imageRUNNER 2202/2002 Series

Product Overview

Technology

Periodical Service

Parts Replacement and Cleaning

Adjustment

Troubleshooting

Error Code

Service Mode

Installation

Appendix

Service Manual Rev0

987654321

Application

This manual has been issued by Canon Inc. for qualied persons to learn technical theory,

installation, maintenance, and repair of products. This manual covers all localities where the

products are sold. For this reason, there may be information in this manual that does not

apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements

or changes in products. When changes occur in applicable products or in the contents of this

manual, Canon will release technical information as the need arises. In the event of major

changes in the contents of this manual over a long or short period, Canon will issue a new

edition of this manual.

0-2

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks

of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may

not be copied, reproduced or translated into another language, in whole or in part, without the

consent of Canon Inc.

Copyright CANON INC. 2013

Caution

Use of this manual should be strictly supervised to avoid disclosure of condential

information.

0-2

0-3

Explanation of Symbols

The following symbols are used throughout this Service Manual.

Symbols Explanation Symbols Explanation

Check. Remove the claw.

Check visually. Insert the claw.

Check the noise. Use the bundled part.

Disconnect the connector. Push the part.

Connect the connector. Plug the power cable.

Remove the cable/wire

from the cable guide or wire

saddle.

Turn on the power.

1. Each chapter contains sections explaining the purpose of specic functions and the

relationship between electrical and mechanical systems with reference to the timing of

operation.

In the diagrams,

accompanies the symbol, the arrow

signal.

The expression "turn on the power" means ipping on the power switch, closing the

front door, and closing the delivery unit door, which results in supplying the machine with

power.

2. In the digital circuits, '1' is used to indicate that the voltage level of a given signal is

"High", while '0' is used to indicate "Low". (The voltage value, however, differs from

circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD

signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked

in the eld. Therefore, the operations of the microprocessors used in the machines

are not discussed: they are explained in terms of from sensors to the input of the DC

controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product

improvement or other purposes, and major changes will be communicated in the form of

Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service

Manual and all relevant Service Information bulletins and be able to identify and isolate faults

in the machine

represents the path of mechanical drive; where a signal name

indicates the direction of the electric

Set the cable/wire to the

cable guide or wire saddle.

Remove the screw.

Tighten the screw.

The following rules apply throughout this Service Manual:

0-3

0

0-5

Description of Control Panel ------------------------------------------------------------1-12

Contents

0 Safety Precautions

CDRH Act -----------------------------------------------------------------------0-7

Laser Safety --------------------------------------------------------------------0-7

Handling of Laser System --------------------------------------------------0-8

Turn power switch ON -------------------------------------------------------0-9

Power Supply ------------------------------------------------------------------0-9

Safety of Toner --------------------------------------------------------------- 0-10

About Toner ------------------------------------------------------------------------ 0-10

Toner on Clothing or Skin ------------------------------------------------------- 0-10

Notes When Handling the Lithium and Ni-MH Batteries ----------0-10

Notes Before it Works Serving -------------------------------------------0-10

Notes On Assembly/Disassembly --------------------------------------- 0-11

1 Product Overview

Product Lineup -----------------------------------------------------------------1-2

Host machine ----------------------------------------------------------------------- 1-2

Option --------------------------------------------------------------------------------- 1-3

Feature --------------------------------------------------------------------------1-4

Product feature --------------------------------------------------------------------- 1-4

Specications ------------------------------------------------------------------1-4

Product Specications ------------------------------------------------------------ 1-4

Productivity (Print speed) -------------------------------------------------------- 1-5

Paper Type -------------------------------------------------------------------------- 1-6

Pickup ----------------------------------------------------------------------------------------- 1-6

Name of Parts ------------------------------------------------------------------1-8

External View ----------------------------------------------------------------------- 1-8

Network model ------------------------------------------------------------------------------ 1-8

Local print model---------------------------------------------------------------------------- 1-9

Cross Sectional View ------------------------------------------------------------1-10

Control Panel ---------------------------------------------------------------------- 1-11

Power Switch -------------------------------------------------------------------------------1-11

2 Technology

Basic Conguration -----------------------------------------------------------2-2

Functional Conguration --------------------------------------------------------- 2-2

Basic sequence -------------------------------------------------------------------- 2-2

Basic Operation Sequence --------------------------------------------------------------- 2-2

Original Exposure System --------------------------------------------------2-3

Construction ------------------------------------------------------------------------- 2-3

Specications/controls/functions -------------------------------------------------------- 2-3

Major Components ------------------------------------------------------------------------- 2-3

Basic Sequence -------------------------------------------------------------------- 2-4

Basic Sequence at Power-On ----------------------------------------------------------- 2-4

Basic Sequence at Start Key ON (book mode/1 original) ------------------------ 2-4

Basic Sequence at Start Key ON (ADF mode/1 original) ------------------------- 2-5

Controls ------------------------------------------------------------------------------ 2-6

Controlling the Scanning Drive System ----------------------------------------------- 2-6

CIS (contact image sensor)

Magnication Change --------------------------------------------------------------------- 2-8

Dust Detection ------------------------------------------------------------------------------- 2-8

Image Processing -------------------------------------------------------------------------- 2-9

Service Tasks ----------------------------------------------------------------------2-11

Periodically Replaced Parts ------------------------------------------------------------- 2-11

Consumable Parts ------------------------------------------------------------------------- 2-11

Periodical Servicing ----------------------------------------------------------------------- 2-11

Action to take when replacing parts --------------------------------------------------- 2-11

Controller System ----------------------------------------------------------- 2-12

Overview ---------------------------------------------------------------------------- 2-12

Functional Conguration -----------------------------------------------------------------2-12

Controls -----------------------------------------------------------------------------2-13

Boot Sequence -----------------------------------------------------------------------------2-13

Soft Counter ---------------------------------------------------------------------------------2-13

Fan --------------------------------------------------------------------------------------------2-14

Power Supply Control --------------------------------------------------------------------2-14

Service Operations --------------------------------------------------------------- 2-15

Periodically Replaced Parts -------------------------------------------------------------2-15

Consumable Parts ------------------------------------------------------------------------2-15

Outline ----------------------------------------2-7

0

0-5

0

0-6

Periodical Servicing -----------------------------------------------------------------------2-15

Action to take when replacing parts ---------------------------------------------------2-15

Laser Exposure System --------------------------------------------------- 2-16

Construction ------------------------------------------------------------------------2-16

Specications/Controls/Functions -----------------------------------------------------2-16

Main Conguration Parts ----------------------------------------------------------------2-16

Control System Conguration ----------------------------------------------------------2-17

Various Control --------------------------------------------------------------------2-18

Laser control signal -----------------------------------------------------------------------2-18

BD signal -------------------------------------------------------------------------------------2-18

Controlling the Intensity of Laser Light -----------------------------------------------2-18

Controlling the Polygon Motor ----------------------------------------------------------2-18

Controlling the Laser Shutter -----------------------------------------------------------2-19

Service Tasks ----------------------------------------------------------------------2-19

Periodically Replaced Parts -------------------------------------------------------------2-19

Consumable Parts -------------------------------------------------------------------------2-19

Periodical Servicing -----------------------------------------------------------------------2-19

Action to take when replacing parts ---------------------------------------------------2-19

Image Formation System ------------------------------------------------- 2-20

Basic Conguration ---------------------------------------------------------------2-20

Specications of Image Formation System -----------------------------------------2-20

Major Components of Image Formation System ----------------------------------2-20

Image Formation Process ---------------------------------------------------------------2-21

Basic Sequence -------------------------------------------------------------------2-22

Controls -----------------------------------------------------------------------------2-23

Drum Unit ------------------------------------------------------------------------------------2-23

Developing Assembly ---------------------------------------------------------------------2-24

Toner Cartridge -----------------------------------------------------------------------------2-25

Transfer Unit -------------------------------------------------------------------------------- 2-26

Periodically Replaced Parts -------------------------------------------------------------2-27

Consumable Parts -------------------------------------------------------------------------2-27

Periodical Servicing -----------------------------------------------------------------------2-27

Action to take when replacing parts ---------------------------------------------------2-27

Fixing System ---------------------------------------------------------------- 2-28

Overview ---------------------------------------------------------------------------- 2-28

Features --------------------------------------------------------------------------------------2-28

Specications -------------------------------------------------------------------------------2-28

Major parts conguration ----------------------------------------------------------------2-29

Controls -----------------------------------------------------------------------------2-30

Fixing temperature control---------------------------------------------------------------2-30

Print temperature control ----------------------------------------------------------------2-31

Down sequence control ------------------------------------------------------------------2-32

User mode related to xing grade -----------------------------------------------------2-35

Paper loop amount control before xing ---------------------------------------------2-35

Protection features ------------------------------------------------------------------------2-36

Work of Service -------------------------------------------------------------------2-37

Periodically Replaced Parts -------------------------------------------------------------2-37

Consumable Parts -------------------------------------------------------------------------2-37

Periodical Servicing -----------------------------------------------------------------------2-37

Action to take when replacing parts ---------------------------------------------------2-37

Pickup Feed System ------------------------------------------------------- 2-38

Overview ---------------------------------------------------------------------------- 2-38

Specication --------------------------------------------------------------------------------2-38

Parts Conguration ------------------------------------------------------------------------2-38

Diagram of Paper Paths -----------------------------------------------------------------2-40

Controls -----------------------------------------------------------------------------2-41

Overview -------------------------------------------------------------------------------------2-41

Cassette Pickup Assembly --------------------------------------------------------------2-41

Multi-Purpose Pickup Assembly -------------------------------------------------------2-44

Fixing / Registration Assembly ---------------------------------------------------------2-44

Duplex / Delivery Assembly -------------------------------------------------------------2-45

Detecting Jams -----------------------------------------------------------------------------2-46

Work of Service -------------------------------------------------------------------2-47

Periodically Replaced Parts -------------------------------------------------------------2-47

Consumable Parts -------------------------------------------------------------------------2-47

Periodical Servicing -----------------------------------------------------------------------2-47

Action to take when replacing parts ---------------------------------------------------2-47

3 Periodical Service

Consumable and Cleaning Parts ------------------------------------------3-2

4 Parts Replacement and Cleaning

List of Parts ---------------------------------------------------------------------4-2

External View ----------------------------------------------------------------------- 4-2

Front Side ------------------------------------------------------------------------------------- 4-2

0

0-6

0

0-7

Rear Side ------------------------------------------------------------------------------------- 4-2

Internal View --------------------------------------------------------------------------------- 4-3

List of Main Unit -------------------------------------------------------------------- 4-4

List of Main Unit(1/2) ----------------------------------------------------------------------- 4-4

List of Main Unit(2/2) ----------------------------------------------------------------------- 4-5

List of periodically replacement parts, consumable parts and locations

for cleaning -------------------------------------------------------------------------- 4-6

PCB ----------------------------------------------------------------------------------- 4-7

Solenoid ------------------------------------------------------------------------------ 4-7

Sensor -------------------------------------------------------------------------------- 4-8

Motor ---------------------------------------------------------------------------------- 4-9

FAN ------------------------------------------------------------------------------------ 4-9

Switch --------------------------------------------------------------------------------4-10

Clutch --------------------------------------------------------------------------------4-10

Others -------------------------------------------------------------------------------- 4-11

External Covers ------------------------------------------------------------- 4-12

Removing the Front Cover -----------------------------------------------------4-12

Removing the Rear Cover ------------------------------------------------------4-13

Removing the Left Cover Unit -------------------------------------------------4-13

Removing the Reader Rear Cover -------------------------------------------4-14

Removing the Right Cover -----------------------------------------------------4-15

Removing the Reader Front Cover -------------------------------------------4-16

Removing the Cassette 1 -------------------------------------------------------4-16

Removing the Control Panel Unit ---------------------------------------------4-17

Removing the Right Front Cover ----------------------------------------------4-18

Removing the Delivery Tray Cover -------------------------------------------4-18

Removing the Left Front Cover ------------------------------------------------4-19

Removing the Front Inner Cover ----------------------------------------------4-20

Original Exposure System ------------------------------------------------ 4-21

Removing the CIS Unit ---------------------------------------------------------- 4-21

Adjustment for the Reader Upper Unit Replacement -----------------------------4-24

Removing the Reader Unit -----------------------------------------------------4-26

Controller System ----------------------------------------------------------- 4-27

Removing the Controller PCB -------------------------------------------------4-27

Adjustment for the Controller PCB replacement -----------------------------------4-28

Removing the HVT PCB --------------------------------------------------------4-30

Removing the Fixing Cooling Fan --------------------------------------------4-30

Laser Exposure System --------------------------------------------------- 4-34

Removing the Laser Scanner Unit --------------------------------------------4-34

Image Formation System ------------------------------------------------- 4-35

Removing the Toner Cartridge -------------------------------------------------4-35

Removing the Drum Unit --------------------------------------------------------4-35

Removing the Developing Assembly -----------------------------------------4-36

Removing the Developing Cylinder ------------------------------------------4-37

Removing the Transfer Roller --------------------------------------------------4-39

Fixing System ---------------------------------------------------------------- 4-40

Removing the Fixing Assembly ------------------------------------------------4-40

Removing the Fixing Film Unit -------------------------------------------------4-42

Removing the Pressure Roller -------------------------------------------------4-44

Pickup Feed System ------------------------------------------------------- 4-46

Removing the Multi-purpose Tray Pickup Roller --------------------------4-46

Removing the Multi-purpose Tray Separation Pad -----------------------4-47

Removing the Cassette 1 Separation Pad ---------------------------------4-48

Removing the Cassette 1 Pickup Roller ------------------------------------4-49

Removing the Cassette 1 Feed Roller ---------------------------------------4-51

Removing the Main Drive Unit -------------------------------------------------4-52

Removing the Registration Roller ---------------------------------------------4-54

5 Adjustment

Outline ---------------------------------------------------------------------------5-2

Adjustment When Replacing Parts -------------------------------------------- 5-2

Image Position Adjustment ------------------------------------------------------ 5-2

Adjustment When Replacing Parts ---------------------------------------5-3

Scanning System ------------------------------------------------------------------ 5-3

Adjustment for the CIS Unit Replament ----------------------------------------------- 5-3

Adjustment for the Controller PCB replacement ------------------------------------ 5-5

Image Position Adjustment -------------------------------------------------5-6

Leading Edge Margin Adjustment --------------------------------------------- 5-6

Left Edge Margin Adjustment (Front Side) ---------------------------------- 5-6

Left Edge Margin Adjustment (Reverse Side) ------------------------------ 5-7

6 Troubleshooting

0

0-7

0

0-8

Initial Check --------------------------------------------------------------------6-2

Initial check items list ------------------------------------------------------------- 6-2

Test Print ------------------------------------------------------------------------6-3

Overview ----------------------------------------------------------------------------- 6-3

Select the test print TYPE ------------------------------------------------------- 6-3

Troubleshooting items -------------------------------------------------------6-4

Troubleshooting items list -------------------------------------------------------- 6-4

Image Failure ----------------------------------------------------------------------- 6-4

Scattered image at center ---------------------------------------------------------------- 6-4

Paper Reverse Side Stained with Toner ---------------------------------------------- 6-5

Stained Leading/Trailing Edge of Paper --------------------------------------------- 6-5

Image Transfer Wrong/Text Void -------------------------------------------------------- 6-6

White Dot at Reverse Trailing Edge of HT ------------------------------------------- 6-6

Irregular Transfer Roller Pitch (50mm) ------------------------------------------------ 6-7

Operation failure ------------------------------------------------------------------- 6-7

Too Large Curl ------------------------------------------------------------------------------- 6-7

Paper Jam due to Solid Image Printed on the Paper with Small Leading-Edge

Margin (1-4 mm) ---------------------------------------------------------------------------- 6-8

"Set the drum" Indication ----------------------------------------------------------------- 6-8

Special mode (User mode) ------------------------------------------------------ 6-9

Upgrading Targets and Procedure -------------------------------------- 6-10

Outline ------------------------------------------------------------------------------- 6-10

Preparation ------------------------------------------------------------------------- 6-10

System Requirements --------------------------------------------------------------------6-10

Preparation ----------------------------------------------------------------------------------6-10

Downloading System Software ------------------------------------------------ 6-11

Log Collector ----------------------------------------------------------------- 6-13

OutLine ------------------------------------------------------------------------------ 6-13

Scope of Application ----------------------------------------------------------------------6-13

What to Prepare ----------------------------------------------------------------------------6-13

Operation Procedure----------------------------------------------------------------------6-13

Troubleshooting ----------------------------------------------------------------------------6-13

7 Error Code

Overview ------------------------------------------------------------------------7-2

Outline -------------------------------------------------------------------------------- 7-2

Error Code ----------------------------------------------------------------------7-3

Error Code Details ----------------------------------------------------------------- 7-3

Jam Code -----------------------------------------------------------------------7-6

Main Unit (Included with the Cassette Feeding Module-AB1 and the

Duplex Unit-C1) -------------------------------------------------------------------- 7-6

DADF-AM1 -------------------------------------------------------------------------- 7-7

Alarm Code ---------------------------------------------------------------------7-8

Alarm Code Details ---------------------------------------------------------------- 7-8

8 Service Mode

Outline ---------------------------------------------------------------------------8-2

Outline of Service Mode ---------------------------------------------------------- 8-2

Backing up Service Mode -------------------------------------------------------- 8-2

Screen ow of Service Mode --------------------------------------------------- 8-3

Screen ow of Service mode --------------------------------------------------- 8-3

COPIER -------------------------------------------------------------------------8-4

DISPLAY ----------------------------------------------------------------------------- 8-4

VERSION

CCD -------------------------------------------------------------------------------------------- 8-4

SPDTYPE ------------------------------------------------------------------------------------ 8-6

I/O -------------------------------------------------------------------------------------- 8-7

R-CON ----------------------------------------------------------------------------------------- 8-7

FEEDER -------------------------------------------------------------------------------------- 8-7

ADJUST ------------------------------------------------------------------------------ 8-7

ADJ-XY ---------------------------------------------------------------------------------------- 8-7

CCD -------------------------------------------------------------------------------------------- 8-9

FEED-ADJ ------------------------------------------------------------------------------------ 8-9

FIXING ---------------------------------------------------------------------------------------8-10

LASER ----------------------------------------------------------------------------------------8-11

FUNCTION ------------------------------------------------------------------------- 8-11

CCD ------------------------------------------------------------------------------------------- 8-11

CLEAR ---------------------------------------------------------------------------------------8-12

MISC-R ---------------------------------------------------------------------------------------8-13

MISC-P ---------------------------------------------------------------------------------------8-13

SYSTEM ------------------------------------------------------------------------------------- 8-13

SPLMAN ------------------------------------------------------------------------------------- 8-13

INSTALL --------------------------------------------------------------------------------------8-14

PART-CHK ----------------------------------------------------------------------------------8-14

----------------------------------------------------------------------------------------- 8-4

0

0-8

0

0-9

OPTION ----------------------------------------------------------------------------- 8-14

BODY -----------------------------------------------------------------------------------------8-14

USER ----------------------------------------------------------------------------------------- 8-17

COUNTER --------------------------------------------------------------------------8-18

TOTAL ----------------------------------------------------------------------------------------8-18

PICK-UP -------------------------------------------------------------------------------------8-19

FEEDER -------------------------------------------------------------------------------------8-19

JAM -------------------------------------------------------------------------------------------8-19

FEEDER ----------------------------------------------------------------------- 8-21

ADJUST -----------------------------------------------------------------------------8-21

FUNCTION ------------------------------------------------------------------------- 8-22

TEST MODE ----------------------------------------------------------------- 8-23

PRINT --------------------------------------------------------------------------------8-23

9 Installation

How to check this Installation Procedure -------------------------------9-2

When Using the parts included in the package ---------------------------- 9-2

Symbols in the Illustration ------------------------------------------------------- 9-2

Making Pre-Checks -----------------------------------------------------------9-2

Selecting the Site of Installation ------------------------------------------------ 9-2

Type of Model ----------------------------------------------------------------------- 9-3

Points to Make Before Installation ----------------------------------------9-3

Checking the Contents ------------------------------------------------------9-4

Unpacking and Installation Procedure -----------------------------------9-5

Unpacking the Machine and Removing the Packaging Materials ----- 9-5

Installing the Toner Cartridge --------------------------------------------------- 9-6

Setting the Cassettes ------------------------------------------------------------- 9-8

Connecting the cord --------------------------------------------------------------- 9-9

Turning ON the Main Power / Stirring Toner / Initial setting ------------- 9-9

Setting the Date and Time ------------------------------------------------------9-10

Checking the Operation and the Print Image -----------------------------9-10

About the USB Cable (for Network Model ) -------------------------------- 9-10

About the LAN Cable (for Network Model of Asia, Korea and Taiwan) ---9-10

Checking the Connection to the Network (for Network Model ) ------9-10

Platen Cover Type-T Installation Procedure ------------------------- 9-11

Check the Contents --------------------------------------------------------------9-11

Main Power Switch OFF --------------------------------------------------------9-11

Installation Outline Drawing ---------------------------------------------------- 9-11

Installation Procedure ------------------------------------------------------------ 9-11

Heater Kit-M1 Installation Procedure ---------------------------------- 9-13

Checking the Contents ----------------------------------------------------------9-13

Main Power Switch OFF --------------------------------------------------------9-13

Installation Outline Drawing ---------------------------------------------------- 9-13

Product Name ---------------------------------------------------------------------9-13

Preparation of the Host Machine ----------------------------------------------9-14

Connecting Heater Kit-M1 with the Host Machine ------------------------9-15

After Installing the Heater Kit --------------------------------------------------9-17

Cassette Heater Unit-40 Installation Procedure -------------------- 9-18

Checking the Contents ----------------------------------------------------------9-18

Main Power Switch OFF --------------------------------------------------------9-18

Installation Outline Drawing ---------------------------------------------------- 9-18

Points to Note Before Installation ---------------------------------------------9-18

Connecting Cassette Heater Unit-40 with the Host Machine ----------9-19

Connect Cassette Heater Unit-40 with Cassette Feeding Module

AB1(Option Cassette) -----------------------------------------------------------9-20

After Installing the Heater -------------------------------------------------------9-21

Appendix

Service Tools ----------------------------------------------------------------- 10-2

Special Tools --------------------------------------------------------------------------------10-2

Oils and Solvents --------------------------------------------------------------------------10-2

General Circuit Diagram --------------------------------------------------- 10-3

General Circuit Diagram --------------------------------------------------------10-3

General Circuit Diagram (1/5) ----------------------------------------------------------10-3

General Circuit Diagram (2/5) ----------------------------------------------------------10-4

General Circuit Diagram (3/5) ----------------------------------------------------------10-5

General Circuit Diagram (4/5) ----------------------------------------------------------10-6

General Circuit Diagram (5/5) ----------------------------------------------------------10-7

General Timing Chart ------------------------------------------------------ 10-8

2 Prints, Continuous, Cassette 1 ----------------------------------------------10-8

Backup Data ------------------------------------------------------------------ 10-9

0

0-9

0

0-10

Soft Counter Specications --------------------------------------------- 10-10

Soft counter specications ---------------------------------------------------- 10-10

0

0-10

Safety Precautions

CDRH Act

■

Laser Safety

■

Handling of Laser System

■

Turn power switch ON

■

Power Supply

■

Safety of Toner

■

Notes When Handling

■

the Lithium and Ni-MH

Batteries

Notes Before it Works

■

Serving

0

Safety Precautions > Laser Safety

0-12

CDRH Act

The Center for Devices and Radiological Health of the US Food and Drug Administration put

into force regulations concerning laser products on August 2, 1976. These regulations apply

to laser products manufactured on and after August 1, 1976, and the sale of laser products

not certied under the regulations is banned within the Untied States. The label shown here

indicates compliance with the CDRH regulations, and its attachment is required on all laser

products that are soled in the United States.

CANON INC.

30-2,SHIMOMARUKO,3-CHOME,OHTA-KU,TOKYO,JAPAN

MANUFACTURED:

THIS PRODUCT CONHORMS WITH DHHS RADIATION

PERFORMANCE STANDARD 21CFR CHAPTER 1

SUBCHAPTER J.

F-0-1

Laser Safety

Laser beam radiation may pose a danger to the human body. A laser scanner mounted on the

machine is sealed with the protection housing and external cover to prevent the laser beam

from leaking to the outside. The laser beam never leaks out of the scanner as far as users

operate the machine normally.

The following warnings are given to comply with Safety Standard (EN60950-1).

Sicherheit des Lasers

Laserstrahlen können für den menschlichen Körper gefährlich sein. Aus diesem Grund ist das

optische Lasersystem mit einem Schutzgehäuse und einer Außenabdeckung

dicht verschlossen und hat eine Struktur, die keine Laserstrahlen nach außen dringen lässt.

Unter der Voraussetzung, dass der Benutzer dieses Gerät normal

bedient, ist ein Austritt von Laserstrahlen daher ausgeschlossen.

A different description may be used for a different product.

Safety Precautions > Laser Safety

0

0-12

0

Safety Precautions > Handling of Laser System

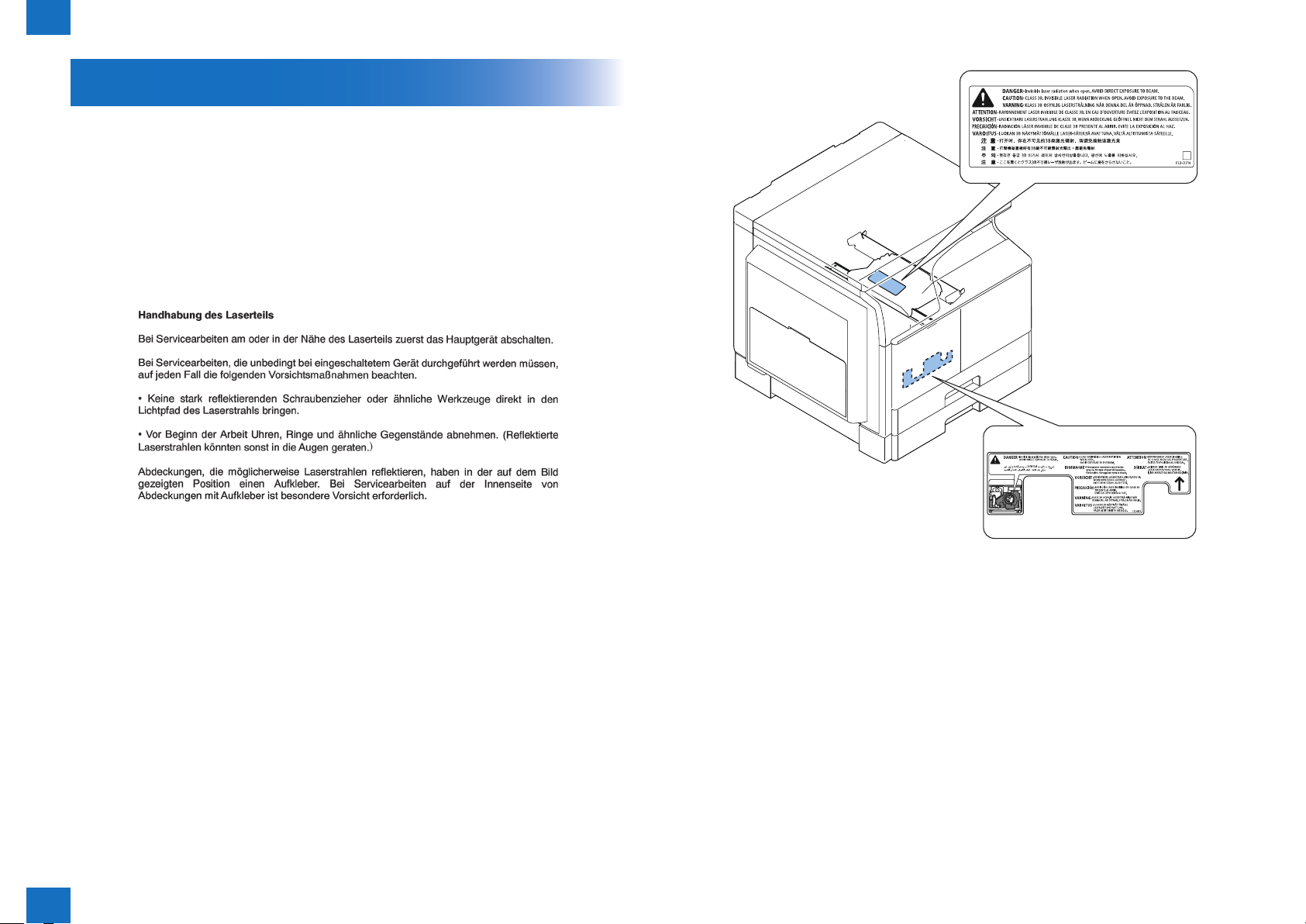

Handling of Laser System

When servicing the area around the laser assembly, be sure to turn off the main power.

If you must servicr while the power is turned on, be sure to keep the followings:

- Do not use a screwdriver or tools that have a high level of reectance in the laser path.

- Remove watches and rings before starting the work. (They can reect the laser beam,

possibly hitting the eye.)

The machine's covers that can reect laser light are identied by means of a warning label

(Figure). If you must detach a cover showing the label, be sure to take

extra caution during the work.

The following warnings are given to comply with Safety Standard (EN60950-1).

0-13

Safety Precautions > Handling of Laser System

0

F-0-2

F-0-3

This product is certicated as a Class 1 laser product under IEC60825-1:2007.

0-13

0

Safety Precautions > Power Supply

0-14

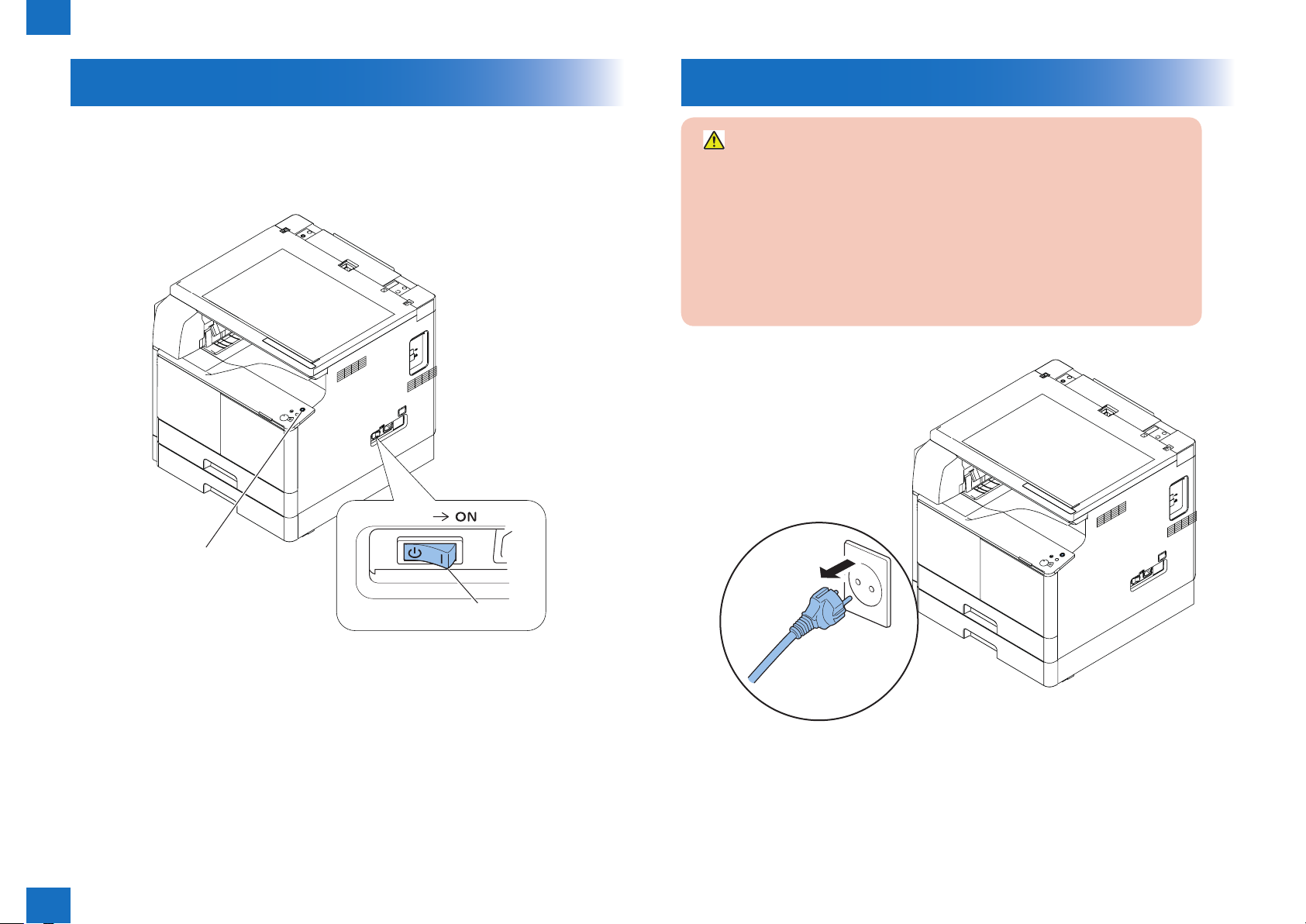

Turn power switch ON

The machine is equipped with 2 power switches: main power switch and energy saver key.

The machine goes on when the main power switch is turned on (i.e., other than in low power

mode, sleep mode).

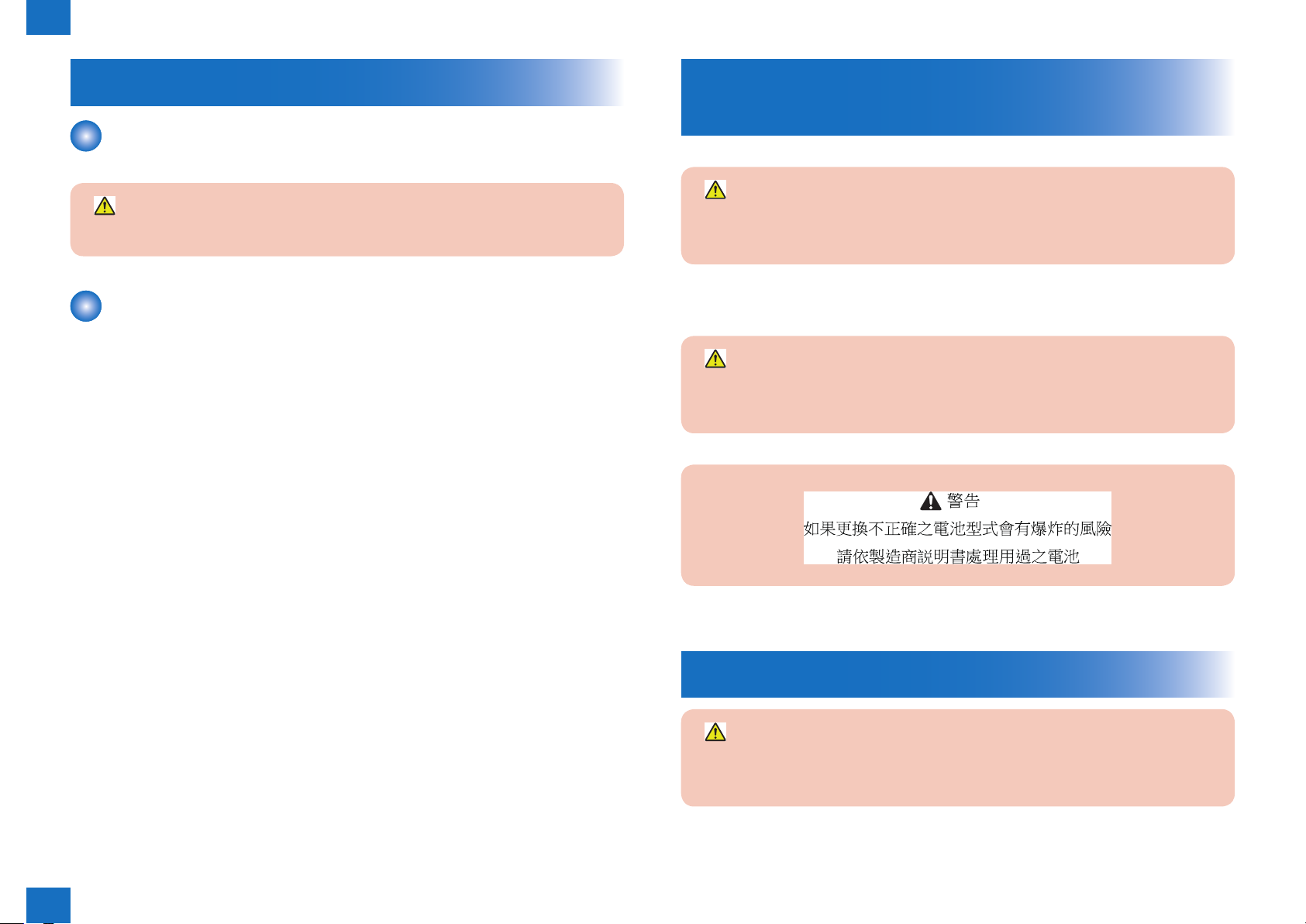

Power Supply

1. As a general rule, do not use extension cords. Using an extension cord may

result in a re or electrical shock. If an extension cord must be used, however,

use one for local rated voltage and over, untie the cord binding, and insert the

power plug completely into the extension cord outlet to ensure a rm connection

between the power cord and the extension cord.

2. The socket-outlet shall be installed near the equipment and shall be easily

accessible.

Energy Saver Key

Safety Precautions > Power Supply

0

Main Power Switch

F-0-4

F-0-5

0-14

0

Safety Precautions > Notes Before it Works Serving

0-15

Safety of Toner

About Toner

The machine's toner is a non-toxic material made of plastic, iron, and small amounts of dye.

Do not throw toner into re. It may cause explosion.

Toner on Clothing or Skin

• If your clothing or skin has come into contact with toner, wipe it off with tissue; then, wash it

off with water.

• Do not use warm water, which will cause the toner to jell and fuse permanently with the

bers of the cloth.

• Tonner is easy to react with plastic material, avoid contact with plastic.

Notes When Handling the Lithium and Ni-MH Batteries

RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECT TYPE.

DISPOSE OF USED BATTERIES ACCORDING TO THE INSTRUCTIONS.

The following warnings are given to comply with Safety Principles (EN60950).

Wenn mit dem falschen Typ ausgewechselt, besteht Explosionsgefahr.

Gebrauchte Batterien gemäß der Anleitung beseitigen.

Safety Precautions > Notes Before it Works Serving

0

Notes Before it Works Serving

At servicing, be sure to turn OFF the power source according to the specied steps and

disconnect the power plug.

0-15

0

Safety Precautions > Notes On Assembly/Disassembly

Notes On Assembly/Disassembly

Follow the items below to assemble/disassemble the device.

1. Disconnect the power plug to avoid any potential dangers during assembling/disassembling

works.

2. If not specially instructed, reverse the order of disassembly to reinstall.

3. Ensure to use the right screw type (length, diameter, etc.) at the right position when

assembling.

4. To keep electric conduction, binding screws with washers are used to attach the grounding

wire and the varistor. Ensure to use the right screw type when assembling.

5. Unless it is specially needed, do not operate the device with some parts removed.

6. Never remove the paint-locked screws when disassembling.

F-0-6

0-16

Zweipolige bzw. Neutralleiter-Sicherung

Safety Precautions > Notes On Assembly/Disassembly

0

ACHTUNG

F-0-7

0-16

Product Overview

1

Product Lineup

■

Feature

■

Specications

■

Name of Parts

■

Product Overview

1

1

Product Overview > Product Lineup > Host machine

1-2

Product Lineup

Host machine

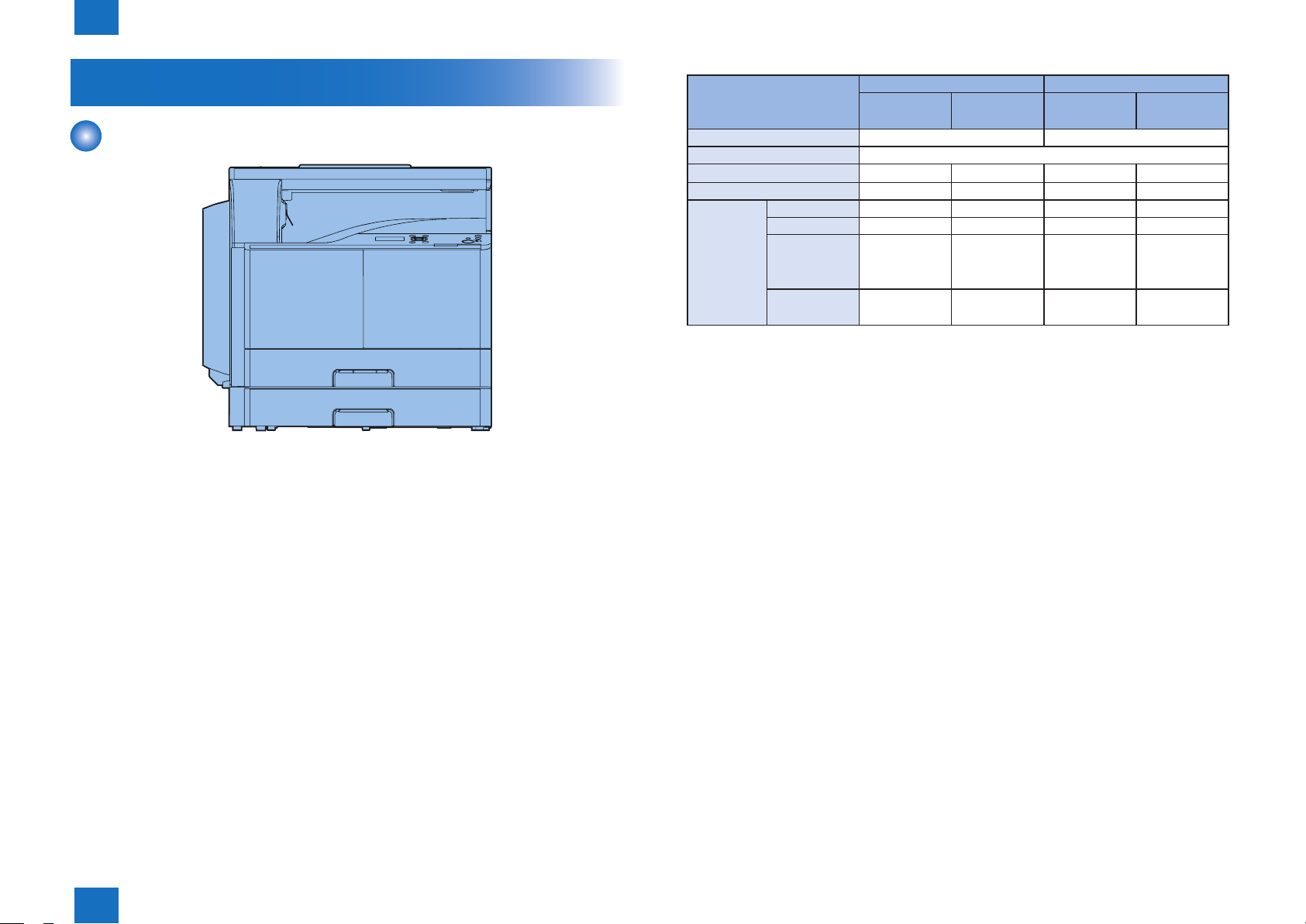

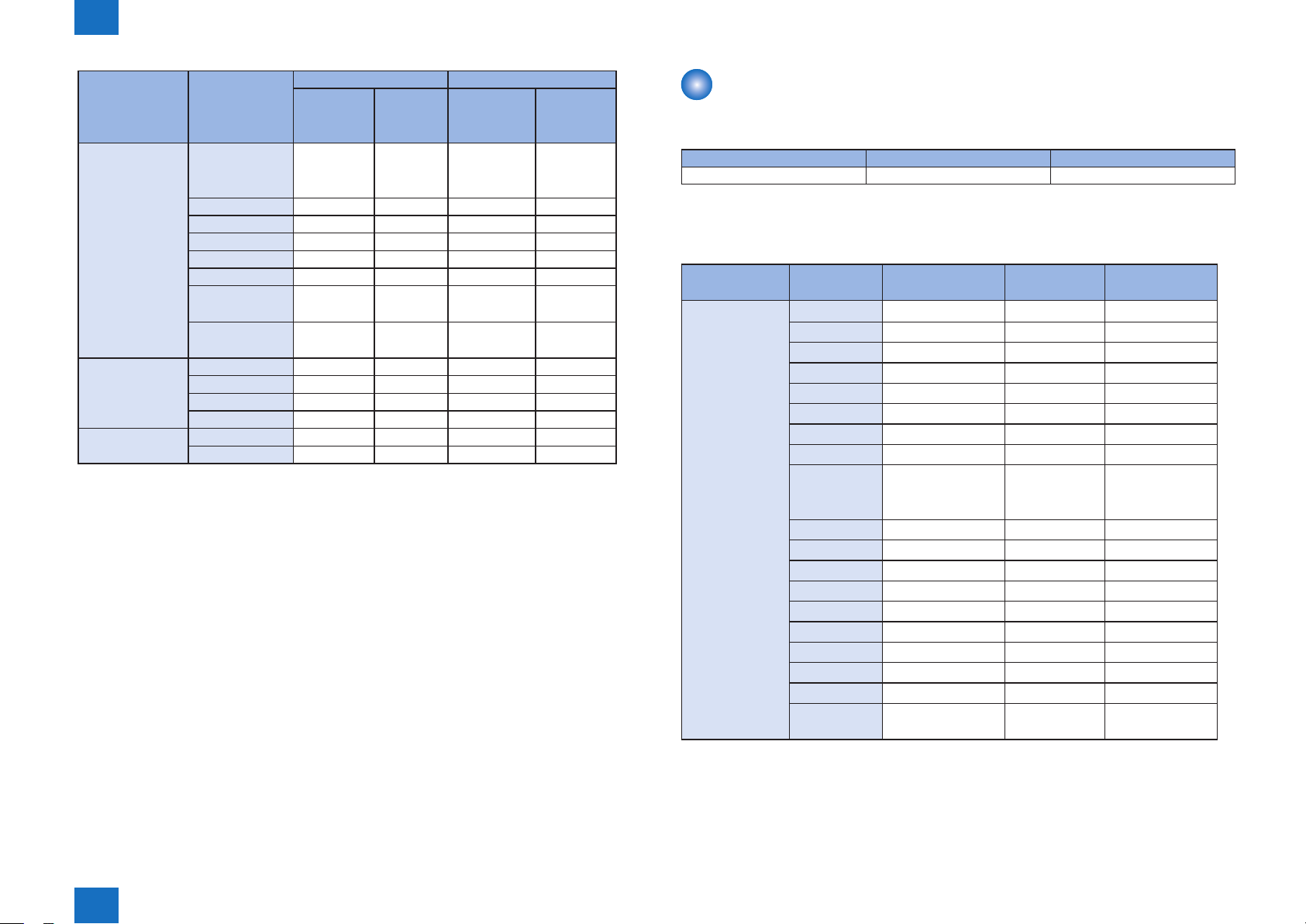

F-1-1

Print Speed

Positioning

LAN Port

USB Port

Option

Conversion

iR2202 iR2002

Network model Local print

model

22ppm 20ppm

Target machine: iR2422/2420 Series

Yes - Yes -

Yes Yes Yes Yes

ADF

Duplex Unit Yes - Yes -

Cassette

Feeding

Module

Cassette

Heater

Yes - Yes -

Yes - Yes -

Yes Yes Yes Yes

Network model Local print

model

T-1-1

Product Overview > Product Lineup > Host machine

1

1-2

1

Product Overview > Product Lineup > Option

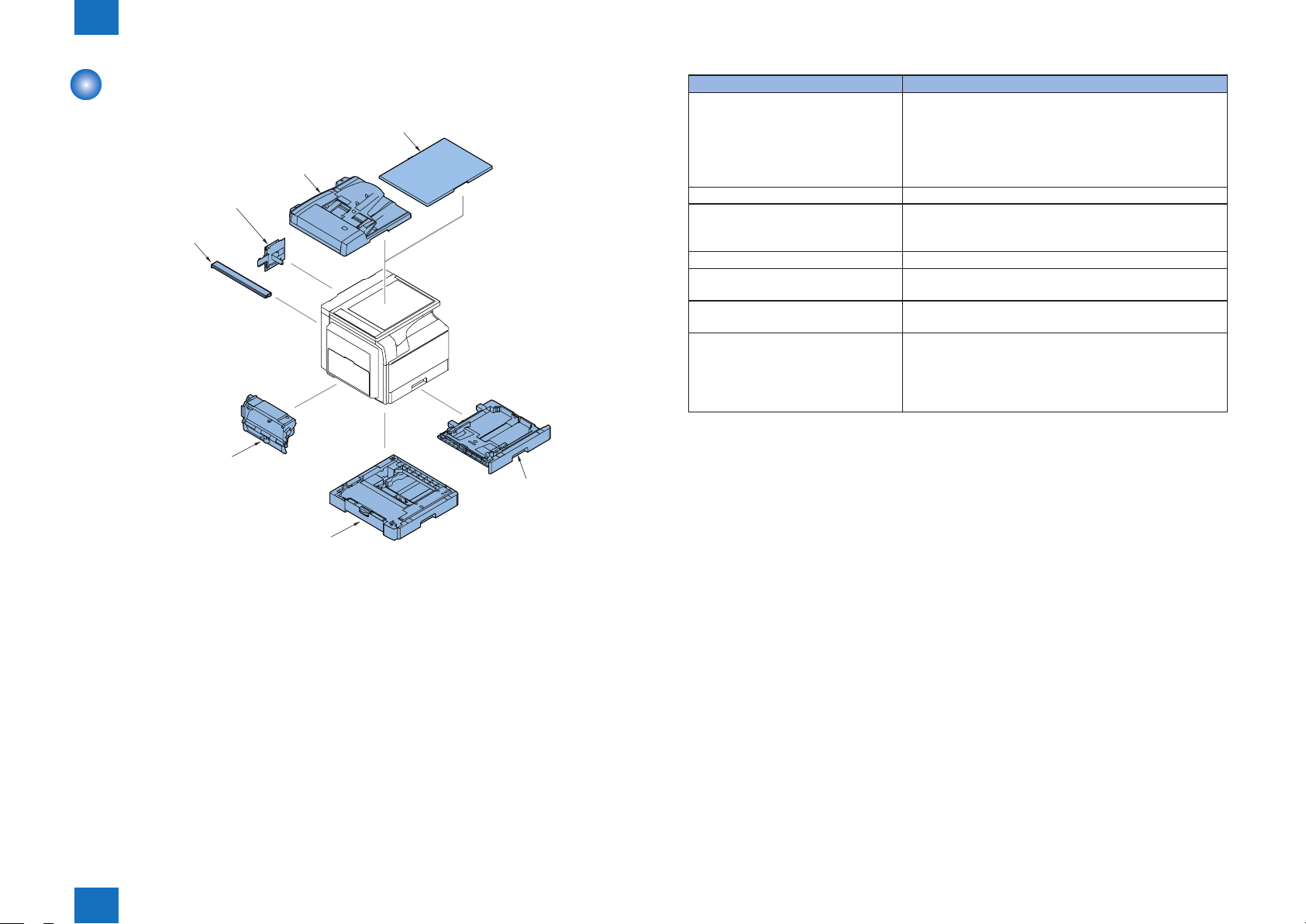

1-3

Option

Heater Kit-M1

Cassette Heater Unit-40

Duplex Unit-C1

DADF-AM1

Platen Cover Type T

FL Cassette-AU1

Product name Required options, conditions, etc.

DADF-AM1 Opiton for network model

Paper weight:

<Single feed> 37 to 128 g/m

<Continuous feed> 52 to 105 g/m

Stacking capacity:

50 sheets (80 g/m2, A4 or LTR)

Platen Cover Type T Standard or option

Cassette Feeding Module-AB1 Opiton for network model

Standard or option

Pickup capacity: 250 sheets (80 g/m

FL Cassette-AU1 Option for 1st cassette of the main body

Duplex Unit-C1 Opiton for network model

Standard or option

Heater Kit-M1 Heater Kit-M1 is required when installing the optional

heater.

Cassette Heater Unit-40 Option for cassette of main body and Cassette Feeding

Module-AB1.

Use it to suppress the moisture absorption of the paper in

the cassette.

Heater Kit-M1 is required.

2

2

2

)

T-1-2

Cassette Feeding

Product Overview > Product Lineup > Option

1

Module-AB1

F-1-2

1-3

1

Product Overview > Specications > Product Specications

1-4

Feature

Product feature

Reader unit

- The mold frame was adopted.

Small-size/weight-saving

Drum unit

- Installed at the time

of factory shipment.

Improved installability

Toner

- The toner of the low

melting was adopted.

Paper loading improvement

(High-temperature and

high-humidity environment )

Controller PCB

- The DC controller and

the main controller

were unified.

Space-saving

Main body frame

- The mold frame was adopted.

Small-size/weight-saving

F-1-3

Specications

Product Specications

Copyboard

Body

Light source type

Photosensitive medium

Image reading method

Reproduction method

Exposure method

Charging method

Development method

Transfer method

Separation method

Pickup method

Fixing method

Delivery method

Reproduction ratio

Drum cleaning method

Toner type

Toner replenish method

Toner level detection function

Top image margin

Left image margin

Warm-up time

Number of gradations

Reading resolution

Writing resolution

First print time

Paper type (Cassette)

Paper type (Multi-purpose

pickup tray)

Paper size (Cassette 1)

Paper size (Cassette 2)

Stream reading, original xed reading

Desktop

LED (RGB)

OPC drum (30 mm dia)

CIS

Indirect electrostatic method

Laser exposure system

Roller charge

Dry single component projection developing

By transfer roller

Curvature and static eliminator

1st cassette: Pad separation method

2nd cassette: Retard separation method

Multi-purpose pickup tray: Pad separation method

On demand

Face down delivery (in-body delivery)

25 to 400%

By cleaning blade

Single component magnetic negative charge toner

Toner cartridge

Yes

3.0 ± 1.5 mm

3.0 ± 2.0 mm

At power ON: 13 sec or less

256 gradations

600 x 600 dpi

600 x 600 dpi

7.9 sec or less

Plain paper (64 to 90 g/m2), recycled paper (64 to 80 g/m2), color

paper (64 to 80 g/m2), pre-punched paper

Plain paper (64 to 90 g/m2), recycled paper (64 to 80 g/m2), color

paper (64 to 80 g/m2), pre-punched paper, bond paper(75 to 90 g/

m2), heavy paper 1 (91 to 105 g/m2), heavy paper 2 (106 to 128 g/

m2), OHP, labels, Envelopes (No.10(COM10), Monarch, ISO-C5,

DL)

A4, A4R, A3, A5R, B4, B5, B5R, LTR, LTRR, LGL, 11" x 17" (279

mm X 432 mm), STMTR, 8K, 16K, 16KR

A4, A4R, A3, A5, B4, B5, B5R, LTR, LTRR, LGL, 11" x 17" (279

mm X 432 mm), STMT, 8K, 16K, 16KR

Product Overview > Specications > Product Specications

1

1-4

1

Product Overview > Specications > Productivity (Print speed)

1-5

Paper size (Multi-purpose

pickup tray)

Pickup capacity

Duplex method

Noise

Ozone

Power supply rating

Power

consumption

Maximum

power

consumption

At the time of

printing

At the time of

sleep (Deep

Sleep)

Dimensions (W x D x H)

Weight

A4, A4R, A3, A5, A5R, B4, B5, B5R, LTR, LTRR, LGL, 11" x 17"

(279 mm X 432 mm), STMT, STMTR, EXEC, 8K, 16K, 16KR,

Custom paper size (95 x 148 mm to 297 x 431.8 mm), Envelopes

(No.10(COM10), Monarch, ISO-C5, DL)

Cassette1/2: 250 sheets (80 g/m2)

Multi-purpose pickup tray: 80 sheets (80 g/m2)

Through path duplex

imageRUNNER 2202:

At the time of printing: 66.7 dB or less / At the time of standby: 48

dB or less

imageRUNNER 2002:

At the time of printing: 66 dB or less / At the time of standby: 48

dB or less

1.5 mg/h or smaller

Network model

120 - 127 V AC, 60Hz, 4.6 A

220 - 240 V AC, 50Hz/60Hz, 2.7 A

Local print model

220 - 240 V AC, 50Hz/60Hz, 2.4 A

1.5 kW or less

Network model

imageRUNNER 2202 : Approx. 470 Wh (Reference)

imageRUNNER 2002 : Approx. 433 Wh (Reference)

Local print model

imageRUNNER 2202 : Approx. 416 Wh (Reference)

imageRUNNER 2002 : Approx. 398 Wh (Reference)

2.0 W or less

622 mm x 589 mm x 502 mm (with the platen cover and single

cassette)

622 mm x 589 mm x 567 mm (with the platen cover and double

cassette)

622 mm x 589 mm x 692 mm (with the feeder and double

cassette)

Min (With the platen cover and single cassette: 29.7 kg (included

with the drum unit and toner cartridge)

Max (with the feeder and double cassette): 41.3 kg (included with

the drum unit and toner cartridge)

T-1-3

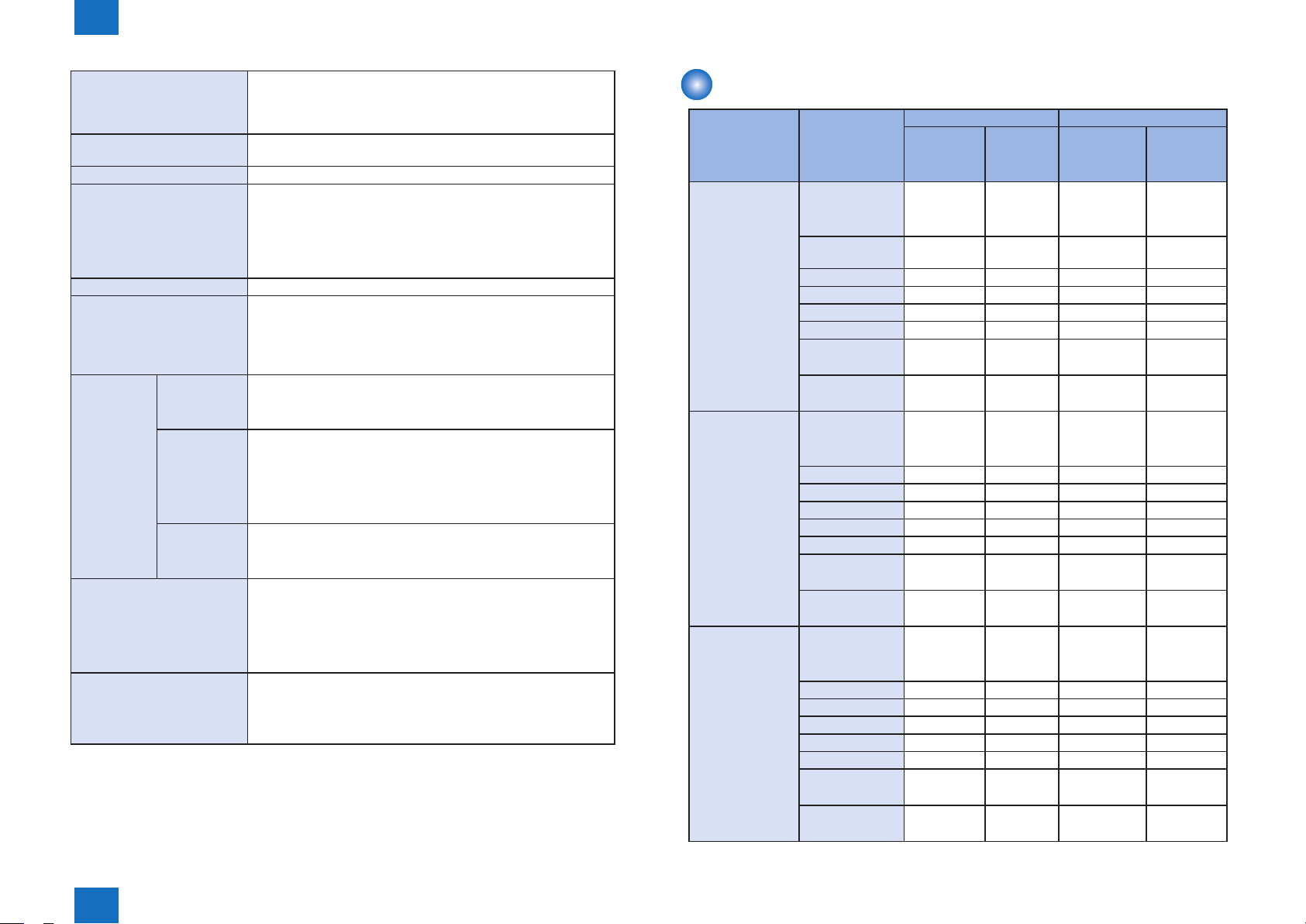

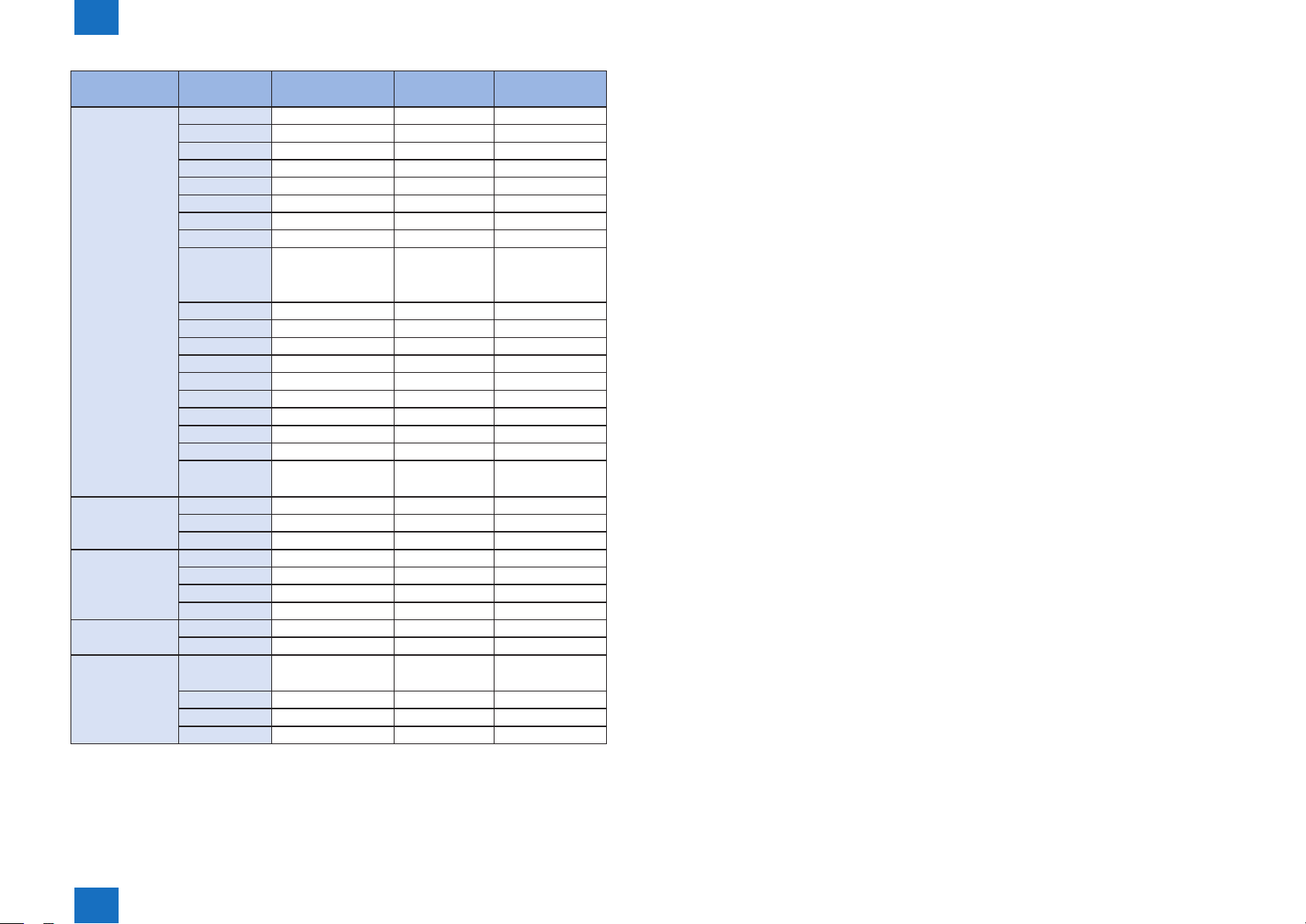

Productivity (Print speed)

Fixing mode Size 1-sided 2-sided

Plain paper mode

(color paper,

recycled paper,

plain paper (64

to 90 g/m

2

), pre-

punched paper)

Heavy paper L

mode (heavy

paper 1 (91 to

105 g/m

2

), label)

Heavy paper

mode (Heavy

paper 2 (106 to

128 g/m

2

))

A3, 11" x 17"

(279 mm X 432

mm)

A4, LTR, 16K

B4, LGL, 8K

B5, EXEC

A4R, LTRR

A5, STMT

A5R, B5R,

STMTR, 16KR

Custom paper

size

A3, 11" x 17"

(279 mm X 432

mm)

A4, LTR, 16K

B4, LGL, 8K

B5, EXEC

A4R, LTRR

A5, STMT

A5R, B5R,

STMTR, 16KR

Custom paper

size

A3, 11" x 17"

(279 mm X 432

mm)

A4, LTR, 16K

B4, LGL, 8K

B5, EXEC

A4R, LTRR

A5, STMT

A5R, B5R,

STMTR, 16KR

Custom paper

size

Cassette

pickup

iR2202: 11

iR2002: 10

iR2202: 22

iR2002: 20

10 10 6.7 6.7

20 20 14 .2 14 .2

11 11 7.8 7.8

23 23 - 13 13 9.1 9.1

5 5 - -

- 8 - -

- 12 - -

- 8 - -

- 12 - -

- 10 - -

- 13 - -

- 10 - -

- 5 - -

- 7 - -

- 10 - -

- 6 - -

- 10 - -

- 8 - -

- 11 - -

- 7 - -

- 5 - -

Multi-

purpose

Cassette

pickup

pickup

10 iR2202: 6.9

iR2002: 6.7

20 iR2202: 14.7

iR2002: 14.2

Multi-

purpose

pickup

iR2202: 6.9

iR2002: 6.7

iR2202: 14.7

iR2002: 14.2

Product Overview > Specications > Productivity (Print speed)

1

1-5

1

Product Overview > Specications > Paper Type > Pickup

1-6

Fixing mode Size 1-sided 2-sided

Super heavy

paper mode

(Bond paper (75

to 90 g/m

Envelope Monarch

OHP A4R

2

))

A3, 11" x 17"

(279 mm X 432

mm)

A4, LTR, 16K

B4, LGL, 8K

B5, EXEC

A4R, LTRR

A5, STMT

A5R, B5R,

STMTR, 16KR

Custom paper

size

COM10

ISO-C5

DL

LTRR

Cassette

pickup

- 5 - -

- 7 - -

- 5 - -

- 6 - -

- 4 - -

- 5 - -

- 4 - -

- 3 - -

- 4 - -

- 4 - -

- 4 - -

- 4 - -

- 11 - -

- 11 - -

Multi-

purpose

pickup

Cassette

pickup

Multi-

purpose

pickup

T-1-4

Paper Type

Following shows the types of usable papers.

See the table below for the custom paper size.

Type Feeding direction (mm) Width direction (mm)

Custom paper size 148 to 431.8 95 to 297

■Pickup

Usable paper types are shown.

Paper type Size Multi-purpose

pickup tray

Color paper,

recycled paper,

plain paper (64 to

2

)

90 g/m

A3

B4

A4R

A4

B5R

B5

A5

A5R

11" x 17" (279

mm X 432

mm)

LGL

LTR

LTRR

STMTR

STMT

EXEC

K8

K16

K16R

Custom paper

size

Yes Yes Yes

Yes Yes Yes

Yes Yes Yes

Yes Yes Yes

Yes Yes Yes

Yes Yes Yes

Yes No Yes

Yes Yes No

Yes Yes Yes

Yes Yes Yes

Yes Yes Yes

Yes Yes Yes

Yes Yes No

Yes No Yes

Yes No No

Yes Yes Yes

Yes Yes Yes

Yes Yes Yes

Yes No No

Cassette 1 Cassette 2

T-1-5

Product Overview > Specications > Paper Type > Pickup

1

1-6

1

Product Overview > Specications > Paper Type > Pickup

1-7

Paper type Size Multi-purpose

pickup tray

Heavy paper 1

(91 to 105 g/m

heavy paper 2

(106 to 128 g/

2

), bond paper

m

(75 to 90 g/m

A3

2

B4

),

A4R

A4

B5R

2

B5

)

A5

A5R

Yes No No

Yes No No

Yes No No

Yes No No

Yes No No

Yes No No

Yes No No

Yes No No

11" x 17" (279

mm X 432

Yes No No

mm)

LGL

LTR

LTRR

STMTR

STMT

EXEC

K8

K16

K16R

Custom paper

size

Label A4R

A4

LTR

Pre-punched

paper

A4R

A4

LTR

LTRR

OHP A4

LTR

Envelope No.10

(COM10)

Monarch

ISO-C5

DL

Yes No No

Yes No No

Yes No No

Yes No No

Yes No No

Yes No No

Yes No No

Yes No No

Yes No No

Yes No No

Yes No No

Yes No No

Yes No No

Yes Yes Yes

Yes Yes Yes

Yes Yes Yes

Yes Yes Yes

Yes No No

Yes No No

Yes No No

Yes No No

Yes No No

Yes No No

Cassette 1 Cassette 2

T-1-6

Product Overview > Specications > Paper Type > Pickup

1

1-7

1

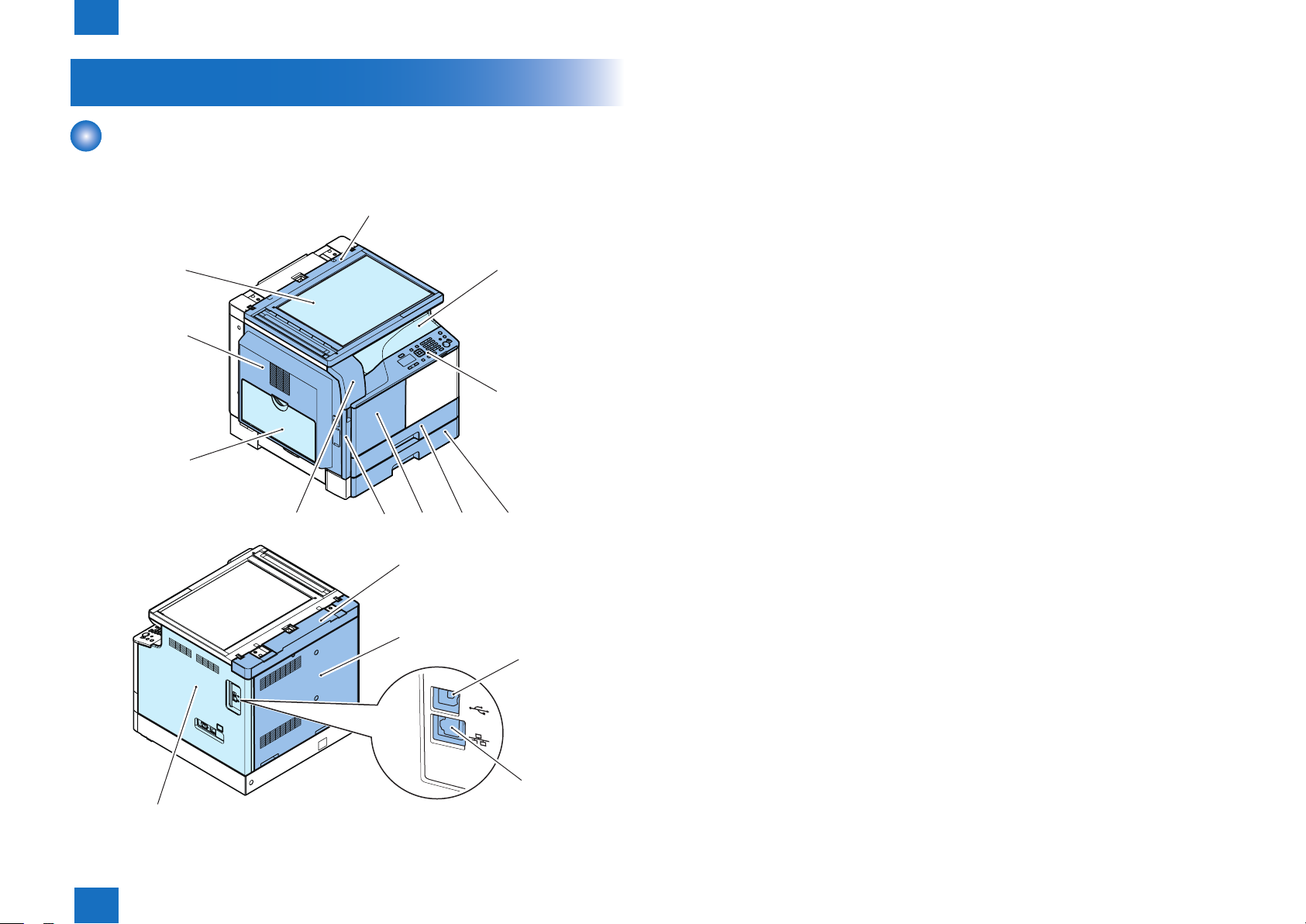

Product Overview > Name of Parts > External View > Network model

1-8

Name of Parts

External View

■Network model

[9]

[10]

[11]

[8]

[1] [2] [3] [4]

[12]

[7]

[6]

[5]

[1] Reader front cover

[2] Left front cover

[3] Front cover

[4] Cassette 1

[5] Cassette 2

[6] Control panel assembly

[7] Delivery tray cover

[8] Reader upper unit

[9] Platen glass

[10] Left cover unit

[11] Multi-purpose pickup tray

[12] Reader rear cover

[13] Rear rover

[14] Right cover

[15] USB Port

[16] LAN Port

F-1-4

[13]

[14]

Product Overview > Name of Parts > External View > Network model

1

[15]

[16]

F-1-5

1-8

1

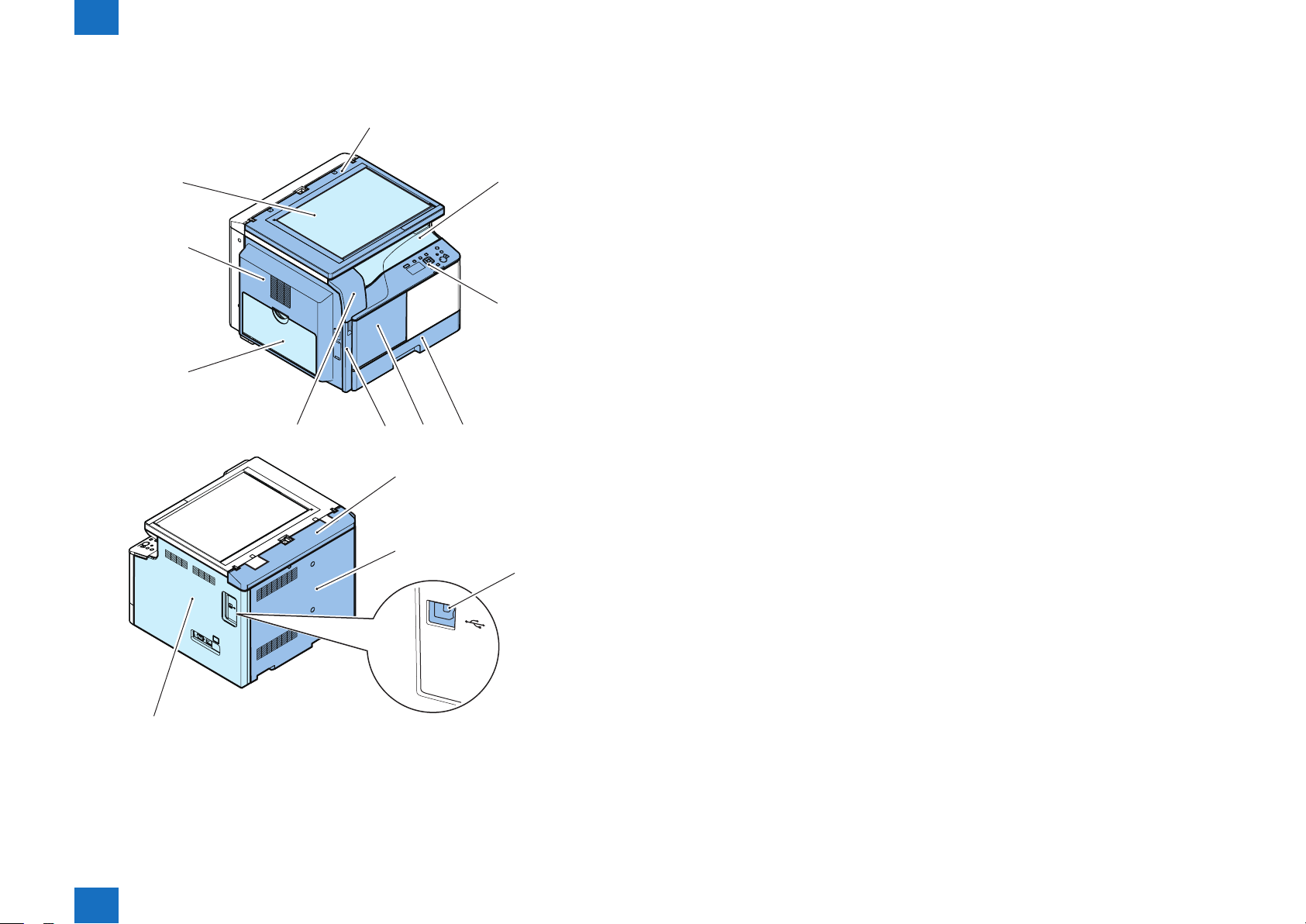

Product Overview > Name of Parts > External View > Local print model

1-9

■Local print model

[8]

[9]

[10]

[7]

[1] [2] [3] [4]

[11]

[6]

[5]

[1] Reader front cover

[2] Left front cover

[3] Front cover

[4] Cassette 1

[5] Control panel assembly

[6] Delivery tray cover

[7] Reader upper unit

[8] Platen glass

[9] Left cover unit

[10] Multi-purpose pickup tray

[11] Reader rear cover

[12] Rear rover

[13] Right cover

[14] USB Port

F-1-6

[12]

[13]

Product Overview > Name of Parts > External View > Local print model

1

[14]

F-1-7

1-9

1

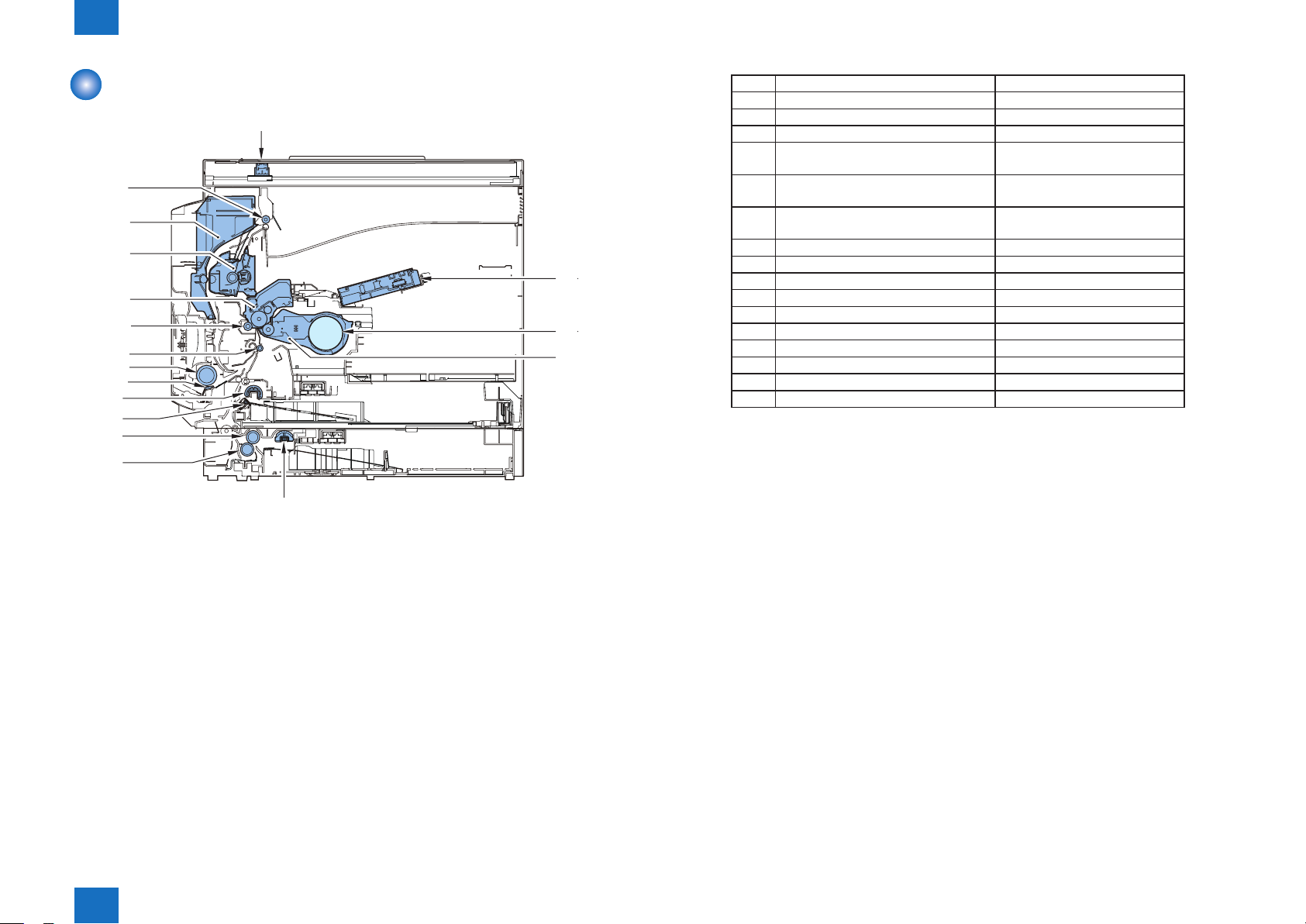

Product Overview > Name of Parts > Cross Sectional View

1-10

Cross Sectional View

[1]

[17]

[16]

[15]

[14]

[13]

[12]

[11]

[10]

[9]

[8]

[7]

[6]

[5]

[2]

[3]

[4]

[1] CIS unit

[2] Laser scanner unit

[3] Toner cartridge

[4] Developing assembly

[5] Cassette 2 pickup roller If equipped with the 1-cassette

module.

[6] Cassette 2 separation roller If equipped with the 1-cassette

module.

[7] Cassette 2 feed roller If equipped with the 1-cassette

module.

[8] Cassette 1 separation pad

[9] Cassette 1 pickup roller

[10] Multi-purpose tray separation pad

[11] Multi-purpose tray pickup roller

[12] Registration roller

[13] Transfer roller

[14] Drum unit

[15] Fixing assembly

[16] Duplex unit If equipped with the duplex unit.

[17] Delivery roller

F-1-8

Product Overview > Name of Parts > Cross Sectional View

1

1-10

1

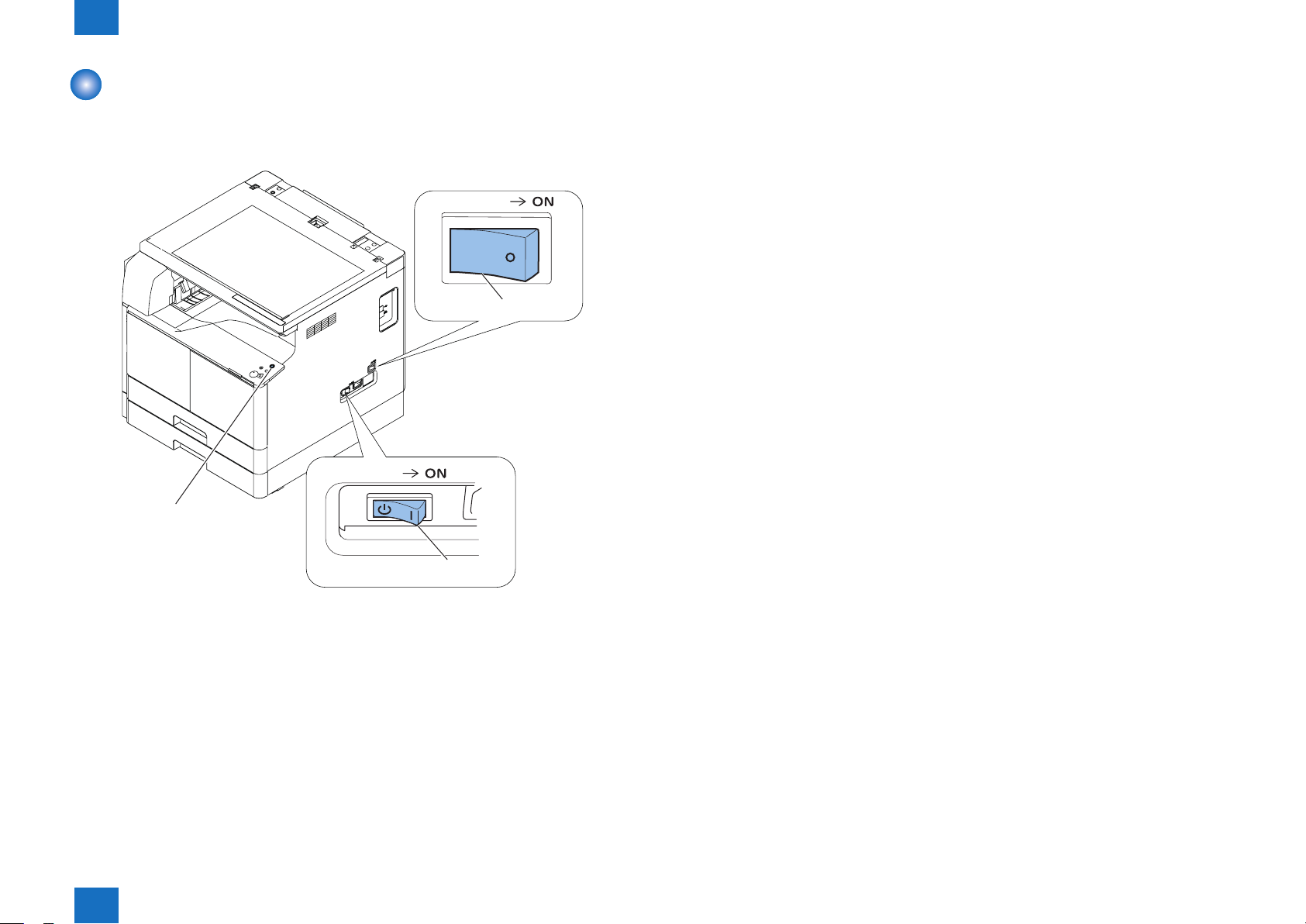

Product Overview > Name of Parts > Control Panel > Power Switch

1-11

Control Panel

■Power Switch

●Types of power switch

Energy Saver Key

●Points to Note on Turning ON/OFF the Power Switch

• To turn off the power, turn off the Main power Switch. (Conventional shutdown sequence

operation is not required.)

• After power-off (After the Main power Switch is turned off), do not reactivate the Main

power Switch until a screen disappears.

• Do not turn off the power while download is processing.

Heater Switch

Main Power Switch

F-1-9

This machine has the Main Power Switch, the Heater Switch and the Energy Saver Key.

[1] Main Power Switch

This switch is used to turn OFF / ON the power of host machine.

[2] Heater Switch (option)

This switch is used to turn OFF / ON the power of the cassette heater.

[3] Energy Saver Key

This switch is used to shift the machine to power-save mode or to restore it to normal

mode.

Product Overview > Name of Parts > Control Panel > Power Switch

1

1-11

1

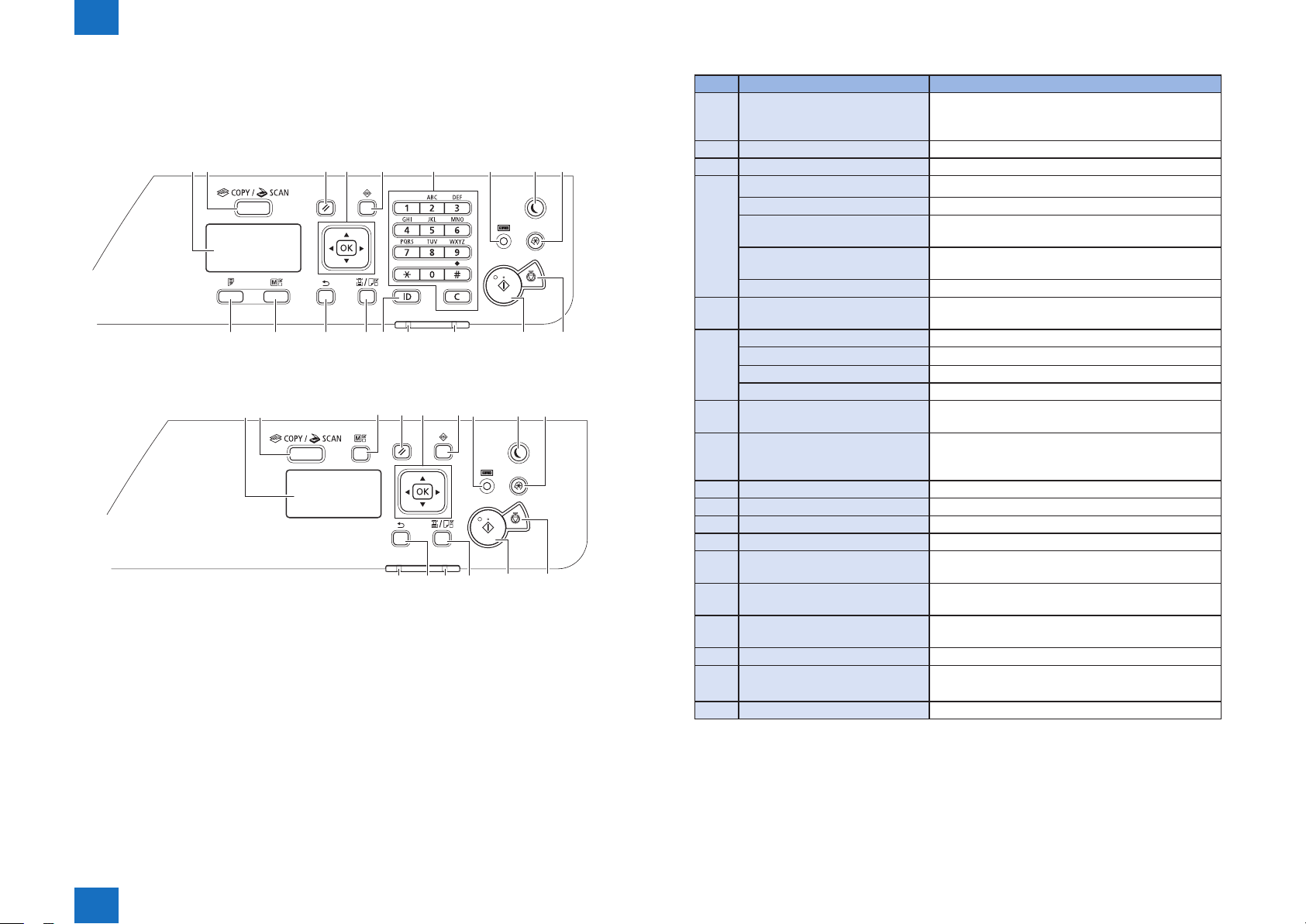

Product Overview > Name of Parts > Control Panel > Description of Control Panel

1-12

■Description of Control Panel

●Control Panel

Network model

[1] [2] [3] [4] [5] [6] [7] [8] [9]

Local print model

No. Name Function

[1] Display

[2] [COPY/SCAN] key

[3] [Reset] key

[4] [▲] key

[▼] key

[◄] key

[►] key

[OK] key

[5] [Status Monitor] Key

[10][11][12][13][14][15][16][17][18]

F-1-10

[3] [4] [5][1] [2] [17]

[7] [8] [9]

[15]

[12][13]

[10][11][16]

F-1-11

[6]*1 Numeric keys ([0]-[9])

[*] Key

[#] Key

[C] Key

[7] [Counter Check] Key

[8] [Energy Saver] Key

[9] [Settings/Registration] Key

[10] [Stop] Key

[11] [Start] Key

[12] [Error] Indicator

[13] [Processing/Data] Indicator

[14]*1 [Log In/Out]

[15] [Select Paper/Settings] Key

[16] [Back] Key

[17] [ID Card Copy/Favorite

Settings] Key

[18]*1 [2-Sided] Key

*1: Network model only

During normal operation, displays messages and

prompts. When adjusting the settings, displays your

selections, text, and numbers.

Press to switch the mode to copy or scan.

Press to reset the settings.

Press to scroll up or to increase the value.

Press to scroll down or to decrease the value.

Press to return to the previous screen, or move the

cursor to the left.

Press to proceed to the next screen, or move the

cursor to the right.

Press to conrm an action or setting.

Press to view the status of jobs or cancel jobs. Also

check the status of the network or the machine.

Press to enter characters and numbers.

Press to switch the character entry mode.

Press to enter symbols.

Press to delete entered characters and numbers.

Press this to display the total number of copies or

prints (performed by the machine) on the display.

Press to manually set or cancel the Sleep mode.

The Energy Saver indicator lights green while in the

Sleep mode.

Press to specify or register various settings.

Press to cancel jobs.

Press to start a job.

Flashes when an error occurs.

Flashes when the device is in operation, is on when

there is a job waiting to be processed.

Press to log in/out when Department ID

Management has been set.

Press to select a paper source, such as a drawer or

multi-purpose tray, and register paper size and type.

Press to return to the previous screen.

Press to use the ID Card Copy and Favorite

Settings.

Press to set 2-sided copies.

T-1-7

Product Overview > Name of Parts > Control Panel > Description of Control Panel

1

1-12

Technology

2

Basic Conguration

■

Original Exposure System

■

Controller System

■

Laser Exposure System

■

Image Formation System

■

Fixing System

■

Pickup Feed System

■

2

Technology

2

Technology > Basic Conguration > Basic sequence > Basic Operation Sequence

2-2

Basic Conguration

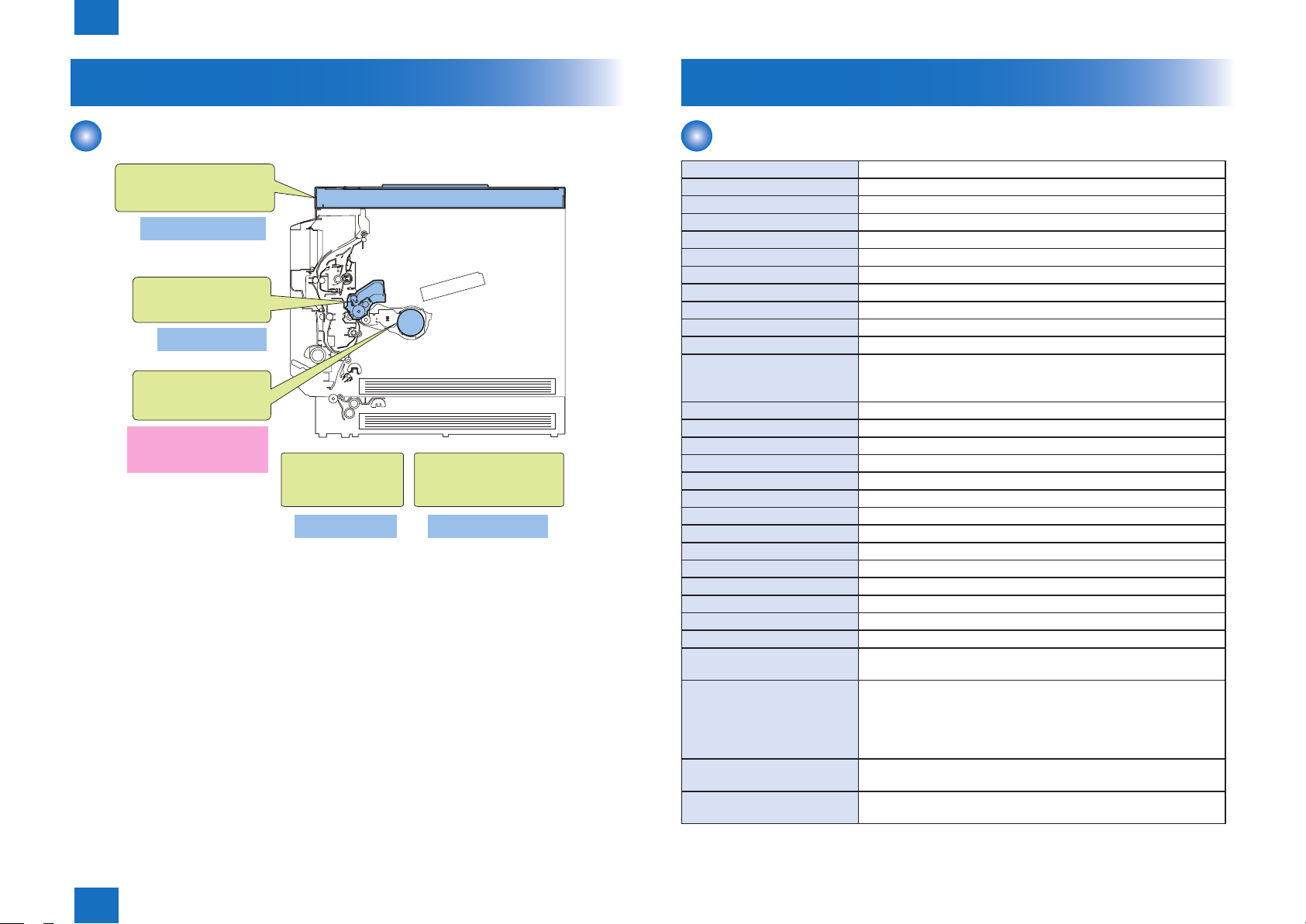

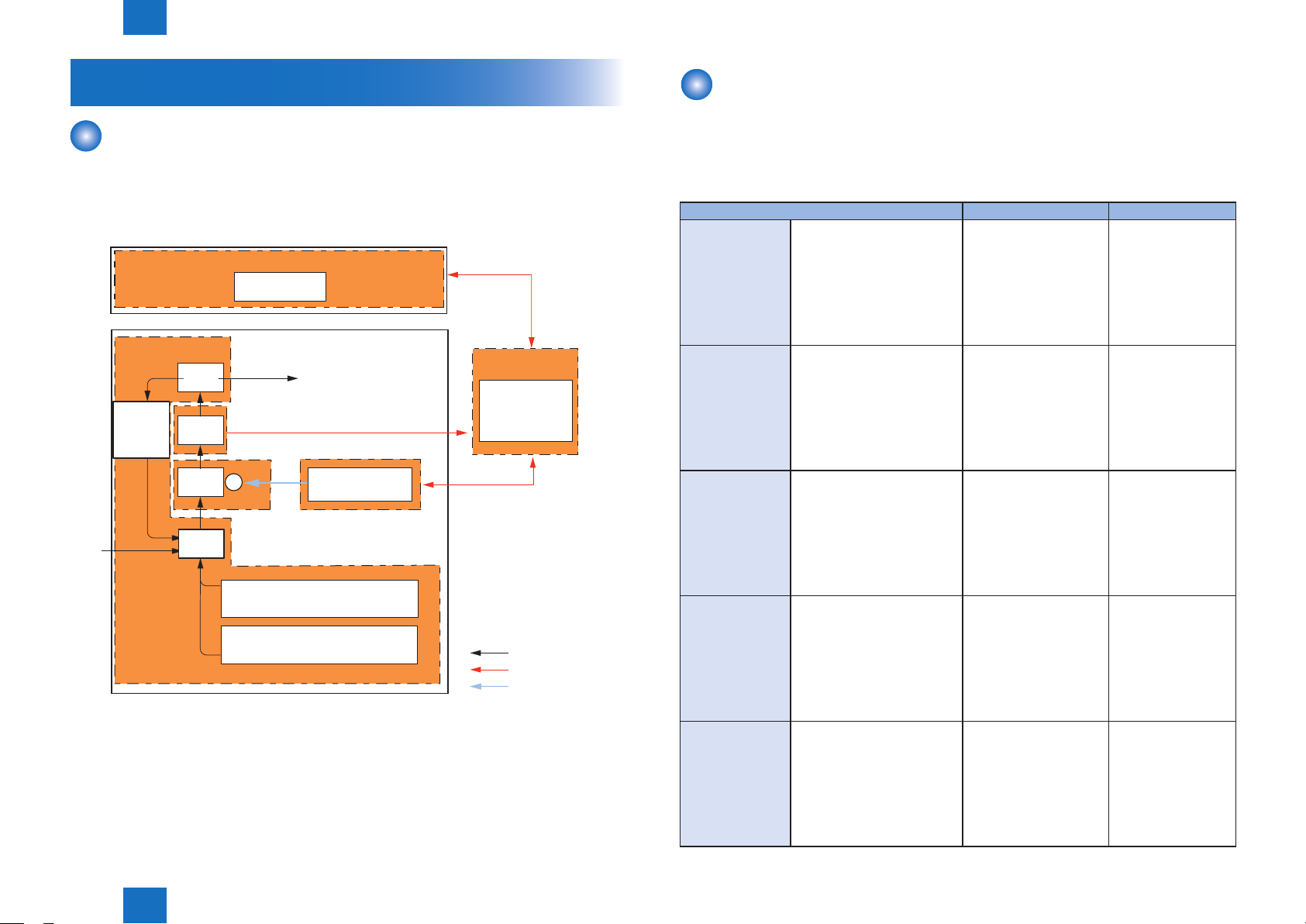

Functional Conguration

The host machine is constructed by following functional system blocks; Document

Exposure System, Controller System, Laser Exposure System, Image Formation System,

Fixing System and Pickup/Feed System.

Original exposure system

CIS unit

Controller system

Controller system

・Engine control

・System control

Duplexing

feed

Delivery

Fixing

Transfer

Pickup

Fixing

system

Laser exposure system

Laser scanner unit

Image

formation

system

Basic sequence

■Basic Operation Sequence

Basic Operation Sequence is controlled by engine controller. Each sequence, from main

power switch ON until the main motor stops, is described as below. See timing chart for

detail in the Appendix chapter.

Zone Purpose Remarks

WAIT

(wait)

STBY

(standby)

INTR

(initial rotation)

From main power switch ON

until the main motor stops

initial rotating.

From WAIT end or LSTR end

until print indication command

is entered from the controller

PCB (PCB1).

From print indication command

is entered from the controller

PCB (PCB1) until the Pickup

solenoid turns ON.

Eliminates charging

on the surface of the

photosensitive drum

and cleans the transfer

roller and keeps heater

temperature const.

Keeps the host machine

standby.

Keeps photosensitive

drum stable sensitivity

for print advance

preparations and cleans

the transfer roller.

Detects the toner

cartridge while

it keeps heater

temperature constant.

Pickup/feed

system

Technology > Basic Conguration > Basic sequence > Basic Operation Sequence

Cassette 1

Cassette 2

Paper flow

Signal flow

Laser beam

2

F-2-1

PRINT

(print)

LSTR

(last rotation)

From INTR end until top edge

of the paper detect sensor

detects end edge of the paper.

From PRINT end until the

main motor stops.

Forms image on

the photosensitive

drum, based on

Video signal (/VDO1,/

VDO2,VDO1,VDO2)

from the controller PCB

(PCB1). It transfers toner

image onto the paper.

Eliminates the paper on

the nal job completely.

Directly starts INTR

after LSTR ends

when print indication

command is entered

from the controller

PCB (PCB1).

T-2-1

2-2

2

Technology > Original Exposure System > Construction > Major Components

Original Exposure System

Construction

■Specications/controls/functions

The main specications, controls and functions of the original exposure and feed system are

described below.

Item Specication/Function

Original exposure LED

Original scan In book mode mobile CIS scanning

In ADF mode xed CIS scanning

Read resolution B/W: 600 dpi (main scanning) x 600 dpi (sub scanning)

Color SEND: 300 dpi (main scanning) x 600 dpi (sub scanning)

Gradation 256 gradation

Carriage position detection Contact Sensor HP Sensor(SR402)

Magnication 25% to 400%

Main scanning

direction

Sub scanning

direction

Lens Rod lens array

CMOS sensor Number of lines:1

CIS drive control Reader Motor(M301)

Original size

detection

*1 Controls differ depending on magnications. Refer to Magnication Change for detail.

In book mode No

In ADF mode Main scanning direction: photo interrupter

Image is processed on the controller PCB

In book mode: Image is procesed by carriage speed and

controller PCB *1

In ADF mode: Image is processed by paper delivery speed and

controller PCB *1

Number of pixels: Total 7344 (incl. 7276 effective pixels)

Maximum original scan width: 308mm

Sub scanning direction: photo interrupter

T-2-2

2-3

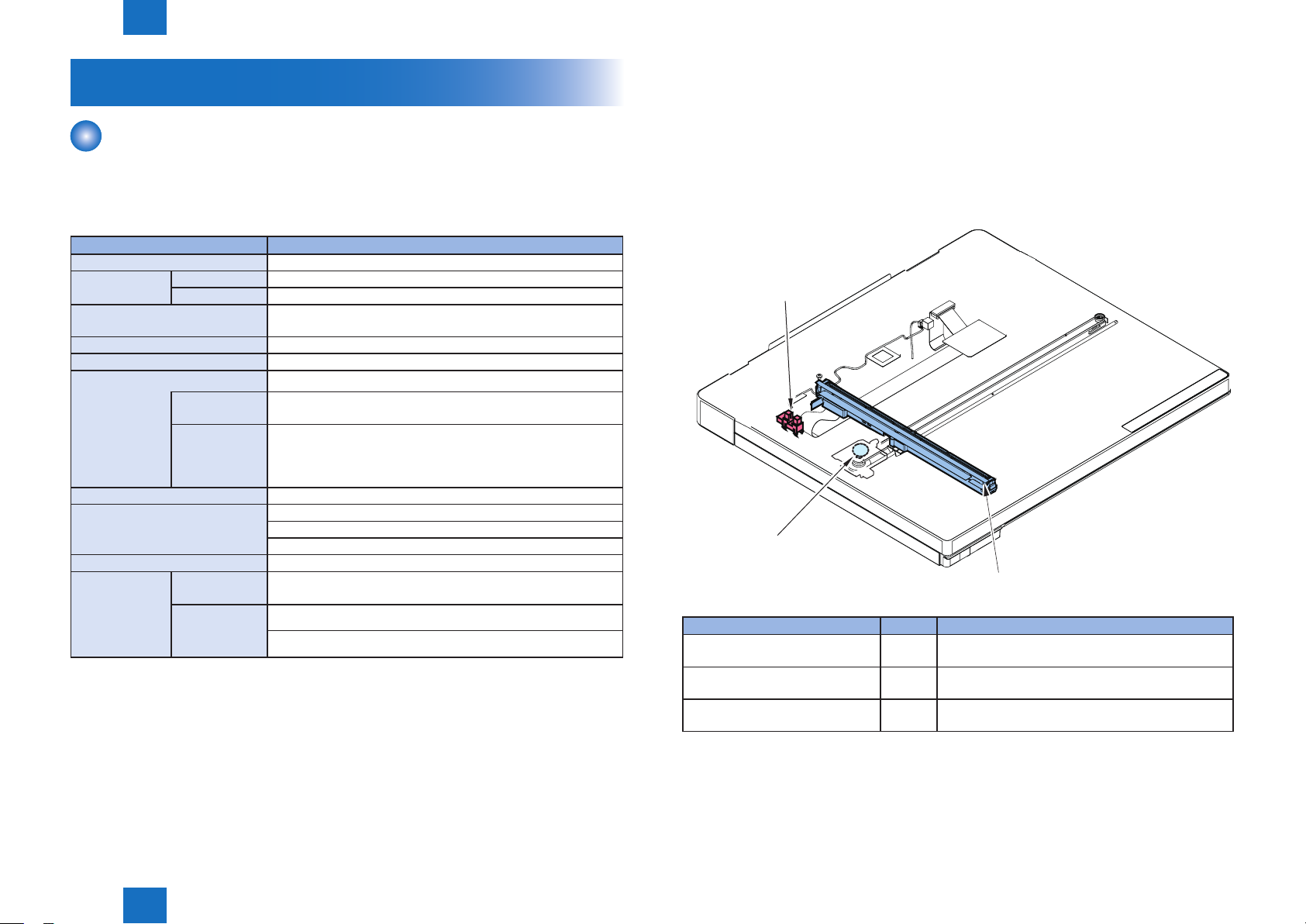

■Major Components

Major components of the original exposure system is shows below.

Contact sensor HP sensor

(SR402)

Reader motor

(M301)

CIS unit

F-2-2

Item Code Specication/Function

Reader Motor M301 Pulse Motor: carriage drive control

Contact Sensor HP Sensor SR402 Photo interrupter: CIS home position detection

Technology > Original Exposure System > Construction > Major Components

2

CIS unit - LED Indirect exposure

T-2-3

2-3

Loading...

Loading...