Page 1

CONTROL PANEL

h

FOR 24 V GEARMOTORS

FA00044-EN

INSTALLATION MANUAL

ZLJ14

E

nglis

Page 2

2

FA00 044-EN

1

IMPORTANT SAFETY INSTRUCTIONS WHEN INSTALLING

WARNING! IMPROPER INSTALLATION MAY RESULT IN SERIOUS DAMAGE, FOLLOW ALL INSTALLATION INSTRUCTIONS

THIS MANUAL IS EXCLUSIVELY INTENDED FOR PROFESSIONAL, SKILLED STAFF

LEGEND

This symbol shows which parts to read carefully.

This symbol shows which parts describe safety issues

⚠

This symbol shows which parts to tell users about.

☞

REFERENCE REGULATIONS

The product complies to the reference regulations in effect.

DESCRIPTION

Multi-function control pane for one-swing-leaf gates, with graphic programming-and-alert-display plus self-diagnosing of safety devices.

The functions on the input and output contacts, the time settings and user management, are set and viewed on the graphic display.

All connections are quick-fuse protected.

Intended use

Control panel Gearmotor

ZLJ14 AMICO - AXO - F4000 - FAST - FERNI - FROG - FROG J - MYTO

Any installation and/or use other than that specified in this manual is forbidden.

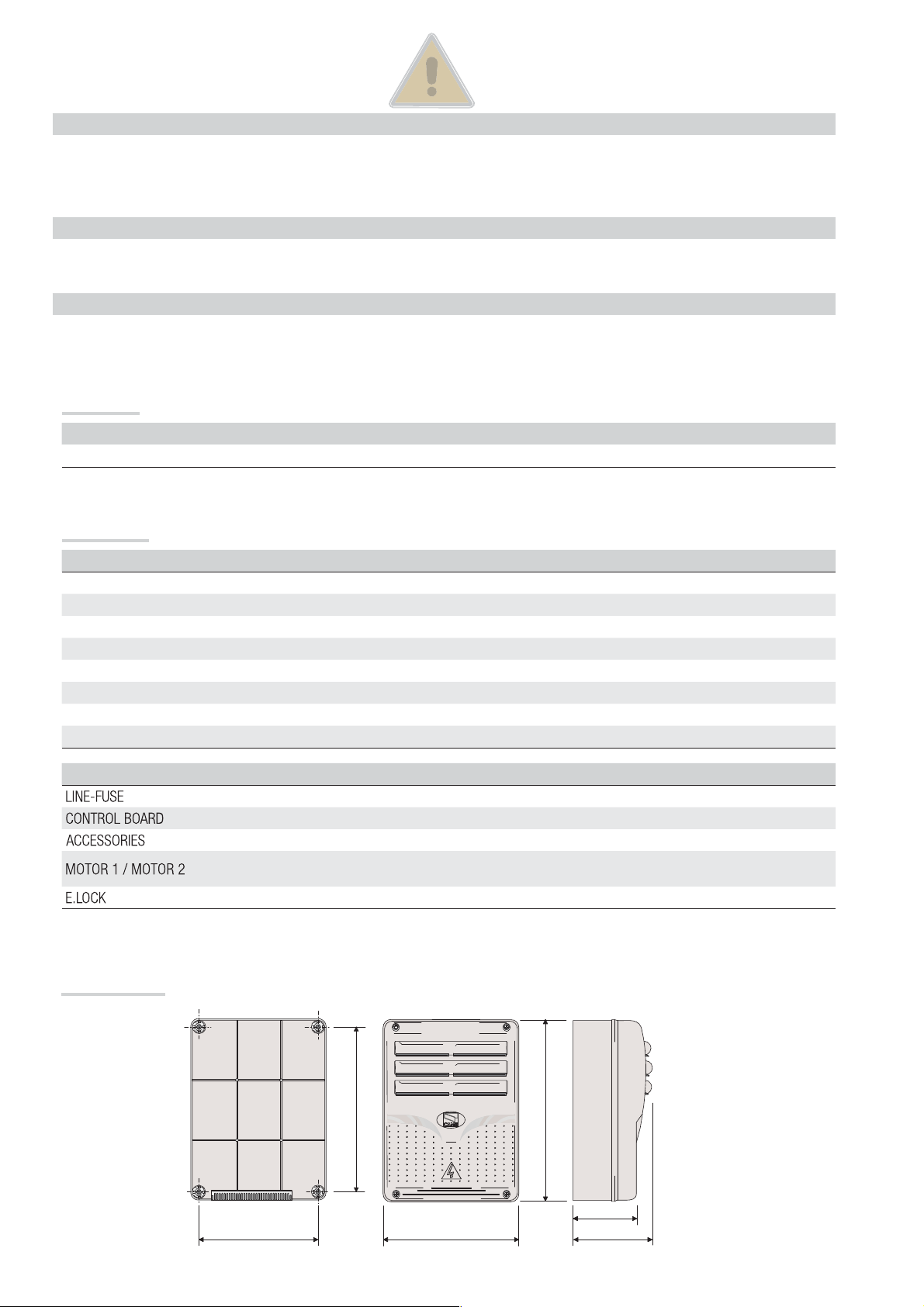

Technical data

Type ZLJ14

Protection rating (IP) 54

Power supply (V - 50/60 Hz) 230 AC

Maximum power (W) 250

Maximum power of the 24 V (W) accessories 50

Stand-by consumption (W) 5

Operating temperature (°C) -20 ÷ +55

Items ABS

Apparatus class II

Fuses ZLJ14

- Line

- Card

- Accessories

- Electrolock

- Motor

10 A - 250 V Ø 6.3x22 UFG632310

(Spare parts code 119RIR316)

1.6 A-F

630 mA-F

2 A-F

3.15 A-F

Dimensions (mm)

1- 03/2016 - © Came S.p.A. - The manual's contents may be edited at any time without notice.

FA00044-EN v.

2 - Manual code:

p.

Page 3

3

FA00 044-EN

1

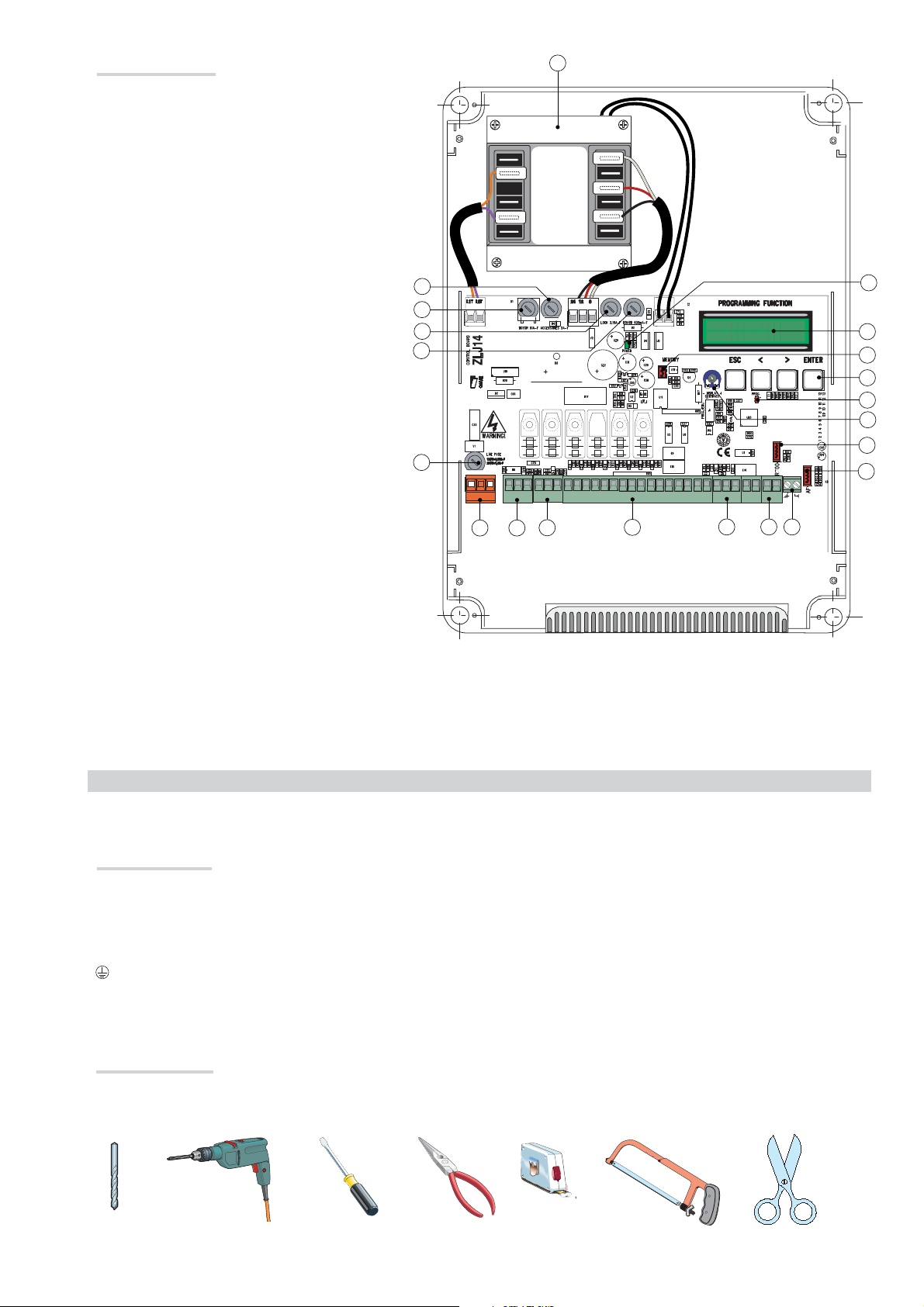

Description of parts

1. Transformer

2. Power supply on warning LED

3. Display

4. Memory roll board connector

5. Programming buttons

6. Programming warning LED

7. Display brightness adjusting trimmer

8. Connector for the R700 card

9. AF card connector

10. Antenna terminal

11. Terminals for transponder

12. Endstop terminals

13. Terminals for control and safety devices

14. Encoder terminals

15. Terminals for gearmotors

16. Power supply terminals

17. Line fuse

18. Control-board fuse

19. Electric-lock fuse

20. Motor fuse

21. Accessories fuse

21

20

19

18

17

L N

120V=3,15A-F

230V=1,6A-F

1

0V

0

17V

26V

230V

24 12 0L1T L2T

+ E - M N ENC

10 11 TS E E3 ES 1 2 3 3P 4 5 7 CX CY CZ

2

3

4

5

6

7

8

9

B1 B2 2 FA FC S1 GND

14

1516

13

101112

GENERAL INSTRUCTIONS FOR INSTALLING

Only skilled, qualified staff must install this product.

⚠

Before working on the control panel, cut off the main current supply and, if present, remove any batteries.

⚠

Preliminary checks

Before installing the control panel it is necessary to:

⚠

• make sure that the point where the control panel is fastened is protected from any impacts and that the anchoring surface is solid enough, and

that proper tools are used (that is, screws, anchors, and so on); • make sure you have set up a suitable dual pole cut off device along the power

supply that is compliant with the installation rules. It should completely cut off the power supply according to category III surcharge conditions

(that is, with minimum contact openings of 3 mm);

•

Make sure that any connections inside the container (ones that ensure continuity to the protection circuit) are fitted with additional insulation

with respect to those of other electrical parts inside.

Tools and materials

Make sure you have all the tools and materials you will need for installing in total safety and in compliance with applicable regulations. The figure

1- 03/2016 - © Came S.p.A. - The manual's contents may be edited at any time without notice.

shows some of the equipment installers will need.

FA00044-EN v.

3 - Manual code:

p.

Page 4

4

FA00 044-EN

1

Cable types and minimum thicknesses

Connection Cable type

Cable length

1 < 15 m

230 V AC power-supply to control panel H05RN-F 3G x 1.5 mm

Encoder gearmotor power supply*

3 x 1.5 mm

Power supply to gearmotor** 2 x 1.5 mm

Flashing light 2 x 0.5 mm

Photocell transmitters 2 x 0.5 mm

Photocell receivers 4 x 0.5 mm

FROR CEI 20-22

CEI EN

50267-2-1

Command and safety device 2 x 0.5 mm

Endstop*** 3 x 1.5 mm

2

2

2

Cable length

15 < 30 m

3G x 2.5 mm

3 x 2.5 mm

2 x 2.5 mm

2

2

2

2

2

2

2

2

Antenna the RG58 antenna max 10 m

Encoder**** 2402C 22AWG max 30 m

* AXO ** FROG-A24, F4024, F1024, FROG-A24E, F7024E *** FROG-A24, F4024, F1024 **** FROG-A24E, F7024E, F4024E

If cable lengths di er from those specifi ed in the table, establish the cable sections depending on the actual power draw of the connected

devices and according to the provisions of regulation CEI EN 60204-1.

For multiple, sequential loads along the same line, the dimensions on the table need to be recalculated according to the actual power draw and

distances. For connecting products that are not contemplated in this manual, see the literature accompanying said products

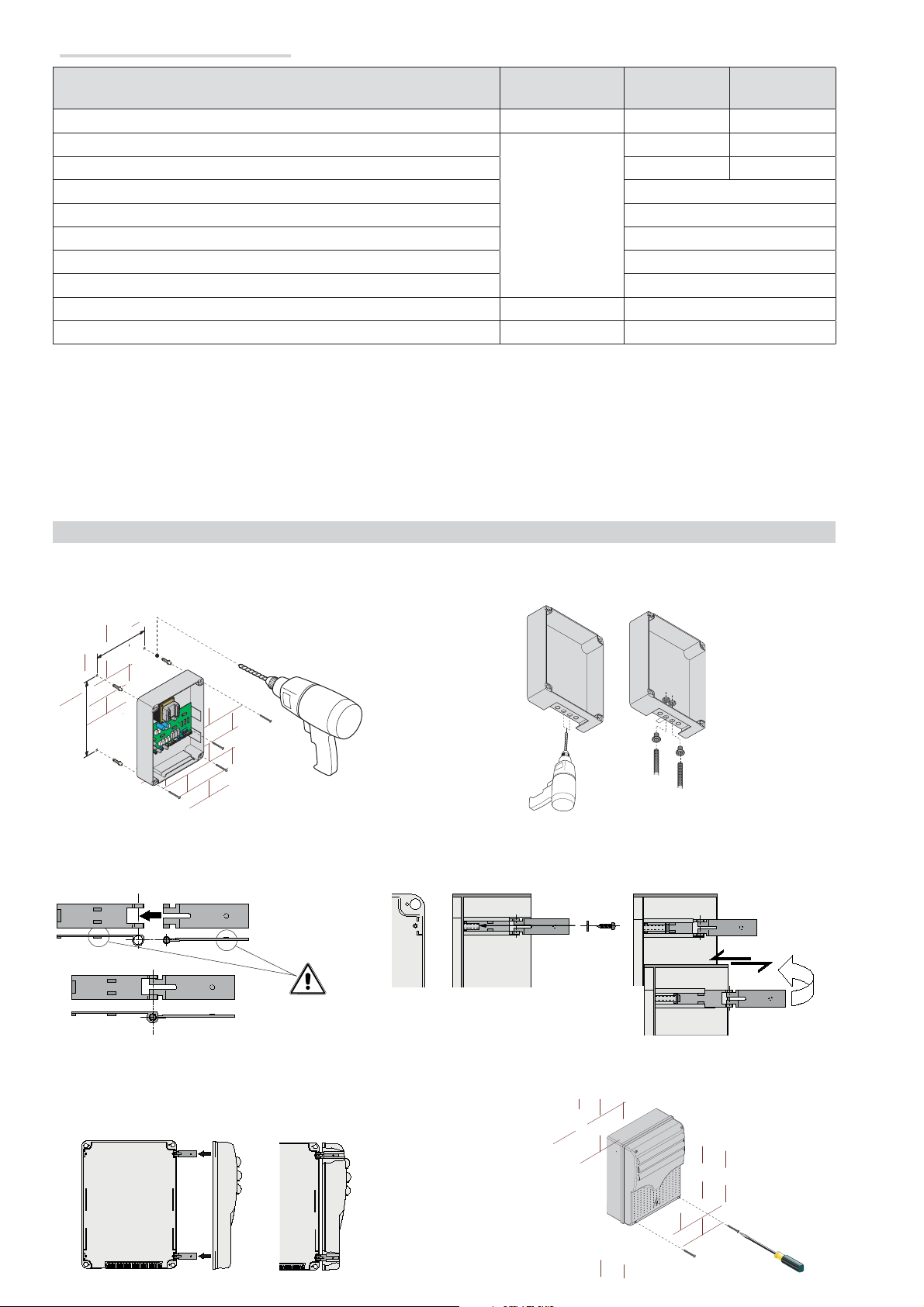

INSTALLATION

Fasten the control panel in a protected area using suitable screws. anchors and braces.

Drill through the pre-perforated holes and fit the cable gland with corrugated pipes for passing through the electric cables.

Pre-perforated hole diameter: 20 mm.

Assemble the pressure hinges.

Fit the hinges into the box (either on the right or left) and fasten them using the supplied screws and washers.

slide to rotate

15 mm~

Snap the cover onto the hinges. Close it and secure it using the supplied screws.

After performing the settings and adjustments, fasten the cover using the supplied screws.

1- 03/2016 - © Came S.p.A. - The manual's contents may be edited at any time without notice.

FA00044-EN v.

4 - Manual code:

p.

Page 5

5

FA00 044-EN

1

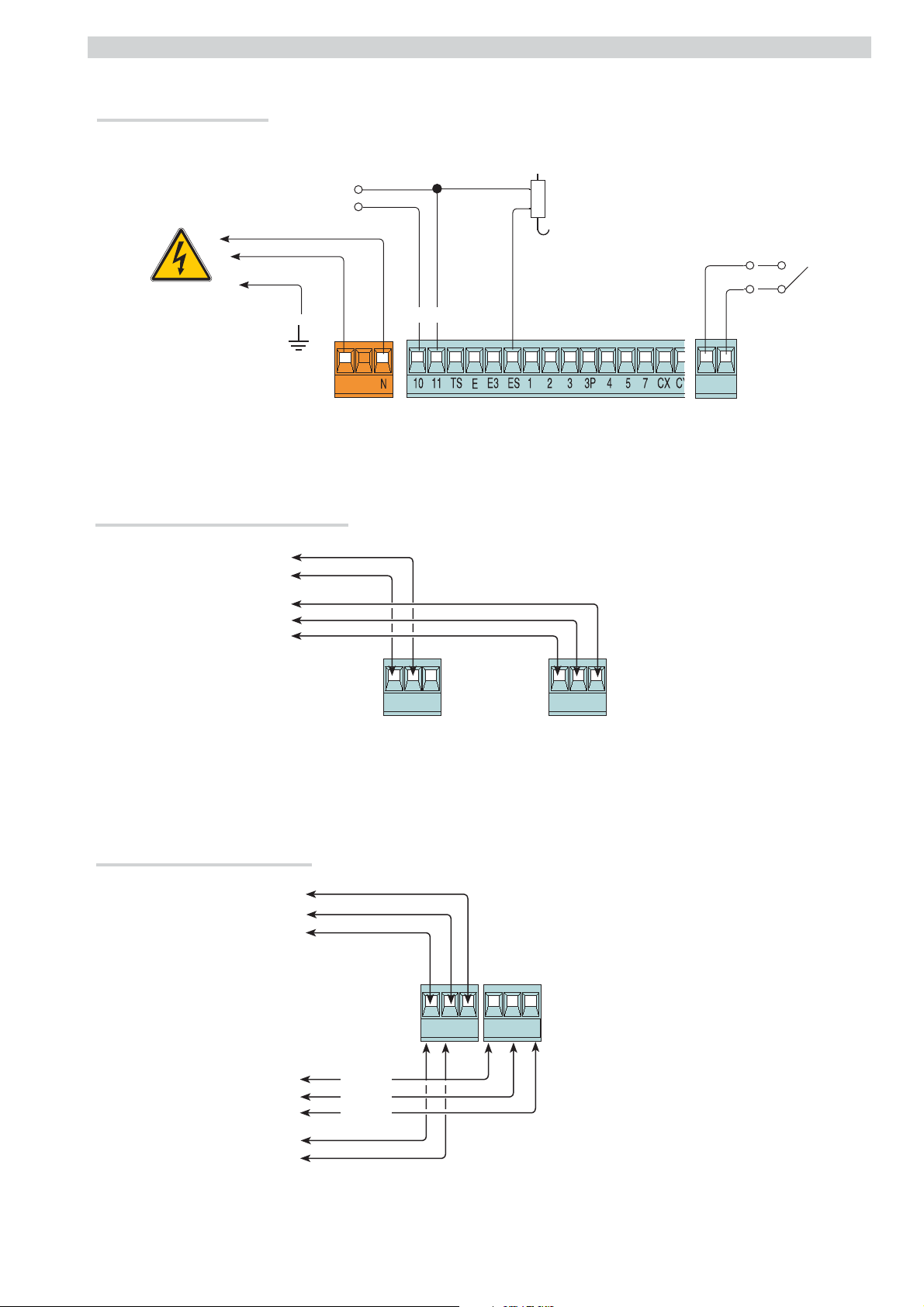

ELECTRICAL CONNECTIONS

Power supply to accessories

Terminals for powering the 24 V AC/DC

accessories Maximum power: 50 W

Electric-lock connection

rated at 12 V - 15 W max

Possible output of the

second radio-receiver

channel (NO contact).

Contact rated for:

500 mA - 24 V DC.

230 V AC - 50/60 Hz

Connecting the gearmotors with endstops

N

M

24 V DC gearmotor

FC

FA

F

+ -

L

MNENC 2FAFC

" "

Connecting the encoder gearmotors

24 V DC gearmotor

1- 03/2016 - © Came S.p.A. - The manual's contents may be edited at any time without notice.

FA00044-EN v.

5 - Manual code:

p.

E

N

M

MNENC +E-

+

E

-

White

Brown

Green

M

N

Page 6

CY

6

FA00 044-EN

1

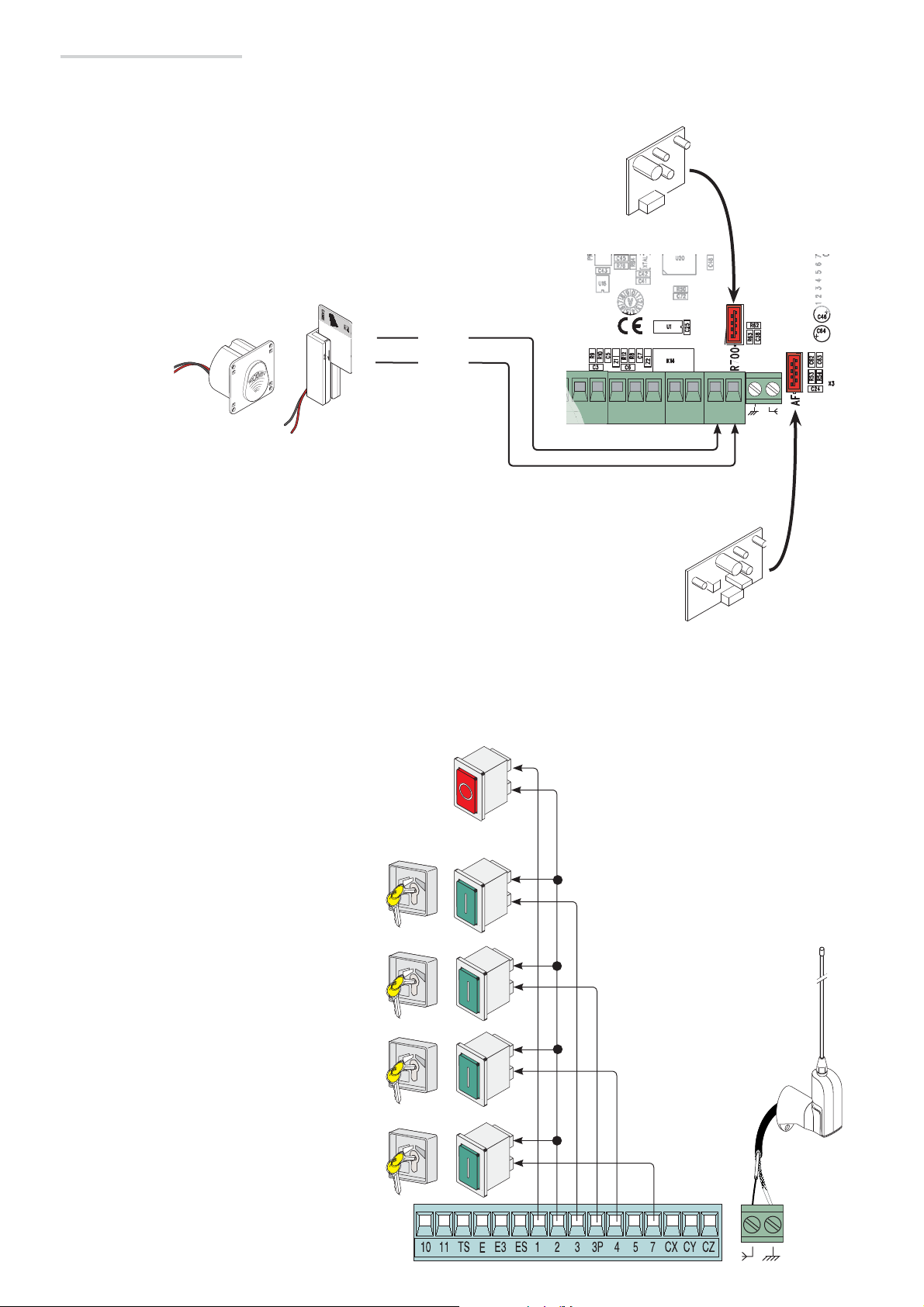

Command and control devices

Command and control devices

Before fitting any snap-in cards (such as the AF or R700), YOU MUST CUT OFF THE POWER MAINS, and disconnect the power

⚠

mains.

Transponder or

card reader

Fit the R700 decoding card for recognition of the TSP00

sensor or the LT001 card reader.

ACCESS CONTROL

Red

Black

CAME

CY CZ

Fit the AF card to control the operator

via transmitter.

R700

B1 B2 2 FA FC S1 GND

AF

Stop button (NC contact). For stopping the gate leaves while excluding

automatic closing. To resume movement press the control button or

use another control device.

If unused, select [Disabled] from the [Total Stop] in the

[FUNCTIONS].

OPEN ONLY function from control device with NO

contact.

PARTIAL OPENING feature from command device (NO

contact).

See the [Partial open] function, for opening times in the

[SET TIMES] menu.

ONLY CLOSE function from control device (NO

contact).

OPEN-STOP-CLOSE-STOP sequential function /

OPEN-CLOSE-INVERT step-step from a control

device (NO contact).

See the [2-7 command] in the [FUNCTIONS].

Antenna with RG58 cable

1- 03/2016 - © Came S.p.A. - The manual's contents may be edited at any time without notice.

FA00044-EN v.

6 - Manual code:

p.

Page 7

7

FA00 044-EN

1

Signaling devices

Signaling devices

Courtesy light (contact rated for: 24 V - 25 W max).

Auxiliary connection of an outdoor light which can be positioned

where you like, to increase lighting in the driveway/parking area.

It stays on for a settable time.

See the [Courtesy Time] function in the [SET TIMES] menu.

Flashing light or cycle light

(contact rated for: 24 V - 25 W max).

Flashing light: it flashes during the gate's opening and

closing phases.

Cycle light: it stays on from the moment the leaf starts

opening until it again closes completely (including the

automatic-closing time)

See the [Light E] in the [FUNCTIONS].

Gate open warning light (Contact rated for:

24 V - 3 W max).

To warn that the gate is open.

It switches o when the gate is closed.

CAME

Safety devices

Photocells

Configure contact CX, CY or CZ (NC), input for EN 12978

safety devices like photocells.

See [CX input], [CY input] or [CZ input].

- C1 reopening during closing. When the leaf is closing,

opening the contact causes the leaf to invert its direction of

movement until it is completely open;

- C2 closing during opening. When the leaf is opening ,

opening the contact causes the leaf to invert its direction of

movement until it is completely closed;

- C3 partial stop. Leaf stops, if it is moving, and sets up for

automatic closing (if the automatic closing function has been

activated;

- C4 obstruction wait. Leaf stops, if it is moving, and starts

back again once the obstruction is removed.

If unused, contacts CX, CY and CZ should be disabled

during programming.

RX

DIR DELTA-S

RX TX

./

#.#

DELTA

TX

Sensitive Safety Edges

Configure contact CX, CY or CZ (NC), input for EN 12978

safety devices such as sensitive safety-edges.

See [CX input], [CY input] or [CZ input].

- C7 reopening during closing. When the leaf is closing,

opening the contact causes the leaf to invert its direction

of movement until it is completely open;

- C8 reclosing during opening. When the leaf is opening,

opening the contact, causes it to invert its movement

1- 03/2016 - © Came S.p.A. - The manual's contents may be edited at any time without notice.

until it is completely closed.

If unused, contacts CX, CY and CZ should be

disabled during programming.

FA00044-EN v.

7 - Manual code:

p.

DFW

DFW with control

board of the DFI

connections

Page 8

8

FA00 044-EN

1

Connecting the safety devices (i.e. the safety test)

At each opening or closing command, the card checks the efficiency of the safety devices, such as photocells). Any anomalies will inhibit all

commands.

Select from the [Safety Test] which of inputs CX, CY or CZ to turn on.

FUSIBILE 200m A

+

C

10 2 T X

-

DELTA

+

N.O.

C.

N.C.

+

-

+

NC

DIR /

TX 2

TX

2

DELTA S

-

-

1- 03/2016 - © Came S.p.A. - The manual's contents may be edited at any time without notice.

FA00044-EN v.

8 - Manual code:

p.

Page 9

9

FA00 044-EN

1

PROGRAMMING

PROGRAMMING

Description of programming commands

the <-----> signs on the display are for:

- showing the currently selected item

{

The ESC button is for:

- exiting menus;

- cancelling changes.

The < > keys are for:

- moving from one item to another;

- increasing or decreasing values.

To enter the menu, keep the ENTER

button pressed for at least one

second.

To select menu items,

use the arrow keys ...

{

{

The ENTER key is for:

- entering menus;

{

- confirming or memorizing set values.

LANGUAGE

< English >

FUNCTIONS

Imp. Run

.. then press ENTER

< TIMING ADJ >

also for the submenus,

use the arrow keys to

select ...

If the < > arrows are set to the

Cycle Time

< 90s. >

1- 03/2016 - © Came S.p.A. - The manual's contents may be edited at any time without notice.

Cycle Time

< 100s. >

[Cycle time], you may edit their

value.

... the press ENTER to confirm ...

< A.C.T. >

< Cycle Time >

90s.

... to exit the menu wait 30

seconds, or press ESC, until the

start up screen appears.

.. then press ENTER

To increase or reduce the value

use the arrows...

FA00044-EN v.

9 - Manual code:

p.

Page 10

10

FA00 044-EN

1

Meaning of the menu items abbreviations

[Travel sens] Gate Run Sensibility

[Partial open] Partial Opening

[Maint Action] Maintained Action

[Auto Close] Automatic Closing

[Config

]

Configuration

[Assoc Function] Associated Function

[Set Travel] Set gate-leaf Travel

[

Open Accel]

[Close

[

Opn Slw Dwn]

[Cls

Opening Soft-Stop as a percentage

Accel]

Closing Soft-Stop as a percentage

Opening Slow Down as a percentage

Slw Dwn]

Closing Slow Down as a percentage

[Change Code] Mod. name

[Start message] Starting message

[Soft Start] Slowed-down Start

[Enc Slow Down] Opening and closing slow-downs with ENCODER

[Obstruc Detct

]

Obstruction Detection

[Delete user] Remove User

[Amper. Sens.] Amperometric Sensitivity

[Travel sens] Travel Sensitivity

[Slw Dwn sens] Sensitivity of Slow Downs

[Closing thrust] Closing thrust

[Ram jolt

time]

Ram-jolt Time

[Preflash time] Preflashing Time

[Slow down

time]

Slow-down Time

[Lock time] Lock Time

[ACT] Automatic Closing Time

[

PartialACT]

[Slow dwn s

peed]

Slow-down Speed

Partial Automatic Closing Time

[Travel rate %] Gate-leaf Travel Speed

Menu map

[LANGUAGE] Default

[Italiano] / [English] / [Français] / [Deutsch] / [Español] / [Portugues euro]/[Portugues bras]

English

[FUNCTIONS] Default

[Auto Close] [Disabled] / [Enabled] [Enabled]

[Maint Action] [Disabled] / [Enabled] / [Closing] [Disabled]

[Obstruc Detct] [Disabled] / [Enabled] [Disabled]

[Safety Test] [Disabled] / [CX] / [CY] / [CZ] / [CX+CY] / [CX+CZ] / [CY+CZ] / [CX+CY+CZ] [Disabled]

[Preflashing] [Disabled] / [Enabled] [Disabled]

[Ram Jolt] [Disabled] / [Closing] / [Opening] / [Open-Close] [Disabled]

[Total Stop] [Disabled] / [Enabled] [Enabled]

[CX input] [Disabled] / [C1] / [C2] / [C2] / [C4] / [C7] / [C8] [C1]

[CY input] [Disabled] / [C1] / [C2] / [C2] / [C4] / [C7] / [C8] [C3]

[CZ input] [Disabled] / [C1] / [C2] / [C2] / [C4] / [C7] / [C8] [C2]

[Closing thrust] [Disabled] / [Enabled] [Disabled]

[Lock] [Disabled] / [Closing] / [Opening] / [Open-Close] [Closing]

[LockType] [Pulsed] / [Continuous] [Pulsed]

[Config] [Time Lmt Swtch] / [End Stop] / [Slow Down] / [Op LS-Cl Sl Dn] / [ENCODER] [ENCODER]

[End Stop] [N.C. / N.O.] [N.C.]

[2-7 command] [Open-Close] / [Opn Stp Clse] [Open-Close]

[Light E] [Flashing light] / [Courtesy] / [Cycle] [Flashing light]

[B1-B2 output] [Bistable] / [Monostable] [Monostable]

[IMP. TRAVEL] Default

[Motor type] [FROG-F4024E] / [FROG J] / [FROG-FL] / [AMICO] / [MYTO] / [AXO] / [FAST] / [FERNI] [FROG-F4024E]

[Travel rate %] [20%]

⇨

[100%] [100%]

[Slow dwn speed] [5%] ⇨ [80%] [50%]

[Soft Start] [Enabled] / [Disabled] [Disabled]

[Amper. Sens.]* [Enabled] / [Disabled] [Enabled]

[Travel sens]* [

-◦+

[Slow downtime]** [0 s] ⇨ [30 s] [20 s]

*This function does not appear if [ENCODER] from the [Config].

**This function only appears if [Slow Down]or [Op LS-Cl Sl Dn] from the [Config].

1- 03/2016 - © Came S.p.A. - The manual's contents may be edited at any time without notice.

FA00044-EN v.

]

10 - Manual code:

p.

Page 11

11

FA00 044-EN

1

[ENCODER] Default

[Sensibility] [Enabled] / [Disabled] [Enabled]

[Travel sens] [

[Slw Dwnsens] [

-◦+

-◦+

[Enc Slow Down] [ON] / [OFF] [ON]

[

Opn Slw Dwn]

[C

ls SlwDwn

[C

Close Accel]

[

OpenAccel]

[1%] ⇨ [40%] [10%]

] [1%] ⇨ [40%] [10%]

[1%] ⇨ [15%] [15%]

[1%] ⇨ [15%] [15%]

[Travel calibr] [Confirm? (No)] / [Confirm? (Yes)]

SET TIMES Default

[ACT] [0 s]

[

PartialACT]

[0 s]

⇨

[300 s] [10 s]

⇨

[300 s] [10 s]

[Cycle time] [10 s] ⇨[150 s] [90 s]

[Preflash time] [1 s] ⇨ [60 s] [5 s]

[Lock time] [1 s] ⇨ [5 s] [2 s]

[Ram jolt time] [1 s]

⇨

[3 s] [1 s]

[Partial open] [5 s] ⇨ [60 s] [10 s]

[Courtesy Time] [1 s] ⇨ [300 s] [300 s]

[USERS]

[Add User] (250 max)

[Change Name]

[Change Code]

[Assoc Function] [2-7] / [Open] / [B1-B2] / [2-3P] / [Disabled];

[Delete user]

[Delete ALL] [Confirm? (No)] / [Confirm? (Yes)]

[Save memory] [Confirm? (No)] / [Confirm? (Yes)]

[Load memory] [Confirm? (No)] / [Confirm? (Yes)]

]

]

[INFO]

[Version] / [No. of travels] / [Start message] / [Reset system]

[MOTORS TEST]

[OPEN =>]

IMPORTANT! Start programming by performing the first function, that is, [MOTOR TYPE], [TOTAL STOP] and [TRAVEL

CALIBR]

.

Language menu

[LANGUAGE]

[Italiano] / [English] / [Français] / [Deutsch] / [Español] / [Portugues euro] / [Portugues bras]

Select one of the available languages

Functions menu

[FUNCTIONS]

1- 03/2016 - © Came S.p.A. - The manual's contents may be edited at any time without notice.

[Auto Close] [Disabled] / [Enabled]

The fi rst automatic-closing wait starts when the opening endstop point is reached and can be set to between 0 and 300 s. The automatic

closing does not turn on if any of the safety devices trigger when an obstruction is detected, after a total stop or during a power outage.

FA00044-EN v.

[Maint Action] [Disabled] / [Enabled] / [Closing]

The leaf opens and closes by keeping a button pressed. Opening button on contact 2-3 and closing button on contact 2-4. All other control

devices, even radio-based ones, are excluded.

11 - Manual code:

p.

Page 12

12

FA00 044-EN

1

[Obstruc Detct] [Disabled] / [Enabled]

With the leaf closed, open or after a total stop, the operator remains idle if the safety devices, like photocells or sensitive safety-edges)

detect and obstruction.

[Safety Test]

After every opening or closing command, the board will check whether the photocells are working properly

[Disabled] / [CX] / [CY] / [CZ] / [CX+CY] / [CX+CZ] / [CY+CZ] / [CX+CY+CZ]

.

[Prefl ashing] [Disabled] / [Enabled]

After an opening or closing command, the fl ashing light connected to 10-E, fl ashes before the maneuver starts.

To set the time, see

[Preflash time]

in the

SET TIMES menu

.

[Ram Jolt] [Disabled] / [Closing] / [Opening] / [Open-Close]

Before each opening and closing, the gate-leaf gives a fi nal thrust to assist the electric-lock release. To adjust the thrust time, select

jolt time]

in the

SET TIMES menu

.

[Ram

[Total Stop] [Enabled] / [Disabled]

NC input - Leaf stop while excluding any automatic closing; to resume movement, use the control device. The safety device is inserted into

[1-2].

[CX input] [Disabled] / [C1] / [C2] / [C3] / [C4] / [C7] / [C8]

NC input – Can associate: C1 = reopening during closing by photocells, C2 = reclosing during opening by photocells, C3 = partial stop, C4

= obstruction wait, C7 = reopening during closing by sensitive safety-edges, C8 = reclosing during opening by sensitive safety-edges.

[CY input] [Disabled] / [C1] / [C2] / [C3] / [C4] / [C7] / [C8]

NC input – Can associate: C1 = reopening during closing by photocells, C2 = reclosing during opening by photocells, C3 = partial stop, C4

= obstruction wait, C7 = reopening during closing by sensitive safety-edges, C8 = reclosing during opening by sensitive safety-edges.

[CZ input] [Disabled] / [C1] / [C2] / [C3] / [C4] / [C7] / [C8]

NC input – Can associate: C1 = reopening during closing by photocells, C2 = reclosing during opening by photocells, C3 = partial stop, C4

= obstruction wait, C7 = reopening during closing by sensitive safety-edges, C8 = reclosing during opening by sensitive safety-edges.

[Closing thrust] [Disabled] / [Enabled]

At each closing endstop, the operator thrusts the fi nal closing of the leaf for a a few seconds.

[Lock]

[Disabled] / [Closing] / [Opening] / [Open-Close]

Set the electric lock to lock the leaves,

by choosing among one of the available choices.

[Lock Type] [Pulsed] / [Continuous]

Setting the type of electric lock:

- impulse electric lock - it activates for a few seconds when the gate is either open or closed. The activation time is adjusted by the[Lock

time] function

- continuous electric lock - it activates during the entire opening or closing maneuver.

[Confi g]

[Slow Down] / [Op LS-Cl Sl Dn] / [ENCODER] / [Time Lmt Swtch] / [End Stop]

Configuring the opening and closing slow-downs

[Slow Down]*

[Lsop-Clos. Slw]

[ENCODER]

[Time Lmt Swtch]

[End Stop]

➡opening and closing slow-downs.

*

➡opening endstop and closing slow-down.

➡slow-down management, obstruction detection and sensitivity.

➡timed endstop.

➡opening and closing endstop.

* slowdowns configurable with the [Slow down time] in the [Set Travel]

[End Stop] [N.C] / [N.O]

Configuring the endstops as normally opened or closed contacts.

This function only appears if option is selected between

[End Stop], [Lsop-Clos. Slw]

or

[Slow Down]

from the

[Confi g] function

.

[2-7 command] [Open-Close] / [Opn Stp Clse]

Configuration contact 2-7 in step-step (open-close) or sequential (open-stop-close-stop).

[Light E] [Cycle] / [Flashing light]

Configuring the light connected to 10-E:

- cycle: freely positionable outdoor light for increasing lighting in the driveway/parking area. It stays lit from the moment that the gate leaf

starts opening until it is completely closed (including the automatic closing time). In case the automatic closing is off, it stays on only during

the gate-leaves' movement.

- flashing: to alert when the moving leaf is either closing or opening.

[B1-B2 output] [Monostable] / [Bistable]

Configuring contact B1-B2 in Monostable or Bistable mode (switch).

1- 03/2016 - © Came S.p.A. - The manual's contents may be edited at any time without notice.

FA00044-EN v.

12 - Manual code:

p.

Page 13

13

FA00 044-EN

1

Gate run setting menu

[Set Travel]

[Motor type] [FROG-F4024E] / [FROG-J] / [FROG-FL] / [AMICO] / [MYTO] / [AXO] / [FAST] / [FERNI] / [ATI]

Setting the type of operator installed in the system.

⇨

[Travel rate %] [50%]

[100%]

Adjusting the maneuvering speed, calculated as a percentage.

[Slow dwn speed] [10%] ⇨ [50%]

Adjusting the slow-down speed, calculated as a percentage.

[Soft Start] [Disabled] / [Enabled]

After each opening and closing command, the leaves start at slowed down speed for a few seconds.

[Amper. Sens.] [Disabled] / [Enabled]

Obstruction detection sensibility.

This function does not appear if [Encoder] is set in the [Config] function.

When an obstruction is met the function intervenes in the following way:

- [Time Lmt Swtch]it stops the gate leaves during a maneuver;

- [End Stop] it inverts the gate leaves during a maneuver;

- [Slow Down] it inverts the gate leaf movement during a maneuver and stop the movement during a slow down.

- [Lsop-Clos. Slw] it inverts the gate leaves during a maneuver and stops them only during the closing slow-down.

When the function is disabled, it stops the gate leaves when the maximum voltage threshold is exceeded.

[Travel sens]

[

-◦+

]

Adjusting the Amperometric sensibility.

You need to turn on the [Amper. Sens.] in the [Set Travel].

[Slow down time] [OFF] ⇨ [30 s]

Slow-down time of the gate leaves before every endstop. The time can be set to between zero and 30 s.

This function only appears if the [Slow Down] or [Lsop-Clos. Slw] from the [Config] function.

ENCODER menu

The [ENCODER] menu appears only when the [Config] in the [FUNCTIONS] menu.

[ENCODER] menu

[Sensitivity] [Enabled] / [Disabled]

Obstruction detection sensibility.

[Travel sens] [

-◦+

]

Obstruction detection sensitivity during gate run (both opening and closing).

You need to turn on the [Sensitivity] in the [ENCODER] menu.

[Slw Dwn sens] [

-◦+

]

Obstruction detection sensitivity during slow-down (both opening and closing).

You need to turn on the [Sensitivity] in the [ENCODER] menu.

[Enc Slow Down] [ON] / [OFF]

Activating the opening and closing slow-down starting points.

[Opn Slw Dwn] [1%] ⇨ [40%]

Adjusting the starting slow-down point before the opening endstop.

The starting slow-down point is calculated as a percentage ( from 1% to 40% of the complete leaf-travel).

This function only appears if the [Enc Slow Down] in the [ENCODER] menu.

1- 03/2016 - © Came S.p.A. - The manual's contents may be edited at any time without notice.

[Cls Slw Dwn [1%] ⇨ [40%]

Adjusting the starting slow-down point before the closing endstop.

The starting slow-down point is calculated as a percentage ( from 1% to 40% of the complete leaf-travel).

FA00044-EN v.

This function only appears if the [Enc Slow Down] in the [ENCODER] menu.

[Close Accel] [1%] ⇨ [15%]

Adjusting the soft-spot starting point calculated as a percentage (from 1% to 15% of the complete travel) before the closing endstop point.

13 - Manual code:

p.

Page 14

14

FA00 044-EN

1

[Open Accel] [1%] ⇨ [15%]

Adjusting the soft-spot starting point as a percentage (from 1% to 15% of the complete travel) before the opening endstop point.

[Travel calibr]

Automatic calibration of the gate-leaf run (see the TRAVEL CALIBRATION paragraph)

Time settings menu

SET TIMES

[ACT] [0 s] ⇨ [300 s]

The fi rst automatic-closing wait starts when the opening endstop point is reached and can be set to between 0 and 300 s. The automatic

closing does not turn on if any of the safety devices trigger when an obstruction is detected, after a total stop or during a power outage.

[Partial ACT] [0 s] ⇨ [300 s]

Leaf waiting-time when open, after a partial close command. Once this time elapses, a closing maneuver is automatically performed. The

waiting time can be set to between 0 and 300 seconds.

[Cycle time] [10 s]

⇨

[150 s]

Gearmotor working time during opening and closing. The working time can be set to between 10 and 150 seconds.

[Prefl ash time] [1 s]

⇨

[60 s]

After an opening or closing command, the flashing light connected on 10-E, flashes between one and sixty seconds before starting the

maneuver.

[Lock time] [1 s]

⇨

[5 s]

Intervention time for the electrolock to release after each opening command. The intervention time can be adjusted to between one second

and fi ve seconds.

[Ram jolt time] [1 s] ⇨ [3 s]

The closing and opening jolt thrust-time of the geartmotors after each command. The thrust time can be set to between one and three

seconds.

[Partial open]

[5 s]

⇨

[60 s]

Leaf opening time. The time can set between 5 s and 60 s.

[Courtesy Time] [60 s] ⇨ [300 s]

Supplementary light. It stays on for the time needed during the gate's opening or closing maneuvers.

contact output [10-E3]. It is adjustable between 60 s and 300 s.

Users Menu

Users Menu

[USERS]

[USERS]

[Add User]

Entering up to 250 users and associating to each one a function of choice among those included. The entering must be done via transmitter or other control device (see ENTERING NEW USERS).

[Change Name]

To change the number or name of users

[Change Code]

To modify the command code that is associated to a user.

[Assoc Function]

[

2-7]

[Open]

[2-3P]

[B1-B2]

➡

Step-step command (open-close) or sequential command (open-stop-close-stop)

➡

Open only command

➡

Pedestrian or partial opening

➡

Contact B1-B2 output

[Delete user]

To remove a user. Confirm removal with ENTER.

[Delete ALL]

To remove all users. Confirm removal with ENTER.

1- 03/2016 - © Came S.p.A. - The manual's contents may be edited at any time without notice.

FA00044-EN v.

14 - Manual code:

p.

Page 15

15

FA00 044-EN

1

[Save memory]

To save system users and settings in memory roll. Confirm saving with ENTER.

[Load memory]

For uploading the data saved in the memory roll onto the electronic board.

If the boards feature different versions, you may only upload the users.

Info menu

[INFO]

[Version]

View software version.

[No. of travels]

View the number of completed maneuvers.

[Start message]

View opening message. To edit the text, press ENTER. Use ENTER to move the cursor forward, ESC for moving the cursor backward and <

> to select the letter of figure. Confirm text by pressing the ENTER key for some seconds.

[Reset system]

To restore the initial settings. Press ENTER to confirm the Reset.

Motors Test menu

[MOTORS TEST]

[OPEN =>]

For checking the proper rotation direction of the gearmotors.

Keep the < key pressed for some seconds and check that the leaf actually opens. If the rotation direction is wrong, invert the motor's

phases.

1- 03/2016 - © Came S.p.A. - The manual's contents may be edited at any time without notice.

FA00044-EN v.

15 - Manual code:

p.

Page 16

16

FA00 044-EN

1

Entering a new user

1. From the

[USERS], select

[Add User]. Press

ENTER to confirm.

< Add User >

2. Select [Confirm?

(Yes)] and press

ENTER to confirm.

Add User

<Confirm?(yes)>

3. Select the function

to associate to users.

Press ENTER to

confirm...

5. Once the code

is entered, the user

number will appear

with the memorized

number ...

Modify user name

Assoc Function

< 2-7 >

--001-Radio

4. ... a code to enter will

be requested.

Send the code from

the transmitter, with

the swipe card or

transponder.

6. ... or, if the code is

already entered, then

[Existing code].

Wait for code

>>>>>>

ACCESS CONTROL

Existing code

001: --U001--

1. From the

[USERS], select

[Change Name].

Press ENTER to

confirm

3. Use ENTER to move

the cursor forward,

ESC for moving the

cursor backward and

< > to select the

letter of figure.

< Change Name >

Change Name

--001--

2. Select the user

number or name to edit

and press ENTER to

confirm.

4. Press ENTER for a

few seconds to confirm

the text.

Select user

< 001: --U001-- >

Change Name

JOHN----

1- 03/2016 - © Came S.p.A. - The manual's contents may be edited at any time without notice.

FA00044-EN v.

16 - Manual code:

p.

Page 17

17

FA00 044-EN

1

Modify code

1. From the

[USERS], select

[Change Code].

Press ENTER to

confirm

3. ... a code to enter

will be requested.

Send the code from

the transmitter, with

the swipe card or

transponder.

< Change Code >

Wait for code

>>>>>>

ACCESS CONTROL

2. Select the user name

of which you want to

edit the code and press

ENTER to confirm.

4. ... once the code

is entered, the user

number and type of

memorized command

will appear...

Change Code

Change Code

< 002: --U002-- >

002

Radio

Function related to the user

1. From the

[USERS], select

[Assoc Function].

Press ENTER to

confirm

3. Select the new

function to relate to

the user. Press ENTER

to confirm.

1- 03/2016 - © Came S.p.A. - The manual's contents may be edited at any time without notice.

<Assoc Function>

Assoc Function

Assoc Function

< 2-7 >

5. Select [Confirm?

(Yes)] and press ENTER

to confirm.

2. Select the user

name for which you

want to change the

function and press

ENTER to confirm.

4. Select [Confirm?

(Yes)] and press ENTER

to confirm.

Change Code

<Confirm?(yes)>

Select user

Select user

< 002: --U002-- >

Assoc Function

<Confirm?(yes)>

FA00044-EN v.

17 - M anual code:

p.

Page 18

18

FA00 044-EN

1

Travel calibration

Before calibrating the gate run, check that the maneuvering area is free from any obstruction and that there are both opening and

⚠

closing mechanical stops.

The mechanical end-stops are obligatory.

⚠

Important! During the calibration, all safety devices will be disabled except for the PARTIAL STOP one.

1. From the [ENCODER]

menu, select [Travel

calibr]. Press ENTER to

confirm

3. The gate-leaf will close

until the final strike-point ...

<Travel calibr>

Travel calibr

Close

2. Select [Confirm?

(Yes)] and press

ENTER to confirm.

4. ... then, the gate-

leaf, will open until the

final strike-point.

Travel calibr

Travel calibr

<Confirm?(yes)>

Travel calibr

Open

5. Once the procedure is

over, the display will show

[Travel calibr OK] for a few

seconds.

Memory Roll Card

For memorizing user and system configuration data, then using them on another control board.

After memorizing the data, it is best to remove the Memory Roll card while the control board is in operation.

ERROR MESSAGE

Travel calibr

OK

Memory roll

1- 03/2016 - © Came S.p.A. - The manual's contents may be edited at any time without notice.

Error messages appear on the display.

[Encoder - ERROR], [Error!] Broken encoder or wrong connection.

[Safety Test - ERROR] Safety devices malfunctioning.

[End Stop - ERROR] Malfunctioning endstop contacts

[Cycle time - ERROR] Insufficient working time

[Safety - STOP], [C1], [C3], [C4], [C7] or [C8] Malfunctioning safety devices or wrong connection

FA00044-EN v.

18 - Manual code:

p.

Page 19

19

FA00 044-EN

1

DIAGRAM OF THE SLOW-DOWN AND FINAL APPROACH POINTS AND FOR THE ENCODER DEVICE

The run area and slow down and approach points are tested according to the parameters set forth by Technical Standards EN 12455 and

EN 12453 for compliance with the impact forces generated by the running leaves.

D

I

G

B

A

C

F

B

D

E

I

H

A = Normal speed

B* = Slowed-down speed

C = Encoder intervention zone with movement inversion

D = Encoder intervention zone with movement stopped

E = Opening slow-down starting point [OP. SlwDwn%]

F = Closing slow-down starting point [CL. SlwDwn%]

G** = Closing soft-stop starting point [Acc. CL%]

H = Opening soft-stop starting point [Acc. OP%]

I = Final strike-point

* Minimum 600 mm from the strike plate.

** Set the fi nal approach percentage for the function [Acc. CL%] and [Acc. OP%] from the [ENCODER] menu so as to obtain a distance of

between 1 and 50 mm maximum from the fi nal strike plate point.

DISMANTLING AND DISPOSAL

Always make sure you comply with local laws before dismantling and disposing of the product. The packaging materials (cardboard, plastic, and

so on) should be disposed of as solid urban waste, and simply separated from other waste for recycling.

Whereas other components (control boards, batteries, transmitters, and so on) may contain hazardous pollutants. These must therefore be

disposed of by authorized, certified professional services.

DO NOT DISPOSE OF IN NATURE!

1- 03/2016 - © Came S.p.A. - The manual's contents may be edited at any time without notice.

FA00044-EN v.

19 - Manual code:

p.

Page 20

www. came.com

Came S.p.A.

Dos son di Cas ier

Treviso

Sesto al Reghena

Pordenone

Engl is h

FA00 044-EN

1

1 - 03/2016 - © Came S.p. A.

FA00044-EN v.

English - Manual code:

The data and information in this manual may be changed at any time and without notice.

Came S.p.A.

Via Martiri Della Libertà, 15 Via Cornia, 1/b - 1/c

Dosson di Casier

31030

Treviso - Italy

(+39) 0422 4940

(+39) 0422 4941

www. came.com

Sesto al Reghena

33079

Pordenone - Italy

(+39) 0434 698111

(+39) 0434 698434

Loading...

Loading...