Canon GP605, Gp-605v, Gp-600 Service Manual Finisher D2

SADDLE

FINISHER - D2

SERVICE

MANUAL

REVISION 0

AUG. 1999

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER - D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

FY8-13G9-000

IMPORTANT

THE INFORMATION CONTAINED HEREIN IS PUBLISHED BY CANON, INC., JAPAN.

SPECIFICATIONS AND OTHER INFORMATION CONTAINED HEREIN MAY DIFFER SLIGHTLY FROM

ACTUAL MACHINE VALUES OR THOSE FOUND IN ADVERTISING AND OTHER PRINTED MATTER.

ANY QUESTIONS REGARDING INFORMATION CONTAINED HEREIN SHOULD BE DIRECTED TO THE

COPIER SERVICE DEPARTMENT OF THE SALES COMPANY.

COPYRIGHT 1999 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be strictly

supervised to avoid disclosure of confidential information.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIVISION

CANON INC.

5-1, Hakusan 7-chome, Toride-City, Ibaraki, 302-8501 Japan

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER - D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

INTRODUCTION

This Service Manual contains basic data and figures on the Saddle Finisher-D2

needed to service the machine in the field.

CHAPTER 1 General Description introduces the finisher's features and specifications,

and shows how to operate the finisher.

CHAPTER 2 Basic Operation provides outlines of the finisher's various mechanical

workings, and explains the principles used for the finisher's various control mechanisms in

view of the functions of electrical and mechanical units and in relation to their timing of

operation.

CHAPTER 3 Mechanical System shows how the finisher's various mechanical

workings are constructed, and how the finisher may be disassembled/assembled and

adjusted.

CHAPTER 4 Maintenance and Servicing provides tables of periodically replaced parts

and consumables/durables and scheduled servicing charts.

CHAPTER 5 Troubleshooting provides tables of maintenance/inspection, standards/

adjustments, and problem identification (image fault/malfunction).

APPENDIX contains a general timing chart and general circuit diagrams.

The descriptions in this Service Manual are subject to change without notice for

product improvement or other purposes, and major changes will be communicated in the

form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this

Service Manual and all relevant Service Information bulletins and be able to identify and

isolate faults in the machine.

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER - D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CONTENTS

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES.................................1-1

II. SPECIFICATIONS......................1-2

A. Specifications.........................1-2

B. Cross Section ......................1-10

III. OPERATING THE FINISHER...1-14

A. Removing Jams from the Finisher

.............................................1-14

B. Removing Jams from the Saddle

Stitcher Unit ......................... 1-19

C. Removing Jams from the Paper

Folding Unit..........................1-23

D. Removing Jams from the Cover

Inserter.................................1-26

E. Replacing the Staple Case in the

Stapler Unit ..........................1-28

CHAPTER 2 OPERATIONS

I. BASIC OPERATIONS ................ 2-1

A. Specifications .........................2-1

B. Outline of Electrical Circuitry .2-2

C. Inputs to and Outputs from the

Finisher Controller PCB.........2-3

II. FEEDING / DRIVE SYSTEM ....2-27

A. Outline..................................2-27

B. Feeding / Delivery................2-32

C. Job Offset.............................2-37

D. Releasing the Knurled Belt . 2-44

E. Buffer Path...........................2-49

III. CONTROLLING THE PADDLE

..................................................2-54

IV. CONTROLLING THE TRAY

AUXILIARY PLATE................... 2-55

V. STAPLING ................................2-57

VI. TRAY MOVEMENT...................2-65

VII. PUNCH UNIT ............................2-72

VIII.FANS.........................................2-84

IX. POWER SUPPLY .....................2-86

X. DETECTING JAMS (FINISHER)

..................................................2-92

XI. CUTTING OFF THE MODULES

..................................................2-94

F. Removing Jammed Staples from

the Stapler Unit ....................1-30

G. Replacing the Saddle Stitcher

Unit Staple Cartridges..........1-32

H. Removing Jammed Staples from

the Saddle Stitcher Unit.......1-34

I. Removing Punch waste.......1-37

J. Module Separation Switch ...1-38

K. Operating the Module Separation

Switch ..................................1-39

IV. MAINTENANCE BY THE USER

..................................................1-41

XII. SADDLE STITCHER.................2-95

A. Basic Opration .....................2-95

B. Feed and Drive System .......2-97

C. Paper Collection System ...2-103

D. Stitcher System..................2-117

E. Folding and Delivery System

...........................................2-120

F. Jam Detection ....................2-128

G. Power Supply.....................2-134

XIII.PAPER FOLDING UNIT B1....2-135

A. Outline................................2-135

B. Block Diagram of Electrical

Circuit.................................2-136

C. Basic Operation .................2-137

D. Feed Drive System ............2-139

E. Jam Detection....................2-149

F. Power Supply.....................2-153

XIV.INSERTER (COVER INSERTION

UNIT - A1)...............................2-154

A. Outline................................2-154

B. Outline of Power Circuit.....2-155

C. Basic Operation .................2-156

D. Feed Drive System ............2-159

E. Inserter Pick - up................2-161

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER - D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

F. Saddle Stitcher Mode Feeding

...........................................2-163

G. Jam Detection....................2-165

CHAPTER 3 MECHANICAL SYSTEM

H. Power Supply.....................2-167

I. FINISHER UNIT..........................3-1

A. Externals and Controls ..........3-1

B. Processing Tray Unit ...........3-13

C. Tray A Unit / Tray B Unit......3-19

D. Knurled Belt Releasing Unit

.............................................3-27

E. Knurled Belt .........................3-29

F. Buffer Roller Unit .................3-30

G. Stapler Unit ..........................3-34

H. Punch Unit ........................... 3-40

I. Printed Circuit Boards (PCB)

.............................................3-48

II. SADDLE STITCHER .................3-49

CHAPTER 4 MAINTENANCE AND SERVICING

I. PERIODICALLY REPLACED

PARTS ........................................ 4-1

II. GENERAL SERVICE LIVES OF

CONSUMABLE PARTS..............4-1

A. Saddle Unit ..........................3-49

III. PAPER FOLDING UNIT A1

(FOLDER) .................................3-67

A. External Covers ...................3-67

B. Paper Folding Unit ...............3-67

C. Transport Mechanism ..........3-71

D. Drives...................................3-79

E. Removing the Folder Driver PCB

.............................................3-84

IV. INSERTER ................................3-85

A. External Controls .................3-85

B. Pick - Up Unit.......................3-91

III. PERIODIC MAINTENANCE .......4-3

CHAPTER 5 TROUBLESHOOTING

I. ADJUSTMENT............................5-1

A. Electrical System ...................5-1

B. Mechanical...........................5-20

II. ARRANGEMENT OF ELECTRICAL

PARTS ......................................5-24

A. Finisher ................................5-24

B. Saddle Stitcher .................... 5-36

C. Paper Folding Unit B1 (folder)

.............................................5-46

D. Cover Insertion Unit - A1 .....5-48

E. LEDs and Check Pins by PCB

.............................................5-50

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER - D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

F. Downloader PCB .................5-62

III. TROUBLESHOOTING..............5-71

A. Finisher ................................5-71

B. Saddle Stitcher .................... 5-84

C. Folder...................................5-90

D. Inserter................................. 5-91

IV. SELF DIAGNOSIS ....................5-92

A. Self - diagnostics .................5-92

B. Alarms..................................5-98

APPENDIX

A. GENERAL TIMING CHART

.............................................. A-1

B. LIST OF SIGNALS /

ABBREVIATIONS................. A-3

C. FINISHER UNIT GENERAL

CIRCUIT DIAGRAM ............. A-7

D. SADDLE STITCHER UNIT

GENERAL CIRCUIT DIAGRAM

.............................................. A-9

E. PAPER FOLDING UNIT

GENERAL CIRCUIT DIAGRAM

............................................ A-11

F. COVER INSERTION UNIT - A1

GENERAL CIRCUIT DIAGRAM

............................................ A-12

G. SOLVENTS AND OILS LIST

............................................ A-13

H. SPECIAL TOOLS ............... A-14

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER - D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1

GENERAL DESCRIPTION

I. FEATURES.................................1-1

II. SPECIFICATIONS......................1-2

A. Specifications.........................1-2

B. Cross Section ......................1-10

III. OPERATING THE FINISHER...1-14

A. Removing Jams from the Finisher

.............................................1-14

B. Removing Jams from the Saddle

Stitcher Unit ......................... 1-19

C. Removing Jams from the Paper

Folding Unit..........................1-23

D. Removing Jams from the Cover

Inserter.................................1-26

E. Replacing the Staple Case in the

Stapler Unit ..........................1-28

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER-D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

F. Removing Jammed Staples from

the Stapler Unit ....................1-30

G. Replacing the Saddle Stitcher

Unit Staple Cartridges..........1-32

H. Removing Jammed Staples from

the Saddle Stitcher Unit.......1-34

I. Removing Punch waste.......1-37

J. Module Separation Switch...1-38

K. Operating the Module Separation

Switch ..................................1-39

IV. MAINTENANCE BY THE USER

..................................................1-41

CHAPTER 1 GENERAL DESCRIPTION

I . FEATURES

1. Two Types of Stacking Trays

• There are two types of stacking trays, tray A and tray B, which are used for different purposes.

2. Large Capacity

• Tray B is capable of holding a stack of sheets 285 mm in height (small size)/145 mm in

height (large size), while tray A is capable of holding a stack of sheets 145 mm in height.

3. Wide-Ranging Paper Types

2

• The sheets may be of 64 to 200 g/m

paper.

4. Stack Job Offset Function

• The stack job offset function is offered for sorting non-staple stacks.

5. Three Types of Auto Stapling

• As many as three different types (position) are offered (front slant, rear slant, 2-point).

6. High Productivity by a Buffer Roller

• The use of a buffer roller has enabled continuous feeding of sheets from the copier while

stapling or offset operation is taking place.

7. Punching Function

• The use of a punch unit enables holes for filing the paper in a binder to be punched in the

paper prior to delivery. (This function can be used with 64-200 g/m

2

paper, but not with

intermediate paper or OHP paper.)

8. Saddle Stitcher Function

• Up to 15 sheets can be delivered stapled in the middle and folded in half.

9. Inserter Function

• The cover can be picked up from the inserter which is separate from the cassette.

10. Folding Function

• This function enables Z-folding to be carried out of paper of A3, B4 or 279.4 x 431.8mm (11

x 17) size. Paper of 64-80 g/m

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER-D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2

can be folded.

1-1

CHAPTER 1 GENERAL DESCRIPTION

II . SPECIFICATIONS

A. Specifications

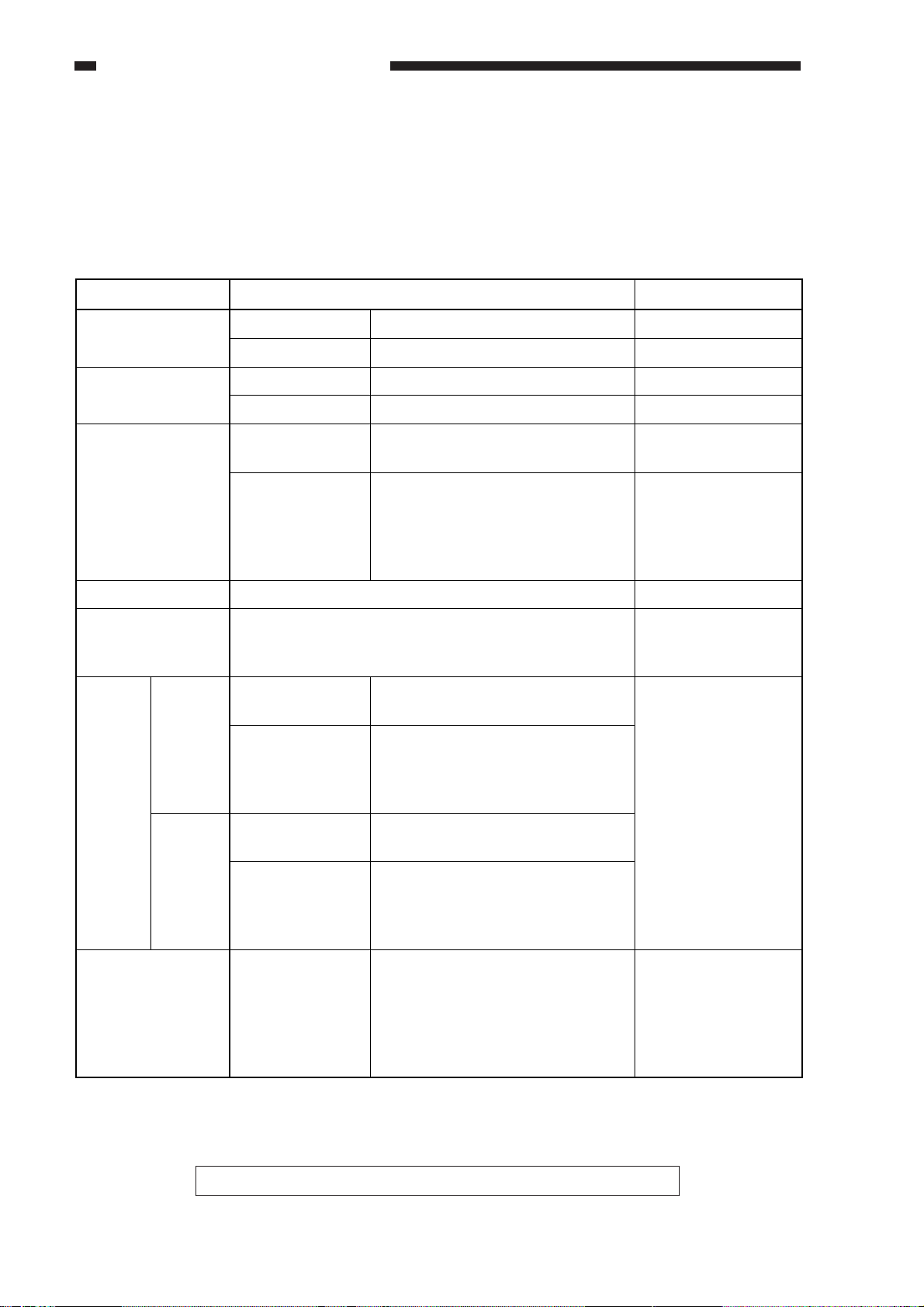

1. Saddle Finisher D2

1-a. Finisher

SpecificationsItem Remarks

Lifting system

Stacking

Stack size

Paper weight

Modes

Stack

thickness

Nonstaple

sort

Tray A Up/down

Tray B

Tray A

Tray B

Tray A

Tray B

64 to 200 g/m

Staple stacking, non-staple stacking

Tray A

Tray B

Up/down

Same as the copier delivery method.

Face-down

Postcard to A3/

279.4mm × 431.8mm

A5/STMT to A3/

279.4mm × 431.8mm

2

1000-sheet equivalent (small/large

size) 145mm

2,000-sheet equivalent (small-size)

285mm

1,000-sheet equivalent (large-size)

145mm

Postcards are for R

feeding only.

A5/STMT is for R

feeding only.

B5/A4/LTR is for

horizontal feeding

only.

Mixed stacking is

possible under

certain conditions

Paper equivalent to

80 g/m

2

Staple

sort

Staple/non-staple

mix

1-2

Tray A

Tray B

Tray B

1,000-sheet equivalent or 100 sets

(small/large size)

2,000-sheet equivalent or 100 sets

(small-size)

1,000-sheet equivalent or 100 sets

(large-size)

Stops when either of the conditions

below is met

2,000-sheet equivalent or 100 sets

(small-size)

1,000-sheet equivalent or 100 sets

or 30 folded sheets (large-size)

Stacking ability is not

guaranteed.

Treated as large size

when 1 large-size

sheet is included.

Table 1-201

The specifications are subject to change for product improvement.

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER-D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

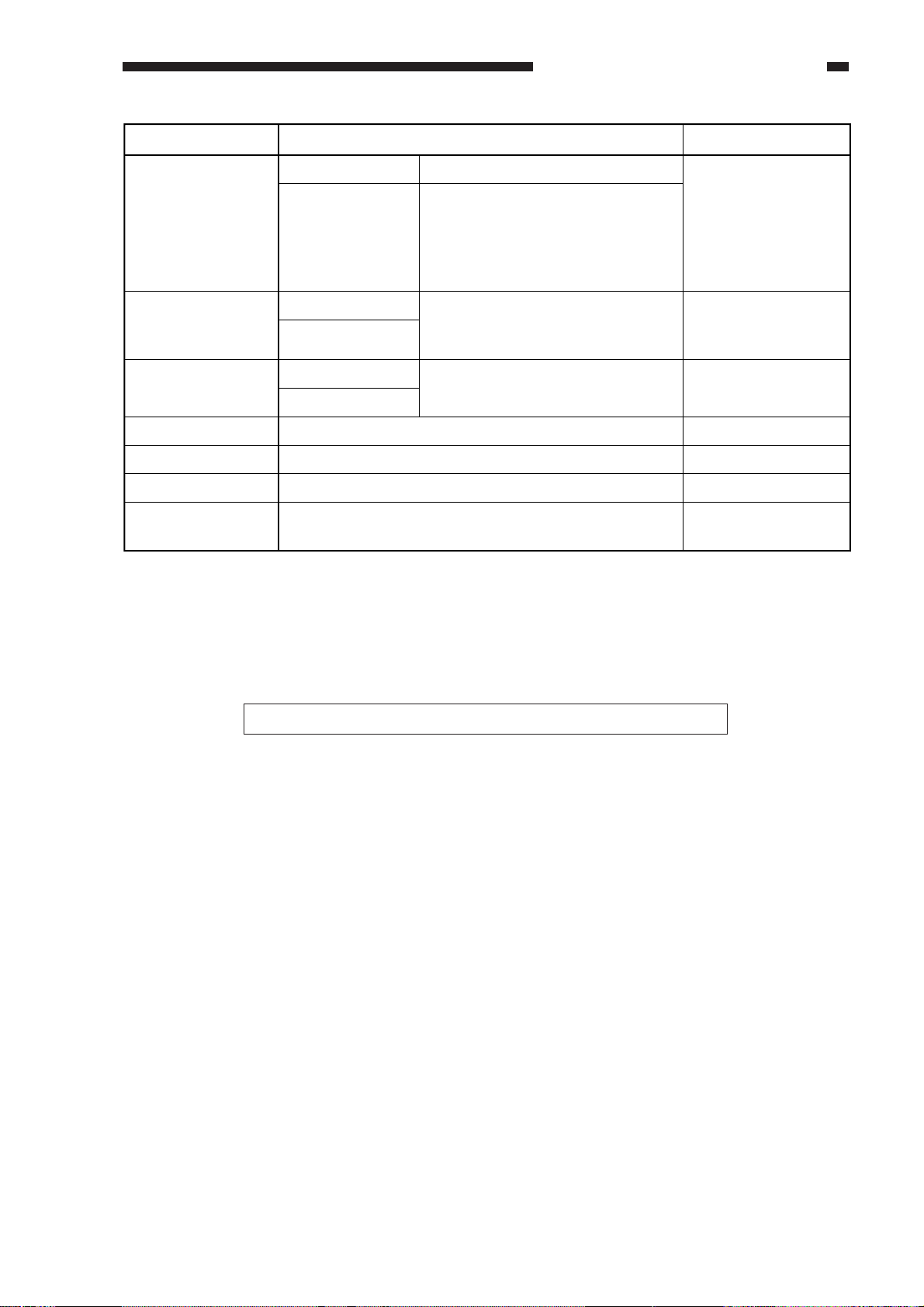

CHAPTER 1 GENERAL DESCRIPTION

SpecificationsItem Remarks

Folded paper mix

stack thickness

Tray A Max. 20 sheets of folded paper

Tray B

Max. 10 sheets of folded paper per

Paper equivalent to

80 g/m

2

stack / Max. 30 sheets of folded

paper per 1 job (1 folded sheet is

regarded as 5 sheets of normal

paper)

Stacking condition

Paper detection

Tray A

Tray B

Tray A

Front/rear stack offset

Staple: 20 mm

Non-staple: 30 mm (LGL: 36mm)

Yes

No offset stacking on

tray A for non-sort

delivery

Tray B

Control panel

No

Display No

Installation Latching with mount (height adjusted by caster)

Dimensions 802 mm (W) × 738 mm (D) × 995 mm (H) /

5

31 -

/8" (W) × 29 - 1/8" (D) × 39 - 3/8" (H)

Note 2

Note 1: The term “small-size” refers to A4, A5, B5, postcard, LTR, and STMT, while the term “large-

size” refers to A3, B4, 279.4 mm × 431.8 mm, and LGL.

Note 2: Width when folder is connected: 986mm / 38 -

13

/16"

Height when inserter is connected:1,138mm / 44 - 13/16" (auxiliary tray open)

Table 1-201-2

The specifications are subject to change for product improvement.

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER-D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-3

CHAPTER 1 GENERAL DESCRIPTION

SpecificationsItem Remarks

W eight

Power supply

Maximum power

consumption (230V)

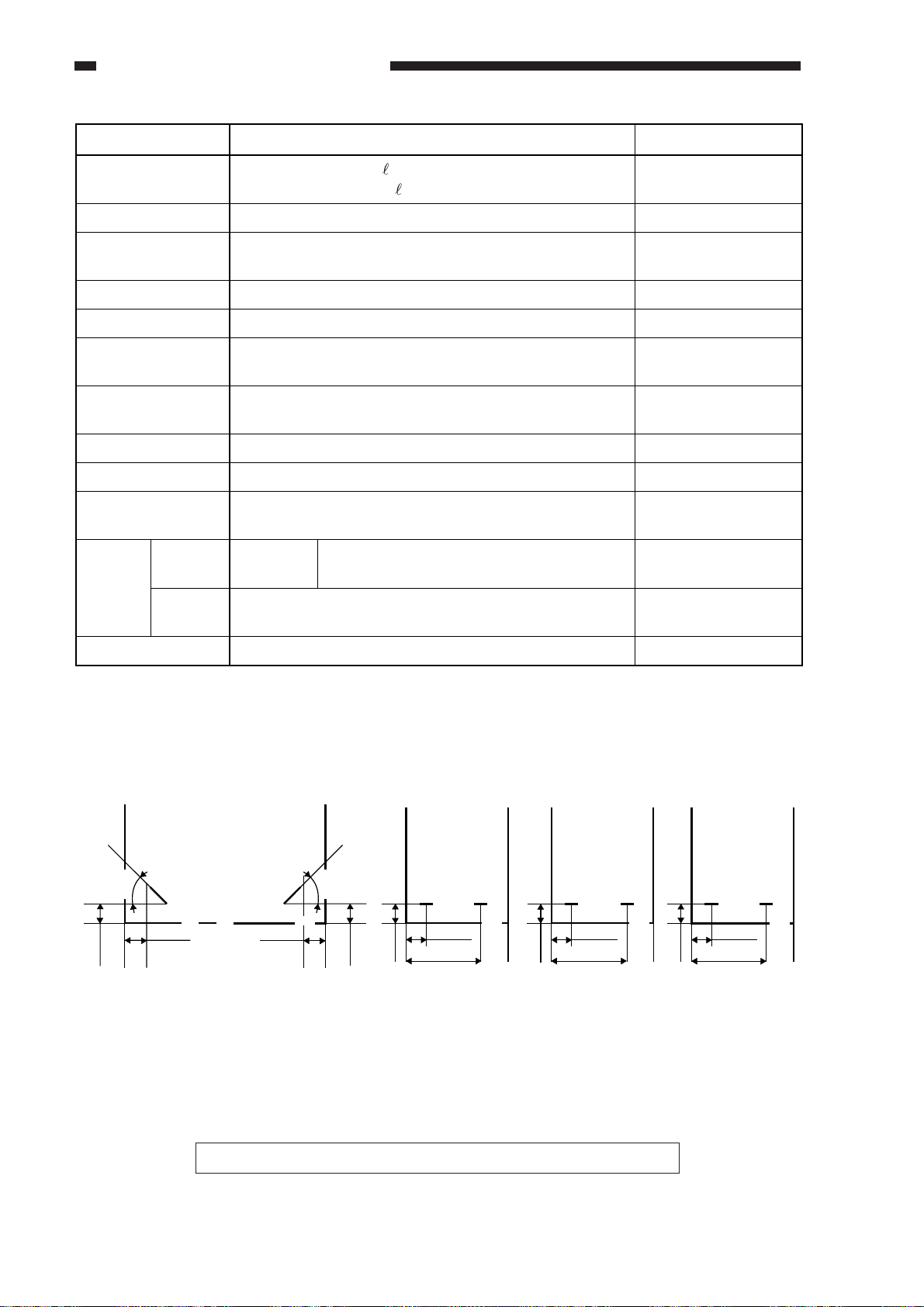

Stapling

Stapling position

Stapling thickness

Staple

compartment

Staples

Staple detection

automatic staple

reposition

Stapling

size

1-point

stapling

2-point

stapling

Approx. 106 kg (233 b)

Approx. 170 kg (373.7

b) (including inserter and folder)

100 to 120V/50; 60Hz, 230V/50Hz

During wait : 160W / during stand-by : 60W / during

operation : 200W (staple sort)

Punching by a rotating cam. (face-down stapling)

See figure below.

2

48 sheets (80 g/m

) + 2 sheets (200 g/m2), or thick paper

of 5.5 mm or less

Special cartridge (5,000 staples)

Special staples

Yes

Within 10 times

Front/rear

A3, A4, B4, B5, 279.4mm × 431.8 mm,

LGL, LTR

A3, A4, B4, B5, 279.4mm × 431.8 mm, LTR

Manual stapling

1-point stapling

(front)

45˚

*2

5±2

None

1-point stapling

(rear)

*2

5±25±2

Unit: mm

Table 1-202

2-point stapling

279.4mm×

431.8mm

(11×17),

6±2

45˚

5±2

A3, A4 B4, B5

88.5±4 68.5±4 79.5±4

6±2

208.5±4 188.5±4 199.5±4

*2 *2 *2

*1 *1 *1

6±2

*1 The stapling interval may be adjusted in user mode.

*2 The stapling position may be adjusted using a DIP switch.

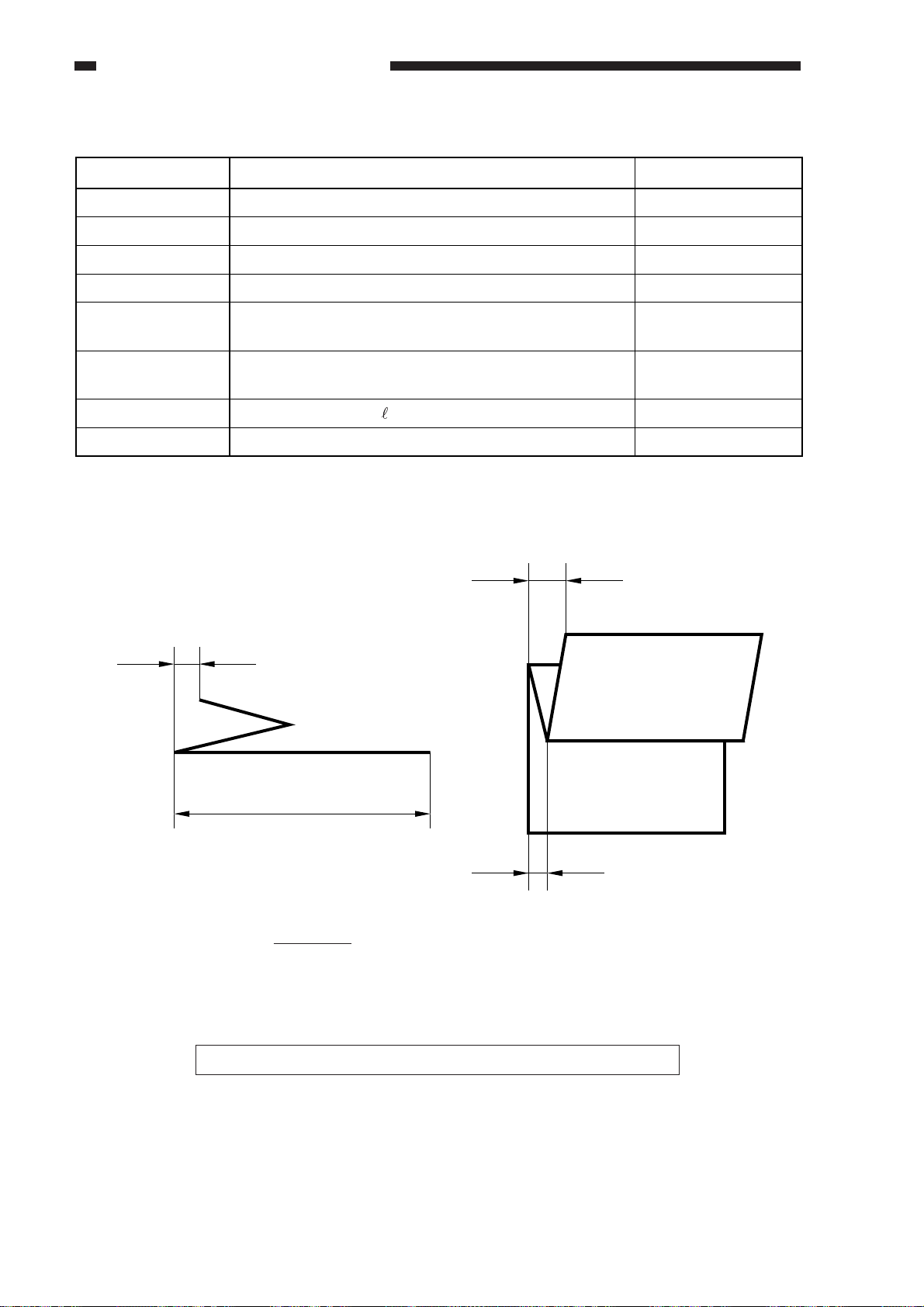

Figure 1-201

LTR

1-4

The specifications are subject to change for product improvement.

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER-D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

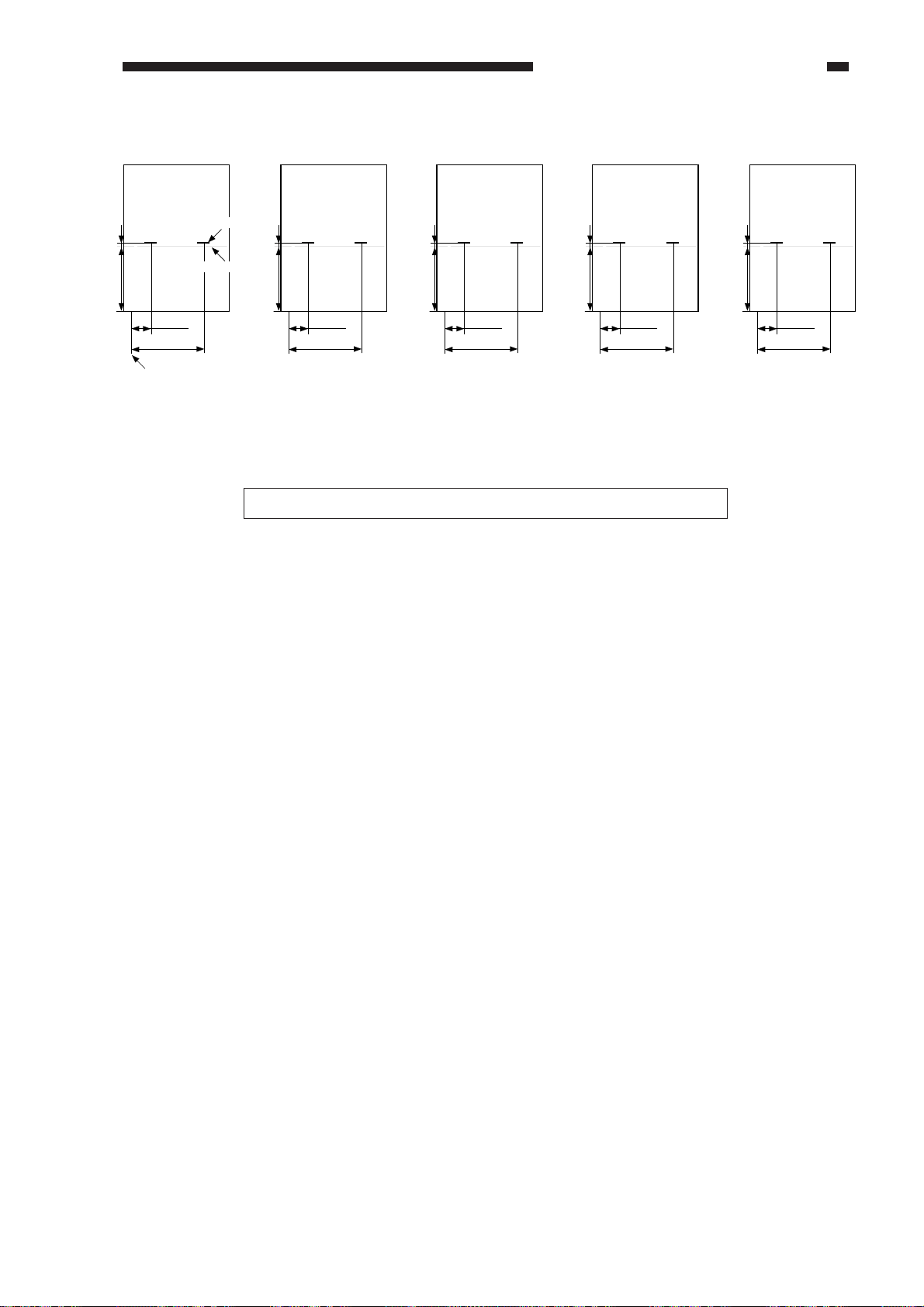

CHAPTER 1 GENERAL DESCRIPTION

12±3mm

31.5±3mm

108±0.5mm 108±0.5mm

Feed

direction

12±3mm

80±0.5mm

*1

*1 : A4/A3=108.5±3mm

: B4/B5=88.5±3mm

Feed

direction

Item Specifications

Punching method Rotary punch (one after another as paper passes)

Paper type 64 to 200 g/m

2

(Not possible with OHP paper)

Punch position 100/230V 115V

Paper size 100 V / 230 V : A3, B4, A4, B5

115 V : 279.4 mm × 431.8 mm, LTR

Maximum power

consumption (230V)

200W (punch staple sort)

Punch (No. and diameter

of holes)

100/230V : 2 holes, 6.5mm

115V : 3 holes, 8mm

Punch waste capacity 100/230V : Approx. 20,000 sheets or more (when using 80 g/m2 paper)

115V : Approx. 10,000 sheets or more (when using 80 g/m

2

paper)

Punch waste “full”

indicator

Displayed on main control panel

Punch mode designation

method

Designated on main control panel

Punch unit-related items

Table 1-203

The specifications are subject to change for product improvement.

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER-D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-5

CHAPTER 1 GENERAL DESCRIPTION

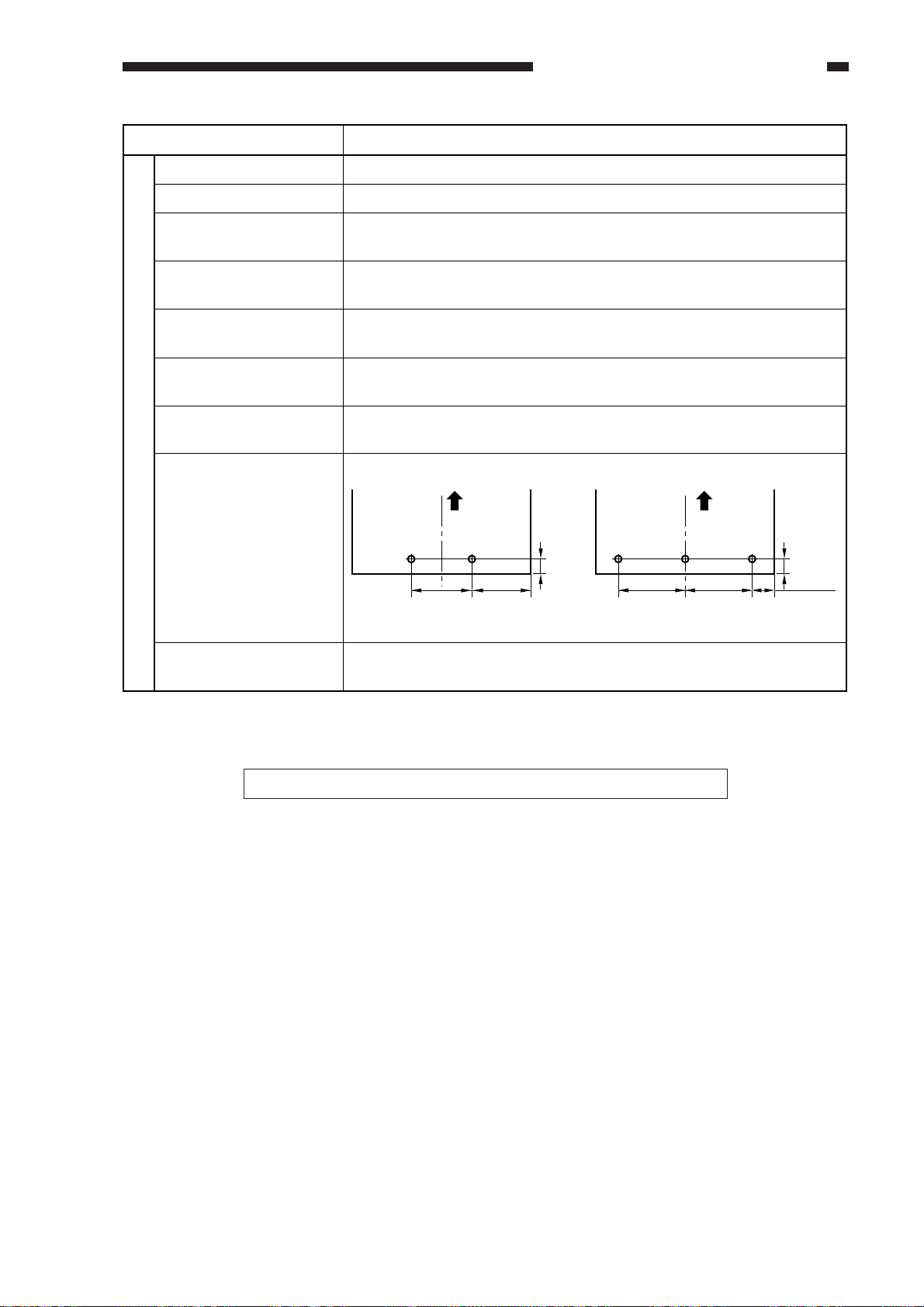

1-b.Saddle Stitcher

Item Specifications

Stapling method

Stapling position

Paper size

No. of sheets

Paper weight

No. of sets for

stacking

Stapling

specifications

Folding

specifications

Staple in middle, then fold in half

See Figure 1-202.

A3, B4, A4R, 279 mm × 432 mm (11 × 17), LTRR

15 sheets (including cover) (Note 1)

64 g/m

2

to 80 g/m2 (1 cover up to 200 g/m2) (Not possible with special paper or

OHP paper)

30 sets (special tray, front stop shift)

Stapling position

Staple capacity

Staple loading

2 points (equidistant from center, fixed interval)

2000 staples

Special cartridge

method

Staples

Staple detection

Folding method

Folding mode

Folding position

Special staples (Staple Cartridge D2)

Yes

Folding by roller pressure

Folding in two (1 sheet is not stapled)

Center of paper

Folding position

Yes

adjustment

function

Power supply

Supplied from finisher

24V, 2-systems

Trimmer (Note 2)

Power consumption

No

190W (book mode)

(230 V)

Note 1: When using thick paper over 90 g/m2 in cover mode, depending on the type of paper, feeding may

not go smoothly with stacks of 14 sheets or over. If this happens, change the setting to 13 sheets

or less.

Note 2: The term “trimmer” refers to the function for trimming the edges of the stacks.

Table 1-204

The specifications are subject to change for product improvement.

1-6

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER-D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

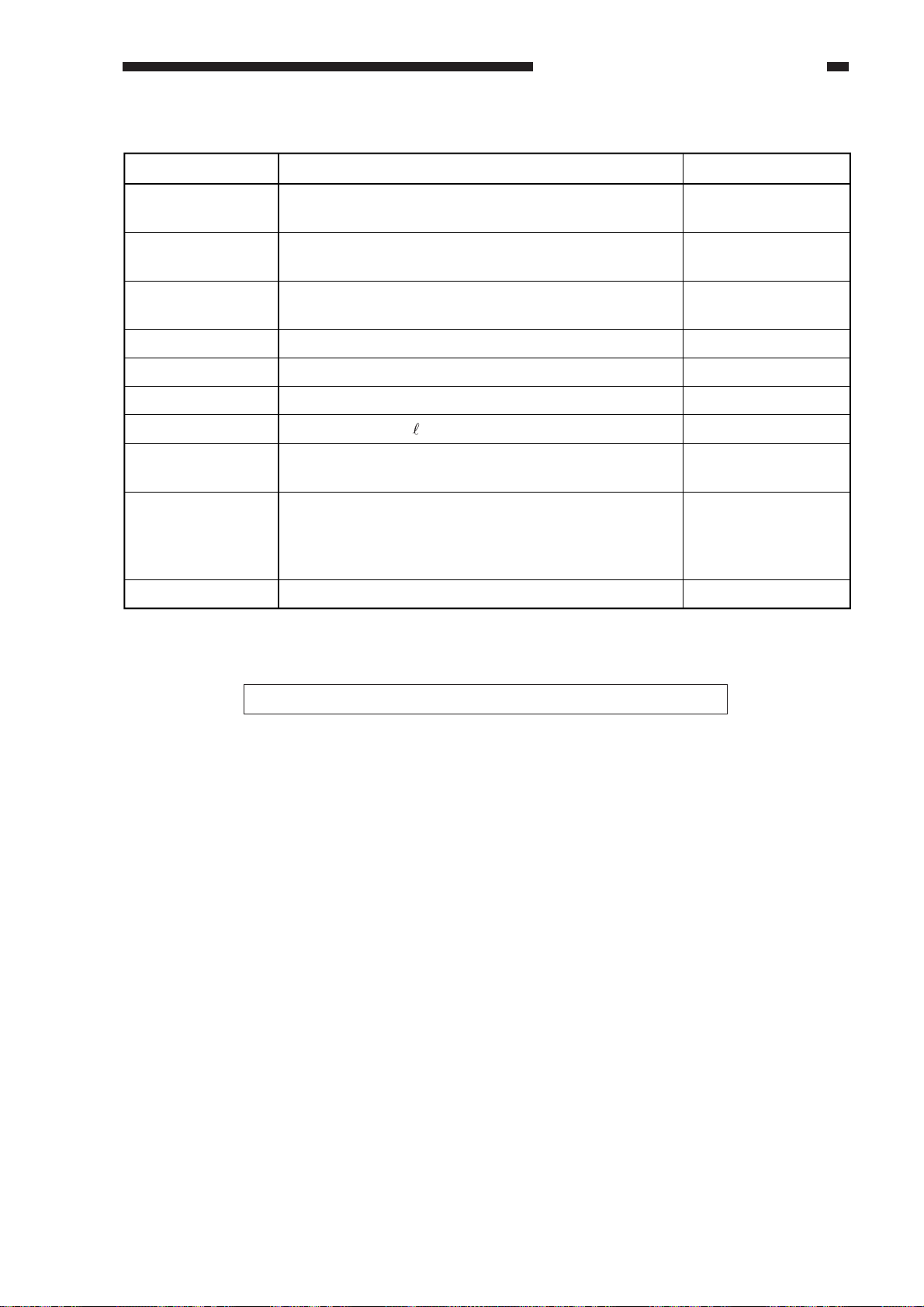

Stapling and folding position (saddle stitcher)

CHAPTER 1 GENERAL DESCRIPTION

A3

Stapling position

L

Folding position

210±1mm

88.5±2mm

208.5±2mm

Front edge of stack

L (difference between folding

position and stapling

position) = ± 0.5mm

B4

L

182±1mm

68.5±2mm

188.5±2mm

L (difference between folding

position and stapling

position) = ± 0.5mm

A4R

L

148.5±1mm

45±2mm

165±2mm

L (difference between folding

position and stapling

position) = ± 0.5mm

279mm×432mm

(11×17)

L

216±1mm

79.7±2mm

199.7±2mm

L (difference between folding

position and stapling

position) = ± 0.5mm

Figure 1-202

The specifications are subject to change for product improvement.

LTRR

L

139.7±1.5mm

48±2mm

163±2mm

L (difference between folding

position and stapling

position) = ± 0.5mm

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER-D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-7

CHAPTER 1 GENERAL DESCRIPTION

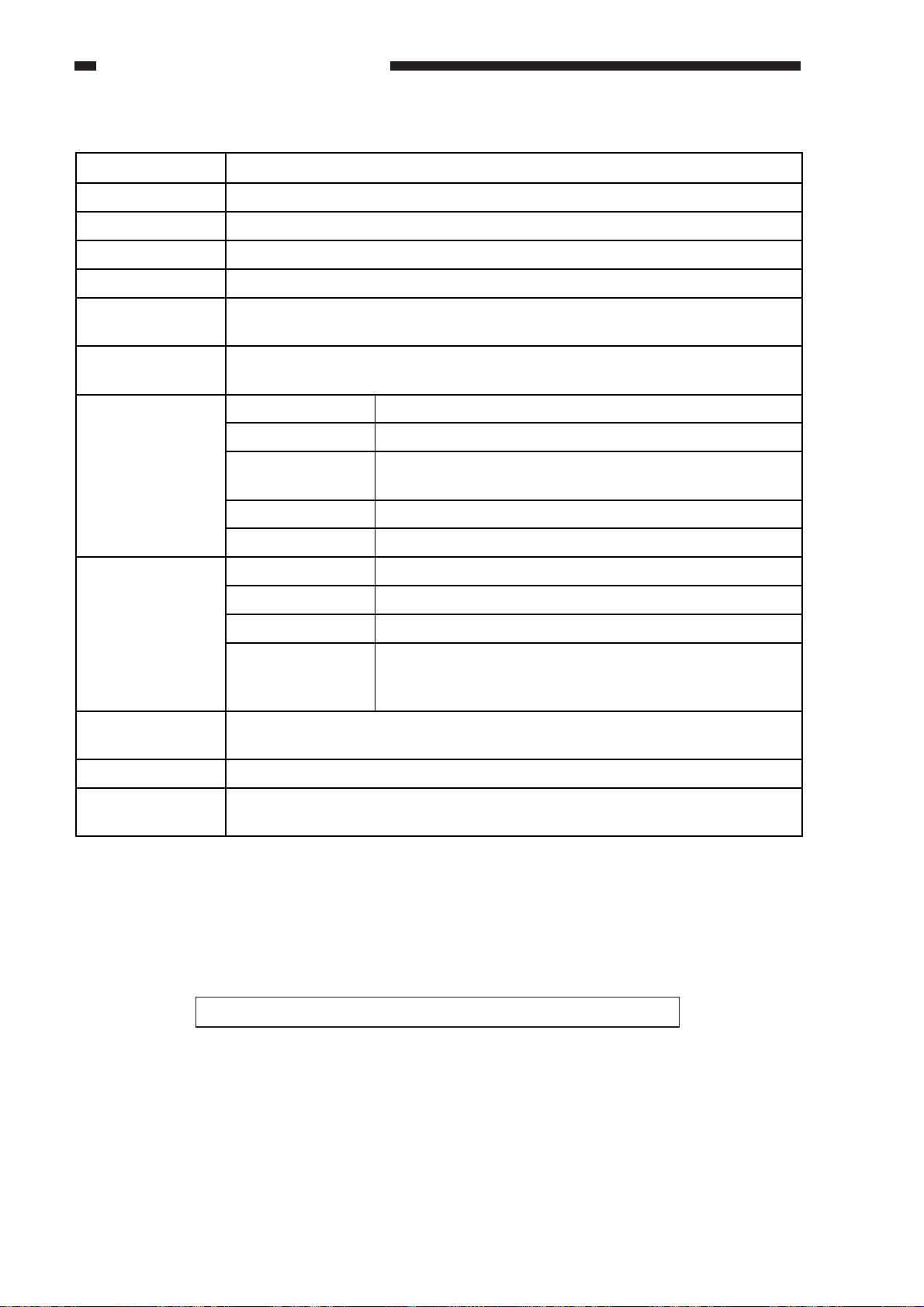

2. Folder (Paper Folding Unit B1)

SpecificationsItem Remarks

Folding method

Paper weight

Paper size

Folding mode

Dimensions

Power consumption

(230V)

Weight

Power supply

Folding Position

Roller pressure (folded one after another as paper passes)

64 to 80 g/m

2

A3, B4, 297 mm × 432 mm (11 × 17)

Z-folding

184 mm (W) × 675 mm (D) × 995 mm (H) /

1

7 -

/4" (W) × 26 - 5/8" (D) × 39 - 1/4" (H)

240 W (Z-fold, punch staple mode)

Approx. 45 kg / 99.2

b

Supplied from finisher

Table 1-205

Z3

Including casters

Z1

Z2

Z4

Z1: Within 2 mm

Z2: Within

+2

-1

paper length

2

± 2 mm

Z3, Z4: Within ± 1.5 mm

In case of high temperature/high

humidity or low temperature

Z3, Z4: Within ± 2.0 mm

Figure 1-203

The specifications are subject to change for product improvement.

1-8

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER-D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

3. Inserter (Cover Insertion Unit-A1)

SpecificationsItem Remarks

Stacking capacity

Paper weight

100 sheets (small-size) / 50 sheets (large-size)

64 to 200 g/m

2

(including colored copy paper)

CHAPTER 1 GENERAL DESCRIPTION

2

Face-up, 80 g/m

paper

Not possible with

OHP paper

Paper size

Mixed stacking

Separation method

Position standard

Weight

Power consumption

(230V)

Dimensions

Power supply

The specifications are subject to change for product improvement.

B5 to A3/ 279mm × 432mm (11 × 17)

No

Upper separation by belt

Center standard

Approx. 20kg / 44

b

240 W (Z-fold, cover mode, pumch, staple-sort)

Auxiliary tray open: 561mm (W) × 584mm (D) ×

144mm (H) / 22 -

1

/8" (W) × 23" (D) × 5 - 5/8" (H)

Auxiliary tray closed: 402mm (W) × 584mm (D) ×

132mm (H) / 15 -

7

/8" (W) × 23" (D) × 5 - 1/4" (H)

Supplied from finisher

Table 1-206

B5 is for standard

feeding only

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER-D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-9

CHAPTER 1 GENERAL DESCRIPTION

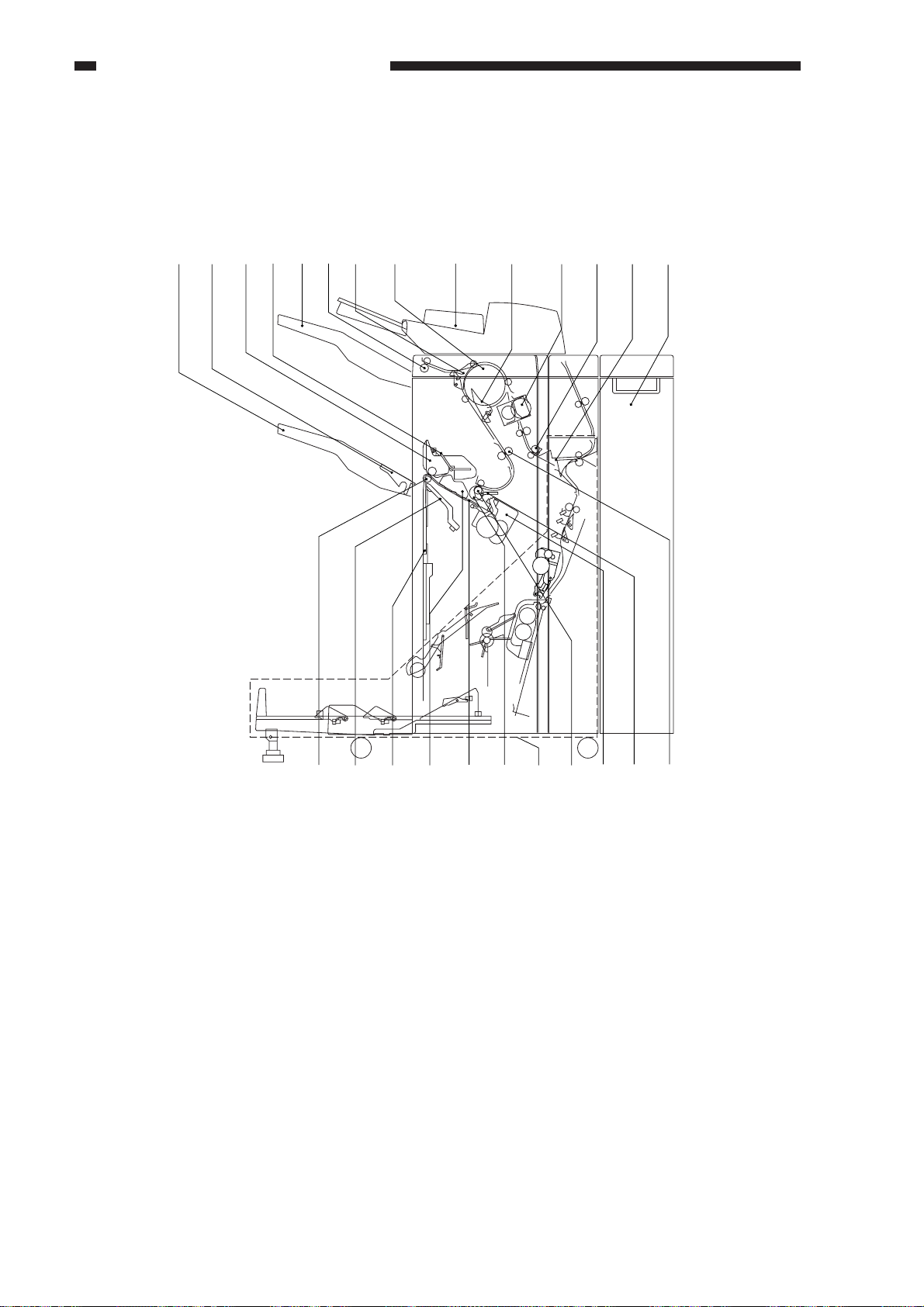

B. Cross Section

1. Finisher

[1] [1A] [2] [3] [4] [5] [6] [7] [8] [9] [10][11] [12] [13]

[1] Tray B

[1A] Sub tray (attached when folder at-

tached)

[2] Swing guide

[3] Paddle

[4] Tray A

[5] Non-sort delivery roller

[6] Upper path switching flapper

[7] Buffer roller

[8] Inserter (Cover Insertion Unit-A1)

[9] Buffer switching flapper

[10] Punch unit

[11] Inlet roller

[22][23][24] [17][19][20][21] [18]

[12] Saddle inlet paper deflector

[13] Folder (Paper Folding Unit-B1)

[14] Pre-delivery roller

[15] Mobile roller

[16] Stapler

[17] Delivery roller

[18] Saddle stitcher

[19] Knurled belt

[20] Processing tray

[21] Jogging plate (front, rear)

[22] Shutter

[23] Tray auxiliary plate

[24] Stack delivery roller

Figure 1-204

[16] [15][14]

1-10

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER-D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

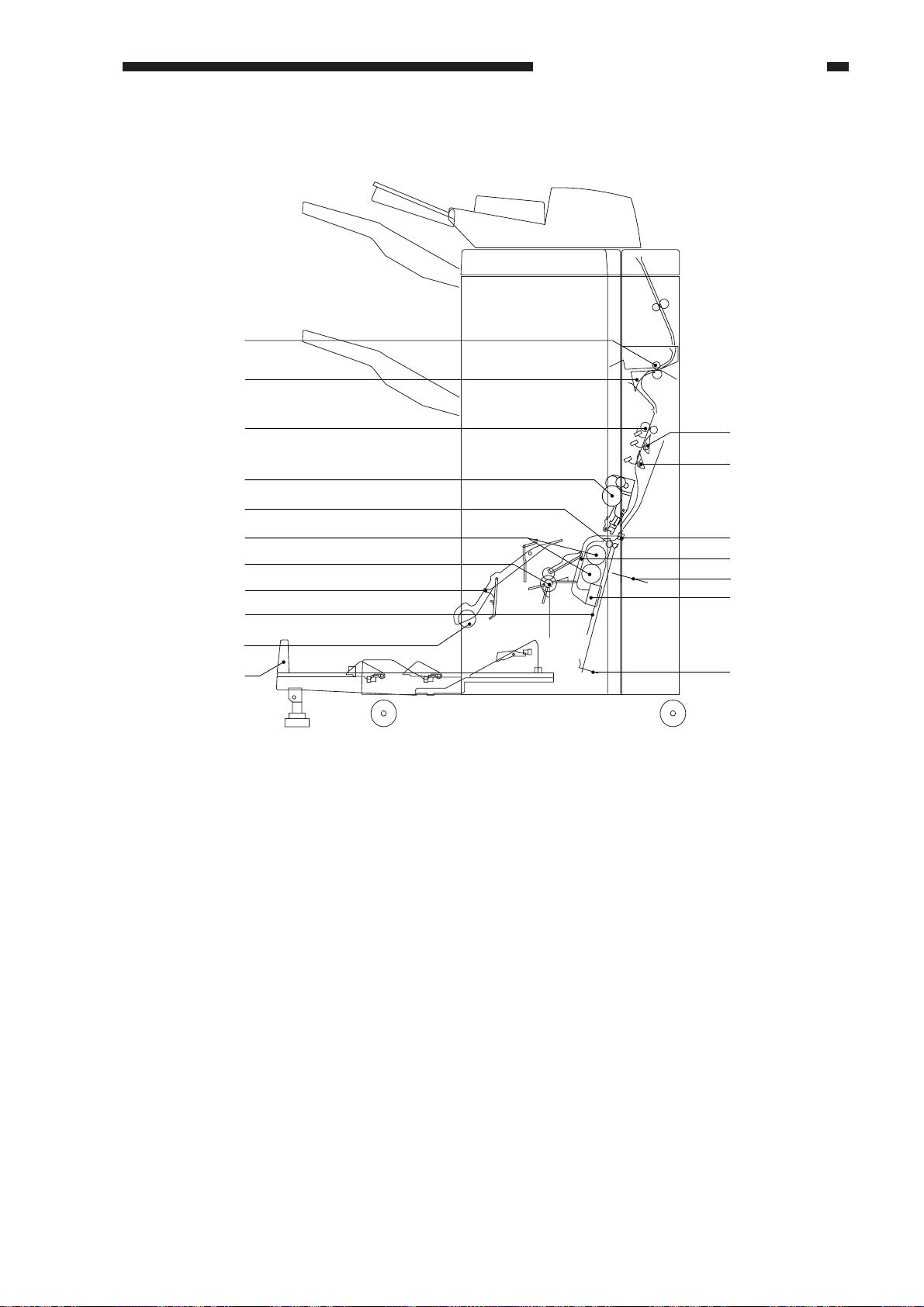

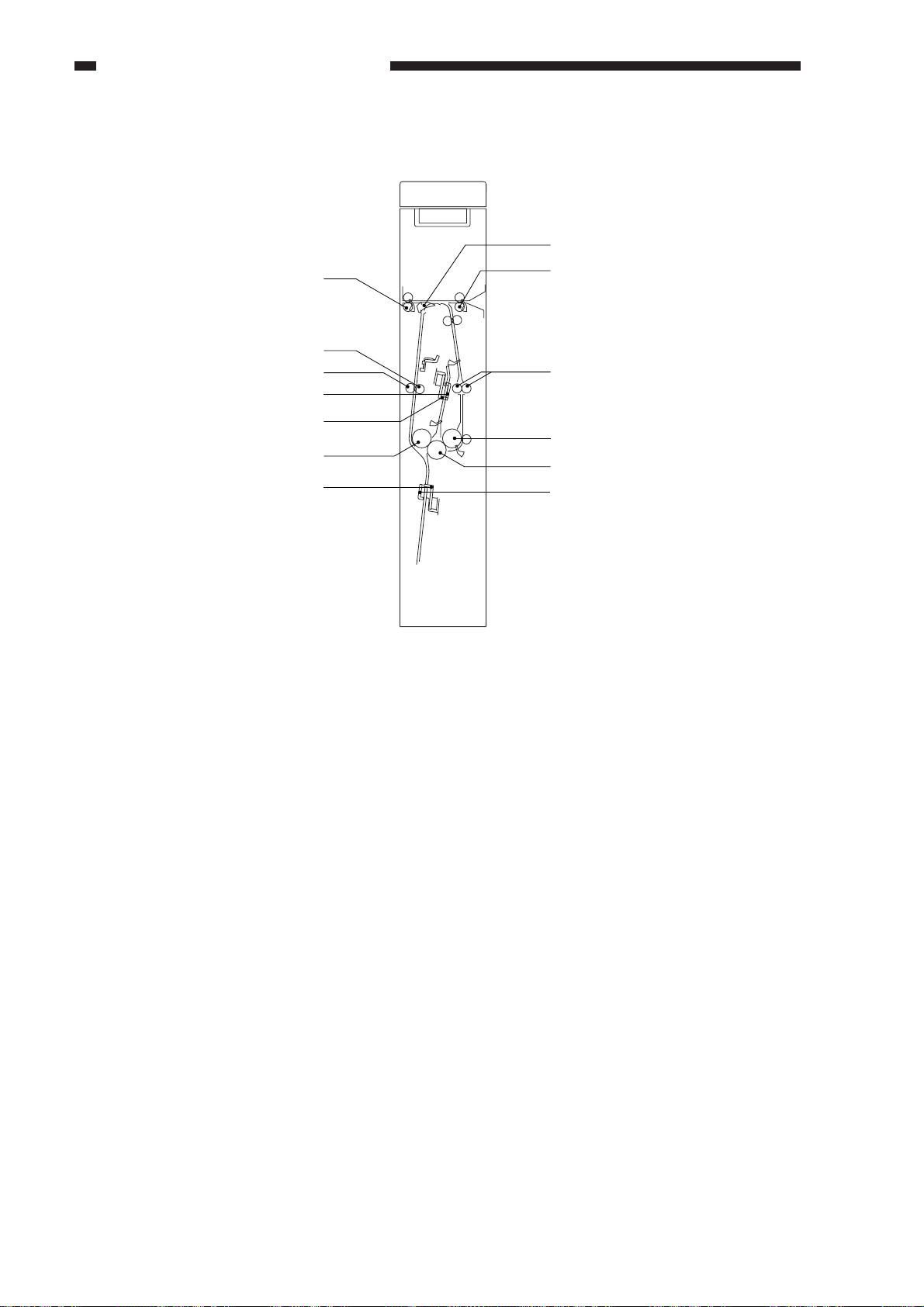

2. Saddle Stitcher Unit

[11]

[10]

CHAPTER 1 GENERAL DESCRIPTION

[9]

[8]

[7]

[6]

[5]

[4]

[3]

[2]

[1]

[1] Saddle delivery tray

[2] Delivery guide roller

[3] Guide plate

[4] Delivery guide

[5] Delivery roller

[6] Folding roller (top, bottom)

[7] Intermediate roller 2

[8] Stitcher (front, rear)

[9] Intermediate roller 1

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[10] Saddle inlet paper deflector

[11] Saddle inlet roller

[12] Paper deflector 1

[13] Paper deflector 2

[14] Stitch support

[15] Jogging plate (front, rear)

[16] Pressure plate

[17] Crescent roller

[18] Positioning plate

Figure 1-205

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER-D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-11

CHAPTER 1 GENERAL DESCRIPTION

3. Folder

[13]

[12]

[11]

[10]

[9]

[8]

[7]

[1]

[2]

[3]

[4]

[5]

[6]

[1] Folder inlet flapper

[2] Feed roller 1

[3] Folding roller 2

[4] Folding roller C

[5] Folding roller A

[6] 1st stopper

(A3/279.4mm × 431.8mm (11 × 17))

[7] 1st stopper (B4)

[8] Folding roller B

[9] 2nd stopper (B4)

[10] 2nd stopper

(A3/279.4mm × 431.8mm (11 × 17))

[11] Skew correction roller

[12] Pressure roller

[13] Feed roller 2

Figure 1-206

1-12

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER-D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

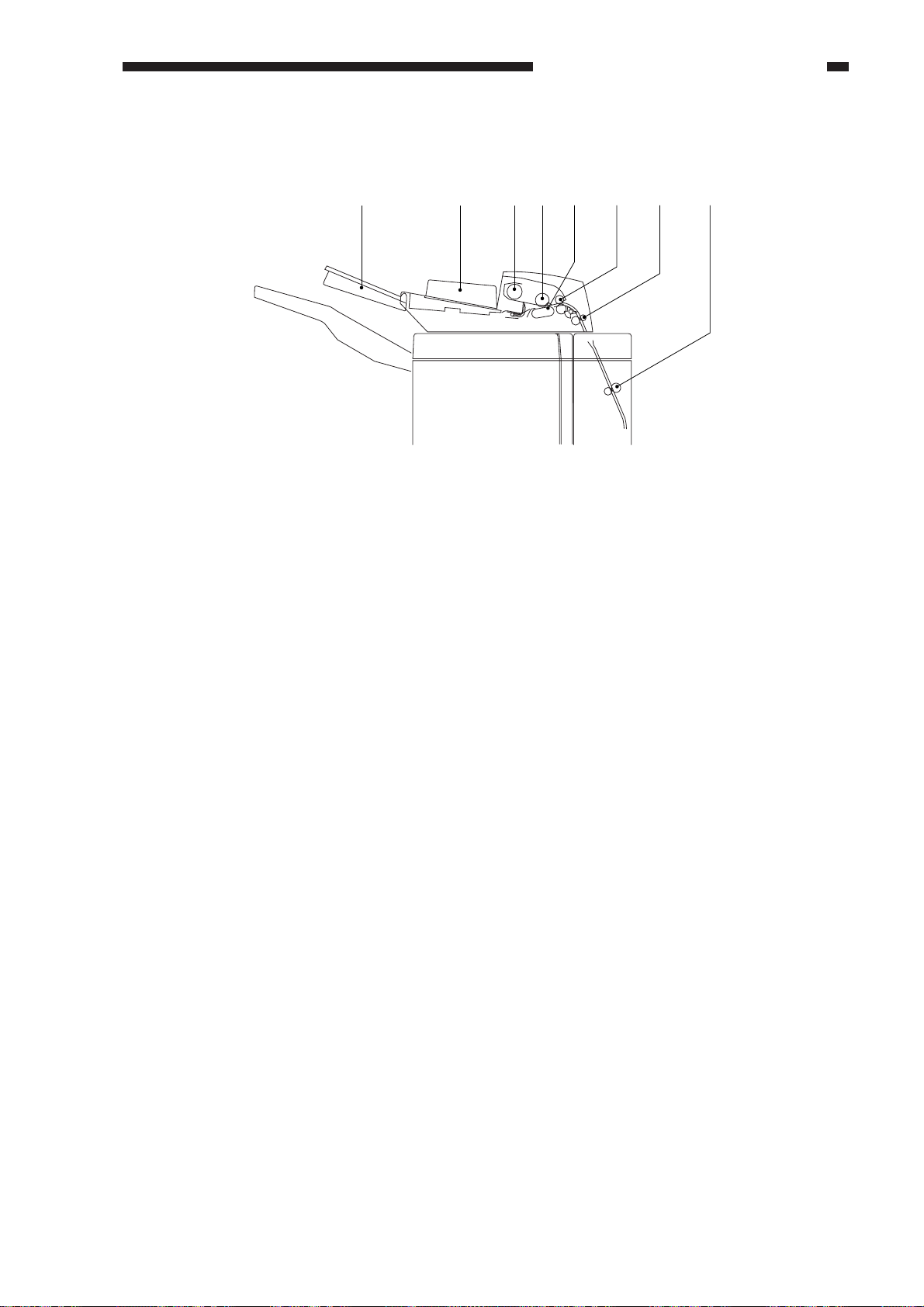

4. Inserter

CHAPTER 1 GENERAL DESCRIPTION

[1] [2] [3] [4] [5] [6] [7] [8]

[1] Auxiliary tray

[2] Side guide (front, rear)

[3] Pick-up roller

[4] Feed roller

[5] Separation belt

[6] Extraction roller

[7] Intermediate feed roller

[8] Inserter lower feed roller

Figure 1-207

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER-D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-13

CHAPTER 1 GENERAL DESCRIPTION

III . OPERATING THE

FINISHER

A. Removing Jams from the

Finisher

1. Paper Jam in the Top Cover

A paper jam has occurred in the area

which appears in the display. Follow the procedure described below to remove the jammed

paper.

1) Remove any paper protruding from the

output tray.

Figure 1-301

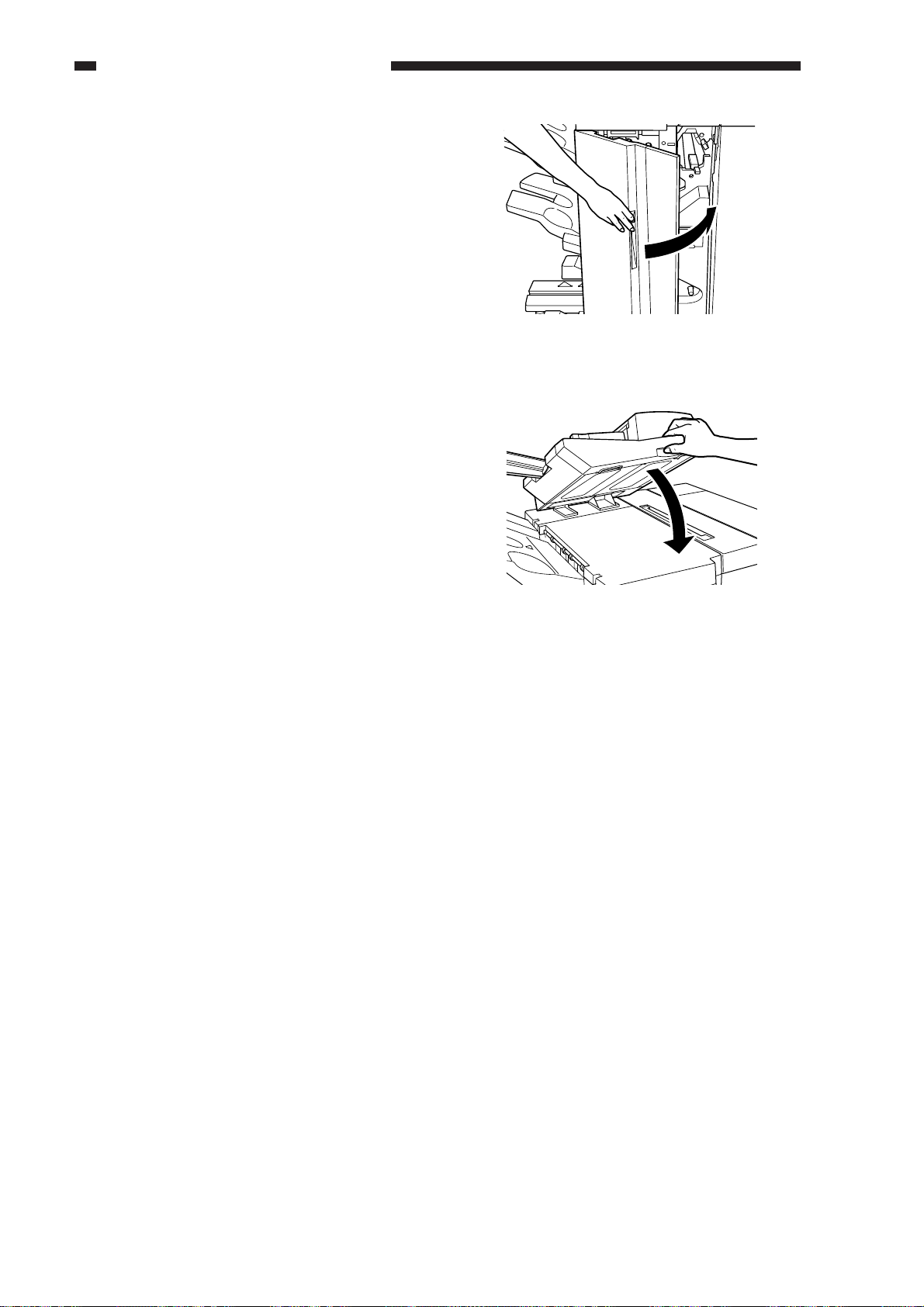

2) Open the cover inserter.

• This procedure is not necessary if the cover

inserter is not attached to the finisher.

3) Open the front cover.

Figure 1-302

Figure 1-303

1-14

Figure 1-304

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER-D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

4) Push the knob to the back and align the

of the knob to the range of .

5) Open the top cover and check the inside of

the finisher.

CHAPTER 1 GENERAL DESCRIPTION

Figure 1-305

6) Turn the green knob and remove any

jammed paper.

7) Close the top cover.

Figure 1-306

Figure 1-307

Figure 1-308

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER-D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-15

CHAPTER 1 GENERAL DESCRIPTION

8) Close the front cover.

9) Close the cover inserter.

• This procedure is not necessary if the cover

inserter is not attached to the finisher.

Figure 1-309

10) Follow the instructions in the display.

Figure 1-310

1-16

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER-D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

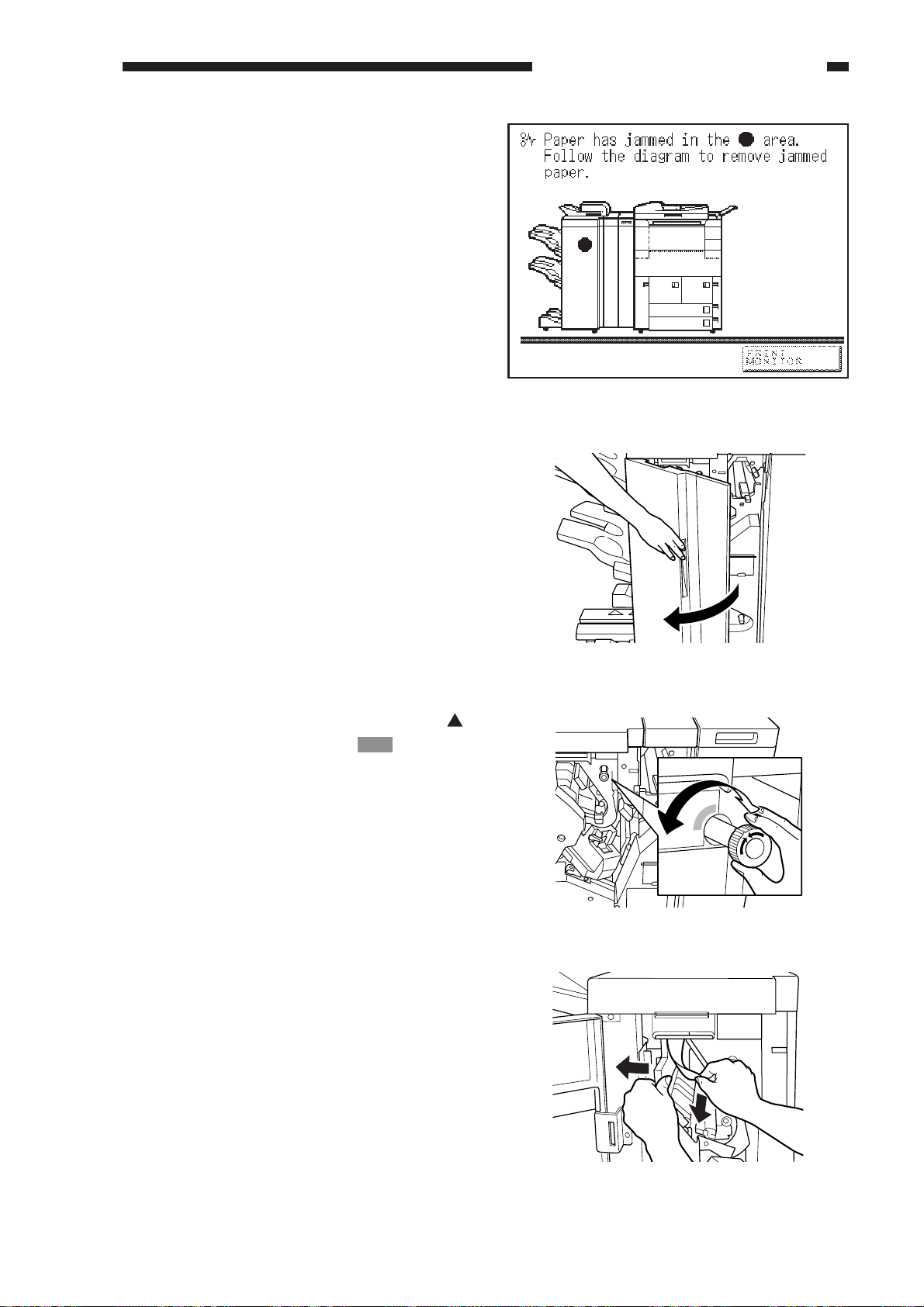

2. Paper Jam in the Front Cover

A paper jam has occurred in the area

which appears in the display. Follow the procedure described below to remove the jammed

paper.

1) Open the front cover.

CHAPTER 1 GENERAL DESCRIPTION

Figure 1-311

2) Push the knob to the back and align the

of the knob to the range of .

3) Open the paper delivery guide and re-

move any jammed paper.

Figure 1-312

Figure 1-313

Figure 1-314

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER-D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-17

CHAPTER 1 GENERAL DESCRIPTION

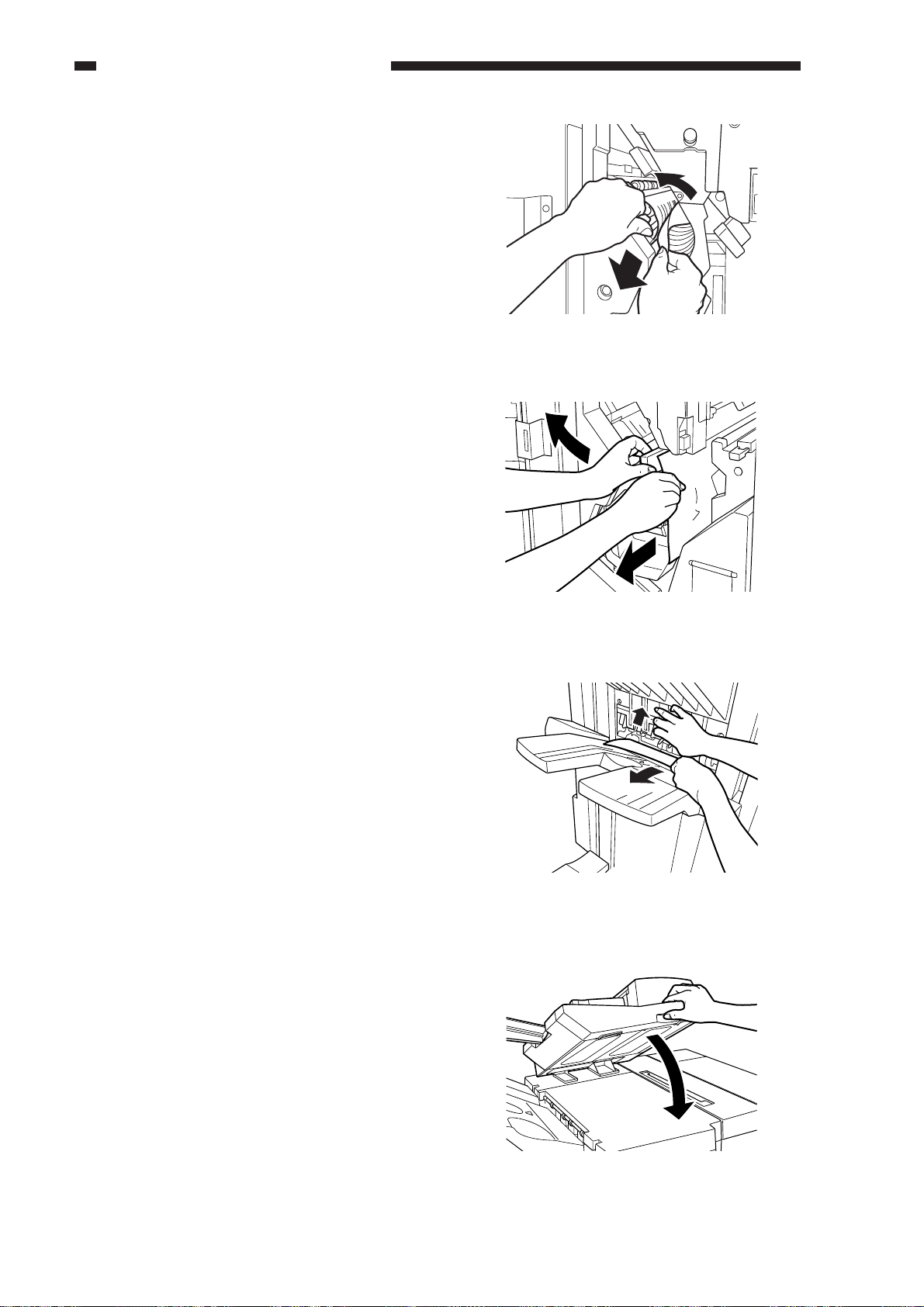

4) Lift the lever and remove any jammed paper.

5) Pull open the guide, and remove any

jammed paper.

• This procedure is not necessary if the sheet

is not fed from the cover inserter.

Figure 1-315

6) Open the open/close guide, and remove

any jammed paper from inside of the finisher.

• Do not remove any paper from the tray while

a copy job is being performed.

7) Close the cover inserter.

Figure 1-316

Figure 1-317

8) Follow the instructions in the display.

1-18

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER-D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Figure 1-318

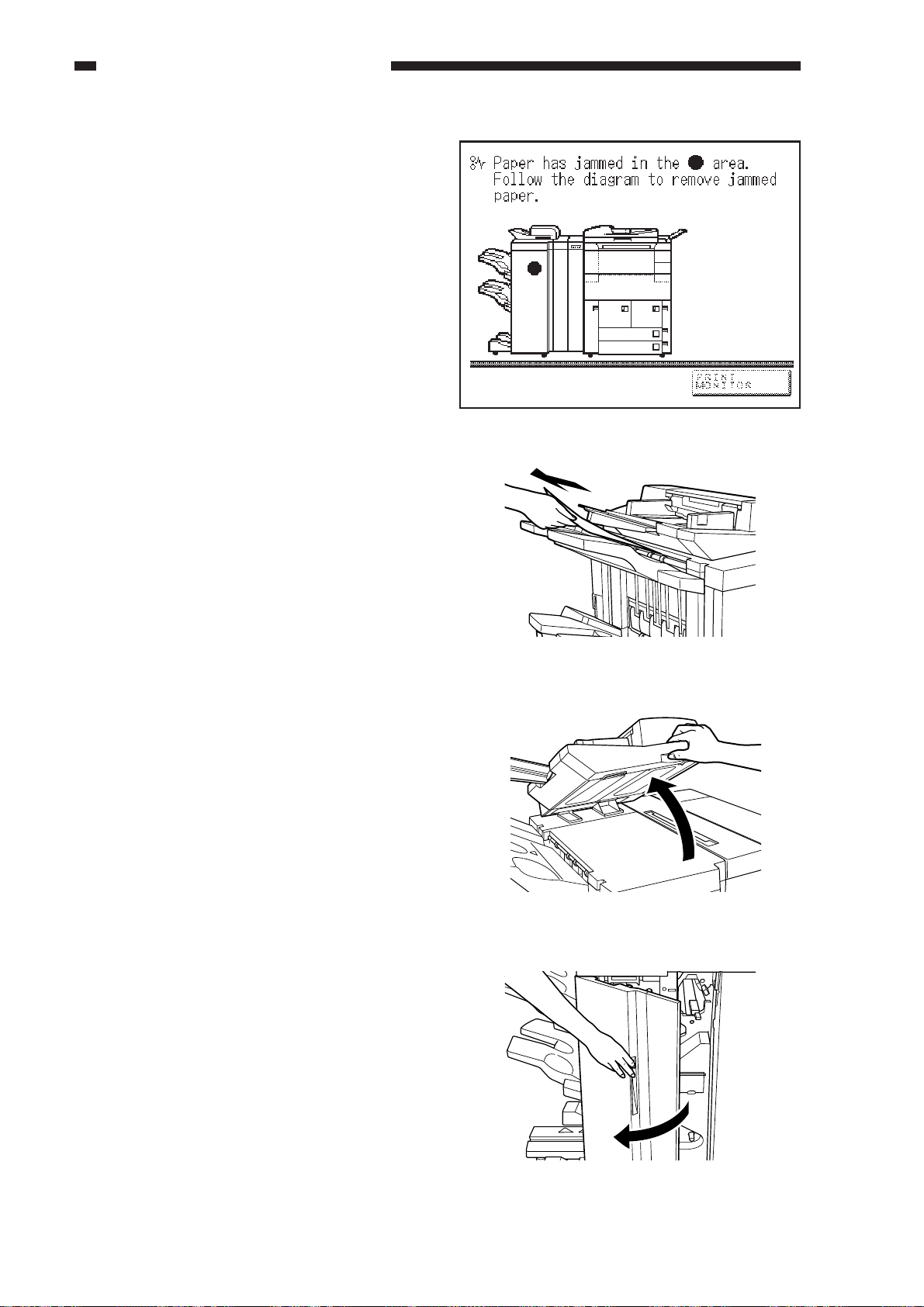

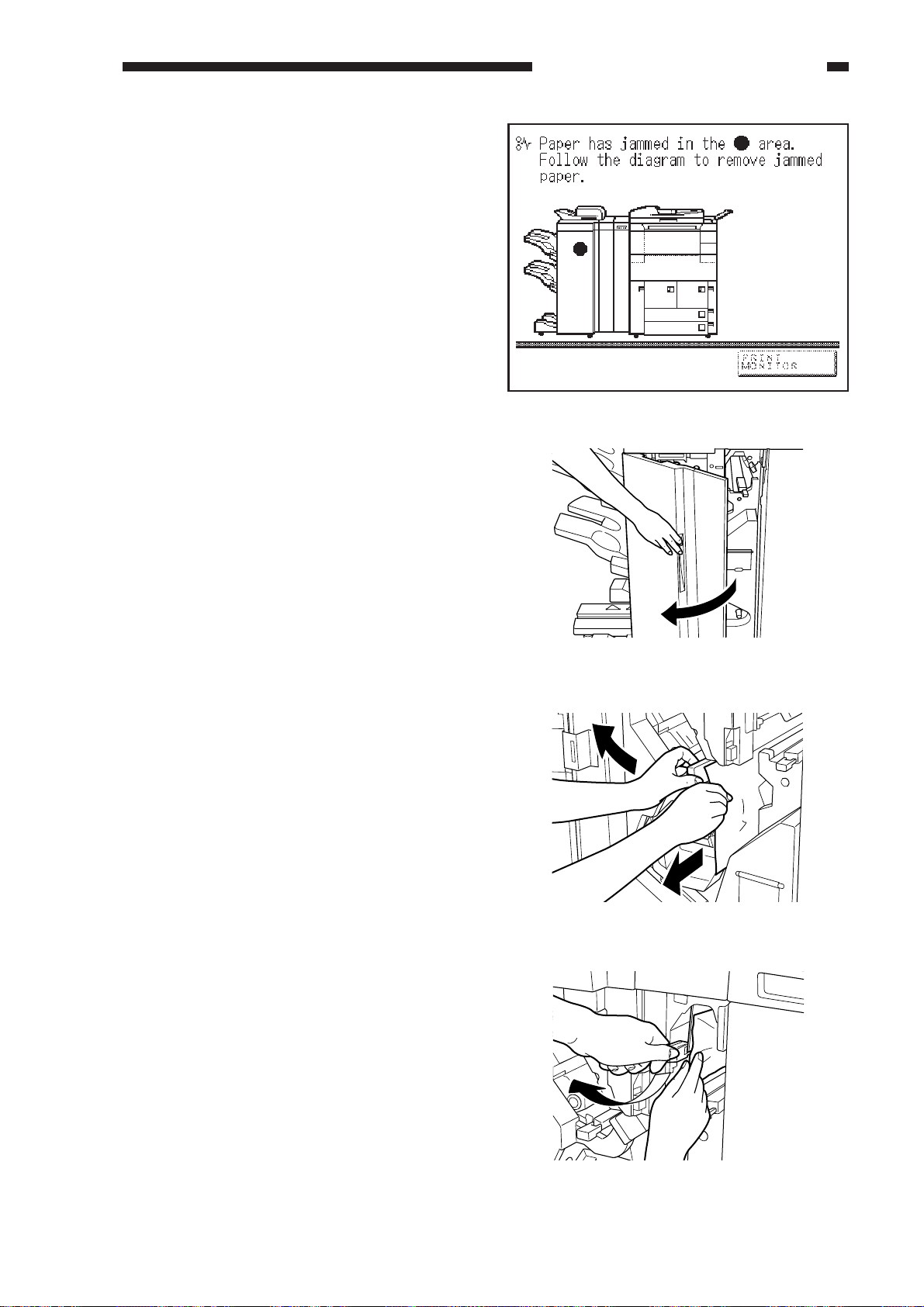

B. Removing Jams from the

Saddle Stitcher Unit

1. Paper Jam in the Saddle Stitcher

Unit

A paper jam has occurred in the area

which appears in the display. Follow the procedure described below to remove the jammed

paper.

1) Open the front cover.

CHAPTER 1 GENERAL DESCRIPTION

Figure 1-319

2) Open the guide, and remove any jammed

paper.

• This procedure is not necessary if the sheet

is not fed from the cover inserter.

3) Pull the upper guide of the saddle stitcher

unit to the left, and remove any jammed

paper.

• This procedure is not necessary if the sheet

is not fed from the cover inserter.

Figure 1-320

Figure 1-321

Figure 1-322

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER-D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-19

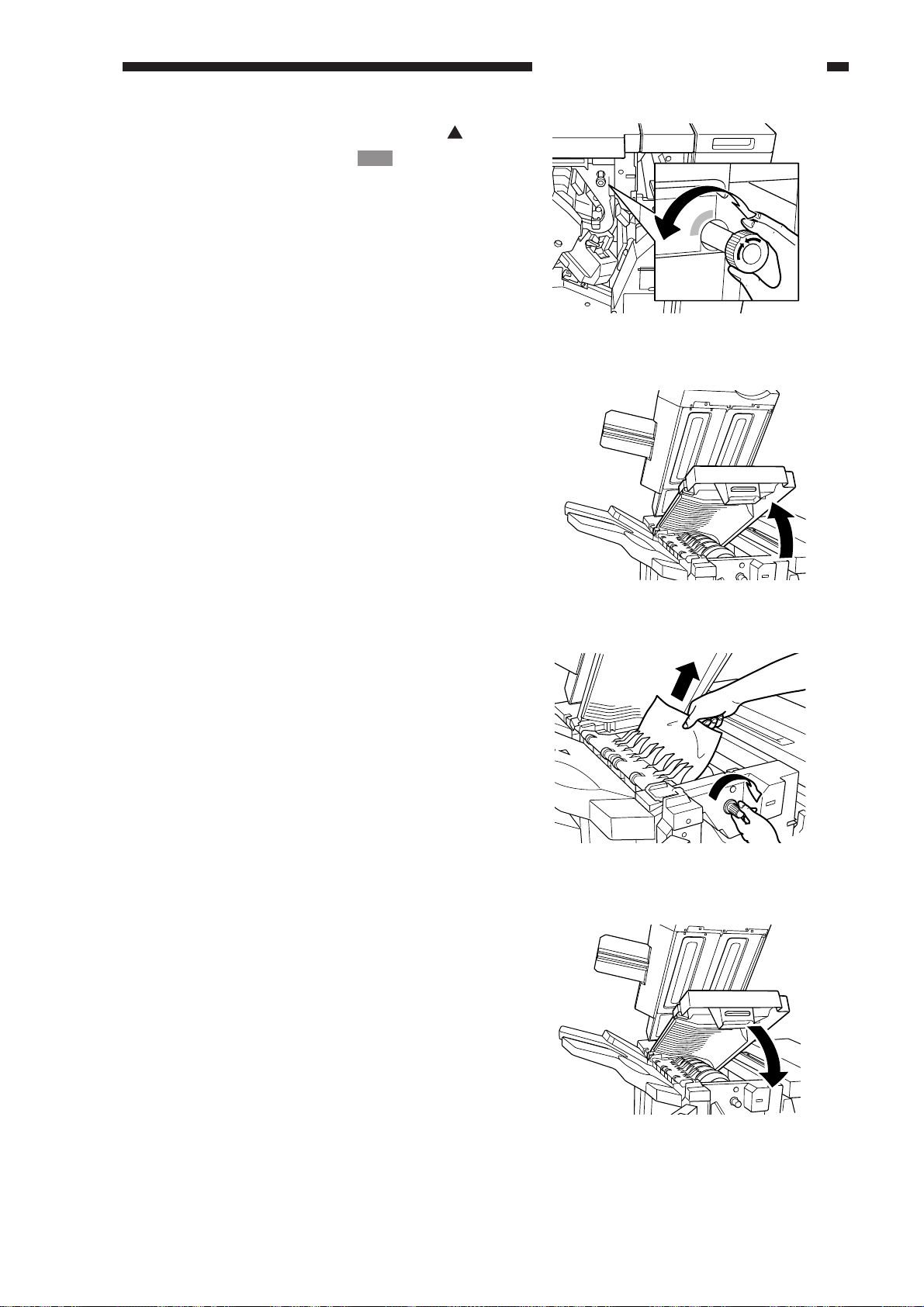

CHAPTER 1 GENERAL DESCRIPTION

4) Return the upper guide to its original position.

5) Pull up the lower guide of the saddle

stitcher unit, and remove any jammed paper.

Figure 1-323

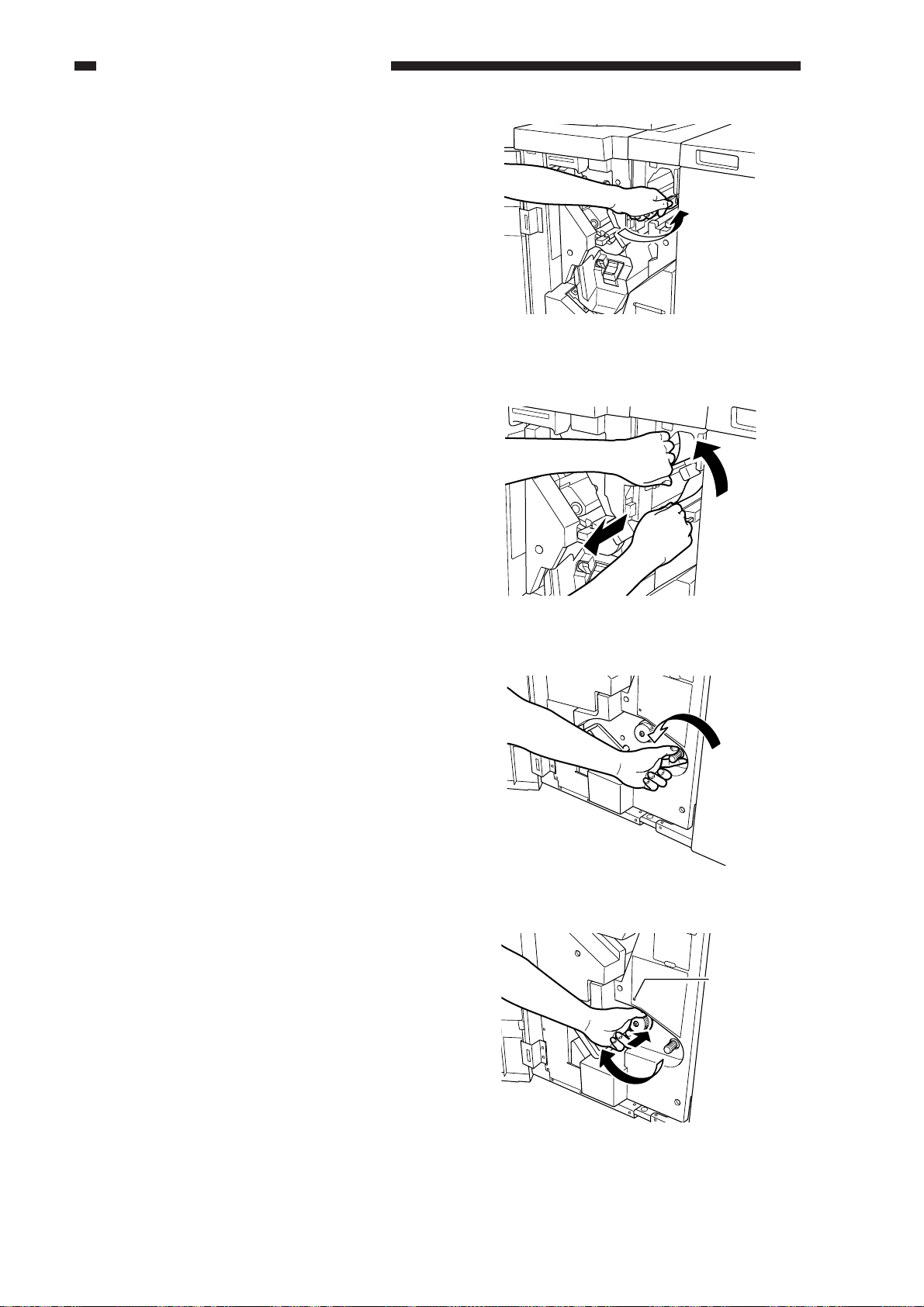

6) Turn the right knob to the left until it

stops.

7) Push in and turn the left knob to the right

until the lamp turns off.

Figure 1-324

Figure 1-325

Lamp

1-20

Figure 1-326

COPYRIGHT © 1999 CANON INC. CANON SADDLE FINISHER-D2 REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Loading...

Loading...