Page 1

ROADSTER

PREDELIVERY

Bulletin

October 27, 2009 Subject:Can-Am™ Spyder™ RT Predelivery

Inspection

YEAR MODEL MODEL NUMBER

2010

Underlined text(s) between arrows is (are) added element ( s) to the previous publication.

Spyder RT SM5

Refer to table on next pages for complete listing All

Spyder RT SE5

TABLE OF CONTENTS

Page Page

IMPORTANT NOTICE ....................... 2

MODEL LISTING............................. 3

UNCRATING .................................. 3

Crate Cover Removal .......................... 3

Parts and Sub-crate Removal ................. 3

Parts Check...................................... 4

Front Wheels Installation .. . .... ..... .... . .... . 5

Vehicle Removal ................................ 7

PARTS TO BE INSTALLED................. 9

Front Cargo Module . . .... .... . .... . .... ... . . ... 9

Battery Charging and Installation............. 15

Front Cargo Module (continued).. ..... .... . .. 17

Front Fenders . .... . .... .... . .... ..... .... . .... .. 17

Mudguards . . .... . .... .... . .... .... . .... ..... .... 18

Windshield....................................... 19

Antenna (Option Package) ................ 20

Hang Tag and Safety Labels .................. 20

Licence Plate.................................... 20

Accessories Installation........................ 21

Vehicle Decals................................... 21

Key Barrel - Trailer RT 622..................... 21

Clutch Fluid (SM5 Model) .... ..... .... . .... ... 23

Engine Coolant.................................. 24

Brake Fluid....................................... 25

SET-UP......................................... 25

Tire Pressure .................................... 25

Brake Disc Cleanup ............................ 26

ADJUSTMENTS ............................. 26

Guidelines ....................................... 26

Drive Belt ........................................ 26

Clutch Lever ..................................... 27

Suspension .... . .... ... . . .... ..... .... . .... ..... . 27

Lights............................................. 28

B.U.D.S. Programming......................... 30

ASSEMBLY INSPECTION .................. 32

FINAL INSPECTION ......................... 33

Vehicle Test Run ................................ 33

Vehicle Cleaning ................................ 34

Delivery to Customer .......................... 34

SPECIFICATIONS ............................ 35

No. 2010-1

REVISION 3

August 12, 2010

SERIAL

NUMBER

FLUIDS......................................... 21

General Guidelines ............................. 21

Fuel . .... ..... .... . .... .... . .... ... . . .... ..... .... . 21

Engine Oil........................................ 22

Printed in Canada. (rbl2010-002 en DM/AB/AP)

©2009 Bombardier Recreational Products Inc. and BRP US Inc. All rights reserved.

®™ and the BRP logo are trademarks of Bombardier Recreational Products Inc. or its affiliates.

1/39

Page 2

IMPORTANT NOTICE

IMPORTANT NOTICE

This bulletin must be used in conjunction with the check list enclosed in the bag with the

GUIDE

. Make sure that Spyder roadster

PRE DELIVERY CHECK LIST

is completed and signed.

OPERATOR’S

WARNING

To obtain warranty coverage, predelivery procedures must be performed by an authorized BRP

Can-Am roadster dealer/distributor. Apply all necessary torques as indicated.

NOTE: The information and components/system descriptions contained in this document are correct at

the time of publication. BRP however, maintains a policy of continuous improvement of its products without imposing upon itself any obligation to install them on products previously manufactured.

Due to late changes, there might be some differences between the manufactured product and the descriptions and/or specifications in this document. BRP reserves the right at any time to discontinue or

change specifications, designs, features, models or equipment without incurring obligation.

The illustrations in this document show the typical construction of the different assemblies and may not

reproduce the full detail or exact shape of the parts. However, they represent parts that have the same

or similar function.

The content of this bulletin is designed as a guideline only. All mechanics performing predelivery

procedures should have attended the current model-year service training.

Further information or inquiries should be directed to your service representative and specific

SHOP MANUAL

Make sure the customer receives the

SAFETY DVD

and

sections.

OPERATOR’S GUIDE,PREDELIVERY CHECK LIST

signed copy

WARNING

Torque wrench tightening specifications must be strictly adhered to. Where specified, install new

locking devices (e.g. lock tabs, elastic stop nuts). If the efficiency of a locking device is impaired,

it must be renewed.

2 / 39 2010-1 PREDELIVERY

Page 3

UNCRATING

MODEL LISTING

MODEL COLOR MODEL NUMBER

A3AA, A3AB,

A3AC, A7AA,

A7AC

A7AD, A7AF

A9AA, A9AC

A9AD, A9AF

A4AA, A4AB,

A4AC, A4AD

A4AE

(P/N 703 100 263)

RT

RT -S

Full Moon

SM5

SE5

SM5

SE5

MODEL PDI KIT P/N

All

Silver

Orbital Blue

Full Moon

Silver

Orbital Blue

Timeless Black B5AA, B5AB

Orbital Blue B5AC

Timele ss B lack

Orbital Blue

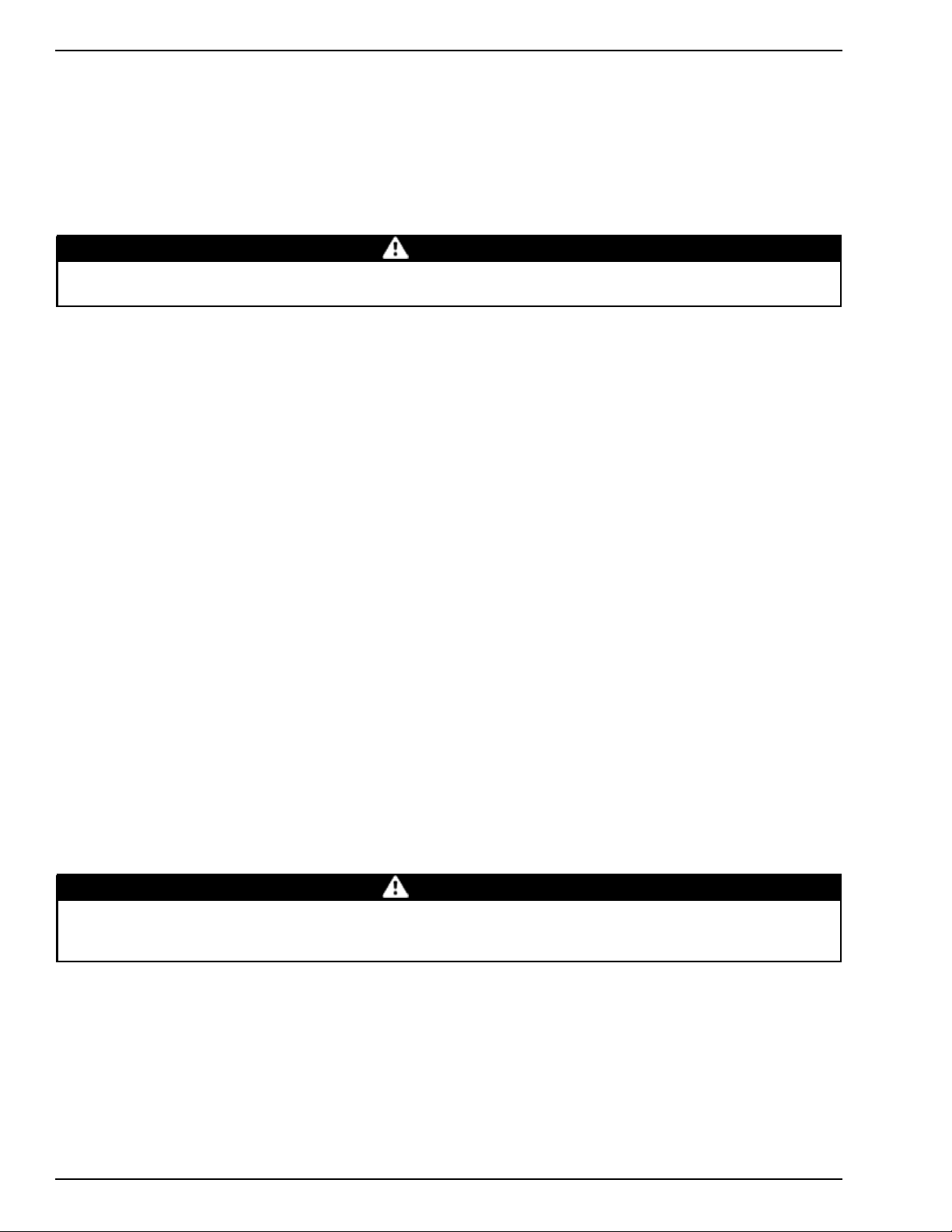

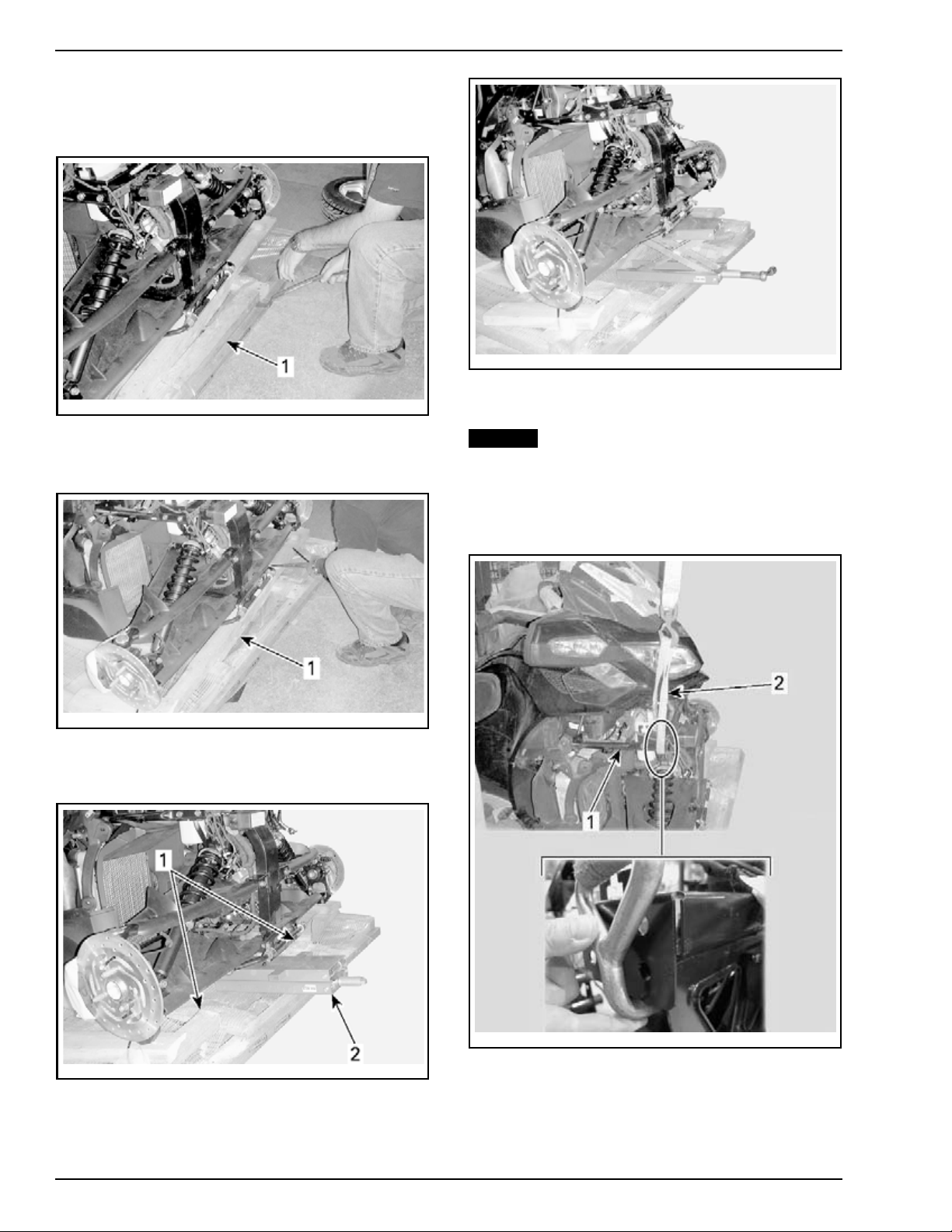

UNCRATING

NOTICE

Do not raise cover vertically. Tilt

cover located on the front side of the vehicle.

Refer to illustration.

rbl2010-002-003

TILT COVER THEN PULL IT

Crate Cover Removal

NOTICE

serious damage to vehicle.

1. Position the crate on a firm, level surface.

2. Carefully cut both ends of crate tarpaulin to locate the front of vehicle.

rbl2010-002-001

CUT BOTH END OF CRATE TARPAULIN

3. Remove all screws holding crate cover to crate

base.

4. Tilt cover from the front side of the vehicle then

pull cover toward you to clear vehicle fascia.

Allowing the crate to drop may cause

rbl2010-002-004_a

FRONT OF VEHICLE

1. Pull crate cover to clear front fascia of th e vehicle

NOTICE

The crate cover must be pulled toward the outside while lifting it to avoid to

damage vehicle.

NOTE: Screws that are used are Robertson

†

#2

type (or equivalent) that require the use of an appropriate screwdriver.

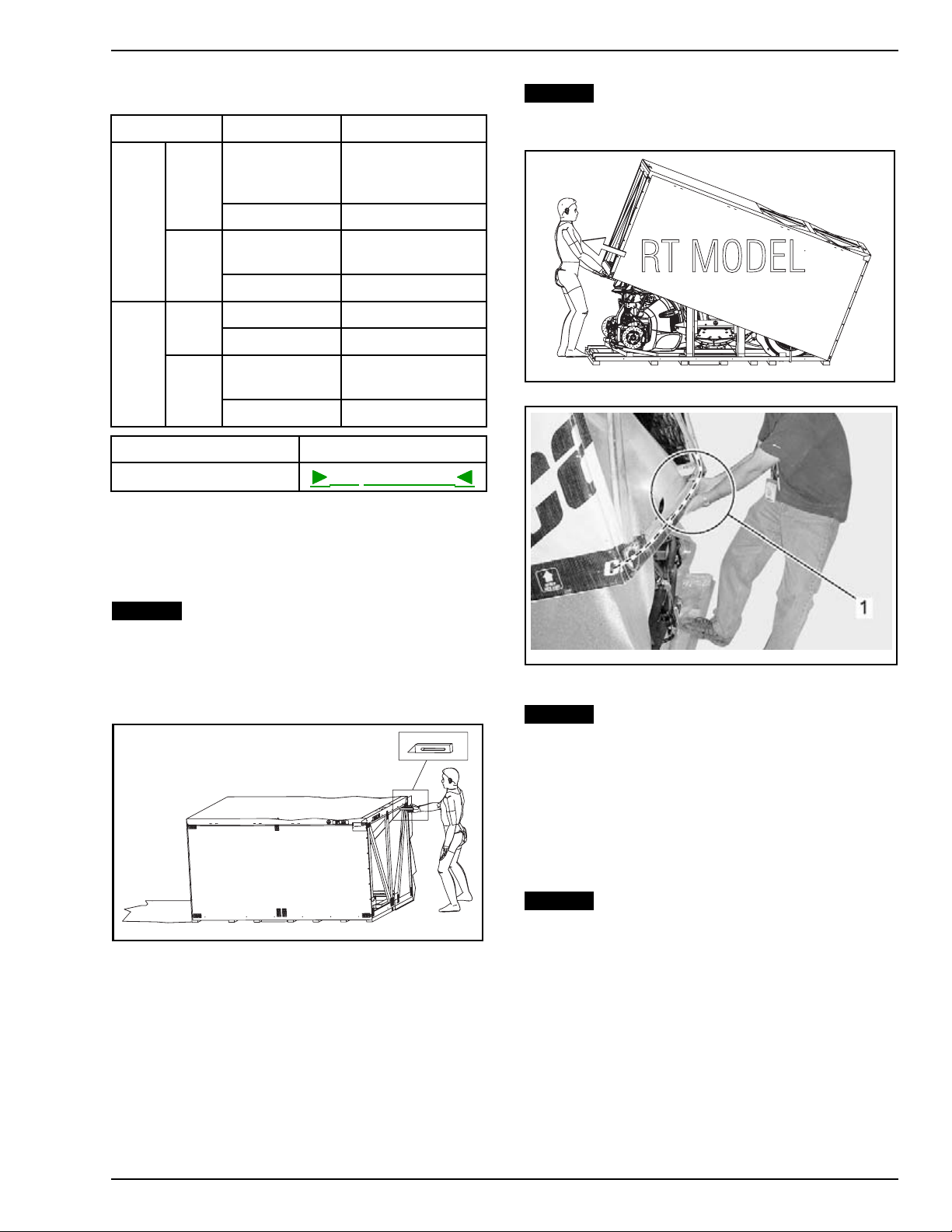

Parts and Sub-crate Removal

NOTICE

bumper and the front fascia.

NOTE: The sub-crate is located on the left side of

vehicle and it contains the front cargo module.

1. Remove protective foam from vehicle.

Be careful not to scratch the cover

† Robertson is a registered trademark of Robertson Inc.

PREDELIVERY 2010-1 3 / 39

Page 4

UNCRATING

All Models

rbl2010-002-005

2. Remove windshield and front wheels from

crate base.

rbl2010-002-006_a

1. Windshield

2. Front wheels

3. Remove front fenders from crate base.

rbl2010-002-008_a

1. Sub-crate

5. Assisted by another person, carefully lift up the

sub-crate.

rbl2010-002-009

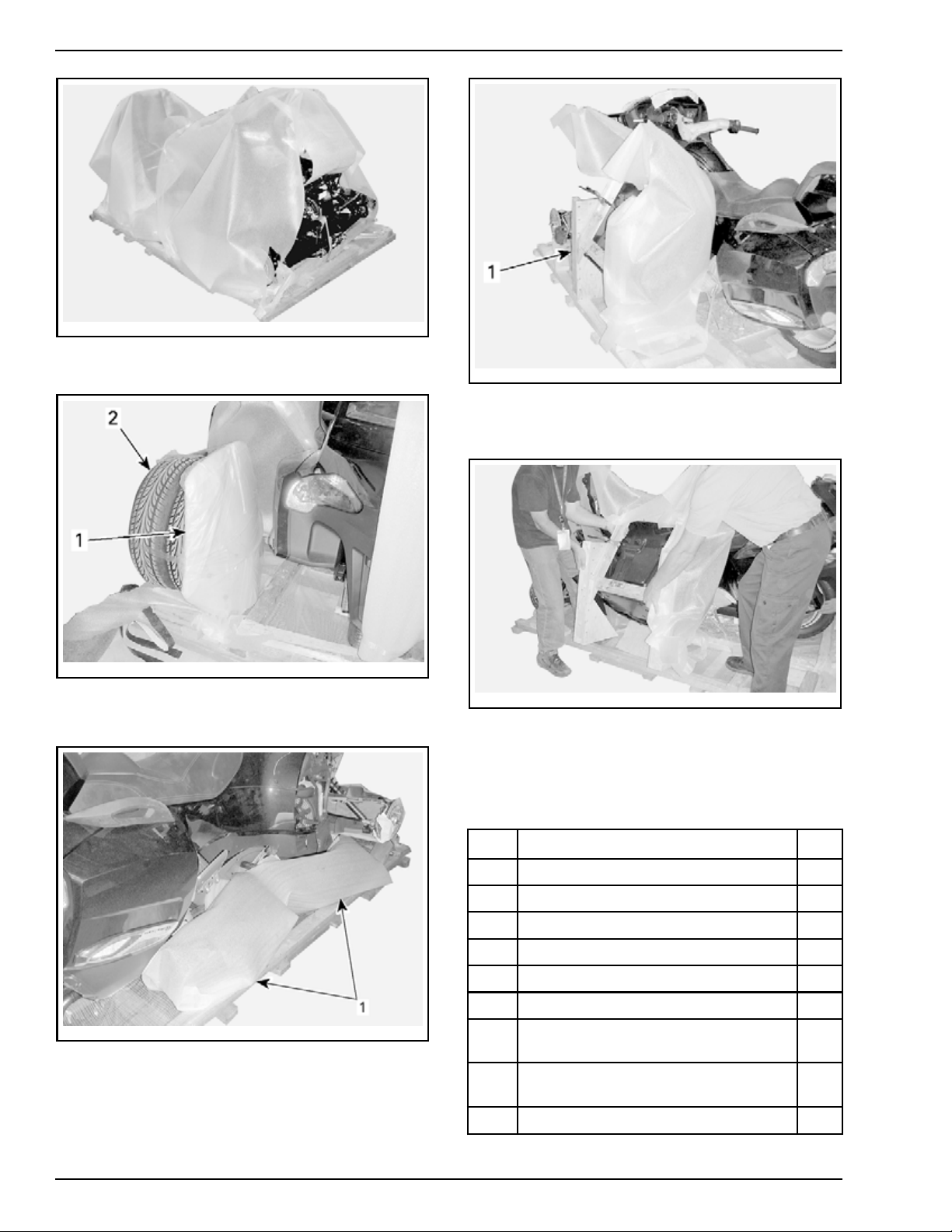

Parts Check

1. Ensure that the crate includes the following

items:

ITEM DESCRIPTION (LOCATION) QTY

1

Wheel

lug nut (front wheels)

6

2 Wheel cap (front wheels) 2

3 Bushing (rear suspension) 2

010-002-007_a

rbl2

1. Front fenders

4. Remove all screws holding sub-crate to crate

base.

4

M10 x

5

M10 nu t (rear suspension)

140 (rear suspension)

6 M6 caged nut (front cargo module)

ck M6 x 20 screw (front cargo

Bla

7

module)

d M6 x 20 screw (front cargo

Gol

8

module)

9

vice cover (front cargo module)

Ser

1

1

1

4

2

2

4 / 39 2010-1 PREDELIVERY

Page 5

UNCRATING

Op tion Package

ITEM DESCRIPTION (L

Service cover plastic rivet (front cargo

10

module)

11

Battery post screw (battery) 2

12 M6 x 20 screw (front panels) 2

13 Plastic wash

14

M14 nut (headlights) 2

15

Clip (h eadlights)

16 M8 x 20 screw (

17

Windshield trim 2

18 M6 x 20 screw (windshield)

19 M5 x 20 scre

20 M5 retaining nut (windshield) 2

21 Mudguard 2

22 M6 retain

23 M6 x 20 screw (Mudguards)

ing nut (Mudguards)

OCATION)

er (front panels)

front fenders)

w (windshield)

QTY

2

2

2

8

4

2

4

4

rbl2010-002-010_a

1. Front strap

2. Remove strap retaining side of vehicle to crate

base.

ITEM DESCRIPTION QTY

24 Antenna

25 Antenna rubber cap

26 M6 stainless steel lock washer

1

1

1

Front Wheels Installation

WARNING

SE5 mo

posit

secur

block

No one should be standing in front or at the

back of the vehicle while straps are being cut.

1. Remove strap retaining front of vehicle to crate

base.

dels are automatically set in neutral

ion when engine is stopped. Always

e the rear wheel of vehicle with proper

s to avoid moving.

WARNING

-002-011_a

rbl2010

1. Side strap

3. Remove strap on the RH caliper.

rbl2010-002-012_a

1. Caliper strap

NOTE: The following steps will describe two

methods to install front wheels on vehicle. The

conventional one uses a hydraulic jack and the

alternate one uses a chain block. Use the proper

method according to your shop layout.

PREDELIVERY 2010-1 5 / 39

Page 6

UNCRATING

Co nventional Method

Alternate

Method

1. Remove top crate board located at the front of

vehicle.

rbl2010-002-016

rbl2010-002-013_a

1. Stud to remove

2. Cut second

vehicle us

rbl2010-002-014_a

1. Stud to cut

crate board located at the front of

ing a proper saw.

3. Install a jack under the front lower beam of

frame.

5. Refer to

(CONTINUED)

NOTICE

FRONT WHEELS INSTALLATION

to complete the procedure.

Never lift vehicle by the suspension

arm.

1. Install proper straps on RH and LH lateral supports of vehicle.

rbl2010-002-020_a

1. RH lateral support

rbl2010-002-015_a

d that was cut

1. Stu

2. Hydraulic jack

4. Lift the vehicle.

2. Proper strap

2. Hook straps on an appropriate lifting kit.

3. Lift vehicle using a chain block.

6 / 39 2010-1 PREDELIVERY

Page 7

UNCRATING

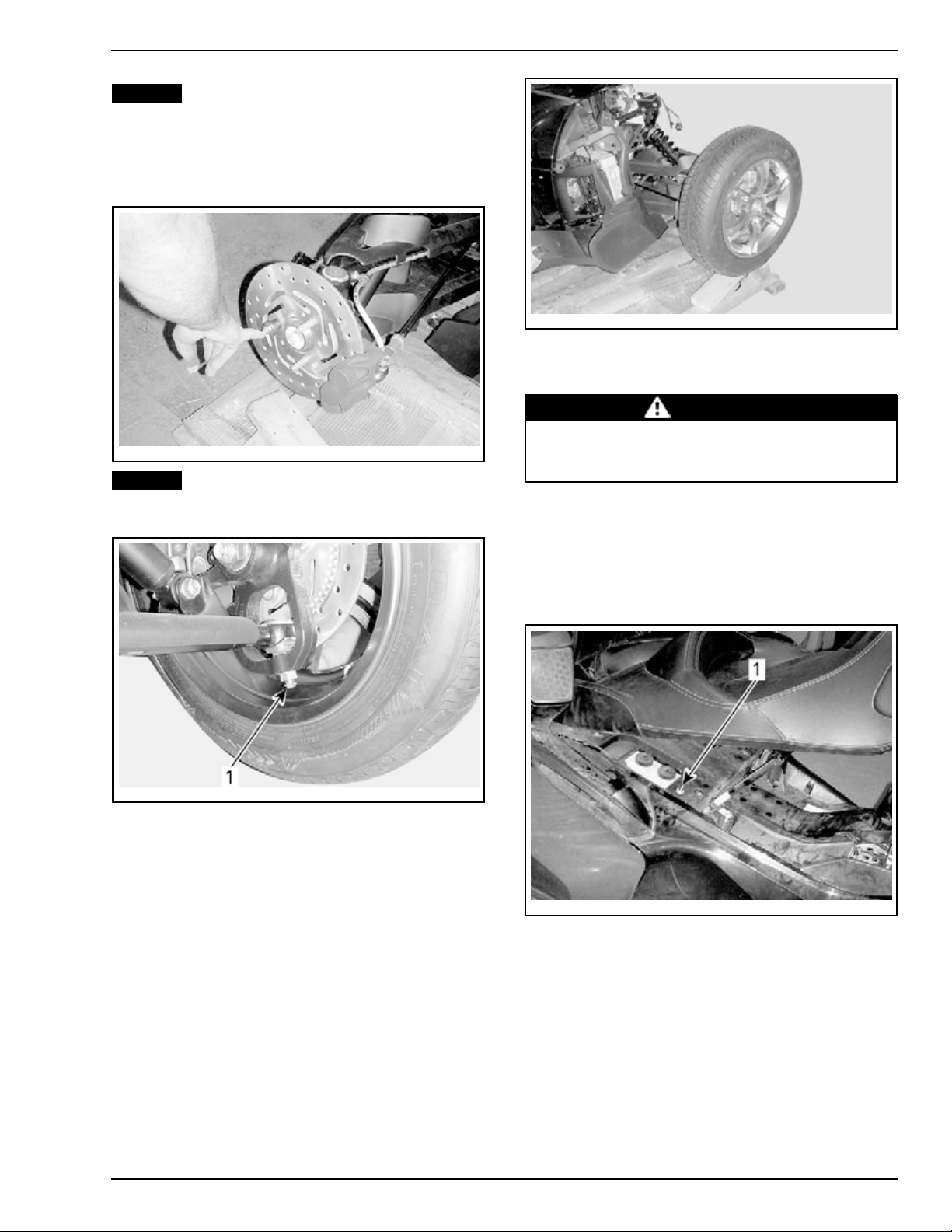

Front Wheels Installa tion (continued)

NOTICE

Never lift vehicle by the suspension

arm.

1. Remove nut securing front brake discs to vehicle.

rbl2010-002-017

NOTICE

Be careful not to scratch front wheels

with ball joint cotter pins during wheels installation.

rbl2010-002-019

6. Torque whee

ls lug nuts to 105 N•m (77 lbf•ft).

7. Install wheel caps (from PDI kit).

WARNING

The tires a

rection. D

wheels.

re only designed to rotate in one di-

o not switch the left and right front

Vehicle Removal

-002-018_a

rbl2010

1. Ball joint cotter pin

2. Install front wheels on vehicle.

3. Ensure that the rotation direction shown by the

arrow is respected.

4. Tight

en wheels lug nuts by hand (from PDI kit).

5. Lower vehicle on crate base.

1. Open seat.

2. Locate ACS suspension pneumatic valve then

unscrew cap.

rmo2010-001-056_a

1. Pneu

matic valve

3. From underneath of vehicle, locate the bottom

of the rear shock absorber.

4. Get

the following hardware from the PDI kit:

– M10 x 140 bolt

– M10 nut

stic bushings.

–Pla

5. Install the 2 plastic bushings over the steel

sleeve at the bottom of the shock absorber.

PREDELIVERY 2010-1 7 / 39

Page 8

UNCRATING

6. With the help of another person, gently inflate

the A CS spring while your assistant, from the

LH side of the vehicle, monitors the alignment

of the bottom of the shock absorber (anchoring

holes) with the bottom of the lower brackets.

rbs2010-012-010_a

1. Lower bracket hole

2. Anchoring holes

rbs2010-012-011_a

1. ACS position sensor lever

2. Link

7. Ensure that ACS position sensor lever orientation is correct.

NOTICE

Adding air may create rapid high

changes because of the small air volume

in the ACS spring. The anchoring hole of

shock absorber must NEVER exceed the lower

bracket holes when adding air into ACS spring.

To avoid damaging the ACS system, DO NOT

exceed 551 kPa (80 PSI) into the ACS spring.

rbs2010-012-004_a

1. Lower bracket hole

NOTICE

On RT-S vehicle, exceeding air pressure may damage the ACS suspension sensor

and the ACS spring plate by excessively pull

downward on the ACS suspension sensor, its

lever and its link as illustrated below.

rbs2010-012-001

CORRECT ORIENTATION

rbs2010-012-002_a

INCORRECT ORIENTATION

8. Secure shock absorber as follows:

8.1 Using the passenger grab handles, slightly

lift the rear of the vehicle by HAND to align

both bushings on lower bracket hole.

8.2 Install M10 x 140 bolt.

8.3 Install and torque M10 nut to 48 N•m

(35 lbf•ft).

8 / 39 2010-1 PREDELIVERY

Page 9

rbl2010-002-022_a

1. Shock absorber bo lt

2. Lower bracket

SE5 models a

position wh

secure the r

blocks to a

NOTICE

foot as you

no brake le

pedal is i

NOTICE

en engine is stopped. Always

ear wheel of vehicle with proper

void moving.

Be ready to

move the vehicle since there is

ver on the handlebars. The brake

n front of the right footpeg.

Always move vehicle rearward out of

the crate base.

WARNING

re automatically set in neutral

apply brake with your

PARTSTOBEINSTALLED

rbl2008-003-204_a

1. Bolt and nut holding the bottom section

2. Bolts and nuts holding the top section

NOTE: Be careful not to lose the caged nut located

in the bottom fixation hole of the front cargo module.

2. Open front storage compartment cover.

3. Ensure that the front storage compartment in-

cludes the following items:

– Operator's Guide

– Predelivery (PDI) Check List

–SafetyDVD

– Service covers (2x)

–PDIkit.

– Windshield trim (2x)

– Mudguard (2x)

4. Ensure that the following cables and connec-

tors are accessible prior to installing front cargo

module, cut locking ties if required.

NOTE: Brake pedal applies the brakes for the

three wheels. Press it down to operate.

9. With the help of your assistant, move vehicle

rearward out of the crate base.

rbl2010-002-021_a

PARTS TO BE INSTALLED

Front Cargo Module

1. Remove and discard bolts and nuts holding the

bottom and the top sections of sub-crate.

rbl2010-002-023_a

TO THE FOLLOWING TABLE FOR ITEMS DESCRIPTION

REFER

ITEMS DESCRIPTION

1

2

3

4

AAPTS sensor connector

Horn connector (hidden on

the illustra tio n)

RH and LH auxiliary light connector

- Low beam light (CE)

- Fog light (option package)

DLC connector (B.U.D.S.)

PREDELIVERY 2010-1 9 / 39

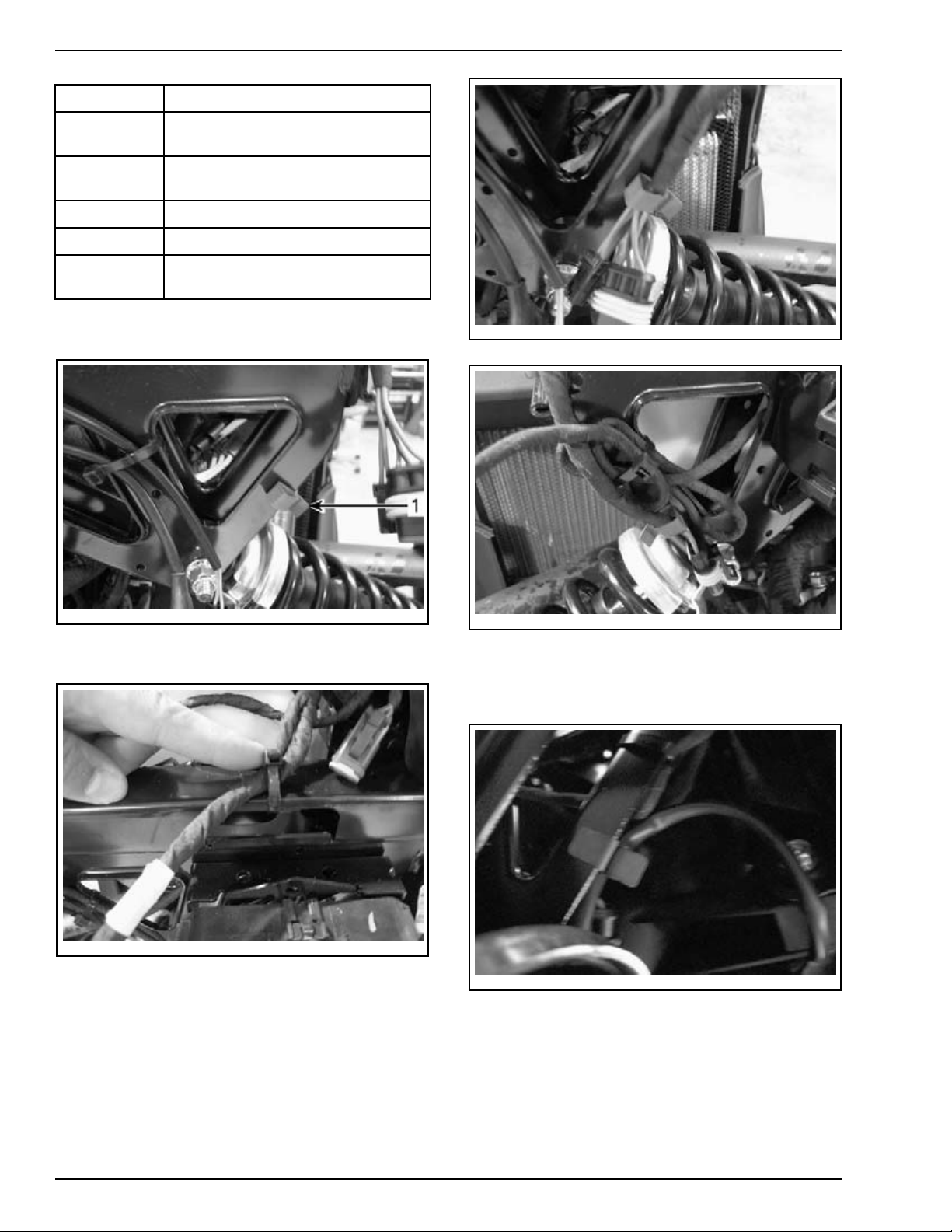

Page 10

PARTS TO BE INSTALLED

ITEMS DESCRIPTION

5

6

7

Storage cover actuator connector

(option packag

e)

Storage cover switch connector

(option packag

e)

Storage cover cable

8 12 V power outlet

9

Storage compa

(option package)

rtment light

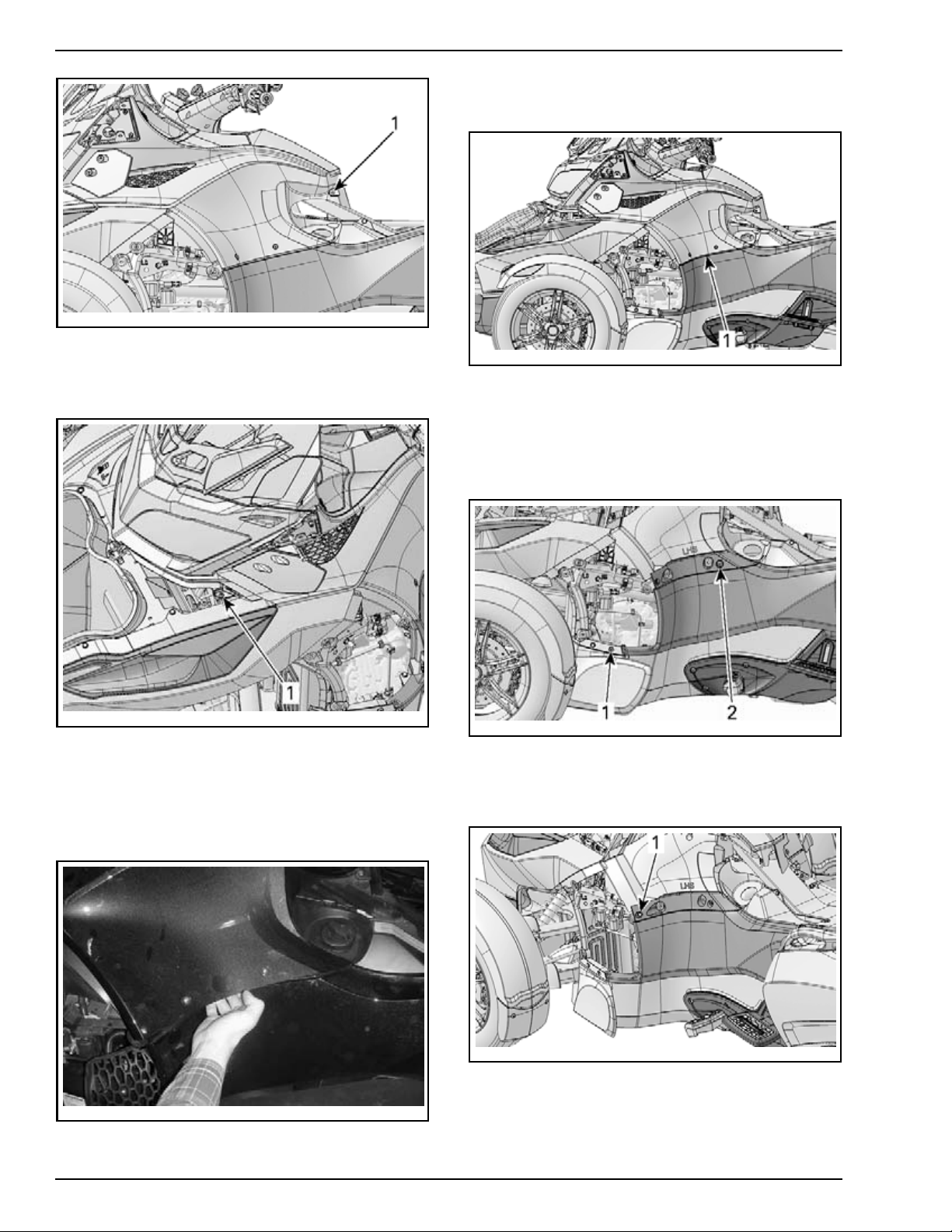

5. Install headlight harness clip (from PDI kit) on

vehicle frame as shown (on both side).

rbl2010-002-352

LH SIDE

rbl2010-002-350_a

1. Headligh

t h arness clip

6. Cut locking tie holding headlight harness.

rbl2010-002-351

7. Insert headlights harness into clips as shown.

rbl2010-002-353

RH SIDE

8. Do not let auxiliary lights harness hang near

shock absorber. Properly insert it into clips (on

both sides).

rbl2010-002-354

CT INSTALLATION

CORRE

10 / 39 2010-1 PREDELIVERY

Page 11

rbl2010-002-355_a

WRONG INSTALLATION

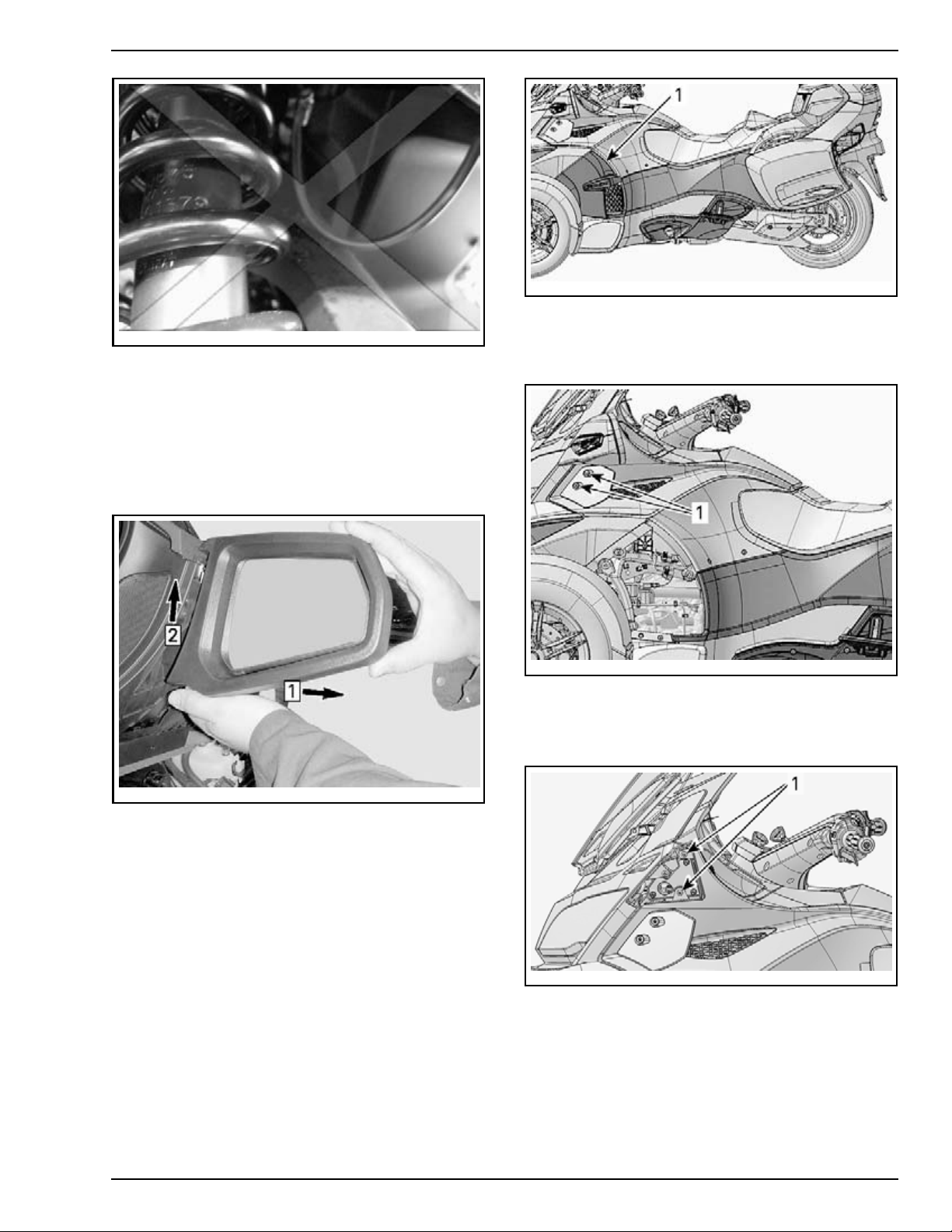

9. Remove mirrors as follows:

9.1 Pull lower part of mirror toward the outside

to unlock it.

9.2 Slide mirror upwards to unhook it from upper slot.

9.3 Disconnect connector.

PARTSTOBEINSTALLED

rbl2010-002-318_a

TYPICAL

1. Middle side panel

11. Remove retaining screws from lower wind deflectors.

rmr2010-038-301_a

Step 1: Pull toward the outside

Slide upwards

Step 2:

10. Remove middle side panels as follows:

10.1 P ull p

anel toward the outside to remove

m grommets at the front.

it fro

10.2 Unhook the rear.

rbl2010-002-319_a

TYPICAL

1. Retaining screws of wind deflector

12. Remove upper retaining screws from top side

panels.

rbl2010-002-320_a

TYPICAL

1. Upper retaining screws

13. Remove rear retaining screw from top side

panels.

PREDELIVERY 2010-1 11 / 39

Page 12

PARTS TO BE INSTALLED

rmr2010-038-006_a

TYPICAL

1. Rear retaining screw

14. Remove front retaining screw from top side

panels.

16. Remove top side panels by lifting them upwards.

-009_a

rmr2010-038

TYPICAL

1. Top side panel

17. Remove fron

t retaining screw of LH rear side

panel.

18. Remove upper retaining screw and washer

from LH rear side panel.

rbl2010-002-321_a

TYPICAL

1. Front r

etaining screw

15. Pull out lower part of top side panel to remove

it from grommets.

NOTE: D

o not remove lower screws from top side

panel.

rbl2010-002-305

rmr2010-038-010_a

1. Front retaining screw

2. Upper retaining screw

19. Remove front plastic rivet from LH rear side

panel.

2010-038-011_a

rmr

1. Front plastic rivet

20. Open LH storage compartment cover.

21. Remove rear retaining screws from LH rear

side panel.

12 / 39 2010-1 PREDELIVERY

Page 13

rmr2010-038-012_a

1. Rear retaining screws

22. Remove top retaining screw of LH rear side

panel.

PARTSTOBEINSTALLED

rmr2010-038-022_a

TYPICAL

1. Upper retaining screw

25. Remove middle retaining screws from front

fascia.

rmr2010-038-013_a

1. Top reta

NOTICE

rbl2010-002-356_a

LH REAR SID E PANEL

1. Lower tabs

ining screw

Be careful not to break lower tabs.

23. Remove LH rear side panel from vehicle.

24. Remove upper retaining screws from front

fascia.

rmr2010-038-023_a

TYPICAL

1. Middle retaining screw

26. Remove lower retaining screws and washers

from front fascia.

rmr2010-038-024_a

TYPICAL

1. Lower retaining screw

27. Remove front fascia from vehicle.

28. Use the following hardware to fix front cargo

module on vehicle.

PREDELIVERY 2010-1 13 / 39

Page 14

PARTS TO BE INSTALLED

CE Models

rbl2010-002-100_a

1. Black M6 screws from PDI kit

2. Gold M6 screws from PDI kit

3. M6 caged nut from PDI k it

NOTE: The second caged nut is already installed

on front cargo module.

29. Assisted by another person, position front

cargo module into support slots of vehicle.

30. Connect the following front cargo module connectors and cable:

– AAPTS sensor connector

– Horn connector

– RH and LH auxiliary light connector (CE and

Option Package)

– DLC connector (B.U.D.S.) stowed in its re-

ceptacle

– Storage cover actuator connector (option

package)

– Storage cover switch connector (option

package)

– Storage cover cable

– 12 V power outlet

– Storage compartment light (option pack-

age).

31. Install auxiliary light adjustment cable as follows:

31.1 Install adjustment cable through hole in

panel.

31.2 Tighten nut securing adjustment cable

(from PDI kit).

rmo2010-001-009_d

LEFT SIDE SHOWN

1. Install through this hole

32. Install caged nut (from PDI kit) on a bottom

hole of storage compartment.

33. Install gold M6 screws to secure bottom of

storage compartment.

34. Do not tighten gold M6 screws for the moment.

0-038-026_a

rmr201

1. Gold M6 screws

35. Install black M6 screws to secure top of storage compartment.

rmr2010-038-025_a

1. Black M6 screws

14 / 39 2010-1 PREDELIVERY

Page 15

36. Torque upper and lower M6 screws to

4.5 N•m (40 lbf•in).

37. Do not reinstall body panels for the moment,

follow

TION

ule as per

TINUED)

BATTERY CHARGING AND INSTALLA-

procedure then finalize front cargo mod-

FRONT CARGO MODULE (CON-

procedure.

Battery Charging and

Installation

WARNING

Always connect RED positive cable first and

then BLACK negative cable.

CAUTION Neve

while instal

led on vehicle.

r charge or boost battery

PARTSTOBEINSTALLED

rbl2010-002-302_a

4. Unplug pillion rider (passenger) switch.

NOTICE

Always charge battery before its in-

stallation on the vehicle.

NOTICE

Make sure not to squeeze battery ca-

bles between vehicle components.

NOTE: The ba

it needs to b

ery. To perf

need to rem

NOTE: Refer to the latest edition of

ROADSTER BATTERIES SERVICE BULLETIN

ttery is filled and serviced. However

e fully charged prior to vehicle deliv-

orm charging of the battery you will

ove battery from vehicle.

CAN-AM

for

proper activating, charging and maintenance procedures.

1. Open seat

2. Disconne

ct cylinder from seat base.

rbl2010-002-304_a

1. Pillion rider switch connector

5. Remove

LH side

the battery access panel located at the

of vehicle.

6. Disconnect rear heated grip switch if applicable.

rmr2010-027-003_a

rbl2010-002-301_a

1. Cylinder

TYPICAL - LH SIDE OF VEHICLE

1. Battery access panel

2. Battery access panel retaining screws

3. Rear heated grips switch

3. Lift seat and secure it using a piece of wood.

NOTICE

Discard bag containing battery hardware from underneath battery rubber strap.

This hardware supplied with battery must not

be installed. Use post screws from PDI kit

(longer).

PREDELIVERY 2010-1 15 / 39

Page 16

PARTS TO BE INSTALLED

7. Install battery screws on battery posts (from

PDI kit).

8. Remove battery holding strap.

9. Cut locking ties securing battery cables together.

10. Move electrical harness outward to make

room around battery.

rbl2010-002-310_a

11. Lift the leading edge of the battery and care-

fully pull it out of the battery rack.

17. Close RED rubber boot cover.

rbl2010-002-032

18. Connect BLACK (-) negative battery cables as

shown:

18.1 Position BLACK (-) main battery cable

(large) on negative (-) battery post.

18.2 Position BLACK (-) regulator/rectifier ca-

ble (small) on negative (-) battery post.

rbl2010-002-315_a

rbl2010-002-311_a

12. Charge battery. Refer to

BATTERIES SERVICE BULLETIN

NOTICE

It is of the upmost importance for the

CAN-AM ROADSTER

.

1. BLACK (-) main battery cable (large)

2. BLACK

(-) regulator/rectifier cable (small)

18.3 Tighten negative post battery screw to

4N•m (35lbf•in).

19. Inst

all battery holding strap.

battery life span that the battery initial charging

be performed.

13. Install charged battery in battery rack.

WARNING

Always connect RED (+) cable first.

14.Co

15. Tighten positive post battery screw to 4 N•m

16. Apply

16 / 39 2010-1 PREDELIVERY

nnect RED (+) positive battery cables.

(35 lbf•in).

DIELECTRIC GREASE (P/N 293 550 004) on

battery posts.

Page 17

PARTSTOBEINSTALLED

rbl2010-002-316_a

1. Battery holding strap

20. Position electrical harness in their original location.

rbl2010-002-317

21. Connect rear heated grip switch if applicable.

22. Install the battery access panel.

23. Connect pillion rider (passenger) switch.

24. Connect shock absorber on seat base.

rmo2010-001-009_e

LEFT SIDE SHOWN

1. M6 x 20 screw and plastic washer (from PDI kit)

3. Torque front fascia retaining screws to 2.5 N•m

(22 lbf•in).

4. Torque top side panel retaining screws to

2.5N•m (22lbf•in).

5. Install service covers (from PDI kit) as follows:

5.1 Open front storage compartment cover.

5.2 Insert upper tabs of service cover into the

vehicle grooves.

5.3 Push lower portion of service cover then

install plastic rivet (from PDI kit).

NOTICE

For the RH service cover, pay at-

tention not to damage the FCS switch.

Front Cargo Module

(continued)

1. Install the following body panels as the reverse

of removal procedure:

– Front fascia

– LH rear side panel

– Top side panels

– Middle side panels

– Mirrors.

2. Install M6 x 20 screws and plastic washers

(from PDI kit) to secure side panels.

PREDELIVERY 2010-1 17 / 39

rmr2010-038-021_a

1. RH service cover

2. Plastic rivet

Front Fenders

1. Cut locking tie that hold harness bracket on

fender.

Page 18

PARTS TO BE INSTALLED

rbl2010-002-024_a

1. Locking tie

2. Position front fender on vehicle.

3. Route front brake hose on fender hook.

rbl2010-002-026_a

1. Fender screws to hold fender

2. Harness bracket

3. Fender screw to hold harness bracket and fender

8. Connect fender light connector on vehicle.

9. Secure connector to vehicle.

-002-025_a

rbl2010

1. Brake hose

2. Fender hook

4. Instal

l 3 fender screws (from PDI kit) by hand to

hold fe

nder in place, refer to illustration.

5. Align harness bracket on the remaining hole

then install a fender screw (from PDI kit).

6. Torque all fender screws to 24 N•m (18 lbf•ft).

7. Prope

rly insert cable grommets on harness

et.

brack

rbl2010-002-027_a

1. Fender

light connecto r

10. Carry out the same procedure for the other

side.

Mudguards

1. From inside mudguards, check for proper loca-

tion (LH or RH side).

18 / 39 2010-1 PREDELIVERY

Page 19

PARTSTOBEINSTALLED

3. Torque windshield retaining screws to 4.5 N•m

(40 lbf•in).

4. Place a sheet of paper on windshield to protect

it, refer to illustration.

rbl2010-002-029_a

1. Installation side

2. Position mudguards on proper fender.

3. Secure mudguards using M6 x 20 screws and

M6 retaining nuts (from PDI kit).

rmr2010-038-026_b

1. Mudguard

NOTICE

If this precaution is not taken, scratch

on the windshield may occur and will not be

covered under warranty.

rbl2010-002-028

5. Install windshield trim panels as follows:

5.1 Insert M5 retaining nut (from PDI kit) on

trim panel.

5.2 Insert trim panel into windshield slot.

5.3 Push trim panel upwards.

5.4 From inside windshield, secure trim panel

using M5 x 20 screw (from PDI kit).

Windsh

1. Align

ield

windshield on windshield support.

2. Install M6 x 20 screws (from PDI kit) to secure

windshield.

rmr2010-038-043_a

1. Windshield trim panels screws

5.5 Tor

que windshield trim panel screw to

N•m (22 lbf•in).

2.5

6. Remove sheet of paper.

rmr2010-038-045_a

1. Windshield M6 x 20 screws

PREDELIVERY 2010-1 19 / 39

Page 20

PARTS TO BE INSTALLED

RT Audio & Convenience and RT-S Models

Antenna (Option Package)

1. Detach antenna from the sub-crate .

rbl2010-002-033_a

1. Antenna

2. Insert the M6 stainless steel lock washer (fro m

PDI kit) and rubber cap onto antenna.

3. Apply one

800 060) o

NOTICE

ening problems, do not add the threadlocker in

other location and do not apply more than the

recommended quantity of threadlocker.

drop of L OCTITE 243 (BLUE) (P/N 293

n the first thread of t h e a n t e nna.

To avoid hydro-lock or further loos-

rbl2010-002-031_a

1. Rubber cap

2. Antenna

5. Tighten antenna then install rubber cap on vehicle (tighten by hand) .

Hang Tag and Safety Labels

This vehicle comes with a hang tag and labels

containing important safety information. The

labels are considered permanent parts of the

vehicle and should not be removed. Hang tag is

to be removed by the owner only.

Any person who rides this vehicle should read and

understand all the information given on hang tag

and safety labels before riding.

Safety labels of several language can be chosen

by customer, according to availability.

rbg2010-007-002_a

1. Drop of LOCTITE 243

2. M6 stainless steel lock washer

4. Posit

ion antenna on RH side of rear carg o mod-

ule.

rmo2008-001-102

Licence Plate

NOTE: When a license plate needs to be installed

or replaced, ensure to install new damping pad

(P/N 293 740 028).

1. Remove existing plate on vehicle (if applicable).

2. Pea

20 / 39 2010-1 PREDELIVERY

l off backing of new damping pad.

Page 21

FLUIDS

Vehicle Decals

1. Install decals on vehicle according to customer

country language and local legislation.

2. Ensure that the new decals are installed at the

same location and over the factory installed decals.

rmo2008-002-509_a

1. Damping pad backing

3. Position new damping pad on vehicle plate support.

rmo2010-001-053_a

1. Plate su

pport

4. Secure upper portion of license plate on vehicle

plate support using existing hardware.

Key Barrel - Trailer RT 622

An extra key barrel is supplied with each Spyder

RT. This allows the use of the vehicle key for the

trailer.

Refer to the trailer RT 622 PDI Bulletin for all the

details.

FLUIDS

General Guidelines

All fluids (except fuel) have already been filled

at factory, it is only necessary to validate them.

However, if refill is needed, refer to the appropri-

ROADSTER SHOP MANUAL

ate

procedure.

Fuel

1. Unlatch and lift seat.

2. Add fuel in the fuel reservoir.

for the proper

rmo2010-001-051_b

1. Fuel cap

rmo2010-001-054_a

1. Existing hardware

5. Squeeze license plate and support together at

the center.

Recommended Fuel

Use unl

tainin

The gas

tane nu

eaded gasoline or oxygenated fuel con-

g no more than 10% ethanol or methanol.

oline used must meet the following oc-

mber:

Accessories Installation

1. Install accessories (if any) as per their installation instructions (included in each kit).

2. Install any other equipment required by law (if

any).

PREDELIVERY 2010-1 21 / 39

Page 22

FLUIDS

FUEL OCTANE RAT

INSIDE NORTH AMERICA

Recommended Minimum

91

(RON + MON)/2)

Use premium unleaded fuel for optimum engine

performance.

FUEL OCTANE R

OUTSIDE NORTH AMERICA

Recommended Minimum

95 RON 92 RON

Use premium unleaded fuel for optimum engine

performance.

ING

87

(RON + MON)/2)

ATING

WARNING

Never top off the fuel tank before placing

the vehicle in a warm area. As temperature

increases, fuel expands and may overflow.

Fuel is flammable and explosive under certain conditions. Always wipe off any fuel or

oil spillage from the vehicle.

NOTICE

formance and damage critical parts in the fuel

system and engine.

Other fuel can degrade vehicle per-

NOTICE

To avoid damaging the clutch, do not

use a motor oil meeting the API service SM or

ILSAC GF-4 classification. Clutch slippage will

occur. Motorcycle oils designed for use with a

wet-clutch are the best alternative.

Engine Oil Level Verification

WARNING

Before starti

well ventilat

come from the

anti corrosi

and engine bu

NOTICE

necessary t

sure that th

ature. If oi

at operatin

tween lowe

NOTICE

ification is performed when the engine is cold.

1. Park the vehicle on a level surface.

2. Remove the LH middle side panel as follows:

2.1 Pull pane

then unho

ng vehicle ensure vehicle in a

ed area or is outside. Smoke will

engine for 10 minutes as the

on coating on the exhaust system

rns off.

For an accur

ate oil level reading, it is

o ride vehicle for 5–7 minutes to en-

e engine is at its operating temper-

l level is verified when vehicle is not

g temperature, oil level must be be-

r and upper marks on dipstick.

Never add oil in the engine if the ver-

l out of its grommets at the front

ok the rear.

Engine Oil

NOTICE

Spyder r

differe

day. Pro

this sec

The proce

oadster oil level and replacing oil are

nt from most of the motor vehicles to-

perly follow instructions provided in

tion.

Recommended Engine Oil

NOTE: For SM5 models, the same oil lubricates

the engine, the gearbox and the clutch.

NOTE: Fo

engine,

drauli

Use

(P/N 293 600 121)

If not available, use a 5W 40 semi-synthetic (minimum) or synthetic motorcycle oil meeting the requirements for API service SL, SJ, SH or SG classification. Always check the API service label on

the oil container.

r SE5 models, the same oil lubricates the

the gearbox, the clutch and the HCM (hy-

c control module).

XPS SYNTHETIC BLEND OIL (SUMMER GRADE)

dures for checking the

.

rmr2010-038-003_a

1. Middle side panel

3. With the engine already at normal operating

temperature, start engine and let it run for at

least 30 seconds.

NOTE: Running engine for at least 30 seconds al-

lows the suction oil pump to drain the oil from the

engine crankcase back into the oil tank. Not carrying out this step could result in overfilling the engine oil.

4. Stop engine.

5. Unscrew and remove the oil dipstick.

22 / 39 2010-1 PREDELIVERY

Page 23

rmo2010-001-062_a

1. Oil dipstick

2. Oil tank

6. Wipe off the dipstick.

7. Reinsert and completely screw in the dipstick

to assure an accurate reading.

8. Unscrew and remove the dipstick again.

9. Check the oil level on the dipstick. It should be

near or equal to the upper mark.

FLUIDS

Clutch Fluid (SM5 Model)

Recommended Clutch Fluid

Use DOT 4 brake fluid from a sealed container.

An opened container may be contaminated or may

have absorbed moisture from the air.

Clutch Fluid Level Verification

The clutch fluid reservoir is near the reverse button on the left handlebar.

1. Park the vehicle on a firm, level surface.

2. Set the handlebar in the straight ahead position.

3. Wipe clean the cap area.

4. Use the Phillips head screwdriver located in the

toolkit.

5. Unscrew cap retaining screws.

08-011-102_a

rmr20

1. Full

2. Add

3. Opera

ting range

If Oil Level is at or Near Upper Mark:

– Properly insert and tighten dipstick.

all the LH middle side panel as the reverse

–Inst

moval.

of re

If Oil Level is Under Operating Range:

–Adda

small amount of recommended oil.

– Repeat the previous steps until oil level reaches

the dipsticks upper (F) mark. Do not overfill.

– Properly insert and tighten dipstick.

tall the LH middle side panel as the reverse

–Ins

emoval.

of r

rmo2010-001-005

6. Carefully remove cap. Pay attention not to drop

the cap seal.

7. Look inside the reservoir to see the fluid level.

8. Level should be within the maximum level line

and the minimum level indicated by the protuberances in the bottom of reservoir.

PREDELIVERY 2010-1 23 / 39

Page 24

FLUIDS

Coolant Level Verification

WARNING

When opening the reservoir, the coolant can

be very hot and spray out if the engine is hot.

In order to avoid getting burned, check the

coolant level when the engine is cold.

rmo2010-001-006_a

FLUID REMOVED FOR CLARITY PURPOSE

1. Maximum level line

2. Minimum level (top of protuberance)

9. Add recommended fluid as required. Do not

overfill.

WARNING

Avoid getting brake fluid on skin or in eyes

— it may cause severe burns. In case of contact with the skin, wash thoroughly. In case

of contact with the eyes, immediately rinse

with plenty of water for at least 10 minutes

and then consult a doctor immediately.

10. Immedia

11. Ensure that the seal located inside the cap is

collapsed.

12. Reinstall the cap to the reservoir.

13. Tighte

14. Wipe off reservoir if necessary.

tely wipe up spills if necessary.

n cap screws.

1. Park the vehi

cle on a firm, level surface.

2. Open the front storage compartment.

3. Remove the plastic rivet from the right service

cover.

rmr2010-038-021_a

1. Right service cover

2. Plastic rivet

4. Lift lower portion of service cover then pull it

toward the front.

5. Check the coolant level. Coolant must be visible without exceeding the MAX. level mark.

Engine

Coolant

WARNIN

G

When opening the reservoir, the coolant can

be very hot and spray out if the engine is

hot. In order to avoid getting burned, check

coolant level when engine is cold.

Recommended Coolant

The cooling system must be filled with distilled

water and antifreeze solution (50% distilled water,

50% antifreeze).

For best performance, use

COOLANT (P/N 219 700 362)

BRP PREMIXED

24 / 39 2010-1 PREDELIVERY

rmo2008-001-039_a

CAL

TYPI

1. Coolant MAX. level mark

2. Coolant m ust be visible

6. If re

quired, add recommended coolant until it

isible in the reservoir without exceeding the

is v

. level mark. Use a funnel to avoid spillage.

MAX

ot overfill.

Do n

7. Reinstall the service cover.

Page 25

Brake Fluid

Avoid contact o

because it may c

of contact with

case of contac

rinse with ple

utes and then c

nty of water for at least 10 min-

SET-UP

WARNING

fbrakefluidwithskinoreyes

ause severe burns. In case

the skin, wash thoroughly. In

t with the eyes, immediately

onsult a doctor immediately.

NOTICE

Do not overfill brake fluid reservoir.

Recommended Fluid

Use only DOT 4 brake fluid from a sealed container. An opened container may be contaminated

or may have absorbed moisture from the air.

NOTICE

To avoid serious damage to the braking system, do not use non-recommended fluids. Brake fluid can damage plastic and painted

surface. Handle with care.

Brake Fluid Level Verification

WARNING

Clean fille

DOT 4 brake f

1. Park the vehicle on a firm, level surface.

2. Unlatch and lift the seat.

3. Check the brake fluid level in both reservoirs,

near the back of the seat. They should both be

above the MIN. mark.

r cap before removing. Use only

luid from a sealed container.

rmo2010-001-091_a

1. Brake fluid MAX. level mark

2. Brake fluid MIN. level mark

rmo2010-001-092_a

A. Operating range

6. Immediately wipe up spills if necessary.

7. Reinstall both caps of the reservoir.

8. Close the seat and ensure it is fully latched.

SET-UP

Tire Pressure

WARNING

Low pressure may cause tire to deflate and

rotate on wheel. Overpressure may burst the

tire. Always follow recommended pressure.

NOTICE

cold before using the vehicle.

NOTE: Tire pressure changes with temperature

and altitude. Recheck pressure if one of these

conditions has changed (e.g., significant weather

rmo2010-001-013_b

1. Brake fluid reservoir

4. Clean

the filler caps before removing.

5. Add recommended fluid as required. Do not

change, driving in the mountains).

1. Inflate tires to the specified air pressure. Refer

to the following table.

COLD TIRE PRESSURE RECOMMENDATION

overfill.

Nominal.: 103 kPa (15 PSI) Nominal.: 193 kPa (28 PSI)

PREDELIVERY 2010-1 25 / 39

Always check pressure when tires are

FRONT REAR

Page 26

ADJUSTMENTS

Brake Disc Cleanup

1. Clean front and rear brake discs using PULLEY

FLANGE CLEANER (P/N 413 711 809)

.

NOTICE

A thin layer of anticorrosion treatment is present on the brake discs and must

be removed before using the vehicle. Not conforming to this procedure may lead to a brake

chattering squeaking and brake pad replacement would be necessary.

ADJUSTMENTS

Guidelines

All adjustments have already been performed

at factory. It is only necessary to validate them.

However, if readjustment is needed, refer to the

appropriate

ROADSTER SHOP MANUAL

proper procedure.

Drive Belt

NOTICE

all parts at room temperature and the rear

wheel lifted of the ground.

1. Place vehicle on a level surface.

NOTE: The area must be protected against wind

and must have a very low background noise.

2. Set transmission to NEUTRAL.

3. Lift rear of vehicle by the frame until rear wheel

is off the ground.

Always verify drive belt tension with

for the

529036115

5. Enter the following specifications to program

the meter.

MASS WIDTH SPAN

8.4 g/m 28.0 mm /R 1028 mm

rmr2008-031-002

SONIC TENSION METER DISPLAY

NOTE: Ref

set the in

er to the manufacturer's instructions to

formations into the device.

6. Turn rear wheel to align a wheel spoke with the

swing arm.

NOTICE

Do not lift under rear shock absorber.

Always lift by the frame. Refer to illustration.

rmr2008-031-003

TYPICAL - SWING ARM ALIGNS WITH A SPOKE

7. Position the sensor under the LH passenger

footrest and hold the sonic tension meter sen-

rmr2008-030-009

TYPICAL - LIFT BY THE FRAME

sor approximately 1 cm (1/2 in) from belt or

closer without touching the belt.

4. To check the drive belt tension use the BELT

TENSION METER (P/N 529 036 115)

.

26 / 39 2010-1 PREDELIVERY

Page 27

rbs2010-006-001

SPYDER RT

ADJUSTMENTS

8. Tap the belt to make the belt vibrate and read

the measurement.

9. Take a secon

d measurement to confirm the first

one.

10. Note the first value obtained at step 8 if the

measurement at step 9 is w ithin ±25N.

NOTE: If the second value is not within ±25N, re-

peat steps 8 and 9.

11. Repeat mea

spokes to

surements at every spoke (3

tal).

The average of the 3 obtained values (at the 3

spokes) must be within the following range:

DRIVEBELTTENSION

(PARTS AT ROOM TEMPERATURE AND

REAR WHEEL LIFTED)

450N ± 150N

If the tension of drive belt is out of specification,

adjust drive belt as per

JUSTMENT

the proper

. Refer to

CAN-AM ROADSTER SHOP MANUAL

DRIVE BELT TENSION AD-

DRIVE SYSTEM

section in

Clutch Lever

NOTE: The distance between the clutch lever and

handgrip can be adjusted from position 1 (greatest

distance) to position 4 (smallest distance).

1. Adjust the clutch lever as per the owner’s preference.

1.1 Push the clutch lever forward to release

the adjuster dial. Hold in position.

1.2 Turn the adjuster dial to the desired posi-

tion aligning the dial number with the dot

on the lever.

1.3 Release the clutch lever.

rmo2010-001-033_a

CLUTCH LEVER ADJUSTMENT

1. Clutch lever

2. Adjuster dial

3. Dot

Suspension

WARNING

Left and right adjusting cams must always

be set at the same position. Never adjust

one adjusting cam only. Uneven adjustment

can cause poor handling and loss of stability,

which could lead to an accident.

Front Suspension

NOTICE

front of vehicle using a jack to extend the suspension. This will ease turning the adjustment

cam and will prevent a potential breakage of

the adjustment plate.

1. Adjust the spring preload as per the owner’s

.

preference.

1.1 Place the vehicle on a level surface.

1.2 Engage the parking brake.

1.3 Adjust the spring preload by turning the

rmr2008-029-002

FRONT SUS PE N S ION ADJUSTING WRENCH

Before adjusting suspension, lift the

cam with the adjusting wrench (stored in

the tool kit).

PREDELIVERY 2010-1 27 / 39

Page 28

ADJUSTMENTS

Models Without Compressor (Manual

Adjustment)

North American Models

WARNING

MINIMUM PRESSURE 10 PSI / 70 kPa

Do not exceed recommended pressure by 10 PSI / 70 kPa

PASSENGER + CARGO (lb /kg)

PSI/kPa

PSI/kPa PSI/kPa

40/275 50/345 60/415

50/345

60/415 70/485 80/555

60/415

704902072

LOAD

Lb/Kg

150/70 20/135

200/90 30/205

DRIVER

250/115

0 100/45 150/70 200/90 250/115

PSI/kPa

40/275

70/485

PSI/kPa

70/485

80/555

90/625

rmr2008-029-003

FRONT SUSPENSION CAM ADJUSTMENT

rmr2008-030-004_c

A. Smooth adjustment (position 1)

B. Hard adjus

RECOMMENDED FRONT SHOCK ADJUSTMENT

68 kg (150 lb)) rider with cargo 3

91 kg (200 lb) rider with cargo

Rider w

ACS Rea

tment (position 5)

LOAD

68 kg (150 lb) rider 1, 2

91 kg (20

ith passenger and cargo

0 lb) rider

CAM

POSITION

3

4

5

r Suspension

The suspension pressure is adjustable by deflatingorinflatingtheairspring. Useanaircompressor and a pressure gauge.

ten suspension, reduce the air pressure and

To sof

den suspension, increase air pressure.

to har

1. Adjust the air spring as per the owner’s preference.

2. Refer to the following chart for proper adjustment.

NOTICE

Do not exceed the maximum allowed

pressure. This might damage the air suspension.

NOTE: When adjusting the pressure, do not put

your weight on the vehicle and do not load cargo

in the storage compartment.

The air spring is connected directly to an air hose

with a schrader valve located under the seat.

rmo2010-001-056_a

1. Schrader valve

NOTE: On

ment, it

setting

the fac

fer to t

for det

models equipped with a remote adjust-

is not necessary to adjust the suspension

. The air spring will inflate automatically at

tory setting after the vehicle start up. Re-

he

2010 SPYDER RT OPERATOR'S GUIDE

ails.

Lights

Headlights Aiming Verification

1. Positi

on the vehicle 10 m (33 ft) in front of a test

ce (wall or screen).

surfa

28 / 39 2010-1 PREDELIVERY

Page 29

ADJUSTMENTS

CE Models (Low Beam)

CE Models (High Beam)

B

A

90°

rmo2010-001-007_a

A. 10 m (33 ft)

B. 91 kg (200 lb)

90°

rmo2010-001-008_a

2. On the test surface, trace a mark at 642 mm

(25.3 in) above ground then another at 732 mm

(28.8 in).

3. Have someone weighing at least 91 kg (200 lb)

sit on the operator's position.

4. Select low beam.

5. Beam aiming is correct when the focus point

(brightest spot) of the headlight reflection is

within the marks.

B

A

90°

rmo2010-001-007_a

A. 10 m (33 ft)

B. 91 kg (200 lb)

90°

rmo2010-001-008_a

2. On the test surface, trace a mark at 415 mm

(16.3 in) above ground then another at 515 mm

(20.3 in).

3. Have someone weighing at least 91 kg

(200 lb)sit on the operator's position.

4. Select low beam.

5. Beam aiming is correct when the focus point

(brightest spot) of the headlight reflection is

within the marks.

2 3

1

rmo2010-001-302_a

TYPICAL REFLECTION ON SURFACE TEST

1. Groun

2. Focus point

3. Focus point within the marks

A. Mark a

B. Mark at 732 mm (28.8 in) above ground

d

t 642 m m (25.3 in) above ground

A

B

NOTE: This verification is valid for either left-hand

or right-hand traffic regulations.

1. Posi

tion the vehicle 10 m (33 ft)in front of a test

ace (wall or screen).

surf

2 3

1

rmo2010-001-302_a

TYPICAL HEADLIGHT REFLECTION ON SURFACE TEST

1. Groun

2. Focus point

3. Focus point within the marks

A. Mark a

B. Mark at 515 mm (20.3 in) above ground

d

t 415 mm (16.3 in) above ground

A

B

NOTE: As the low beam and high beam are sep-

arate units, this verification is valid for either lefthand or right-hand traffic regulations.

w the same procedure as per the low beam

Follo

elect the high beam.

but s

PREDELIVERY 2010-1 29 / 39

Page 30

ADJUSTMENTS

All Models

Beam aiming is correct when the focus point

(brightest spot) of the headlight reflection is

within the marks.

2 3

B

1

rmo2010-001-301_a

TYPICAL HEADLIGHT REFLECTION ON SURFACE TEST

1. Ground

2. Focus point

3. Focus point within the marks

A. Mark at 800 mm (31.5 in) above ground

B. Mark at 850 mm (33.5 in) above ground

A

Headlights Aiming Adjustment

1. Each headlight can be adjusted by turning the

adjustment screws located behind the middle

side panel.

2. Remove both middle side panels. Refer to

FRONT CARGO MODULE INSTALLATION

.

3. Use the Allen key located in toolkit.

4. Insert the Allen key through the rear adjustment

hole into the adjustment screw.

rmo2010-001-009_b

LEFT ADJUSTMENT SCREW

1. To raise headlight beam

rmo2010-001-009_a

LEFT SIDE SHOWN

1. Adjus

t th rough this hole

5. Turn the adjustment screw clockwise to raise

the headlight beam and conversely turn the adjustment screw counterclockwise to lower the

headlight beam. Adjust both headlights evenly.

:

NOTE

same

The high beam becomes adjusted at the

time.

rmo2010-001-009_c

ADJUSTMENT SCREW

1. To lower headlight beam

6. Reinstall middle side panels as the reverse of

removal procedure.

B.U.D.S. Programming

NOTE: MPI-1 will not allow communication with

these vehicles. Only the MPI-2 must be used.

529036019_a

30 / 39 2010-1 PREDELIVERY

Page 31

NOTE: Do not use D.E.S.S. POST INTERFACE

(P/N 529 036 019)

with the KW2000 (500K) protocol. DESS Post Interface will not allow communicationwiththesevehicles.

NOTE: B.U.D.S.isnotusedtoprogramthehard

keys (included keys are ready to use).

Use B.U.D.S. to

– Enter Customer's Name

– Reset Trip Hours and Trip Distances

– Reset Last Service

– Set Speedometer Units

– Set Cluster Language

– Check fault codes (if any).

ADJUSTMENTS

Connecting PC to Vehicle

1. Remove service cover from vehicle.

2. Connect the PC to vehicle. Refer to the latest

edition of

WARE AND COMMUNICATION TOOLS

CAN-AM ROADSTER B.U.D.S. SOFT-

for the

proper connecting procedure.

3. Ensure that the status bar shows the proper

protocol and proper ECU number. Refer to the

following table.

MODEL PROTOCOL

SM5

SE5

KW2000 500K

KW2000 500K 6

ECU

QUANTITY

5

4. Press READ DATA button from the tool bar to

initiate communication with the vehicle.

Entering Customer's Name

NOTE: Wh

tion dis

for exam

tomer's

be visib

1. Click on the VEHICLE tab to open the vehicle

information page.

en starting the vehicle, the multifunc-

play will show the name of the customer;

ple: “HI JOHN SMITH”. If the cus-

name is not programmed, only “HI” will

le when turning the vehicle ON.

vbl2006-007-001

2. Type the na

vbl2006-007-002

me of the customer.

3. Click on WRITE DATA to save the information

in the vehicle ECM.

NOTE: A

B.U.D.

on the s

fter you are finished typing the name,

S. automatically updates the Delivery Date

creen.

Resetting Trip Hours and Trip Distances

1. Ensure that the VEHICLE tab is selected.

2. Click

on the RESET TRIP buttons to reset the

mation.

infor

rbl2008-003-003

PREDELIVERY 2010-1 31 / 39

Page 32

ASSEMBLY INSPECTION

NOTE: It can also be done directly on the info-cen-

ter, using the selector button.

Resetting Last Service

1. Click on the RESET SERVICE button to reset

the informations.

7-004

vbl2006-00

NOTE: After each maintenance service, Last Ser-

vice should be reset to keep a good track of vehicle service history.

Ending a B.U.D.S. Session

NOTICE

been solved. This will properly reset the appropriate counter(s).

1. Click on FAULT tab and check if there are active

faults. If so, service vehicle then clear the faults

in B.U.D.S.

2. Click on WRITE DATA button to transfer new

settings and information to the modules.

vmr2006-012-100_ben

WRITE DATA BUTTON

Clear the fault(s) after a problem has

Speedometer Units

NOTE: The speedometer is factory preset in miles

but it is possible to change it to kilometer reading.

Any unit modification is applied to the speedometer, odometer and trip meter.

1. Select the SETTING tab in B.U.D.S.

2. Select CLUSTER page.

3. Select Metric or Imperial from the Cluster

Units section.

NOTE: No data will be lost when changing this set-

ting.

Cluster Language (chosen by customer

according to availability)

NOTE: The default language displayed in the multi-

function gauge is English. To change the language

displayed in the multifunction gauge.

1. Select SETTING tab at the top of the page.

2. Select CLUSTER tab at the bottom of the page.

3. Select desired language in the Cluster Lan-

guage field.

NOTE: If the language selection is not available,

the gauge may not have the latest software version available.

3. Click on E

XIT button (right most) to end session.

4. Reinstall DCL connector into its housing.

5. Reinstall service cover on vehicle.

ASSEMBLY INSPECTION

Inspect t

vehicle i

1. Front compartment cover and seat locks

2. Passenger grab handles

3. Front wh

(77 lbf•

4. Rear shock absorber retaining nuts torque

(must be 48 N•m (35 lbf•ft))

5. Suspension arm ball joint cotter pins

6. Tie rod

7. Rear axle nut and cotter pin

8. Gearshift pedal operation

9. Parki

10. Brake lines

11. Foot pegs.

NOTE

firm

he following parts to make sure that the

s properly assembled.

eel nuts torque (must be 105 N•m

ft))

end nuts and cotter pins

ng brake operation

:

Refer to the Predelivery Check List to con-

that all items are covered by your inspection.

32 / 39 2010-1 PREDELIVERY

Page 33

FINAL INSPECTION

FINAL INSPECTION

Vehicle Test Run

Ride the vehicle to ensure proper operation of all

systems and components and check the following

items:

1. Instrument cluster operation.

2. Indicator-warning pilot lamps functioning on

power up.

3. Display of safety message in cluster.

4. Starter interlock mechanism operation.

4.1 Press start button to make sure engine can

not be started if M button is not depressed

to acknowledge safety message.

5. Cluster mode button and set button operation.

6. Error messages in cluster (correct if necessary).

7. LH handlebar multifunction switch operation.

8. Ignition keys allow the engine to start.

9. Reverse button operation.

9.1 Start engine.

9.2 Shift in first gear, slightly apply on throttle

then release.

9.3 Shift in reverse, slightly apply on throttle

then release.

9.4 Shift in neutral position, slightly apply on

throttle then release.

10. Throttle operation.

– The throttle is the right handgrip, and it

controls engine speed. To increase engine

speed, roll the throttle toward you. To decrease engine speed, roll the throttle away

from you. The throttle is spring loaded and

should return to idle when you release it.

11. Clutch lever operation (SM5 Model).

– The clutch lever is in front of the left hand-

grip. The clutch controls the transmission

of power from the engine to the rear wheel.

The lever is squeezed to disengage power

and released to engage power.

12. Engine stop switch operation.

– The engine stop switch is near the right

handgrip. It has two positions and must be

set to the run position before you can start

the engine. It allows you to stop the engine

anytime without removing your hand from

the handlebar.

13. Operation of the following lights:

– Headlights (HI and LO beam)

– Taillights

– Brake light

– Position lights

– Turn signal lights

– Hazard lights

– Licence plate light

– Back up light

– Front storage light (option package).

14. Dimmer switch operation.

15. Headlight overrun button operation.

– There is a headlight override button on the

front of the right handgrip.

16. Horn operation.

– The horn button is located near the left

handgrip.

17. Brake operation.

– The brake pedal is in front of the right foot-

peg.

– Press it down to operate.

– This pedal brakes all three wheels.

17.1 Ensure brake pedal is firm when pressure

is applied and that it returns freely.

18. Electronic parking brake operation.

– The parking brake switch is located on the

central panel.

18.1 Press it down to apply the parking brake.

18.2 Press the switch down a second time to

release the parking brake.

18.3 Ensure parking brake is shut-off.

19. Shifter operation.

20. Leakage of the following fluids:

– Fuel

– Engine oil

– Engine coolant

– Brake fluid

– Clutch fluid

21. Proper operation of seat release and hood re-

lease using key.

22. Absence of abnormal noises or vibrations.

23. Tool kit, DVD and Operator’s Guide in front

storage compartment.

24. Radio operation using, front and rear controls

(option package).

25. Front and rear heated grips operation (option

package).

PREDELIVERY 2010-1 33 / 39

Page 34

FINAL INSPECTION

26. iPod®and MP3 audio player wires stowed in

rear top storage compartment.

27. Complete applicable recall or factory-directed

modification.

28. Ensure that hang tag is on vehicle handle bars

(to be removed by owner).

Vehicle Cleaning

NOTICE

kaline or acid cleaner, gasoline or solvent to

avoid windshield damage.

NOTICE

plastic cleaner or polisher.

NOTICE

clean the vehicle. USE LOW PRESSURE ONLY

(like a garden hose). The high pressure can

cause electrical or mechanical damage.

NOTICE

plastic parts to avoid damaging surfaces.

NOTICE

plastic cleaner because the seat may become

slippery.

Do not clean the windshield with al-

Do not polish windshield with any

Never use a high pressure washer to

It is necessary to use flannel cloths on

Do not wash the seat with a vinyl or

NOTE: Any person who rides this vehicle should

read and understand all the information given on

hang tag and safety labels before riding.

NOTICE

Certain plastic or vinyl cleaners will

damage the seat cover. Use only mild detergent, such as soap specially formulated for motorcycles or automobiles.

1. Wet the vehicle thoroughly with water.

2. Wash the vehicle with water mixed with a mild

detergent, such as soap specially formulated

for motorcycles or automobiles.

3. Dry the vehicle with a chamois or a soft towel.

NOTE: While washing the vehicle, check for

grease or oil. If necessary, use a mild automotive

degreaser and follow the manufacturer's instructions.

Delivery to Customer

1. Complete the

2. Give

OPERATOR’S GUIDE

customer.

NOTE: The customer and dealer must read and

sign the

NOTE: Hang tag is to be removed by the owner

PRE DELIVERY CHECK LIST

only.

PRE DELIVERY CHECK LIST

and

SAFETY DVD

.

.

to

iPod is a trademark of Apple Inc.

34 / 39 2010-1 PREDELIVERY

Page 35

SPECIFICATIONS

SPECIFICATIONS

MODEL SPYDER RT

ENGINE

Engine type

Number of cylinders

Number of valves 8valves

Bore

Stroke

Displacement

Compression ratio

Type Dry sump with separate oil tank and oil cooler

Engine BRP Rotax paper type, replaceable

Transmission (SE5) BRP Rotax paper type, replaceable

Oil change with new

engine filter

Oil change with new

engine filter

Oil change with new

engine and

HCM filters

SM5

SE5

Lubrication

Oil filter

Engine oil

Capacity

4-stroke, Dual Over Head Camshaft (DOHC), liquid cooled

XPS SYNTH

Recommended Engine Oil

SM5 model

Clutch

SE5 model

Exhaust system 2 into 1 with catalytic converter

Air filter Paper eleme nt

GEARBOX

Type

COOLING SYSTEM

Type Liquid cooled, single radiator with cooling fan

Coolant

SM5 Sequential Manual 5-speed (SM5) with reverse

SE5 Sequential Electronic 5-speed (SE5) with reverse

Type

Capacity

Typ e

Fluid DOT 4

Typ e

Engagement

Stall 3200 +/- 200 RPM (centrifugal)

600 121)

motorcycle oil meeting the requirements for API service

Wet, multi-plate, manual operation through a hydraulic

ugal clutch + wet multi-plate clutch automatically

Centrif

Ethyl glycol/water mix (50% coolant, 50% water). Use

PREMIXED COOLANT (P/N 219 700 362)

specifically designed for aluminum engines

ROTAX 991 60° V-Twin

2

97 mm (3.82 in)

68 mm (2.68 in)

998 cm³ (60.9 in³)

12.2:1

3.9 L (4.1 qt (U.S. liq.))

4.2 L (4.4 qt (U.S. liq.))

4.3 L (4.5 qt (U.S. liq.))

ETIC BLEND OIL (SUMMER GRADE) (P/N 293

or a 5W 40 semi-synthetic (minimum) or synthetic

SL, SJ, SH

2000 +/- 200 RPM (centrifugal)

or SG classification.

piston, vacuum assist

controlled by TCM

or coolant

3.2 L (.85 U.S. gal.)

BRP

PREDELIVERY 2010-1 35 / 39

Page 36

SPECIFICATIONS

MODEL SPYDER RT

ELECTRICAL SYSTEM

Magneto generator output 650 W

Ignition system type Electronic ignition with dual output coil

Ignition timing Electronically controlled, not adjustable

Quantity

Spark plug

Engine RPM limiter setting Forward 9500 RPM

Battery

Fog light (Spyder RT-S) 2 x 35 W Halogen

Taillight/brake light 2 x 0.25 W/2 x 2.5 W

Turn signal lights

Position lights 2x5W

License plate light 5W

Backup light 2x20W

Day light (Spyder RT-S) 0.5 W

Front storage compartment light (Spy der RT-S) 0.15 W

Lights: tail, position, plate & day

Vbat: Cluster, VIM & DLC

Vbat Control: main relays

AS, YRS, VCM, ECM, D.E.S.S., PRS &

Vkey: S

MSR

Vbat: Main relay

Vrelayed: WPM, CL, FG, CTG, PBS pilot light,

TCM, DPS

Vbat: Cooling fan relay 15 A

Fuse

(In storage

Compartment)

Vbat: Hazard, brake light switch 10 A

Vbat: radio (XM, CB, GPS, "iPod") 15 A

Vbat: Backup actuator & trailer module 10 A

Vbat: Horn, shedding relay

ayed: suspension relay, heated grips, HA, LED

Vrel

Pilot lights: CSS, FHS, FGS

Vbat: Accessory plugs 10 A

Vrelayed: ECM 5 A

Vrelayed: Injectors & ignition coils 15 A

Vrelayed: HO 2S1 & 2, EVAP, CAPS, fuel pump motor, CSV,

pre-starting relay

Make and type

Gap

Type Maintenance free

Voltage 12 volts

Nominal rating 21 A•h

Recommended charging rate 2 A

CA/US Models 2 x 55 W Halogen

CE Models

Front 2 x 4.5 W

Rear 2 x 20 W

NGK DCPR9E (apply heat-sink paste P12 (P/N 420 897

186) on spark plug thread)

0.7 mm to 0.8 mm (.028 in to .031 in)

High beam: 2 x 55 W HalogenHeadlight

Low beam: 2 x 60 W Halogen

2

15 A

10 A

20 A

20 A

15 A

36 / 39 2010-1 PREDELIVERY

Page 37

SPECIFICATIONS

MODEL SPYDER RT

Accessories 40 A

TCM valves (SE5 model) 20 A

Rectifier 60 A

Fuse

(Under seat)

FUEL SYSTEM

Fuel delivery Type

Fuel pump Type Electrical module in fuel tank

Idle speed 1400 ± 100 RPM (electronically controlled, not adjustable)

Fuel

Fuel tank capacity

DRIVE SYSTEM

Final drive type Carbon reinforced drive belt

Final drive ratio 28/79

STEERING

Type Dynamic Power Steering (DPS)

FRONT SUSPENSIO N

Suspension type Double A-arm with anti-roll bar

Suspension travel

Shock absorber

Spring preload adjustment 5 position cam adjustment

REAR SUSPENSION

Suspension type

Suspension travel

Shock absorber

Preload adjustment (ACS with manual adjustment) Adjustable air pressure:135 kPa to 625 kPa (20 PSI to 90 PSI)

oad adjustment (ACS with remote adjustment)

Prel

Main fuse 40 A

Dynamic Power Steering (DPS) motor 40 A

VSS pump 40 A

Headlights 30 A

VSS valves 25 A

Multi-point Electronic Fuel Injection (EFI)

with ETC (Electronic Throttle Control)

Dual thrott

Type Regular unleaded gasoline

Inside North America

Octane rating

Outside North America

Recommended for optimum performance: 91 (R+M)/2

Recommended for optimum performance: 95 RON

le body (51 mm) with an actuator

Minimum: 87 (R+M)/2

Minimum: 92 RON

25 L (6.6 U.S. gal.)

151 mm (5.9 in)

Qty

Type Oil dampe r

Air Controlled Suspension (ACS)

Compressor-controlled (ACS with remote adjustment only)

Swing

Qty

Type Oil dampe r

2

arm with monoshock

5 pos

(5.7 in)

1

itions

145 mm

PREDELIVERY 2010-1 37 / 39

Page 38

SPECIFICATIONS

MODEL SPYDER RT

BRAKES

Type

Front brake Dual discs (250 mm (9.8 in) x 6 mm (.24 in)) with 4 piston ca lipers

Rear brake Single disc (250 mm (9.8 in) x 6 mm (.24 in)) with 1 piston caliper

Brake fluid

Parking brake Mechanical, electrically actuated to the rear caliper

Minimum brake pad thickness

Minimum brake disc thickness

Maximum brake disc warpage

TIRES

Type (use only tires recommended by

BRP)

Pressure

Minimum tire tread depth

WHEELS

Size (diameter X width)

Front wheel nuts torque

Rear drive axle nut torque

DIMENSIONS

Overall length

Overall width

Overall height

Seat (top) height

Wheelbase

Front wheel track

Ground clearance, front and under engine

Capacity

Type DO T 4

Front Kenda KR21 MC 165/65R14 47H (special motorcycle type)

Rear Kenda KR21 MC 225/50R15 68H or 76H (special motorcycle type)

Front

Rear

Front

Rear

Front

Rear

Foot-actuated, fully integrated hydraulic 3-wheel braking

system with ABS and EBD

530 ml (17.9 U.S. oz)

1mm (.04in)

5.33 mm (.21 in)

0.13 mm (.005 in)

Nominal.: 103 kPa (15 PSI)

Min.: 89 kPa (13 PSI)

Max.: 117 kPa (17 PSI)

Nominal.:

Min.: 179 kPa (26 PSI)

Max.: 207 kPa (30 PSI)

193 kPa (28 PSI)

NOTE: The pressure difference between the left and right side

tire should not exceed 3.4 kPa (.5 PSI).

2.5 mm (3/32 in)

4 mm (5/32 in)

355 mm (14 in) x 127 mm (5 in)

381 mm (15 in) x 178 mm (7 in)

90 N•m to 120 N•m (66 lbf•ft to 89 lbf•ft)

123 N•m to 137 N•m (91 lbf•ft to 101 lbf•ft)

2 667 mm (105 in)

1 572 mm (62 in)

1 600 mm (63 in)

750 mm (29.5 in)

1 708 mm (67 in)

1 384 mm (54.5 in)

115 mm (4.5 in)

38 / 39 2010-1 PREDELIVERY

Page 39

MODEL SPYDER RT

WEIGHT AND LOADING CAPACITY

Dry weight (Spyder RT)

Dry weight (Spyder RT Audio &

Convenience Package)

Dry weight (Spyder RT-S)

Front storage compartment

Glove box

Side storage compartment

Rear storage compartment

Total vehicle load allowed (including operator, passenger, cargo and added

accessories)

Gross vehicle weight rating (GVWR)

Maximum weight on trailer tongue

Maximum towed weight (trailer and cargo)

Capacity

Maximum load

Capacity

Maximum load

Capacity

Maximum load

Capacity

Maximum load

SPECIFICATIONS

400 kg (882 lb)

413 kg (911 lb)

422 kg (930 lb)

55 L (14.5 U.S. gal.)

16 kg (35 lb)

1.8 L (.5 U.S. gal.)

2kg (4lb)

23.5 L (6.2 U.S. gal.)

7kg (15lb)

40.5 L (10.7 U.S. gal.)

9kg (20lb)

240 kg (525 lb)

663 kg (1,462 lb)

18 kg (40 lb)

180 kg (400 lb)

Because of our ongoing commitment to product quality and innovation, BRP reserves the right, at any time, to

make changes in design and specifications and/or to make additions to, or improvements in its products without

imposing any obligation upon itself to install them on its previously manufactured products.

PREDELIVERY 2010-1 39 / 39

Loading...

Loading...