Burnham 53A, 79A, Alliance AL-26A, ALLIANCE 119A, Alliance AL-40A Installation, Operating And Service Instructions

...

®

Y

9

Price - $3.00

INST ALLATION, OPERA TING

AND

SERVICE INSTRUCTIONS

TM

ALLIANCE

INDIRECT-FIRED WATER HEATERS

MODELS AL-26A, 40A, 53A, 79A and 119A

SERIES

for SINGLE W ATER

HEATER

INSTALLATIONS

For serv ice or repairs to the water heater, call your heating c ontractor. When s eek ing information on water

heater, provide Model N umber and Serial Number as shown on Rating Label.

Model Number

_ AL _____ __

Serial Number

_ _ _ _ _

Installation Date

Heating C ontractor Phone Number

Address

8140817R3-3/00

AMERICA’S BOILER COMPAN

BurnhamCorporation

1

Lancaster, PA 17604-307

IMPORTANT INFORMATION - READ CAREFULLY

NOTE: The equipment shall be installed in accordance with those installation regulations required in the area where the

installation is to be made. These regulations shall be carefully followed in all cases. Authorities having jurisdiction

shall be consulted before installations are made.

All wiring on water heaters installed in the USA shall be in accordance with the National Electrical Code and/or local

regulations.

All wiring on water heaters installed in Canada shall be in accordance with the Canadian Electrical Code and/or local

regulations.

The following defined terms are used throughout this manual to bring attention to the presence of hazards of various risk levels,

or to important information concerning the life of the water heater.

DA NGER

Indicates an imminently hazardous situation

which, if not avoided, will result in death,

serious inju ry or substa ntial proper t y dama ge.

WARNING

Indicat es a potentia ll y hazardo us situ ation

which, if not avoided, could result in death,

serious injury or substantial property damage.

CAUTION

Ind icates a poten tially h aza rdous si tuation

which, if not avoided, may result in

moderate or minor injury or prop erty

damage .

NO TIC E

Indi cates spec ial ins truction s o n

ins tall ation, op e ratio n, or m ai nt enan c e

whi ch are impor tant b ut not relate d to

persona l injury ha zards .

DO NOT store or use gasoline or other flammable vapors or liquids in the vicinity of this or any

other appliance.

If you smell g as vapors, DO NOT try to o perate any ap pliance - DO NOT touch any electrical

switch or use any phone in the building. Immediately, call the gas supplier from a remotely

located phone. Follow the g as su pp lier's instructions or if the supplier is un availab le, contact the

fire department.

DA NGE R

2

I. General Information

WAR N IN G

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, personal injury or loss of life. Read and understand the entire manual before

attempting installation, start-up operation, or service. Installation and service must be

perfo rmed on ly by an exp erienced, s killed ins taller or serv ice ag ency.

Installation is not complete unless a pressure and temperature relief valve is installed into

the side of the water heater. See Piping Section of this manual for details.

This water heater contains very hot water under high pressure. D o not unscrew any pipe

fittings nor attempt to disconnect any components of this water heater w ithout positively

assuring the water is cool and has no pressure. Always wear protective clothing and

equipment when installing, starting up or servicing this water heater to prevent scald

injuries. Do not rely on the pressure and temperature gauges to determine the temperature

and pressure of the water heater. This water heater contains components which become

very hot when the boiler is operating. Do not touch any components unless they are cool.

Water heater materials of construction contain urethane, heavy metals and/or other toxic or

harmful substances which can cause death or serious injury and which are known to the

state of California to cause cancer, birth defects and other reproductive harm. Always use

proper safety clothing, respirators and equipm ent when servicing or working nearby this

water heater.

Failure to follow all instructions in the proper order can cause personal injury or death.

Read all instructions, including all those contained in component manufacturers' manuals

which are provided with the water heater before installing, starting up, operating, maintaining

or servicing.

NOTICE

The A lliance wa ter hea ter must be installe d with a pre ssure a nd tempe rature relief valve. Th e

valve is not supplied with the water heater and must be provided by the installer.

T able of Contents

Section I - General Information ............................ 3

Ratings, Capacities, Weights, & Dimensions....... 4

Section V - Operation.......................................... 16

Section VI - Service Instructions ........................ 17

Section II - Pre-Installation................................... 5

Section III - Piping ................................................ 8

Section IV - Electrical ......................................... 15

Section VII - Trouble Shooting........................... 18

Section VIII - Repair Parts.................................. 19

Warranty ..............................................Back Cover

3

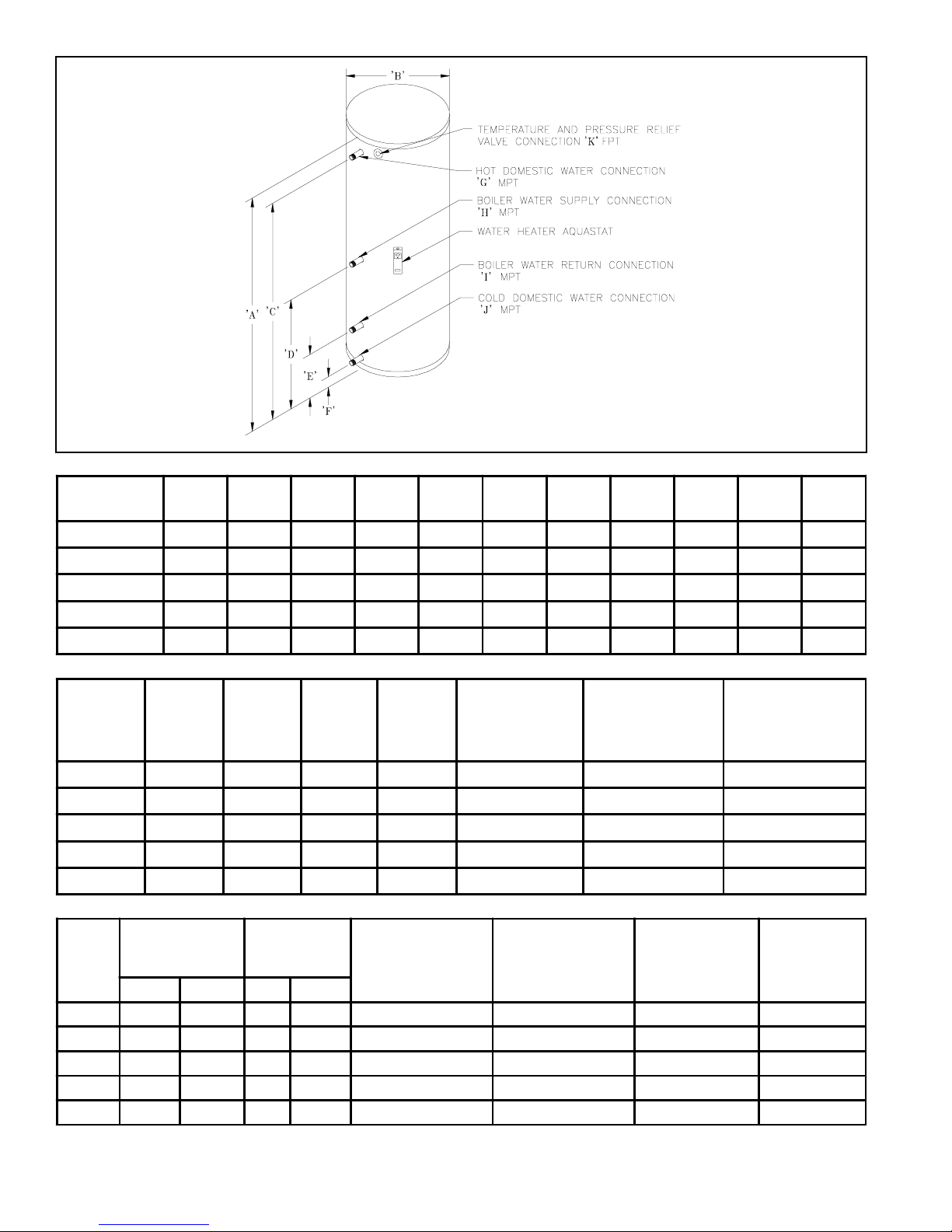

Table 1: Alliance Water Heater Dimension (Inches)

ALLIANCE

MOD EL

AL26A 40 20-1/4 31-1/2 22-1/2 9-3/4 2 3/4 3/4 3/4 3/4 3/4

AL40A 55 20-1/4 46-1/2 25-3/4 9-3/4 2 3/4 3/4 3/4 3/4 3/4

AL53A 70-5/8 20-1/4 62-1/8 28-3/4 9-3/4 2 3/4 3/4 3/4 3/4 3/4

AL7 9A 69-3/8 23-3/4 60-7/8 29-1/4 10-1/4 1-5/8 1 3/4 3/4 1 1

AL119A 66 29-1/2 52-3/4 39-1/4 12-3/4 2-1/2 1-1/4 1-1/4 1-1/4 1-1/4 1

ABCDEFGH I JK

Table 2: Alliance Water Heater Capacities

M AXIMU M

ALLOWA BLE

WOR KI NG

P RESSUR E ( PSI)

HYDROSTATIC

DESIGN

P RESSUR E ( PSI)

ALLI ANC E

MOD EL

TANK

VOL UME

(GA L )

COIL

VOL UME

(GA L )

DRY

WEIGHT

(LBS)

WET

WEIGHT

(LBS)

COIL HEAT

TRANSFER

AREA ( SQ. F T. )

AL26A 26.4 1. 0 49 269 6.5 150 300

AL40A 39.6 1. 2 66 396 8.6 150 300

AL53A 52.8 1. 4 82 522 9.7 150 300

AL79A 79.3 2. 2 170 831 15.1 150 300

AL119A 119.4 2.9 183 1178 24.3 150 300

Table 3: Alliance Water Heater Performance

MAXIMUM FIRST

MO DEL

AL2 6A 142 197 1.93 2.84 110,000 8.0 2.5 2.4

AL4 0 A 175 242 2.26 3.38 133,000 11.4 6.1 7.2

AL5 3 A 224 310 2.85 4.29 164,000 10.9 6.5 9.0

AL7 9 A 253 350 2.90 4.51 190,000 10.6 8.4 9.1

AL11 9A 350 409 3.84 4.83 386,000 15.4 11.6 16.4

NOTES:

tank (when applicable).

HO UR RAT ING

GAL/HR @

14 0F 115F 14 0F 115F

All ra tings based o n 200F bo iler w ate r tem pera ture, 50F d omestic w ater inlet tempera ture, and a fully recovered

CONTINUOUS

RATING

GAL/MIN @

BOILER D OE

H E AT IN G C A PA CI TY

NEEDED FOR

R ATING S (BTU/HR )

MINIMUM BOILER

WATER FLO W

THROUGH HEATER

C O IL ( GA L / M IN )

PRESSURE

DRO P THROUGH

COIL AT MIN.

FLOW (F T. W .C .)

MINUTES OF

140F WATER

AVAILABLE AT

5 GPM DRAW

4

CA UTION

The heat transfer m edium must be water or other non-toxic fluid having a toxicity rating or class

of 1, as listed in clinical Toxicolog y of Commercial Products, 5th edition.

The pressur e of the heat tran sfer m edium must be limited to a maxim um of 30 psig b y an

approved safety or relief valve.

NOTICE

This water heater has a limited warranty, a copy of which is printed on the back o f this m anu al.

It is the respon sibility of the in stalling cont ractor to see th at all contro ls a re correctly installed

and are operating properly when the installation is complete.

II. Pre-Installation

Inspect shipment carefully for any sign of damage. All

equipment is carefully manufactured, inspected and

packed. Burnham Corporation's responsibility ceases

upon delivery of water heater to the carrier in good

condition. Any claim for damage or shortage in

shipment must be filed immediately against the carrier

by the consignee. No claims for variances or shortages

will be allowed by Manufacturer, unless presented

within sixty (60) days after receipt of equipment.

Installation must conform to the requirements of the

authority having jurisdiction. In the absence of such

requirements, installation must conform to National

Plumbing Code and National Electrical Code,

ANSI/NFPA No. 70, current edition.

present.

Consult Burnham for size recommendations for

installation with unusual water demand.

Refer to Table 3 for water heater performance

specifications.

2. Boiler DOE Heating Capacity The Alliance™

water heater will provide the rated performance

only if used in conjunction with a boiler with a

DOE heating capacity at least as much as the

minimum noted in Table 3. If the boiler has less

capacity, the output of the tank will be reduced. To

determine the approximate reduction in output from

the tank use the following formula:

IMPORTANT DECISIONS REQUIRED BEFORE

INSTALLATION:

A. Sizing

1. Alliance™ Model - Choose the Alliance™ model

based on the expected water usage of the building.

The average residence with one shower or more

will require a model AL40A or larger. The AL26A

should only be considered for residences with

minimal water demand or for commercial

application where showers are not present.

Factors which dramatically increase water demand

include high flow shower heads, whirlpool tubs,

and the use of multiple showers at the same time.

Upsize the tank size if any of these factors are

For example, what would the first hour rating be if

a model AL53A were installed with a boiler having

a DOE heating capacity of 120,000 BTU/h?

Increasing the boiler DOE heating capacity above

the values listed in Table 3 will not increase the

rating of the water heater.

3. Circulator Sizing - Refer to Table 3 for the

minimum flow rate through the water heater coil

and the corresponding pressure drop through the

coil. Calculate the pressure drop of all straight pipe

and fittings on the supply and return of the water

heater at the minimum flow rate. Add the piping/

fitting pressure drop to the pressure drop through

the water heater coil.

5

Select a circulator which will provide at least the

minimum flow rate at combined pressure drop.

B. System Zone Control The Alliance

heater must be installed as a zone separate from the

space heating system. The domestic hot water zone's

piping and circulator must be sized for a minimum

flow rate with all zones in use and a maximum flow

rate with only the water heater in use. For this reason,

the preferred method of zone control is with

circulators.

1. Circulators - With space heating zones using

circulators, the Alliance™ should be added as an

additional zone with a circulator.

2. Zone Valves - Select a valve with low pressure

drop to assure adequate flow through the water

heater.

3. Hybrid - The space heating zone can be zoned

using zone valves and Alliance™ zoned with a

circulator. Refer to Figures 3 and 5.

TM

water

C. Domestic Hot Water Priority Two options are

available, Priority and Non-Priority.

during simultaneous space and domestic hot water

heating operations, depending on such factors as

boiler output, boiler over sizing, number of space

heating zones calling for heat and ratio of domestic

hot water load to space heating load.

D. Component Location

1. Alliance™ Location

When such a location cannot be avoided, a suitable

drain pan must be installed under the water heater.

The drain pan must be connected to a drain.

Adequate clearance from combustible materials and

for service must be provided.

1. Priority Demand for space heating is interrupted

or postponed until the domestic hot water demand

is satisfied. This option provides maximum delivery

of domestic hot water. Priority is recommended

when:

a. Boiler net output is 100,000 Btu per hour or

less, or

b. When boiler output required to satisfy domestic

hot water demand is at least 50% of the boiler

output required to satisfy space heating demand,

or

c. When an interruption in space heating can be

tolerated during a long domestic hot water draw.

The delay in space heating may not be noticed due

to the fast recovery time of the AllianceTM water

heater. Certain water heater system malfunctions

(such as domestic hot water zone circulator failure)

could delay space heating indefinitely.

When zoning with zone valves, priority can be

provided with a three-way valve. Carefully size the

valve for proper flow to all zones.

The AllianceTM is design certified for installation on

combustible flooring.

The Alliance™ may be installed in a closet or

alcove.

2. Boiler Location - Locate the boiler as close to the

Alliance™ as practical.

3. Fixture Locations - For fastest delivery of hot

water, place AllianceTM close to points of use.

E. Additional Recommended Components

2. Non-Priority Boiler output is divided between

space heating and domestic hot water heating.

Delivery of domestic hot water can be reduced

1. Shut-off Valves - Allows isolation of water heater

from domestic water system and/or boiler system

during service.

2. Unions - Allows water heater movement during

service if adequate clearance cannot be provided.

3. Vacuum Breaker - Protects water heater's tank

from possible collapse if a hot tank is allowed to

6

cool to room temperature, or if tank is drained

without opening a hot water faucet. A Watts

Model No. N36 is an appropriate vacuum relief

valve.

4. Thermal Expansion Tank If water heater is

installed in a closed water supply system, such as

one having a back-flow preventer in the cold water

line, provide thermal expansion control. Contact

the water supplier or local plumbing inspector for

additional information. An Amtrol Model ST-12 is

an appropriate diaphragm style thermal expansion

tank for most installations.

F. Removal of Existing Domestic Water

Heating System

1. External Tankless Heater - Disconnect from

boiler piping and domestic water system.

2. Tankless and Storage Heaters - Disconnect from

domestic water system. Heater does not need to be

removed from boiler. If left in place, do not plug

®

inlet and outlet tappings.

G. Water Quality Improper water quality will reduce

the expected life of the Alliance™ water heater. Hard

water, sediment, high or low water Ph, and high levels

of chlorides in the domestic water should be avoided.

Sediment and hard water will coat the water heater coil

surfaces and reduce the rating of the water heater and

may, eventually, cause a failure. High or low Ph and/

or high chloride concentrations will cause the stainless

steel water heater components to corrode and

eventually fail. A filter is strongly recommended

where sediment is present in the water. A water

softening system is recommended for areas with hard

water.

In areas where water quality is unknown, a water

quality test should be performed.

WARN I N G

Do not operate ALLIANCE™ water heater in areas where water Ph is above 8.0 or below 6.0,

and/or with chloride concentra tions g reater than 80 parts p er million (pp m). Bu rnham' s Standard

Warranty does not cover problems caused by improper water Ph or excessive levels of chlorides.

7

III. Piping

A. Drain domestic water system.

1. Shut off cold water supply at main shut-off valve.

2. Open one or more system faucets to relieve

pressure. Open system drain valve, leaving faucets

open to relieve vacuum.

3. Disconnect existing domestic water heating system

(if applicable).

B. Position Alliance™ in final location.

C. Connect domestic hot water piping (see Figure 1).

1. Install piping and union out of indicated supply

connection.

2. Install Temperature-Pressure Relief Valve (installer

supplied) in the indicated location. Do not place

shut-off valve between the tank and relief valve.

3. Pipe relief valve discharge to floor.

4. Connect from supply union to hot water supply

system using vacuum breaker, shut-off valve, and

heat trap (to prevent thermal siphoning during nondraw periods).

D. Connect cold water supply piping (see Figure 2).

1. Install piping into connection on bottom of tank as

indicated.

2. Connect to cold water supply system using union,

shut-off valves, expansion tank (where required),

back flow preventer (where required), and filter

(recommended to prevent sediment buildup in

tank).

E. Fill Alliance™ tank.

1. Open all faucets to allow air to purge from tank and

piping. Remove screens on faucet.

2. Open domestic hot water shut-off valve.

3. Open cold water inlet shut-off valve.

Figure 1: Hot Water and Relief Valve Piping

8

4. Purge air from domestic water system. Allow water

to run so the tank is thoroughly purged of any

debris. Run water long enough so that a minimum

of five (5) volume changes of the tank are

accomplished. Close faucets. Reinstall screens.

5. Check system for leaks. Repair as necessary.

F. Connect water boiler return piping (See Figures 3

thru 6).

(For connection to a steam boiler skip ahead to H on

page 12).

1. Determine where in the boiler and space heating

piping system the Alliance™ connections should be

made by identifying the type of system from Figures

3 thru 6.

2. In all cases, the Alliance™ connection labeled

"BOILER RETURN" should be piped to the boiler

return piping as close to the boiler as possible and

especially after any flow control or check valves in

the space heating return piping. The use of a union

and a shut-off valve is recommended. The use of a

flow control or check valve is required to prevent

back flow through the water heater during

operation of the space heating system.

Figure 2: Cold Water Supply Piping

9

Figure 3: Water Boiler Piping with Zone Valves and a Boiler Bypass

G. Connect water boiler supply

piping (See Figures 3 thru 6).

1. For a space heating system that

utilizes ZONE VALVES AND

A BOILER BYPASS, refer to

Figure 3. The Alliance™

connection labeled "BOILER

SUPPLY" should be piped to

the boiler supply piping as

close to the boiler as possible

and especially before the

bypass piping. Mount the

circulator as close as possible

to the water heater making

sure the flow arrow points

toward the water heater. The

use of a shut-off valve is

recommended for future

service convenience. The use

of an air purger and vent is

recommended to eliminate air

in the system during warmer

periods when the space heating

system is not operating.

Otherwise, if air noises occur

during summer months the

space heating system would

have to be operated to purge

air at the main purger.

Figure 4: Water Boiler Piping with Zone Circulators and a Boiler

Bypass

2. For a space heating system that

utilizes ZONE

CIRCULATORS AND A

BOILER BYPASS, refer to

Figure 4. The Alliance™

connection labeled "BOILER

SUPPLY" should be piped to

the boiler supply piping as

close to the boiler as possible

and especially before the

bypass piping. Mount the

circulator as close as possible

to the water heater making

sure the flow arrow points

toward the water heater. The

use of a shut-off valve is

recommended for future

service convenience. The use

of an air purger and vent is

recommended to eliminate air

in the system during warmer

periods when the space heating

system is not operating.

Otherwise, if air noises occur

during summer months the

space heating system would

have to be operated to purge

air at the main purger.

10

3. For a space heating system

that utilizes ZONE

VALVES WITHOUT A

BOILER BYPASS, refer to

Figure 5. The Alliance™

connection labeled

"BOILER SUPPLY" should

be piped to the boiler

supply piping after the air

purger and before the space

heating circulator. Mount

the water heater circulator

as close as possible to the

water heater making sure

the flow arrow points

toward the water heater.

The use of a shut-off valve

is recommended for future

service convenience.

Figure 5: Water Boiler Piping with Zone Valves and without a Boiler

Bypass

4. For a space heating system

that utilizes ZONE

CIRCULATORS

WITHOUT A BOILER

BYPASS, refer to Figure

6. The Alliance™

connection labeled

"BOILER SUPPLY"

should be piped to the

boiler supply piping after

the air purger and before

the space heating takeoffs.

Mount the water heater

circulator as close as

possible to the water heater

making sure the flow

arrow points toward the

water heater. The use of a

shut-off valve is

recommended for future

service convenience.

Figure 6: Water Boiler Piping with Zone Circulators and without a

Boiler Bypass

11

H. Connect steam boiler piping (See Figures 7 thru 10).

1. Burnham V-7 Series steam boiler (Refer to Figure

7).

a. For satisfactory supply of hot water, the V-7

steam boiler must be equipped with a special

tapped rear heater coil cover plate contained in

both of the following kits:

Part No.

6032702 Includes tapped cover plate, mounting

hardware, water temperature limit with well,

and installations instructions.

6032703 As above, except less limit and well.

b. The Alliance™ connection labeled "BOILER

RETURN" should be piped to tapping "R"

(lower left hand ¾" tapping in front of boiler).

The use of unions, a shut-off valve, and a drain

valve is recommended for future service

convenience. The use of a flow control or check

valve is required to prevent back flow through

the water heater during operation of the space

heating system.

c. The Alliance™ connection labeled "BOILER

SUPPLY" should be piped to the 1" NPT

tapping in the boiler's aforementioned tapped

cover plate. The circulator should be floor

mounted with full size 1" piping from the boiler

and no flow restrictions in this piping. Be sure

the flow arrow on the circulator points toward

the water heater. The use of a union, shut-off

valves, and a drain valve is recommended for

future service convenience. The use of an inline "Y" style strainer is required to prevent

accumulation of sludge in the water heater's

coil.

2. Burnham Independence® Series steam boiler (Refer

to Figure 8).

a. The Alliance™ connection labeled "BOILER

RETURN" should be piped to tapping "M" on

the left side of the Independence boiler. The use

of unions, a shut-off valve, and a drain valve is

recommended for future service convenience.

The use of a flow control or check valve is

required to prevent back flow through the water

heater during operation of the space heating

system.

Figure 7

b. The Alliance™ connection labeled "BOILER

SUPPLY" should be piped to tapping "N" on the

right side of the Independence boiler. The water

heater circulator should be floor mounted with

full size 1¼" piping from the boiler and no flow

restrictions in this piping. Be sure the flow

arrow on the circulator points toward the water

heater. The use of a union, shut-off valves, and

a drain valve is recommended for future service

convenience. The use of an in-line "Y" style

strainer is required to prevent accumulation of

sludge in the water heater's coil.

12

3. Typical steam boiler with connections available

below the water line (Refer to Figure 9).

a. The Alliance™ connection labeled "BOILER

RETURN" should be piped to a tapping in the

boiler that is below the lowest permissible water

level. The use of unions, a shut-off valve, and a

drain valve is recommended for future service

convenience. The use of a flow control or check

valve is required to prevent back flow through

the water heater during operation of the space

heating system.

b. The Alliance™ connection labeled "BOILER

SUPPLY" should be piped to a tapping in the

Figure 8

boiler section furthest away from the return

tapping to prevent short circuiting in the boiler.

This tapping should be high enough to provide

hot water but must be below the lowest

permissible water level. The water heater

circulator should be floor mounted with full size

(1" minimum) piping from the boiler and no

flow restrictions in this piping. Be sure the flow

arrow on the circulator points toward the water

heater. The use of a union, shut-off valves, and

a drain valve is recommended for future service

convenience. The use of an in-line "Y" style

strainer is required to prevent accumulation of

sludge in the water heater's coil.

Typical Steam Boiler w/Connections Available Below Water Line

Figure 9

13

Figure 10

4. Steam boiler without hot water connections

available below the water line (Refer to Figure 10).

a. Supplying the Alliance™ from the bottom

tappings in a steam boiler is not recommended

due to insufficient water temperature, especially

during warmer months when the space heating

system is not operational. Boiler water

temperature at the bottom of a steam boiler can

be 50°F lower than the boiler's water

temperature limit setting during such periods.

I. Fill boiler system.

1. On new boiler installations, do not purge the boiler

or space heating system through the water heater.

During any boiler or space heating system flushing,

cleaning, or purging, the water heater should be

isolated to avoid possible attack on the copper coil

by chemical additives.

2. Purge air from boiler/water heater piping.

3. Check system for leaks. Repair as necessary.

14

IV. Electrical

1. Install electric wiring in accordance with National

Electrical Code or the Canadian Electrical Code

and local regulations. See Figure 11 for the wiring

diagram and the boiler's Installation manual.

2. The Alliance™ models contain an aquastat

assembly and will require an installer supplied

double pole, single throw (DPST) relay with a

normally open (NO) contact, a normally closed

(NC) contact, and a 120 volt coil for priority

domestic water. A Honeywell R4222D1013 is an

appropriate relay. Refer to Figure 11. For nonpriority, a SPST relay with one NO contact is

sufficient. For non-priority and space heating with

zone circulators, treat the water heater as an

additional zone.

Figure 11: Priority Wiring Diagram - Multizone Space Heating with Zone Valves

or Single Zone Space Heating

15

V. Operation

A. System Start-Up

1. Follow boiler installation instructions to place

boiler in operation.

2. Turn aquastat dial clockwise to desired setting.

a. An initial setting of 120°F is recommended.

b. Turning the knob clockwise from "100" position

will cause an audible click indicating the desired

temperature is higher than the current tank

water temperature.

B. Sequence of Operation

1. Aquastat senses stored water temperature drops

below desired setting.

a. Aquastat contacts close to start domestic hot

water circulator and energize relay.

b. Normally open contacts close to initiate boiler

ignition sequence.

c. Domestic hot water priority only: normally

closed contacts open to interrupt space heating.

2. Aquastat satisfied

2. For the most energy efficient operation, adjust

aquastat for the minimum water temperature

necessary to meet domestic hot water needs.

3. After the water heater completes a heat-up cycle,

check the water temperature at a faucet. Adjust

water heater's temperature setting as necessary.

a. Adjusting to a lower temperature setting will not

immediately affect water temperature. Draw

sufficient water or allow the water heater to sit

until a heat-up cycle is initiated. Repeat step 3.

a. Aquastat contacts open, turning off domestic hot

water circulator and de-energizing relay.

b. Normally open contacts open, stopping boiler

operation.

c. Domestic hot water priority only: normally

closed contacts close, returning boiler control to

space heating.

C. Water Temperature Adjustment

1. The aquastat controls the maximum water

temperature in the tank. It's differential is fixed at

5°F. It's maximum setting is 160°F.

D. To Shut-off Water Heater

b. Adjusting to a higher temperature may not

immediately affect water temperature. If a heatup cycle begins, go to step 3. If a heat-up cycle

does not begin, draw sufficient water or allow

the water heater to sit until a heat-up cycle is

initiated. Repeat step 3.

1. Turn power off to the Alliance.

2. Follow boiler operating instructions to turn off

boiler.

WARN IN G

Never operate water heater with temperatures in excess of 200°F. Severely reduced water heater

life will result.

16

VI. Service Instructions

A. The Alliance™ is intended to provide a service life of

many years. Components that require service,

however, may be subject to failure. Failure to use the

correct procedures or parts in these circumstances may

make the water heater unsafe.

The owner should arrange to have the following

inspections and simple maintenance procedures

performed by qualified service personnel at the

frequencies suggested.

1. Boiler and Domestic Water Piping (Annual)

Check all piping for signs of leakage at joints,

unions, and shut-off valves. Repair as needed.

2. Temperature-Pressure Relief Valve (Annual)

Follow instructions packed with valve.

3. Sediment (Annual, but harsh water quality may

dictate more frequent service)

Depending on water conditions, a varying amount

of sediment may collect in the tank. Levels

requiring service are indicated by a small

temperature difference in the supply and return

lines. (See also "Scale" below.) Repeated flushing

usually clears such material. As a preventive

measure, water should be drawn from the tank at

the drain valve until it runs clear.

4. Scale (Annual)

Hard water may cause scale to build-up on the

outside of the heat exchanger coil. A water softener

will prevent this problem. (See also "Sediment"

above.) Symptoms would be reduced recovery

capacity or reduced temperature differential

between boiler supply and return lines. Repeated

flushing should resolve the problem. If not,

proceed to B.

B. Chemical cleaning of heat exchanger coil

1. To avoid water damage to nearby areas in

subsequent steps, shut off the cold water supply to

the water heater.

2. Make a note of the temperature control setting on

the water heater, then turn the unit off.

3. Relieve the water pressure in the tank by opening a

hot water faucet. This will reduce the risk of scald

injury.

4. Remove the relief valve from the water heater

taking care to avoid contact with the hot water

which may drain out of the lines leading to the

domestic uses.

5. Drain the water heater until the water within the

tank is even with the top of the heat exchanger coil.

The water heater cover plate should be removed

from the tank to view the inside of the tank and

assure the coil is just covered with water.

6. Using a funnel, pour one gallon of commercial ice

maker cleaning solution into the tank through the

cover plate opening. Follow solution

manufacturer's instructions, cautions and warnings.

7. Set the water heater's temperature control to its

highest setting and operate the system until the

control is satisfied. Boiler may cycle on its high

limit several times during this period. If the tank

temperature setting has not been satisfied after 45

minutes of boiler operation, turn aquastat to the

lowest setting to stop boiler operation.

8. Allow heated solution to set in tank for 30 minutes.

9. Drain tank completely using fittings and hose, as

required, to reach a floor drain.

10. Fill the water heater's tank with fresh, cold,

conditioned water and drain completely at least two

(2) times to flush all cleaning solution from the

tank.

11. Reinstall the relief valve, cover plate, and piping.

12. Open the cold water supply and fill the tank with

water. Then purge air from lines and tank by

operating hot and cold water faucets in the house.

13. Return the temperature control to the setting noted

in Step 2.

C. Alternate heat exchanger coil cleaning methods

The chemical cleaning process is most effective if done

properly. Other methods may also give satisfactory

results including, high velocity water wash using a

wand through the cover plate.

17

VII. T rouble Shooting

PROBLEM CAUSE SOLUTION

No hot water at faucet Boiler does not ope rate Refe r to boiler i nstall ation i nstruct ions

Check main service switch

Check fu sed disconnect

Circulator does not operate Check power supply

Chec k sh aft cou plin g

Impr oper aquasta t set ting or c alibra ti on Turn tank aquas tat t o higher setti ng

Zone valve does not open (i f used) Check pow er supply

Elect rical problem (relay, wiring, fus e, e tc.) Check fus e a nd r eplace

Check ci rcuit breaker and reset (if applicable)

Check pow er supply

Scale build-up If boiler, circulator and tank are operat ing satisfactorily, coil

Clog ged cold water filter or boiler supply

strai ner (if u sed )

Insufficient hot w ate r Aquastat setting too low Adjust aquastat t o highe r set ti ng

Undersized boiler with no priority to

domestic hot wate r

Peak us e of hot w ater is greater than tank

storage capa city

Scale build-up If boiler, circulator and tank are operat ing satisfactorily, coil

Fau lt y t ank aquastat Replace aq uastat

Water at faucet too hot Aq uastat s et t oo hi gh Lower aquas tat setting

Improper system plumbing Compare pl umbing t o Section I II: P iping

Improper system wiring Compare wiring t o Section IV: Elect rical

Boiler cycl es mor e

tha n 5 times p e r

day in sum mer

Excessive demand Reduce demand or consi der l arger tank

Faulty aquas tat Repl ace aquastat

Boile r high limit set too low Increase boiler high limit setting

may have scale coating. See Section VI: Servic e I nstruction s

Clean or repl ace fil ter or s traine r

Rewi re for p rior ity

Dete rmine peak usage and com pare t o tank v olume

may have scale coating. See Section VI: Servic e I nstruction s

Scale Build-up If boiler, circulator and tank are operat ing satisfactorily, coil

may have scale coating. See Section VI: Servic e I nstruction s

18

VIII. Repair Parts

1 Aquastat (Honeywell L4006A2114)

2 Handhole Cover

3 Handhole Cover Gasket

4 Handhole Cover Bracket

5 Handhole Cover Nut

6Jacket

AL119A 8040807

8010812

8050802 AL40A

8200804 AL53A

8050803 AL79A 8040809

8080804 AL1 19A 8040810

AL26A 8040803

7 Top Cover

AL26A

8040808

AL26A

8040811AL40A 8 040804 AL40A

8 Bo ttom Co v er *

AL53A 8 040805 AL53A

AL79A 8 040806 AL79A 8 040812

9Plastic Rivet *

10 Double Sided Tape *

8040813

8040814

* N ot a pplicab le to AL 119A

19

All Alliance™ Series repair parts may be obtained through your local Burnham Wholesale Distributor. Should you

require assistance in locating a Burnham Distributor in your area, or have questions regarding the availability of

Burnham products or repair parts, please contact your Burnham Regional Sales Office as listed below.

Burnham Corporation Regional Offices

A. B urnham Corporation - Centr al & Western Regions

P.O. Box 3079

La ncast er, PA 17604-3079

Phone: (717) 481-8400

FAX: (717) 481-8408

B. B urnham Sales Cor poration - Northeast Region

19 -27 Mystic Av enue

Somerville, MA 02145

Phone: (617) 625-9735

FAX: (617) 625-9736

C. Burnham Corporation - Metropolitan Region

P.O. Box 3079

Lancas ter, PA 17604-3079

Phone: (717) 481-8400

FAX: (717) 481-8409

D. Burnham Corporation - Mid-A tlantic Region

P.O. Box 3079

La ncast er, PA 17604-3079

Phone: (717) 481-8400

FAX: (717) 481-8409

Contact Regional Office Indicat ed f or your State

Alabama A Nebraska A Oregon A

Alaska A N e vad a A Pe n nsylva ni a D

Arizona A New H a mp s hir e B Rh ode I sla nd B

Arkansas A Ne w J er sey South Car oli na A

Californ ia

Colora do A

Connecticut B

Delawar e D

A

Atlan tic, Burlin gton, C amd en,

Ca pe May, C umbe rla nd,

Glou cester, Merc er,

Monmouth, Oce an, Sale m

South Dak ota A

Tennes see A

D

Te xas A

Utah A

Fl o rida A

Ge or g ia A

Hawaii A New Mexico A

Ida ho A Ne w York

Illinois A

Indiana A

Iowa A

Kansas A

Kentuc ky A

Loui sia na A North Carolina A W est Virginia D

Maine B North Dakot a A Wis consin A

M aryla nd D Ohio Wy omi ng A

Ma ss ach use tts B

Mic h igan A

Min n esot a A

M ississippi A

Missouri A

Co unties

All other Co unties

Albany, F ulton , M ontgomery,

Re nss ela er, S ara to ga, Pr inc e Wil liam Cou nties

Sch enect ady, Schohar ie, A ll other C o unties

Warren, Washington Counties

All O the r C o unt ies

Athens, Belmont, Gallia,

Jef fers on, Lawrenc e, Meigs,

Monro e, an d Was hing ton

Co unt ies

All other Co unties

Vermont B

C Vir gin ia

Arl ing to n, Ac co mac k,C l ark e,

Fairfax,Fr ederic k,Fauq uier,

Loudoun , Northampto n a nd

B

Washington A

C Washington, D.C. D

D

A

D

A

Montana A Oklahom a A Cana da A

20

Inspection / Service Schedule

DATE INSPECTION AND/OR SERVICE PERFORMED

21

22

Loading...

Loading...