Page 1

ZE5 V.7

AUTOMAZIONE PER CHIUSURA INDUSTRIALE

INSTALLATION MANUAL

CONTROL PANEL FOR EMEGA SERIES

Page 2

All the data and information contained herein is considered subject to change at any time and at our discretion.

2

ENGLISH

The ZE5 electrical panel is designed to control EMEGA (E306-E456) automation units in the movement

of garage-type doors with double or single motor.

230V electric panel for EMEGA series automation systems; 50÷60 Hz frequency.

Wholly designed and built by CAME Cancelli Automatici S.p.A.

Guaranteed 24 months if not tampered with.

4.2 Technical Information

THIS SYMBOL INDICATES SECTIONS TO BE READ WITH PARTICULAR CARE.

THIS SYMBOL INDICATES SECTIONS CONCERNING SAFET Y.

THIS SYMBOL INDICATES NOTES TO COMMUNICATE TO USERS

The following standards were complied with for this product: EN 12978, UNI EN 954-1, CEI EN 60335-1,

and UNI EN 12453.

2.1 Destination

4.1 Components

Electric Panel

Power supply: 230V, 50÷60 Hz.

Maximum power allowed: 400 W

Absorption at rest: 150 mA

Maximum power for 24V accessories: 20 W

Maximum power for 230V accessories: 120 W

Degree of protection: IP54

Insulation type: II

Material: ABS

Working temperature:

#

#

-Observe distances and cable diameters as indicated in the table in chapter 5.4

2.2 Limits of Use

“IMPORTANT SAFETY INSTRUCTIONS TO FOLLOW DURING INSTALLATION”

WARNING - IMPROPER INSTALLATION MAY CAUSE SERIOUS DAMAGE. FOLLOW ALL INSTALLATION

INSTRUCTIONS

THIS MANUAL IS MEANT FOR PROFESSIONAL INSTALLERS OR QUALIFIED PERSONNEL ONLY.

2 Use Applications and Destination

1 Legend

4 Device Description

3 Standards followed

TRUCTIONS

TO

SE SER

RUCTION

Page 3

3

All the data and information contained herein is considered subject to change at any time and at our discretion.

ENGLISH

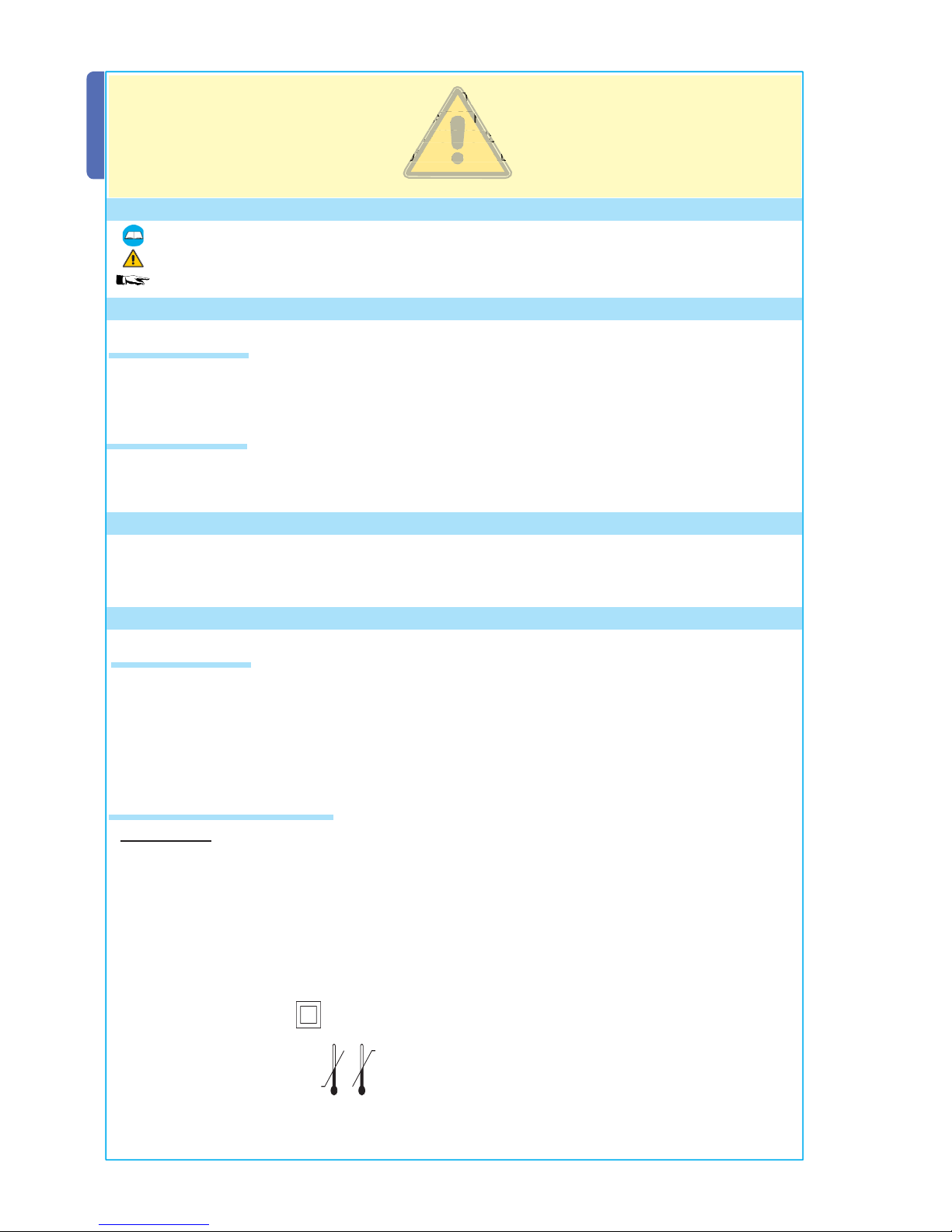

4.3 Main Components

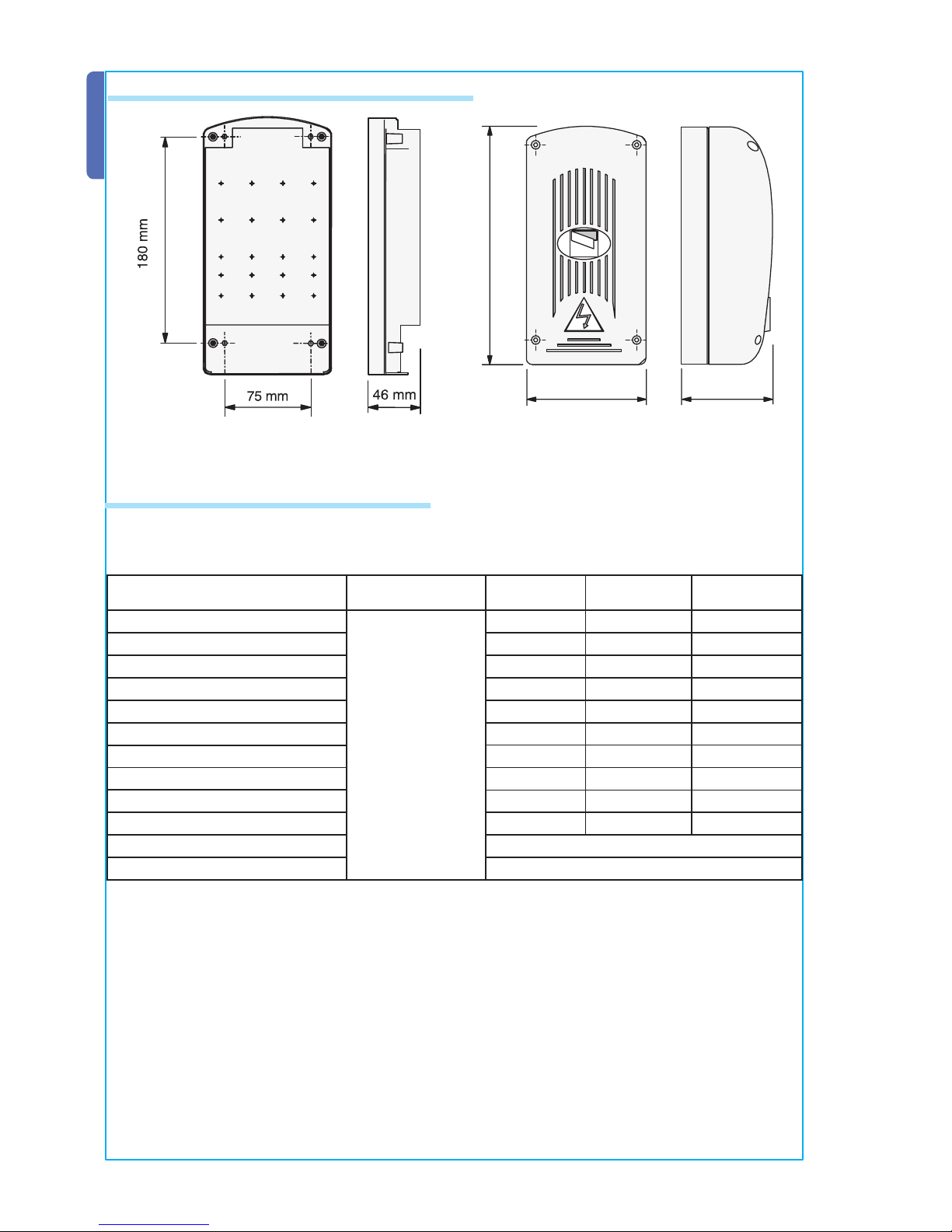

Before proceeding with the installation, it is necessary to:

• Make sure the mains power is off.

• Check that the control panel is installed in an area protected from bumps and that the anchorage

surface is solid, and that it is secured with suitable elements (screws, inserts, etc).

• Install suitable tubes and ducts for electric cable passage to guarantee protection against

mechanical damage.

•

Connections inside the case made for protection circuit continuity are allowed as long as they

include additional insulation with respect to other internal drive parts.

5 .1 Equipment and materials

5.2 Attrezzi e materiali

Make sure all the necessary tools and materials are available to carry out the installation with the maximum safety, in compliance with regulations in force. Here are some examples:

1 630 mA board fuse

2 1.6 A fuse for accessories

3 Dip-Switch for function selector

4 Keys for radio code memorisation and for end-

stop programming

5 LED indicator

6 Trimmer for adjusting automatic closing times

7 Encoder sensitivity adjustment trimmer

8 Trimmer for adjusting operation times

9 Radiofrequency board coupling

10 5 A line fuse

11 Encoder connection terminal board

12 Aerial connection terminal board

13 Connection terminal board

14 Power feed terminal board

5 Installation

ZE7

CH1/OP.

AF

AF

L

N

V

W

U

E1

E3

1234

ON

5678

910

101011111 2 3 5 7 C1C1FA

FA

24

12

0

L1T

L2T

VA

VB

+

E

-

- AMP. S+

- A.C.T.+

- S. DELAY +

4

1

2

3

9

13

14

11

12

5

10

6

7

8

Page 4

All the data and information contained herein is considered subject to change at any time and at our discretion.

4

ENGLISH

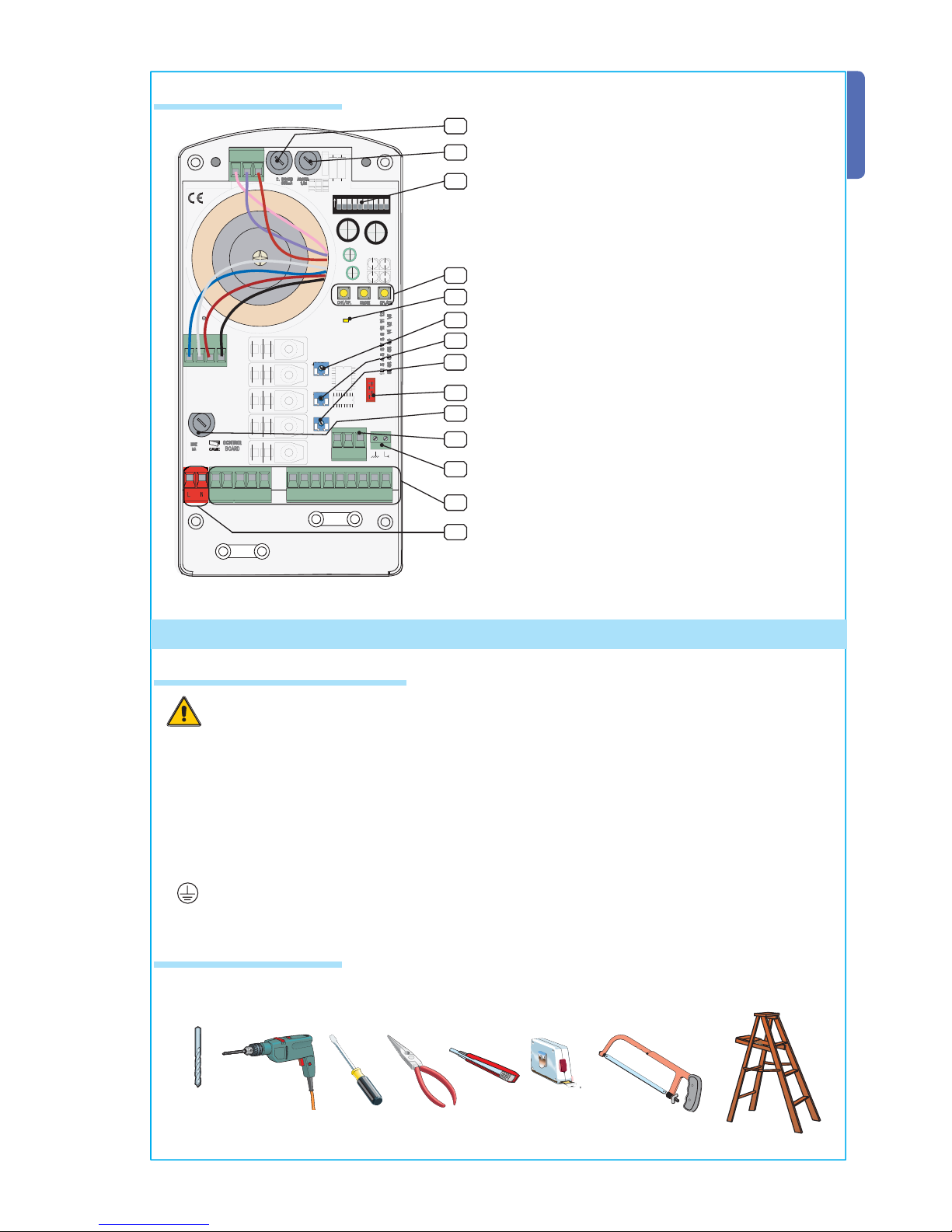

5.3 Dimensions, axle bases and fastening holes

5.4 Minimum thicknesses and cables types

#!-%

MM

MM

MM

Connections

Cable Type

1<10 m Cable

Length

10<20 m

Cable Length

20<30 m Cable

Length

230V 2F power supply

FROR CEI 20-22

CEI EN 50267-2-1

3G 1,5mm² 3G 2,5mm² 3G 4mm²

230V 2F motors 4G 1mm² 4G 1,5mm² 4G 2,5mm²

230V fl ashing lamp 2 x 0,5mm² 2 x 1mm² 2 x 1,5mm²

230V cycle / courtesy lamps 3G 0,5mm² 3G 1mm² 3G 1,5mm²

Power for 24V accessories 2 x 0,5mm² 2 x 0,5mm² 2 x 1mm²

24V pilot lamp 2 x 0,5mm² 2 x 0,5mm² 2 x 1mm²

24V “in movement” output 2 x 0,5mm² 2 x 0,5mm² 2 x 1mm²

Safety contacts 2 x 0,5mm² 2 x 0,5mm² 2 x 0,5mm²

N.O./N.C. command keys 2 x 0,5mm² 2 x 0,5mm² 2 x 0,5mm²

End-stop 2 x 0,5mm² 2 x 1mm² 2 x 1,5mm²

Aerial connection (max 10m) RG58

Encoder connection (max 30m) Shielded cable 2402C 22AWG

N.B. The evaluation of the section of cables with lengths other than the ones stated in the table should be

considered according to the real absorption of the connected devices, in compliance with the prescriptions in

CEI EN 60204-1 standard.

Table dimensioning should be recalculated according to real absorption and distances for connections requiring more than one charge (sequential) on the same line.

Page 5

5

All the data and information contained herein is considered subject to change at any time and at our discretion.

ENGLISH

Rosso

Nero

FA K E WVUF

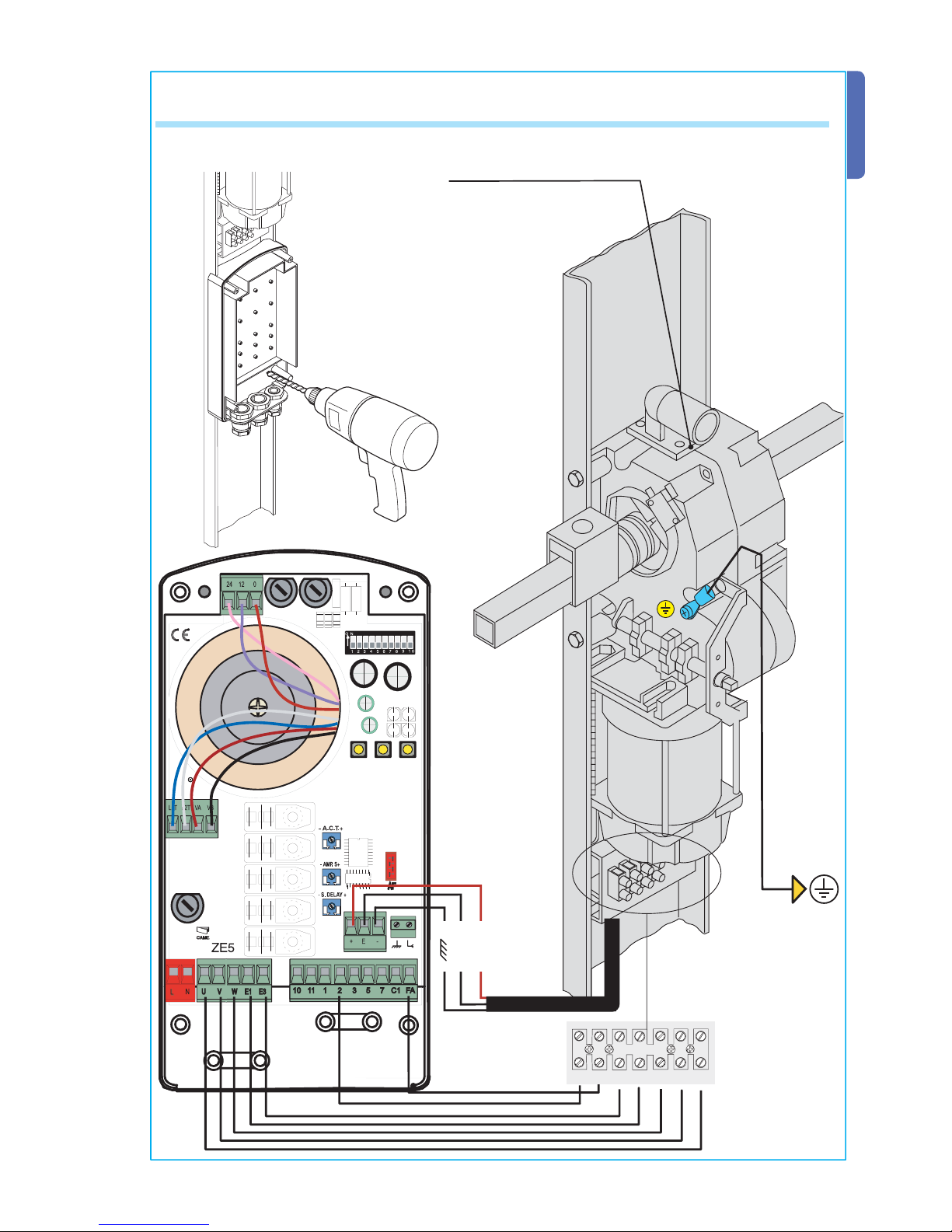

5.5 Pre-settings, Fixing the Electric Board to the Ground Guide (Art. 001E001) and

Ratiomotor Electric Connections

E306/E456 Ratiomotor

Use a ø 5 drill bit to bear a hole

observing the distance between

the centres as specifi ed in

paragraph 5.3, and secure the

control panel to the ground guide

using M 4x39 screws (provided).

Page 6

All the data and information contained herein is considered subject to change at any time and at our discretion.

6

ENGLISH

5.6 Connections

LINE

-ENC+

ZE7

CONTROL

5A

BOARD

FUSE 5x20

L

N

V

W

U

E1

E3

101011111 2 3 5 7 C1C1FA

FA

L

N

U

W

V

E1

E3

W

E1

230V (a.c.) power supply

230V (a.c.) max. 400 W single-phase motor

230V (a.c.) output in movement (e.g. fl ashing lamp - max. 25W)

230V (a.c.) courtesy lamp output (max. 60W)

10

11

24V (a.c.) (max. 20W) accessory power feed

24V-15W max. electric lock connection (set dip-switch 9 to OFF)

(24V-3W max.) “open door” signalling pilot light (set dip-switch 9 to ON)

Stop key (N.C.)

Opening key (N.O.)

Key for commands (N.O.) see selection on dip-switch 2 or closing key in the “sustained action” function (dip 6 to ON)

(N.C.) Contact “opening during closing”

Opening end-stop connection

Aerial connection

1

2

2

3

2

7

10

5

N.B. All the usually closed (N.C.) contacts and keys should be deactivated via dip-switch or short-circuited.

2

C1

2

FA

#!-%

10

5

Page 7

7

All the data and information contained herein is considered subject to change at any time and at our discretion.

ENGLISH

5.7 Dip-switch Functions

5.8 Trimmer Adjustments

1 ON Automatic closing activated;

2 ON “Open-stop-close-stop” with key (2-7) and radio remote control (AF board inserted) activated;

2 OFF “Open-close” with key (2-7) and radio remote control (AF board inserted) activated;

3 ON “Opening only” with radio remote control (AF board inserted) activated;

4 ON “Pre-fl ashing during the opening and closing phases activated; after receiving an opening or closing

command, the fl ashing lamp connected on W-E1 fl ashes for 5 seconds prior to obeying the command.

5 ON Obstacle detection activated; with the motor stopped (door closed, open or after a total stop com-

mand), it prevents movement of any sort if the safety devices (e.g. photoelectric cells) detect an obstacle;

6 ON “Dead man” mode activated; the door functions by keeping the key pressed, key connected to (2-3) for

opening and (2-7) for closing, without including the remote control function;

7 OFF Reopening during closure activated; the safety device (2- C1) detects an obstacle during the door’s

closing phase and causes the door to invert movement until the door is completely open (7ON deactivated);

8 ON Encoder programming activated; it enables the opening and closing end-stop calibration procedure;

9 ON “Door Open” pilot light connected on terminals 10-5 activated; it signals the open position of the garage

door, and switches off when the door is closed.

9 OFF Electric lock connected to terminals 10-5 activated;

10 ON motor closing thrust increase activated.

5-10 ON Increased thrust during closing and surge function in operation.

1234

ON

5678

910

ON

OFF

A.C.T. Trimmer = automatic closing time adjustment from a minimum of to a maximum

of 120s

AMP.S Trimmer = adjustment of door sensitivity during movement when obstacles are

detected.

S. DELAY Trimmer= adjusting operating time

AF

- AMP. S+

- A.C.T.+

- S. DELAY +

A.C.T.

120"

1"

Page 8

All the data and information contained herein is considered subject to change at any time and at our discretion.

8

ENGLISH

MM

5.9 Encoder Programming

Cam

End-Stop Micro-

Switch

IMPORTANT: READ INSTRUCTIONS CAREFULLY BEFORE PROCEEDING WITH PROGRAMMING.

Adjustment of stop micro-switch during opening

Release the ratiomotor and move the door manually to approximately 30 mm from the desired opening.

Rotate the cam until the micro-switch can be inserted and tighten the screw in the cam.

Relock the ratiomotor.

Closing End-Stop

Set dip-switch 8 to ON: the LED indicator fl ashes

1234

ON

5678

910

8 ON

Press the “CLOSE” key and allow the garage door to arrive at the point of closing.

Press the “OP/CL” key: the LED indicator remains lighted to signal that the closing end-stop has been

recorded.

Page 9

9

All the data and information contained herein is considered subject to change at any time and at our discretion.

ENGLISH

Opening End-Stop

Press “CH1/OP” and allow the door to open completely.

Press the “OP/CL” key: the LED indicator remains lit to signal the memorisation of the open end-stop.

Note: if the “CH1/OP” key is pressed twice within 15”, the slowing during closing mode is deactivated and the

“thrust reduction” function is automatically inserted, the function is made active when the door is about to

close. The LED indicator will resume fl ashing after having pressed the key for the second time.

Reset dip-switch 8 to OFF. Note: if the LED indicator begins to fl ash rapidly after resetting dip 8, it is necessary

to repeat the procedure from the beginning.

1234

ON

5678

910

8 OFF

General notes during programming make sure to have memorised the closing end-stop fi rst, otherwise the

data will not remain memorised.

Page 10

All the data and information contained herein is considered subject to change at any time and at our discretion.

10

ENGLISH

5.10 Connecting Two Motors

Should two motors be installed, connect them in parallel.

Use terminals U, V and W of the ZE5 control panel to connect both motors.

Note: Connect the encoder and the opening end-stop of a single motor.

WARNING!

WARNING!

ACCES.

ACCES.

LINE

LINE

-A.C.T.+

-A.C.T.+

-ENC+

-ENC+

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12

05 06 07 08 09 V1 V2 V3

05 06 07 08 09 V1 V2 V3

ZE7

ZE7

OP./CL.

OP./CL.

CONTROL

CONTROL

5A

5A

C. BOARD

C. BOARD

1,6A

1,6A

CH1/OP.

CH1/OP.

CLOSE

CLOSE

BOARD

BOARD

630mA

630mA

FUSE 5x20

FUSE 5x20

AF

AF

L

N

V

W

U

E1

EX

1234

ON

5678

910

101011111 2 3 5 7 C1C1FA

FA

24

12

0

L1T

L2T

VA

VB

+

E

-

&! + % 76 5&

567%% &!

&! + % 76 5&

%

2OSSO

2ED

2OUGE

2OT

2OJO

.ERO

"LACK

.OIR

3CHWARZ

.EGRO

#!-%

Page 11

Please read the following instructions carefully prior to installation:

- preparing the radio board (par. 6.1);

- transmitter encoding procedure (par. 6.2);

- control board code memorisation (par. 6.3).

2) The AF board should be MANDATORILY inserted only when the mains power is off, because the

motherboard only recognizes it when it is powered up

1) For transmitters with 433.92 AM frequencies

(TOP and TAM series) position the jumper on the

AF43S board, as illustrated.

TOP TAM

T262M - T264M - T2622M - T302M - T304M - T3022M common encoding procedure

1 mark a code (even for the archive)

2 insert J code jumper

3 record it

4 unplug J jumper

/.

/&&

0

0

Press P1 or P2 in sequence to record the code; on

the tenth impulse, a double beep will confi rm the

memorisation has taken place.

Frequency/MHz Board Transmitter

FM 26.995 AF130 TFM

FM 30.900 AF150 TFM

AM 26.995 AF26 TOP

AM 30.900 AF30 TOP

AM 433.92 AF43S / AF43SM TAM / TOP

AM 433.92 AF43SR ATOMO

AM 40.685 AF40 TOUCH

1 2 3 4 5 6 7 8 9

1 2 3 4 5 6 7 8 9 10 11 12

05 06 07 08 09 V1

05 06 07 08 09 V1 V2 V3

OP./CL.

CH1/OP.

CLOSE

AF

AF

Top quarzite series

11

All the data and information contained herein is considered subject to change at any time and at our discretion.

ENGLISH

6 Radio Remote Control Installation Procedure

6.1 Preparing the Radio Board (AF)

Scheda base

“AF ” Board

6.2 Transmitter Encoding Procedure

Page 12

0 0

The fi rst code should be recorded by keeping the jumpers

positioned for channels 1 and 2 as in fi g. A; see fi g. B for any

further settings on different channels.

TOP

T262M - T302M

FIG.A

FIG.B

0 0

0 0

T264M - T304M

0 0

0 0

/.

/&&

0

0

T2622M - T3022M

P1 = CH1

P2 = CH2

P3 = CH3

P4 = CH4

P1 = CH1

P2 = CH2

P1 = CH1 - P2 = CH3 P1 = CH3 - P2 = CH2

P1 = CH1 - P2 = CH4 P1 = CH3 - P2 = CH4

1° Code

P1 = CH1

P2 = CH2

2° Code

P3 = CH1

P4 = CH2

All the data and information contained herein is considered subject to change at any time and at our discretion.

12

ENGLISH

Page 13

0 0

/. /. /. /.

/. /. /. /.

TOP

T432M - T312M

Set the code to dip-switch C and the channel to D (P1 = CH1 and P2 = CH2, default

setting)

D

C

P1

CH1

TOP

T434M - T314M

0 0

0 0

C

Set the code only

P1 = CH1

P2 = CH2

P3 = CH3

P4 = CH4

TOP

T432S - T432SA - T434MA - T432NA - T434NA

See instructions in the

package

TAM

T432 - T434 - T438 - TAM432SA

See instructions

sheet included in

the package

TFM

T132 - T134 - T138

T152 - T154 - T158

See instructions sheet

included in the package

CAME

AT01 - AT02 - AT04

See the instructions sheet included

with the AF43SR board.

CAME

TCH 4024 - TCH 4048

See instructions in the package

Top Series

P2

CH2 CH3 CH4

CH1 CH2 CH3 CH4

Atomo Series

Touch Series

13

All the data and information contained herein is considered subject to change at any time and at our discretion.

ENGLISH

Page 14

-Keep the “CH1/OP” key pressed down on the control board (the LED indicator fl ashes);

- the code is sent by means of a transmitter key, and the LED indicator will remain lighted to signal that that

THE GARAGE DOOR DOES NOT MOVE:

- CHECK the 230 V AC power supply on terminals L-N.

- Check the fuses.

- Check the 24V power supply on terminals 10-11.

- Check the STOP key connection, if unused, short-circuit terminals 1-2.

- Repeat encoder programming.

THE GARAGE DOOR REMAINS OPEN:

- check the automatic closing function, (dip-switch 1).

- check if control devices are functioning properly.

- check if there is something obstructing the safety devices.

- check if all the n.c. contacts are set to on (if not being used).

All the data and information contained herein is considered subject to change at any time and at our discretion.

14

ENGLISH

6.3 Code Memorisation

!#4

LED indicator flashes

!#4

LED indicator is lit

7 Solving Problems

Page 15

15

All the data and information contained herein is considered subject to change at any time and at our discretion.

ENGLISH

8 Demolition and Disposal

In its premises, CAME CANCELLI AUTOMATICI S.p.A. implements an Environmental Management

System certifi ed in compliance with the UNI EN ISO 14001 standard to ensure environmental protection.

Please continue our efforts to protect the environment—which CAME considers one of the cardinal elements

in the development of its operational and market strategies—simply by observing brief recommendations

as regards disposal:

DISPOSAL OF PACKAGING – Our packaging is made up of various types of materials. Most of them

(paper, plastics, etc.) may be disposed of in normal garbage collection bins and can be recycled by disposing

of in specifi c recyclable material collection bins and disposal in authorized centres.

Prior to disposal, it is always advisable to check specifi c regulations in force in the place of disposal.

PLEASE DISPOSE OF PROPERLY!

PRODUCT DISPOSAL – Our products are made up of various types of materials. Most of them (aluminium,

plastics, iron, electric cables etc.) may be disposed of in normal garbage collection bins and can be recycled

by disposing of in specifi c recyclable material collection bins and disposal in authorized centres. Other

components (electric boards, batteries and radio remote controls, etc.), however, may contain hazardous

substances. They should therefore be removed and given to qualifi ed service companies for proper disposal.

Prior to disposal, it is always advisable to check specifi c regulations in force in the place of disposal.

PLEASE DISPOSE OF PROPERLY!

9

Maker’s statement

Also, they furthermore represent and warrant that the product/s that are the

subject of the present Declaration are manufactured in the respect of the

following main harmonized provisions:

EN 292

PART 1 AND 2 MACHINERY SAFETY.

EN 12453 INDUSTRIAL, COMMERCIAL AND OTHER CLOSING MECHANISMS.

EN 12445 I

NDUSTRIAL, COMMERCIAL AND OTHER CLOSING MECHANISMS.

EN 12978 S

AFETY DEVICES FOR POWER OPERATED DOORS AND GATES ....

EN 60335 - 1 S

AFETY IN APPARATUSES FOR HOME USE.

EN 60204 - 1 MACHINERY SAFETY.

EN 61000 - 6 - 2 ELECTROMAGNETIC COMPATIBILITY.

EN 61000 - 4 - 4 E

LECTROMAGNETIC COMPATIBILITY.

EN 61000 - 4 - 5 E

LECTROMAGNETIC COMPATIBILITY.

IMPORTANT CAUTION!

It is forbidden to market/use product/s that are the subject of this declaration

before completing and/or incorporating them in total compliance with the

provisions of Machinery Directive 98/37/CE

Signatures of the Representatives

MANUFACTURER’S DECLARATION

As per Enclosure II B of Machinery Directive 98/37/CE

Enclosed with the technical documentation (the original copy of the Declaration is available on request)

Date of the present declaration 07/12/2001

The representatives of

CAME Cancelli Automatici S.p.A.

via Martiri della Libertà, 15

31030Dosson di Casier - Treviso - ITALYtel

(+39) 0422 4940 - fax (+39) 0422 4941

internet: www.came.it - e-mail: info@came.it

Hereby declare, under their own respons ibility, that the product/s

called ...

… comply with the Italian National Legal Provisions that transpose

the

following Community Directives (where specifi cally applicable):

M

ACHINERY DIRECTIVE 98/37/CE

L

OW VOLTAGE DIRECTIVE 73/23/EEC - 93/68/EEC

L

ECTROMAGNETIC COMPATIBILITY DIRECTIVE 89/336/EEC - 92/31/EEC

R&TTE D

IRECTIVE 1999/5/CE

TECHNICAL MANAGER

Mr. Gianni Michielan

MANAGING DIRECTOR

Mr. Paolo Menuzzo

ZE5

Page 16

ZE5v0.7_319T92 Vo1

CAME UNITED KINGDOM LTD

UNIT 3, ORCHARD BUSINESS PARK

TOWN STREET, SANDIACRE

NOTTINGHAM - NG10 5BP - U.K.

Tel 0044 115 9210430

Fax 0044 115 9210431

Loading...

Loading...