Burnham Indirect - Fired Water Heater AL SL, Alliance 27SL, Alliance 35SL, Alliance 50SL, Alliance 70SL Installation & Service Instructions Manual

...Page 1

INSTALLATION, OPERATING AND

SERVICE INSTRUCTIONS FOR

Alliance SL™

Indirect - Fired Water Heater

Including

Warranty

Information

For service or repairs to the water heater, call your heating contractor. When seeking information on the water heater, provide Model Number and Serial Number as shown on Rating Label.

Model Number

AL SL

Heating Contractor Phone Number

Address

100934-01R1-11/07

Serial Number

U.S. Boiler Company, Inc.

Installation Date

Price - $5.00

1

Page 2

GENERAL INFORMATION

PLEASE READ INSTRUCTIONS CAREFULLY

BEFORE INSTALLING WATER HEATER

U.S Boiler Company, Inc. – Burnham Hydronics (herein called the Company) intends that this Alliance SL™

Indirect-Fired Water Heater be used as a separate zone to a heating system boiler.

This appliance is designed to heat water by circulating water from the boiler through the internal coil in the

tank. We specically do not warrant this tank for high temperature applications such as wood stoves or

steam producing systems. Such use of this product will automatically void the warranty.

The design anticipates the proper installation and care in use of the product. There is risk of property damage and personal injury inherent in the use of any hot water system. The Company cannot supervise the

installation and therefore makes it a specic condition of the warranty that the customer will supervise the

installation and use of this product to be sure they are performed in accordance with safe guidelines and

proper local or national codes.

Generalized instructions and procedures cannot anticipate all situations. For this reason, only qualied

installers should perform the installation. A qualied installer is a person who has licensed training and a

working knowledge of the applicable codes, regulations, tools, equipment and methods necessary for safe

installation of a boiler system and an indirect water heater.

An installation checklist has been provided to help the customer ensure that all procedures for a safe installation have been followed.

If questions regarding installation arise, check with your local plumbing and electrical inspectors for proper

procedures and codes. Local codes take a precedent over instructions in this manual.

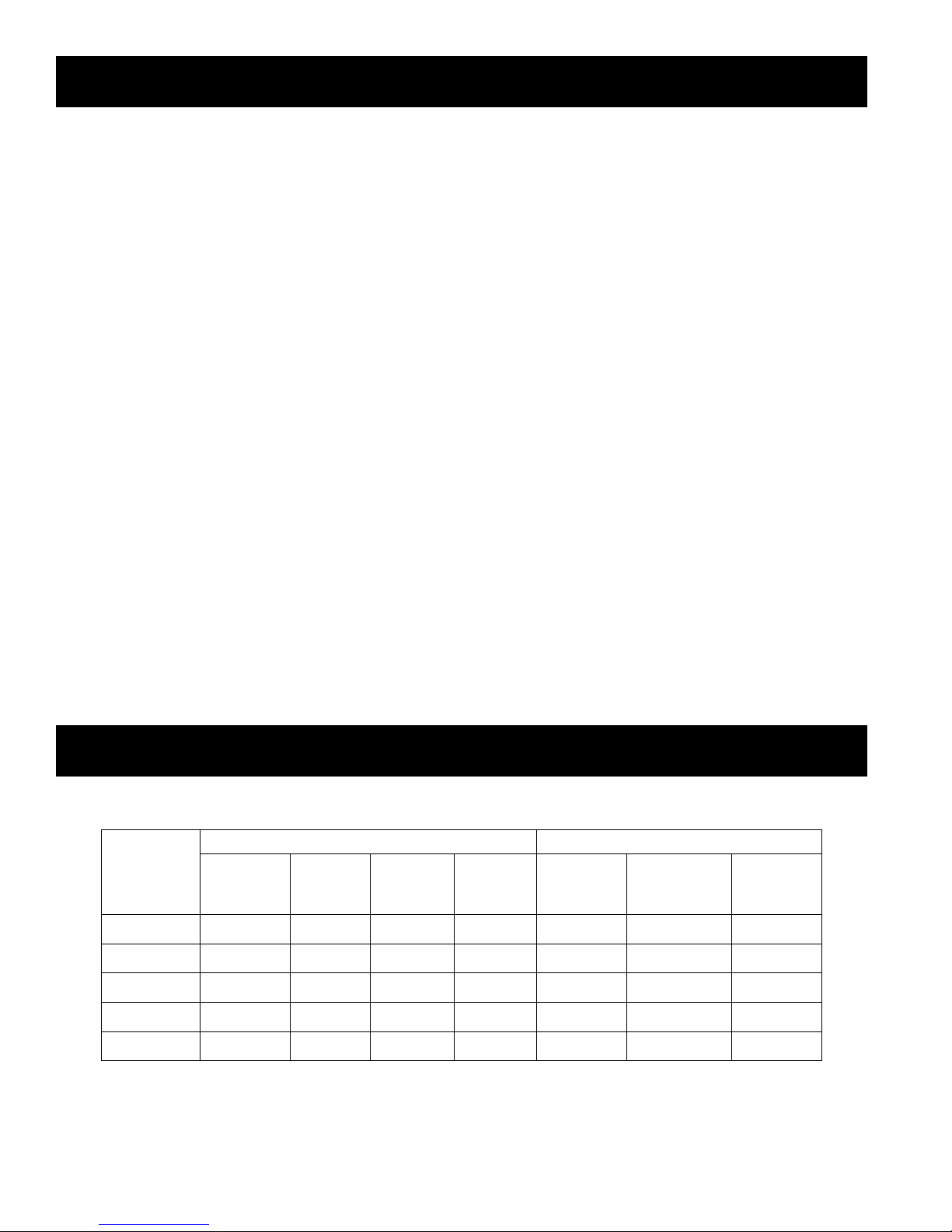

SPECIFICATIONS & RATINGS

Specications Ratings

Potable

Alliance SL

Model

AL 27SL

AL 35SL 35 39.25 22.75 198 200 162 0.72

AL 50SL 50 40.75 26.00 248 225 171 0.56

Volume

(gal.)

27 39.25 20.00 170 192 162 0.97

Height

(in.)

Diameter

(in.)

Weight

(lbs.)

1st Hour

(gal./hr)

Cont. Draw

(gal./hr)

Standby

Loss

(°F/hr)

AL 70SL 70 45.75 28.00 300 294 217 0.45

AL 119SL

2

119 67.75 26.00 480 339 235 0.39

Domestic Water Inlet / Outlet = 3/4”M — T&P Valve = 3/4”F

Boiler Water Supply / Return = 3/4”M — except AL 119SL = 1.0”M

Page 3

INDEX

General Information ..................................................................................................................... 2

Specications & Ratings .............................................................................................................. 2

Installation Guidelines ................................................................................................................. 4

Installation Checklist .................................................................................................................... 7

Service Information ...................................................................................................................... 8

TPI Control Diagrams (#1-3) ....................................................................................................... 10

Installation Piping Figures (#1 & 2) .............................................................................................. 12

Top Mount Coil Details & Tightening Sequence (Figure #3) ........................................................ 13

Circulator & Burner Control Wiring Diagrams .............................................................................. 14

Zone Valve Wiring Diagrams ....................................................................................................... 15

Switching Relay Wiring Diagrams ............................................................................................... 16

How to Obtain Service Assistance ............................................................................................... 18

Warranty ...................................................................................................................................... 29

Model and Serial Number Information ......................................................................................... 21

Optional Lifetime Warranty .......................................................................................................... Back Cover

To fully understand the purchaser’s responsibilities for

installing the water heater, please read the warranty.

U.S. Boiler Company, Inc., – P.O. Box 3079 – Lancaster, PA 17604

www.burnham.com

3

Page 4

INSTALLATION GUIDELINES

3/4” x 28” x 28” Plywood

Solid Blocks Under Plywood

A. INSPECTING AND PREPARING THE WATER HEATER

q AL27SL thru AL70SL - Remove the cardboard box, which comes packaged with the heater.

It should contain the following: TPI thermostat, T&P valve and a “Tee”, foamed lid and screws.

q AL119SL - Remove the cardboard boxes, which come packaged with the heater. One box should

contain the following: TPI thermostat, T&P valve and a “Tee”, foamed lid and screws. The other box

should contain the heat exchanger.

B. LOCATION

q Do not place the water heater where there is a risk of property damage in the event of a leak.

q Place the water heater on a solid foundation in a clean, dry location nearest the boiler.

q The water heater should be protected from freezing and water lines should be insulated to reduce

energy and water waste.

q Leave sufcient headroom to service the heat exchanger and electrical controls.

q Do not install in an area where ammable liquids or combustible vapors are present.

q CAUTION: The water heater’s outer jacket is plastic and can melt.

q Do not install in close proximity to wood burning stove or other high temperature apparatus.

NOTE: If Water Heater is Placed On Blocks To Raise It From The Floor,

Be

Sure to Support The Entire Bottom With At Least ¾ “ Plywood On The Top Of The Blocks.

C. PROTECTION FROM WATER DAMAGE

q CAUTION: All water heaters have a risk of leakage at some unpredictable time.

q IT IS THE CUSTOMER’S RESPONSIBILITY TO PROVIDE A CATCH PAN OR OTHER ADEQUATE

MEANS, SO THAT THE RESULTANT FLOW OF WATER WILL NOT DAMAGE FURNISHINGS OR

PROPERTY. (See Figure 1)

D. RELIEF VALVE

q WARNING: A POTENTIAL HAZARD TO LIFE AND PROPERTY MAY EXIST IN ANY WATER

HEATER IF AN APPROVED TEMPERATURE-AND-PRESSURE RELIEF VALVE IS NOT

PROPERLY INSTALLED.

q For protection against excessive pressures and temperatures in this water heater, install tempera ture-and-pressure protective equipment by local codes, but not less than a combination temperature and-pressure relief valve certied by a nationally recognized testing laboratory that maintains

periodic inspection of production of listed equipment of materials, as meeting the requirements for

Relief Valves and Automatic Gas Shutoff for Hot Water Supply Systems, ANSI Z21.22-1971. This

4

Page 5

valve must be marked with maximum set pressure not to exceed the marked maximum allowable

working pressure of the water heater (150psi). Install the valve into the opening provided and

marked for this purpose in the water heater, and orient it or provide the tubing so that any discharge

from the valve will exit only within 6 inches above, or at any distance below the structural oor and

cannot contact any live electrical parts. The discharge opening must not be blocked or reduced in

size under any circumstances.

q CAUTION: A relief valve is designed to discharge excessively hot water. THE CUSTOMER IS

RESPONSIBLE TO PROTECT PROPERTY AND PERSONNEL FROM HARM WHEN THE VALVE

FUNCTIONS.

q Install the T&P provided on hot water outlet of tank as shown in Figures 1 and 2.

q Care must be taken to be sure that the stem of the pressure-and-temperature relief valve is

immersed in the water within the top 6 inches of the tank.

q The drain line from the relief valve must not be concealed or blocked and must be protected from

freezing.

q WARNING: IF THE WATER SUPPLY IS FROM A WELL, OR KNOWN TO HAVE HARD WATER, IT

IS RECOMMENDED TO USE A PRESSURE RELIEF VALVE IN THE COLD WATER LINE AS

WELL AS A T&P VALVE IN THE HOT WATER LINE.

E. INSTALLING THE REMOVABLE HEAT EXCHANGER

q Heat exchanger is installed at the factory except for the AL119SL which is shipped loose. The

following is provided for servicing or removing the heat exchanger.

q Insert heat exchanger with plastic o-ring housing and align holes in cover plate with holes in ange

and plastic o-ring housing.

q WARNING: Plastic o-ring housing must be properly installed. (See Figure 3). Failure to do

this will void the warranty.

• Insert and secure the bolts to the nuts one at a time in the following manner:

• Place the nut beneath the ange opening.

• Hold the nut in place with one hand – insert the bolt with the other.

• Thread the bolt into the nut and tighten in proper order.

NOTE: Be sure to place bolts in all of the openings.

q Heat exchanger connections are 3/4” male threaded ttings, except for the AL119SL which has 1

inch male threaded ttings.

q Connect the supply line (from the boiler) to the “Hx In” ttings of the heat exchanger. It is recom-

mended to use a union as per Figures 1 and 2.

q Connect the return line (back to the boiler) to the “Hx Out” ttings on the ange of the heat

exchanger. It is recommended to use a union as per Figures 1 and 2.

WARNING: Plastic o-ring housing must be installed properly (See Figure 3) to prevent corrosive

action. Failure to do this will void the warranty. Must use new o-ring if replaced or removed.

F. WATER SUPPLY CONNECTIONS

q WARNING: Some local codes mandate the use of a backow preventer or check valve or

pressure-reducing valve. An adequate expansion tank (or other adequate means) must be

installed to prevent pressure build up or damage from thermal expansion when a check valve

or backow preventer or pressure-reducing valve is used. Failure to do so could result in

tank leakage and therefore void the warranty. (See Figures 1 and 2 for proper location)

q All water supply ttings on this heater are brass – do not over tighten or strip threads.

q It is recommended to use a union as per Figures 1 and 2.

5

Page 6

q Do not apply heat directly to the cold-water inlet as it is made of plastic and will melt.

G. BOILER SUPPLY CONNECTIONS

q WARNING: Boiler temperature must be controlled by the boiler high limit not to exceed 200°.

Failure to do so will create a hazardous installation and void the applicable limited warranties.

q All water supply ttings on this heater are brass – do not over tighten or strip threads.

q It is recommended to use a union as per Figures 1 and 2.

NOTE: Be sure to connect Boiler Supply Line (from the boiler) to the “HX in” tting and Boiler

Return Line (to the boiler) to the “HX Out” tting.

H. FILLING THE HEATER

q Check that the temperature-and-pressure relief valve has been properly installed (mandatory

requirement).

q Completely close the drain valve.

q Open the highest hot water faucet to allow air to escape from piping.

q Open the valve to the cold-water inlet and allow the heater and piping system to completely ll, as

indicated by a steady ow of water from the open faucet.

I. TPI THERMOSTAT INSTALLATION

q Attaching TPI Thermostat to tank:

Place hole in back of TPI thermostat over immersion well. TPI thermostat should t ush against the

tank without immersion well protruding beyond cover of TPI case. Use self-tapping screw provided

(Screw A) to attach TPI directly to the Alliance SL tank. (See TPI Diagram 2)

q Inserting the Temperature Sensor:

Slide temperature sensor all the way into the immersion well – until it contacts the end.

(See TPI Diagram 2)

q The sensor will measure temperature adequately by resting against the bottom of the immersion

well.

(Note: Sensor does NOT need to make intimate contact with entire well surface to work properly)

CAUTION: Sensor is soldered directly to TPI. DO NOT BEND SHARPLY OR OVERWORK.

J. TPI WIRING CONTROLS

NOTE: THE TPI CONTROL ELECTRONICS MUST BE POWERED WITH 24VAC.

q Incoming 24VAC power must be connected to 24VAC connectors on the bottom right corner of TPI

Thermostat.

(See TPI Diagram 3)

q The TPI 24VAC only requires 20mA, or about 0.5 Watts.

q Connect control wiring to PUMP/TT normally open relay connections (rated for both 24V and 110V

wiring) on the bottom left corner of TPI control. (See TPI Diagram 3)

q TPI Wiring will vary depending on the type of boiler and valve controls in the system. Consult

attached Wiring Diagrams for appropriate wiring conguration for your system.

q The Alliance SL water heater may operate as a separate heating zone using either the heating

system circulator and an appropriate zone valve, or a separate circulator dedicated for water heating.

(See Figure 1 & 2).

q In both systems, the Alliance SL is controlled through the TPI thermostat on the heater.

(See Figures 1 & 2).

q TPI thermostat calls for the heat when the temperature in the tank is below the set point (120°F) and

either activates a circulator or zone valve depending upon installation design.

6

Page 7

q Run all 24VAC wiring thru the square notch on bottom of TPI case. (See TPI Diagram 3)

q Incoming 24VAC power must be connected to 24VAC connectors on the bottom right corner of TPI

control. (See TPI Diagram 3)

q Connect control wiring to PUMP/TT normally open relay connections (rated for both 24V and 110V

wiring) on the bottom left corner of TPI control. (See TPI Diagram 3)

q All and only 110VAC wiring must go through an appropriate chase nipple installed in the knockout at

bottom of TPI case.

q Be certain to replace TPI cover using Black Screw provided.

INSTALLATION CHECKLIST

A. INSPECTING AND PREPARING THE WATER HEATER

q Remove the cardboard box, which comes packaged with the heater. It should contain the following:

TPI thermostat, T&P valve and a “Tee”, foamed lid and screws.

B. LOCATION

q Solid foundation and dry location.

q Protect heater water lines from freezing.

q Area free of ammable vapors.

q Sufcient room to service heater.

q Not in close proximity to wood burning stove.

q Where leak will not damage property.

C. PROTECTION FROM WATER DAMAGE

q Be sure to make provisions to protect area from water damage if a leak should occur in the

tank or connected ttings.

D. RELIEF VALVE

q Warning: Improper installation will present potential hazard to life and property.

q Check to be sure that proper relief valve requirements are met.

q T&P installed as shown in Figures 1 and 2.

q 3/4” discharge pipe – properly protected from freezing and restrictions.

q No valve between tank and relief valve or in drain line.

q Provision for hot water discharge from relief valve.

E. INSTALLING THE REMOVABLE HEAT EXCHANGER

q Heat Exchanger is installed at the factory except for the AL119SL. The following is provided for ser vicing.

q Insert heat exchanger with plastic o-ring housing.

q WARNING: Plastic o-ring housing must be installed properly. (See Figure 3).

q For proper installation of Heat Exchanger See Figure 3.

F. WATER SUPPLY CONNECTIONS (See Figure 1 & 2).

q Do not over tighten brass threads.

q Mark the water shutoff for future reference.

7

Page 8

q Do not apply heat to cold inlet.

q If there is a check valve (sometimes in water meter), backow preventer or pressure-reducing valve,

install an adequate size expansion tank.

G. FILLING THE HEATER

q Completely ll heater.

q Water connections completed and free of leaks.

q Check for proper installation of relief valve.

q Close drain valve.

q Open highest hot water faucet.

q Open cold water inlet valve and ll system.

H. WIRING

See Figure 1 & 2 and separate TPI control wiring diagrams.

q TPI requires 24V to operate. See TPI installation for details.

q Wire either as a heating zone or separate circulator.

q Water heater temperature is controlled by TPI thermostat.

q WARNING: Boiler must have high limit control set no more than 200°F.

SERVICE INFORMATION

WATER TEMPERATURE REGULATION

WARNING: Exposure to 125°F or hotter water can cause scalding injuries. Appropriate caution

must be taken when using hot water. Special supervision must be given to those who cannot act

quickly such as children, disabled or elderly persons.

The input of heat into the tank is controlled by an immersion thermostat. These automatic controls are set

at the factory to maintain a water temperature of 120°F. Note: Although these thermostats are designed to

industry standards, they can fail to control temperature properly without any notice, and therefore should be

tested periodically for your protection.

DANGER: IF YOU DISCOVER EXTREME HOT WATER COMING FROM THE FAUCET, IMMEDIATELY

SHUT OFF THE MAIN SWITCH TO THE BOILER AND CALL COMPETENT SERVICE PERSONNEL.

ANY OVERHEATED WATER IS A POTENTIAL HAZARD TO LIFE AND PROPERTY. DO NOT OPERATE UNTIL THE SOURCE OF THE PROBLEM HAS BEEN DETERMINED AND ELIMINATED.

• Water temperature over 125°F can cause severe burns instantly or death

from scalds.

• Children, disabled and elderly persons are at the highest risk of being scalded.

• See instruction manual before setting temperature at the water heater.

• Feel water before bathing or showering.

Proper maintenance is important for any product. It is suggested that the

purchaser follow the preventive maintenance program outlined below.

8

Page 9

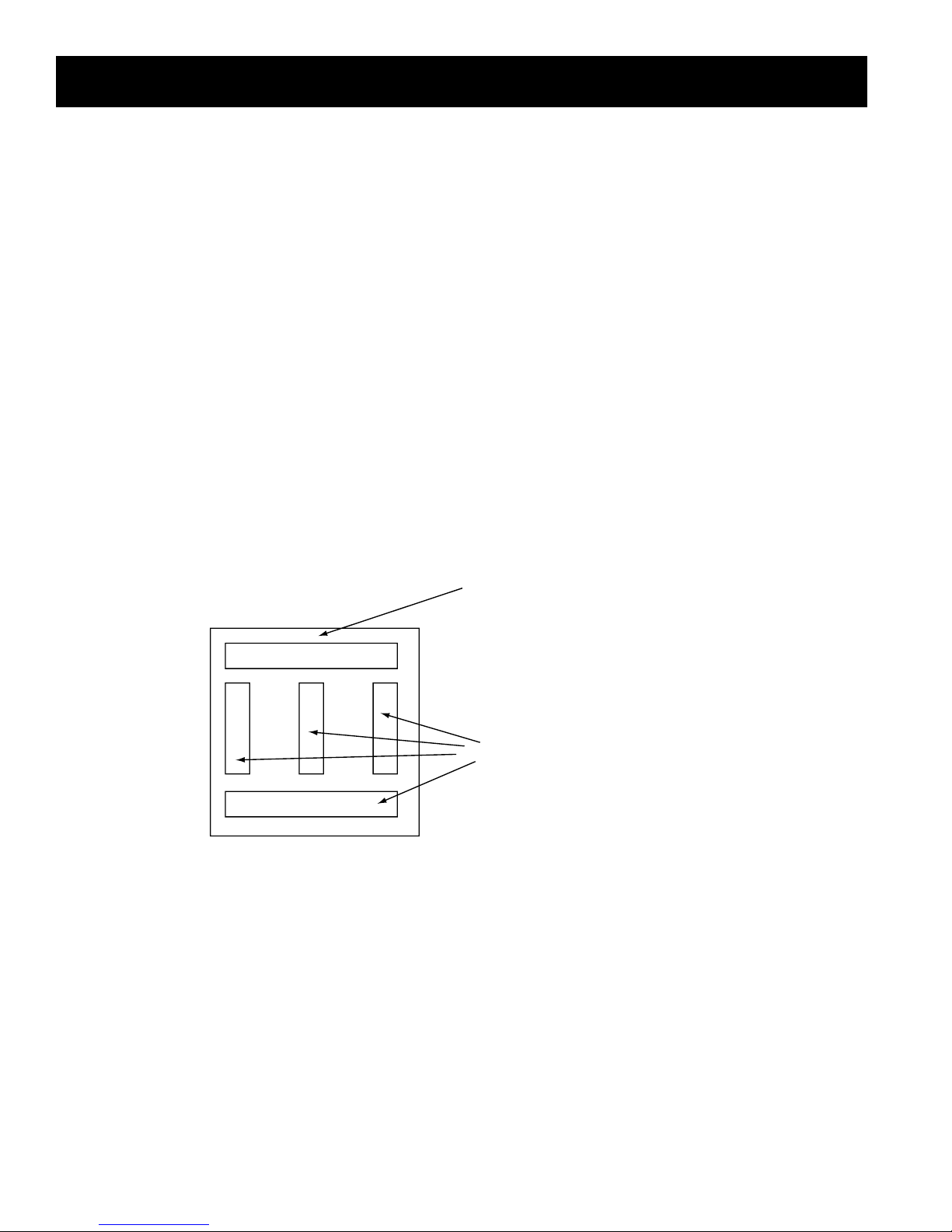

WATER TEMPERATURE CONTROLS

TemperatureDifferential

Pump/TT 24v

LED

flashing green = calling for heat

solid green = at temperature

red = error

20°

15°

10°

5°

160°

150°

140°

130°

120°

110°

Probe

®

®

A periodic inspection of the operating controls, heat exchanger and wiring should be made by qualied service personnel. Temperature of the water should be tested periodically at the faucet to be sure thermostat

is working properly.

TEMPERATURE ADJUSTMENT

The TPI comes with a factory set temperature setting of 120°F and differential

setting of 10°F. Any temperature adjustment of the thermostat must be made

by qualied service personnel, as shown below.

WARNING: See SERVICE INFORMATION Water Temperature Regulation,

regarding safe water temperature before proceeding. Hot water can cause

scalding injuries.

1. Shut off or disconnect all electrical supply to heater.

2. Remove cover to TPI control.

3. Adjust right side lever to the desired temperature. Moving lever down will

decrease temperature. (See Figure at right and TPI Diagram 1).

NOTE: Markings on slide are approximate. Check temperature at faucet

to ensure safe operating temperature.

4. Adjust left side lever to the desired differential. (See Figure at right and TPI

Diagram 1) The TPI thermostat will call for heat when the tank temperature

has fallen to the set differential degrees below the temperature set point.

5.

Reattach cover.

6. Reconnect electrical supply.

7. Check faucet temperature to verify desired temperature is achieved.

In order to set the temperature above 140°F {NOT RECOMMENDED} you must remove the SCALD

DANGER label attached to the temperature slide.

Caution: Do not increase temperature above 140°F without a properly installed mixing valve in the

system – See Water Temperature Regulation and SCALD WARNING.

Indicator Light operation:

The TPI thermostat has an integral indicator light at the top of the case.

(See TPI Diagram 1 or Inside Cover of TPI)

Indicator light will come on (Green) when TPI is powered.

When TPI is calling for heat, the Indicator light will blink.

When TPI is satised, the Indicator light will be solid.

During normal operation, Indicator light is Green.

If TPI detects a failure, Indicator light will ash Red. Replace TPI.

EMERGENCY

Should the heater be subject to ood, re or other damaging conditions, turn the power and water to the

heater off. DO NOT place water heater in operation again until it has been thoroughly checked by qualied

service personnel.

9

Page 10

TPI CONTROL - DIAGRAM 1

Indicating Light Temperature Adjust

Differential

Adjust

TPI CONTROL - DIAGRAM 2

Screw A

10

Page 11

TPI CONTROL - DIAGRAM 3

Outgoing 24V

wires to relay

or zone valve

Outgoing 110V

wires to

circulator

Incoming 24V

power

connection

Incoming 24V

power

connections

Chase Nipple

Conduit

NOTE: Use proper conduit

and chase nipple

11

Page 12

FIGURE 1 - Installation Using Zone Valves

Installation Diagram Using Zone Valves

FIGURE 2 - Installation Using Circulator

Installation Diagram Using Separate Circulator

12

Page 13

FIGURE 3 - Coil Detail & Tightening Sequence

Bolt

Steel Washer

Coil Plate

Plastic O-Ring

Housing

Tank

Flange

‘L’ Nut

Small

outside

O-ring

Large

inside

O-ring

3

2

Proper Tightening Sequence for Top Mount Coil

7

2

4

6

1

1

8

Incorrect Correct

Note: Same as car tire lugs

5

3

CAUTION: Does not require excessive force to seal properly.

13

Page 14

Low Voltage

120 Volts

L1 Hot

120 Volts

L2 Neutral

Circulator

24v

TemperatureDifferential

Pump/TT 24v

LED

flashing green = calling for heat

solid green = at temperature

red = error

20°

15°

10°

5°

160°

150°

140°

130°

120°

110°

Probe

Switched Hot

®

®

T

T

Switching Relay

Transformer

Thermostat

Burner

TV

W

T

Z

C1 C2

L1 L2

B1

B2

120 Volt

Boiler

Circulator

TemperatureDifferential

Pump/TT 24v

LED

flashing green = calling for heat

solid green = at temperature

red = error

20°

15°

10°

5°

160°

150°

140°

130°

120°

110°

Probe

®

®

Circulator & Burner Control Wiring Diagrams

Standard Wiring for Circulator with Boiler

Maintaining a Temperature of 180°

Wiring for Burner Control L8148E

14

Page 15

L o w V oltage

120 V olts

120v

24v

B oiler

C onnec tions

T

1

T

2

3

H ot N eutr al

Z one V alv e

120v

24v

T o B oiler C onnec tions

/C ir cula t or

H ot N eutr al

4 W ir e Z one V alv e

M ot or

E nd S wit ch

T T

T emperature Differential

P ump/T T 24v

LED

flashing green = calling for heat

solid green = at temperature

red = error

20 °

15 °

10 °

5 °

160 °

150 °

140 °

130 °

120 °

1 10 °

P r ob e

T emperature Differential

P ump/T T 24v

LED

flashing green = calling for heat

solid green = at temperature

red = error

20 °

15 °

10 °

5 °

160 °

150 °

140 °

130 °

120 °

1 10 °

P r ob e

®

®

®

®

Zone Valve Wiring Diagrams

Wiring for 3 Wire Zone Valve

Wiring for 4 Zone Valve

15

Page 16

Switching relay Wiring Diagrams

Switching Relay R8845U or SR 501

16

Switching Relay SR-502 or SR-503

Page 17

Switching relay Wiring Diagrams (con’t)

L o w V oltage

120 V olts

FUSE 1 AMP

C OM / 24 V A C

FOUR Z ONE SWIT CHING REL A Y

WITH OPTIONAL PRIORIT Y

Z ONE 1

Z ONE 2 Z ONE 3 Z ONE 4

Z ONE 4

PRIORIT Y

ON

OFF

Z ONE 1 Z ONE 2 Z ONE 3 Z ONE 4 PO WER

120 V OL T CIR CUL A T ORS

X X

END SWIT CH

Z C ZR

INPUT

SR 504

Z ONE 1

Z ONE 2

Z ONE 3

Z ONE 4

PO WER

120 V OL T REL A Y

120 V A C INPUT

T T ON BOILER

W a t er H ea t er C ir cula t or

T emperature Differential

P ump/T T 24v

LED

flashing green = calling for heat

solid green = at temperature

red = error

20 °

15 °

10 °

5 °

160 °

150 °

140 °

130 °

120 °

1 10 °

P r ob e

®

®

Switching Relay SR-504 with Priority Option

17

Page 18

HOW TO OBTAIN SERVICE ASSISTANCE

U.S. Boiler Company, Inc. – Burnham Hydronics does not have a service department or personnel to ser-

vice your heater in the eld. A qualied installer or service technician must do all service work. Therefore,

if you have any questions about your new water heater concerning service adjustment, repair, routine maintenance, or replacement - rst contact your installer, plumbing contractor or service agency.

In the event that the contractor, for whatever reason, is unable to help, refer to the telephone directory commercial listings for qualied service assistance.

If neither action has solved your problem, contact U.S. Boiler Company, Inc. – Burnham Hydronics as fol-

lows to obtain the number of a qualied service person in your area:

SALES SUPPORT

U. B. BOILER COMPANY, INC.

BURNHAM HYDRONICS

P.O BOX 3079

LANCASTER, PA 17604

Or call 888-432-8887

When contacting Burnham Hydronics the following information should be made available:

A. Model and serial number of the water heater as listed on inside back cover of this manual or on

the rating plate on the heater.

B. Address where water heater is installed.

C. Name and address of dealer from whom the heater was purchased and installer’s name and

address

D. Date of original installation and any service work performed since then.

E. Details of the problem as you can best describe.

F. List of people who have been contacted regarding the problem.

18

Page 19

Alliance SL™ Indirect-Fired Water Heater

10/2/1 LIMITED WARRANTY

Ten Year Limited Tank Replacement Warranty

Two Year Limited Tank Replacement Labor Allowance

One Year Limited Parts Warranty

U.S. Boiler Company, Inc. – Burnham Hydronics, (hereinafter called the company) offers the following Limited Tank Replacement Warranty, Limited Tank Replacement Labor Allowance, and Limited Parts Warranty

to the original purchaser/owner of this stone-lined Alliance SL™ indirect-red water heater. These warranties are not transferable beyond the original purchaser/owner, and are not valid if the tank is removed from

initial installation site. The Company reserves the right to require proof of purchase and inspection and/or

testing of tank as a condition of these warranties.

TEN (10) YEAR LIMITED TANK REPLACEMENT WARRANTY DURATION:

1. STANDARD DURATION: Ten (10) years from the date of manufacture as indicated by the serial

number.

2. OPTIONAL LIFETIME DURATION: (available to residential, single family homes only). For as long as

the original purchaser owns the home in which the Alliance SL™ was originally installed. Optional Life

time replacement Warranty is not effective unless U.S. Boiler Company, Inc. – Burnham Hydronics

receives completed registration card and payment within 30 days of purchase (see cover for details).

IF NO CARD IS RETURNED OR PAYMENT RECEIVED, THE REPLACEMENT WARRANTY WILL BE

THE STANDARD 10-YEAR WARRANTY AND WILL BEGIN FROM THE MANUFACTURED DATE

INDICATED BY THE SERIAL NUMBER ON THE ALLIANCE SL™ WATER HEATER.

COVERAGE: Replacement warranty covers only the storage tank for leaks caused by the corrosive ef-

fects of water under normal and proper use. Subject to prior Company approval.

COMPANY OBLIGATION: Repair of the original tank or replacement of the entire heater with a new

comparable model is at the option of the Company and constitutes the fulllment of ALL obligations of the

Company hereunder. In replacing or repairing the Alliance SL™ Water Heater, the company reserves the

right to make such changes in details of design, construction or material as shall in their judgment constitute an improvement of former practices.

REPLACEMENT: When a replacement is made under the terms of this warranty, the replacement unit

will have a warranty of replacement and labor allowance only for the remaining time under the original

warranty. The Company reserves the right to require the return of the defective unit at the expense of the

purchaser.

LIMITATION: The duration of the tank replacement warranty on the tank assembly shall be reduced to a

period of ve years if (1) the purchaser is a business, partnership or corporation, or if (2) the Alliance SL™

Water Heater is used for a commercial, institutional, industrial, non-residential or multi-application. All

repairs or replacements will be made F.O.B. the company. The purchaser must pay for transportation service, labor, installation, administrative fees or other costs involving the repair or replacement of such part.

YOUR ACTION: When you discover a defect, immediately notify the dealer from whom the heater was

purchased. If you cannot locate the dealer, contact the Company.

TWO (2) YEAR LIMITED TANK REPLACEMENT LABOR ALLOWANCE: The Company shall pay up to

a maximum of $200, for the labor to exchange a tank that is leaking due to the corrosive effects of water

within two years from date of installation. This labor allowance is for tank replacement only, and not for any

service work on the heater such as cleaning of the heat exchanger (due to the build-up of calcium or other

minerals or metals), leakage from plumbing connections, relief valves, heat exchanger gaskets, thermo-

stats, or any other component of the heater. This labor must be performed by a qualied installer. Proof of

labor costs may be required as a condition of payment of the Tank Replacement Labor Allowance.

LIMITATION: All other repairs or replacements will be made F.O.B the Company. The purchaser must

pay for all transportation, service, labor, installation, administrative fees or other cost involving the repair of

replacement of such component parts.

YOUR ACTION: When you discover a defect, immediately notify the dealer from whom the heater was

purchased. If you cannot locate the dealer, contact the Company.

19

Page 20

ONE (1) YEAR LIMITED PARTS WARRANTY

DURATION: The warranty is effective for one (1) year beginning with the date of original purchase. This

warranty shall begin from the date of manufacture as indicated by the serial number.

COVERAGE: The warranty covers any component part of the Alliance SL™ water heater proven to be

defective in workmanship or material. Subject to prior Company approval.

COMPANY OBLIGATION: The warranty covers any component of the Alliance SL™ water heater proven

to be defective in workmanship or material.

EXCLUSIONS AND LIMITATIONS

Limited Warranty and Tank Replacement Warranty are valid only if you comply with the following conditions

and limitations:

1. The Alliance SL™ Water Heater is correctly installed according to the installation manual provided with

the unit and all applicable local and national codes.

2. The unit is operated within the factory calibrated temperature limits and water pressure not exceeding

150 psi.

3. Any failure or malfunction that does not result from improper or negligent operation, accident, abuse

(including freezing), misuse, unauthorized alteration or improper maintenance.

4. Any failure or malfunction that does not result from failure to keep the tank full of potable water, free

to circulate at all times; and free of damaging water sediment or scale deposits. In areas where adverse

water conditions are suspected (i.e. calcium and other minerals), it is essential that the water be tested

and appropriate action be taken to prevent damage to the Alliance SL™ tank. It may be necessary to

remove the heat exchanger for cleaning to maintain maximum performance in poor water areas.

Diminished performance due to the build-up of calcium or other minerals, metals, or deposits on the

heat exchanger is specically not included in the coverage of these warranties.

5. THE FOREGOING EXPRESS LIMITED WARRANTIES ARE THE ONLY WARRANTIES OF ANY KIND,

EITHER EXPRESS OR IMPLIED. THERE ARE NO EXPRESS OR IMPLIED WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, PERFORMANCE OR NON INFRINGEMENT, OR OTHER EXPRESS OR IMPLIED WARRANTIES. EXCEPT FOR THE LIMITED

WARRANTIES SET FORTH HEREIN, THE COMPANY DISCLAIMS ALL OTHER WARRANTIES OR

CONDITIONS, EXPRESS OR IMPLIED, REGARDING THE PRODUCT OR ITS OR THEIR FITNESS

FOR A PARTICULAR PURPOSE OR ITS OR THEIR MERCHANTABILITY. PURCHASER SHALL

HAVE SOLE RESPONSIBILITY FOR SELECTING APPROPRIATE WATER HEATER FOR THE

PURCHASER’S NEEDS AND USE AND THE COMPANY DOES NOT WARRANT THE FITNESS FOR

THE WATER HEATER’S INTENDED USE WITHIN ANY SPECIFIC SYSTEM. THE COMPANY DOES

NOT AUTHORIZE COMPANY REPRESENTATIVES OR OTHER PERSONS TO VARY THE TERMS

OF THE WARRANTIES HEREIN OR TO ASSUME FOR THE COMPANY ANY OTHER OBLIGATIONS

OR LIABILITIES WITH RESPECT TO THIS PRODUCT.

6. The remedies set forth above shall be the sole and exclusive remedies for breach of any warranty.

IN NO EVENT SHALL THE COMPANY BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES WHATSOEVER.

Consumer Notications: The foregoing warranty limitations shall be effective to the maximum extent

permitted by applicable law, and, to the extent that any such limitations would have an unconscionable

result or would otherwise be inconsistent with applicable law, such provision shall be reformed to the extent

necessary to avoid such unconscionable result or inconsistency. With respect to the limitations on implied

warranties set forth above, the Company hereby noties each person to whom such warranty is made as

follows: Some states do not allow exclusions of such warranties, limitations on how long an implied warranty lasts or the exclusion or limitation of incidental or consequential damages, so the above limitations,

or exclusions, may not apply to you. The limited warranty gives you specic legal rights, and you may also

have other rights which vary from state to state.

20

Page 21

MODEL & SERIAL NUMBER INFORMATION

The following information should be noted

At time of installation and retained

for Future reference.

Model No.

Serial No.

Date Installed

Dealer’s Name

Address

City

State Zip

U.S. Boiler Company, Inc., – P.O. Box 3079 – Lancaster, PA 17604

www.burnham.com

21

Page 22

NOTES

22

Page 23

NOTES

23

Page 24

Optional Lifetime Warranty Registration Card

Available to Residential, Single Family Homes Only

Yes, I wish to purchase the Optional Lifetime Warranty!

DATE _____________________________________________________________________

PURCHASER’S NAME _______________________________________________________

HOME ADDRESS ___________________________________________________________

CITY ____________________________STATE _________________ ZIP _____________

HOME PHONE ____________________ EMAIL ___________________________________

ALLIANCE SL™ WATER HEATER SERIAL NUMBER (9 DIGITS)

COMPANY PURCHASED FROM ________________________________________________

INSTALLING COMPANY NAME _________________________________________________

ADDRESS _________________________________________________________________

CITY ____________________________STATE _________________ ZIP _____________

COMPANY PHONE __________________________________________________________

DATE OF INSTALLATION _____________________________________________________

NOTE: To obtain the Optional Lifetime Warranty, this card must be lled out completely

and returned to U.S. Boiler Company, Inc. along with payment of one hundred dollars

($100) within 30 days of installation/occupancy.

METHOD OF PAYMENT (Check One):

CHECK PAYABLE TO: U.S. BOILER COMPANY, INC. ENCLOSED.

OR CHARGE MY: VISA MASTERCARD

CARD NUMBER ___________________________________________ “V” number _______

(Verication “V” number is last three digits of number printed on back of credit card.)

CREDIT CARD EXPIRATION DATE _____________________________________________

NAME ON CREDIT CARD _____________________________________________________

SIGNATURE ________________________________________________________________

Complete form, cut along dotted line, and return with payment to:

Attn: Alliance SL™ Extended Warranty Program

P.O. Box 3079 – Lancaster, PA 17604

24

U. S. Boiler Company, Inc.

Loading...

Loading...