Canon S6300 User Manual

REVISION 0

COPYRIGHT 2001 CANON INC. CANON S6300 0801 XX 0.00-0 PRINTED IN JAPAN (IMPRIME AU JAPON)

AUG. 2001

082001 XX 0.00-0

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation,

maintenance, and repair of products. This manual covers all localities where the products are sold. For

this reason, there may be information in this manual that does not apply to your locality.

Corrections

This manual could include technical inaccuracies or typographical errors due to improvements or

changes in the products. When changes occur in applicable products or in the content of this manual,

Canon will release technical information as the need arises. In the event of major changes in the

contents of this manual over a long or short period, Canon will issue a new edition of this manual

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names described in this manual are the registered trademarks of the

individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be

copied, reproduced or translated into another language, in whole or in part, without the written consent

of Canon Inc., except in the case of internal business use.

Copyright 2001 by Canon Inc.

CANON INC.

i Printer Technical Support Dept. 11

16-1, Shimonoge 3-chome, Takatsu-ku, Kawasaki, Kanagawa 213-8512, Japan

This manual has been produced on an Apple Power Macintosh 7300/180 personal computer and OKI

MICROLINE 803 PSIIV laser beam printer; printing films were printed on Agfa SelectSet Avantra 25. All

page layouts, logos, and parts-list data were saved with Canon Optical Disc Subsystem mo-5001S™ and

Optical Disc Cartridge mo-502M™, and Interface Kit mo-IF2™ for Macintosh. All graphics were produced

with MACROMEDIA FREEHAND™ 7.0J. All documents and all page layouts were created with

QuarkXpress™ 3.3 Japanese version.

I

I. ABOUT THIS MANUAL

This manual consists of four parts containing information for servicing the product.

Part 1: Product Specifications

Product overview and specifications.

Part 2: Troubleshooting

A guide to troubleshooting the product and identifying parts needing replacement.

Troubleshooting solutions are listed according to the error indications displayed by the

status indicator and by problem descriptions.

Part 3: Technical Reference

Block diagrams and information on the hardware's new technologies.

Part 4: Appendix

Pin configurations.

Disassembly and reassembly procedures are not fully covered in this manual.

Refer to the illustrations in the separate Parts Catalog as well.

Product

Specifications

Tr oubleshooting

Appendix

Technical

Reference

II. TABLE OF CONTENTS

Page

Part 1:

PRODUCT SPECIFICATIONS

1 - 1 1. PRODUCT OVERVIEW

1 - 1 1.1 Product Overview

1 - 2 2. SPECIFICATIONS

1 - 2 2.1 Printer Specifications

1 - 2 2.1.1 Printer specifications

1 - 3 2.1.2 Printer service life

1 - 3 2.1.3 BJ cartridge service life

1 - 4 2.2 Paper Specifications

1 - 4 2.2.1 Paper sizes and weights

1 - 4 2.2.2 Paper types and settings

1 - 5 2.2.3 Printing area

1 - 6 2.3 BJ Cartridge Specifications

1 - 6 2.4 Printer and Scanner Drivers

1 - 7 3. PACKING CONFIGURATION

1 - 8 4. PARTS CODE LIST

Part 2: TROUBLESHOOTING

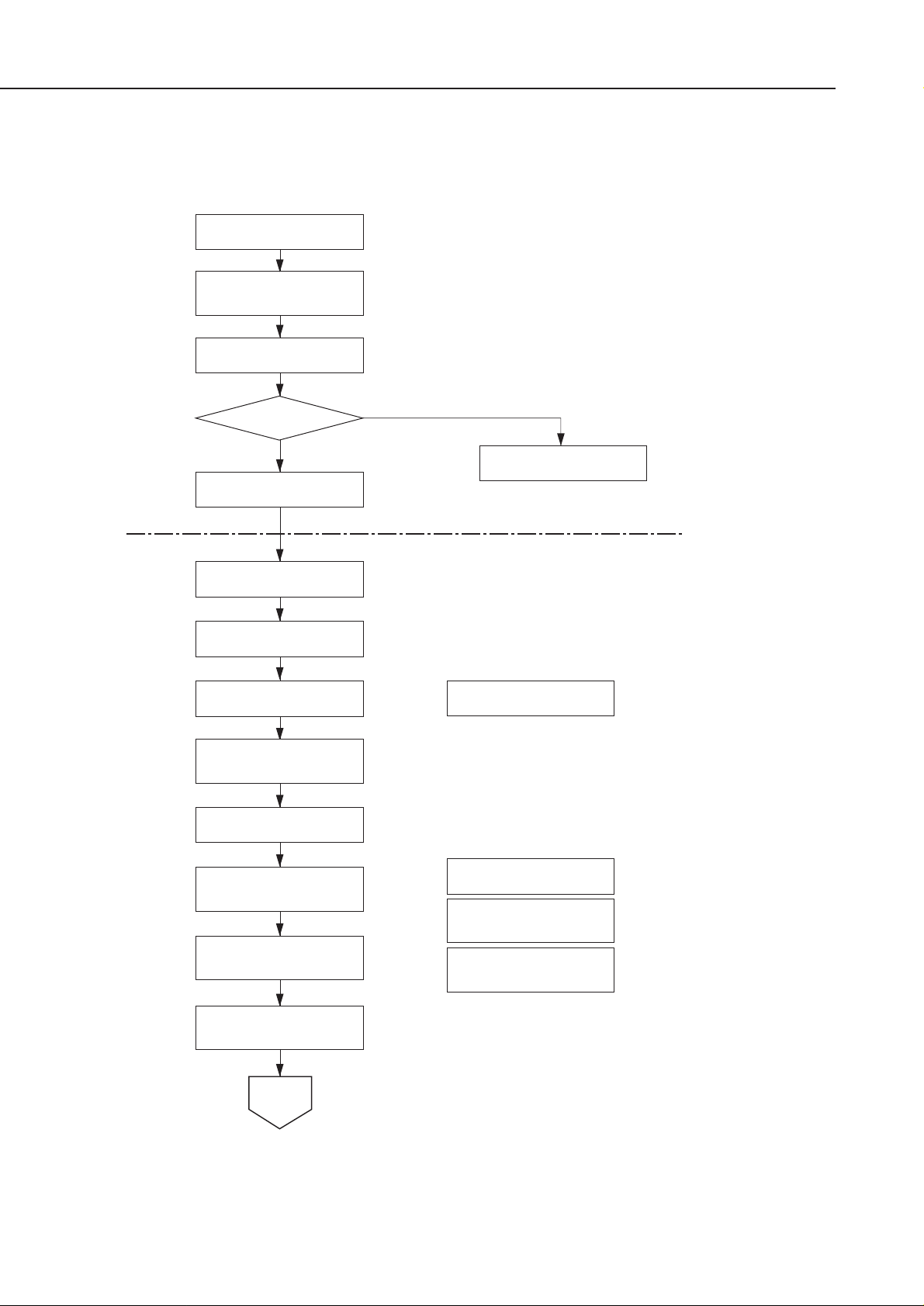

2 - 1 1. PRINTER OPERATION

2 - 1 1.1 Printer Operation Procedure

2 - 1 1.2 Status Indicator

2 - 2 1.3 Operating the Printer

2 - 2 1.3.1 Cleaning operation

2 - 2 1.3.2 Printing the nozzle check pattern

2 - 4 1.3.3 Roller cleaning operation

2 - 5 2. SERVICING

2 - 5 2.1 Before Troubleshooting

2 - 6 2.2 Detectable Problems from System Start to Exit

2 - 9 2.3 Troubleshooting Problems

2 -10 2.4 Troubleshooting Error Indications

2 -13 3. DISASSEMBLY AND REASSEMBLY

2 -13 3.1 Cautions for Disassembly and Reassembly

2 -13 3.1.1 Cautions for ink stains (Ink path/ink mist)

2 -13 3.1.2 Damage by static electricity

2 -13 3.1.3 Deformation of spur tips

2 -14 3.2 Exploded View

2 -15 3.3 Disassembly and Reassembly

2 -15 3.3.1 Carriage lock release

2 -16 3.3.2 Removing and installing tap screws

2 -16 3.3.3 Installing and removing the carriage encoder film

2 -17 3.3.4 Handling encoder film

2 -17 3.3.5 Removing and installing the control board

2 -17 3.3.6 Removal of red screws prohibited

2 -18 3.3.7 Installing the logic board cover

2 -18 3.3.8 Handling the purge unit

2 -19 3.4 Adjustments and Settings After Disassembly and Reassembly

2 -19 3.4.1 Adjustments

2 -20 3.4.2 Applying grease

2 -21 3.4.3 Print head position adjustment

2 -22 3.4.4 Print head seam stripe adjustment

II

Page

2 -23 3.4.5 Setting the EEPROM

2 -24 4. OPERATION CHECK AFTER DISASSEMBLY AND REASSEMBLY

2 -24 4.1 Check Procedure

2 -25 5. TRANSPORTING THE PRINTER

2 -25 5.1 Procedure

2 -26 6. PARTS REPLACEMENT, PERIODIC INSPECTIONS, & TOOLS

2 -26 6.1 Parts Replacement

2 -26 6.2 Periodic Inspections

2 -26 6.3 Tool List

2 -27 7. SERVICE-RELATED FEATURES

2 -27 7.1 Service Mode Operations

2 -28 7.2 Test Printout

2 -29 7.3 Printing the EEPROM Information

2 -30 7.4 Resetting the EEPROM

2 -30 7.5 Setting the Printer Settings in the EEPROM

Part 3: TECHNICAL REFERENCE

3 - 1 1. PRINTER CONTROL SECTION

3 - 1 1.1 Printing Data and Control Signal Flow

3 - 2 1.2 Print Drive Method

3 - 3 1.2.1 Print drive control

3 - 4 1.2.2 Print driving method

3 - 5 1.3 Control During Printing

3 - 5 1.3.1 2-dot Pair + Bi-directional printing

3 - 5 1.3.2 Seam stripe control

3 - 5 1.3.3 Rest between scans (Border detection control)

3 - 6 1.3.4 Smear control and rest between pages

3 - 6 1.3.5 Automatic power ON/OFF

3 - 6 1.3.6 Print head protection from overheating

3 - 6 1.3.7 Power motor control

3 - 7 1.4 Detection Functions

3 - 7 1.4.1 Detection by sensors

3 - 7 1.4.2 Paper-end sensor

3 - 8 1.4.3 Ink sensor (Same as for BJ F600)

3 - 8 1.4.4 Cover sensor

3 - 8 1.4.5 Pump sensor

3 - 9 1.4.6 Internal temperature sensor

3 - 9 1.4.7 Head temperature sensor

3 - 9 1.4.8 ASF sensor

3 - 9 1.4.9 Carriage encoder/paper feed encoder

3 - 9 1.5 Other Sensing Features

3 - 9 1.5.1 Waste-ink detection

3 - 9 1.5.2 Print head detection

3 -10 2. ELECTRICAL DRIVE SECTION

3 -10 2.1 Block Diagram

3 -11 2.2 Electrical Section

3 -12 3. PRINTER'S MECHANICAL PARTS

3 -12 3.1 Overview of the Printer's Mechanical Parts

3 -12 3.1.1 Carriage

3 -12 3.1.2 Purge section

3 -13 3.1.3 Paper feed section

3 -14 3.2 Purge Section

3 -14 3.2.1 Purge section functions

III

Page

3 -15 3.2.2 Purge section components

3 -17 3.3 Paper Feed Section

3 -17 3.3.1 Paper feed components

3 -18 3.3.2 Friction separation system

3 -18 3.3.3 Paper transport section

3 -18 3.3.4 Paper discharge section

3 -19 4. LOGIC BOARD COMPONENTS

3 -22 5. OPERATION WITH A COMPUTER

3 -22 5.1 Printing Operation with the Basic Settings Sheet

3 -22 5.2 Using the Utility Sheet

3 -23 6. INK SUCTION AMOUNT IN THE CLEANING MODE

3 -24 7. TECHNICAL REFERENCE

3 -24 7.1 Printing Mode List

3 -25 8. PRINT HEAD

Part 4: APPENDIX

4 - 1 1. CONNECTOR LOCATIONS AND PIN CONFIGURATIONS

4 - 5 1.1 Carriage Board

4 - 7 1.2 Print Head

4 - 8 2. CIRCUIT DIAGRAM

IV

III. ILLUSTRATION INDEX

Page

Part 1:

PRODUCT SPECIFICATIONS

1 - 1 Figure 1 - 1 Printer Exterior

1 - 3 Figure 1 - 2 1500 Characters Pattern

1 - 3 Figure 1 - 3 JIS SCID No. 5

1 - 5 Figure 1 - 4 Printable Area

1 - 7 Figure 1 - 5 Packing Configuration

Part 2: TROUBLESHOOTING

2 - 1 Figure 2 - 1 Operation Panel

2 - 3 Figure 2 - 2 Nozzle Check Pattern Printout

2 -14 Figure 2 - 3 Exploded View

2 -15 Figure 2 - 4 Carriage Lock Release

2 -16 Figure 2 - 5 Encoder Film

2 -17 Figure 2 - 6 Do not Remove the Red Screws

2 -18 Figure 2 - 7 Installing the Logic Board Cover

2 -18 Figure 2 - 8 Handling the Purge Unit

2 -20 Figure 2 - 9 Applying Grease

2 -21 Figure 2 -10 Printing Position Adjustment Pattern

2 -22 Figure 2 -11 Seam Stripe Adjustment Pattern

2 -28 Figure 2 -12 Service/Factory Test Printout (Sample)

2 -29 Figure 2 -13 EEPROM Information Printout (Sample)

Part 3: TECHNICAL REFERENCE

3 - 1 Figure 3 - 1 Printing Signal Flow

3 - 2 Figure 3 - 2 Serial Data

3 - 3 Figure 3 - 3 Print Driving

3 - 4 Figure 3 - 4 Printing Driving Method

3 - 7 Figure 3 - 5 Location of Sensors

3 - 8 Figure 3 - 6 Ink Sensor

3 -10 Figure 3 - 7 Block Diagram

3 -12 Figure 3 - 8 Printer's Mechanical Parts

3 -15 Figure 3 - 9 Purge Section Components

3 -16 Figure 3 -10 Pump Operation

3 -17 Figure 3 -11 Paper Feeding

3 -19 Figure 3 -12 Control Board

3 -22 Figure 3 -13 Basic Settings Sheet (Sample)

3 -25 Figure 3 -14 Nozzle Array

Part 4: APPENDIX

4 - 1 Figure 4 - 1 Control Board

4 - 5 Figure 4 - 2 Carriage Board

4 - 7 Figure 4 - 3 BJ Cartridge

V

IV. TABLE INDEX

Page

Part 1: PRODUCT SPECIFICATIONS

1 - 9 Table 1- 1 PARTS CODE

Part 2: TROUBLESHOOTING

2 -10 Table 2- 1 ERROR INDICATIONS

Part 3: TECHNICAL REFERENCE

3 -24 Table 3 - 1 PRINTING MODE LIST

VI

Part 1

PRODUCT

SPECIFICATIONS

Page

1 - 1 1. PRODUCT OVERVIEW

1 - 1 1.1 Product Overview

1 - 2 2. SPECIFICATIONS

1 - 2 2.1 Printer Specifications

1 - 4 2.2 Paper Specifications

1 - 6 2.3 BJ Cartridge Specifications

1 - 6 2.4 Printer and Scanner Drivers

1 - 7 3. PACKING CONFIGURATION

1 - 8 4. PARTS CODE LIST

I. PRODUCT OVERVIEW

1.1 Product Overview

“High-Performance Personal and Business Use Color Printer”

While emphasizing out-of-box performance, the S6300 offers default setting

high-speed and high-quality printing on plain paper.

With the same engine as the S600, the printer takes full advantage of the S600’s

features, and supports up to A3+ sized paper to function as a high-performance

business-use printer.

Differences from the S600 are as follows:

(1) Supported size of paper

Up to A3+ (S600: A4)

(2) Print speed (measured with A4-sized paper)

Monochrome printing, text (HS): 17 ppm (New monochrome pattern*1)

Color printing, DTP (HS): 12 ppm (New color pattern*1)

Color printing (for reference): 2.5 ppm (A4 full address pattern*2)

(3) Paper eject support function to prevent smearing

*1: Standard pattern to measure print speed, in use since 1998.

*2: Dot-by-dot printing performed at 1,200 x 1,200 dpi on A4-sized paper

"Standard Color Printer for Personal Use"

1-1

S6300

Part 1: Product Specifications

Product

Specifications

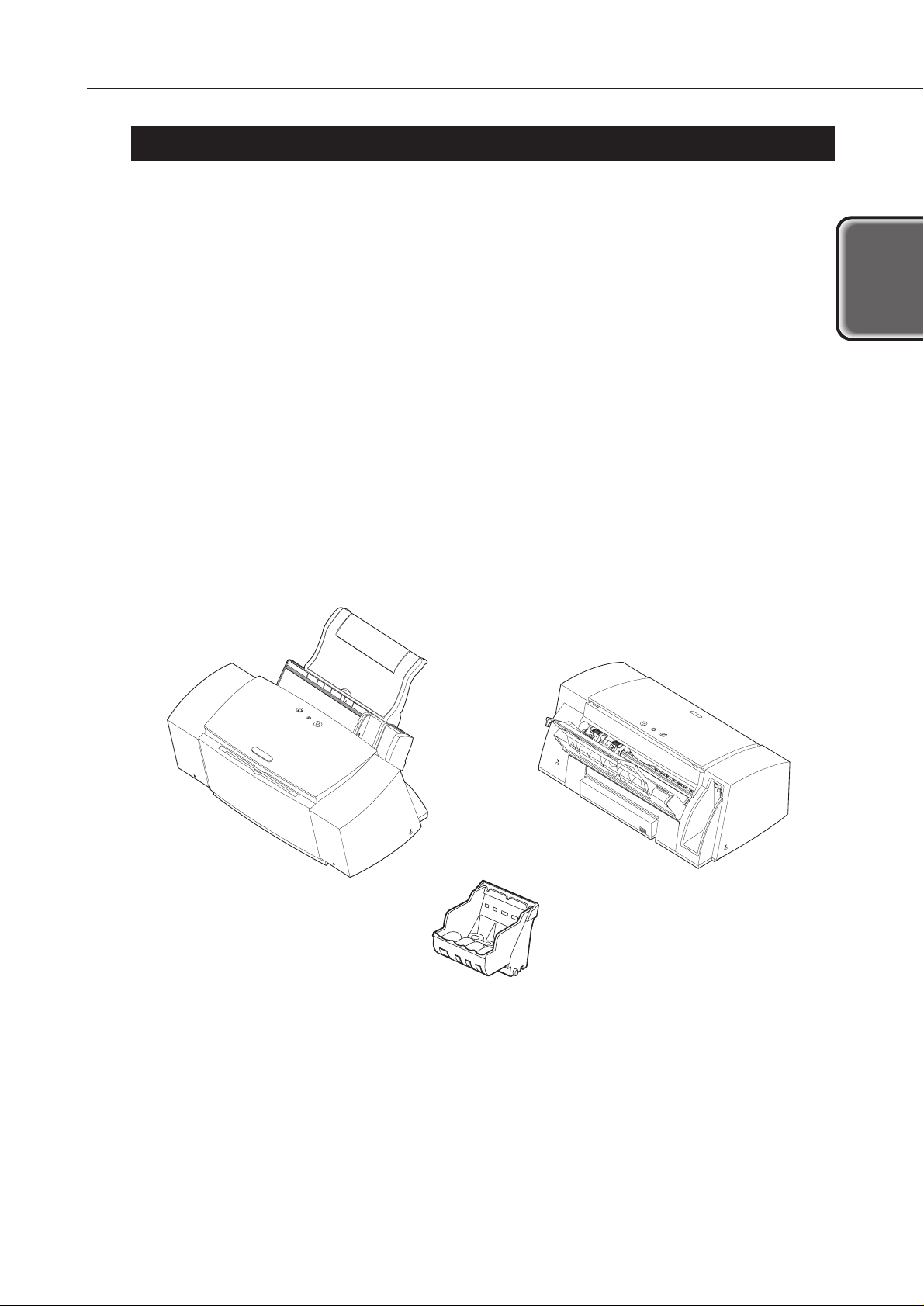

Printer(Front) Printer(Rear)

Print Head

Figure 1-1 Printer Exterior

2. SPECIFICATIONS

2.1 Printer Specifications

2.1.1 Printer specifications

Part 1: Product Specifications

S6300

1-2

Type

Paper Feed System

Resolution

Throughput

Printing Direction

(Plain/Special

paper)

Max. Printing Width

Interface

ASF Capacity

Sensors

Operating Noise (at

HQ)

Ambient Conditions

Power Source

External

Dimensions

Weight

Certification

(Printer & adapter)

Serial No. Location

Desktop serial printer

Automatic feed only (No manual feed)

2400 × 1200 dpi (Max. resolution)

Bk: 17 ppm

Color: 12 ppm

HS mode (600 dpi × 600 dpi...): Single-pass bi-directional

HQ mode (600 dpi × 600 dpi/1200 dpi × 1200 dpi):

Single-pass unidirectional/double- or triple-pass bi-directional

Fine1 mode (1200 dpi × 1200 dpi/As above):

1.2-pass unidirectional/4- or 6-pass bi-directional

Fine2 mode (As above/As above):

4-pass bidirectional/4-pass unidirectional or bi-directional

Fine3 mode (.../2400 dpi × 1200 dpi):

4-pass unidirectional or 6-pass bi-directional

322.2mm (12.7inch) wide

IEEE 1284-standard, 8-bit parallel, USB (No HUB function)

Plain paper: Max. 10 mm (Approx. 100 sheets with 75 g/m2or

approx. 110 sheets with 64 g/m2)

Front cover-open sensor, Print Head-loaded sensor, No-ink sensor,

Printing position sensor, Paper sensor (paper out detector), Wasteink capacity sensor, Internal temperature sensor, Pick-up roller

sensor, Paper-feed roller position sensor, Carriage position sensor,

Paper interval sensor

39 dB (A) Sound pressure level conforms to ISO 9296.

During operation: Temperature 5°C-35°C (41°F-95°F)

Humidity 10%-90% RH (No condensation)

During non-operation: Temperature 0°C-40°C (32°F-95°F)

Humidity 5%-90% RH (No condensation)

Power voltage/frequency Power consumption During standby When Off

100-127 VAC 50/60 Hz Max. approx. 33 W Approx. 3 W Approx. 1 W

220-240 VAC 50/60 Hz Max. approx. 33 W Approx. 3 W Approx. 1 W

Approx. 573 mm (W) × 335 mm (D) × 194 mm (H)

Approx. 7 kg (excluding Print Head)

Radio wave interference: VCCI, FCC, IC, C-Tick, Taiwan/Korea

EMC, CCIB (EMC)/CCEE

Electrical safety: Electrical appliance regulation, UL, Cul,

CE Mark, TUV, FIMKO, SASO, AS, PSB,

Korean Electric Commerce, CB/CCIB/CCEE

Environmental: Energy Star, Blue Angel

Carriage ribbon cable holder (visible when the access cover is open)

2.1.2 Printer service life

Whichever comes first:

(1) A total of 30,000 sheets printed with 1,500 standard characters in black ink.

(2) A total of 10,000 sheets printed with 7.5% duty per color.

(3) Five years of use.

2.1.3 BJ cartridge service life

(1) Service life

For monochrome printing (1500-character standard text pattern printing): 30,000

pages

For color printing (7.5% duty pattern printing per color): 10,000 pages

(2) Ink tank service life (printable pages per tank)

Monochrome (black): 695 pages (1500 characters pattern*1/Printing quality:

Standard)

Color (Cyan): 460 pages (JIS SCID No. 5*2/Printing quality: Standard)

(Magenta): 395 pages ( As above )

(Yellow): 300 pages ( As above )

*1 Printing duty: Equivalent to 2.22% pattern

*2 Printing duty: Equivalent to 3.68% (cyan) pattern

Equivalent to 5.12% (magenta) pattern

Equivalent to 6.10% (yellow) pattern

1-3

S6300

Part 1: Product Specifications

Product

Specifications

Figure 1-2 1500 Characters Pattern

Figure 1-3 JIS SCID No. 5

Part 1: Product Specifications

S6300

1-4

2.2 Paper Specifications

2.2.1 Paper sizes and weights

(1) Paper sizes

See the table below.

(2) Weight

For automatic feeding, the paper's weight should be 64-105 g/m2.

2.2.2 Paper types and settings

If the paper spacing lever is not properly set, problems with paper feeding

or printing may occur.

Type Size Sheet Feeder Capacity

Paper Spacing

Lever Position

Plain paper 64-105 g/m2A3+/A3/b4/A4+/A4 Less than 10 mm Left (Narrow)

B5/A5/LGL/LTR

High-quality paper HR-101 A3/b4/A4+/A4/B5/A5 Less than 80 sheets Left (Narrow)

LGL/LTR

A3+ Less than 20 sheets

Photo glossy paper GP-301 A4+/A4/LTR 10 sheets Left (Narrow)

A3+/B4/LGL 1 sheet

Photo paper PR-101 A4/LTR 1 sheet Left (Narrow)

Glossy film HG-201 A4/LTR 1 sheet Left (Narrow)

Transparency film CF-102 A4/LTR Less than 30 sheets Left (Narrow)

Banner BP-101 A4/LTR 1 sheet Right (Wide)

T-shirt transfer TR-201 A4/LTR 1 sheet Right (Wide)

Mouse pad MK-101 --- 1 sheet Left (Narrow)

Glossy postcard KH-201 148 mm × 100 mm Less than 20 Left (Narrow)

Photo glossy card FM-101 118.6 mm × 213.9 mm Less than 20 Left (Narrow)

Japan Post Office

postcard

--- 148 mm × 100 mm Less than 40 Left (Narrow)

Japan Post Office

postcard for ink jet

printing

--- 148 mm × 100 mm Less than 40 Left (Narrow)

Pro photo postcard PH-101 148 mm × 100 mm Less than 20 Left (Narrow)

Envelope COM#10 241 mm × 106 mm Less than 10 Right (Wide)

DL-size 220 mm × 110 mm Less than 10 Right (Wide)

No. 4 235 mm × 105 mm Less than 10 Right (Wide)

No. 6 190 mm × 98 mm Less than 10 Right (Wide)

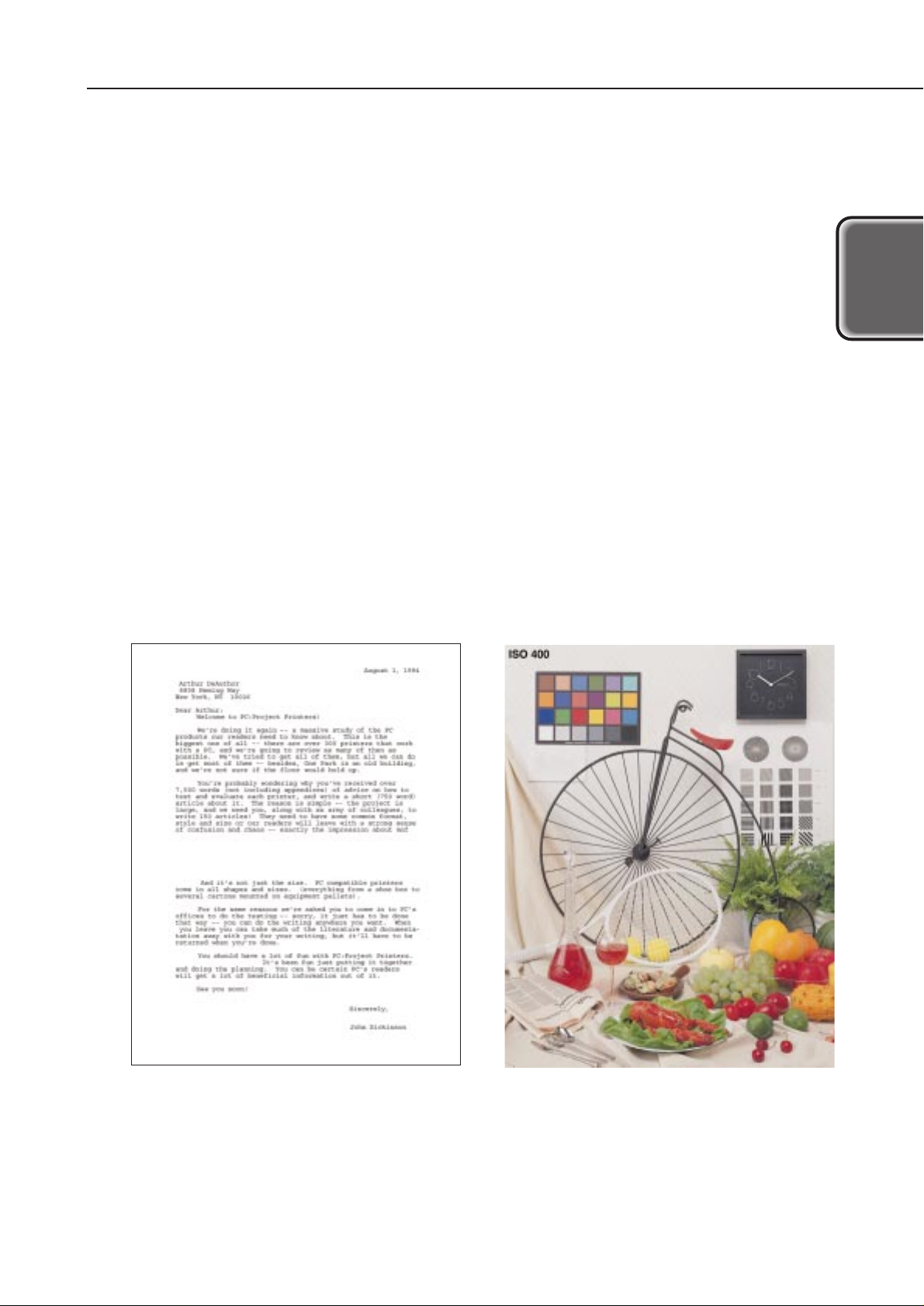

2.2.3 Printing area

1-5

S6300

Part 1: Product Specifications

Product

Specifications

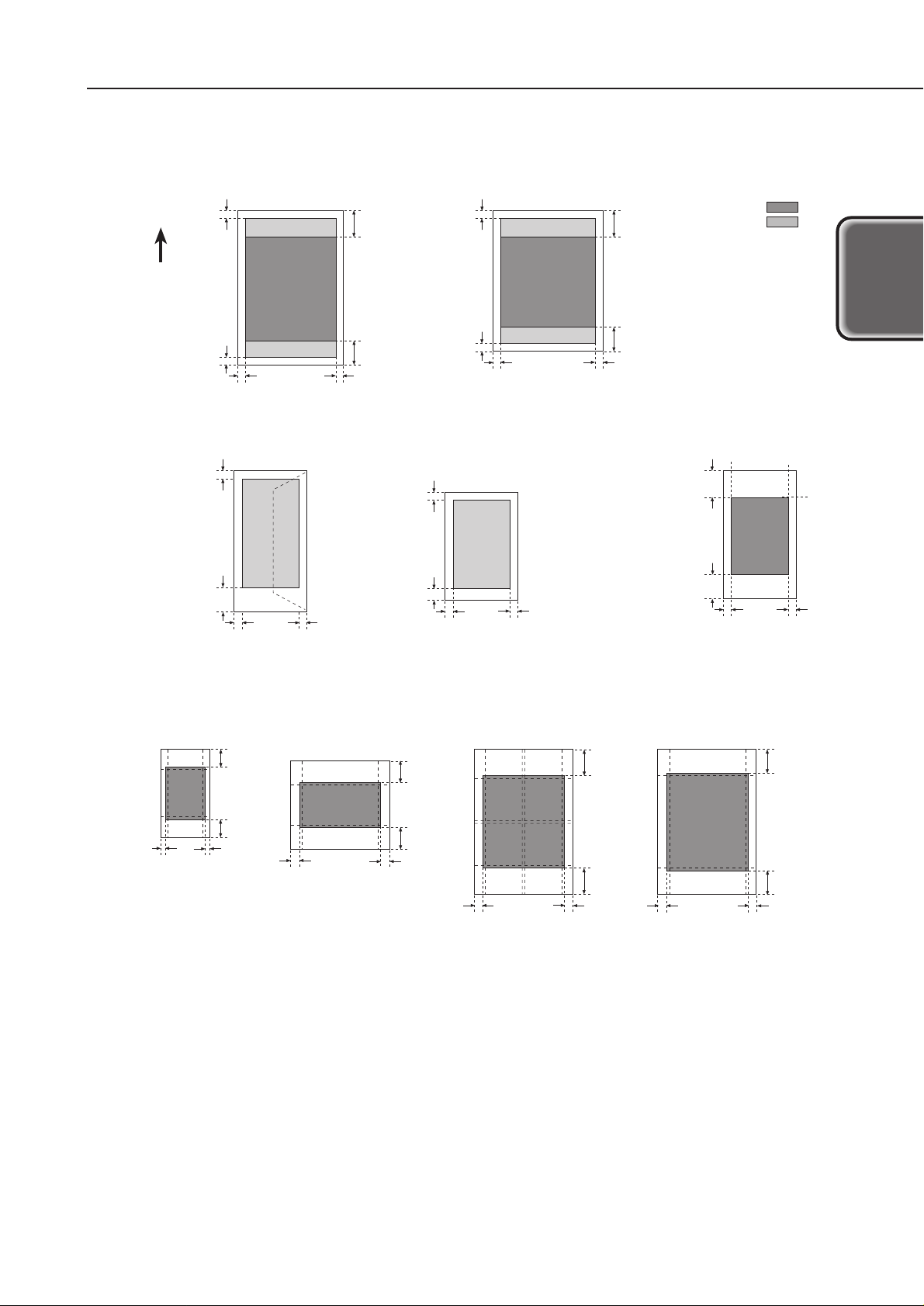

■ Pro Photo Card

■ Envelope (No. 4/No. 6)

PC-101 L: L size PC-101 2L: 2L size

Recommended

printing area:

Printable area:

■ A3+,A3,B4,A4+,A4, B5, A5

■ Glossy postcard/Japan Post Office postcard/ Japan Post

Office postcard for ink jet printing/Pro photo postcard

■ Photo glossy card

PC-101 D: DCS size cut into 4 PC-101 W: 8x10 in. for digital cameras

5.0 mm

3.4 mm

±1.5*

1

3.4 mm

±1.5

26.5 mm

28.0 mm

3.0 mm

±1.5*

1

5.0 mm

6.4 mm

±1.5

6.4 mm

±1.5

26.5 mm

28.0 mm

3.0 mm

±1.5

3.0 mm

±3.0

26.5 mm

3.4 mm

±2.0

3.4 mm

±2.0

3.0 mm

±1.5

5.0 mm

3.4 mm

±1.5

3.4 mm

±1.5

28.0 mm

26.0 mm*

2

5.1 mm

4.1 mm

28.8 mm

3.3 mm

3.3 mm

28.8 mm

25.0 mm*

2

13.0 mm

13.0 mm

25.0 mm

29.0 mm

9.0 mm

9.0 mm

29.0 mm

25.0 mm

7.0 mm

7.0 mm

25.0 mm

()

()

()

()

*1 For recycled paper, it will be 3.0mm ±3 or 3.4mm ±2.

*2 If the bottom margin goes beyond the plain paper's printable area, the software application's specifications

will apply.

The region inside the dotted lines is the printable area where print quality can be guaranteed.

Note: The right margins in parentheses indicate that the dimension depends on the paper size.

Paper-feeding direction

■ Letter,Leger

Figure 1-4 Printable Area

2.3 BJ Cartridge Specifications

2.4 Printer and Scanner Drivers

The user interface of the drivers has been greatly improved. See page 3-22 for details.

1 Windows drivers

Win95/98/ME BJ raster driver (V. 7.10)

Win9NT4.0 BJ raster driver (V. 4.40)

Win2000 BJ raster driver (V. 1.40)

2 Macintosh driver

Mac BJ printer driver (V. 3.75)

3 Scanner driver

None.

Part 1: Product Specifications

S6300

1-6

Configuration

Print Head

Ink Colors*

Ink Tank

Weight (Net value)

Print Head

Detachable ink tanks for each color and BK/Cl (C, M, Y)

integrated head

BK: 320 nozzles, 2-column vertical array

Cl: 256 nozzles/color, 2-column vertical array/color

Pigment BK, dyes C, M, Y

BCI-3eBK, BCI-3eC, BCI-3eM, BCI-3eY

BK: 32 g Cl (C, M, Y): 11 g

1-7

S6300

Part 1: Product Specifications

Product

Specifications

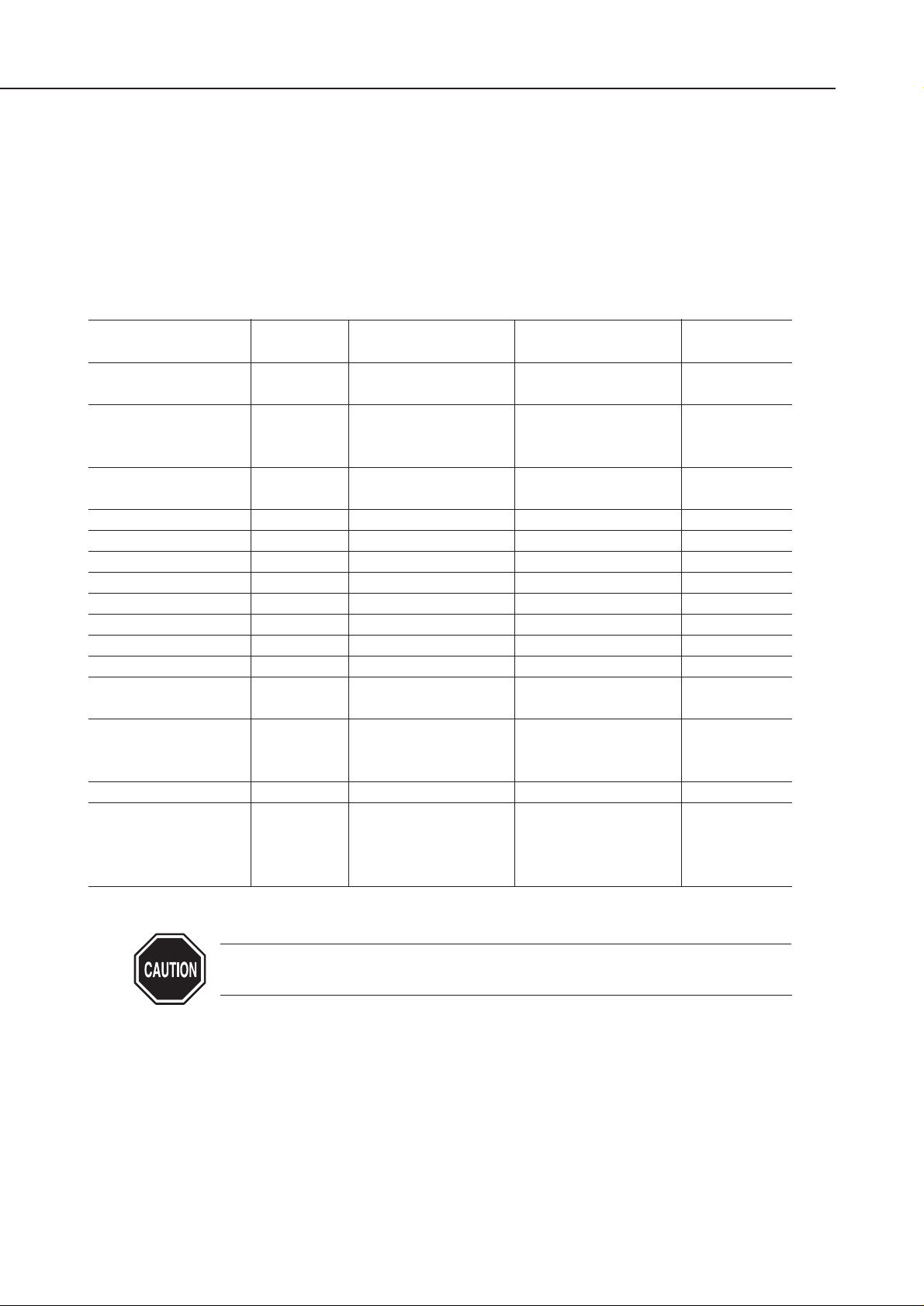

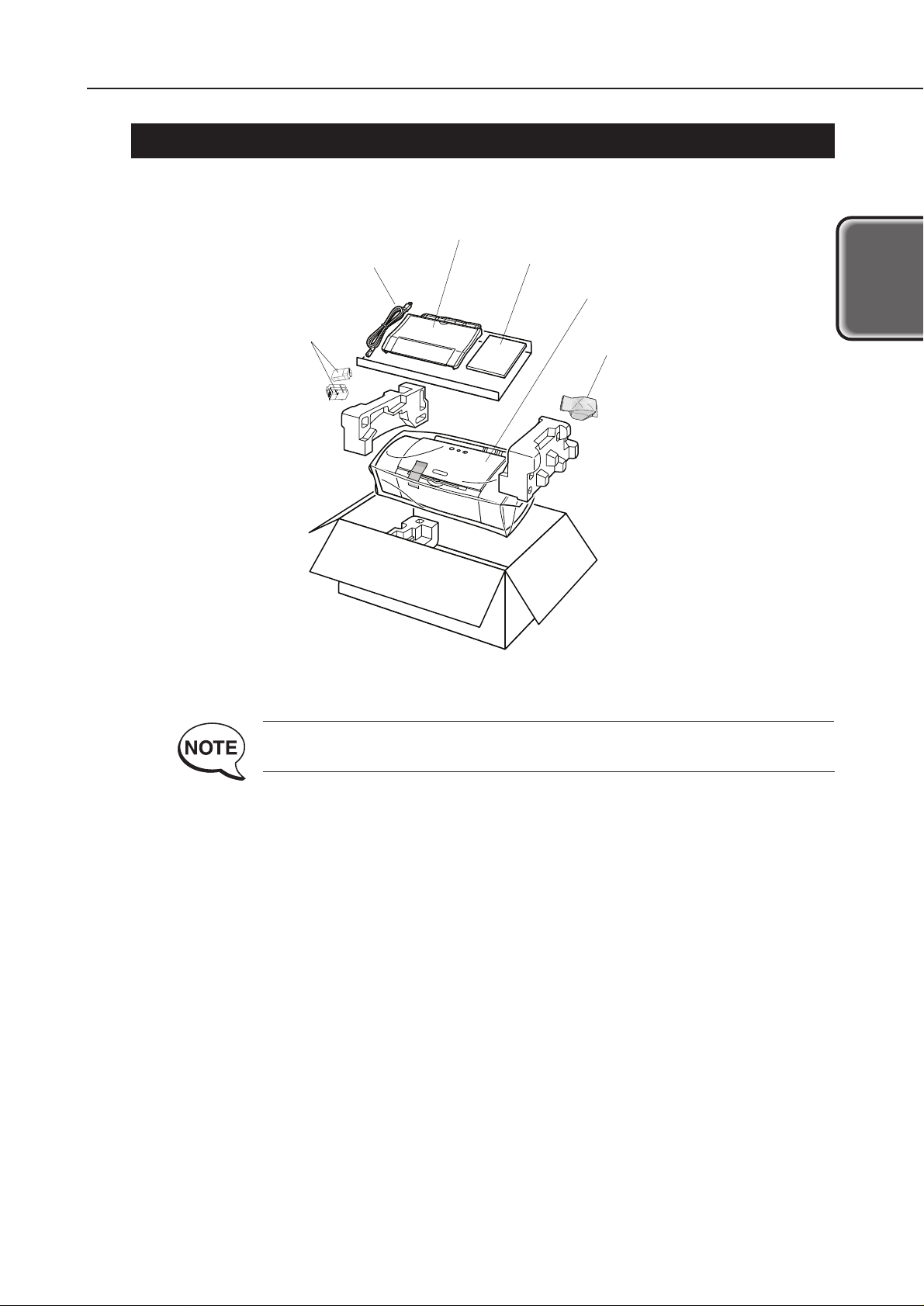

3. PACKING CONFIGURATION

After opening the box, make sure all the items below are included.

There is no storage box for storing the Print Head.

Power Cord

Ink Tank

Paper Support

Instruction Manuals

Print Head

Printer

Figure 1-5 Packing Configuration

4. PARTS CODE LIST

A list of printer parts, consumables, and optional equipment are listed below.

The printer's BJ cartridge (print head) will be supplied only as a spare part for servicing.

*1 Supplied only as a spare part for servicing. It will not be supplied as a consumable or

optional part.

Part 1: Product Specifications

S6300

1-8

Table 1-1 PARTS CODE

Item

Printer

Print Head*

1

Ink tank

---

--Black

Cyan

Magenta

Yellow

Designation

S6300

BJ S6300

--BCI-3eBK

BCI-3eC

BCI-3eM

BCI-3eY

Parts Code

Q30-3480 (CCSEK)

Q30-3482 (HK/TW)

Q30-3481

QY6-0034

F47-3131

F47-3141

F47-3151

F47-3161

1-9

S6300

Part 1: Product Specifications

Product

Specifications

This page intentionally left blank

Part 2

TROUBLESHOOTING

Page

2 - 1 1. PRINTER OPERATION

2 - 1 1.1 Printer Operation Procedure

2 - 1 1.2 Status Indicator

2 - 2 1.3 Operating the Printer

2 - 5 2. SERVICING

2 - 5 2.1 Before Troubleshooting

2 - 6 2.2 Detectable Problems from System Start to Exit

2 - 9 2.3 Troubleshooting Problems

2 -10 2.4 Troubleshooting Error Indications

2 -13 3. DISASSEMBLY AND REASSEMBLY

2 -13 3.1 Cautions for Disassembly and Reassembly

2 -14 3.2 Exploded View

2 -15 3.3 Disassembly and Reassembly

2 -19 3.4 Adjustments and Settings After Disassembly and Reassembly

2 -24 4. OPERATION CHECK AFTER DISASSEMBLY AND REASSEMBLY

2 -24 4.1 Check Procedure

2 -25 5. TRANSPORTING THE PRINTER

2 -25 5.1 Procedure

2 -26 6. PARTS REPLACEMENT, PERIODIC INSPECTIONS, & TOOLS

2 -26 6.1 Parts Replacement

2 -26 6.2 Periodic Inspections

2 -26 6.3 Tool List

2 -27 7. SERVICE-RELATED FEATURES

2 -27 7.1 Service Mode Operations

2 -28 7.2 Test Printout

2 -29 7.3 Printing the EEPROM Information

2 -30 7.4 Resetting the EEPROM

2 -30 7.5 Setting the Printer Settings in the EEPROM

1. PRINTER OPERATION

The printer's operation procedures are explained below. You can operate the printer

either by itself or with a computer. Both methods are explained below.

1.1 Printer Operation Procedure

The printer's operation panel has a

POWER

button and a

RESUME

button to cancel

printing operation or to cancel an error. With a computer, you can use the printer

driver to adjust the print head's position and to change various settings. For details on

using the printer driver with the computer, see page 3-22.

1.2 Status Indicator

When you operate the printer by itself, you can find out the printer's operation status

with the indicator. When an error occurs, the nature of the error can be determined by

the number of times the indicator blinks.

Normal Operation

Error

2-1

S6300

Part 2: Troubleshooting

Tr oubleshooting

Indicator Display

Green light

Blinks green

(Long/short)

Light off

Operation Status

Power ON

Power ON in progress, power OFF in progress, resume

operation in progress, cleaning in progress, test printing in

progress, front cover open, printing in progress

Power OFF

Indicator Display

Blinks orange

(Long/short)

Green/orange

(Toggle blinking)

Operation Status

The number of blinks differs depending on the error. See page

2-10 for details.

The blinking method differs depending on the error. See page

2-11 for details.

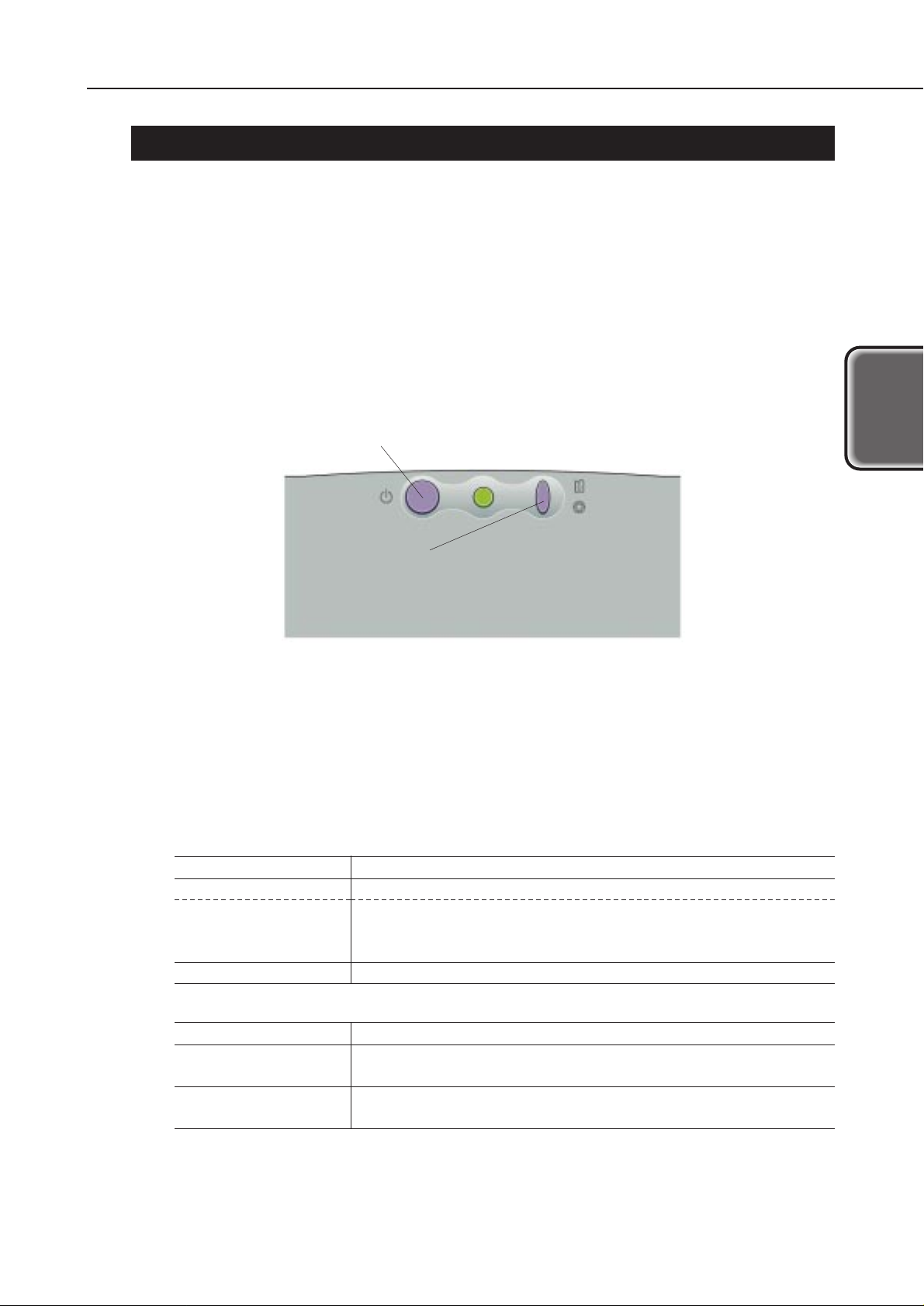

POWER button

Turns the printer ON/OFF and cancels

test printing.

RESUME button

Cancels printing operation or an error.

The cleaning and nozzle check pattern can be selected

by the number of blinks of the indicator.

Figure 2-1 Operation Panel

1.3 Operating the Printer

The printer has an offline operation mode that works when the printer is not connected

to a computer and the power is on.

To conduct the operations below, with the power turned on, hold down the

RESUME

button until the green indicator blinks for the specified number of times.

1.3.1 Cleaning operation

To start the cleaning operation, turn on the printer and hold down the

RESUME

button

until the green indicator blinks once. Then let go of the button. Cleaning will then start.

The black and color ink nozzles will be cleaned simultaneously by suction. This is the

same as using the printer driver to clean all of the ink nozzles.

1.3.2 Printing the nozzle check pattern

With the printer turned on, hold down the

RESUME

button until the green indicator

blinks twice. The printer will then start printing the nozzle check pattern. If any

printing flaws show up in this test printout, clean the BJ cartridge.

Printing the nozzle check pattern requires B5 or larger paper. If the

paper's width is narrower than the nozzle check pattern, the printer will

print on the bare platen, dirtying the platen with ink.

To stop printing of the test pattern midway, press the

POWER

button.

Printing will stop and the paper will be ejected. The printer will remain on.

If the problem persists even after cleaning the BJ cartridge three times,

Perform Deep Cleaning of from the driver. If that still does not resolve the

problem, replace the BJ cartridge.

Part 2: Troubleshooting

S6300

2-2

Operation

Cleaning operation

Nozzle check pattern

printing

Roller cleaning

operation

---

Indicator Blink Count

Once

Twice

3 times

4 times

Remarks

--Load a sheet of B5 or larger

paper.

Load no paper or load A4 paper.

Execute no operations.

2-3

S6300

Part 2: Troubleshooting

Tr oubleshooting

Figure 2-2 Nozzle Check Pattern Printout

1.3.3 Roller cleaning operation

This is to remove the paper dust adhering to the auto sheet feeder's rollers. With the

printer turned on, hold down the

RESUME

button until the green indicator blinks once.

The cleaning of the rollers will then start.

There are two cleaning methods:

(1) Rotating the rollers without paper

Execute roller cleaning without placing any paper on the auto sheet feeder.

(The rollers will rotate ten times.)

Do this three times.

(2) Passing plain paper throughtest

Place a sheet of plain paper on the auto sheet feeder and execute roller cleaning.

Do this three times.

Do not execute the cleaning operation more times than necessary.

Excessive cleaning will generate rubber dust which can affect the printer's

operation.

Part 2: Troubleshooting

S6300

2-4

2. SERVICING

2.1 Before Troubleshooting

Before troubleshooting, check the following and see if any of the applicable problems

can be fixed.

2-5

S6300

Part 2: Troubleshooting

Tr oubleshooting

Problem

The printer does not

operate at all.

Paper feeding does

not work.

No printing.

Stripes appear in the

printout.

Probable Cause

The power outlet is not supplying

the required voltage.

The power cord is not properly

connected to the printer or power

outlet.

An internal plug is disconnected.

The recommended paper is not

being used.

There is foreign matter in the

paper feed section (sheet feeder,

pinch roller, LF roller, platen,

spur).

The Print Head needs cleaning.

The ink cartridge is empty.

The Print Head has not been

used for a prolonged period.

The print head position has not

been adjusted.

Solution

Connect the AC cord to a power

outlet which supplies the

required voltage.

Check that the power cord is

connected properly.

Disconnect and reconnect the

plug.

Use the recommended paper.

Remove the foreign matter.

Clean the Print Head.

Replace the ink cartridge.

Clean the cartridge. If the

problem still persists, replace the

cartridge.

Execute print head position

adjustment.

See page 2-23.

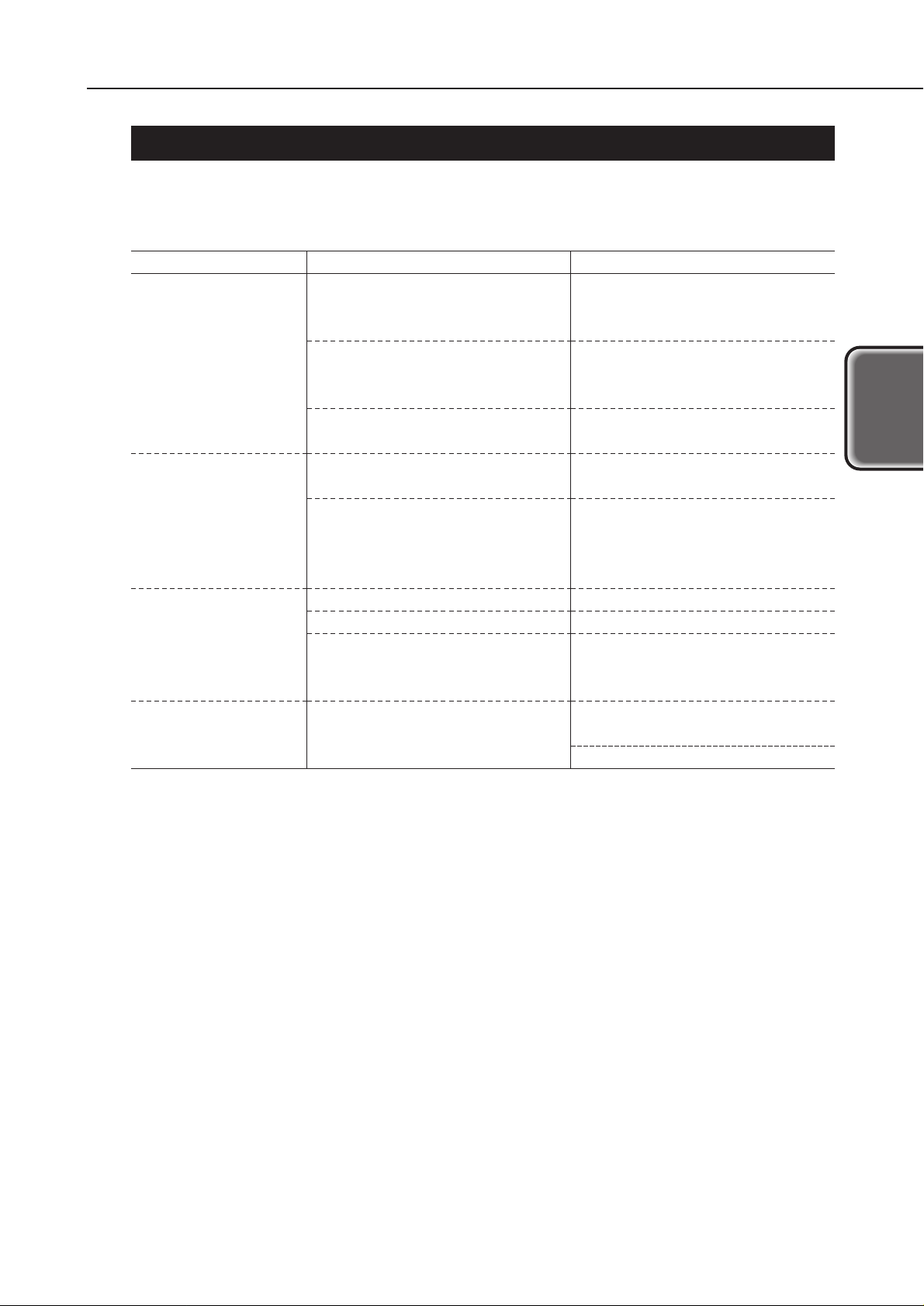

2.2 Detectable Problems from System Start to Exit

Errors unresolvable by the user can be checked before system startup is completed.

Part 2: Troubleshooting

S6300

2-6

To next

page

AC power connection

Power LED lights

Power ON

DRAM check

EEPROM check

EEPROM error

Cartridge error (a)

Abnormal internal

temperature error

Abnormal head

temperature error

CPU & printer

controller initialization

Error check

Key input detection

prohibited

Sensor power ON

Head presence

detection

Interrupt error

detection starts

Paper feed encoder

home position obtained

Checksum

VSEN ON

Take the cartridge to the home

position.

Yes

No

OK?

RAM error

Orange lamp

lights

Orange/green

toggle blinking 9

times

Orange blinks 7

times

Orange/green

toggle blinking 6

times

Orange/green

toggle blinking 8

times

Loading...

Loading...