Page 1

See Warranty on page 12 for important information about commercial use of this product.

Operating Instructions PW182501, PW183501

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and

others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for

future reference.

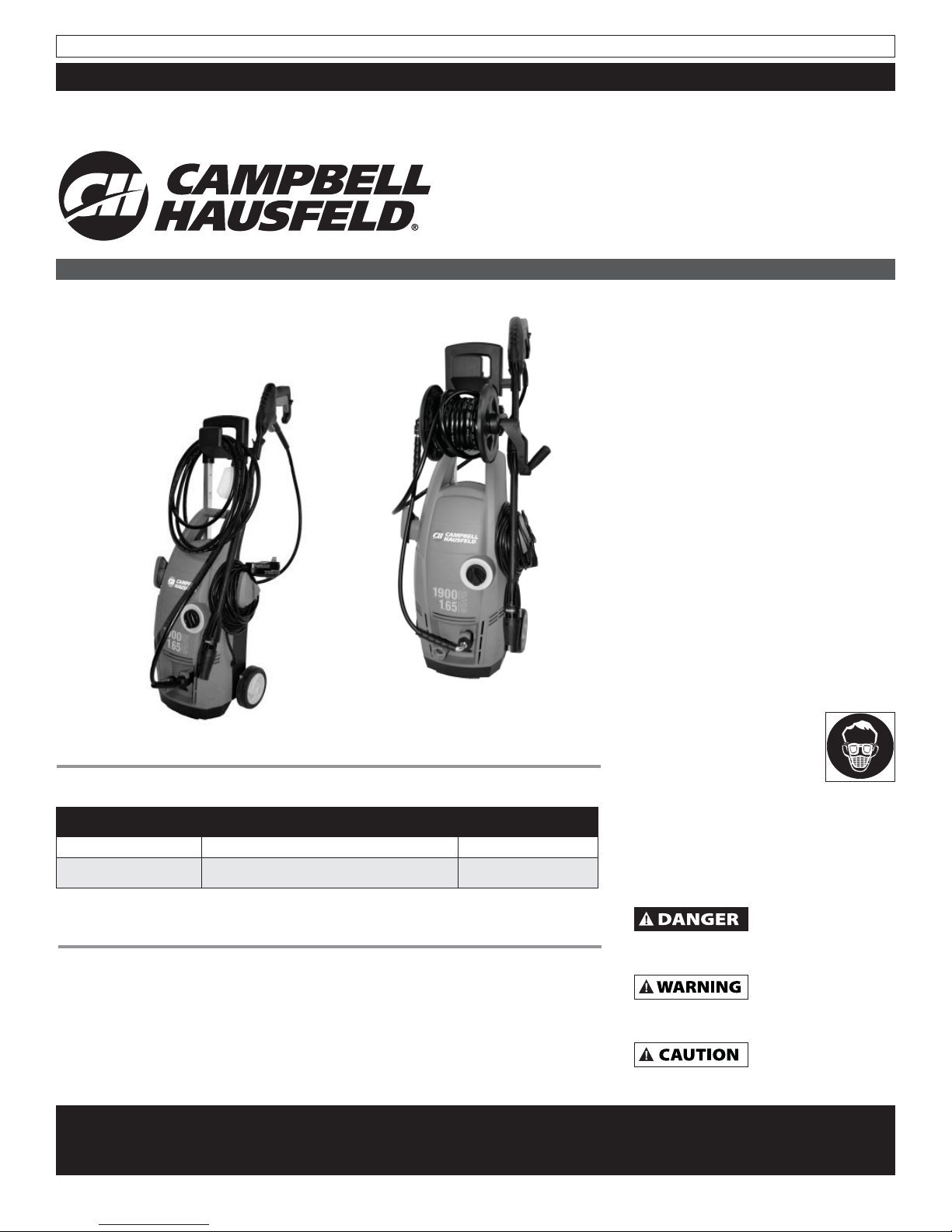

Campbell Hausfeld Electric

Powered Pressure Washers

REGISTER YOUR PRODUCT ONLINE NOW! http://www.campbellhausfeld.com

Description

These Campbell Hausfeld electric

pressure washers are perfect for all

around the home cleaning projects.

The units operate quietly, efficiently and

without fuel emissions. Each model

features “instant start stop” (ISS) which

shuts the motor off when the gun is not

engaged. This conserves water and

electricity, as well as extends the life of

the pump.

The pressure washers are powered by a

reliable universal motor and conveniently

plug into household 120V – 15 Amp

outlets. Both models are ETL approved to

meet UL and ETL standards in the US and

Canada.

Figure 1 - Model PW182501, and PW183501

Specifications

Model Pressure Volt

PW182501 1900 psi / 13,100 kPa 120

PW183501 1900 psi / 13,100 kPa 120

Please record Model Number and Serial Number for use when contacting the

manufacturer:

Model No.: __________________________________________________________________

Serial No.: __________________________________________________________________

Purchase Date: ______________________________________________________________

Purchase Place: ______________________________________________________________

For information about this product, call 1-800-330-0712.

READ & FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

DO NOT DISCARD

Safety Guidelines

This manual contains

information that is very

important to know and

understand. If you have any

questions, please call 1-800-330-0712

for customer assistance. This information

is provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

recognize this information, observe the

following symbols.

Danger indicates an

imminently

hazardous situation which, if not avoided,

WILL result in death or serious injury.

Warning indicates

a potentially

hazardous situation which, if not avoided,

COULD result in death or serious injury.

Caution indicates

a potentially

hazardous situation which, if not avoided,

MAY result in minor or moderate injury.

REMINDER: Keep your dated proof of purchase for warranty purposes!

Attach it to this manual or file it for safekeeping.

READ AND FOLLOW ALL INSTRUCTIONS • SAVE THESE INSTRUCTIONS • DO NOT DISCARD

© 2014 Campbell Hausfeld/Scott Fetzer IN471200AV 11/14

For parts, product & service information

visit www.campbellhausfeld.com

Page 2

Operating Instructions

Safety Guidelines (Continued)

Notice indicates important information,

that if not followed, may cause damage to

equipment.

NOTE: Information that requires special attention.

Safety Symbols

The following Safety Symbols appear throughout this manual

to alert you to important safety hazards and precautions.

Read Manual

First

Risk of Falling

When using tools, basic precautions should

always be followed, including the following:

CALIFORNIA PROPOSITION 65

This product or its power cord

known to the State of California to cause cancer and birth

defects or other reproductive harm. Wash hands after handling.

You can create dust when you cut, sand,

metal, concrete, cement, or other masonry. This dust often

contains chemicals known to cause cancer, birth

defects, or other reproductive harm. Wear protective

gear.

GENERAL SAFETY

a. To reduce the risks of electric shock, fire,

and injury to persons, read all the instructions before

using the tool. Failure to follow warnings, dangers, and

cautions could result in DEATH or SERIOUS INJURY.

b. Be thoroughly familiar with the controls and the proper use of

the equipment. Follow all instructions. Contact your Campbell

Hausfeld representative if you have any questions, 1 (800)

330-0712.

c. Only persons well acquainted with these rules of safe

operation should be allowed to use the unit.

d. Follow all safety codes as well as the Occupational Safety

and Health Act (OSHA).

WORK AREA

a. Keep operation area clear of all persons.

b. To reduce the risk of injury, close supervision is necessary

when the product is used near children.

c. Do not operate the tool in explosive atmospheres, such as in

the presence of flammable liquids, gases, or dust. The tool

is able to create sparks resulting in the ignition of the dust or

fumes.

Risk of

Explosion

Risk of Personal

Injury

may contain chemicals, including lead,

drill or grind materials such as wood, paint,

Risk of Fire

Wear Eye

and Hearing

Protection

d. NEVER spray flammable liquids or use pressure

washer in areas containing combustible dust,

liquids, or vapors.

e. Never operate this machine in a closed building or

in or near an explosive environment.

PERSONAL SAFETY

a. Stay alert. Watch what you are doing and use

common sense when operating the tool. Do not use the

tool while tired or under the influence of drugs, alcohol, or

medication. A moment of inattention while operating the tool

increases the risk of injury to persons.

b. Dress properly. Wear closed toe shoes (no flip flops.) Do not

wear loose clothing or jewelry. Contain long hair. Keep hair,

clothing, and gloves away from moving parts. Loose clothes,

jewelry, or long hair increases the risk of injury to persons as a

result of being caught in moving parts.

c. Do not overreach. Keep proper footing and

balance at all times. Proper footing and balance

enables better control of the tool in unexpected

situations.

Risk of injection or severe injury. Keep clear

of nozzle. Do not discharge streams

at persons. This product is to be used only by trained

operators. Always remove lance from gun before cleaning

debris from nozzle.

d. Keep clear of nozzle. NEVER direct high pressure

spray at a person, animal, or yourself.

e. NEVER put hand or fingers over the spray nozzle while

operating the unit.

f. NEVER try to stop or deflect leaks with any body part.

Ensuring that the tool is used

only when the operator and all other

personnel in the work area are wearing ANSI Z87 eye

protection equipment, and when required, other appropriate

protection equipment such as head, hearing protection,

gloves, rubber boots, protective clothing when operating and

performing maintenance. Serious eye or permanent hearing

loss could result.

ELECTRICAL SAFETY

Risk of electrocution:

a. This product is provided with a ground fault circuit interrupter,

GFCI, built into the power cord plug. Be sure to inspect cord

and GFCI prior to use. Any repair or replacement of the power

cord must be performed by a qualified (licensed or certified)

electrical technician. If replacement of the plug or cord is

needed, use only identical replacement parts.

b. NEVER use an extension cord with this product.

c. Inspect cord before using - Do not use if cord is damaged.

d. Keep all electrical connections dry and off the ground.

e. Do not touch plug with wet hands.

f. Do not spray electrical apparatus and wiring.

www.campbellhausfeld.com

2

Page 3

Safety Guidelines (Continued)

TOOL USE AND CARE

Do not use pressure that exceeds the operating

pressure of any of the parts (hoses, fi ttings, etc.)

in the pressurized system. Ensure all equipment and accessories are

rated to withstand the maximum working pressure of the unit.

a. Maintain the tool with care. A properly maintained tool

reduces the risk of problems and is easier to control.

b. Ensure safety devices are operating properly before each

use. DO NOT remove or modify any part of the gun or unit.

c. NEVER operate the machine without all components properly

connected to the machine (handle, gun/wand assembly,

nozzle, etc.).

d. Point gun in safe direction. Unit will start spraying when

trigger is squeezed if “On/Off” switch is in “ON” position.

e. Know how to stop this product and bleed pressure quickly.

Be thoroughly familiar with the controls.

f. ALWAYS engage the trigger safety latch in the safe position

when spraying is stopped even if only for a few moments.

g. NEVER permanently engage the trigger mechanism on the

gun.

h. ALWAYS follow detergent manufacturer’s label

recommendations for proper use of detergents. Always

protect eyes, skin, and respiratory system from detergent

use.

i. NEVER disconnect the high pressure discharge hose from

the machine while the system is pressurized. To depressurize

machine, turn power and water supply off, then press the gun

trigger 2-3 times.

j. Unplug unit when not in use.

k. Follow the maintenance instructions specified in the manual.

l. ALWAYS turn water supply “ON” before turning pressure

washer “ON.” Running pump dry causes serious damage.

m. Do not operate the pressure washer with the inlet water

screen removed. Keep screen clear of debris and sediment.

n. NEVER operate pressure washer with broken or missing

parts. Check equipment regularly and repair or replace worn

or damaged parts immediately.

o. Use only the lances supplied with this machine.

p. NEVER leave the wand unattended while the machine is

running.

q. ALWAYS hold gun and wand firmly when starting and

operating the machine.

r. Release the trigger when changing from high to low pressure

modes. Failure to do so could result in damage to the nozzle.

s. NEVER store the pressure washer outdoors or where it could

freeze. Freezing temperatures can seriously damage the

pump.

t. Pressure washer is not meant to pump hot water. Do not

connect to hot water supply.

Equipment damage:

Models: PW182501, PW183501

SERVICE

a. When servicing a tool, use only identical replacement parts.

Use only authorized parts.

Servicing of a Double-Insulated Appliance

In a double-insulated product,

two systems of insulation are

provided instead of grounding.

No grounding means are provided

for a double-insulated product,

nor should grounding means be

added to the product. Servicing a

double-insulated product requires

extreme care and knowledge of

the system, and should be done

only by qualified service personnel.

Replacement parts for a doubleinsulated product must be identical to the original parts. A

double-insulated product is marked with the words “Double

Insulation” or “Double Insulated.” Product may also be marked

with symbol shown above.

The DANGER, WARNING, CAUTION, and NOTICE

notifications and instructions in this manual cannot cover

all possible conditions and situations that may occur.

It must be understood by the operator that caution is a

factor which cannot be built into this product, but must be

supplied by the operator.

SAVE THESE INSTRUCTIONS

DO NOT DISCARD

Double Insulated Symbol

3

www.campbellhausfeld.com

Page 4

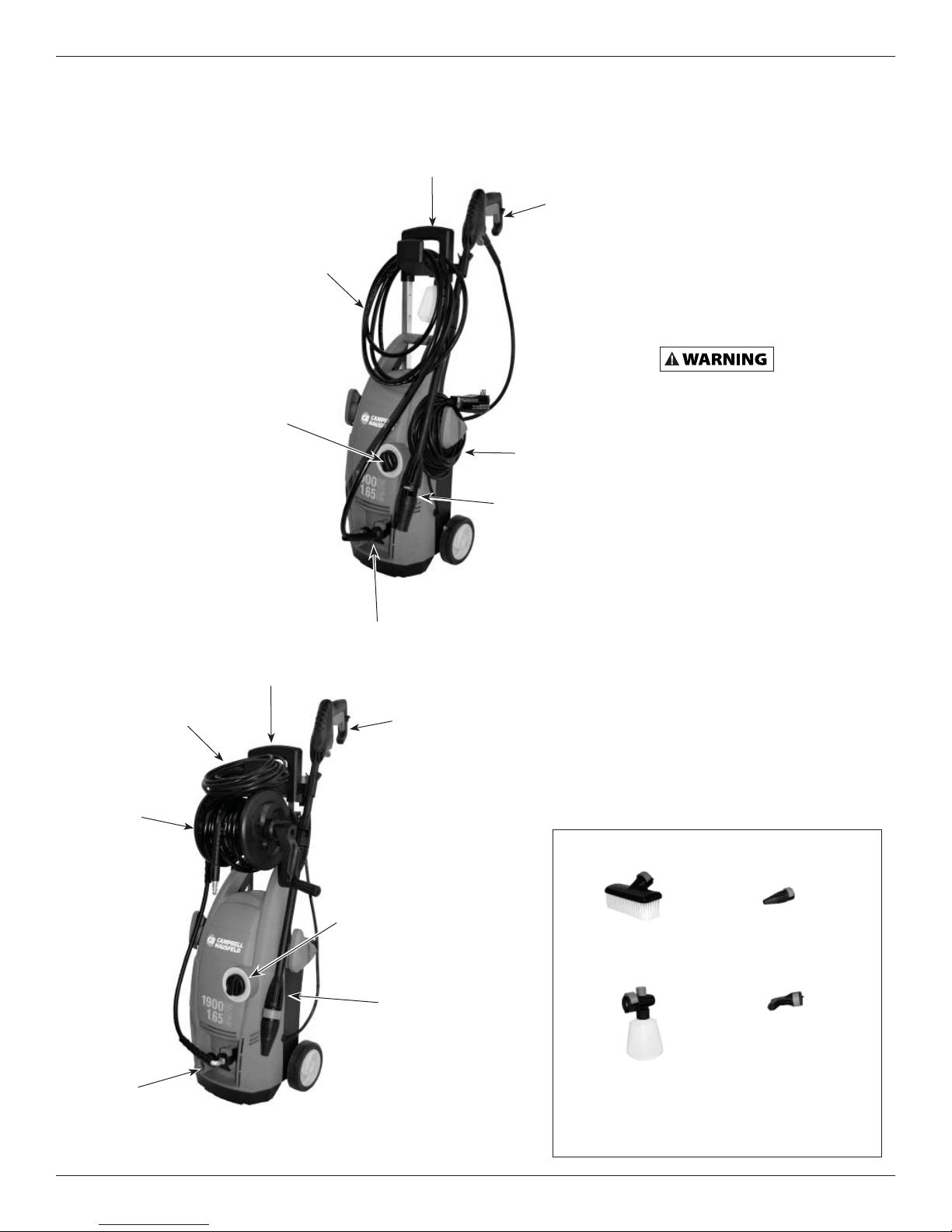

Operating Instructions

Unpacking

On/Off Switch

Power Cord

High Pressure

Hose

Handle

Handle

High Pressure

Hose Outlet

Gun with

Trigger

Power

Cord

Lance

PW182501

Gun with

Trigger

After unpacking the unit, inspect

carefully for any damage that may

have occurred during transit. Check

for loose, missing or damaged

parts. Make sure to tighten fittings,

bolts, etc., before using the pressure

washer. Check to be sure all supplied

accessories are enclosed with the

unit. If any parts are missing, DO

NOT RETURN THE UNIT TO THE

RETAILER. Know the unit’s model

number, serial number and date code

(located on the back of the pressure

washer) and call 1-800-330-0712 for

replacement parts.

Do not operate the

unit if it’s damaged

during shipping, handling, or use. Damage

could result in bursting and cause injury or

property damage.

RECOMMENDED USES FOR THIS

PRESSURE WASHER

◆ Deck

◆ Siding

◆ Vehicles

◆ Gutters (with right angle nozzle)

ADDITIONAL ITEMS NOT

INCLUDED

◆ ANSI Z87 Eye Protection

◆ Garden Hose

NOTE: For the PW183501 only - Hold

on to the handle of the unit while

unreeling the hose. This will prevent

the unit from toppeling over.

High Pressure

Hose

Water Hose

Outlet

Figure 2 - Components of the Pressure Washer

www.campbellhausfeld.com

PW183501

On/Off Switch

Lance

Accessories

Brush

(PW183501 only)

Turbo Nozzle

(PW183501 only)

Right Angle

Nozzle

Detergent Bottle

(PW183501 only)

(Both models)

Accessory kit available for purchase.

Part Number PW091400AV

4

Page 5

Assembly and Preoperation

Always make sure that

the garden hose is turned on before turning on

the pressure washer. Running the pressure washer without water will

damage the pumps seals.

Do not disassemble the lance or gun on this

pressure washer. Replacement parts are not available for the gun or

lance.

PW182501 & PW183501

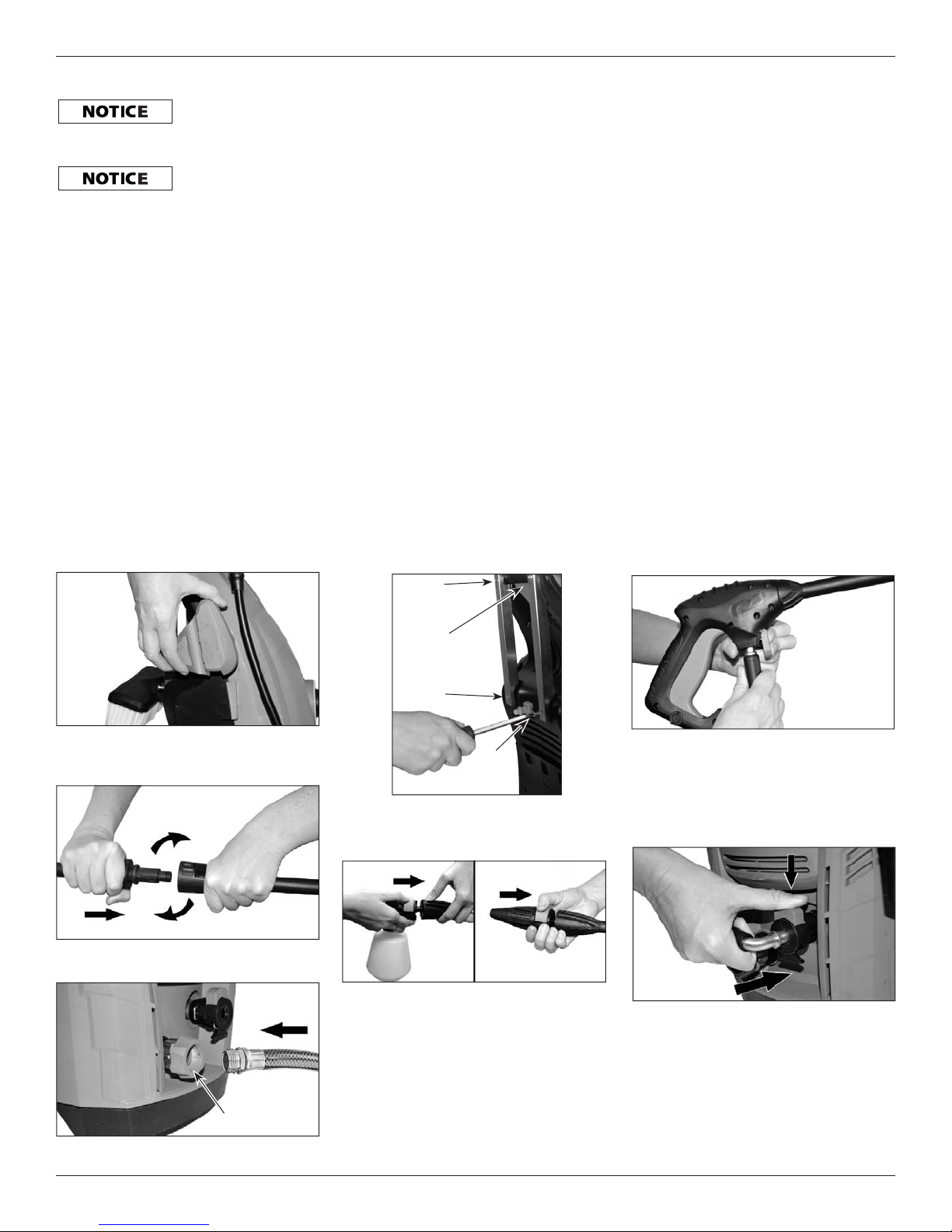

1. Attach storage hooks.(see Figure 3)

2. Slide handle (1) onto unit, attach with 4 phillips screws. (see

Figure 4)

3. Attach high pressure hose to high pressure outlet (see Figure

8)

4. Attach high pressure hose to gun (see Figure 5).

5. Attach lance to gun, twist and lock. Attach nozzle or

detergent bottle to lance by pressing the Easy Connect

button and inserting into Quick Connect on lance. (see

Figures 6 & 7)

6. Attach garden hose to unit (see Figure 9).

7. Press Easy Connect button while inserting Quick Connect

fitting. (see Figure 5, 7 & 8)

Models: PW182501, PW183501

Figure 3 - Attach storage hooks

(PW182501 only)

Figure 6 - Attach lance to gun

1

2

3

4

Figure 4 -Attach phillips screws

(PW182501 only)

Figure 7- Attach nozzle to lance or detergent

bottle

Figure 5 - Attach high pressure hose to gun

Figure 8 - Attach high pressure hose

Water inlet

Figure 9 - Attach garden hose to unit

5

www.campbellhausfeld.com

Page 6

Operating Instructions

Assembly and Preoperation (Continued)

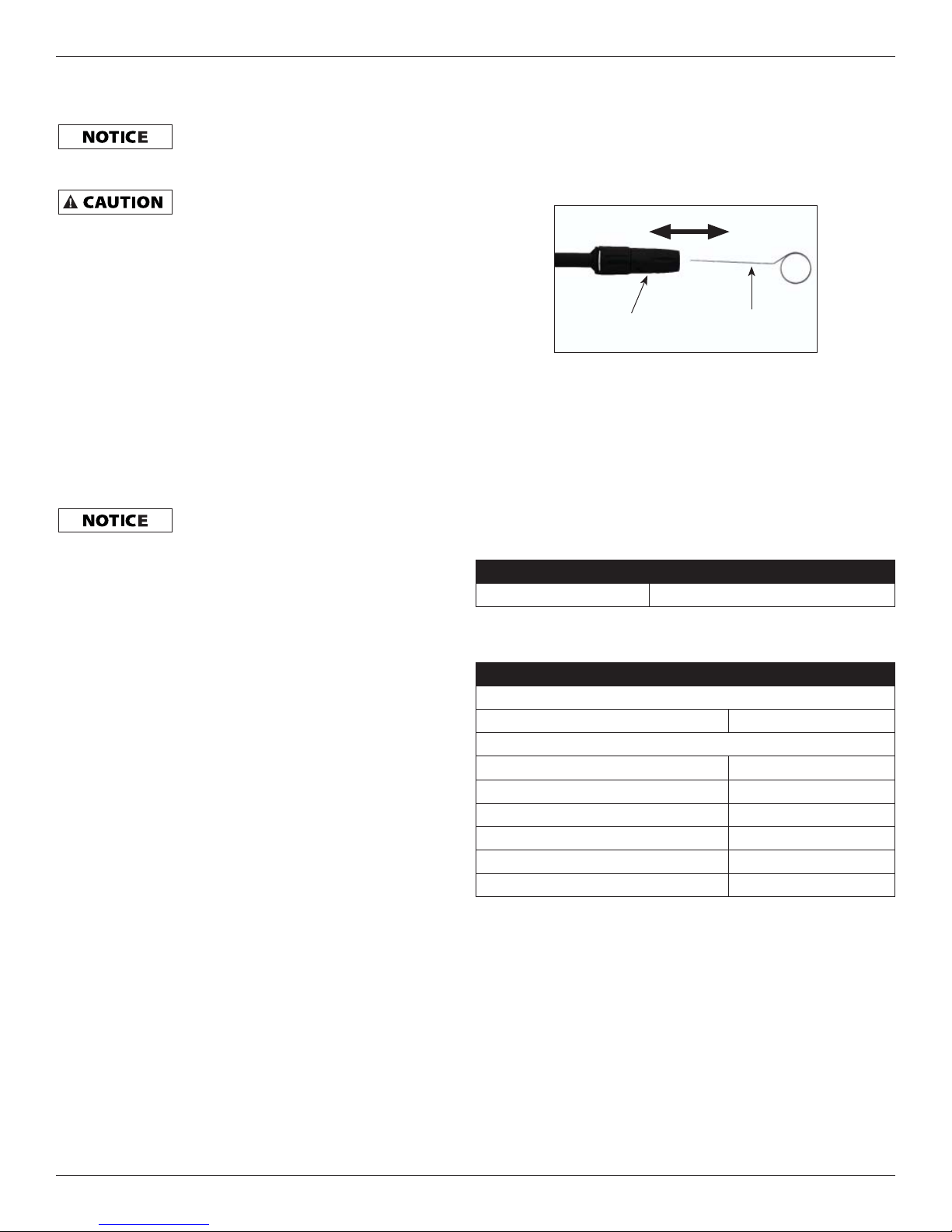

TRIGGER SAFETY LATCH

In the engaged position, the trigger safety latch prevents the gun

from being triggered accidentally. Push the button in to engage

it. (See Figure 10)

Always engage the trigger safety latch when the unit is not in

use.

Trigger

Safety Lock

Figure 10 - Trigger safety latch

OPERATION

! IMPORTANT !

This pressure washer is equipped with a microswitch

sensitive to water flow. This Instant Start/Stop switch

(ISS) senses water flow in the pump. When the trigger is

released, water stops flowing through the pump. The ISS

then automatically turns the motor off to protect pump

from overheating.

OPERATION

1. Turn on water.

2. Pull trigger on gun.

3. Turn the “ON/OFF” switch to “ON”.

4. Release trigger. The pressure washer motor will stop running.

5. To spray again, pull trigger and motor and pump will restart.

NOTE: Occasionally the motor may run for a short time

to bring fresh, cool water into the pump even if trigger is

released. This is part of normal operation and will not damage

the unit.

Always turn the “ON/OFF” switch

to “OFF” then trigger gun to release hose

pressure before unplugging power cord.

Risk of equipment damage. Always

make sure the “ON/OFF” switch on the unit is

“OFF” and unit is unplugged prior to storage.

Risk of Injection. Unit will start

spraying when trigger is squeezed if ON/OFF

switch is in “ON” position. Always point gun in safe direction.

SURFACE PREPARATION

The following cleaning procedure will help you organize your

cleaning task and ensures that you will achieve the best results in

the shortest amount of time. Gallons Per Minute (GPM), the more

water per minute can mean faster cleaning, especially when

washing off materials like mud and road tar. GROUND FAULT

CURRENT INTERRUPTER (GFCI) protects user from accidental

electrocution (for electric powered pressure washers only).

Remember to use the spraying / cleaning techniques mentioned

in the following section.

Before starting a pressure washer cleaning job, prepare the

surface you intend to clean. Clear furniture from the area and

make sure that all windows and doors are closed tightly. Also,

protect all plants and trees near the cleaning area with a drop

cloth. A covering ensures that your plants won’t be sprayed by

the detergents.

START UP

ALWAYS use this start up procedure to ensure that the unit is

started safely and properly.

If water has frozen in the pressure washer, thaw

the pressure washer in a warm room before

starting. DO NOT pour hot water on or into the pump; internal parts will

be damaged.Check for leaks.

1. Ensure that the power switch is in the “OFF” position.

2. Attach a garden hose to the inlet side of the pump and

connect it to the water supply. Use a hose with an internal

diameter (I.D.) of 5/8 in. (1.58 cm) and a length of 50 ft. (15 m)

or less.

Some local plumbing codes require backfl ow

prevention when connecting to a fresh water supply. Install a backfl ow

preventer upstream from the pump if necessary.

a. If inlet water pressure is over 100 psi, install a regulating

water valve at the garden hose connection.

b. Do not exceed 100˚ F (38˚ C) inlet water temperature.

NOTE: The inlet water supply must have a minimum flow rate of

5 gpm (19 lpm).

4. Turn the water supply ON.

Never run the unit dry. Be sure the water supply is

completely turned on before operating the unit.

5. Trigger the gun until water sprays from the nozzle indicating

that all air is purged from the system. Set the trigger safety

latch.

6. Plug the power cord into a grounded 120V outlet, that is on a

dedicated circuit. Do not use extension cord. Press the reset

button on the GFCI plug adapter. This must be done each

time the unit is plugged into an outlet. (Figure 11)

SYSTEM CONNECTION

(See page 5 for Assembly Instructions)

1. Plug the power cord into a grounded 120V outlet.

2. Turn water on.

3. Unlock trigger lock by moving lock right to left.

4. Depress and hold the trigger on the gun for one minute to

release pressure and remove any air trapped in the system.

5. Turn the “ON/OFF” switch to the “ON” position.

www.campbellhausfeld.com

6

Page 7

Operation (Continued)

INITIAL HIGH PRESSURE RINSE

Spray the cleaning surface with water to clear off any dirt or

grime that may have collected on the surface. Doing so allows

the detergent to attack the deep down dirt that has worked its

way into the cleaning surface.

Trigger the gun 3 to 5 times to get any trapped air out of the

system.

ADJUSTING THE SPRAY FAN ANGLE

1. The lance is affected by pressure during operation; therefore

hold it firmly with both hands and point the nozzle toward the

ground.

2. Activate by pulling the trigger of the gun/spray handle.

3. Adjust the distance to the cleaning surface, which will also

adjust your pressure of the nozzle.

4. Spray pattern shape and intensity can be changed by

twisting the spray adjuster at the end of the lance (see Figure

12 & 13). Keep hands clear of the front of the lance to prevent

injury.

Pressure can also be adjusted by moving closer or further away

from the cleaning surface and by adjusting the spray fan angle as

shown.

Models: PW182501, PW183501

Reset

Figure 11 - Grounded plug/reset button

Figure 12 - Spray Adjust

ANGLE TO THE CLEANING SURFACE

When spraying water against a surface, you can generate

maximum impact by striking the surface head on. However, this

type of impact can cause dirt particles to embed in the surface

and can prevent the desired cleaning action.

The optimum angle for spraying water against a cleaning surface

is 45 degrees to effeciently remove debris. (Figure 14)

Figure 13 - Adjust spray pattern

Figure 14 - Optimum angle to cleaning surface

7

www.campbellhausfeld.com

Page 8

Operating Instructions

Operation (Continued)

Distance From Cleaning Surface

The distance between the spray nozzle and the cleaning surface

is another factor that affects the impact force of the water. The

impact force of the water increases as the nozzle is moved closer

to the surface.

How to Avoid Damaging Surfaces

Damage to cleaning surfaces occurs because the impact force

of the water exceeds the durability of the surface. You can vary

the impact force by controlling the spray nozzle angle to the

cleaning surface and the distance from the cleaning surface

and by adjusting the spray nozzle. NEVER use a narrow high

impact stream on a surface that is susceptible to damage. Avoid

spraying windows with a narrow high impact stream. Doing so

may break the window. The most sure way to avoid damaging

surfaces is to follow these steps:

1. Place the spray nozzle approximately 4-5 feet (1,22-1,52 m)

away from the cleaning surface. Then hold the lance and

spray nozzle at a 45 degree angle to the cleaning surface.

Trigger the gun.

2. Vary the fan pattern spray angle and the distance to the

cleaning surface until optimum cleaning efficiency is achieved

without damaging the surface.

DETERGENT APPLICATION

NOTE: Use only detergents formulated for pressure washers.

Test detergent in an inconspicuous area before use. DO NOT use

bleach in pressure washer.

Detergents

The use of detergents can dramatically reduce cleaning time

and assist in the removal of difficult stains. Many detergents are

customized for pressure washer use on specific cleaning tasks.

Pressure washer detergents are as thick as water. Using thicker

detergents – like dish detergent – will clog the chemical injection

system and prevent the application of the detergent.

Once applied to a cleaning surface, detergents take time to

break down dirt and grime. Detergents work best when applied

at low pressure.

You can effectively clean surfaces by combining the chemical

action of detergents with high pressure rinses. On vertical

surfaces, apply the detergent starting at the bottom and work

your way upward. This method prevents the detergent from

sliding down and causing streaks. Begin high pressure rinsing

at the top and work your way down to surface. On particularly

tough stains, use a brush in combination with detergents and

high pressure rinsing.

1. Follow manufacturer’s label directions for mixing correct

concentrations of detergent/detergents. The detergent

detergent to water ratio through the pump is approximately

10% (1 to 10).

◆ PW182501 & PW183501: Pour detergent into detergent

container.

General Cleaning Tips

1. Apply the detergent so that it thoroughly covers the cleaning

surface. Apply the detergent from bottom to top to prevent

the detergent from sliding down and streaking. Wait a couple

of minutes for the detergent to break down the dirt and grime.

Use a brush to lightly scrub heavily soiled areas. Never allow

the detergent to dry on the cleaning surface.

2. Rinse with high pressure.

CLEANING POWER

The easiest way to regulate the cleaning power of your pressure

washer is by changing the distance from the surface you are

cleaning. Begin spraying with a wide fan pattern while standing

several feet from the surface. Slowly move closer to the object

you are cleaning, adjusting the spray pattern as necessary, until

you find the most effective cleaning technique.

FINAL RINSE

The final rinse should start at the top and work down to surface.

Make sure that you thoroughly rinse the surface and that you

remove all detergent.

PRESSURE RELIEF PROCEDURE

To reduce the risk of bodily injury or property damage, always

follow this procedure whenever spraying is stopped, when work

is completed, and before checking or repairing any part of the

system.

1. Engage the trigger safety latch.

2. Turn the unit off.

3. Shut off the water supply.

4. Disengage the trigger safety latch and trigger the gun to

relieve pressure.

5. Re-engage the trigger safety latch.

6. When checking or repairing unit, remove the wall outlet plug

from the wall.

7. Before overnight storage, long term storage, or transporting

unit, disconnect the water supply.

SHUTDOWN

1. Fully rinse detergent attachement with clean water.

2. Turn the motor OFF.

3 Turn the water supply OFF.

4. After the motor and water supply are turned off, trigger the

gun to depressurize the system.

www.campbellhausfeld.com

8

Page 9

Models: PW182501, PW183501

Operation (Continued)

NEVER turn the water supply off before turning

the engine/motor off. Serious damage could occur to the pump and/or

engine/motor.

NEVER disconnect the high pressure discharge

hose from the machine while the system is

pressurized. To depressurize, turn engine/motor off, turn water supply

off and squeeze gun trigger 2-3 times.

5. After each use, wipe all surfaces of the pressure washer with

a clean, damp cloth.

STORAGE

• Do not store the pressure washer outdoors.

• Do not store the pressure washer where it might freeze unless

it has been properly winterized.

Winterizing Instructions

1. Disconnect the high pressure hose from the pump.

2. Insert a 12 inch to 14 inch piece of garden hose into the

pump inlet.

3. Place a funnel in the other end of the garden hose.

Read the manufacturer’s instructions for safe

handling and disposal of RV antifreeze.

4. Pour approximately 6 oz. of RV antifreeze into the funnel.

5. Jog the On/Off Switch briefly until the RV antifreeze comes

out of the pump outlet.

6. Disconnect the high pressure hose from the gun and drain

the hose. Hold the gun and lance in a vertical position and

squeeze the trigger to drain the water out.

NOZZLE CLEANING INSTRUCTIONS

A clogged or partially clogged nozzle can cause a significant

reduction of water coming out of the nozzle and cause the unit to

pulsate while spraying.

To clean out the nozzle:

• Turn off unit.

• Turn off water supply. Relieve any pressure trapped in the

hose by squeezing trigger 2-3 times.

• Separate lance from gun.

• Rotate nozzle to the narrow stream setting. This opens up the

fan blades.

• Using the included nozzle cleaner, or an un-folded paper clip,

insert wire into the nozzle hole and move back and forth until

debris is dislodged (refer to Figure 15).

• Remove additional debris by back-flushing water through

the nozzle. To do this, remove the lance from the gun, place

end of a garden hose (with water running) nozzle to nozzle

pushing water and debris out the back opening of the lance.

TIPS FOR EXTENDING THE LIFE OF YOUR PRESSURE WASHER

1. Never operate the unit without water.

2. Your pressure washer is not meant to pump hot water. Never

connect your pressure washer to a hot water supply as it will

significantly reduce the life of the pump.

Nozzle Nozzle Cleaner

Figure 15

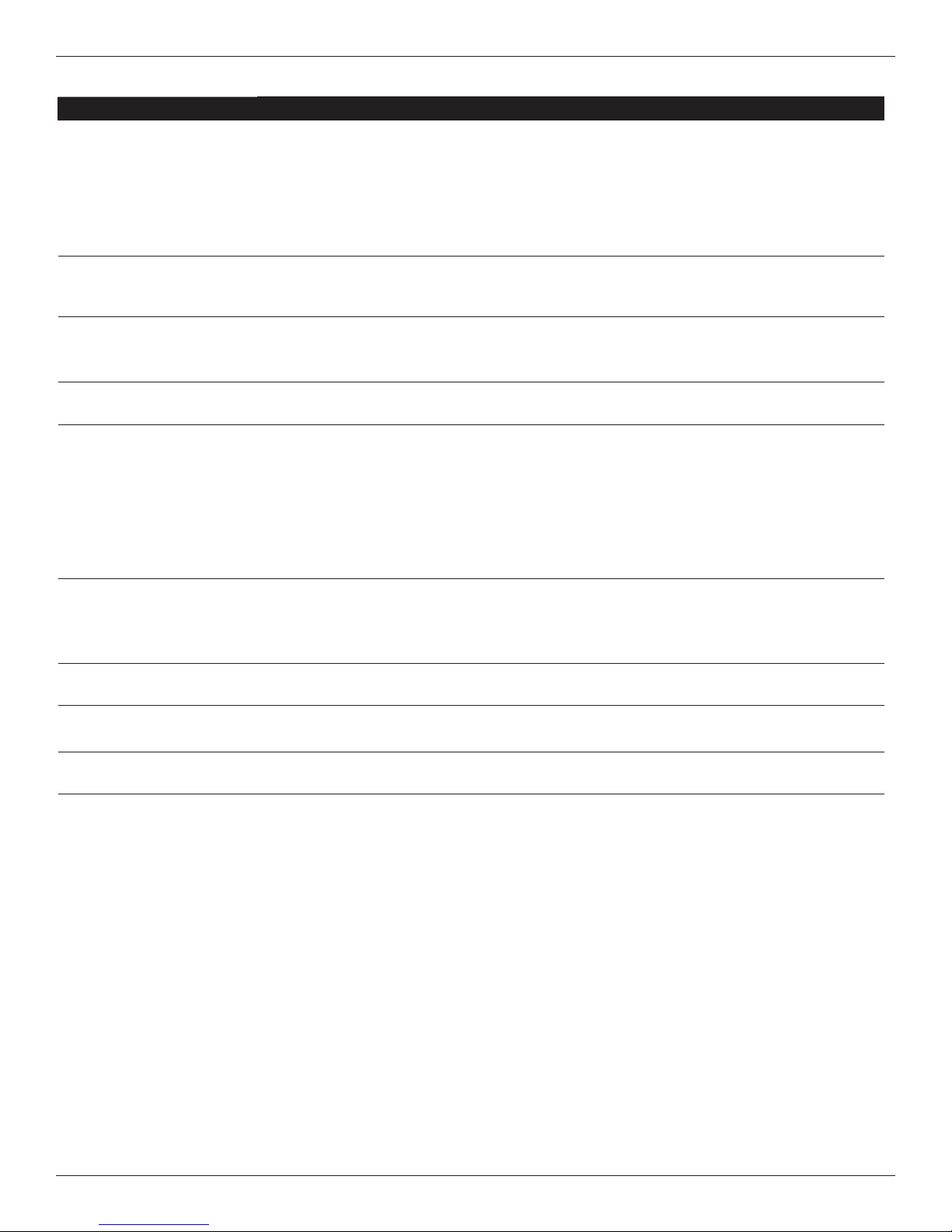

MAINTENANCE

Observe regular maintenance intervals to ensure maximum

performance and life from the pressure washer. Refer to the

schedule for recommended maintenance. If you operate the

pressure washer in dusty conditions, perform maintenance checks

more often.

MAINTENANCE SCHEDULE

Maintenance Schedule Action needed

Daily Check water inlet screen and filter.

TECHNICAL AND CONSUMER INFORMATION

Horizontal Oriented Pressure Washers

Pump Detergent Suction

Water to detergent ratio 10 to 1 (10% detergent)

Water Supply Requirements

Minimum inlet pressure 20 psi

Maximum inlet pressure 100 psi

Maximum inlet temperature 100˚ F

Minimum inlet flow rate 5 gpm

Inlet garden hose size 5/8 in. I.D.

Maximum inlet garden hose length 50 ft

9

www.campbellhausfeld.com

Page 10

Operating Instructions

Troubleshooting Guide

SYMPTOM CAUSE SOLUTION

Low pressure and/or pump

runs rough

Strong surging at the inlet and

low pressure

Fluctuating pressure 1. Pump drawing in air 1. Ensure hoses and fittings are tight. Purge air from

Pressure drops after period of

normal use

Pressure washer does not

start up

Motor stops suddenly 1. Extension cord ( see page 2 Electrical

Unit begins to smoke Overheated, overloaded or damaged

Pump noisy / pump runs

rough

Pressure washer will not spray

detergent

1. Worn nozzle 1. Replace nozzle

2. Inlet filter on pump clogged 2. Clean. Check more frequently

3. Restricted inlet 3. Check garden hose, may be collapsed or kinked.

Check inlet water flow

4. Leaking high pressure hose 4. Replace high pressure hose

5. Pump drawing in air 5. Ensure hoses and fittings are tight

1. Foreign particles in the inlet or

discharge valve or worn inlet and/or

discharge valves

2. Nozzle clogged 2. Clean or replace

1. Nozzle worn 1. Check and replace

1. GFCI has tripped 1. Push reset button on plug

2. Plug is not well connected or electric

socket is faulty

3. Extension cord ( see page 2 Electrical

Safety section b) or wire size too small

4. Main voltage supply too low 4. Check that main supply voltage is adequate

5. Thermal safety switch has tripped 5. Switch off unit and allow motor to cool down

Safety section b) or wire size too small

2. Thermal safety switch has tripped due

to overheating

motor

1. Pump drawing in air/low water supply 1. Ensure fittings are tight. Increase water pressure

2. Water too hot 2. Reduce temperature below 100° F

1. Not using detergent dispenser 1. Change nozzle and detergent dispenser

1. Call 1-800-330-0712

garden hose

2. Check plug, socket and fuses

3. Remove extension cord, product cannot be used

with extension cord

1. Remove extension cord, product cannot be used

with extension cord

2. Check that main supply voltage corresponds to

specifications

Turn off unit and call 1-800-330-0712

Continued on next page

www.campbellhausfeld.com

10

Page 11

Models: PW182501, PW183501

Troubleshooting Guide (Continued)

SYMPTOM CAUSE SOLUTION

Motor will not start The gun trigger is not being pulled while

starting

Low pressure testing Pump, gun or lance problem 1. Remove the black high-pressure hose from the

1. Turn the water supply off. Disconnect the garden hose

and the black high- pressure hose from the unit. This will

relieve any pressure from the pump.

2. Plug the unit in to the electrical outlet. Make sure the unit

is in the OFF position.

3. If your unit is equipped with a GFCI plug, push the top

button, then the bottom button and then top button

again. You should have a light showing on the small

window above these buttons. If no red light is showing,

you are not getting power to the unit. The unit can be

taken to a service center for repair.

4. Hook the water supply back to the unit and turn the

water on. Press the on button and see if it will start. If it

does, shut the water and the unit off, attach the gun and

hose and go to step 5.

5. With the unit in the OFF position, pull the trigger on the

gun and make sure a small stream of water is coming

out. Keep the trigger pressed while turning the unit ON.

pressure washer.

2. Hook up the garden hose.

3. Turn on the water supply the water should flow

through the pressure washer.

4. Turn on the pressure washer. The water should

shoot 8-10 feet from the pump out of the pipe

where the high-pressure hose hooks up.

5. If water does shoot 8-10 feet, then the pump is

fine. If not, then the pump needs to be cleaned.

Turn the water off to the pressure washer and call

Technical Support at 1-800-330-0712 for further

instructions.

6. If the pump is fine, then attach the black highpressure hose to the pressure washer. Remove the

nozzle from the lance.

7. Turn the water back on and trigger the gun. Water

should shoot 10-20 feet from the gun.

8. If water does not shoot 10-20 feet from the gun,

then the trigger valve in the gun is bad and the gun

needs to be replaced. If it does shoot 10-20 feet,

then the nozzle needs to be checked for clogs.

See page 9 for Nozzle Cleaning Instructions.

11

www.campbellhausfeld.com

Page 12

Operating Instructions

REGISTER YOUR PRODUCT ONLINE NOW!

http://www.campbellhausfeld.com

Limited Warranty

1. DURATION: From the date of purchase by the original purchaser as follows: One Year.

2. WHO GIVES THIS WARRANTY (WARRANTOR): Campbell Hausfeld / Scott Fetzer Company, 100 Production Drive, Harrison,

Ohio 45030, Telephone: (800) 330-0712.

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the Campbell

Hausfeld pressure washer.

4. WHAT PRODUCTS ARE COVERED UNDER THIS WARRANTY: This PW1825/PW1835 Campbell Hausfeld Pressure Washer

supplied

5. WHAT IS COVERED UNDER THIS WARRANTY: Substantial defects on material and workmanship which occur within the

duration of the warranty period with the exceptions noted below. Warrantor will also cover normal wear items for a period of 90

days from the date of original purchase against defects in material and workmanship. These wear items include high pressure

hoses, water and oil seals, o-rings, valves, lances, and spray nozzles.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED FROM

THE DATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION. If this pressure washer is used for commercial,

industrial or rental purposes, the warranty will apply for ninety (90) days from the date of purchase. Some States do not allow

limitation on how long an implied warranty lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY

DEFECT, FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD pressure washer. Some States do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

C. Any failure that results from shipping damage, accident, purchaser’s abuse, neglect or failure to install and operate pressure

washer in accordance with instructions provided in the owner’s manual(s) supplied with product.

D. Pre-delivery service, e.g. assembly, oil or lubricants and adjustment.

E. Items or service normally required to maintain the pressure washer.

F. Gasoline engine and components are expressly excluded from coverage under this limited warranty. Such components

should be returned by the purchaser to the original manufacturer or to its authorized repair stations for service.

G. Additional items not covered under the warranty:

1. Motor brushes (Electric models only).

2. Cosmetic defects that do not interfere with functionality.

3. Rusted components.

4. Pump wear or valve damage caused by using improper oil, oil contamination or by failure to follow proper oil

maintenance guidelines.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, pressure washer or

component which is defective, has malfunctioned and/or failed to conform within duration of the warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Call Campbell Hausfeld (800-330-0712) to obtain your warranty service options. Freight costs must be borne by the

purchaser.

C. Use reasonable care in the operation and maintenance of the pressure washer as described in the owner’s manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair or replacement will

be scheduled and serviced according to the normal work flow at the servicing location, and depending on the availability of

replacement parts.

This Limited Warranty applies in the U.S., Canada and Mexico only and gives you specific legal rights. You may also have other rights

which vary from state to state or country to country.

REMINDER: Keep your dated proof of purchase for warranty purposes!

www.campbellhausfeld.com

Attach it to this manual or file it for safekeeping.

12

Page 13

Voir la Garantie à la page 24 Fr pour de l’information importante sur l’utilisation commercial de ce produit.

Instructions d’Utilisation PW182501, PW183501

Veuillez lire et conserver ces instructions. Lire attentivement avant de commencer à assembler, installer, faire fonctionner ou entretenir l'appareil décrit.

Protégez-vous et les autres en observant toutes les informations sur la sécurité. Négliger d'appliquer ces instructions peut résulter en des blessures corporelles

et/ou en des dommages matériels ! Conserver ces instructions pour références ultérieures.

Nettoyeur haute

Pression à Électrique

ENREGISTREZ VOTRE PRODUIT EN LIGNE MAINTENANT ! http://www.campbellhausfeld.com

Description

Ces nettoyeurs électriques haute pression

de Campbell Hausfeld sont idéaux pour

tout projet de nettoyage domestique. Les

unités opèrent sans bruit, efficacement et

sans émissions de combustible. Chaque

modèle présente une fonction “marche-arrêt

immédiat” (ISS), qui arrête le moteur quand

le pistolet n’est pas engagé. Cela conserve

de l’eau et de l’électricité et rallonge la durée

de vie de la pompe.

Les nettoyeurs haute pression sont

actionnés par un moteur universel fiable

et peuvent être branchés commodément

dans les prises de la maison de 120V – 15

ampères. Deux modèles sont homologués

ETL pour satisfaire les normes ETL et UL aux

États-Unis et au Canada.

LIRE ET SUIVRE TOUTES LES

INSTRUCTIONS.

Figure 1 - Modèles PW182501, et PW183501

Spécifications

Modèle Pression Volt

PW182501 13,100 kPa/ 1900 psi 120

PW183501 13,100 kPa/ 1900 psi 120

Veuillez inscrire le No de modèle et le No de série à utiliser pour contacter le fabricant :

N° de modèle :

N° de série : ________________________________________________________________

Date d’achat : ______________________________________________________________

Lieu d’achat : ______________________________________________________________

Pour obtenir de l’information sur le produit, veuillez appeler le 1-800-330-0712.

______________________________________________________________

Conserver ces instructions

Ne les jetez pas

Directives De Sécurité

Ce manuel contient de l’information

très importante qui est fournie pour

la SÉCURITÉ et pour ÉVITER LES

PROBLÈMES D’ÉQUIPEMENT.

Rechercher les symboles suivants pour

cette information.

Danger

indique

une situation dangereuse

imminente qui MÈNERA à

la mort ou à des blessures

graves si elle n’est pas

évitée.

Avertissement

indique une situation

potentiellement dangereuse qui, si elle

n’est pas évitée, POURRAIT mener à la

mort ou à de graves blessures.

Attention indique

une situation potentiellement dangereuse

qui, si elle n’est pas évitée, PEUT mener à

des blessures mineures ou modérées.

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

LIRE ET SUIVRE TOUTES LES INSTRUCTIONS • CONSERVER CES INSTRUCTIONS • NE PAS JETER

© 2014 Campbell Hausfeld/Scott Fetzer IN471200AV 11/14

13 Fr

Page 14

Instructions d’Utilisation

Directives De Sécurité (suite)

Avis indique de l’information importante qui

pourrait endommager l’équipement si elle

n’est pas respectée.

IMPORTANT : Information qui exige une attention spéciale.

Symboles De Sécurité

Les symboles de sécurité suivants apparaissent dans

l’ensemble de ce manuel pour vous aviser des dangers et

précautions importants de sécurité.

Lire le manuel

d’abord

Risque de

blessure

INSTRUCTIONS PORTANT SUR UN RISQUE D’INCENDIE, UN

CHOC ÉLECTRIQUE OU DES BLESSURES AUX PERSONNES

Ce manuel contient des informations concernant la sécurité,

le fonctionnement et l’entretien. Si vous avez des questions,

appeler le 1-800-330-0712 pour le service à la clientèle.

En utilisant les outils, il faut suivre les

précautions de base, y compris ce qui suit :

PROPOSITION 65 DE CALIFORNIE

Ce produit ou son cordon peuvent contenir

des produits chimiques, y compris du plomb,

relevés par l’État de Californie comme cause de cancer, d’anomalies

congénitales ou d’autres problèmes reproductifs. Lavez-vous les

mains après toute manipulation.

GÉNÉRALITÉ

a. Pour réduire les risques de chocs électriques,

d’incendie ou de blessures aux personnes, lire toutes

les instructions avant d’utiliser l’outil. Ne pas suivre

les avertissements, les dangers et les mises en garde

pourrait causer la MORT ou de GRAVES BLESSURES.

b. Se familiariser avec ce produit, ses commandes et son

utilisation. Suivez toutes les instructions. Contacter votre

représentant Campbell Hausfeld si vous avez des questions.

1-800-330-0712

c. Seules les personnes familières avec ces règles

d’utilisation sans danger devraient utiliser cette

unité.

d. Suivez tous les codes de sécurité ainsi que l’Occupational

Safety and Health Act (OSHA).

AIRE DE TRAVAIL

a. Gardez le secteur d’opération libre de toutes personnes.

b. Garder l’aire de travail propre et bien éclairée. Les établis

encombrés et les coins sombres augmentent les

risques de chocs électriques, d’incendie et de

blessures aux personnes.

Risque

d’explosion

Protection

oculaire et

auditive

Risque

d’incendie

Risque de choc

électrique

Risque de

tomber

c. Ne pas faire fonctionner l’outil dans une atmosphère

explosive comme en présence de liquides, gaz ou poussières

inflammables. L’outil peut produire des étincelles

menant à une inflammation de poussières ou de

fumées.

d. NE pulvisérez JAMAIS de liquides inflammables

et n’utilisez jamais le pulvérizateur haute pression dans des

endroits contenant de la poussière, des liquides ou des

vapeurs combustibles.

e. Ne faites jamais fonctionner cet appareil dans un édifice

fermé ou dans ou près d’un environnement explosif.

SÉCURITÉ PERSONNELLE

a.

Rester vigilant. Il faut regarder ce que vous faites et utiliser

son sens commun en faisant fonctionner un outil. Ne pas

faire fonctionner l’appareil si vous êtes fatigué ou sous

l’influence de drogues, d’alcool ou de médicaments. Un

moment d’inattention en faisant fonctionner l’outil augmente

le risque de blessures.

b. Il faut s’habiller correctement. Fermer les orteils

chaussures (pas de tongs)

Ne pas porter de bijoux

ou de vêtements amples. Attacher les cheveux

longs. Garder les cheveux, les vêtements et les

gants loin des pièces mobiles. Les vêtements amples, les

bijoux ou les cheveux longs augmentent le risque

de blessures si quelque chose se prend dans les

pièces mobiles.

c. Ne pas trop se pencher. Garder bon pied et bon

équilibre en tout temps. Ceci permet d’avoir un

meilleur contrôle de l’outil dans les situations imprévues.

Risque d’injection ou de blessures

pas de jets vers les personnes. Ce produit doit être utilisé

seulement par un opérateur formé. Retirez toujours la tige

du pistolet avant de nettoyer les débris de l’embout.

graves. Restez loin du gicleur. Ne déchargez

d. Restez loin du gicleur. NE dirigez JAMAIS le jet

haute pression vers une personne, un animal, ou

vous-même.

e. Ne mettez jamais la main ou les doigts sur l’embout de

pulvérisartion en opérant l’appareil.

f. N’essayez jamais d’arrêter ou de dévier les fuites vers toute

partie du corps.

S’assurer que l’outil n’est utilisé

dans l’aire de travail portent un équipement de protection oculaire

ANSI Z87, et s’il y a lieu, d’autre équipement de protection approprié

comme une protection de la tête, auditive, des gants, des bottes de

caoutchouc, des vêtements protecteurs en utilisant et exécutant la

maintenance. De graves blessures oculaires ou une perte auditive

permanente pourraient en résulter.

que lorsque l’opérateur et tout autre personnel

g. Haute pression – le pistolet a un recul – Tenir le pistolet des

deux mains.

h. Garder le tuyau loin d’objets tranchants. Les tuyaux

qui éclatent peuvent causer des blessures. Examiner

régulièrement les tuyaux et les remplacer s’ils sont

endommagés. Ne jamais essayer de réparer un tuyau

endommagé.

SÉCURITÉ ÉLECTRIQUE

Risque d’électrocution :

a. Ce produit est fourni avec un disjoncteur de fuite à la terre

intégré dans la prise du cordon. Assurez-vous d’inspecter le

cordon et le disjoncteur de fuite à la terre avant de l’utiliser.

14 Fr

Page 15

Modèles PW182501, et PW183501

Directives De Sécurité (suite)

Toute réparation ou tout remplacement du cordon doit se

faire par un technicien électrique qualifié (agréé ou certifié).

S’il faut remplacer la fiche ou le cordon, utilisez seulement

des pièces de rechange identiques.

b. NE JAMAIS utiliser de rallonge avec ce produit.

c. Inspecter le cordon avant d’utiliser l’appareil - Ne pas utiliser

si le cordon est endommagé.

d. Garder toutes les connexions électriques sèches et loin du

sol.

e. Ne pas toucher la fiche avec les mains humides.

f. Ne pas pulvériser d’appareils électriques et de câblage.

UTILISATION ET ENTRETIEN DE L’OUTIL

N’utilisez pas de pression qui dépasse la

pression d’exploitation de toute pièce

(fl exibles, raccords, etc.) du système sous pression. Assurez-vous que

tout équipement et accessoires sont du calibre voulu pour résister à

la pression d’exploitation maximum de l’appareil.

a. Il faut entretenir l’outil avec soin. Un outil bien entretenu

réduit le risque de problèmes et est plus facile à contrôler.

b. Assurez-vous que tous les dispositifs de sécurité

fonctionnenet correctement avec chaque utilisation. NE

retirez PAS et ne modifiez pas toute pièce du pistolet ou de

l’appareil.

c. Ne jamais faire fonctionner la machine sans les appareils

branchés correctement la machine (poignée, Assemblée de

pistolet/lance, buse, etc..).

d. Pointer le pistolet dans une direction sans danger. L’unité

commencera à pulvériser lorsque la gâchette est pressée

si l’interrupteur « marche/arrêt » est à la position «ON»

(Pulvérisateur à pression (marche).

e. Sachez comment arrêter ce produit et dégager rapidement la

pression. Soyez bien au fait des contrôles.

f. Engagez toujours le verrou de sécurité de la gâchette en

position sûre à la fin de la pulvérisation même si ce n’est que

pour quelques instants.

g. N’engagez jamais en permanence le mécanisme de la

gâchette sur le pistolet.

h. Suivez toujours les recommandations du fabricant de

détergents pour la bonne utilisation du produit. Protégez

toujours les yeux, la peau et le système respiratoire du

détergent.

i. Ne débranchez jamais le flexible de décharge de haute

pression de la machine tandis que le système est sous

pression. Pour décompresser, coupez le courant et l’eau,

puis pressez la gâchette du pistolet 2 ou 3 fois.

j. Débrancher l’appareil lorsqu’il n’est pas utilisé.

k. Suivez les instructions d’entretien spécifiées dans le manuel.

o. Utilisez seulement le gicleur fourni avec l’appareil.

p. Ne laissez jamais la rallonge sans surveillance tandis que la

machine est en marche.

q. Tenez toujours le pistolet et la rallonge bien fermement en

démarrant et en faisant fonctionner l’appareil.

r. Ne laissez JAMAIS l’appareil fonctionner avec la gâchette

dégagée (arrêt) pendant plus d’une minute. L’accumulation de

chaleur pourrait endommager la pompe.

s. NE rangez JAMAIS le pulvérizateur haute pression à l’extérieur

ou à des endroits où il pourrait geler. Le gel peut endommager

gravement la pompe.

t. Le pulvérisateur à pression n’est pas conçu pour pomper l’eau

chaude. Ne pas brancher à l’alimentation d’eau chaude.

SERVICE

a. En réparant ou faisant l’entretien d’un outil, utiliser seulement

des pièces de rechange identiques. Utiliser seulement des

pièces autorisées.

Entretien d’un Appareil à Double

Isolation

Dans un appareil à double isolation,

deux systèmes d’isolation sont

fournis à la place d’une mise à la

terre. Aucun système de mise à la

terre n’est fourni sur un appareil à

double isolation et aucun moyen de

mise à la terre ne doit y être ajouté.

Faire l’entretien d’un appareil à

double isolation demande des soins

Symbole de double

isolement

attentifs et une connaissance parfaite du système et ne sera

exécuté que par des personnes compétentes. Les pièces de

rechange pour un appareil à double isolation doivent être identiques

aux pièces qu’elles remplacent. Un appareil à double isolation doit

porter l’inscription « DOUBLE ISOLATION » (Double Insulated). Le

symbole peut aussi se trouver sur l’appareil.

CONSERVER CES INSTRUCTIONS

NE LES JETEZ PAS

NOTE : Les symboles DANGER, AVERTISSEMENT, ATTENTION ET AVIS

ainsi que les instructions de ce manuel ne peuvent pas couvrir toutes

les conditions et situations qui pourraient se produire. L’opérateur doit

comprendre que le bon sens et des précautions sont des facteurs qui ne

peuvent pas être inclus dans ces produits, mais doivent être fournis par

l’opérateur.

Dommage à l’equipement.

l. Mettez TOUJOURS l’eau à “ON” avant de mettre le

pulvérizateur haute pression en marche“ON”. Faire

fonctionner la pompe à sec cause de graves dommages.

m. Ne faites pas fonctionner le pulvérizateur haute pression avec

l’écran d’entrée d’eau retiré. Gardez l’écran libre de tous

débris et sédiments.

n. NE faites JAMAIS fonctionner le pulvérizateur haute

pression avec des pièces brisées ou manquantes. Vérifiez

régulièrement l’équipement et réparez immédiatement toutes

pièces usées ou endommagées.

15 Fr

Page 16

Instructions d’Utilisation

Déballage

Tuyau haute

pression

Interrupteur

marche/arrêt

Prise du tuyau du

pistolet

Poignée

Cordon

d’alimentation

Lance

PW182501

Pistolet à

gâchette

Dès que l’appareil est déballé, inspectezle attentivement pour tout signe de

dommages en transit. Vérifiez s’il y a

des pièces desserrées, manquantes

ou endommagées. Assurez-vous de

resserrer tous les raccords, boulons, etc.

avant d’utiliser la laveuse à pression.

Vérifiez pour vous assurer que tous les

accessoires fournis sont inclus avec

l’appareil. S’il manque toute pièce, NE

RETOURNEZ PAS L’APPAREIL AU

DÉTAILLANT. Consultez le numéro de

modèle de l’appareil (sur l’étiquette du

numéro de série du cadre de la laveuse à

pression) et appelez le 1-800-330-0712

pour les pièces de rechange.

Ne faites pas

fonctionner l’appareil

s’il est endommagé pendant l’expédition, la

manipulation ou l’utilisation. Des dommages

peuvent mener à l’éclatement et provoquer des

blessures ou des dommages à la propriété.

UTILISATIONS RECOMMANDÉES POUR

CETTE LAVEUSE À PRESSION

◆ Terrasse

◆ Revêtement

◆ Véhicules

◆ Gouttières (avec buse à angle droit)

Cordon

Poignée

d’alimentation

Tuyau haute

pression

Interrupteur

marche/arrêt

Prise du tuyau

PW183501

d’eau

Figure 2 - Composants de laveuse à pression

Lance

Pistolet à

gâchette

AUTRES ARTICLES NON INCLUS

◆ ANSI Z87 Protection oculaire

◆ Boyau d’arrosage

NOTE: Seulement pour le PW183501 En déroulant le tuyau, tenez la poignée

de l’unité. Cela empèchera l’unité de se

renverser.

Accessories

BROSSE

(PW183501)

BUSE

TURBO(PW183501)

BUSE À ANGLE

DROIT (PW183501)

BOUTEILLE DE DÉTERGENT

(Deux modèles)

Ensemble de disponibles à l'achat

Numéro de pièce PW091400AV

16 Fr

Page 17

ASSEMBLAGE ET PRÉOPÉRATION

Assurez-vous toujours que le tuyau d’arrosage

est allumé avant d’allumer le nettoyeur haute pression. Faire marcher le

nettoyeur haute pression à sec endommagera les joints de la pompe.

Ne démontez pas la

lance ou le pistolet de ce nettoyeur haute

pression. Des pièces de rechange ne sont pas disponibles pour le

pistolet ou la lance.

Modèles PW182501, et PW183501

PW182501, et PW183501

1. Attachez les crochets de stockage (voir la figure 3).

2. Glisser la poignée sur l'unité (1), attachez avec 2 vis Phillips

(voir la figure 4).

3. Attachez le tuyau haute pression au la sortie haute pression

(voir la figure 8).

4. Attachez le tuyau haute pression au pistolet (voir la figure 5).

5. Attachez la lance au pistolet torsion et de verrouillage,

attachez la lance au embout en appuyant sur le bouton de

connexion facile (voir la figure 6 & 7).

6. Attachez le tuyau d’arrosage à l’unité (voir les figures 9).

7. Appuyez sur le bouton Easy Connect lors de l'insertion

raccord rapide(voir la figure 5, 7 & 8).

1

2

3

Figure 3 - Attachez les crochets de

stockage

(PW182501 seulement)

Figure 7- Attachez la lance au embout.

Figure 8 - Attachez le tuyau d’arrosage à l’unité

Entrée d’eau

4

Figure 9 - Attachez le tuyau d’arrosage à

l’unité

Figure 5 - Attachez le tuyau haute pression au

pistolet (tous les modèles)

Figure 4 - Glisser la poignée sur

(PW182501 seulement)

l'unité

Figure 6 - Attachez la lance au pistolet ou

bouteille de détergent

17 Fr

Page 18

Instructions d’Utilisation

ASSEMBLAGE ET PRÉOPÉRATION (SUITE)

VERROU DE SÉCURITÉ DE LA GÂCHETTE

En position engagée, le verrou de sécurité de la gâchette

empêche le déclenchement accidentel du pistolet. Poussez

entièrement le verrou vers le bas pour l’engager (voir les

figures 10).

Engagez toujours le verrou de sécurité de la gâchette lorsque

vous n’utilisez pas l’appareil.

Gâchette

Verrou de

Sécurité

Figure 10 - Verrou de sécurité de la gâchette

FONCTIONNEMENT

IMPORTANT !

Ce pulvérisateur de lavage est équipé d’un microrupteur

sensible au débit d’eau. Cet interrupteur de Marche/Arrêt

Instantané (Instant Start/Stop - ISS) est sensible au débit

d’eau dans la pompe. Quand la gâchette est lâchée, le

débit d’eau à travers la pompe s’arrête. Le ISS coupe le

moteur automatiquement afin de protéger la pompe contre

le surchauffage.

FONCTIONNEMENT

1. Faire circuler l’eau.

2. Tirez la gâchette du pistolet.

3. Tourner l’interrupteur à « ON » (en marche)

4. Lâcher la gâchette. Le moteur du pulvérisateur de lavage

s’arrêtera.

5. Pour pulvériser de nouveau, tirer sur la gâchette. Le moteur

et la pompe se remettront en marche.

REMARQUE: Le moteur pourrait fonctionner de temps en

temps afin de fournir de l’eau fraîche à la pompe (même

si la gâchette n’est pas actionnée). Ceci est normal et

n’endommagera pas le modèle.

Toujours tourner l’interrupteur « ON/

OFF » (marche/arrêt) à la position « OFF »

(arrêt), et ensuite appuyer sur la gâchette pour dissiper la pression

avant de débrancher le cordon d’alimentation.

Risque de dommage à l’équipement.

Assurez-vous toujours que l’interrupteur

ON/OFF (MARCHE/ARRÊT) de l’appareil est en position « OFF » et

que l’appareil est débranché avant de le ranger.

Risque d’injection. Le modèle

pulvérisera lorsque la gâchette est

actionnée si l’interrupteur « ON/OFF » (MARCHE/ ARRÊT) est dans la

position « ON » (EN MARCHE). Toujours pointer le pistolet dans une

direction hors de danger.

PRÉPARATION DE LA SURFACE

La procédure de nettoyage suivante vous aide à vous organiser

pour la tâche de nettoyage et pour vous assurer d’atteindre

les meilleurs résultats dans le temps le plus court. GALLONS

À LA MINUTE (G/MIN), plus d’eau à la minute peut se traduire

par un nettoyer plus rapide, tout particulièrement en lavant

des matériaux comme la boue et le goudron. DISJONCTEUR

DE FUITE À LA TERRE (GFCI), le disjoncteur de fuite à la terre

protège l’utilisateur de toute électrocution accidentelle (pour les

laveuses à pression alimentées par l’électricité seulement).

Rappelez-vous d’utiliser les techniques de pulvérisation/

nettoyage mentionnées dans les sections suivantes.

Avant de commencer un travail de nettoyage à haute pression,

préparez la surface à nettoyer. Enlevez les meubles et assurezvous que toutes les fenêtres et portes sont bien fermées.

Protégez aussi toutes vos plantes et arbres près du secteur à

nettoyer en couvrant d’une toile pour ne pas les pulvériser de

détergent.

DÉMARRAGE

Utilisez TOUJOURS cette procédure de démarrage pour assurer

un démarrage exact et sans danger.

Si l’eau a gelé dans le pulvérizateur à haute

pression, laissez-la dégeler à température

ambiante avant de commencer. NE versez PAS d’eau chaude sur ou

dans la pompe; les pièces intérieures seraient endommagées. Vérifi er

les fuites.

1. Assurez-vous que l’interrupteur de courant est à la position «

OFF » (arrêt).

2. Fixez un tuyau d’arrosage côté entrée de la pompe et

raccordez-le à l’alimentation d’eau. Utilisez un flexible de D.I.

de 5/8 po et d’une longueur de 50 pi (15 m) ou moins.

Certains codes de plomberie locaux exigent un

dispositif de prévention de retour d’eau en connectant à une source

d’eau fraîche. Installez un dispositif de prévention de retour en amont de

la pompe, au besoin.

a. Si la pression d’eau d’alimentation dépasse 690 kPa,

installez une soupape régulatrice d’eau au raccord du tuyau

d’arrosage.

b. Ne dépassez pas 38° C de température d’eau

d’alimentation.

NOTE : L’approvisionnement d’eau d’alimentation doit avoir un

débit minimum de 19 lpm.

4. Ouvrez l’alimentation d’eau.

Ne laissez jamais l’appareil fonctionner à sec.

Assurez-vous que l’alimentation d’eau est en

marche avant de faire fonctionner l’appareil.

5. Enfoncez et tenez la gâchette du pistolet jusqu’à ce que la

pulvérisation d’eau de la buse indique que tout l’air est sorti

du système. Placez le verrou de sécurité de gâchette.

6. Branchez le cordon d’alimentation dans une prise de courant

de 120 volts mise à la terre qui est sur un circuit réservé. Ne

pas utiliser de rallonges. Enfoncez le bouton de réinitialisation

sur l’adaptateur de fiche à disjoncteur de fuite à la terre. Vous

18 Fr

Page 19

FONCTIONNEMENT (SUITE)

devez faire cela chaque fois que l’appareil est branché dans

une prise. (Figure 18)

BRANCHEMENT DU SYSTÈME

1. Branchez le cordon dans la prise mise à la terre de 120V.

2. Faire circuler l’eau.

3. Déverrouiller le verrou de la gâchette en déplaçant le verrou

de droite à gauche.

4. Appuyer sur et tenir la gâchette du pistolet pendant

une minute afin de dissiper la pression et d’enlever l’air

emprisonné dans le système.

5. Tourner l’interrupteur « ON » (en marche).

RINÇAGE INITIAL À HAUTE PRESSION

Pulvérisez d’eau la surface à nettoyer pour enlever toute

poussière ou saleté accumulée sur la surface. Ceci permet

au détergent de s’attacher à la poussière en profondeur qui a

pénétré dans la surface à nettoyer.

Enfoncer la gâchette du pistolet 3 à 5 fois pour sortir tout air

enfermé dans le système.

Ajuster l’angle d’éventail de pulvérisation

1. Durant le travail, la lance est affectée par la pression ; alors, il

faut la tenir fermement à deux mains et pointer la buse vers le

plancher.

2. Activer en tirant de la gâchette du pistolet pulvérisateur/

poignée.

3. Ajustez la distance selon la surface à nettoyer ; ceci règlera

aussi la pression de l’embout.

4. Le motif de pulvérisation et l’intensité peuvent être changés

en tournant la buse de pulvérisation au bout de la lance (voir

la figure 12 & 13). Pour empêcher toute blessure, ne jamais

mettre les mains devant la lance.

La pression s’ajuste aussi en se déplaçant plus près ou plus loin

de la surface de nettoyage et en ajustant l’angle d’éventail de

pulvérisation tel qu’indiqué. (Figure 14)

Modèles PW182501, et PW183501

Réinitialisation

Figure 11 - Prise de terre/bouton de

réinitialisation

Figure 12 - Réglage de pulvérisation

Figure 13 - Ajustez le motif de pulvérisation

Figura 14 - Angle optimum par rapport à la

surface à nettoyer

19 Fr

Page 20

Instructions d’Utilisation

FONCTIONNEMENT (SUITE)

Angle à la surface de nettoyage

En pulvérisant l’eau contre une surface, vous pouvez obtenir

un impact maximum en frappant la surface directement. Ce

type d’impact peut toutefois faire pénétrer les particules de

poussières dans la surface et ainsi empêcher d’avoir l’action

recherchée.

L’angle optimum de pulvérisation d’eau contre une surface de

nettoyage est de 45 degrés.

Pulvérisez l’eau contre une surface à un angle de 45 degrés pour

atteindre le meilleur impact et retirer efficacement les débris.

Distance de la surface à nettoyer

La distance entre l’embout de pulvérisation et la surface de

nettoyage est un autre facteur qui affecte la force d’impact de

l’eau. La force d’impact de l’eau augmente lorsque l’embout se

rapproche de la surface.

Comment éviter d’endommager les surfaces

Les dommages aux surfaces à nettoyer se produisent à cause

de la force d’impact de l’eau qui dépasse la durabilité de la

surface. Vous pouvez varier la force d’impact en contrôlant

l’angle de la buse de pulvérisation sur la surface de nettoyage et

la distance de la surface de nettoyage et en changeant de buse

de pulvérisation. N’utilisez JAMAIS de jet étroit à fort impact sur

une surface qui pourrait être endommagée. Évitez de pulvériser

les fenêtres avec un jet étroit à fort impact. Ceci pourrait casser

la fenêtre. Le meilleur moyen d’éviter d’endommager les surfaces

est de suivre ces étapes :

1. Avant de tirer le pistolet, assurez-vous que la buse à

raccordement rapide que vous utilisez est appropriée pour

l’application.

2. Placez la buse de pulvérisation à environ 1,22 à 1,52 m (4 à 5

pieds) de la surface de nettoyage. Tenez ensuite la lance et la

buse de pulvérisation à un angle de 45 degrés sur la surface

de nettoyage. Tirer de la gâchette du pistolet.

3. Variez l’angle du jet à eventail et la distance à la surface à

nettoyer jusqu’à ce que vous atteigniez l’efficacité optimale

de nettoyage sans endommager la surface.

APPLICATION DE DÉTERGENT

NOTE : Utilisez seulement les détergents formulés pour les

pulvérizateurs haute pression. Testez le détergent dans un

endroit retiré avant de l’utiliser. NE PAS utiliser de javellisant dans

la laveuse à pression.

Détergents

Utiliser des détergents peut réduire de beaucoup le temps de

nettoyage et aider à retirer les taches rebelles. De nombreux

détergents sont faits pour le pulvérizateur haute pression

pour des tâches de nettoyage précises. Les détergents de

pulvérizateur haute pression sont aussi épais que l’eau. Le

fait d’utiliser des détergents plus épais - comme le savon

de vaisselle - bloquera le système d’injection chimique et

empêchera l’application de détergent.

Appliqués sur la surface, les détergents prennent du temps

pour s’attaquer à la poussière et à la saleté. Les détergents

fonctionnent mieux appliqués à basse pression.

Vous pouvez nettoyer efficacement les surfaces en combinant

l’action chimique des détergents avec les rinçages à haute

pression. Pour les surfaces verticales, appliquez le détergent

en commençant au bas pour aller vers le haut. La méthode

empêche le détergent de glisser vers le bas et de faire des

coulisses. Commencez le rinçage haute pression au bas et allez

vers le haut. Pour les taches particulièrement rebelles, utilisez

une brosse en plus des détergents et du rinçage haute pression.

1. Suivez les directives du fabricant sur l’étiquette pour les

bonnes concentrations de mélange de savon/détergents.

La proportion de détergent savon à eau dans la pompe est

d’environ 10% (1 à 10).

◆ PW182501 et PW183501: Versez du savon dans le récipient

à savon. Ajustez la lance selon la position du savon. Tourner

à basse pression (Figure 20)

Conseils Généraux de Nettoyage

1. Appliquez le détergent pour couvrir entièrement la surface à

nettoyer, de bas en haut pour éviter qu’il ne glisse vers le bas

et fasse des marques. Attendez quelques minutes pour que

le détergent s’attaque à la poussière et à la saleté. Utilisez

une brosse pour frotter un peu les endroits rebelles. Ne

laissez jamais le détergent sécher sur la surface à nettoyer.

2. Rincer à haute pression

PUISSANCE DE NETTOYAGE

Le moyen le plus facile de contrôler la puissance de nettoyage

de votre nettoyeur à pression est de changer la distance de la

surface à nettoyer. Commencez à pulvériser avec un motif large

d’éventail tout en vous plaçant à quelques pieds de la surface.

Rapprochez-vous lentement de l’objet que vous nettoyez et

ajustez le motif de pulvérisation au besoin jusqu’à ce que vous

trouviez la technique de nettoyage la plus efficace.

DERNIER RINÇAGE

Le dernier rinçage devrait commencer du bas vers le haut.

Assurez-vous de bien rincer toute la surface et de retirer toute

trace de détergent.

PROCÉDURE DE DÉCOMPRESSION

Pour réduire les risques de blessures ou de dommages à la

propriété, suivez toujours cette procédure lorsque la pulvérisation

est arrêtée, à la fin du travail et avant de vérifier ou réparer toute

pièce du système.

1. Engagez le verrou de sécurité de la gâchette.

2. Fermez l’appareil.

3. Coupez l’alimentation d’eau.

4. Désengagez le verrou de sécurité de la gâchette et pressez

sur la gâchette pour décompresser.

5. Réengagez le verrou de sécurité de la gâchette.

6. En vérifiant ou réparant l’appareil, retirez la fiche de la prise

murale du mur.

7. Avant de ranger pour la nuit, un rangement à long terme ou le

transport de l’appareil, coupez de l’alimentation d’eau.

ARRÊT

1. Assurez-vous que tout le détergent est vidé du système.

2. Coupez le moteur.

3 Fermez l’alimentation d’eau.

20 Fr

Page 21

Modèles PW182501, et PW183501

FONCTIONNEMENT (SUITE)

4. Après avoir coupé le moteur et l’alimentation d’eau, engagez

le pistolet pour retirer la pression du système.

NE fermez jamais l’alimentation d’eau avant

de couper le moteur. Cela pourrait endommager

la pompe et/ou moteur.

NE déconnectez jamais le fl exible de décharge

de haute pression de l’appareil tandis que

le système est sous pression. Décompressez en coupant le moteur,

fermant l’alimentation d’eau et pressant la gâchette 2 ou 3 fois.

5. Après chaque utilisation, essuyez les surfaces du

pulvérizateur haute pression avec un chiffon propre et

humide.

RANGEMENT

• Ne rangez pas le pulvérizateur haute pression à l’extérieur.

• Ne rangez pas le pulvérizateur haute pression à un endroit où

il pourrait geler à moins de le préparer pour l’hiver.

Instructions Pour L’hiver

1. Déconnectez le flexible haute pression de la pompe.

2. Insérez une longueur de tuyau d’arrosage de 12 à 14 po dans

l’entrée de la pompe.

3. Placez un entonnoir dans l’autre extrémité du tuyau

d’arrosage.

Lisez les instructions du fabricant pour

manipuler et éliminer correctement

l’antigel RV.

4. Versez environ 0,18 L d’antigel RV dans l’entonnoir.

5. Secouez un peu l’interrupteur marche/arrêt jusqu’à ce que

l’antigel RV sorte de la sortie de la pompe.

6. Déconnectez le flexible haute pression du pistolet et drainez

le flexible. Tenez le pistolet et la tige en position verticale et

pressez la gâchette pour drainer toute l’eau.

INSTRUCTIONS DE NETTOYAGE DE L’EMBOUT

Un embout bloqué ou partiellement bloqué peut provoquer une

réduction prononcée d’eau sortant de l’embout et alors l’appareil

aura une pulsion en pulvérisant.

Pour nettoyer l’embout :

• Éteindre l’appareil.

• Éteindre l’alimentation d’eau. Dégager toute pression dans le

tuyau en pressant la gâchette 2 à 3 fois.

• Retirer la lance du pistolet.

• Tourner l’embout à un réglage de jet étroit. Ceci ouvre les

lames en éventail.

• Utiliser le nettoyeur de buse inclus ou un trombone déplié et

insérer le fil dans le trou de l’embout pour ensuite utiliser un

mouvement de va et vient jusqu’à ce que les débris soient

débloqués (se reporter à la figure 15).

• Retirer tous autres débris en rinçant l’embout avec de l’eau.

Pour ce faire, retirer la lance du pistolet, mettre l’extrémité du

tuyau d’arrosage (l’eau courant) contre l’extrémité de la buse

pour pousser l’eau et les débris hors de l’ouverture arrière de

la lance.

CONSEILS POUR PROLONGER LA DURÉE DE VIE DE VOTRE

PULVERIZATEUR HAUTE PRESSION

1. Ne faites jamais fonctionner l’appareil sans eau.

2. Votre pulvérizateur haute pression ne doit pas pomper d’eau

chaude. Ne connectez jamais votre pulvérizateur haute

pression à une source d’eau chaude car cela réduira de

beaucoup la vie de la pompe.

3. Faire fonctionner l’appareil pendant plus d’une minute sans

pulvériser d’eau fera accumuler la chaleur dans la pompe.

Faire fonctionner l’appareil sans pulvériser d’eau pourrait

endommager les composants de la pompe.

ENTRETIEN

Respectez les intervalles d’entretien régulier pour assurer

une performance maximum et une longue durée de vie du

pulvérizateur. Reportez-vous à l’horaire d’entretien recommandé.

Si vous faites fonctionner votre pulvérizateur haute pression dans

des conditions poussiéreuses, faites les vérifications d’entretien

plus souvent.

HORAIRE D’ENTRETIEN

Horaire d’entretien Action nécessaire

Chaque jour Vérifiez le tamis d’entrée d’eau et le filtre

INFORMATION TECHNIQUE ET POUR LES

CONSOMMATEURS

Laveuses à pression à orientation horizontale

Aspiration de détergent de la pompe

Rapport d’eau à détergent 10 à 1 (10 % détergent)

Exigences d’alimentation d’air

Pression d’entrée minimale 138 kPa (20 lb/po²)

Pression d’entrée maximale 690 kPa (100 lb/po²)

Température d’entrée maximale 37,7 ˚C (100 ˚F)

Débit d’entrée minimal 5 g/min (19 l/min)

Taille de boyau d’arrosage

d’entrée

Longueur de boyau d’arrosage

15,9 mm (5/8 po) de

D.I.

15,24 m (50 pi)

d’entrée maximale

Embout Nettoyeur de

buse

Figure 15

21 Fr

Page 22

Instructions d’Utilisation

Guide De Dépannage

Symptôme Cause(s) possible(s) Action corrective

Faible pression et/ou pompe

tourne de manière irrégulière

Forte pompage à l’entrée et

faible pression

Pression fluctuante 1. Pompe aspire de l’air 1. Assurez-vous que les flexibles et raccords sont

Chutes de pression après la

période d’utilisation normale

Laveuse à pression ne

démarre pas

Le moteur s’arrête

soudainement

L’appareil commence à fumer Moteur surchauffé, surchargé ou

Pompe bruyante/pompe

fonctionne de manière

irrégulière

Ne tire pas de détergent 1. En n’utilisant pas la position du savon 1. Ajustez l’embout à la position du savon

Le moteur ne démarre pas La gâchette du pistolet n’est pas tirée au

1. Embout usé 1. Remplacez en utilisant un embout

2. Filtre d’entrée de la pompe bloquée 2. Nettoyez. Vérifiez plus souvent

3. Entrée restreinte 3. Vérifiez le tuyau d’arrosage qui pourrait être

4. Fuite de flexible haute pression 4. Remplacez le flexible haute pression

5. Pompe aspire de l’air 5. Assurez-vous que les tuyaux et raccords soient

Particules étrangères dans la soupape

d’entrée ou de décharge ou soupapes de

décharge et/ou entrée usées

2. Embout bloqué 2. Nettoyer ou remplacer.

1. Gicleur usé 1. Vérifiez et remplacez

2. Embout en position de faible kPa 2. Reculez l’embout à la position de haute pression

1. Le disjoncteur de fuite à la terre s’est

déclenché.

2. La fiche n’est pas bien branchée ou la

prise électrique est défectueuse

3. Rallonge trop (voir page 17Fr chiffre de

sécurité électrique b) ou taille du fil trop

petite

4. Alimentation de tension principale trop

basse

5. L’interrupteur de sécurité thermique a

été déclenché

1. Rallonge trop (voir page 17Fr chiffre de

sécurité électrique b ) ou taille du fil trop

petite

2. L’interrupteur de sécurité thermique a

été déclenché à cause de surchauffe

endommagé

1. Pompe aspire de l’air/faible alimentation

d’eau

2. Eau trop chaude 2. Réduisez la température sous 38°C

2. Blocage, tortillement ou trou dans le

flexible d’aspiration du détergent

3. Flexible trop long 3. Utilisez seulement la longueur fournie lors de

commencement

enfoncé ou tortillé. Vérifiez le débit d’eau d’entrée

bien serrés

Nettoyez ou remplacez les soupapes. Consultez le

centre de réparations.

serrés. Drainez l’air du tuyau d’arrosage