Page 1

CANON Digital Galvano Scanner System

GM-1000 Series

GC-201

Users Manual

Rev. 1.20

Be sure to read this guide before using the product.

Keep this guide carefully for future use.

Page 2

For Safe and Correct Use

To prevent injury to the user or damage to property, this guide gives information for the safe and correct

use of this product.

Before installation, operation, maintenance, or inspection, be sure to read this guide.

Markings

This guide uses the following markings:

Warning

This indicates the possibility of death or serious injury by a fire or electric shock.

Caution

This indicates the possibility of injury or damage to property.

Warning

・Do not use the product in an atmosphere of inflammable or explosive gas or vapor.

・Use the product at the specified voltage.

・Connect the power supply line correctly.

・Do not install, operate, maintain, or inspect the product with wet hands.

・Do not disassemble or alter this product.

・Do not drop or cause impact to the product.

Caution

・Before installation, operation, maintenance, or inspection, thoroughly check that the device is safe.

・When connecting a connector, check the pin numbers with the power off.

・When connecting oscilloscope probes to the test pins, be careful not to apply tension to them.

・Since this product is a precision device, use it under the specified environmental conditions.

・Do not store or transport this product in a place exposed to direct sunlight, moisture, dust, or temperature

of 60ºC or higher.

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

2

Page 3

Contents

1. Product Outline ............................................................................................................................. 5

1.1. Features ............................................................................................................................................ 5

1.2. Configuration ..................................................................................................................................... 5

2.

Specifications ................................................................................................................................ 6

2.1. Galvano Motor (GM-1010, GM-1015, and GM-1020) ........................................................................ 6

2.2. Controller (GC-201) ........................................................................................................................... 7

2.3. Dimensions ....................................................................................................................................... 8

2.4. Power Supply .................................................................................................................................. 11

2.5. Connections .................................................................................................................................... 11

2.6. Connector and Pin Assignment ....................................................................................................... 13

2.7. Optional Cables ............................................................................................................................... 17

2.8. Control Specifications ...................................................................................................................... 19

2.8.1. Number of Encoder Pulses .................................................................................................... 21

2.8.2. RS-232C command input .................................................................................................. 22

2.8.3. High-speed serial communication .................................................................................... 26

2.8.3.1. Origin Offset ....................................................................................................................... 32

2.8.3.2. High-speed serial communication motor drive timing ......................................................... 33

2.8.4. Status (High-speed Serial Communication STS) .......................................................... 34

2.8.5. RS-232C Communication Command Input and High-Speed Communication

Switching .......................................................................................................................................... 37

2.9. Heat Radiation and Installation........................................................................................................ 38

3. Software .......................................................................................................................................... 39

3.1. Supported PC Environment ............................................................................................................. 39

3.2. Installation CD ................................................................................................................................. 39

3.3. Control Software Installation ........................................................................................................... 40

3.4. Software Start Up ............................................................................................................................ 43

3.5. Control Screen ................................................................................................................................ 45

4.

Operating Procedure ............................................................................................................... 47

4.1. Controller Start Up ........................................................................................................................... 47

4.2. Step Movement ............................................................................................................................... 49

4.2.1. Step Movement Responce Time Measurement ............................................................ 51

4.2.1.1. Measurement Data Display Zoom Method ......................................................................... 54

4.2.1.2. Reference Data Comparison Method ................................................................................. 56

4.3. Raster Scan .................................................................................................................................... 59

4.4. Position Command Input by High-speed Serial Communication ..................................................... 61

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

3

Page 4

5. Monitor Output and Digital Input Functions ............................................................. 62

5.1. Connector Pin Assignment .............................................................................................................. 62

5.2. Analog Monitor Output Selecting ..................................................................................................... 66

5.3. Digital Input-Output Function ........................................................................................................... 69

6.

Other - Operation Setting ..................................................................................................... 70

6.1. Setting Controller Start Up Mode..................................................................................................... 70

6.2. Controller LED Display .................................................................................................................... 72

6.3. Operation that Synchronizes with External Trigger Signal input (Raster Scan) ............................... 74

7.

Tuning .............................................................................................................................................. 76

7.1. Tuning ............................................................................................................................................. 76

7.2. Frequency Characteristic (FFT) Measurement ................................................................................ 77

7.3. Easy Auto Tuning ............................................................................................................................ 81

7.4. X and Y Axis Matching ..................................................................................................................... 87

8.

Commands .................................................................................................................................... 95

8.1. List of Commands ........................................................................................................................... 95

8.2. Command Details ............................................................................................................................ 97

9.

Parameters .................................................................................................................................. 108

9.1. List of Parameters ......................................................................................................................... 108

9.2. Parameter Details .......................................................................................................................... 110

9.3. Modifying Parameters ................................................................................................................... 126

9.4. Writing Parameters into ROM ....................................................................................................... 127

9.5. Saving a Parameter File ................................................................................................................ 128

10.

Safety Functions .................................................................................................................... 129

10.1. Safety Functions .......................................................................................................................... 129

10.2. Errors .......................................................................................................................................... 130

11.

Appendix ..................................................................................................................................... 132

11.1. Firmware Update ......................................................................................................................... 132

11.1.1. Writing Procedure ................................................................................................................ 133

11.2. Parameter Changes from the Number of Encoder Divisions ....................................................... 137

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

4

Page 5

1. Product Outline

1.1. Features

The Canon Digital Galvano Scanner System is fully digitally controlled with a high-precision

optical encoder on the galvano motor and a high-speed digital signal processor (DSP) on the

controller.

This system has the following features:

z High positioning precision

z Low temperature drift

z Fast and stable operation by a unique control system

z Easy tuning with parameter settings

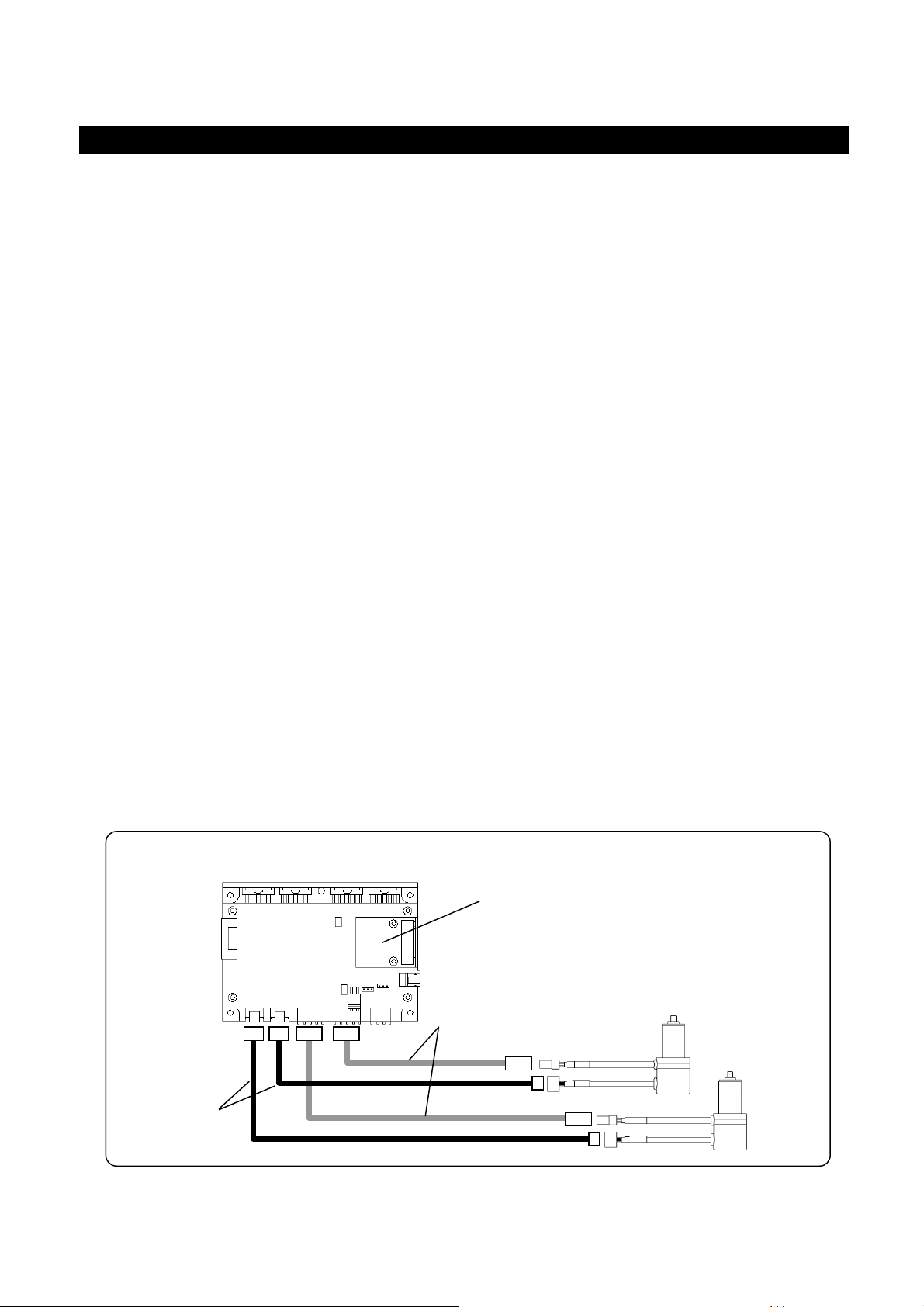

1.2. Configuration

This system supports various applications by the combination of a galvano motor and a controller.

Galvano motor: Encoder-mounted galvano motor

GM-1010

GM-1015

GM-1020

Controller: Digital servo-controller

GC-201

IF board: IF board for high-speed serial communication

GC-422

GC-LVDS

Extension cable: Extension cable for galvano motor and controller connection

GM-EC10, 20, 30

GM-MC10, 20, 30

・・・・ Encoder extension cable (1, 2, 3 m)

・・・・ Motor extension cable (1, 2, 3 m)

・・・・ Beam diameter: φ8 to φ10 mm

・・・・ Beam diameter: φ10 to φ15 mm

・・・・ Beam diameter: φ15 to φ30 mm

・・・・ Controller for two-axis control

・・・・ IF board for 5V-TTL (RS-422)

・・・・ IF board for LVDS level

Controller

IF board

Motor extension

cable

Galvano motor

Encoder

extension cable

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

5

Page 6

2. Specifications

2.1. Galvano Motor (GM-1010, GM-1015, and GM-1020)

Performance and shape

Conforming

beam diameter

Scan angle

Encoder cycle

number

Number of encoder

pulses

Command

resolution

Torque constant

Weight

(Reference)

For details about encoder cycle number, number of encoder pulses, and command resolution, see2.8.1. “Number

of Encoder Pulses”.

Environmental conditions

GM-1010 GM-1015

Φ8 to φ10 φ10 to φ15

±20 deg ±20 deg

1000 pulses/rotation 1500 pulses/rotation

8,192,000 pulses 12,288,000 pulses 12,288,000 pulses

0.77 μrad 0.51 μrad

0.0127 Nm/A 0.0226 Nm/A

200 g 300 g

GM-1020

φ15 to φ30

±20 deg

1500 pulses/rotation

0.51 μrad

0.0415Nm/A

600g

Operating temperature and humidity 0 to 50ºC, 90% RH or less (No condensation)

Storage temperature and humidity –20 to 60ºC, 90% RH or less (No condensation)

Note: The above operating temperature and humidity conditions depend on the operating and heat

radiation conditions.

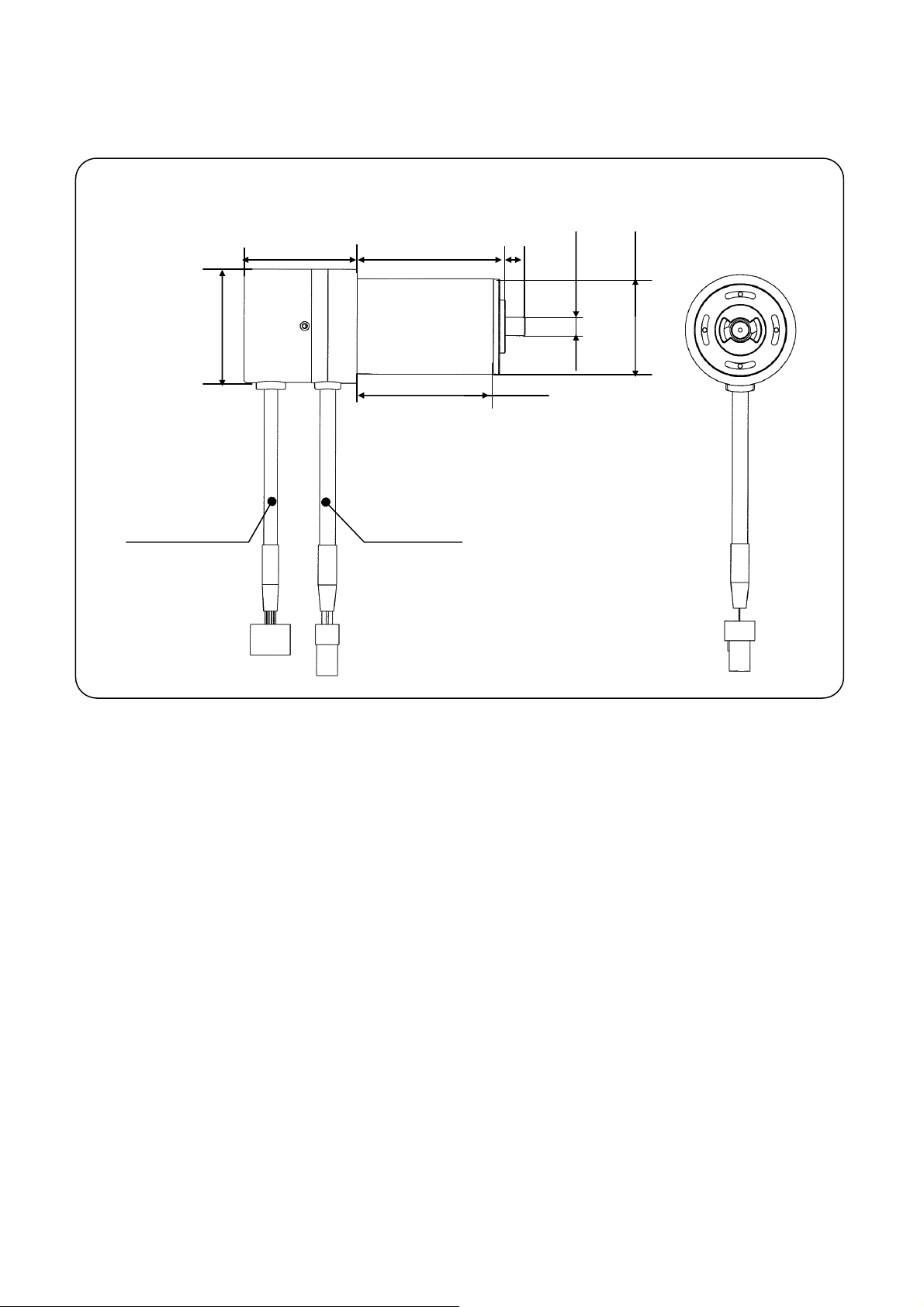

Part names

Stopper

Motor cable

Encoder

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

Encoder cable

6

Page 7

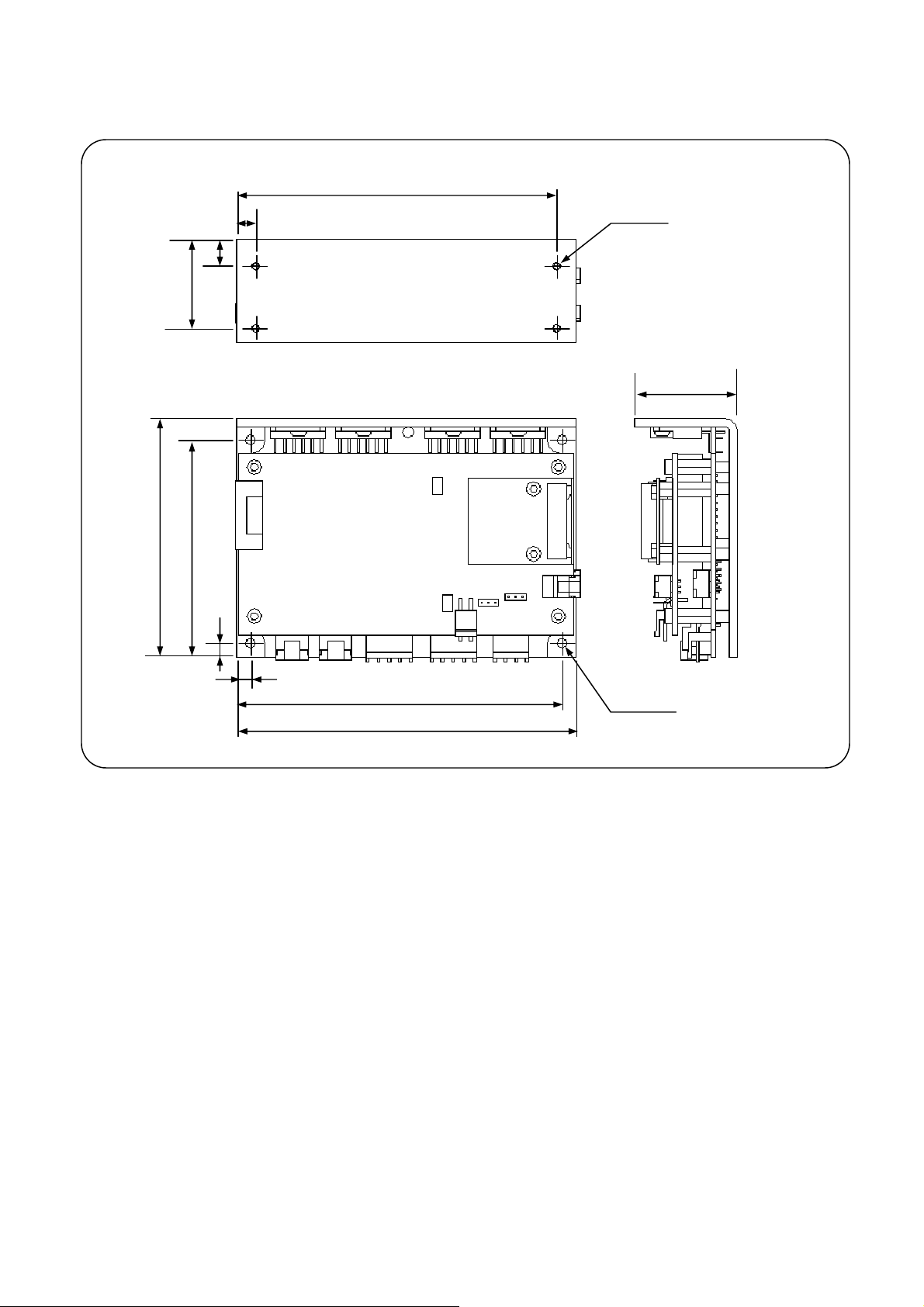

2.2. Controller (GC-201)

Performance and Dimensions

GC-201

Number of control axes 2

Control sampling 100 kHz

Maximum drive current Peak 10 A (each axis)

Interface RS-232C , High-speed serial communication(XY2-100)

Digital notch filter ×2

Notch filter

Weight 350 g

Environmental conditions

Operating temperature and humidity 0 to 50ºC, 90% RH or less (No condensation)

Storage temperature and humidity -20 to 60ºC, 90% RH or less (No condensation)

Digital low-pass filter ×1

Analog notch filter ×2

Note: The above operating temperature and humidity conditions depend on the operating and heat

radiation conditions.

Section names

Mounting screw

hole (M3 × 4)

Mounting screw

hole (φ3.5 × 4)

Heat radiation

frame

IF board

Digital board (upper)

Analog board (lower)

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

7

Page 8

φ

φ

2.3. Dimensions

GM-1010

36 36 6

-0.005

φ5 -0.015

0

φ22 -0.03

GM-1015

33

32 (Clamp area)

Motor cable Encoder cable

36

46

6

-0.005

φ6 -0.015

-0

φ28 -003

33

42 (Clamp area)

Encoder cable

Motor cable

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

8

Page 9

φ

GM-1020

Encoder Cable

43

42.7

56

Motor Cable

7.5

-0.005

51.4 (Clamp Area)

-0

φ7 -0.015

φ36 -003

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

9

Page 10

GC-201

118

7

10

4-M3

33

38

80

88

5

5

120

125

4-φ3.5

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

10

Page 11

2.4. Power Supply

Power supply specifications

+24 V ± 10% (For motor drive) Peak 10 A × 2 axes

RMS 2.5 A × 2 axes

(RMS value differs according to operating conditions, the above conditions GM-1010, Ymirror、

±5°, 200Hz)

+5 V ± 5% (For control circuit) 2.8 A

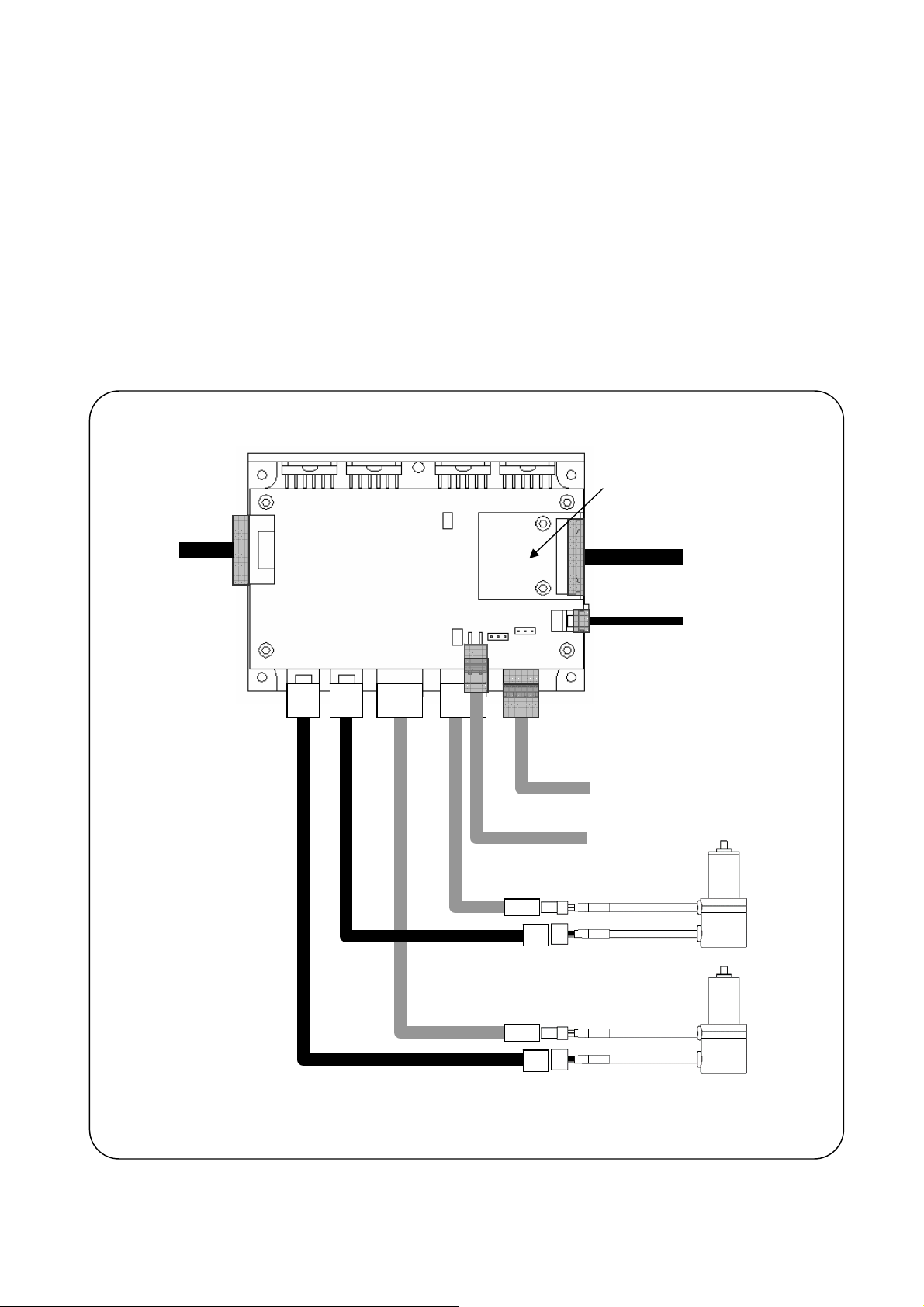

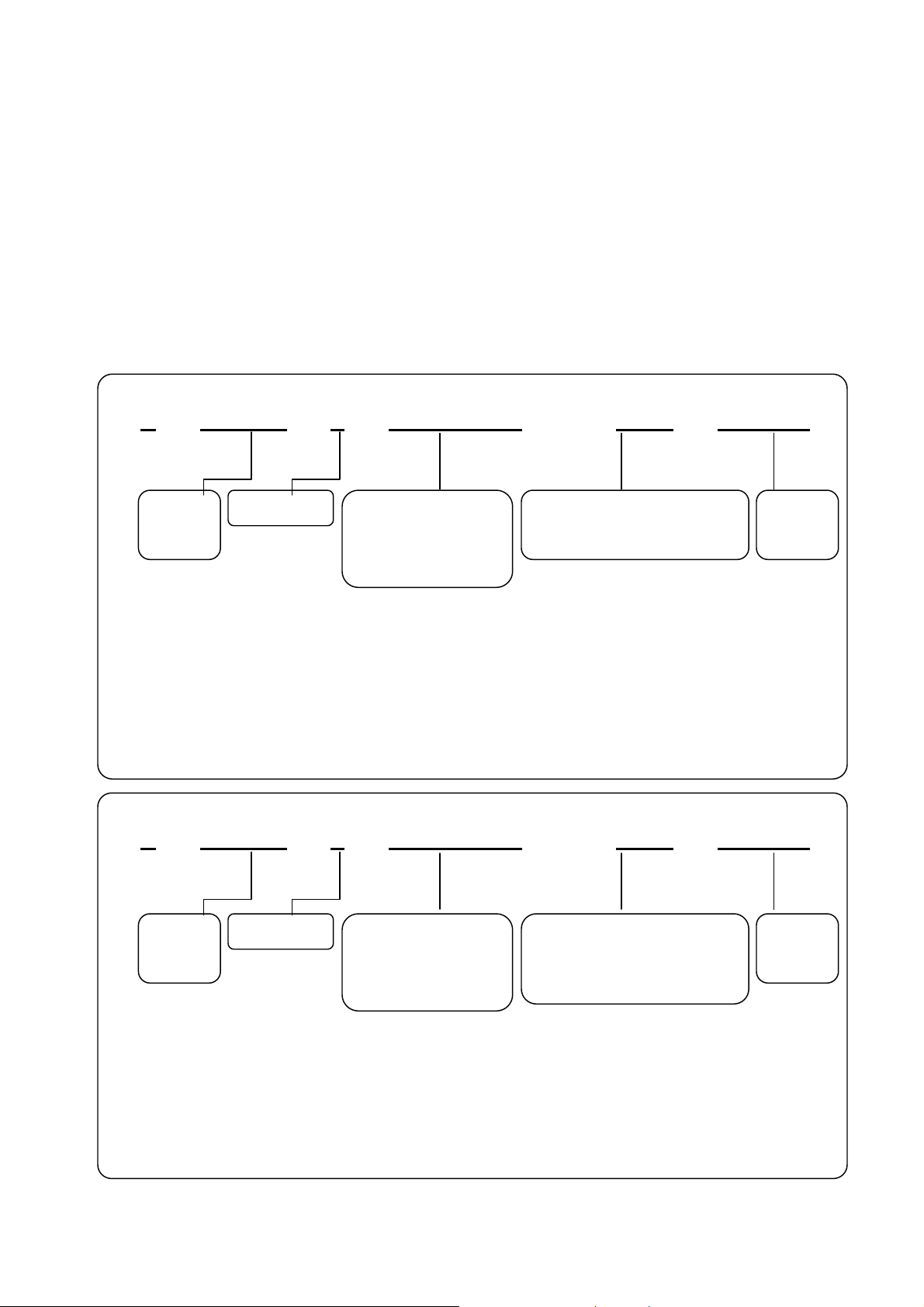

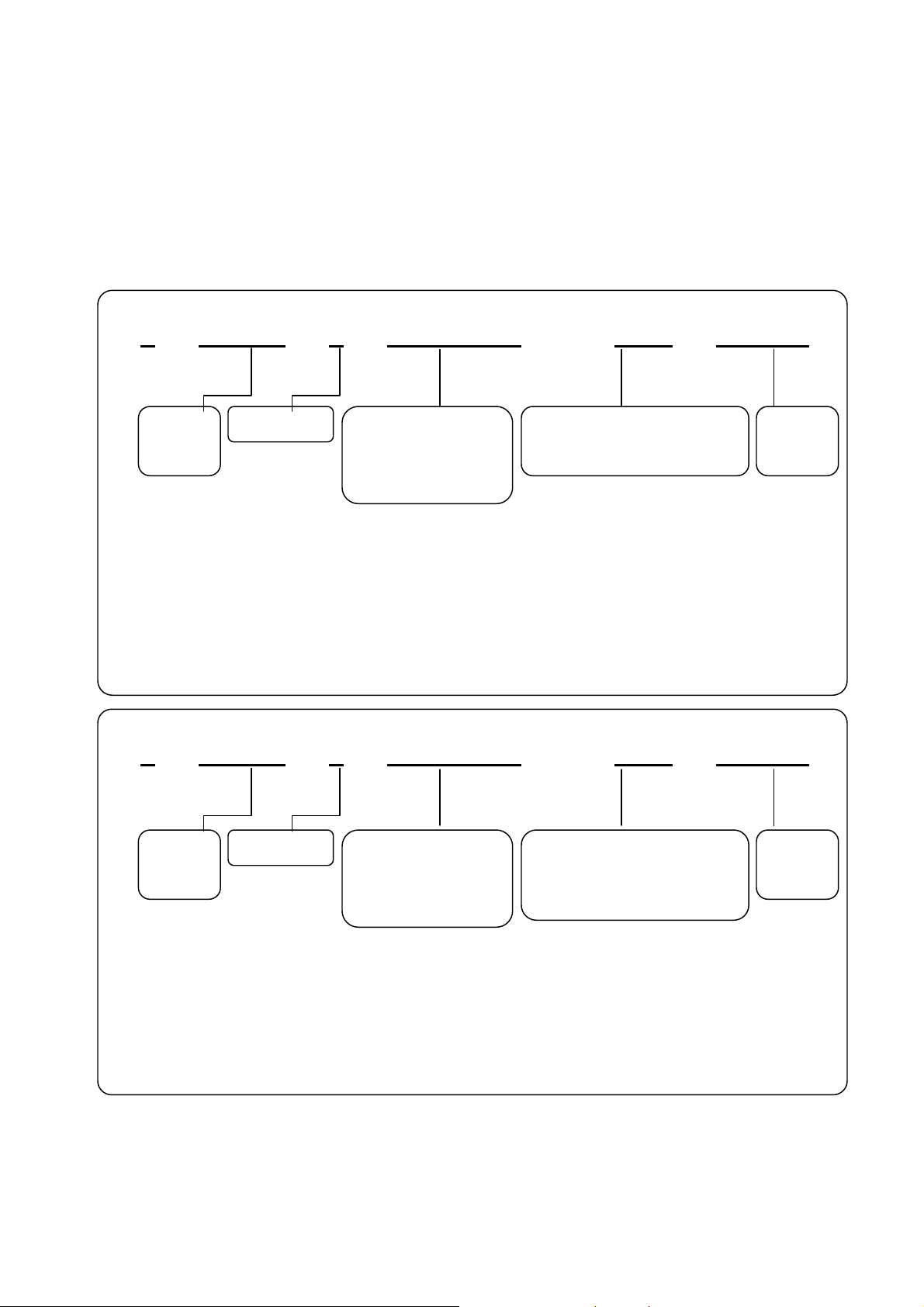

2.5. Connections

Digital

input/output

IF board

High-speed serial

communication

RS-232C

+24 V power

+5 V power

Axis 2

Axis 1

Galvano motor

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

11

Page 12

Note:

Connecting the power +24 V, and GND in reverse will damage the GC-201 controller. Take

caution when connecting.

Connecting the power +5 V, and GND in reverse will damage the GC-201 controller. Take

caution when connecting.

+5V

+

-

+24V

--++

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

12

Page 13

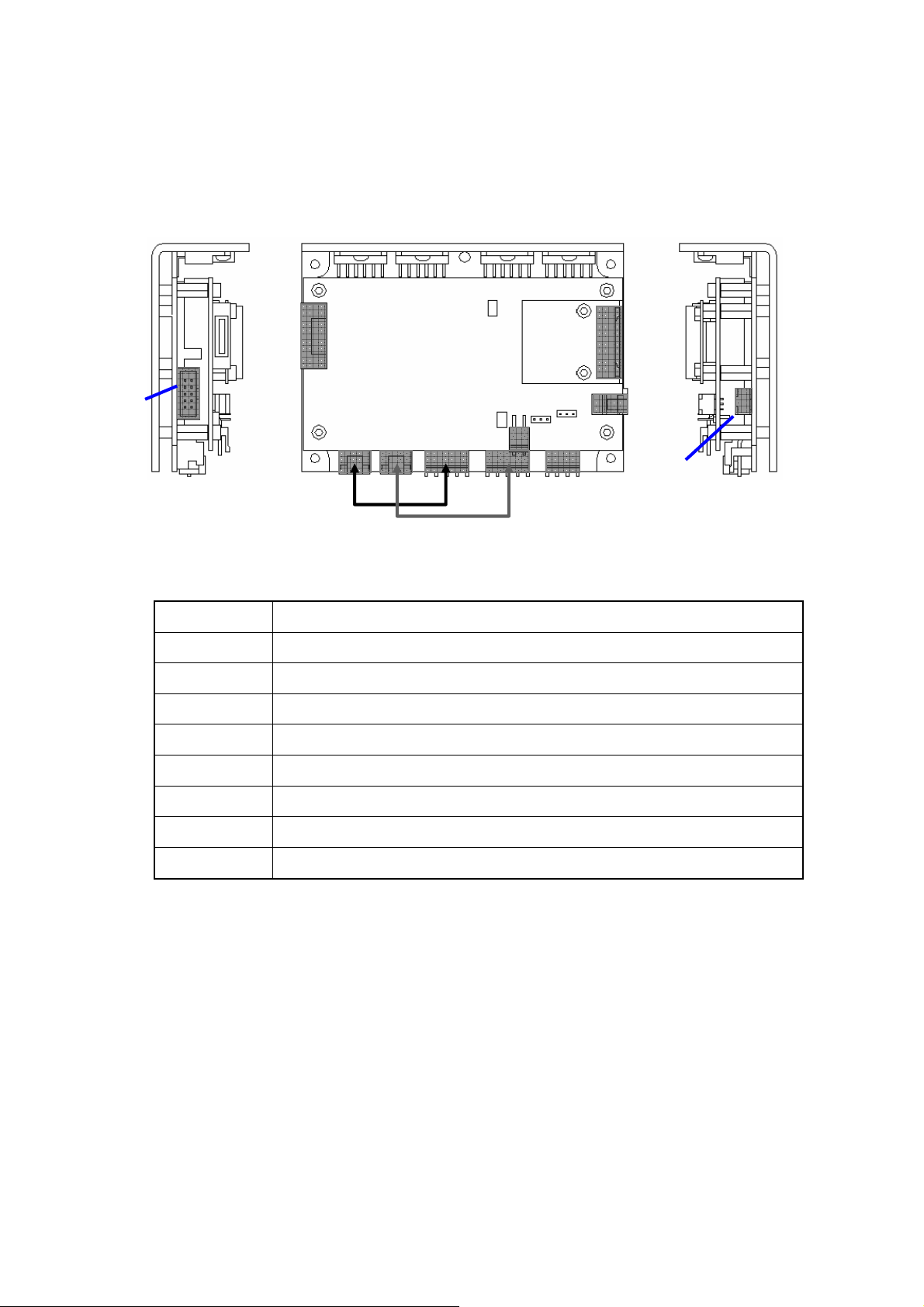

2.6. Connector and Pin Assignment

(Connector types)

⑦

⑥

⑧

③

⑤

④

⑨

①

②

①

②

③

④

⑤

⑥

Axis 1 motor encoder connector

Axis 2 motor encoder connector

+5 V power supply

+24 V power supply

RS-232C

High-speed serial communication

⑦

⑧

⑨

Digital input/output

Analog monitor

Fan power supply (+24 V)

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

13

Page 14

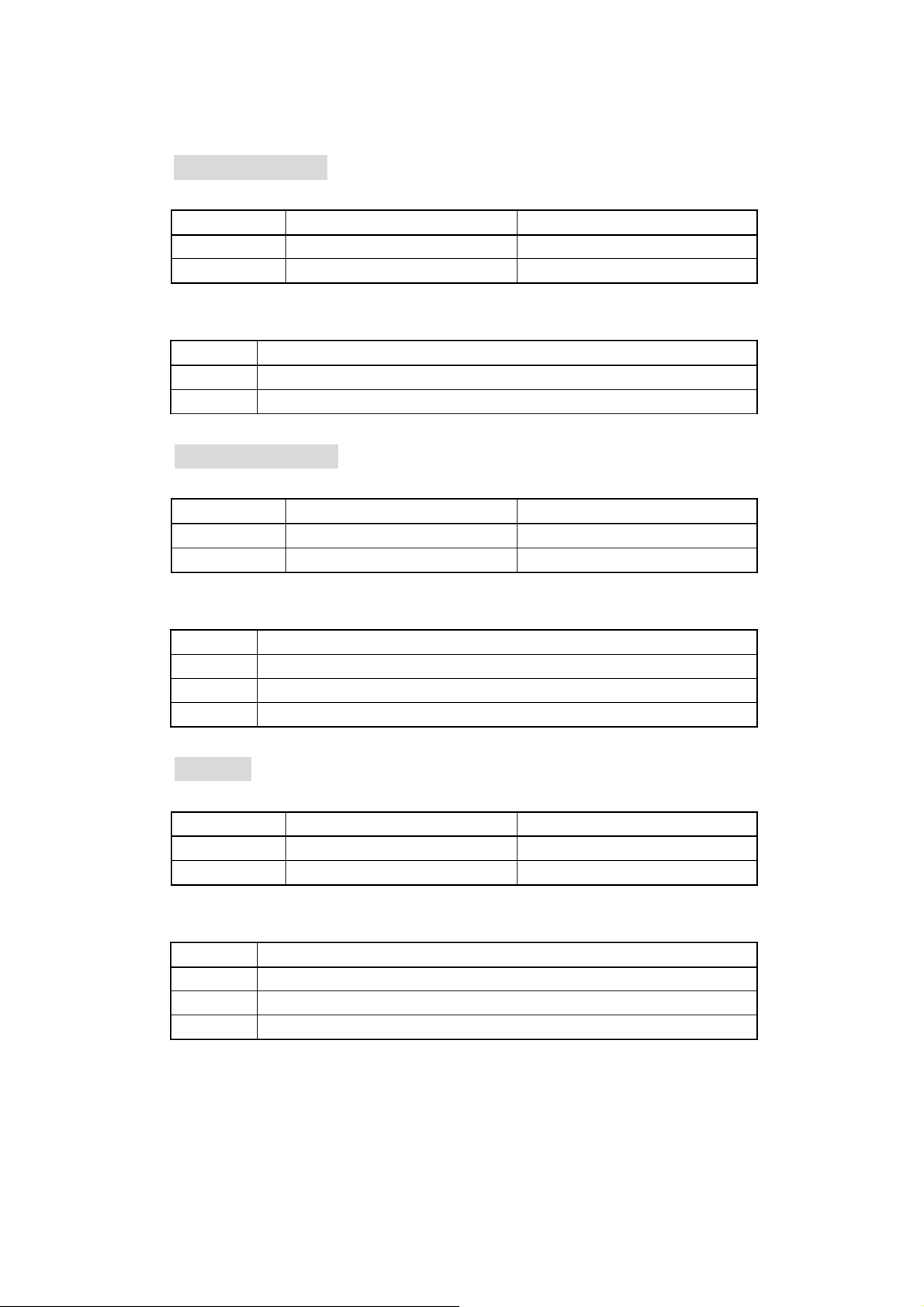

(Connector model number & pin assignment)

③ +5 V power supply

(Connector model number)

Connector Model No. Manufacturer

Board side S2P-VH JST

Cable side VHR-2N JST

(Connector pin assignment)

Pin No. Signal Description

1 +5 V

2 GND

④ +24 V power supply

(Connector model number)

Connector Model No. Manufacturer

Board side S4P-VH JST

Cable side VHR-4N JST

(Connector pin assignment)

Pin No. Signal Description

1 +24 V input for Axis 1

2 +24 V input for Axis 2

3,4 GND

⑤ RS-232C

(Connector model number)

Connector Model No. Manufacturer

Board side S03B-PASK-2 JST

Cable side PAP-03V-S JST

(Connector pin assignment)

Pin No. Signal Description

1 Send data (Signal level complying with RS-232C)

2 Receive data (Signal level complying with RS-232C)

3 GND

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

14

Page 15

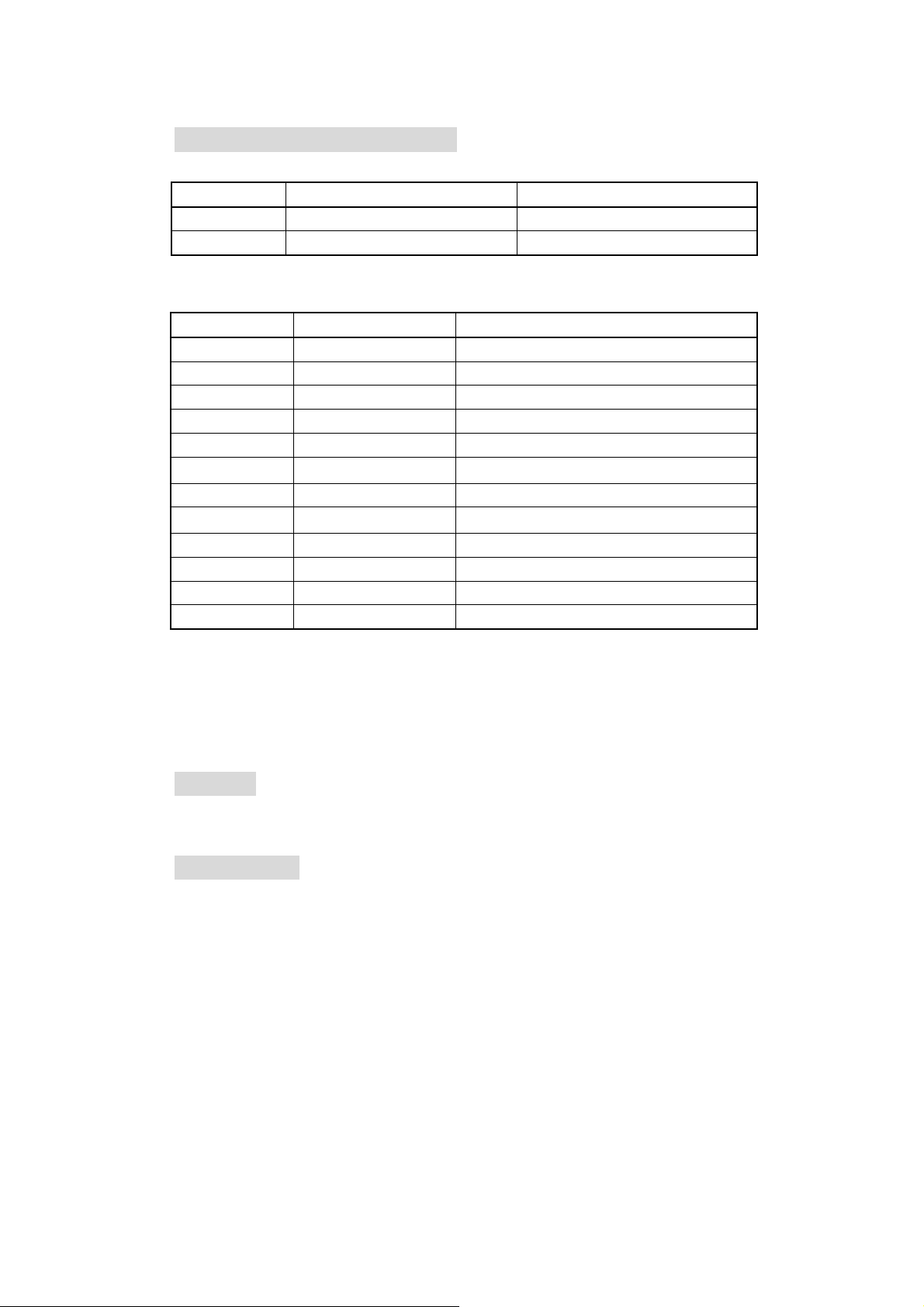

⑥ High-speed Serial Communication

(Connector model number)

Connector Model No. Manufacturer

Board side SM12B-PASS-1-TB JST

Cable side PAP-12V-S JST

(Connector pin assignment )

Pin No. Signal Name Signal Description

1 CLK- Clock (-)

2 CLK+ Clock (+)

3 FS- Frame sync (-)

4 FS+ Frame sync (+)

5 DAT(AXIS 1) - Axis 1 Target position data (-)

6

7 DAT(AXIS 2) - Axis 2 Target position data (-)

8

9 STS- Status (-)

10 STS+ Status (+)

11 GND System GND

12 FG Frame GND

DAT(AXIS 1)+

DAT(AXIS 2)+

Axis 1 Target position data (+)

Axis 2 Target position data (+)

The signal levels depend on the IF board.

GC-422 - Receiver: AM26LV32C (TI), Driver: SN75179B (TI)

GC-LVDS - Receiver: SN65LVDS32 (TI), Driver: SN65LVDS179 (TI)

⑦ Digital I/O

See 5.1. “Connector Pin Assignment”

⑧ Analog Monitor

See 5.1. “Connector Pin Assignment”

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

15

Page 16

⑨ Cooling Fan Power Supply

(Connector model number)

Connector Model No. Manufacturer

Board side S04B-PASK-2 JST

Cable side PAP-04V-S JST

(Connector pin arrangement)

Pin No. Signal Description

1 +24 V Output

2 GND

3 (No connection)

4 (No connection)

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

16

Page 17

2.7. Optional Cables

Optional cables are prepared for power and communications cables.

Connector pin assignment for each cable as follows.

Verify details with your sales representative.

Option cables

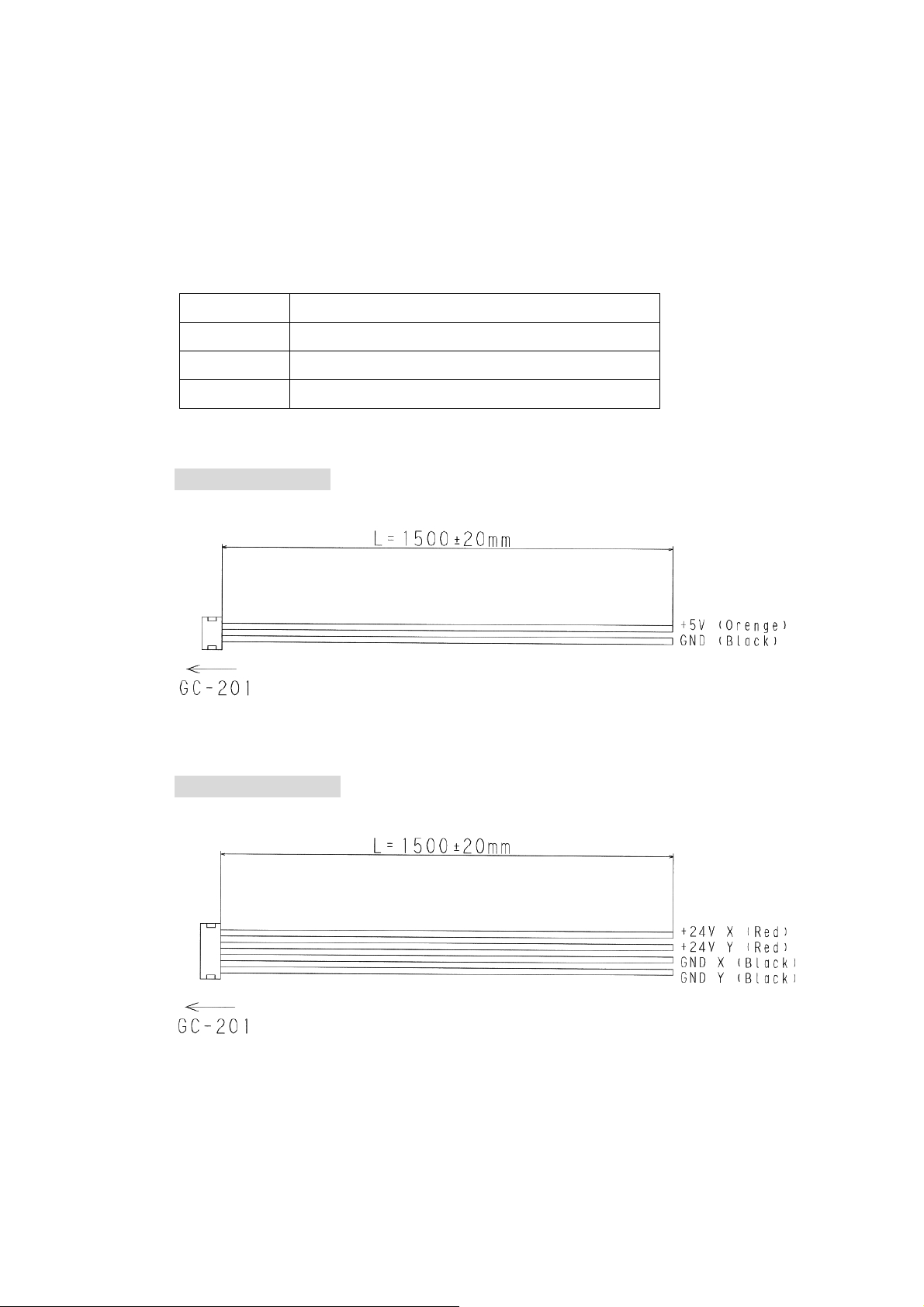

① Power cable (+5 V)

② Power cable (+24 V)

③ RS-232C cable

④ High-speed serial communication cable

① Power Cable +5 V

② Power Cable +24 V

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

17

Page 18

③ RS-232C Cable

PC side (D-sub 9 pin)

Pin Signal

2 RX

3 TX

5 GND

④ High-Speed Serial Communication Cable

PC side (D-sub 25pin)

Pin Signal Pin Signal

1 Clock - 14 Clock +

2 FS - 15 FS +

3 Data (Axis 1) - 16 Data (Axis 1) +

4 Data (Axis 2) - 17 Data (Axis 2) +

5 Do not connect 18 Do not connect

6 Status - 19 Status +

7 Do not connect 20 Do not connect

8 Do not connect 21 Do not connect

9 Do not connect 22 Do not connect

10 Do not connect 23 GND

11 GND 24 GND

12 Do not connect 25 Do not connect

13 Do not connect

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

18

Page 19

2.8. Control Specifications

The controller (GC-201) is operated by:

• RS-232C command input

• High-speed serial communication

Features

RS-232C

communication command input

- Raster scan and step movement etc.

can be performed easily.

- In order to obtain synchronization

with external equipment, operation

can be started with an external

trigger signal. (Fluctuating delays

may occur within the internal control

sampling time.)

High-speed serial communication

- Vector scans with control over the

desired locations of two axes are

possible. This is used in laser

marking etc.

- Complete synchronization with

external equipment can be obtained

in order to use high-speed serial

communication clock pulses by

controlling the controller.

- As it can be operated with XY2-100

communication specifications, a

controller compliant with XY2-100

can be connected.

Target position

command

Operation

setting

parameter

setting

Control clock

- A target position command input by an RS-232C communication command, or a target position

command from a high-speed serial communication can be mutually switched with a command. (See

2.8.5. “RS-232C Communication Command Input and High-Speed Communication Switching”)

RS-232C communication command High-speed serial communication

RS-232C communication command RS-232C communication command

Uses the controller GC-201 internal

circuit clock pulses

Uses high-speed serial

communication clock pulses

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

19

Page 20

- With the default settings at shipping, power-on starts up the controller with in RS-232 Communication

Command Input mode.

- The parameter can be set to determine which mode the controller starts after power-on. (See 6.1.

“Setting Controller Start Up Mode”)

Note:

For start up when set to the High-Speed Serial Communication mode, in order to use high-speed

serial communication clock pulses internally, signal input by high-speed serial communication is

necessary at power-on. When there is no signal input, a Clock Lack error occurs. (See 10.2. “Errors”)

After an error occurs, and input of a high-speed serial communication signal begins correctly,

operation begins automatically from the high-speed serial communication signal.

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

20

Page 21

2.8.1. Number of Encoder Pulses

This section explains the relationship between the galvano scanner motor rotating angle and the

number of encoder pulses.

Control commands and some of the parameter angle settings use the number of encoder pulses.

The controller divides one encoder cycle into 8,192, and this is the number of encoder pulses.

Depending on the type of encoder included on the motor, caution is necessary as the number of

pulses for the same specified angle can differ.

Many commands use pulses as a unit in the RS-232C communication command parameter data used

for operations.

In the case of the GM-1010 for example

1 rotation (360°) = 1,000 cycles = 1,000 × 8,192 = 8,192,000 pulses

1° (angle of equipment) = 8,192,000 pulses × 1 / 360 = 22,756 pulses

Resolution = 360° ÷ 8,192,000 pulses = 0.0000429° = 0.77 urad

Each motor is as follows.

Motor type GM-1010 GM-1015, GM-1020

Included encoder cycles / 1

rotation

Number of pulses 8,192,000 pulses 12,288,000 pulses

Command resolution (1 pulse) 0.77 urad 0.51 urad

360°

1,000 cycles 1,500 cycles

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

21

Page 22

2.8.2. RS-232C command input

RS-232C command input allows the following:

• Operation setting

• Parameter setting

• Error processing

• Status check

(For details, see 8. “Commands”)

In case not using high-speed serial communication, RS-232C communication command input is enough

for the following function:

• Step movement

• Raster scan (Continuous oscillation of a certain angle at a fixed frequency)

(Communication specifications)

Wiring Cross wiring

Communication rate 38400 bps

Data length 8 bits

Stop bit 1

Parity None

Data format ASCII code

Delimiter code LF (0x0a) or CR (0x0d)

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

22

Page 23

(Command specifications)

In response to command send, the controller returns a reply with data.

The data contents depend on the command. (For details, see 8.2. “Command Details”)

Command send

A Axis No. C Command ID / Data Delimiter

Axis No.

1 or 2

Command

Command ID

Decimal, 3-digit

(See 7.1 for details)

Data

Added to command as

required (decimal)

E.g. Servo ON ID = 4 Data = 1

A1C004 / 1 (LF)

(ASCII code: 0x41 0x31 0x43 0x30 0x30 0x34 0x2f 0x31 0x0a)

A 1 C 0 0 4 / 1 (LF)

Command reply

A Axis No. C Command ID / Data Delimiter

Axis No.

1 or 2

Command

Command ID

Decimal, 3-digit

(See 7.1 for details)

Return value

Delimiter

LF or CR

Delimiter

LF or CR

E.g. Servo ON ID = 4 Data = 1

A1C004 / 1 (LF)

(ASCII code: 0x41 0x31 0x43 0x30 0x30 0x34 0x2f 0x31 0x0a)

A 1 C 0 0 4 / 1 (LF)

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

23

Page 24

Parameters of the GC-201 can be changed by the following sending method to the controller.

Also in response to parameters sent, the controller always returns a reply with data.

The data contents depend on the command. (For details, see 9.2. “Parameter Details”)

When a parameter is changed, in order to start up with the same setting the next time power is turned

on, it is necessary to write the changed parameter to the ROM.

(See 9.4. “Writing Parameters into ROM” for methods of writing to ROM with control software)

(Note: Carry out writing parameters to ROM only after thoroughly verifying the content. Depending on

the changed values, the controller may not start normally.)

Parameter send

A Axis No. P Parameter ID / Data Delimiter

Axis No.

1 or 2

Parameter

Command ID

Decimal, 3-digit

(See 7.1 for details)

Parameter setting

Decimal

E.g. LQ gain parameter ID = 6 Data = 4500

A1P006 / 4500 (LF)

(ASCII code: 0x41 0x31 0x50 0x30 0x30 0x36 0x2f 0x34 0x35 0x30 0x30 0x0a)

A 1 P 0 0 6 / 4 5 0 0 (LF)

Parameter reply

A Axis No. P Parameter ID / Data Delimiter

Axis No.

1 or 2

Parameter

Command ID

Decimal, 3-digit

(See 7.1 for details)

Parameter setting

successful / unsuccessful

0 or 1

Delimiter

LF or CR

Delimiter

LF or CR

E.g. LQ gain parameter ID = 6 Data = 4500

A1P006 / 4500 (LF)

(ASCII code: 0x41 0x31 0x50 0x30 0x30 0x36 0x2f 0x30 0x0a)

A 1 P 0 0 6 / 0 (LF)

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

24

Page 25

Writing parameters to ROM is also possible with commands via RS-232C.

When writing parameters to ROM, a reply that definitely contains data will be sent by a controller.

The content of data is different by a parameter. (For details, see 9.2. “Parameter Details”)

(Note: Carry out writing parameters to ROM only after thoroughly verifying the content. Depending on

the changed values, the controller may not start normally.)

Parameter ROM Write send

E Axis No. P Parameter ID / Data Delimiter

Axis No.

1 or 2

Parameter

Parameter ID

Decimal, 3-digit

(See 7.1 for details)

Parameter setting

Decimal

E.g. LQ gain parameter ID = 6 Data = 4500

E1P006 / 4500 (LF)

(ASCII code: 0x45 0x31 0x50 0x30 0x30 0x36 0x2f 0x34 0x35 0x30 0x30 0x0a)

E 1 P 0 0 6 / 4 5 0 0 (LF)

Delimiter

LF or CR

Parameter ROM Write reply

E Axis No. P Parameter ID / Data Delimiter

Axis No.

1 or 2

Parameter

Parameter ID

Decimal, 3-digit

(See 7.1 for details)

Parameter setting

successful / unsuccessful

0 or 1

E.g. LQ gain parameter ID = 6 Data = 4500

E1P006 / 4500 (LF)

(ASCII code: 0x45 0x31 0x50 0x30 0x30 0x36 0x2f 0x30 0x0a)

E 1 P 0 0 6 / 0 (LF)

Delimiter

LF or CR

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

25

Page 26

A

1

A

1

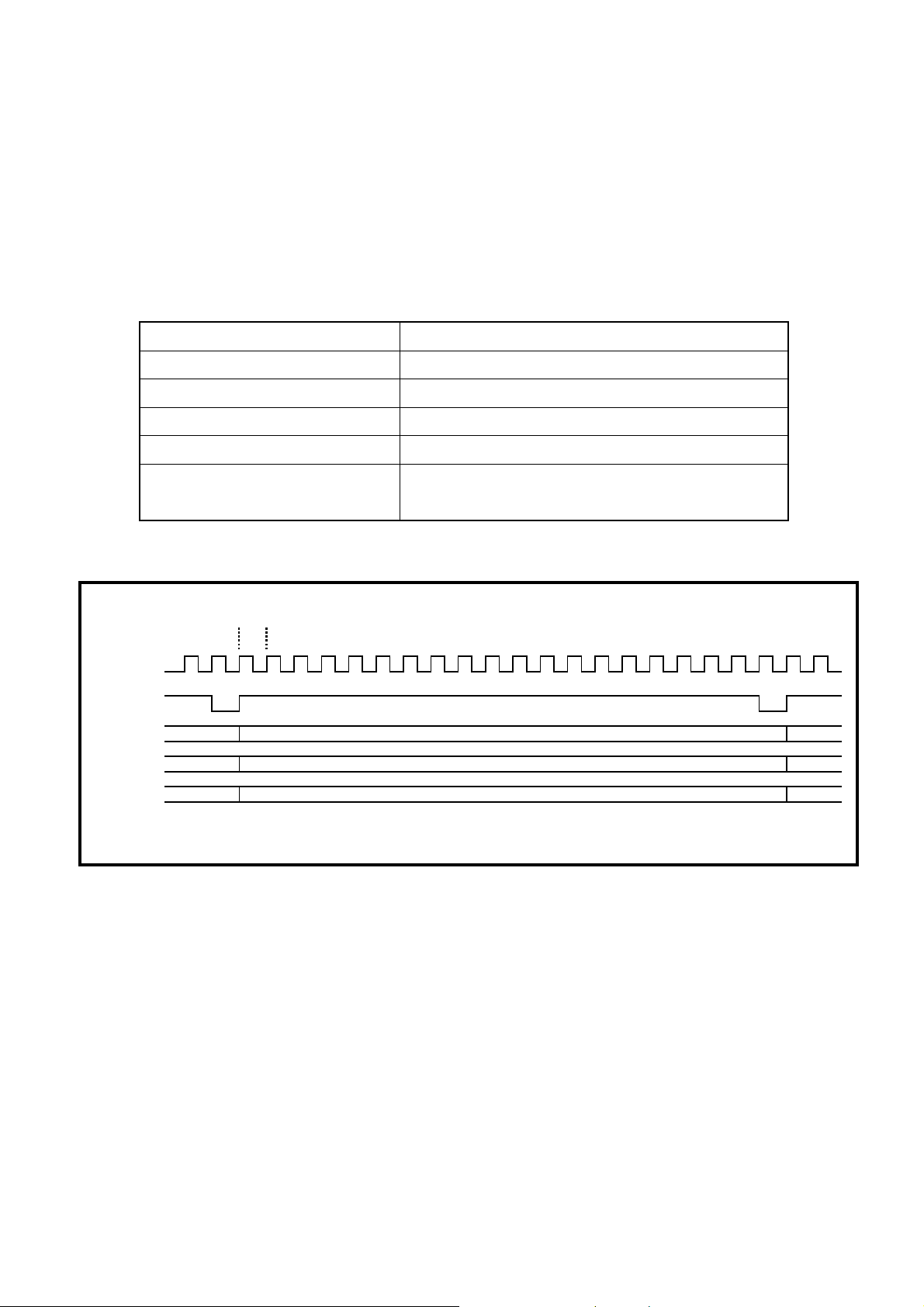

2.8.3. High-speed serial communication

To control the mirror to an arbitrary position by marking or any other application, target position data

updated as required can be given to the controller by using high-speed serial communication.

By setting, the controller can be started up in the mode of tracking a target position specified by

high-speed serial communication. (For details, see 6.1. “Setting Controller Start Up Mode”)

(Communication specifications)

Base clock (CLK) 2 MHz

Frame sync (FS) 100 kHz

Data (DAT) 20 bits (Position data: 16 bits)

Status (STS) 20 bits

Transmission system Differential signal

Signal level

(Selectable by the optional IF board)

(Timing Diagram)

5V-TTL, LVDS

Timing Diagram

CLK

2MHz

1234567891011121314151617181920

FS

DAT (AXIS 1)

DAT (AXIS 2)

STS

AXIS 1 DATA -1 AXIS 1 DATA

AXIS 2 DATA -1 AXIS 2 DATA

Status -1 Status Status +1

Input Signal to GC-201 : CLK , FS , DAT

Ounput Signal from GC-201 : STS

As indicated in the above timing diagram, it is necessary to always continuously input the CLK, FS,

XIS 1 DATA +

XIS 2 DATA +

and DAT signals to the GC-201. In the event that the signal is disconnected, or the signal’s timing is

incorrect, the GC-201 will output an error signal (Clock Lack). (For details, See 10.2. “Errors”.)

When switching to high-speed serial communication mode, or starting up in high-speed serial

communication mode when turning on the controller’s power supply, input of the high-speed serial

communication signal (all of CLK, FS, and DAT) beforehand is necessary.

For the support of other communication specifications, contact the Sales Department.

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

26

Page 27

(Target Position Data) DAT (AXIS1), DAT (AXIS 2)

It is possible to switch the length of data used as target position data from the DAT (AXIS1), DAT (AXIS

2) 20 bit (every 100 kHz) signals. Please set appropriately to match the signal specifications of the

scanner controller that outputs a high-speed serial communication signal, and other output equipment.

Note: The length of data input in the GC-201 is always 20 bit (every 100 kHz). The bits of the target

position data that get used and sent are switched from within 20 bit data.

When there is a big difference in the target position specified in the high-speed serial communication,

and the actual operation position, it is possible this parameter setting is incorrect. Please verify.

The data length of the target position data by the high-speed serial communication can be changed by

two following parameters.

(Target position data length)

Can be changed by 16 bit – 20 bit.

Parameter ID DATA

16: 16bit Data *

17: 17bit Data

67

(Data position)

The least significant bit position of the target position data of high-speed serial communication 20bit

data can be set by following parameter. The specified number of bits is shifted right, making the target

position data.

Parameter ID DATA

68

18: 18bit Data

19: 19bit Data

20: 20bit Data

0: 0bit position

1: 1bit position *

2: 2bit position

3: 3bit position

4: 4bit position

With the default settings at shipping, the setting is * (16 bit position data length, data least significant bit 1

bit position). This communication specification is compatible with XY2-100. When using the scanner

controller of XY2-100 specifications, please use this setting.

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

27

Page 28

(Paramete

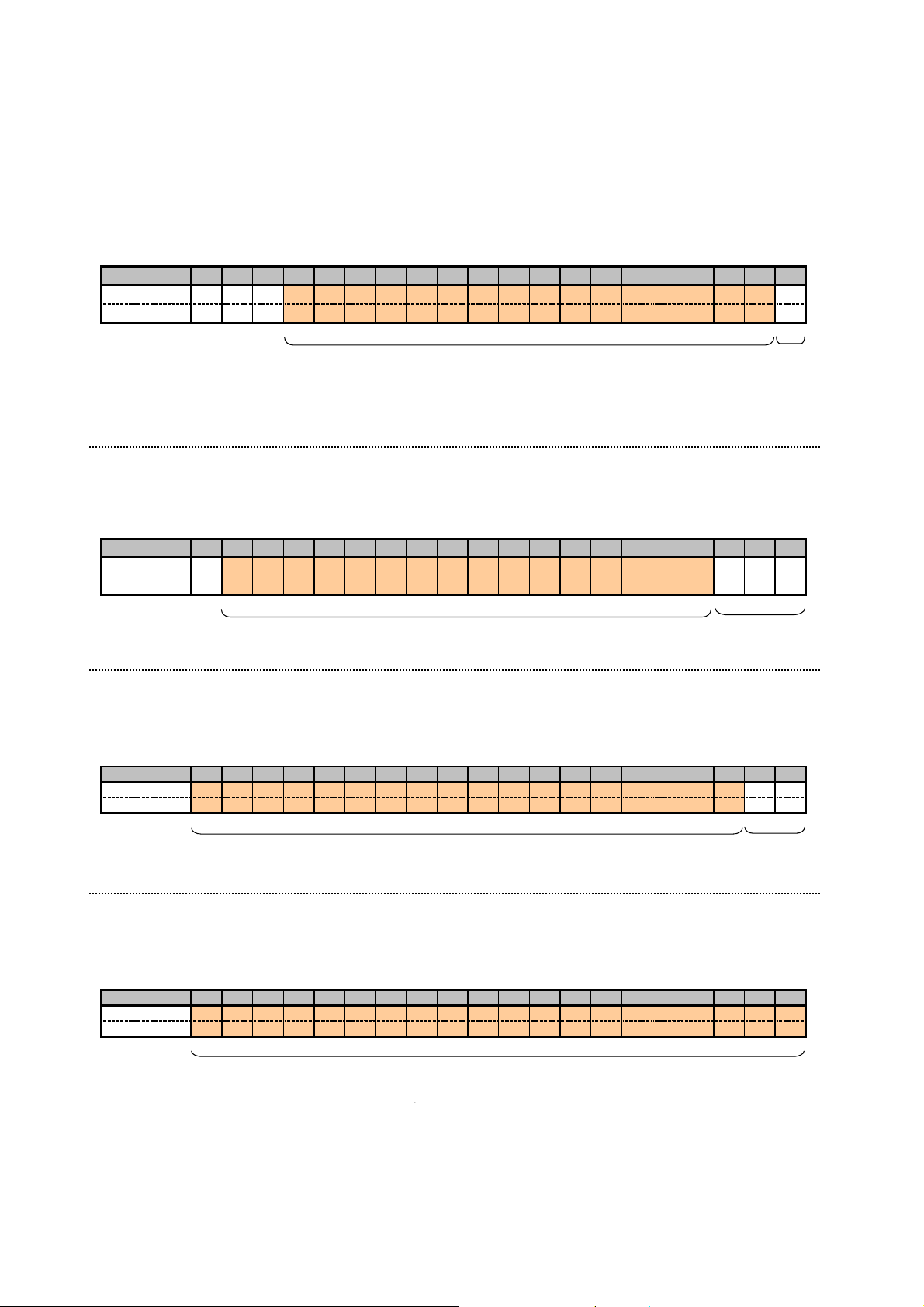

Examples of the settings are as follows.

(Example 1) Parameter ID = 67 16

Parameter ID = 68 1

XY2-100 specification compatible

Bit

DATA (AXIS 1)

DATA (AXIS 2)

1234567891011121314151617181920

N N ND15D14D13D12D11D10D9D8D7D6D5D4D3D2D1D0 N

N N ND15D14D13D12D11D10D9D8D7D6D5D4D3D2D1D0 N

(Parameter

16bit

パラメータ

(

ID = 67) (

Note: The above N bit data is not used. It does not matter if it is either 1 or 0.

(Example 2) Parameter ID = 67 16

Parameter ID = 68 3

1bit

(Parameter

パラメータ

ID = 68)

Bit

DATA (AXIS 1)

DATA (AXIS 2)

1234567891011121314151617181920

ND15D14D13D12D11D10D9D8D7D6D5D4D3D2D1D0 N N N

ND15D14D13D12D11D10D9D8D7D6D5D4D3D2D1D0 N N N

(Example 3) Parameter ID = 67 18

Parameter ID = 68 2

Bit

DATA (AXIS 1)

DATA (AXIS 2)

1234567891011121314151617181920

D17 D16 D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0 N N

D17 D16 D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0 N N

(Example 4) Parameter ID = 67 20

Parameter ID = 68 0

Bit

DATA (AXIS 1)

DATA (AXIS 2)

1234567891011121314151617181920

D19 D18 D17 D16 D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

D19 D18 D17 D16 D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

16bit

パラメータ

(Parameter

(

18bit

パラメータ

(

(Parameter

ID = 67) (

ID = 67) (

(Parameter

(Parameter

3bit

パラメータ

2bit

パラメータ

ID = 68)

ID = 68)

20bit

パラメータ

(

ID = 67) (

r

(Parameter

0bit

パラメータ

ID = 68)

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

28

Page 29

This section explains the motor rotating angle for the high-speed serial communication data.

Default settings have the following relationships.

Data 1 = 1 pulse (factory setting)

See 2.8.1. “Number of Encoder Pulses" for the relationship between the motor rotating angle and the

number of pulses.

・ In the case of 16 bit data

(GM-1010)

Maximum

position

0 pulse

position

Minimum

position

(GM-1015, GM-1020)

Maximum

position

High-speed communication

Target position data value

0xFFFF -32767 pulses -1.44 deg

0x8000 0 0

0x0000 +32768 pulses +1.44 deg

High-speed communication

Target position data value

0xFFFF -32767 pulses -0.96 deg

16bit

16bit

Motor

Number of pluses Motor rotating angle

Motor

Number of pluses Motor rotating angle

0 pulse

position

Minimum

position

Note: The motor rotating angle + direction when viewed from the rotation axis appear as clockwise.

When set to the factory default, rotation is only possible up to angles above.

If a greater angle is specified, set a magnification by using the following parameter.

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

0x8000 0 0

0x0000 +32768 pulses +0.96 deg

29

Page 30

Parameter ID Data

13

(High-speed serial communication

conversion gain parameter)

E.g. For x2 (parameter ID = 13 setting: 2000), the following angle can be specified:

-1.44 × 2 deg ~ 1.44 × 2 deg (GM-1010)

-0.96 × 2 deg ~ 0.96 × 2 deg (GM-1015, 1020)

The command resolution will be two times

Magnification ×1000

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

30

Page 31

• In the case of 20 bit data

Usually data 1 = 1 pulse.

(GM-1010)

Maximum

position

0 pulse position 0x80000 0 0

Minimum position 0x00000 +524288 pulses +23.04 deg

(GM-1015, GM-1020)

Maximum

position

0 pulse position 0x80000 0 0

High-speed communication

Target position data value

20bit

0xFFFFF -524287 pulses -23.04 deg

High-speed communication

Target position data value

20bit

0xFFFFF -524287 pulses -15.36 deg

Number of pluses Motor rotating angle

Number of pluses Motor rotating angle

Motor

Motor

Minimum position 0x00000 +524288 pulses +15.36 deg

However, the maximum rotating angle specification is ±20°.

Maximum movable range of the motor is set with Parameter ID = 0, 1 (CW limit, CCW limit).

The position data of high-speed serial communication can not exceed this range.

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

31

Page 32

2.8.3.1. Origin Offset

It is possible to change the origin position of high-speed serial communications.

Parameter ID Data

15

High-speed serial communication

offset

Unit is pulse.

High-speed serial communication offset is not influenced by the parameter ID = 13 high-speed serial

communication conversion gain setting.

E.g.

When parameter ID = 15 setting 2276 pulse (=0.1°) is set, regardless of the parameter ID = 13 setting, it

will always operate with a 0.1° (CW direction) offset.

Note) Current position output data of Next heading 2.8.4. is actual motor encoder position data.

Current position output data

Unit: pulse

= High speed serial communication command position + High speed serial communication offset

So, Current position data is not equal to High speed serial communication command position that

you specify.

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

32

Page 33

2.8.3.2. High-speed serial communication motor drive timing

The following diagram indicates actual motor drive signal output timing when the high-speed serial

communication position command is received.

COMMAND

COMMAND

10us

10us

XY-2 COMMAND

XY-2 COMMAND

FRAME SYNC

FRAME SYNC

Target

Target

Position1

Position1

Target

Target

Position2

Position2

Target

Target

Position3

Position3

Target

DSP Sampling Clock

DSP Sampling Clock

5us

5us

5us

5us

10us

10us

Target

Position1

Position1

CONTROL

CONTROL

5us

20us

20us

5us

Output to MOTOR

Output to MOTOR

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

33

Page 34

A

A

A

A

A

A

A

A

A

A

A

A

2.8.4. Status (High-speed Serial Communication STS)

The controller status is sent by the high-speed serial communication STS line.

The contents of status sent from a controller can be changed by the following parameter.

Note: Status output will only be output when controlled by the high-speed serial communication mode.

During operation in a RS-232C communication input mode (internal clock), there will be no status

output (raster scan, status transfer etc.).

Parameter ID Data

0: Controller condition 1

1: Controller condition 2

66

2: Current position (Axis 1)

3: Current position (Axis 2)

4: Current position (Axis1, Axis2)

Each of the status contents are as follows.

S19 (reserve) 0 Axis1data bit19

S18 (reserve) 0 Axis1data bit18

S17 (reserve) 0 Axis1data bit17

S16 POW OK 0 Axis1data bit16

S15 TEMP OK 0 Axis1data bit15

S14 (reserve) 0 Axis1data bit14

S13 Axis2 INPOS Axis1 READY Axis1data bit13

S12 Axis1 INPOS

S11 (reserve)

S10 0 Axis1 INPOS Axis1data bit10

S09 1 0 Axis1data bit9 Axis2 data bit9 Axis1(2) data bit9

S08 POW OK 0 Axis1data bit8 Axis2 data bit8 Axis1(2) data bit8

S07 TEMP OK 0 Axis1data bit7 Axis2 data bit7 Axis1(2) data bit7

S06 (reserve) 0 Axis1data bit6 Axis2 data bit6 Axis1(2) data bit6

S05 Axis2 INPOS 0 Axis1data bit5 Axis2 data bit5 Axis1(2) data bit5

S04 Axis1 INPOS 0 Axis1data bit4 Axis2 data bit4 Axis1(2) data bit4

S03 (reserve) Axis2 READY Axis1data bit3 Axis2 data bit3 Axis1(2) data bit3

S02 0

S01 1

S00 (reserve) Axis2 INPOS Axis1data bit0 Axis2 data bit0 Axis1(2) data bit0

Mode-0 Mode-1 Mode-2 Mode-3 Mode-4

xis1 ALARM 1Axis1data bit12Axis2 data bit12Axis1(2) data bit12

xis1 ALARM 2Axis1data bit11Axis2 data bit11 Axis1(2) data bit11

xis2 ALARM 1Axis1data bit2 Axis2 data bit2 Axis1(2) data bit2

xis2 ALARM 2Axis1data bit1 Axis2 data bit1 Axis1(2) data bit1

xis2 data bit19Axis flag

xis2 data bit18Axis1(2) data bit18

xis2 data bit17Axis1(2) data bit17

xis2 data bit16Axis1(2) data bit16

xis2 data bit15Axis1(2) data bit15

xis2 data bit14Axis1(2) data bit14

xis2 data bit13Axis1(2) data bit13

xis2 data bit10Axis1(2) data bit10

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

34

Page 35

• Mode-0 : Controller condition 1

Outputs the status of the controller.

POW OK : No problem with the power supply

TEMP OK : No problem with the internal temperature

Axis2 INPOS : Axis 2 in-position signal

Axis1 INPOS : Axis 1 in-position signal

(When current position moves into the in-position range, this signal will be

output.)

• Mode-1: Controller condition 2

Outputs the status of the controller.

READY : Servo ON and ready to control by high-speed serial communication.

ALARM 1 : Alarm output (priority high)

(See 5.3. “Digital Input-Output Function”. Same as Axis 1 Error 1, Axis 2

Error 1)

ALARM 2 : Alarm output (priority low)

(See 5.3. “Digital Input-Output Function”. Same as Axis 1 Error 2, Axis 2

Error 2)

INPOS : In-position signal

(When it moves into the parameter ID = 3 in-position range, this signal will

be output.)

• Mode-2: Current position data (Axis 1)

Outputs the axis 1 encoder position.

Data length: 20 bits.

High-speed communication

Position data value

20 bits

Maximum

position

0 pulse

position

Minimum

position

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

0xFFFFF

0x80000

0x0000F

35

Page 36

• Mode-3: Current position data (Axis 2)

Outputs the Axis 2 encoder position.

Data length: 20 bits.

• Mode-4: Current position data (Axis 1, Axis 2)

The encoder position of Axis 1 and Axis 2 is output alternately.

Data length: 19 bits.

The first 1 bit indicates the axis (Axis Flag).

Axis Flag = 0 Axis 1

Axis Flag = 1 Axis 2

Data information for the current position data of Mode-2, 3, and 4 is output with the timing as follows.

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

36

Page 37

2.8.5. RS-232C Communication Command Input and High-Speed Communication

Switching

A position command input can be switched with a RS-232C communication command.

Command ID Data

23

0: RS-232C command communication

7: High-speed serial communication

Command ID = 23 Data 7

A1C023/7

*Command also sent to Axis 2

A2C023/7

RS-232C command

communication

Command ID = 23 Data 0

A1C023/0

A2C023/0

*Command also sent to Axis 2

High-speed serial

communication

Note: In the case of two axis control, it is necessary to execute this command for each axis.

It is possible to receive input of RS-232C communication commands even when switching to

high-speed serial communication. However, as position commands give priority to the input of

high-speed serial communication, operation commands such as RS-232C communication command

step movement, and raster scans will be ignored.

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

37

Page 38

2.9. Heat Radiation and Installation

Since the controller and motor generate heat, their heat radiation should be considered carefully.

Generated heat depends on the operating conditions. Determine a heat radiation method according to

the operating conditions.

The controller and motor have a temperature detection sensor (thermistor) in the heat generating

section. As a safety function, the thermistor stops control if the detector temperature reaches:

Controller About 70ºC

Motor About 70ºC

(For details, see 10.1. “Safety Functions”)

The controller and motor require heat radiation so that their temperatures will not exceed the above values.

Controller installation methods

The controller can be installed by either method A or B below.

At installation, put the controller frame in contact with a heat-radiating structure (heat sink or cabinet).

Method A has higher heat radiation efficiency. However, select either method by considering the

operating conditions and cable routing. When installing the controller frame, apply thermal grease or

attach a thermal conductive sheet to the contact surface.

Under some operating conditions, forced air cooling by a fan is necessary. Cool the heat-radiating

structure (heat sink or cabinet) and the controller.

A B

Output amplifier

Control circuit

In addition to the output amplifier, the control circuit section (DSP) generates heat.

Allow as much space as possible around the equipment.

Caution

The controller becomes hot during operation.

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

38

Page 39

3. Software

The controller (GC-201) bundles the dedicated control software.

Using the control software makes the following controller operations easy:

z Parameter setting

z Operation setting (Step movement and raster scan)

z Status check

z Servo tuning (Frequency characteristic measurement)

Most of the functions that can be performed by the control software can also be executed by external

commands input through RS-232C connection without using the control software. This manual

describes operations both by the control software and by RS-232C command input.

Note: The following function can be executed by the control software only, and not by RS-232C

command input:

z Frequency characteristic (FFT) measurement

z Auto tuning

z XY matching

z Step response measurement function

3.1. Supported PC Environment

Supported OS MS-Windows 2000, XP, Vista

Connection port RS-232C port (with USB-RS-232C conversion cable)

3.2. Installation CD

Installation folder structure of the bundled control software

Control Software (Control software installer)

Manual (GC-201, GC-251 manual)

The necessary software is not included in 11.1. “Firmware Update”. Please contact your sales

representative.

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

39

Page 40

3.3. Control Software Installation

・ Insert the bundled control software installation CD into the CD drive.

・ Execute Setup.exe in the Control Software folder.

D:¥

・ Press the Next button.

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

40

Page 41

・ Specify an installation folder and press the Next button.

(Recommendation: Usually this is not changed.)

・ Press the Next button.

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

41

Page 42

・ Press the Close button. This completes installation.

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

42

Page 43

3.4. Software Start Up

・ Connect the controller and the PC with the optional RS-232C cable.

・ Select Windows “START” - “Programs” - “Canon Scanner” - “Control Software”.

・ Setting the COM port

Select the connected RS-232C port and press the OK button.

・ The control screen is displayed.

While communication with the controller has not started yet, the screen displays “DISCONNECT”

in gray at the upper left as the connection status.

Connection

status

Note: The value of each item on the above screen differs depending on the controller status.

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

43

Page 44

・ When the power to the controller is turned on, communication automatically starts.

When communication starts, the connection status at the upper left changes to “CONNECT” in

green.

Connection

status

The control software can be started up after power to the controller has been turned on.

Communication then starts automatically. (“CONNECT” is displayed.)

Note: The value of each item on the above screen differs depending on the controller status.

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

44

Page 45

3.5. Control Screen

This section explains the buttons and other items on the control screen.

①

⑦

⑧

⑨

② ③ ④ ⑤ ⑥

⑫

⑬

⑩ ⑪

The status of RS-232 connection to the controller is displayed.

①

Connection display

②

③

④

Position display

Axis selection

Origin control

(Homing to origin)

Connected: CONNECT (green)

Not connected: DISCONNECT (gray)

The encoder position (Mechanical angle) of each axis is displayed.

(Unit: pulse)

Note: Since the number of encoder pulses per rotation depends on

the galvano motor, the relationship between the number of pulses

and the angle also differs with the motor type.

Select an axis for control and information display.

(#1 = Axis 1, #2 = Axis 2)

The screen can display the information of only one axis selected

here, although the position displayed at ② and the status

displayed at ⑨ always show the information of both axes.

Press this button to go to origin or detect the origin.

The operation depends on the controller status.

(During ordinary servo control)

Moving to the origin (where the position display is 0)

Invalid during high-speed serial communication

(After servo OFF and soft reset) Starting origin detection

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

45

Page 46

⑤

⑥

⑦

⑧

⑨

⑩ Alarm clear Clears the alarm. The alarm lamp turns off.

⑪

⑫

Servo ON/OFF Start or stop servo control.

Select the high-speed serial communication command or RS232C

High-speed serial

communication

selection

Tab selection

Control display

Status display

Soft reset button Press this button for soft reset.

Command input

screen

command input for position specification.

(For details, see 4.4. Position Command Input by High-speed

Serial Communication)

(Start = High-speed serial communication, OFF = RS-232C

command)

The screen of each function can be displayed by tab selection.

(A detailed explanation of the screen is shown when each function

is displayed.)

This area displays the screen of each function selected by a tab at

⑦.

The controller status of two axes is displayed.

If press the alarm button during alarm light on, windows content the

alarm details will come up.

Allows direct command input.

⑬

DSP version

display

The version of the controller software is displayed.

During troubleshooting, the support staff may ask for the version

number.

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

46

Page 47

4. Operating Procedure

This chapter explains how to use the system.

Operations by [Control Software] and by [RS-232C command] are explained together.

4.1. Controller Start Up

When the power (+5 V, +24 V) is turned on, the controller execute the following automatically:

・Read saved parameters from ROM

・Home to the origin

・Correct the encoder (high-speed oscillation of a fixed angle)

It takes about 15 seconds until the controller is started up.

With the default settings at shipping, the controller is started up with RS-232C communication

command input (internal clock) mode.

The completion of start up can be confirmed as follows:

Control Software

Changes to

‘CONNECT’

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

Light on

47

Page 48

RS-232C command

Sends RS-232C command ID=14 “Status read”

SRVON, SYNC, INPOS = High

ORGN = Low

(For details, see 8.2. “Command Details”)

and checks the following status:

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

48

Page 49

4.2. Step Movement

Execute step movement for a fixed angle.

Control Software

④

②

①

③

・Select the Step Move tab. ①

・Select an axis for step movement. ②

・Specify the displacement (angle or pulse count) for relative position (STEP) and absolute position.

③

・Press the STEP button (either positive or negative position direction can be specified) or GO

button. ③

Note: Uncheck the ④ checkbox when moving continuously. If it is checked, the stabilization time

measurement function on the next page operates, and as it takes time to display the results, moving

continuously is not possible.

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

49

Page 50

RS-232C command

・ Target value setting mode (Command ID = 10)

・ Target position setting (Command ID = 20)

・ Movement start (Command ID = 8)

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

50

Page 51

4.2.1. Step Movement Responce Time Measurement

Control Software has a function that measures the step movement response time. This function is can

only be executed by the control software. It cannot be executed by a RS-232C command.

• Put a check in the Enable Scope checkbox ①

②

③ ①

• Select the time range for step movement response to be measured ②

(As the response time depends on the displacement, change when necessary.)

• Specify the displacement (angle and pulse count) for relative position (STEP) and absolute position.

③

• Press the STEP button (either positive or negative position direction can be specified) or GO button.

③

• The Scope and Measurement window appears automatically

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

51

Page 52

① ②

④

⑤

⑥ ⑦

(Scope and Measurement window explanation)

Scope and Measurement window

③

①

②

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

Step response

waveform

Cursor location

(Step response

waveform)

Displays the step response waveform by the deviation from the

target position.

0 usec (left edge) position is the movement start time.

① Displays the cursor location in the step response waveform

graph.

52

Page 53

Measured step response waveforms can be saved temporary as

Reference data

reference data. The next measured data can be overwritten and

③

(Save, display, hide)

compared.

(See 4.2.1.2 “the Reference Data Comparison Method.”)

Displays the

④

difference of MAIN

This displays the difference between measurement data and

reference data.

and reference data

⑤ Motor drive current Displays the motor drive current.

Use the zoom button to zoom in and display detailed data.

⑥ Zoom button

(See 4.2.1.1 “the Measurement Data Display Zoom Method.”)

⑦ Saving data This saves measurement data as a text file.

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

53

Page 54

4.2.1.1. Measurement Data Display Zoom Method

A zoomed display is possible in order to confirm measurement data details.

(Specify horizontal (time) zoom)

• Drag the step response display cursor (red) to the width you want to display enlarged ①

(Adjust while looking at the X Cursors display below)

• Press the Horizontal ZOOM button ②

①

②

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

54

Page 55

(Specify vertical (angle) zoom)

• Drag the step response display cursor (green) to the width you want to display enlarged ①

(Adjust while looking at the Y Cursors display below)

• Press the Vertical ZOOM button ②

①

②

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

55

Page 56

4.2.1.2. Reference Data Comparison Method

This displays step response waveforms with two different measurement conditions, and makes a

comparison possible.

• Display the step response waveform with the first measurement condition, and press the “Save

MAIN to REF” button. ①

Measured waveform data (MAIN) is copied to the reference data (REF).

There is no change to the screen display at this time.

(The above display is the measurement results for 0.1 deg (Mechanical) step movement.)

• Returns to the control software window without closing the Scope and Measurement window.

①

• Measuring the step response with different measurement conditions.

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

56

Page 57

• The step response waveform displays (blue).

(The above display is the measurement results for 0.12 deg (Mechanical) step movement.)

• Press the REF button. ②

• The response waveform (gray) saved in reference data is overwritten.

REF

MAIN

②

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

57

Page 58

• Press the following button when you want to delete the waveform display for each of MAIN (blue)

and REF (gray).

MAIN button ③ -> Wfm OFF button ⑤

REF button ④ -> Wfm OFF button ⑤

To display again, press the MAIN, or OFF buttons.

③ ④

⑤

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

58

Page 59

4.3. Raster Scan

Execute oscillation of a fixed angle at a fixed frequency.

Control Software

②

①

③

④

⑤

・Select the Raster Scan tab. ①

・Select an axis for raster scan. ②

・Specify the operation parameters (Scan Time, Scan Angle, Duty, and Interval). ③

・Press the Scan Start button to start operation. ④

・Press the Scan Stop button to stop operation. ⑤

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

59

Page 60

RS-232C command

・ Raster scan interval setting (Parameter ID = 26)

・ Raster scan duty ratio setting (Parameter ID = 27)

・ Raster scan oscillation angle setting (Parameter ID = 28)

・ Scan start (Command ID = 23 Data = 3)

・ Scan stop (Command ID = 23 Data = 0)

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

60

Page 61

4.4. Position Command Input by High-speed Serial Communication

In order to carry out a vector scan, target position data is given to the controller by high-speed serial

communication, and the data is updated as required.

It is possible to change the mode of the controller to the mode of receiving target position data by

high-speed serial communication. For changing the mode, it is necessary to enter high-speed serial

communication signals into the controller in advance.

Control Software

①

・ Switch HiSpeed Serial to Start. ①

This switching makes the controller follow target position data by high-speed serial communication.

・ Switch HiSpeed Serial to OFF. ②

Input of the MOVE command is awaited.

RS-232C commands

・ Switch to high-speed serial communication (Command ID = 23 Data = 7)

・ Return to internal clock operation (Command ID = 23 Data = 0)

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

61

Page 62

5. Monitor Output and Digital Input Functions

The controller has an analog monitor output connector for monitoring the operation status and a digital

I/O connector for external signal input.

5.1. Connector Pin Assignment

The controller is equipped with the following:

Analog monitor output connector ×1

Digital I/O connector ×1

Digital I/O

connector

Analog monitor output

connector

In order to evaluate this galvano scanner, the above output connectors are connected, and a monitor

board for evaluation that can confirm analog output signals and the I/O of a digital signal is prepared

as an optional product. Please contact the Sales Department for details.

The signal name is displayed on the evaluation monitor board. Please check the signal after referring

to the table of the following pin arrangement.

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

Monitor Board for

evaluation

62

Page 63

Evaluation Monitor Board Pin Assignment

Pin Assignment of the optional monitor board for evaluation is as follows.

D15

D16

D1

D18

D9

D10

D12

GND GND

Digital I/O

D4

D5

D1

D2

D3 D6 D11

A7

A8

A5

A6

Analog Monitor

A3

A4

A1

A2

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

63

Page 64

Analog monitor output connector

Connector model number

Connector Model No. Manufacturer

Board side XG4C-1034 OMRON

Cable side XG4M-1030-T OMRON

Connector pin assignment

Monitor Board for

Pin No.

1 A1 Axis 1 current command value

2 A2 Axis 1 analog monitor 1 (Monitor item switching)

3 A3 Axis 1 analog monitor 2 (Monitor item switching)

4 A4 Axis 1 analog monitor 3 (Monitor item switching)

5 A5 Axis 2 current command value

6 A6 Axis 2 analog monitor 1 (Monitor item switching)

7 A7 Axis 2 analog monitor 2 (Monitor item switching)

8 A8 Axis 2 analog monitor 3 (Monitor item switching)

9 A9 Analog GND

10 A10 Analog GND

The controller has three monitor terminals for each of the two axes to check the operation status.

The output signal contents can be changed and the output magnification can also be changed.

(For details, see 5.2. “Analog Monitor Output Selecting”)

Evaluation

Signal Name

Signal Description

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

64

Page 65

Digital I/O connectors

Connector model number

Connector Model No. Manufacturer

Board side 8931E-020-178L KEL

Cable side 8925E-020-179 KEL

Connector pin assignment

Monitor

Pin

No.

A1 D1 Output Axis 1 error 1 (Priority high) High : Error See Circuit 1 below.

B1 D2 Output Axis 1 error 2 (Priority low) High : Error See Circuit 1 below.

A2 D3 Output Axis 1 servo interrupt period Edge See Circuit 1 below.

B2 D4 Output Axis 2 error 1 (Priority high) High : Error See Circuit 1 below.

A3 D5 Output Axis 2 error 2 (Priority low) High : Error See Circuit 1 below.

B3 D6 Output Axis 2 servo interrupt period Edge See Circuit 1 below.

A4 DG1 - GND

B4 DG2 - GND

A5 D9 Input External Sampling Signal ↑: INT generation See Circuit 2 below.

B5 D10 Input External Trigger Signal High : ON See Circuit 2 below.

A6 D11 Input Start up mode switching See Circuit 2 below.

B6 D12 No connection

A7 DG3 - GND

B7 DG4 - GND

A8 D15 No connection

B8 D16 No connection

A9 D17 No connection

B9 D18 No connection

A10 No connection

B10 No connection

board for

evaluation

Signal

Name

I/O Signal Description Logic Remarks

Connection specifications

(Circuit 1)

(Circuit 2)

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

FPGA

3.3V-TTL, max. 3 mA

FPGA

3.3V-TTL

R: 100Ω Connector

R: 100Ω Connector

65

Page 66

5.2. Analog Monitor Output Selecting

The analog monitor output can be switched to monitor various operation and signal statuses.

This switching can be executed from [Control Software] or [RS-232C command send].

Output contents

Terminal

2 (Axis 1)

6 (Axis 2)

3 (Axis 1)

7 (Axis 2)

4 (Axis 1)

8 (Axis 2)

The signal level differs between signals. The output magnification can be switched individually.

Monitor Board

Signal Name

A2 (Axis 1)

A6 (Axis 2)

A3 (Axis 1)

A7 (Axis 2)

A4 (Axis 1)

A8 (Axis 2)

Power-on

Selection

Phase A of Encoder Head 1

Phase A of Encoder Head 2

Phase A of encoder after synthesis

* Positional deviation signal 1.5 mV / pulse

Position 0.091 mV / pulse

* Velocity 0.091 mV / pulse / 10

Coarse angle

Fine angle

Phase B of Encoder Head 1

Phase B of Encoder Head 2

Phase B of encoder after synthesis

* Target position 0.091 mV / pulse

Signal Description Signal Level (At

Power-on)

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

66

Page 67

Control Software

②

③ ④

・Select the Monitor tab. ①

・Select the Monitor tab. ①

①

⑤

・Select an axis for monitor output switching. ②

・Select the monitor item of each output terminal. ③

・Select an output signal magnification. ④

・Press the SET button. ⑤

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

67

Page 68

Note:

・The analog monitor output is from the D/A converter of the controller.

Since the output range of the D/A converter is from -3 to +3 V, output is repeated by the

magnification setting if it exceeds this range.

・The relationship between encoder pulse and angle differs depending on the galvano motor.

E.g. GM-1010

360° = 1000 pulses × 8,192 divisions = 8,192,000 pulses

1° = 8,192,000 pulses / 360° = 22,756 pulses

At the monitor output position (0.091 V/pulse), the analog monitor output changes:

1° = 22,756 × 0.091 = 2.071 V

When the magnification is 1x, and there is a position change of 0° → 1°, analog output will

change from 0V → 2.071V.

E.g. GM-1015 , GM-1020

360° = 1500 pulses × 8,192 divisions = 12,288,000 pulses

1° = 12,288,000 pulses / 360 = 34,133 pulses

At the monitor output position (0.091 V/pulse), the analog monitor output changes:

1° = 34,133×0.091 = 777 mV

When the magnification is 1x, and there is a position change of 0° → 1°, analog output will

change from 0V → 777 mV.

RS-232C Commands

・ Monitor Output Selection (A2, A8) Command ID = 40

・ Monitor Output Selection (A3, A9) Command ID = 41

・ Monitor Output Selection (A4, A10) Command ID = 42

・ Monitor Magnification Setting (A2, A8) Command ID = 44

・ Monitor Magnification Setting (A3, A9) Command ID = 45

・ Monitor Magnification Setting (A4, A10) Command ID = 46

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

68

Page 69

5.3. Digital Input-Output Function

The controller has a digital input-output function for checking the status of the controller.

Pin

No.

A1

B1

B2

A3

A2

B3

In addition, the following digital I/O is prepared as an operation setting of the controller.

Pin

No.

A5 Input External Sampling Signal

I/O Signal Description Logic Explanation

Output Axis 1 Error 1 (Priority high) High: Error If an error occurs, the

Output Axis 1 Error 2 (Priority low) High: Error

Output Axis 2 Error 1 (Priority high) High: Error

Output Axis 2 Error 2 (Priority low) High: Error

Output Axis 1 servo interrupt period Edge Output is timed according to

Output Axis 2 servo interrupt period Edge

I/O Signal Description Logic Explanation

↑: INT

generation

corresponding error signal is

output.

According to the priority of the

error, Error 1 or 2 is output.

See 9-2, “Errors.”

an internal controller servo

interrupt..

Input when an external signal is

used for servo sampling clock.

(Do not use it usually.)

See 6-2, “Operation that

B5 Input External Trigger Signal High: FG_ON

A6 Input Start up mode switching

synchronizes with external

trigger signal input (raster scan)

See 6-1, “Setting Controller Start

Up Mode”

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

69

Page 70

6. Other - Operation Setting

6.1. Setting Controller Start Up Mode

Clock selection

With the default settings at shipping, a parameter is set to start up the controller in RS-232C

communication command input mode (internal clock). When assembling the device, however, the

mode can be switched for start up with an external clock (high-speed serial communication). For this

switching, the following parameter is set:

Parameter ID Data

64

P64 = 1: Start up with internal clock

Bit 1 0: RS-232C communication command input

1: High-speed serial communication

P64 = 3: Start up by high-speed serial communication

(Bit 0 of P64 is used to enable or disable encoder correction when homing to the origin; it is usually set

to 1. For details, see 9.2. , “Parameter Details”)

Start up mode

Power-on usually executes the following automatically:

・Reading parameters from EEPROM

・Starting homing and servo control

If there is a problem with the parameters read from EEPROM or if oscillation occurs when homing and

servo control are executed automatically, the start up mode can be changed.

For this switching, the switches (SW1 and SW2) on the controller board and the logic of the digital I/O

terminal (A6) are combined.

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

70

Page 71

Axis 1

SW2

SW1

1

2

SW1

OFF

SW2

ON

SW1-2 Terminal A6

Auto EEPROM

Read

12

OFF

ON

Auto Homing

OFF 0 Disabled Disabled

OFF 1 or open Enabled Disabled

ON 0 Enabled Disabled

ON 1 or open Enabled Enabled

Axis 2

SW2-2 Terminal A6

OFF 0 Disabled Disabled

OFF 1 or open Enabled Disabled

ON 0 Enabled Disabled

ON 1 or open Enabled Enabled

: Setting at shipping

Auto EEPROM

Read

Auto Homing

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

71

Page 72

6.2. Controller LED Display

The controller (GC-201) is equipped with an LED that indicates the controller status.

After turning on the power, when the controller starts up normally, the display will be as follows.

LED1

(Blinks in approx 2 sec. intervals)

LED2

(Blinks in approx 2 sec.intervals)

LED3

(Blinks in approx 1 sec. intervals)

LED4 (Red)

(Not turns on)

LED5 (Red)

(Not turns on)

LED7

(Turns on)

LED6

(Turns on)

Meaning of each LED

LED No. Meaning Remarks

Always blinks in approximately 2 sec. intervals if

LED1 DSP1 operation (for Axis 1)

DSP1 start up correctly.

Always blinks in approximately 2 sec. intervals if

LED2 DSP1 operation (for Axis 2)

DSP1 start up correctly.

Always lit if FPGA start up correctly.

LED3 FPGA Start up

This LED (red) is lit when a malfunction occurs with

LED4 ALARM display (for Axis 1)

the controller.

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

72

Page 73

A response is necessary after confirming the error

details with the control software, or RS-232C

command ID = 15 error read.

This LED (red) is lit when a malfunction occurs with

the controller.

LED5 ALARM display (for Axis 2)

LED6 DSP2 operation (for Axis 1)

LED7 DSP2 operation (for Axis 2)

Note: When connecting only one axis of the motor and operating the controller (GC-201), an error will

always occur for the axis that is not connected. As a result, either LED4 or LED5 will light up, however,

as there is no problem with the operation of the connected axis, use it as is.

A response is necessary after confirming the error

details with the control software, or RS-232C

command ID = 15 error read.

Always lights in approximately 1 sec. intervals if

DSP2 start up correctly.

Always lights in approximately 1 sec. intervals if

DSP2 start up correctly.

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

73

Page 74

6.3. Operation that Synchronizes with External Trigger Signal input (Raster Scan)

“4.3. Raster Scan” can be operated in synchronization with an external trigger signal.

The Movement Pattern

There are two kinds of movement patterns.

① (The raster scan of one coming and going operates whenever the external trigger signal is input.)

Raster Scan position

(Current Angle Position)

Angle

External Trigger Signal

Voltage

② (The raster scan of one way operates whenever the external trigger signal is input.)

Raster Scan position

(Current Angle Position)

External Trigger Signal

Angle

Voltage

① and ② operation pattern can be selected by RS-232C command (Command ID = 23 ‘Operation

Mode setting‘)

CANON Digital Galvano Scanner System GM-1000 Series

Users Manual 1.20

74

Page 75

Input the external trigger signal

The external trigger signal is input from the digital I/O connector.

(See 5-1 ‘Connector Pin Arrangement)

Connector pin arrangement

Pin

No.

B5 D10 Input External Trigger Signal High: ON See Circuit below.

Connection Specifications

3.3V TTL Input

Operation procedure

(Raster Scan Parameter Settings)

・Set Parameter ID =26 Raster Scan Time Setting

・Set Parameter ID =27 Raster Scan Duty Ratio Setting

・Set Parameter ID =28 Raster Scan Angle Setting