Carrier 39LH Installation, Start-up And Service Instructions Manual

Installation, Start-Up and

Service Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 1,2

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Unit Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

PREINSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

Rigging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Suspended Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Service Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Condensate Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

External Vibration Isolators. . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-35

Base Rail Split . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Mixing Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Condensate Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Variable Frequency Drive (VFD). . . . . . . . . . . . . . . . . . . . . . . 16

Install Fan Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Install Sheaves on Motor and Fan Shafts . . . . . . . . . . . . . 16

Install V-Belts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Water and Steam Coil Piping Recommendations . . . . . 19

Coil Freeze-Up Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Refrigerant Piping, Direct Expansion (DX) Coils . . . . . . 24

Electric Heaters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Discharge Modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35,36

Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36-46

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Fan Motor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Coil Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Winter Shutdown (Chilled Water Coil Only) . . . . . . . . . . . 36

Field-Installed Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Coil Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Changing Coil Hand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Fan Shaft Bearing Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Fan and Shaft Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Fan Sled Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

METRIC CONVERSION CHART . . . . . . . . . . . . . . . . . . . . . . . 47

39LA,LB,LC,LD,LF,LG,LH03-25

Indoor Air-Handling Units

DANGER

NEVER enter an enclosed fan cabinet or reach into a unit

while the fan is running.

LOCK OPEN AND TAG the fan motor power disconnect

switch before working on a fan. Take fuses with you and

note removal on tag. Electric shock can cause personal

injury or death.

LOCK OPEN AND TAG the electric heat coil power disconnect switch before working on or near heaters.

WARNING

CHECK the assembly and component weights to be sure

that the rigging equipment can handle them safely. Note

also, the centers of gravity and any specific rigging

instructions.

CHECK for adequate ventilation so that fumes will not

migrate through ductwork to occupied spaces when welding or cutting inside air-handling unit cabinet or plenum.

WHEN STEAM CLEANING COILS be sure that the area

is clear of personnel.

DO NOT attempt to handle access covers and removable

panels on outdoor units when winds are strong or gusting

until you have sufficient help to control them. Make sure

panels are properly secured while repairs are being made to

a unit.

DO NOT remove access panel fasteners until fan is completely stopped. Pressure developed by a moving fan can

cause excessive force against the panel which can injure

personnel.

DO NOT work on dampers until their operators are

disconnected.

BE SURE that fans are properly grounded before working

on them.

SAFETY CONSIDERATIONS

Air-handling equipment is designed to provide safe and

reliable service when operated within design specifications. To

avoid injury to personnel and damage to equipment or property

when operating this equipment, use good judgment and follow

safe practices as outlined below.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53390016-01 Printed in U.S.A. Form 39L-7SI Pg 1 816 3-14 Replaces: 39L-6SI

WARNING

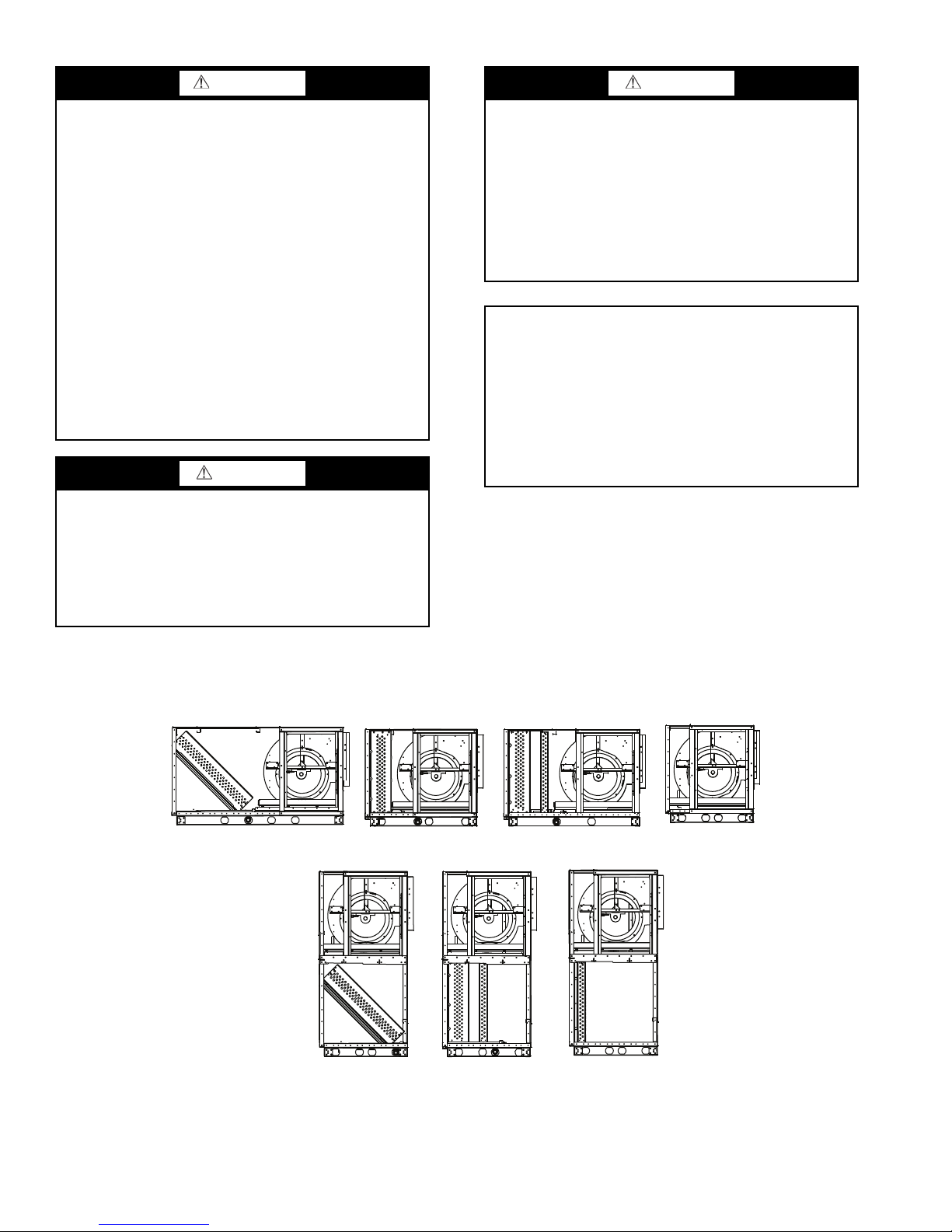

39LA

39LB

39LC

39LD

39LF

39LG

39LH

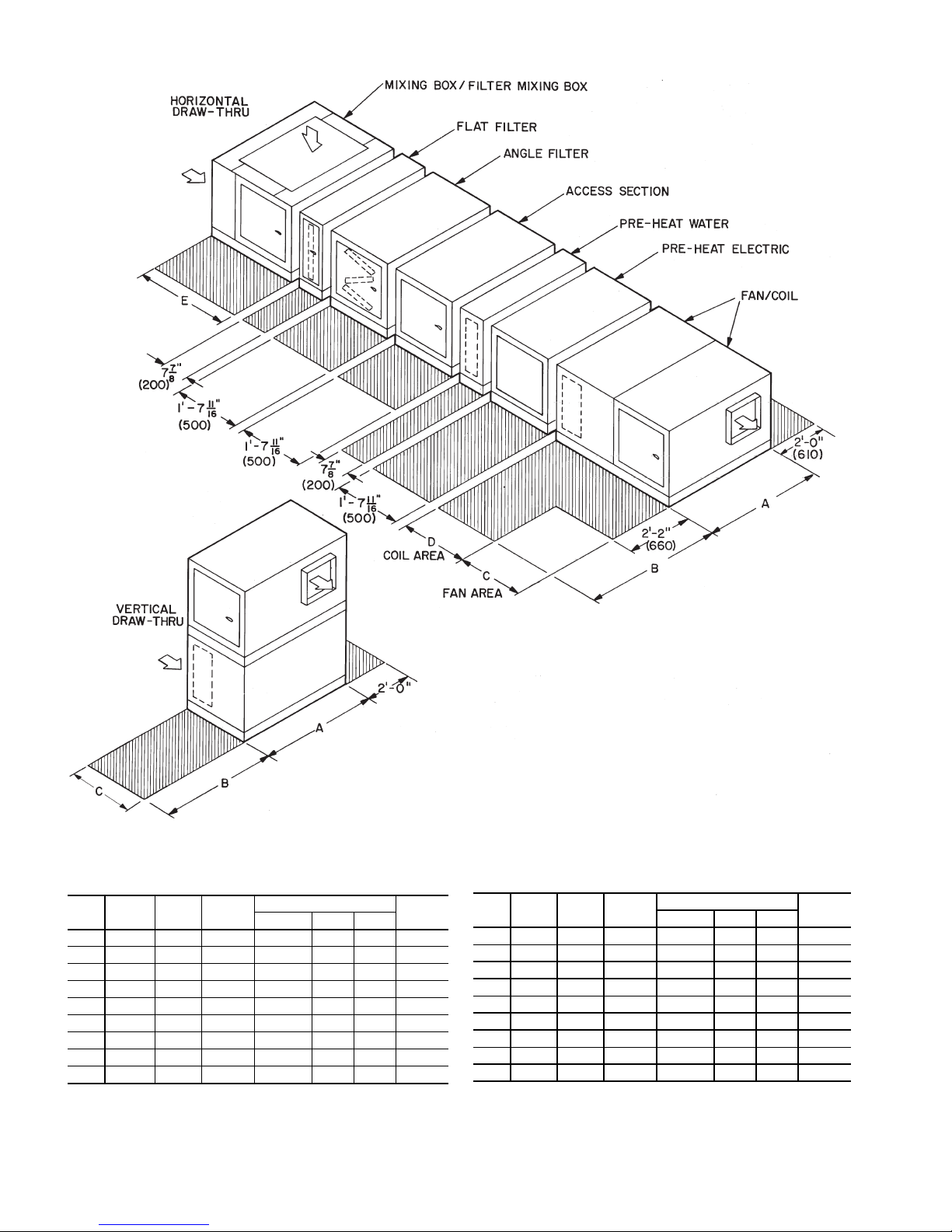

HORIZONTAL DRAW-THRU

VERTICAL DRAW-THRU

Fig. 1 — Unit Identification

a39-4440

CAUTION

DO NOT USE TORCH to remove any component. System

contains oil and refrigerant under pressure.

To remove a component, wear protective gloves and goggles and proceed as follows:

a. Shut off electrical power to unit.

b. Recover refrigerant to relieve all pressure from sys-

tem using both high-pressure and low pressure ports.

c. Traces of vapor should be displaced with nitrogen

and the work area should be well ventilated. Refrigerant in contact with an open flame produces toxic

gases.

d. Cut component connection tubing with tubing cutter

and remove component from unit. Use a pan to catch

any oil that may come out of the lines and as a gage

for how much oil to add to the system.

e. Carefully unsweat remaining tubing stubs when nec-

essary. Oil can ignite when exposed to torch flame.

Failure to follow these procedures may result in personal

injury or death.

CAUTION

DO NOT re-use compressor oil or any oil that has been

exposed to the atmosphere. Dispose of oil per local codes

and regulations. DO NOT leave refrigerant system open to

air any longer than the actual time required to service the

equipment. Seal circuits being serviced and charge with

dry nitrogen to prevent oil contamination when timely

repairs cannot be completed. Failure to follow these procedures may result in damage to equipment.

SECURE drive sheaves with a rope or strap before working on a fan to ensure that rotor cannot free-wheel.

DO NOT restore power to unit until all temporary walkways inside components have been removed.

NEVER pressurize equipment in excess of specified test

pressures.

PROTECT adjacent flammable material when welding or

flame cutting. Use sheet metal or asbestos cloth to contain

sparks. Have a fire extinguisher at hand and ready for

immediate use.

IMPORTANT: The installation of air-handling units and all

associated components, parts, and accessories which make

up the installation and subsequent maintenance shall be in

accordance with the regulations of ALL authorities having

jurisdiction and MUST conform to all applicable codes. It

is the responsibility of the installing contractor to determine

and comply with ALL applicable codes and regulations.

Field-supplied motors should be Underwriters Laboratories

(UL) or Canadian Standards Association (CSA) approved.

Field wiring must comply with National Electrical Code

(NEC) and all local requirements.

INTRODUCTION

Unit Identification —

the 18-digit part number listed on the serial plate. The part

number describes all component, coil, motor, drive, and control

selections. See Fig. 1-9 for unit identification.

The 39L units are identified by

2

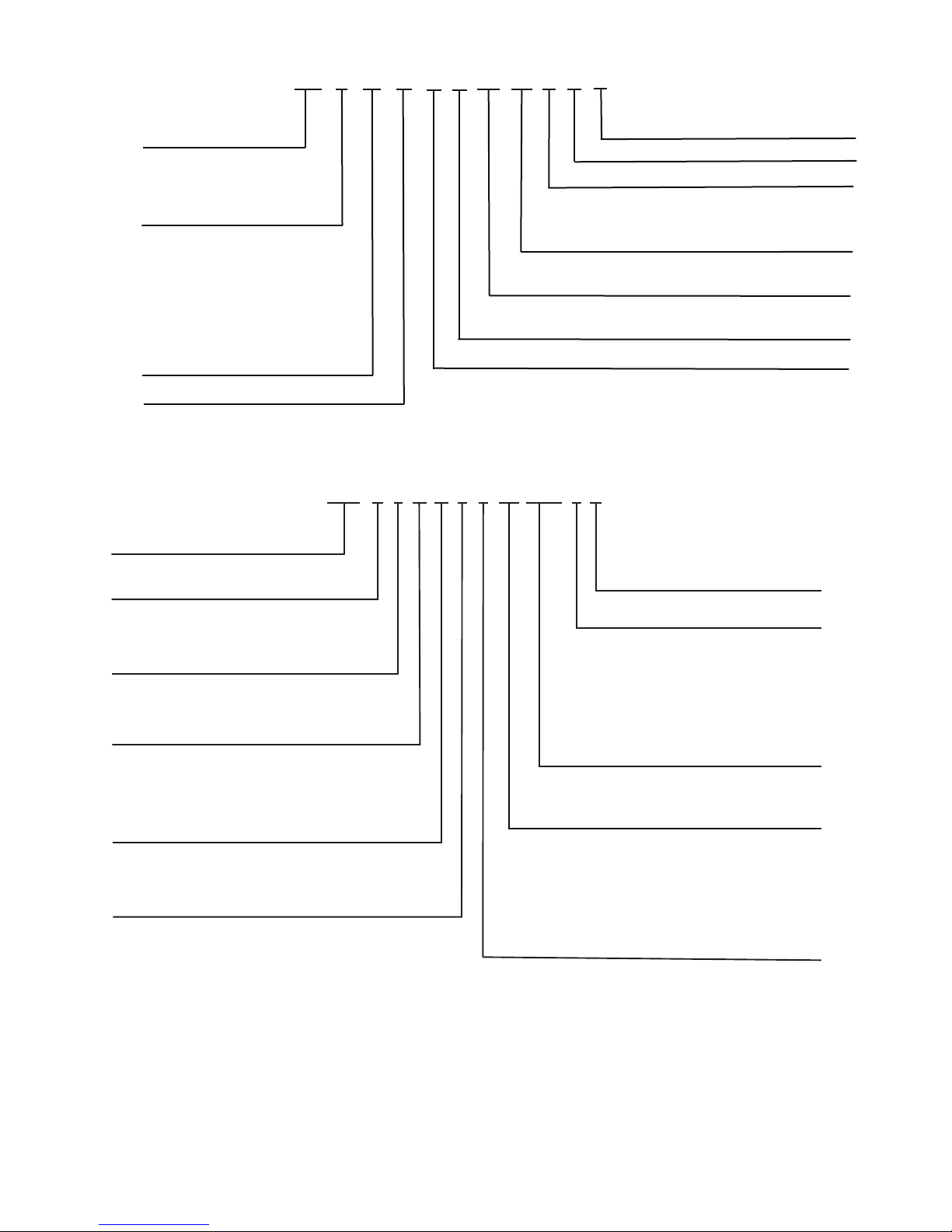

39L C 03

Fig. 2 — 39L Model Number Nomenclature

a39-4441

28N

28N – Coil Model Number

Coil Type

A – Chilled Water

Coil Orientation

S – Slant

V – Vertical

F – Full

A S 4

Rows

4

6

8

12

12

16

20

22

26

32

Tubes in Face

24

30

36

38

Q

Circuiting

Q – Quarter

H – Half

D – Double

Fin Material

Fins Per Inch

Casing Material

A – AL 8 GALV.

B

C – AL 14 GALV.

G – CU 8 ST. STL.

H

J – CU 14 ST. STL.

– AL 11 GALV.

– CU 11 ST. STL.

AB

Tube Size (Copper)

A – 0.016 Std. H-Pin

B – 0.025 Std. H-Pin

066

Nominal Length

Between Tube

Sheets (cm)

166

096

136

066

086

116

X

– Non-ferrousX

R

Hand

– Right Hand

– Left Hand

R

L

Fig. 3 — Chilled Water Coil Model Number Nomenclature

a39-4442

HB

-

A

A

CA

C

AHK

1

39L – 39L

Air Handler

Model

A

F

B

G

C

H

D

Unit Size

03

06

08

10

12

15

18

21

25

Draw-Thru Options

Special Order

Insulation/Suspension Package/Hand Side

N/A

Fan Discharge – Motor Frequency

Fan Speed

Motor HP – Type – Voltage

Base Unit Coil Description

Base Unit Coil Coil Type

and Arrangement

Preheat Coil

3

28N

28N – Coil Model Number

Coil Type

B – Hot Water

Coil Orientation

V – Vertical

F – Full

BV1

Rows

1

2

16

12

16

20

26

Tubes in Face

30

36

H

Circuiting

H

– Half

Fin Material

Fins Per Inch

Casing Material

A – AL 8 GALV.

B

C – AL 14 GALV.

G – CU 8 ST. STL.

H

J – CU 14 ST. STL.

– AL 11 GALV.

– CU 11 ST. STL.

AA

Tube Size (Copper)

A – 0.016 Std. H-Pin

B – 0.025 Std. H-Pin

086

Nominal Length

Between Tube

Sheets (cm)

166

096

136

066

086

116

X

– Non-ferrousX

L

Hand

– Right Hand

– Left Hand

R

L

Fig. 4 — Hot Water Coil Model Number Nomenclature

a39-4443

28N

28N – Coil Model Number

Coil Type

E – Direct Expansion

Coil Orientation

V – Vertical

B

– Face Split Half Circuit

EV4

Rows

4

6

16

12

16

20

26

Tubes in Face

30

36

H

Circuiting

A

– Face Split Quarter Circuit

Fin Material

Fins Per Inch

Casing Material

A – AL 8 GALV.

B

C – AL 14 GALV.

G – CU 8 ST. STL.

H

J – CU 14 ST. STL.

– AL 11 GALV.

– CU 11 ST. STL.

AA

Tube Size (Copper)

A – 0.016 Std. H-Pin

B – 0.025 Std. H-Pin

086

Nominal Length

Between Tube

Sheets (cm)

166

096

136

066

086

116

Z

– Standard (varies with coil)Z

L

Hand

– Right Hand

– Left Hand

R

L

S – Vertical

8

22

243238

C

– Face Split Full Circuit

D

– Double Circuit

E

– Row Split Quarter Circuit

F

– Row Split Half Circuit

G

– Row Split Full Circuit

Fig. 5 — Direct Expansion Coil Model Number Nomenclature

a39-4444

4

28L

28L – Coil Model Number

Coil Type

Z – Steam Distributing Tube (1 in. OD)

Coil Position

Z24

Rows

1

06

04

06

08

10

Tubes in Face

12

F

Circuiting

F

– Non-Freeze Full Circuit

D 3

Tub e Size (Copper)

3 – 1 in. OD x 0.030 Wall

086

Nominal Length

Between Tube

Sheets (cm)

166

096

136

066

086

116

--

[Blank]

2

14

Fin Material

Fins Per Inch

Casing Material

C – AL 6 GALV.

DE – AL 9 GALV.

– AL 12 GALV.

--

[Blank]

Fig. 6 — Steam Distributing Tube Model Number Nomenclature

a39-4445

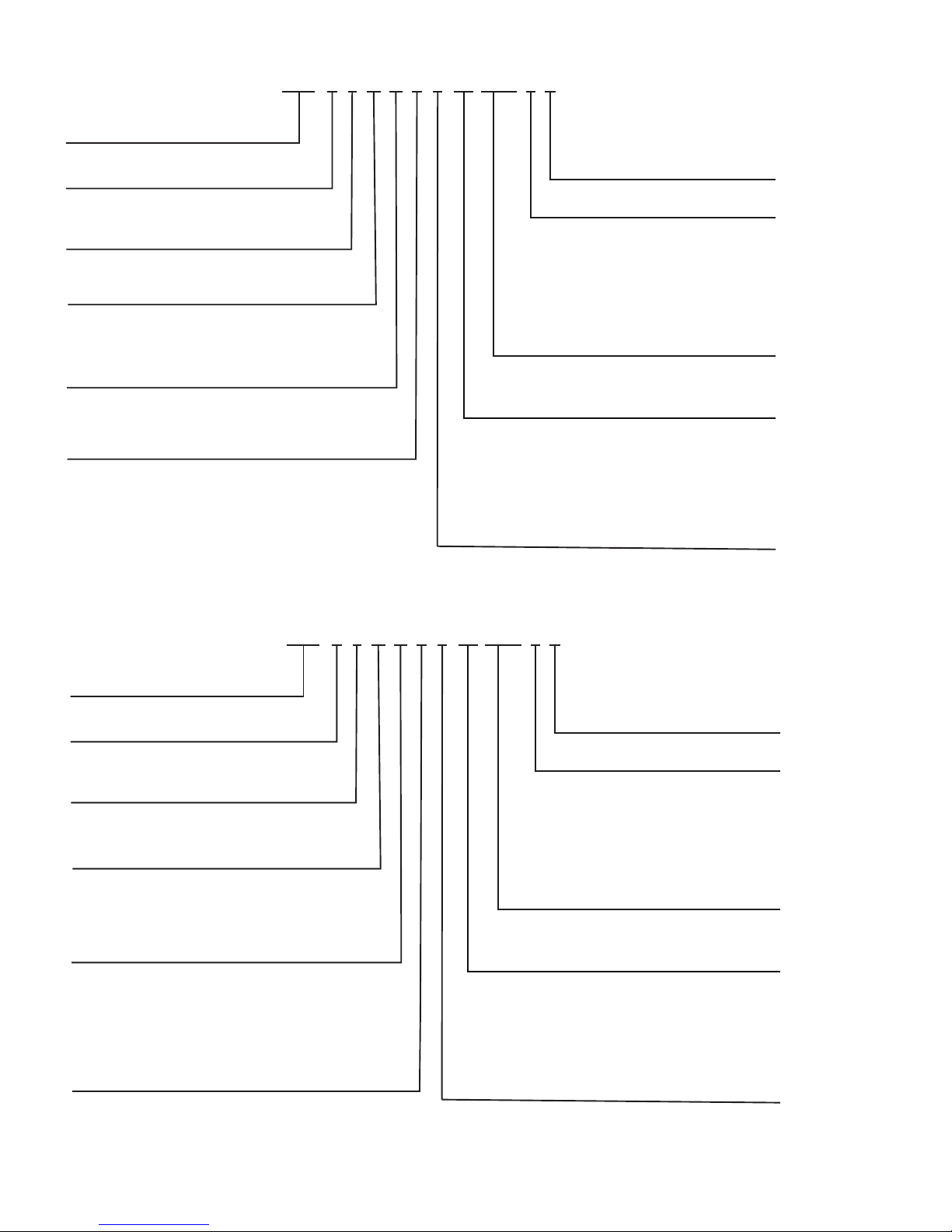

39L

28L – Drive Package Model Number

Drive Type

V – Variable Speed

Fan Type

K212

Unit Size

Large Face Area (sq. ft.)

10 B A 1250

Position 12 is 0 if rpm is 3 digits

1

Motor Horsepower

– Constant SpeedK

– Forward Curve without VFD

2 – Forward Curve with VFD

03

06

08

10

12

15

18

21

25

01

02

03

04

05

06

07

08

09

10

11

12

13

– ½ hp

– ¾ hp

– 1 hp

– 1 ½ hp

– 2 hp

– 3 hp

– 5 hp

– 7 ½ hp

– 10 hp

– 15 hp

– 20 hp

– 25 hp

– 30 hp

Motor rpm

60 Hz

– 1200A

BC – 1800

– 3600

50 Hz

– 1000D

EF – 1500

– 3000

Motor Type

XL (Across-the-Line)

– Open Drip ProofA

BC – Totally Enclosed, Non-Ventilated

– Totally Enclosed, Fan-Cooled

D

– Explosion Proof

E

– Encapsulated (Open Drip Proof Frame)

PW (Part-Wind)

– Open Drip Proof

– Totally Enclosed, Non-Ventilated

– Totally Enclosed, Fan-Cooled

– Explosion Proof

– Encapsulated (Open Drip Proof Frame)

F

G

H

J

K

Fan Speed rpm

3

3

Safety Factor

– 1 Set Belt

1.5 Safety Factor

Fig. 7 — Drive Package Model Number Nomenclature

a46-4446

5

PRE-HEAT

WATER

OR

PRE-HEAT

STEAM

PHW

LEGEND

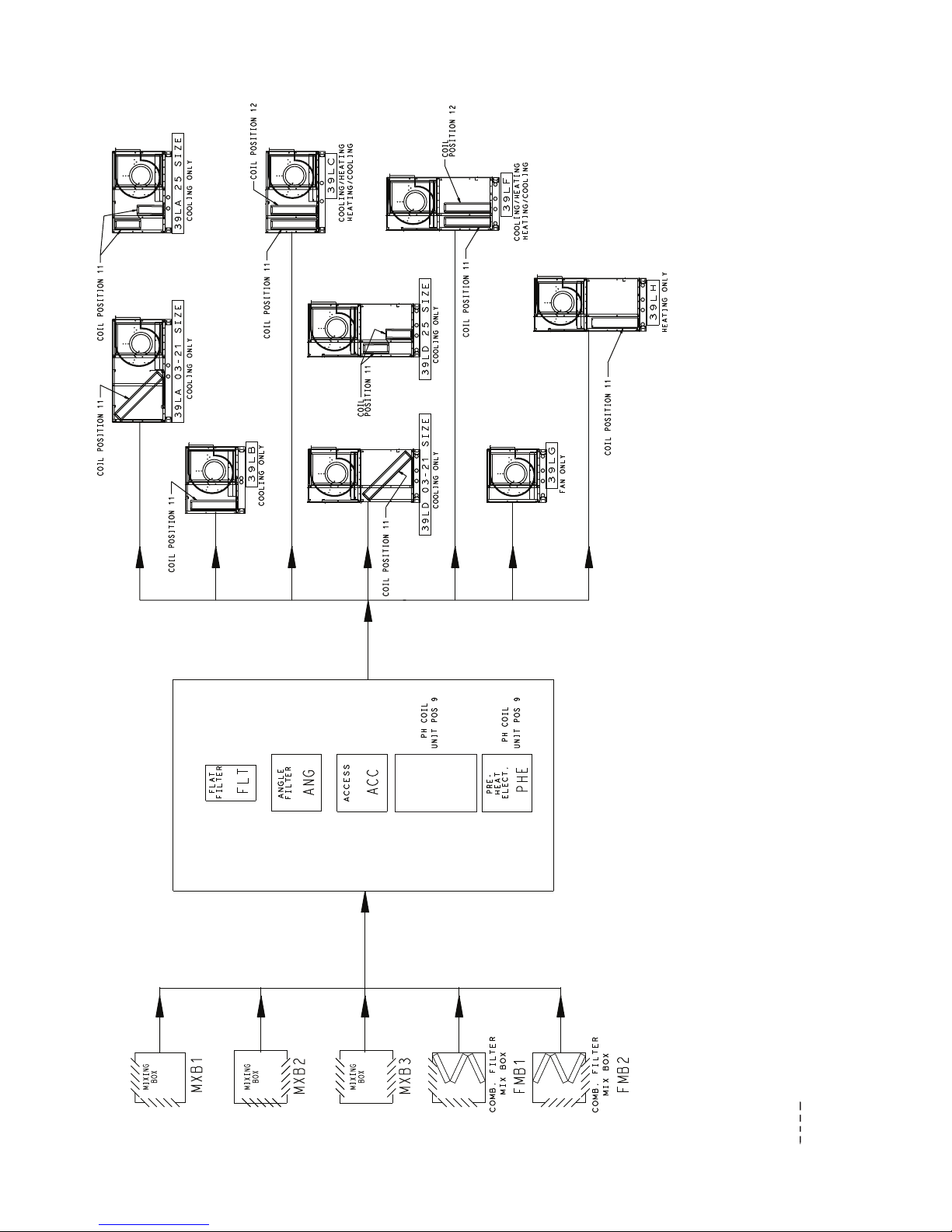

Fig. 8 — Position 4, Unit Configuration Model

(Component Sequence Also Shown)

COMB. — Combination

PH — Preheat

POS. — Position

Factory-installed option components

6

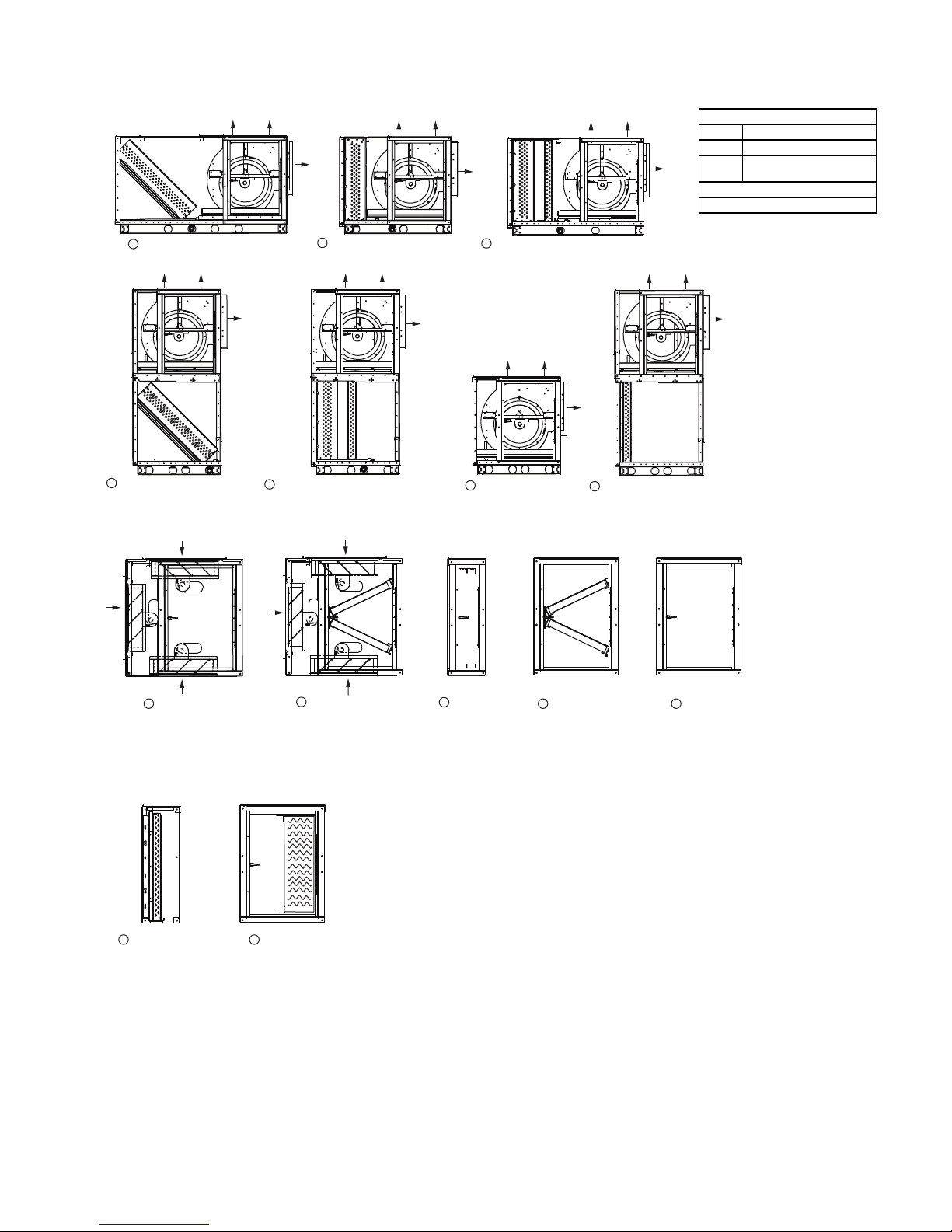

39LA – HORIZONTAL COOLING

LARGE FACE AREA

1

AB

PRIMARY COIL/FAN SECTIONS

C

39LB – HORIZONTAL COOLING

SMALL FACE AREA

2

AB

C

39LC – HORIZONTAL COOLING/HEATING

SMALL FACE AREA

3

AB

C

39LD – VERTICAL COOLING

LARGE FACE AREA

4

AB

C

39LF – VERTICAL COOLING/HEATING

SMALL FACE AREA

5

AB

C

39LG – FAN ONLY

6

AB

C

39LH – VERTICAL HEATING

SMALL FACE AREA

AB

C

7

ACCESSORY SECTIONS

Fig. 9 — Section Details

Fan Configurations

Available Configurations

A Upblast Rear Discharge

B Upblast Front Discharge

C

Top Horizontal Front

Discharge

Fan Section Access

Hinged Door on Hand Side

NOTE: Item numbers refer to Table 1.

a39-4447

a39-4448

MIXING BOX8

PREHEAT SECTIONS

13

HOT WATER

OR STEAM

PREHEAT COIL

9

FILTER MIXING BOX

FILTER MIXING BOX

14

ELECTRIC

PREHEAT

COIL

10

FLAT FILTER

11

ANGLE FILTER

12

PLENUM

7

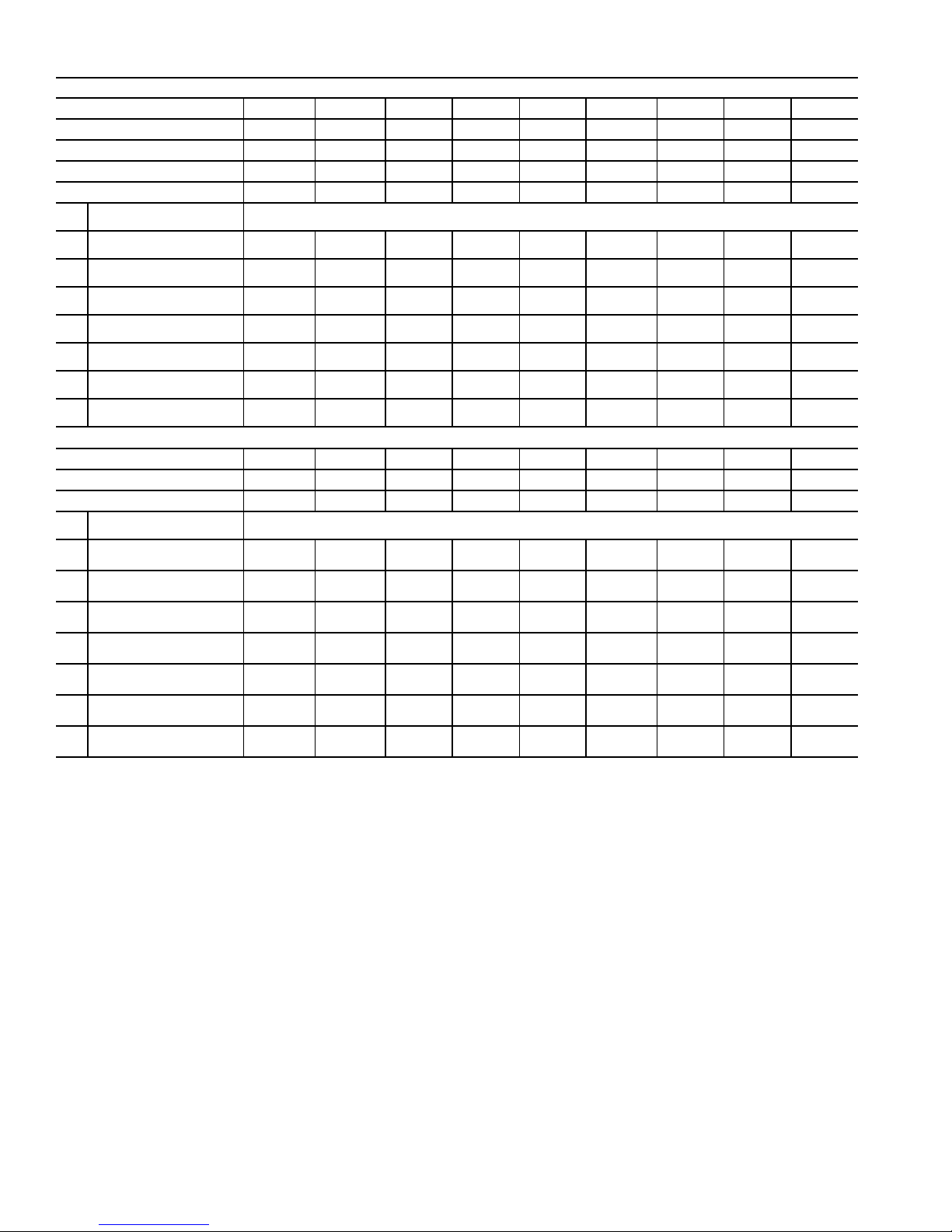

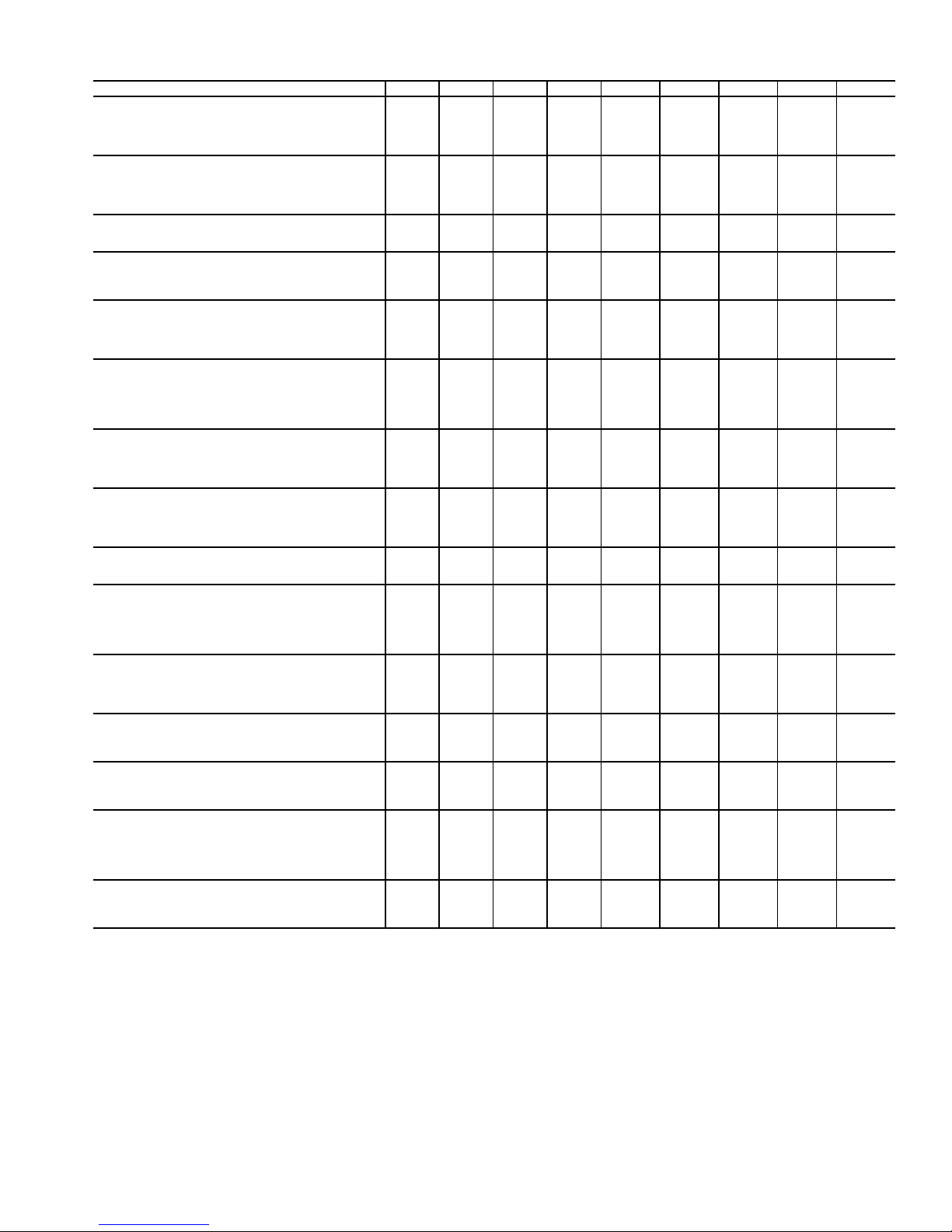

Table 1 — Section Dimensions and Weights

LEGEND

AWL — Airway Length

NOTE: Unit weights do not include coils and motors.

SECTION DIMENSIONS (in.) AND WEIGHTS (lb)

Nominal cfm at 500 fpm 1,500 3,000 4,000 5,000 6,000 7,500 9,000 10,500 12,500

Unit Size 03 06 08 10 12 15 18 21 25

Height (in.) LA, LB, LC, LG 24.3 28.2 32.1 32.1 32.1 40.0 43.9 43.9 43.9

Height (in.) LD, LF, LH 45.5 53.3 61.3 61.3 61.3 76.9 84.8 84.8 100.6

Width (in.) 37.9 45.8 49.7 57.6 65.1 65.1 65.1 77.3 77.3

ITEM

NO.*

1 39LA

2 39LB

3 39LC

4 39LD

5 39LF

639LG

7 39LH

ACCESSORIES

ITEM

NO.*

8 Mixing Box Section

9 Filter Mixing Box

10 Flat Filter Section

11 Angle Filter Section

12 Access Section

13

14 Preheat (Electric) Section

DESCRIPTION

Unit Size 03 06 08 10 12 15 18 21 25

Height (in.) 24.3 28.2 32.1 32.1 32.1 40.0 43.9 43.9 43.9

Width (in.) 37.9 45.8 49.7 57.6 65.1 65.1 65.1 77.3 77.3

DESCRIPTION

Preheat (Hot Water or

Steam) Section

40.9 48.8 56.7 56.7 56.7 72.4 80.3 80.3 76.4

200 280 411 470 540 620 695 740 820

29.1 33.1 37.0 37.0 37.0 44.9 48.8 48.8 56.7

150 210 308 352 405 465 521 555 615

37.0 40.9 44.9 44.9 44.9 52.8 56.7 56.7 64.6

170 238 349 400 459 527 590 629 697

21.3 25.2 29.1 29.1 29.1 37.0 40.9 40.9 48.8

230 322 472 540 621 713 799 851 943

21.3 25.2 29.1 29.1 29.1 37.0 40.9 40.9 48.8

230 322 472 540 621 713 799 851 943

21.3 25.2 29.1 29.1 29.1 37.0 40.9 40.9 48.8

120 168 246 282 324 372 417 444 492

21.3 25.2 29.1 29.1 29.1 37.0 40.9 40.9 48.8

220 308 452 517 594 682 764 814 902

27.6 27.6 27.6 27.6 27.6 27.6 35.4 35.4 35.4

139 164 193 219 226 244 283 272 311

27.6 27.6 27.6 27.6 27.6 27.6 35.4 35.4 35.4

150 173 208 227 245 279 327 340 395

7.9 7.9 7.9 7.9 7.9 7.9 7.9 7.9 7.9

37 43 48 50 55 74 75 86 90

19.7 19.7 19.7 19.7 19.7 19.7 19.7 19.7 19.7

75 82 97 107 114 134 140 159 185

19.7 19.7 19.7 19.7 19.7 19.7 19.7 19.7 19.7

48 55 60 64 68 74 77 87 92

7.9 7.9 7.9 7.9 7.9 7.9 7.9 7.9 7.9

36 42 43 46 49 52 54 53 57

19.7 19.7 19.7 19.7 19.7 19.7 19.7 19.7 19.7

49 56 61 66 72 74 76 87 89

AWL (in.)

Weight (lb)

AWL (in.)

Weight (lb)

* Item numbers refer to Fig. 9.

8

PREINSTALLATION

1. Check items received against packing list. Notify Carrier

of any discrepancy.

2. Refer to Fig. 10 for service area requirements.

3. To transfer unit from truck to storage site, refer to rigging

details in Fig. 11 and section on unit rigging for proper

handling. See Tables 1 and 2 for section and component

weights.

CAUTION

If a fork lift truck is used, lift only from heavy end of skid.

Minimum recommended fork length is 48 inches.

4. Do not stack unit components or accessories during storage. Stacking can cause damage or deformation.

5. If unit is to be stored for more than 2 weeks prior to installation, observe the following precautions:

a. Choose a dry storage site that is reasonably level

and sturdy to prevent undue stress or permanent

damage to the unit structure or components. Do not

store unit on vibrating surface. Damage to stationary bearings can occur. Set unit off ground if in

heavy rain area.

b. Remove all fasteners and other small parts from

jobsite to minimize theft. Tag and store parts in a

safe place until needed.

c. Cover entire unit with a tarp or plastic coverall.

Extend cover under unit if stored on ground.

Secure cover with adequate tiedowns or store

indoors. Be sure all coil connections have protective shipping caps.

d. Monthly — Remove tarp from unit, enter fan

section through access door or through fan inlet,

and rotate fan and motor slowly by hand to redistribute the bearing grease and to prevent bearing

corrosion.

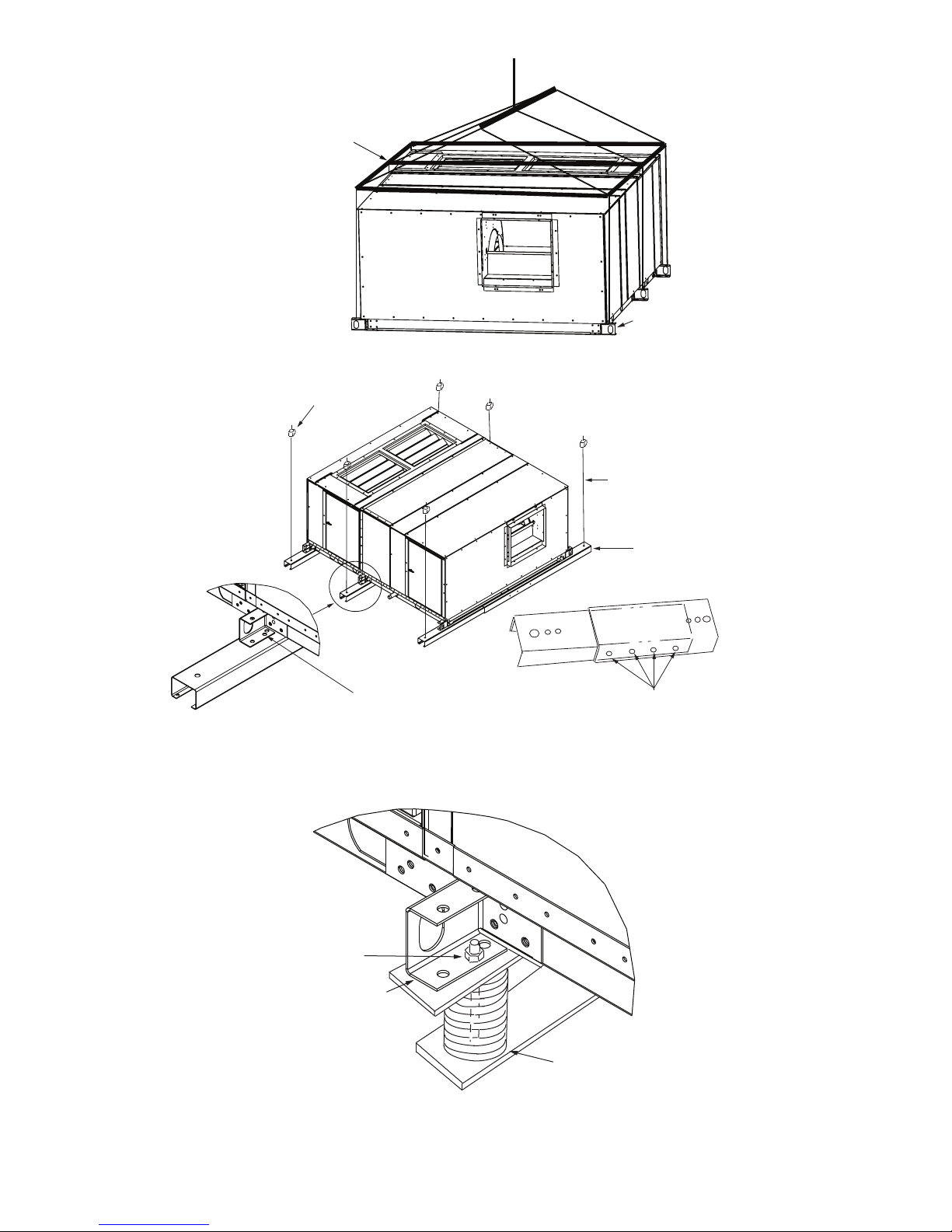

Rigging (Fig. 11) — All 39L units can be rigged by

means of the lifting brackets on bottom of unit.

Units are shipped fully assembled. Do not remove shipping

skids or protective covering until unit is ready for final placement. Use slings and spreader bars as applicable to lift unit. Do

not lift unit by coil connections or headers.

Do not remove protective caps from coil piping connections

until ready to connect piping.

Do not remove protective cover or grease from fan shaft until ready to install sheave.

Lay rigid temporary protection such as plywood walkways

in unit to prevent damage to insulation or bottom panel during

installation.

Suspended Units — Figure 12 shows overhead suspen-

sion of unit using optional factory-supplied suspension

channels.

Each support channel consists of 2 pieces, the smaller of

which fits inside the larger one. This allows the channel to be

adjusted to the required length for installation.

Channels are shipped on top of the unit. The 2 sections of

each channel are shipped one inside the other, and are held in

place during shipping by the panel screws in the top panel.

Hardware required for installation of suspension channels is

shipped in a package inside the fan section.

At least 2 suspension channels are shipped with each fan

and coil unit. One or more extra channels will be supplied

depending on the number of accessories ordered. Be sure to

install all the suspension channels shipped with a unit. Refer to

39L Isolator Mounting (Suspended Unit) certified drawing for

details.

To install suspension channels:

1. Remove panel screws to free suspension channels for installation. Replace screws in top panel.

2. Adjust channel to required length by sliding one channel

section inside the other. The channel must extend at least

9 in. but not more than 12 in. beyond the edge of the unit.

Set length of channel by installing factory-supplied bolts

through the overlapping channel sections.

3. Mount unit to suspension channel using factory-supplied

nuts and bolts through

7

/16-in. diameter holes in unit lift-

ing bracket.

4. Install field-supplied suspension rods through

9

/16-in. diameter holes provided at outer edges of channel. Be sure

hanger rods are securely fastened in place.

Service Clearance — Provide adequate space for unit

service access (fan shaft and coil removal, filter removal, motor access, damper linkage access, etc.) as shown in Fig. 10.

Condensate Drain — To prevent excessive build-up of

condensate in drain pan, adequate trap clearance must be provided beneath the unit. See Installation, Condensate Drain section on page 16 for additional details.

External Vibration Isolators — Install vibration iso-

lators per certified drawings, and in accordance with the job

specifications and the instructions of the vibration isolator

manufacturer. The coil piping must be isolated or have a flexible connection to avoid coil header damage because of unit

motion. A flexible connection should be installed at the fan discharge.

Fig. 12 and 13 show isolation location for overhead suspen-

sion or floor mounting of unit.

9

NOTE: Dimensions are in inches, ( ) are in mm.

DIMENSIONS (ft-in.)

SIZE A B C

D

E

39LA 39LB 39LC

03 3-17/83-13/41-91/41- 711/160-77/81-33/42- 39/

16

06 3-93/43-95/82-13/161-115/80-77/81-33/42- 39/

16

08 4-111/164-19/162-51/82- 39/160-77/81-33/42- 39/

16

10 4-99/164-97/162-51/82- 39/160-77/81-33/42- 39/

16

12 5-51/165-55/162-51/82- 39/160-77/81-33/42- 39/

16

15 5-51/165-55/163-1 2-119/160-77/81-33/42- 39/

16

18 5-51/165-55/163-415/163- 33/80-77/81-33/42-117/

16

21 6-51/46-51/83-415/163- 33/80-77/81-33/42-117/

16

25 6-51/46-51/84-015/162- 39/160-77/81-33/42-117/

16

DIMENSIONS (mm)

SIZE A B C

D

E

39LA 39LB 39LC

03 952 959 540 500 200 400 700

06 1162 1159 640 600 200 400 700

08 1262 1259 740 700 200 400 700

10 1462 1459 740 700 200 400 700

12 1653 1659 740 700 200 400 700

15 1653 1659 940 900 200 400 700

18 1653 1659 1040 1000 200 400 900

21 1962 1959 1040 1000 200 400 900

25 1962 1959 1240 700 200 400 900

Fig. 10 — Service Area Requirements

10

Table 2 — Additional Component Weights

UNIT SIZE 03 06 08 10 12 15 18 21 25

TYPICAL DRY COIL WEIGHTS (lb)

Large Face Area Cooling Coils,

1

/

-in. OD (Chilled Water & DX)*

2

4-Row 56 84 98 109 137 178 198 251 280

6-Row 63 95 123 138 174 234 270 327 363

Small Face Area Cooling Coils,

1

/

-in. OD (Chilled Water & DX)*

2

4-Row 45 72 91 105 133 161 182 211 238

6-Row 53 85 113 129 162 197 225 270 307

8-Row 61 92 129 143 189 228 263 324 377

Hot Water Coils,

1-Row 19 34 38 48 58 62 77 86 95

2-Row 28 43 51 61 76 89 104 117 130

Steam Coils, 1-row, 1-in. OD

6-FPI 50 70 85 95 110 135 150 180 215

9-FPI 55 80 100 115 125 155 175 214 256

12-FPI 60 85 115 130 145 180 205 248 297

FAN

Wheel Diameter (in.) 9

Wheel Width (in.) 7

Shaft Diameter (in.) 3/4 1

Maximum Fan Rpm 2500 2000 2000 1600 1600 1400 1300 1100 1000

OPERATING CHARGE (Approximate),

DIRECT EXPANSION COIL

Refrigerant R-410A or R-22 (lb)

4-Row Coil 1-2 2-3 3-4 4-5 4-5 5-6 6-7 6-8 6-9

6-Row Coil 1-2 2-4 5-6 5-6 6-8 8-10 9-11 11-13 11-16

8-Row Coil 2-3 3-5 5-6 5-7 7-9 10-12 12-14 13-19 16-24

COIL VOLUME (gal. water)

Chilled Water,

Large Face Area

4-Row 2.5 3.5 4.5 5.2 5.6 7.3 8.5 10.4 12.0

6-Row 3.2 4.7 6.0 6.8 7.7 10.1 11.7 14.2 16.3

Chilled Water,

Small Face Area

4-Row 2.1 3.3 3.9 4.1 5.1 6.3 7.3 8.7 9.8

6-Row 2.4 3.7 5.1 5.9 6.6 8.3 9.5 11.8 13.5

8-Row 2.7 4.1 6.4 7.4 8.4 10.7 12.1 14.7 17.2

Hot Water,

1-Row 0.5 0.8 1.0 1.3 1.5 1.8 2.1 2.5 2.9

2-Row 0.7 1.3 1.6 2.0 2.4 2.9 3.4 4.0 4.8

COOLING COILS

Chilled Water

(4, 6 Row) Large Face Area

Face Area (sq ft) 3.63 5.90 7.90 9.54 11.18 14.91 17.71 21.6 25.0

Number of Tubes/Face 16 20 24 24 24 32 38 38 44

Finned Tube Length (in.) 26.1 34.0 37.9 45.8 53.7 53.7 53.7 65.5 65.5

Chilled Water

(4, 6, 8 Row) Small Face Area

Face Area (sq ft) 2.72 4.72 6.58 7.95 9.32 12.12 13.98 17.1 20.5

Number of Tubes/Face 12 16 20 20 20 26 30 30 36

Finned Tube Length (in.) 26.1 34.0 37.9 45.8 53.7 53.7 53.7 65.5 65.5

1

DX

/

-in. OD Tube

2

(4, 6 Row) Large Face Area

Face Area (sq ft) 3.63 5.90 7.90 9.54 11.18 14.91 17.71 21.6 25.0

Finned Tube Length (in.) 26.1 34.0 37.9 45.8 53.7 53.7 53.7 65.5 65.5

1

DX

/

-in. OD Tube

2

(4, 6, 8 Row) Small Face Area

Face Area (sq ft) 2.72 4.72 6.58 7.95 9.32 12.12 13.98 17.1 20.5

Finned Tube Length (in.) 26.1 34.0 37.9 45.8 53.7 53.7 53.7 65.5 65.5

HEATING COILS

Hot Water

U-Bend (1, 2 Row)

Face Area (sq ft) 2.72 4.72 6.58 7.95 9.32 12.12 13.98 17.1 20.5

Number Tubes/Face 12 16 20 20 20 26 30 30 36

Finned Tube Length (in.) 26.1 34.0 37.9 45.8 53.7 53.7 53.7 65.5 65.5

Steam 1-in. OD (1 Row)

Face Area (sq ft) 2.13 4.18 6.22 7.53 8.85 11.06 13.28 16.2 18.9

Number Tubes/Face 4688 8 10121214

Finned Tube Length (in.) 25.5 33.4 37.3 45.2 53.1 53.1 53.1 53.1 64.9

LEGEND

DX — Direct Expansion

FPI — Fins Per Inch

1

/

2

1

/

-in. OD Tube,

2

1

/

-in. OD Tube,

2

1

/

-in. OD Tube

2

1

/

-in. OD Tube,

2

1

/

-in. OD Tube

2

1

/

-in. OD Tube,

2

-in. OD*

1

/

2

1

/

8

5

12

/

1

9

/

2

3

/

16

5

12

/

8

1

11

3

1

/

15 15 18

8

/

16

1

11

8

/

8

3

1

/

16

15 15 13

3

1

/

16

1

/

7

1

/

16

20 20 25

8

1

/

2

7

1

/

16

18 15

7

1

/

16

11

1

/

16

*Coils have 14 aluminum fins per inch on copper tubes.

NOTE: See Table 1 for section weights and dimensions.

11

SPREADER

BAR

LIFTING

BRACKET

Fig. 11 — Unit Rigging Details

NOTE: Lift in one piece. Use slings and

spreader bars at each lifting bracket.

a39-4449

LIFTING BRACKET

DETAILS

7

16

/

IN. DIAM. HOLE

VIBRATION ISOLATORS

(FIELD SUPPLIED)

SUSPENSION ROD

(FIELD SUPPLIED)

SUSPENSION CHANNEL

(FACTORY-SUPPLIED OPTION)

MOUNT UNIT TO SUSPENSION CHANNELS

THROUGH

PROVIDED IN LIFTING BRACKET

7

16

/

IN. DIAM. HOLES

FACTORY-SUPPLIED BOLTS

CONNECTING SUSPENSION

CHANNEL SECTIONS

OVERHEAD SUSPENSION

Fig. 12 — Unit Support Details, Overhead Suspension

a39-4450

SPRING ISOLATOR

ISOLATION BRACKET

7

16

/

IN. DIAM. HOLE

ISOLATION DETAIL – FLOOR MOUNT

Fig. 13 — Unit Support Details, Floor Mount

a38-4451

12

INSTALLATION

T-BRACKET

LIFTING LUG

Fig. 14 — Base Rail Split — T-Bracket

a39-4453

FLANGES

FLANGES

Fig. 15 — Base Rail Split — Flanges

a39-4454

Fig. 16 — Base Rail Split — Screws

a39-4455

Base Rail Split —

coil/fan section and the accessory sections is optional. If this

option has ben selected, the 39L unit will arrive at the job site

assembled as one piece. The split allows the unit to be separated at the joint.

If the unit must be separated in the field, follow this procedure:

1. Remove the lifting lugs on the inlet side of the coil/fan

section and those on the outlet side of the accessory section to liberate the T-bracket. See Fig 14.

2. Unscrew the flanges (top and sides) around the coil/fan

section and the accessory section. See Fig. 15.

A base rail split between the primary

CAUTION

Ensure that a good seal is created between both sections

before continuing. A poor seal may result in equipment

damage.

NOTE: If the section-to-section gasket installed at the factory

is damaged while splitting the unit, obtain the required length

1

of

/8 in. x 1 1/4 in. foam gasketing locally.

1

After rejoining the split sections, fully tighten all AB

/4 in.-3/

in. screws on the flanges and the AB 1/4 in-5/8 in. screws on the

flanges. See Fig. 16.

4

AB ¼-

5

SCREWS

8

/

13

AB ¼-¾ SCREWS

Mixing Box

MXB — Mixing Box

Fig. 18 — Mixing Box Ductwork Attachment

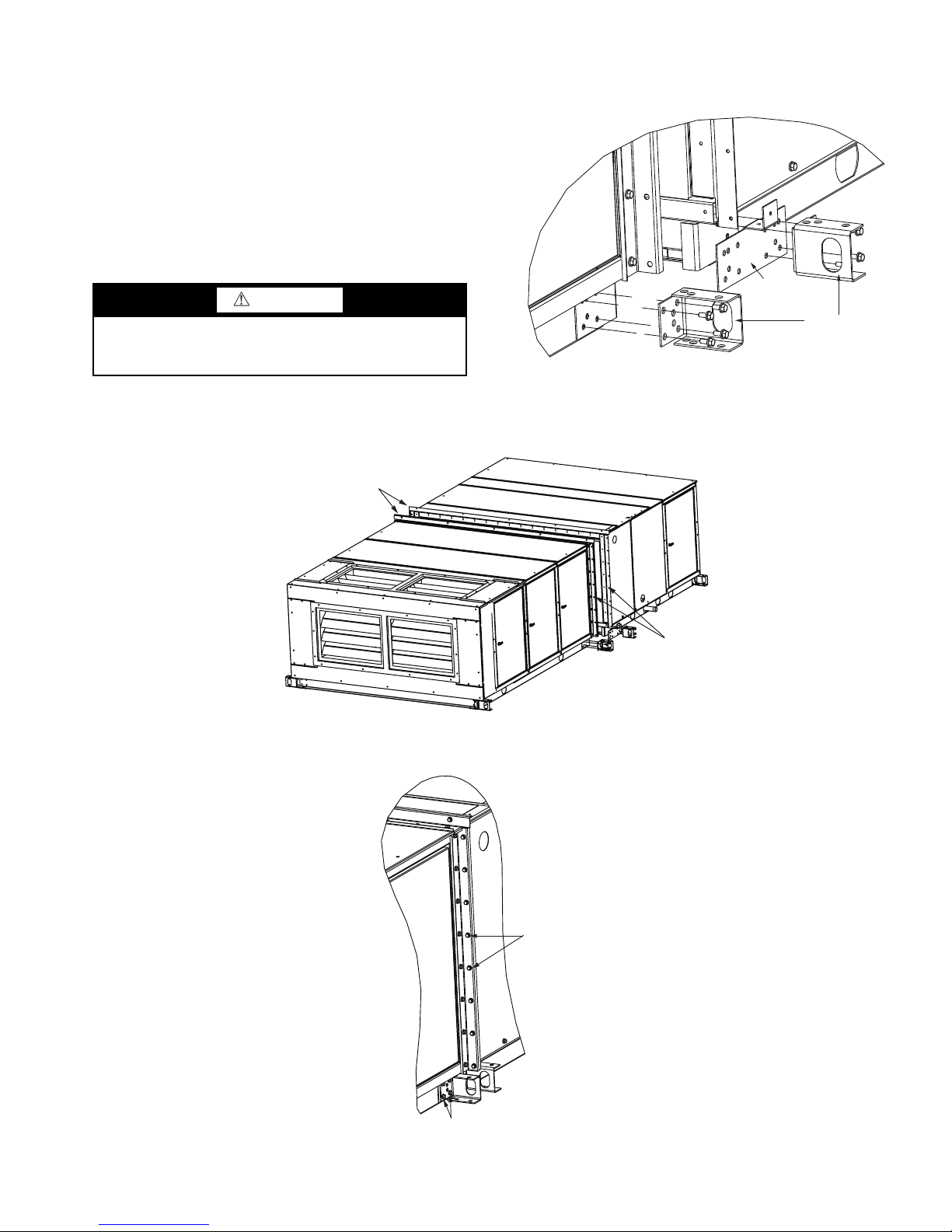

Fig. 17 — Typical Mixing Box Actuator Mounting

DAMPER ACTUATORS — The 39L mixing boxes are supplied with low leak dampers and blade and edge seals. Damper

operating torques are shown in Table 3.

The actuator and mounting brackets are field supplied and

may be mounted inside or outside the unit. A typical inside

mounting bracket is shown in Fig. 17. For external mounting of

actuators, drill or punch a hole in the exterior panel.

NOTE: If the unit is shipped with AirManager™ controls,

actuator(s) are factory-supplied. Refer to Table 4.

To ensure torque is transmitted equally to both damper sections, actuator must be connected to the 1-in. hollow jackshaft

that drives the interconnecting linkage bar. Connection to any

other shaft is not recommended.

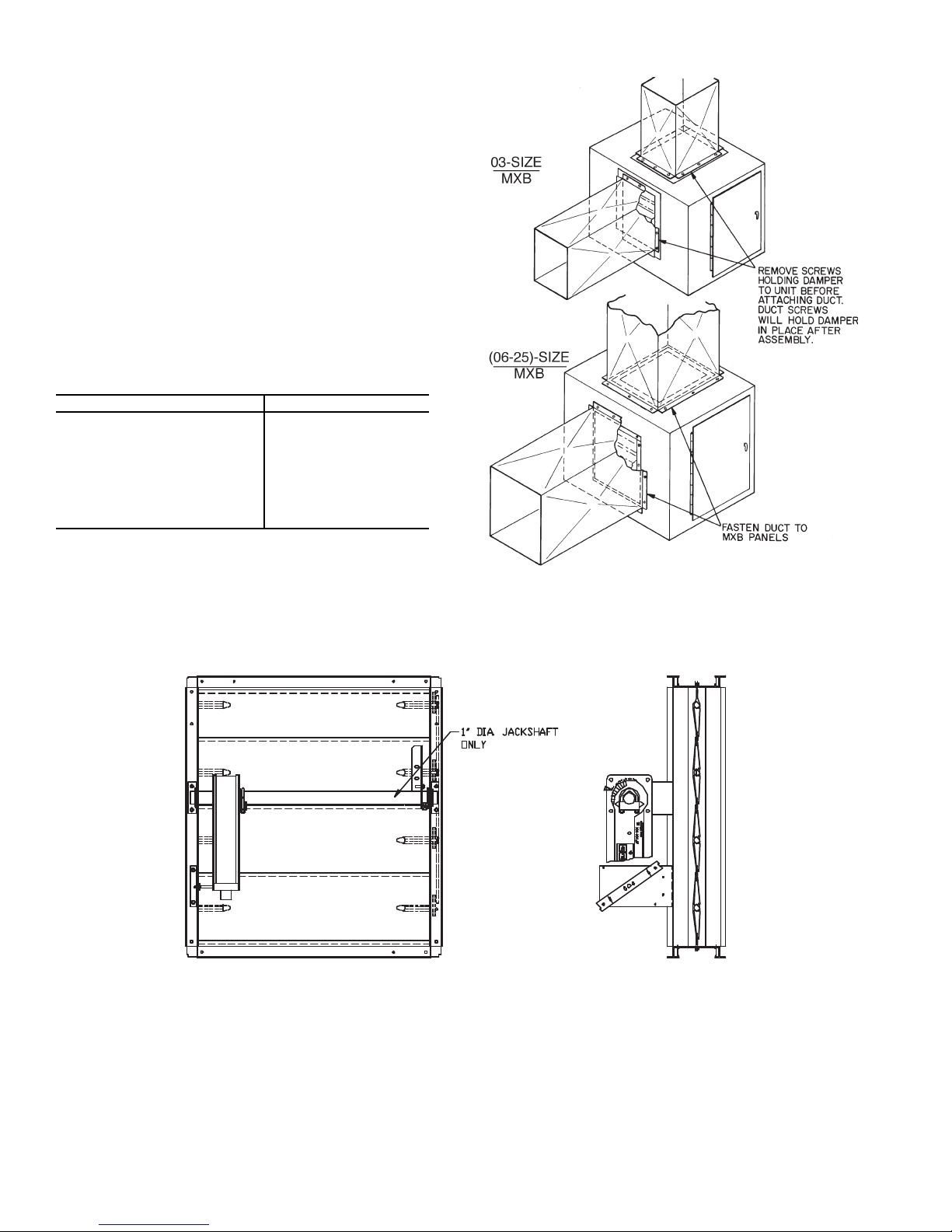

DUCTWORK ATTACHMENT — Ductwork should be

flanged out and attached to the mixing box panels as shown in

Fig. 18. See Fig. 19 for duct connection sizes.

Table 3 — Mixing Box Damper Operating Torque

(in.-lb)

39L UNIT SIZE TORQUE

03 20

06 20

08 26

10 29

12 33

15 41

18 52

21 56

25 76

NOTES:

1. Torque values are based on interconnected dampers driven by

one operator. For units with separate operators for each

damper, calculate torque as follows: Table values x .80 = torque

per damper section.

2. Damper shaft moves 90 degrees from open to closed position.

14

Table 4 — Recommended Actuators

DIMENSIONS (ft-in.)

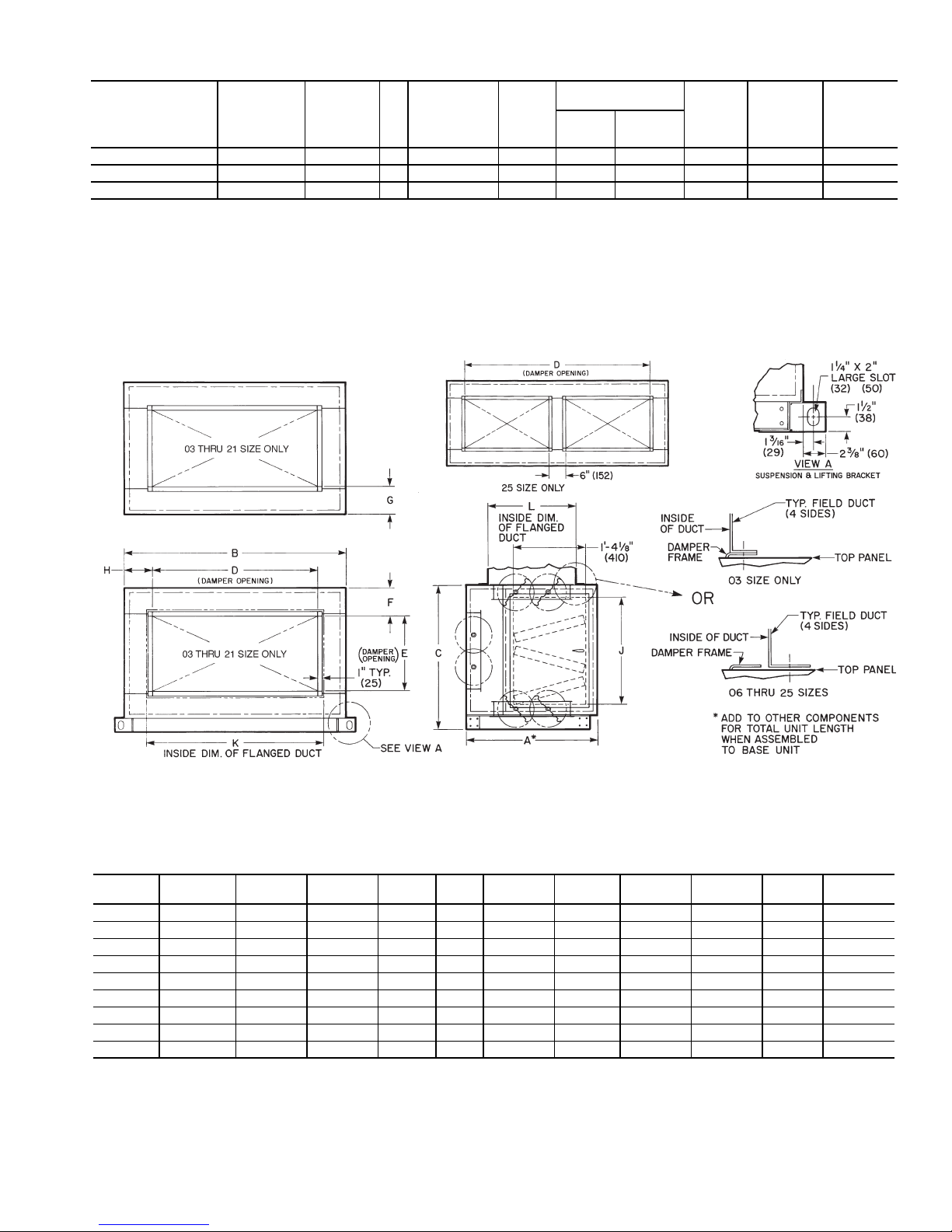

Fig. 19 — Mixing Box Duct Connections

UNIT

39L-

A B C D E F G H J K L

03 2- 39/

16

3-17/

8

2-01/

4

1- 5 1-5 0- 15/

8

0-61/

16

0-101/

2

1-43/

4

1-51/

4

1- 51/

4

06 2- 39/

16

3-93/

4

2-43/

16

1-11 1-5 0- 41/

8

0-61/

16

0-113/

8

1-811/

16

2-11/

4

1- 71/

4

08 2- 39/

16

4-111/

16

2-81/

8

3- 1 1-5 0- 61/

16

0-61/

16

0- 63/

8

2-05/

8

3-31/

4

1- 71/

4

10 2- 39/

16

4-99/

16

2-81/

8

3- 5 1-5 0- 61/

16

0-61/

16

0- 85/

16

2-05/

8

3-71/

4

1- 71/

4

12 2- 39/

16

5-57/

16

2-81/

8

3-11 1-5 0- 61/

16

0-61/

16

0- 91/

4

2-05/

8

4-11/

4

1- 71/

4

15 2- 39/

16

5-57/

16

3-4 3-11 1-9 0- 8 0-41/

16

0- 91/

4

2-81/

2

4-11/

4

1-111/

4

18 2-117/

16

5-57/

16

3-715/

16

3-11 2-3 0- 7 0-5 0- 91/

4

3-07/

16

4-11/

4

2- 51/

4

21 2-117/

16

6-51/

4

3-715/

16

3-11 2-5 0- 6 0-4 1- 31/

8

3-07/

16

4-11/

4

2- 71/

4

25 2-117/

16

6-51/

4

4-313/

16

5- 4 2-5 0- 97/

8

0-4 0- 65/

8

3-85/

16

5-61/

4

2- 71/

4

NOTES:

1. Hand is determined by the location of the fan drive and/or coil connection when viewed

while facing the direction toward which air is flowing.

2. Dimensions are in inches, ( ) are in millimeters.

ACCESSORY

PACKAGE

NO.

ACTUATOR

PART NO.

VOLTAGE

(50/60 Hz)

VA

ROUND

SHAFT

SIZE

MIN-MAX

(in.)

TIMING

(sec)

DAMPER AREA

(sq ft)

Parallel Opposed

TORQUE

(in.-lb)

MAXIMUM

STROKE

(degrees)

MAXIMUM

WIRE

LENGTH

33AMACTDMP133 HF27BJ035* 24 10 0.750-1.050 150 44 53 133 90 300

33AMACTGV-133 HF27BJ033 24 4 0.375-0.625 < 150 N/A N/A 133 90 725

33AMACTGV-266 HF27BJ034 24 6 0.475-0.750 135 N/A N/A 266 90 450

*Actuator is spring-return type.

NOTES:

1. All actuators are direct coupled type, designed to be directly

mounted into jackshaft assembly.

2. All actuators are equipped with a plenum rated cable, factoryterminated to the actuator. Part No. HF27BB035 and 034 are

16 ft, HF27BB033 is 9.5 ft.

3. Damper areas are nominal and based on low leakage type

dampers.

4. For larger damper assemblies, multiple activators may be used.

5. Part No. HF27BB033 and 034 are designed for inlet guide vane

and face and bypass applications, but may be used for external

relief dampers if spring return is not required.

(ft)

15

Loading...

Loading...