The image is unusual & No image

Normal signal is

obtained at each

terminal of J1?

YES YES

Circuit current flows

normally?

YES YES

Av1 video signal is

obtained at L12?

YES YES

Av2 video signal is

obtained at L9?

YES YES

VCC3(3.3V) is obtained

at Pin-2 of U16?

YES YES

AVCC3(3.3V) is

obtained at Pin-2 of

U18?

YES YES

VCC18(1.8V) is

obtained at Pin-2 of

U19?

Check the J1, Input

connection flexible

NO

cables and its

Go to item (3)NoPower

NO

Check the J1, Input

connection flexible

NO NO

cables and its

Check the J3 andJ7

Input connection

NO

flexible cables and their

Go to item (3)NoPower

NO

Go to item (3)NoPower

NO NO

Go to item (3)NoPower

NO

Replace LCD panel

Normal signal is

obtained at each

terminal of J4?

Panel-VCC(5V) is

obtained at L22?

VCC12V is obtained at

L30?

RGB signal for LCDis

obtained at Pin-22 to

Pin-24 of J4?

Normal Vcom signal is

obtained at Tp3?

Check the Y2 at27

Mhz?

Check the J4, Input

connection flexible

NO

cables and its

Go to item (3)NoPower

Go to item (3)NoPower

NO

Check the Q6 toQ8and

its periphery.

NO

Check the L32 andits

periphery.

Check the Y2 andits

periphery.

NO

VMA770

VMA773

YES

- 2-

Page 3

2. No sound

AV1 Audio-L signal is

obtained at L3?

YES YES

AV1 Audio-R signal is

obtained at L4?

YES YES

AV2 Audio-L signal is

obtained at L7?

YES YES

AV2 Audio R signal is

obtained at L8?

Audio L signal is

obtained at C93?

-

YES YES

END

Check the J1, Input

connection flexible

NO

cables and its

Check the J1, Input

connection flexible

NO NO

cables and its

Check the J3 andJ7

Input connection

NO

flexible cables and their

Check the J3 andJ7

Input connection

flexible cables and their

NO

Check the U11 andtheir

periphery.

NO

IR_Aurio-R signal are

YES

obtained at Pin-1 &Pin-

Check the TP2 at3.8

Mhz of IR_CHB_AudioR?

Check the TP1 at3.2

Mhz of IR_CHB_AudioL?

Check the TP2 at2.8

Mhz of IR_CHA_AudioR?

Check the TP1 at2.3

Mhz of IR_CHA_AudioL?

VA5_IR is obtained at

L26?

NO

YES

NO

NO

NO

NO

IR_Audio-R and

Check U13, U14 and

their periphery.

Check U12, U14 and

their periphery.

Check U12, U14 and

their periphery.

Check U12, U14 and

their periphery.

Check U12, U14 and

their periphery.

Go to item (3)NoPower

YES

Audio R signal is

obtained at C89?

YES

VA5 is obtained atL23?

3. No Power

F1(fuse) is broken out?

YES YES

DC12V is obtained at

L1?

YES YES

VCC12 is obtained at

L27

YES YES

YES

Check the U8 andtheir

periphery.

NO

Go to item (3)NoPower

NO

YES

Replace F1.

NO

Check the F1, input

flexible cables and their

NO

periphery.

Check Q1, Q2 andtheir

periphery.

NO NO

Audio_R OUT signal is

obtained at L5?

YES

Audio_L OUT signal is

obtained at L6?

END

VCC12V is obtained at

L25 (For IR_LED)?

VCC12V is obtained at

L30 (For U17 Inverter

control IC)?

NO

NO

NO

Check the U9, U10,J3,

J6 Input connectiog

flexible cables and their

Check the U9, U10,J3,

J6 Input connectiog

flexible cables and their

Check Q20, Q21, Q23

and their periphery.

Check Q10, Q11, Q12

and their periphery.

5VSTB is obtained at

L29?

YES YES

VCC5 is obtained at

L28?

YES YES

VCC3(3.3V) is obtained

at Pin-2 of U16?

YES YES

AVCC3(3.3V) is

obtained at Pin-2 of

U18?

Check U15, Q15, Q16

NO

and their periphery.

Check Q17, Q18, Q19

and their periphery.

NO

Check U16 and their

periphery.

NO NO

Check U18 and their

periphery.

NO

YES

VA5_IR is obtained at

L26?

VA5 is obtained atL23?

PANEL-VCC is

obtained at L22?

VCC18(1.8V) is

obtained at Pin-2 of

U19?

NO

NO

NO

- 3-

Check L26 and their

periphery.

Check L23 and their

periphery.

Check Q3, Q4, Q5and

their periphery.

Check the U19 andtheir

periphery.

VMA770

VMA773

Page 4

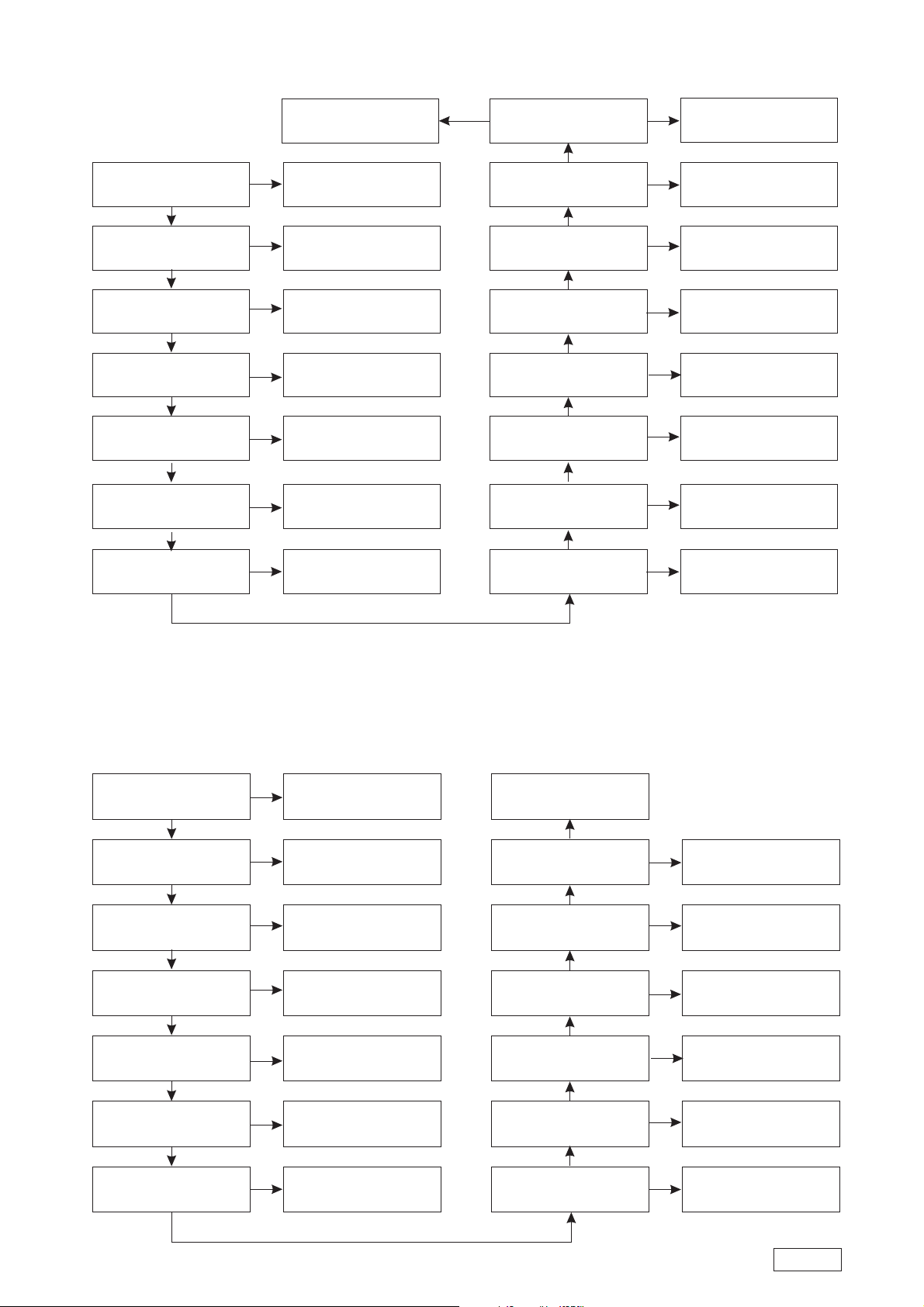

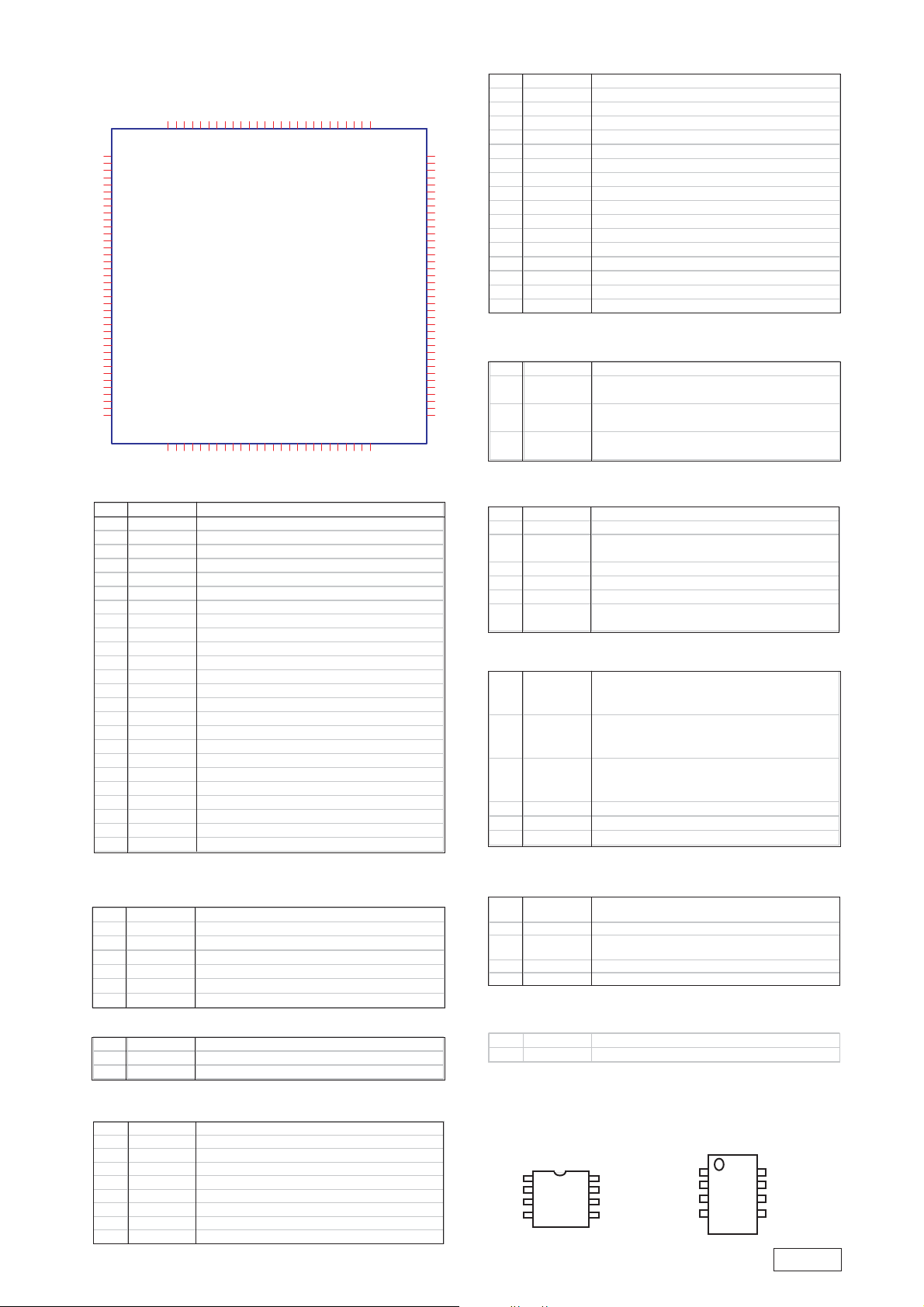

EXPLANATION OF IC

Pin# NAME DESCRIPTION

1 OUT Open collector transistor output

2 VCC IC power supply

3 COMP Error Amplifier feedback output

4 FB error amplifier inverting input

5 SCP short circuit protection input

6 DTC dead-time control input

7 RT A resistance of Oscillator

8 GND IC Ground

Pin# NAME DESCRIPTION

1 IA0 DATA INPUTS

2 IA1 DATA INPUTS

3 IA2 DATA INPUTS

4 GND GROUND

5 YA DATA INPUTS

6 S0 SELECT INPUT

7 S1 SELECT INPUT

8VCCPOWER

Pin# NAME DESCRIPTION

1 Vcc1 Power supply

2 Modu1 FM. Modulation in

3 Fadj1 Frequency adjust

4Vss1GND

5 Modu2 FM. Modulation in

6 Fadj2 Frequency adjust

7Vss2GND

8 Fo2 Frequency out

9 Tc Off timecontrol

10 Tr2 Trigger on

11 Vcc2 Power supply

12 Fo1 Frequency out

13 No

14 Tr1 Trigger on

Pin# NAME DESCRIPTION

1 P4.2 Bit2 of port 4

2 P1.0/T2 Bit0 of port 1& timer 2 clock out

3 P1.1/T2EX Bit1 of port 1& timer 2 control

4 P1.2 Bit2 of port 1

5 P1.3 Bit3 of port1& SPWM channel 0

6 P1.4 Bit4 of port1& SPWM channel 1

7 P1.5 Bit5 of port1& SPWM channel 2

8 P1.6 Bit6 of port1& SPWM channel 3

9 P1.7 Bit7 of port1& SPWM channel 4

10 RST REST

11 P3.0/RXD Bit0 of port3& Receiver data

12 P4.0 Bit0 of port 4

12 P4.3 Bit3 of port 4

13 P4.3/INT2 Bit1 of port3& Transmit data

14 P3.1/INT0 Bit 2 of port 3&low true interrupt 0

15 P3.3/INT1 Bit 3 of port 3&low true interrupt 1

16 P3.4/T0 Bit4 of port 3 & Timer 0

17 P3.5/T1 Bit5 of port 3 & Timer 1

18 P3.5/T1P3.6/WR Bit6 of port 3 & ext. memory write

19 P3.7/RD Bit7 of port 3& ext. memory read

20 XTAL2 Crystal out

21 XTAL1 Crystal in

22 GND Sink Voltage, Ground

24 P2.0/A8 Bit0 of port 2 & bit8 of ext.memory add.

25 P2.1/A9 Bit1 of port 2 & bit9 of ext.memory add.

26 P2.2/A1.0 Bit2 of port 2 & bit10 of ext.memory add.

27 P2.3/A11 Bit3 of port 2 & bit11 of ext.memory add.

28 P2.4/A12 Bit4 of port 2 & bit12 of ext.memory add.

29 A13/P2.5 Bit5 of port 2 & bit13 of ext.memory add.

30 A14/P2.6 Bit6 of port 2 & bit14 of ext.memory add.

31 A15/P2.7 Bit7 of port 2 & bit15 of ext.memory add.

32 PSEN Progr a mstorag eenable

33 ALE add. latch enable

34 P4.1 Bit1 of port 4

35 EA External access

36 AD7/P0.7 Bit7 of port 0 & data/add. bit 7of ext. memory

37 AD6/P0.6 Bit6 of port 0 & data/add. bit 6of ext. memory

38 AD5/P0.5 Bit5 of port 0 & data/add. bit 5of ext. memory

39 AD4/P0.4 Bit4 of port 0 & data/add. bit 4of ext. memory

40 AD3/P0.3 Bit3 of port 0 & data/add. bit 3of ext. memory

41 AD2/P0.2 Bit2 of port 0 & data/add. bit 2of ext. memory

42 AD1/P0.1 Bit1 of port 0 & data/add. bit 1of ext. memory

43 AD0/P0.0 Bit0 of port 0 & data/add. bit 0of ext. memory

44 VDD Driver Voltage

Pin# NAME DESCRIPTION

1 BR Analog Dimming

2 IL Lamp Current Feedback Sense Input

3 BOS Burst Oscillator Timing

4 T/B Test/Burst ModeDimming

5 EN Chip Enable. Do not float this pin.

6 DR Internally Generated MOSFET Gate Driver Supply Voltage (6V)

7 IN Power Supply I nput

8 OUTL Output to Load (tank circuit)

9 PGND Power Ground

10 BSTL Regulated Output Voltage for Bootstrap Capacitor on Phase L

11 BSTR Regulated Output Voltage for Bootstrap Capacitor on Phase R

12 PGND Power Ground

13 OUTR Output to Load (tank circuit)

14 IN Power Supply Input

15 REF Internally Generated Reference Voltage Output (5V)

16 COMP Loop Compensation Capacitor

17 FT Fault Timer

18 OL Open Lamp Detect(Lamp Voltage Feedback.)

19 FB Shorted Lamp Detect (Secondary Current Feedback)

20 AGND Small Signal Ground

(For the MP1010BEF,connect the exposed paddleto

AGND(Pin20))

SM5964

7

P1.5

8

P1.6

9

P1.7

10

RST

11

P3.0 / RXD

12

P4.3 / INT2

13

P3.1 / TX D

14

P3.2 / INT0

15

P3.3 / INT1

16

P3.4 / T0

17

P3.5 / T1

4

6

5

3

P1.2

P1.4

P1.3

T2EX/P1.1

XTAL2

XTAL1

P3.7 / RD

P3.6 / WR

20

21

19

18

42

43

44

41

1

2

VCC

T2/P1.0

AD1/P0.1

AD0/P0.0

INT3/P4.2

GND

P2.2 / A10

P2.0 / A8

P2.1 / A9

P4.0

24

23

25

22

26

27

AD2/P0.2

P2.3 / A11

40

28

AD3/P0.3

P2.4 / A12

AD4 / P0.4

AD5 / P0.5

AD6 / P0.6

AD7 / P0.7

EA

P4.1

ALE

PSEN

A15 / P2.7

A14 / P2.6

A13 / P2.5

MP1010B

BR 1

IL 2

BOS 3

T/B 4

EN 5

DR 6

IN 7

OUTL 8

PGND 9

39

38

37

36

35

34

33

32

31

30

29

BSTL 10

20 AGND

19 FB

18 OL

17 FT

16 COMP

15 REF

14 IN

13 OUTR

12 PGND

11 BSTR

VMA770

VMA773

- 4-

FP5001

1

2

3

4

FP5001

PI5C3309

8-Pin

L, U

8Vcc

7S1

6S0

5YA

IA0 1

IA1 2

IA2 3

GND 4

HS2K219

1

VDD

2

L/I

3

L_ADJ

4

GND

5

R/I

6

R_ADJ

7

GND

TRI

NC

L/D

VDD

TRI

DTC

R/D

8

7

6

5

14

13

12

11

10

9

8

Page 5

38 TCCLK/FPCLK TCON Column Driver Clock Flat Panel Clock O utput

26 TCLRL/GPIO1 Left Right selection (Left:hight,Right low) GPIO1

41 TCSPL/FPHS TCON Column Driver Start Pulse (Left to right scan)

Horizontal sync output for flat panel

37 TCLP Column Driver Load Pulse

35 TCPOLP Co lumnDriverPola rity(Po sitiv e)

36 TCPOLN Column Driver Polarity(Negative)

34 TCINV/TCREV TCONColumn Driver Inversion

TCON Column Dri ver Reverse

44-47

50-53

FPR[0:7] Red Flat Panel O utput bits

*44=CP0+:Charge Pump 0+

*45=CP0-:Charg Pump 0-

55-58

60-63

FPG[0:7] green Flat Panel Output bits

*55=CP1+:Charge Pump 1+

*56=CP0-:Charg Pump 1-

65-68

70-73

FPB[0:7] Blue Flat Panel Output bits

*65=TCSPR:TCONColumn Driver Start Pulse (right to left scan)

*66=TRSPB: RowDriver Starting Pulse (Bottomstart)

29 FPBIAS Power on/off control for panel backlight bias

30 FPPWC Power on/off control for flat panel display

31 FPPWM PWMcontrol for panel backlight

117 AVDD SS-PLL Analog +3.3V

118 AVSS SS-PLL Analog ground

15 AVDD ADCAnalog +3.3V

16 AVDD ADCAnalog +3.3V

17 ROUT DACAnalog Red data output

18 GOUT DACAnalog Green data output

29 BOUT DAC Analog Blue data output

20 VSUB DAC Sub. (Analog ground)

21 AVSS DAC Analog ground

27 VDD18 1.8V Digital core Power

28 VSS18 1.8V Digital core Return

39 CSS33 3.3V Digital I/O Return

43 VDD33 3.3V Digital I/O Power

48 VSS18 1.8V Digital core Return

49 VDD18 1.8V Digital core Power

54 CSS33 3.3V Digital I/O Return

59 VDD33 3.3V Digital I/O Power

64 CSS33 3.3V Digital I/O Return

69 VDD33 3.3V Digital I/O Power

74 CSS33 3.3V Digital I/O Return

82 VDD18 1.8V Digital core Power

83 VSS18 1.8V Digital core Return

103 VDD33 3.3V Digital I/O Power

104 CSS33 3.3V Digital I/O Return

110 VDD18 1.8V Digital core Power

111 VSS18 1.8V Digital core Return

Power

22 SEN0 Analog sensing 0 Input

23 SEN1 Analog sensing 1 Input

24 COM_OUT Analog VCOM Output

32 TR CLK RowDr iver Shift Clock

33 TRUDL/GPIO2 Up Down selection(Up:hight ,Down low)

GPIO2

40 TRSPT/FPVS R owDriver Starting Pulse(Top Start)

Vertical sync output for flat panel

42 TROE/FPDE RowDriver Output Enable

Datavalidforflat p ane l

Pin# NAME DESCRIPTION

1 YUOT Y output(Y out or Y + C out)

2 SOYIN Sync On Y(or Green) input

3 YIN3 Analog composite or luma input 3

4 YIN2 Analog composite or luma input 2

5 YIN1 Analog composite or luma input 1

6 YIN0 Analog composite or luma input 0

7 YGND Y input ground

8 AGND1 Analog ground

9 ACDD1 Analog VDD +3.3V

10 CIN2 Analog component C input 2

11 CIN1 Analog component C input 1

12 CIN0 Analog component C input 0

13 VIN1 Analog component V input 1

14 VIN0 Analog component V input 0

119 DVD D Analog Digital Power +1.8V

120 VSS Digital ground

121 AGND 3 Analog ground

122 AVDD3 Analog VDD+3.3V

123 AVDD2 Analog VDD+3.3V

124 AGND 2 Analog ground

125 PVDD PLL(Intemal Analog) VDD

126 FILT Filter Input

127 PGND PLL(Intemal Analog) ground

128 HSYNC Digital HSYNCINPUT

84-102

105-109

DTVD[0:23] Digital input

112 DTVCLK Clock input for DTV interface

113 DTVE/DTVRHS Data valid for DTV interface or raw HSYNC for DTV interface

(Set by register 0xF6 bit=1)

114 DTVHS Horizontal sync for DTV interface

115 DTVVS Vertical sync for DTV interface

25 GPIO[0] General Purpose Input/Output

75 PWR_DN Power Down pin

76 XTAL270 Crystal terminal(if crystal is used)

77 XTAL271 Crystal terminal(if crystal is used)or oscillatorinput

78 RESET# Reset pin

79 TEST1 Production test pin

80 SDAT 2-wire microprocessor interface data pin

81 SCLK 2-wire microprocessor interface clock pin

116 EXT_CK/VSYNC Extermal Clock

TW8806

1

YOUT

2

SOYIN

3

YIN3

4

YIN2

5

YIN1

6

YIN0

7

YGND

8

AGND1

9

AVDD1

10

CIN2

11

CIN1

12

CIN0

13

VIN1

14

VIN0

15

AVDD

16

AVDD

17

ROUT

18

GOUT

19

BOUT

20

VSUB

21

AVSS

22

SEN0

23

SEN1

24

COM_OUT

25

GPIO0

26

GPIO1/TCLRL

27

VDD18

28

VSS18

29

FPBIAS

30

FPPWC

31

FPPWM

32

TRCLK

33

GPIO2/TRUDL

34

TCINV/TCREV

35

TCPOLP

36

TCPOLN

37

TCLP

38

FPCLK/TCCLK

ADC I/F signals

128

HSYNC

VSS33

39

126

125

127

123

124

FILT

PVDD

PGND

AGND2

VDD33

FPHS/TCSPL

FPDE/TROE

FPVS/TRSPT

40

42

41

44

43

117

116

120

118

119

122

121

AVDD3

AVDD2

FPR0/CP0+

FPR1/CP0-

46

45

115

114

113

VSS

AVSS

AVDD

DVDD

DTVVS

VSS18

48

DTVHS

EXT_CK/VSYNC

FPR4

VDD18

FPR6

FPR7

FPR5

50

54

49

53

51

52

AGND3

FPR2

FPR3

47

112

DTVDE

VSS33

55

DTVCLK

FPG0/CP1+

111

VSS18

FPG1/CP1-

56

107

103

108

105

110

109

106

104

VSS33

VDD33

DTV22

DTV19

DTV21

VDD18

DTV23

DTV20

FPB1/TRSPB

FPB0/TCSPR

FPG7

FPG4

FPG3

FPG6

FPG2

58

57

VSS33

VDD33

FPG5

60

62

64

61

63

59

DTV18

DTV17

DTV16

DTV15

DTV14

DTV13

DTV12

DTV11

DTV10

DTV9

DTV8

DTV7

DTV6

DTV5

DTV4

DTV3

DTV2

DTV1

DTV0

VSS18

VDD18

SCLK

TEST1

RESET#

XTAL27I

XTAL27O

PWR_DN

VSS33

FPB7

FPB6

FPB5

FPB4

VDD33

FPB3

FPB2

SDA

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

Row (Gate) driver signals

Column (Source) Driver signals

DAC I/F signals

Charge Pump and VCOM I/Fsignals

Other I/F Signals

- 5-

LCD

DTV I/F Signals

PLL Powers

PT2259

LIN 1

LOUT 2

VSS 3

SDA 4

PT2259

8RIN

7ROUR

6VDD

5SCL

TS488IST-MINISO-8

OUT(1) 1

VIN(1) 2

BYPASS 3

GND 4

8VCC

7OUT(2)

6VIN(2)

5 SHUTDOWN

VMA770

VMA773

Page 6

■ELECTRICAL PART LIST

MAIN BOARDASS'YSection

VMA770

VMA773

- 6-

Page 7

- 7-

VMA770

VMA773

Page 8

VMA770

VMA773

- 8-

Page 9

PHONE BOARDASS'Y Section(PC06119-32A-1R)

- 9-

VMA770

VMA773

Page 10

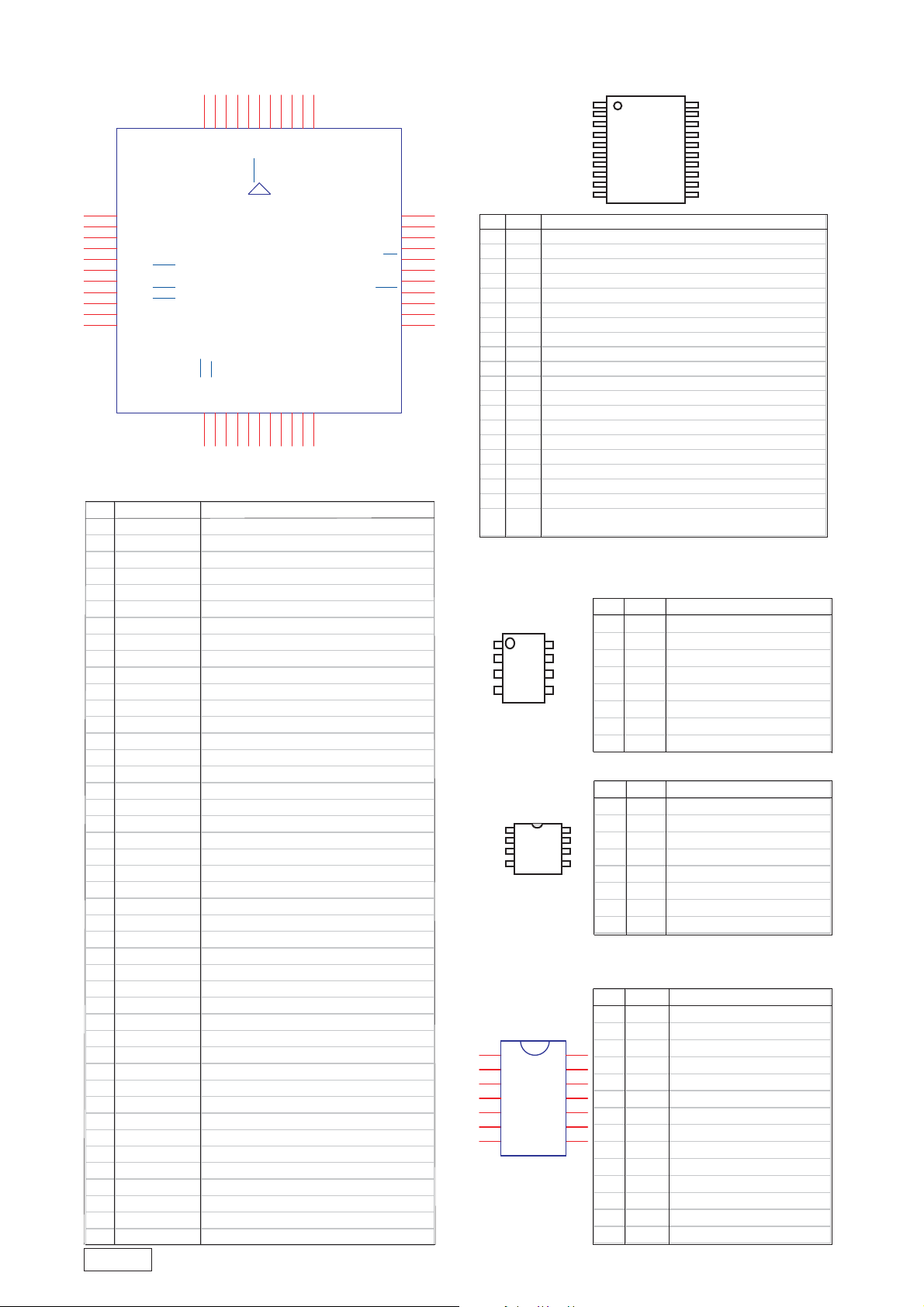

EXPLODED VIEW / PARTSLIST

REF PART No DESCRIPTION Q'TY

1 PL-1005-0102A-1R IR Cover HLM-0561/0706 1

2 PL-1001-0047-1R Front cover HLM-0706(VMA770) 1

2 PL-1001-0041-1R Front cover HLM-0706(VMA773) 1

3 PL-1001-0075A-1R IR Lens HLM-0561/0706 1

4 QM-01-2002 Screw M2.0*2.0 1

5 PL-1007-0076-1R Power Li ghtHLM-0561/0706 1

6 PL-1006-0092-1R Control key 1part HLM-0706 1

7 PL-1006-0093-1R Control key 2part HLM-0706 2

8 QM-01-2504 Screw M2.5x4 2

9 LD-0701-03A-1R LCD PanelA070FW03 1

10 MZ-0003-06-1R Insulator 20x20x0.5 HLM-0706 1

11 PA2B612003-1R Cushion 14x8x2.5 2

12 HD-0500-08-1R Insulator HLM-0706 1

13 MS-0706-04-1R Left-BKT HLM-0706 1

14 QM2A603-82-1R Screw M2.6x3 2

15 Main / Phone Bord Ass'y 1

16 QT-21-2606A Screw TP2.6x6 6

17 MS-0561-04-1R Cabele BKT HLM-0561/0706 1

18 PL-1002-0028-1R Rear Cover HLM-0706 1

19 QM2A605-86-1R Screw M2.6*5 black 1

20 QT2A606-16 Screw M2.6*L6 black 1

21 MS-0706-05-1R Stand BKT HLM-0706 3

22 PA2B617005-1R Insert Card HLM-0706(VMA770) 1

22 PA2B612005-1R Insert Card HLM-0706(VMA773) 1

23 QT-0206-26-1R Screw TP2.0x6 black 6

24 PL-1007-0074-1R Bucket Monitor HLM-0706 1

BLOCK DIAGRAM

I/O

AUX CVBS

AUX IN

AUX CVBS

AUXAUDIO

AV IN

AV CVBS

AV AUDIO

HEADPHONE

EARAUDIO OUT

IR LED

IRAUDIO OUT

DC JACK

DC12V

VMA770

VMA773

AV CVBS

IR

KEY

AUXAUDIO

AV AUDIO

MCU

EEPROM

24C16

VIDEO

SCALER

TW8806

MCU

IC5964

AUDIO

AUDIO

SWITCH

PI5C3309

VCOM

VGH

VGL

AUDIO

VOLUME

CONTROL

PT2259

AUDIO

OPAMP

BA4558

- 10 -

BA4558

74HC14

74HC14

AUDIO

OPAMP

TS488

IR TRANS

HS2K219

LCD Panel

7" AU A070FW03

EARAUDIO OUT

IRAUDIO OUT

DC12V

5V STB

INVERTER

INVERTER

MP1010B

SWITCHING

REGULATOR

FP5001

XN4601

ST4435

LINEAR

REGULATOR

LD117A

LINEAR

REGULATOR

LD117A

POWER

LCD Panel

7" AU A070FW03

5V STB

3.3V

1.8V

Page 11

J

I

H

G

F

E

D

BC

A

CIRCUIT DIAGRAM

7

MAIN VIDEO section

to P.1 4

to P.1 4

VSS

FILT

PGND

HSYNC

AVSS

PVDD

AGND2

AVDD

DVDD

AVDD2

AVDD3

AGND3

DTV23

DTV22

DTV21

DTV20

DTV19

VSS33

VSS18

DTVVS

DTVHS

DTVDE

DTVC

EXT_CK/VSYNC

V

V

6

to LCD

to P.1 2P.14

SDAT

to P.1 2P.14

to P.1 3P.14

TW_R EST

to P14

5

8

3

G2

G3

G4G5G6

R2

R3

R4R5R6

R7

DD18

G0/CP1+

R0/CP0+

R1/CP0-

VSS3

DD33

PVS/TRSPT

PDE/TROE

PHS/TCSPL

G7

G1/CP1-

DD33

7

6

5

4

3

to P.1 4

2

4

3

2

1

J

I

H

- 11 -

VMA770

VMA773

E

DG

BC

A

1

Page 12

A

MAIN AUDIO section

7

6

to P. 14

to P. 14

B C

AUDI O_SET

to P. 14

D

E

F

G

H

I

J

7

to P. 11P.1 4

EO_L

to P. 14

6

AUDIO _SET

to P. 14

to P. 14

to P. 14

AUDI O_SET

to P. 14

5

to P. 11P.1 4

4

IR_S EL1

IR_S EL2

3

to P. 14

to P. 14

to P. 14

AUDIO _SET

to P. 14

EO_R

5

to P. 14

4

3

2

1

A

B C

- 12 -

VMA770

VMA773

E

F

G

H

I

2

1

J

Page 13

J

MAIN POWER section

7

to P. 14

to P. 14

6

I

H

G

F

E

D

BC

A

7

EO_L

to P. 14

AUD IO_SEL

to P. 14

AUDI O_SCL

to P. 14

6

to P. 14

to P. 14

AUD IO_SEL

to P. 14

to P. 11P.1 4

5

4

IR_S EL1

IR_S EL2

to P. 14

3

to P. 14

to P. 14

AUDI O_SDA

to P. 14

EO_R

to P. 14

5

4

3

2

1

J

I

H

- 13 -

VMA770

VMA773

E

DG

BC

A

2

1

Page 14

A

MAIN MCU & IO section

7

Pigtail Cable

P2

6

5

2

5

8

7

P2

No

Description Function

1

AUDIO L Audio left channel Input

2

AUDIO GND Audio Ground

AUDIO R Audio right channel Input

3

AUDIO GND Video input port Ground

4

5

VIDEO Video input port

GND Power Ground

6

IR IR data output

7

8

ACC +12V ACC + 12V Power Input

GND Power Ground

9

ZD7

NC

5VSTB

to P14

to P14

IR_IN

IR

SCL

SDA

F

U1

AP1702

1

5VSTB

G

H

I

J

7

SCL

to P14

SDA

TW_RESET

PDN_XTAL

to P12

to P12

to P12

to P12

10

11

12

13

14

15

16

17

7

8

9

U2

P1.5

P1.6

P1.7

RST

P3.0 / RXD

P4.3 / INT2

P3.1 / TXD

P3.2 / INT0

P3.3 / INT1

P3.4 / T0

P3.5 / T1

to P12

to P12

C8

22pF

Y1

27MHz

5VSTB

12345

6

P1.2

P1.3

P1.4

VCC

T2/P1.0

AD1/P0.1

AD0/P0.0

INT3/P4.2

T2EX/P1.1

SM5964

P3.6 / WR

P3.7 / RD

XTAL2

XTAL1

GND

P4.0

P2.0 / A8

P2.1 / A9

C9

22pF

P2.2 / A10

1819202122232425262728

PWR

to P13

INV_EN

to P13

PANEL_EN

to P11

4041424344

AD3/P0.3

AD2/P0.2

39

AD4 / P0.4

38

AD5 / P0.5

37

AD6 / P0.6

36

AD7 / P0.7

35

EA

34

P4.1

33

ALE

32

PSEN

31

A15 / P2.7

30

A14 / P2.6

29

A13 / P2.5

P2.3 / A11

P2.4 / A12

SW1 TACT_SW

SOURCE

SW2 TACT_SW

DOWN

SW3 TACT_SW

UP

SW4 TACT_SW

MENU

SW5 TACT_SW

POWER

SCLK

SDAT

AUDIO_SCL

AUDIO_SDA

23

OUTVCC

GND

TC1

NC

R7

NC

to P14

MUTE

AUDIO_SEL

RST

RX

TX

IR_IN

to P14

INV_RESET

to P11

to P11

R211 NC

R6 4K7

INV_SW

IR_SEL1

IR_SEL2

IR_EN

5VSTB

5VSTB

to P13

to P12

to P12

to P12

SOURCE

DOWN

UP

MENU

POWER

PDN_XTAL

TW_RESET

TX

RX

SDA

MUTE

AUDIO_SEL

SCL

AUDIO_SDA

AUDIO_SCL

SDAT

SCLK

PWR

INV_EN

PANEL_EN

INV_SW

IR_SEL1

IR_SEL2

IR_EN

6

7

8

6

7

8

8

7

6

8

7

6

8

7

6

8

7

6

RN1

4K7 X 4

RN2

4K7 X 4

RN3

4K7 X 4

RN4

4K7 X 4

RN5

4K7 X 4

RN6

4K7 X 4

5VSTB

PWR

45

3

2

1

45

3

2

1

1

2

3

45

1

2

3

45

1

2

3

45

6

5

1

2

3

45

DC12V

A K

to P14

INV_RESET

D2

SK34

D

IR

R1

4K7

ZD1

5V1_ZENER

R5

10K

B

R8

3K3

AUX_V

to P11

CE

C4

0.1uF

Q2

2N3904

R2

22K

C3 0.1uF

U3

1

S0

2

S1

3

S2

4 5

GND SDA

24C16

B C

P1

1

J1

+12V

GND

GND

IR

AUX_V

AUX_L

AUX_R

GND

JST-8PIN-2.0P

1

2

3

4

5

6

7

8

3AF1

A

L33

FB601_3A

D12

D11

NC/LDP24A

NC/LDP24A

VCC12 5VSTB

4

3

+

EC12

NC

L1

FB601_3A

C1

0.1uF

R104

4K7

ZD2

6V8_ZENER

R198

4K7

6

R199

9

5K6

L2 FB080

C5

100pF

D1

SK34

A K

C2

0.1uF

R105

4K7

CE

B

Q21

2N3904

D3 SK34

A K

C6

100pF

Q1

1

S

2

S

3

SGD

4

SI4435DY

VCC

WC

SCL

D

D

D

8

7

6

E

VCC12

8

7

6

5

2.0mm_4PIN

5VSTB

R3 33

R4 33

IR1

IRM-4838F4

VCC

GND

OUT

5VSTB

J2

1

TX

2

RX

3

4

to P12

SCLK

R204

0

R201 NC

R202 NC

R203

0

SDAT

to P12

5VSTB

R10

R9

4K7

100

3

2

1

C7

0.1uF

R11 33

R12 33

L3 FB601

4

J3

1

R1_OUT

2

L1_OUT

3

3

Headphone Jack

AV IN Jack

GND1

GND1

AUX_L

AUX_V

GND2

GND3

AUX_R

9PIN_2.0p_DIP

4

5

6

7

8

9

ZD8

NC

ZD9

NC

A

R13

4K7

A

R15

4K7

A

R17

NC

C10

100pF

L4 FB601

C12

100pF

L5 FB601

C14

2200pF

L6 FB601

Headphone Jack

C16

R21

4K7

A

R19

NC

R23

4K7

2200pF

L7 FB601

C18

100pF

L8 FB601

C20

100pF

Symbol Function

L1_OU T Au di o left ch an ne l input

R1_OU T Au di o right c ha nn el i npu t

GND GRO UN D

2

1

AV IN Jack

Symbol Function

AUX_L A ud io l eft cha nn el i np ut

AUX_R A ud io r ight ch an ne l in put

GND GRO UN D

AUX_V V id eo c hanne l In pu t

ZD6

ESD

ZD3

ESD

ZD4

NC

ZD5

NC

R235 0

R236 0

C15

100pF

C17

100pF

R233 1K

R234 1K

R18

NC

R20

NC

C11

100pF

C13

100pF

C19

100pF

C21

100pF

AV_V

EO_R

EO_L

R22

NC

R24

NC

R14

NC

R16

NC

to P11

to P12

to P12

AV_R

AV_L

AUX_L

AUX_R

to P12

to P12

to P12

R223 0

R224 0

to P12

R225 0

R226 0

R227 0

Bottom Link

STEP 1

a. Set DC Vo lt ag e as 1 3. 2V a nd turn on th e po we r sw it ch o f the power s up pl ie r.

b. HLM-05 61 w il l po we r on a utomati ca ll y an d in O SD m ode, disp la y wh it e “AV1”w or d

and blue ba ck gr ou nd .

STEP 2.

Adjustm en t th e Vp -p v ol tage of Vco m as 5 .0 V.

STEP 3.

Adjustm en t th e VD C vo lt age of Vc om a s 1. 8V:

STEP 4.

Continu al ly p re ss “ SW 4” butt on t o di sp la y IR O FF mode, an d pr es s “S W2 ” or “ SW3”t o

display :

IR A:

L: the fr eq ue nc y of c ha nn el is 2.3 ±0 .0 08 MH z.

R: the fr eq ue nc y of c ha nn el is 2.8 ±0 .0 08 MH z.

IR B:

L: the fr eq ue nc y of c ha nn el 3.2± 0. 00 8M Hz .

R: the fr eq ue nc y of c ha nn el 3.8± 0. 00 8M Hz .

STEP 5.

a. Press “S W1 (S OU RC E)” butto n to c ha ng e to AV1 mode :

b. AV sel ec to r bo x wa s switche d to AV1 c ol or bar to ins pe ct i f th e ou tp ut screen i s

A A

GND

R228 0

R229 0

R230 0

normal. c . Pr es s “S W3 ”and adju st t he (▲) v ol um e to 3 0 to inspec t th at t he w av e

patte rn o f CH 1 an d CH 2 on t he oscill os co pe o f th e ou tput soun d ar en ’t d is to rted.

d. Press “S W1 (S OU RC E)” butto n to s wi tc h to A V1 2mode:

e. AV sel ec to r bo x wa s sw itched to A V2 c ol or b ar t o in spect if th e ou tp ut s cr ee n is

normal.

f. Insp ec t th at t he w av e pattern o f CH 1 an d CH 2 on t he o scillos co pe o f th e ou tp ut

R231 0

R232 0

PWB adjustment working steps

STEP 6.

Wireles s ea rp ho ne s te st:

a. Press “S W1 ( SO UR CE )” button t o ch an ge t o AV 1 mo de and the AV s el ec to r bo x wa s

switche d to A V1 D VD m od e.

b. Contin ua ll y pr es s “S W3” til l IR m od e di sp la yed on OSD an d pr es s “S W2 ” or “ SW1” to

select IR A , IR B o r IR o ff m od e.

c. If sel ec t IR A m od e an d th en the sele ct ed c ha nn el o f wireles s ea rp ho ne s mu st be A

to make sur e if t he o ut pu t sound is no rm al .

d. If sel ec t IR B m od e an d th en the sele ct ed c ha nn el o f wireles s ea rp ho ne s mu st be B

to make sur e if t he o ut pu t sound is no rm al .

e. If sel ec t IR O FF m od e; i nfrared r ay s wi ll b e of f. T here is no so un d ou pu t.

STEP 7.

Remote co nt ro ll er t es t:

a. Press“ SW 2 (S OU RC E) ” butto n to c ha ng e to A V1 m ode and the A V se le ct or b ox w as

switche d to A V1 m od e.

b. Use th e cl ar io n’ s re mo te cont ro ll er a nd c he ck i f the fun ct io ns a re n or mal.

STEP 8.

Press“S W5 ( PO WE R) ” an d HLM-056 1 wi ll p ow er o ff a nd then L ED 1 li gh t of f.

Notic e:

1.Out pu t ea rp ho ne s: use 33 Ω loa di ng .

2.TV ty pe ( Eu ro pe ): s et video pa tt er n as PAL and D VD p layer as NT SC .

TV type ( US A) : se t vi de o pattern a s NT SC a nd D VD p la yer as PAL .

3. Th e in sp ec to rs must wea r ES D ri ng .

4

3

2

1

sound are n’ t di st or te d.

A

A

B C

- 14 -

VMA770 VMA770

VMA773 VMA773

E

F

G

H

I

J

Page 15

J

I

H

G

F

E

D

BC

A

PRINTED WIRING BOARD 1 of 2

7

Q19

Q

U U7

Q18

U17

Q20

Q2

Q22Q17

Q1

Q12

Q11

U8

Q23

U15

U11

Q10 Q1 6

Q15

Q13

U2

Q21

U13

U12

U3

U14

Q13

Q8

Q7

U10

Q6

Q14

U16

U19

Q9

U9

U6

U4

Q5

U18

TOP VIEW (REAR COVER SIDE)

6

5

7

6

5

4

3

Pigtail Cable

4

3

1

2

5

8

2

1

P2

No

7

1

2

3

4

5

6

7

8

9

4

3

6

9

Description

AUDIO L

AUDIO GND

AUDIO R

AUDIO GND

VIDEO

GND

IR

ACC +12V

GND

2

1

AV IN Jack

J

I

H

F

E

DG

BC

Headphone Jack

A

- 15 -

Page 16

A

PRINTED WIRING BOARD 2 of 2

7

B C

D

E

F

G

H

I

J

7

6

5

4

6

5

4

3

2

MENU

1

Headphone Jack

A

AV IN Jack

B C

D

E

SOURCE

F

POWER

G

IR

H

I

3

2

1

J

- 16 -

VMA770

VMA773

Loading...

Loading...