Canon GP605, Gp-605v, Gp-600 Schematics

SERVICE

HANDBOOK

REVISION 0

JAN. 1999

COPYRIGHT © 1999 CANON INC. CANON GP605/GP605V REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

FY8-23AW-000

IMPORTANT

THE INFORMATION CONTAINED HEREIN IS PUBLISHED BY CANON, INC., JAPAN.

SPECIFICATIONS AND OTHER INFORMATION CONTAINED HEREIN MAY DIFFER SLIGHTLY FROM

ACTUAL MACHINE VALUES OR THOSE FOUND IN ADVERTISING AND OTHER PRINTED MATTER.

ANY QUESTIONS REGARDING INFORMATION CONTAINED HEREIN SHOULD BE DIRECTED TO

THE COPIER SERVICE DEPARTMENT OF THE COMPANY.

COPYRIGHT 1999 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be strictly

supervised to avoid disclosure of confidential information.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIVISION

CANON INC.

5-1, Hakusan 7-chome, Toride, Ibaraki, 302-8501 Japan

COPYRIGHT © 1999 CANON INC. CANON GP605/GP605V REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CONTENTS

1

CHAPTER 1 MAINTENANCE / INSPECTION

I. SCHEDULED SERVICING ITEMS

....................................................1-1

A. Copier ....................................1-1

B. Work Steps ............................1-4

1. Work 1 ..............................1-4

2. Work 2 ..............................1-5

II. PERIODICALLY REPLACED

PARTS ........................................ 1-9

III. DURABLES TABLE ..................1-10

CHAPTER 2 STANDARDS AND ADJUSTMENTS

A. Adjusting Images ...................2-1

1. Adjusting the Image Position

..........................................2-1

2. Adjusting the Left/Right Image

Margin...............................2-2

3. Adjusting the Image Leading

Edge Margin .....................2-6

4. Adjusting the Left/Right Non-

Image Width......................2-6

5. Adjusting the Image Leading

..........................................2-7

B. Scanner System ....................2-8

1. Replacing the Scanner Drive

Cable ................................2-8

2. Adjusting the Scanner Mirror

Mount..............................2-10

3. After Replacing the Scanning

Lamp...............................2-11

C. Image Formation System.....2-12

1. Routing the Primary Charging

Assembly Grid Wire........2-12

2. Routing the Charging

Assembly Charging Wires

........................................2-13

3. Mounting the Drum Cleaning

Blade...............................2-16

4. Replacing the Developing

Blade...............................2-17

A. Copier ..................................1-10

B. Side Paper Deck ..................1-13

IV. POINTS TO NOTE FOR

SCHEDULED SERVICING.......1-15

V. IMAGE ADJUSTMENT BASIC

PROCEDURE ...........................1-16

1. Checking the Printer Side....1-16

2. Checking the Scanner Side

.............................................1-18

5. Replacing the Potential

Sensor/Potential Control PCB

........................................2-19

D. Pickup/Feeding System.......2-21

1. Orienting the Deck/Cassette

Pickup Roller................... 2-21

2. Orienting the Deck/Cassette

Separation Roller............2-22

3. Orienting the Deck/Cassette

Pickup Assembly Feeding

Roller ..............................2-22

4. Orienting the Manual Feed

Tray/Side Paper Deck Pickup

Roller ..............................2-23

5. Orienting the Manual Feed

Pickup Roller................... 2-24

6. Orienting the Side Paper Deck

Feeding Roller ................2-24

7. Adjusting the Pressure of the

Deck/Cassette Separation

Roller ..............................2-25

8. Adjusting the Pressure of the

Manual Tray Pickup/Feeding

Roller ..............................2-26

9. Mounting the Solenoids

........................................2-27

9-1.Position of the Fixing Inlet

Guide Solenoid (SL1) .....2-28

2

3

4

5

9-2.Position of the Fixing Cleaning

Belt Solenoid (SL2).........2-29

9-3.Position of the Delivery

Flapper Solenoid (SL3)

........................................2-30

9-4.Position of the Fixing/Feeding

Unit Locking Solenoid (SL4)

........................................2-30

9-5.Position of the Multifeeder

Pickup Latching Solenoid

(SL6) ...............................2-31

9-6.Position of the Deck (right)

Pickup Solenoid (SL7)....2-32

9-7.Position of the Deck (left)

Pickup Solenoid (SL8)....2-33

9-8.Position of the Cassette 3/4

Pickup Solenoid (SL9/10)

........................................2-34

9-9.Position of the Side Paper

Deck Pickup Roller Releasing

Solenoid..........................2-35

10. Routing the Manual Feed Tray

Assembly Side Guide Timing

Belt..................................2-35

11. Routing the Drive Belt.....2-36

E. Fixing System ......................2-37

1. Point to Note When Mounting

the Fixing Heater ............2-37

2. Position of the Fixing

Assembly Inlet Guide......2-37

3. Adjusting the Lower Roller

Pressure (nip) .................2-39

F. Laser Exposure System.......2-40

1 After Replacing the Laser Unit

........................................2-40

2 Checking the Laser Power

........................................2-41

G. Electrical Parts .....................2-45

1 After Replacing the CCD Unit

........................................2-45

2 After Replacing the Image

Processor PCB ...............2-46

3 After Replacing the MFC PCB

........................................2-47

4. After Replacing the Hard Disk

........................................2-48

5. After Replacing the DC

Controller PCB................2-49

6. Checking the Surface

Potential Control System

........................................2-49

7. Checking the Potential

System............................2-55

8. Potential Control System

Conversion Table ...........2-57

9. Checking the Environment

Sensor ............................2-61

10. Checking the

Photointerrupters ............2-62

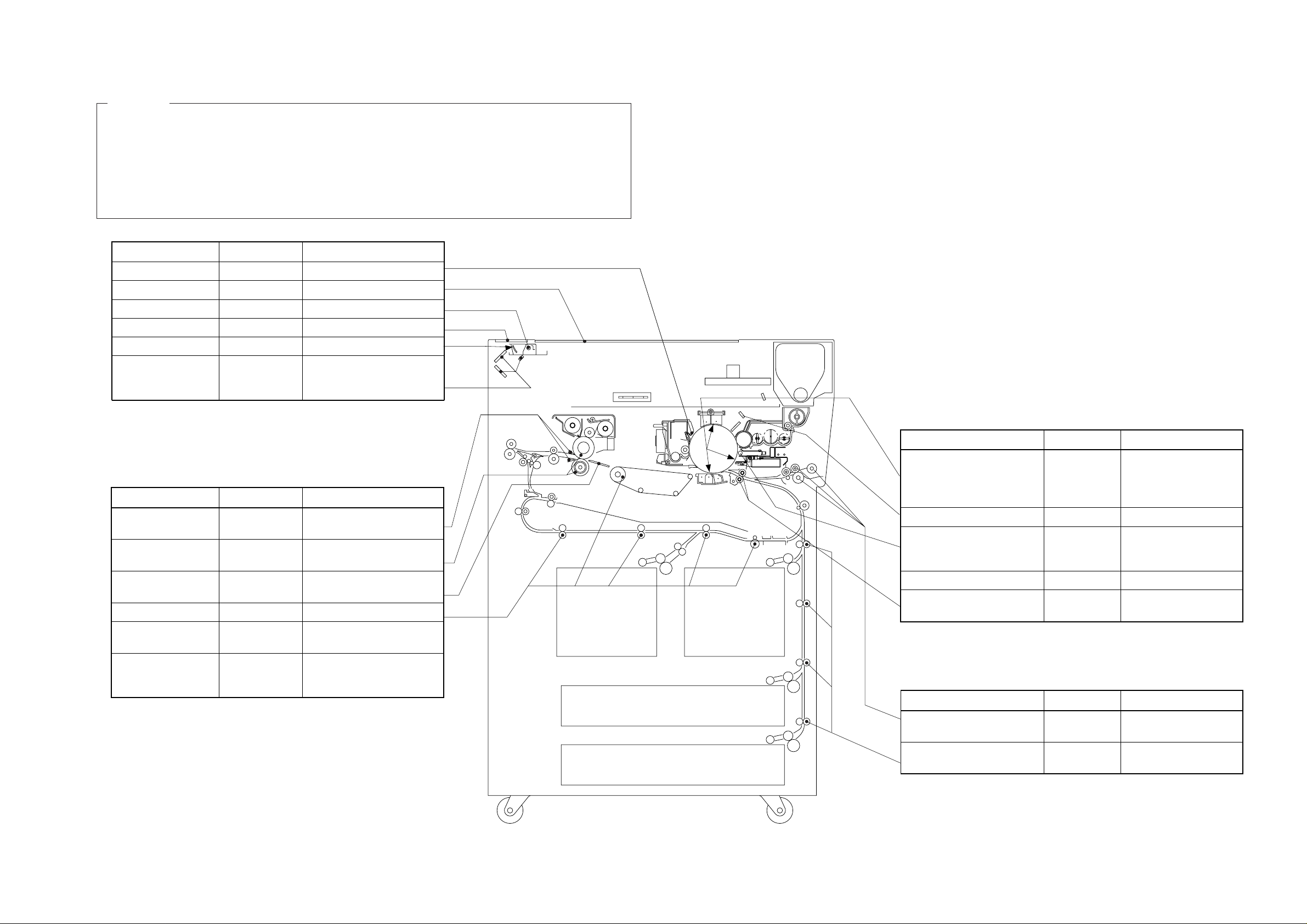

CHAPTER 3 ARRANGEMENT AND FUNCTION OF

ELECTRICAL PARTS

A. Clutches .................................3-2

B. Solenoids ...............................3-4

C. Motors ....................................3-6

D. Fans .......................................3-8

E. Sensors 1.............................3-10

F. Sensors 2 .............................3-12

G. Switches...............................3-14

H. Counters, Heaters, Fuses, and

Others ..................................3-16

I. PCBs....................................3-18

J. Side Paper Deck..................3-20

1. Sensors and Switches

........................................3-20

2. Motors, Clatches, Solenoids,

and PCBs........................3-22

K. Variable Registers (VR), Light-

Emitting Diodes, and Check Pins

by PCB.................................3-24

1. MFC PCB........................3-25

2. Image Processor PCB

........................................3-26

3. DC Controller PCB .........3-27

4. DC Power Supply PCB

........................................3-28

5. Relay PCB ......................3-28

6. Control Panel CPU PCB

........................................3-29

7. HV-DC PCB ....................3-30

8. Side Deck Driver (side paper

deck) ...............................3-31

CHAPTER 4 SERVICE MODE

A. Outline....................................4-1

1. Starting Service Mode and

Selecting an Item..............4-2

2. Ending Service Mode

..........................................4-3

3. Backing Up the RAM ........4-3

4. Basic Operation ................4-4

B. DISPALY Control Display Mode

...............................................4-6

CHAPTER 5 SELF DEAGNOSIS

A. Copier Self Diagnosis ............5-1

B. ADF Self Diagnosis................5-9

APPENDIX

C. I/O Input/Output Display Mode

.............................................4-16

D. ADJUST Adjustment Mode

.............................................4-43

E. FUNCTION Operation/Inspection

Mode ....................................4-56

F. OPTION Settings Mode .......4-67

G. PG Test Print .......................4-78

H. COUNTER Mode .................4-82

C. Finisher Self Diagnosis........5-10

A. GENERAL TIMING CHART....... A-1

B. LIST OF SIGNALS/

ABBREVIATIONS ...................... A-3

C. GENERAL CIRCUIT DIAGRAM

................................................... A-9

D. SPECIFICATIONS ................... A-17

1. Copier ................................. A-17

2. Side Paper Deck-C1........... A-25

E. SPECIAL TOOLS TABLE ........ A-26

F. SOLVENTS/OILS..................... A-28

CHAPTER 1 MAINTENANCE / INSPECTION

I . SCHEDULED SERVICING ITEMS

Caution:

Do not use solvents/oils other than those shown herein.

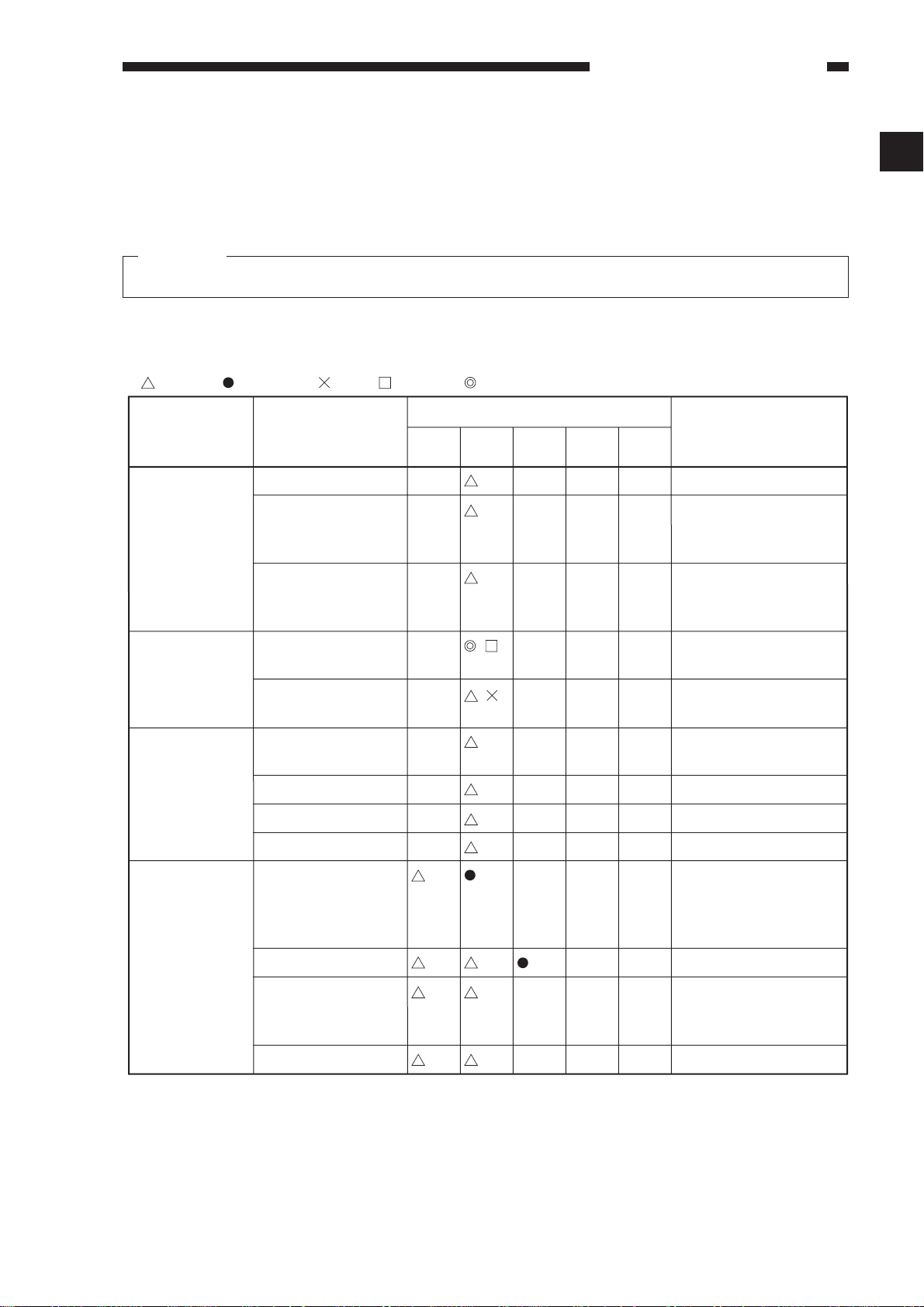

A. Copier

MAINTENANCE / INSPECTION

1

: Clean

Unit

Externals/

controls

Scanner

Optical path

: Replace : Oil : Adjust : Inspect

Intervals

Part

Copyboard glass

Ozone filter

(FM2, FM8)

Dust-proofing filter

(FM1, FM3, FM4;

FM10, FM14)

Scanner cable Check/adjust for the

Scanner rail Apply silicone oil

No. 1 through

No. 3 mirrors

Dust-proofing glass

Reflecting plate

Instal-

lation

every

250,000

every

500,000

every

750,000

every

1,000,000

Remarks

Remove the dust from

the surface of the filter.

See Figure 1-101.

Remove the dust from

the surface of the filter.

See Figure 1-101.

first 250,000 copies.

(FY9-6011).

Charging

assembly

Standard white plate

Charging wire

(primary, pretransfer,

transfer/separation)

Grid wire (primary)

Charging assembly

shield plate (each

assembly)

Roller electrode

Table 1-101-1

1-1

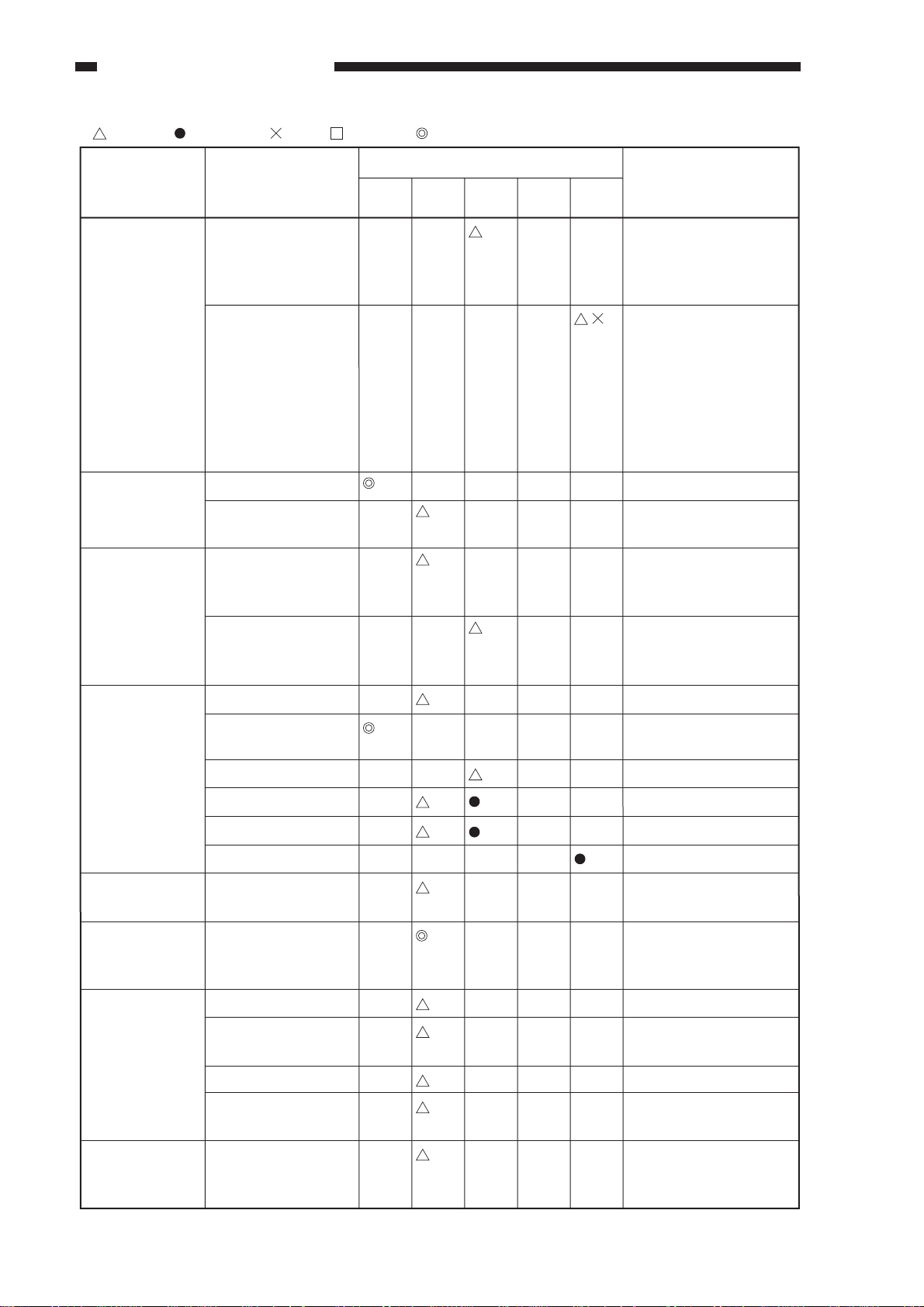

MAINTENANCE / INSPECTION

: Clean

Unit

Photosensitive

drum

Developing

assembly

Cleaner

: Replace : Oil : Adjust : Inspect

Intervals

Part

Photosensitive

drum

Slip ring electrode

(for drum heater)

Developing cylinder

Developing

assembly roll

Toner replace the

(rear/front)

Instal-

lation

every

250,000

every

500,000

every

750,000

every

1,000,000

Use alcohol and drum

cleaning powder (CK-

0429); for steps, see

B.2. "Work Steps."

Clean the following with

alcohol; then, apply

grease (FY9-6008):

• electrode of the slip

• protrusion of

• static brush

For details of work,

see item 1 of

B.1."Work."

Remarks

ring

electrode

Fixing

assembly

Delivery

assembly

Waste toner

collecting

mechanism

Pickup/feeding

assembly

Magnet roller For details of work,

see item 2 of

B.2."Work."

Inlet guid

Cleaning belt Remove the slack at

installation.

Oil receptacle

Thermistor

No. 2 thermistor

Thermal switch

Separation claw

(upper/lower)

Waste toner case Check/remove.

Transfer guide

Registration roller

(upper, lower)

Feeding belt

Duplexing

assembly

1-2

Various feeding

rollers

Duplexing

horizontal

registration sensor

Table 1-101-2

Ozone filter for FM8

MAINTENANCE / INSPECTION

Ozone filter

for FM2

Dust-proofing filter for FM4

Dust-roofing filter

for FM10

Dust-proofing filter

for FM1

Dust-proofing filter

for FM14

Dust-proofing filter

for FM3

Figure 1-101

1-3

MAINTENANCE / INSPECTION

B. Work Steps

Perform the following for the parts associ-

ated with the drum:

1. Work 1

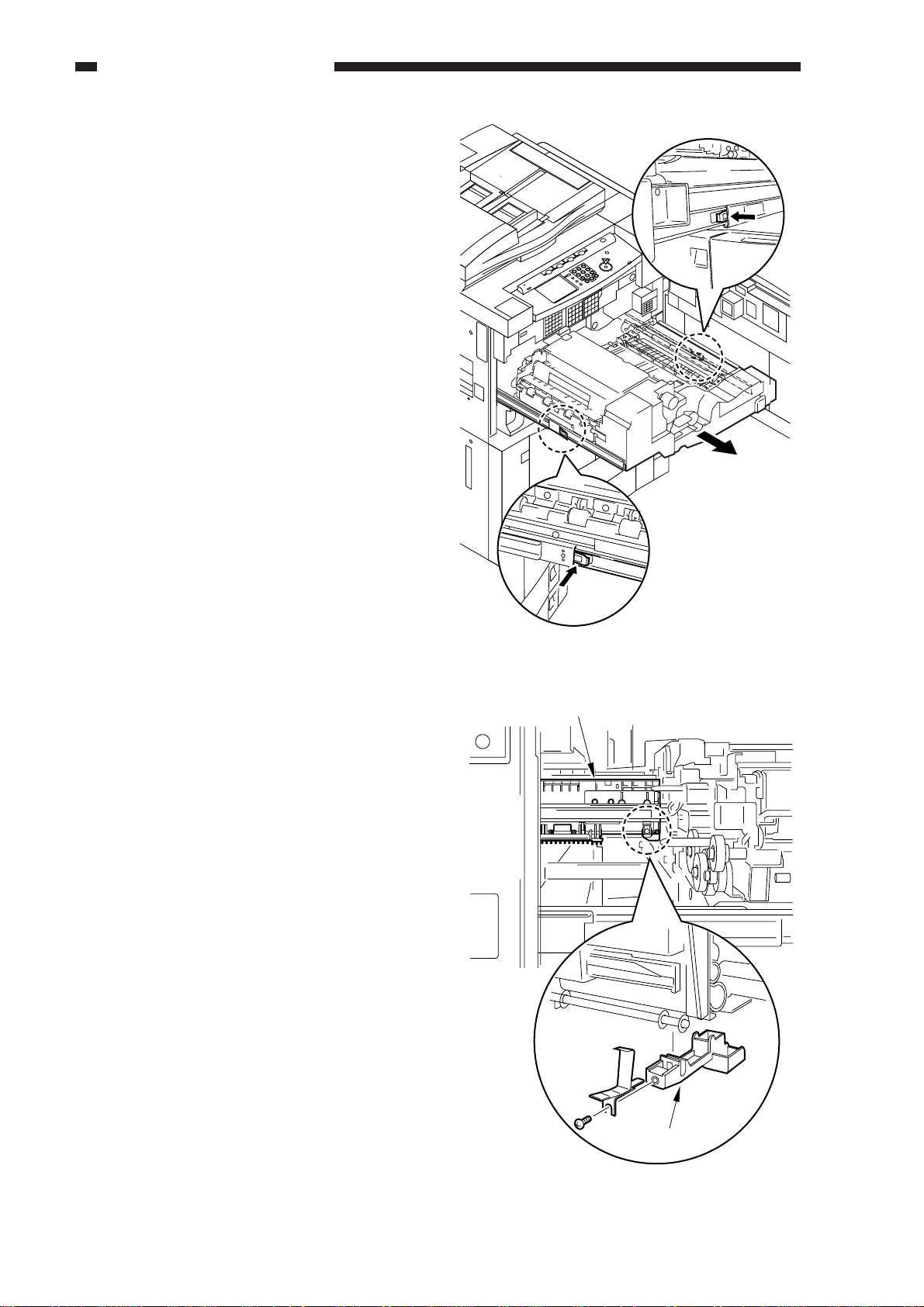

a. Cleaning the toner pan

1) Slide out the fixing feeding unit from the

copier.

2) Unlock the slide rails, and slide the fixing/

feeding unit farther out.

3) Remove the screw [3], and remove the

toner pan (rear, front); then, remove the

toner from the toner pan.

Figure 1-102

Cleaning assembly

[3]

1-4

Toner pan

Figure 1-103

MAINTENANCE / INSPECTION

[1]

[2]

[3]

CK-0429

Cleaning assembly

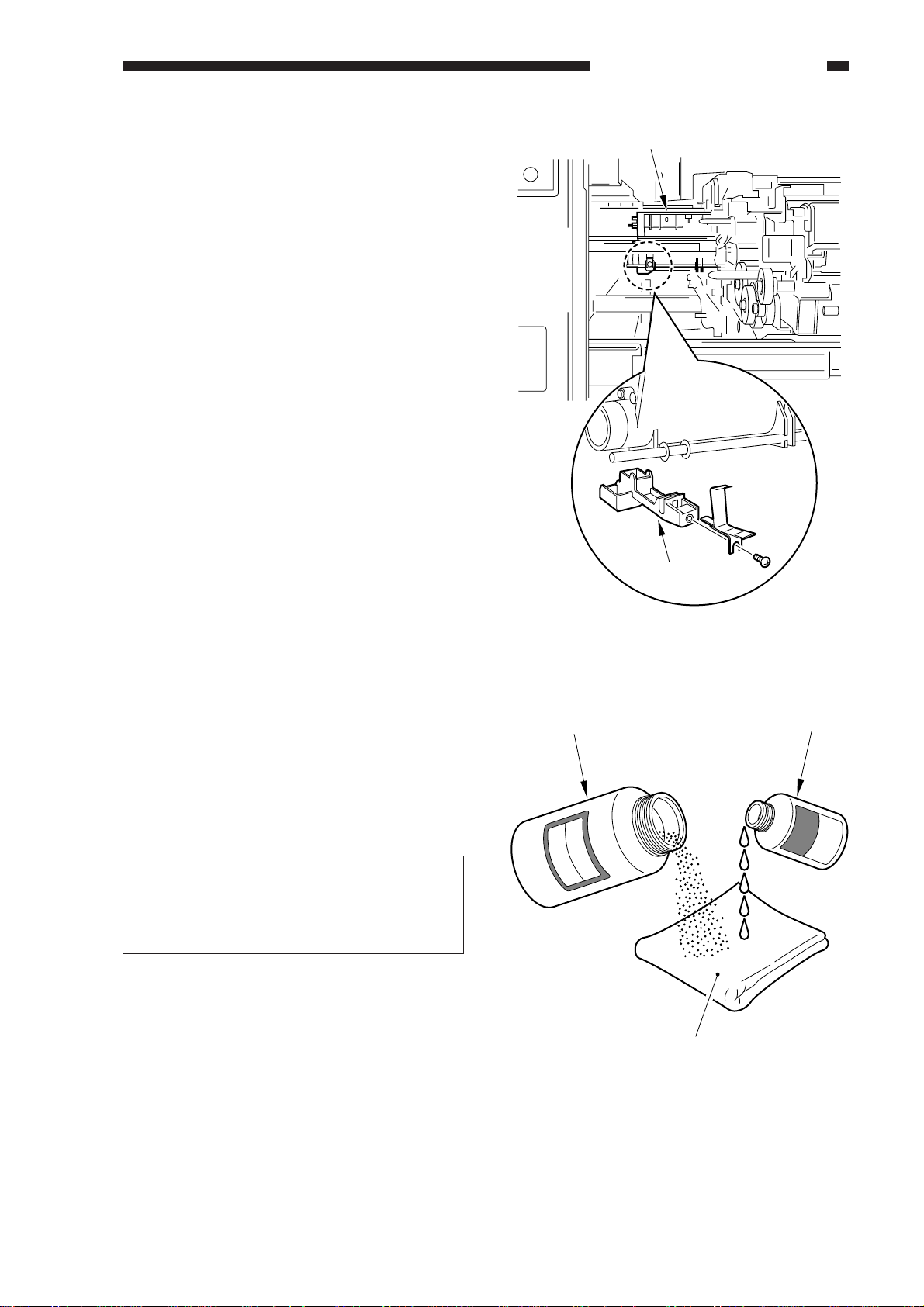

2. Work 2

a. Cleaning the photosensitive drum.

b. Removing the toner from the magnet

roller assembly.

c. Reversing/replacing the cleaning

blade.

Caution:

Do not rotate the magnet roll drive assembly during work. Otherwise, waste

toner may fall through the cleaner assembly.

1) Slide out the process unit. (Be sure to

place the drum protective sheet over the

fixing/feeding unit.)

2) Take out the photosensitive drum.

3) Moisten lint-free paper [1] with 5 to 10 cc

of alcohol [2]; then, pour 0.2 to 0.3 g of

drum cleaning powder (CK-0429) [3] on

the lint-free paper.

[3]

Toner pan

Figure 1-104

Figure 1-105

1-5

MAINTENANCE / INSPECTION

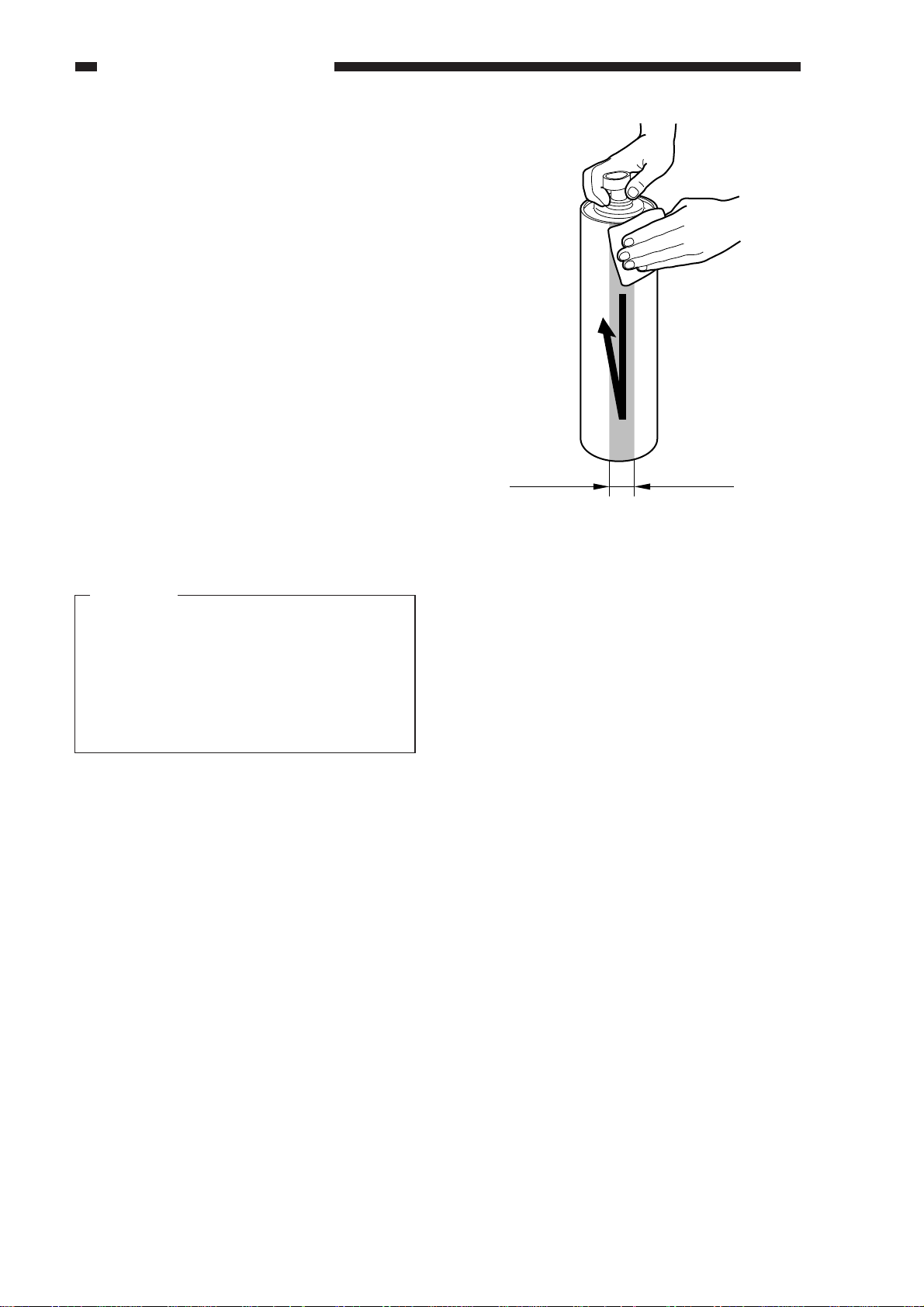

4) While butting the lint-free paper relatively

strongly against the photosensitive drum,

wipe the surface of the drum from the

front to the rear and from the rear to the

front.

5 to 10cm

Caution:

• Keep the widths of cleaning to 5 to 10

cm in the peripheral direction of the

drum.

• Move the lint-free paper back and forth

15 to 20 times over a single area.

Forcing the lint-free paper will not affect the life of the drum.

5) When the alcohol has evaporated, dry

wipe the surface with lint-free paper. If

the area is uneven, go back to step 4), and

increase the back-and-forth movements.

6) Rotate the drum for the width (5 to 10

cm), and repeat steps 3) through 5) until

the entire area of the surface has been

cleaned.

7) Remove the cleaning blade assembly.

Figure 1-106

1-6

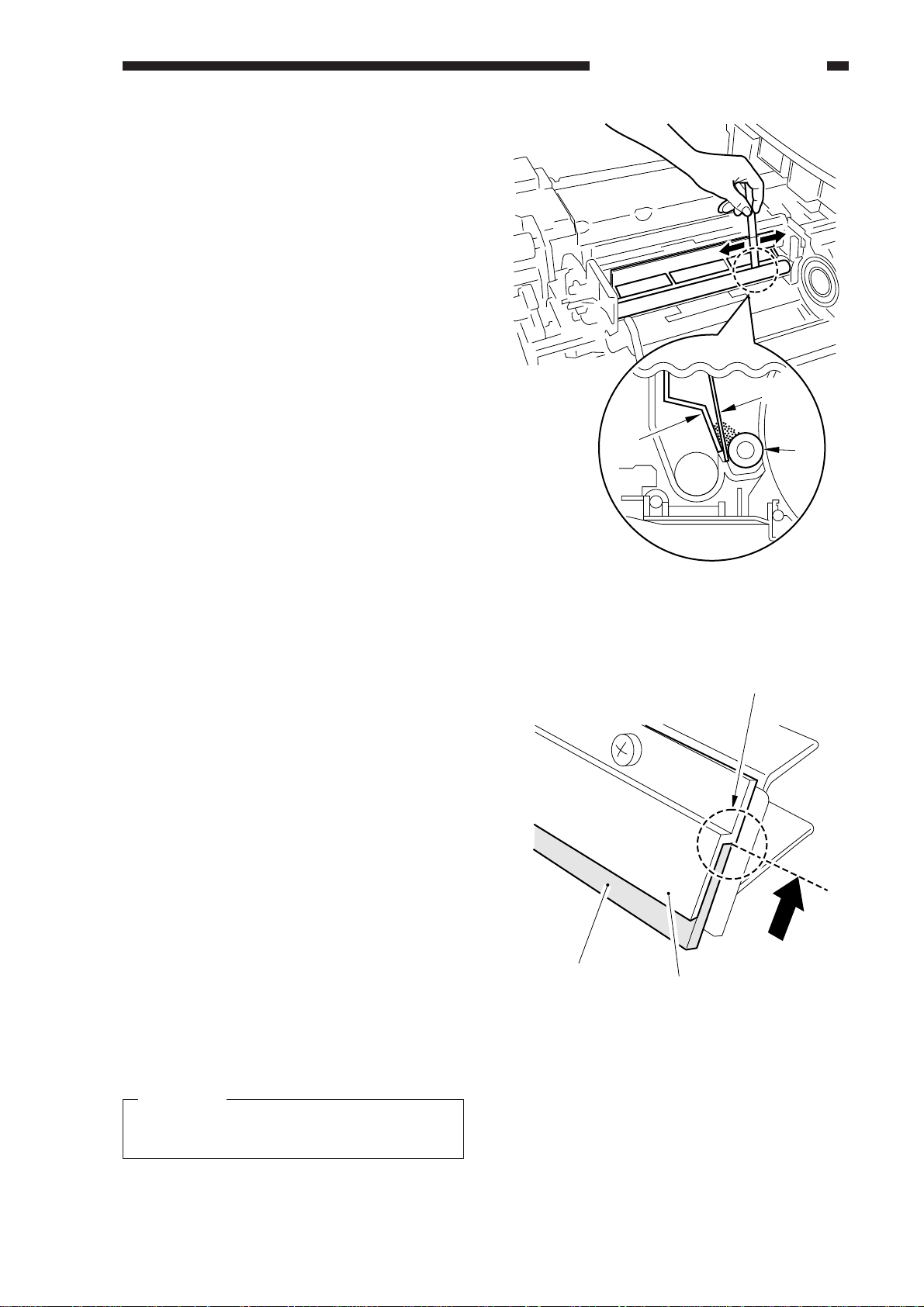

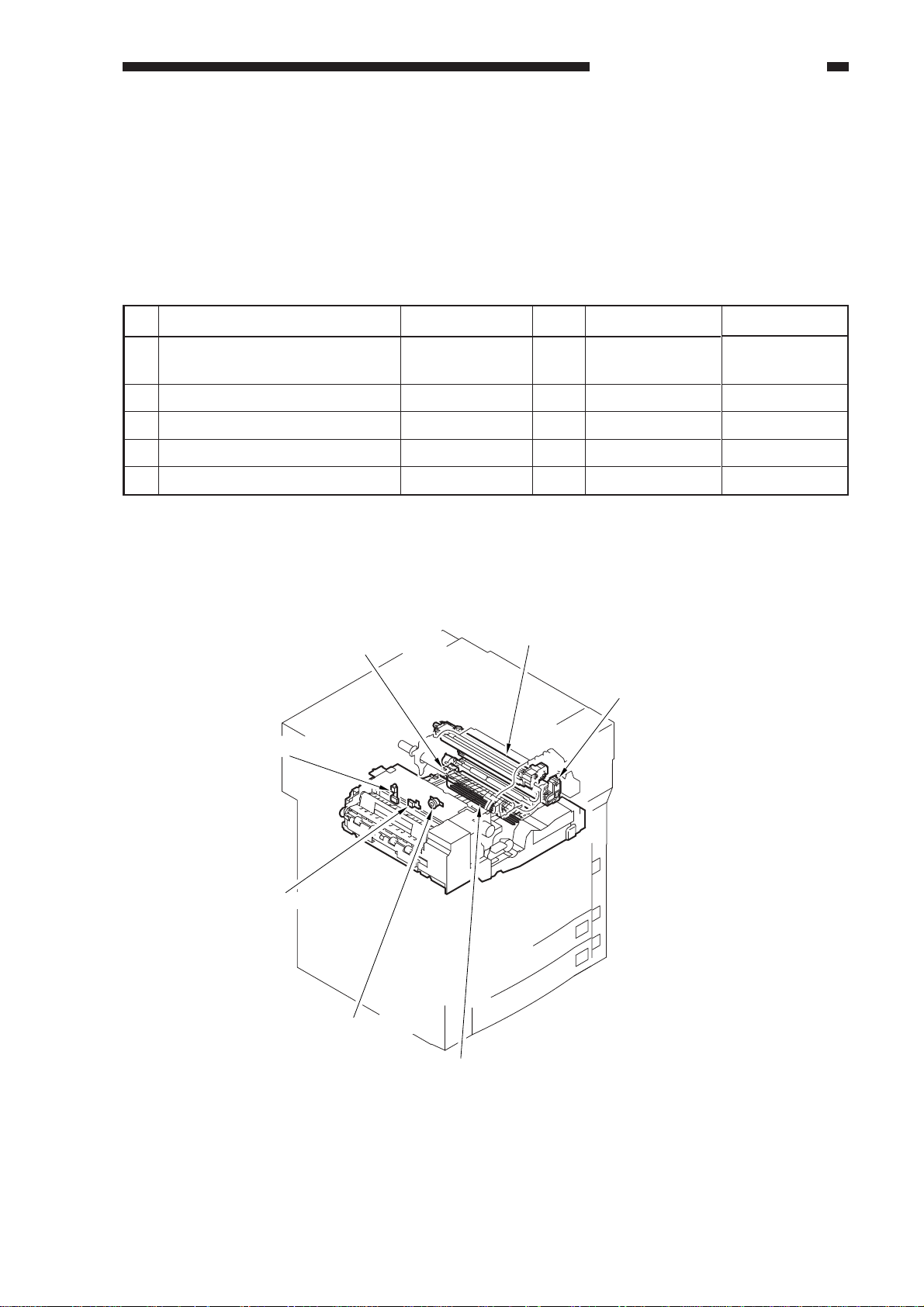

8) Insert a ruler [6] between the magnet roll

[7]

[8]

Butted against the edge.

[4] and the scraper [5], and move it from

the front to the rear and then from the rear

to the front to break any cake of toner.

MAINTENANCE / INSPECTION

[6]

9) Remove the cleaning blade from the

cleaning blade assembly.

10) Put the reversed or new cleaning blade [7]

against the edge of the rear of the blade

retaining plate [8].

[5]

Figure 1-107

[4]

Figure 1-108

Caution:

When butting the cleaning blade, be sure

to apply force to eliminate any gap.

1-7

MAINTENANCE / INSPECTION

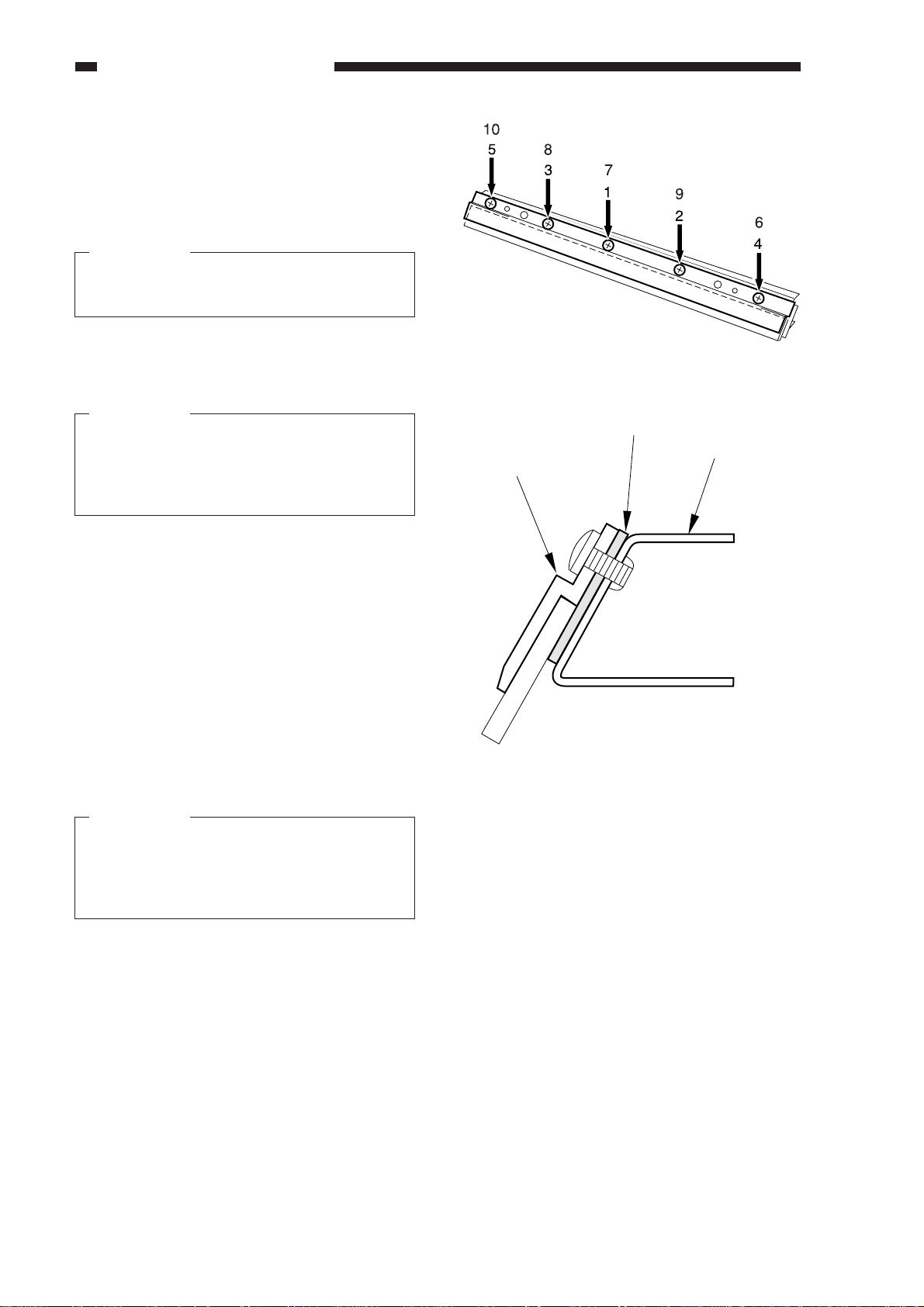

11) Tighten the screws on the blade retaining

plate in the order indicated.

• Tighten temporarily for screws 1

through 5.

Caution 1:

While the blade is held in place with the

plate, tighten the screws temporarily.

• Tighten fully for screws 6 trough 10.

Figure 1-109

Caution 2:

When mounting the cleaning blade, be

sure to put the blade auxiliary plate between the blade support plate and the

blade back plate.

Caution 3:

After mounting the cleaning blade, rotate the drum; if toner slips through the

blade, repeat the foregoing steps. If the

fault is not corrected, replace the blade.

Blade auxiliary plate

Blade back plate

Blade support plate

Figure 1-110

1-8

MAINTENANCE / INSPECTION

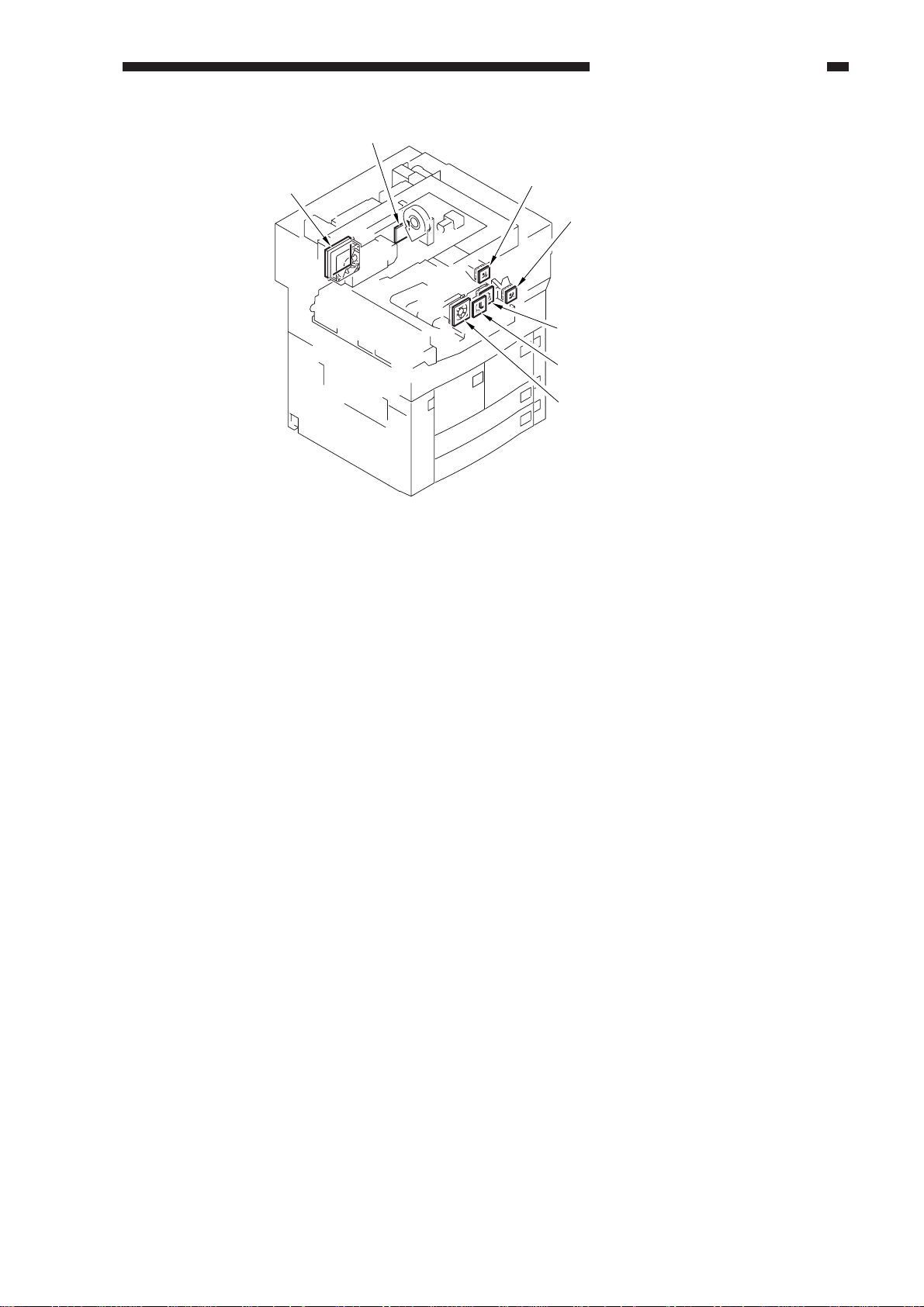

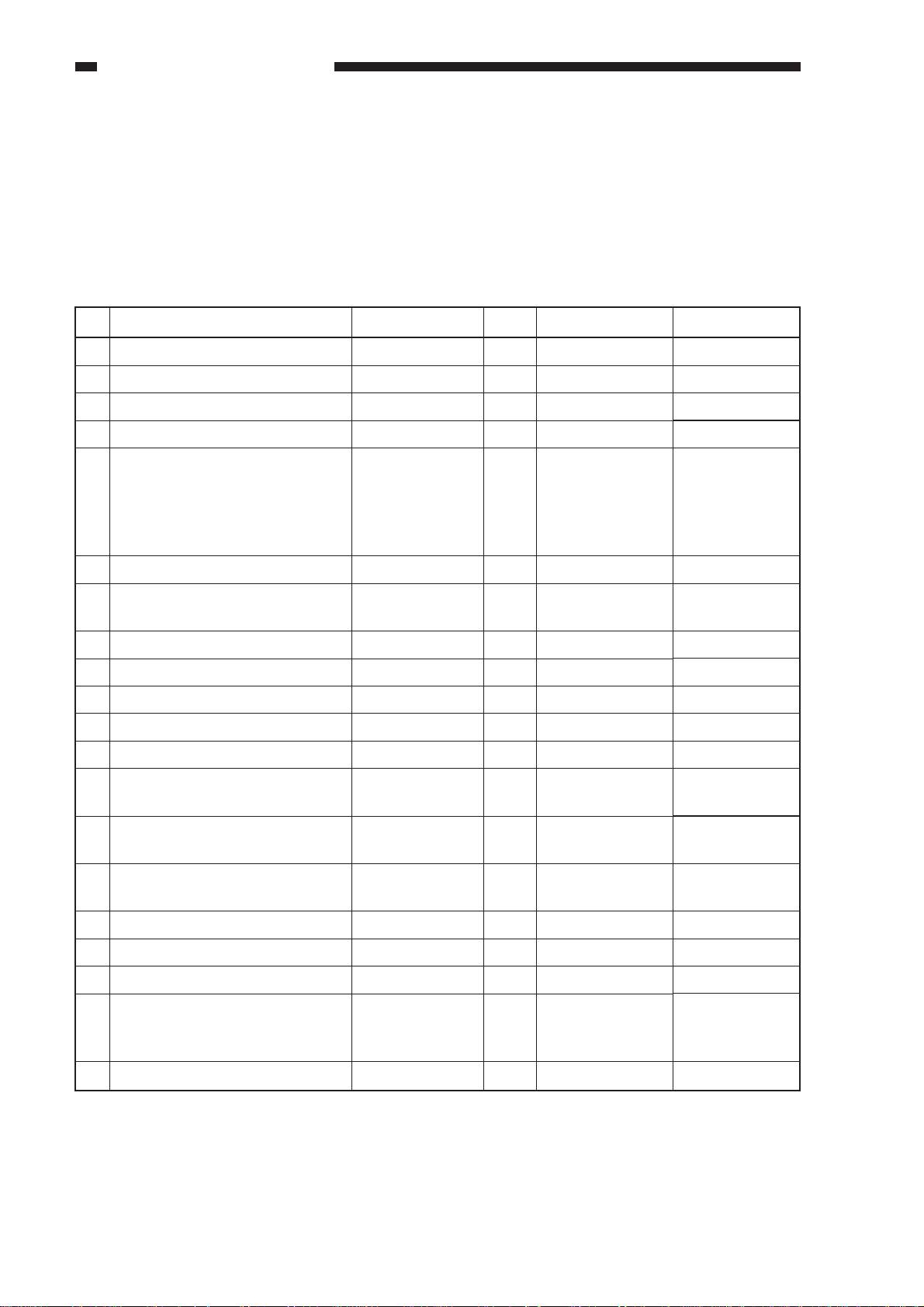

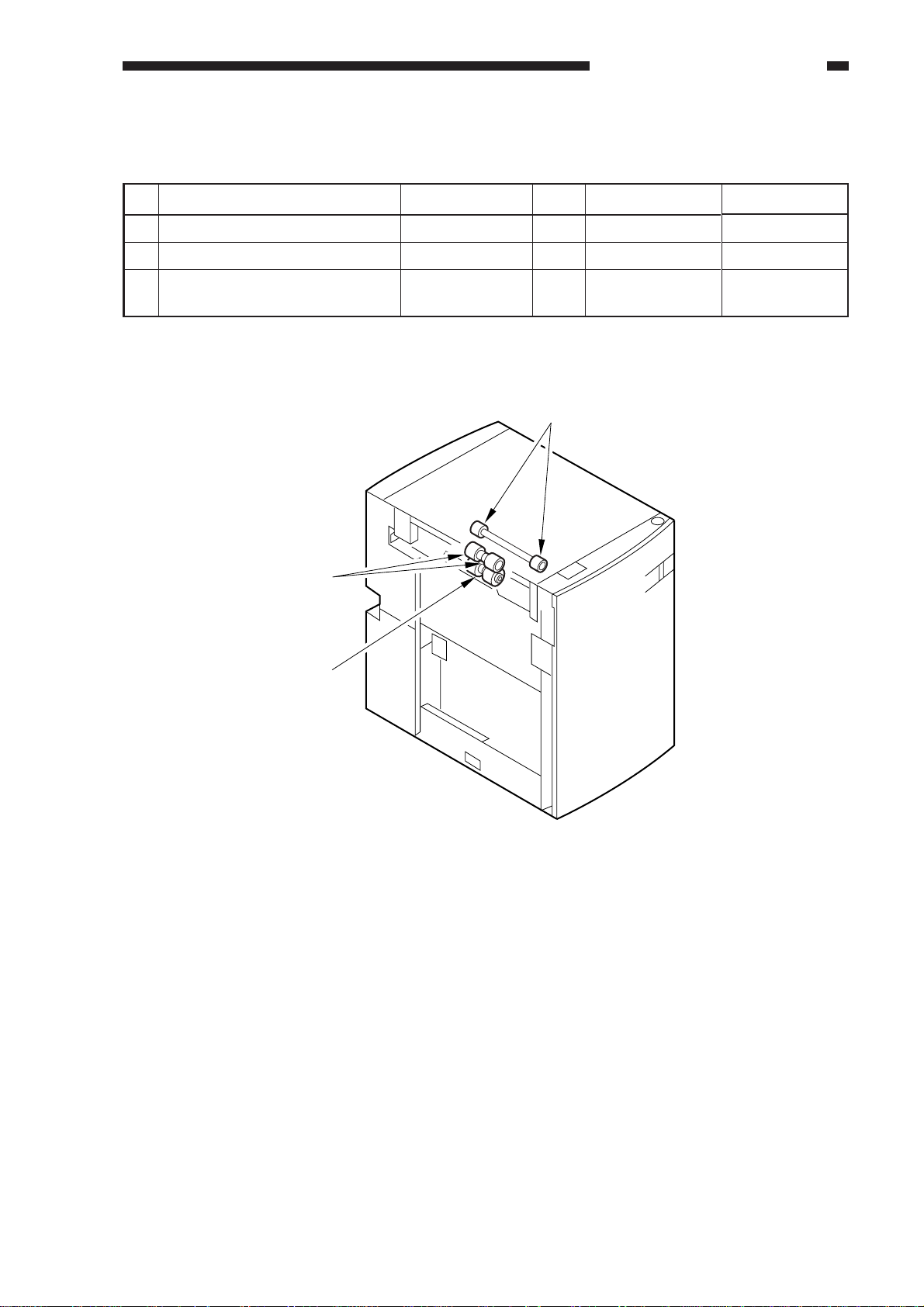

II . PERIODICALLY REPLACED PARTS

To maintain the performance of the machine at a specific level, you must replace the parts in

Table 1-201 on a periodical basis. (Once they fail, they will appreciably affect the machine regardless of external change or damage.)

Schedule the replacement so that it will coincide with a periodical visit.

As of December 1998

No.

1

Primary, pre-transfer, separation

charging wire

2

Primary grid wire

3

Thermistor

4

No. 2 thermistor

5

Thermal switch

Note: The above values are estimates only, and are subject to change based on future data.

Parts name

Parts No.

FY3-0030-000

FY1-0883-000

FY7-7463-000

FH7-7464-000

FH7-6281-000

Q’ty

AR

AR

1

1

1

Life (copies)

250,000

500,000

500,000

500,000

1,000,000

Table 1-201

[1] Transfer/separ ation

charging assembly

[4] No. 2 thermistor

[1] Primary charging assembly

[1] Pre-transfer

charging assembly

Remarks

[3] Thermistor

[5] Thermal switch

[2] Primary grid wire

Figure 1-201

1-9

MAINTENANCE / INSPECTION

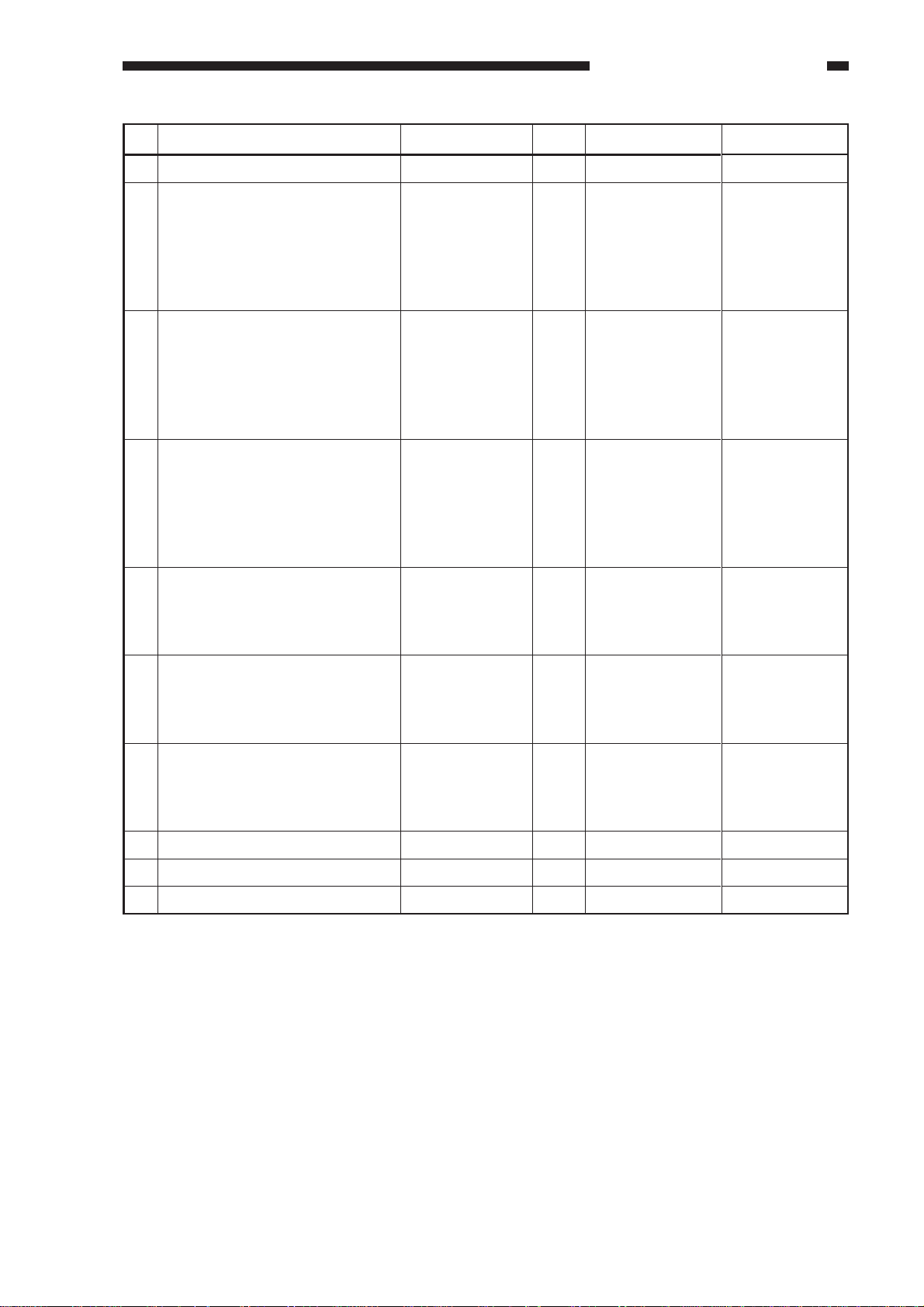

III . DURABLES TABLE

Table 1-301 shows the parts that may require replacement because of deterioration or damage

at least once over the period of machine warranty. Replace them when they have failed.

A. Copier

As of December 1998

No.

1

Scanning lamp

2

Developing cylinder

3

Developing assembly roll

4

Cleaner separation claw

5

Cleaning blade

6

Primary charging assembly

7

Transfer/separation charging

assembly

8

Pre-transfer charging assembly

9

Primary charging wire cleaner 1

10

Primary charging wire cleaner 2

11

Transfer charging wire cleaner 1

12

Transfer charging wire cleaner 2

Parts name

Parts No.

FH7-3347

FB4-1819

FS5-6579

FB4-8018

FB4-1596

FG6-2015

FG6-2045

FG6-2016

FF2-3552

FF2-3551

FF5-6883

FF5-6884

Q’ty

1

1

2

3

1

1

1

1

2

2

1

1

Life (copies)

200hr

1,000,000

1,000,000

250,000

1,000,000

1,000,000

1,000,000

1,000,000

250,000

250,000

500,000

500,000

Remarks

Use both edges;

one for 500,000

copies. Apply

toner after

replacement.

13

Separation charging wire

cleaner

Pre-transfer charging wire

14

cleaner

15

Pre-transfer charging assembly

scraper

16

Upper fixing roller

17

Lower fixing roller

18

Fixing cleaning belt

19

Insulating bush (front, rear)

20

Delivery upper separation claw

FF5-7891

FF5-3090

FF5-7934

FB2-7200

FB4-2220

FB4-7491

FB2-7239

FC1-0391

Table 1-301-1

1

1

1

1

1

1

2

6

250,000

500,000

500,000

500,000

500,000

500,000

500,000

500,000

Simultaneously

with upper

fixing roller.

1-10

MAINTENANCE / INSPECTION

No.

21

Delivery lower separation claw

22

Pickup roller (deck, cassette)

23

Pickup/feeding roller (deck,

cassette)

24

Separation roller (deck, cassette)

25

Pickup roller (manual feed tray)

Parts name

Parts No.

FA2-9037

FB4-2033

FB4-2034

FB2-7777

FB4-2033

Q’ty

2

8

8

4

2

Life (copies)

1,000,000

250,000

250,000

250,000

120,000

Remarks

Actual copies

made; may be

checked in

service mode.

(Use 2 for each

holder.)

Actual copies

made; may be

checked in

service mode.

(Use 2 for each

holder.)

Actual copies

made; may be

checked in

service mode.

(Use 2 for each

holder.)

Actual copies

made; may be

checked in

service mode.

26

Pickup/feeding roller (manual

feed tray)

27

Separation roller (manual feed

tray)

28

Decurling guide (Rear)

29

Decurling guide (Center)

30

Decurling guide (Front)

FB4-2035

FB2-7545

FF5-9544

FF5-9413

FF5-9543

Table 1-301-2

2

1

1

1

1

120,000

120,000

500,000

500,000

500,000

Actual copies

made; may be

checked in

service mode.

Actual copies

made; may be

checked in

service mode.

1-11

MAINTENANCE / INSPECTION

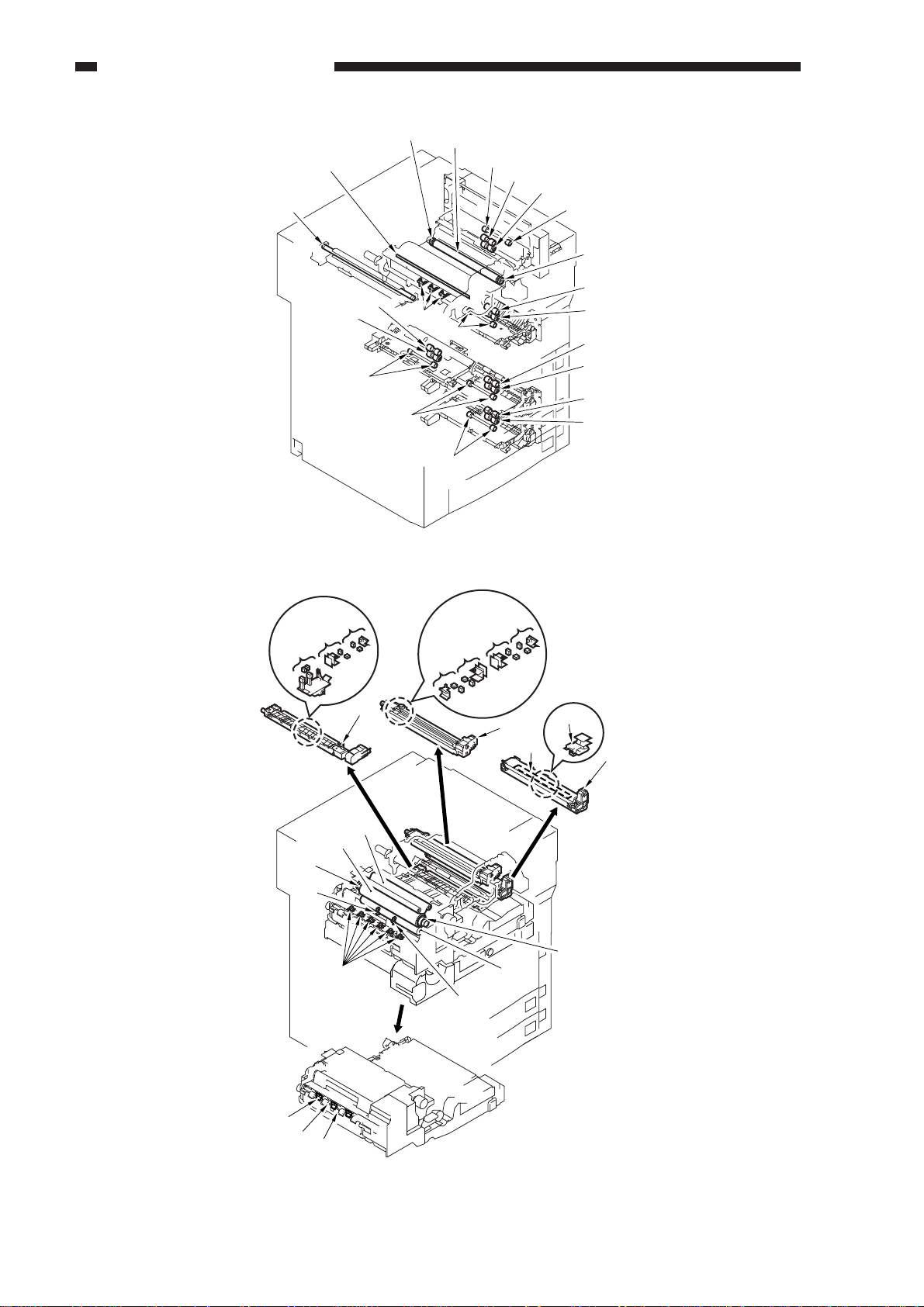

[1]

[5]

[3]

[2]

[24]

[26]

[27]

[25]

[3]

[13]

[11]

[23]

[24]

[22]

[22]

Figure 1-301a

[12]

[7]

[4]

[9]

[22]

[22]

[10]

[10]

[6]

[9]

[15]

[23]

[24]

[23]

[24]

[23]

[24]

[14]

[8]

1-12

[28]

[19]

[29]

[20]

[30]

[16]

[20]

[18]

[19]

[17]

[21]

Figure 1-301b

B. Side Paper Deck

MAINTENANCE / INSPECTION

As of November 1998

No.

1

Side paper deck pickup roller

2

Side paper deck feeding roller

3

Side paper deck separation

roller

Parts name

[2]

Parts No.

FB4-2033-000

FB4-2034-000

FB2-7777-020

Table 1-302

Q’ty

2

2

1

[1]

Life (copies)

250,000

250,000

250,000

Remarks

[3]

Figure 1-302

1-13

IV . POINTS TO NOTE FOR SCHEDULED SERVICING

Caution:

•Check to make sure that the block (front, rear) is free of melting, thermal deformation, cracking,

or yellowing because of leakage. If noted, replace it with a new part.

• Check and clean as far as the inside of the block (front, rear).

• Do not use a cloth soiled with metal powder for cleaning.

• Do not use a moist cloth. Instead, dry wipe with lint-free paper, and then use alcohol;

thereafter, make sure that alcohol has completely evaporated before mounting to the copier.

• Try to finish scheduled servicing and scheduled replacement within a specific period of time.

Part

Pre-exposure lamp

Copyboard glass

Scanning lamp

Standard white plate

Reflecting plate

No. 1 mirror through

No. 3 mirror

Part Tool/solvent

Separation claw

Upper roller,

lower roller

Paper guide

Feeding assembly

Re-pickup assembly,

reversing roller

Re-pickup assembly,

pickup roller,

registration roller

*Make sure no droplet of water remains.

Tool/solvent

Alcohol

Alcohol

Lint-free paper

Lint-free paper

Blower brush

Blower brush

or lint-free

paper

Solvent and

lint-free paper

Cleaning oil,

lint-free paper

Solvent and

lint-free paper

Moist cloth*

Alcohol, lint-

free paper

Alcohol and

lint-free paper

Work

Cleaning.

Cleaning.

Dry wiping.

Dry wiping.

Cleaning.

Cleaning by a blower brush;

if dirt is excessive, cleaning

with lint-free paper.

Work

Cleaning.

Cleaning.

Cleaning.

Cleaning.

Cleaning.

Cleaning.

Part

Primary charging assembly,

transfer/separation assembly,

pre-transfer assembly

Dust-proofing glass

Dust-collecting roller

Developing assembly mount

Registration roller

*Make sure no droplet of water remains.

Part

Manual feed tray, pickup

roller, feeding roller

Vertical path roller

Tool/solvent

Alcohol and

lint-free paper

Lint-free paper

Moist cloth*

Alcohol and

lint-free paper

Tool/solvent

Alcohol and

lint-free paper

Alcohol and

lint-free paper

Work

Dry wiping; then,

cleaning with lint-free

paper moistened with

alcohol.

Cleaning

Disposing of toner

collecting around the

dust-collecting roller.

Cleaning.

Cleaning.

Work

Cleaning.

Cleaning.

1-15

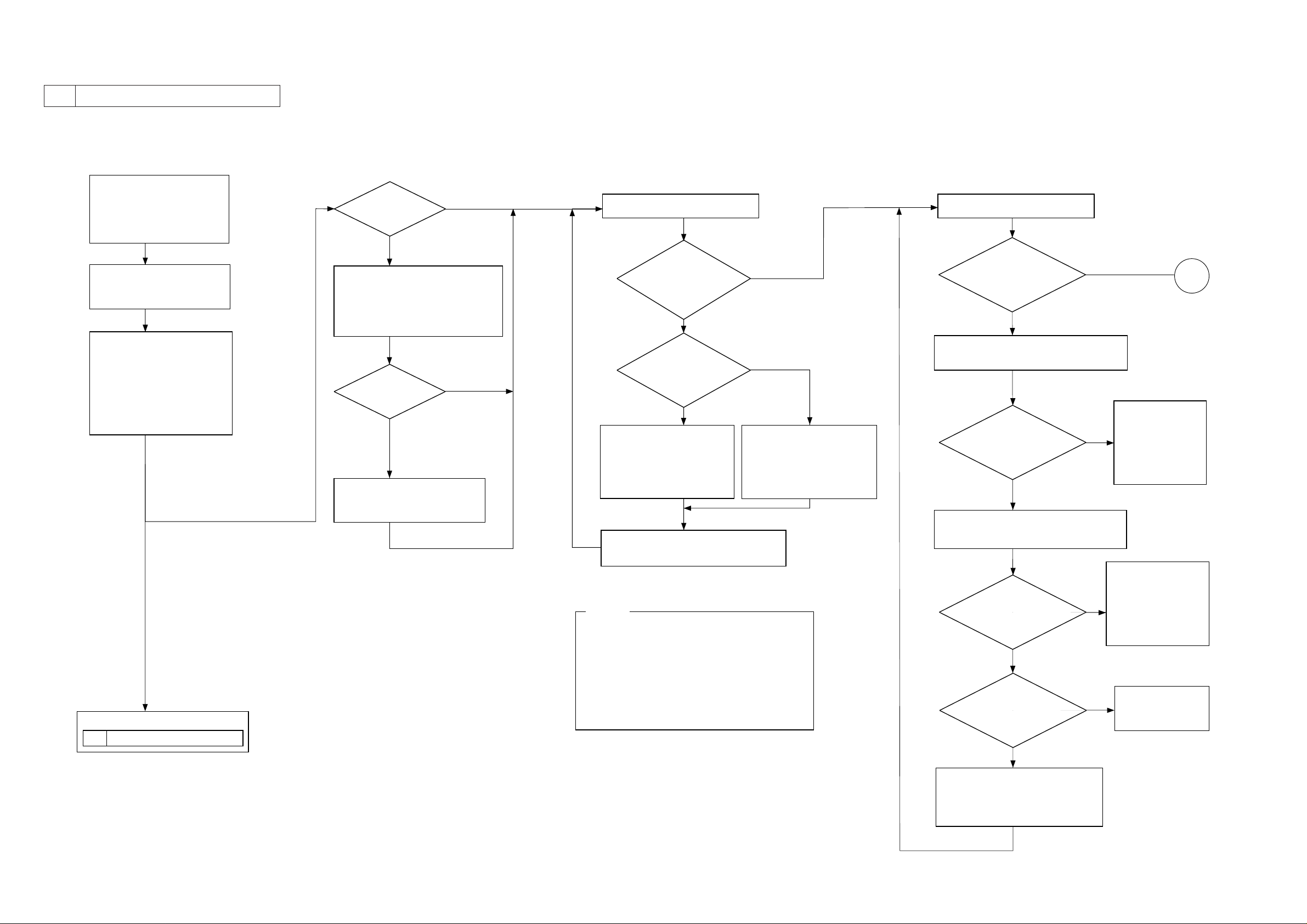

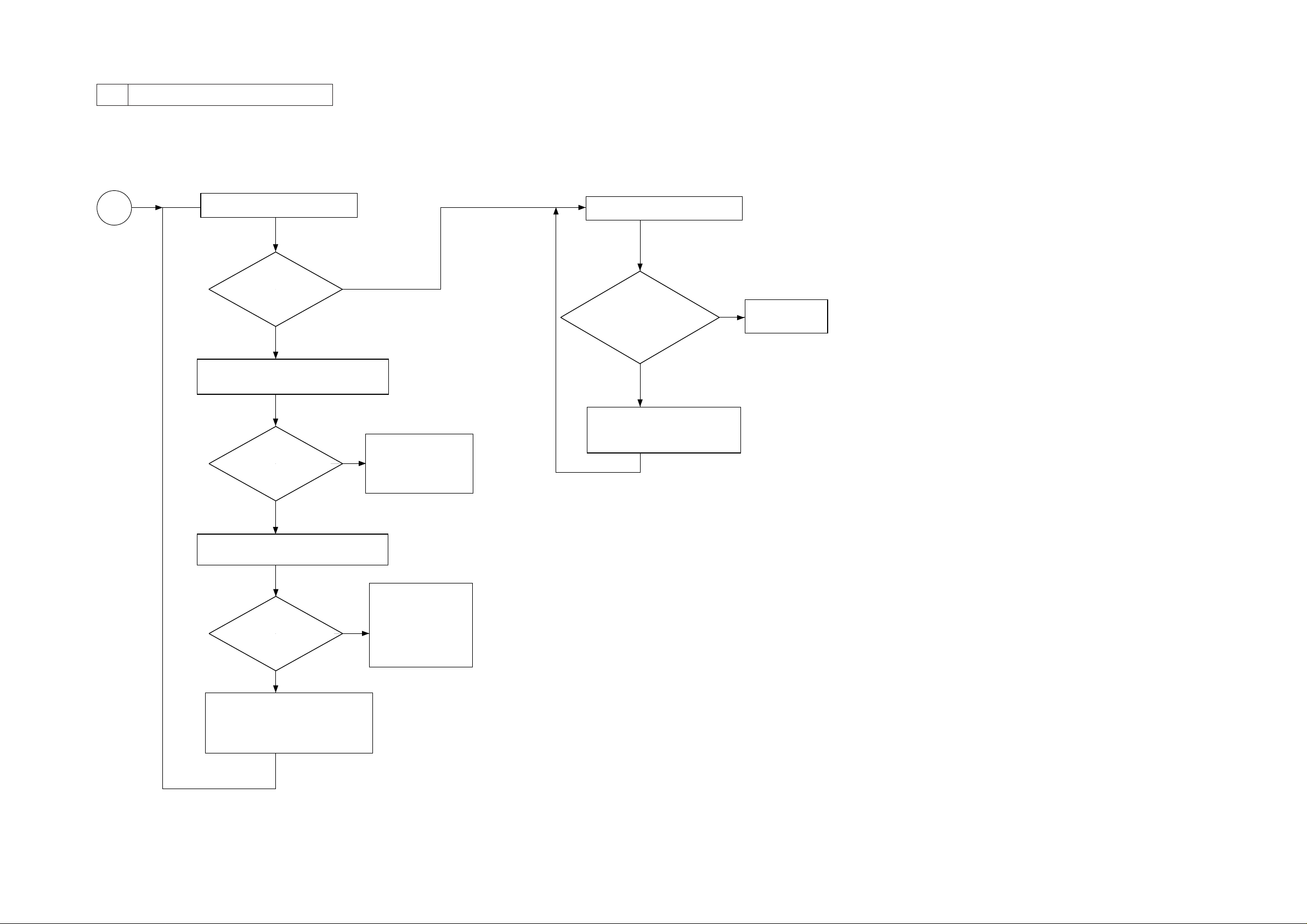

V . IMAGE ADJUSTMENT BASIC PROCEDURE

1 Checking the Printer Side (1/2)

<Making Pre-Checks>

Clean the following:

[1] Grid wire

[2] Primary charging wire

[3] Pre-transfer charging wire

[4] Transfer charging wire

Check the following:

[1] Wire height.

[2] Fixing roller nip

Make several copies of the

NA3 Chart.

Generate several of the

following test prints:

[1] PG4 halftone (printer)

[2] PG6 blank (reader)

[3] PG7 halftone (reader)

[4] PG8 solid black (reader)

Output Conditions

· AE OFF

· Fat 5

· Potential control ON

Checking the Scanner Side

2

If the test prints have a fault,

If a copy image has a fault,

Go to

<Making Image Initial Checks>

Does

the copy have

vertical lines?

YES

Clean the following, and check for

adhesion of foreign matter:

[1] Dust-proofing glass

[2] Charging assemblies Clean the

following, and check for

adhesion of foreign matter:

Does the

copy have vertical

lines?

YES

Check the following:

[1] Drum cleaning blade

[2] Separation claws

NO

NO

<Checking the Density Slope>

Check PG7 (halftone).

Is there

a difference in

density between front

and rear?

YES

Is the rear

lighter?

YES

Turn the adjusting screw at

the front of the primary

charging assembly

counterclockwise. (1.5 mm

max. in one direction)

Execute potential

control.

Turn off and then on the power switch,

and generate one test print of PG7.

Caution:

[1] If the difference in density still exists after

turning the adjusting screw 1.5 mm in one

direction (a single full turn causes a change of

0.7 mm), check the charging assembly,

scanning lamp, and scanner for dirt.

[2] When turning the adjusting screw

counterclockwise, be sure that the height of the

wire is not 7.5 mm or less.

NO

NO

Turn the adjusting screw at

the rear of the primary

charging assembly

counterclockwise. (1.5 mm

max. in one direction)

<Checking Solid Black>

Check PG8 (solid black).

Is

the copy

free of fuzzy images

and is its density

proper?

NO

Select COPIER>DISPLAY>DPOT>VDM

in service mode.

Is the

reading of VDM

between 432

and 452?

YES

Select COPIER>DISPLAY>DPOT>VL1M

in service mode.

Is

the reading

of VL1M between 62

and 82?

YES

Is the test

print of PG6 (blank)

foggy?

NO

YES

NO

Check the following;

if normal, replace the

appropriate part:

NO

[1] Laser output

[2] Potential control

YES

A

Check the

potential control

system; if normal,

replace the

photosensitive

drum.

system

Replace the

developing

assembly.

1-16

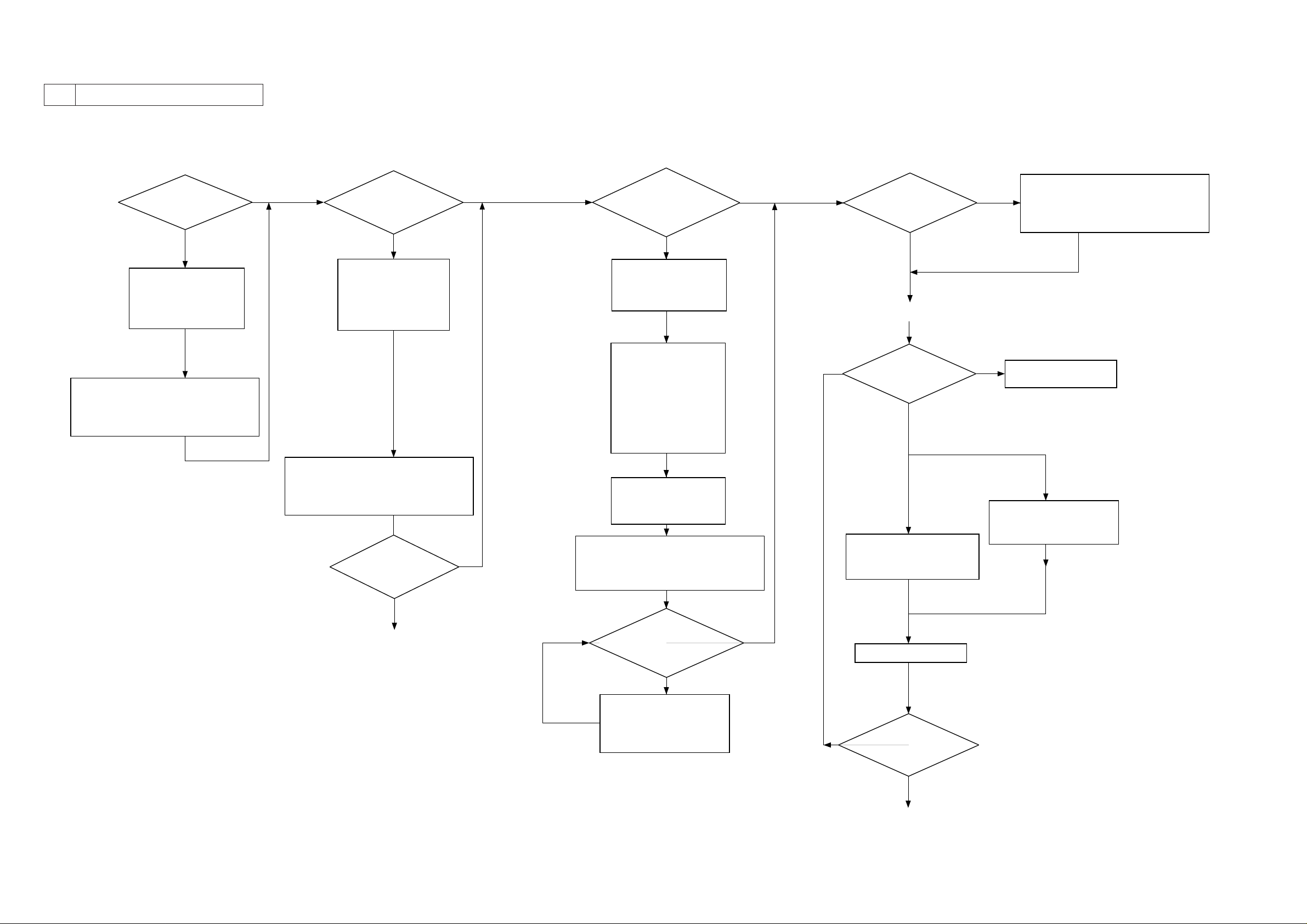

Set OPTION>BODY>CNT-W/HM

in service mode between 2 and 7.

· A higher setting increases the

density.

1 Checking the Printer Side (2/2)

A

<Checking for Fogging>

Check PG6 (blank)

NO

Is the copy foggy?

YES

Select COPIER>DISPLAY>DPOT>VDM

in service mode.

Is the

reading of VDM

between 432 and

452?

Check the potential

NO

controller system; if

normal, replace the

photosensitive drum.

<Checking Halftone Density>

Check PG4 (halftone)

Is the

density

appreciably low (lighter)

compared to the density of No.

3 (halftone) of the Test

Chart?

YES

Increase the setting of

ADJUST>DEVELOP>DE-OFST

in service mode.

NO

End.

YES

Select COPIER>DISPLAY>DPOT>VL1M

in service mode.

Check the following;

if faulty, replace the

Is the

reading of VL1M

between 62 and

82?

YES

Decrease the setting of

ADJUST>DEVELOP>DE-OFST.

· A lower setting decreases the

density.

appropriate part:

NO

[1] Laser output

[2] Potential control

system

1-17

2 Checking the Scanner Side

<Making Initial Checks>

Does the

copy have vertical

lines?

YES

Clean the following:

[1] Mirrors

[2] Lens

[3] Standard white plate

Execute

COPIER>FUNCTION>CCD>CCD-ADJ

in service mode.

NO

<Checking the Density Slope>

Is there a

difference in density

between front and

rear?

YES

Check to see if the

standard white plate is

properly mounted. If

there is a gap, correct

it.

Execute

COPIER>FUNCTION>CCD>CCD-ADJ

in service mode.

Is there a

difference in density

between front and

rear?

NO

NO

<Checking Solid Black Density>

Is

the density

of gray scale No. 1

(solid black) too low

(light)?

YES

Check the scanning

lamp. If it has reached

its end, replace it.

Clean the following

parts:

[1] Mirrors

[2] Lens

[3] Standard white plate

[4] Dust-proofing glass

[5] Scanning lamp

[6] Reflecting plate

Execute potential

control.

Turn off and on the

power switch, and

make one copy.

Execute

COPIER>FUNCTION>CCD>CCD-ADJ

in service mode.

NO

<Checking for Fogging>

Is gray

scale No. 10

(blank) foggy?

NO

<Checking Halftone Density>

Is the

density of gray scale

No. 3 proper?

NO

If too light,

Increase the setting in

COPIER>ADJUST>DENS>

DENS-ADJ in service mode.

YES

YES

If too dark,

Execute

COPIER>FUNCTION>CCD>CCD-ADJ

in service mode.

End.

Decrease the setting of

COPIER>ADJUST>DENS>

DENS-ADJ in sevice mode.

1-18

YES

Check the printer side.

Is the

density of gray

scale No. 1 (solid black)

too low (light)?

YES

Increase the setting of

COPIER>ADJUST>DENS>

DENS-ADJ in service

mode.

NO

YES

Make one copy.

Does the

density of gray scale

No. 3 (halftone)

change?

NO

Check the printer side.

STANDARDS AND ADJUSTMENTS

CHAPTER 2 STANDARDS AND ADJUSTMENTS

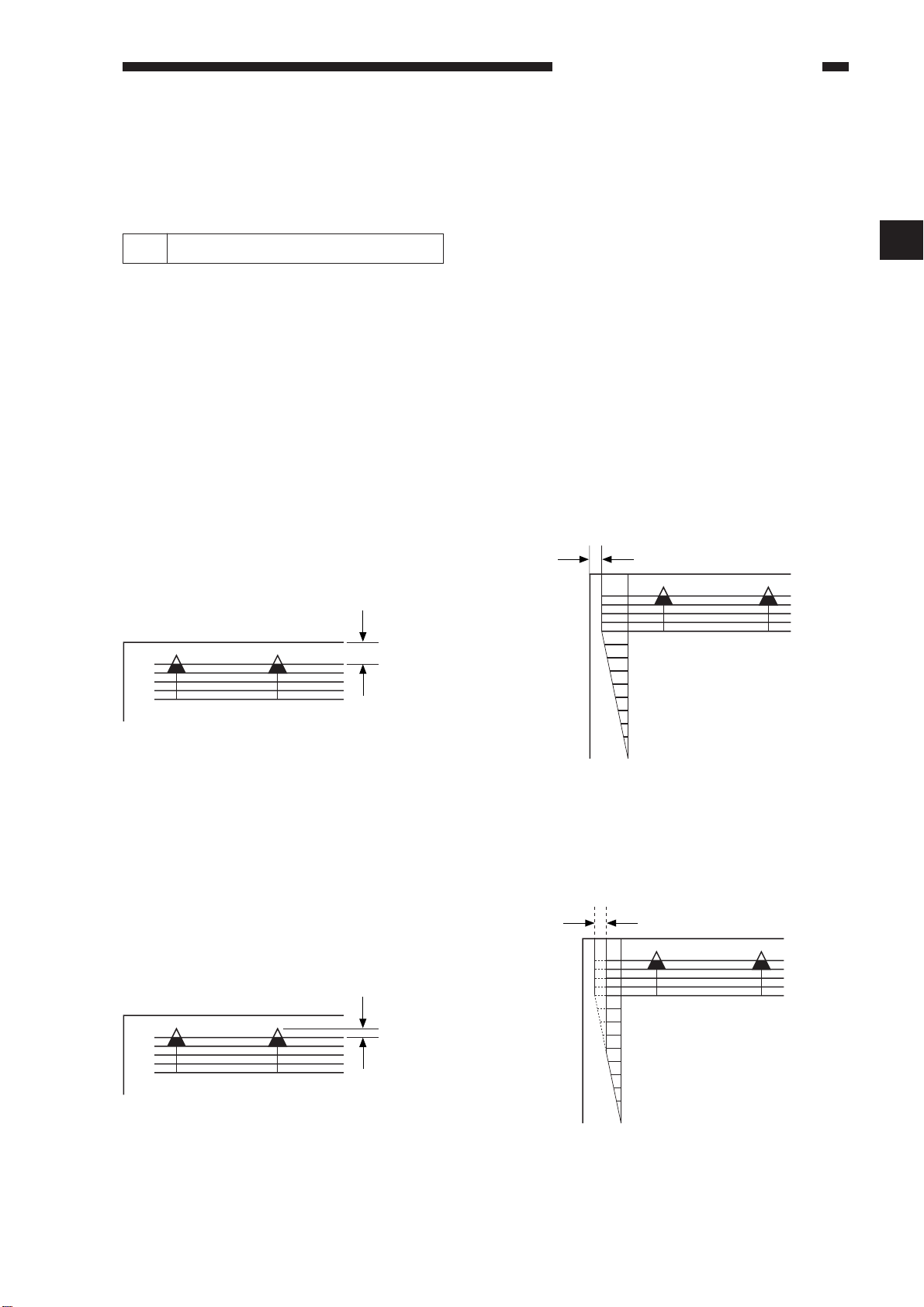

A. Adjusting Images

1 Adjusting the Image Position

Make 10 prints from each of the following sources of paper to see if the image margin and the

non-image width are as indicated:

• Cassette (each)

• Front deck (left, right)

• Manual feed tray

• Duplexing feeding unit

• Side paper deck

The image margin and the non-image width must be as follows on prints made in Direct:

2.5±1.5mm

0

2

4

4.0

+1.5mm

—

1.0mm

2

Figure 2-A101 Image Leading Edge

Margin

+1.5mm

4.0

—

1.0mm

6

8

10

Figure 2-A102 Left/Right Image

Margin

2.5mm±1.5

0

2

4

6

8

10

Figure 2-A103 Image Leading Edge

Non-Image Width

Figure 2-A104 Left/Right Non-Image

Width

2-1

STANDARDS AND ADJUSTMENTS

2 Adjusting the Left/Right Image Margin

If not as indicated, adjust the image position in the following order:

[1] Left/right image margin (registration adjustment)

[2] Image leading edge margin (registration adjustment)

[3] Left/right non-image width (CCD read start position)

[4] Image leading edge non-image width (scanner image leading edge position)

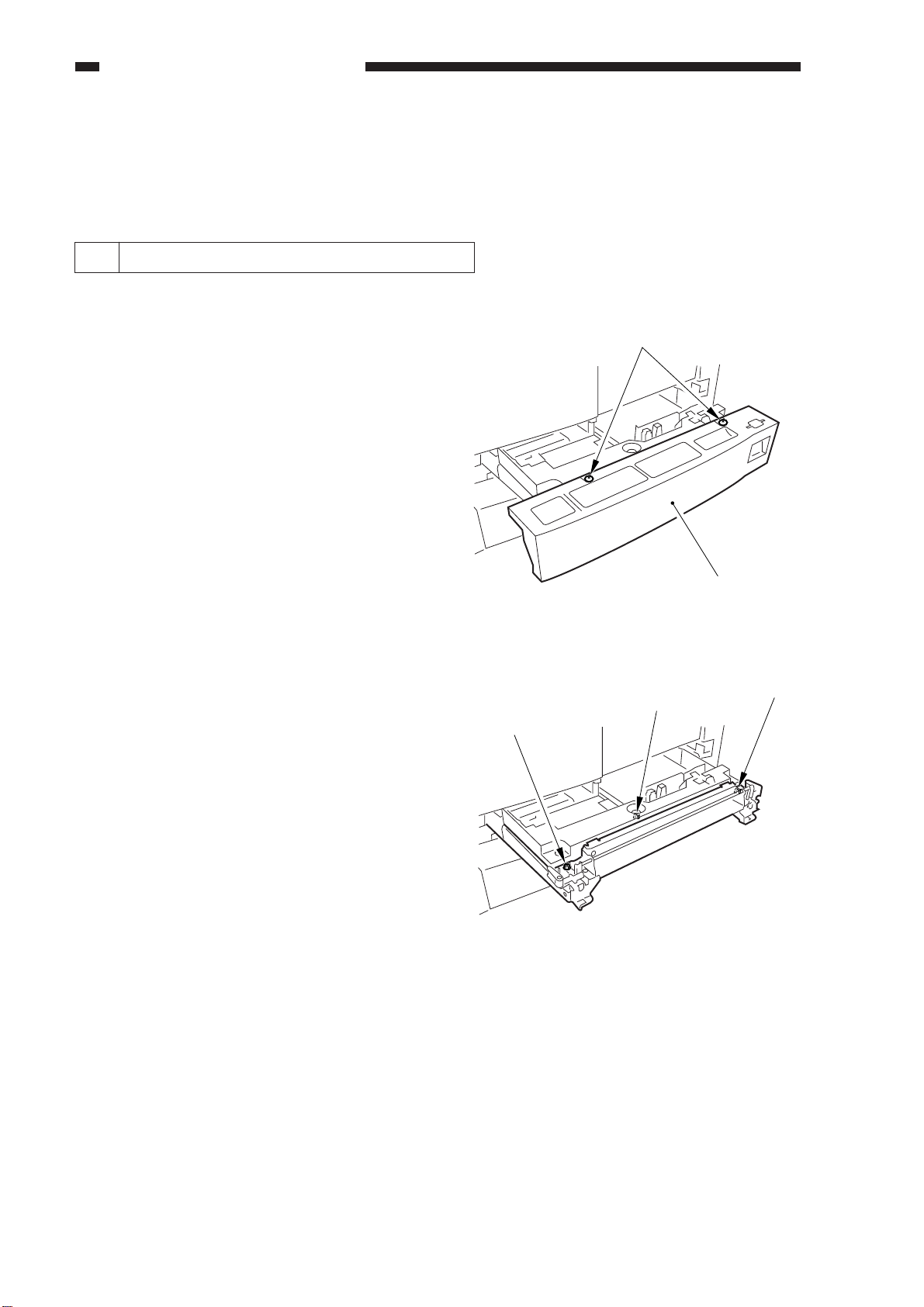

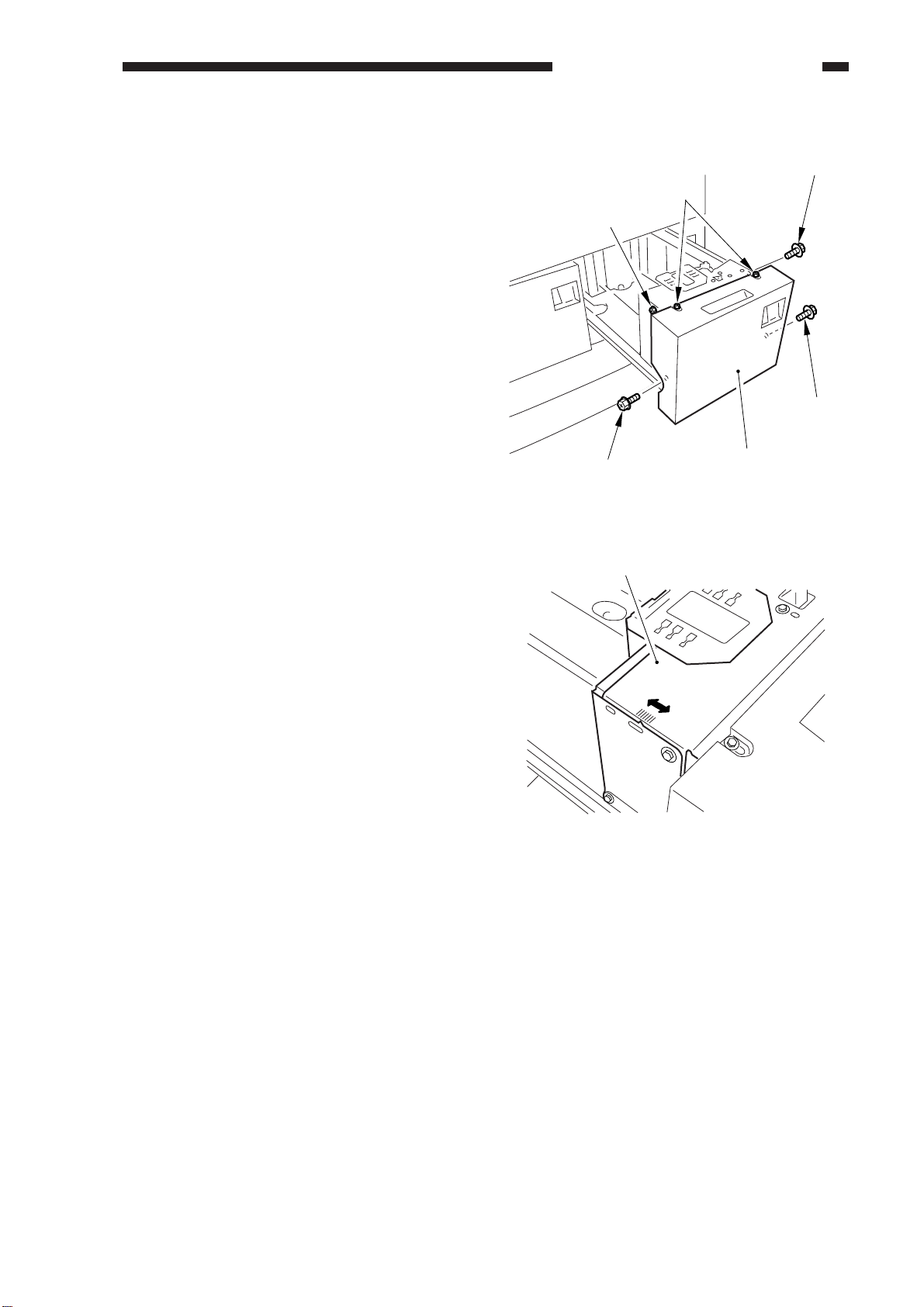

a. Cassette 3/4

1) Remove the two screws [2], and detach

the cassette front cover [1].

[2]

2) Loosen the two fixing screws [3] on the

left and right of the cassette; then, make

adjustments using the adjusting screw [4].

3) After adjustment, be sure to execute

COPIER>FUNCTION>CST>C3STMTR/A4R or C4-STMTR/A4R in

service mode.

[1]

Figure 2-A105

[3]

[4]

[3]

Figure 2-A106

2-2

b. Front Deck (left/right)

1) Loosen the four screws [2] and the two

fixing screws [3] on the cassette front

cover [1].

STANDARDS AND ADJUSTMENTS

[3]

[2]

[3]

[2]

2) Move the cassette guide assembly (front)

[4] to the front or the rear to make adjustments.

[2]

Figure 2-A107

[4]

Figure 2-A108

[1]

2-3

STANDARDS AND ADJUSTMENTS

c. Manual Feed Tray

1) Loosen the two mounting screws on the manual tray, and adjust the position of the manual tray.

[1]

[1]

Figure 2-A109

d. Duplexing Feeding Unit (2nd side of double-sided print)

1) Correct the image margin as specified using service mode (COPIER>ADJUST>FEEDADJ>ADJ-REFE).

Edge of paper

Decrease the setting of

ADJ-REFE. (A decrease

of 23 decreases the

margin by 1 mm.)

Figure 2-A110

Increase the setting of

ADJ-REFE. (An increase

of 23 increases the

margin by 1 mm.)

2.5mm±2.0

0

0

2

2

4

4

6

6

8

8

10

10

2-4

STANDARDS AND ADJUSTMENTS

e. Side Paper Deck

1) Slide out the compartment, and adjust the position of the latch plate of the deck open solenoid

using the two screws. (At this time, use the scale graduations on the latch plate as a guide.)

Scale graduations

Latch plate

Screws

Figure 2-A111 Left Rear of the Compartment

2-5

STANDARDS AND ADJUSTMENTS

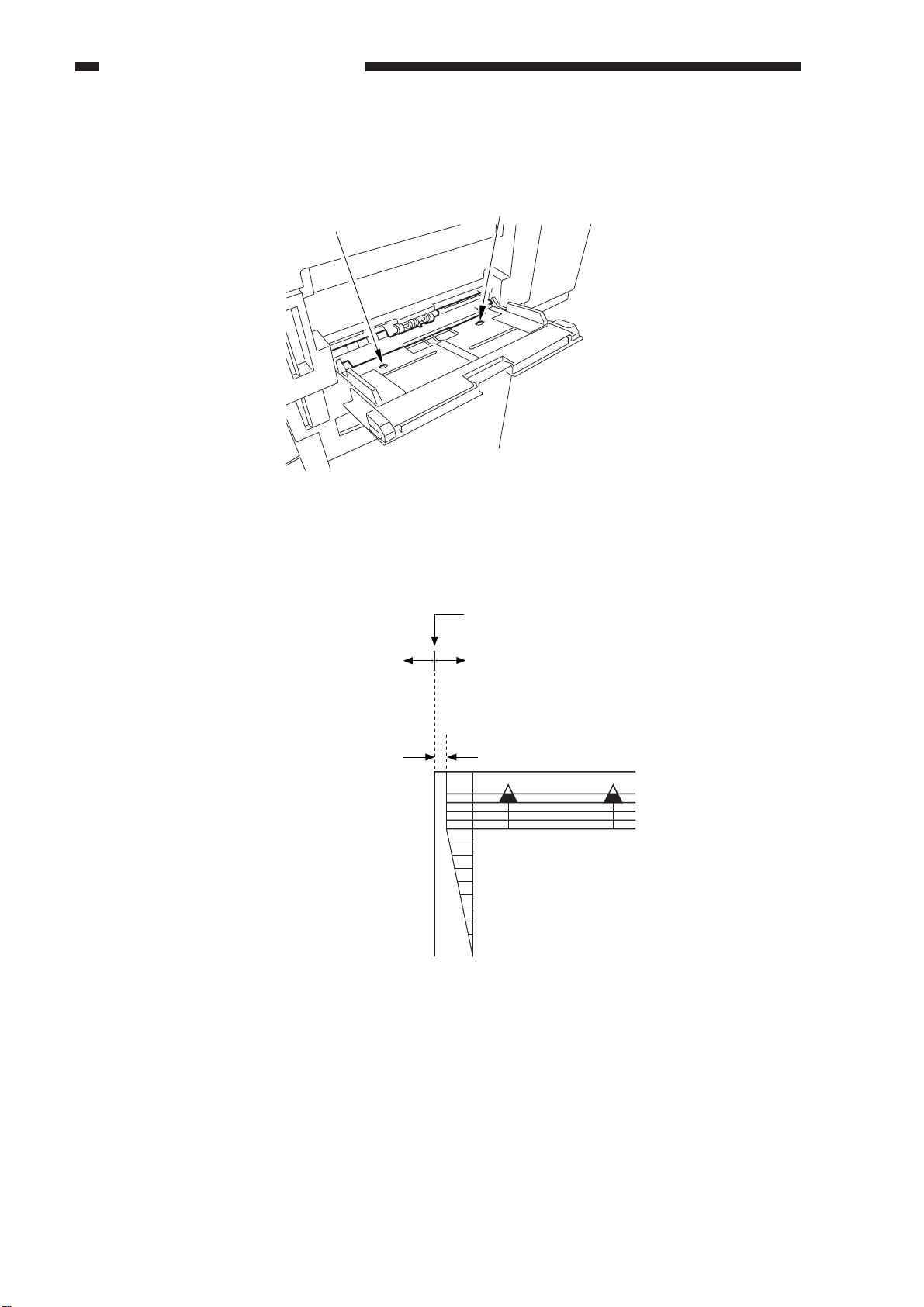

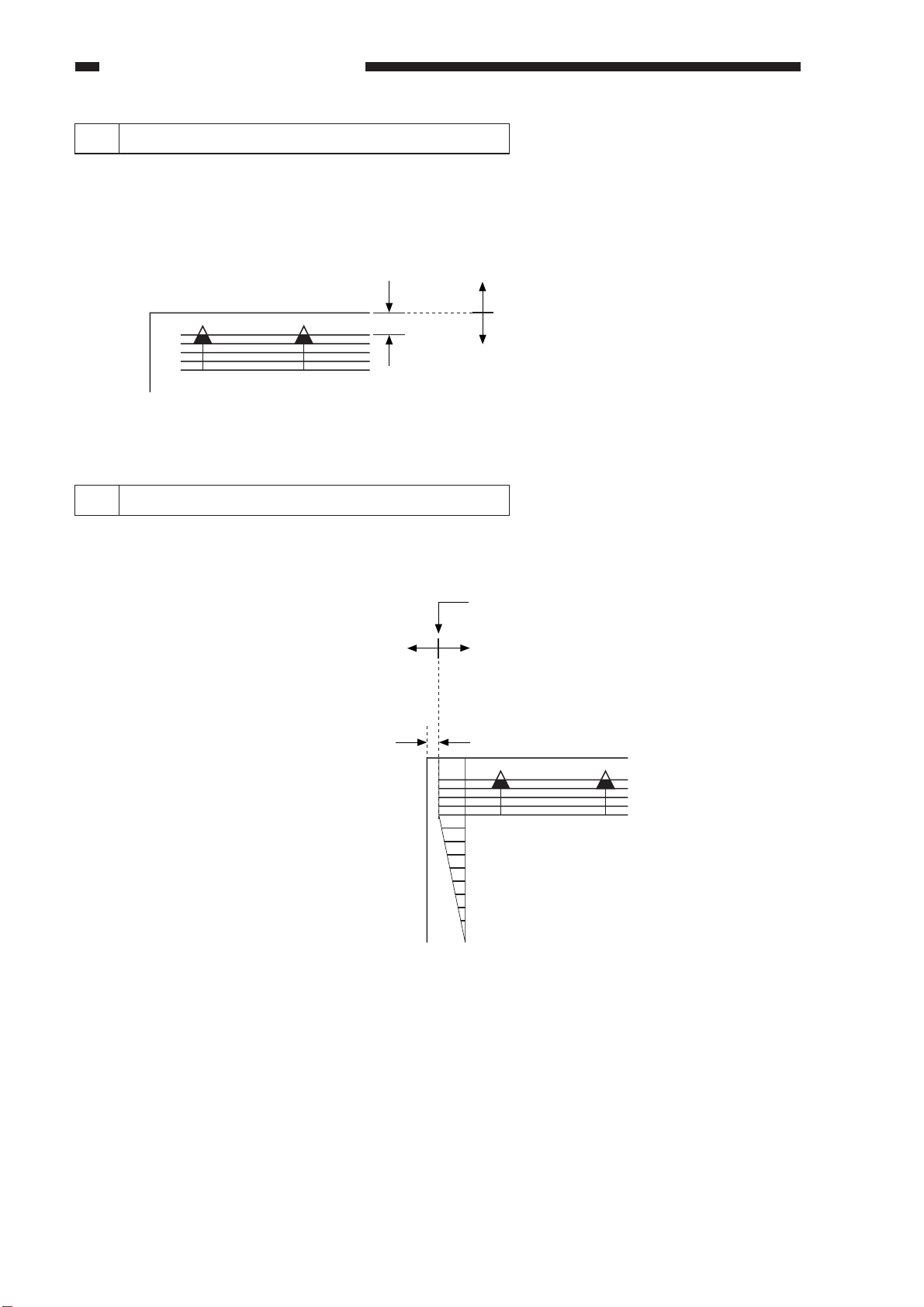

3 Adjusting the Image Leading Edge Margin

1) Set the image margin as specified in service mode (COPIER>ADJUST>FEEDADJ>REGIST).

Decrease the setting of REGIST.

(An increase of 23 increases the

margin by 1 mm.)

Leading edge of paper

Increase the setting of REGIST.

(A decrease of 23 decreases the

margin by 1 mm.)

Figure 2-A112

4 Adjusting the Left/Right Non-Image Width

1) Correct the non-image width as specified in service mode (COPIER>ADJUST>ADJXY>ADJ-Y).

Image edge

Decrease the setting of

ADJ-Y. (A decrease of 12

decreases the non-image

width by 1 mm.)

Increase the setting of

ADJ-Y. (An increase of

12 increases the image

width by 1 mm.)

2.5mm±2.0

0

2

4

6

8

10

Figure 2-A113

2-6

Loading...

Loading...