Carrier 38GP User Manual

Carrier

International

Corporation

Installation, Operation,

and Maintenance Instructions

Important—Read Before Installing

Check the power supply: Voltage, frequency, and phase

must correspond to that specified on the unit rating plate.

The power supply must be able to handle the additional elec

trical load imposed by this equipment.

The Model 38GP Condensing Unit does not have a trans

former; therefore, the fan-coil or blower package trans

former (or another source) must be used as a low-voltage

supply. The low-voltage supply must have an additional

capacity of 15VA to handle the load imposed by this

equipment.

The compressor motor is equipped with em internal protec

tor. Excessive current or temperature wiU cause the protec

tor to open, giving the indication of an open circuit in the

motor winding. Sufi&cient time should be allowed for the

overload to reset before assuming the compressor has an

open winding.

The compressor motor is designed to start under low-load

conditions only (high- and low-side pressures equalized) and

within the specified operating voltage range. Make sure

that system pressures have equahzed before attempting to

start the unit. Equahzation takes approximately 3 minutes.

The owner should be informed not to short-cycle the unit

with the thermostat as this wiU cause the compressor to

tripout on overload.

Each condensing unit is shipped with a refrigerant charge

that is adequate for most systems using matching coils and

refrigerant tubing kits. This charge is adequate for up to 25

feet of interconnecting tubing. For tube lengths greater or

less than 25 feet, the refrigerant charge must be adjusted.

See Table II for charge quantity and refer to refrigeranttube sizing. Tables IV through VII, for the adjustment re

quirements.

NOTE: If additional refrigerant is needed, a crankcase heater

wül probably be required. (Refer to the appropriate refriger

ant-tube sizing table.) When a crankcase heater is used,

inform the homeowner that power must be turned on to the

air conditioning unit at least 12 hours before the thermostat

is turned to the COOLING position for spring startup.

A filter-drier is not normally required in the system when a

complete system is used (condensing unit, refrigerant tub

ing, and evaporator coil). For exceptions to this rule, see

Section II, “Installing Refrigerant Tubing,” of the Stand

ard Installation Practices booklet packaged with the unit.

To obtain optimum performance and efficiency with match

ing or mix-matched evaporator coils, it may be necessary to

change the metering device. See Table IX for necessary

changes.

^Carrier International Corporation 1984

38GP

(50-HZ)

Figure 1—Model 38GP

GENERAL

The condensing unit, as shipped from the factory, includes:

a compressor, a condenser fan and motor, hquid and suction

service valves, an air-cooled condenser coil, and all neces

sary electriceil controls.

The condensing unit is designed for use with matching

evaporator coils. An expansion valve is not required. How

ever, the unit can be used with a suitable evaporator coil

that uses an expansion valve with a pressure equalization

feature during the off cycle. Expansion valves with this fea

ture.are available from your Distributor.

Installation comprises the following steps (sections):

I. Locating the Unit

II. InstaUing Refrigerant Tubing

III. Leak Testing

IV. Purging (if required)

V. Evacuation (if required)

VI. Electrical Connections

VII. Checking Charge

VIII. Adjusting Charge

38GP-C12SI-CIC

AIR IN

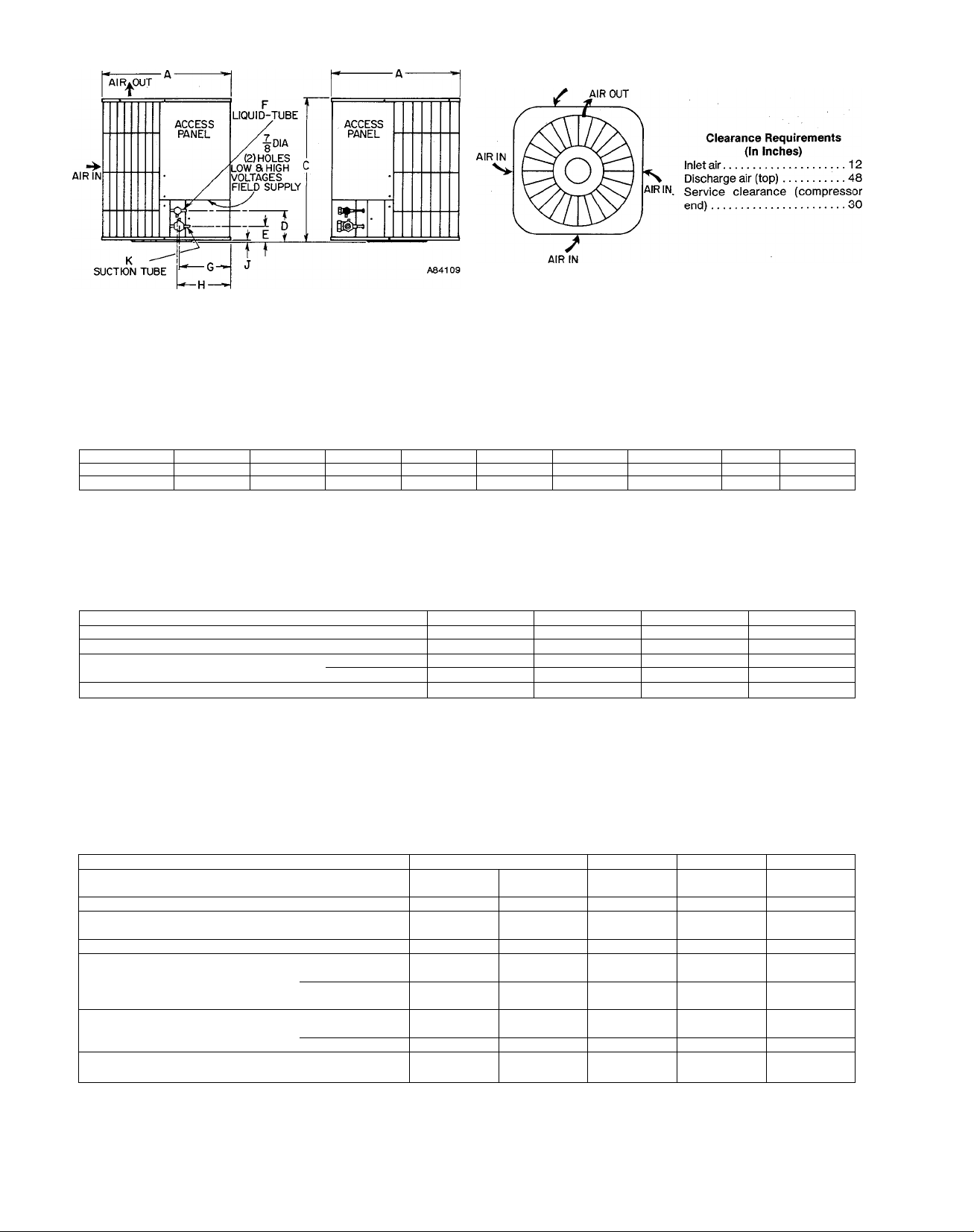

NOTE: Fan position on motor shaft should be as close to motor as possible without touching.

Figure 2—Dimensional Drawing

TABLE I—DIMENSIONS (In Inches)

Size

025

040, 047 & 054

----------X---------27-3/8 24-9/16 6-3/8 1-7/8 3/8

27-3/8 30-9/16 6-3/8 1-7/8 3/8

----------C----------

D

----------1----------

F G

11-9/16

11-9/16

H

11-3/4

11 -3/4

11/32 3/4

11/32

3/4

K

TABLE II—SPECIFICATIONS

Refrigerant Type R-22

Size 025

Factory Refrigerant Charge Lbs-oz 4-8

040

R-22 R-22

6-8 7-2

Refrigerant Tube^ Liquid 3/8 3/8

Connection Size (Compatible) Vapor 3/4 3/4

Approx Shipping Weight Lbs 155 200

♦Refer to appropriate refrigerant tube sizing table to determine correct liquid- and suction-tube diameters.

047

3/8

3/4

230

054

R-22

6-11

3/8

3/4

232

TABLE III—ELECTRIC CONNECTIONS

Nameplate

Size 025 040

Volts—Phase (60-Hertz) 230—1—50

Operating Voltage Range

207-253 360-440 360-440 360-440 360-440

400—3—50

400—3—50

Unit Ampacity for Elec

trical Conductor Sizing. 18.5 6.7 9.2 14.1

Total Unit Amps 15.1 5.6 7.6

Min Branch Circuit

Wire Size

Copper

Conductor^

AWG No.

Max Length

In Ftt

12 14 14 14

94 321 236 156 228

Largest Wire Size

Terminal Will

, Accommodate

Type Conn

AWG No. 6

Screw Screw

6 6 6 6

Screw

Max Branch. Circuit

Fuse Sizet

Amps 25

10

15

NOTE: Use copper wire only between disconnect switch and unit.

♦If other than 75° C copper conductor is used, determine size from unit-ampacity and the National Electric Code. Voltage drop of wire must be less

than 2% of unit rated voltage.

fLength shown is as measured one way along the wire path between the unit and service panel-for minimum 2% voltage drop.

$Sing)e-phase units may use fuses or HACFI-type circuit breakers of same size as noted.

047 054

400—3—50 400—3—50

15.4

11.5 12.5

12

Screw Lug

20 20

All of the above steps are covered in general by the likenumbered sections of the Standard Installation Practices in

the back of this manual; therefore, this Installation Instruc

tion will contain only supplementary information applicable

to installing the condensing unit. It should be noted that

evacuation and purging are not normally required when a

complete matching system is installed. However, if any of

the component parts are subject to contamination, or if tub

ing kits and matching coUs are not used, the system must

be purged or evacuated.

NOTE; Be sure to adjust system airflow per requirements of

the fan-coil, evaporator coil, and condensing unit

combination.

In addition, the following sections should be reviewed by

the equipment owner;

IX. Sequence of Operation

X. Care and Maintenance

I. LOCATING THE UNIT

(Supplementary Instructions)

Select a location for the unit where water, ice, emd snow will

not fall from an overhang and damage the unit top or fan

blade. Care must be exercised to maintain the clearance

requirements listed on page 2 to assure proper access for

servicing and to avoid recirculation of condenser air.

II. INSTALLING REFRIGERANT TUBES

(Supplementary Instructions)

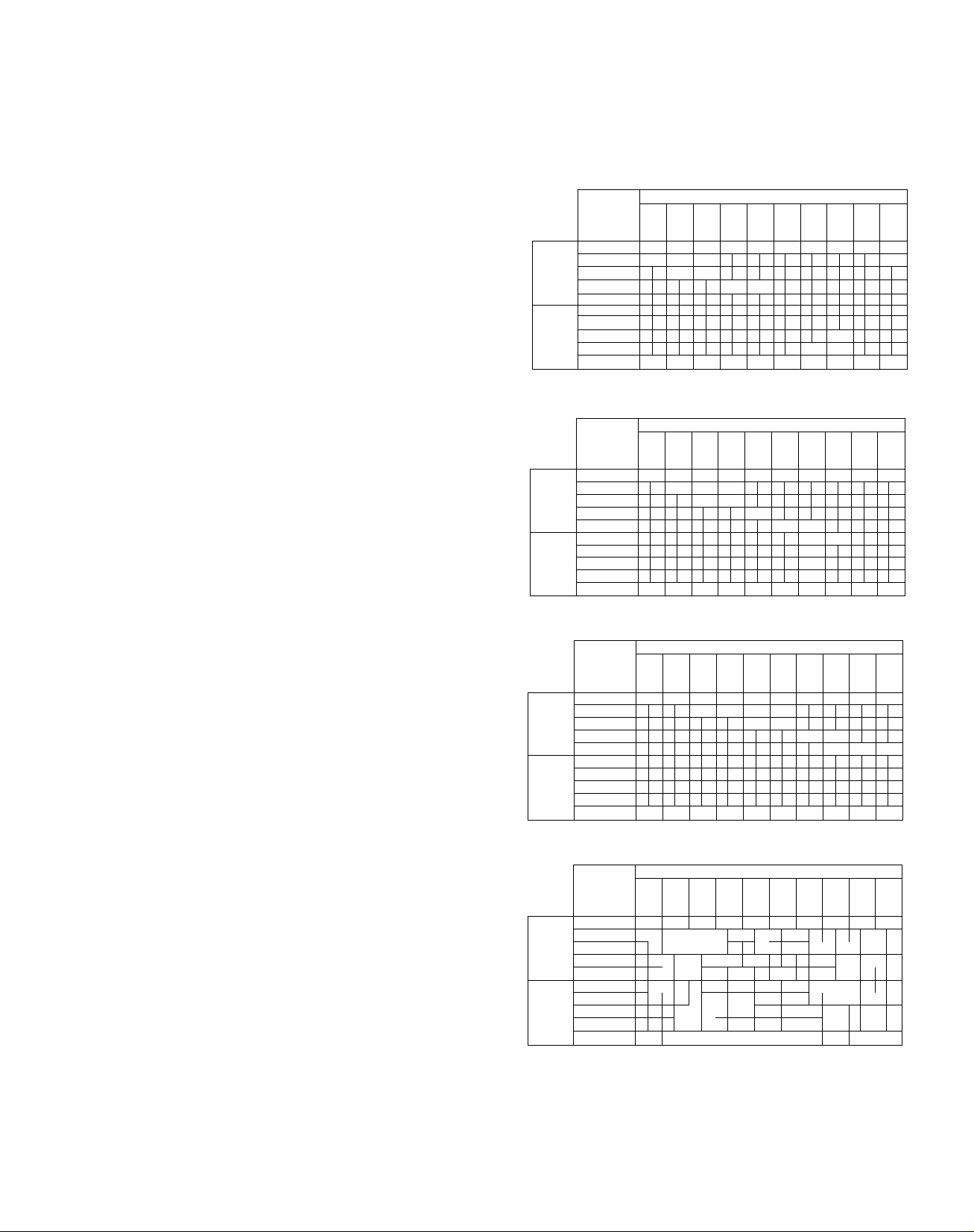

A. Determining Liquid-Tube Diameter

The correct liquid-tube diameter cem be determined by using

the appropriate table as described in steps 1 through 7

which follow. Be certain to use only the hquid-tube table

that matches the size unit being installed. (See Tables IV

thru VII.)

1. Measure total one-way horizontal distance for intended

tubing path.

2. Measure total one-way vertical distance for intended

tubing path.

3. At left-hand end of table, select value that matches

measured vertical length. Be sure to note that upper

section of table is used if coohng coü is above unit,

whereas lower section is used if cooUng coil is below

unit.

4. Move across this Une towards right-hand side until cor

rect vertical column is reached for measured horizontal

length.

5. Correct diameter will be indicated at intersection of

these lines.

6. If point of intersection falls within shaded area, crank

case heater must be added.

7. For apphcations where coohng coil is to be placed more

than 50 feet below unit, see your Distributor for spe

cific recommendations.

Here is an example; Unit is size 025. Coohng coil is located

43 feet above unit. Horizontal distance is 72 feet.

First, in the section marked “Coü Above Unit,” find the hne

showing measurement of 41-50 feet. Follow this line

towards the right until it intersects the vertical colunrn

marked 71-80 feet. The correct tube size is 5/16-inch OD,

and the fact that the 5/16-inch size falls in the shaded area

means that the unit wih require a crankcase heater.

B. Instructions for Total System Charge

The total system refrigerant charge includes the condensing

unit, the evaporator coü, and the interconnecting tubing.

The factory charge is sufficient for a system using 25 feet of

interconnecting tubing and a matching evaporator coil. For

systems using tubing lengths other than 25 feet, adjust the

charge in accordance with the notes under the proper table

(IV through VII).

TABLE IV—UNIT SIZE 025

Vertical

Distance to to to

(Ft) 10 20 30 40

Coil

Above 21 to 30 1/4 1/4

Unit

Coil

Below

Unit

41 to 50

31 to 40, 1/4

11 to 20 1/4 1

Oto 10

Oto 10

11 to 20

21 to 30

31 to 40 1/4

41 to 50 1/4 1/4 51«; /3«,

D 11 21 31

5/16 5/16 5/46 5/16

Horizontal Distance- -Feet

to to to

5/16 5/-16 5/16

t

t

4,/4,<

41 51

50 60 70 80 90 100

61

to to

5/16

71 81 91

to to

5/16 3/8

5/16

1/4

1

5/16

5/J6

5/16

5/16

TABLE V—UNIT SIZE 040

Horizontal Distance— Feet

Vertical a

Distance to to to to to to to to to to

(Ft)

Coil 31 to 40

Above 21 to 30 1./4

Unit 11 to 20 1/4

Coil 11 to 20

Below

Unit

41 to 50 1/4 5/16 5/16 5/16 5/16 5/16 5,'16 5/16 5/16 5/16

Oto 10 1/4

Oto 10 1/4

21 to 30 1/4

31 to 40

41 to 50 1/4 1/4 1/4 1/4 1/4 1,-4

11 21 31 41 51 61 71 81

10 20 30 40 50 60 70 80 90 100

1/4

t

t

1/4

Î

5/16

5/16

5./16

91

5/16

TABLE VI—UNIT SIZE 047

Horizontal Distance— Feet

Vertical 11 21 31

Distance to to to to to to to to to to

(Ft)

41 to 50 5/16 5/16 3/8 3/8

Coil 31 to 40 5/16 5/16

Above 21 to 30 5/16

Unit 11 to 20 5/16 5/16

Oto 10

Oto 10

Coil 11 to 20

Below 21 to 30

Unit 31 to 40

41 to 50 5/16 5/16 5/16 5/16 5/16 5/16 5/16 5/16 5/16

10 20 30 40 50 60 70 80 90 100

41

51 61 71 81 91

3/8 3/8 3/8

3/8

m/§

.t

5/16

t

5/16 5/16

5/16

TABLE VII—UNIT SIZE 054

Vertical 11 21 31 41 51 61 71 81 91

Distance to to to to to to to to to to

(Ft)

Coil 31 to 40

Above 21 to 30

Unit 11 to 20 5/ 5.'16

Coil

Below

Unit

(1) Unit charge adequate for 3/8-in. OD tube lengths up to 25 ft. For lengths

(2) Unit charge adequate for 1/4-in. OD tube lengths up to 75 ft. For lengths

(3) Unit charge adequate for 5/16-in. OD tube lengths up to 40 ft. For lengths

(4) If tube size falls within shaded area, add crankcase heater.

41 to 50

Oto 10

Oto 10

11 to 20

21 to 30

31 to 40

41 to 50 5/16

below or above 25 ft, adjust charge at rate of 0.6 oz/ft. This may be done by

using superheat charging label.

above 75 ft, adjust charge at rate of 0.2 oz/ft.

above 40 ft, adjust charge at rate of 0.4 oz/ft.

10

3/8 3/8 3/8 3/8

5/ 16

' ’

Horizontal Distance— Feet

30 40 50

20

t

5.'16] 5/ 1 6

5/16|5/16|5/16|5/16|5/16 3/8 3/8 3/8 3/8

3 5

1'

i J

70 80 90

60

3./8 3/8 3/8 3,'8 3/8

5/16

5 1 6

1

i

6

...

4

100

—3—

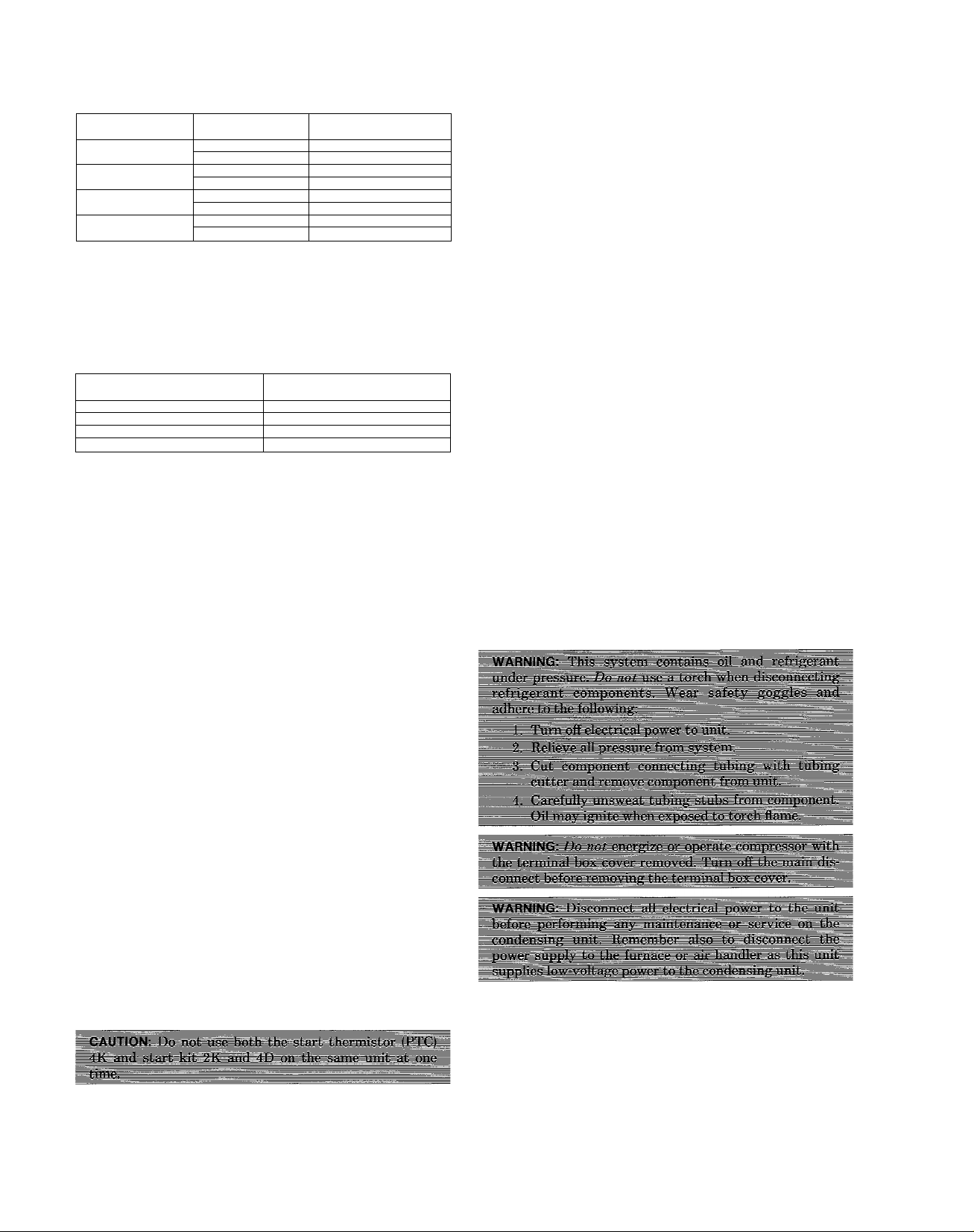

TABLE Vili—RECOMMENDED

SUCTION-TUBE DIAMETERS

Suction-Tube

Size

025 0 to 120 5/8

040 Oto 60

047

054 0 to 65 1-1/8

NOTE: The above table is based on a tube loss of 2°F. Longer lengths

can be used in each diameter listed, or smaller diameters may

be used, but the result will be larger tube losses with a lower

unit capacity and efficiency rating. Refer to your Distributor for

specific details.

Length (Feet)

120 to 150 7/8

60 to 135 7/8

Oto 85 7/8

85 to 150 1-1/8

65 to 150 1-3/8

Recommended

Diameter (inches)

3/4

TABLE IX—REQUIRED PISTON SIZE FOR

INDOOR COIL

Condensing

Unit Size

025

040 76

047

054 88

NOTE: The piston sizes listed in this table are for systems where the

vertical separations between indoor and outdoor units do not

exceed 10 feet. For vertical separations exceeding 10 feet,

consult the factory for the proper piston sizes.

Piston

identification No.

59

82

If other than matching interconnecting tubing or evapora

tor coU is being used, use an accurate scale or volumetric

charging cylinder (such as a Dial-A-Charge) and weigh in the

refrigerant until the desired superheat temperature is

obtained. See the superheat charging label attached to each

condensing unit.

When system charging has been completed, stamp the total

amount of refrigerant in the block provided on the condens

ing unit rating plate. The total system charge is the same as

the field charge.

C. Determining Suction-Tube Diameter

The correct suction-tube diameter can be determined by

using Table VIII as follows:

1. Measure total length (vertical and horizontal) of

intended tubing path.

2. Find correct unit size at left of table.

The tube lengths are shown in the center of the table

with the appropriate diameters on the right.

iX. SEQUENCE OF OPERATiON

When the thermostat “calls for cooling,” the thermostat

contacts close, energizing contactor holding coil 2D or 2M

from a 24-volt external power source. The contactor closes,

energizing compressor motor 3F or 3J and condenser fan

motor 3C or 3D with supply voltage.

When the thermostat is satisfied, the contacts open,

deenergizing contactor holding coil 2D or 2M and, in turn,

breaking the supply voltage circuit. AH motors should stop.

Optional Start Assist (When Used)

Start thermistor 4K is wired in parallel to run capacitor 4G

on single-phase units. Its purpose is to provide additional

start assist. When compressor 3J starts, start thermistor

4K builds its internal resistance to a level where it effec

tively removes itself electrically from circuit. When contac

tor 2D or 2M is deenergized, start thermistor 4K will auto

matically reset itself in approximately 3 to 5 minutes.

Start Kit 2K and 4D

The start kit consists of start relay 2K and start capacitor

4D. Start capacitor 4D helps compressor 3J start. When the

compressor starts, start relay 2K disconnects start capaci

tor 4D from the circuit, allowing compressor 3J to run on

run capacitor 4A or 4G. When contactor 2D or 2M deener

gizes, start relay 2K reconnects the start capacitor in the

circuit, making it ready for the next compressor start.

X. CARE AND MAINTENANCE

For continuing high performance, and to rnmirnize possible

equipment failure, it is essential that periodic maintenance

be performed on this equipment. Consult your local Dealer

for the proper frequency or maintenance and the availability

of a maintenance contract.

The air for the condenser coil is drawn into the unit on four

sides and discharged out the top. Keep the air inlet and out

let grilles unplugged and clear of any obstructions at all

times. Never cover the unit or lean anything against it

which might restrict airflow or cause hot air from the top

grille to recirculate into the sides. Keep trash and debris

away from the uiut at all times. Never stand on the unit or

use it as a support for ladders, etc.

The refrigerant tubing connecting this unit with the coohng

coil is easily crushed or crimped. Therefore, do not hang or

stand anything on it. Do not move the unit after it has been

installed, as this may crimp the tubing and cause the unit to

malfunction.

The ability to properly perform maintenance on this equip

ment requires certain mechanical skills and tools. If you do

not possess these, contact your Distributor for

maintenance.

The minimum maintenance that should be performed on

this equipment is as follows:

1. Check condenser coü for cleanliness each month during

cooling season. Clean as necessary, but at least once at

the beginning of each cooling season. To insure reliable

performance in sea coast or contaminated atmosphere

installations, the unit must be kept free of debris and

the condenser coil flushed with fresh water at least

once a month. See Section X, item A, for proper

procedures.

—4—

Loading...

Loading...