Canon FY8-13G3-000 Service Manual

COPYRIGHT © 1999 CANON INC. CANON CLC1120/1130/1150 REV.0 MAR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

REVSION 0

MAR. 1999

FY8-13G3-000

COLOR LASER COPIER

1120/1130/1150

fineline6

service-repairmanual.com

COPYRIGHT © 1999 CANON INC. CANON CLC1120/1130/1150 REV.0 MAR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

IMPORTANT

THIS DOCUMENTATION IS PUBLISHED BY CANON INC., JAPAN, TO SER VE AS A SOURCE

OF REFERENCE FOR WORK IN THE FIELD.

SPECIFICATIONS AND OTHER INFORMATION CONTAINED HEREIN MAY VARY SLIGHTLY

FROM ACTUAL MACHINE VALUES OR THOSE FOUND IN ADVERTISING AND OTHER

PRINTED MATTER.

ANY QUESTIONS REGARDING INFORMA TION CONTAINED HEREIN SHOULD BE DIRECTED

TO THE COPIER SERVICE DEPARTMENT OF THE SALES COMPANY.

THIS DOCUMENTATION IS INTENDED FOR ALL SALES AREAS, AND MAY CONTAIN INFORMATION NOT APPLICABLE TO CERTAIN AREAS.

COPYRIGHT © 1999 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be strictly supervised to avoid disclosure of confidential

information.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIVISION

CANON INC.

5-1, Hakusan 7-chome, Toride, Ibaraki, 302-8501 Japan

fineline6

service-repairmanual.com

COPYRIGHT © 1999 CANON INC. CANON CLC1120/1130/1150 REV.0 MAR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

i

INTRODUCTION

This Service Manual contains basic data and figures on the plain paper CLC1120/

1130/1150 needed to service the machine in the field. The copier is designed to enable

fully automated copying work, and may be configured with the following options:

1. RDF-E2

2. Stapler Sorter-F1

3. Film Projector-D1

4. Paper Deck-E1

For the RDF-E2, Stapler Sorter-F1, and Film Projector-D1, see their respective

Service Manuals for details. This Service Manual covers the copier itself, and consists of

the following chapters:

Chapter 1

General Description

introduces the copier’s features and specifications,

shows how to operate the printer unit, and explains how copies are made.

Chapter 2

Basic Operation

provides outlines of the steps used to generate copies.

Chapter 3

Exposure System

discusses the principles of operation used for the

mechanical/electrical operations of the copier’s exposure system. It also

explains the timing at which the various units involved are operated, and

shows how they may be disassembled/assembled and adjusted.

Chapter 4

Image Processing System

discusses the principles of operation used for

the mechanical/electrical operations of the copier’s image processing

system. It also explains the timing at which the various units involved are

operated, and shows how they may be disassembled/assembled and

adjusted.

Chapter 5

Laser Exposure System

discusses the principles of operation used for the

mechanical/electrical operations of the copier’s laser exposure system. It

also explains the timing at which the various units involved are operated,

and shows how they may be disassembled/assembled and adjusted.

Chapter 6

Image Formation System

discusses the principles of how images are

formed. It also explains the timing at which the various units involved in

image formation are operated, and shows how they may be disassembled/

assembled and adjusted.

Chapter 7

Pick-Up/Feeding System

discusses the principles of how the printer unit

picks up and moves paper inside it. It also explains the timing at which the

various units involved are operated, and shows how they may be

disassembled/assembled and adjusted.

Chapter 8

Fixing System

discusses the principles of how the printer unit fuses toner

images to paper. It also explains the timing at which the various units

involved are operated, and shows how they may be disassembled/

assembled and adjusted.

fineline6

service-repairmanual.com

COPYRIGHT © 1999 CANON INC. CANON CLC1120/1130/1150 REV.0 MAR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

ii

Chapter 9

Externals/Auxiliary Mechanisms

shows the copier’s external parts, and

explains the principles used for the copier’s various control mechanisms in

view of the functions of electrical and mechanical units and in relation to

their timing of operation. It also shows how these units may be

disassembled/assembled and adjusted.

Chapter 10

Paper Deck

discusses the principles of operation used for the series of

operations between pickup and delivery performed by the paper deck. It

also explains the timing at which the various units involved are operated,

and shows how they may be disassembled/assembled and adjusted.

Chapter 11

Installation

introduces requirements for the site of installation, and shows

how the printer unit may be installed using step-by-step instructions.

Chapter 12

Maintenance and Servicing

provides tables of periodically replaced parts

and consumables/durables and scheduled servicing charts.

Chapter 13

Troubleshooting

provides tables of maintenance/inspection, standards/

adjustments, and problem identification (image fault/malfunction).

Appendix contains a general timing chart and general circuit diagrams.

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions

and the relationship between electrical and mechanical systems with

reference to the timing of operation.

In the diagrams,

represents the path of mechanical drive where a

signal name accompanies the symbol , the arrow indicates the direction

of the electric signal.

The expression “turn on the power” means flipping on the power switch,

closing the front door, and closing the delivery unit door, which results in

supplying the machine with power.

2. In the digital circuits, ‘1’ is used to indicate that the voltage level of a given

signal is “High,” while ‘0’ is used to indicate “Low.” (The voltage value,

however, differs from circuit to circuit.) In addition, the asterisk (*) as in

“DRMD*” indicates that the DRMD signal goes on when ‘0’.

In practically all cases, the internal mechanisms of a microprocessor cannot

be checked in the field. Therefore, the operations of the microprocessors used

in the machines are not discussed: they are explained in terms of from sensors

to the input of the DC controller PCB and from the output of the DC controller

PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for

product improvement or other purposes, and major changes will be communicated in the

form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this

Service Manual and all relevant Service Information bulletins and be able to identify and

isolate faults in the machine.

fineline6

service-repairmanual.com

COPYRIGHT © 1999 CANON INC. CANON CLC1120/1130/1150 REV.0 MAR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

iii

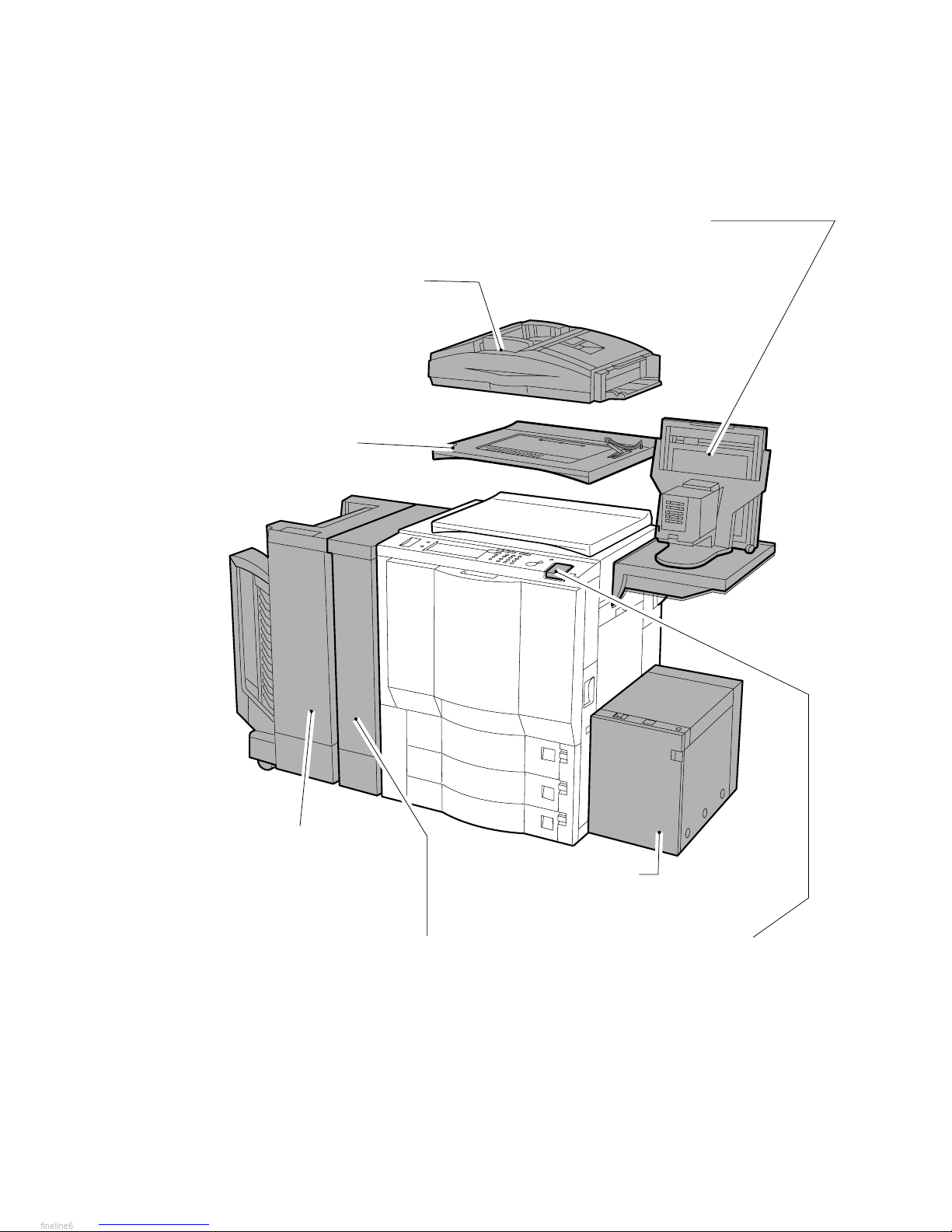

System Configuration

The CLC1120/1130/1150 may be configured as follows to make up a system (the shaded areas

indicate accessories):

The figures above represents the CLC1150; however, the CLC1120/1130 may be configure in

the same way.

CLC1120: 2-cassette model

CLC1130: 3-cassette model

CLC1150: 2-cassette model with a duplexing unit.

RDF-E2

Feeds a large number of originals

automatically for continuous

copying. Accepts double-sided

originals.

CLC Film Projector-D1

Projects 35mm negative or

positive film, large-size negative

film, or transparencies for making

color copies.

Editor-F1

Enables selecting areas and

colors using a point pen.

Stapler Sorter-F1

Sorts or groups copies.

Staples sorted copies.

CLC Buffer Path Unit 1

Limits curling of copied paper.

CLC Paper Deck-E1

Accommodates as many as 2500 sheets of

copy paper (A4/B5/LTR).

Control Card-V

Enables control of copying

work by group.

fineline6

service-repairmanual.com

fineline6

service-repairmanual.com

Loading...

Loading...