Campbell Hausfeld PW2120, PW2221, PW2458 Assembly Instructions And Replacement Parts Manual

Gasoline Powered

Pressure Washers

Assembly Instructions and PW2120, PW2221, PW2458

Replacement Parts Manual

IN457901AV 1/01

Please record Model No. and Serial No. for use when contacting

the manufacturer:

Model No. ______________ Purchase date ____________________

Serial No. ______________ Purchase place ____________________

For Information About This Product,

call 1-800-330-0712

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or

maintain the product described. Protect yourself and others by observing all safety information. Failure to

comply with instructions could result in personal injury and/or property damage! Retain instructions for

future reference.

Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Replacement Parts Ordering Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Service Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Contents Page

Refer to Product Manual for Detailed Safety Instructions

© 2001 Campbell Hausfeld

For parts, product & service information

visit www.chpower.com

BUILT TO LAST

TM

Gasoline Powered Pressure Washers

This manual contains information that

is very important to know and understand. This information is provided for

SAFETY and to PREVENT EQUIPMENT

PROBLEMS. To help recognize this information, observe the following symbols.

Danger indicates

an imminently

hazardous situation which, if not

avoided, WILL result in death or serious injury.

Warning indicates

a potentially hazardous situation which, if not avoided,

COULD result in death or serious

injury.

Caution indicates

a potentially hazardous situation which, if not avoided,

MAY result in minor or moderate

injury.

Notice

indicates important information, that if not followed,

may cause damage to equipment.

Remove the equipment and all parts

from the carton. The carton should

contain the following:

One (1) Pressure washer (pump,

engine, cart base)

One (1) Cart handle Assembly

One (1) Basket (not included with

all models)

One (1) Spray gun

One (1) Lance with nozzle

Five (5) Spray tips (not included

with all models)

One (1) High pressure hose

One (1) Pack of nuts, bolts,

manuals and Chemical Suction

Tube with Filter

If any parts are missing, DO NOT

return unit to the retailer. Know

model number (located on serial number tag on frame) and call 1-800-3300712 for replacement.

After unpacking the product, inspect

carefully for any damage that may

have occurred during transit. Make

sure to tighten fittings, bolts, etc.,

before putting unit into service.

Do not operate

unit if damaged

during shipping, handling or use.

Damage could result in bursting and

cause injury or property damage.

See Product Manual for

General Safety Information

1. Slide handle over legs and secure

with bolts provided.

2. Insert removable spray tips and

rubber grommets into holes provided on frame (if applicable).

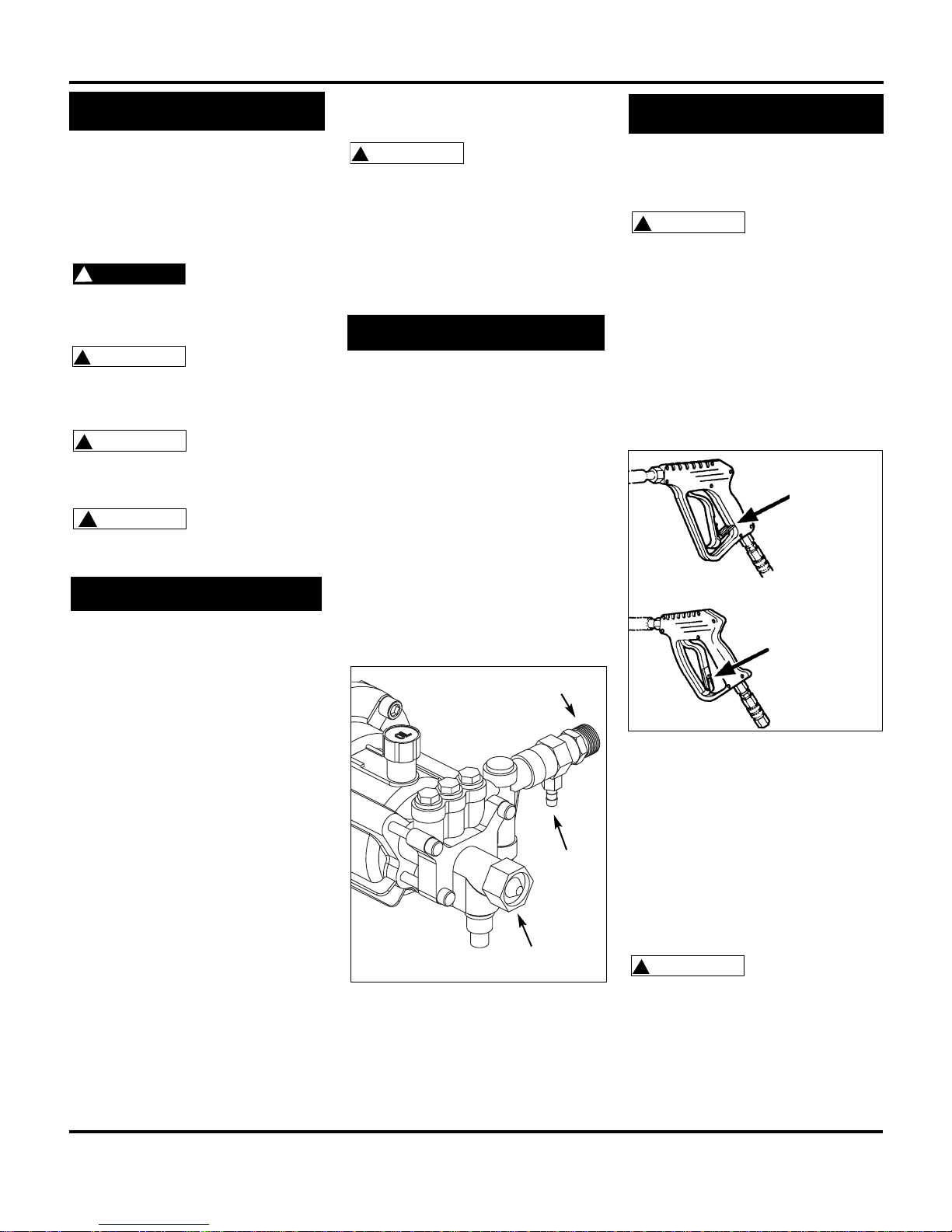

3. Connect the clear plastic chemical

suction tube with filter to chemical

injector hose barb on the pump.

4. Connect the high-pressure hose to

the pump outlet.

5. Connect the high-pressure hose to

the gun.

6. Attach lance with nozzle to the

gun.

ALWAYS use this start up procedure to

ensure that the unit is started safely

and properly.

If water has

frozen in the pressure washer, thaw in a warm room

before starting. DO NOT pour hot

water on or into the pump; internal

parts will be damaged.

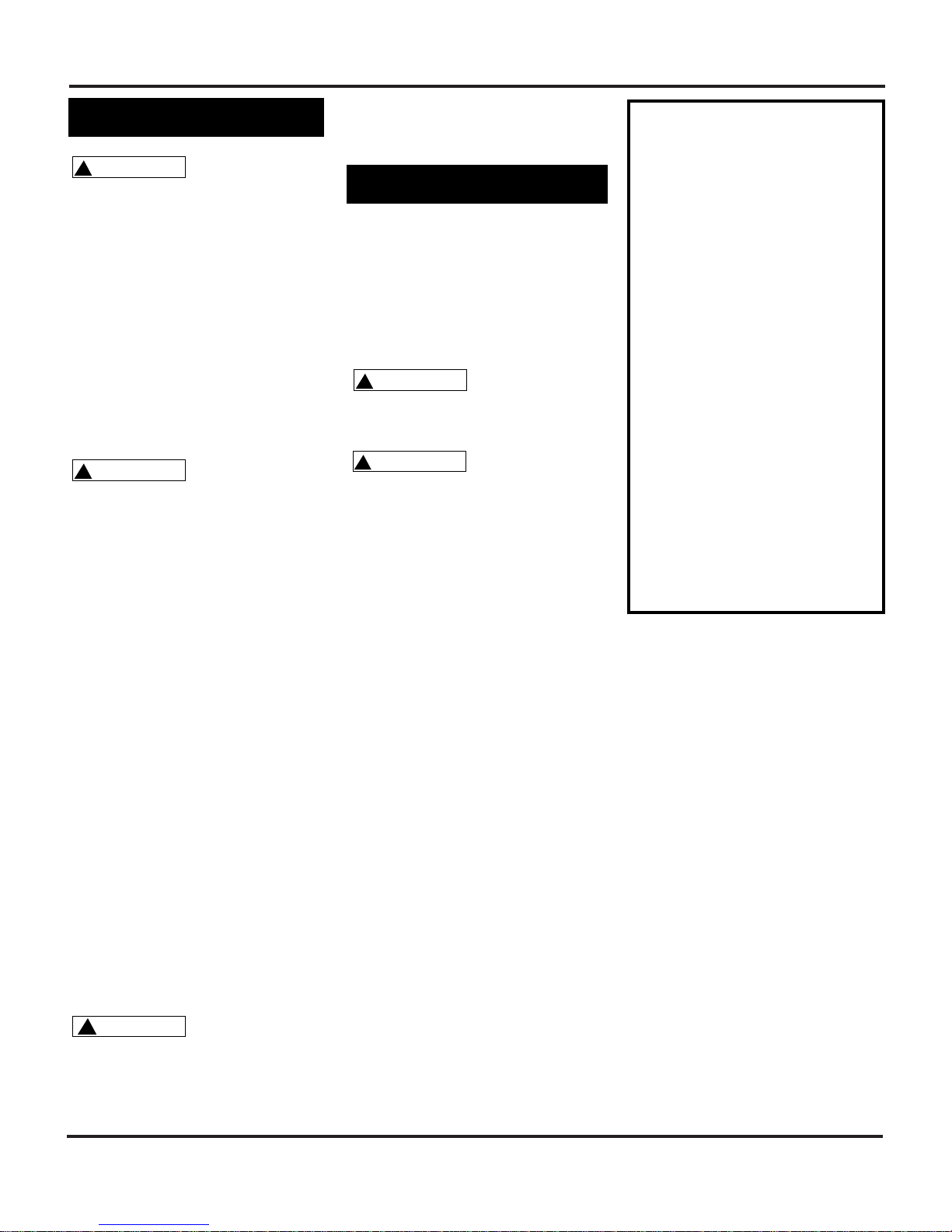

TRIGGER SAFETY LATCH

In the engaged position, the trigger

safety latch prevents the gun from

being triggered accidentally. Push

latch fully down to engage (See Figure

2). Always engage trigger safety latch

when unit is not in use.

1. Check oil levels. Add oil as necessary.

NOTE: Some units are equipped with a

low-oil sensor that shuts engine off if

oil level falls below a certain level. If

unit stops unexpectedly, check both oil

and fuel levels. Check oil level each

time unit is refueled.

2. Check fuel level.

DO NOT refuel a

hot engine.

Refueling a hot engine could cause a

fire. Use only fresh, clean regular or

unleaded gasoline. Close the fuel

shutoff valve during refueling.

3. Attach garden hose to inlet side of

pump and connect to water supply.

Hose should have an I.D. of 5/8” and

not be longer than 50 ft. (15 M).

2

Figure 1 - Pump hook up

Pump inlet

Pump outlet

Chemical

injector

hose barb

Safety Guidelines

Assembly

Start Up

Figure 2 - Trigger Lock

Engaged

Disengaged

Unpacking

www.chpower.com

!

DANGER

!

WARNING

!

CAUTION

!

NOTICE

!

WARNING

!

CAUTION

!

WARNING

3

PW2120, PW22221, PW2458

up in the high pressure hose. Go

back to step 7 and repeat until

engine starts.

1. Be sure all detergent is flushed

from system.

2. Turn off engine.

3. Turn off water supply.

4. After engine and water supply are

turned off, trigger the gun to

depressurize the system.

NEVER turn the

water supply off

before turning the engine off. Serious

damage could occur to the pump

and/or engine.

NEVER disconnect

the high pressure

discharge hose from the machine

while the system is pressurized. To

depressurize, turn engine off, turn

water supply off and squeeze gun

trigger 2-3 times.

5. After each use, wipe all surfaces of

the pressure washer with a clean,

damp cloth.

Some local plumb-

ing codes require

backflow prevention when connecting

to a fresh water supply. Install backflow preventer upstream from the

pump if necessary.

a. If inlet water pressure is over 100

psi (7 bar) a regulating water

valve must be installed at the garden hose connection.

b. Do not exceed 100¯ F (38¯ C) inlet

water temperature.

NOTE: The inlet water supply must

have a minimum flow rate of 5 gpm

(19 lpm).

4. Turn on the water supply.

Never run the unit

dry. BE SURE water

supply is completely turned on before

operating unit.

5. Trigger gun until water sprays from

tip indicating all air is purged from

system. Set trigger safety latch.

6. Open fuel shutoff valve (if unit is

equipped with valve). Be sure spark

plug ignition cable is pushed firmly

onto spark plug. On units equipped

with an ignition shutoff switch, put

switch in the “ON” position and put

throttle in the “RUN” position.

7. Start engine.

If engine is cold, completely close

engine choke. Grasp starter rope,

brace one foot on chassis then pull

rope rapidly and firmly. Continue

holding rope as it returns. Pull and

return the rope until engine starts.

In cool weather, the choke may have

to be kept closed for 10 to 30 seconds to keep the engine running.

Otherwise, open choke as soon as

engine starts.

If engine is warm, leave choke open

or just partially closed. Start engine

then open choke completely.

Never let starter

rope return by

itself. This could jam the recoil system.

8. If engine does not start after 2-3

pulls, squeeze the gun trigger to

release the pressure that has built

Start Up (Continued)

Shutdown

PRESSURE RELIEF

PROCEDURE

To reduce the risk of bodily injury

or property damage, always follow this procedure whenever

spraying is stopped, when work is

completed and before checking

or repairing any part of the system.

1. Engage the trigger safety

latch.

2. Turn unit off.

3. Remove ignition cable from

spark plug.

4. Shut off water supply.

5. Disengage trigger safety latch

and trigger gun to relieve

pressure.

6. Re-engage trigger safety latch.

7. Before overnight or long term

storage or transporting unit,

disconnect water supply and

turn off the fuel supply valve.

www.chpower.com

!

CAUTION

!

CAUTION

!

NOTICE

!

CAUTION

!

WARNING

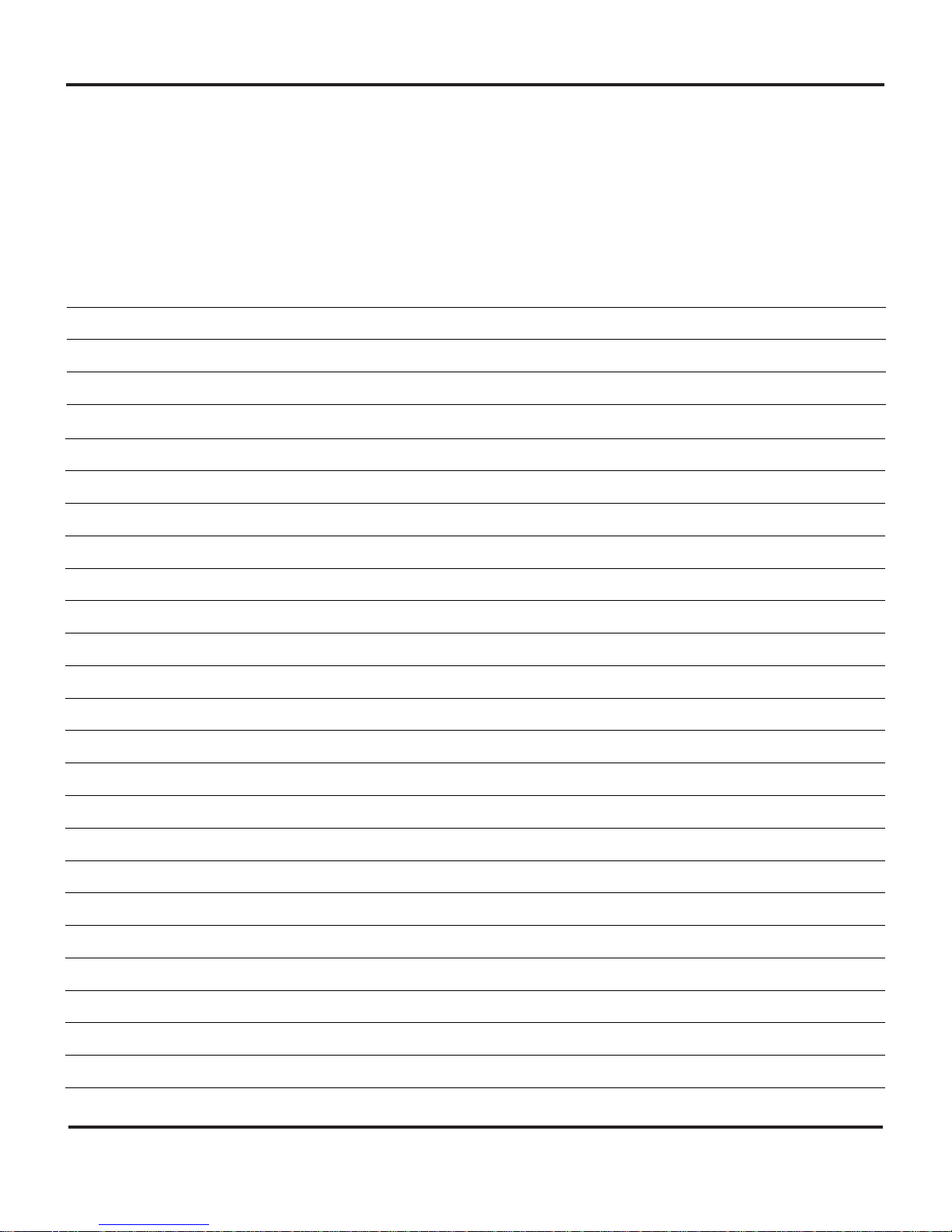

Gasoline Powered Pressure Washer

4

For Replacement Parts, Call 1-800-330-0712

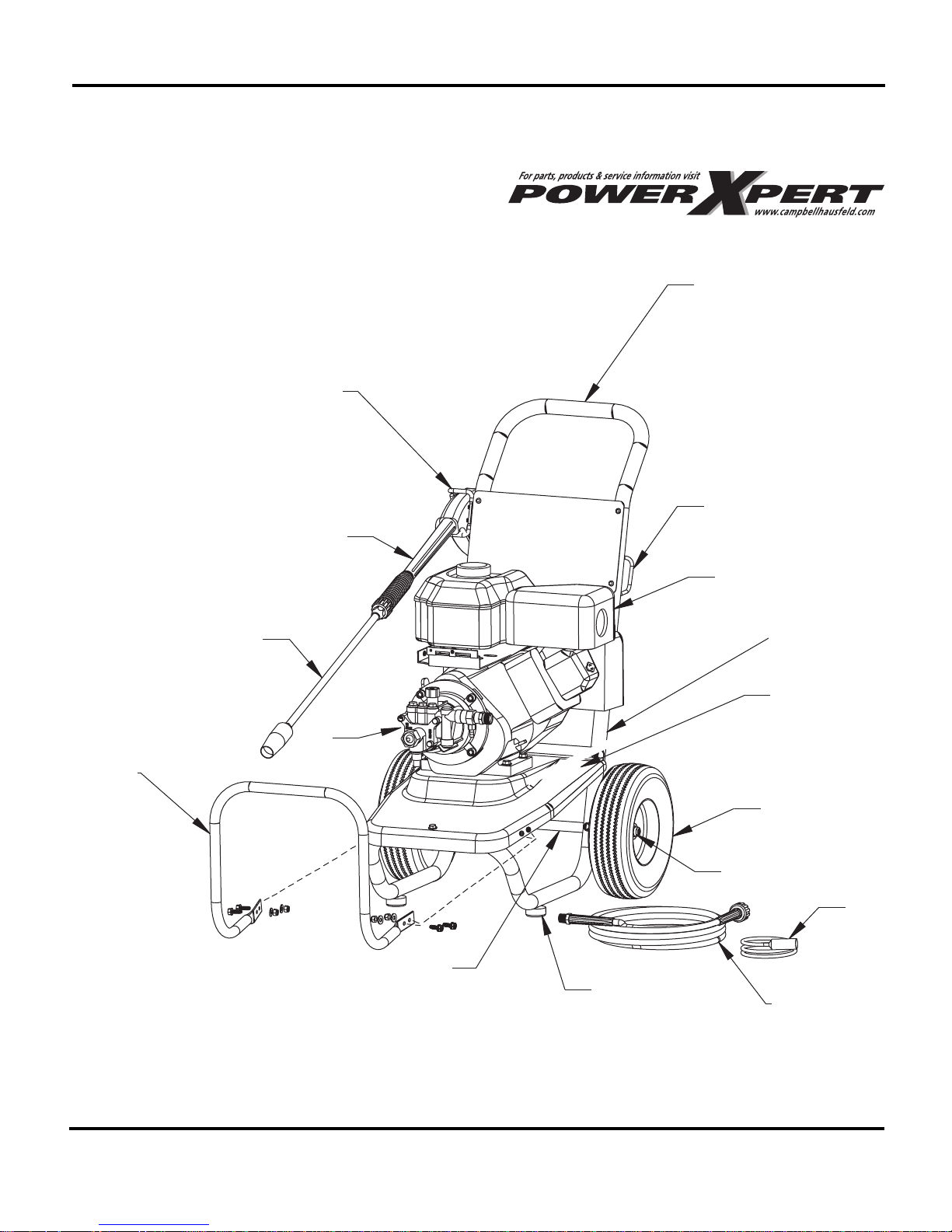

1

2 (2)

3 (2)

4 (4)

1

2 (2)

3 (2)

4 (4)

5***

20

11 (right side)

12 (left side)

15 (2)

16 (2)

17 (2)

24

25

13

14 (2)

3 (2)

4 (4)

18 (2)

19 (2)

10

2 (3)

3 (3)

4 (6)

21

23

22a

PW2120, PW22221, PW2458

26 ****

27 (4)

3 (4)

4 (4)

Model PW2458 Only:

Assembly Required

www.chpower.com

5

PW2120, PW22221, PW2458

Ref.

No. Description PW2120 PW2221 PW2458 Qty.

1 Handle/Placard assembly PM060020SJ PM060020SJ PM236000SJ 1

2 1/4-20 x 1.75 Hex head bolt* PM001903AV PM001903AV PM001903AV 5

3 1/4-20 Nylock nut* ST073808AV ST073808AV ST073808AV 11

4 Flatwasher, 1/4-20* PM002000AV PM002000AV PM002000AV 18

5 Hose Rack PM223700AV PM223700AV PM223700AV 1

6 Gun Rack PM033410AV PM033410AV PM033410AV 1

7 10-24 x 1.75 Socket head cap screw* MJ103803AV MJ103803AV MJ103803AV 2

8 10-24 Nylock Nut* ST073803AV ST073803AV ST073803AV 2

9 Flatwasher, 10-24* ST070906AV ST070906AV ST070906AV 6

10 Baseplate PM223200AV PM223200AV PM235700AV 1

11 Leg, right side PM223610BH PM223610BH PM223610BH 1

12 Leg, left side PM223620BH PM223620BH PM223620BH 1

13 Axle PM224501BH PM235601BH PM235601BH 1

14 1/4-20 x 2.25 Hex head bolt* MJ101104AV MJ101104AV MJ101104AV 2

15 Wheel WA005100AV WA004900AV WA004900AV 2

16 Hub Cap◆ PM224400AV N/A N/A 2

17 Push nut MJ104700AV AL066300AV AL066300AV 2

18 Rubber bumper AL062300AV AL062300AV AL062300AV 2

19 1/4-20 x .75 Self tapping screw* MJ102100AV MJ102100AV MJ102100AV 2

20 Engine PM004050AV PM004100AV PM041902AV 1

21 Pump Assembly** PM041810SJ PM004610SJ PM041803SJ 1

22a Gun PM005133AV PM005133AV PM005133AV 1

22b Gun o-ring◆ PM232210SV PM232210SV PM232210SV 2

22c Gun back-up o-ring◆ PM232211SV PM232211SV PM232211SV 1

23 Lance PM035150AV PM005116AV PM035140AV 1

24 Hose PM012904AV PM005001AV PM005001AV 1

25 Detergent tube and filter PM013800AV PM013800AV PM013800AV 1

26 Front guard N/A N/A PM080830AV 1

27 1/4-20 X .75 Self tapping screw blk* N/A N/A MJ106206AV 4

* Item available at local hardware store

** See separate pump breakdown sheet for replacement pump parts.

** * Components not included with handle/placard assembly (ref #1)

****Available only on model PW2458

◆ Item not shown

Replacement Parts List

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown in parts list

Address parts correspondence to:

The Campbell Group

Attn: Parts Department

100 Production Drive

Harrison, OH 45030 U.S.A.

www.chpower.com

Gasoline Powered Pressure Washer

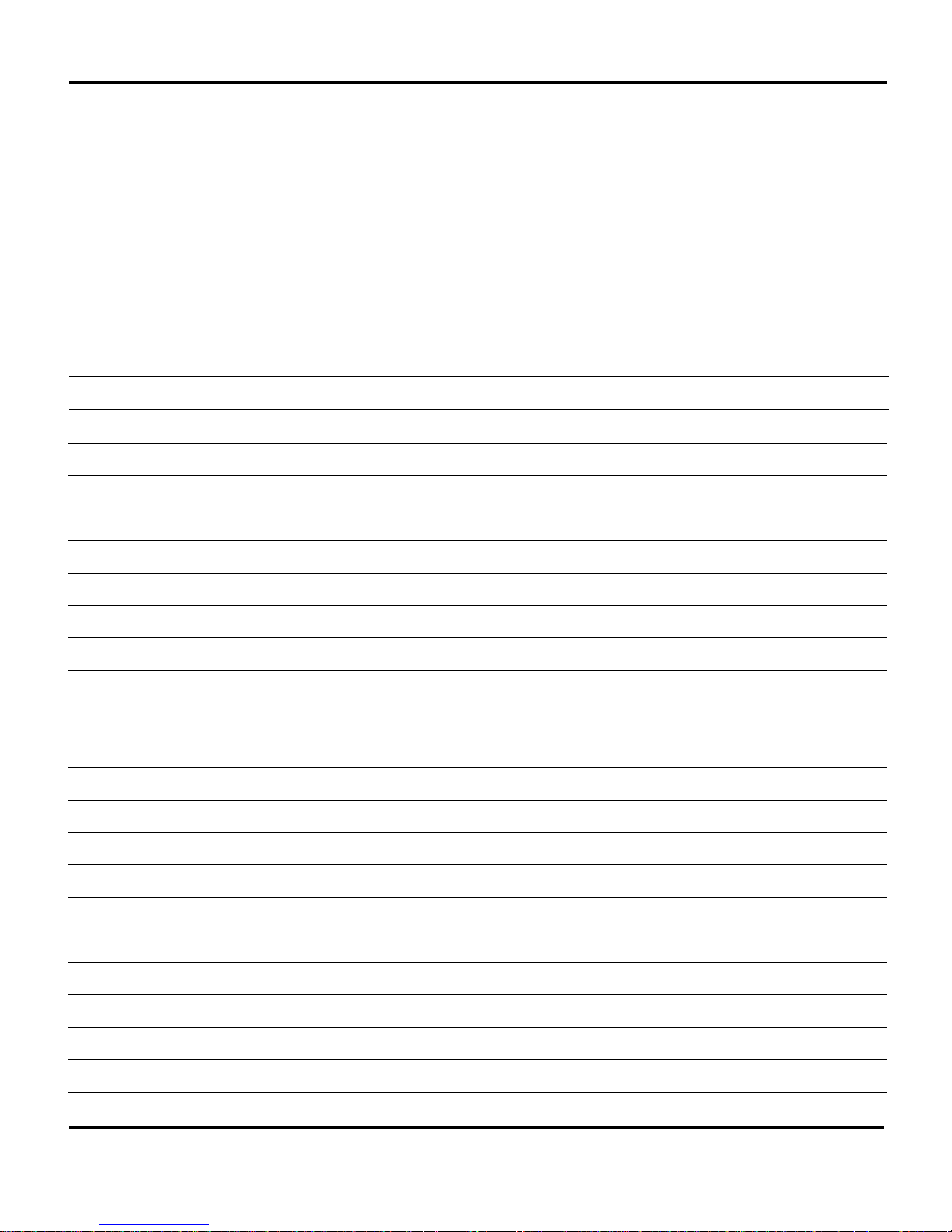

6

Maintenance

Daily

After first 5 hours of

operation

Every 25 hours of

operation

Each 100 hours of

operation or every 3

months

Each 500 hours of

operation or every 6

months (horizontal shaft

units only)

Check water inlet screen and filter

Check engine and pump oil levels. Fill as necessary

Check gasoline level. Fill as necessary

Change engine break-in oil. Drain oil when warm

Use SAE30 or 10W-30 detergent oil

Clean and remove air cleaner filter (if applicable)

Wash with water and mild detergent. Dry thoroughly. Rub with oil and squeeze to distribute oil

Clean or replace paper air cleaner cartridge. Tap

gently to remove dirt

Change engine oil. Use SAE30 detergent oil

Change pump oil. Use SAE30 non-detergent oil

Maintenance Schedule Action needed

Maintenance Schedule

Observe regular maintenance intervals to ensure maximum performance

and life from the pressure washer.

Refer to the schedule for recommended maintenance. If unit is operated

in dusty conditions, perform maintenance checks more often.

Service Record

Date Maintenance performed Replacement components required

www.chpower.com

7

PW2120, PW22221, PW2458

Notes

www.chpower.com

Gasoline Powered Pressure Washer

Notes

www.chpower.com

Loading...

Loading...