Page 1

Quickstart

English

Type 3360, 3361, AE3360, AE3361

Electromotive control valve

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© Bürkert Werke GmbH & Co. KG, 2016 – 2019

Operating Instructions 1905/07_EU-ML_00810487 / Original DE

Page 3

Type 3360 and 3361

english

Contents

1 THE QUICKSTART .......................................................................................4

1.1 Definition of the term "device" ................................................ 4

1.2 Symbols ....................................................................................... 5

2 INTENDED USE .............................................................................................5

3 BASIC SAFETY INSTRUCTIONS ..........................................................6

4 GENERAL INFORMATION ........................................................................7

4.1 Contact address ........................................................................ 7

4.2 Warranty ...................................................................................... 7

4.3 Information on the Internet ......................................................7

5 STRUCTURE AND FUNCTION...............................................................8

5.1 Structure of the electromotive control valve .......................8

5.2 Display of the device state ..................................................... 9

6 TECHNICAL DATA ........................................................................................9

6.1 Conformity ................................................................................... 9

6.2 Standards .................................................................................... 9

6.3 Approvals ....................................................................................9

6.4 Rating plate ...............................................................................10

6.5 Operating conditions ..............................................................10

6.6 General technical data ...........................................................12

7 INSTALLATION OF THE VALVE .......................................................... 15

7.1 Installation of devices with threated socket connection,

flange connection or clamp connection .............................16

7.2 Installation of devices with welded connection ................17

7.3 Rotating the actuator ..............................................................21

7.4 Holding device .........................................................................22

8 ELECTRICAL INSTALLATION ............................................................... 22

8.1 Electrical installation with circular plug-in connector ......22

8.2 Electrical connection fieldbus gateway ..............................25

8.3 Electrical installation with cable gland ................................26

8.4 After electrical installation ............................................................. 30

9 START-UP .................................................................................................... 31

9.1 Prior to Preparation for Use ..................................................31

9.2 Setting options for start-up ...................................................31

9.3 Base settings............................................................................31

9.4 Setting safety position ............................................................33

9.5 Adjust the position control – running X.TUNE .................34

9.6 Set standard signal for set-point position .........................36

9.7 Select physical unit for process control .............................36

9.8 Parameterize process values ................................................37

9.9 Scaling process control .........................................................38

9.10 Setting dead band of the process control .........................38

9.11 Set up process control – run P.LIN, P.TUNE ....................39

9.12 Setting operating state...........................................................40

10 OPERATION

10.1 Display elements ............................................................................. 41

10.2 Control elements .....................................................................42

11 DISPLAY OPERATION (OPTION) ...................................................... 43

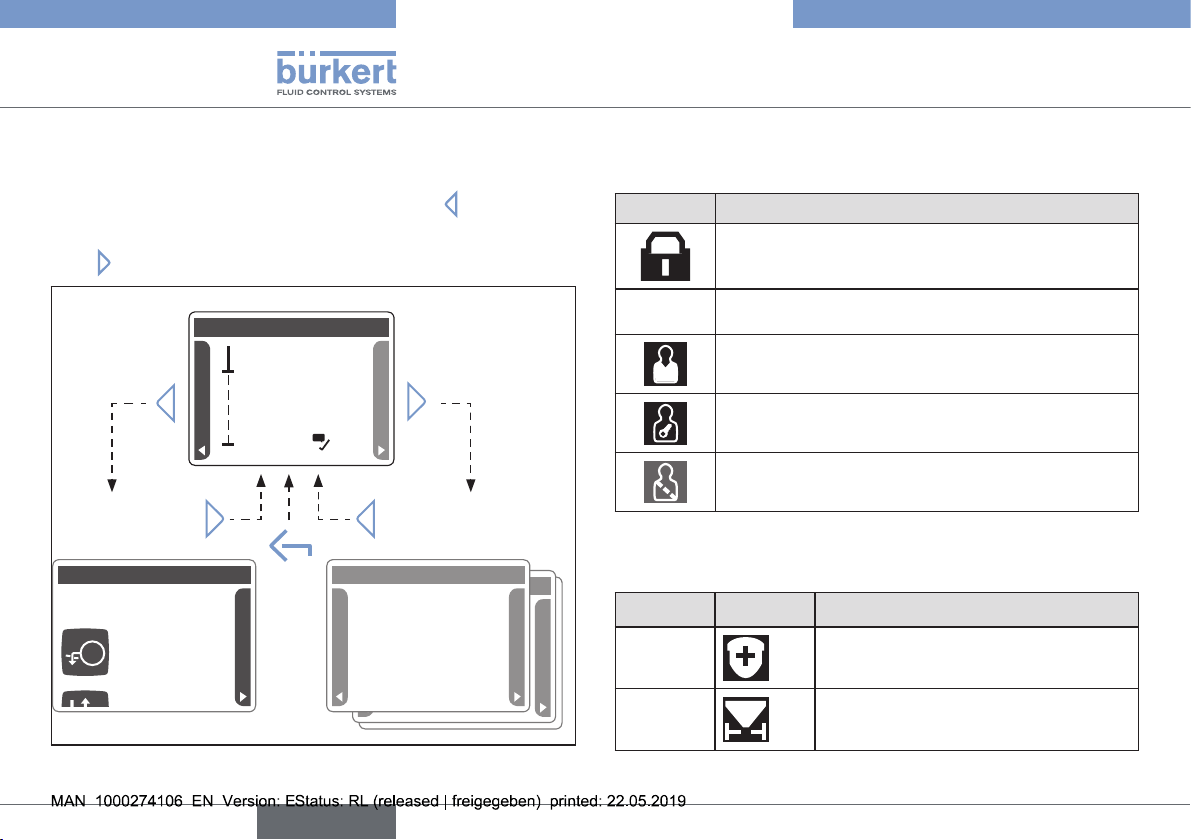

11.1 User interface ...........................................................................43

11.2 Description of the keys ..........................................................43

11.3 Display views ............................................................................44

11.4 Description of the symbols....................................................44

..................................................................................................41

3

Page 4

Type 3360 and 3361

english

The Quickstart

12 MANUAL ACTUATION OF THE VALVE ........................................... 46

12.1 Actuating valve electrically ....................................................46

12.2 Actuating valve mechanically ................................................48

13 INDUSTRIAL ETHERNET ....................................................................... 50

13.1 Feldbus gateway .....................................................................50

13.2 Access to the büS Service interface ..................................50

14 CANopen

15 büS

16 MAINTENANCE, TROUBLESHOOTING ......................................... 51

16.1 Visual inspection ......................................................................51

17 CLEANING

18 ACCESSORIES

18.1 Communications software.....................................................51

18.2 büS Service interface .............................................................51

19 DISASSEMBLY

20 PACKAGING, TRANSPORT, STORAGE ..........................................52

21 DISPOSAL

........................................................................................................50

....................................................................................................................50

..................................................................................................... 51

........................................................................................... 51

............................................................................................ 52

..................................................................................................... 52

1 THE QUICKSTART

The quickstart contains the most important information and notes

regarding the use of the device. A detailed description can be found

in the operating instructions for Type 3360 and 3361.

Keep the quickstart in a location which is easily accessible to every

user and make it available to every new owner of the device.

Important Safety Information!

Read the Quickstart carefully and thoroughly. Study in particular

the chapters entitled Basic safety instructions and Intended use.

▶ The Quickstart must be read and understood.

The operating instructions can be found on the Internet at:

www.burkert.com

1.1 Definition of the term "device"

• The term "device" used in these instructions applies to all valve

types described in these instructions:

Type 3360, electromotive angle seat control valve

Type 3361, electromotive globe control valve

• In these instructions, the abbreviation "Ex" stands for

"explosion-risk".

• The term “büS” (Bürkert system bus) used in this manual stands

for the communication bus developed by Bürkert, based on the

CANopen protocol.

4

Page 5

Type 3360 and 3361

english

Intended use

1.2 Symbols

The following symbols are used in these instructions.

DANGER!

Warns of an immediate danger.

▶ Failure to observe the warning will result in fatal or serious injuries.

WARNING!

Warns of a potentially dangerous situation.

▶ Failure to observe the warning may result in serious injuries or death.

CAUTION!

Warns of a possible danger.

▶ Failure to observe this warning may result in a moderate or minor

injury.

NOTE!

Warns of damage to property.

Important tips and recommendations.

Refers to information in these operating instructions or in

other documentation.

▶ ▶ Designates an instruction to avoid a danger.

→ → Designates a work step to be performed.

Indicates a result.

MENUE

Representation of software interface text.

2 INTENDED USE

Non-authorized use of the electromotive control valve

Type 3360 and 3361 may be a hazard to people, nearby

equipment and the environment.

The electromotive control valve Type 3360 and 3361 is

designed to control the flow of liquid and gaseous media.

▶ Standard devices must not be used in the potentially explosive

area. They do not have a separate Ex rating plate which indicates approval for the explosion-proof area.

▶ The surfaces of the device must not be cleaned with alkaline

cleaning agents.

▶ If the valve position is relevant as regards safety in the event of

a power failure: Use only those devices which have the

SAFEPOS energy-pack (optional energy pack).

▶ Use according to the authorized data, operating conditions,

and conditions of use specified in the contract documents and

operating instructions.

▶ Protect the device against harmful environmental influences

(e.g. radiation, air humidity, vapors, etc.)! If in doubt, consult the

relevant sales company.

Use the device

▶ only in conjunction with third-party devices and components

recommended and authorized by Bürkert.

▶ Use only when in perfect condition and always ensure proper

storage, transportation, installation and operation.

▶ Use only as intended.

5

Page 6

Type 3360 and 3361

english

Basic safety instructions

3 BASIC SAFETY INSTRUCTIONS

These safety instructions do not consider any contingencies or incidents

which occur during installation, operation and maintenance.

The operator is responsible for observing the location-specific safety

regulations, also with reference to the personnel.

Risk of injury from high pressure.

▶ Before working on the system or device, switch off the pressure

and vent or drain lines.

Danger of burns and risk of fire.

Following an extended duty cycle or as a result of a hot medium,

the surface of the device may become hot.

▶ Only touch the device when wearing protective gloves.

▶ Keep the device away from highly flammable substances and

media.

Risk of crushing due to mechanically moving parts.

▶ Perform installation work on control cone, diaphragm and valve

body in the isolated state only.

▶ Devices with SAFEPOS energy-pack: Completely drain

SAFEPOS energy-pack. Wait until LED illuminated ring goes out;

the LED status must not be in

▶ Keep clear of the openings in the valve body.

Danger due to an uncontrolled process in the event of

a power failure.

If devices do not have the optional SAFEPOS energy-pack, the valve

remains in an undefined position in the event of a power failure.

LED off mode.

▶ If the valve position is relevant as regards safety in the event of

a power failure: Use only those devices which have the

SAFEPOS energy-pack (optional energy pack).

▶ In the SAFEPOS select a valve position which is safe for the

process.

Danger due to loud noises.

▶ Depending on the operating conditions, the device may generate loud

noises. More detailed information on the likelihood of loud noises is

available from the relevant sales office.

▶ Wear hearing protection when in the vicinity of the device.

Leaking medium when the packing gland is worn.

▶ Regularly check relief bore for leaking medium.

▶ If medium is leaking out of the relief bore, change the packing gland.

▶ If the media is hazardous, protect the area surrounding the discharge

point against dangers.

General hazardous situations.

To prevent injuries:

▶ In a hazardous area, the device may be used only in accordance

with the specification on the separate Ex rating plate.

▶ To use the device in an explosion-risk area, observe the addi-

tional information with safety instructions for the explosion-risk

area enclosed with the device or the separate explosion-risk

operating instructions.

▶ Devices without a separate Ex rating plate may not be used

in a potentially explosive area.

▶ Only feed in the media types specified in chapter “6 Technical

data” to the media connections.

6

Page 7

Type 3360 and 3361

english

General information

▶ Do not make any internal or external changes on the device and

do not subject it to mechanical stress.

▶ Transport, install and dismantle a heavy device with the help of

another person and with appropriate tools.

▶ Secure to prevent unintentional actuation.

▶ Only trained technicians may perform installation and mainte-

nance work.

▶ Note the plant-specific safety regulations.

▶ After an interruption, ensure that the process is restarted in

a controlled manner. Observe sequence.

1. Apply supply voltage.

2. Charge the device with medium.

▶ Observe the general rules of technology.

▶ The valves must be installed in accordance with the regulations

applicable in the country.

NOTE!

Electrostatic sensitive components / modules.

The device contains electronic components which react sensitively

to electrostatic discharge (ESD). Contact with electrostatically

charged persons or objects are hazardous to these components.

In the worst case scenario, they will be destroyed immediately or

will fail after start-up.

• Observe the requirements in accordance with EN 61340-5-1 to

minimize or avoid the possibility of damage caused by a sudden

electrostatic discharge.

• Do not touch electronic components while the supply voltage is

switched on.

4 GENERAL INFORMATION

4.1 Contact address

Germany

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Germany

Tel. + 49 (0) 7940 - 10-91 111

Fax + 49 (0) 7940 - 10-91 448

Email: info@burkert.com

International

Contact addresses can be found on the final pages of the printed

operating instructions.

And also on the Internet at:

www.burkert.com

4.2 Warranty

The warranty is only valid if the device is used as intended in accordance

with the specified application conditions.

4.3 Information on the Internet

Operating instructions and data sheets for Types 3360 and 3361 can

be found on the Internet at:

www.burkert.com

7

Page 8

Type 3360 and 3361

english

Structure and function

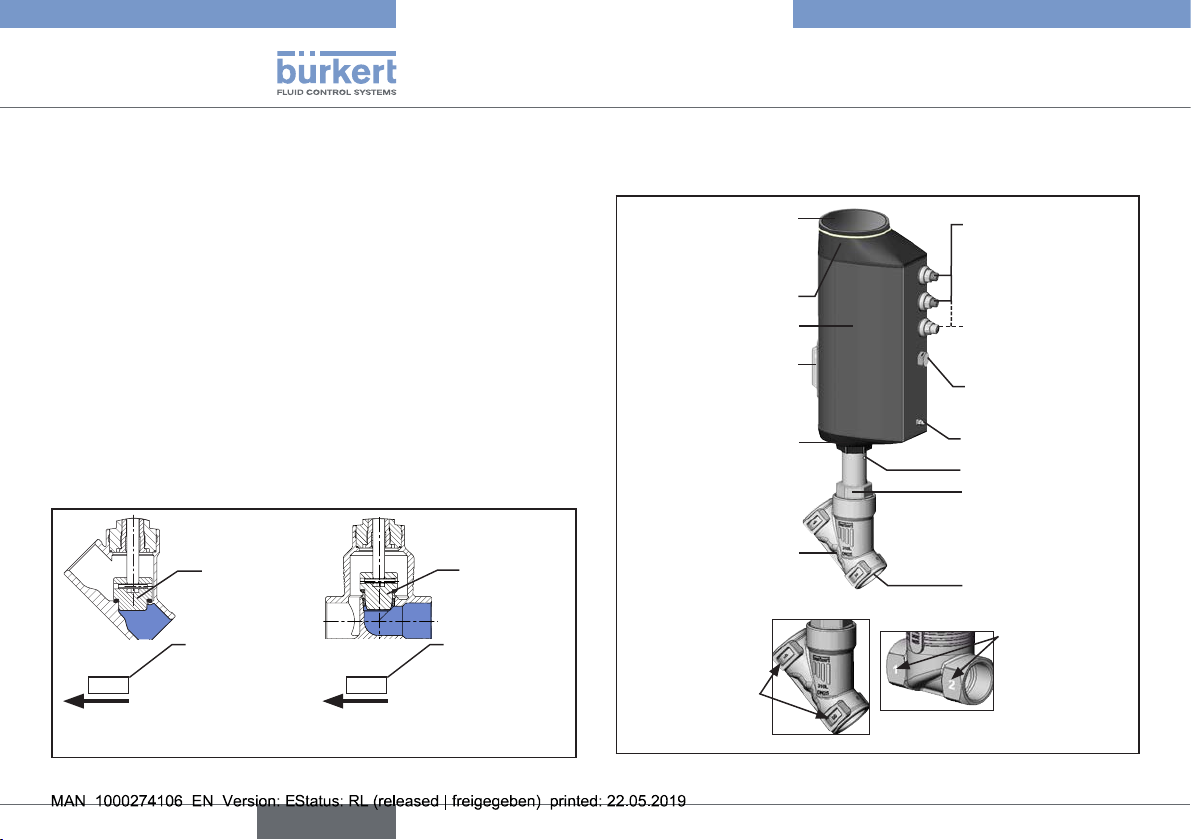

5 STRUCTURE AND FUNCTION

The electromotive control valve consists of an electromotively driven

linear actuator, a control cone and a 2-way globe valve body or a 2-way

angle seat valve body.

• The incoming flow is always under the seat.

Valve seats:

• In the case of the globe control valve, the valve seat is screwed in.

The seat size can easily be reduced by replacing the screwed-in

valve seat.

• In the case of the angle seat control valve, the valve seat is incorporated in the valve body. It is therefore not possible to reduce the

seat size.

As the valve seat is always closed against the medium flow, the flow

direction must be specified so that the incoming flow is under the

valve seat.

Valve seat

Marking on the

body

1 2 1 2

Flow direction Flow direction

Angle seat control valve

Type 3360

Fig. 1: Incoming flow under the seat, flow direction

Globe control valve

Type 3361

Valve seat

Marking on the

body

5.1 Structure of the electromotive control valve

Dummy cover or display

with illuminated display

and bayonet catch

Actuator cover

Actuator housing

Transparent window with

position indicator

Actuator base with

wrench flat

Angle seat valve body

Numbers for

indicating the flow

direction

Fig. 2: Structure, electromotive control valve Type 3360 and 3361

Electrical connections

(circular plug-in connector or cable gland)

Applies only to devices

with process controller

function

Do not unscrew pressure

compensation element!

FE functional ground

Relief bore

Body connection

(with wrench flat)

Port connection

Numbers for

indicating the flow

direction

8

Page 9

Type 3360 and 3361

english

Technical data

5.2 Display of the device state

To indicate device status and valve position, different LED modes can

be set (for description see main instructions).

LED mode set at the factory: “Valve mode w/ warnings”.

5.2.1 Displays in valve mode w/ warnings

When device status “Normal”: Permanently lit in the color of the valve

position.

If device status deviates from “Normal”: The colors for valve position

and device status flash alternately.

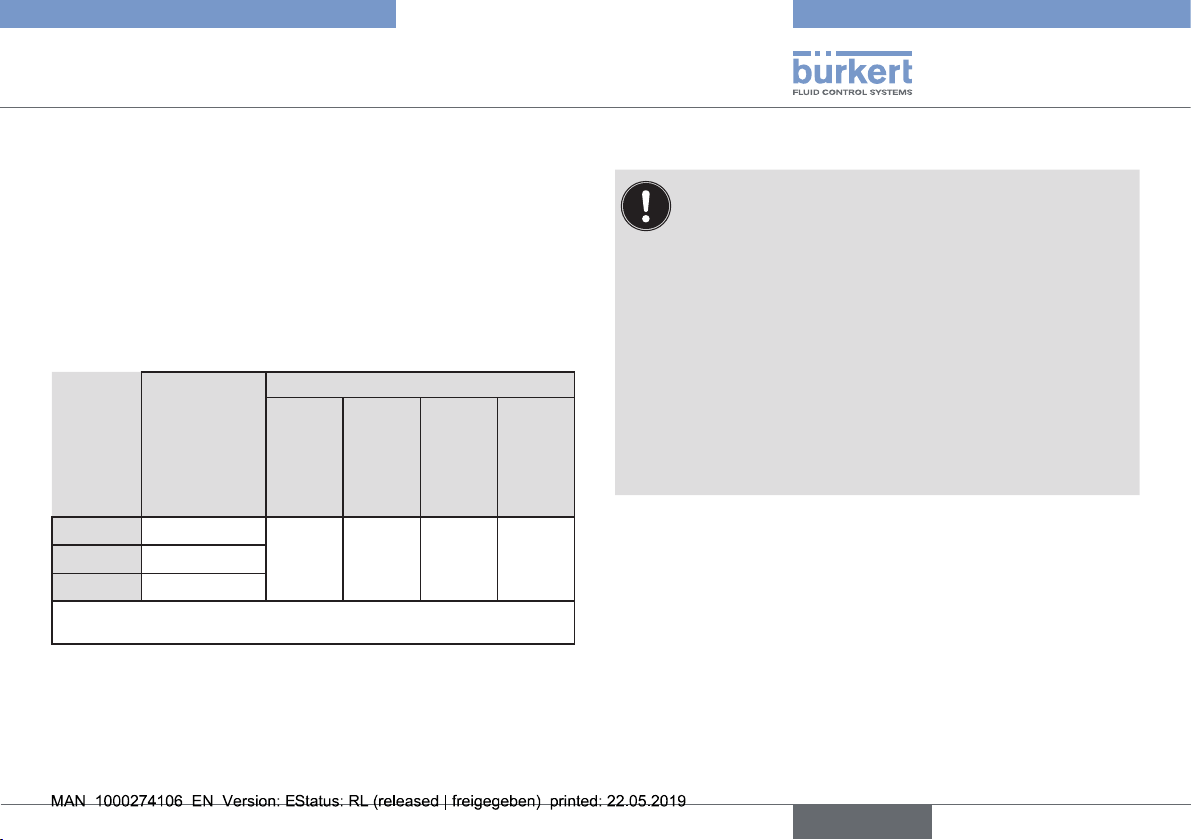

Valve

position

open

between

closed

* Factory setting; colors can be changed (see software description with

reference to Type 3360-3361 at www.burkert.com).

Tab. 1: Display of device state in valve mode w/ warnings

If several device statuses exist simultaneously, the device status with

the highest priority is displayed.

The priority is determined by the severity of the deviation from standard

operation (red = failure = highest priority).

Color of valve

position

yellow* red orange yellow blue

white

green*

Color of device status

Failure, error

or fault

Function

check

Out of

specification

Maintenance

requirement

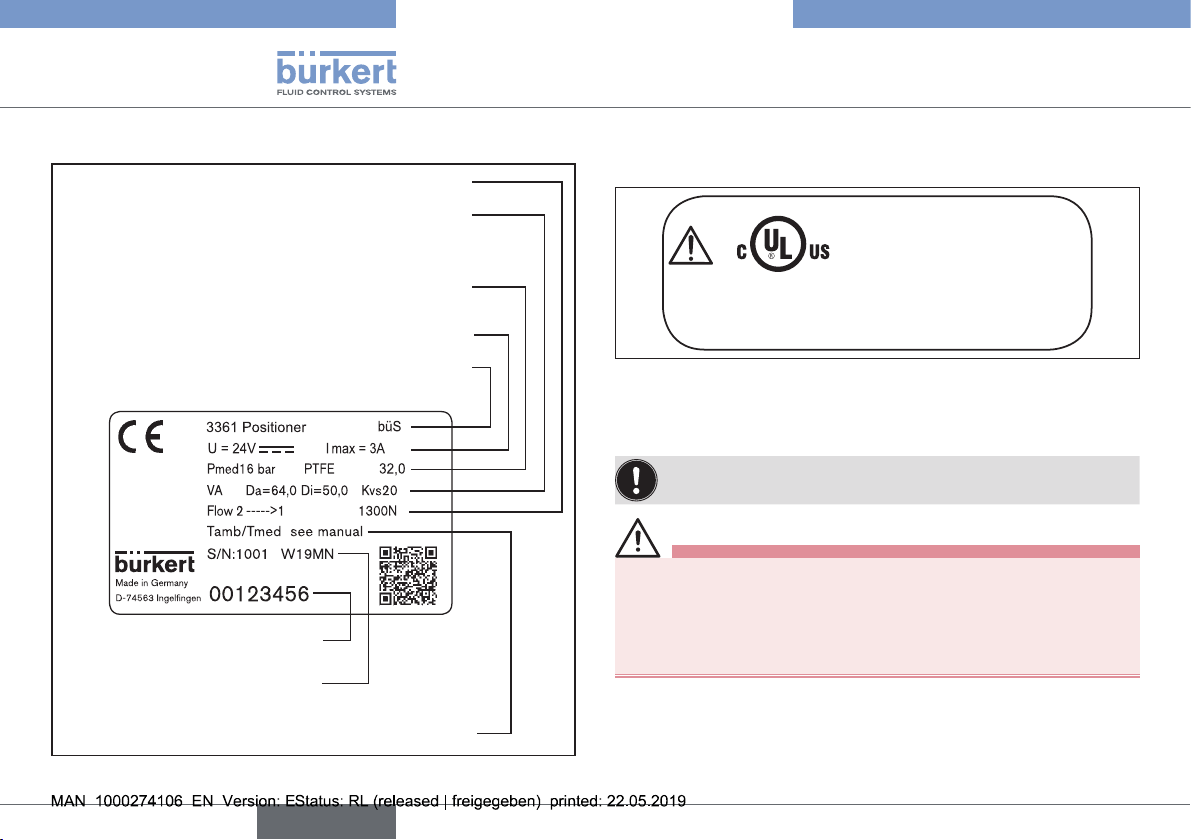

6 TECHNICAL DATA

The following product-specific information is indicated

on the rating plate:

• Voltage [V] (tolerance ±10%) and current type

• Seal material and material of the valve body

• Fieldbus standard

• Seat size of the valve

• Flow capacity

• Actuator size

• Port connection

• Maximum permitted medium pressure

• Flow direction

6.1 Conformity

The electromotive control valves Type 3360 and 3361 are compliant

with EC directives as stated in the EC Declaration of Conformity.

6.2 Standards

The applied standards, which are used to demonstrate compliance

with the EC Directives, are listed in the EC type test certificate and/or

the EC Declaration of Conformity.

6.3 Approvals

The product is cULus-approved. For notes on operation in the UL area,

see the chapters below.

9

Page 10

Type 3360 and 3361

english

Technical data

6.4 Rating plate

Flow direction, actuator size (nominal force)

Material valve body,

port connection Da (ø outer) Di (ø inner),

flow capacity

Maximum permitted medium pressure, seal material,

seat size of the valve

voltage, direct current, maximum current

Type, function (position controller / process controller),

fieldbus standard

Identification number of the device

Serial number,

date of manufacture (encoded)

Permitted temperature range (environment/medium)

6.4.1 Additional type label for UL approval

(example)

Type AE3360

Power Supply

LISTED

Process Control Equipment

E238179

Fig. 4: Additional type label for UL approval (example)

6.5 Operating conditions

For operation of the device observe the product-specific

information on the rating plate.

WARNING!

Malfunction if the temperature exceeds or drops below the

permitted temperature range.

▶ Never expose the device outdoors to direct sunlight.

▶ The temperature must not exceed or drop below the permitted

ambient temperature range.

SELV / PELV only!

Fig. 3: Description of the rating plate (example)

10

Page 11

Type 3360 and 3361

english

Technical data

WARNING!

Reduced sealing function if medium pressure too high.

As the valve seat is closed against the medium flow, the medium

pressure may become too high and prevent the valve seat from

closing tightly.

▶ The medium pressure must not be greater than the maximum

value specified on the rating plate.

Maximum permitted medium pressure: see rating plate

Media: neutral gases and vapor.

Liquid media: water, alcohol, oil, propellant,

hydraulic fluid, saline solution, alkali, organic

solvent.

Degree of protection: (veried by Bürkert / not evaluated by UL)

IP65 as per IEC 529, EN 60529 (IP67 on

request).

NEMA 250 4x (not guaranteed for installation location: actuator facing downward).

Flow direction: is specified on the rating plate by an arrow

and the numbers 1 and 2.

The 1 and the 2 stand for identification also

on the valve body.

The flow direction is below the seat with flow

direction from port 2 to port 1.

Operating altitude: up to 2000 m above sea level.

6.5.1 Permitted temperature ranges

Minimum temperatures

Environment: –25 °C (–13 °F)

Medium: –10 °C (14 °F) (–40 °C on request)

Maximum temperatures

Environment: depends on the medium temperature,

see following temperature graph.

Medium: depends on the ambient temperature,

see following temperature graph

On devices with valve seat seal PTFE/steel

max. +130 °C (266 °F).

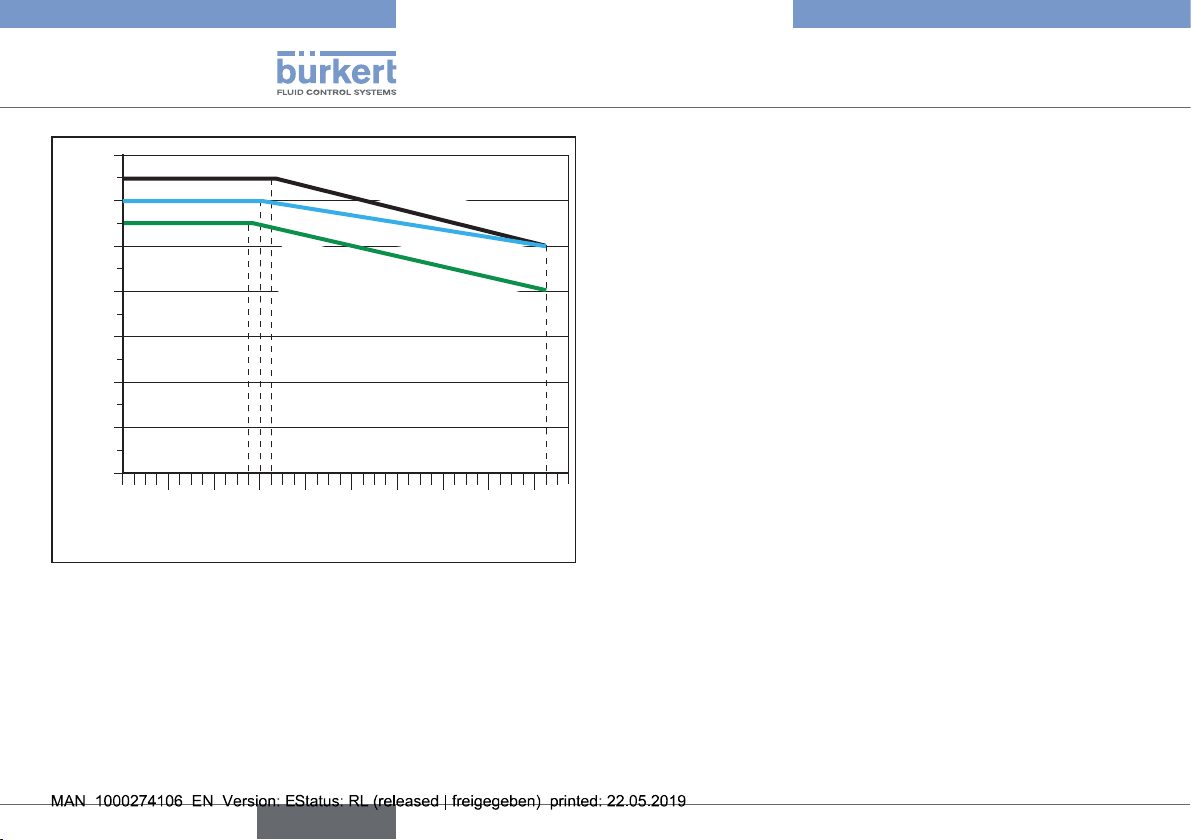

Temperature graph

The maximum permitted temperature for the environment and the

medium depend on each other. The permitted maximum temperatures

must be determined using the temperature graph.

The values were determined under the following maximum operating

conditions: orifice DN32 when 100% duty cycle at 16 bar medium

pressure.

For deviating operating conditions an individual verification can be

performed. Please contact your Bürkert office for more information.

11

Page 12

Type 3360 and 3361

english

Technical data

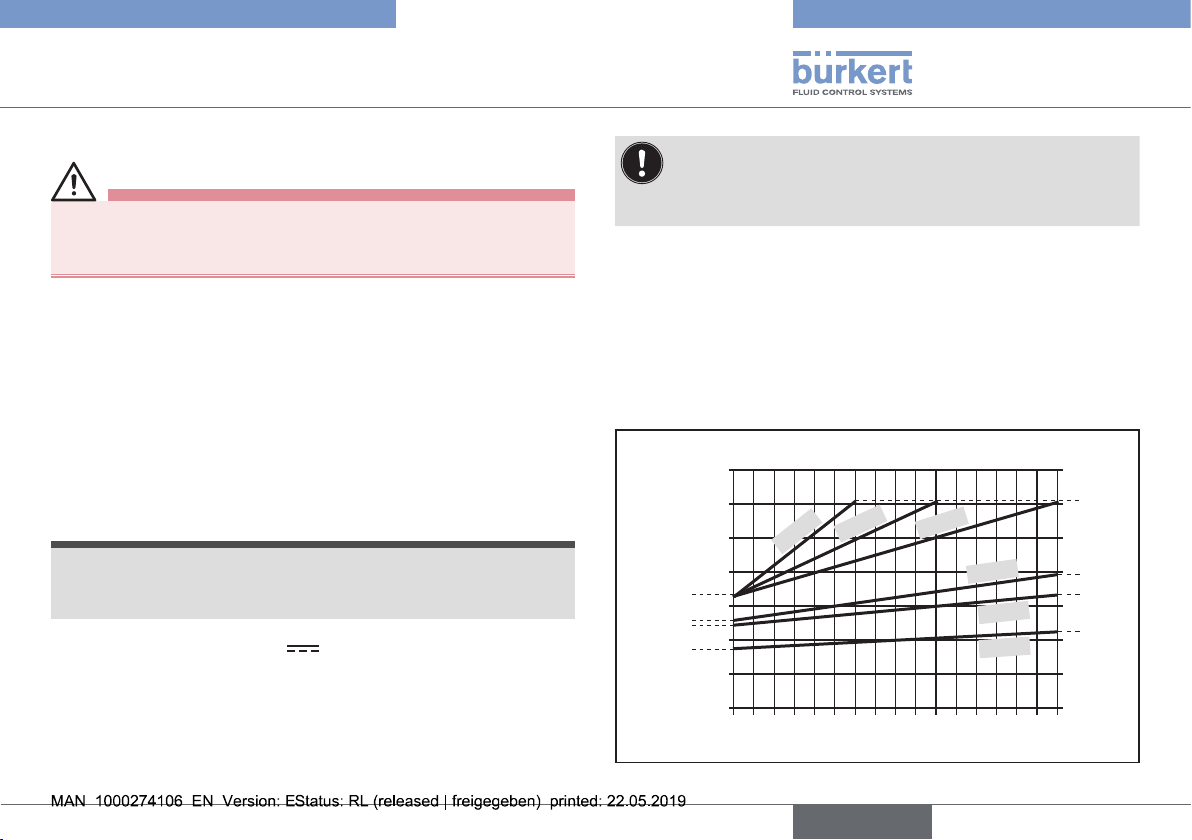

70

Devices without display module

60

Devices with display module

50

40

Devices with SAFEPOS energy-pack*

or fieldbus gateway with or without

display module

30

20

Ambient temperature [°C]

10

0

0 20 60 100 140 18040 80 120 160

Medium temperature [°C]

Fig. 5: Temperature graph

*

Service life of the SAFEPOS energy-packs depends on the medium tem-

perature and the ambient temperature (see chapter Electrical data).

6.6 General technical data

Materials Actuator: PPS and aluminum

powder-coated

Valve body: 316L

Body connection: 316L / 1.4401

Spindle: 1.4401 / 1.4404

Spindle guide: 1.4401 / 1.4404/316L with

carbon-filled PTFE

Packing gland: PTFE V-rings with spring com-

pensation (carbon-filled PTFE)

Seal material Sealing element

actuator housing: EPDM

Valve seat seal: See rating plate

Fluid connection

Connection types: Threated socket connection G ½...G 2 (NPT,

RC on request)

Welded connection in accordance with

EN ISO 1127 (ISO 4200), DIN 11850 series 2

Clamp connection according to ISO 2852, DIN

32676, ASME BPE, BS 4825

Also for globe control valves of Type 3361:

Flanged connection in accordance with

DIN 2634, ANSI B16.5 class 150, JIS 10K

Other fluid connections on request

Installation position: position, preferably with actuator face up

Sound pressure level: <70 dB (A), may be higher depending on the

usage conditions.

Electrical connection: by connection terminals or circular plugs any

12

Page 13

Type 3360 and 3361

english

Technical data

6.6.1 Electrical data

DANGER!

Electric shock.

Protection class III is only guaranteed if a SELV power supply unit

or PELV power supply unit is used.

Protection class: 3 in accordance with DIN EN 61140

(VDE 0140)

Electrical connections

Devices with

position controller function: Cable gland, 2x M20 or 2 circular plug-

in connectors M12, 5-pin and 8-pin

Devices with

process controller function: Cable gland, 3x M20 or

Circular plug-in connectors 2x M12,

5-pin and 1x M12, 8-pin

NOTE!

Consider voltage drop in supply line.

For example, a cable cross-section of 0.34 mm

2

must not exceed

a line length of 8 meters for a copper cable.

Operating voltage: 24 V ± 10%, max. residual ripple 10%

Operating current [A]**:

max. 3 A, (at 25 °C / 77 °F)

including actuator at max. load and charging

current of the optional SAFEPOS energypack (charging current approx. 1 A) for the

design of the power supply unit

The operating current can be reduced if necessary:

1. Reducing the control speed X.TIME.

2. For devices with the SAFEPOS energy-pack: Setting the

function “Control if ready”. See also Operating instructions.

Standby consumption [W]**:

Min. 2 W, max. 5 W

Average consumption [W]**

Electronics without actuator standard consumption: typically 3 W

Option analog and binary outputs: 0.5 W

SAFEPOS energy-pack: 0.5 W

Fieldbus gateway: 1 W

Energy consumption actuator for 1 cycle [Ws]**

(see following graphs)

Type 3360, angle seat control valve

140

120

100

DN50

DN40

80

66

60

51

49

40

36

20

Energy for 1 cycle in [Ws]

DN32

DN25

DN20

DN15

121

79

66

44

0

0 5 10 15

Medium pressure in [bar]

Fig. 6: Energy consumption actuator Type 3360

13

Page 14

Type 3360 and 3361

english

Technical data

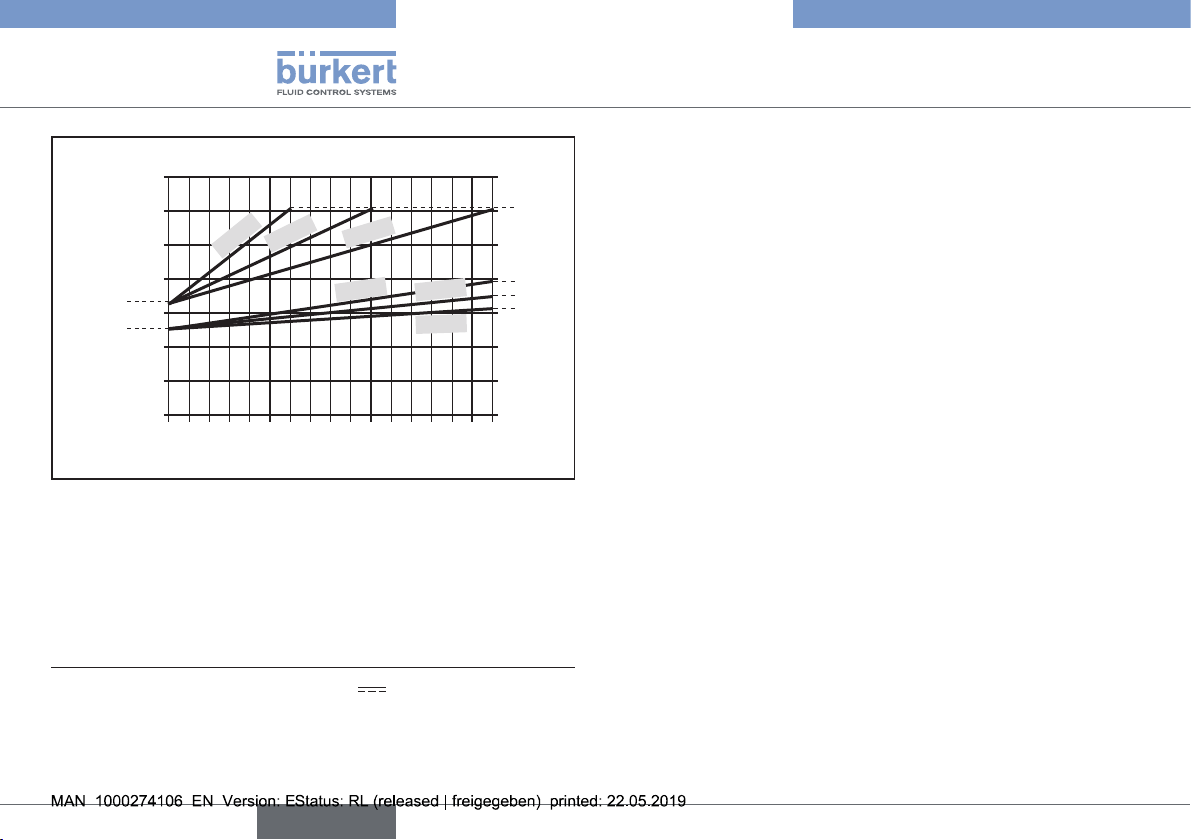

Type 3361, globe control valve

140

120

DN32

DN25

DN20

DN15

66

51

100

80

60

DN50

DN40

40

20

Energy for 1 cycle in [Ws]

0

0 5 10 15

Medium pressure in [bar]

Fig. 7: Energy consumption actuator Type 3361

Supply voltage transmitter: 24 V ±10 %

Available only for devices with process

controller function

Supply current transmitter:

Max. 150 mA, Available only for devices

with process controller function

** All values refer to a supply voltage of 24 V at 25 °C (77 °F)

ambient temperature and medium temperature.

Note: At minimum ambient and medium temperatures, the operating

current can be up to 5 A (incl. 1 A charging current for the optional

SAFEPOS energy-pack).

121

79

70

62

SAFEPOS energy-pack

Charging time: maximum 100 seconds (depending on the condi-

tions of use)

Service life: up to 10 years (depending on the conditions of use).

The determined service life of 5 years was determined under the

following conditions:

Ambient temperature 30 °C

Medium temperature 165 °C

Duty cycle 100%

Medium pressure 5 bar

Orifice DN32

Analog inputs: (galvanically isolated from the supply voltage and

analog output)

Input data for set-point value signal

0/4...20 mA: Input resistance 60 Ω

Resolution 12 bits

0...5/10 V: Input resistance 22 kΩ

Resolution 12 bit, resolution with regard to

0...10 V

Input data for actual value signal (optional)

4...20 mA: Input resistance 60 Ω

Resolution 12 bits

Frequency: Measuring range 0.2...6500 Hz

Input resistance > 30 kΩ

Precision 0.1 % of measured value

Input signal > 300 mVss

Waveform Sine wave, rectangle wave,

triangle wave

14

Page 15

Type 3360 and 3361

english

Installation of the valve

Pt 100: Measuring range –20...+220 °C

Precision 0.01 °C

Measurement

current

Analog output (optional)

Max. current: 10 mA (for voltage output 0...5/10 V)

Burden (load): 0...800 Ω (for current output 0/4...20 mA)

Digital outputs (optional)

Current limit: 100 mA,

Digital inputs: 0...5 V = log "0", 10...30 V = log "1"

inverted input reversed accordingly (input current < 6 mA)

Communication interface to the PC: büS service interface, connection is established using the USB-büS-Interface

Communications software or PC: “Bürkert Communicator”

The digital input, the digital outputs and the analog output are

not galvanically isolated for the operating voltage. They refer

to the GND potential of the operating voltage.

Current limit: in the event of an overload the output voltage is

reduced.

1 mA

7 INSTALLATION OF THE VALVE

WARNING!

Risk of injury from improper assembly.

▶ The assembly may be carried out only by trained technicians

and with the appropriate tools.

▶ Secure system against unintentional activation.

▶ After installation, ensure that the process is restarted in a con-

trolled manner. Observe sequence!

1. Apply supply voltage.

2. Charge the device with medium.

CAUTION!

Risk of injury due heavy devices!

▶ During transport or during assembly, the device may fall and

cause injury.

▶ Do not transport, install or remove heavy devices without the aid

of a second person and using suitable auxiliary equipment.

▶ Use appropriate tools.

NOTE!

Damage to valve body, valve seat seal or diaphragm.

▶ To prevent damage, the device must be in the MANUAL operat-

ing state during installation.

Devices are delivered with the MANUAL operating state preset.

15

Page 16

Type 3360 and 3361

english

Installation of the valve

7.1 Installation of devices with threated socket connection, flange connection or clamp connection

7.1.1 Required work steps

1. If not preset, set operating state MANUAL

2. If the device is already electrically connected, switch off the supply

voltage. Wait until LED illuminated ring goes out.

3. Mount the device in the pipeline.

4. Electrical installation of the device.

5. Set operting state AUTOMATIK.

7.1.2 Mounting the device in the pipeline

Preconditions: MANUAL operating state, supply voltage switched off.

Installation preparations:

1. Clean pipelines (sealing material, swarf, etc.).

2. Install filter: Required for devices with approval in accordance with

EN 161. In accordance with DIN EN 161 “Automatic Shut-off Valves

for Gas Burners and Gas Appliances”, a strainer must be installed

upstream of the valve in the pipeline to prevent a 1 mm test pin

from penetrating.

3. Observe installation conditions.

NOTE!

Note the following when installing the device in the plant.

The device and the relief bore must be accessible to allow inspection

and maintenance work.

Installation position: any position; preferably with actuator facing up.

Pipelines: Ensure that the pipelines are aligned.

Flow direction: is specified on the rating plate by an arrow and the

numbers 1 and 2. The 1 and the 2 stand for identification also on the

valve body. The flow direction is below the seat with flow direction

from port 2 to port 1.

Installation:

DANGER!

Risk of injury from high pressure.

▶ Before working on the system, switch off the pressure and vent

or drain lines.

WARNING!

Risk of crushing due to mechanically moving parts.

▶ Keep clear of the openings in the valve body.

→ Connect valve body to pipeline.

Ensure installation is de-energized and low-vibration.

Holding device

To protect the valve actuator from damage due to forces and

vibrations, a holding device is recommended. This is available

as an accessory. See operating instructions on the Homepage

www.burkert.com

Next steps:

Electrical installation, set operting state AUTOMATIK.

16

Page 17

Type 3360 and 3361

english

Installation of the valve

7.2 Installation of devices with welded connection

NOTE!

Damage to valve body, valve seat seal.

▶ To avoid damage, the valve should only be mounted in the

opened valve position and in the MANUAL operating state.

Devices are delivered with the MANUAL operating state preset.

Damage to the electronics of the actuator by the effect of

heat.

• Before welding in the valve body, remove the actuator.

7.2.1 Required work steps

1. If not preset, set operating state MANUAL.

2. If the valve is in the closed position, move the valve to the open

position, chapter “12”, page 46.

3. If the device is already electrically connected, switch off the supply

voltage. Wait until LED illuminated ring goes out.

4.Remove actuator from valve body.

5. Weld valve body into the pipeline.

6. Mount actuator on the valve body.

7. Electrical installation of the device.

8. To adjust the position control, running the X.TUNE function.

9. Set operting state AUTOMATIK.

7.2.2 Removing actuator from valve body

Preconditions: MANUAL operating state, valve position at least 1/3

open, supply voltage switched off.

WARNING!

Risk of injury due to electric shock.

Risk of crushing due to mechanically moving parts.

▶ Switch off supply voltage.

▶ Devices with SAFEPOS energy-pack: Wait until LED illuminated

ring goes out.

NOTE!

Damage to valve body or valve seat seal.

To prevent damage, the valve must be open when removing the

actuator.

→ Clamp the valve body into a holding fixture.

→ Place a suitable open-end wrench on the body connection.

Do not unscrew the body connection with a tool which

could damage the body connection (e.g. pipe wrench).

→ Unscrew the actuator off the valve body.

17

Page 18

Type 3360 and 3361

english

Installation of the valve

Mechanical position

Valve position

Fig. 8: Installation of electromotive actuator (example angle seat control

indicator

Open

Closed

When unscrewing

the actuator, the valve

must not be closed.

valve)

Actuator

Body

connection

Valve body

7.2.3 Installation requirements

Installation position: any position

Flow direction: is specified on the rating plate by an arrow and the

numbers 1 and 2. The 1 and the 2 stand for identification also on the

valve body. The incoming flow is under the seat.

Pipelines: Ensure that the pipelines are aligned.

Filter:

7.2.4 Welding valve body into the pipeline

DANGER!

Risk of injury from high pressure.

▶ Before working on the system, switch off the pressure and vent

or drain lines.

NOTE!

Damage to the electronics of the actuator by the effect of heat.

• Before welding in the valve body, remove the actuator.

Preparation:

1. Clean pipelines (sealing material, swarf, etc.).

2. Install filter: Required for devices with approval in accordance with

EN 161. In accordance with DIN EN 161 “Automatic Shut-off Valves

for Gas Burners and Gas Appliances”, a strainer must be installed

upstream of the valve in the pipeline to prevent a 1 mm test pin

from penetrating.

3. Observe installation conditions.

18

Page 19

Type 3360 and 3361

english

Installation of the valve

NOTE!

Note the following when installing the device in the plant.

The device and the relief bore must be accessible to allow inspection

and maintenance work.

Installation position: any position; preferably with actuator facing up.

Pipelines: Ensure that the pipelines are aligned.

Flow direction: is specified on the rating plate by an arrow and the

numbers 1 and 2. The 1 and the 2 stand for identification also on the

valve body. The flow direction is below the seat with flow direction

from port 2 to port 1.

Welding:

→ Weld valve body into the pipeline.

Ensure installation is de-energized and low-vibration.

Next steps:

Mounting actuator on the valve body, electrical installation, running

the X.TUNE function, set operting state AUTOMATIK.

7.2.5 Mounting actuator on the valve body

Preconditions: MANUAL operating state, valve position at least 1/3

open, supply voltage switched off.

→ Before mounting the actuator, check whether the graphite

seal of the valve body is available and undamaged.

→ Replace damaged or missing graphite seal.

Graphite

seal

Fig. 9: Graphite seal of the valve body

DANGER!

Danger if incorrect lubricants used.

Unsuitable lubricant may contaminate the medium. In oxygen

applications there is a risk of an explosion.

▶ Only use approved lubricants for specific applications, such as

oxygen or analytical applications.

NOTE!

Damage to valve body or valve seat seal.

To prevent damage, the valve must be open when mounting the

actuator.

Angle seat valveGlobe valve

Graphite seal

19

Page 20

Type 3360 and 3361

english

Installation of the valve

→ Grease the external thread of the body connection (e.g. with

Klüber paste UH1 96-402 from Klüber).

→ Place the internal thread of the valve body on the external thread

of the body connection. “Fig. 8”, page 18.

→ Place a suitable open-end wrench on the body connection.

Do not screw on the body connection with a tool which

could damage the body connection.

WARNING!

Risk of injury due to non-observance of the tightening torque.

Non-observance of the tightening torque is hazardous as the

device may be damaged.

▶ Observe tightening torque.

→ Screw actuator onto the valve body.

Orifice connection

(valve body) [DN]

10/15 45 ±3 33 ±2

20 50 ±3 37 ±2

25 60 ±3 44 ±2

32, 40 65 ±3 48 ±2

50 70 ±3 52 ±2

65 100 ±3 74 ±2

80 120 ±5 89 ±2

100 150 ±5 111 ±2

Tab. 2: Tightening torques for body connection

Tightening torque for body connection

[Nm] [lbf ft]

Holding device

To protect the valve actuator from damage due to forces

and vibrations, a holding device is recommended. This is

available as an accessory. See operating instructions on the

Homepage www.burkert.com

Next steps:

• Electrical installation.

The position of the connections can be aligned by rotating the

actuator through 360°. For description see chapter “7.3 Rotating

the actuator”.

• To adjust the position control, running the X.TUNE function,

chapter “9.5”, page 34.

NOTE!

Damage to valve body, valve seat seal or diaphragm.

▶ To prevent damage, first run the X.TUNE function after making

the electrical connection. Only then set the operating state to

AUTOMATIC.

• Set operting state AUTOMATIK

20

Page 21

Type 3360 and 3361

english

Installation of the valve

7.3 Rotating the actuator

The position of the connections can be aligned by rotating the actuator

through 360°.

NOTE!

Damage to the valve seat seal and valve seat contour when

valve is closed.

If the valve is closed when the actuator is rotated, the valve seat

seal and the valve seat contour may be damaged.

• If the valve is closed: Before rotating the actuator, open the

valve using the mechanical manual control. For description see

“12.2 Actuating valve mechanically”.

→ In the case of devices which are not installed, clamp the valve body

in a holding device.

→ Place an open-end wrench (width across flats M41) on the hexagon

of the actuator.

→ Move the actuator into the required position by turning it, preferably

in a clockwise direction.

If the actuator is installed in such a way that it can be turned in a

counter-clockwise direction only, observe the following safety warning:

WARNING!

Risk of injury due to discharge of medium and pressure release.

If the actuator is turned in a counter-clockwise direction, the body

connection may become detached.

▶ When turning the actuator in a counter-clockwise direction,

counter with a 2nd open-end wrench on the hexagon of the body

connection.

Rotate clockwise

Hexagon on the actuator

Hexagon of the body

connection

Fig. 10: Rotating the actuator

21

Page 22

Type 3360 and 3361

english

Electrical installation

7.4 Holding device

→ Attach holding device to the pipe between valve body and actuator

as shown in the diagram.

If there is a relief bore:

NOTE!

Ensure that the relief bore, which is used to detect leakages, is not

covered.

→ Fix the holding device in place using suitable means.

Relief bore

Holding device

Fig. 11: Attaching the holding device

8 ELECTRICAL INSTALLATION

The electromotive control valve is available with one of 2 different

connections:

• With circular plug-in connector (multipole version)

• Cable gland with connection terminals

Signal values

Operating voltage: 24 V

Set-point value: 0...20 mA; 4...20 mA, 0...5 V; 0...10 V

8.1 Electrical installation with circular

plug-in connector

WARNING!

Risk of injury from improper installation.

▶ Installation may be carried out by authorized technicians only

and with the appropriate tools.

▶ Observe the general rules of technology during installation.

Risk of injury from unintentional activation of the system and

uncontrolled restart.

▶ Secure system against unintentional activation.

▶ Following installation, ensure a controlled restart.

NOTE!

To ensure electromagnetic compatibility (EMC) the functional ground

must be grounded with a short cable (max. 1m). The functional

ground must have a cross-section of 1.5 mm².

22

Page 23

Type 3360 and 3361

english

Electrical installation

Using the set-point value input 4...20 mA

If several devices of Type 3360 or 3361 are connected in

series and the power supply to a device in this series connection fails, the input of the failed device becomes highly

resistive. As a result, the 4...20 mA standard signal fails.

Selection of the connection line:

When selecting the length and cross-section of the individual wires, consider the voltage drop with reference to the

maximum supply current.

8.1.1 Description of the circular plug-in

connectors

2

3

4

3

4

5

6

X3 – circular plug M12,

5-pole

1

operating voltage

5

2

X1 – circular plug M12,

1

8-pole

8

input and output signals

7

2

X2 – M12 socket, 5-pole

1

3

Input signals process

actual value

5

4

FE functional ground

→ Connect the device according to the tables.

8.1.2 X1 – M12 circular plug, 8-pole

Pin Wire

Input signals from the control centre (e.g. PLC)

8 red

7 blue Set-point value –

1 white Digital input +

Output signals to the control center (e.g. PLC) required for analog

output and/or digital output option only

6 pink Analog output+ (0/4...20 mA or 0...5/10 V)

5 gray Analog output –

4 yellow Digital output 1 (24 V / 0 V)

3 green Digital output 2 (24 V / 0 V)

2 brown Digital inputs and digital outputs GND

*

The indicated wire colors refer to the connection cable,

part no. 919061, available as an accessory.

Tab. 3: X1 – M12 circular plug, 8-pole

Assignment (From point of view of the device)

color*

Set-point value + (0/4...20 mA or 0...5/10 V) galvanically

isolated for the operating voltage

0...5 V (log. 0)

10...30 V (log. 1)

Fig. 12: Description of the circular plug-in connectors

23

Page 24

Type 3360 and 3361

english

Electrical installation

8.1.3 X2 – M12 socket, 5-pole, input signals

process actual value (for process

controller function only)

Signal

type*

4...20 mA

- internally

supplied

4...20 mA

- externally

supplied

Frequency

- internally

supplied

Wire

Pin

1 brown +24 V supply

2 white PV1: not used

3 blue GND (identical with

4 black PV2: output of

5 gray

1 brown not used

2 white not used

3 blue not used

4 black PV2: prozess actual + 4

5 gray PV3: prozess actual – 5 GND 4...20 mA

1 brown +24 V sensor supply 1 +24 V

2 white PV1: clock input + 2 Clock +

3 blue GND 3 GND

4 black PV2: not used

5 gray PV3: bridge to

Assignment

color

transmitter

GND operating voltage)

transmitter

PV3: bridge to GND

(GND from

3-wire transmitter)

GND (GND from

3-wire transmitter)

On the

device

side

1

2

3

4

5

5 Clock –

External

circuit

Transmitter

GND

4...20 mA

(identical with

GND operating

voltage)

I

Signal

type*

Frequency

- externally

supplied

Pt 100

(see note

below)

* Can be adjusted by software: Inputs / Outputs → PV → ANALOG.type

(signal source: PV.source → Analog).

Tab. 4: X2 – M12 socket, 5-pole, input signals process actual value (only

Wire

Pin

1 brown not used

2 white PV1: clock input + 2

3 blue not used

4 black PV2: not used

5 gray PV3: clock input – 5

1 brown not used

2 white PV1: process actual 1

3 blue not used

4 black PV2: process actual 2

5 gray PV3: process actual 3

available for devices with process controller function)

color

Assignment

(current feed)

(compensation)

GND

On the

device

side

2

4

5

External

circuit

Clock +

Clock –

Pt 100

NOTE!

For reasons of wire resistance compensation, connect the

Pt 100 sensor via 3 wires. Always bridge Pin 4 and Pin 5 on

the sensor.

Connection lines may be a maximum of 20 m long.

NOTE!

A shielded 5-wire cable must be used for the electrical connection

of the büS/CANopen network.

24

Page 25

Type 3360 and 3361

english

Electrical installation

8.1.4 X3 – M12 circular plug, 4-pole or 5-pole,

operating voltage (Devices without büS/

CANopen network)

A 4-pole female connector can be used as a counterpart.

Pin Wire color* Assignment

1 - do not connect

2 white +24 V

3 blue GND

4 - do not connect

5 - do not connect

The indicated wire colors refer to the M12 connection cable, 4-pole, part

*

no. 918038, available as an accessory.

Tab. 5: X3 – M12 circular plug, 5-pole, operating voltage

±10 %, max. residual ripple 10 %

8.1.5 X3 – M12 circular plug, 5-pole, büS/

CANopen network and operating

voltage

Pin Wire color* Assignment

1 CAN shield

2 red +24 V

3 black GND / CAN_GND

4 white CAN_H

5 blue CAN_L

* The specified wire colours refer to the büS cable, which is available as

an accessory. See the cabling guideline,

link: Guide for planning of büS networks

Tab. 6: X3 – M12 circular plug, 5-pole, büS/CANopen network and

operating voltage

±10 %, max. residual ripple 10 %

8.2 Electrical connection fieldbus gateway

The fieldbus gateway is connected with a circular plug-in connector

M12, 4-pole.

Socket M12, 4 pole

Ethernet,

port 1 and 2

43

2

Fig. 13: Electrical connection and pin assignment of fieldbus gateway

1

NOTE!

To ensure electromagnetic compatibility (EMC), a shielded Ethernet cable must be used. Ground the cable shield on both sides,

i.e. on each of the connected devices.

As the metal housing of the M12 circular plug-in connector is

connected to the actuator housing, the functional ground must be

grounded on the actuator housing. For the grounding use a short

line (max. 1m) with a cross-section of at least 1.5 mm

FE functional ground

Fig. 14: Functional earth

Pin Assignment

1 Transmit +

2 Receive +

3 Transmit –

4 Receive –

2

.

25

Page 26

Type 3360 and 3361

english

Electrical installation

8.3 Electrical installation with cable gland

WARNING!

Risk of injury from improper installation.

▶ Installation may be carried out by authorized technicians only

and with the appropriate tools.

▶ Observe the general rules of technology during installation.

Risk of injury from unintentional activation of the system and

uncontrolled restart.

▶ Secure system against unintentional activation.

▶ Following installation, ensure a controlled restart.

Using the set-point value input 4...20 mA.

If several devices of Type 3360 or 3361 are connected in

series and the power supply to a device in this series connection fails, the input of the failed device becomes highly

resistive. As a result, the 4...20 mA standard signal fails.

NOTE!

To ensure electromagnetic compatibility (EMC) the functional

ground must be grounded with a short cable (max. 1m).

The functional ground must have a cross-section of 1.5 mm².

8.3.1 Access to the connection terminals

To access the terminals, open the device as described below.

1. Remove display module or dummy cover:

NOTE!

Carefully remove display module ensuring that the connection cable and the HMI interface are not damaged.

Devices with ATEX approval or IECEx approval are

secured with a magnetic lock.

The removal of the cover is described in the additional

manual for electromotive control valves with ATEX approval

and IECEx approval.

→ To release the display module or the dummy cover, rotate

counter-clockwise and remove.

On the display module pay attention to the connection cable

leading to the HMI interface.

Release

dummy

cover

Release

display

module

26

Fig. 15: Removing dummy cover or display module

Page 27

Type 3360 and 3361

english

Electrical installation

Device version with display module:

→ Disconnect the connection cable from the HMI interface.

2. Removing LED and storage module:

Removing LED and storage module:

Fastening

screws

Metal housing

of the LED and

storage module

Fig. 16: Remove LED and storage module and remove actuator cover

Actuator cover

Removing actuator cover:

Fastening

screws

→ Remove the 2 fastening screws (hexalobular-internal screws

T20).

→ Take hold of the LED and storage module on both sides of the

metal housing and lift out.

3. Removing actuator cover:

→ Loosen the 4 fastening screws

(hexalobular-internal screws T25).

The screws are integrated in the actuator cover to prevent them

from falling out.

→ Remove the actuator cover.

The connection terminals are now accessible.

8.3.2 Connecting the cables

→ Push the cables through the cable gland.

NOTE!

Allow for connection to spring-type terminals.

▶ Minimum length of the wire end ferrule: 8 mm

▶ Maximum cross-section of the wire end ferrule: 1.5 mm2 (with-

out collar), 0.75 mm

2

(with collar)

→ Strip at least 8 mm insulation from the wires and crimp on wire

end ferrules.

→ Connect the wires. The terminal assignment can be found in the

tables below, starting on page 28.

→ Tighten the union nut of the cable gland (tightening torque

approx. 1.5 Nm (1.1 lbf ft)).

NOTE!

Damage or malfunction due to ingress of dirt and moisture.

To comply with the degree of protection IP65 and IP67:

▶ Close all unused cable glands with dummy plugs.

▶ Tighten the union nuts on the cable glands. Tightening

torque depends on cable size or dummy plug approx. 1.5 Nm

(1.1 lbf ft).

27

Page 28

Type 3360 and 3361

english

Electrical installation

Connection terminals

Cable glands

FE functional ground

Fig. 17: Connecting the cables

→ Connect the device according to the tables.

8.3.3 Terminal assignment – operating

voltage

Terminal Assignment

10 +24 V

9 GND

Tab. 7: Terminal assignment – operating voltage

±10 %, max. residual ripple 10 %

8.3.4 Terminal assignment – input signal

from the control center (e.g. PLC)

Terminal Assignment (From point of view of the device)

8 Set-point value +

(0/4...20 mA or 0...5/10 V)

galvanically isolated for the operating voltage

7 Set-point value –

5 Digital input +

4

Tab. 8: Terminal assignment – input signal from the control center (e.g. PLC)

Digital input GND

based on operating voltage GND (terminal GND)

0...5 V (log. 0)

10...30 V (log. 1)

8.3.5 Terminal assignment - output signals

to the control center (e.g. PLC) required

for analog output and/or digital output

option only

Terminal Assignment (From point of view of the device)

19

20 Analog output –

18 Digital output 1 (24 V / 0 V)

17 Digital output 2 (24 V / 0 V)

16 Digital output GND

Tab. 9: Terminal assignment – output signal to the control center

Analog output+

(0/4...20 mA or 0...5/10 V)

(e.g. PLC)

28

Page 29

Type 3360 and 3361

english

Electrical installation

8.3.6 Terminal assignment – process actual

value input (for process controller

function only)

Signal

type*

4...20 mA

- internally

supplied

4...20 mA

- externally

supplied

Frequency

- internally

supplied

Terminal Assignment

22 +24 V supply

transmitter

15 PV1: not used

21 GND (identical with

GND operating voltage)

14 PV2: output of

transmitter

13 PV3: bridge to

GND (GND of

3-wire transmitter)

22 not used

15 not used

21 not used

14 PV2: process actual + 14

13 PV3: process actual – 13 GND 4...20 mA

22 +24 V supply sensor 22 +24 V

15 PV1: clock input + 15 Clock +

21 GND 21 GND (identical

14 PV2: not used

13 PV3: bidge to

GND (GND of

3-wire transmitter)

On the

device

side

22

15

21

14

13

13 Clock –

External circuit

Transmitter

GND

4...20 mA

with GND operating voltage)

I

Signal

type*

Frequency

- externally

supplied

Pt 100

(see note

below)

* Can be adjusted via software:

Inputs / Outputs → PV → ANALOG.type

(signal source: PV.source → Analog).

Tab. 10: Terminal assignment – process actual value input (only available

Terminal Assignment

22 not used

15 PV1: clock input + 15

21 not used

14 PV2: not used

13 PV3: clock input – 13

22 not used

15 PV1: process actual 1

(current feed)

21 not used

14 PV2: process actual 2

(compensation)

13 PV3: process actual 3

GND

for devices with process controller function)

On the

device

side

15

14

13

External circuit

Clock+

Clock–

Pt 100

NOTE!

For reasons of wire resistance compensation, connect the

Pt 100 sensor via 3 wires.

Always bridge terminal 14 and terminal 13 on the sensor.

Connection lines may be a maximum of 20 m long.

29

Page 30

Type 3360 and 3361

english

Electrical installation

8.3.7 Closing the device

ATTENTION!

Damage or malfunction due to ingress of dirt and moisture.

Before closing the device, comply with the degree of protection

IP65 and IP67 by ensuring:

▶ that the seal is inserted in the actuator housing/actuator cover

and is not damaged.

▶ The sealing surfaces must be clean and dry.

Dummy cover or

display module

LED and storage

module

Actuator cover

Dummy cover or display

module closed

Marking

1. Attaching the actuator cover

→ Place actuator cover on the actuator housing.

→ Slightly screw in the 4 fastening screws (hexalobular-internal

screws T25) crosswise, firstly by hand and then tighten (tightening torque: 5.0 Nm (3.7 lbf ft)).

2. Inserting LED and storage module

→ Insert LED and storage module and fix with the 2 fastening

screws (tightening torque: 1.1 Nm (0.8 lbf ft)).

3. Close device with dummy cover or display module

Device version with display module:

→ Insert the connection cable into the HMI interface.

→ Fit the display module and turn clockwise until the marking at the

edge is directly over the marking for the drive cover.

Device version with dummy cover:

→ Fit the dummy cover and turn clockwise until the marking at the

edge is directly over the marking for the drive cover.

8.4 After electrical installation

→ When the operating voltage is applied make the required basic

settings and adjustments for the electromotive control valve. For a

description see chapter “9 Start-up”.

Fig. 18: Closing the device

30

Page 31

Type 3360 and 3361

english

Start-up

9 START-UP

WARNING!

Risk of injury from improper operation.

Improper operation may result in injuries as well as damage to the

device and the environment.

▶ The operating personnel must know and have understood the

contents of the operating instructions.

▶ Observe the safety instructions and intended use.

▶ Only adequately trained personnel may start up the equipment/

the device.

9.1 Prior to Preparation for Use

NOTE!

Observe for devices which were removed for installation.

If the actuator was removed, the X.TUNE function must be run

again before commissioning. Chapter “9.5 Adjust the position

control – running X.TUNE”.

9.2 Setting options for start-up

• Setting with the PC software “Bürkert Communicator” on the

PC or tablet

This type of setting is possible for all device types and device

variants.

The PC software “Bürkert Communicator” can be downloaded free of charge from the Bürkert homepage.

To do this, the USB büS interface set, available as an

accessory, is required.

Communication is established by the büS service interface

of the device.

• Setting on the display of the device (optional)

Possible only for devices with display module.

• Adjust the position control using 2 capacitive buttons in the

device (X.TUNE function)

Possible only for devices without display module.

9.3 Base settings

A start-up wizard, which runs gradually through the base

setting, is available for the “Bürkert Communicator” and the

display.

(Configuration area → Position controller or Process controller → STA RT-UP)

The devices are delivered with the base settings made at the

factory. See overview below.

31

Page 32

Type 3360 and 3361

english

Start-up

9.3.1 Basic settings position control

Overview:

Type of basic setting (Observe sequence) Factory presetting

1. Setting safety position

Adjustment of position control

2.

(X.TUNE function)

Set standard signal for set-point

3.

position

4 Setting AUTOMATIC operating state MANUAL

Tab. 11: Basic settings for position control

Close/ Open (depending on

the device variant)

Performed at the factory (note

information on page 31)

Signal type analog: 4...20 mA

Gateway: is specified by the

fieldbus

9.3.2 Basic settings process control

Overview:

Type of basic setting (Observe sequence) Factory presetting

1. Setting safety position Close

2. Adjustment of position control

(X.TUNE function)

3. Select physical unit for process control Percentage

4. Parameterize process values

a) Select standard signal for process

set-point value

b) Scale process set-point value

c) Select standard signal for process

actual value

d) Scale process actual value Minimum 0 %, maximum 100 %

Performed at the factory (note

information on page 31)

Signal type analog: 4...20 mA

Gateway: is specified by the

fieldbus

Minimum 0 %, maximum 100 %

4...20 mA

Type of basic setting (Observe sequence) Factory presetting

5. Scaling process control Minimum 0 %, maximum 100 %

6. Setting dead band of the process

control

7. Set up process control

a)

Linearize process characteristic

(P.LIN function)

In addition for devices without a display:

To activate the correction characteristic, set the DIP switch 2 to ON.

b)

Adjust process control

(P.TUNE function)

8. Setting AUTOMATIC operating state

Tab. 12: Overview: Basic settings for process control

Only required if the process characteristic deviates greatly from the lin-

1)

earity. Linearization with the P.LIN function takes a longer time for slow

processes.

2)

The P.TUNE function supports the setting up of the process control by

automatic optimization of the process parameters.

The fine adjustment of the process parameters is described in the

software description with reference to Type 3360, 3361.

2)

1)

1 %

-

-

MANUAL

32

Page 33

Type 3360 and 3361

english

Start-up

9.4 Setting safety position

Setting option: Using the PC software “Bürkert Communicator” or on the display of the device (option)

Display operation: Key functions

select, activate confirm back

To set the safety position, you must change to the detailed view

parameters for position controller.

Changing to the detailed view:

→ When setting with “Bürkert Communicator” in the navigation

area, select

Position controller.

→ When setting on the display switch from home screen to

CONFIGURATION and select

You are in the detailed view parameter.

Setting the safety position:

Position controller.

→ Select SAFEPOS.

→ Select FUNCTION.

The following safety positions can be selected:

Close

Open

User-Defined

Inactive

Valve tightly closed.

Valve open.

Freely defined safety position. The input of the

position in this menu is described below.

Valve stops in an undefined position.

→ Select safety position.

Input of the freely defined safety position (applicable only when

selecting safety position User-Defined).

→ Select Position.

→ Input safety position

(0% = closed, 100% = open).

You have set the safety position.

33

Page 34

Type 3360 and 3361

english

Start-up

9.5 Adjust the position control – running X.TUNE

When the X.TUNE function is running, the position control is adjusted

to the physical stroke of the actuating element used.

Devices are delivered with the X.TUNE function run at the

factory.

NOTE!

Do not run X.TUNE without requirement.

The X.TUNE function must be run again only when the actuator

has been removed afterwards or the valve body has been changed.

WARNING!

Danger due to uncontrolled process after running the X.TUNE

function.

If the X.TUNE is running under medium pressure, the controller will

be incorrectly adjusted. This will result in an uncontrolled process.

▶ Never run the X.TUNE under medium pressure.

▶ Secure system against unintentional activation.

When the X.TUNE is running, the LED illuminated ring is lit orange.

When the X.TUNE ends, the LED illuminated ring is reset to its pre-

vious status.

9.5.1 Adjustment of the position control

using the buttons in the device

The 2 buttons for running the X.TUNE are located under the dummy

cover.

Release dummy cover

Fig. 19: Adjustment of the position control using the buttons in the device

OPEN button

CLOSE button

→ To release, rotate the dummy cover counter-clockwise and remove.

Devices with ATEX approval or IECEx approval are secured

with a magnetic lock.

The removal of the cover is described in the additional manual

for electromotive control valves with ATEX approval and IECEx

approval.

Running the X.TUNE function:

Ensure that no medium pressure is applied!

Do not run the X.TUNE unless it is absolutely essential.

→ Simultaneously hold down the OPEN and CLOSE buttons for 5 s.

34

Page 35

Type 3360 and 3361

english

Start-up

9.5.2 Adjustment of the position control via

PC or display on the device

The setting is made on the PC via the büS Service interface

and by using the “Bürkert Communicator” software. To do

this, the USB büS interface set, available as an accessory, is

required.

Display operation: Key functions

select, activate confirm back

To run the X.TUNE function, you must change to the detailed view

maintenance for position controller.

Changing to the detailed view:

→ When setting with “Bürkert Communicator” in the navigation

area, select P

osition controller and switch to MAINTENANCE.

→ When setting on the display switch from home screen to

CONFIGURATION, select P

MAINTENANCE.

You are in the detailed view maintenance.

Running the X.TUNE function:

Ensure that no medium pressure is applied!

osition controller and switch to

→ Select CALIBRATION.

→ Select X .TUNE.

The following text appears: „Choose seal material (see type label)!

→ Select seal material.

The following question appears: “Do you really want to start the

X.TUNE?

Do not start the X.TUNE unless it is absolutely essential to

run the X.TUNE.

→ Start X.TUNE.

The X.TUNE function is running.

If the X.TUNE is canceled by the user or due to an error,

a message appears (see table below).

Possible messages when

X.TUNE is canceled

There are device errors. There is an error which is pre-

Time limit exceeded The X.TUNE could not be run

Motor current is too high. The motor current is too large for

Lower end position of the

valve is not detected.

Tab. 13: Possible error message following cancellation of the X.TUNE

function

Description

venting X.TUNE from running.

within the time limit due to an error.

running the X.TUNE function.

The lower end position of the valve

cannot be detected by the travel

sensor.

35

Page 36

Type 3360 and 3361

english

Start-up

9.6 Set standard signal for set-point

position

Setting option:

Using the PC software “Bürkert Communicator” or on the

display of the device (option)

Display operation: Key functions

select, activate confirm back

To set the standard signal, you must change to the detailed view

parameters for inputs / outputs.

Changing to the detailed view:

→ When setting with “Bürkert Communicator” in the navigation

area, select

Inputs / Outputs.

→ When setting on the display switch from home screen to

CONFIGURATION and select

You are in the detailed view parameter.

Setting the standard signal:

Inputs / Outputs.

→ Select CMD.

→ Select ANALOG.type.

→ Select standard signal.

You have set the standard signal.

9.7 Select physical unit for process control

Setting option:

Using the PC software “Bürkert Communicator” or on the

display of the device (option)

Display operation: Key functions

select, activate confirm back

To select the physical unit, you must switch to the detailed view

parameters for process controller.

Changing to the detailed view:

→ When setting with “Bürkert Communicator” in the navigation

area, select

Process controller.

→ When setting on the display switch from home screen to

CONFIGURATION and select

You are in the detailed view parameter.

Selecting the physical unit for the process control:

Process controller.

→ Select UNIT.

→ Select physical unit.

You have selected the physical unit.

36

Page 37

Type 3360 and 3361

english

Start-up

9.8 Parameterize process values

Setting option:

Using the PC software “Bürkert Communicator” or on the

display of the device (option)

Display operation: Key functions

select, activate confirm back

To parameterize the process values, you must switch to the detailed

view parameters for inputs / outputs.

Changing to the detailed view:

→ When setting with “Bürkert Communicator” in the navigation

area, select

Inputs / Outputs.

→ When setting on the display switch from home screen to

CONFIGURATION and select

You are in the detailed view parameter.

9.8.1 Select and scale standard signal for

process set-point value

Selecting the standard signal for the process set-point value:

Inputs / Outputs.

→ Select SP / CMD.

→ Select ANALOG.type.

→ Select standard signal.

You have selected the standard signal for the process set-point

value.

Scaling the process set-point value:

→ Select SP .scale.

→ Input minimum and maximum.

You have parameterized the process set-point value.

9.8.2 Select and scale standard signal for

process actual value

Selecting the standard signal for the process actual value:

→ Select PV.

→ Select ANALOG.type.

→ Select standard signal.

You have selected the standard signal for the process actual value.

Scaling the process actual value:

→ Select PV.scale.

→ Input minimum and maximum.

You have parameterized the process actual value.

37

Page 38

Type 3360 and 3361

english

Start-up

9.9 Scaling process control

The scaling of the process control affects the following functions:

• Dead band of the process control

• Sealing function (CUTOFF), if the process control (P.CO) has

been selected in the menu CUTOFF → CUTOFF.type.

Setting option:

Using the PC software “Bürkert Communicator” or on the

display of the device (option)

Display operation: Key functions

select, activate confirm back

To scaling the process control, you must switch to the detailed view

of parameters for process controller.

Changing to the detailed view:

→ When setting with “Bürkert Communicator” in the navigation

area, select Process

controller.

→ When setting on the display switch from home screen to

CONFIGURATION, select Process

You are in the detailed view parameter.

Scaling the process control:

controller.

→ Select P.CO.scale.

→ Input minimum and maximum.

You have scaled the process control.

9.10 Setting dead band of the process control

Setting option:

Using the PC software “Bürkert Communicator” or on the

display of the device (option)

Display operation: Key functions

select, activate confirm back

To set the dead band, you must switch to the detailed view of

parameters for position controller.

Changing to the detailed view:

→ When setting with “Bürkert Communicator” in the navigation

area, select

Process controller.

→ When setting on the display switch from home screen to

CONFIGURATION and select

You are in the detailed view parameter.

Setting the dead band:

Process controller.

→ Select PID.PARAMETER.

→ Select DBND.

→ Enter percentage value.

You have set the dead band.

38

Page 39

Type 3360 and 3361

english

Start-up

9.11 Set up process control – run P.LIN, P.TUNE

Setting option: Using the PC software “Bürkert Communicator” or on the display of the device (option)

Display operation: Key functions

select, activate confirm back

To set up the process control, you must switch to the detailed view

maintenance for process controller.

Changing to the detailed view:

→ When setting with “Bürkert Communicator” in the navigation

area, select Process

controller and switch to MAINTENANCE.

→ When setting on the display switch from home screen to

CONFIGURATION, select Process

MAINTENANCE.

You are in the detailed view maintenance.

9.11.1 Linearize process characteristic (P.LIN)

Linearizing the process characteristic:

controller and switch to

→ Select CALIBRATION.

→ Select P. LIN.

→ The following text appears: “Do you really want to start the P.Lin?”

→ Start P.LIN.

The P.LIN function is running.

9.11.2 For devices without a display - activate

the correction characteristic

The correction characteristic is activated with DIP switch 2 which is

located under the dummy cover.

→ To release, rotate the dummy cover counter-clockwise and

remove.

→ Set DIP switch 2 to ON. The correction characteristic is now

activated.

DIP switches

Release

dummy cover

Fig. 20: Activating the correction characteristic

DIP 2 ON

→ Close the dummy cover.

9.11.3 Adjustment to process control (P.TUNE)

Running the P.TUNE function:

→ Select P.TUNE. The following text appears: “Do you really want

to start the P.Tune?”

→ Start P.TUNE.

The P.TUNE function is running.

When the P.LIN and P.TUNE functions are running, the LED

illuminated ring is lit orange. If terminated due to an error, a

message appears.

39

Page 40

Type 3360 and 3361

english

Start-up

9.12 Setting operating state

Setting operating state for devices without display module:

The DIP switch for the setting is located under the dummy cover.

→ To release, rotate the dummy cover counter-clockwise and remove.

Devices with ATEX approval or IECEx approval are secured

with a magnetic lock.

The removal of the cover is described in the additional manual

for electromotive control valves with ATEX approval and IECEx

approval.

DIP switches

Release dummy cover

Fig. 21: DIP switches

Setting operating state

AUTOMATIC:

DIP 4 downwards

MANUAL:

DIP 4 upwards (ON)

Setting operating state for devices with display module:

The operating state is set on the display in home screen.

The setting is made in the MANU / AUTO layout.

View 1 of x

POS 71 %

Symbol for MANUAL operating

state

View 2

Arrow symbols

CONFIGURATION