Carrier 48SX User Manual

Combination Gas Heating/Electric Cooling Units

A Guide To Operating and Maintaining Your

Gas Heating/Electric Cooling Unit

48SS

48SX

NOTE TO INSTALLER

This manual should be left with the equipment owner.

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity of this or any other appliance.

Improperinstallation,adjustment,alteration,service or maintenance can cause injury or propertydamage. Refer to this manual. For assistance

or additional information, consult a qualified installer, service agency, or the gas supplier.

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Donot touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from

a neighbor’sphone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

Before performing recommended maintenance,

be sure gas supply and main power switch to

unit are turned off.Electrical shock could cause

personal injury.

Model 48SS Without Base Rail Shown

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 1a 6a

PC 111 Catalog No. 564-993 Printed in U.S.A. Form 48SS,SX-3SO Pg 1 5-98 Replaces: 48SS,SX-2SO

Model 48SX With Optional Base Rail

Your combination heating/cooling unit is equipped with

an automatic direct sparkignitionandpowercombustionblower .

Do not attempt to light by hand; personal injury may

result.

TO LIGHT UNIT

1. Do not turn off the electrical power to unit without

first turning off the gas supply.

2. Before attempting to start the gas heating section, familiarize yourself with all the procedures that must

be followed.

If you do not follow these instructions exactly, a fire or

explosion may result, causing property damage, injury,

or loss of life.

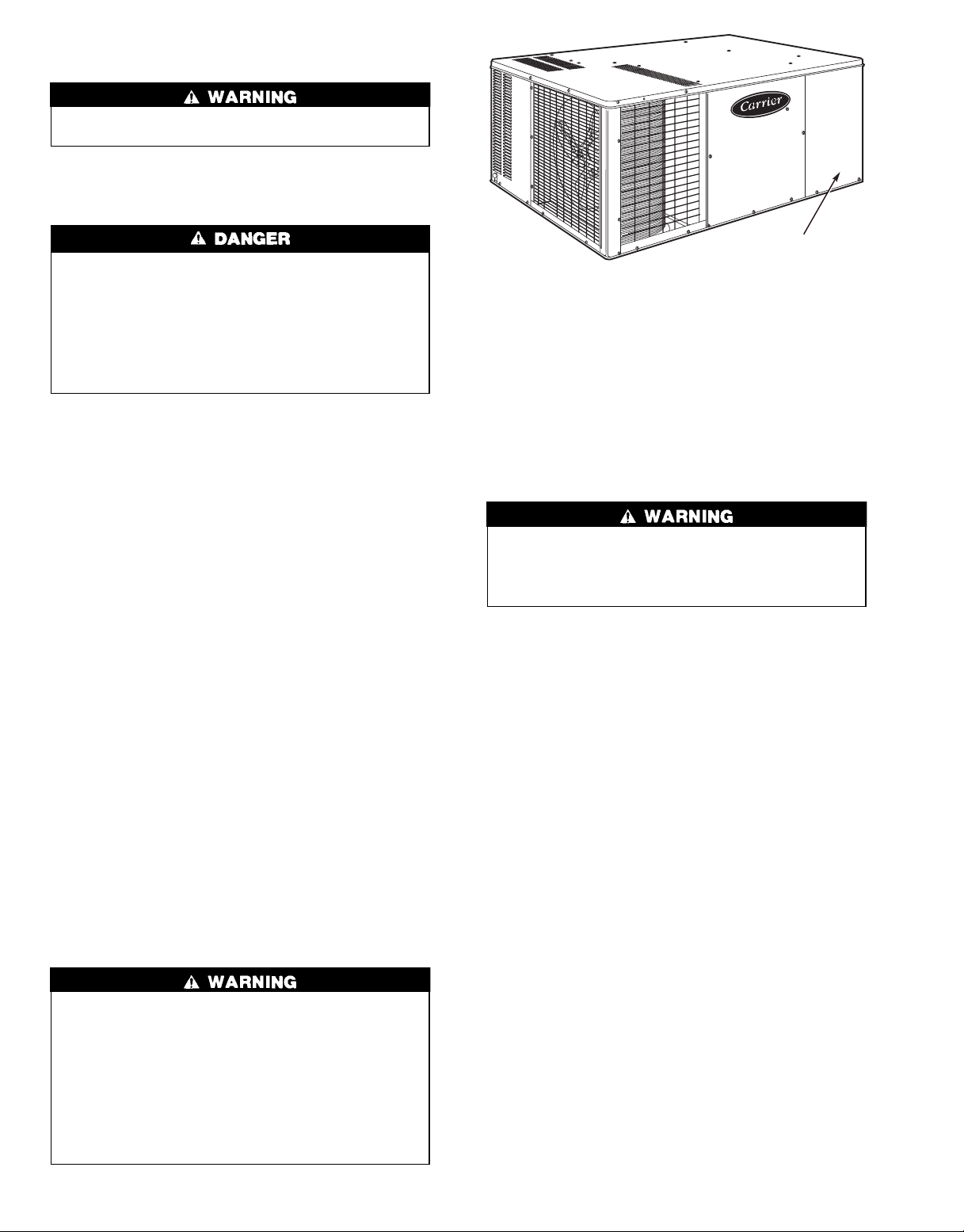

Refer to Fig. 1. See Fig. 2 for location of gas valve. Refer

to Fig. 3 while proceeding with the following steps.

Step 1 — Set the temperature selector on room thermo-

stat to the lowest temperature setting and set system switch

to HEAT.

Step 2 — Close the external manual shutoff valve.

Step 3 — Turn off the electrical supply to the unit.

Step 4 — Remove the burner access panel with a

nut driver.

5

⁄16-in.

Step5 — Turn the control switch on the internal gas valve

to the OFF position and wait 5 minutes.

Step6 — Turn the control switch on the internal gas valve

to the ON position.

Step 7 — Replace the burner access panel.

Step 8 — Turn on the electrical supply to unit.

Step 9 — Open the external manual shutoff valve.

Step 10 — Set the temperature selector on room thermo-

stat slightly above room temperature to start unit. The induceddraft combustion-air fan will start. Main gas valve will open

and main burners should ignite within 5 seconds. If the burner

does not light within 5 seconds, the ignition module will go

into a Retry mode after a period of approximately 22 seconds (following the 5-second ignition period).

If the burners do not light within 15 minutes of the initial

call for heat, there is a lockout.

Step 11 — Set the temperature selector on room ther-

mostat to desired setting.

BURNER

ACCESS PANEL

Fig. 1 — Gas Heating/Electric Cooling Unit

(Unit 48SS Shown)

TO SHUT UNIT OFF

Do not turn off the electrical power to unit without first

turning off the gas supply.

Failure to follow these procedures can result in serious

fire or personal injury.

NOTE: If unit is being shut down because the heating season has ended, make sure to turn on power to cooling

system.

If unit is being shut down because of a malfunction, call

your dealer as soon as possible.

Should overheating occur or the gas supply fail to shut

off, shut off the manual gas valve to the unit before shutting

off the electrical supply.

Do not use this unit if any part has been under water. Immediately call a qualified service technician to inspect the

unit and to replace any part of the control system and any

gas control which has been under water.

Refer to Fig. 4 while proceeding with the following steps.

Step 1 — Set the temperature selector on room thermo-

stat to lowest temperature setting and set system switch to

OFF.

Step 2 — Close the external manual shutoff valve.

1. If the main burners fail to light, or the blower fails

to start, shut down gas heating section and call your

dealer for service.

2. Never attempt to manually light the main burners on

unit with a match, lighter, or any other flame. If the

electric sparking device fails to light the main burners, refer to the following shutdown procedures, then

call your dealer as soon as possible.

Failure to follow these requirements could result in serious

personal injury.

Step 3 — Turn off the electrical power supply to the unit.

Step 4 — Remove the burner access panel.

Step5 — Turn the control switch on the internal gas valve

to the OFF position.

Step 6 — Replace the burner access panel.

Step 7 — Restore electrical power to the unit and set sys-

tem switch to COOL to ensure operation of the cooling system during the cooling season.

2

ROUTINE MAINTENANCE

All routine maintenance should be handled by skilled, experienced personnel. Your dealer can help you establish a

standard procedure.

For your safety, keep the unit area clear and free of combustible materials, gasoline, and other flammable liquids and

vapors.

To assure proper functioning of the unit, flow of combustion and ventilating air must not be obstructed from reaching

the unit. Clearance of at least 30 in. is required on all sides

except the duct side.

MAINTENANCE AND CARE FOR THE

EQUIPMENT OWNER

Before proceeding with those things you might want to

maintain yourself, please carefully consider the following:

Air Filters — Air filter(s) should be checked at least ev-

ery 3 or 4 weeks and changed or cleaned whenever it becomes dirty.Dirty filters produce excessive stress on the blower

motor and can cause the motor to overheat and shut down.

Table 1 indicates the correct filter size for your unit. Refer

to Fig. 5 to access the filter(s).

To replace or inspect filter(s) (or accessory filter rack when

supplied):

5

1. Remove the filter access panel using a

2. Remove the filter(s) by pulling the filter(s) out of the unit.

If the filter(s) is dirty, clean or replace with new one.

When installing the new filter(s), note the direction of the

airflow arrows on the filter frame.

If you have difficulty in locating your air filter(s), or if

you have questions concerning proper filter maintenance, contact your dealer for instructions. When replacing filters, always use the same size and type of filter that was supplied

originally by the installer.

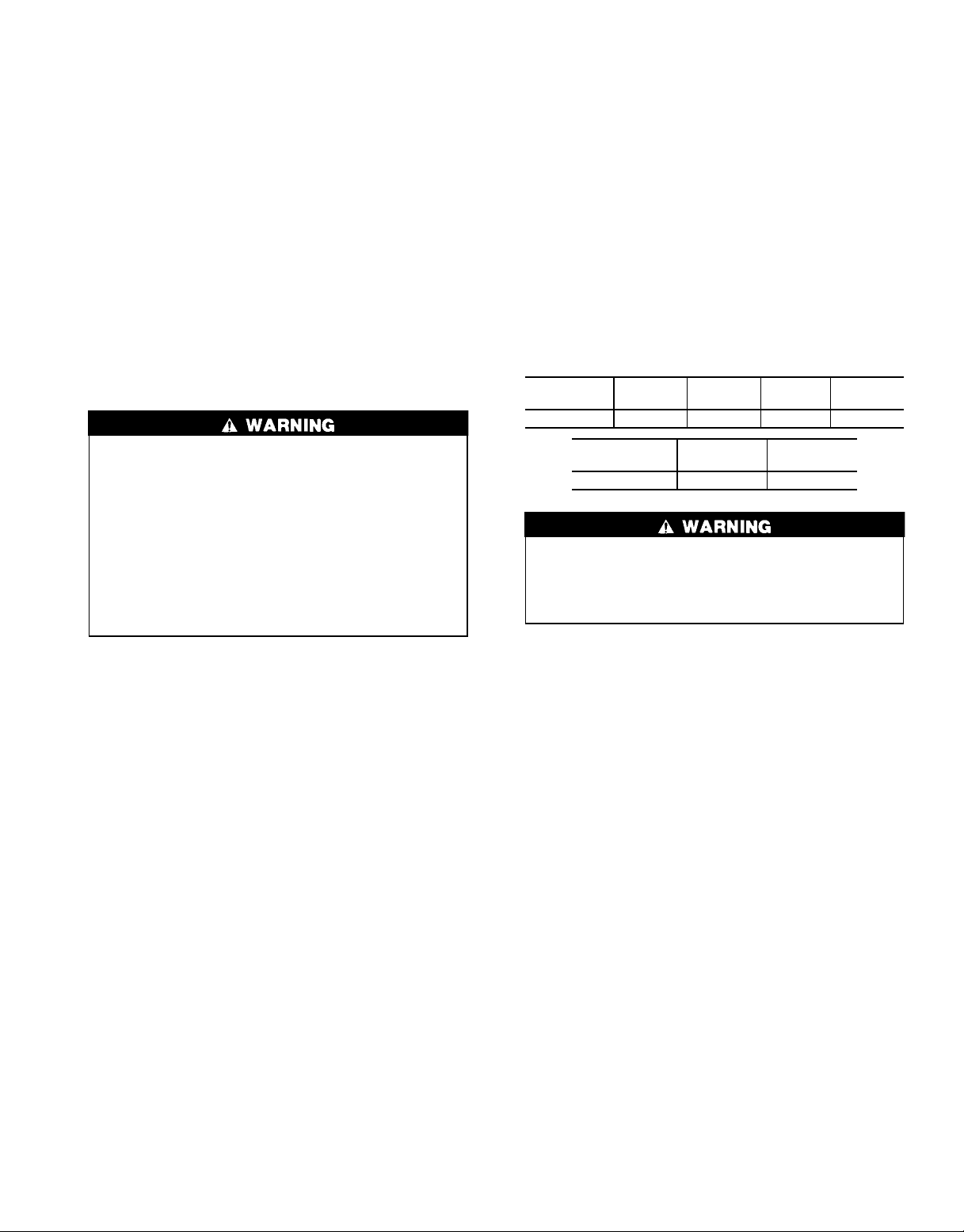

Table 1 — Indoor-Air Filter Data

UNIT SIZE

48SS

Filter Size 20x20 20x24 24x24 24x30

018-024 030-036 042 048-060

⁄16-in. nut driver.

1. TURN OFF GAS SUPPLY AND ELECTRICAL

POWER TO YOUR UNIT BEFORE SERVICING

OR PERFORMING MAINTENANCE.

2. Do not turn off electrical power to this unit without

first turning off the gas supply.

3. When removing access panels or performing maintenance functions inside your unit, be aware of sharp

sheet metal parts and screws. Although special care

is taken to reduce sharp edges to a minimum, be extremely careful when handling parts or reaching into

the unit.

UNIT SIZE

48SX

Filter Size 24x24 24x30

024-036 042-060

Never operate your unit without filters in place. Failure

to heed this warning may result in damage to the blower

motor and/or compressor. An accumulation of dust and

lint on internal parts of your unit can cause loss of efficiency and, in some cases, fire.

3

Heat Exchanger — To ensure dependable and efficient

heating operation, the heat exchanger should be checked by

a qualified maintenance person before each heating season,

and cleaned when necessary. This checkout should not be

attempted by anyone not having the required expertise and

equipment to properly do the job. Checking and/or cleaning

the heat exchanger involves removing the gas controls assembly and the flue collector box cover and, when completed, reinstalling the gas controls assembly for proper operation. Also, the flue collector box cover must be replaced

correctly so that a proper seal is maintained. Contact your

dealer for the required periodic maintenance.

Fans and Fan Motor — Periodically check the con-

dition of fan wheels and housings and fan-motor shaft

bearings. No lubrication of condenser- or evaporator-fan

bearings or motors is required or recommended.

Evaporator and Condenser Coils — Cleaning of

the coils should only be done by qualified service personnel. Contact your dealer for the required annual

maintenance.

Condensate Drain — The drain pan and condensate

drain line should be checked and cleaned at the same time

the cooling coils are checked by your dealer.

Compressor— All compressors are factory-shipped with

a normal charge of the correct type refrigeration grade oil in

them and should rarely require additional oil. The service

person must be certain the proper oil level is maintained in

the compressor when it is installed and running.

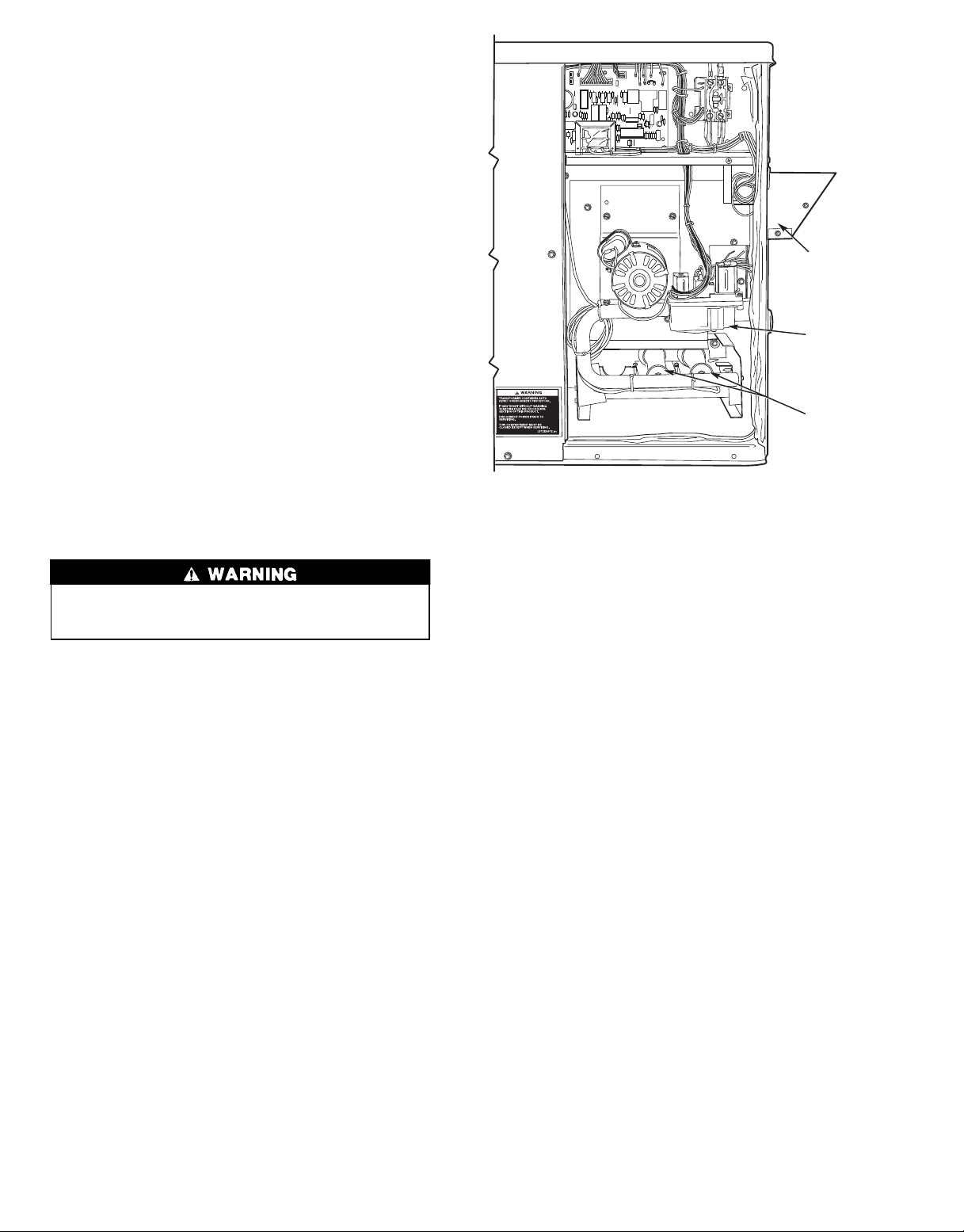

Condenser Fan

FLUE HOOD

GAS VALVE

BURNERS

Fig. 2 — Gas Heating/Electric Cooling Unit

(Unit 48SS Shown)

Do not poke sticks, screwdrivers, or any other object

into revolving fan blades. Severe bodily injury may

result.

The fan must be kept free of all obstructions to ensure proper cooling. Contact your dealer for any required

service.

4

Loading...

Loading...