FINISHER - D1

SERVICE

MANUAL

REVISION 0

FEB. 1999

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

FY8-13FF-000

IMPORTANT

THE INFORMATION CONTAINED HEREIN IS PUBLISHED BY CANON, INC., JAPAN.

SPECIFICATIONS AND OTHER INFORMATION CONTAINED HEREIN MAY DIFFER SLIGHTLY FROM

ACTUAL MACHINE VALUES OR THOSE FOUND IN ADVERTISING AND OTHER PRINTED MATTER.

ANY QUESTIONS REGARDING INFORMATION CONTAINED HEREIN SHOULD BE DIRECTED TO THE

COPIER SERVICE DEPARTMENT OF THE SALES COMPANY.

COPYRIGHT 1999 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be strictly

supervised to avoid disclosure of confidential information.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIVISION

CANON INC.

5-1, Hakusan 7-chome, Toride-City, Ibaraki, 302-8501 Japan

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

INTRODUCTION

This Service Manual contains basic data and figures on the Finisher-D1 needed to

service the machine in the field.

CHAPTER 1 General Description introduces the finisher's features and specifications,

and shows how to operate the finisher.

CHAPTER 2 Basic Operation provides outlines of the finisher's various mechanical

workings, and explains the principles used for the finisher's various control mechanisms in

view of the functions of electrical and mechanical units and in relation to their timing of

operation.

CHAPTER 3 Mechanical System shows how the finisher's various mechanical

workings are constructed, and how the finisher may be disassembled/assembled and

adjusted.

CHAPTER 4 Maintenance and Servicing provides tables of periodically replaced

parts and consumables/durables and scheduled servicing charts.

CHAPTER 5 Troubleshooting provides tables of maintenance/inspection, standards/

adjustments, and problem identification (image fault/malfunction).

APPENDIX contains a general timing chart and general circuit diagrams.

The descriptions in this Service Manual are subject to change without notice for

product improvement or other purposes, and major changes will be communicated in the

form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this

Service Manual and all relevant Service Information bulletins and be able to identify and

isolate faults in the machine.

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CONTENTS

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES ................................1-1

II. SPECIFICATIONS......................1-2

A. Specifications ........................1-2

B. Cross Section ........................1-4

III. OPERATING THE FINISHER .... 1-5

A. Removing Jams from The

Finisher..................................1-5

B. Removing Jams in Sort, Group, or

Staple Sort Mode ...................1-7

CHAPTER 2 OPERATIONS

I. BASIC OPERATIONS ................ 2-1

A. Specifications ........................ 2-1

B. Outline of Electrial Circuitry ...2-2

C. Inputs to and Outputs from the

Finisher Controller PCB .........2-3

II. FEEDING/DRIVE SYSTEM ...... 2-14

A. Outline .................................. 2-14

B. Feeding/Delivery ................. 2-19

C. Job Offset.............................2-22

D. Releasing the Knurled Belt

............................................ 2-29

C. Replacing the Staple Cartridge

.............................................1-10

D. Removing Staple Jams in the

Stapler Unit ..........................1-13

IV. MAINTENANCE BY THE USER

.................................................. 1-15

E. Buffer Path ...........................2-34

III. CONTROLLING THE PADDLE

.................................................. 2-39

IV. CONTROLLING THE TRAY

AUXILIARY PLATE .................. 2-40

V. STAPLING ................................ 2-42

VI. TRAY MOVEMENT .................. 2-50

VII. FANS ........................................ 2-54

VIII. POWER SUPPLY ..................... 2-56

IX. DETECTING JAMS .................. 2-59

CHAPTER 3 MECHANICAL SYSTEM

I. EXTERNALS AND CONTROLS

.................................................... 3-1

II. PROCESSING TRAY UNIT ..... 3-13

III. TRAY B UNIT ...........................3-21

IV. KNURLED BELT RELEASING UNIT

.................................................. 3-28

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

V. KNURLED BELT ...................... 3-30

VI. BUFFER ROLLER UNIT ..........3-31

VII. STAPLER UNIT ........................ 3-35

VIII. PCBs ......................................... 3-42

CHAPTER 4 MAINTENANCE AND SERVICING

I. PERIODICALLY REPLACED

PARTS ........................................ 4-1

II. CONSUMABLES AND DURABLES

.................................................... 4-1

CHAPTER 5 TROUBLESHOOTING

I. ADJUSTMENT ...........................5-1

A. Electrical System ...................5-1

II. ARRANGEMENT OF ELECTRICAL

PARTS ...................................... 5-14

A. Sensors ................................ 5-14

B. Microswitches ...................... 5-16

C. Motors .................................. 5-18

D. Solenoids ............................. 5-20

APPENDIX

III. SCHEDULED MAINTENANCE . 4-1

E. PCBs .................................... 5-22

F. Fans ..................................... 5-24

G. Light-Emitting Diodes and Check

Pins by PCB ........................5-25

III. TROUBLESHOOTING .............5-30

IV. SELF DIAGNOSIS ....................5-38

A. Self Diagnosis ...................... 5-38

B. Alarms .................................. 5-40

A. GENERAL TIMING CHART

.............................................. A-1

B. LIST OF SIGNALS /

ABBREVIATIONS ................ A-3

C. GENERAL CIRCUIT DIAGRAM

.............................................. A-5

D. SOLVENTS AND OILS LIST

.............................................. A-7

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1

GENERAL DESCRIPTION

I. FEATURES ................................ 1-1

II. SPECIFICATIONS ......................1-2

A. Specifications ........................ 1-2

B. Cross Section ........................1-4

III. OPERATING THE FINISHER ....1-5

A. Removing Jams from the

Finisher..................................1-5

B. Removing Jams in Sort, Group, or

Staple Sort Mode ...................1-7

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

C. Replacing The Staple Cartridge

.............................................1-10

D. Removing Staple Jams in the

Stapler Unit ..........................1-13

IV. MAINTENANCE BY THE USER

.................................................. 1-15

CHAPTER 1 GENERAL DESCRIPTION

I . FEATURES

1. Two Types of Stacking Trays

• The delivery tray (tray B) is designed for stapling and job offset delivery, while the interrupt

tray (tray A) is designed for ordinary delivery.

2. Large Capacity

• Tray B is capable of holding 2000 sheets, while tray A is capable of holding 250 sheets, a total

of 2250 sheets.

3. Wide-Ranging Paper Types

2

• The sheets may be of 64 to 200 g/m

paper.

4. Stack Job Offset Function

• The stack job offset function is offered for sorting non-staple stacks.

5. Three Types of Auto Stapling

• As many as three different types (position) are offered (front slant, rear slant, 2-point).

6. High Productivity by a Buffer Roller

• The use of a buffer roller has enabled continuous feeding of sheets from the copier while

stapling or offset operation is taking place.

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-1

CHAPTER 1 GENERAL DESCRIPTION

II . SPECIFICATIONS

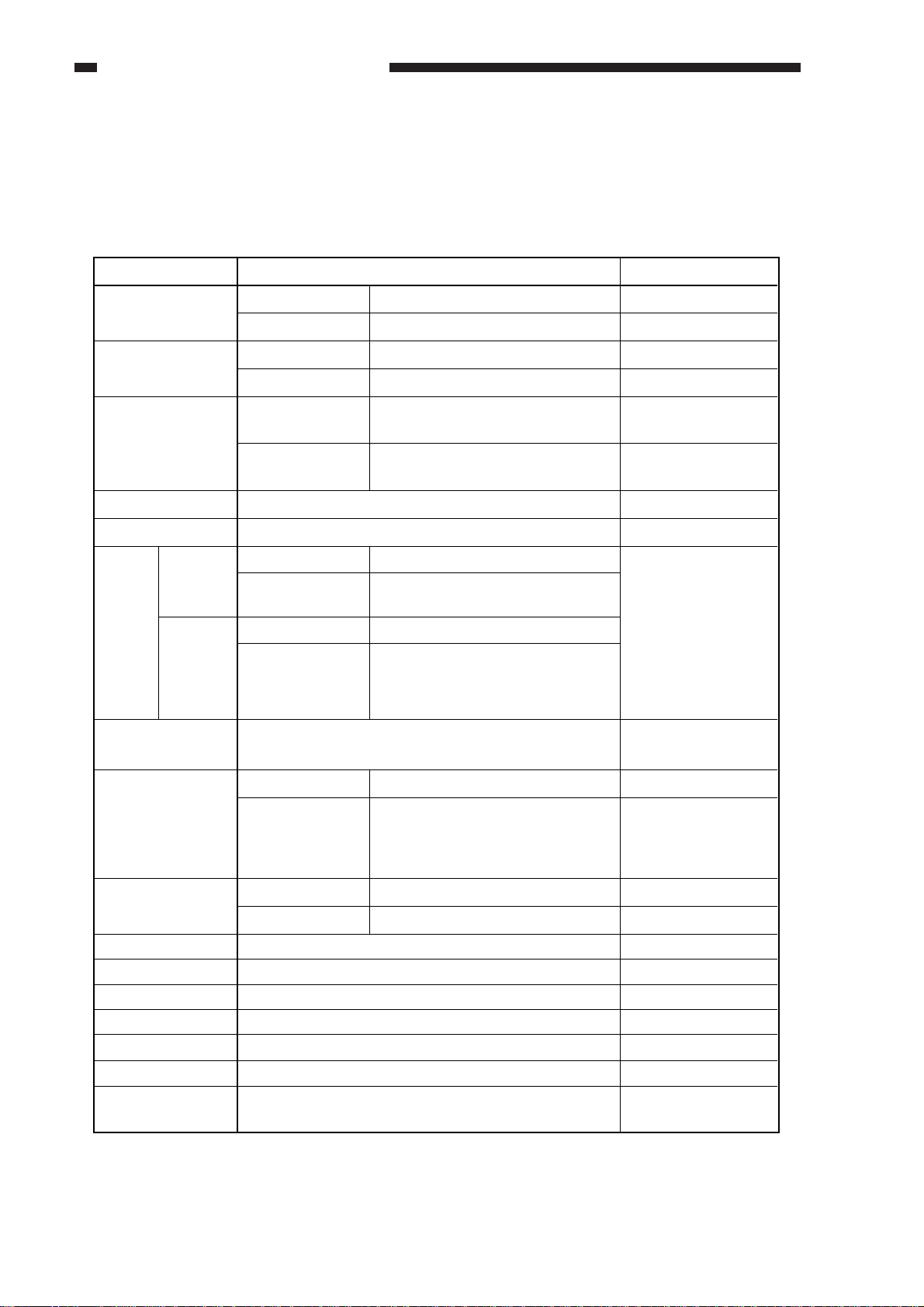

A. Specifications

1. Type

Item

Fixed type

Stacking

Stack size

Paper weight

Modes

Stack

thickness

Staple/non-staple

mix

Non-staple

sort

Staple sort

Specifications

Tray A

Tray B

Tray A

Tray B

Tray A

Tray B

64 to 200g/m

Staple stacking, non-staple stacking

Tray A

Tray B

Tray A

Tray B

Possible with conditions

Fixed

Mobile type

Same as the copier's delivery method.

Face-down

Postcard to A3/LDR

A5/STMT to A3 /LDR

2

250 sheets (small-/large-size)

2,000 sheets (small-size)

1,000 sheets (large-size)

Not possible

2,000-sheet equivalent or 100 sets

(small-size)

1,000-sheet equivalent or 100 sets

(large-size)

Remarks

Postcards are for R

feeding only.

A5/STMT is for R

feeding only.

Paper of 80 g/m

2

.

Stacking

Paper detection

Control panel

Display

Installation

Dimensions

Weight

Power supply

Maximum power

consumption

Note 1: The term "small-size" refers to A4, A5, B5, postcard, LTR, and STMT, while the term

"large-size" refers to A3, B4, LDR, and LGL.

Tray A

Tray B

Non-sort tray

Sort tray

No

No

Latching with mount (height adjusted by caster)

665mm (W) ×708mm (D) ×995mm (H)

65kg

100 to 120V/50; 60Hz, 230V/50Hz

350W or less

No offset

Front/rear stack offset

Staple: 20 mm offset

Non-staple: 30 mm offset

(offset on the internal processing tray)

No

Yes

Table 1-201

1-2

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

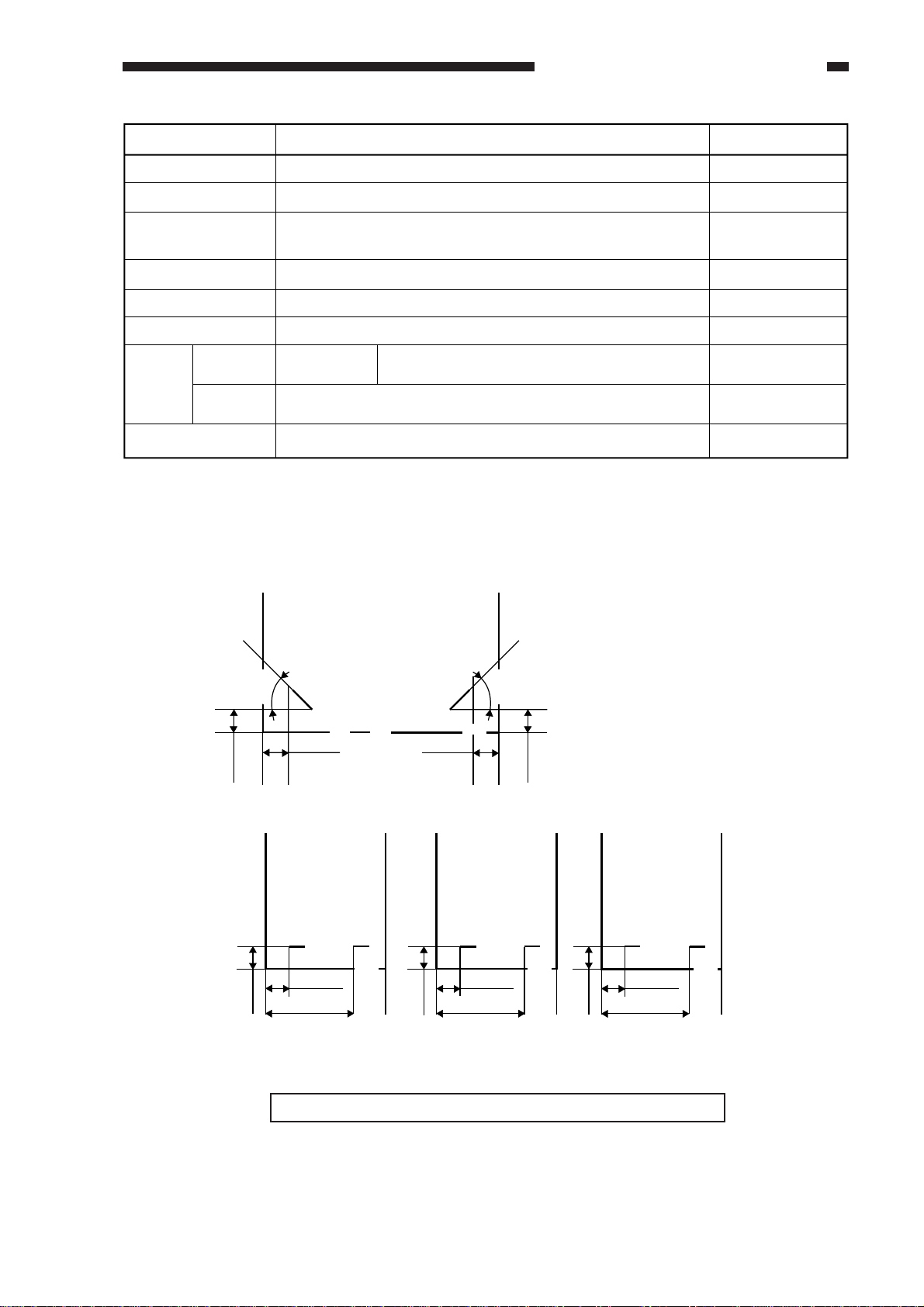

Item

Stapling

Stapling position

Stapling thickness

Staple compartment

Staples

Staple detection

Stapling

size

1-point

stapling

2-point

stapling

Manual stapling

1-point stapling

(front)

Specifications

Punching by a rotating cam. (face-down stapling)

See Figure 1-201.

48 sheets (80 g/m2) + 2 sheets (200 g/m2), or thick paper

of 5.7 mm or less

Special cartridge (5,000 staples)

Special staples

Yes

Front/rear

A3, A4, B4, B5, LDR, LGL, LTR

A3,A4, B4, B5, LDR, LTR

None

Table 1-202

1-point stapling

(rear)

Remarks

45˚

*2

5±2

5±2

2-point stapling

A3, A4 B4, B5

88.5±4 68.5±4 79.5±4

6±2

208.5±4

Unit: mm

*1 The stapling interval may be adjusted in user mode.

*2 The stapling position may be adjusted using a DIP switch.

The specifications are subject to change for product improvement.

*2 *2 *2

*1 *1 *1

5±2

6±2

188.5±4 199.5±4

45˚

*2

5±2

6±2

297mmx423mm

(LDR),

LTR

Figure 1-201

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-3

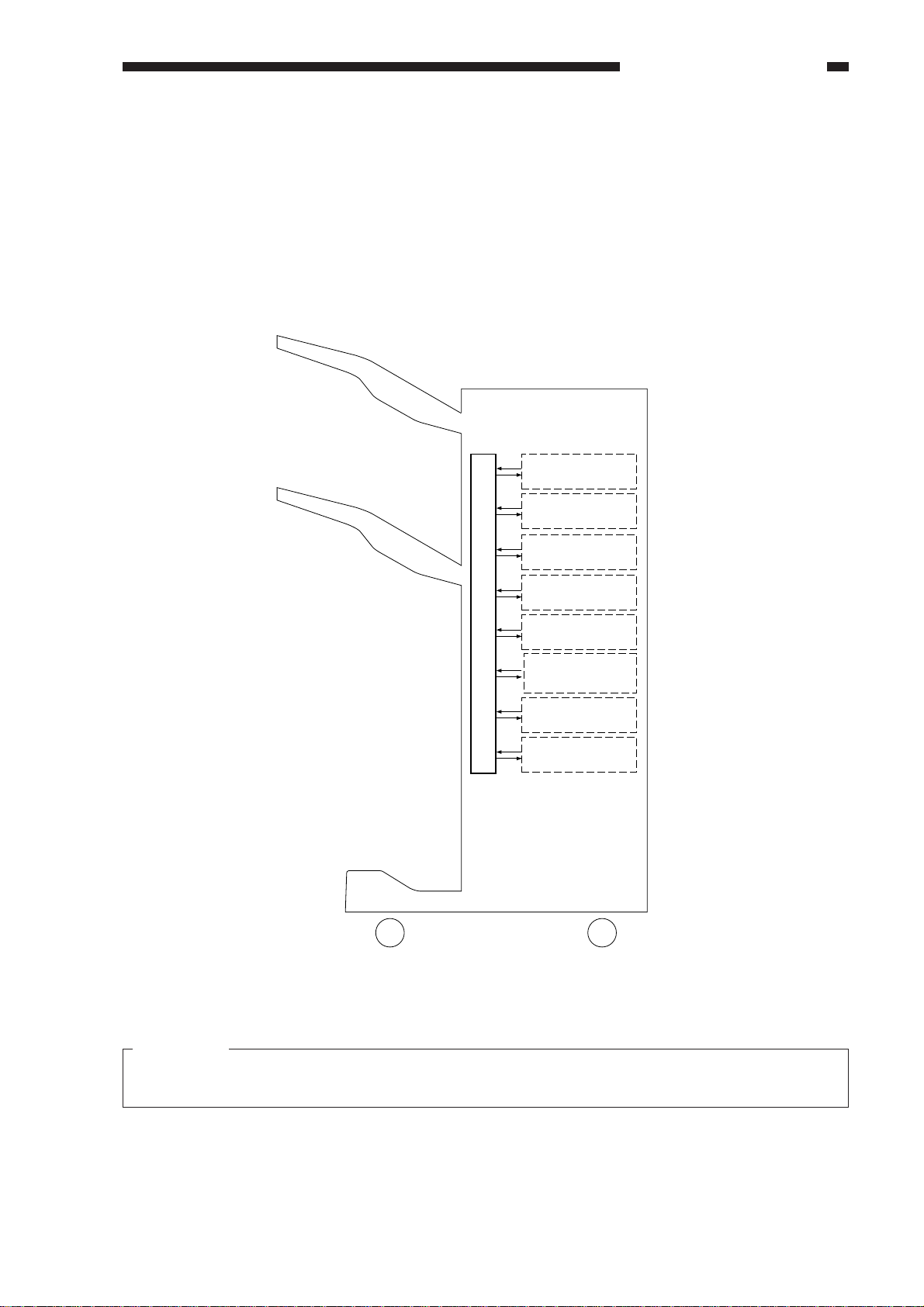

CHAPTER 1 GENERAL DESCRIPTION

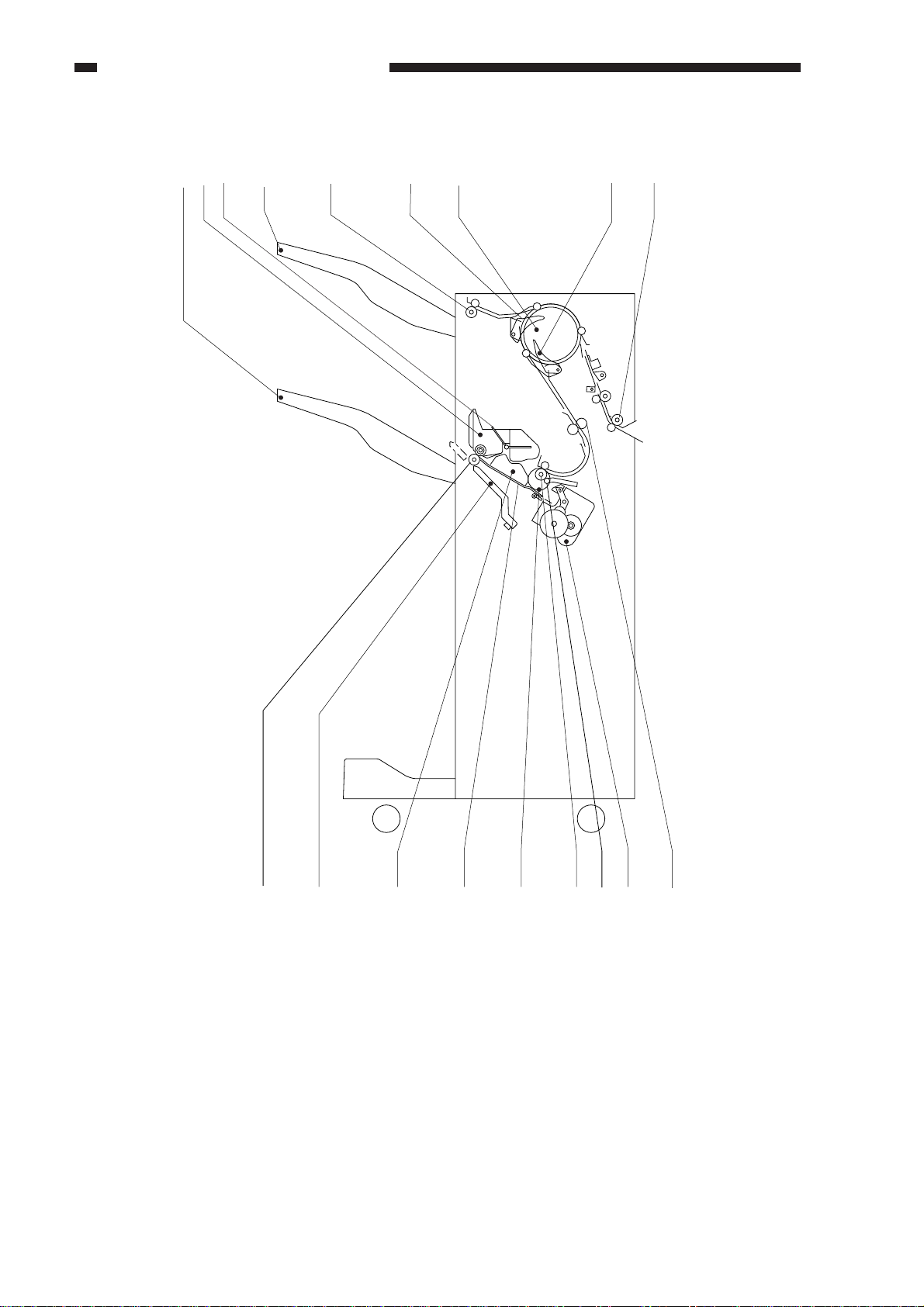

B. Cross Section

[1][2] [4][3] [5] [6] [7] [8] [9]

[1] Tray B

[2] Swing guide

[3] Paddle

[4] Tray A

[5] Non-sort delivery roller

[6] Upper path switching flapper

[7] Buffer roller

[8] Buffer switching flapper

[9] Inlet roller

1-4

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

[10][11][12][13][14][15][16][17][18]

[10] Pre-delivery roller

[11] Stapler

[12] Mobile roll

[13] Sort delivery roller

[14] Knurled belt

[15] Processing tray

[16] Jogging plate (front, rear)

[17] Tray auxiliary plate

[18] Stack delivery roller

Figure 1-202

III . OPERATING THE

FINISHER

A. Removing Jams from the

Finisher

If the Jam indicator turns on, perform the

following:

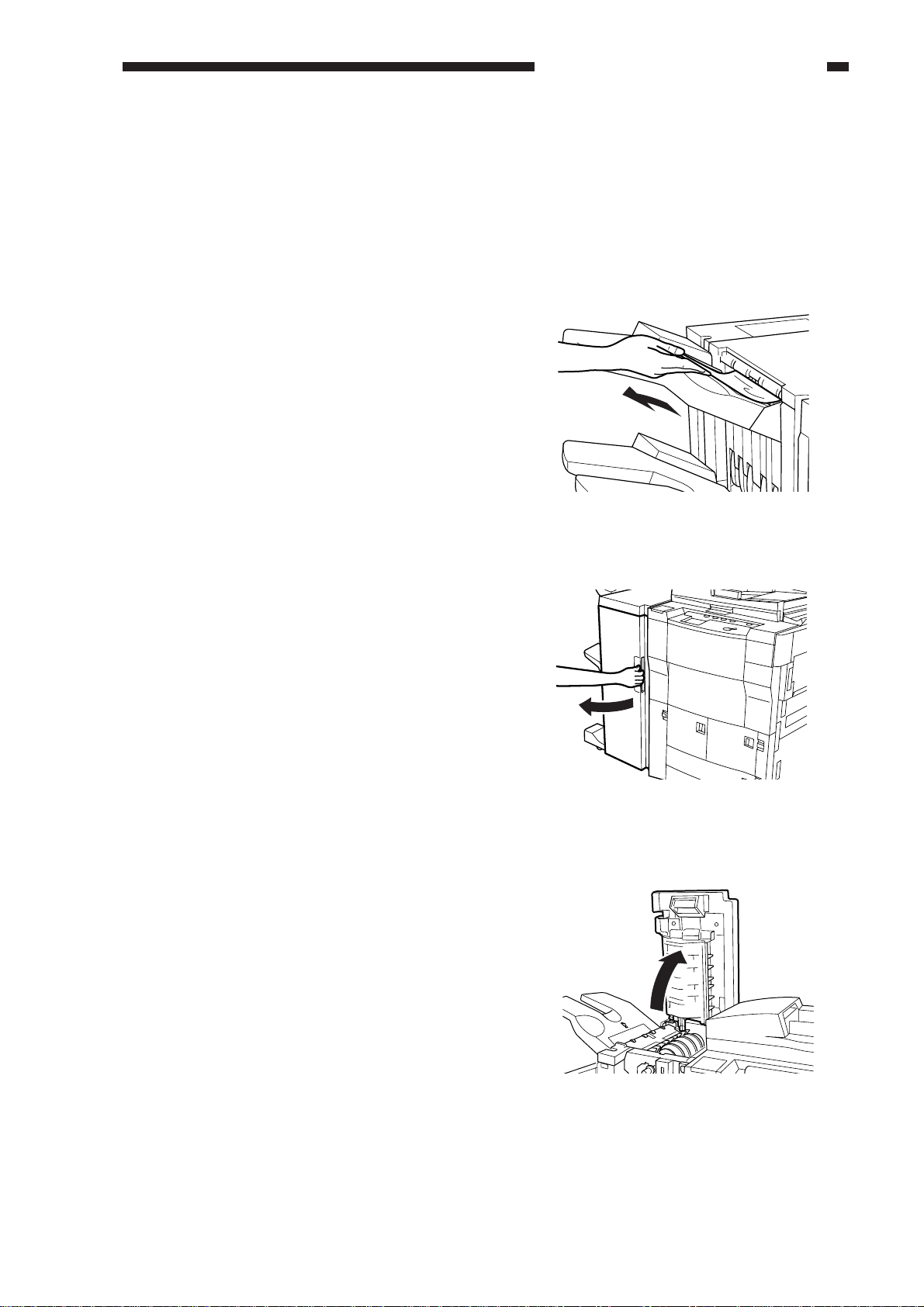

1) Remove the paper visible from the outside.

CHAPTER 1 GENERAL DESCRIPTION

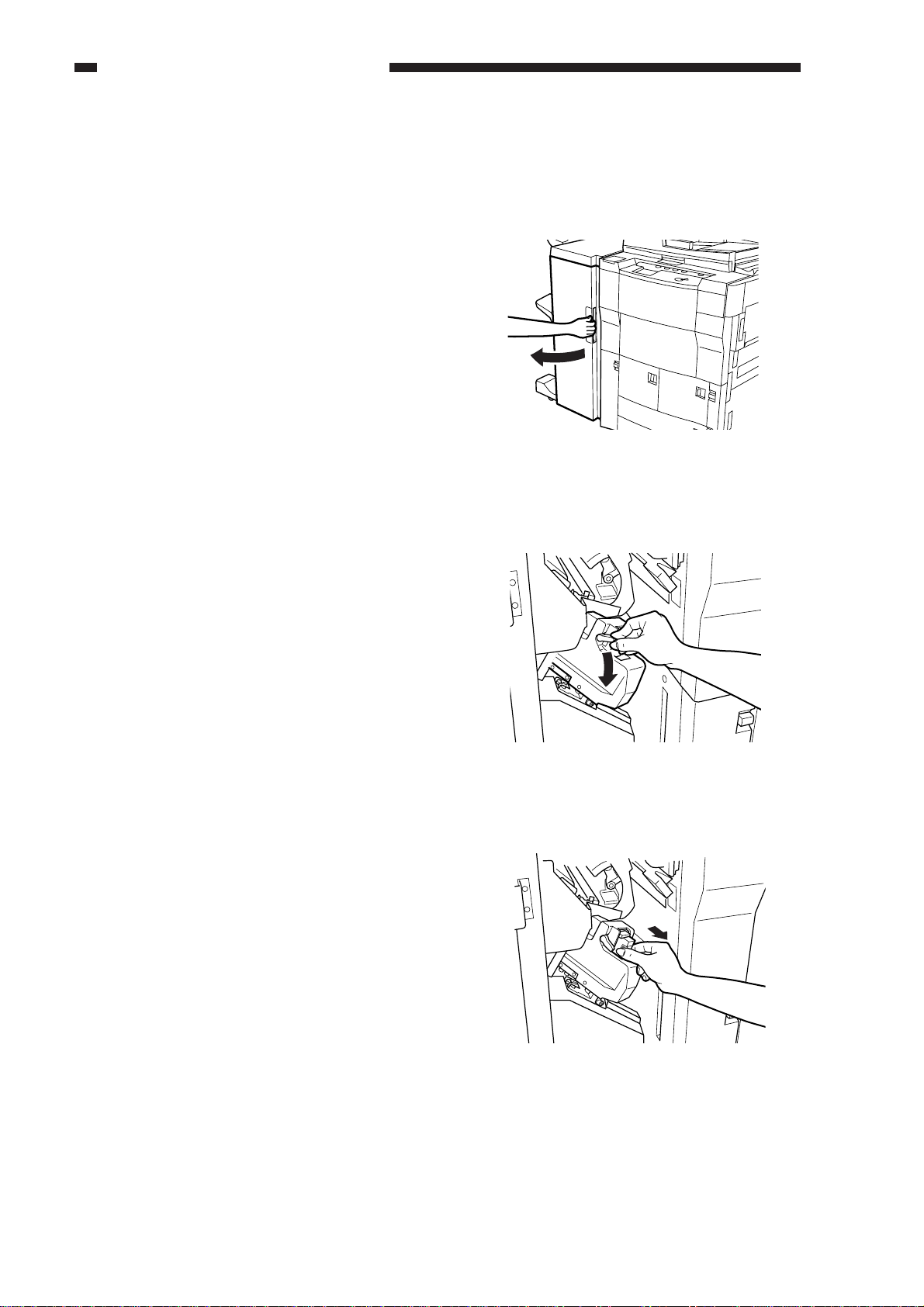

2) Open the front cover.

3) Open the upper cover, and check the inside of the finisher.

Figure 1-301

Figure 1-302

Figure 1-303

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-5

CHAPTER 1 GENERAL DESCRIPTION

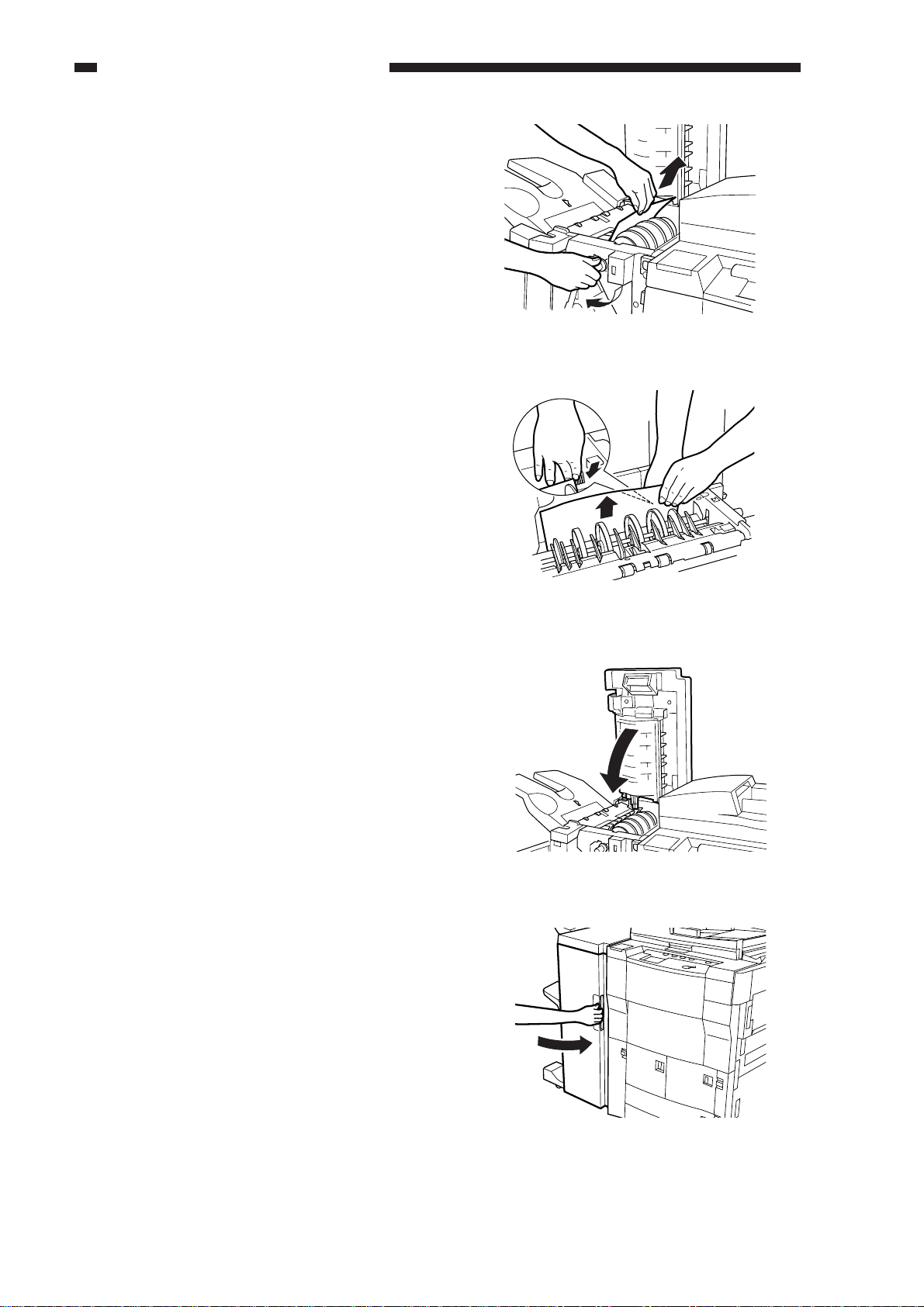

4) Turn the green knob, and remove the jam.

5) Push the green lever, and remove the jam.

Figure 1-304

6) Close the upper cover.

7) Close the front cover.

Figure 1-305

Figure 1-306

1-6

Figure 1-307

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

B. Removing Jams in Sort,

Group, or Staple Sort

Mode

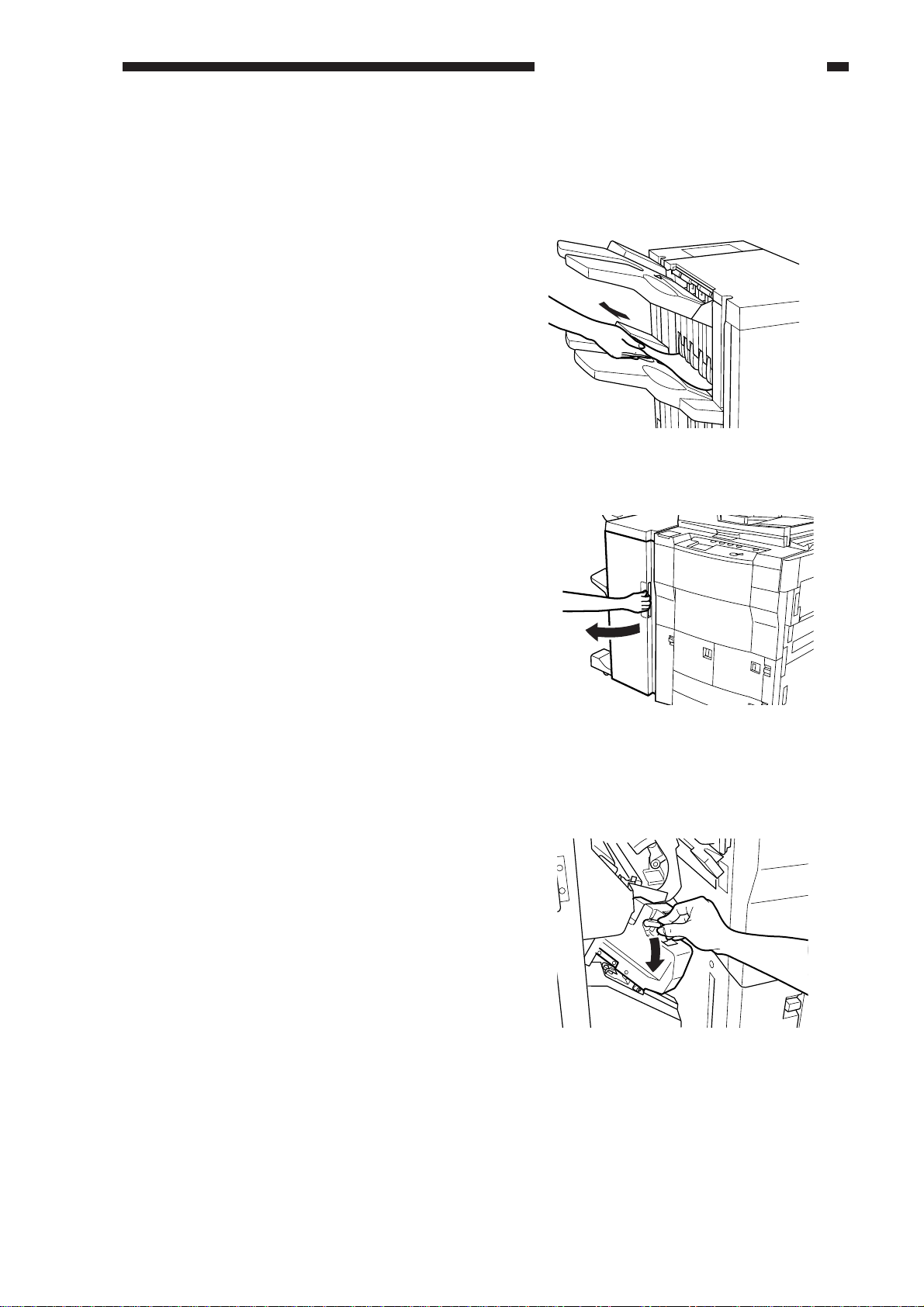

If a jam occurs in sort, group, or staple

sort mode, perform the following:

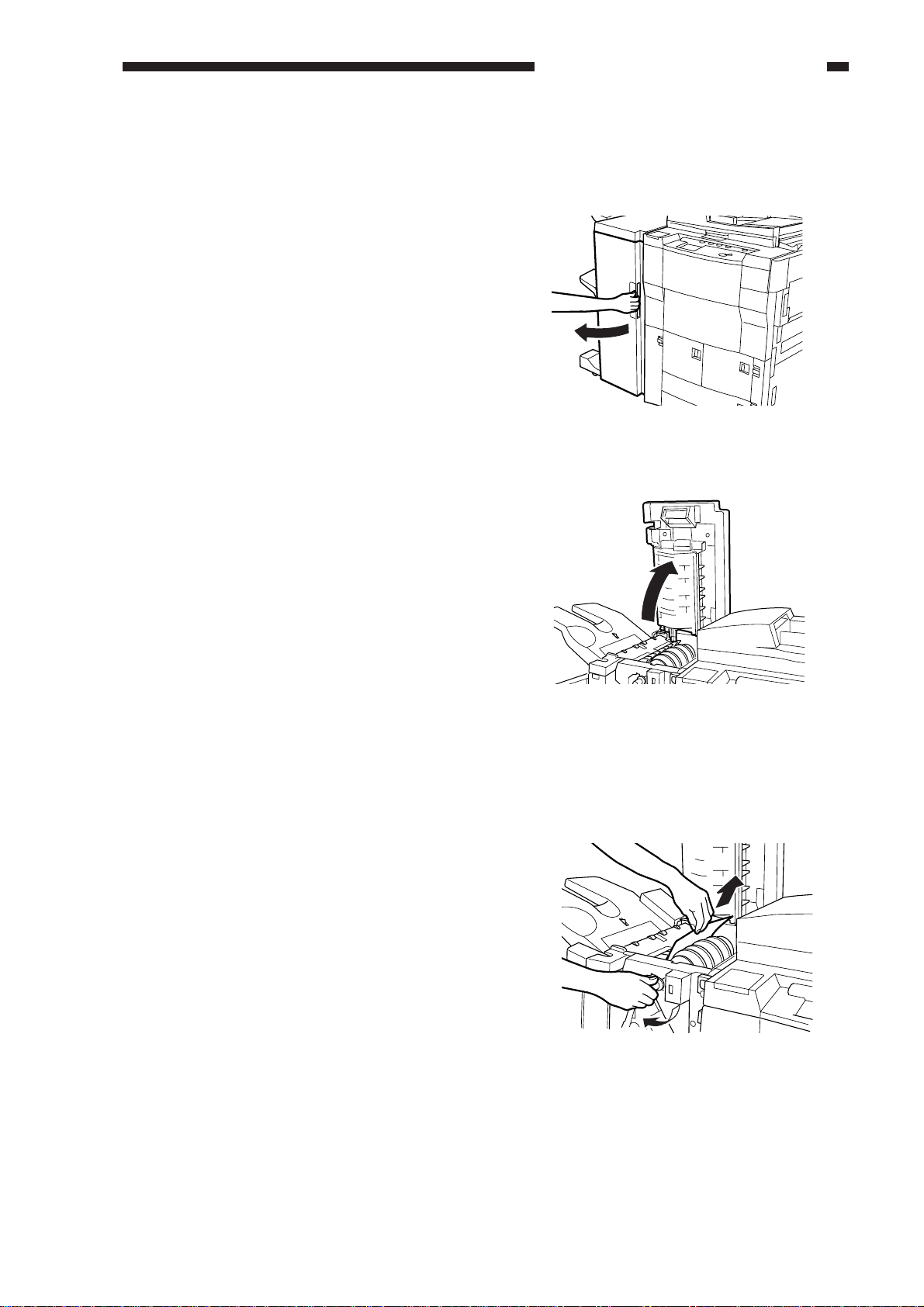

1) Open the front cover.

2) Open the upper cover, and check the inside of the finisher.

CHAPTER 1 GENERAL DESCRIPTION

Figure 1-308

3) Turn the green knob, and remove the jam.

Figure 1-309

Figure 1-310

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-7

CHAPTER 1 GENERAL DESCRIPTION

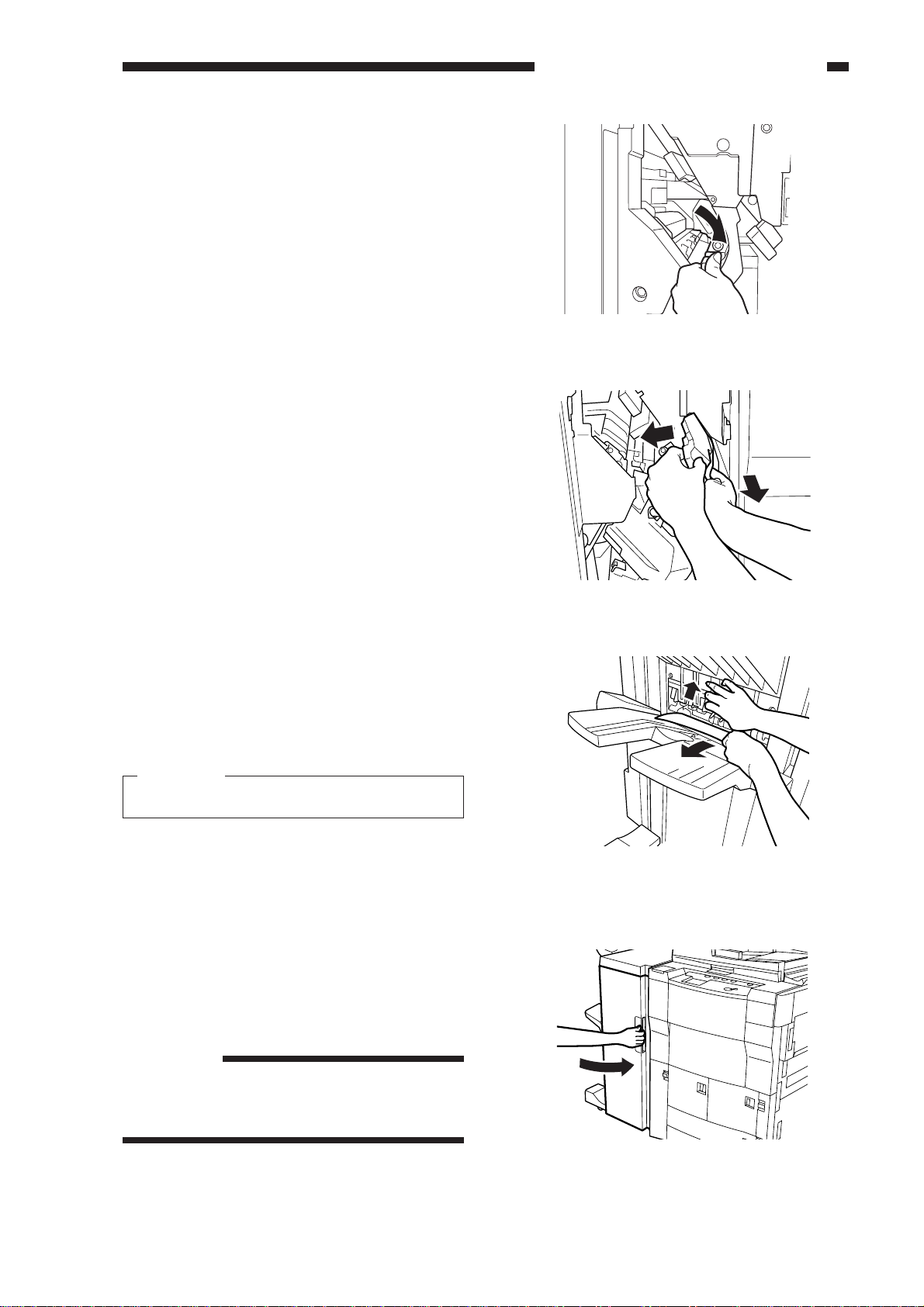

4) Push the green lever, and remove the jam.

5) Close the upper cover.

Figure 1-311

6) Open the guide, and remove the jam.

7) Shift up the lever, and remove the jam.

Figure 1-312

Figure 1-313

1-8

Figure 1-314

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

8) Shift the lever back to its initial position.

9) Open the guide, and remove the jam.

CHAPTER 1 GENERAL DESCRIPTION

Figure 1-315

10) Open the open/close guide, and remove

the jam from inside the finisher.

Caution:

Do not remove the stack being handled.

11) Close the front cover.

Reference:

The Jam message may remain on the

display. If so, check for a jam once

again according to the instructions.

Figure 1-316

Figure 1-317

Figure 1-318

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-9

CHAPTER 1 GENERAL DESCRIPTION

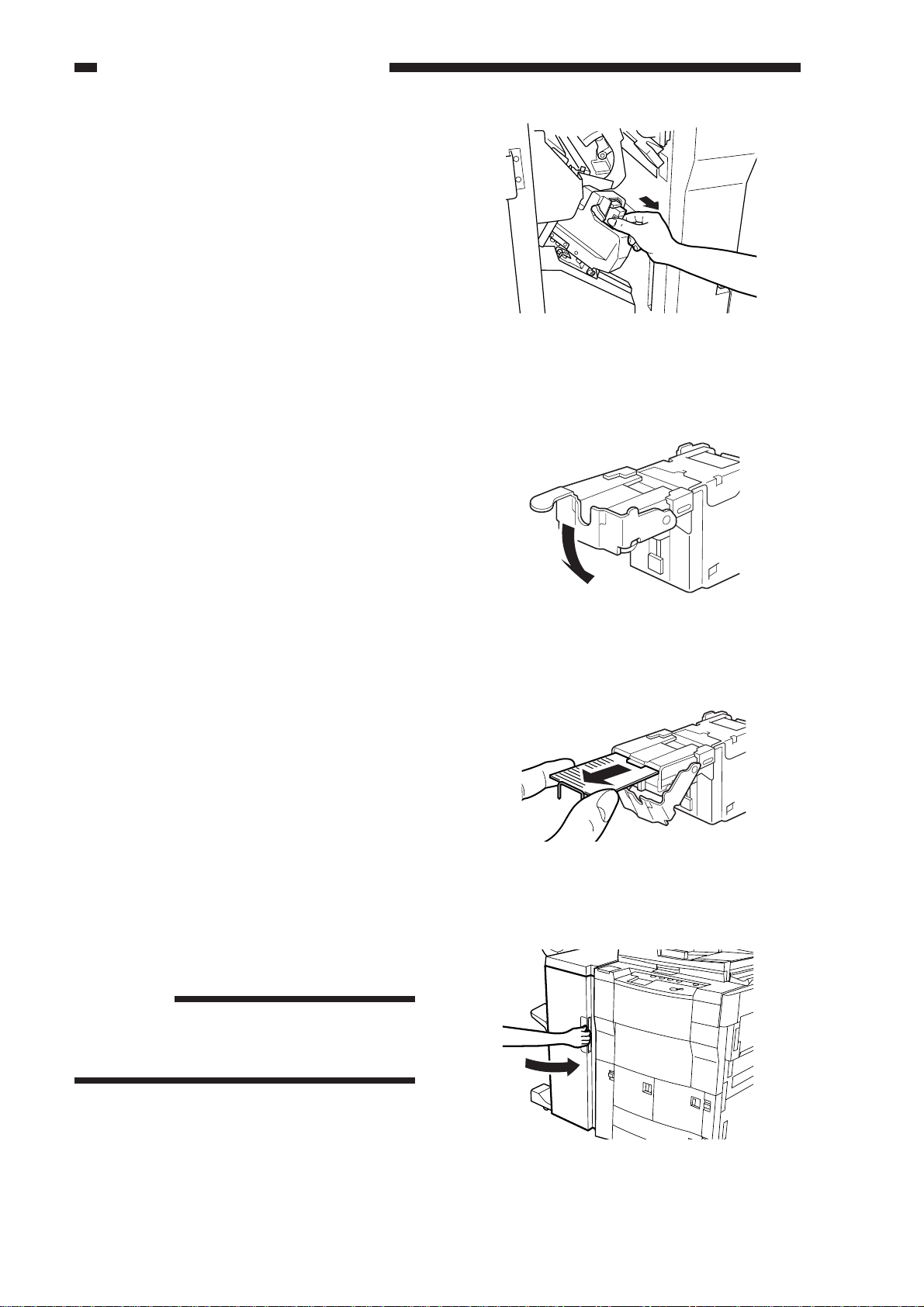

C. Replacing the Staple

Cartridge

If a staple jam occurs while the stapler is

being used, perform the following:

1) Open the front cover.

2) Shift down the green lever.

3) When the staple cartridge has slid out on

its own, pick it on its left and right and

slide it out.

Figure 1-319

Figure 1-320

1-10

Figure 1-321

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

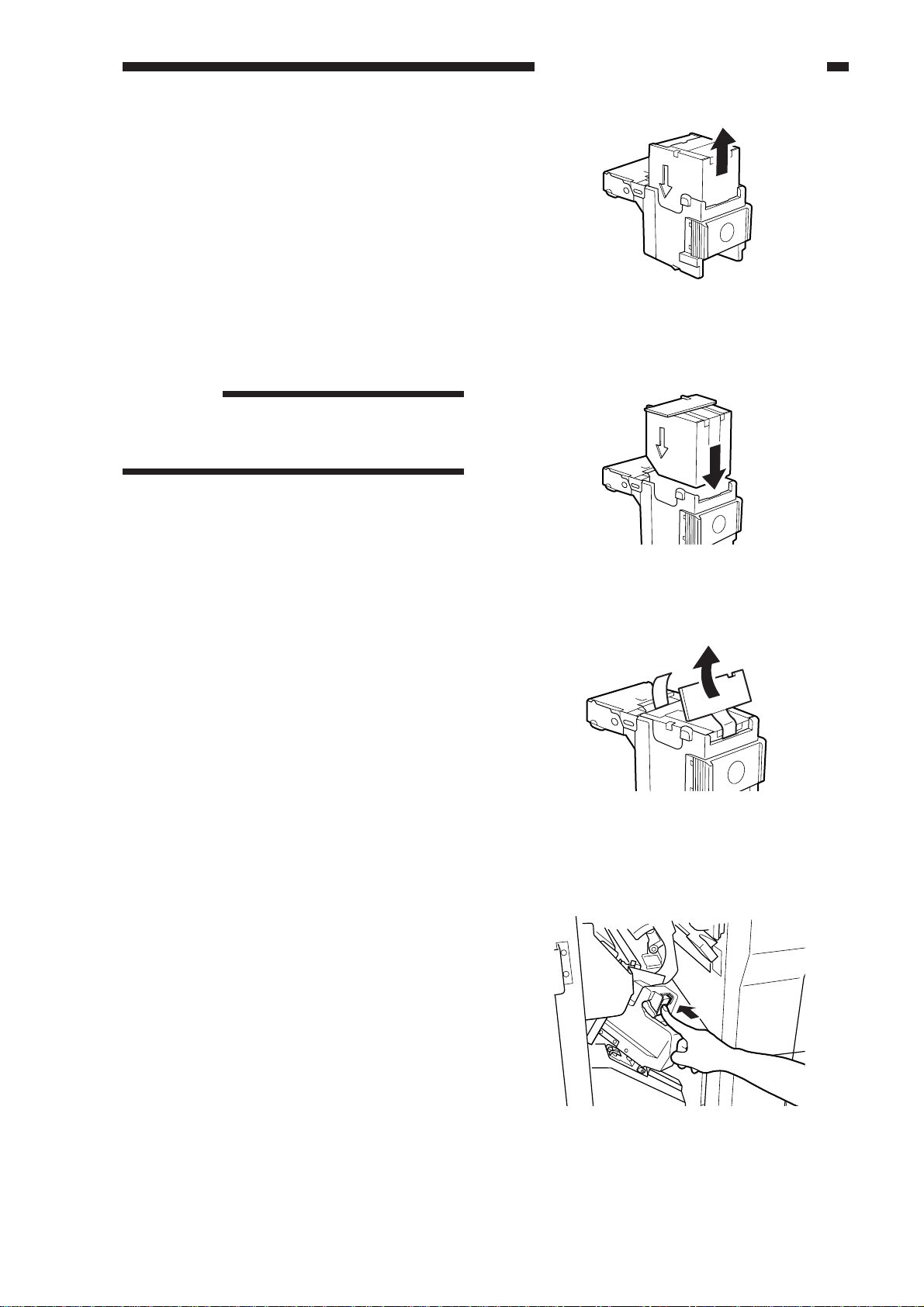

4) Pick the empty staple case on its left and

right, and slip it off.

5) Set the new staple case.

Reference:

Be sure to set no more than one staple

case. Further, be sure that the staple

case is one designed for the finisher.

CHAPTER 1 GENERAL DESCRIPTION

Figure 1-322

6) Remove the seal used to keep the staples

together by pulling it straight off.

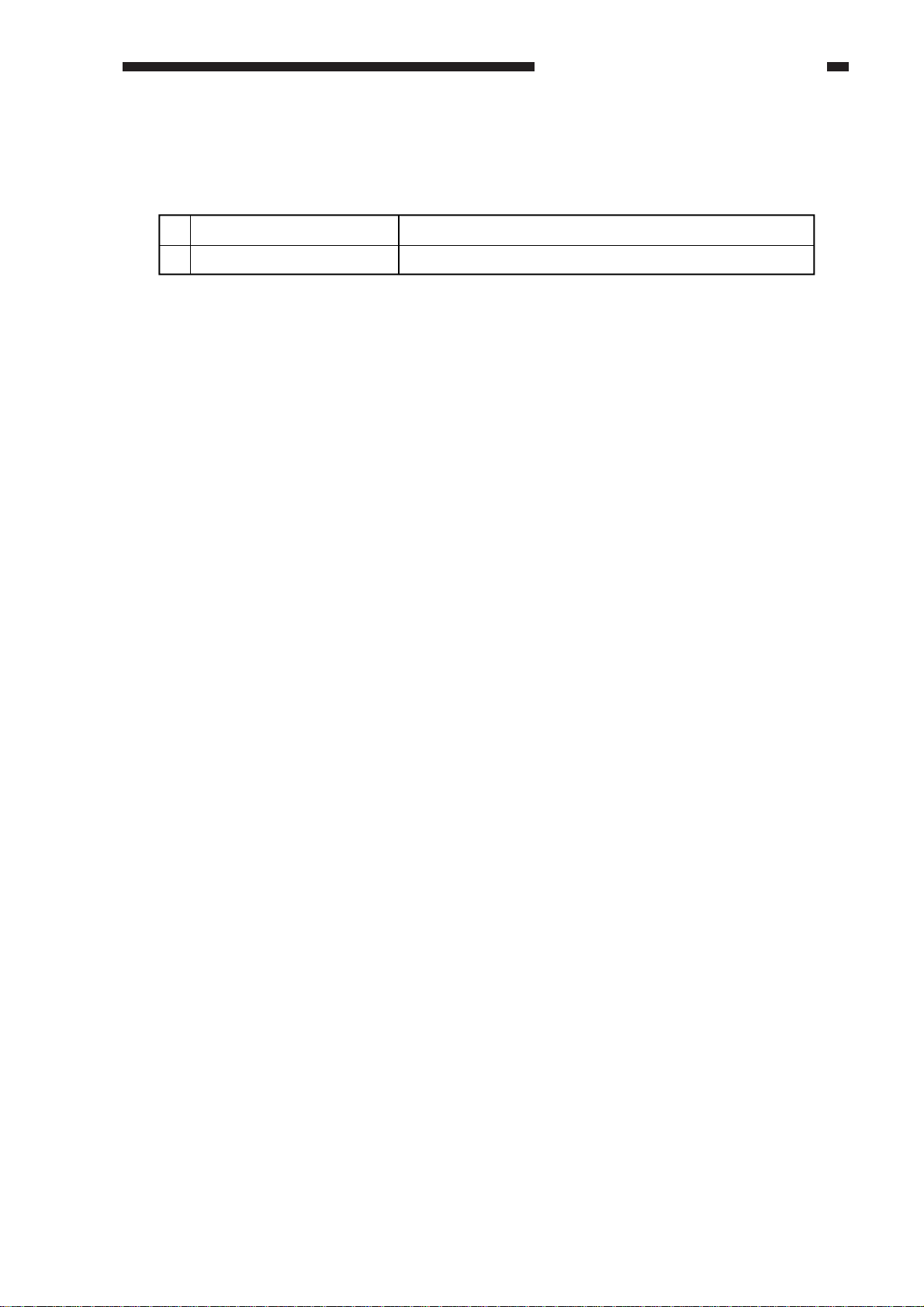

7) Push in the stapler unit until the green lever returns to its previous position.

Figure 1-323

Figure 1-324

Figure 1-325

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-11

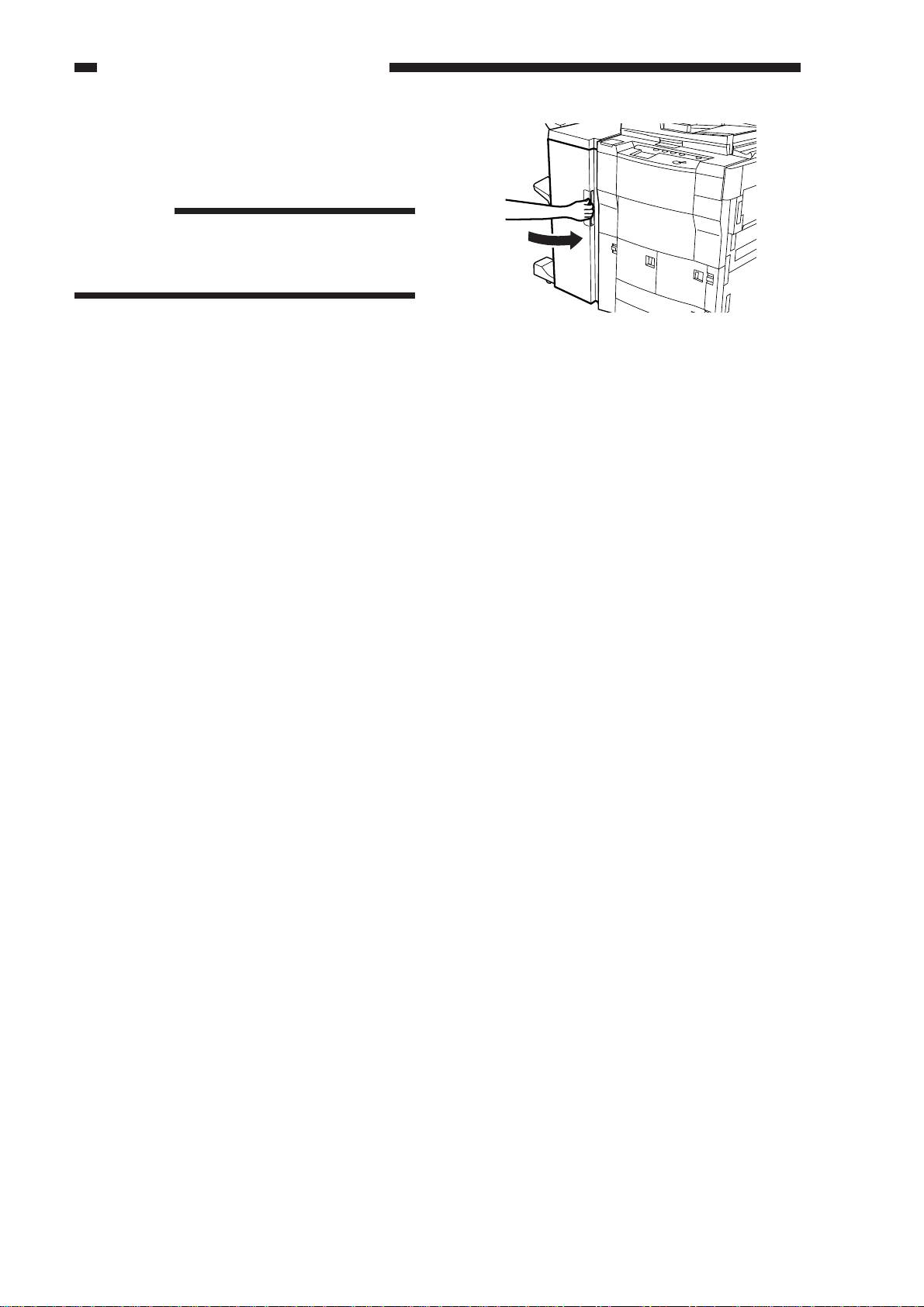

CHAPTER 1 GENERAL DESCRIPTION

8) Check to make sure that the stapler unit

has been secured in place, and close the

front cover.

Reference:

When the cover is closed, the stapler

unit performs idle stapling several times

automatically to edge out the staples.

Figure 1-326

1-12

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

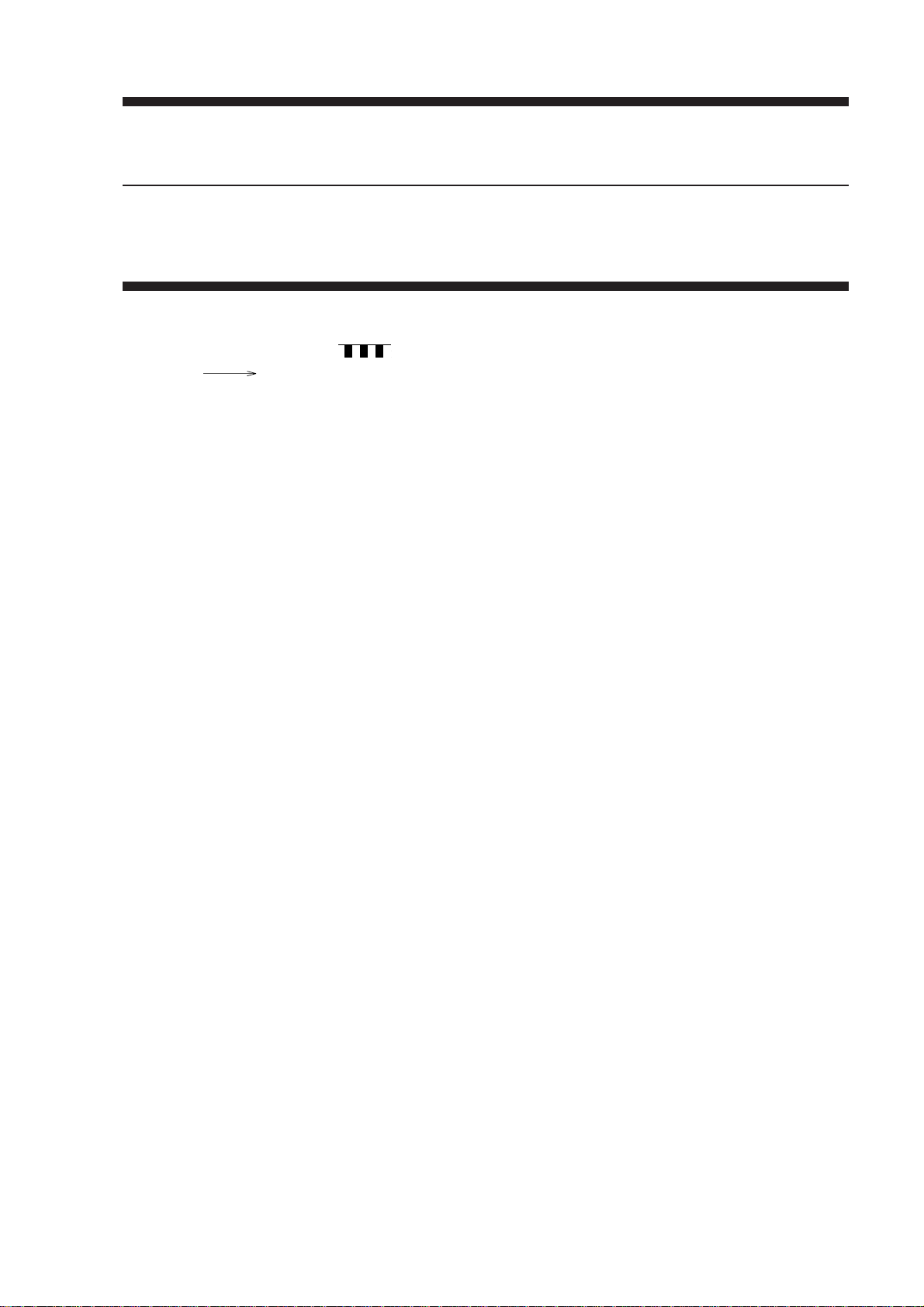

D. Removing Staple Jams in

the Stapler Unit

If the Staple Jam message is indicated,

perform the following:

1) Remove the stack of sheets waiting to be

stapled.

2) Open the front cover.

CHAPTER 1 GENERAL DESCRIPTION

Figure 1-327

3) Shift down the green lever.

Figure 1-328

Figure 1-329

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-13

CHAPTER 1 GENERAL DESCRIPTION

4) When the staple cartridge has slid out on

its own, pick it on its left and right and

slide it out.

5) Shift down the tab of the staple cartridge.

Figure 1-330

6) Remove all staples which slid out of the

staple case.

7) Put the staple cartridge tab back to its pervious position.

8) Put the staple cartridge back to its initial

position, and close the front cover.

Reference:

When the cover is closed, the stapler

unit performs idle stapling several times

automatically to edge out the staples.

Figure 1-331

Figure 1-332

1-14

Figure 1-333

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

IV . MAINTENANCE BY THE USER

As of January 1999

No.

Staple cartridge replacement

1

Item

Timing

When the message turns on (on the copier's control panel).

Table 1-401

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-15

CHAPTER 2

OPERATIONS

1. In outline diagrams,

and

2. Signals in digital circuits are identified as '1' for High and '0' for Low. The

voltage of signals, however, depends on the circuit.

Nearly all operations of the machine are contorolled by microprocessors; the

internal workings of these processors are not relevant to the service person's work

and, therefore, are left out of the discussions. By the same token, no repairs are

prescribed for the PCBs at the user's premises; for this reason, PCBs are

discussed by means of block diagrams rather than circuit diagarams.

For the purpose of explanation, discussions are divided into the following: from

sensors to finisher controller PCB input ports; from finisher controller output ports to

loads; and minor control circuits and functions.

indicates electrical signal paths.

represents mechanical drive paths,

I. BASIC OPERATIONS ................ 2-1

A. Specifications ........................ 2-1

B. Outline of Electrial Circuitry ...2-2

C. Inputs to and Outputs from the

Finisher Controller PCB .........2-3

II. FEEDING/DRIVE SYSTEM ...... 2-14

A. Outline .................................. 2-14

B. Feeding/Delivery ................. 2-19

C. Job Offset .............................2-22

D. Releasing the Knurled Belt

............................................ 2-29

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

E. Buffer Path ...........................2-34

III. CONTROLLING THE PADDLE

.................................................. 2-39

IV. CONTROLLING THE TRAY

AUXILIARY PLATE .................. 2-40

V. STAPLING ................................ 2-42

VI. TRAY MOVEMENT .................. 2-50

VII. FANS ........................................ 2-54

VIII. POWER SUPPLY ..................... 2-56

IX. DETECTING JAMS .................. 2-59

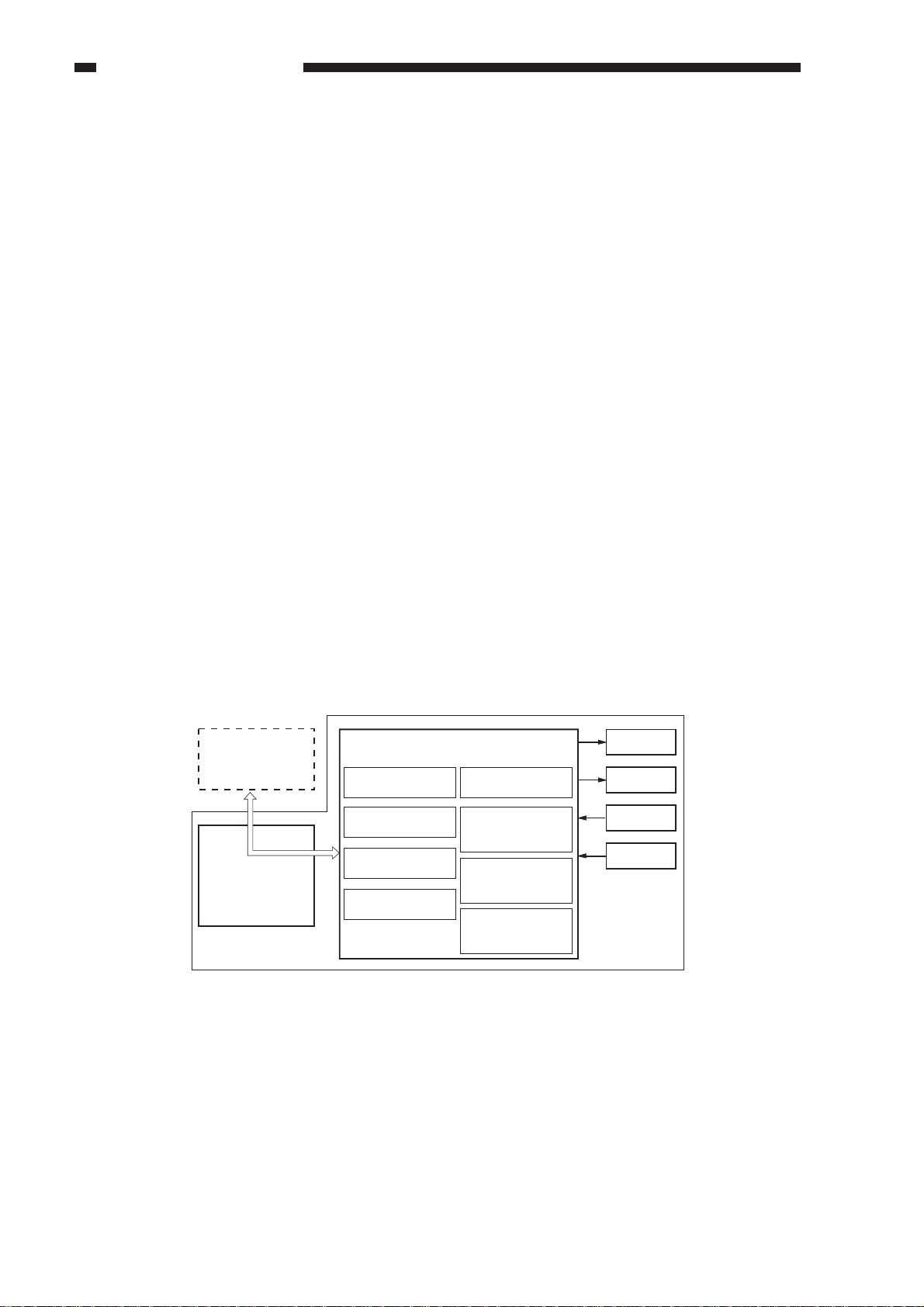

CHAPTER 2 OPERATIONS

I . BASIC OPERATIONS

A. Specifications

The finisher is designed to receive sheets from its host copier and deliver them after performing

specific jobs on them: i.e., non-sort stacking, job offset (Note), and stapling.

The series of operations are controlled by the finisher controller PCB, and some of them are

driven in response to various commands from the copier.

Swing guide

control system

Alignment

control system

Stapler control

system

Delivery control

system

Feeding control

system

Control system

Tray control

system

Inlet control

system

Buffer control

system

Figure 2-101

Caution:

The term "job offset" refers to shifting each arriving stack toward the front or rear slightly

away from the previous stack, thereby sorting the sets.

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-1

CHAPTER 2 OPERATIONS

B. Outline of Electrical Circuitry

The series of operations of the finisher are controlled by the finisher controller PCB, which is an

8-bit microprocessor (CPU). The finisher controller PCB serves to control sequences of operations

and to communicate in serial with the host copier.

The finisher controller PCB drives the solenoids and motors in response to various commands

from the host copier through a serial communication line. It also communicates data on various

sensors and switches to the host copier using the serial communication line.

The functions of the major ICs mounted on the finisher controller PCB are as follows:

• IC101 (master CPU)

Controls sequences of operations.

• IC102 (master EEPROM)

Backs up adjustment values.

• IC105 (master EPROM)

Contains sequence programs.

• IC106 (master RAM)

Backs up initial data.

• IC108 (communications IC)

Communicates with the host copier.

• IC121 (slave CPU)

Controls sequences of operations.

• IC122 (slave RAM)

Backs up initial data.

• IC123 (DRAM)

Controls communication between master

CPU and slave CPU.

Figure 2-102 shows the flow of signals between the finisher and the option controller.

Finisher

Copier DC

controller PCB

CPU

Fuse PCB

Finisher controller PCB

IC101

Master CPU

IC102

Master EEPROM

IC105

Master EPROM

IC106

Master RAM

IC108

Communications IC

IC121

Slave

CPU

IC122

Slave

RAM

IC123

DPRAM

Motor

Solenoid

Switch

Sensor

2-2

Figure 2-102

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

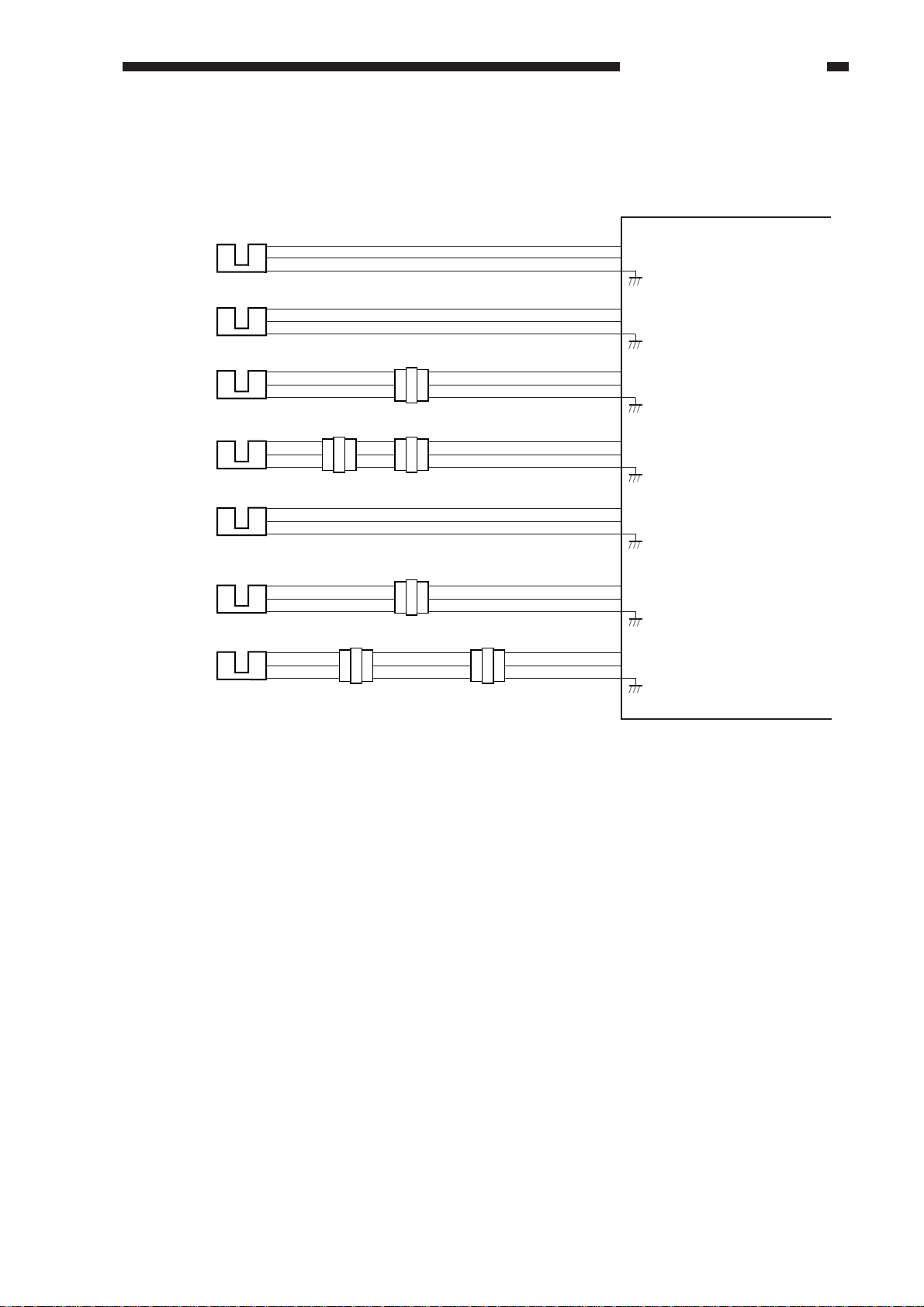

CHAPTER 2 OPERATIONS

C. Inputs to and Outputs from the Finisher Controller PCB

1. Inputs to the Finisher Controller PCB

Finisher controller PCB

Front cov er

open sensor

Inlet path

sensor

Buffer path

rear sensor

Sort delivery

sensor

Upper cover

open sensor

Non-sort

delivery

sensor

Front jogging

plate home

position sensor

PI1

PI2

PI3

PI4

PI5

PI6

PI7

J9-3

-1

-2

J11-3

J15-3

J70-3

J21-3

J23-3

J29-3

J121B-4

+5V

-6

FDROPN

-5

J121B-1

J120A-9

J120B-1

J119-6

J119-3

J104B-1

+5V

-3

ENTPASSPA

-2

+5V

-7

BFPSSXIT

-8

+5V

-3

STDLV

-2

+5V

-8

UPCVROPN

-7

+5V

-5

NSTDLV

-4

+5V

-3

FJOGHP

-2

-1

-2

J20

-3

-1

-2

J26B

-10

-8

-9

-7

-5

-6

-1

-3

-2

-1

-3

-2

-1

-2

-1

-1

-3

-2

-2

-1

-2

-1

-2

-1

-1

-3

-2

-2

J13

J19

J22

-1

-3

-2

-5

-3

-4

-3

-1

-2

-1

-3

-2

-10

-8

-9

J25B

When the front cover is

open, '1'.

When paper is present

at the inlet path sensor,

'1'.

When paper is present

at the buffer path outlet,

'1'.

When paper is present

at the sort delivery

assembly, '1'.

When the upper cover

is open, '1'.

When paper is present

in the non-sort delivery

assembly, '1'.

When the front jogging

plate is at the home

position, '1'.

Figure 2-103

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-3

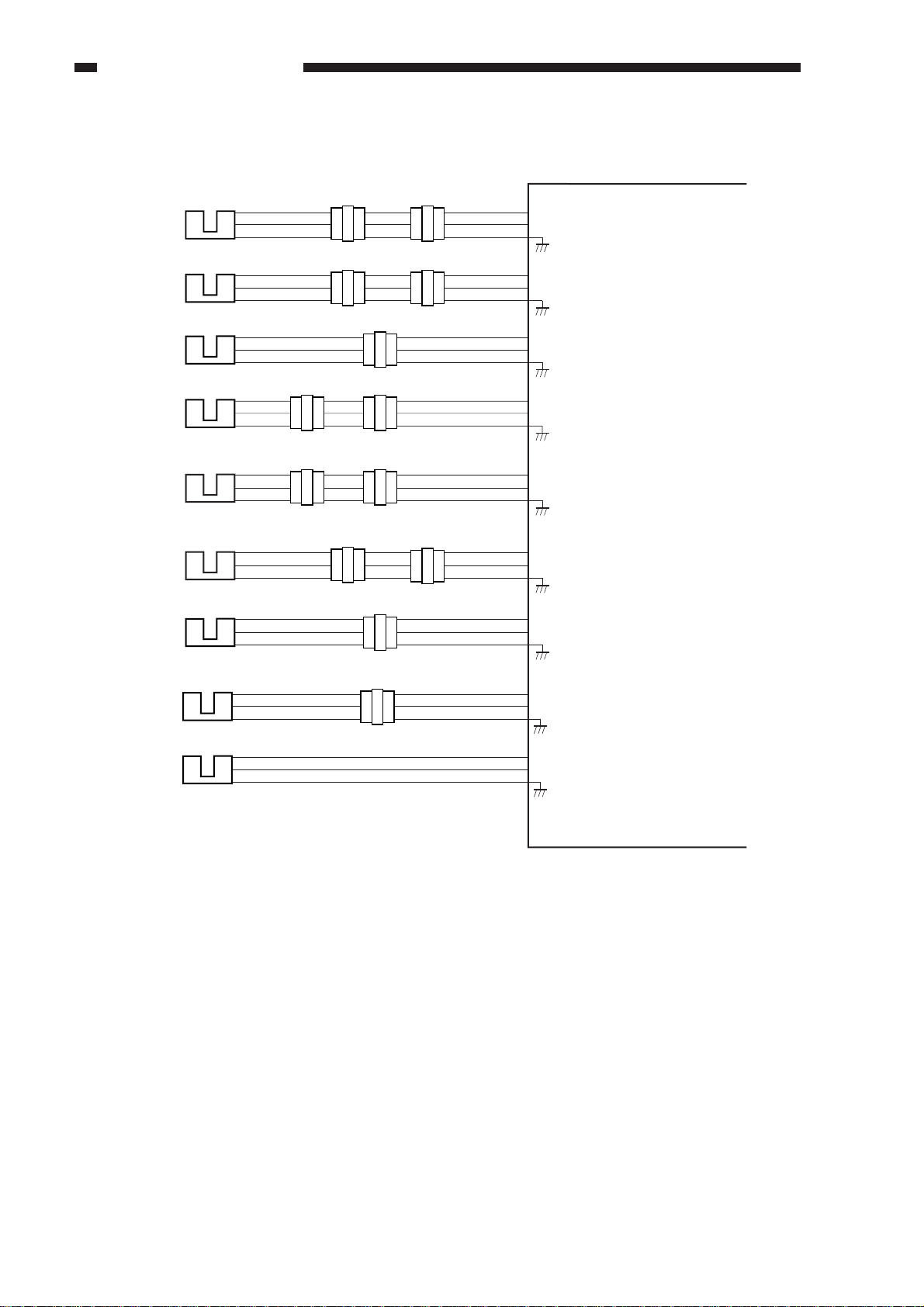

CHAPTER 2 OPERATIONS

2. Inputs to the Finisher Controller PCB

Finisher controller PCB

Stack delivery

sensor

Rear jogging

plate home

position

sensor

Swing motor

clock sensor

T r ay auxiliary

plate

retraction

sensor

Stack feeding

motor clock

sensor

Paddle home

position

sensor

Swing guide

closed sensor

PI8

PI9

PI10

PI11

PI12

PI14

PI15

J30-3

J31-3

J35-3

J36-3

J37-3

J46-3

J48-3

-4

-1

-2

-1

-2

-1

-2

-1

-2

-1

-2

-1

-2

-1

-2

-6

-5

-7

-9

-8

-1

-3

J71

-2

-4

-6

J71

-5

-6

-8

-7

-7

-4

-5

-6

-6

-5

J126B

-4

-2

-3

J126B

-1

-3

-2

J32B

-6

-4

-4

-6

-5

-5

J32B

-3

-7

-1

-9

-2

-8

J32B

-3

-1

J69

-2

-1

-3

-2

J45B

J125B

-7

-9

-8

J125B

-9

-7

-8

-6

-4

-5

-3

-1

-2

-6

-8

-7

J45A

-8

-6

-7

J104B-4

-7

-5

-6

+5V

-6

BNDLDEL V

-5

When paper is present

on the processing tray

or in the stack delivery

assembly, '1'.

J104B-7

-4

-2

-3

-3

-1

-2

J105B-1

J105B-4

J105B-7

J108A-6

J108B-1

+5V

-9

RJOGHP

-8

+5V

-3

SWGMTRCLK

-2

+5V

-6

SPTTRYIN

-5

+5V

-9

BFDMTRCLK

-8

+5V

-8

PDLHP

-7

+5V

-3

SWDGDCL

-2

When the rear jogging

plate is at the home

position, '1'.

When the swing motor

is rotating, alternately '1'

and '0'.

When the tray auxiliary

plate is in, '1'.

When the stack fed

motor is rotating,

alternately '1' and '0'.

When the paddle is at

the home position, '0'.

When the swing guide is

closed, '0'.

Swing guide

open sensor

Stapler shift

home

position

sensor

PI16

PI17

J49-3

J55-3

-1

-2

-1

-2

-4

-6

-5

J45B

-5

-3

-4

J108B-4

J112-6

+5V

-6

SWOPN

-5

+5V

-8

STPLHP

-7

When the swing guide is

open, '0'.

When the stapler is at

the shift home position,

'1'.

Figure 2-104

2-4

COPYRIGHT © 1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Loading...

Loading...