Canon FY8-13FW-000DADF-A1, DADF-A1 Service Manual

DADF-A1

REVSION 0

DEC. 1998

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

FY8-13FW-000

IMPORTANT

THIS DOCUMENTATION IS PUBLISHED BY CANON INC., JAPAN, TO SERVE AS A SOURCE

OF REFERENCE FOR WORK IN THE FIELD.

SPECIFICATIONS AND OTHER INFORMATION CONTAINED HEREIN MAY VARY SLIGHTLY

FROM ACTUAL MACHINE VALUES OR THOSE FOUND IN ADVERTISING AND OTHER

PRINTED MA TTER.

ANY QUESTIONS REGARDING INFORMA TION CONTAINED HEREIN SHOULD BE DIRECTED

TO THE COPIER SERVICE DEPARTMENT OF THE SALES COMPA NY.

THIS DOCUMENT ATION IS INTENDED FOR ALL SALES AREAS , AND MA Y CONTAIN INFORMA TION NOT APPLICABLE T O CERTAIN AREAS.

COPYRIGHT © 1998 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be strictly supervised to avoid disclosure of confidential

information.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DEPARTMENT 1

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIVISION

CANON INC.

5-1, Hakusan, 7-chome, Toride-City , Ibaraki-Pref ., 302-8501, Japan

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

INTRODUCTION

This Service Manual provides information needed to service the DADF in the field. This Service

Manual consists of the following chapters:

Chapter 1 “General Description” introduces the DADF’s features and specifications, and

shows how to operate it.

Chapter 2 “Basic Operation” introduces the ADAF’s mechanical and electrical systems; it also

explains the principles used in these systems and the timing at which they are

operated with reference to the ADAF’s electrical circuitry.

Chapter 3 “Mechanical System” explains the ADAF’s mechanical construction and how its

parts may be disassembled/assembled and adjusted.

Chapter 4 “Maintenance and Servicing” provides tables of periodically replaced parts and

consumables/durables and scheduled servicing charts.

Chapter 5 “Troubleshooting” provides tables of maintenance/inspection, standards/

adjustments, and problem identification (image fault/malfunction).

Appendix contains a general timing chart and general circuit diagrams.

The descriptions in this Service Manual are subject to change without notice for product

improvement or other purposes, and major changes will be communicated in the form of Service

Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service

Manual and all relevant Service Information bulletins, and be able to identify and isolate faults in the

machine.

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

i

CONTENTS

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES ................................1-1

II. SPECIFICATIONS ......................1-2

A. DADF-A1...............................1-2

III. NAMES OF PARTS ....................1-4

A. External View.........................1-4

B. Cross Section ........................1-4

CHAPTER 2 BASIC OPERATION

I. BASIC CONSTRUCTION ...........2-1

A. Outline of the Electrical Circuitry.

...............................................2-1

B. Communication with the Copier

...............................................2-2

C. Inputs to the D ADF Controller

PCB.......................................2-3

D . Outputs to the DADF Controller

PCB.......................................2-5

II. BASIC OPERATION ................... 2-6

A. Outline ................................... 2-6

B. Operation............................... 2-7

C. Detecting Originals.............. 2-12

D. Picking Up Originals............ 2-17

IV. OPERATION...............................1-5

A. Original Set Indicator .............1-5

B. Warning and Actions..............1-5

C. Routine Maintenance by the

User.......................................1-6

E. Reversal .............................. 2-25

F. Reduced Page Composition

.............................................2-27

G. Delivery ............................... 2-34

H. Stamping Function...............2-40

I. Controlling the Pick-Up Motor

.............................................2-43

J. Controlling the Belt Motor

.............................................2-45

K. Detecting Original Jams

.............................................2-47

L. Improper Placement of

Originals ..............................2-50

III. POWRE SUPPLY ..................... 2-53

A. Outline .................................2-53

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

iii

CHAPTER 3 MECHANICAL SYSTEM

I. BASIC CONSTRUCITON........... 3-1

A. External Covers .....................3-1

B. Switches ................................3-3

C. Adjusting the DADF Height

...............................................3-5

II. DRIVE SYSTEM ........................ 3-6

A. Removing the Pick-Up

Motor Unit ..............................3-6

B. Removing the Feeder Motor Unit

...............................................3-6

C. Belt Motor ..............................3-7

D. Removing the Clutch Unit

...............................................3-9

E. Delivery Motor .....................3-10

III. FEEDING SYSTEM .................. 3-11

A. Pick-Up Roller ..................... 3-11

B. Removing the Separation

Belt Unit............................... 3-12

C. Feeding Roller Unit ............. 3-12

D. Registration Roller ............... 3-14

E. Delivery/Resersing Roller

............................................. 3-16

F. Delivery Roller Unit

(bottom Pick-up Mode).........3-20

G. Delviery Roller Unit

(top Pick-up Mode)...............3-20

H. Reversing Guide ..................3-22

I. Stopper Plate Solenoid ........3-24

J. Positioning the Paper Retaining

Plate Solenoid (SL2) ...........3-24

K. Positioning the Paper Deflecting

Solenoid (SL3) .....................3-26

L. Stamp Solenoid ...................3-26

M. Feeding Belt ........................3-28

IV. CLEANING ............................... 3-30

A. Belt Assembly......................3-30

B. Sensors ...............................3-30

C. Separation Flapper..............3-33

D. Separation Guide .................3-33

V. FEEDING .................................3-34

A. Pick-Up Drive Assembly...... 3-34

B. Right Delivery Drive

Assembly............................. 3-34

CHAPTER 4 MAINTENANCE AND SERVICING

I. PERIODICALLY REPLACED

PARTS ........................................ 4-1

II. CONSUMABLES AND

DURABLES ................................4-1

III. SCHEDULED SERVICING

CHART ....................................... 4-2

iv

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 5 TROUBLESHOOTING

I. STANDARDS AND

ADJUSTMENTS ........................ 5-1

A. Mechanical System ...............5-1

B. Electrical System .................5-17

II. TROUBLESHOOTING ..............5-20

A. Troubleshooting

Malfunctions ........................5-20

III. ARRAIGMENT OF THE ELECTRI-

CAL PARTS .............................. 5-24

A. Motors, Solenoids, and

Sensors ...............................5-24

APPENDIX

A. GENERAL TIMING CHART ...... A-1

B. NAMES AND ABBREVIATIONS OF

SIGNALS................................... A-4

C. DADF-A1 GENERAL CIRCUIT

DIAGRAM.................................. A-5

B. PCB .....................................5-26

IV. VARIABLE RESISTORS, LIGHT-

EMITTING DIODES, AND CHECK

PINS BY PCB...........................5-27

A. DADF Controller PCB .......... 5-27

B. Indicator PCB ......................5-29

C. DIP Switch Functions ..........5-30

V. SELF DIAGNOSIS....................5-32

A. DADF Self Diagnosis .......... 5-32

D. DADF CONTROLLER CIRCUIT

DIAGRAM.................................. A-6

E. DISPLAY BOARD .................... A-13

F. SPECIAL TOOLS..................... A-14

G. SOLVENTS AND OILS............ A-15

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

v

CHAPTER 1

GENERAL DESCRIPTION

I. FEATURES .................................1-1

II. SPECIFICATIONS.......................1-2

A. DADF-A1 ...................................1-2

III. NAMES OF PARTS..................... 1-4

A. External View.............................1-4

B. Cross Section ............................1-4

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

IV. OPERATION................................1-5

A. Original Set Indicator .................1-5

B. Warnings and Actions................1-5

C. Routine Maintenance

by the User.................................1-6

CHAPTER 1 GENERAL DESCRIPITON

I. FEATURES

1. Two Types of Pick-Up Mode

Top pick-up: Pick-up starts with the top page.

Bottom pick-up: Pick-up starts with the bottom page.

2. Stamp Marking

The machine can mark originals with a stamp to indicate that they have been processed for fax

transmission.

3. Original Size Identification

The machine can identify the size of an original in terms of its length (feeding direction) and

width for communication to its host copier.

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-1

CHAPTER 1 GENERAL DESCRIPITON

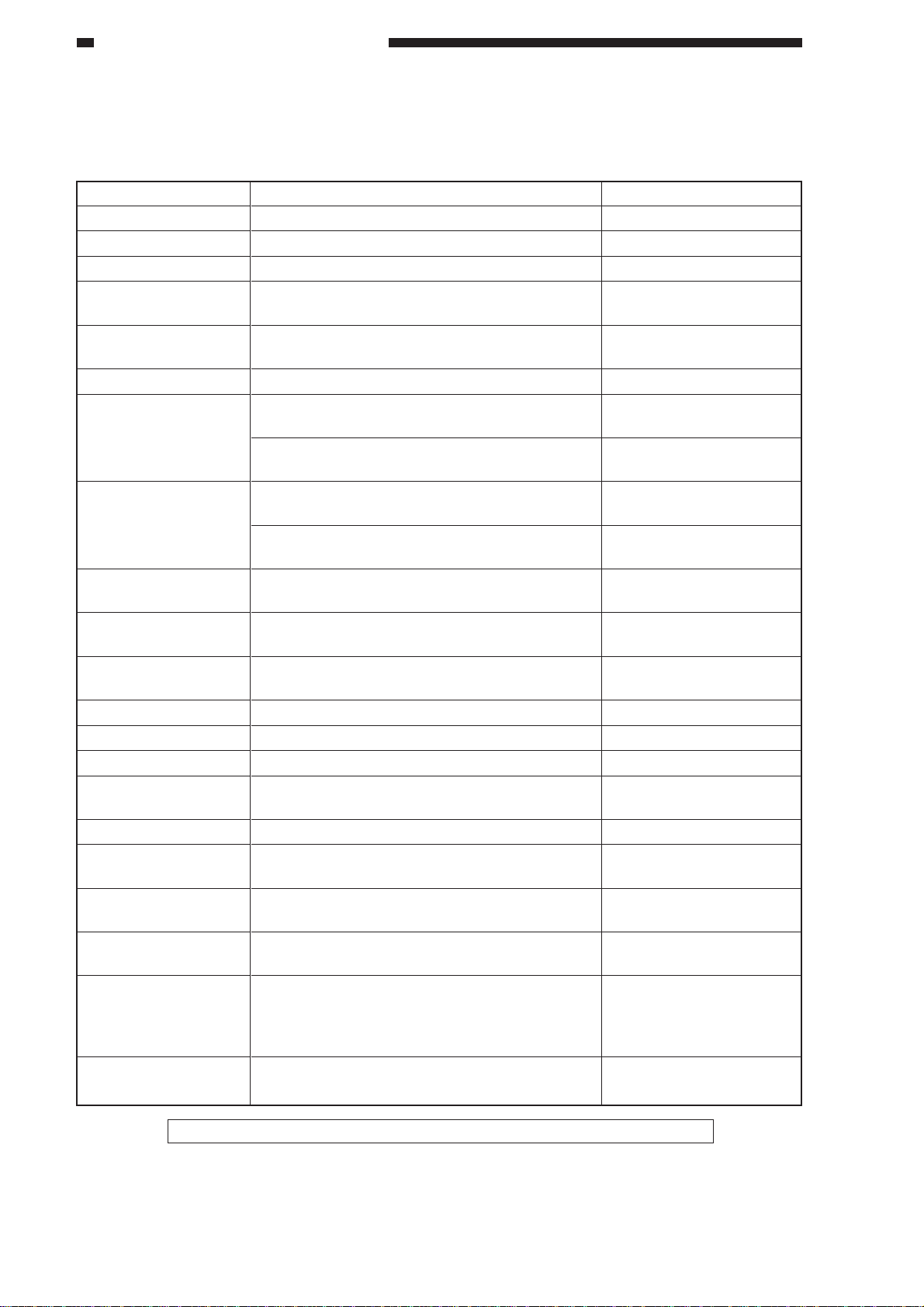

II. SPECIFICATIONS

A. DADF-A1

Item

Original pick-up

Original placement 1

Original placement 2

Original pick-up

Original type

Original size

Original tray

Delivery tray

Original processing

mode

Original size

identification

Residual original

detection

Continuous feeding

Size mix

Communication with

copier

Power supply

Maximum power

consumption

Weight

Dimensions (mm)

Serial No.

Operating conditions

Temperature Humidity

Specifications

Circulating, auto duplexing pick-up method

Face up

Center reference

Top pick-up

Bottom pick-up

Sheet (50 to 105 g/m2), single-sided sheet,

double-sided sheet

A5/STMT to A3/279×432 mm (11"×17")

If small size, 50 sheets, 5.5 mm high max.

(A5, B5, B5R, A4, A4R, STMT, LTR, LTRR)

If large size, 25 sheets (B4, A3, LGL,

279×432 mm (11"×17")

If small size, 50 sheets (A5, B5, B5R, A4,

A4R, STMT, LTR, LTRR)

If large size, 25 sheets (B4, A3, LGL,

279×432 mm (11"×17")

Single-sided, double-sided, reduce image

composition

Length (feeding direction) and width

Possible in conjunction with the host copier.

Possible

Possible

Possible

IPC 2

24 VDC (from the host copier)

170 W or less

14.1 kg (approx.)

684 (W) × 527 (D) × 161 (H)

AB ZLZ xxxxx

INCH/A ZNE xxxxx

A ZNF xxxxx

INCH/AB ZNG xxxxx

Same as the host copier.

Remarks

See p.2-17.

No extra length original.

Paper of 80 g/m2 or less.

Paper of 80 g/m2 or less.

Paper of 80 g/m2 or less.

Paper of 80 g/m2 or less.

For fax processing only.

Of the same width only.

For fax processing only.

Not including the

delivery tray.

Not including the

delivery tray.

1-2

The above specifications are subject to change for product improvement.

Table 1-201

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPITON

Note:

The following must not be used as originals:

• A transparency or paper with an opacity of 80% or less.

• A carbon-backed sheet.

• A sheet with paste-ups or binding.

• A sheet with a cut-off, hole, or tear.

• A sheet with a clip or glue.

• A sheet with curling, wrinkling, or creasing.

Caution:

Do not feed the same original more than 30 times to protect against damage.

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-3

CHAPTER 1 GENERAL DESCRIPITON

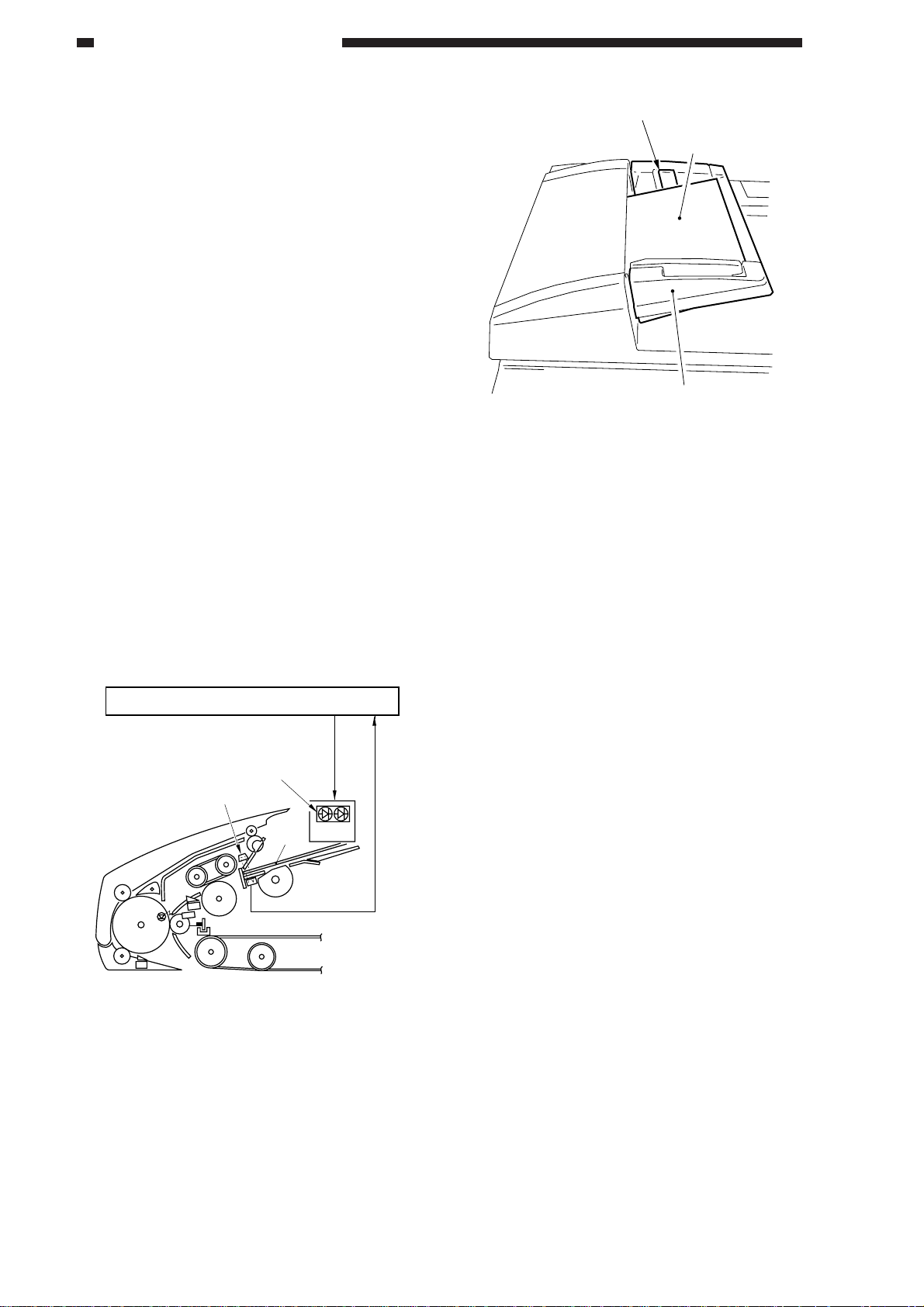

III. NAMES OF PARTS

A. External View

[1] [2] [3] [4] [5] [6] [7] [8]

Figure 1-301

[1] Upper cover

[2] Side guide

[3] Re-circulating guide

[4] Original Set indicator

[5] Original tray

[6] Sub tray

[7] Body cover

[8] Original delivery tray

B. Cross Section

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10]

[1] Delivery/reversing roller

[2] Paper deflecting plate

[3] Feeding roller

[4] Separation belt

[5] Separation flapper

[6] Pre-separation guide

[16] [15] [14] [13] [12] [11]

Figure 1-302

[7] Delivery/pick-up roller

[8] Paper retaining plate

[9] Pick-up roller

[10] Delivery roller

[11] Feeding belt link roller

[12] Retaining rolls

[13] Feeding belt

[14] Paper stopper plate

[15] Feeding belt drive roller

[16] Registration roller

1-4

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPITON

IV. OPERATION

A. Original Set Indicator

The Original Set indicator turns on when

an original is placed on the original tray, and

flashes when an original jams.

A4/B5

A3/B4

Figure 1-401

Operation

1) If the original is B5R or larger or is A5 in

feeding length, open the original sub tray.

2) Set the side guide to suit the size of the

original.

B. Warnings and Actions

If the Original Set indicator flashes while

an original is being fed, suspect a jam and

perform the following:

1) Remove the originals from the original

tray.

2) Open the upper cover, and remove the jam.

Then, open the DADF to reset the

warning. (If any original is on the

copyboard glass, remove it.)

Caution:

If the jam is in the copier, the copier will

run jam recovery mode and will

automatically set the originals. Do not

open the DADF to reset.

3) Set the originals in correct order, and set

the stack in the DADF.

Reference:

The side guide lock must be removed if

the width of the original is larger than 297

mm (A4/A3). For details, see 3. “Side

Guide Lock” on p. 3-3.

3) Place the originals with the first page on

top.

4) As needed, set the appropriate copying

mode on the copier.

5) Press the copier’s Copy Start key.

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-5

CHAPTER 1 GENERAL DESCRIPITON

C. Routine Maintenance by the User

Instruct the user to clean the following at least once a week:

1. Copyboard Glass

Wipe it with a cloth moistened with water or alcohol; then, dry-wipe it.

2. Feeding Belt

Wipe it with water or alcohol.

3. Other Parts

Clean all other parts of the DADF (if soiled) using a solution of mild detergent; then, dry-wipe

them to remove any residue.

4. Feeding Belt and Feeding Roller

Execute cleaning mode in the copier’s user mode.

5. Stamp

If markings start to be fuzzy, replace the stamp using tweezers.

Stamp

Tweezers

Figure 1-402

Caution:

Do not touch the stamp face. If your skin has come into contact with its ink, be sure to wash it

with water immediately.

1-6

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 2

BASIC OPERATION

I. BASIC CONSTRUCTION ........... 2-1

A. Outline of the Electrical

Circuitry......................................2-1

B. Communication with the Copier.2-2

C. Inputs to the DADF

Controller PCB ........................... 2-3

D . Outputs to the D ADF Controller PCB

...................................................2-5

II. BASIC OPERATION.................... 2-6

A. Outline .......................................2-6

B. Operation ...................................2-7

C. Detecting Originals ..................2-12

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

D. Picking Up Originals ................ 2-17

E. Reversal ..................................2-25

F. Reduced Page Composition.... 2-27

G. Delivery ....................................2-34

H. Stamping Function ...................2-40

I. Controlling the Pick-Up Motor ..2-43

J. Controlling the Belt Motor ........2-45

K. Detecting Original Jams...........2-47

L. Improper Placement of

Originals ..................................2-50

III. POWRE SUPPLY ...................... 2-53

A. Outline ..................................... 2-53

CHAPTER 2 BASIC OPERATION

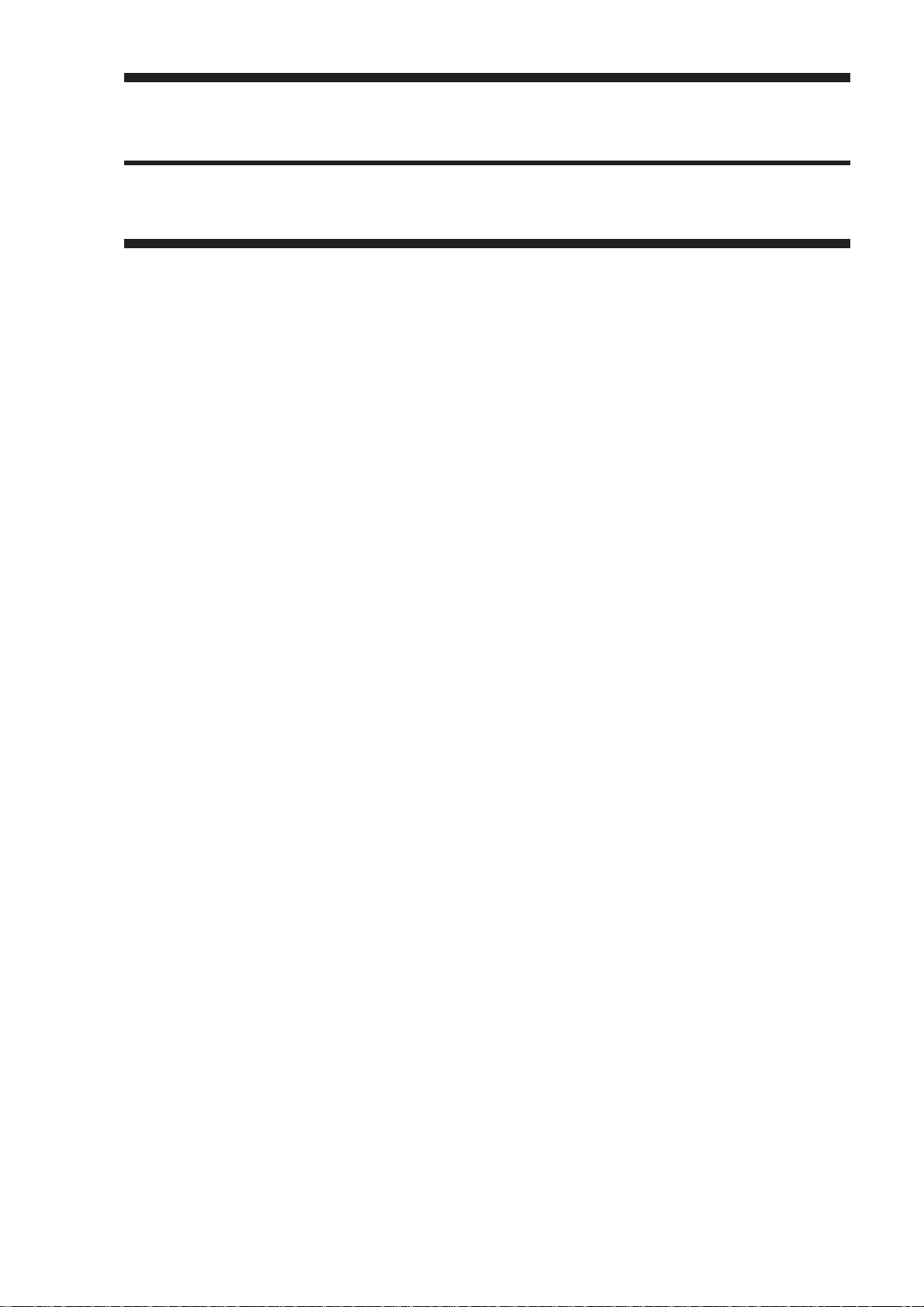

I. BASIC CONSTRUCTION

A. Outline of the Electrical Circuitry

The machine’s electrical mechanisms are controlled by the DADF controller PCB. A

microprocessor (CPU) is used on the DADF controller PCB, and the microprocessor reads the input

signals from the sensors and the copier and generates signals used to drive DC loads (motors,

solenoids) at such times as programmed in advance.

DADF controller PCB

Sensor

V ariable

resistor

CPU

(Q1)

ROM

(Q2)

RAM

(Q4)

Communication

IC(Q3)

24V

Power supply

5 VDC

power

supply

J2-1

circuit

5V

J1-6

Motor

Solenoid

Clutch

Brake

Indicator

LED PCB

Motor

Copierk

Figure 2-101

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-1

CHAPTER 2 BASIC OPERATION

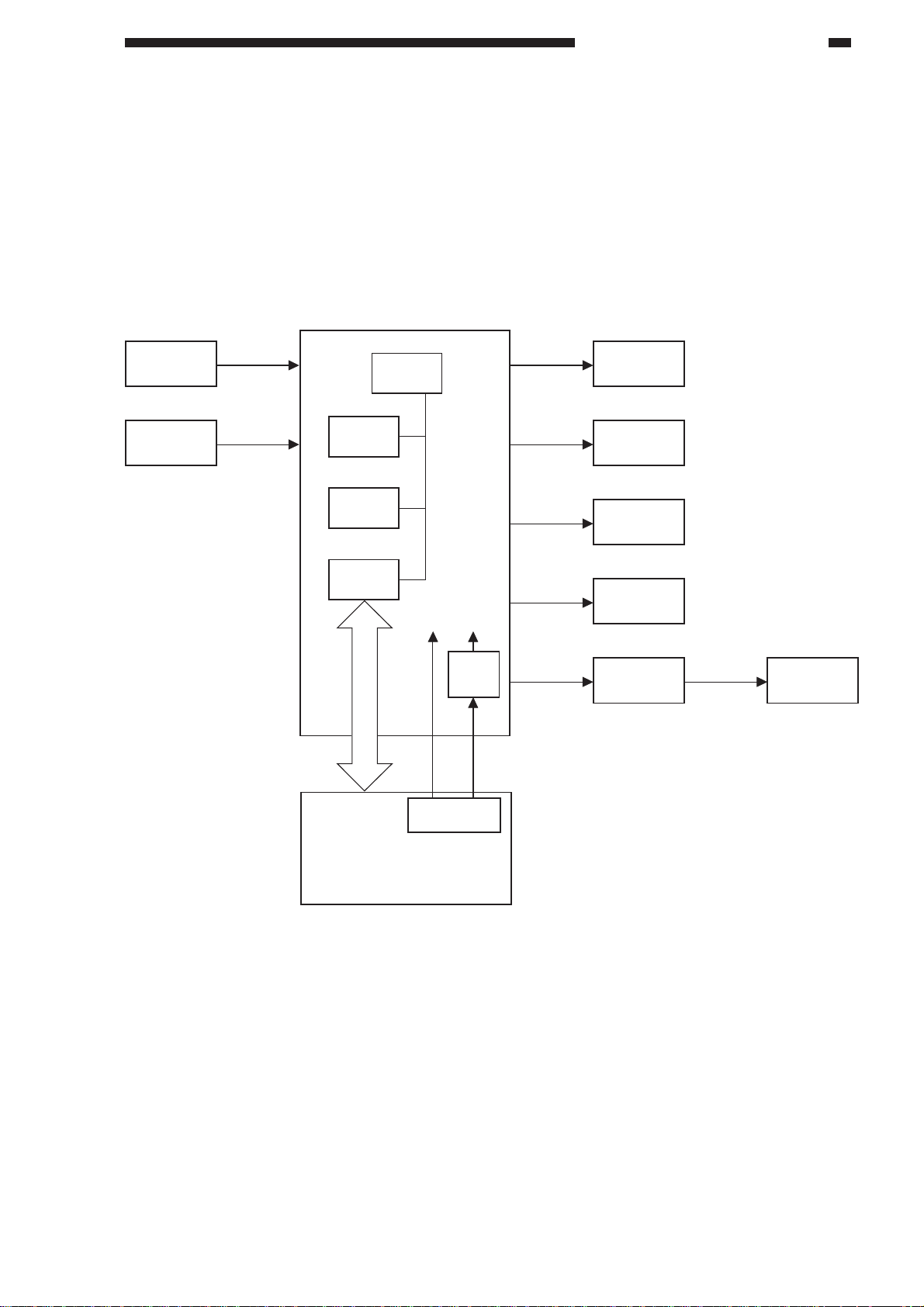

B. Communication with the Copier

The operation modes selected on the copier are communicated to the machine in an IPC

communication method. Likewise, the operation states of the machine are communicated to the

copier in an IPC communication.

If an error occurs in the IPC communication, the copier’s self diagnosis function turns on to

indicate “E400” or “E712” on its control panel.

RSOUT

Communication

IC

RSIN

Communication

IC

CPUCPU

Copier DADF

Figure 2-102

2-2

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

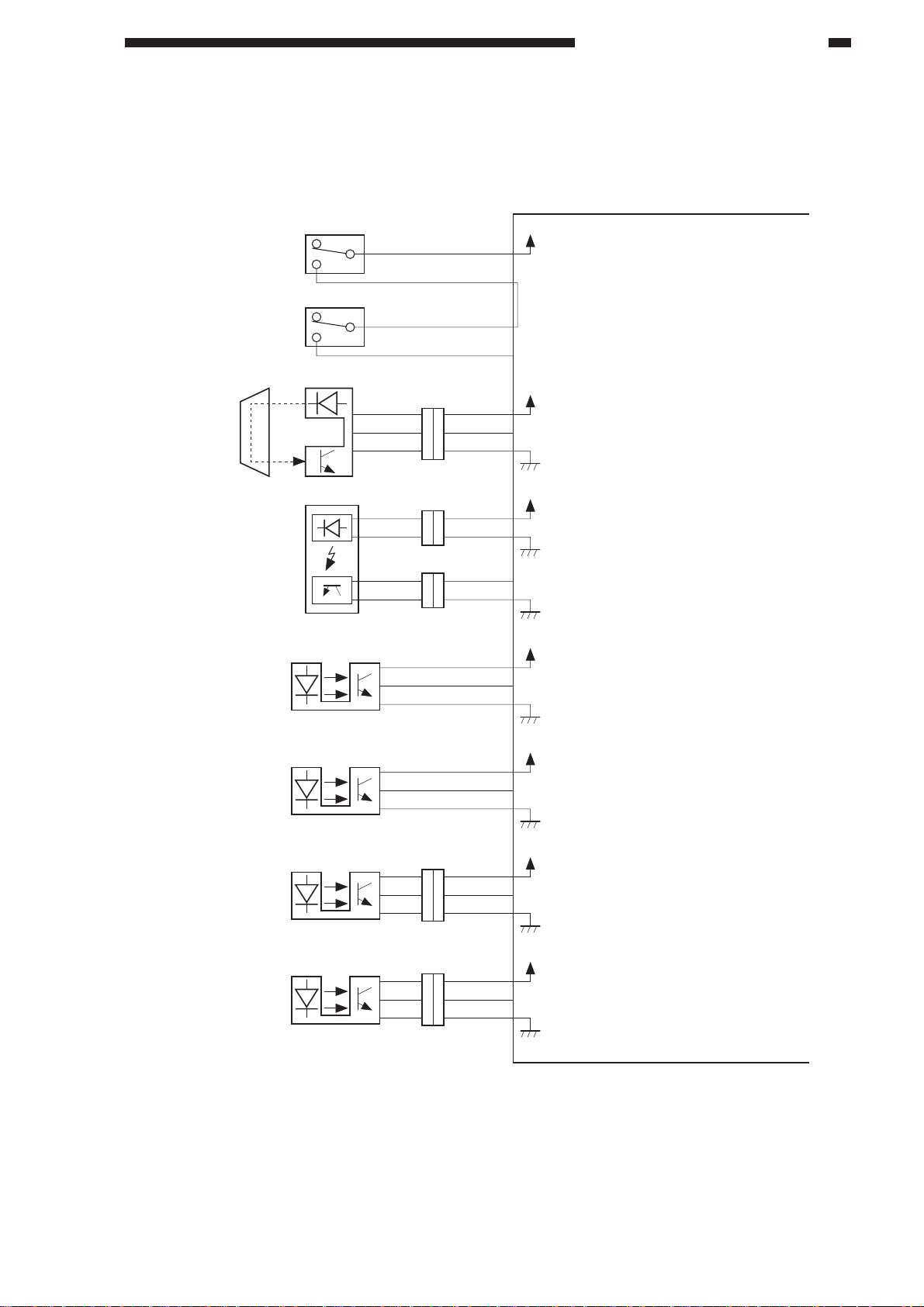

C. Inputs to the DADF Controller PCB

1. Inputs to the DADF Controller PCB (1/2)

DADF switch

MS1

Upper cover switch

MS2

Original tray

paper sensor

S1

COM J2-3

NO

COM

NO

J203

-4

J31-2

J5-7

-8

-9

RFC

UPCC1

EMPS

CHAPTER 2 BASIC OPERATION

DADF controller PCB

+24V

When the RDF is open, '0'.

When the upper cover is open, '0'.

+5V

When an original blocks the sensor, '1'.

Registration

paper sensor

Upper cover

sensor

Pick-up roller sensor

Delivery sensor 1

LED3

S3

S4

S5

S6

-1

-2

+5V

ENTS

+5V

CVRSW

+5V

DCTS

+5V

EJTS1

When an original blocks the sensor, '1'.

When the upper cover is open, '0'.

(The light-blocking plate is at the sensor.)

When the pick-u roller is

at the home position, '1'.

(The light-blocking plate is at the sensor.)

When an original is detected, '1'.

(The light-blocking plate is at the sensor.)

J205

2

J212

2

3

1

2

3

1

2

J207

3

1

1

3

2

2

3

41

1

21

3

1

2

J9-B10

-B9

-B12

-B11

J9-B6

-B8

-B7

J5-3

J9-A1

-A3

-A2

Pick-up sensor

S7

J208

3

1

1

3

2

2

3

1

2

J9-A4

-A6

-A5

+5V

SPRS

When an original is detected, '1'.

(The light-blocking plate is at the sensor.)

Figure 2-103

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-3

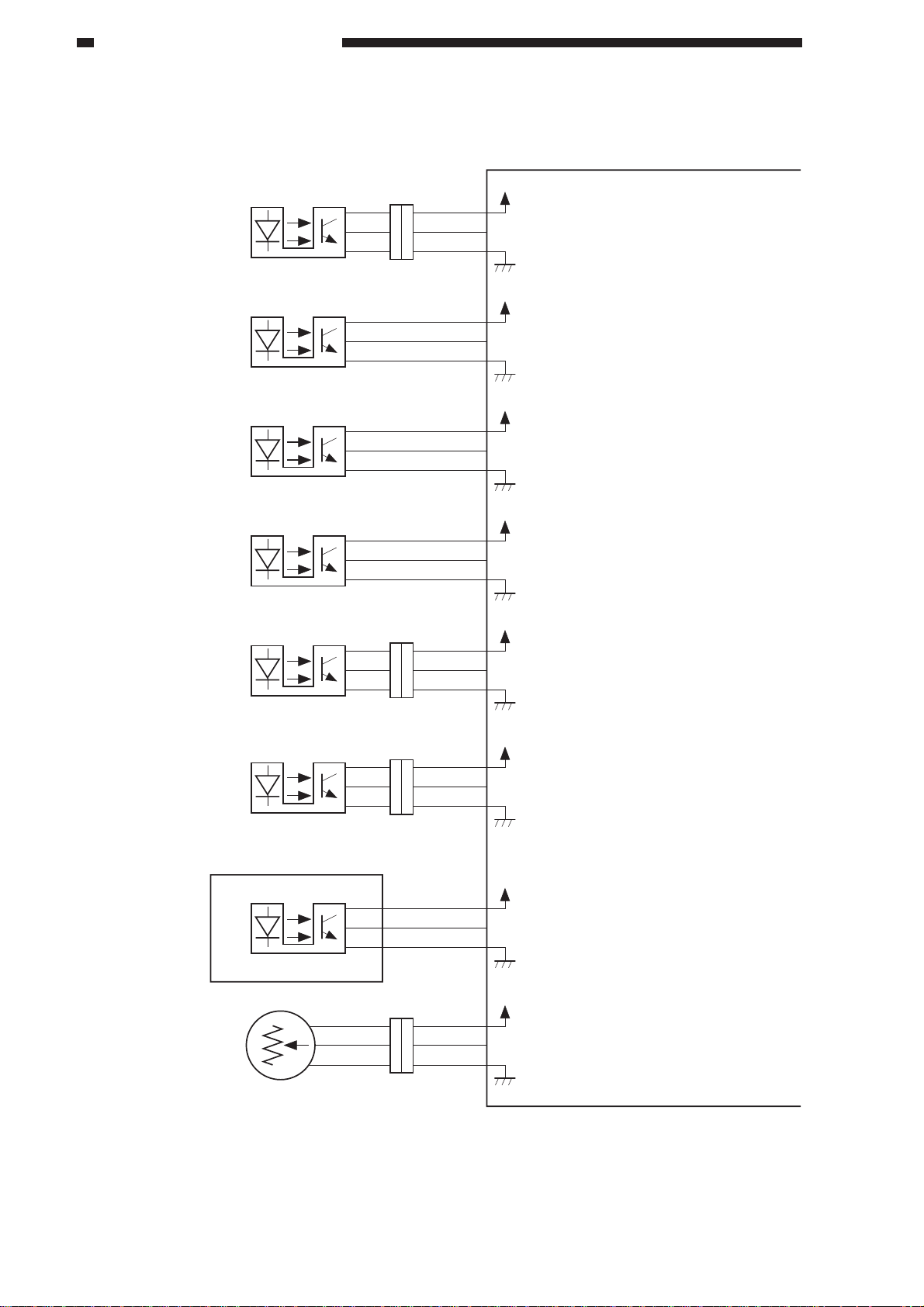

CHAPTER 2 BASIC OPERATION

2. Inputs to the DADF Controller PCB (2/2)

DADF controller PCB

Reversal sensor S8

Feeder motor

S9

clock sensor

Belt motor

S10

clock sensor

Registration roller

S11

clock sensor

Delivery sensor 2 S12

J209

3

1

2

1

2

3

1

2

3

1

2

3

3

1

2

1

3

2

1

3

2

J219

3

1

2

3

1

2

J9-A7

-A9

-A8

J9-A12

-A11

-A10

J9-B5

-B4

-B3

J5-4

-5

-6

J14-4

-6

-5

+5V

TURNS

+5V

FCLK

+5V

BCLK1

+5V

RCLK

+5V

EJTS2

When an original is detected, '1'.

(When the light-blocking plate is

at the sensor.)

While the feeder motor is rotating,

alternates '1' and '0'.

While the feeder motor is rotating,

alternates '1' and '0'.

While the feeder motor is rotating,

alternates '1' and '0'.

When an original is detected, '1'.

(When the light-blocking plate is

at the sensor.)

Delivery motor

clock sensor

Re-circulation

sensor

Original width

detecting VR

S13

Display PCB

S14

J219

1

3

2

2

3

1

J101-3

-2

-1

J218

3

2

1

J14-3

4

-2

5

-1

6

J8-3

-2

-1

1

J8-7

2

-8

3

-9

+5V

ECLK

+5V

RSS

+5V

WIDTH

While the delivery motor is rotating,

alternates '1' and '0'.

When the re-circulation bar is set

on the top original, '1'.

Detects the width of the original

stacked on the original tray.

2-4

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

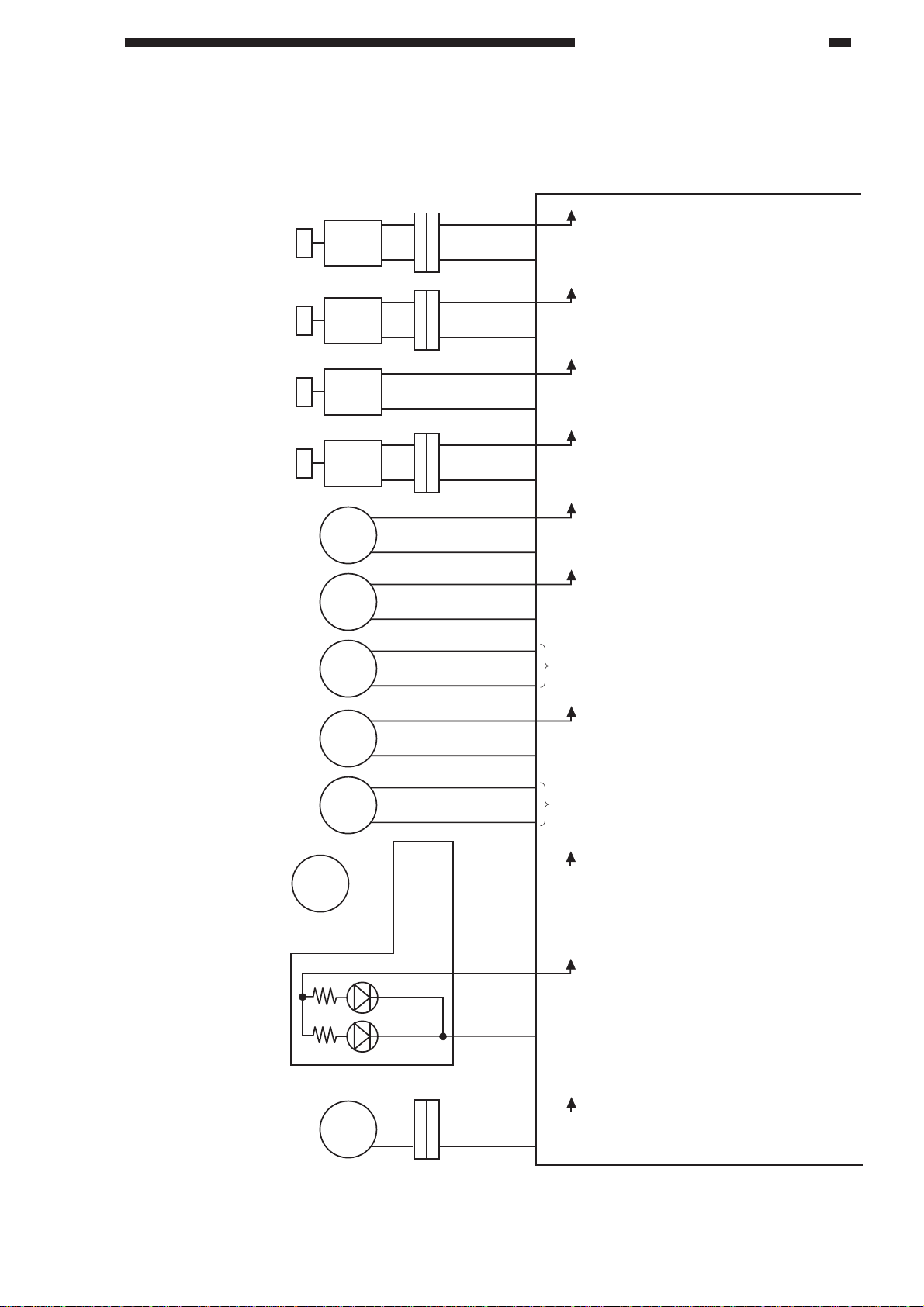

D. Outputs to the DADF Controller PCB

Stopper plate solenoid

When '0', the solenoid (SL1) turns on.

(The stopper plate moves down.)

SL1

J217

1

2

J5-10

-11

+24V

STPSL

2

1

Paper retaining plate

solenoid

When '0', the solenoid (SL2) turns on.

(The paper retaining plate moves down.)

SL2

J216

1

2

J5-12

-13

+24V

WGTSL

2

1

Stamp solenoid

When '0', the solenoid (SL4) turns on.

(The stamp puts a marking on the

original.)

SL4

J220

1

2

J14-9

-10

+24V

SMPSL

Clutch

When '0', the clutch (CL1)

turns on.

CL

J13-1

-2

+24V

CL

Brake

When '0', the brake (BK1)

turns on.

BK

J6-1

-2

+24V

BK

Pick-up motor

See p. 2-43.

M1

J12-1

-2

Feeder motor

When '0', the feeder motor (M2)

turns on.

M2

J11-1

-2

+24V

FMPWM

Belt motor

Delivery motor

See p. 2-45.

M3

J7-1

-2

When '0', the delivery motor (M5)

turns on.

M5

J14-8

-7

+24V

EMPWM

Re-circulation motor

Display PCB

LED101

LED102

When '0', the re-circulation motor (M4)

turns on.

M4

J8-5

-6

-3

-4

J102-1

-2

J101 -5

-6

-3

+5V

RSDRV

When '0', the Original Set indicator

turns on.

+5V

ORGLED

2

1

1

2

3

2

J221

J101-4

Paper deflecting plate

solenoid

When '0', the solenoid (SL3) turns on.

(The paper deflecting plate operates.)

SL3

J9-B2

-B1

+24V

FLPSL1

1. Outputs to the DADF Controller PCB (1/1)

CHAPTER 2 BASIC OPERATION

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-5

CHAPTER 2 BASIC OPERATION

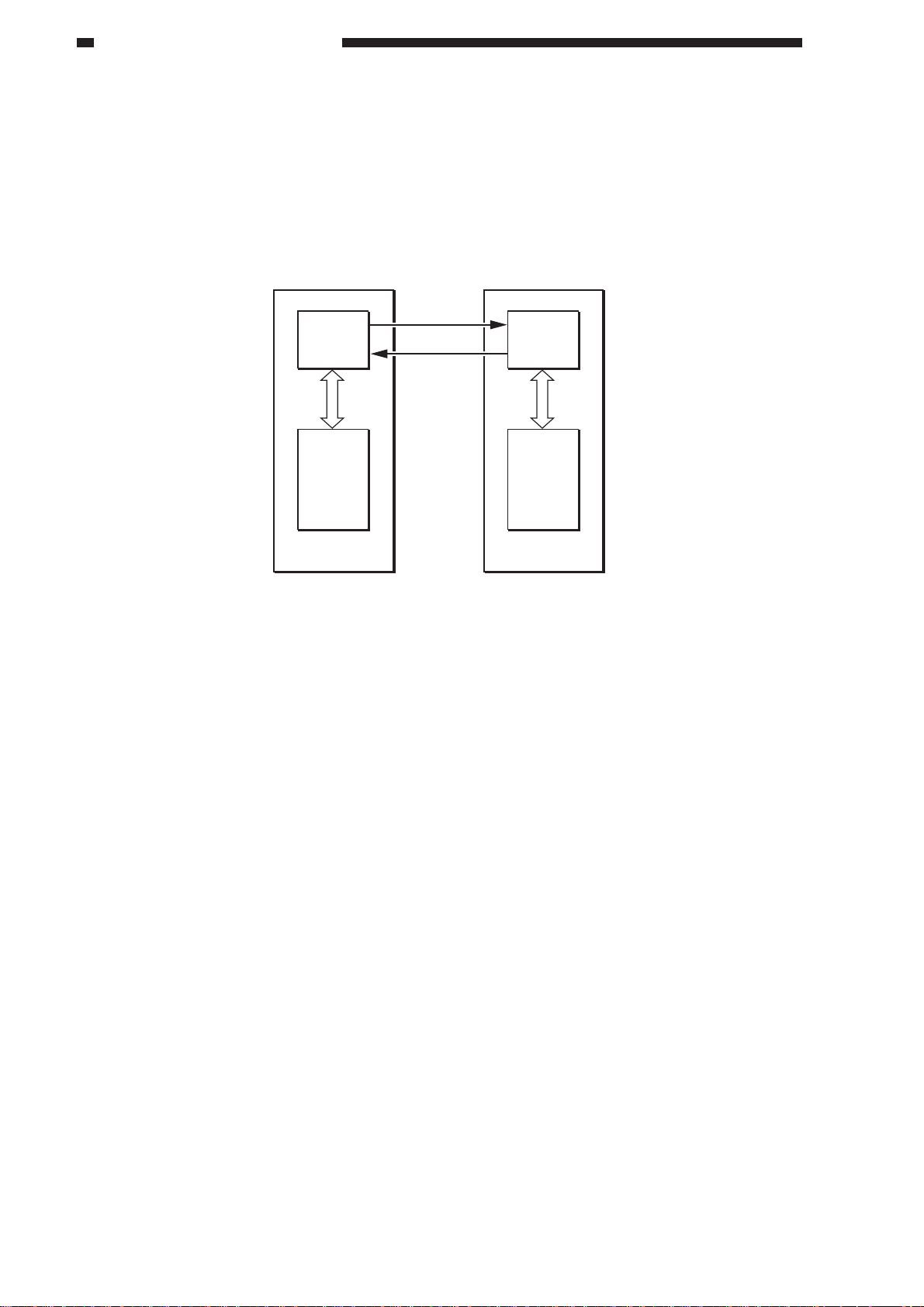

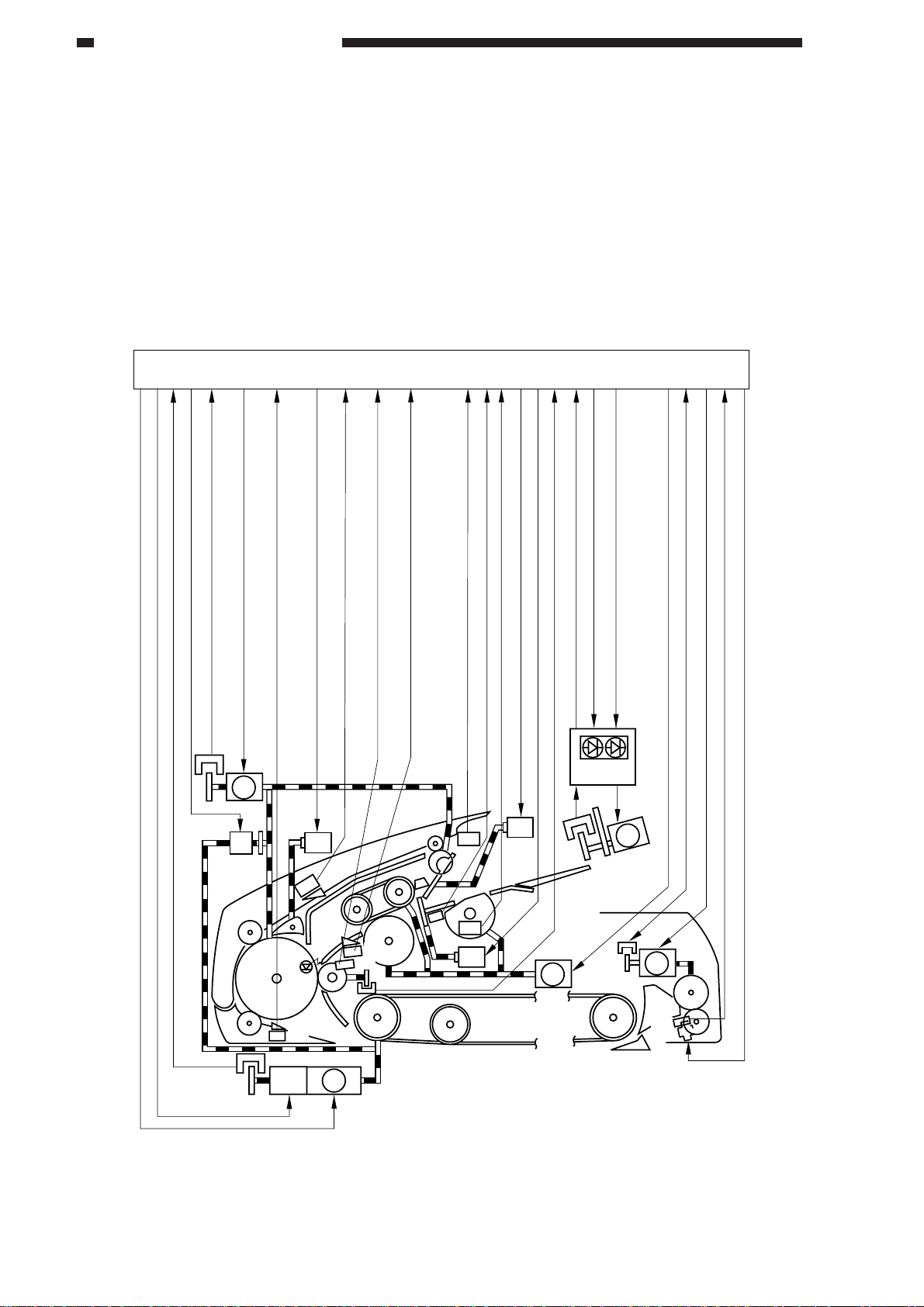

II . BASIC OPERATION

A. Outline

The machine uses four motors and one clutch to pick up, feed, and deliver originals.

The pick-up motor (M1) serves to pick up originals. The feeder motor (M2) serves to reverse and

deliver originals. The belt motor (M3) moves and stops originals to and on the copyboard glass, and

delivers them. The delivery motor (M3) operates to deliver originals to the delivery tray.

The clutch (CL) is used to engage or disengage the drive of the feeder motor (M2) and the belt

motor (M3).

DADF controller PCB

Belt motor clock signal

Feeder belt brake drive signal

Belt motor drive signal

Clutch drive signal

Feeder motor clock signal

S9

S10

Delivery detection signal 1

Reversal/feeder paper detection signal

Feeder motor drive signal

M2

CL

Paper deflecting plate solenoid drive signal

SL3

S6

S8

BK M3

Pick-up registration signal

S7

S3

S11

Registration roller clock signal

Pick-up paper detection signal

S1

Original tray paper signal

Pick-up roller home position detection signal

Upper cover open/closed detection signal 2

S4

S5

SL1

Paper holding solenoid drive signal

SL2

Last original detection signal

Stopper plate solenoid drive signal

Indicator

S14

M1

Delivery motor clock signal

Original set indicator ON signal

Re-circulator motor drive signal

PCB

S13

Pick-up motor drive signal

M4

M5

S12

SL4

Delivery detection signal 2

Delivery motor drive signal

Stamp solenoid drive signal

2-6

Figure 2-201

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 2 BASIC OPERATION

B. Operation

The machine enables the following six

operations:

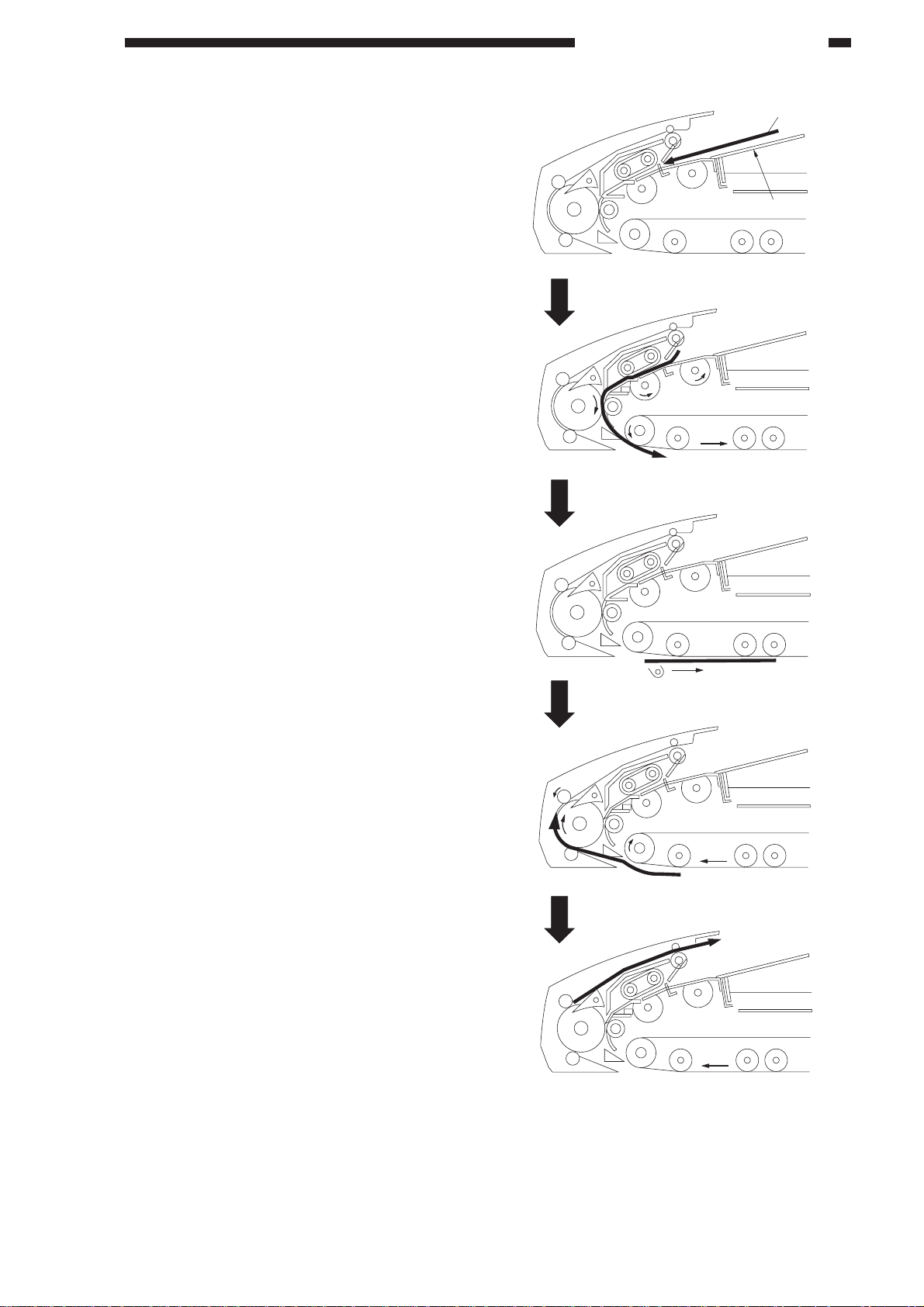

1. Bottom pick-up

2. Double-sided original to single-sided

copy

3. 2 small-size originals to reduced page

composition

4. Single-sided original to double-sided

copy

5. Double-sided original to double-sided

copy

Using auto duplexing unit.

6. Top pick-up mode original feeding

The machine feeds originals in any of

the following five ways according to the

instructions from the copier:

1. Bottom Pick-Up Mode

The machine picks up the originals on the

original tray from the bottom (last page of the

stack), and places each on the copyboard glass.

After copying, it moves the original from

the copyboard glass to the original tray.

Original

Original tray

Original set

Pick-up 2

Copying

Delivery 1

Delivery 2

Figure 2-202

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-7

CHAPTER 2 BASIC OPERATION

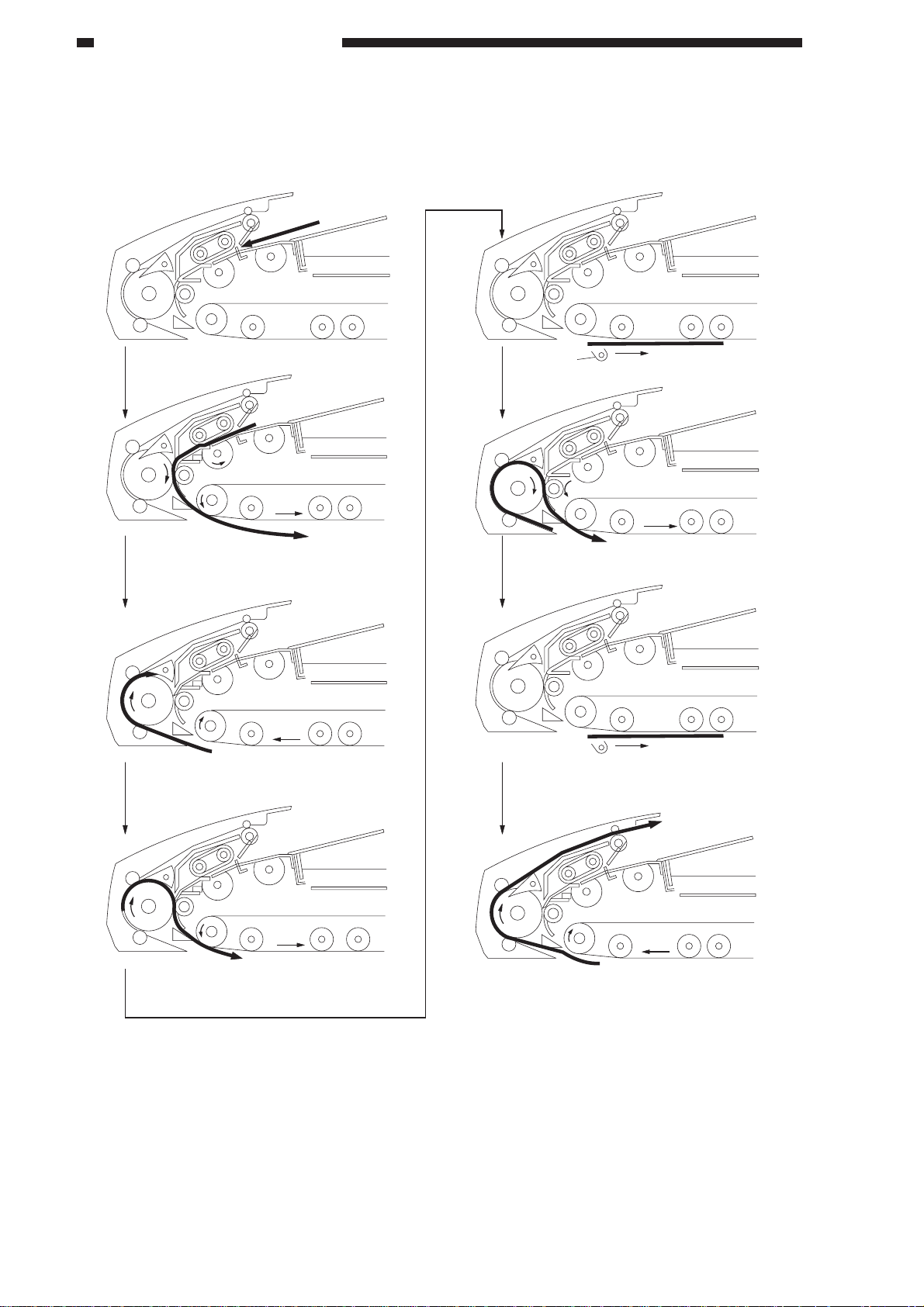

2. Double-Sided Original Mode

When copying the face (1st side) and the back (2nd side) of an original, the machine

automatically reverses the original.

Pick-Up Operation

Picks up an original for the 1st side.

Reverses the original from the 1st side

to the 2nd side.

Scanner

Reverses the original from the

2nd side to the 1st side.

Copies the 2nd side.

Copies the 1st side.

2-8

Delivers the original.

Figure 2-203

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 2 BASIC OPERATION

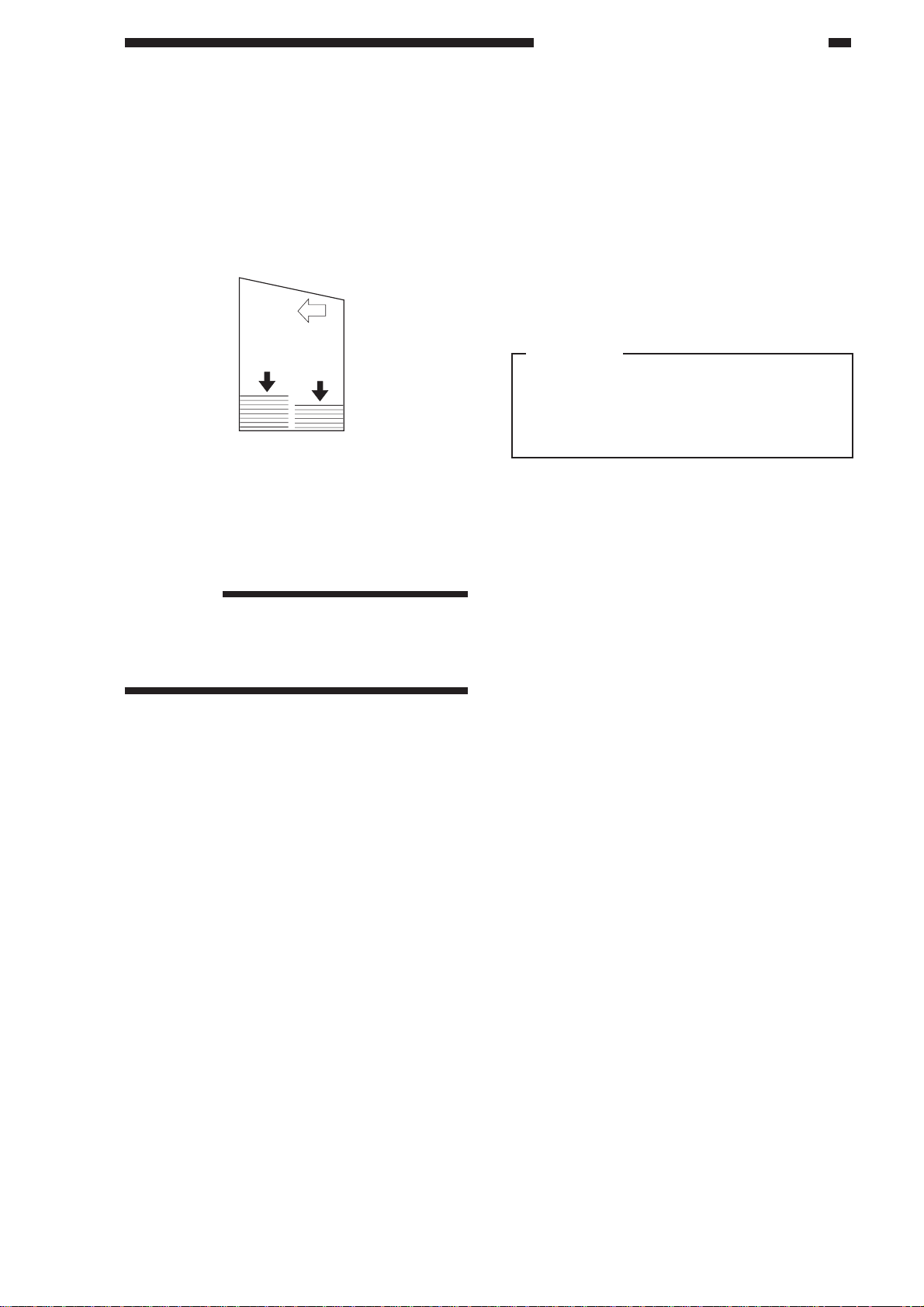

3. Reduced Page Compositon Mode

When reducing and copying two originals in page composition mode, the machine automatically

picks up two originals and places them on the copyboard glass side by side. Table 2-201 shows the

sizes of originals that may be used in the machine.

1st original

Picks up the 1st original.

A/B-configured

A5

B5

A4

Table 2-201

2nd original

INCH-configured

STMT

LTR

–

Reverses the original from the 1st side

to the 2nd side.

Picks up the 2nd original

While reversing the 1st original, picks up

the 2nd original.

(At this time, the order of originals is switched.)

Feeds the 2nd original and the 1st original.

Copying

1st original

2nd original

Delivers the 1st original, and delivers

the 2nd original.

Figure 2-204

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-9

CHAPTER 2 BASIC OPERATION

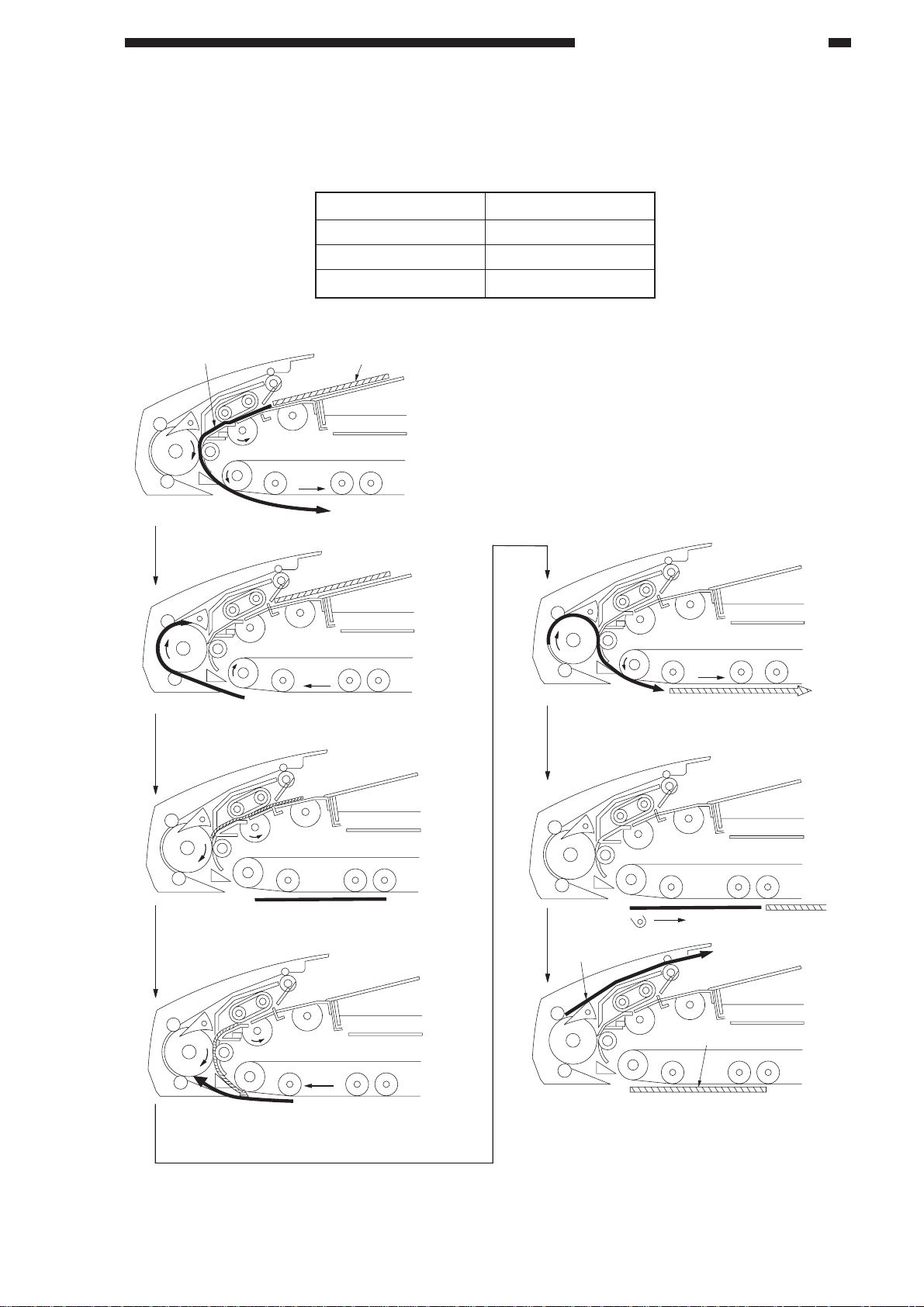

4. Top Pick-Up Feeding

The machine picks up the originals on the

original tray from the top (first page of the

stack), and places them on the copyboard glass.

Each time an original has been read, the

machine moves the original from the

copyboard glass to the original delivery tray.

Placement

Pick-up

Reading

Delivery 1

Delivery 2

2-10

Figure 2-205

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 2 BASIC OPERATION

5. Recirculating Mode

If the copier is not equipped with a sorter, this mode enables sorting of copies. Originals are

copied one after another until one set of copies have been made; and this operation is repeated until as

many sets as desired have been made.

Operation

1) Set originals on the original tray.

2) Select sort mode on the copier.

3) Enter a number (of sets) on the copier’s keypad.

4) Press the Copy Start key.

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-11

CHAPTER 2 BASIC OPERATION

C. Detecting Originals

1. Outline

The machine has the following four types

of document detection:

1. Detects the presence/absence of an

original on the original tray.

2. Detects the size of originals place on

the original try.

3. Detects the number of originals that

have been copied.

4. Detects the trailing edge of the last

original.

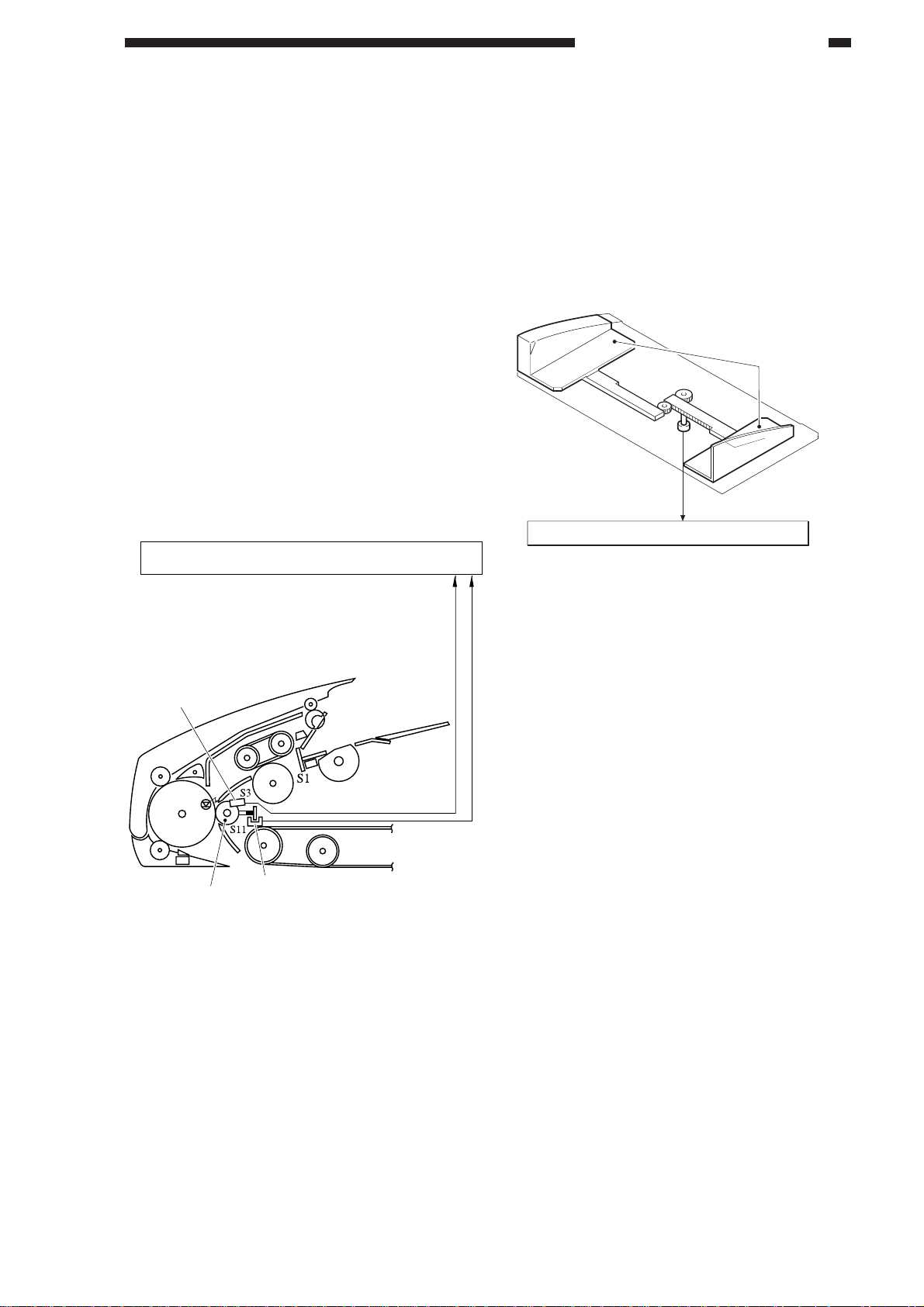

2. Detecting the Presence/Absence of

an Original

The presence/absence of an original on the

original tray is detected by the original tray

paper sensor (PS1).

When an original is set on the original tray,

the light between the original tray paper sensor

(S1) and the prism is blocked, causing the

original tray paper sensor (S1) to generate the

original detection signal (EMPS).

In response to the original detection signal

(EMPS), the DADF controller PCB turns on

the Original Set indicator (LED101, LED102).

Original Set indicator

Original

Original tray

Figure 2-207

DADF controller PCB

LED 101,102

Prism

Original

S1

S11

Figure 2-206

Original Set

indicator ON

signal

Indicator

PCB

Original tray paper signal

2-12

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 2 BASIC OPERATION

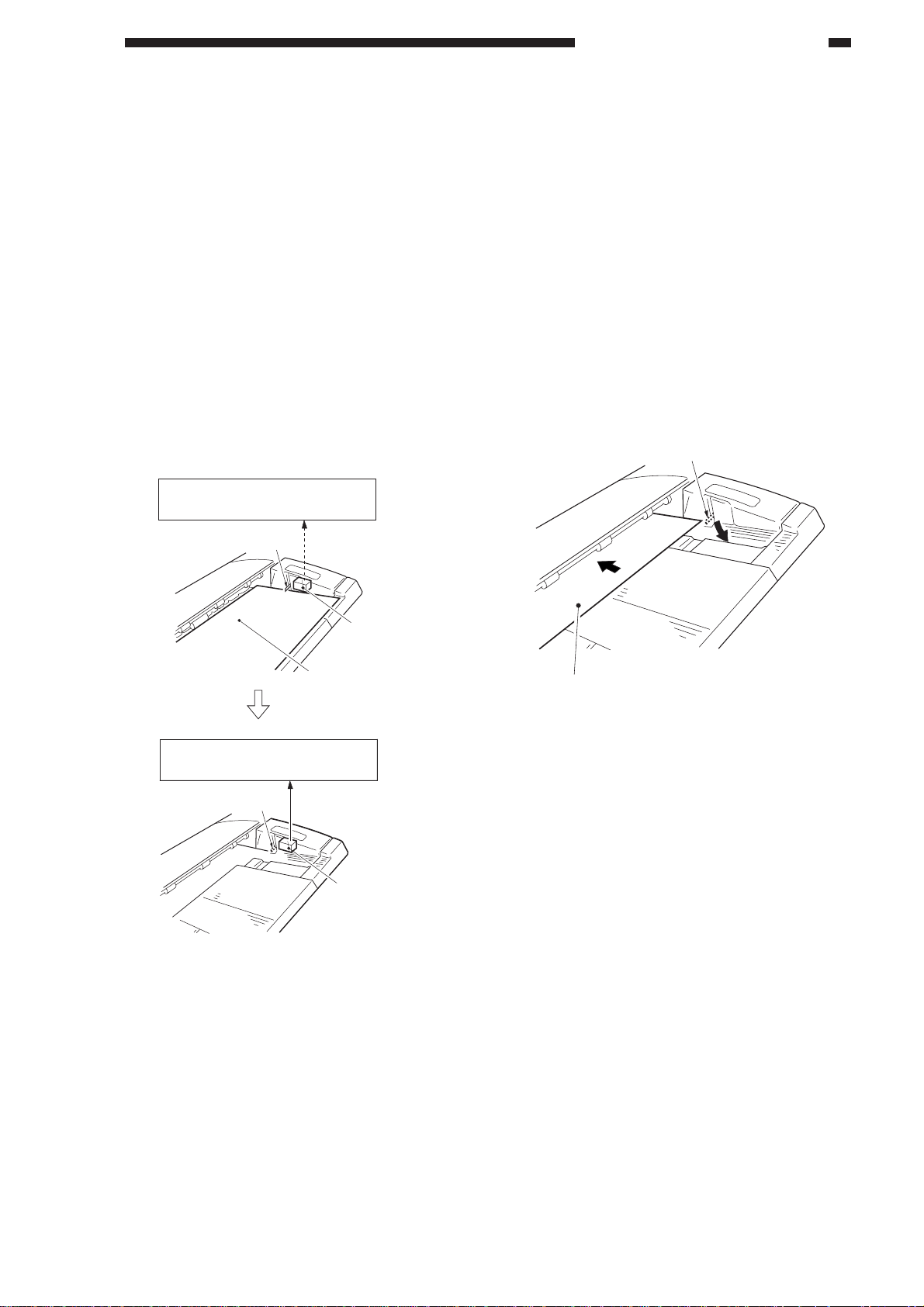

3. Detecting the Size of an Original

a. Outline

The machine detects the size of an original

in relation to the vertical (feeding) and

horizontal directions of the original, ensuring

correct size detection and for use for the

communication protocol of fax mode.

b. Detecting in Vertical (feeding)

Direction

Detection in vertical direction is made by

the registration paper sensor (S3) and the

registration roller clock sensor (S11).

The registration paper sensor detects the

leading and trailing edges of an original, and

the registration roller clock sensor detects the

rotation of the registration roller while the

original moves past the sensor. The rotation of

the registration roller is converted to the length

of the original.

DADF controller PCB

c. Detection in Horizontal Direction

Detection in horizontal direction is made

by the original width detecting volume (VR)

on the original tray. The original width

detecting volume operates in conjunction with

the side guide. As its resistance varies, the

changes are detected by the DADF controller

PCB, which converts them into a length in

horizontal direction.

Side guides

VR

DADF controller PCB

Figure 2-209

Registration

paper sensor

Registration roller

Pick-up detection signal

Registration roller clock signal

Registration roller clock sensor

Figure 2-208

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-13

CHAPTER 2 BASIC OPERATION

The copier identifies the size of an original

in terms of a default size based on the results of

vertical and horizontal lengths communicated

by the machine.

Table 2-202 shows the default sizes that

are identified:

d. A Model, A/B Model

Default

B5R

A5

A4R

FOOLSCAP

B5

B4

COMPUTER

paper

A4

A3

Vertical length

257mm

148.5mm

330mm

330mm

182mm

364mm

381mm

210mm

420mm

Original width

177~187mm

205~215mm

252~262mm

274~284mm

292~302mm

f. Inch Model and Inch/AB Model

Default

B5R

A5

A4R

STMT

LTRR

FOOLSCAP

LGL

B5

B4

LTR

COMPUTER

paper

279mm×432mm

(11"×17")

A4

A3

Original

length

257mm

148mm

297mm

140mm

279mm

330mm

356mm

182mm

364mm

216mm

381mm

432mm

210mm

420mm

Original

width

177~187mm

205~213mm

214~221mm

252~262mm

274~284mm

For vertical direction, a deviation of ±10

mm is ignored; for horizontal direction, a

deviation of ±5 mm is ignored; outside the

ranges, the original will be identified as being

of a non-default size.

Table 2-202

e. Inch Model

Default

STMT

LTRR

FOOLSCAP

LGL

LTR

COMPUTER

paper

297mm×432mm

(11"×17")

Original

length

140mm

279mm

330mm

356mm

216mm

381mm

432mm

Original

width

211~221mm

274~284m

For original length, a deviation of ±10 mm

is ignored; for original width, a deviation of ±5

mm is ignored; outside the ranges, the original

will be identified as being of a non-default size.

Table 2-204

In vertical direction, a deviation of ±10 mm

is ignored; in horizontal direction, a deviation

of ±5 mm is ignored; outside the ranges, the

original will be identified as being of a nondefault size.

Table 2-203

2-14

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 2 BASIC OPERATION

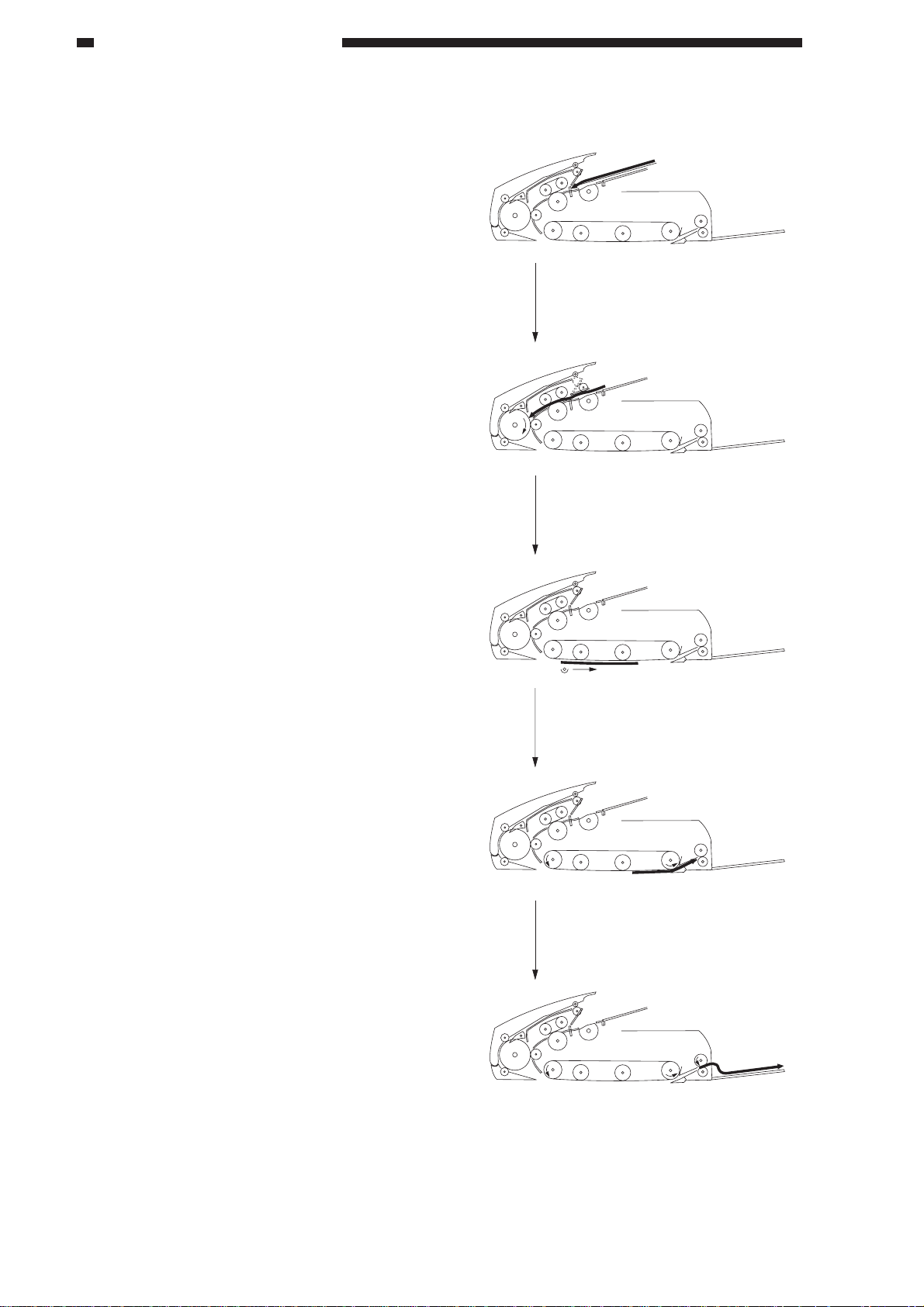

4. Detecting the Number of Originals

The number of originals is detected in

terms of “stack end detection,” “last original

rear edge detection,” and “original count

detection.”

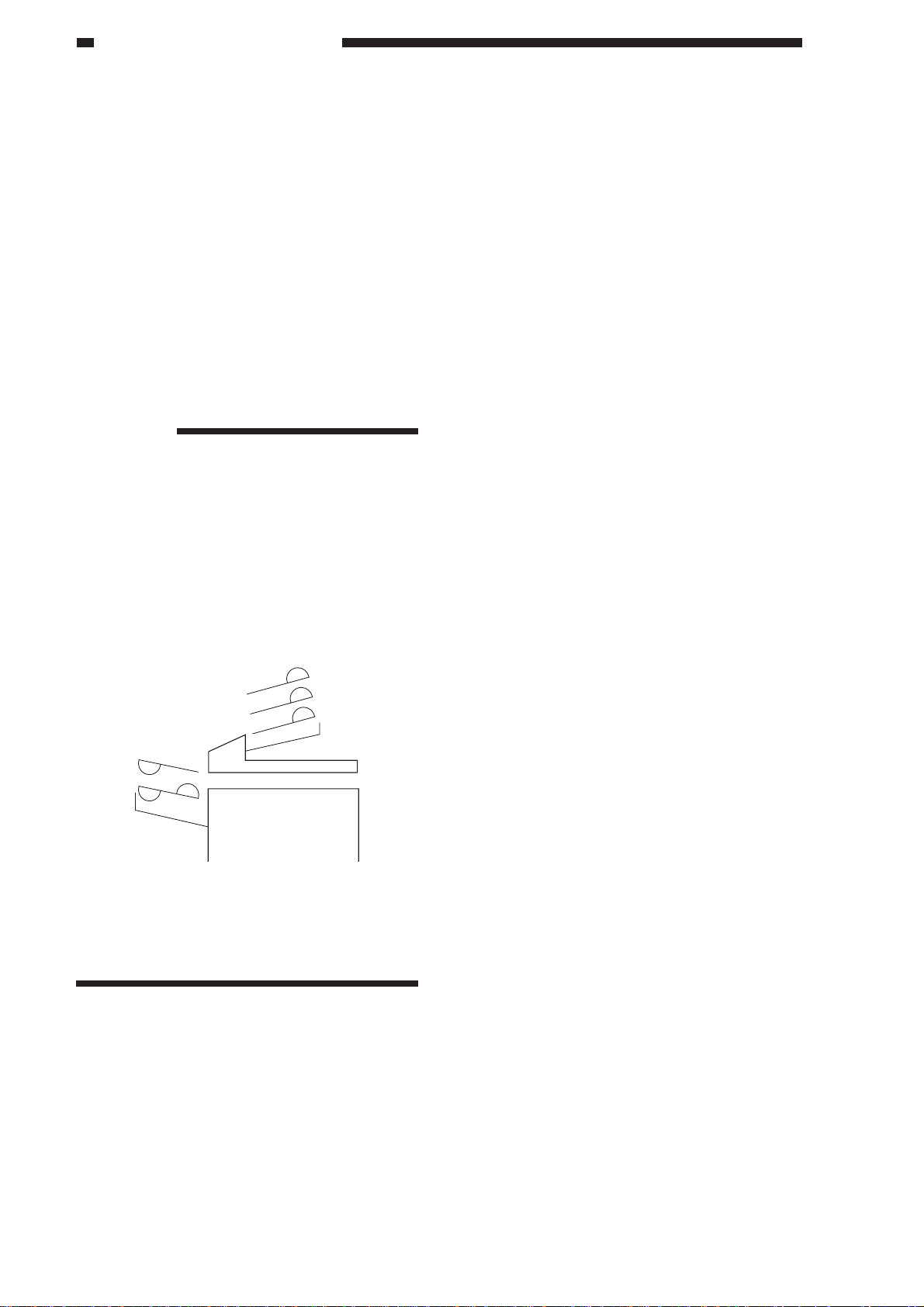

a. Detecting the End of a Stack

The machine picks up and delivers

originals on the same tray, requiring distinction

of originals that have been copied from

originals that have not been copied.

Before picking up originals, the recirculating lever is placed on top of the stack.

The lever will drop on the original tray when

all originals have been picked up, enabling the

re-circulation sensor (S14) to identify the last

original and to generate the last original

detection signal (RSS).

DADF controller PCB

Recirculating lever

b. Detecting the Trailing Edge of the Last

Original

A copier with a long paper path (from the

cassette to the drum) is designed to pick up

copy paper early to speed up copying work. As

such, when the machine picks up the last

original and places it on the copyboard glass,

the next paper is likely to be kept in wait.

To accommodate this, the machine is

designed to pick up originals to suit the timing

at which its host copier picks up copy paper.

If the length of an original is 220 mm or

less, the machine sets the first original on the

copyboard glass, and moves the second

original beyond the registration roller.

Recirculating lever

DADF controller PCB

Re-circulating

lever

Figure 2-210

Original

RSS

Re-circulation

sensor (S14)

Re-circulation

sensor (S14)

2nd original

Figure 2-211

If the re-circulating lever is on the original

tray in this condition, the machine

communicates to the copier that the third and

subsequent originals are present, and the copier

picks up copy paper for the next copying run.

When the re-circulating lever has dropped

on the original tray, the machine communicates

to the copier that there is not third or

subsequent originals (RSS signal) so that the

copier will not pick up copy paper.

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-15

CHAPTER 2 BASIC OPERATION

c. Original Count Detection

The machine need not count originals

when making single-sided copies of singlesided originals, signal-sided originals of

double-sided originals, or double-sided copies

of double-sided originals; as such, it merely

feeds the originals on the original tray in

sequence.

When making double-sided copies of

signal-sided originals, however, the machine

must find out whether there is an odd or even

number of originals.

Holding the copier from making copies,

the DADF picks up and delivers the originals to

find out how many there are.

Reference:

The machine can pick up the last page of

originals first. When making doublesided copies of single-sided originals, it

must decide whether the last page must be

on the face or back of a sheet (odd or even

page).

Figure 2-212 shows what would happen

if an odd number originals were fed

without control. (The first page would be

copied on the back of a sheet.)

1

2

3

1

2

3

Copier

Figure 2-212

On some copiers, you can disable original

count operation in user mode.

2-16

COPYRIGHT © 1998 CANON INC. CANON DADF-A1 REV.0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

Loading...

Loading...