Page 1

h

Z SERIES

CONTROL PANEL FOR 230V OPERATORS

INSTALLATION MANUAL

ZM3E - ZM3EC

Englis

Page 2

2

319U75

2.0

“IMPORTANT INSTALLATION, SAFETY INSTRUCTIONS”

“CAUTION: IMPROPER INSTALLATION MAY CAUSE SERIOUS DAMAGE, FOLLOW ALL INSTALLATION INSTRUCTIONS CAREFULLY”

“THIS MANUAL IS ONLY FOR PROFESSIONAL INSTALLERS OR QUALIFIED PERSONS”

1 Legend of symbols

This symbol indicates sections to be read with particular care.

This symbol indicates sections concerning safety.

This symbol indicates notes to communicate to users.

ENGLISH

2 Intended use and application

2.1 Intended use

The ZM3 control panel is designed to command the following swing-gate operators ATI, AXO, FAST, FERNI, FROG, KRONO.

The ZM3EC control panel is engineered to command CBX - F4000 industrial doors. It comes with its own safety release and buttons.

The use of this product for purposes other than as described above and installation executed in a manner other than as

instructed in this technical manual are prohibited.

2.2 Application

Make sure you respect the distances and cable diameters as shown in “cable types and minimal thicknesses” table.

The overall power of the motors must not exceed 750 W.

3 Reference Standards

For its quality processes management Came Cancelli Automatici is ISO 9001:2000 certified, and for its environmental management it is

ISO 14001 certified. Came designs and manufactures entirely in Italy.

This product complies with the following standards: see Declaration of Compliance.

4 Description

This product is engineered and manufactured by CAME cancelli automatici s.p.a. and complies with current safety regulations.

Guaranteed 24 months if not tampered with.

The control panel works on 230V a.c. of power, 50/60Hz frequency.

Both command and control devices and accessories are 24V powered. Warning! Accessories must not exceed 35 W overall.

All connections are protected by quick fuses, see table.

The input and output contact functions, the timing settings and users’ management, are set and viewed on the display, which is run by

software.

TECHNICAL FEATURES

Power supply 230V - 50/60Hz

max. rated power 750W

Power draw when idling 85mA

Max power of 24V accessories 35W

Insulation rating II

Material ABS

Protection rating IP54

operating temperature -20 / +55°C

FUSES

protection: fuse type:

Electrolock 3.15A-F

Electronic board (power supply line) 5A-F

Accessories 1.6A-F

Control devices 630mA-F

2.0 01/2009 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

319U75 ver.

2 - Manual code:

Pag.

Page 3

#!-%

3

319U75

2.0

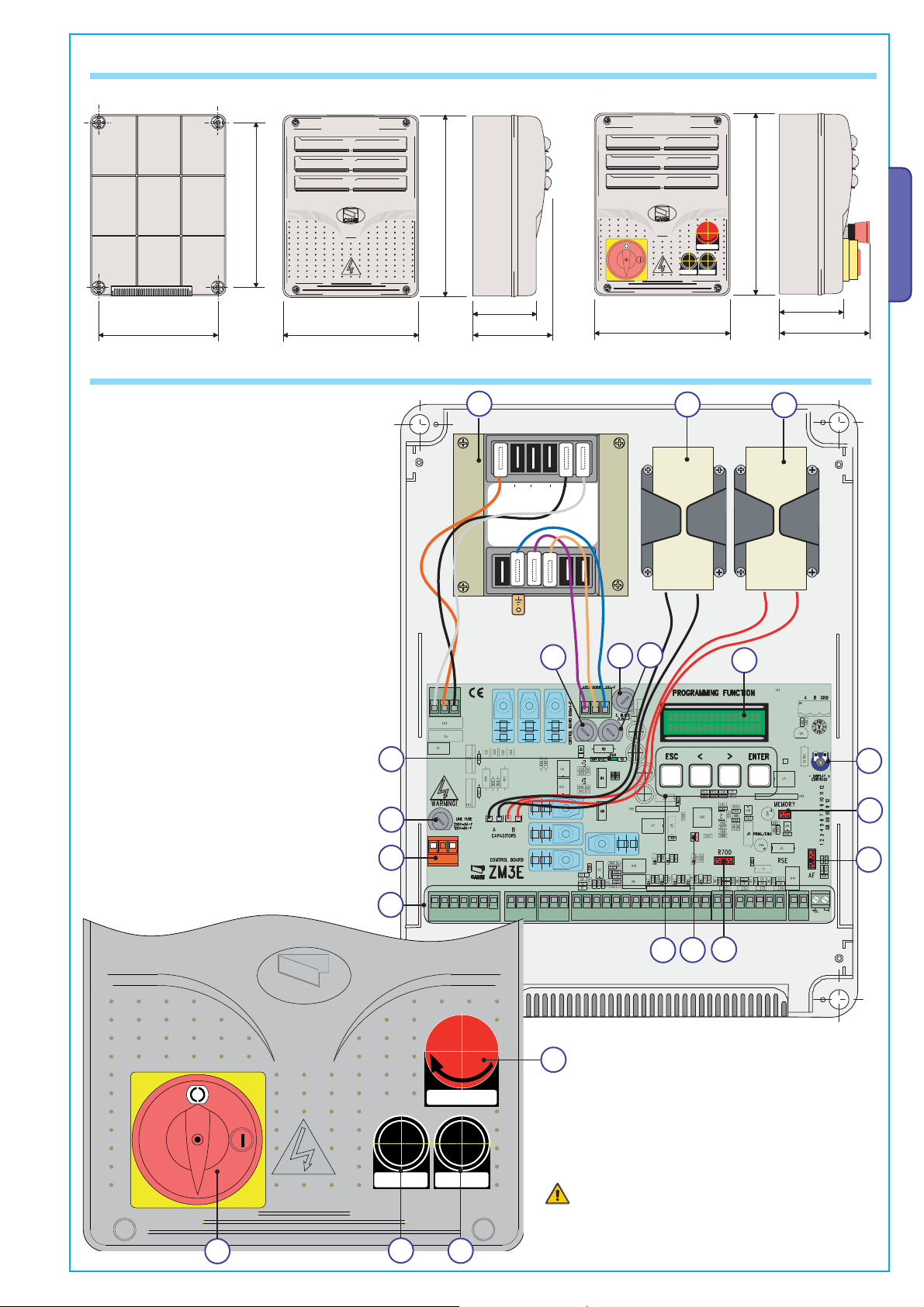

4.1 Dimensions, spans and anchoring holes

(mm)

4.2 Main components

1 - Transformer

2 - M1 gearmotor condenser (black wires)

3 - M2 gearmotor condenser (red wires)

4 - Card fuse

5 - Accessories fuse

6 - Electrolock fuse

7 - Display

8 - Display lighting adjustment trimmer

9 - Memory roll card connector

10 - AF card connector

11 - R700 card connector

12 - Open contact error - warning LED

13 - Programming buttons

14 - Terminal board for connecting

15 - Terminal board for 230V a.c. power grid

16 - Line fuse

17 - 230V-power signalling LED

18 - STOP button

19 - CLOSE button

20 - OPEN button

21 - Safety block

ZM3EC

{

17

16

15

ZM3C

1

ZM3EC

!02%

#()5$%

2

4

3

2

1

6

4

5

3

7

ENGLISH

8

9

10

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

01/2009 © CAME cancelli automatici s.p.a. -

2.0

ver.

319U75

:

Manual code

3 -

Pag.

21

#!-%

14

20

19

11

12

13

18

Warning! Before acting on the machinery, cut off the

main power supply and disconnect any emergency

batteries.

Page 4

4

319U75

2.0

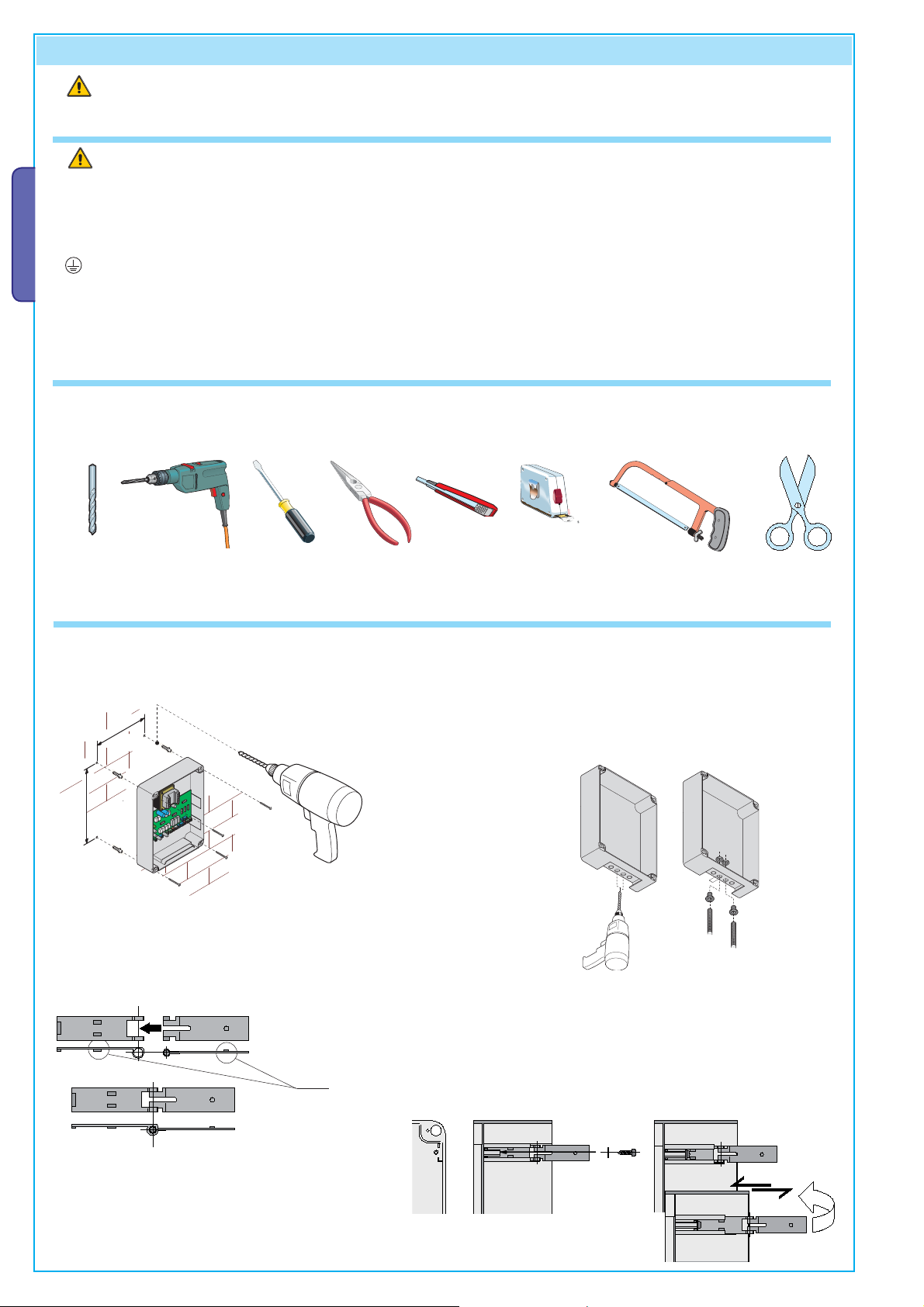

5 Installation

Installation must be carried out by expert qualified personnel and in full observance of regulations in force.

5.1 Preliminary checks

Before installing do the following:

• Check that the panel’s anchoring point is protected from possible blows, and that the anchoring surface is solid. Also check that the

anchoring is done using the appropriate bolts, screws etc.;

• Make sure you have a suitable omnipolar cut-off device with contacts more than 3 mm apart, and independent (sectioned off) power

supply;

ENGLISH

• Make sure that any connections inside the case (that provide continuance to the protective circuit) are fitted with extra insulation

as compared to the other conductive parts inside;

• Make sure you have suitable tubing and conduits for the electrical cables to pass through and be protected against mechanical

damage.

5.2 Tools and materials

Make sure you have all the tools and materials you will need for the installation at hand to work in total safety and compliance with the

current standards and regulations. The following figure illustrates the minimum equipment needed by the installer.

Here are some examples.

5.3 Fixing and mounting the box

1) Fix the base of the panel in a protected area; we suggest

using round top Phillips recessed head screws of max.

6mm in diameter.

3) Assemble the pressure hinges.

2) Perforate the pre-punched holes and insert the cable

glands with the corrugated tubing for the electrical

cables to travel through.

N.B.: diameter of the pre-punched holes: 20 mm.

!!

4) Insert the pressure hinges into the box (on the left or right as you

wish) and set them using the provided screws and washers.

They must slide in

order to tum

15 mm~

2.0 01/2009 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

319U75 ver.

4 - Manual code:

Pag.

Page 5

5

319U75

2.0

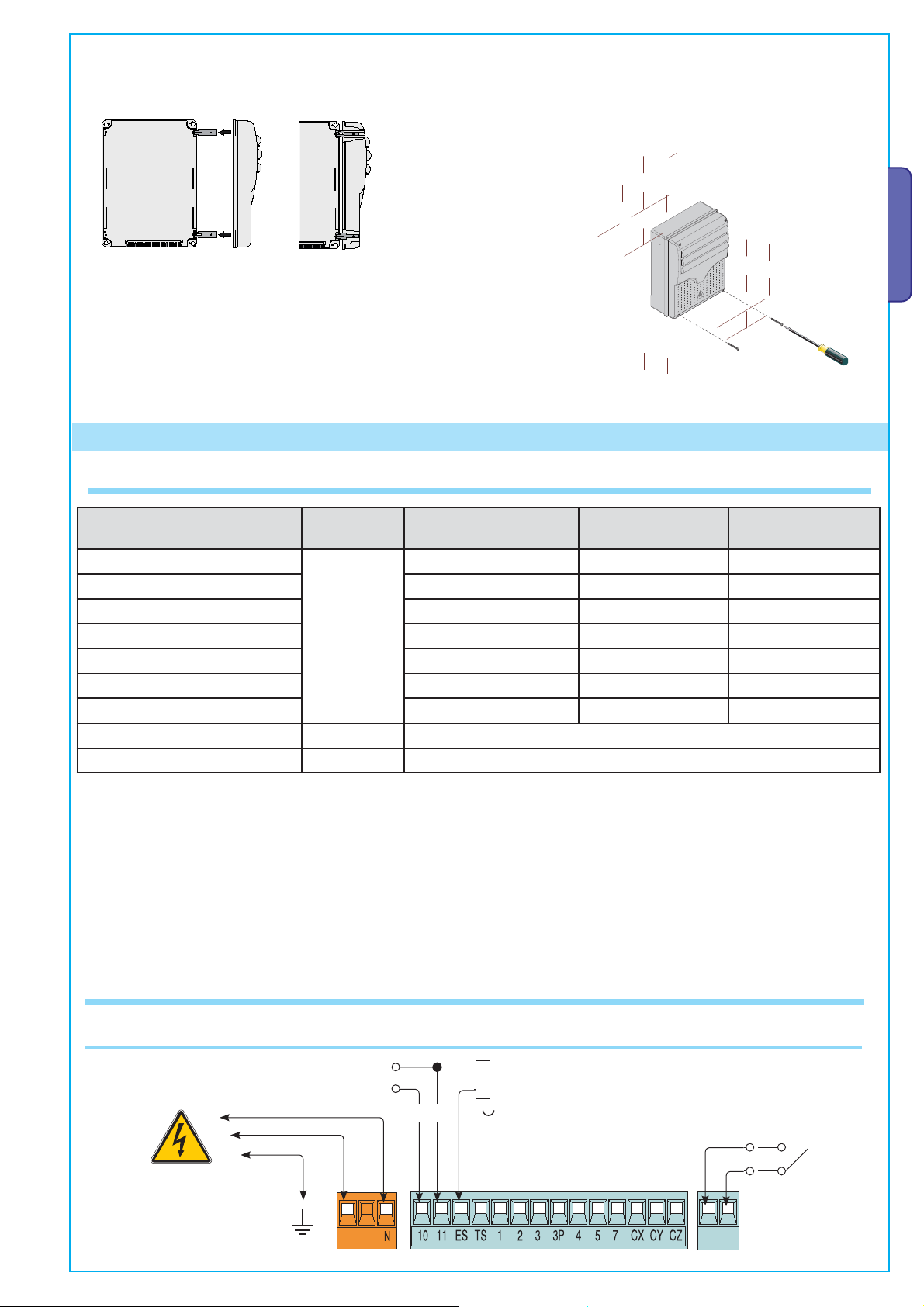

5) Snap the cover into place onto the hinges. Close it and fix it

using the provided screws.

6 Electrical connections

6.1 Cable and type and section

6) After the adjustments and settings, fix the cover

using the provided screws.

ENGLISH

Connections

Type

of cable

Control panel power supply

Motor power supply 3G x 1,5 mm

flashing lamp 2 x 1,5 mm

Transmitter photocells 2 x 0,5 mm

Receiver photocells 4 x 0,5 mm

FROR CEI

20-22

CEI EN

50267-2-1

Power supply to accessories 2 x 0,5 mm

Control and safety devices 2 x 0,5 mm

Length of cable

1 < 10 m

3G x 1,5 mm

Length of cable

10 < 20 m

2

2

2

2

2

2

2

3G x 1,5 mm

3G x 1,5 mm

2 x 1,5 mm

2 x 0.5 mm

4 x 0,5 mm

2 x 0,5 mm

2 x 0,5 mm

2

2

2

2

2

2

2

Length of cable

20 < 30 m

3G x 2,5 mm

3G x 2,5 mm

2 x 1,5 mm

2 x 0,5 mm

4 x 0,5 mm

2 x 1 mm

2 x 0,5 mm

2

2

2

2

2

2

2

Encoder connection 2402C 22AWG max. 30 m

Antenna connection RG58 max. 10 m

N.B.: If the cable length differs from that specified in the table, then you must determine the proper cable diameter based on the actual

power draw from the connected devices and according to the CEI EN 60204-1 standards.

For connections that require several, sequential loads, the sizes given on the table must be re-evaluated based on actual power draw

and distances.

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

When connecting products that are not specified in this manual, please follow the documentation provided with said products.

6.2 Electrical connections

Power supply to accessories

Terminals for powering the following accessories

- 24V A.C. Overall power allowed: 20W

01/2009 © CAME cancelli automatici s.p.a. -

2.0

ver.

319U75

:

Manual code

5 -

Pag.

Power supply

230V (A.C.) 50/60 Hz

:

+

-

Electrolock connection

(12V - 15W max)

Possible output of the radio

receiver’s second channel

(N.O. socket).

Socket rating: 1A-24V (D.C.).

,

" "

Page 6

6

319U75

2.0

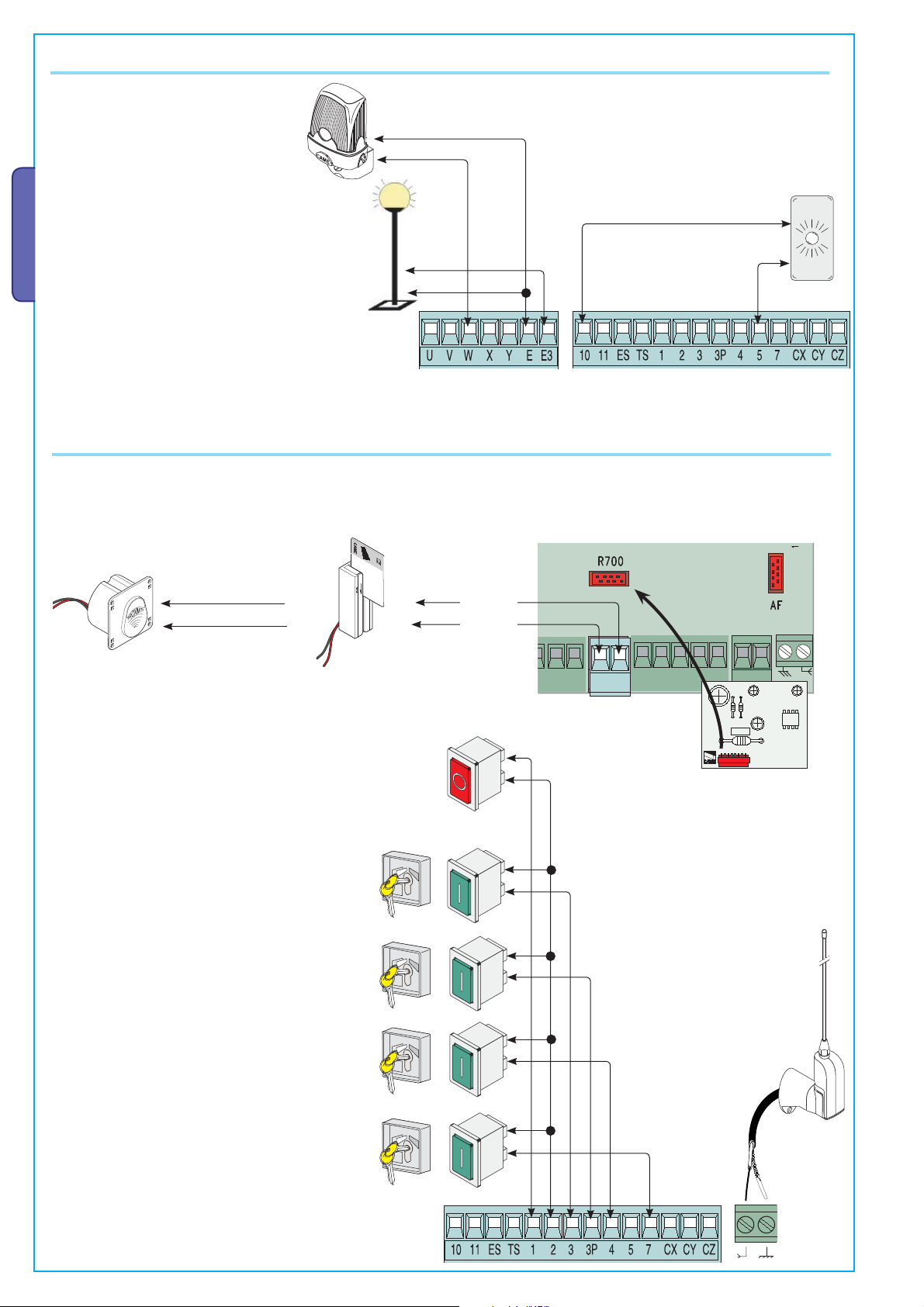

Signalling and Lighting devices

Signal Flasher (socket rating: 230V

- 25W max.) Flashes during opening

and closing phases.

Cycle lamp: (contact rating: 230V – 60W max.)

It lights up the driving area and stays on from the

ENGLISH

moment the gate begins to open until it is fully closed

(including the automatic closing time). If automatic

closing is not activated, the lamp stays on only during

movement or for a set time of 5 minutes if used as a

courtesy lamp.

Command devices

LT001 - Magnetic card reader

TSP00 - Transponder sensor

Open gate indicator-light

(socket rating: 24V - 3W max.).

Turns on when the gate is ajar or open.

It turns off when the gate is closed.

N.B.: insert the R700 emcoding card for the

TSP00 sensors and LT001 card readers to be

recognised.

ACCESS CONTROL

CAME

Stop button (N.C. contact) - Button to stop gate while

excluding the automatic closing cycle. For movement to

resume you must press the command button or transmitter

button.

N.B.: if contact is unused, select Disabled on the

“FUNCTIONS” menu.

Key selector and/or opening button (N.O. contact) -

Gate opening command.

Key selector and/or partial opening button (N.O.

contact) - Partial gate opening for pedestrian

access.

Key selector and/or closing button (N.O. contact) -

Gate closing command.

Black

Red

3'.$

CANCELLI AUTOMATICI

R700

Antenna with RG58

cable for the remote

control.

Key selector and/or commands button (N.O.

contact) - Commands for opening and closing the

gate – pressing the button or turning the keyswitch, inverts the gate’s movement or stops it

depending on how it is set on the 2-7 command in

the “FUNCTIONS” menu.

2.0 01/2009 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

319U75 ver.

6 - Manual code:

Pag.

Page 7

7

319U75

2.0

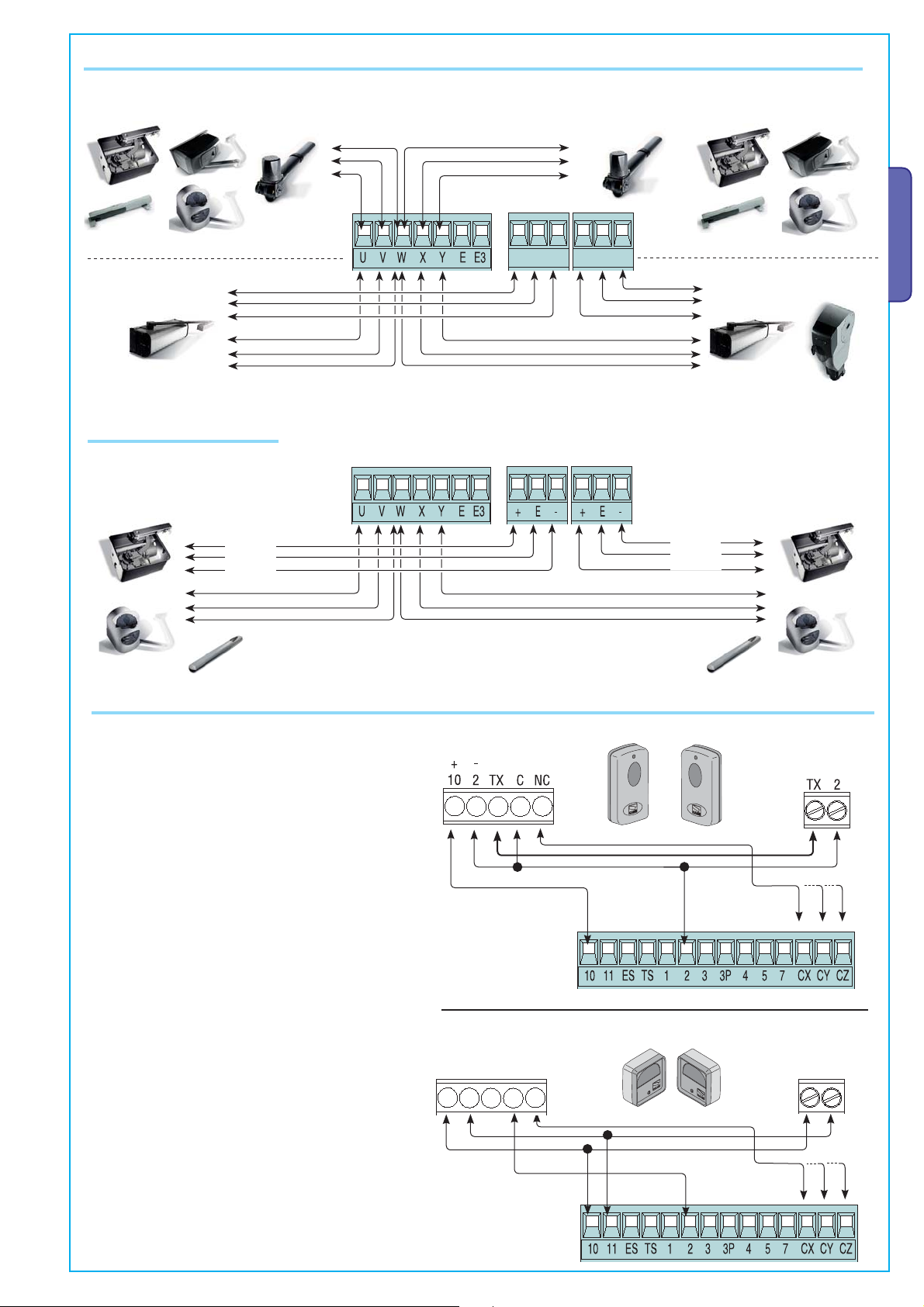

Gearmotor, mechanical stops

M1 - 230V A.C. gearmotor featuring delayed action on opening M2 - 230V A.C. gearmotor featuring delayed action on closing

FROG A

ATI

F4000

FERNI

F7001

Gearmotor, encoder

M1 - 230V A.C. gearmotor featuring

delayed action on opening

FROG AE

White

Brown

Green

KRONO

FROG A

KRONO

&!&# &!&#

ENCODER BENCODER A

M2 - 230V A.C. gearmotor featuring

delayed action on closing

Green

Brown

White

FERNI

ATI

F7001

ENGLISH

CBX

F4000

FROG AE

F7001E

Safety devices

Confi gure either (N.C.) contacts CX, CY or CZ, input

for safety devices such as photocells, that comply

with EN 12978 standards. See CX, CY or CZ input

functions in:

- C1 «re-open during closing phase», When the

gate leaf is closing, opening the contact triggers the

inversion of the direction of movement until the gate

leaf is fully open.

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

- C2 «re-close during opening phase», When gate

is opening, if the contact is opened it triggers an

inversion of the direction until gate is fully closed;

- C3 «partial stop», Halts moving gate leaves and

causes them to automatically close (if this functions

has been selected);

- C4 «stand-by Obstacle», Halts the moving gate

leaves causing them to start moving again once

obstacle is removed.

- Deactivated, if contact is unused.

01/2009 © CAME cancelli automatici s.p.a. -

2.0

ver.

AXOAXO

DIR photocells

RX

RX TX

./ # .#

DOC photocells

F7001E

TX

319U75

:

Manual code

7 -

Pag.

Page 8

8

319U75

2.0

Confi gure either (N.C.) contacts CX, CY or CZ,

input for EN 12978 compliant safety devices such

as sensitive edges. See CX input functions in:

- C7 «Open while closing»,

During gate closing,

opening the contact causes inversion of movement

until gate is fully open;

- C8 «close while opening», During gate opening,

opening the contact causes inversion of movement

until gate is fully close.

ENGLISH

- Deactivated, if contact is unused.

DF

DF with DFI connections

monitor card

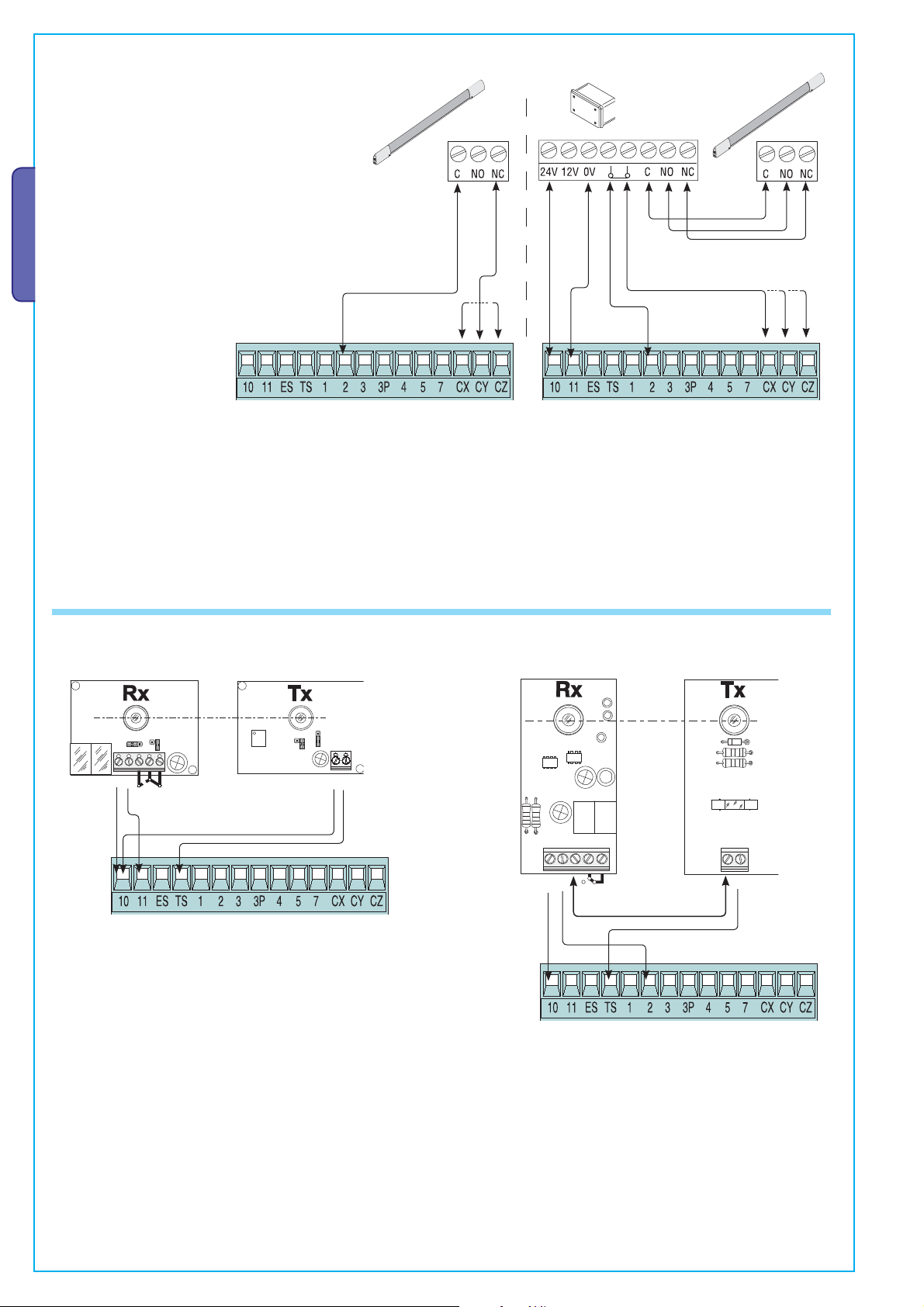

6.3 Electrical connection for the photocells functions test

(DOC)

./

#

.#

(DIR)

48

&53)"),%M!

#

.#

48

48

At each opening and closing command, the control board assesses the effi ciency status of the control devices (photocells). Any

anomaly found is signalled with the fl ashing of the LED on the control panel. Consequently it cancels any commands coming from the

remote control or the button.

Electrical connection to enable the photocell safety test:

- the transmitter and the receiver, must be connected as per the diagram;

- from the functions menu, select “safety tests” and select either CX - CY - CZ input/s to activate the test

.

2.0 01/2009 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

319U75 ver.

8 - Manual code:

Pag.

Page 9

9

319U75

2.0

7 Programming

7.1 Description of display commands

The ESC key is for:

- exiting the menu;

- cancelling modifications.

- shifting from one menu item to another;

- increase or decrease values.

{

The < > keys are for:

7.2 Browsing the menu

To enter the menu, keep the

ENTER key pressed for at least one

second.

Lingua

Italiano

Þß

the <...> symbols on the display are for:

-pointing out the currently, selected item

{

The ENTER key is for:

- entering the menu;

{

- confirming and memorising set values.

{

Þß

LANGUAGE

English

ENGLISH

To select a menu item,

mode using the greater

than-lesser than keys...

also use the greater

than-lesser than keys

for the “sub-menus”...

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

If the <> are on the TIME

Cycle Time

Þß

01/2009 © CAME cancelli automatici s.p.a. -

2.0

Þß

ver.

90s

Cycle Time

100s

function, you may modify the

value.

...then press ENTER to confirm...

Þß

Þß

LANGUAGE

English

Þß

Þß

FUNCTIONS

English

TIMING ADJ.

Þß

A.C.T.

90s

Cycle Time

90s

...to exit the menu, wait 30

seconds, or press ESC, until start

screen is displayed.

...then press ENTER

...then press ENTER

To increase or reduce values,

use the greater than-lesser

than keys...

319U75

:

Manual code

9 -

Pag.

N.B.: when the menu is active, the system cannot be used.

Page 10

10

319U75

2.0

7.3 Menu structure

< LANGUAGE >

< FUNCTIONS >

< ENCODER >

< TIMING ADJ >

ENGLISH

< USERS >

ENTER

>

ENTER

>

ENTER

>

ENTER

>

ENTER

< Add User >

>

<English> <Francais>

>

See detailed functions on pages 17, 18, 19 and 20 (the “ENCODER” function, appears only if

selected from the “Config.” function in the FUNCTIONS menu.

confirm? (no)

ENTER

>

confirm? (yes)

>

>

< T.C.A. >

>

<Pedestrian ACT>

>

<Deutsch>

>

<Espanol><Italiano>

ENTER

>

ENTER

>

< 0s. >

>

< 0s. >

>

< 300s.>

>

< 300s.>

>

Choose User

<001:-U001->

< Mod. name >

>

< Mod. Code >

>

<Relate d Fu nc.>

>

>

< Remove Usr. >

>

ENTER

ENTER

ENTER

ENTER

>

Sel.Utente

<002:-U002->

Choose User

<001:-U001->

>

Sel.Utente

<002:-U002->

Choose User

<001:-U001->

>

Sel.Utente

<002:-U002->

Choose User

<001:-U001->

>

Sel.Utente

<002:-U002->

>

< Cycle Time >

>

< Op. Delay M1 >

>

>

< Cl. Delay M2 >

>

>

<Preflashing T.>

>

>

< Lock time >

>

ENTER

ENTER

ENTER

ENTER

ENTER

< 10s. >

>

< 150s.>

< 1s. >

>

< 1s. >

>

< 1s. >

>

< 1s. >

>

>

>

< 10s. >

>

< 60s >

>

< 60s.>

>

< 5s. >

<Res tore backup>

< INFO >

>

< TEST MOT. >

<D elete all U s r>

>

< Backup data >

>

>

ENTER

ENTER

ESC

confirm? (no)

ENTER

>

confirm? (yes)

confirm? (no)

ENTER

>

confirm? (yes)

confirm? (no)

ENTER

>

confirm? (yes)

< Version >

fw. 3.0

TEST MOT.

< <=M1 M2=> >

>

>

>

< No. of Runs >

>

>

< Ram hit time >

< Ped.opening >

<Slow down time>

16480

< System Reset >

ENTER

>

ENTER

>

ENTER

>

< Standby Msg. >

>

< 1s. >

>

< 5s. >

>

< 0s. >

>

>

>

< 10s. >

>

< 60s.>

>

< 30s.>

2.0 01/2009 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

319U75 ver.

10 - Manual code:

Pag.

Page 11

11

319U75

2.0

< AutoClose >

>

ENTER

< Turn on > < Disabled >

>

>

<M ain tain e d Act>

>

< Obstacle Det. >

>

< Safety d.Te s t >

>

< Preflashing >

>

<Ram hit funct.>

>

< Total Stop >

>

< CX Input >

>

< CY Input >

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

< Disabled > < Turn on >

< Turn on > < Disabled >

< Disabled >

>

<CX+ CY+C Z>

< Turn on > < Disabled >

< Turn on > < Disabled >

< Turn on > < Disabled >

< Disabled >

< C8 >

< Disabled >

>

>

>

< CX >

>

< CY+CZ >

>

>

>

>

>>

>

>

< C1 >

< C7 >

< C1 >

>

< CY >

>

< CX+CZ >

>

>

>

>

< C2 >

>

>

< C2 >

>

<when close>

>

< CZ >

>

< C4 >

>

>

< CX+CY >

< C3 >

< C3 >

>

>

ENGLISH

>

>>

>

< CZ Input >

>

< Cl. Thrust >

>

< Lock >

>

< Config. >

>

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

< endstop >

>

< cmd 2-7 >

>

< cmd 2-3P >

>

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

< Slow run >

<Op.-Stop- Cl.>

<Pedestrian>

< C8 >

< Disabled >

< C8 >

< Turn on > < Disabled >

< Turn on > < Disabled >

>

>

>

<Lim it s witch>

< N.C. > < N.A. >

>

>

>

< C7 >

>

< C1 >

>>

< C7 >

< Fcap-RallCh >

>>

<Open-Close>

< Partial >

>

>

>

< C2 >

>

>

>

< C4 >

< C4 >

< encoder >

< Time of Run >

>

>

>

>

>

< C3 >

>

>

01/2009 © CAME cancelli automatici s.p.a. -

2.0

ver.

319U75

:

Manual code

11 -

Pag.

< lamp E3 >

<output B1-B2>

< No. Motors >

>

<Slow Down Spd>

ENTER

>

ENTER

>

ENTER

>

ENTER

< Cycle >

<Monostable>

< M1 + M2 >

-ooo+

<

•

>

< Courtesy >

>

<Bistable>

>

< M2 >

>

>

-ooo+

<

•

•

>

>

>

>

>

Page 12

12

319U75

2.0

7.4 Main menu

FUNCTIONS

TIMING ADJ.

USERS

< LANGUAGE >

English

TIMING ADJ.

USERS

TEST MOT.

TEST MOT

< LANGUAGE >

English

h

TIMING ADJ.

USERS

TEST MOT.

TEST MOT

TEST MOT.

< LANGUAGE >

English

Press ENTER

for 1 second

< TEST MOT. >

ENGLISH

7.5 Language menu

Select language: selects among the languages displayed.

< LANGUAGE >

English

LANGUAGE

< English >

< FUNCTIONS >

It appears only if selected from the “Config.”

Section in the FUNCTIONS menu.

< INFO >

LANGUAGE

< Francais >

LANGUAGE

< Italiano >

< ENCODER >

< TIMING ADJ. >

< USERS >

250

Max. 250 users

LANGUAGE

< Deutsch >

LANGUAGE

< Espanol >

7.6 Functions menu

Automatic Closing: activates or deactivates the automatic closing function.

The automatic closing timer activates at each opening endpoint. The predetermined time may be adjusted, and is in any case

dependent on any safety devices that may activate; and it does not activate after a total safety “stop” or during a power outage.

< AutoClose >

FUNCTIONS

Turn on

X 2

Maintained action: the gate works by keeping the button pressed (button 2-3 for opening, button 2-4 for closing, or if set to the “On

Closing” function, only with button 2-4.

AutoClose

< Turn on >

AutoClose

< Disabled >

FUNCTIONS

<M ain tain e d Act>

Disabled

X 2

Maintained Act

< Disabled >

Maintained Act

< when close >

Maintained Act

< Turn on >

2.0 01/2009 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

319U75 ver.

12 - Manual code:

Pag.

Page 13

13

319U75

2.0

Obstacle detected: when motor is stopped (gate closed or after a total stop command) it prevents any movement if safety devices,

< LANGUAGE >

English

TIMING ADJ.

USERS

TEST MOT.

TEST MOT

< LANGUAGE >

English

English

TIMING ADJ.

USERS

O

< LANGUAGE >

English

TIMING ADJ.

USERS

TEST MOT.

TEST MOT

<

English

TIMING ADJ.

USERS

TEST MOT.

TEST MOT

such as photocells, detect any obstacles.

X 2

Obstacle Det.

< Disabled >

FUNCTIONS

<Obstacle Det.>

Disabled

X 2

Obstacle Det.

< Turn on >

Safety test: allows the card to check the efficiency of any safety devices (i.e. photocells) after every opening or closing command.

LANGUAGE >

FUNCTIONS

X 3

<Safety d.Test>

Disabled

Safety d.Tes t

< Disabled >

Safety d.Tes t

< CX+CY+CZ >

Safety d.Tes t

< CX >

Safety d.Tes t

< CY >

ENGLISH

X 2

Safety d.Tes t

< CX+CZ >

Safety d.Tes t

< CX+CY >

Safety d.Tes t

< CZ >

Pre-flashing: after an opening or closing command, the flashing light, connected to W-E, starts flashing before the gate begins its run

(to set the time, see “Pre-flashing timing” from the Adjust Timings menu

X 4

Preflashing

< Disabled >

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

FUNCTIONS

< Preflashing >

Disabled

X 2

Ram blow: before any opening run, the gate leaves will press onto the mechanical endstop for a few seconds, to help release the electrolock (to set the time, see “Starting ram timing” in the Adjust Timings menu).

01/2009 © CAME cancelli automatici s.p.a. -

2.0

ver.

319U75

:

FUNCTIONS

X 5

<Ram hit funct.>

Disabled

Ram hit funct.

< Disabled >

X 2

Manual code

13 -

Pag.

NF

Page 14

14

319U75

2.0

Total Stop: this function stops the gate and consequently excludes any automatic closing cycle; for movement to resume, you need to

< LANGUAGE >

EnglishEnglish

TIMING ADJ.

IMING ADJ

USERS

TEST MOT.

TEST MOT.

< LANGUAGE >

EnglishEnglish

TIMING ADJ.

IMING ADJ

USERS

TEST MOT.

TEST MOT.

< LANGUAGE >

EnglishEnglish

TIMING ADJ.

IMING ADJ

USERS

TEST MOT.

TEST MOT.

use the keypad or transmitter. Insert safety device on [1-2]; Insert the safety device on [1 -2]; if unused, select “Deactivated”

X 6

FUNCTIONS

< Total Stop >

Turn on

Total Stop

< Turn on >

X 2

Total Stop

ENGLISH

< Disabled >

CX input: the N.C. safety contact input can take on the following functions: C1 (re-opening when closing), C2 (re-closing when

opening), C3 (partial stop), C4 (obstacle stall), C7 (re-opening when closing, for sensitive edges), C8 (re-closing when opening, for

sensitive edges) or, be deactivated. See safety devices on electrical connections.

X 7

CX Input

< C1 >

< C2 >

FUNCTIONS

NFO

< CX Input >

Disabled

CX Input

< Disabled >

CX Input

< C8 >

CX Input

X 2

CX Input

< C7 >

CX Input

< C4 >

CX Input

< C3 >

CY input: safety contact input can take on the following functions: C1 (re-opening when closing), C2 (re-closing when opening), C3

(partial stop), C4 (obstacle stall), C7 (re-opening when closing, for sensitive edges), C8 (re-closing when opening, for sensitive edges)

or, be deactivated. See safety devices on electrical connections.

X 8

CY Input

< C1 >

CY Input

< C2 >

FUNCTIONS

< CY Input >

Disabled

CY Input

< Disabled >

CY Input

< C8 >

2.0 01/2009 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

X 2

CY Input

< C7 >

CY Input

< C4 >

CY Input

< C3 >

319U75 ver.

14 - Manual code:

Pag.

Page 15

15

319U75

2.0

CZ input: safety contact input can take on the following functions: C1 (re-opening when closing), C2 (re-closing when opening), C3

< LANGUAGE >

English

English

TIMING ADJ.

USERS

TEST MOT.

TEST MOT

< LANGUAGE >

English

h

TIMING ADJ.

USERS

< LANGUAGE >

English

TIMING ADJ.

USERS

< LANGUAGE >

English

h

TIMING ADJ.

TEST MOT.

TEST MOT

(partial stop), C4 (obstacle stall), C7 (re-opening when closing, for sensitive edges), C8 (re-closing when opening, for sensitive edges)

or, be deactivated. See safety devices on electrical connections.

X 9

< CZ Input >

Disabled

FUNCTIONS

CZ Input

< Disabled >

CZ Input

< C1 >

CZ Input

< C8 >

CZ Input

< C2 >

X 2

CZ Input

< C7 >

CZ Input

< C4 >

CZ Input

< C3 >

Closing thrust: at the endpoint stage during closing, the gearmotors perform a final closing-thrust of the doors for a few seconds.

X 10

FUNCTIONS

< Cl. Thrust. >

Disabled

Cl. Thrust.

< Disabled >

X 2

Cl. Thrust.

< Turn on >

Lock: to lock the gate leaves. Required for gate leaves longer than 2.50 m.

ENGLISH

X 11

< Lock >

FUNCTIONS

Disabled

< Disabled >

X 2

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Deceleration configuration: configuring decelerations when opening or closing:

- slow run: decelerations when opening and closing;

- Fcap-RallCh.: end stop when opening and deceleration when closing;

- ecoder: managing decelerations, obstacle detection and sensitivity; (FROG-AE)

- Time of Run: timed end stop (default function); (FROG-A, FERNI 230V, ATI 230V, FAST 230V and KRONO)

- Limit switch (endstop): opening and closing endstop. (C-BX and F4000)

X 12

Config.

< Slow run >

Config.

<Lim it s witch>

<Time of Run>

01/2009 © CAME cancelli automatici s.p.a. -

2.0

ver.

319U75

:

Manual code

15 -

Pag.

< Config. >

Slow run

FUNCTIONS

USERS

X 2

Lock

Lock

< Turn on >

Config.

< Fcap-RallCh >

Config.

< encoder >

Config.

Page 16

16

319U75

2.0

Endstop: configure the endpoints are normally closed or open contacts.

< LANGUAGE >

English

TIMING ADJ.

USERS

TEST MOT.

TEST MOT

< LANGUAGE >

English

TIMING ADJ.

USERS

TEST MOT.

TEST MOT

English

TIMING ADJ.

USERS

TEST MOT.

TEST MOT

< LANGUAGE >

English

TIMING ADJ.

USERS

TEST MOT.

TEST MOT

N.B.: this function appears only if selected from the “Config.” function in the FUNCTIONS menu.

X 13

< endstop >

FUNCTIONS

N.C

endstop

< N.C >

X 2

endstop

< N.A >

ENGLISH

Command 2-7: setting the 2-7 contact to step-by- step mode (open-close) or sequential (open-stop-close-stop).

X 14

cmd 2-7

<Op.-Stop- Cl.>

FUNCTIONS

< cmd 2-7 >

Op.-Stop-Cl.

X 2

cmd 2-7

<Open-Close>

Command 2-3P: setting the 2-3P contact to pedestrian opening (second gate leaf opens fully) or partial (second gate leaf opens

partially depending on the time set on “Partial opening” from the Adjust Times menu).

< LANGUAGE >

FUNCTIONS

X 15

< cmd 2-3P >

Pedestrian

cmd 2-3P

< Pedestrian >

X 2

E3 lamp: configuring the lamp connected to E-E3:

- cycle: outdoor lamp, which can be positioned at leisure, for better illumination in the parking/driveway area.

It stays on from the moment the gate leaf begins to open, until it is fully closed (including automatic closing time).

In case the automatic closing function is not inserted, it stays on only during gate movement.

- courtesy: outdoor lamp, which can be positioned at leisure, for better illumination in the parking/driveway area.

It stays on for a set time of 5 minutes.

X 16

FUNCTIONS

< lamp E3 >

Cycle

lamp E3

< Cycle >

cmd 2-3P

< Partial >

2.0 01/2009 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

X 2

lamp E3

< Courtesy >

319U75 ver.

16 - Manual code:

Pag.

Page 17

17

319U75

2.0

B1-B2 output: setting contact B1-B2 to MONO-STABLE or BI-STABLE (switch) mode.

< LANGUAGE >

English

English

TIMING ADJ.

USERS

TEST MOT.

TEST MOT

< LANGUAGE >

English

English

TIMING ADJ.

USERS

TEST MOT.

TEST MOT

< LANGUAGE >

English

TIMING ADJ.

USERS

TEST MOT.

TEST MOT

< LANGUAGE >

English

TIMING ADJ.

USERS

TEST MOT.

TEST MOT

X 17

FUNCTIONS

< output B1-B2 >

Monostable

X 2

output B1-B2

< Monostable

output B1-B2

< Bistable >

Slow Down: setting the deceleration speed when opening or closing, or, only when closing if said deceleration is configured as (FcapRallCh.).

N.B.: this function only appears if the decelerations are selected.

X 18

FUNCTIONS

X 2

<Slow Down Spd.>

-ooo+

•

Slow Down Spd.

•

<

-ooo+

•

Slow Down Spd.

<

>

-ooo+

•

•

ENGLISH

>

Number of motors: setting the number of motors, either one or two, depending on the number of gate leaves installed on the system.

X 19

FUNCTIONS

< No. Motors >

M1 + M2

No. Motors

< M1 + M2 >

X 2

No. Motors

< M2 >

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Motor Type: setting up the type of swing gate motor installed in the system.

01/2009 © CAME cancelli automatici s.p.a. -

2.0

ver.

< Motor Type >

FROG

FUNCTIONS

Motor Type

< FROG >

Motor Type

< AXO >

319U75

:

Manual code

17 -

Pag.

X 2

Motor Type

< FAST >

Page 18

18

319U75

2.0

< LANGUAGE >

English

English

FUNCTION

TIMING ADJ.

USERS

< LANGUAGE >

EnglishEnglish

FUNCTION

TIMING ADJ.

USERS

English

English

FUNCTION

TIMING ADJ.

USERS

< LANGUAGE >

English

FUNCTION

TIMING ADJ.

USERS

7.7 Encoder Menu (the ENCODER menu, appears only if selected from the “Config.” function in the FUNCTIONS menu.)

< LANGUAGE >

English

English

FUNCTION

TIMING ADJ.

N.B.: before setting the functions in the encoder menu, run the gearmotor checks to verify the proper turning direction.

Sensitivity: the obstacle detection function is activated during gate operation and deceleration.

Se n sibility

< Turn on >

ENGLISH

ENCODER

< Se n s ibility >

Turn on

X 2

Gate operation sensitivity: this adjusts the obstacle detection sensitivity during opening and closing gate operation.

N.B.: this function appears only if the “sensitivity” function is activated in the ENCODER menu.

Sensib. Run

-oooooooo+

<

•

ENCODER

< Sensib. Run >

-oooooooo+

•

X 2

Deceleration sensitivity: it adjusts the obstacle detection sensitivity during opening and closing gate deceleration.

N.B.: this function appears only if the “sensitivity” function is activated in the ENCODER menu.

X 2

Se n sibility

<Disabled>

>

Sensib. Run

-oooooooo+

<

•

•

>

Sensib. Decel.

-oooooooo+

<

•

>

ENCODER

<Sensib. Decel.>

-oooooooo+

•

X 2

Sensib. Decel.

-oooooooo+

<

•

•

Encoder Deceleration: this activates the opening and closing deceleration starting points.

< LANGUAGE >

X 3

Slow run Enc

< ON

>

ENCODER

< Slow run Enc >

ON

X 2

Slow run Enc

< OFF

M1 opening deceleration%: this adjusts the (M1) first motor’s deceleration starting point before the opening endpoint.

The deceleration starting point is calculated as a percentage (from 1% to 40% of a full gate run). See illustration on page 28.

N.B.: this function appears only if it is activated in the “decel. Enc” function in the ENCODER menu.

X 4

>

>

2.0 01/2009 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENCODER

X 2

< M1 Slow.AP.% >

10

M1 Slow.A P.%

< 10

>

M1 Slow.A P.%

< 11

319U75 ver.

18 - Manual code:

>

Pag.

Page 19

19

319U75

2.0

M1 closing deceleration%: this adjusts the (M1) first motor’s deceleration starting point before the closing endpoint.

< LANGUAGE >

English

English

FUNCTION

TIMING ADJ.

USERS

< LANGUAGE >

English

English

FUNCTION

TIMING ADJ.

USERSNFO

< LANGUAGE >

English

FUNCTION

TIMING ADJ.

USERS

< LANGUAGE >

English

English

FUNCTION

TIMING ADJ.

USERS

The deceleration starting point is calculated as a percentage (from 1% to 40% of a full gate run). See illustration on page 28.

N.B.: this function appears only if it is activated in the “decel. Enc” function in the ENCODER menu.

X 5

M1 Slow.CH %

< 10

>

ENCODER

< M1 Slow.CH % >

10

X 2

M1 Slow.CH %

< 11

M2 opening deceleration%: this adjusts the (M2) second motor’s deceleration starting point before the opening endpoint.

The deceleration starting point is calculated as a percentage (from 1% to 40% of a full gate run). See illustration on page 28.

N.B.: this function appears only if it is activated in the “decel. Enc” function in the ENCODER menu.

X 6

M2 Slow.AP %

< 10

>

ENCODER

< M2 Slow.AP % >

10

X 2

M2 Slow.AP %

< 11

ENGLISH

>

>

M2 closing deceleration %: this adjusts the (M2) second motor’s deceleration starting point before the closing endpoint.

The deceleration starting point is calculated as a percentage (from 1% to 40% of a full gate run). See illustration on page 28.

N.B.: this function appears only if it is activated in the “decel. Enc” function in the ENCODER menu.

X 7

M2 Slow.CH %

< 10

>

ENCODER

< M2 Slow.CH % >

10

X 2

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

M2 Slow.CH %

< 11

M1 closing acceleration %: this adjusts the (M1) first motor’s percentage rate of approach to the final closing and opening points

before reaching the opening and closing endpoints. The percentage rate of approach to (goes from 1% to 15% of the full gate run). See

illustration on page 28.

01/2009 © CAME cancelli automatici s.p.a. -

2.0

ver.

319U75

:

Manual code

19 -

Pag.

ENCODER

X 2

X 8

< M1 Appr.CH % >

5

M1 Appr.CH %

< 5

>

M1 Appr.CH %

< 6

>

>

Page 20

20

319U75

2.0

M2 closing acceleration %: this adjusts the (M2) second motor’s percentage rate of approach to the final closing and opening points

< LANGUAGE >

EnglishEnglish

FUNCTION

TIMING ADJ.

USERS

TEST MOT.

< LANGUAGE >

EnglishEnglish

FUNCTION

TIMING ADJ.

USERS

TEST MOT.

< LANGUAGE >

English

h

FUNCTION

USERS

TEST MOT.

TEST MOT

< LANGUAGE >

English

h

FUNCTION

USERS

TEST MOT.

TEST MOT

before reaching the opening and closing endpoints. The percentage rate of approach to (goes from 1% to 15% of the full gate run). See

illustration on page 28.

X 8

ENGLISH

ENCODER

ENCODER

X 2

X 2

X 9

< M2 Appr.CH % >

5

< Set Encoder >

M2 Appr.CH %

< 5

Set Encoder

<confirm?(no)>

M2 Appr.CH %

< 6

Set Encoder

<confirm?(yes)>

>

See detailed

description on

page 28

>

7.8 Time setting menu

Automatic closing: to set the waiting time when gate is in the open position.

Once this time is elapsed, the gate closes automatically. The waiting time can be set to between 0” and 300”.

< A.C.T. >

TIMING ADJ.

10s.

X 2

Automatic Pedestrian Closing: waiting time of the (M2) second gate leaf when in the open position. Once this time interval has

elapsed, the gate automatically closes. The waiting time interval can go anywhere from 0” to 300”.

TIMING ADJ.

<Pedestrian ACT>

10s.

A.C.T.

< 10s. >

A.C.T.

< 11s. >

Pedestrian ACT

< 10s. >

2.0 01/2009 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

319U75 ver.

X 2

Pedestrian ACT

< 11s. >

20 - Manual code:

Pag.

Page 21

21

319U75

2.0

Cycle time: the working time of the motor during opening or closing phases is anywhere from 10” to 150”.

< LANGUAGE >

English

English

FUNCTIONS

FUNCTION

USERS

TEST MOT.

TEST MOT

< LANGUAGE >

English

English

FUNCTIONS

FUNCTION

USERS

TEST MOT.

TEST MOT

<

English

English

FUNCTIONS

FUNCTION

U

S

TEST MOT.

TEST MOT

< LANGUAGE >

English

English

FUNCTIONS

FUNCTION

USERS

TEST MOT.

TEST MOT

X 2

TIMING ADJ.

< Cycle Time >

90s.

Cycle Time

< 90s. >

X 2

NFO

Cycle Time

< 91s. >

M1 delayed opening: the waiting time of the (M1) first gate lead, unlike the (M2) second one, after each opening command. The

waiting time can be set to between 0” and 10”.

X 3

TIMING ADJ.

< Op. Delay M1 >

2s

Op. Delay M1

< 2s >

X 2

Op. Delay M1

< 3s >

ENGLISH

M2 delayed closing: the waiting time of the (M2) second gate leaf, unlike the (M1) first one, after each closing command. the waiting

time can be set to between 0” and 60”.

LANGUAGE >

X 4

TIMING ADJ.

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

SER

< Cl. Delay M2 >

2s

X 2

Cl. Delay M2

< 2s >

Cl. Delay M2

< 3s >

Pre-flashing time: after an opening or closing command is given, the flasher connected to “W-E), flashes for between 1” and 60”,

before the gate begins to move.

01/2009 © CAME cancelli automatici s.p.a. -

2.0

ver.

TIMING ADJ.

319U75

:

X 5

<Preflashing T.>

5s.

Preflashing T.

< 5s. >

X 2

Preflashing T.

Manual code

21 -

Pag.

< 6s. >

Page 22

22

319U75

2.0

Lock time: the time required for releasing the electro-lock after each opening command. The time of operation can be set to between

< LANGUAGE >

English

English

FUNCTION

USERS

TEST MOT.

TEST MOT

< LANGUAGE >

English

English

FUNCTION

USERS

TEST MOT.

TEST MOT

< LANGUAGE >

English

English

FUNCTION

USERS

TEST MOT.

TEST MOT

< LANGUAGE >

LANGUAG

English

FUNCTION

NS

USERS

TEST MOT.

1” and 5”.

X 6

TIMING ADJ.

< Lock time >

2s.

Lock time

< 2s. >

X 2

ENGLISH

Lock time

< 3s. >

Ram hit time: the gearmotor’s thrust time when fully closing after each opening command. The thrust time can be set to between 1”

and 10”.

X 7

TIMING ADJ.

NFO

< Ram hit time >

2s.

X 2

Ram hit time

< 2s. >

Ram hit time

< 3s. >

Partial opening: the opening time of the (M2) second gate leaf. The time can be set to between 5” and 60”.

X 8

TIMING ADJ.

< Ped. opening >

5s.

X 2

Ped. opening

< 5s. >

Ped. opening

< 6s. >

Slow down time: the gate leaf’s deceleration time before every endpoint. The time can be set to between 0” and 30”.

N.B.: this function only appears if the decelerations are selected.

X 9

TIMING ADJ.

< Slow down time >

5s.

Slow down time

< 5s. >

X 2

Slow down time

< 6s. >

2.0 01/2009 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

319U75 ver.

22 - Manual code:

Pag.

Page 23

23

319U75

2.0

7.9 Users Radio Menu

< LANGUAGE >

English

English

FUNCTION

TIMING ADJ.

TEST MOT.

TEST MOT

< LANGUAGE >

English

English

FUNCTION

TIMING ADJ.

TEST MOT.

TEST MOT

<

English

English

FUNCTION

TIMING ADJ.

TEST MOT.

TEST MOT

< LANGUAGE >

English

English

FUNCTION

TIMING ADJ.

TEST MOT.

TEST MOT

Add User: to create a new user and assigned function (max. 250 users).

< Add User >

X 2

USERS

Mod. Name: to change a user number or existing name to another name.

LANGUAGE >

< Mod. name >

X 2

USERS

Add User

<confirm? (no) >

ENGLISH

Add User

<confirm? (yes)>

See detailed

description on

page 26

Choose User

< 001:--001-- >

Choose User

< 002:--002-- >

Mod. Code: to change a user’s current code.

X 2

< Mod. Code >

X 2

USERS

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Related Function: to change the function assigned to the user.

X 3

< Related Func >

01/2009 © CAME cancelli automatici s.p.a. -

2.0

ver.

319U75

:

USERS

X 2

See detailed

description on

page 26

Choose User

< 001:--001-- >

Choose User

< 002:--002-- >

See detailed

description on

page 27

Choose User

< 001:--001-- >

Choose User

< 002:--002-- >

Manual code

23 -

Pag.

See detailed

description on

page 27

Page 24

24

319U75

2.0

Remove user: to remove an exisiting user. Confirm the use you wish to remove with the ENTER key.

< LANGUAGE >

English

FUNCTIONS

TIMING ADJ.

TEST MOT.

< LANGUAGE >

English

English

FUNCTIONS

TIMING ADJ.

TEST MOT.

TEST MOT.

< LANGUAGE >

English

English

FUNCTIONS

TIMING ADJ.

TEST MOT.

< LANGUAGE >

English

English

FUNCTIONS

TIMING ADJ.

TEST MOT.

X 4

< Remove Usr. >

Choose User

< 001:--001-- >

X 2

USERS

ENGLISH

Delete all user: to cancel all registered users. Confirm cancellation of all users with ENTER.

X 5

<D elete all U s r>

Dele te all U sr

<confirm? (no) >

X 2

Choose User

< 002:--002-- >

Remove Usr.

<confirm? (no) >

Remove Usr.

<confirm? (yes)>

USERS

Dele te all U sr

<confirm? (yes)>

Backup data: to save the users in the memory roll. Confirm saving of users on the memory roll with ENTER.

X 6

< Backup data >

Backup data

<confirm? (no) >

X 2

USERS

Backup data

<confirm? (yes)>

Restore backup: to load the data saved on the memory roll onto card.

X 7

Backup data

WRITE:250

USERS

<Restore backu p>

X 2

Restore backu p

<confirm? (no) >

Restore backu p

<confirm? (yes)>

Restore backu p

READ:250

2.0 01/2009 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

319U75 ver.

24 - Manual code:

Pag.

Page 25

C

A

M

E

25

319U75

2.0

7.10 nfo Menu

< LANGUAGE >

English

FUNCTION

TIMING ADJ.

USERS

< LANGUAGE >

English

FUNCTION

TIMING ADJ.

USERS

TEST MOT.

Version: to view software version.

Number of gate runs: to view the number of runs performed by the gate.

Starting Mssg: to view the starting message, confirm with ENTER to change text. Use the ENTER key to move the cursor forward, ESC

to move it backwards and <> to select the letter of number. Confirm the text by pressing the ENTER key for a few seconds.

System reset: it resets the system to its original settings. Press ENTER key to confirm.

< Version >

fw : 3.0

< System Reset >

INFO

7.11 Motor test menu

TEST MOT.: Test to check the proper direction of the gearmotors.

Gate leaf opening

run of the first (M1)

gearmotor. If the

direction is wrong,

invert the motor’s

phases.

< No. of Runs >

< TEST MOT. >

<=M1 M2=>

10

ENGLISH

< Standby Msg. >

- WWW.CAME.IT

ZM3E

Gate leaf opening run

of the second (M2)

gearmotor. If the

direction is wrong,

invert the motor’s

phases.

TEST MOT.

7.12 Decoding card

Connect the required (R700, AF43S cards) to insert, change, remove and command the operator via transmitter, card or transponder.

Insert the memory roll to save and load all setting including users registered by another card.

AF Card

TFM

TOP

ATOMO / TWIN

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

01/2009 © CAME cancelli automatici s.p.a. -

2.0

ver.

319U75

:

Manual code

25 -

Pag.

ACCESS CONTROL

TSP00 LT001

Lingua

Italiano

Þß

R700

CANCELLI AUTOMATICI

R700 Card

Memory roll

Frequency/MHz Card Transmitter

FM 26.995 AF130 TFM

FM 30.900 AF150 TFM

AM 26.995 AF26 TOP

AM 30.900 AF30 TOP

AM 433.92 AF43S TAM / TOP

AM 433.92 AF43TW TWIN

AM 40.685 AF40 TOUCH

AM 868.35 AF868 TOP

TAM

CA

TWIN

ATOMO

E

M

TOUCH

Page 26

26

319U75

2.0

7.13 Inputting users

1) From the Users

menu, select “Add

User”.

Press ENTER to

confirm.

ENGLISH

3) Choose which

function to assign to

the user....

Þß

Add User

2) Select “ confirm

(yes)” and press

ENTER key to confirm.

Related Func.

Þß

2-7

4) .... will ask to input

a code. Send the

code with the radiocommand button or

slide-through card or

transponder.

Add User

confirm? (yes)

Þß

Waiting Code

>>>>

ACCESS CONTROL

5) ... once the code

is inputted, the user

name will come up

showing the type of

command that was

memorised...

7.14 Changing users

1) From the Users

menu, choose

“Mod. name”.

Press ENTER to

confirm.

--001--

radio

... or if the code is

already inputted,

“Existing Code” will

appear.

Mod. name

Þß

2) Choose the user

number or name you

wish to change the

text of and press

ENTER to confirm.

Code exist

001:--001--

Choose User

001:--U001--

Þß

3) Use the ENTER

key to move the

cursor forward, ESC

to move it backwards

and < > to select the

letter or number.

Mod. name

--001--

4) Confirm the text by

pressing the ENTER key

for a few seconds.

Mod. name

JOHN

2.0 01/2009 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

319U75 ver.

26 - Manual code:

Pag.

Page 27

27

319U75

2.0

7.15 Changing code

1) From the Users

menu, choose

“Mod. Code”.

Press ENTER to

confirm.

3) .... you will be

asked to input a

code. Send the code

using the transmitter

button or the slide through card or the

transponder.

Mod. Code

Waiting Code

>>>>

Choose User

2) Choose the user

name for which you

wish to change the

001:--U001--

Þß

Choose User

002:--U002--

Þß

code and press ENTER

to confirm.

ENGLISH

4) .. once the code

is inputted, the user

name will come up

--002--

radio

showing the type of

command that was

ACCESS CONTROL

memorised...

7.16 Function assigned to the user

1) From the Users

menu, choose

“Related Fuc.”.

Press ENTER to

confirm.

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

3) Choose the new

function to assign

to the user. Press

ENTER to confirm.

01/2009 © CAME cancelli automatici s.p.a. -

2.0

ver.

Þß

Þß

Þß

Related Func.

Related Func.

2-7

Related Func.

open

5) Select “ confirm (yes)”

and press ENTER key to

confirm.

2) Choose the user

name fo which you

wish to change the

command function

and press ENTER to

confirm.

4) Choose “confirm

(yes)” and press

ENTER to confirm.

Mod. Code

confirm? (yes)

Þß

Choose User

001:--U001--

Þß

Choose User

002:--U002--

Þß

Related Func.

confirm? (yes)

Þß

319U75

:

Manual code

27 -

Pag.

Page 28

28

319U75

2.0

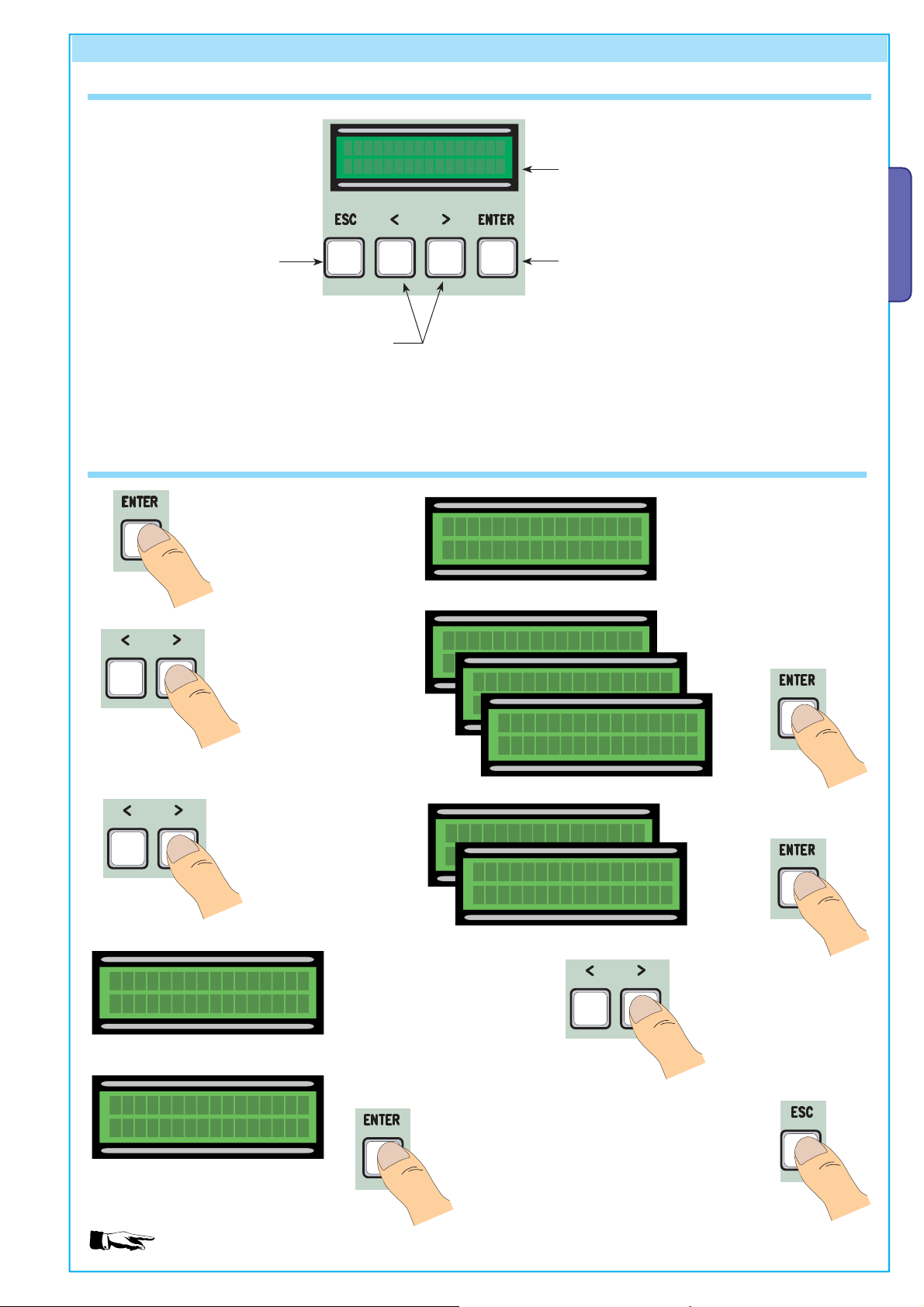

7.17 Gate run calibration

N.B. before calibrating the gate run, check that the manoeuvring area is free of any obstacles and check the proper direction of rotation of the

gearmotors. (para. 7.11)

1) From the Encoder

menu, select “Set

Encoder”. Press ENTER

to confirm.

ENGLISH

3) the gate leaf of the

first motor will perform

a closing run until fully

closed.....

5) …then, the gate leaf

of the second motor, will

perform and opening run

until fully open…

Set Encoder

Þß

2) Select “confirm

(yes) and press ENTER

to confirm.

Set Encoder

Close 1

4) …then, the

gate leaf of the

0

0

second motor will

perform the same

manoeuvre…

Set Encoder

Open 2

6) ...after which,

0

0

the gate leaf of

the first motor will

perform the same

manoeuvre…

Set Encoder

confirm? (no)

Þß

0

0

Set Encoder

confirm? (yes)

<>

Set Encoder

Close 2

0

Set Encoder

Open 1

0

7) When the procedure is

finished, the display will show

“Set Encoder ok” for a few

Set Encoder

OK

seconds.

7.18 Error messages

-“encoder ERROR”: check proper connections or functionality of the device and possibly even the motor’s torque”

-“safety d. test ERROR”: malfunctioning of safety devices, check proper functioning of connections and functionalities;

-“end stop ERROR”: check proper connections on end point connections or functionality of devices;

-“cycle time ERROR”: check the working time settings, the set time may be insufficient to complete the duty cycle.

- Safety STOP, C1, C3, C4”: check proper functioning of connections and functionalities of devices.

2.0 01/2009 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

319U75 ver.

28 - Manual code:

Pag.

Page 29

29

319U75

2.0

7.19 Illustration depicting the areas and points of deceleration and final opening and closing approaches per encoder device.

Note: the areas and points of deceleration and fi nal opening and closing approaches are tested according to the parameters set forth by

Technical Norms EN12445 and EN12453 regarding compatibility of impact forces generated by moving gate leaves.

A = Area of movement at normal speed

B* = Run zone at decelerated speed

C = Encoder intervention zone with

0

movement inversion

D= Encoder intervention zone with

movement stop

B

E = Opening deceleration beginning point

(M1 Open Deceler %)

F = Closing deceleration beginning point

(M1 Close Deceler %)

G = Opening deceleration beginning point

(M2 Open Deceler %)

B

A

C

H = Closing deceleration beginning point

(M2 Close Deceler %)

I** = Closing and opening fi nal phase

beginning point (M1 Final Close %)

L** = Closing and opening fi nal phase

beginning point (M2 Final Close %)

D

E

M

I

M= endstops

* Minimum 600 mm from the Final full stop.

**Set the function’s fi nal phase % “M1 Final Close” for the fi rst (M1) mtors and “M2 Final Close” for the second (M2) motor from the

“ENCODER” menu so as to obtain a distance of between 1 and 50 mm maximum from the fi nal full stop.

M

D

I

F H

D

L

B

A

C

B

G

L

0

ENGLISH

D

M

8 Demolition and disposal

In its premises, CAME CANCELLI AUTOMATICI S.p.A. implements an Environmental Management System certifi ed in

compliance with the UNI EN ISO 14001 standard to ensure environmental protection.

Please continue our efforts to protect the environment—which CAME considers one of the cardinal elements in the development of its

operational and market strategies—simply by observing brief recommendations as regards disposal:

DISPOSAL OF PACKAGING

The packaging components (cardboard, plastic, etc.) are all classifi able as solid urban waste products and may be disposed of easily,

keeping in mind recycling possibilities.

Prior to disposal, it is always advisable to check specifi c regulations in force in the place of installation.

PLEASE DISPOSE OF PROPERLY!

PRODUCT DISPOSAL

Our products are made up of various types of materials. Most of them (aluminium, plastics, iron, electrical wires, etc.) may be disposed

of in normal garbage collection bins and can be recycled by disposing of in specifi c recyclable material collection bins and disposal in

authorized centres. Other components (electrical boards, remote control batteries, etc.), however, may contain polluting substances.

They should therefore be removed and given to qualifi ed service companies for proper disposal.

Prior to disposal, it is always advisable to check specifi c regulations in force in the place of disposal.

PLEASE DISPOSE OF PROPERLY!

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

9 Manufacturer’s warranty

MANUFACTURER’S DECLARATION OF CONFORMITY

CAME Cancelli Automatici S.p.A.

via Martiri della Libertà, 15

31030 Dosson di Casier - Treviso - ITALY

tel (+39) 0422 4940 - fax (+39) 0422 4941

internet: www.came.it - e-mail: info@came.it

Declares under its own responsibility that the equipments for automatic garage doors and gates listed below:

01/2009 © CAME cancelli automatici s.p.a. -

… comply with the National Law related to the following European Directives and to the applicable parts of the

following Standards.

2.0

ver.

2006/95/EC L

2004/108/EC ELECTROMAGNETIC COMPATIBILITY DIRECTIVE

EN 60335-1 EN 61000-6-2

319U75

:

EN 13241-1 EN 61000-6-3

ZM3E - ZM3EC

OW VOLTAGE DIRECTIVE

Pursuant to the Low Voltage Directive 2006/95/EC

Do not use the equipment specifi ed here above, before

In full compliance with the Machinery Directive 98/37/EC

IMPORTANT WARNING!

completing the full installation

MANGING DIRECTOR

Mr. Andrea Menuzzo

Manual code

29 -

Reference code to request a true copy of the original: DDF L EN Z002e

Pag.

Page 30

CAME F ra nce S.a.

CAME France S.a.

Nanter re Cedex -

CAME G mb h Seefeld

Seefel d

CAME A ut omatismes S.a.

Marsei ll e -

CAME G mb h

Korn ta l

CAME A ut omatismos S.a.

Madri d -

CAME A me ricas Aut omation L lc

Sunris e

CAME A ut omatismos Cataluny a S.a.

Sant Vi cenc Del Horts -

CAME M id dle East Fzco

Dubai -

Paf - CA ME

Rio D e Mouro -

CAME P ol ska Sp.Zo .o

Warsza wa -

CAME U ni ted Kingd om Ltd.

Nottin gh am

S.c. C AM E Romania S.r.l.

Bucare st -

CAME B el gium Sprl

Lessi ne s -

CAME R us sia

Moskva

CAME C an celli Aut omatici S .p .a.

Dosso n Di Casier

CAME N or d s.r.l.

Colog no Monzese

CAME S er vice Ital ia S.r.l.

Dosso n Di Casier

Assist en za Tecnic a 800 295 83 0

CAME S ud s.r.l.

Napol i

En glish

119EU 7 5

2.0

7, Rue Des Haras

Z.i. Des Hautes Patures

92737

Nanterre Cedex - FRANCE

(+33) 1 46 13 05 05

(+33) 1 46 13 05 00

CAME Gmbh Seefeld

Akazienstrasse, 9

16356

Seefeld

Bei Berlin - DEUTSCHLAND

(+49) 33 3988390

(+49) 33 39883985

CAME Automatismes S.a.

3, Rue Odette Jasse

13015

Marseille - FRANCE

(+33) 4 95 06 33 70

(+33) 4 91 60 69 05

CAME Automatismos S.a.

C/juan De Mariana, N. 17-local

28045

Madrid - SPAIN

(+34) 91 52 85 009

(+34) 91 46 85 442

CAME Automatismos Catalunya S.a.

P.i. Moli Dels Frares N. 23 C/a

08620

Sant Vicenc Del Horts - SPAIN

(+34) 93 65 67 694

(+34) 93 67 24 505

Paf - CAME

Estrada Nacional 249-4 Ao Km 4,35

Cabra Figa - Trajouce

2635-047

Rio De Mouro - PORTUGAL

(+351) 219 257 471

(+35) 219 257 485

Kornwestheimer Str. 37

Munchingen Bei Stuttgart - DEUTSCHLAND

(+49) 71 5037830

(+49) 71 50378383

CAME Americas Automation Llc

1560 Sawgrass Corporate Pkwy, 4th Floor

Sunrise, FL 33323 - U.S.A

(+1) 305 433 3307

(+1) 305 396 3331

CAME Middle East Fzco

Po Box 17131 Warehouse N. Be02

South Zone - Jebel Ali Free Zone -

(+971) 4 8860046

(+971) 4 8860048

CAME Polska Sp.Zo.o

01-237

Warszawa - POLAND

(+48) 22 8365076

(+48) 22 8363296

CAME Gmbh

70825

Korntal

Dubai - U.A.E.

Ul. Ordona 1

CAME United Kingdom Ltd.

Unit 3 Orchard Business Park

Town Street, Sandiacre

Nottingham - Ng10 5du - UNITED KINGDOM

2.0 01/2009 © CAME cancelli automatici s.p.a.

119EU75 ver.

(+44) 115 9210430

(+44) 115 9210431

CAME Belgium Sprl

Zoning Ouest 7

7860

Lessines - BELGIUM

Buftea, Judet Ilfov

(+32) 68 333014

(+32) 68 338019

S.c. CAME Romania S.r.l.

B-dul Mihai Eminescu, Nr. 2, Bloc R2

Scara A, Parter, Ap. 3

Bucarest - ROMANIA

(+40) 21 3007344

(+40) 21 3007344

CAME Russia

Leningradskij Prospekt, Dom 80

Pod’ezd 3, offi ce 608

125190,

Moskva - RUSSIA

(+7) 495 937 33 07

(+7) 495 937 33 08

English - Manual code:

The data and information repor ted in this installation manual are susceptible to change at any time and without obligation on CA ME cancelli automatici s.p.a. to notify users.

CAME Cancelli Automatici S.p.a.

Via Martiri Della Libertà, 15

31030

Dosson Di Casier (Tv)

(+39) 0422 4940

(+39) 0422 4941

20093

CAME Nord s.r.l.

Piazza Castello, 16

Cologno Monzese (MI)

(+39) 02 26708293

(+39) 02 25490288

Informazioni Commerciali 800 848095

www.came.it

CAME Service Italia S.r.l.

Via Della Pace, 28

31030

Dosson Di Casier (Tv)

(+39) 0422 383532

(+39) 0422 490044

Assistenza Tecnica 800 295830

CAME Sud s.r.l.

Via F. Imparato, 198

Cm2 Lotto A/7

80146

Napoli

(+39) 081 7524455

(+39) 081 7529109

Loading...

Loading...